Method for reliably connecting bridge printed circuit boards of optical transceivers and positioning component

A technology for printed circuit boards and optical transceivers, which is applied in the direction of assembling printed circuits with electrical components and printed circuits connected with non-printed electrical components, and can solve the problem of increasing the internal stress of flexible bridging printed circuit boards and modules Difficult to assemble high-grade products, difficult to control the heating time, etc., to achieve the effect of high one-time pass rate, good consistent shape, and low control difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

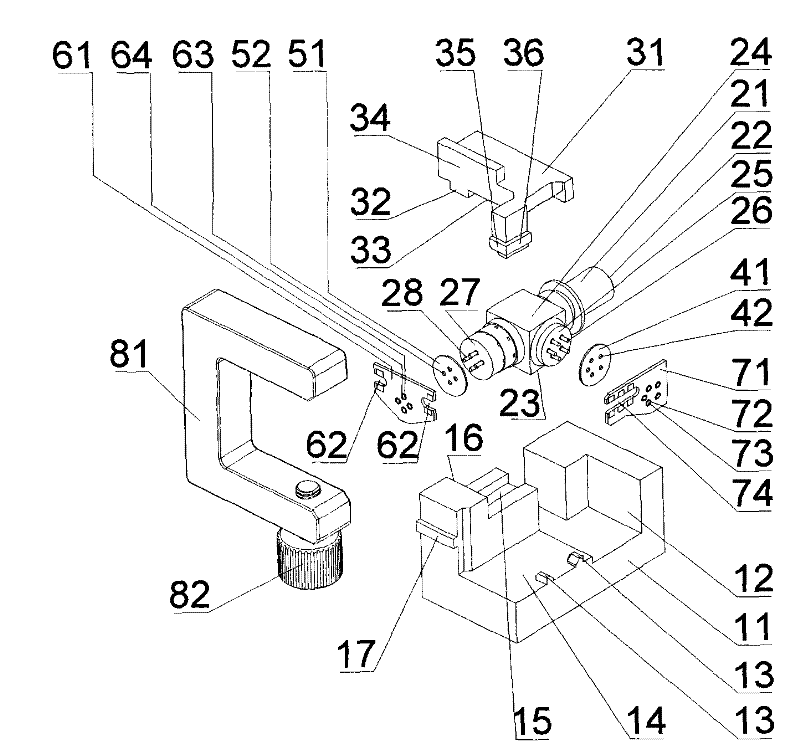

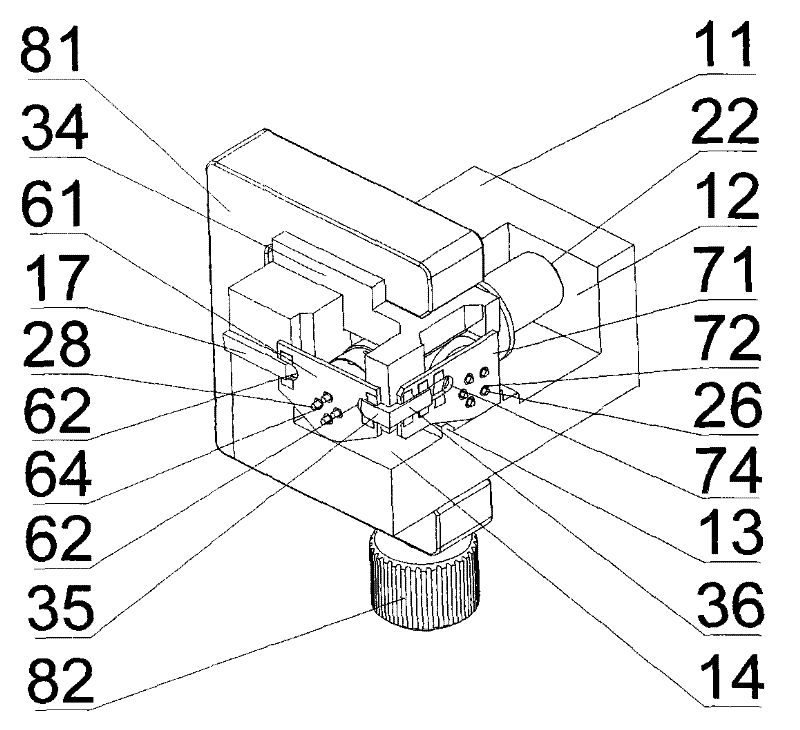

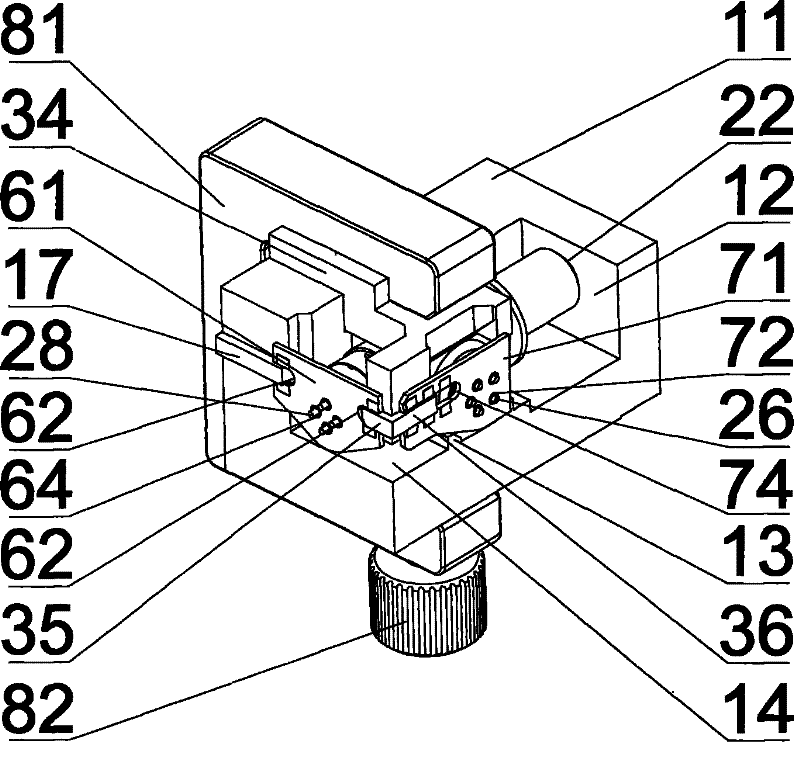

[0020] Below in conjunction with the best embodiment shown in the accompanying drawings, it will be further described in detail.

[0021] refer to figure 1 , the main body of the optical transceiver device 21 is a square structure, on which a receiving end and a sending end with end faces perpendicular to each other and with pins are arranged. The cylindrical body whose one side protrudes vertically from the front end face 22 is a light-conducting metal piece. The cylinder on the side opposite to the light-conducting metal part is the origin of the light-transmitting device 21 . The end face of the originating end is the originating metal end face 27 . The mutually insulated starting pins 28 protrude from the surface of the starting metal end surface 27 . There is a receiving end of the optical transceiver device 21 on one side of the main body in the middle part between the light-conducting metal piece and the sending end. The end face of the receiving end is the receivin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com