Venting structure of pressure cooker and pressure cooker with the same

A pressure cooker and exhaust pipe technology, which is applied in the field of cooking and kitchen utensils, can solve problems such as failure, vertical rib bending, and affecting the service life of the pressure cooker, and achieve the effect of improving the service life, not being easy to bend, and increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

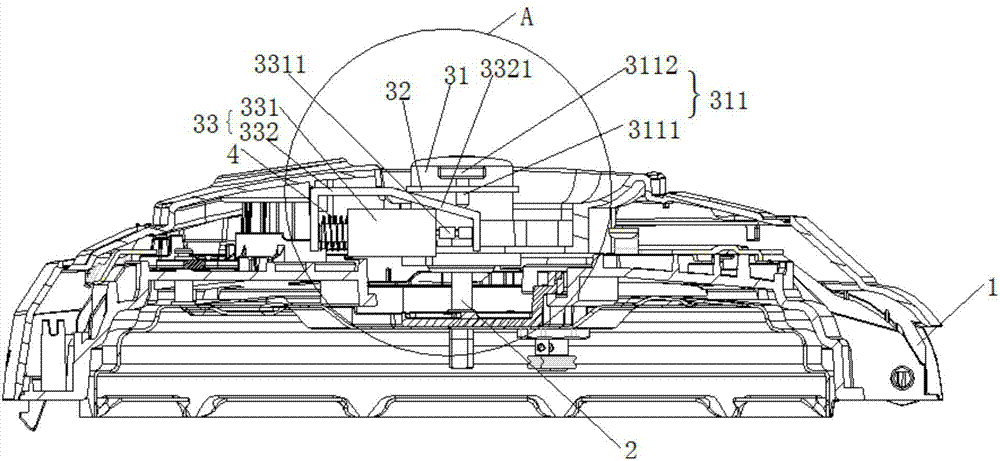

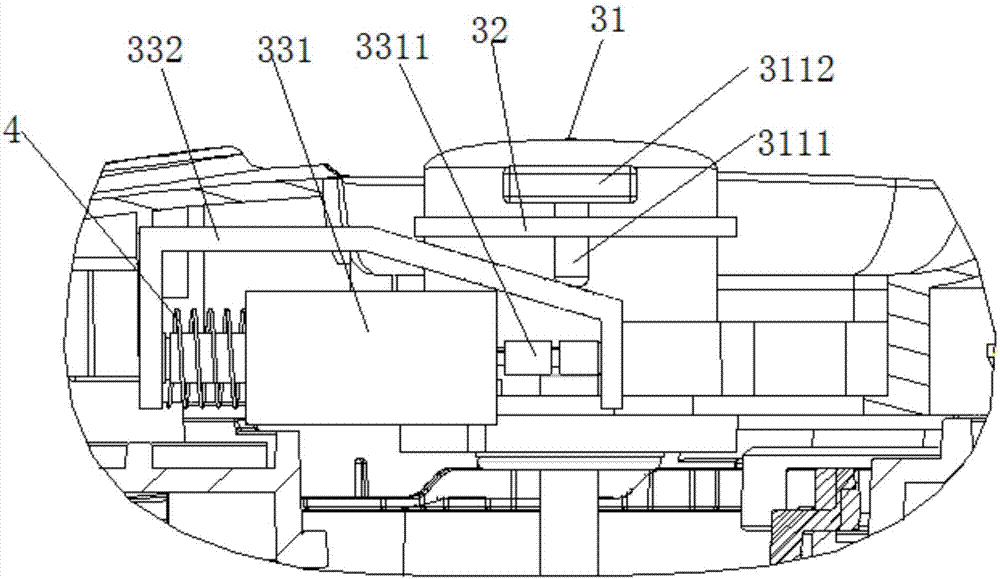

[0031] A kind of pressure cooker, it comprises pot body and the pot cover 1 that covers on described pot body, as figure 1 As shown, the pot cover 1 is provided with an exhaust pipe 2, and the exhaust pipe 2 is provided with an exhaust structure, figure 2 Shown is a schematic diagram of the exhaust structure described in this embodiment, which includes a pressure limiting valve 31, a limiter 32 and a drive assembly 33, the pressure limiting valve 31 is arranged on the exhaust pipe 2, and the pressure limiting valve 31 is The pushing part 311 is fixedly arranged; the limiting part 32 is fixed on the lid 1 of the pressure cooker; the driving assembly 33 drives the pushing part 311; the limiting part 32 restricts the pressure limiting valve 31 to only be able to The pipe axis moves up and down, and the driving assembly 33 drives the pushing member 311 to move up and down along the exhaust pipe axis.

[0032] In this embodiment, the pushing part 311 includes an extension part 31...

Embodiment 2

[0039] An electric pressure cooker, which includes a pot body and a pot cover 1 that is covered on the pot body, the pot cover 1 is provided with an exhaust pipe 2, and the exhaust pipe 2 is provided with an exhaust structure. The exhaust structure in the embodiment includes a pressure limiting valve 31, a limiting member 32 and a driving assembly 33, the pressure limiting valve 31 is arranged on the exhaust pipe 2, and a pushing member 311 is fixedly arranged on the pressure limiting valve 31; The positioning member 32 is fixed on the pot cover 1; the driving assembly 33 drives the pushing member 311; the limiting member 32 restricts the pressure limiting valve 31 to move up and down along the exhaust pipe axis, and the driving assembly 33 The pushing member 311 is driven to move up and down along the axis of the exhaust pipe.

[0040]In this embodiment, the pushing member 311 is a pushing plate extending outward from the side wall of the pressure limiting valve 31 . The lim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com