Patents

Literature

68results about How to "Reduce or eliminate damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

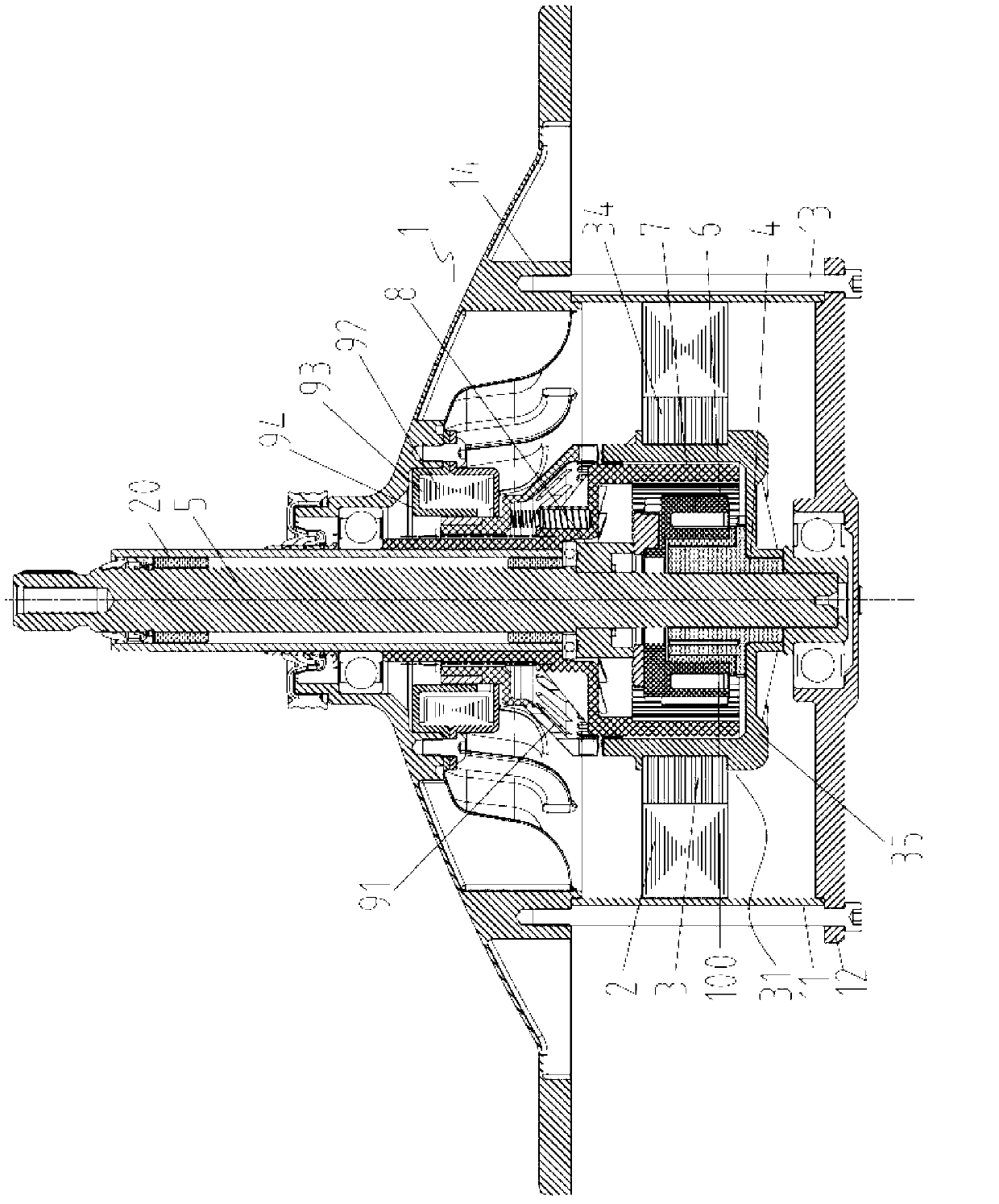

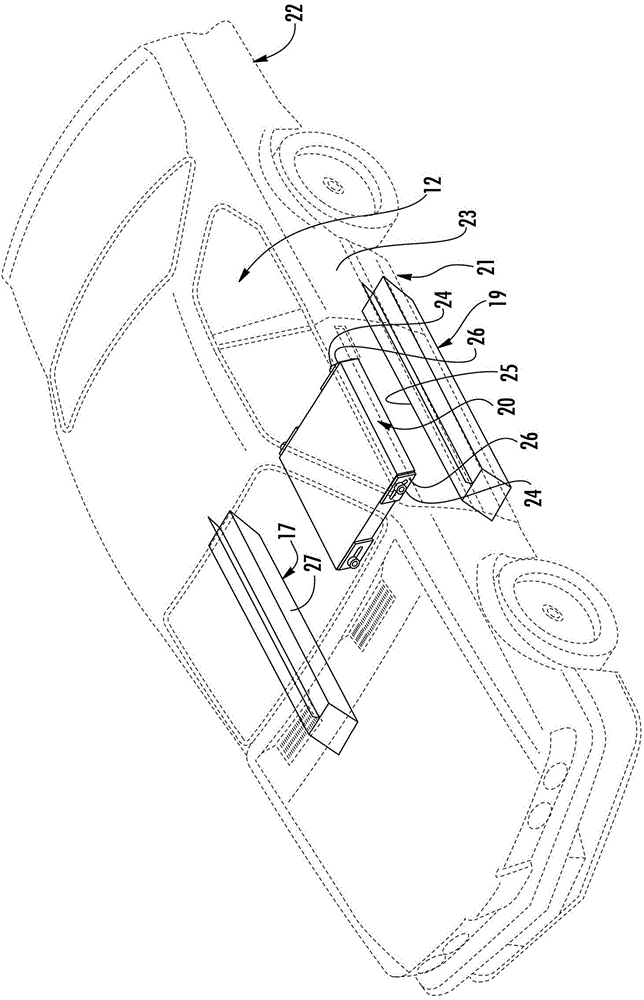

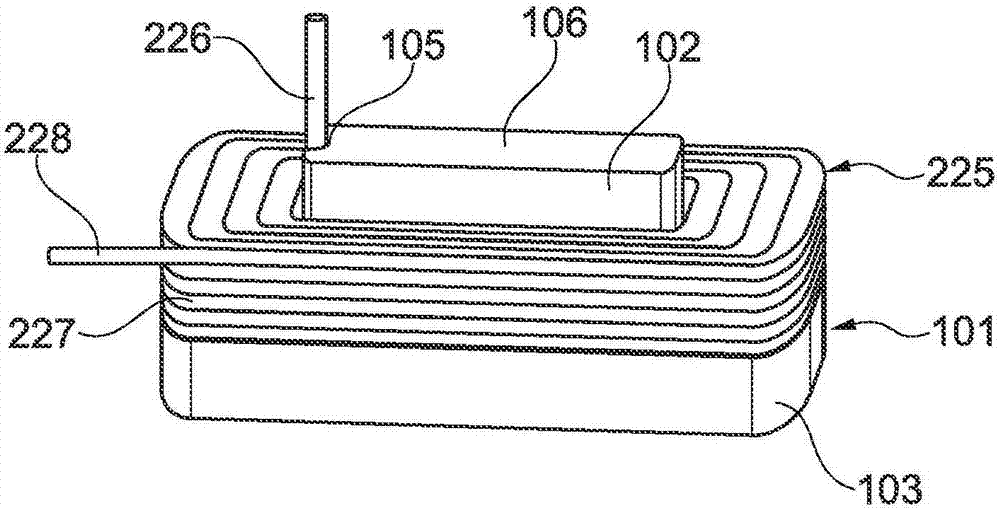

Heart valve delivery system with valve catheter

ActiveCN101291637AEasy to crossReduce or eliminate damageStentsBalloon catheterDelivery systemCatheter device

A heart valve delivery system is provided wherein a prosthetic valve is carried on a valve catheter inside a delivery sleeve. A step balloon protrudes from the delivery sleeve and provides a tapered surface for facilitating advancement through a body vessel. The step balloon also aids in crossing the leaflets of a native valve. After the prosthetic valve is positioned within the native valve, the delivery sleeve is retracted to expose the prosthetic valve. In one embodiment, the delivery sleeve is retracted by the use of a lead screw, which effectuates relative movement between the valve catheter and delivery sleeve. The prosthetic valve is preferably self-expandable. If necessary, the step balloon may be expanded to securely seat the prosthetic valve at the site of the native valve. The prosthetic valve is preferably coupled to the valve catheter by a plurality of flexible extension arms which allow the prosthetic valve to be collapsed after initial deployment such that the prosthetic valve may be repositioned if necessary.

Owner:EDWARDS LIFESCIENCES CORP

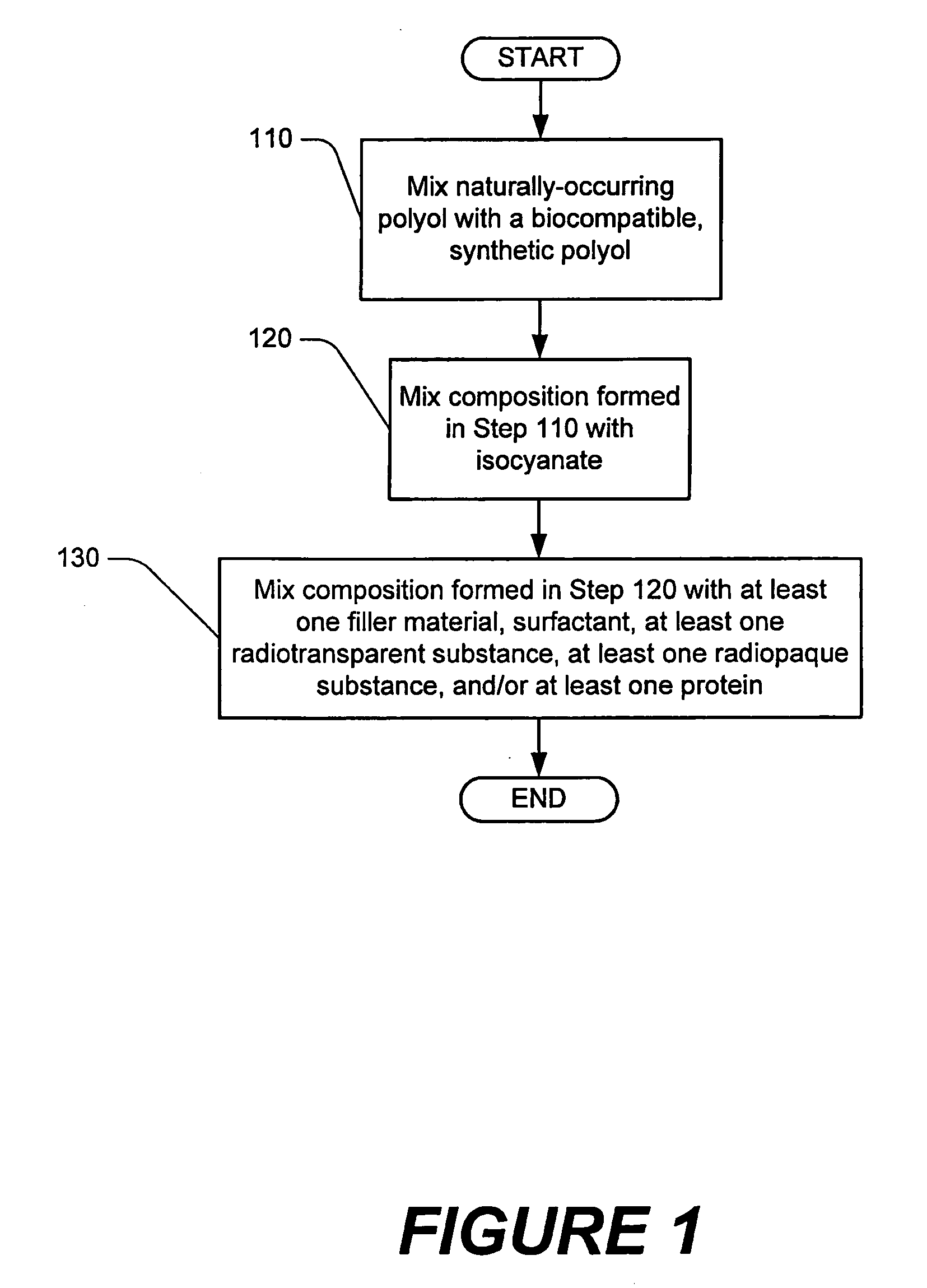

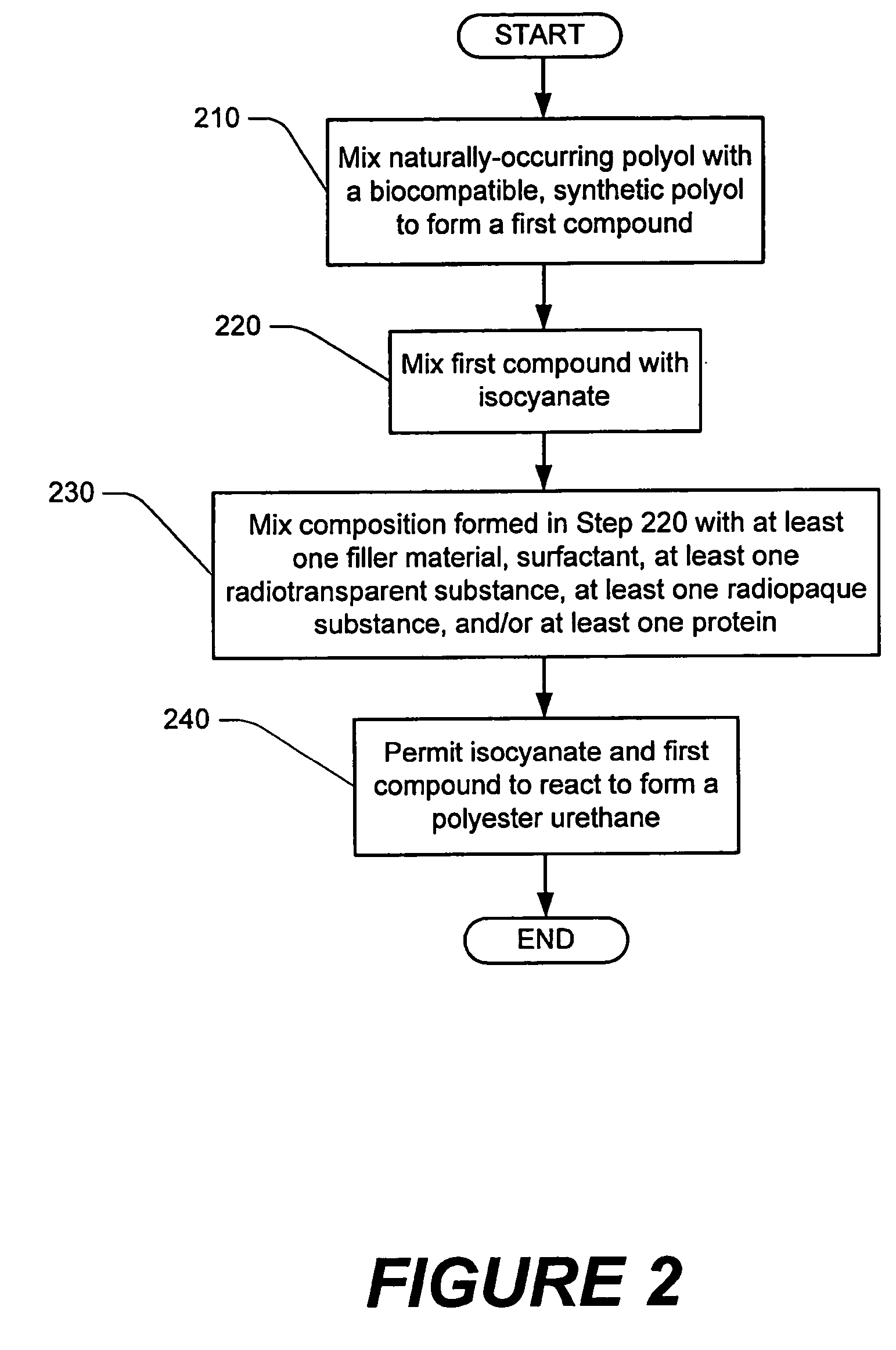

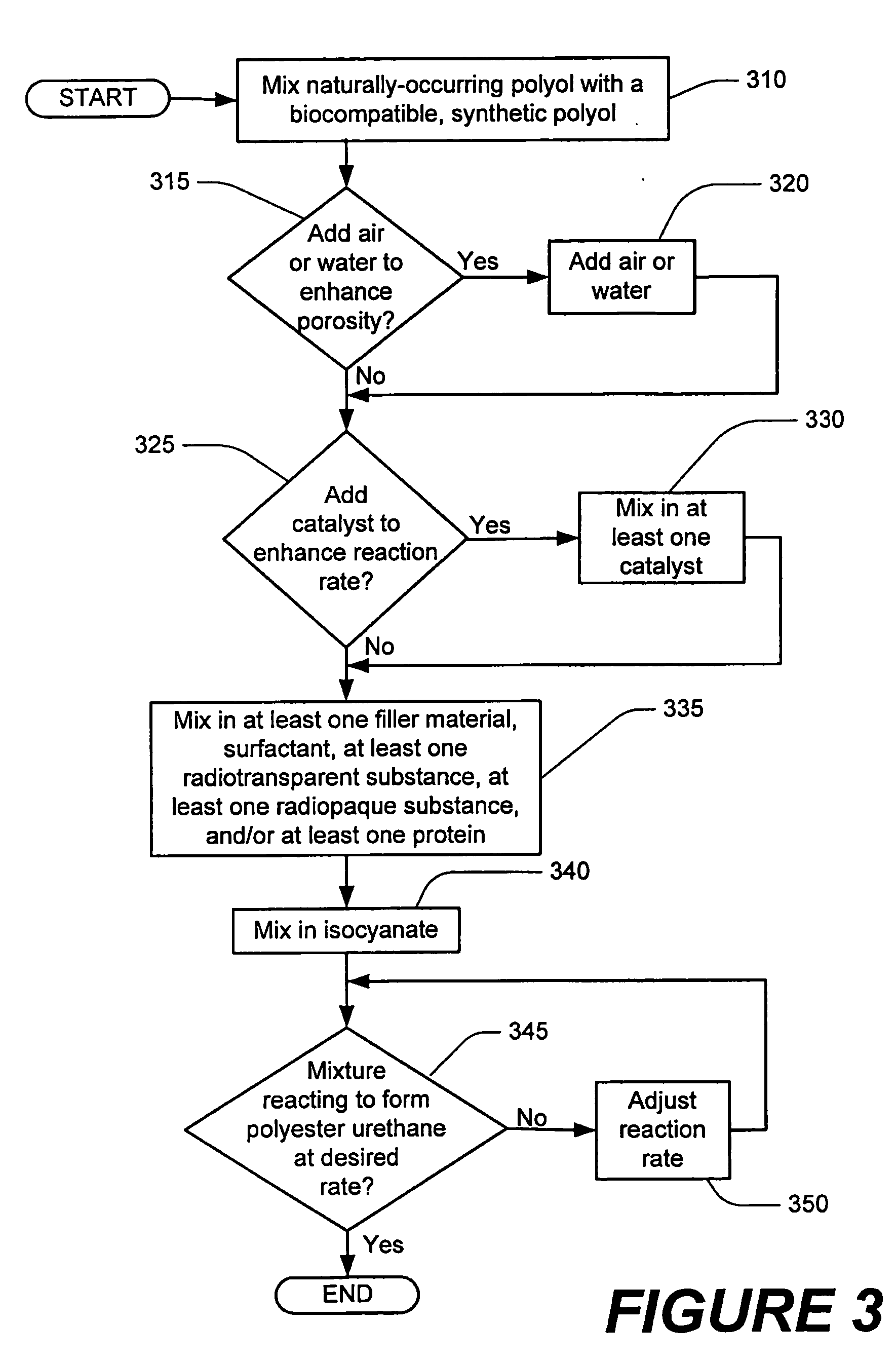

Methods of performing medical procedures which promote bone growth, compositions which promote bone growth, and methods of making such compositions

InactiveUS20050031578A1Promote growthReduce or eliminate damageTissue culturePharmaceutical non-active ingredientsBiomedical engineeringMedical treatment

The present invention provides compositions that may be useful, inter alia, in medical procedures, methods for making such compositions, and methods of performing medical procedures using such compositions. The present invention further provides a kit that includes a first container comprising a dispensing means and a first compound; and a second container comprising a dispensing means and a second compound, wherein the first compound may include, inter alia, a naturally occurring polyol, a biocompatible synthetic polyol, and mixtures thereof, and wherein the second compound may include, inter alia, isocyanate.

Owner:DOCTORS RES GROUP

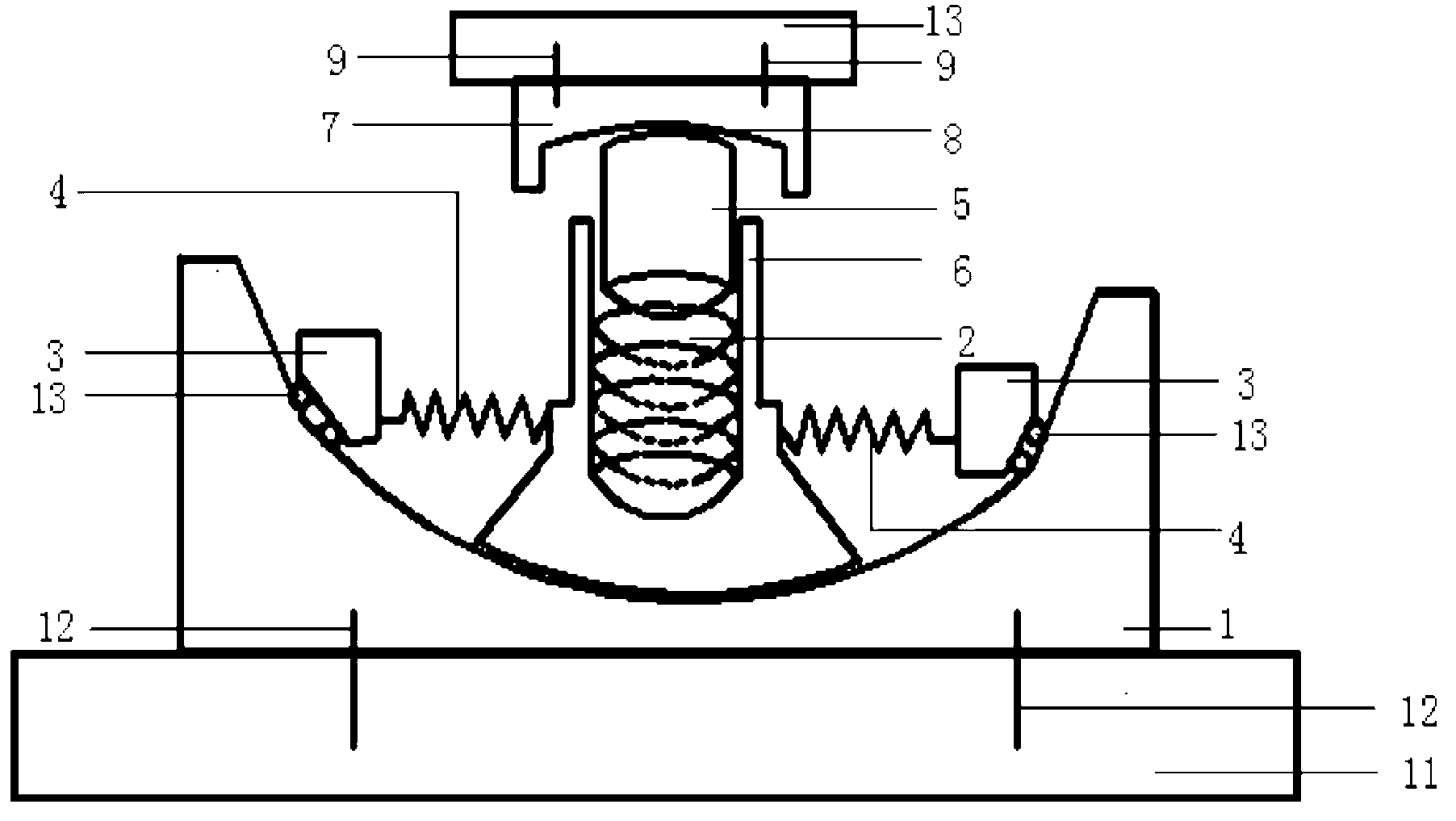

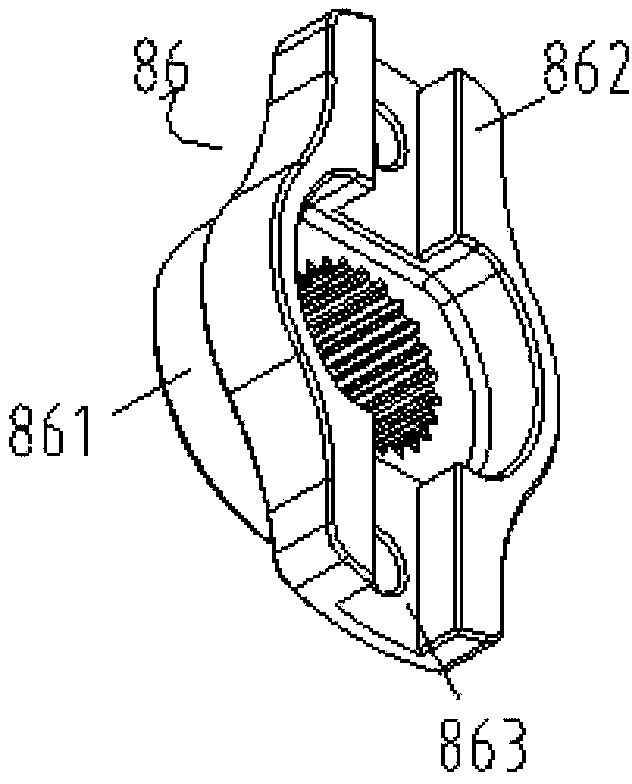

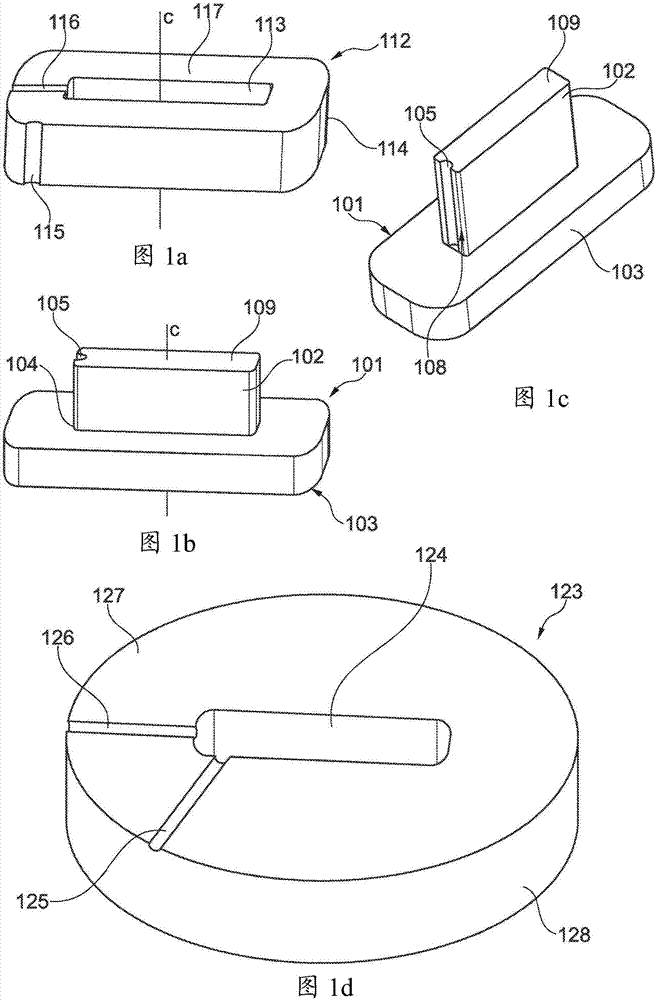

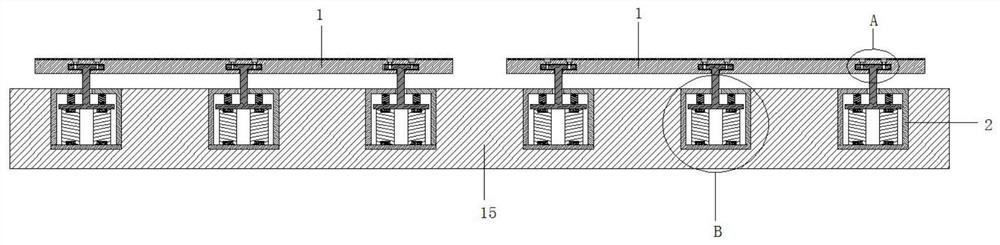

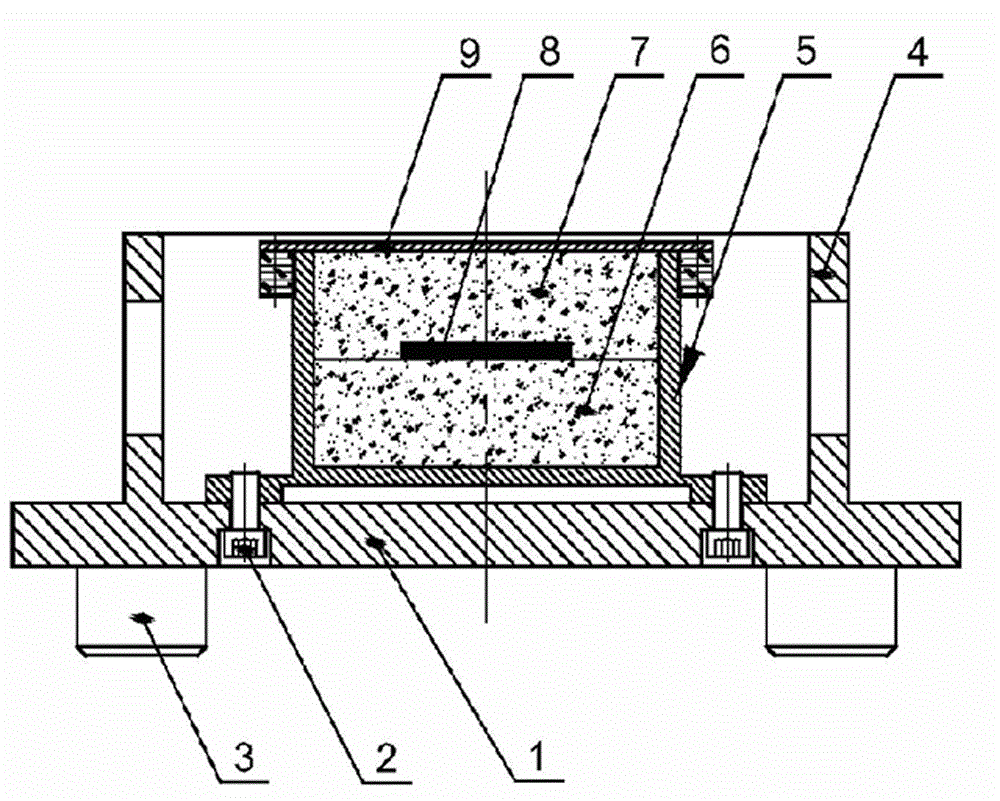

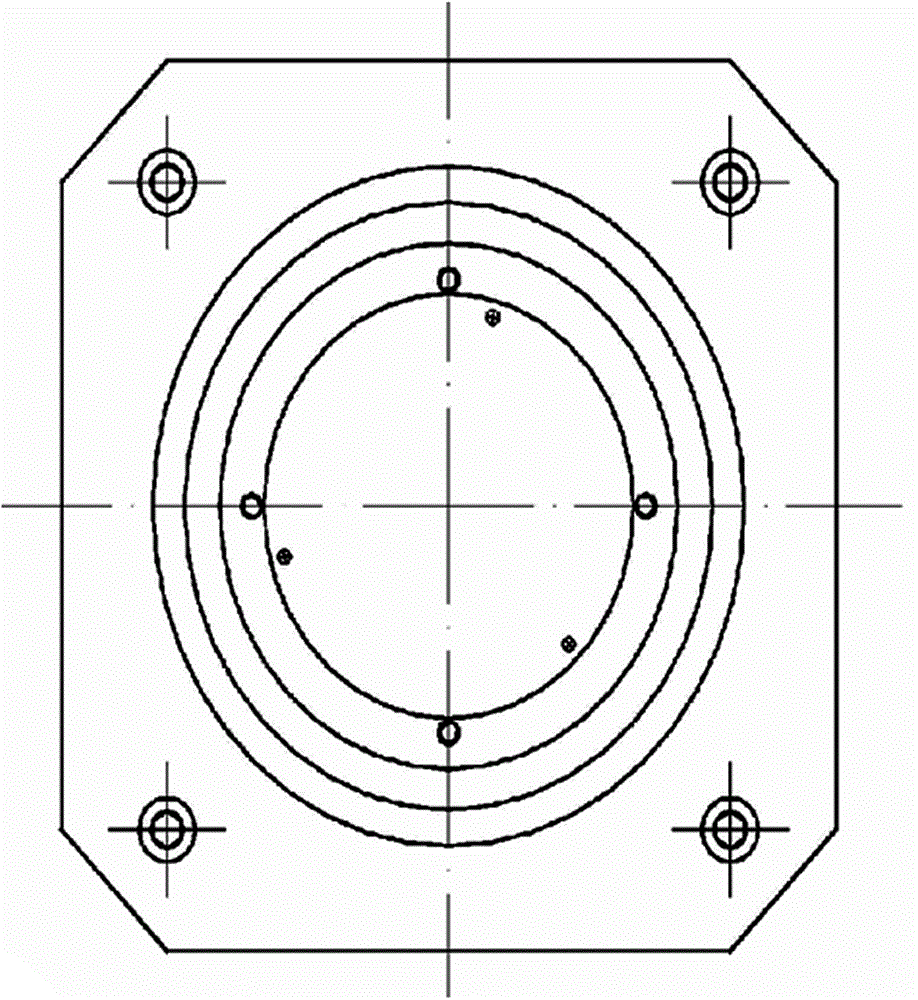

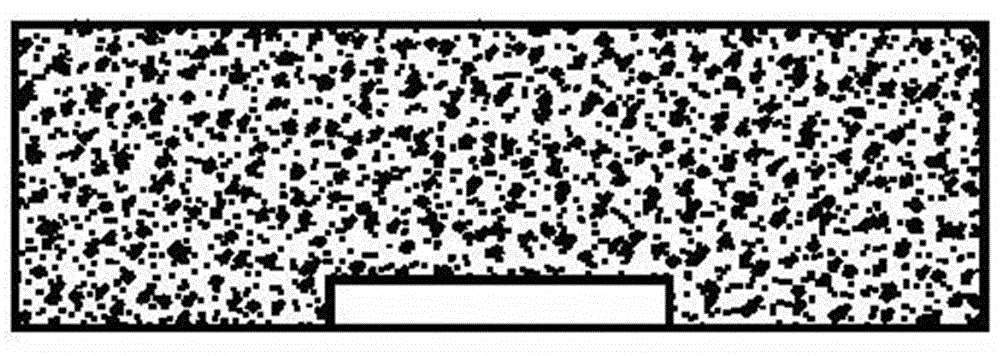

Three-dimensional composite friction pendulum vibration isolator based on nonlinear energy trap

InactiveCN103306316AExtend the natural vibration periodReduce earthquake responseProtective foundationShock proofingSeismic hazardMultiple dimension

The invention discloses a three-dimensional composite friction pendulum vibration isolator based on a nonlinear energy trap. Structural vibration frequency is staggered away from seismic oscillation dominant frequency and a large amount of seismic oscillation input energy is absorbed by using the characteristics of attenuation and absorption of vibration energy, absorption of vibration frequency bandwidth and the like existing in the nonlinear energy trap as well as a vertical vibration isolation disk-shaped spring, so that the multi-dimensional seismic response of a structure is reduced, and seismic hazards of building structures are prevented. The three-dimensional composite friction pendulum vibration isolator comprises a metal sliding sleeve, a disk-shaped spring, a polytetrafluoroethylene sliding joint, a nonlinear energy trap and pile caps, wherein the disk-shaped spring is arranged in the metal sliding sleeve; the polytetrafluoroethylene sliding joint is arranged on the disk-shaped spring; the polytetrafluoroethylene sliding joint is in relative sliding contact with an upper pile cap through a polytetrafluoroethylene coating; the side face of the nonlinear energy trap is connected with the disk-shaped spring through a rigid spring; the nonlinear energy trap is in rolling contact with a lower pile cap through a rolling shaft; sliding surfaces of the upper and lower pile caps are spherical surfaces. The three-dimensional composite friction pendulum vibration isolator is used for resisting possible violent earthquakes.

Owner:NORTHEAST FORESTRY UNIVERSITY +1

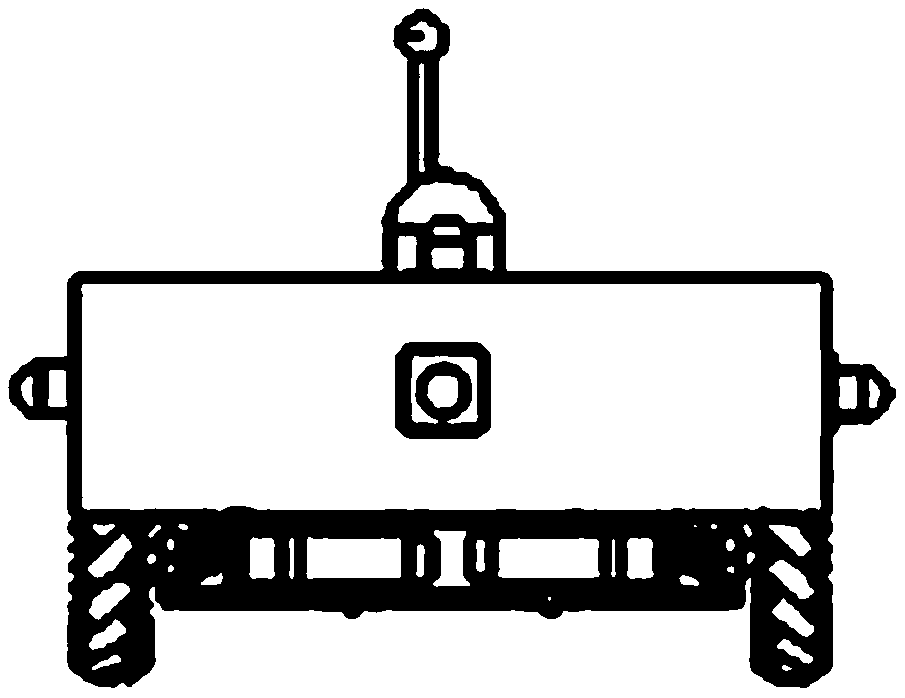

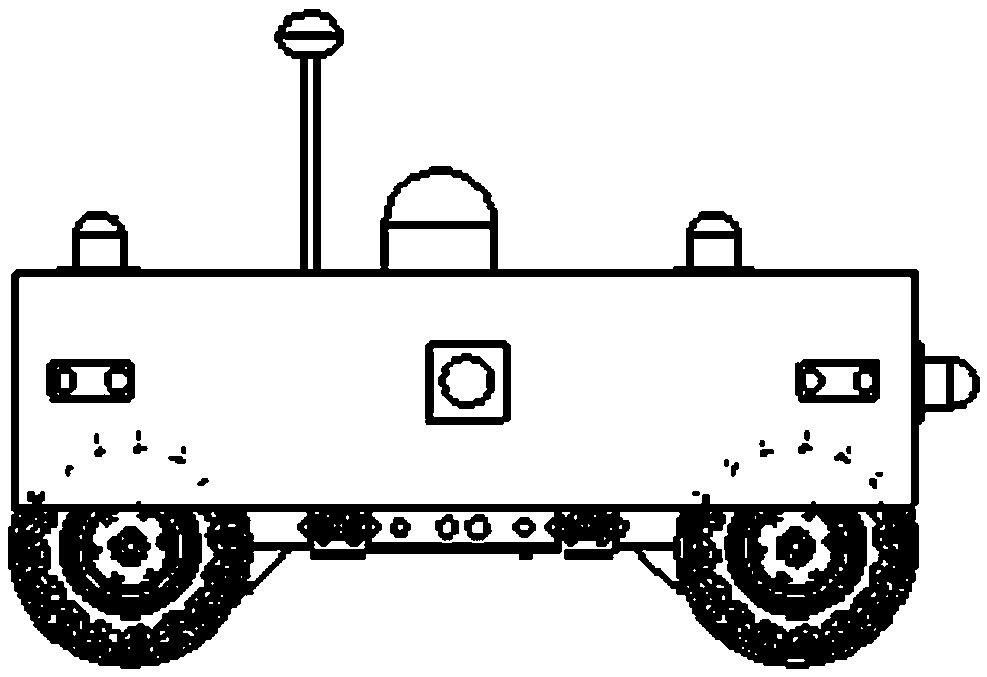

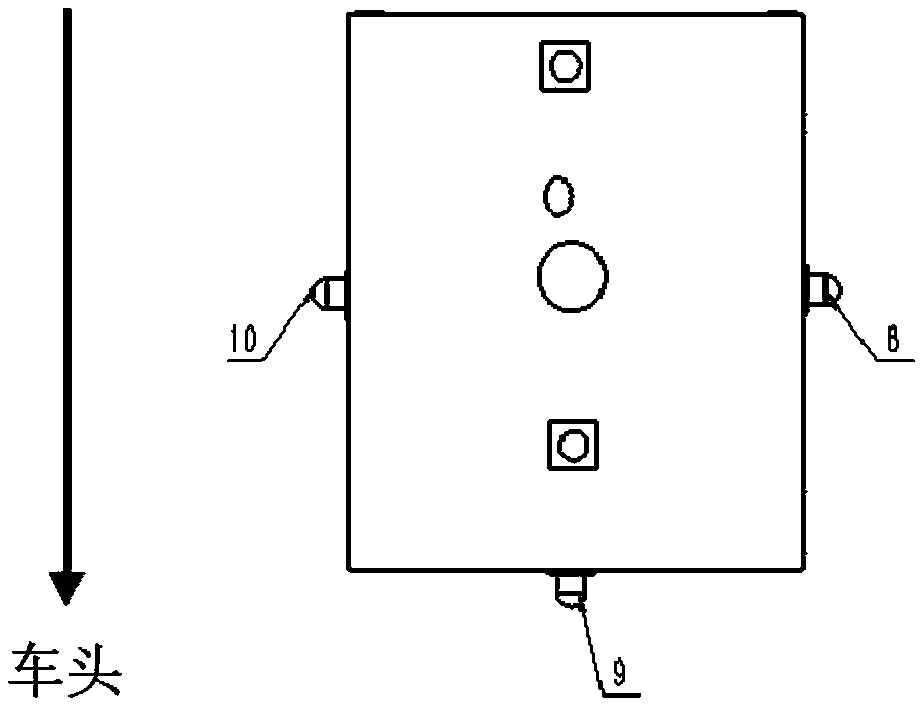

Omnidirectional movement unmanned driving platform method based on highway tunnel crack detection

ActiveCN107589744AImprove accuracyIncrease flexibilityMeasurement devicesPosition/course control in two dimensionsElectric machineryMecanum wheel

The invention provides an omnidirectional movement unmanned driving platform method based on highway tunnel crack detection. The platform comprises a vehicle body and Mecanum wheels arranged at the bottom of the vehicle body. The Mecanum wheels are arranged at the bottom of the vehicle body through pressure springs. The pressure springs at the left side and the right side are configured in a reversed-V-shaped manner in which the pressure springs gradually incline outwards from top to bottom. The Mecanum wheels are connected with a motor in the vehicle body. The motor is connected with a motordriver. The motor driver is connected with a master control single-chip microcomputer. The master control single-chip microcomputer is connected with a computer, an ultrasonic module, a GPS and a nine-axis sensor module. The computer is connected with a laser radar (3) and a camera. The omnidirectional movement unmanned driving platform method has advantages of well settling problems of high speed, high efficiency and high automation in tunnel detection, realizing high significance, reducing wastage of a large amount of manpower and physical resource in highway tunnel crack detection, and greatly improving crack detection accuracy.

Owner:SHENYANG POLYTECHNIC UNIV

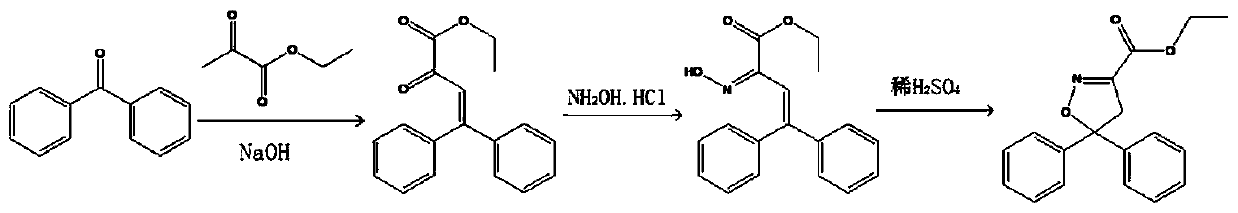

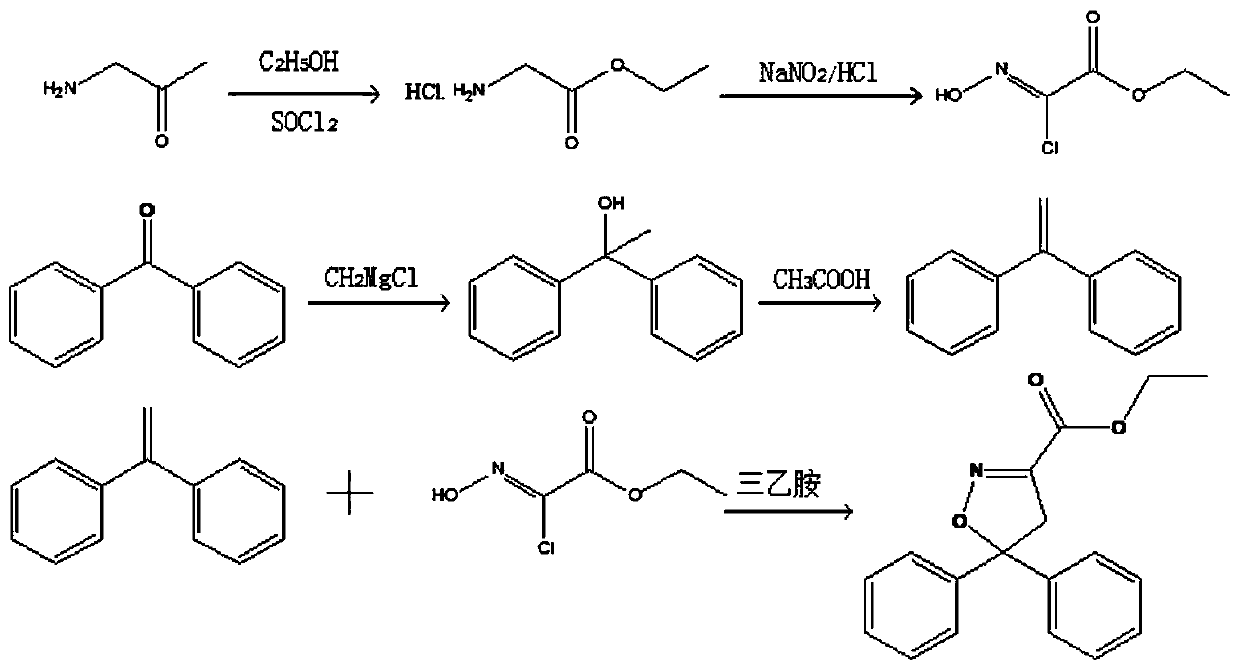

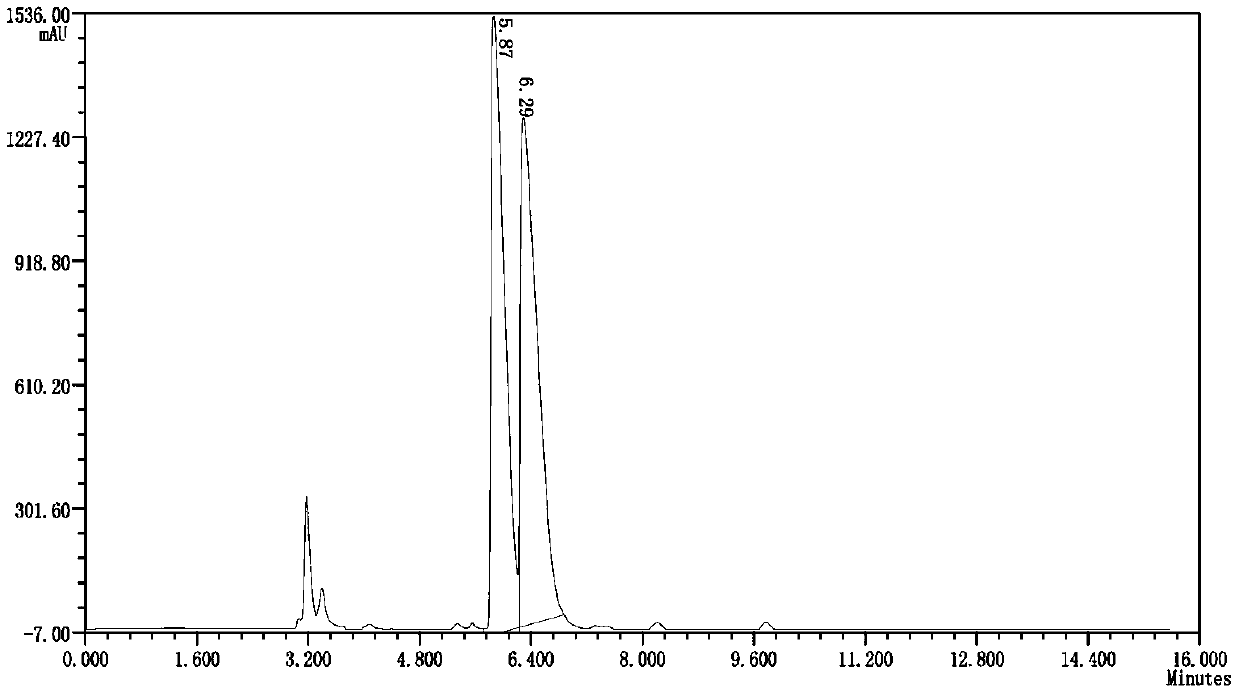

Chiral isoxadifen-ethyl compound and preparation method and application thereof

ActiveCN107652245AAvoid it happening againHigh yieldBiocideOrganic chemistryEnantiomerHerbicide safener

The invention provides a preparation method of a chiral isoxadifen-ethyl compound. The compound prepared by the method is a single enantiomer. The preparation method is simple, few in byproduct, highin product yield and wide in application prospect. In addition, the invention further provides a herbicide safener. The herbicide safener contains the chiral isoxadifen-ethyl compound serving as an active ingredient, so that application range of herbicide can be expanded effectively.

Owner:ZHENGZHOU INST OF CHIRAL DRUGS RES CO LTD

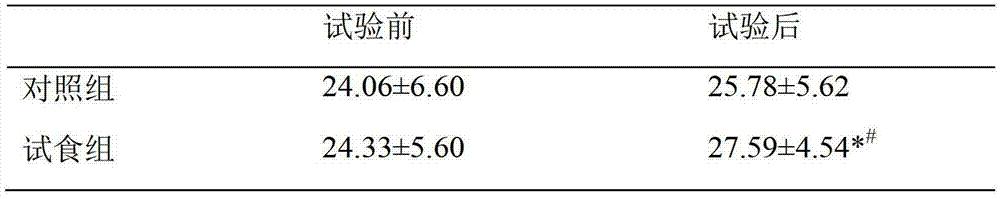

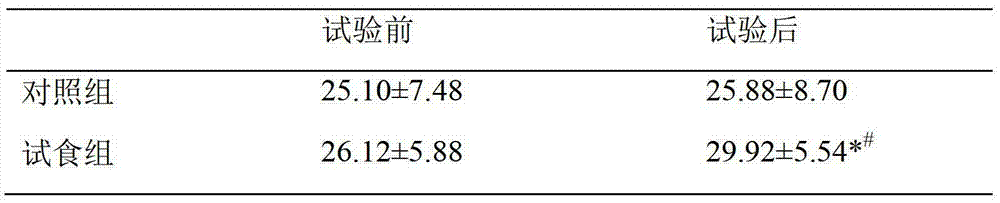

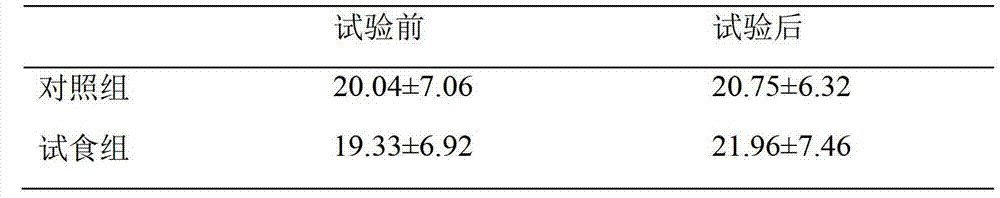

Health-care food with effects of improving eyesight and reinforcing intelligence

The invention discloses a health-care food with effects of improving eyesight and reinforcing intelligence, and belongs to the technical field of health-care foods. The health-care food comprises the following raw materials in parts by weight: 100-600 parts of a needle mushroom extract, 150-500 parts of a Europe blueberry extract, 80-260 parts of a ginkgo leaf extract, 100-400 parts of soyabean lecithin, 50-200 parts of taurine, 80-400 parts of DHA, 0.5-5 parts of VB1, 0.5-5 parts of VB2, 5-20 parts of VB3, 0.25-0.8 part of VA and 5-80 parts of VE. The raw materials are organically combined, so that various different effect components are fused into a product, and the components are matched and coordinated; nutrition is complemented and organisms are conditioned in a systematical and comprehensive manner; and the health-care effects of realizing two functions of improving the memory and relieving the eyesight fatigue are achieved.

Owner:北京三奇医药技术研究所有限公司

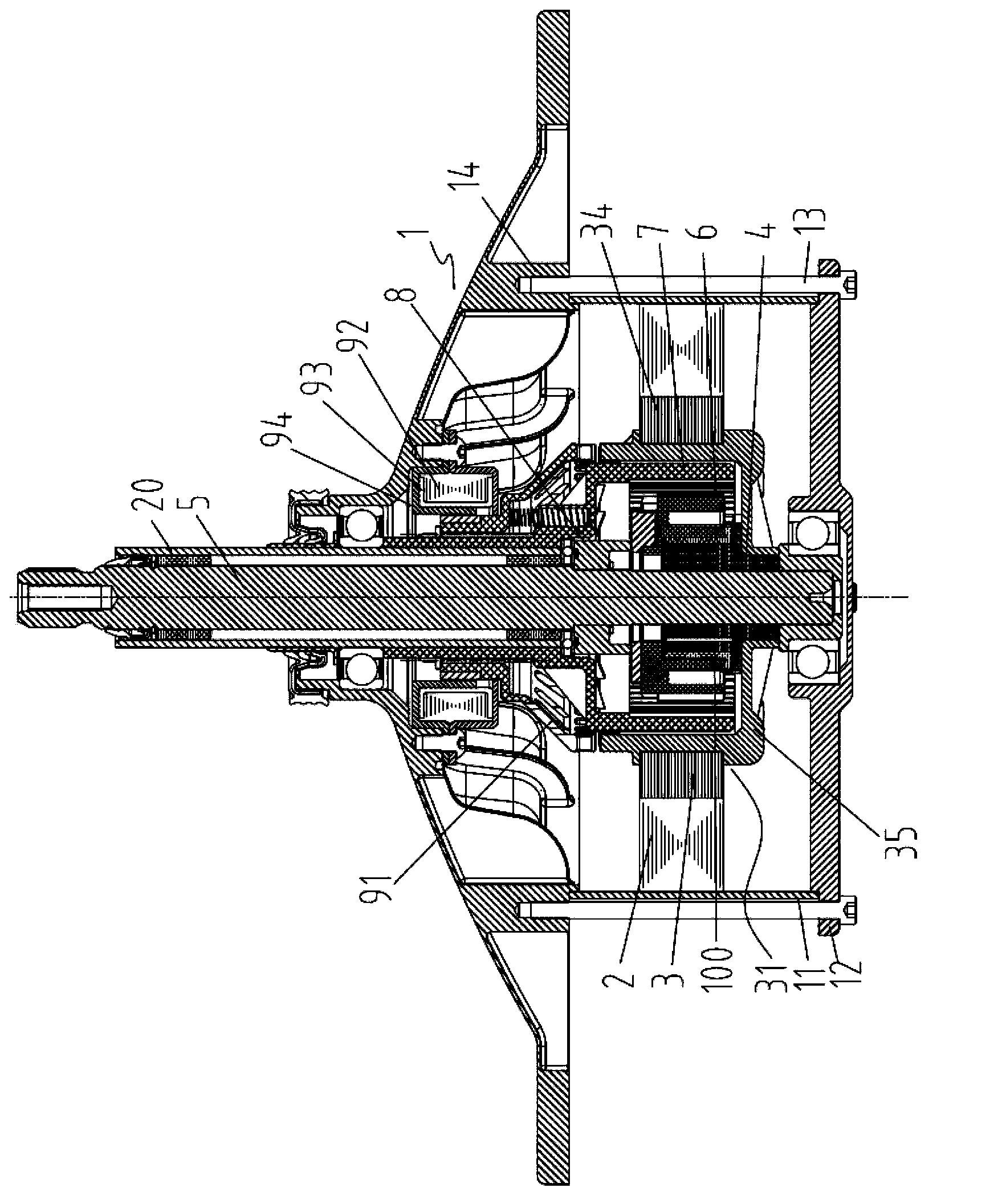

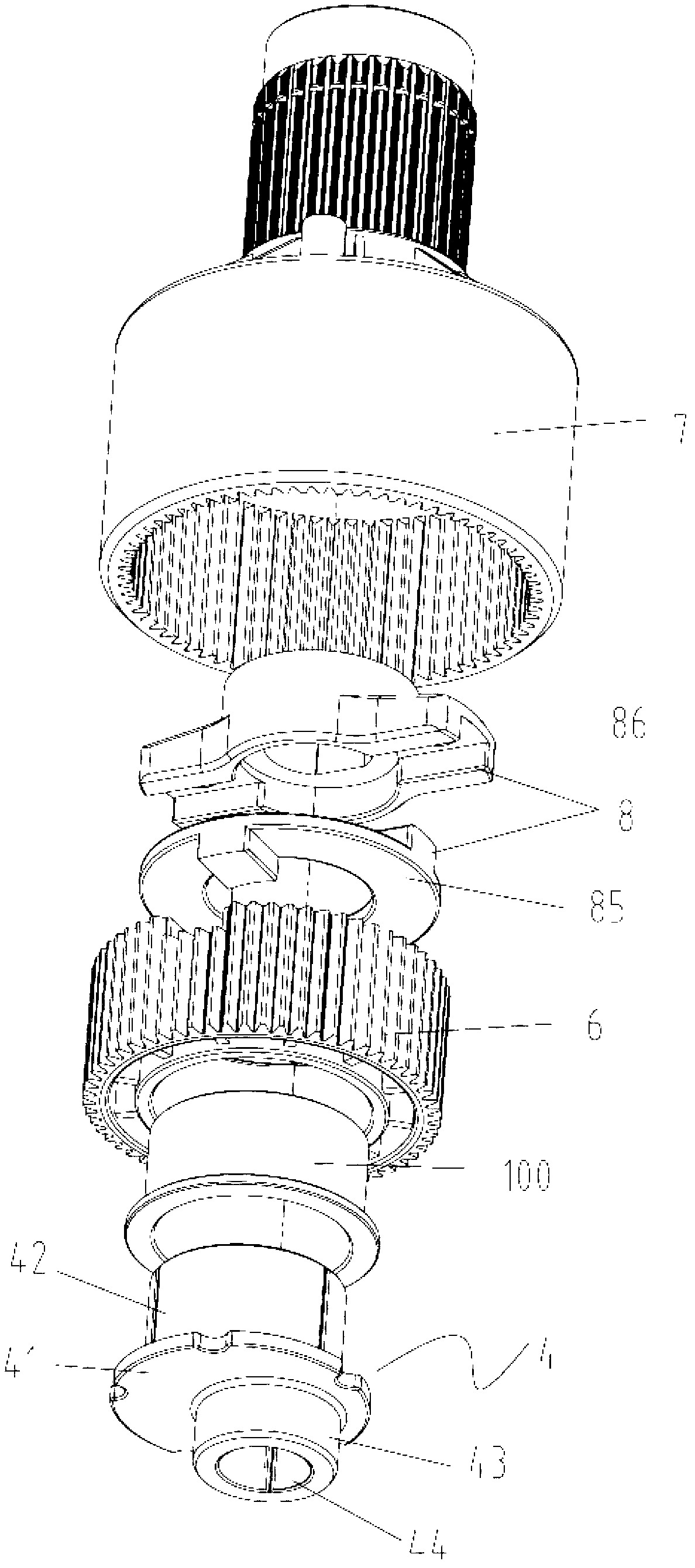

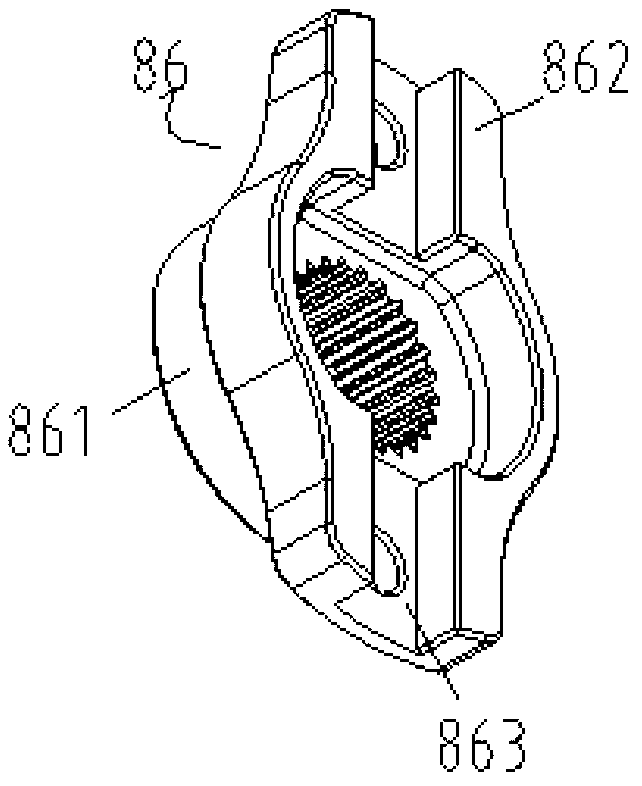

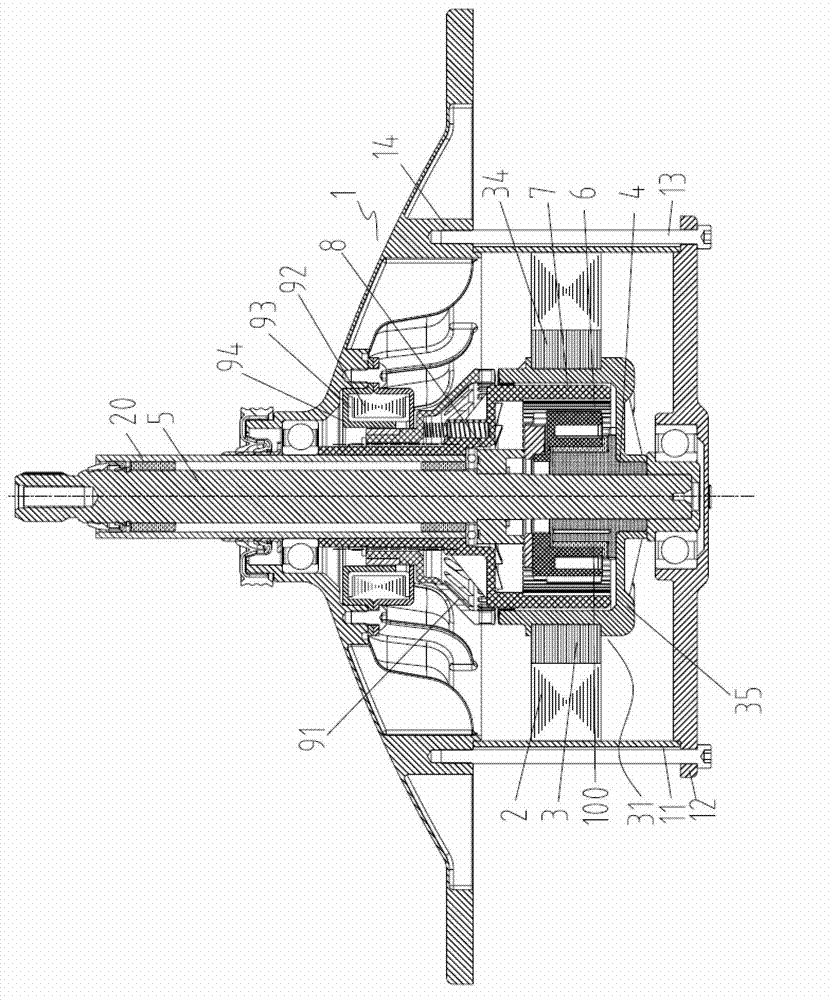

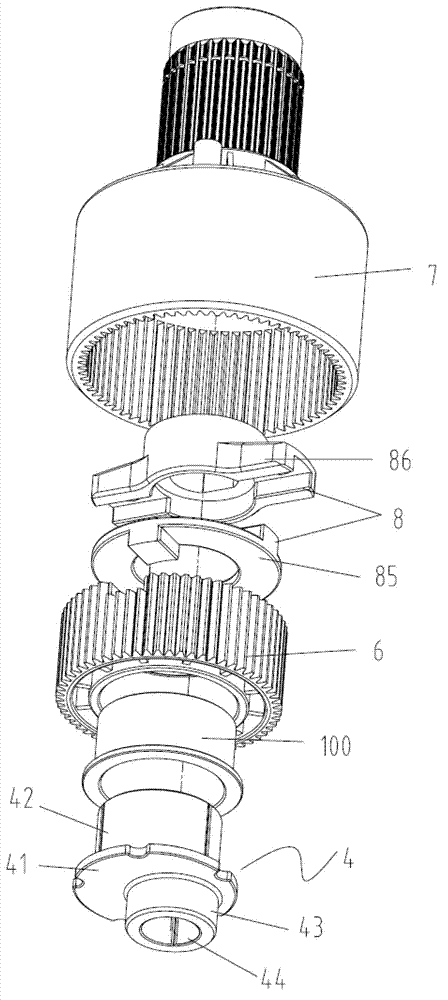

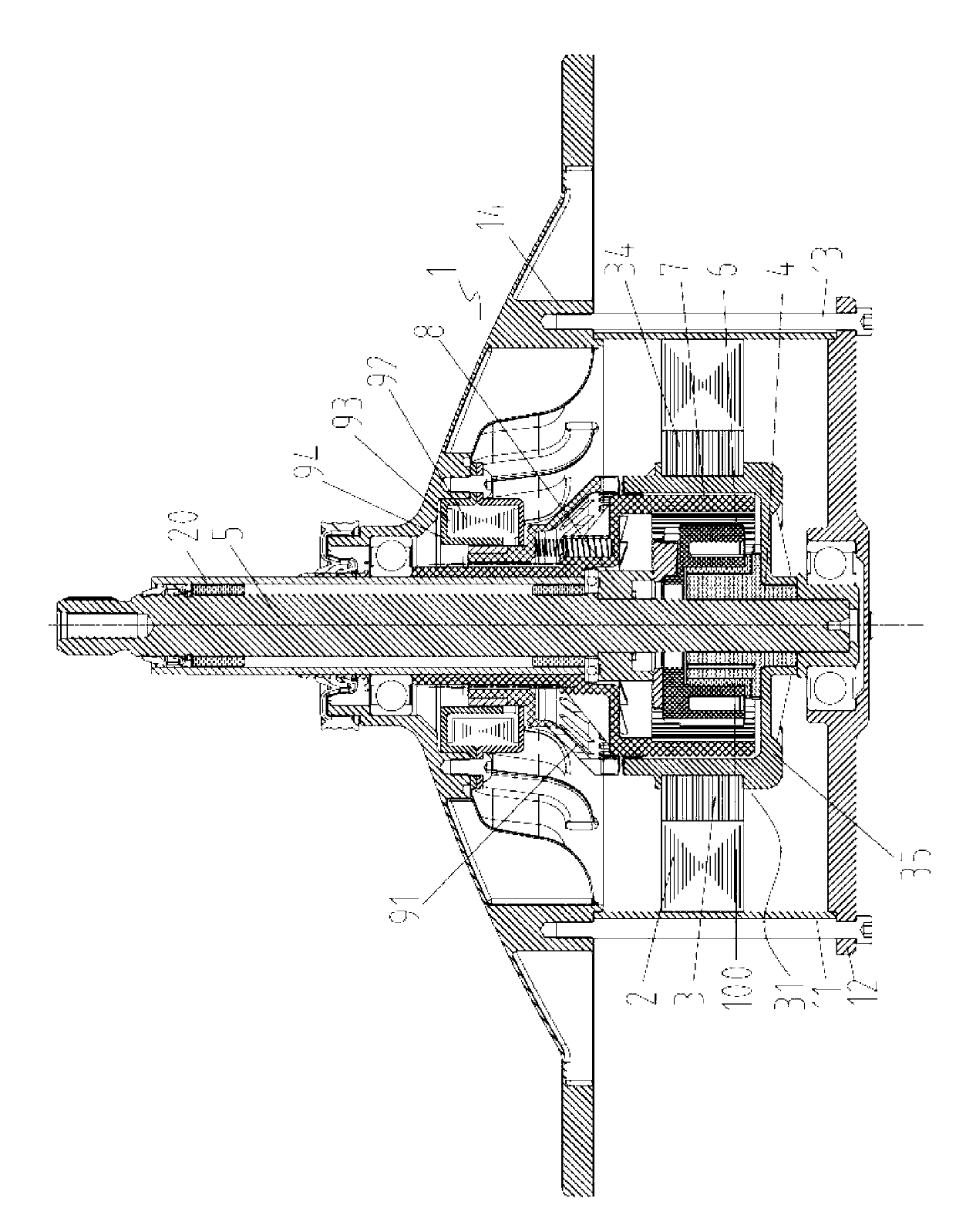

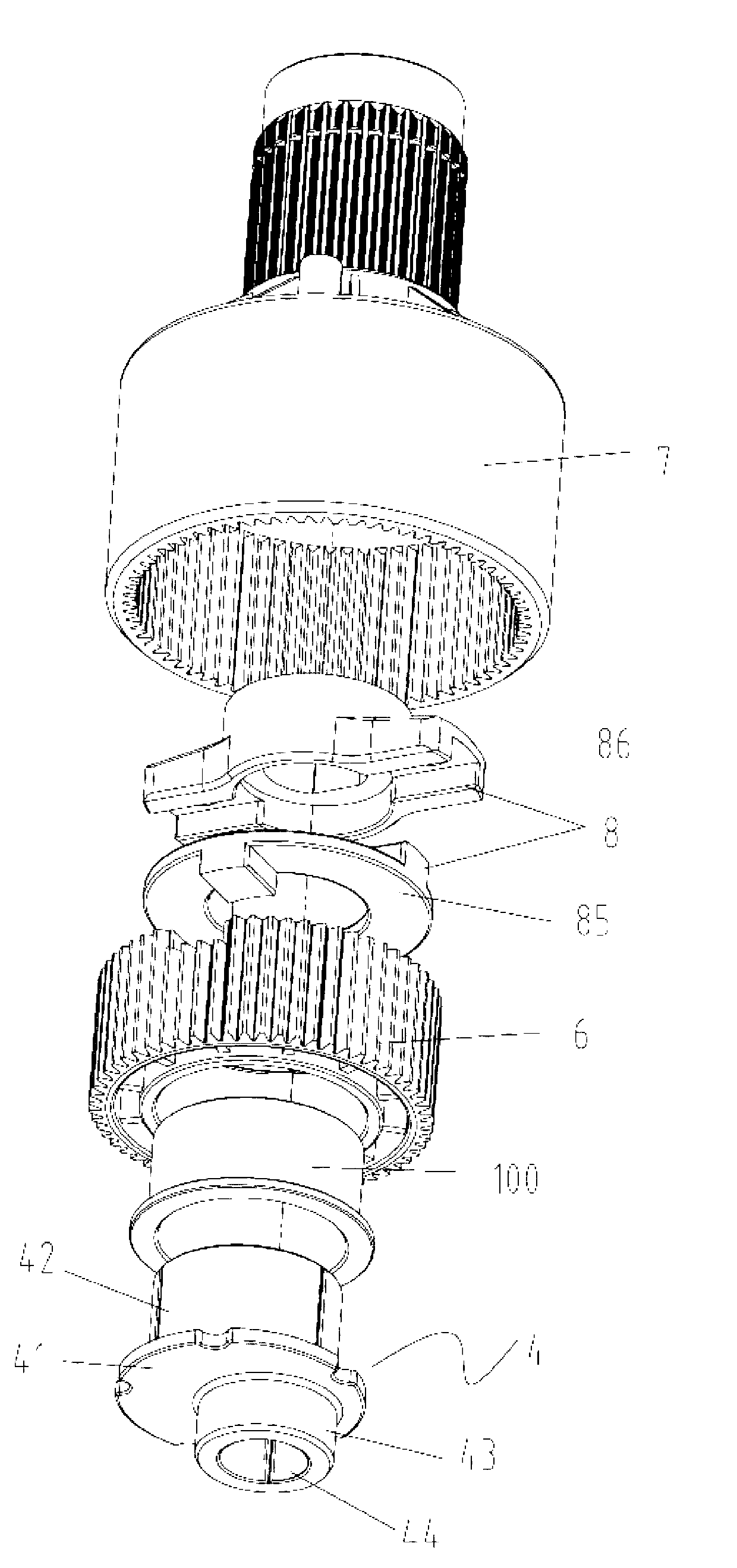

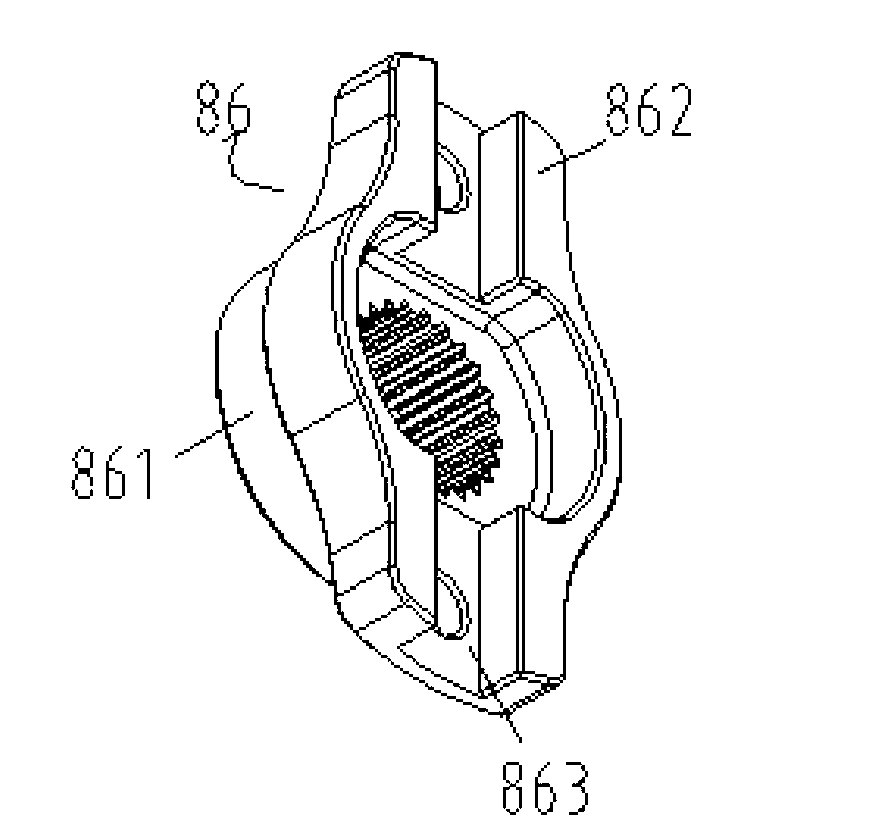

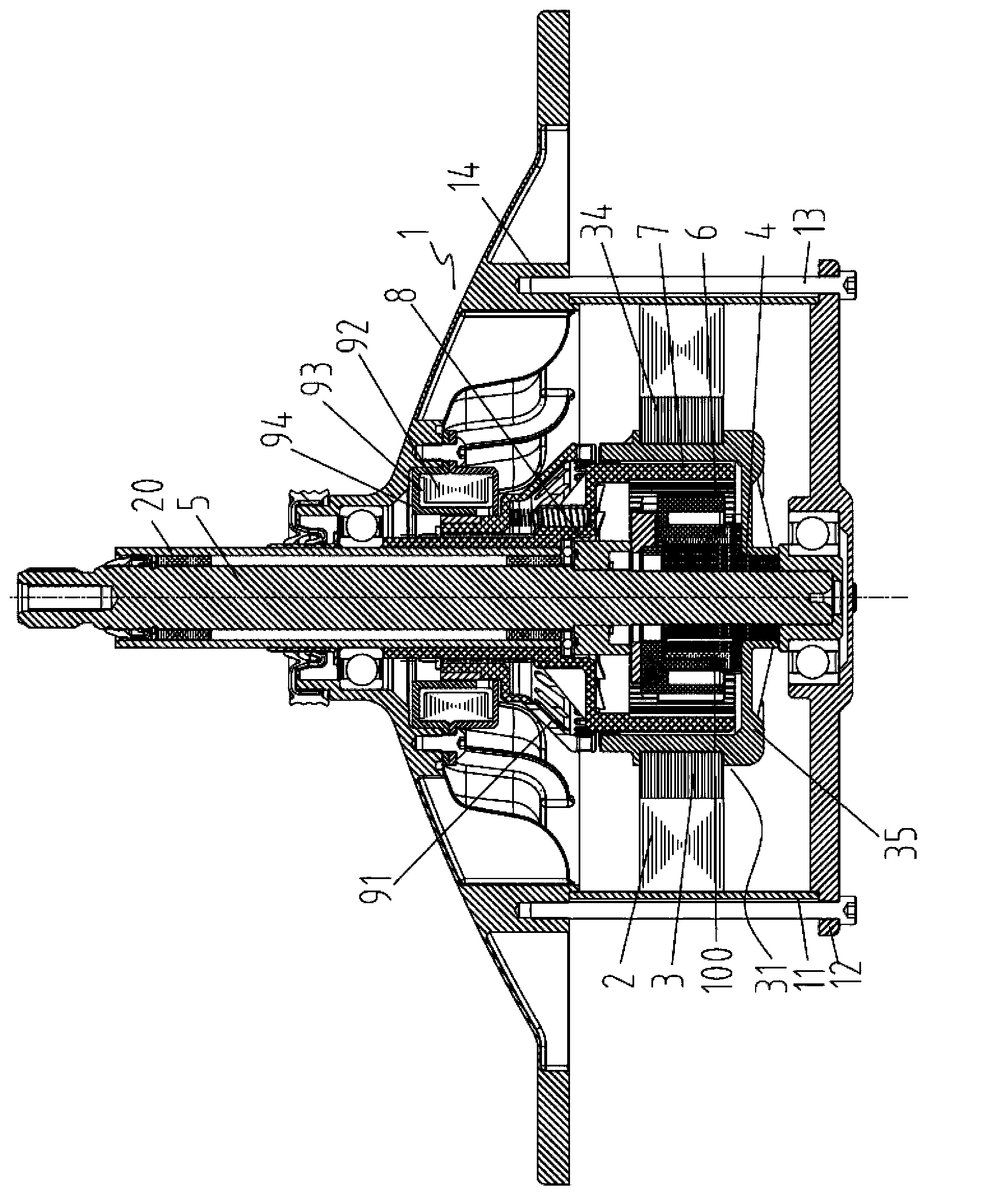

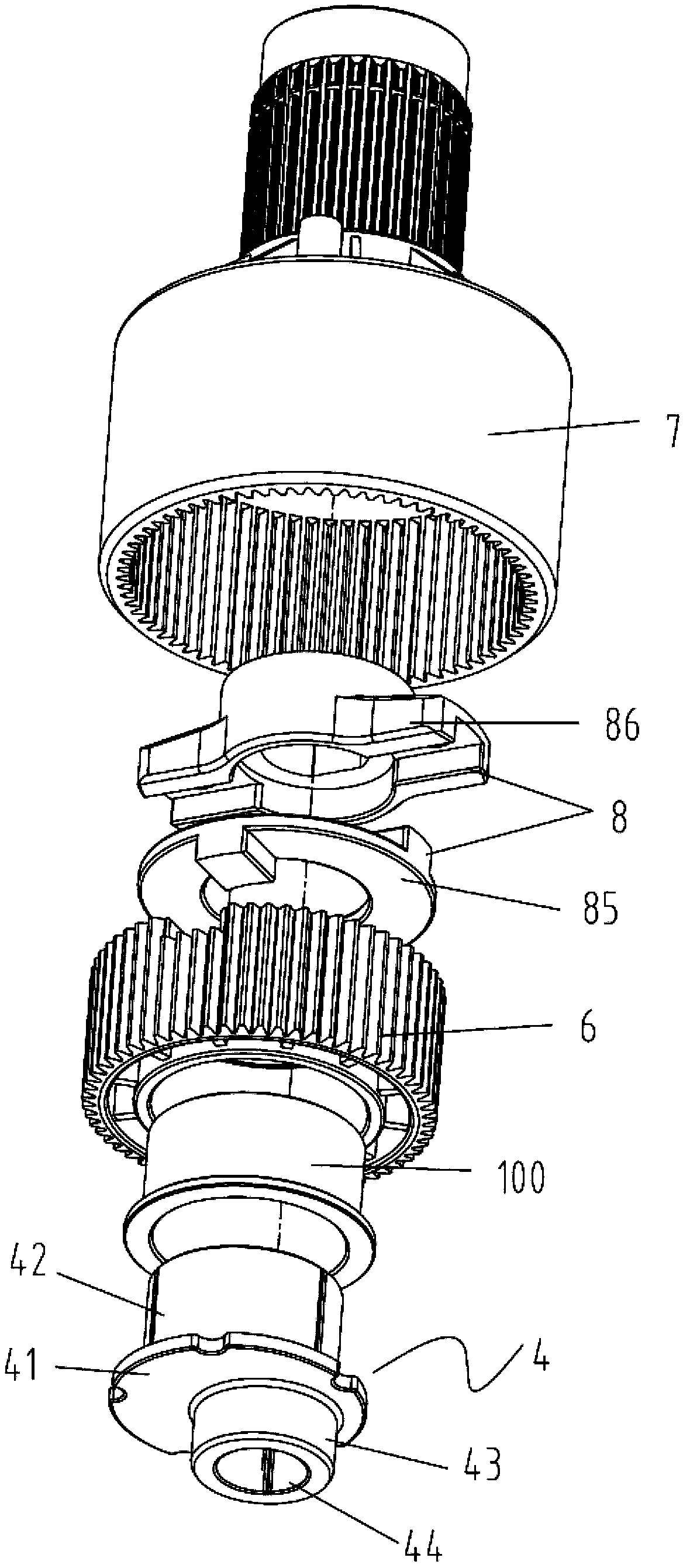

Washing machine double-even-power output method and device, washing machine and washing method

InactiveCN103422325AReduce or eliminate damageAvoid burning accidentsToothed gearingsElectric machinesProcess engineeringPower unit

The invention discloses a washing machine double-even-power output method. The method comprises fixedly connecting an input unit of a reducing mechanism with a power unit for providing rotation kinetic energy; fixedly connecting a dewatering output unit of the reducing mechanism with a dowering shaft casing of a washing machine; connecting a washing output unit with a washing shaft of the washing machine; by connecting the washing output unit with the input unit, enabling the washing output unit to rotate around the axis of the power unit; by connecting the dewatering output unit with the washing output unit through engagement, enabling the dewatering output unit and the washing output unit to achieve self-rotation respectively through the interaction between the dewatering output unit and the washing output unit to drive the washing shaft and the dewatering shaft casing to rotate. The washing machine double-even-power output method enables the rotation speed of the washing shaft to change along with the washing load change.

Owner:CHANGZHOU XINYA ELECTROMOTOR

Washing method and applied washing machine driving mechanism

InactiveCN103103725AReduce or eliminate damageAvoid burning accidentsOther washing machinesControl devices for washing apparatusEngineeringMechanical engineering

The invention relates to a washing method and an applied washing machine driving mechanism. An input member of a reducing mechanism is fixedly connected with a power member which provides rotating motion energy. A dehydration output member of the reducing mechanism is fixedly connected with a dehydration shaft sleeve. A washing output element of the reducing mechanism is connected with a washing shaft. The washing output part is connected with the input element, so that the washing output element rotates around the power element in a revolution mode. The dehydration output element is connected with the washing output element in a meshed mode, so that the dehydration output element and the washing output element respectively rotate by mutual effect through mutual effect. The magnetic damper is arranged and connected outside the dehydration shaft sleeve, and the magnetic damper can produce damping force on the dehydration shaft sleeve, so that rotating speed of the dehydration shaft sleeve is equal to or less than that of a washing shaft. The washing method and the applied washing machine driving mechanism greatly ensure washing effect, and meet the requirement for washing ratio.

Owner:CHANGZHOU XINYA ELECTROMOTOR

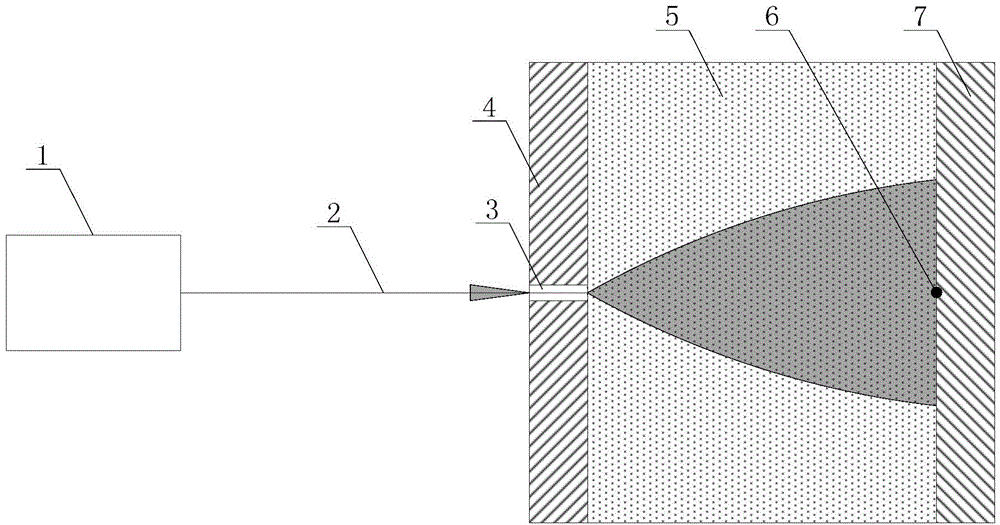

Method for rear wall protection in laser processing of turbine blade by using water and silicon dioxide

InactiveCN104827194AReduce or eliminate damageReduce absorptionLaser beam welding apparatusSilica particleLaser processing

The invention discloses a method for rear wall protection in laser processing of a turbine blade by using water and silicon dioxide, comprising the following steps: grinding the silicon dioxide first; then mixing the silicon dioxide with water to form paste; the paste is injected into a blade runner by virtue of a hole in the top of the turbine blade; punching by adopting pulsed laser; after punching, silicon dioxide particles in the runner are flushed out with flowing water by virtue of the hole in the top of the turbine blade; after the silicon dioxide particles are dried with hot air after being totally flushed out, the laser is scattered, reflected and diffracted by the silicon dioxide particles in front of the rear wall after penetrating through the front wall, and laser spots radiated on the rear wall become large, and the energy is reduced, thus, the power density of the laser radiated on the rear wall becomes small, and accordingly the damage of the laser to the rear wall is weakened or eliminated. The method disclosed by the invention is simple in process and low in cost.

Owner:XI AN JIAOTONG UNIV

Selenium-rich chewing gum

InactiveCN103947816AInhibit synthesisInhibition of replicationChewing gumNormal peopleKappa-selenocarrageenan

The invention relates to a selenium-rich chewing gum. The selenium-rich chewing gum is characterized in that Kappa-selenocarrageenan is added into a chewing gum matrix to supplement 50-200mu g of organic selenium for normal people through chewing every day. According to the selenium-rich chewing gum provided by the invention, the chewing gum is taken as a carrier for supplementing selenium, the concept is novel, the mode of usually taking selenium-containing tablets and capsules by people is broken through, the selenium-rich chewing gum is very convenient to take and carry, Kappa-selenocarrageenan is added into the chewing gum matrix to prepare the selenium-rich chewing gum, Kappa-selenocarrageenan is slowly dissolved in saliva of the people and absorbed during the process that people chew the chewing gum and then, the selenium supplement for people is simple, convenient and direct; furthermore, the price is low and the selenium-rich chewing gum is easily accepted by the people.

Owner:柯志卫

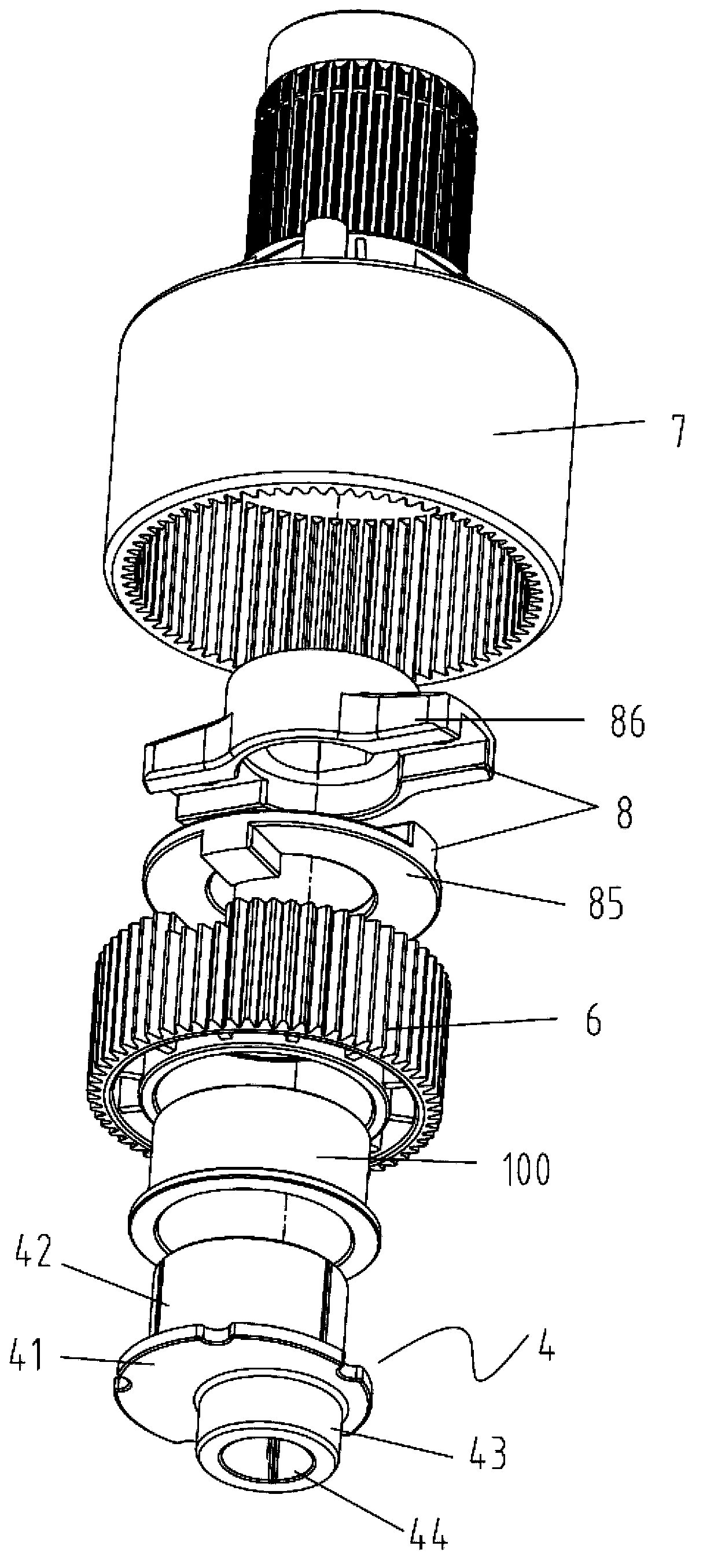

Motor assembly for vertical axis washer

InactiveCN103117631AReduce manufacturing costReduce noiseOther washing machinesAsynchronous induction motorsMaximum torqueActuator

The invention relates to a motor assembly for a vertical axis washer. The vertical axis washer comprises a wash actuator fixedly connected with a wash shaft and a dewatering actuator fixedly connected with a dewatering shaft sleeve. The motor assembly comprises a motor, a reduction mechanism connected with the motor, the wash shaft, the dewatering shaft sleeve, and a clutch device, wherein the wash shaft and the dewatering shaft sleeve are connected with the reduction mechanism and the clutch device is used for switching washing and dewatering modes. The motor assembly is characterized in that the motor is an eight-pole induction motor. The eight-pole induction motor comprises a stator component and a rotor component mounted within the stator component. Rotation axis of the rotor component overlaps with axis of the wash shaft. The motor assembly fully satisfies maximum torque and starting torque required by mechanism operation, enables manufacturing cost to be greatly lowered and is low in noise.

Owner:CHANGZHOU YATONG JIEWEI MOTOR

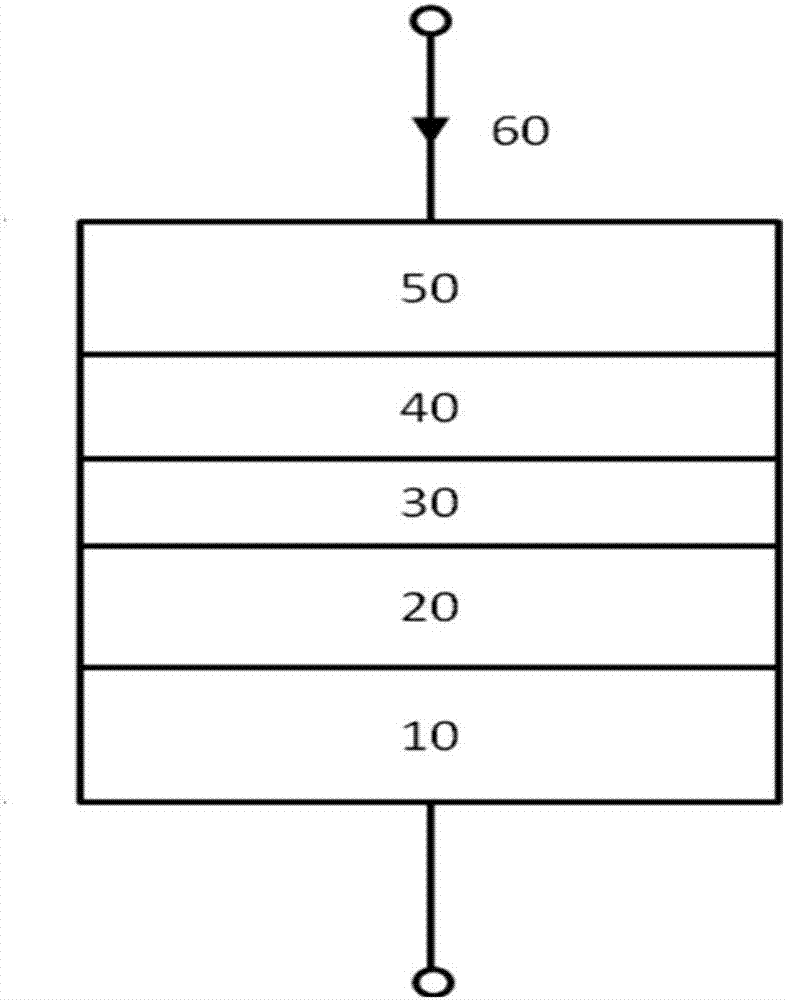

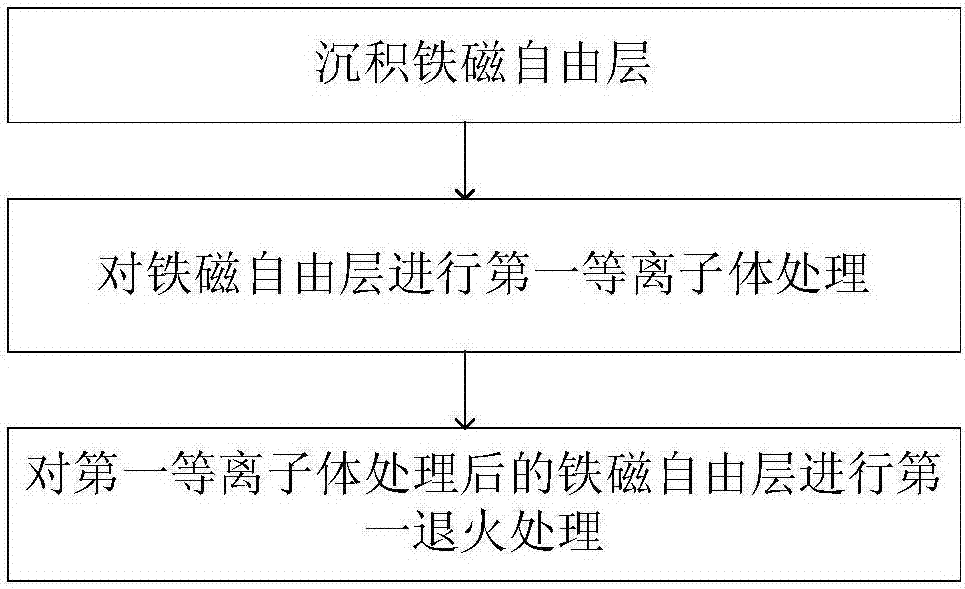

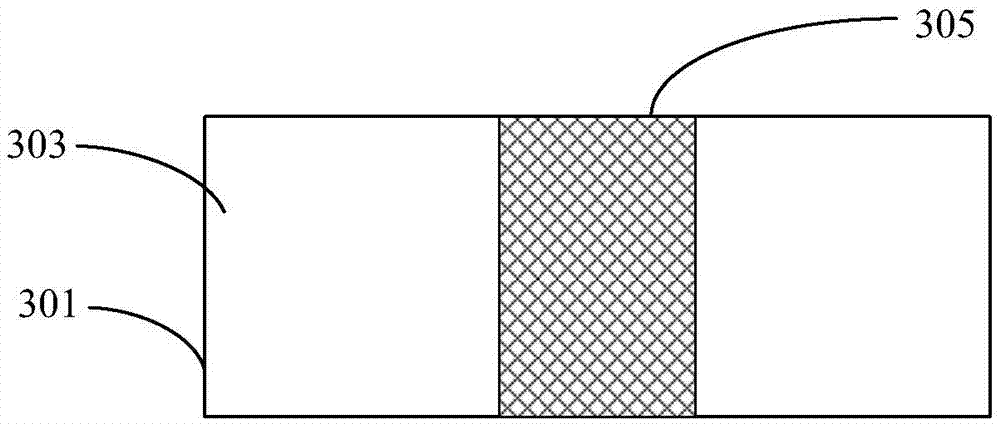

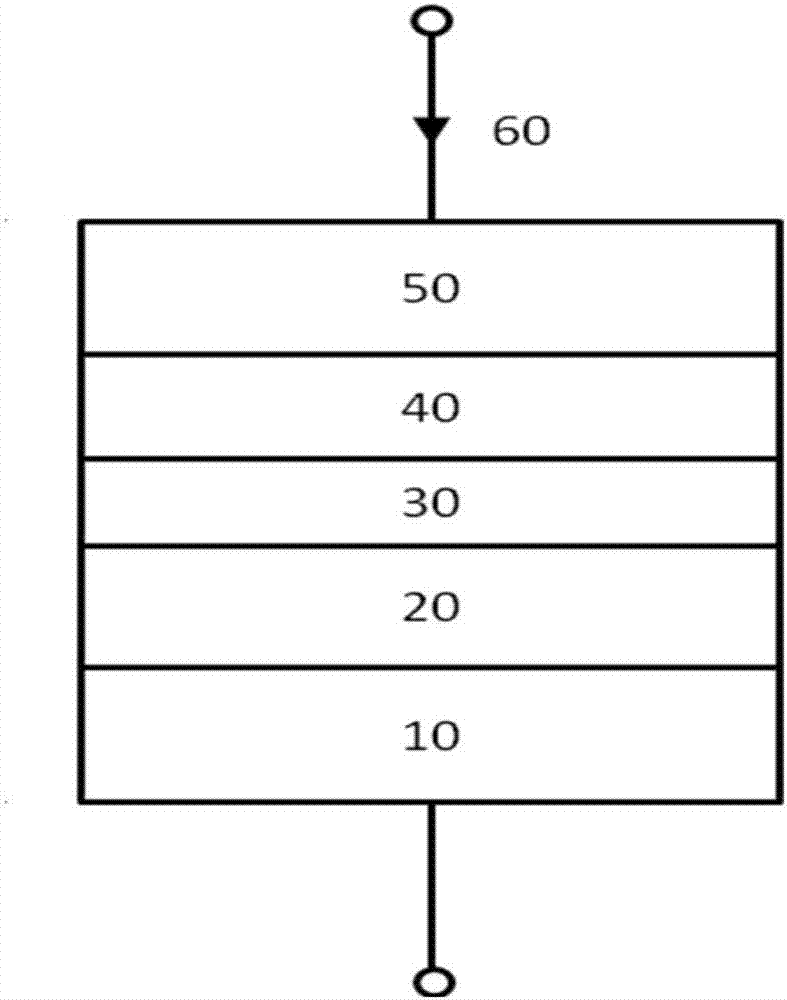

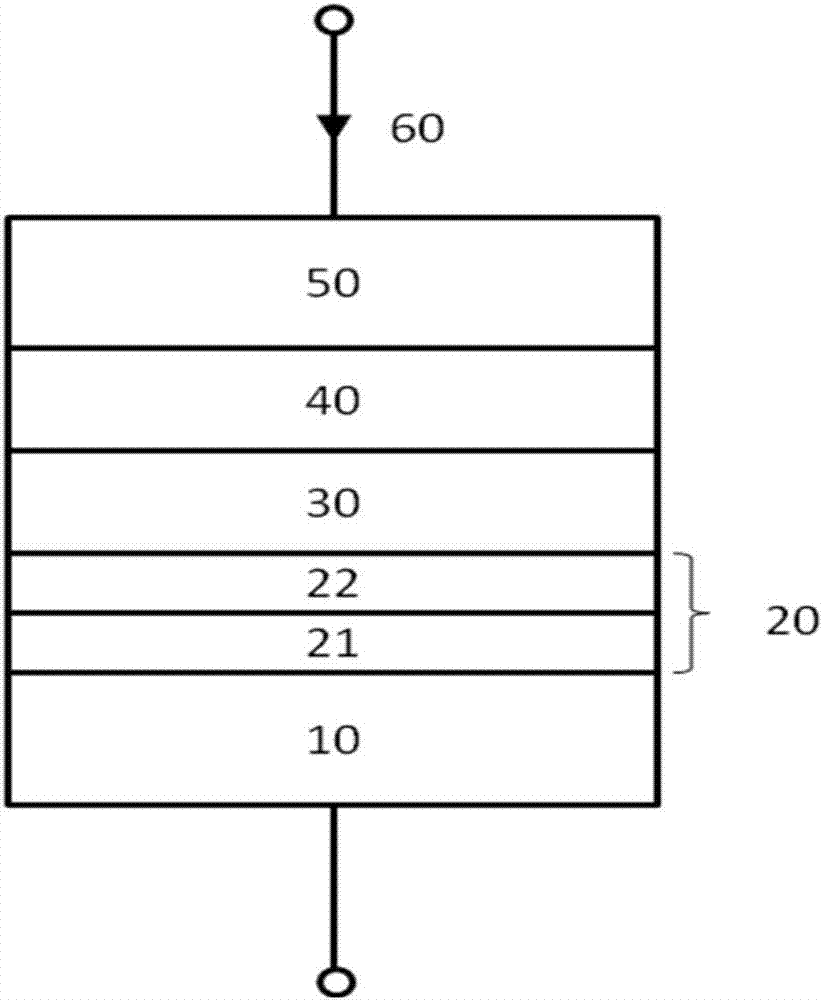

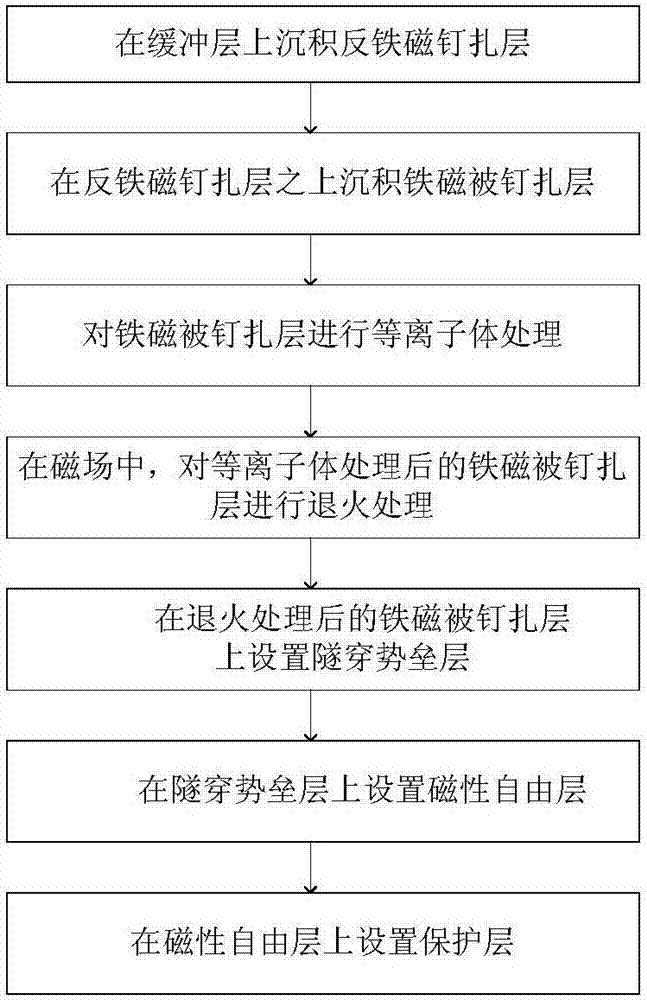

Method for preparing free layer of magnetic tunnel junction and method for preparing magnetic tunnel junction

ActiveCN107958953AImprove surface propertiesImprove performanceGalvano-magnetic device manufacture/treatmentDeposition processTunnel junction

The invention provides a method for preparing a free layer of a magnetic tunnel junction and a method for preparing a magnetic tunnel junction. The method for preparing a free layer of a magnetic tunnel junction includes the steps of setting the films of a free layer through a deposition process, carrying out first plasma treatment on one or more of the films, and carrying out first annealing treatment on the one or more of the films after the first plasma treatment. As in-situ heat treatment is carried out on the one or more films after the first plasma treatment through the first annealing treatment, possible damage or defects caused by the first plasma treatment can be reduced or eliminated, and the surface characteristic of the free layer can be improved. Therefore, the comprehensive performance of a magnetic tunnel junction comprising the free layer can be improved, for example, the TMR value of the magnetic tunnel junction can be improved, and the RA value can be reduced.

Owner:CETHIK GRP +1

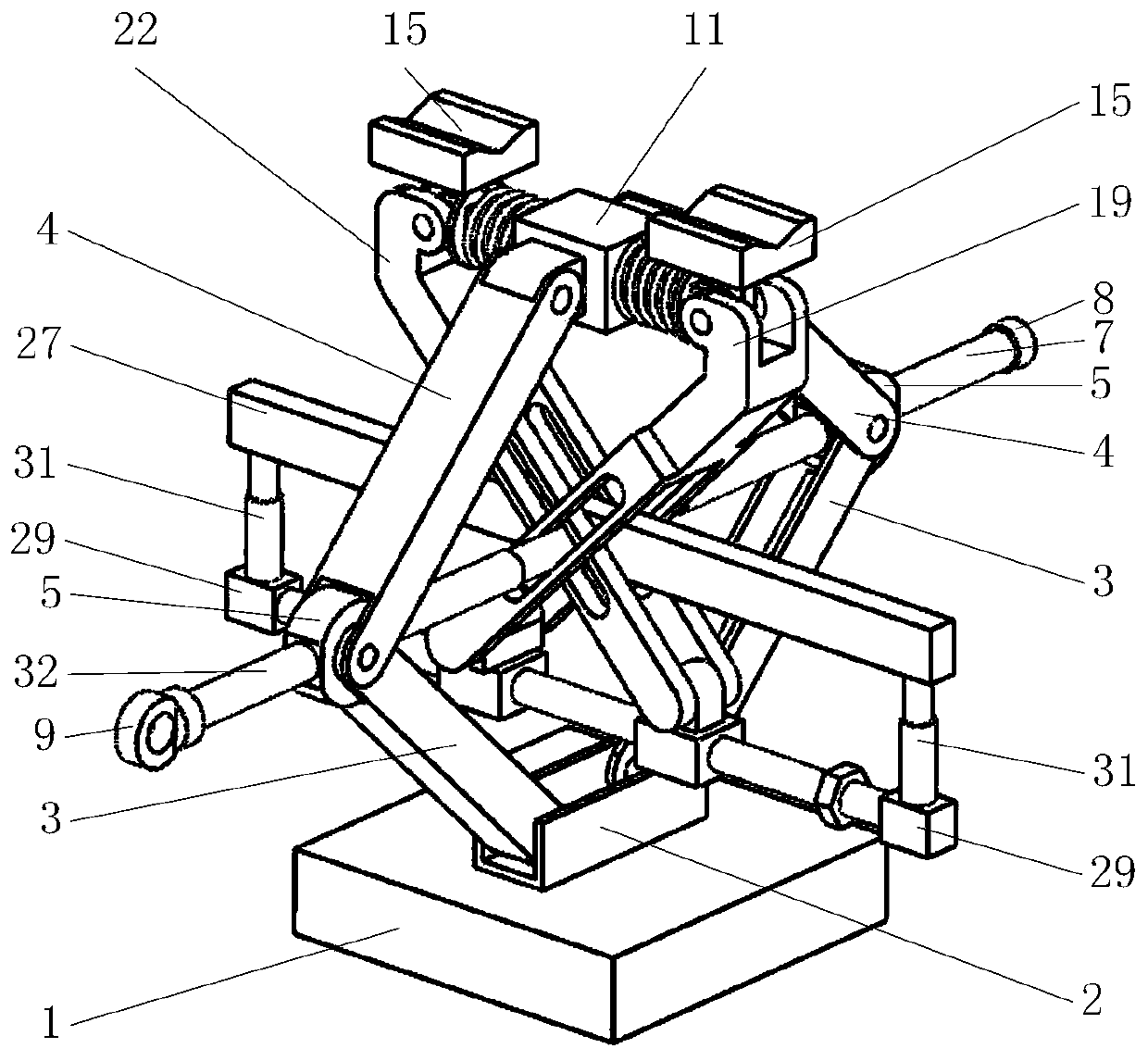

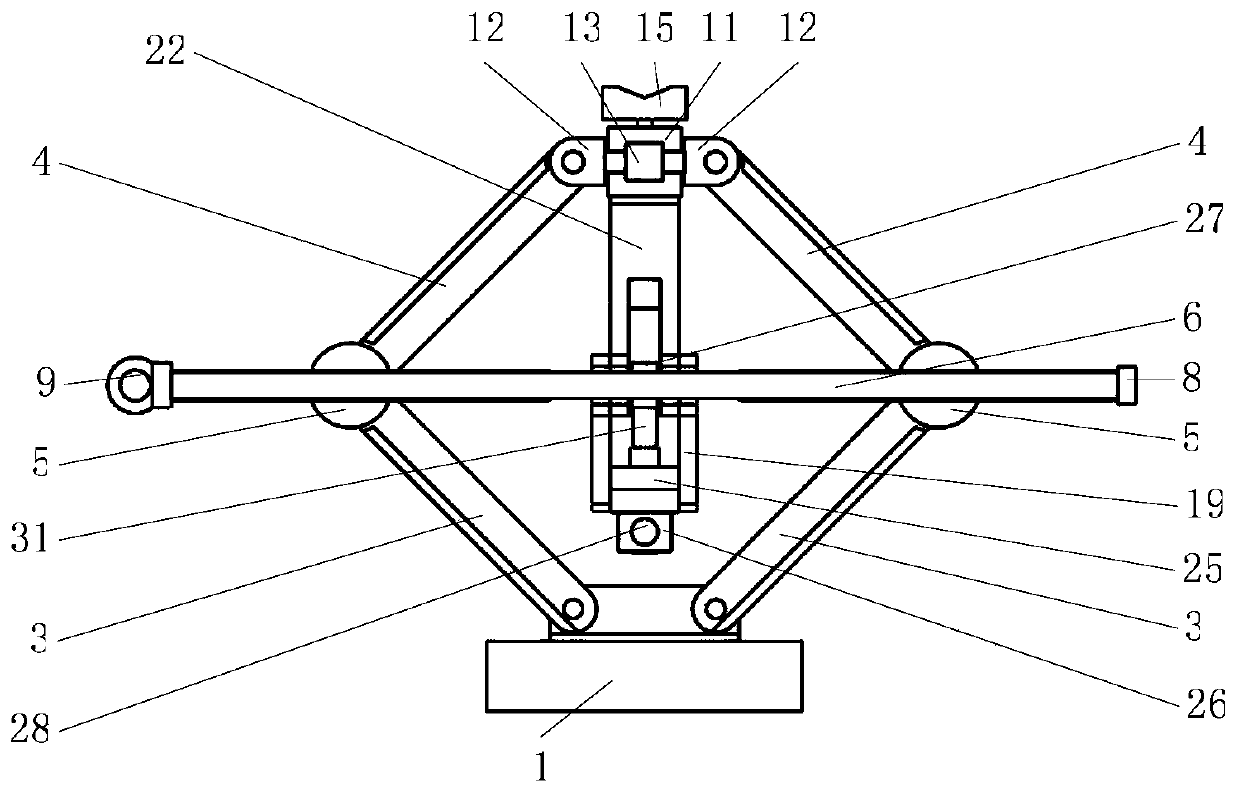

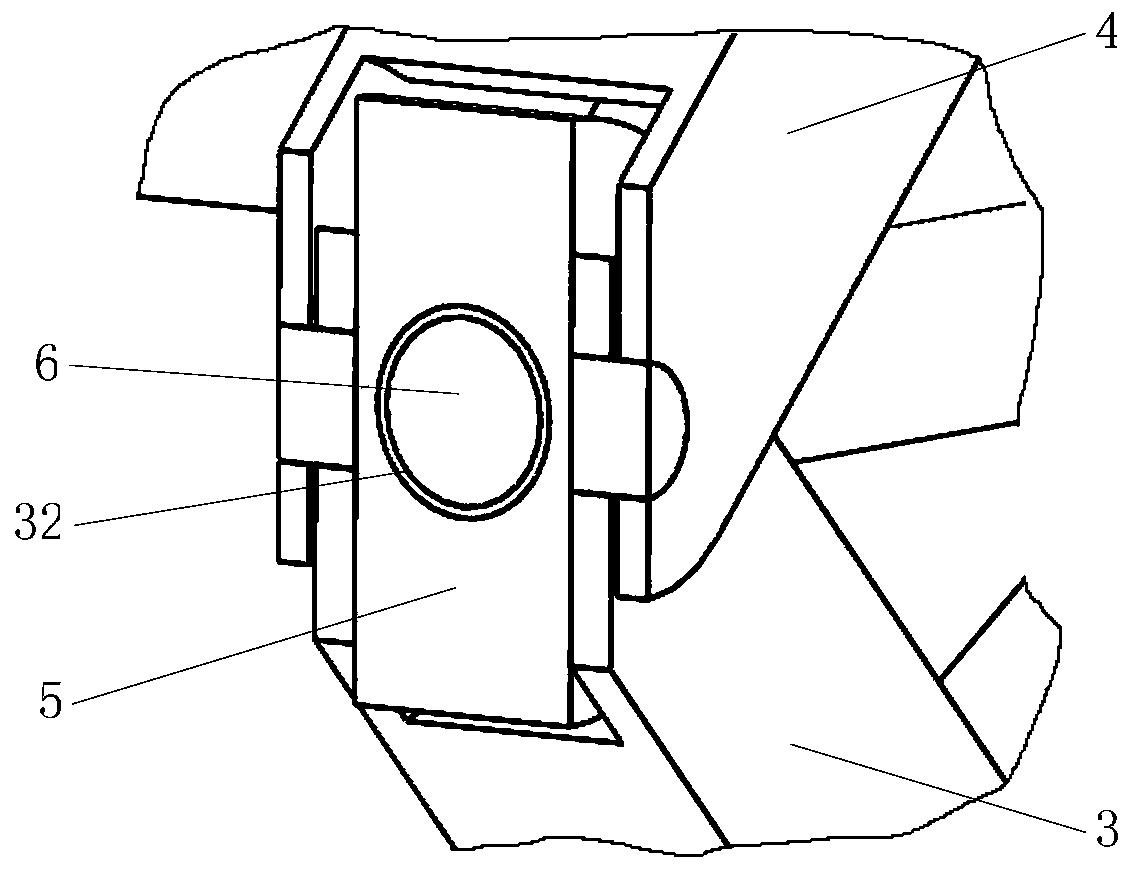

Jack for vulnerable part

The invention belongs to the technical field of jacks, and particularly relates to a jack for a vulnerable part. The jack comprises a base B, lower support arms, upper support arms, a hinge block A, ascrew rod A, a screw rod B and the like, wherein the two lower support arms distributed symmetrically are hinged with the two upper support arms separately; and the ends, which are not hinged with the corresponding upper support arms, of the two lower support arms are hinged with the base B. According to the jack, the situation that the position of an elastic cushion of a traditional shear jack needs to be regulated repeatedly and consequently fatigue deformation of a vehicle body or equipment occurs due to repeated effects on the vulnerable part which must be supported is avoided effectively; in the regulation process of the elastic cushion, reciprocating lifting of the local part of the vehicle body or the equipment is not required, while the vulnerable part of the vehicle body or the equipment is kept unmoved locally all the time; and the vehicle body or the equipment is prevented from being damaged due to reciprocating lifting of the vulnerable part.

Owner:李秀梅

Clothes-washing method

InactiveCN103103724AReal-time adjustment of washing output modeReduce washing energy consumptionOther washing machinesControl devices for washing apparatusLaundry washing machineProcess engineering

The invention relates to a clothes-washing method which comprises the following steps: a washing machine comprises a magnetic damper which is connected with a dehydration shaft sleeve in an arrangement mode, the magnetic damper is connected with the dehydration shaft sleeve in an arrangement mode, and the magnetic damper can produce damping force on the dehydration shaft sleeve. Under the working condition of washing, the damping force which is produced by the magnetic damper is adjusted to achieve adjustment of rotating speed on the dehydration shaft sleeve and further achieve washing output of different modes. Under the working condition of washing, the damping force which is produced by the magnetic damper is adjusted to achieve the adjustment of the rotating speed of the dehydration shaft sleeve to achieve the washing output of the different modes. According to different washing load conditions, a washing output mode is adjusted in real time, washing energy consumption is reduced to the maximum extent, and simultaneously an optimum washing effect is achieved.

Owner:CHANGZHOU XINYA ELECTROMOTOR

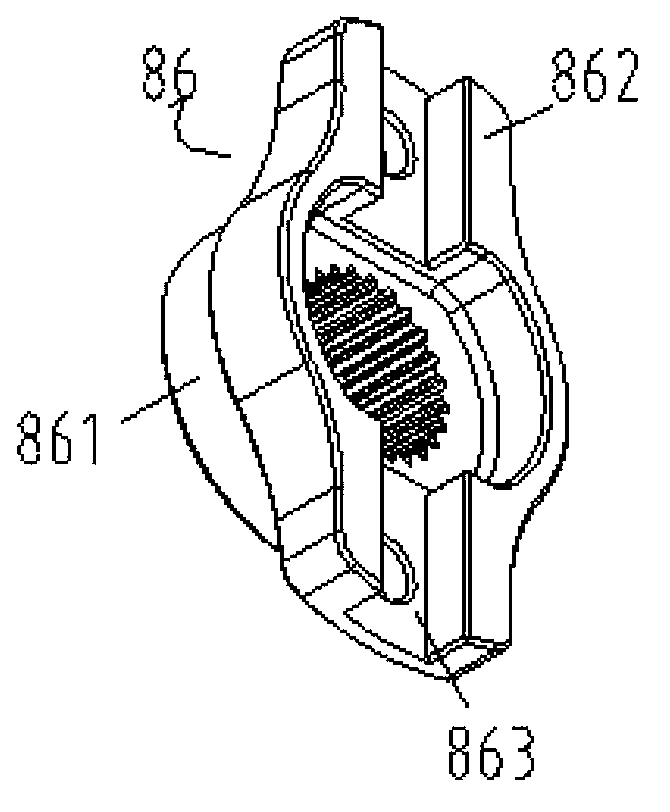

Gear speed reduction device, washing machine and washing method thereof

InactiveCN103422316AReduce volumeMiniaturizationToothed gearingsOther washing machinesReduction driveReducer

The invention discloses a gear speed reduction device. The gear speed reduction device comprises a rotating-shaft-free rotator for providing rotating kinetic energy, a speed reduction input component installed in the rotator, a speed reduction output component connected with the speed reduction input component, a first execution component and a second execution component, wherein the first execution component and the second execution component are connected with the speed reduction output component. The speed reduction input component is used for obtaining the rotating kinetic energy and rotating relative to the axis of the rotator by utilizing the obtained rotating kinetic energy; the speed reduction output component is used for outputting power with the rotating speed equal to or lower than the rotating speed of the rotator; and the first execution component and the second execution component are used for rotating under the power effect of the speed reduction output component. A speed reducer is installed in the rotator, and accordingly the volume of the whole gear speed reduction device is compressed. Besides, the gear speed reduction device is simple and compact in structure, saves energy and is small in noise. The invention further provides a washing machine with the gear speed reduction device and a washing method thereof.

Owner:CHANGZHOU XINYA ELECTROMOTOR

Vehicle

ActiveCN104786805ALower center of gravityEasy rideElectric devicesElectric propulsion mountingEmbedded systemStructural element

Owner:FORD GLOBAL TECH LLC

Compositions and method of controlling fungus

Compositions and methods of phytopathogenic fungus control are provided, the compositions and methods include a first component of dissolved organic matter (DOM) concentrate having natural organic matter of defined composition, suitable for soil, foliar, and seed coating.

Owner:FBSCI HLDG

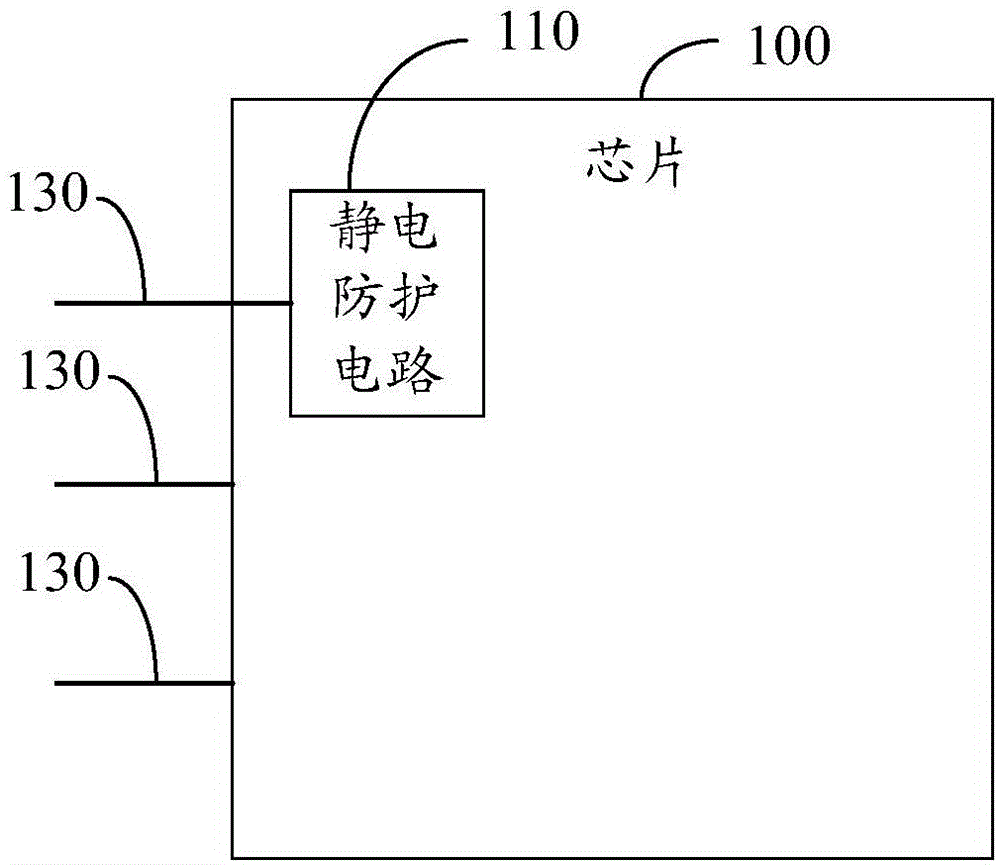

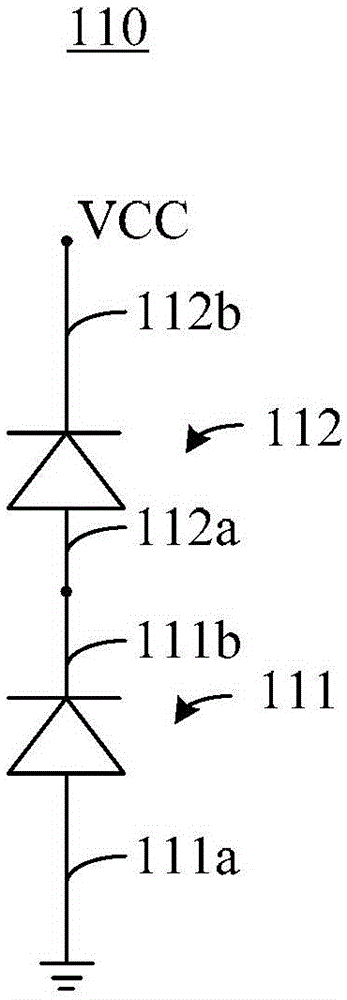

Chip and electronic device

InactiveCN105098756AProtection stabilityFunctional integrationDiodeEmergency protective arrangements for limiting excess voltage/currentElectricityStatic electricity

The invention provides a chip and an electronic device. The chip comprises at least one pin and is characterized in that the internal part of the chip is provided with at least one electrostatic protection circuit, the electrostatic protection circuit is used for reducing or eliminating damages imposed on other components or circuits inside the chip by static electricity, the electrostatic protection circuit is set corresponding to one of the pins, and the electrostatic protection circuit is electrically connected with the pin. The electronic device comprises the chip provided by the invention.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

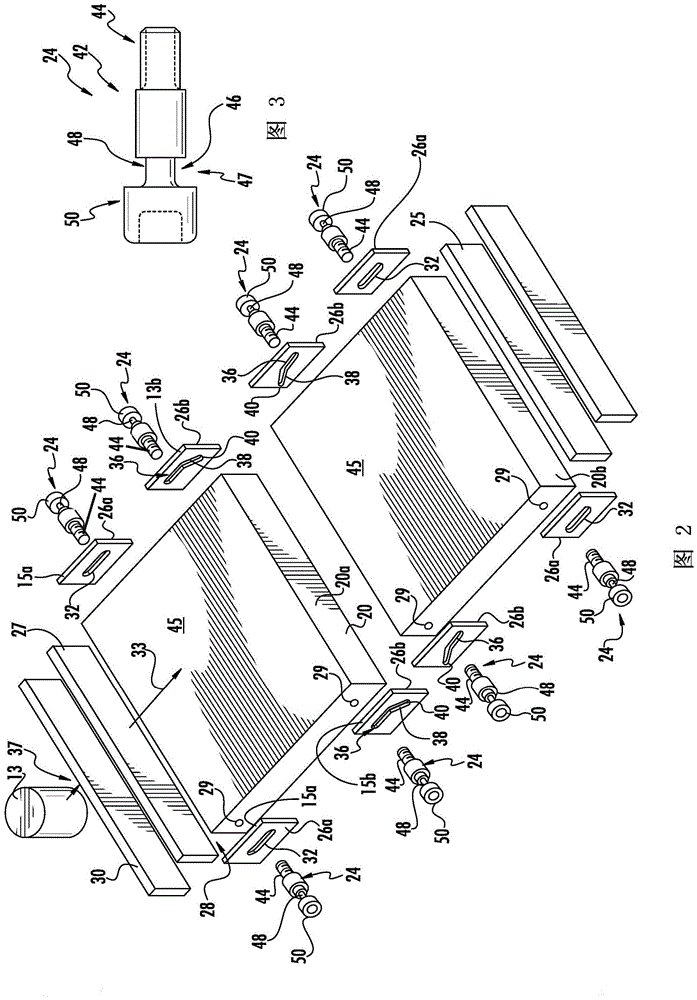

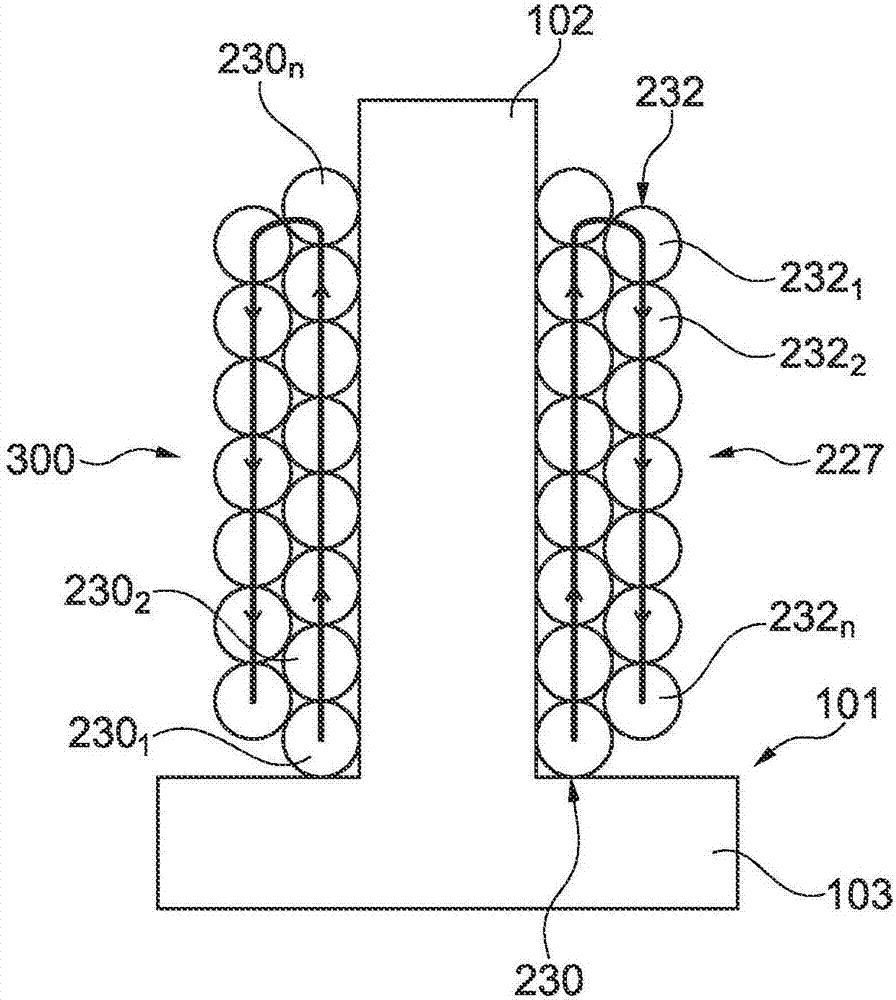

Method and system for manufacture of compressed coil

ActiveCN107112128AReduce or eliminate damageIncreased torque densityWindingsManufacturing dynamo-electric machinesBobbinEngineering

A method of manufacturing a compressed coil and a system for holding a wire during the manufacture of a compressed coil are disclosed. The method includes providing a wire including a first lead section, a central section and a second lead section. The central section of the wire is wound around a bobbin to form a coil. A punch top is located over an end of the bobbin such that the end of the bobbin is located at least partially within a through-hole of the punch top. A second lead section of the wire is located within a groove in an outer surface of the punch top or bobbin and pressure is applied to the bobbin and / or punch top to compress the coil.

Owner:ADVANCED ELECTRIC MASCH GRP LTD

Buffering fender convenient to disassemble, assemble and replace for ship wharf

InactiveCN113481942AReduce or eliminate damageReduce impactClimate change adaptationShipping equipmentFenderWharf

The invention discloses a buffering fender convenient to disassemble, assemble and replace for a ship wharf. The buffering fender comprises a detachable fender plate and a buffering seat, the detachable fender plate is assembled and fixed on the outer side of the buffering seat, the buffering seat is poured and fixed on the edge of the ship wharf, protective rubber is fixedly arranged on the surface of the detachable fender plate, a limiting groove is formed in the interior of the detachable fender plate, a first limiting rib plate is arranged in the interior of the buffering seat in a limiting fit mode, the first limiting rib plate is connected with a second limiting rib plate through a connecting rib plate, two common springs are embedded between the outer side face of the first limiting rib plate and the inner wall of the buffering seat, and two damping springs are embedded between the inner side face of the second limiting rib plate and the inner wall of the buffering seat. The buffering fender is mainly used for relieving the impact force of a ship and a wharf in the docking or mooring process, the buffering fender is of a sectional type, when part of the buffering fender is damaged, the whole buffering fender does not need to be replaced, only the corresponding damaged position needs to be replaced, the buffering fender is easy to operate, convenient to disassemble, assemble and replace and low in later maintenance cost.

Owner:傅英坤

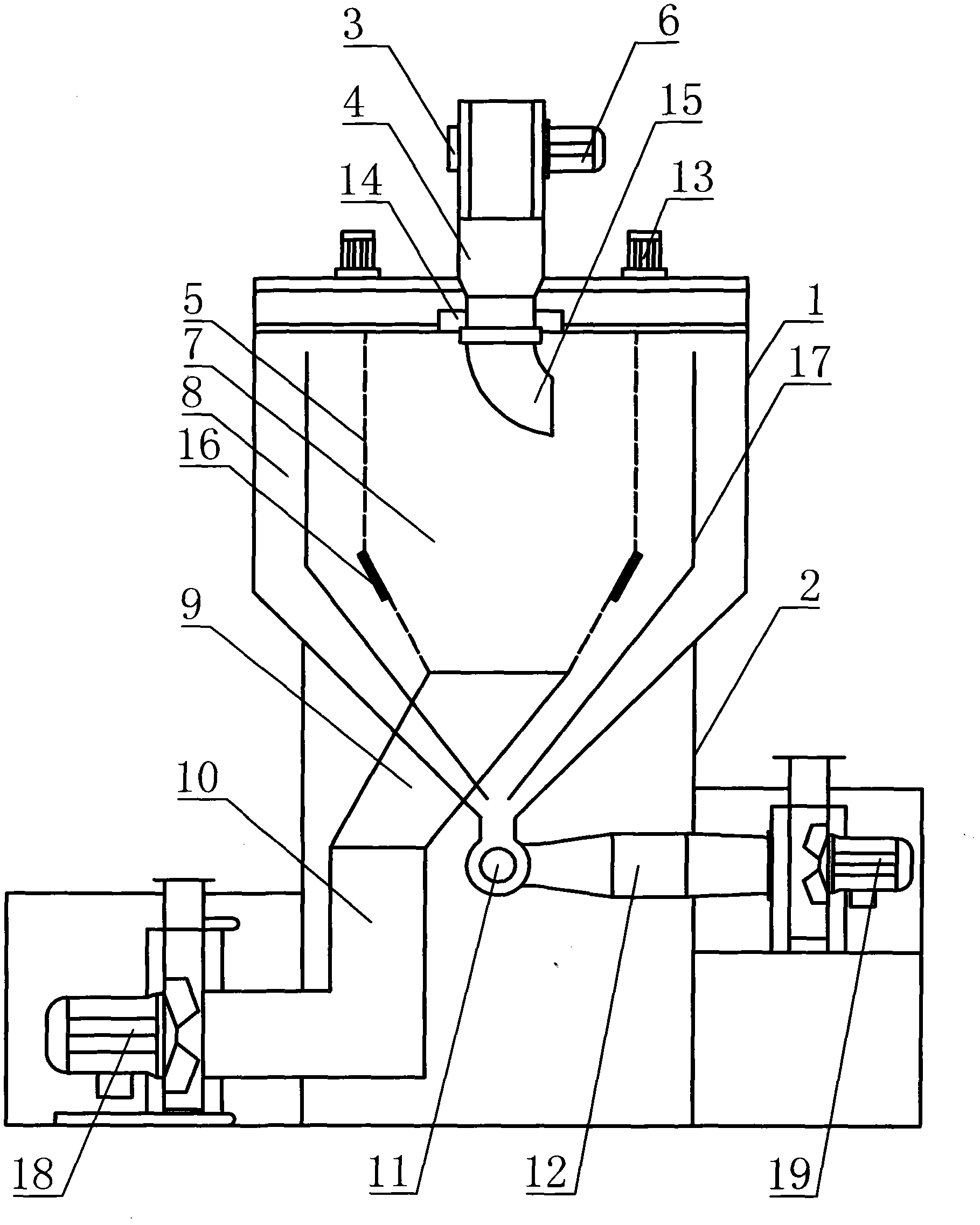

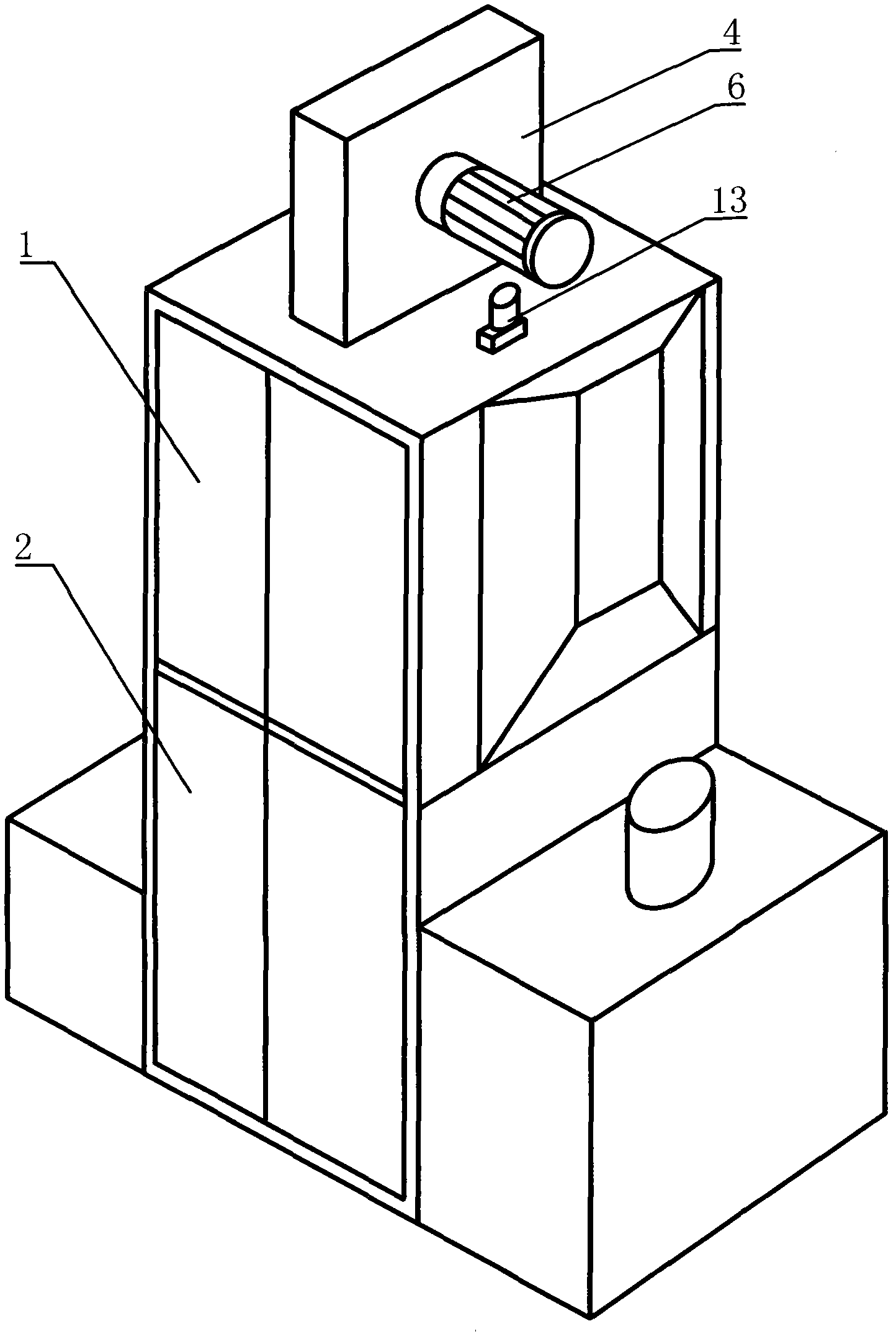

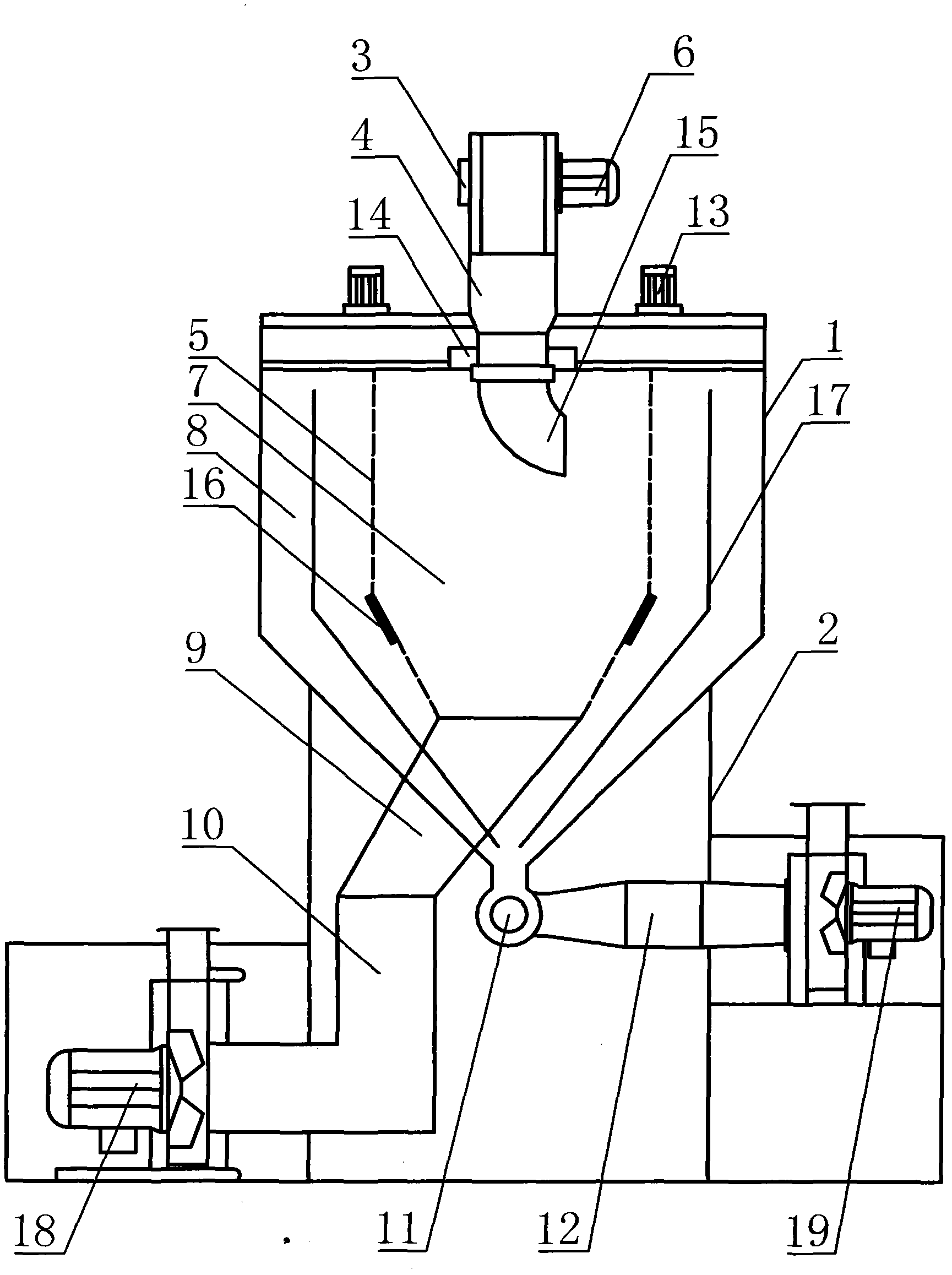

Cage type cotton removing and tiny dust removing machine

InactiveCN102618971AEfficient and full dust removalReduce in quantityFibre cleaning/opening machinesEngineeringCOTTON WOOL

The invention relates to the technical field of textile machines, in particular to a cage type cotton removing and tiny dust removing machine, which has a good tiny dust removing effect and is high in cotton discharging quality and low in failure rate. The machine comprises an upper box body (1), wherein a raw cotton inlet pipe (4) of which one side is provided with a raw cotton inlet (3) is arranged in the center of the top of the upper box body, and a dust removing cage (5) which is communicated with the top of the upper box body (1) is arranged in the internal center of the upper box body; a cotton inlet fan (6) is arranged on one side of the raw cotton inlet pipe (4); a port at one end of the raw cotton inlet pipe, which is extended into the upper box body, is provided with a rotating device; a tiny dust filtering chamber (7) is formed in an internal space of the dust removing cage (5); a tiny dust collecting chamber (8) is formed between the tiny dust filtering chamber (7) and the inner wall of the upper box body (1); a middle section cotton collecting chamber (9) which is connected with the tiny dust filtering chamber (7) is formed on the top of a lower box body (2); and a cotton discharging pipe (10) connected with the outlet of the middle section cotton collecting chamber (9), a dust collecting groove (11) connected with the outlet of the tiny dust collecting chamber (8) and a dust discharging air pipe (12) connected with the outlet of the dust collecting groove (11) are arranged at the bottom of the lower box body (2).

Owner:刘伟

Traditional Chinese medicine containing feed for livestock and poultry and preparation method thereof

InactiveCN106720984AImprove the immunityImprove antioxidant capacityFood processingAnimal feeding stuffWeight gainingLivestock

The invention belongs to the technical field of animal feeds, and specifically relates to a traditional Chinese medicine containing feed for the livestock and poultry and a preparation method thereof. The livestock and poultry feed is prepared from a feed, traditional Chinese medicine liquid, fructose, and ethyl maltol according to a weight ratio of 100:5-10:0.5-1:0.01-0.05; wherein the feed comprises the following raw materials in parts by weight: 20 to 30 parts of corn, 15 to 20 parts of soybean meal, 15 to 25 parts of wheat bran, and 5 to 10 parts of seaweed meal, and the traditional Chinese medicine liquid comprises the following raw materials in parts by weight: 16 to 25 parts of eucommia, 10 to 20 parts of pine needle, 15 to 25 parts of radix codonopsis, 8 to 15 parts of purslane, 15 to 25 parts of Chinese magnoliavine, 10 to 15 parts of haw, and 10 to 15 parts of dried orange peel. The feed is palatable, can enhance the disease resistant performance of livestock and poultry, and prominently promotes the weight gain of livestock and poultry. The feed utilization rate is largely improved. The production cost is reduced.

Owner:ZHENGZHOU SIBIAN TECH CO LTD

Surface hardening process method for camshaft of diesel machine

InactiveCN104646964AReduce or eliminate damageExtended service lifeCamsValve drivesChemical compositionHardness

The invention relates to a surface hardening process method for a camshaft of a diesel machine. The method comprises the following steps: firstly, coarsely processing a part, and preheating the easily-worn surface of the part which is coarsely processed, wherein the preheating temperature is 150-200 DEG C; secondly, covering the easily-worn portion of the part with a material containing high-wear-resistance and high-hardness chemical components in an overlaying way to form the hardened surface, wherein the thickness of the covered hardened surface is 2-3mm; thirdly, hardening and tempering the whole part, and finely processing the part which is qualified by hardening and tempering, so that the size of the part reaches the designed size. According to the surface hardening process method, the surface nitriding process is reduced, the process flow is simplified, and the surface hardness and the wear resistance of a cam are improved.

Owner:田亮

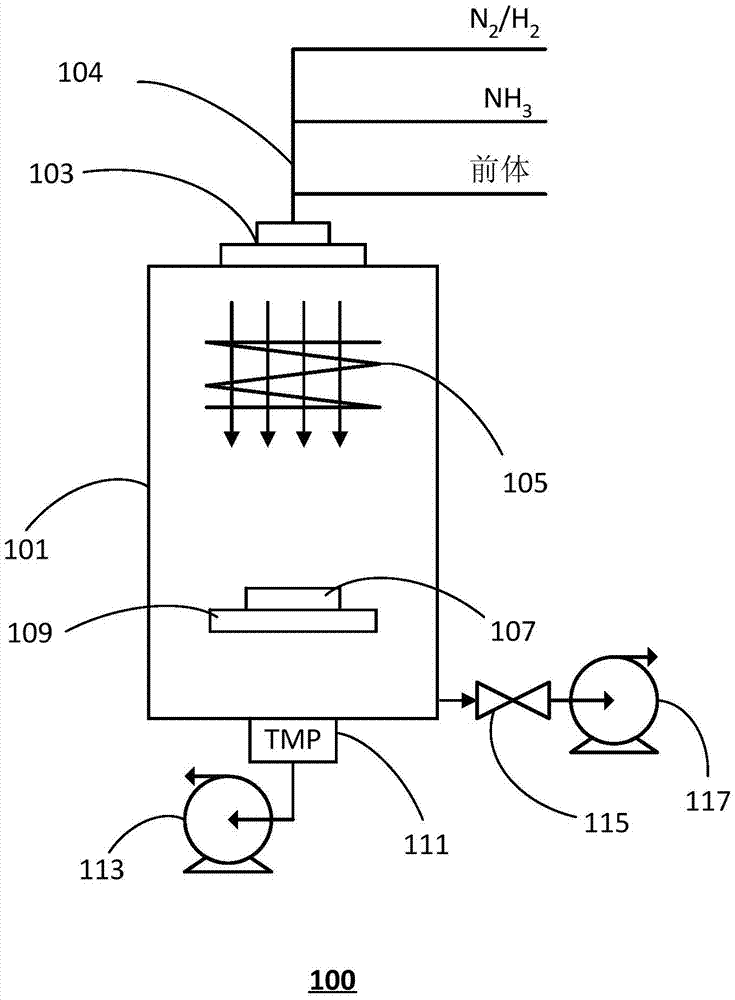

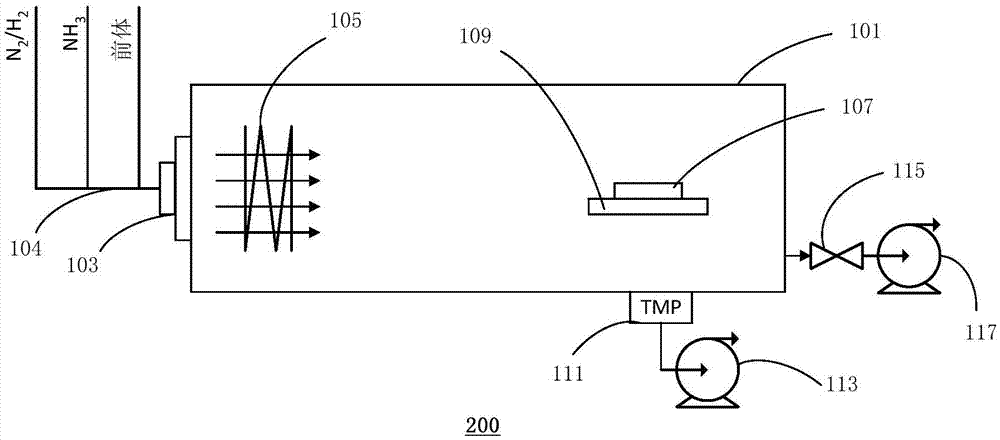

Semiconductor manufacturing device and method

InactiveCN107026100AReduce the introductionExcellent electrical propertiesSemiconductor/solid-state device manufacturingChemical vapor deposition coatingSemiconductorHot plate

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

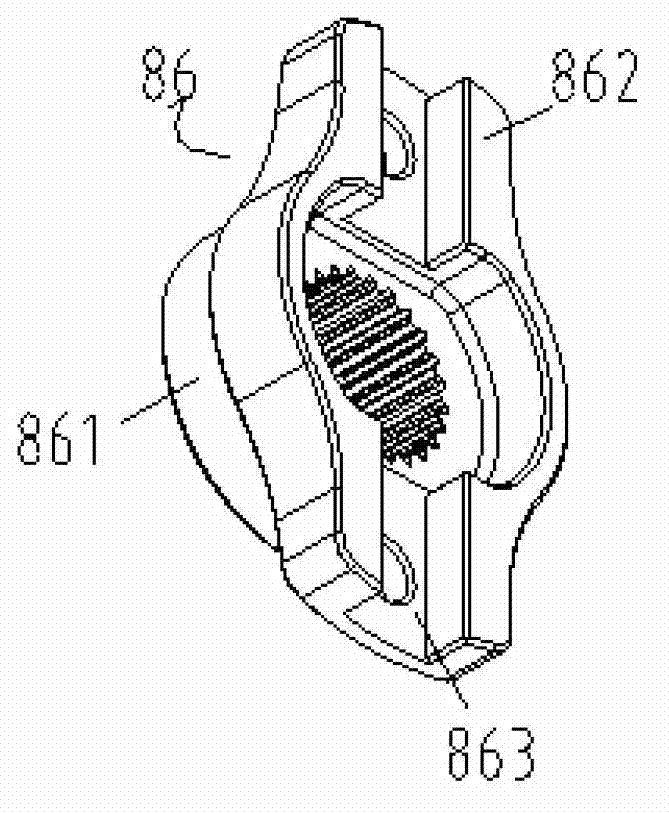

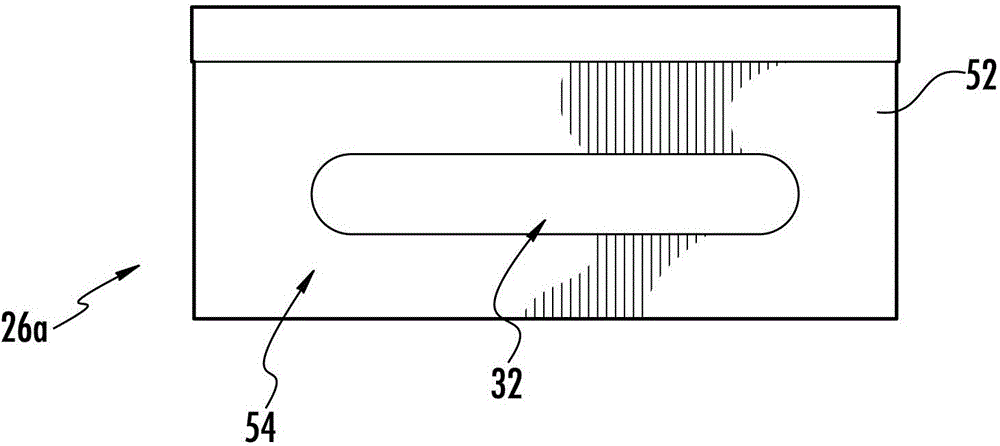

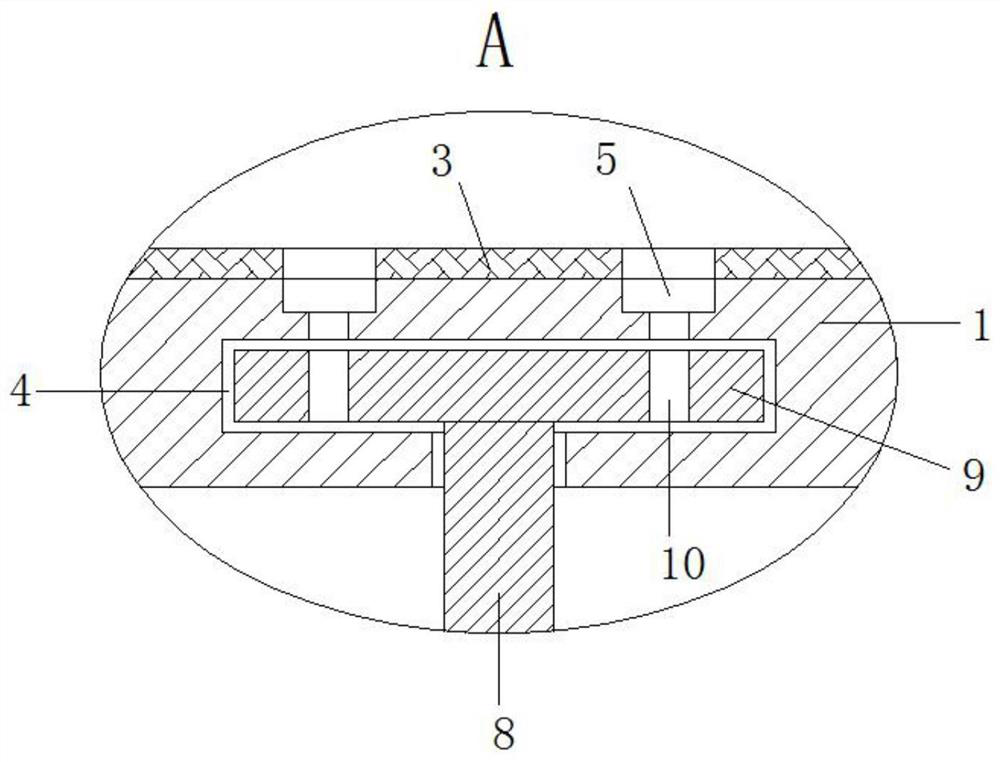

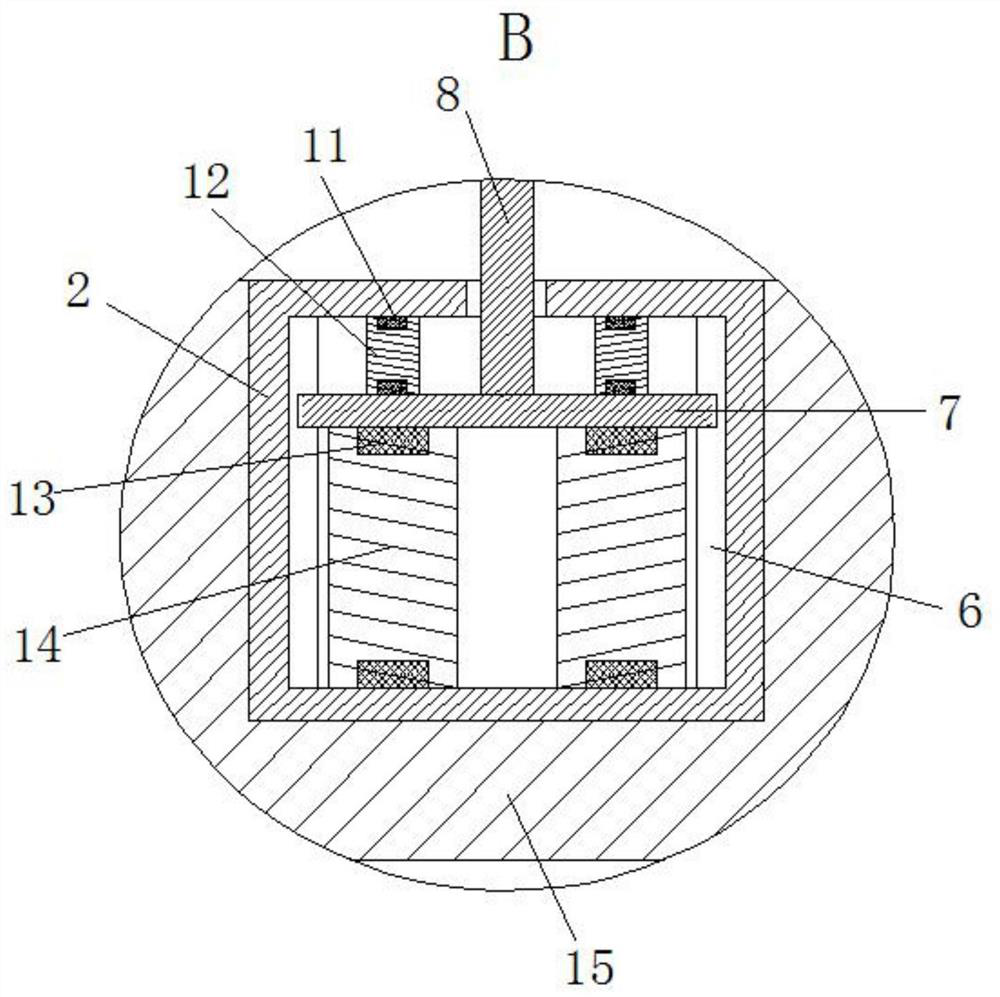

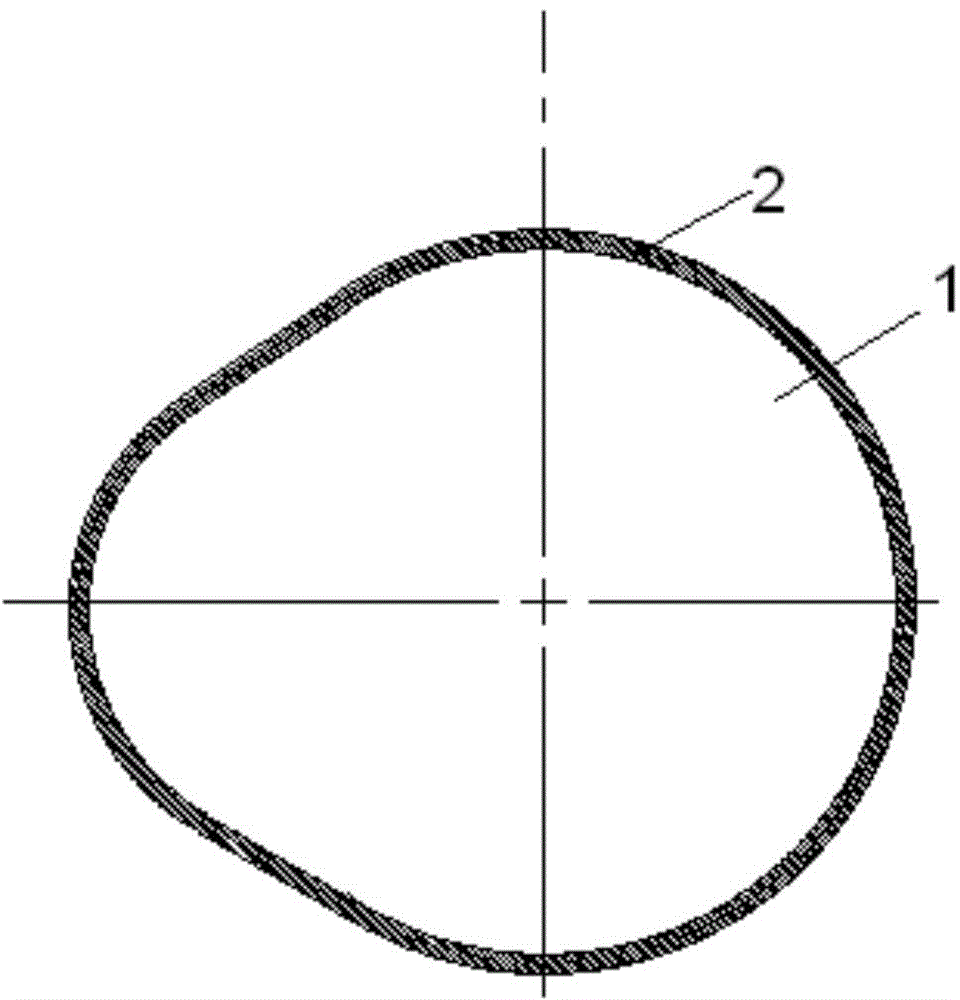

Identification device for high-temperature tank

ActiveCN104636786AReduce or eliminate damageEnhance communication signalRecord carriers used with machinesHeat resistanceIdentification device

The invention discloses an identification device for a high-temperature tank. An RFID (Radio Frequency Identification Device) damping structure and a buffering cushion at the connected part are arranged in the identification device, so that the impact and the vibration which are possibly applied to the axial direction, the circumferential direction and the radial direction of an RFID tag in the operation process can be effectively reduced, and further the working reliability of the tag is improved, and the service life of the tag is prolonged. By improving the material of a casing 5, the integral heat resistance of the device can be further improved; meanwhile, an iron plate with the thickness of 1mm is arranged on the casing to replace a cover plate in the prior art, so the practices prove that the intensity of a communication signal of the RFID tag can be effectively improved.

Owner:HANGZHOU QIANJIANG WEIGHING TECH

External application medicine for treating hypertension

InactiveCN101041027ACoordinating treatment goalsBalanced and continuous playHeavy metal active ingredientsOrganic active ingredientsPinelliaTreatment hypertension

Disclosed is a Chinese medicament for treating hypertension which is prepared from the following raw materials: evodia rutaecarpa 10-90g, pinellia tuber 10-40g, hooked uncaria 10-80g, sulfur 10-35g, Loranthus mulberry mistletoe 10-42g, lodestone 10-48g, Ligusticum wallichii 10-90g, chrysanthemum flower 10-80g, wofberry bark 10-65g, kudzuvine root 10-80g, riddle 10-48g, cassia twig 10-26g, malt 10-33g, earthworm 10-80g, alisol 10-65g, rhubarb horsetails 10-65g, sphene 10-45g, soybean 10-90g, eucommia bark 10-80g, trogopterus dung 10-42g, cattail pollen 10-42g, haw 10-50g, areca-nut 10-42g, weeping-willow leaves 10-90g and nifedipine 2-3g.

Owner:谭怀志

Anti-ageing and wrinkle-removing composition

InactiveCN108324587AIncrease elasticityStay hydratedCosmetic preparationsToilet preparationsWrinkle skinVitamin C

The invention discloses an anti-ageing and wrinkle-removing composition. The anti-ageing and wrinkle-removing composition is prepared from the components including a humectant, an antioxidant and a skin-tightening repairing agent, wherein the antioxidant is prepared from one or more than one of sea cucumber collagen peptide, a parslane herb extracting solution, vitamin E and a derivative thereof;the skin-tightening repairing agent is prepared from one or more than one of collagen, an epidermal growth factor, a laevogyrate vitamin C raw solution and radix ginseng extract. According to the composition disclosed by the invention, the antioxidant is added and free radicals can be effectively removed; oxidization injuries are reduced and an anti-ageing effect is realized; the humectant is added and is used for maintaining skin moisture and improving the elasticity of skin and indirectly has anti-ageing and wrinkle-removing effects; the skin-tightening repairing agent is added and can be used for promoting synthesis of skin collagen and delaying skin ageing; the components interacts so that the composition can have better anti-ageing and wrinkle-removing effects; when the composition isapplied to cosmetics, the cosmetics can have good anti-ageing and wrinkle-removing effects.

Owner:FOSHAN HUIMU CHEM TECH CO LTD

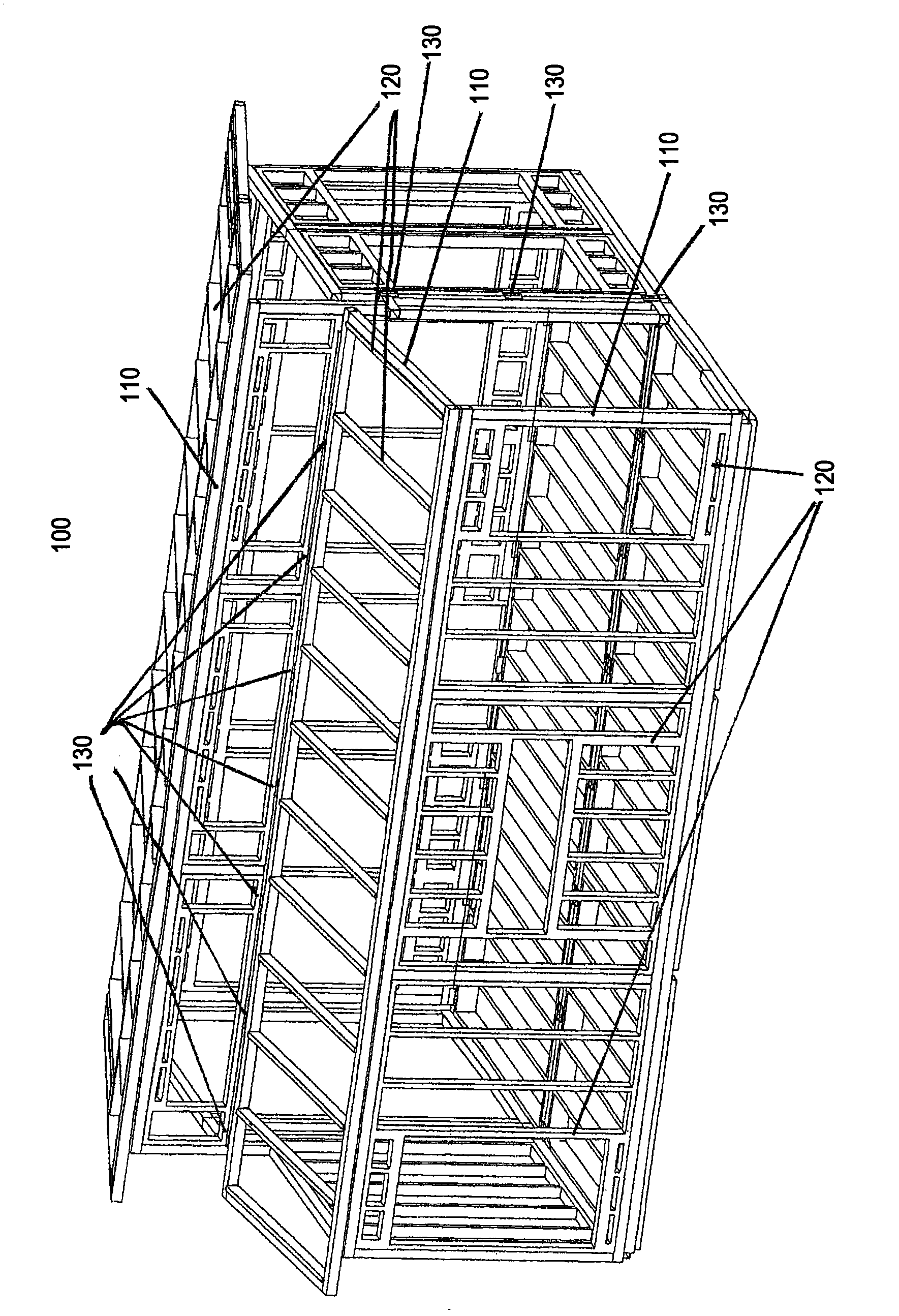

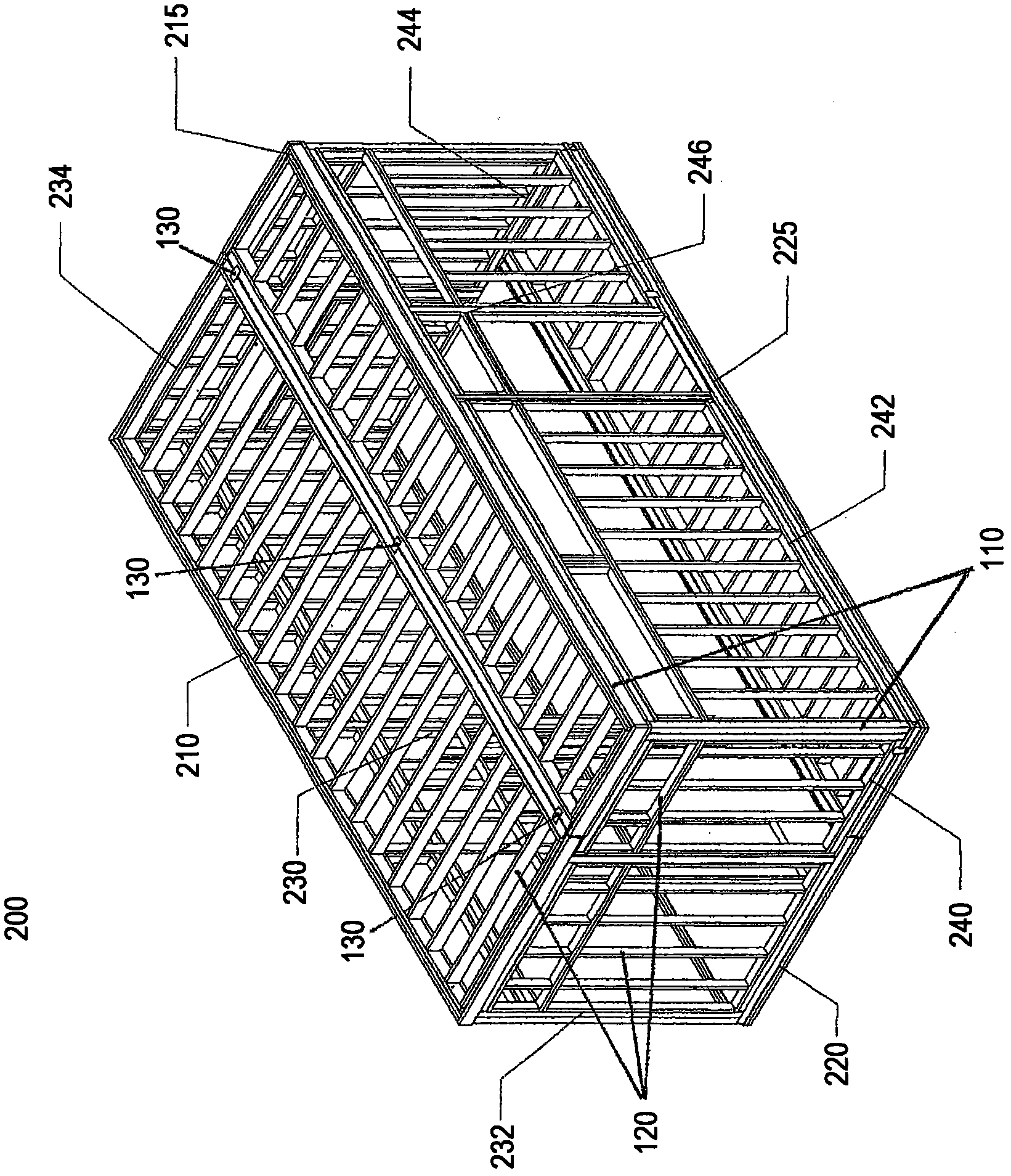

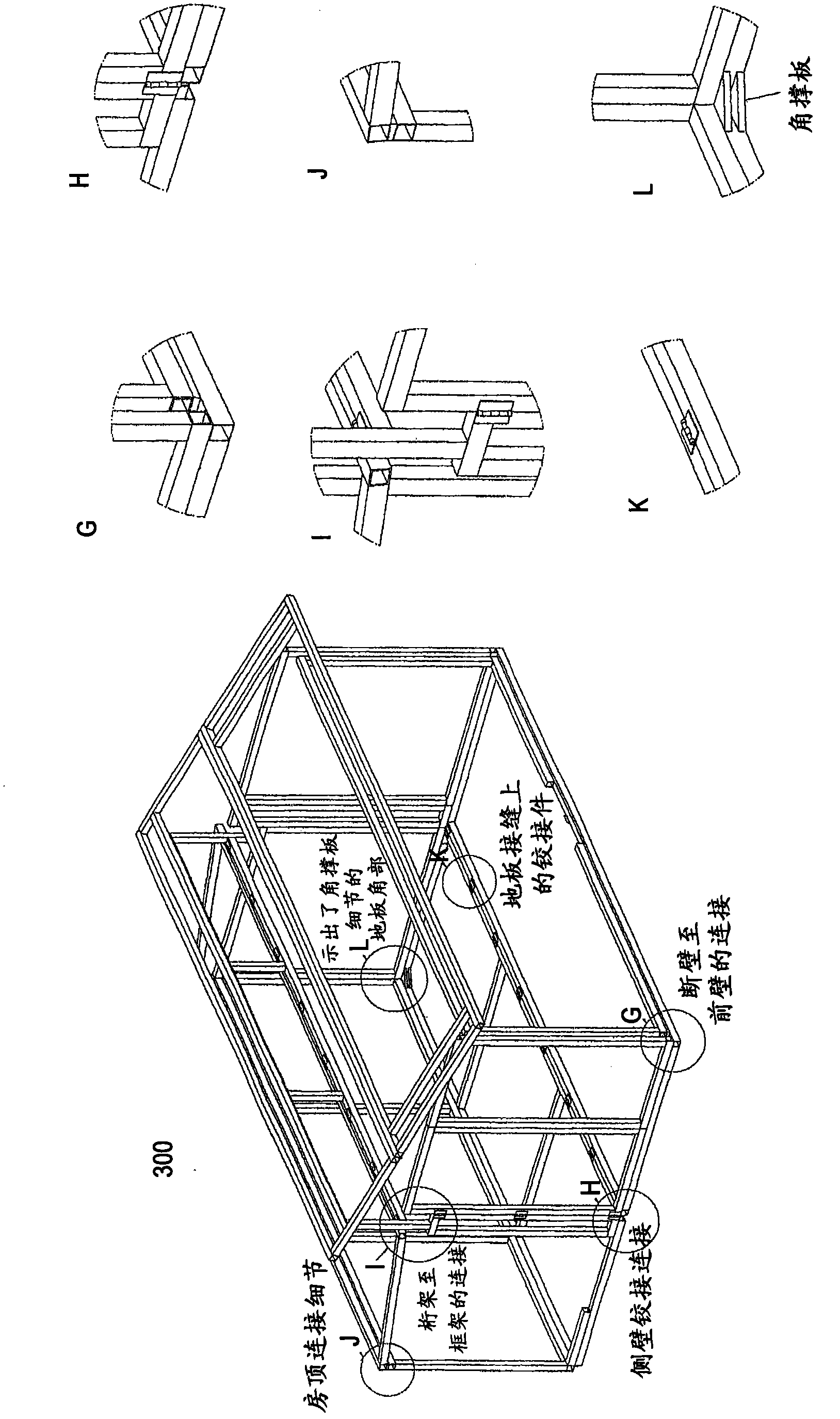

Foldable building units

Owner:BLU HOMES INC

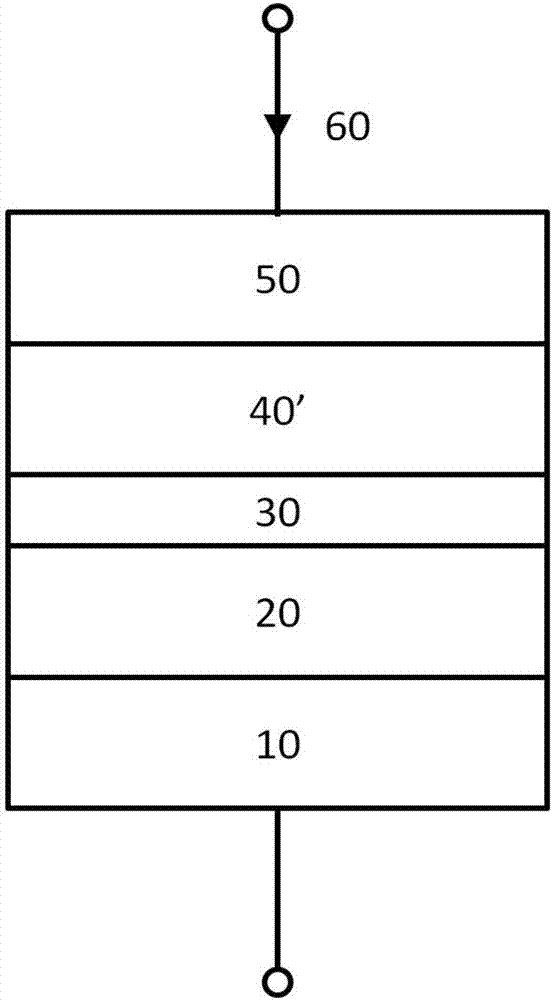

Method for preparing reference layer of magnetic tunnel junction and method for preparing magnetic tunnel junction

ActiveCN107958954AImprove surface propertiesImprove performanceMagnetic-field-controlled resistorsGalvano-magnetic device manufacture/treatmentDeposition processTunnel junction

The invention provides a method for preparing a reference layer of a magnetic tunnel junction and a method for preparing a magnetic tunnel junction. The method for preparing a reference layer of a magnetic tunnel junction includes the steps of setting the films of a reference layer through a deposition process, carrying out plasma treatment on one or more of the films, and carrying out annealing treatment on the one or more of the films after the plasma treatment. As in-situ heat treatment is carried out on the one or more films after the plasma treatment through the annealing treatment, possible damage or defects caused by the plasma treatment can be reduced or eliminated, and the surface characteristic of the reference layer can be improved. Therefore, the comprehensive performance of amagnetic tunnel junction comprising the reference layer can be improved, for example, the TMR value of the magnetic tunnel junction can be improved, and the RA value can be reduced.

Owner:CETHIK GRP +1

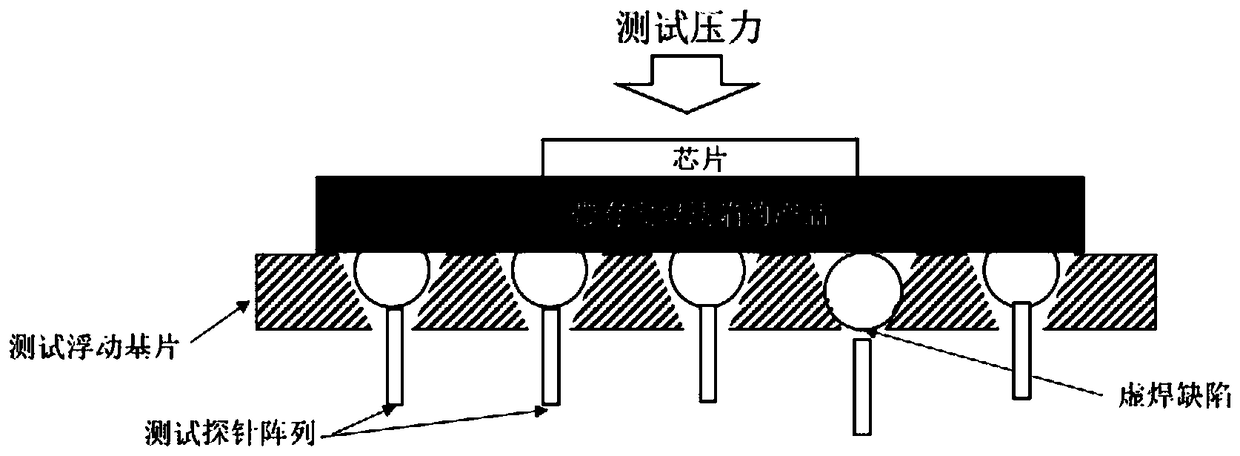

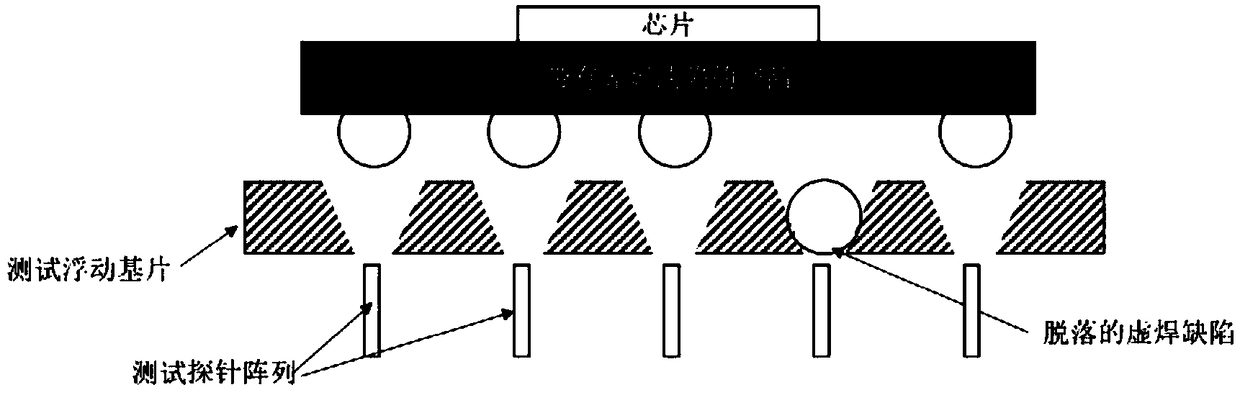

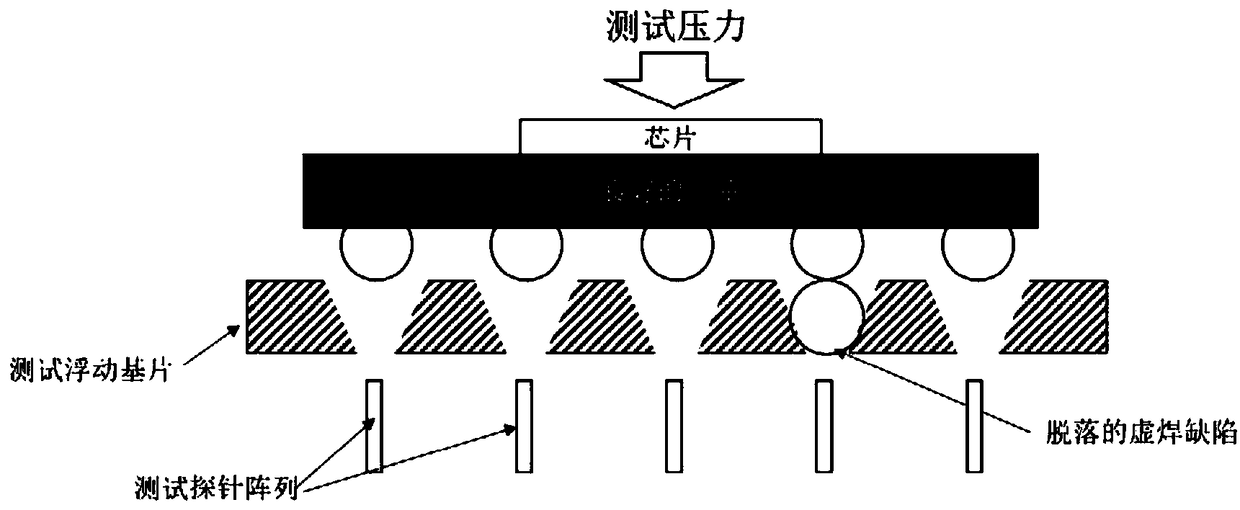

Floating base substrate for chip semiconductor testing

ActiveCN109001501AReduce or eliminate damageChange heightElectrical measurement instrument detailsElectrical testingSolder ballEngineering

The invention discloses a floating base substrate and method for chip semiconductor testing. The floating base substrate at least comprises a substrate provided with at least one same detection cavity, wherein the radius of the upper opening of each detection cavity is greater than the radius of the lower opening, a welding ball used for accommodating to-be-detected products, at least one test probe fixed to the base and adopting an elastic telescopic rod structure, wherein the tops of the test probes can extend into the detection cavity and can move up and down, and the base can be driven tomove up and down by the test probes. Power testing can be conducted by test probe being contact with welding ball. When the detected welding ball falling off caused by virtual welding defect is extruded and deformed, sequential testing is conducted, and whether the welding ball is normal is judged according to the damage surface. The structural model is based on spherical contact array package andvirtual welding. The damage risk of the welding ball is determined by calculating spherical contact array package parameters and mechanical interference of the design size of floating base.

Owner:INTEL PROD CHENGDU CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com