Patents

Literature

714 results about "Mecanum wheel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The Mecanum wheel is a design for a wheel that can move a vehicle in any direction. It is sometimes called the Ilon wheel after its inventor, Bengt Erland Ilon, who came up with the idea when he was an engineer with the Swedish company Mecanum AB. It was patented in the United States on November 13, 1972.

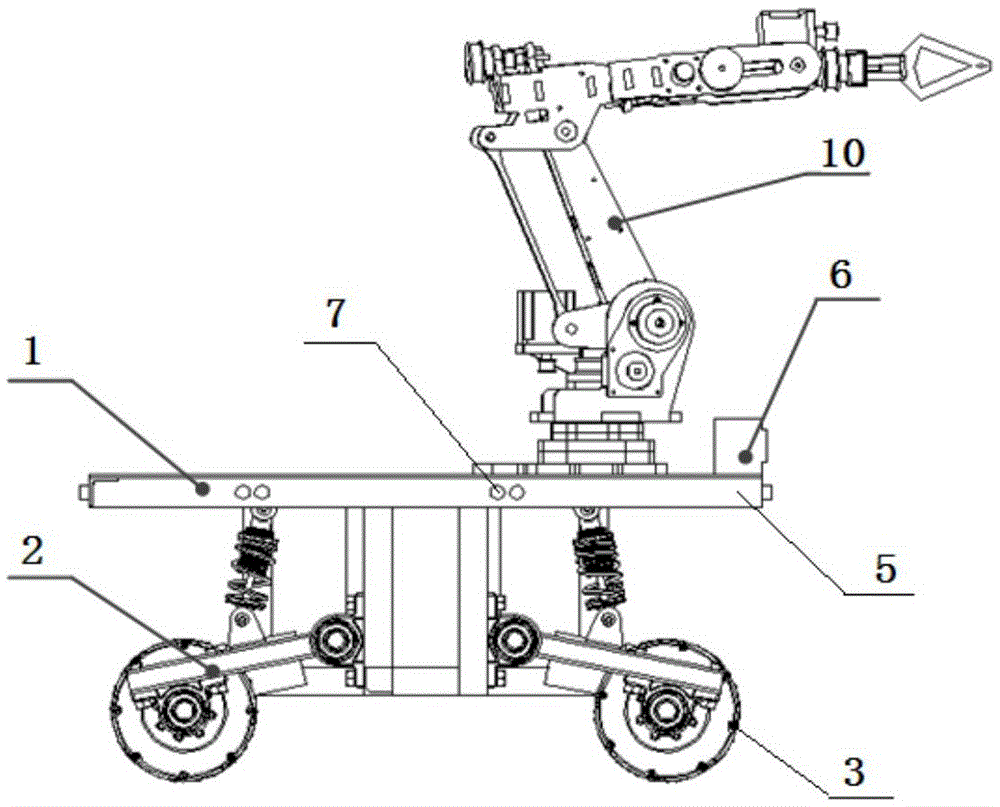

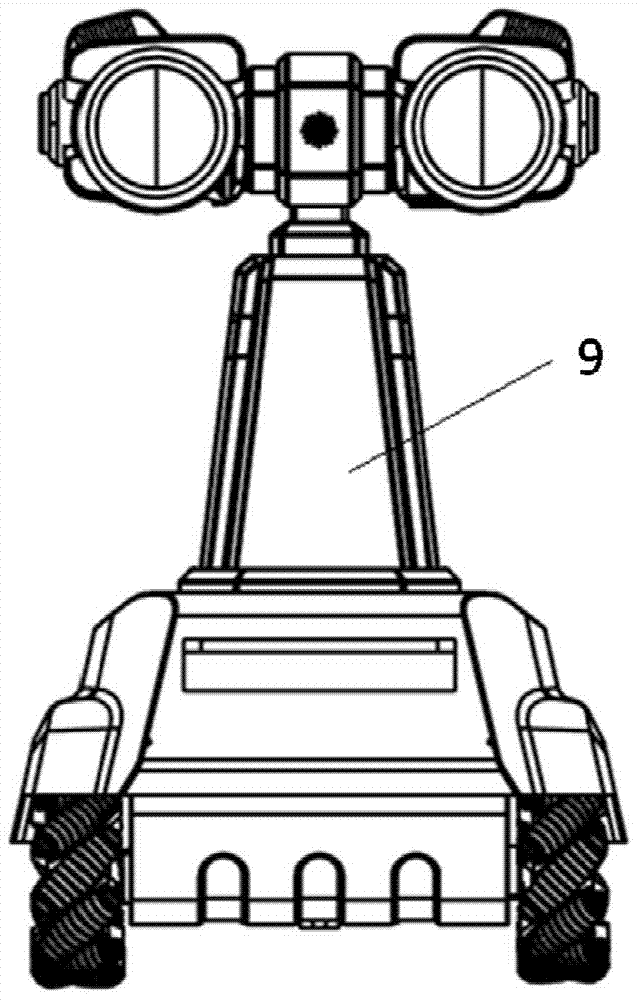

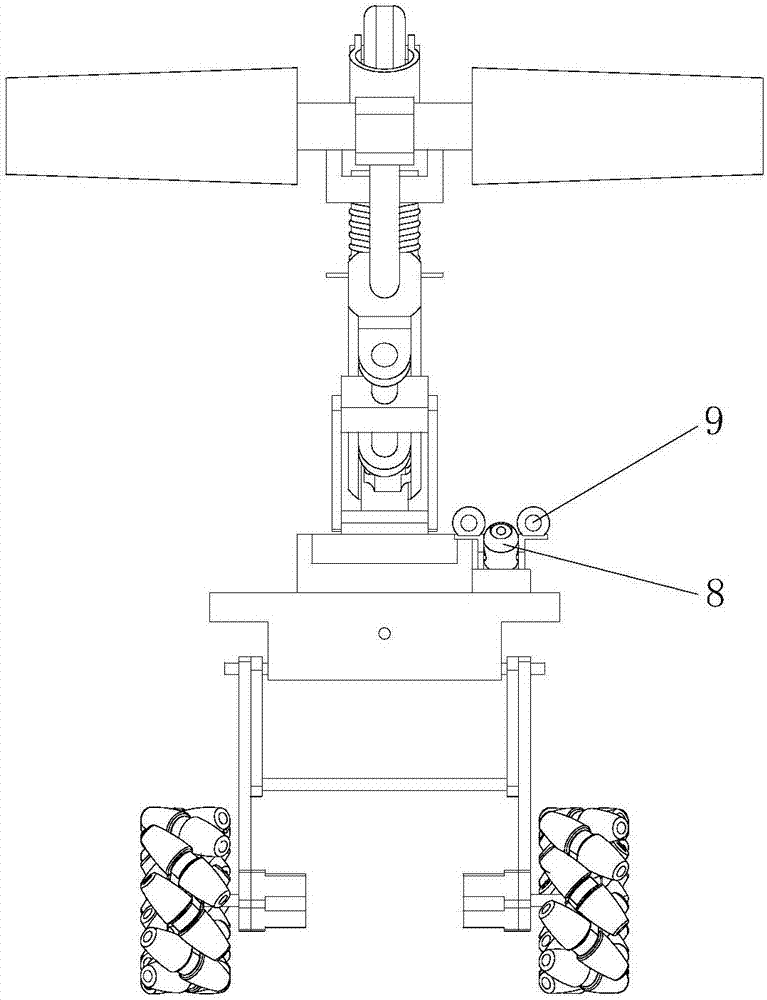

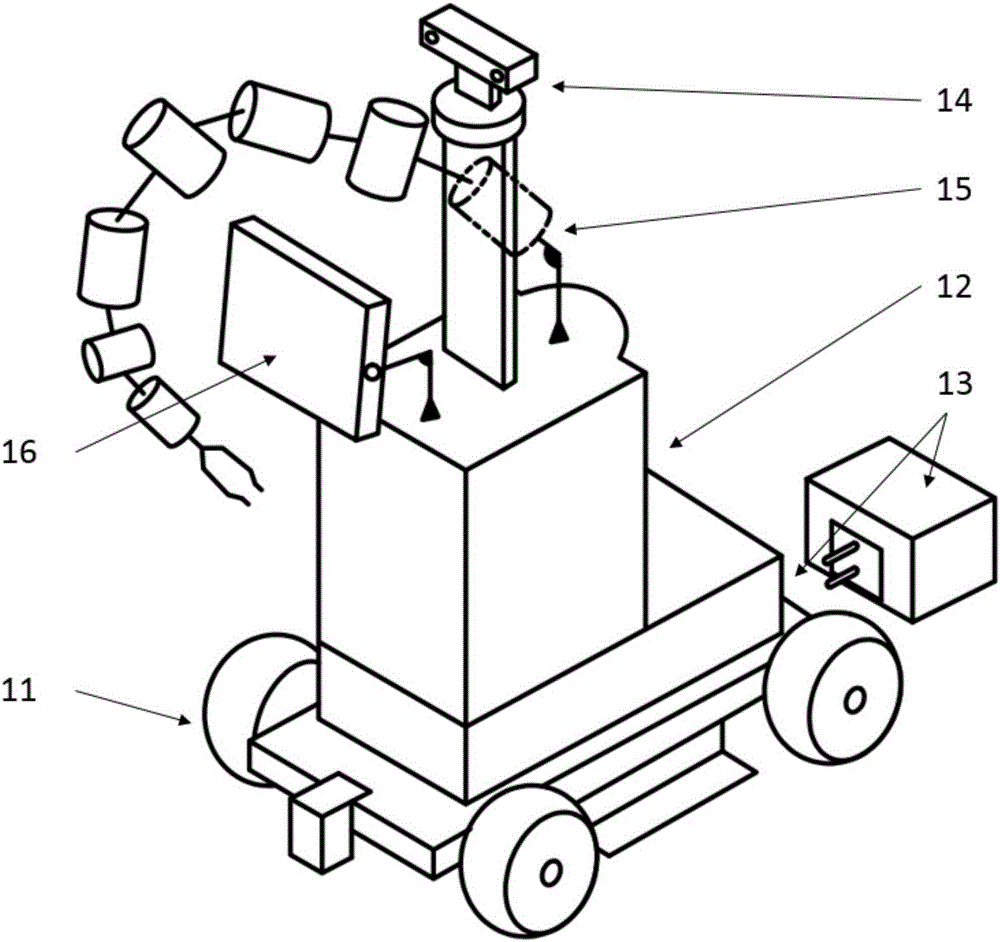

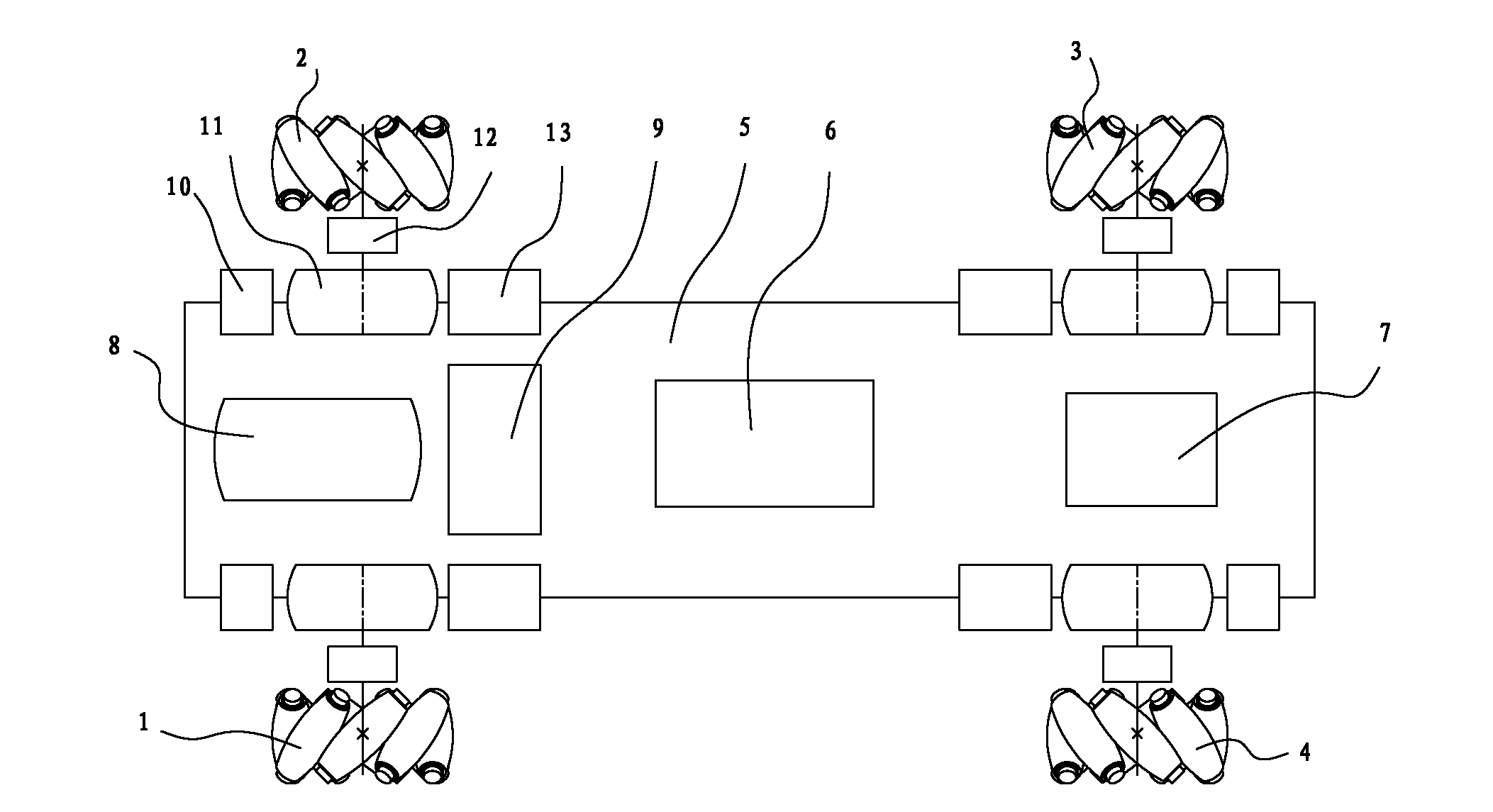

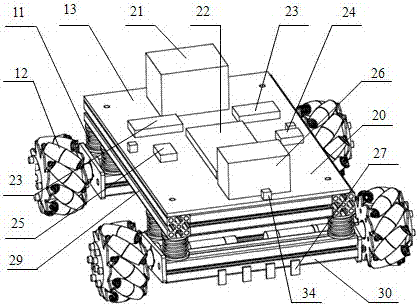

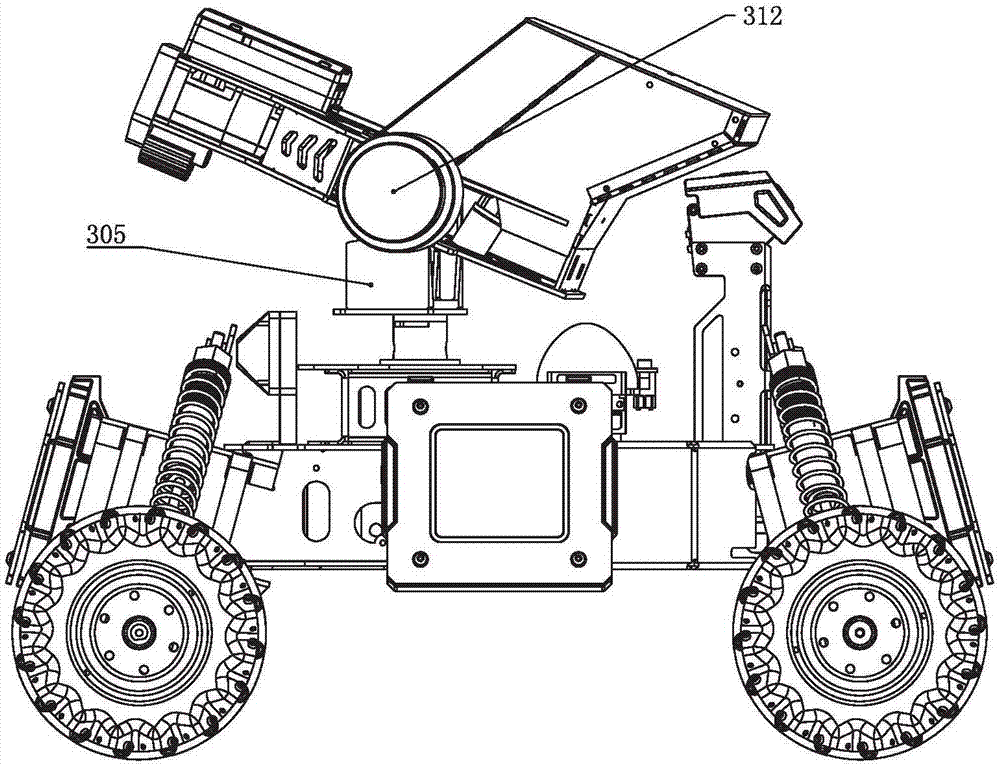

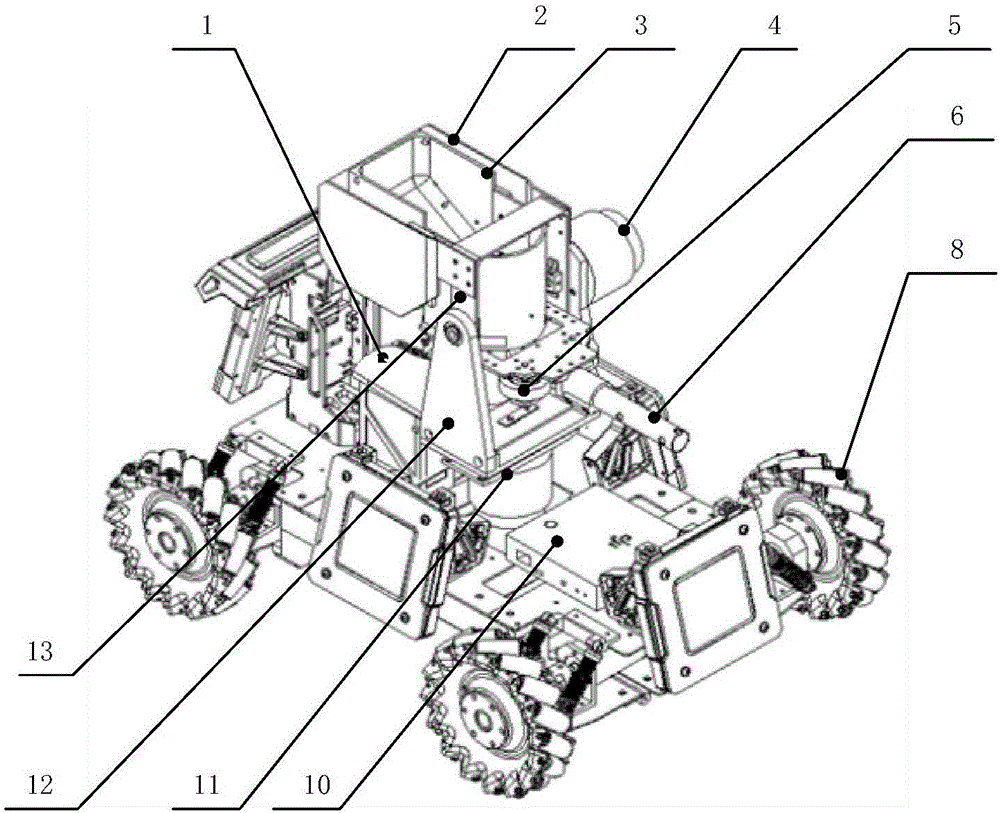

Omnidirectional moving transfer robot with Mecanum wheels

InactiveCN105479433AImprove motor flexibilityHigh degree of intelligenceManipulatorVehicle frameDrive wheel

The invention discloses an omnidirectional moving transfer robot with Mecanum wheels. The omnidirectional moving transfer robot comprises a mechanical arm with six degrees of freedom, an omnidirectional moving base plate, a binocular vision device, a master control box and a remote monitoring device. The omnidirectional moving base plate comprises a frame and the multiple Mecanum wheels arranged below the frame. Each Mecanum wheel is a drive wheel. A plurality of distance measuring sensors are arranged on the periphery of the frame. Each distance measuring sensor is fixedly connected with the frame through an independent suspending module. By means of the structure, the rotating speeds and the steering direction of all the wheels are matched so that a moving platform can move in any direction in the plane, and the moving flexibility of the whole transfer device is remarkably improved; in addition, it can also be ensured that the Mecanum wheels are in full contact with the ground, and operation stability and control precision are improved; and furthermore, the binocular vision device is used for guiding the robot to move and conduct the object carrying and conveying task, the whole process is completed by the robot independently, and the intelligence degree is higher.

Owner:JIANGSU UNIV OF SCI & TECH

Mobile robot

ActiveUS20130140801A1Effective and efficient movementPromote sportsDeflectorsWheel adhesionCouplingControl system

A mobile robot configured to be widely versatile in its use. For example, the mobile robot can be configured for being used on a wide assortment of surfaces, regardless of the orientation and / or shape of the surfaces. Alternatively or in combination, the mobile robot can be configured for effective and efficient movement on the surfaces it traverses. In some cases, the mobile robot is configured with two or more component units. In some cases, the component units are configured with magnets and a control system for orientating the magnets. In some cases, one or more component couplings join the component units. In some cases, the mobile unit is configured with Mecanum wheels.

Owner:HELICAL ROBOTICS

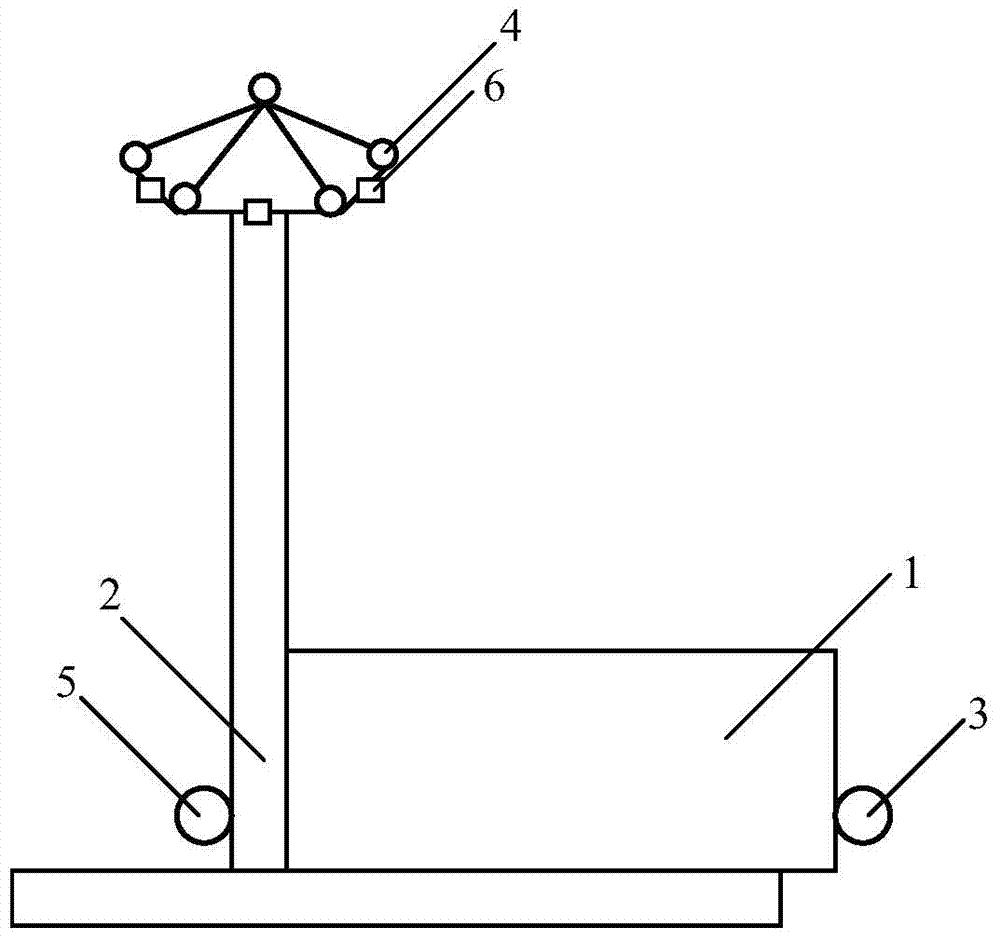

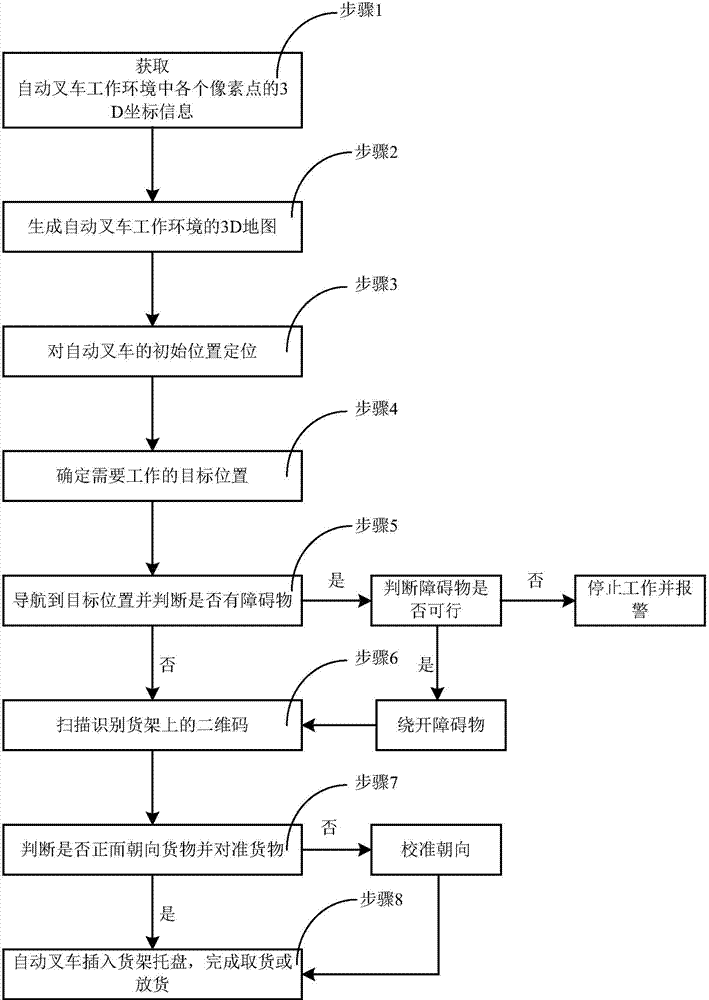

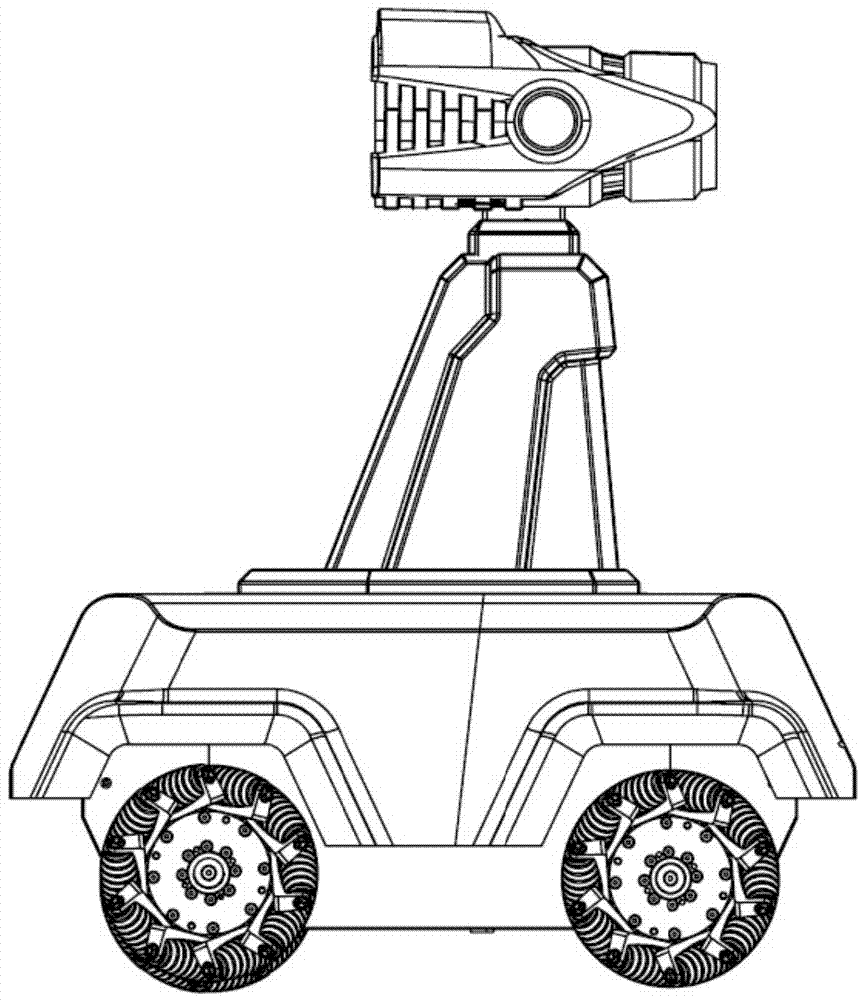

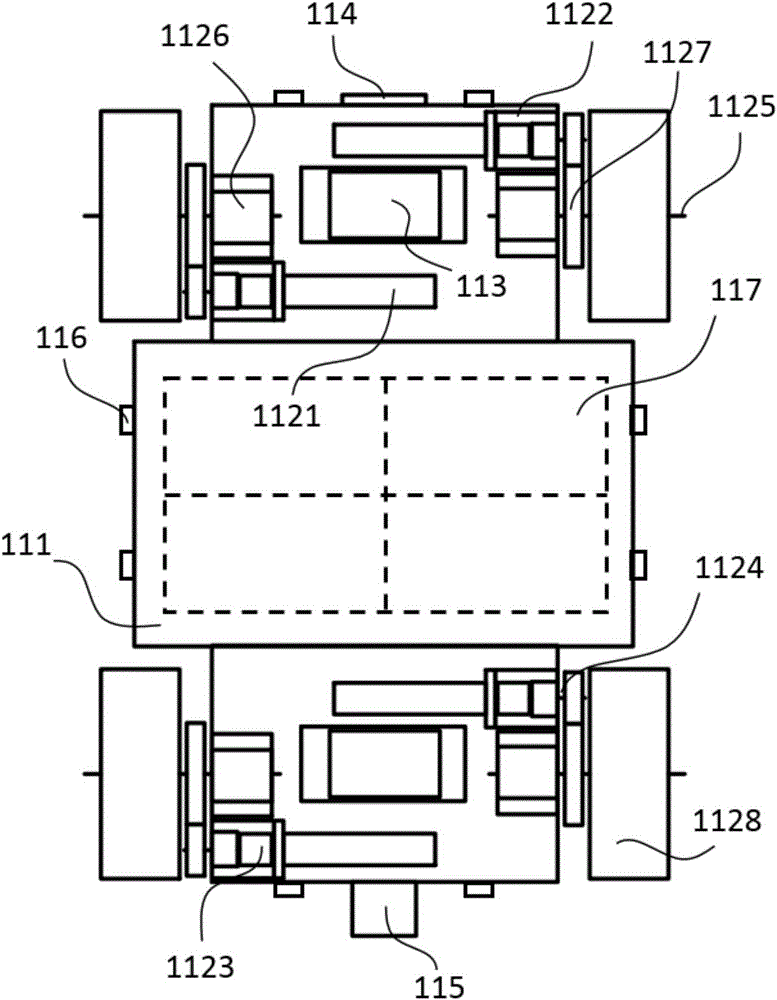

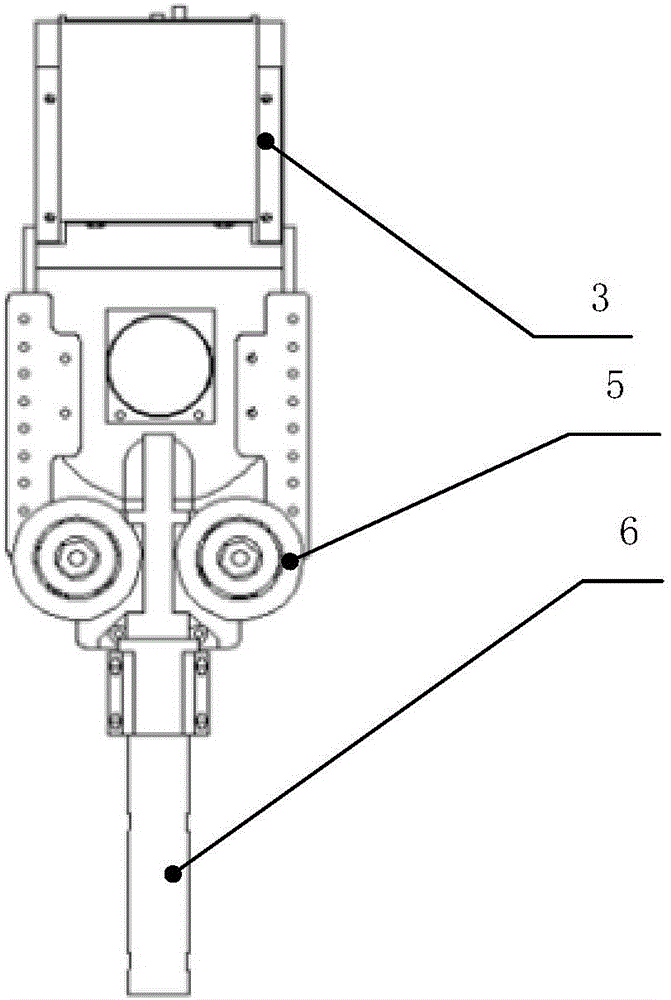

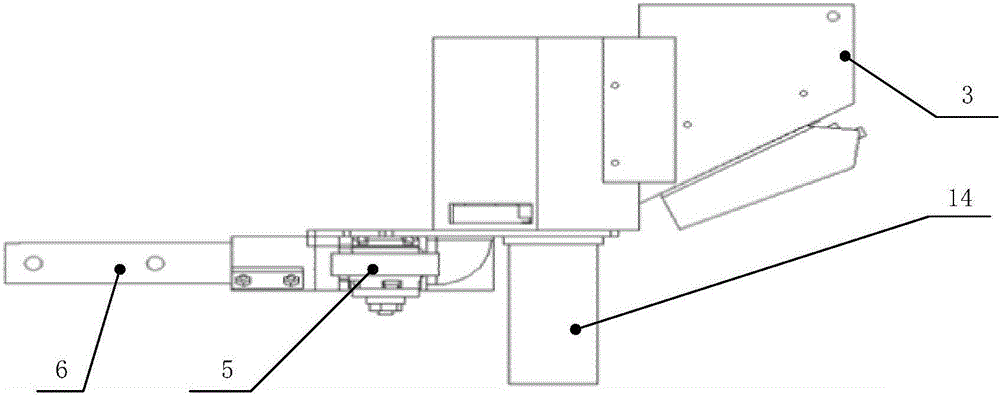

Omni-directional automatic forklift and 3D stereoscopic vision navigating and positioning method

InactiveCN104777835APrecise pick and placeFlexible planningPosition/course control in two dimensionsRadarWorking environment

The invention discloses an omni-directional automatic forklift and a 3D stereoscopic vision navigating and positioning method. The 3D stereoscopic vision navigating and positioning method comprises the following steps: acquiring information of a 3D coordinate in the working environment of the automatic forklift; generating a 3D map; acquiring real-time images and positioning an initial position according to the 3D map; determining a target position; navigating to the target position and judging whether encountering barriers; scanning and identifying two-dimensional codes on a goods shelf; judging whether the automatic forklift is over against the goods and is aligned with the goods; enabling the automatic forklift to insert into a goods shelf tray and completing taking the goods and putting the goods. The omni-directional automatic forklift and the 3D stereoscopic vision navigating and positioning method have the benefits that the 3D map of the working environment is built by a plurality of binocular stereo cameras, the automatic forklift is capable of effectively and accurately positioning, taking the goods and putting the goods with combination of a speedometer, a laser radar and a front camera, three-freedom-degree omni-directional movement on the plane is implemented by Mecanum wheels, the automatic forklift is capable of taking the goods and putting the goods on the same goods shelf without steering, any barriers in the working environment can be effectively avoided in tine by the laser radar and an infrared sensor, and the automatic forklift can be automatically charged by communication between an upper computer and a charging box.

Owner:WUHAN HANDY ROBOTICS TECH

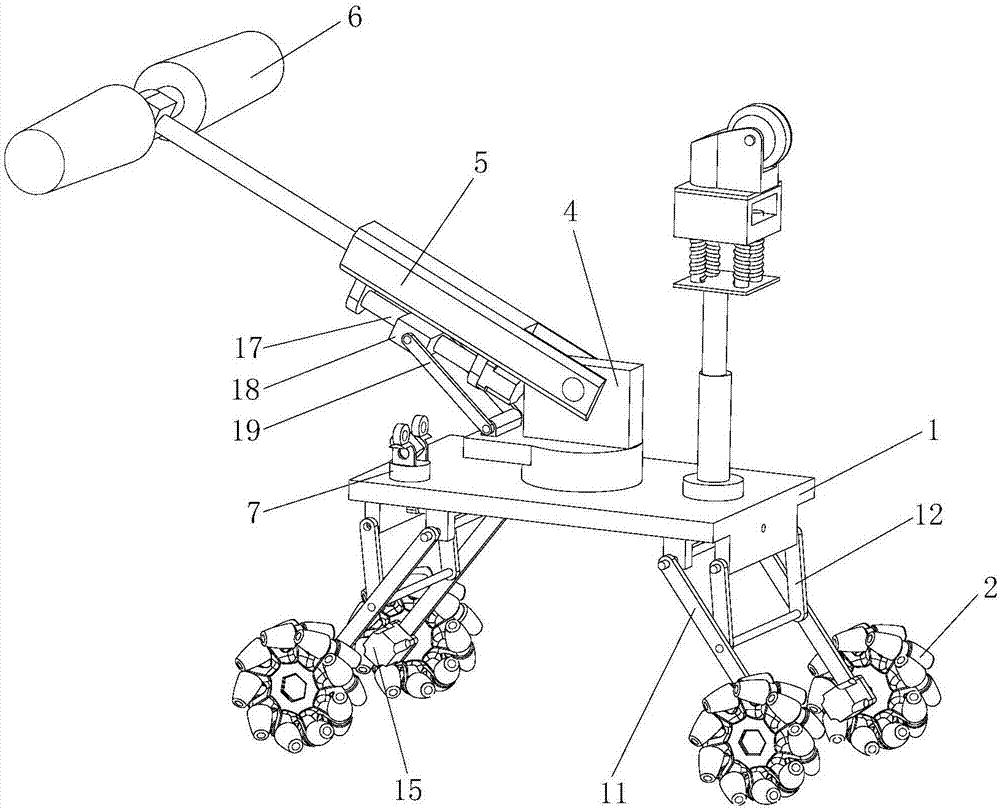

Multifunctional intelligent rehabilitation robot for assisting stand and walk

The invention discloses a multifunctional intelligent rehabilitation robot for assisting stand and walk. The whole robot comprises three parts basically: a mechanical stand assisting device, a chassis moving device and a monitoring control device, wherein the mechanical stand assisting device comprises a support base, a swing arm, an electric push rod and a handrail device; the chassis moving device comprises a base, a motor fixing frame, four Mecanum wheels, a braking ratchet wheel, a braking sheet, and the like; the monitoring control device comprises a force sensor array, a vision sensor, a distance-measuring sensor, and the like; and in addition, the robot also comprises a power source storage battery, and the like. The robot can realize the auxiliary stand and walk assistance to a user, can lift the user up safely and comfortably under the condition of sitting posture, judge the motion intention of the user in the walking process and carry out all-sided collaborative motion; meanwhile, the robot can also detect the moving tread of the user so as to judge the stability of the user and do corresponding assistance to the user at the real time; and the robot can safely and effectively assist patients with lower limbs being injured to carry out rehabilitation training and assist the daily activities of weak old people.

Owner:HUAZHONG UNIV OF SCI & TECH

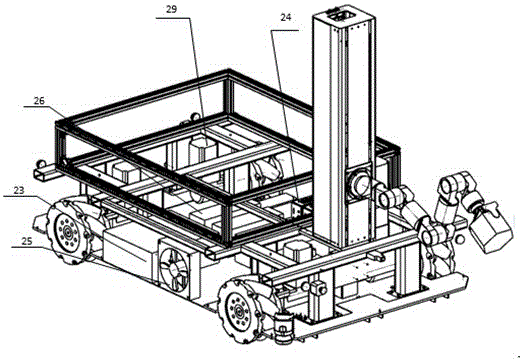

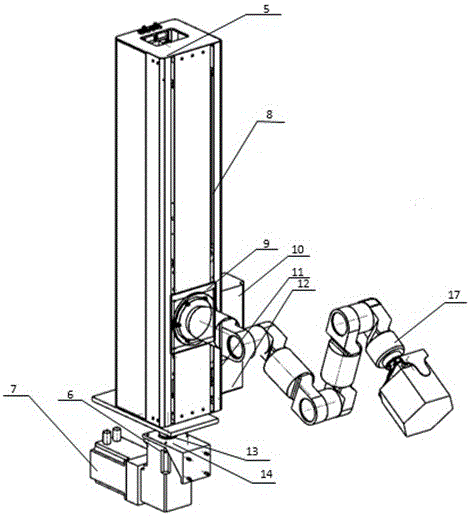

Omni-directional mobile transfer robot

InactiveCN106272415AImprove automationImprove completenessProgramme-controlled manipulatorControl systemSimulation

The invention discloses an omni-directional mobile transfer robot. The omni-directional mobile transfer robot comprises a mobile chassis, a carrying rack, a rotating mechanism, a lifting mechanism, a manipulator, a visual system, a laser sensor, a control system and a charging system. The mobile chassis is provided with Mecanum wheels for realizing omni-directional moving. The lifting mechanism can adjust the height of the manipulator. Rotational motion of a stand column at any angle can be realized through the rotating mechanism. Moreover, through cooperation of the manipulator having seven degrees of freedom, the working range is larger. Precision guidance can be realized through the laser sensor and the visual system. Operation is convenient. Motion is fast. The omni-directional mobile transfer robot is used for replacing manual operation, the working strength is reduced, and the production efficiency is improved. The omni-directional mobile transfer robot has high flexibility.

Owner:SHANGHAI UNIV

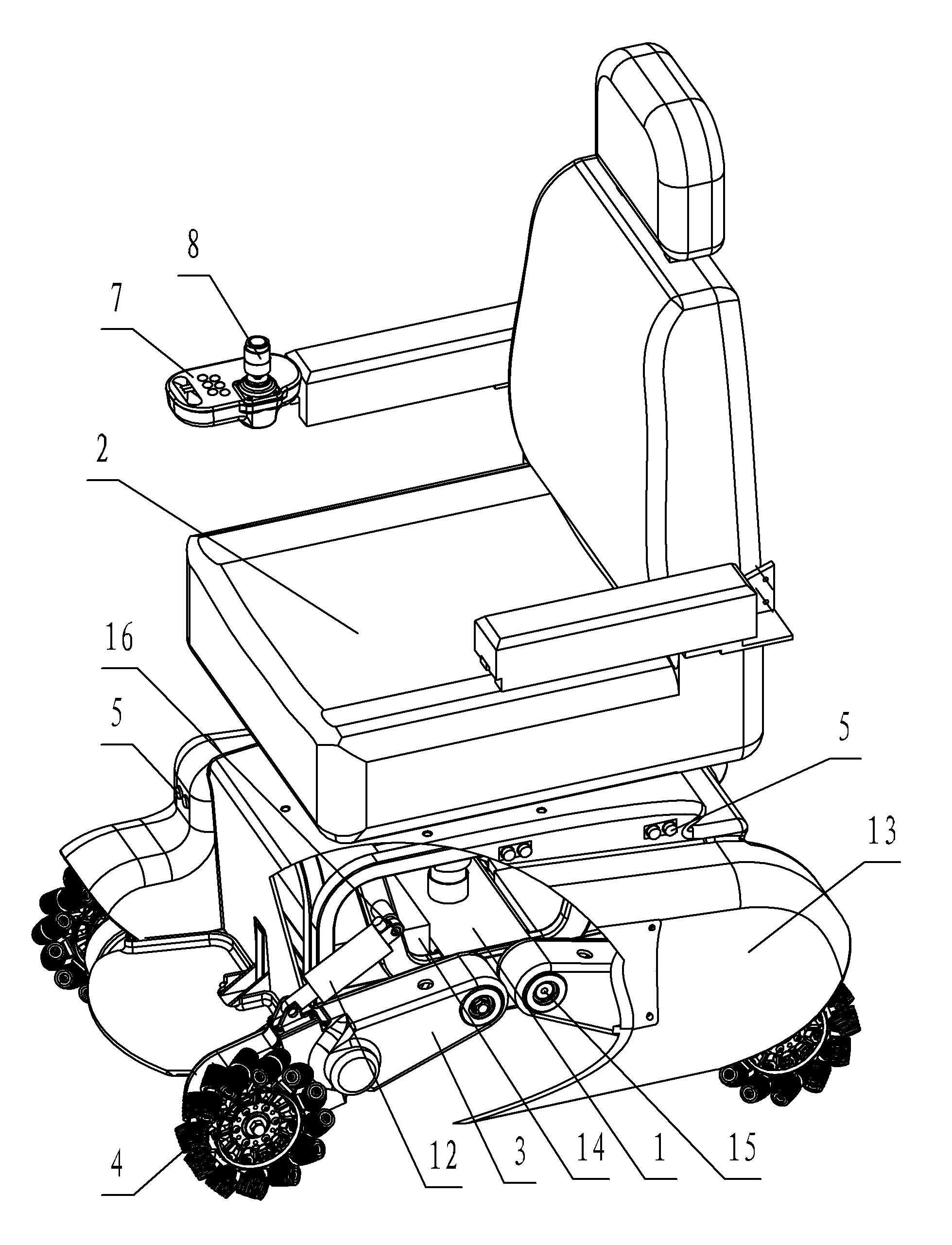

Omni-directional intelligent electric wheel chair

InactiveCN102600026AImprove the safety of useImprove motor flexibilityWheelchairs/patient conveyanceWheelchairUltrasonic sensor

The invention discloses an omni-directional intelligent electric wheel chair, which comprises a chassis frame and a seat, wherein the two sides below the chassis frame are respectively hinged with an actuating arm of which the left and the right correspond; the actuating arm is connected with Mecanum wheels which can be used for forming a pair of front wheels and a pair of rear wheels; the two sides below the seat, the front part of the seat and the upper parts of the front wheels are respectively provided with an ultrasonic sensor; the outer sides of the Mecanum wheels are respectively provided with an infrared sensor; a handle of the seat is provided with a control box and an operating handle; the actuating arm is also provided with a drive control board; and a drive control board circuit is connected with a digital signal processor (DSP). Compared with the conventional two-wheeled rear-drive electric wheel chair, the omni-directional intelligent electric wheel chair provided by the invention has omni-directional moving abilities, such as lateral direction, slant direction and the like, and has larger movement flexibility; and environment around the wheel chair can be detected through the ultrasonic sensor and the infrared sensor, so as to provide a rider with information of a barrier which can hinder the wheel chair to move, realize that the rider can automatically avoid the barrier when driving the wheel chair or can brake the wheel chair, improve use safety of the wheel chair.

Owner:常州汉迪机器人科技有限公司

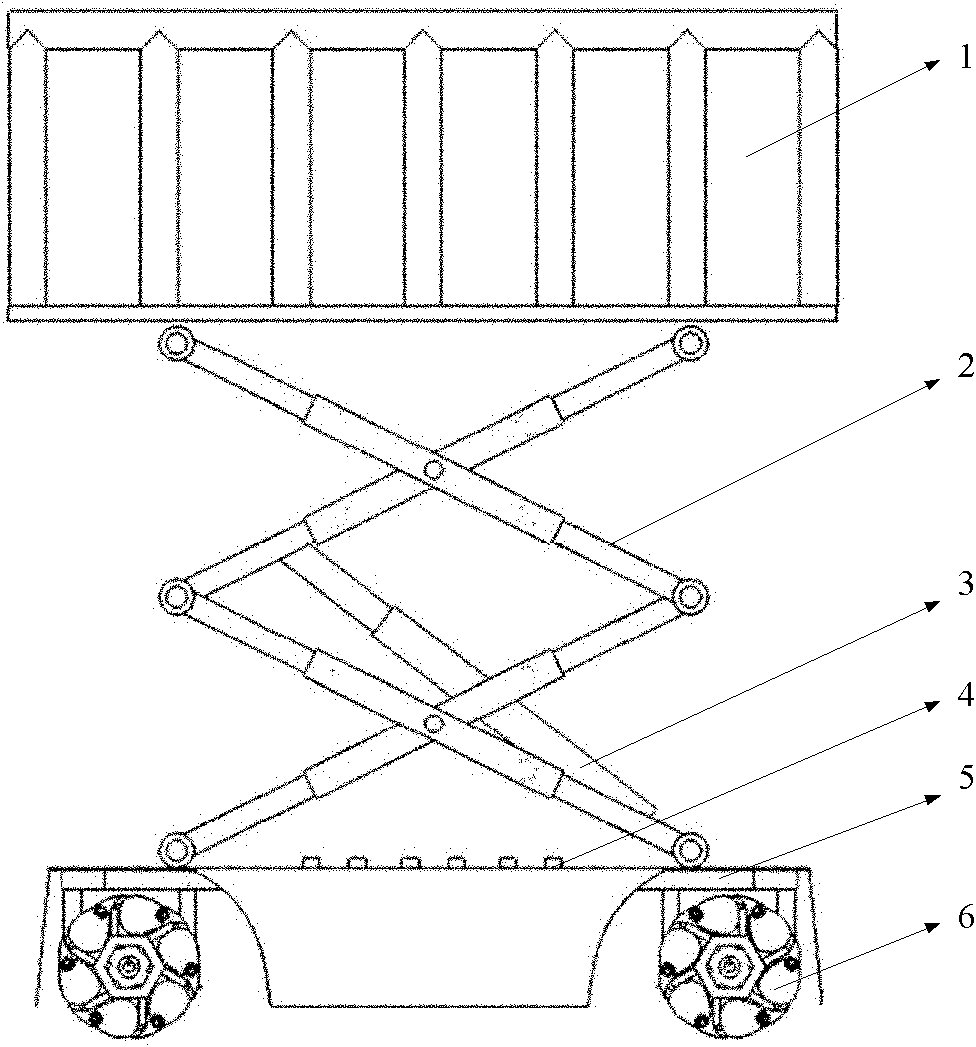

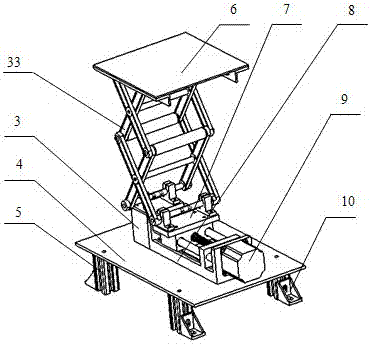

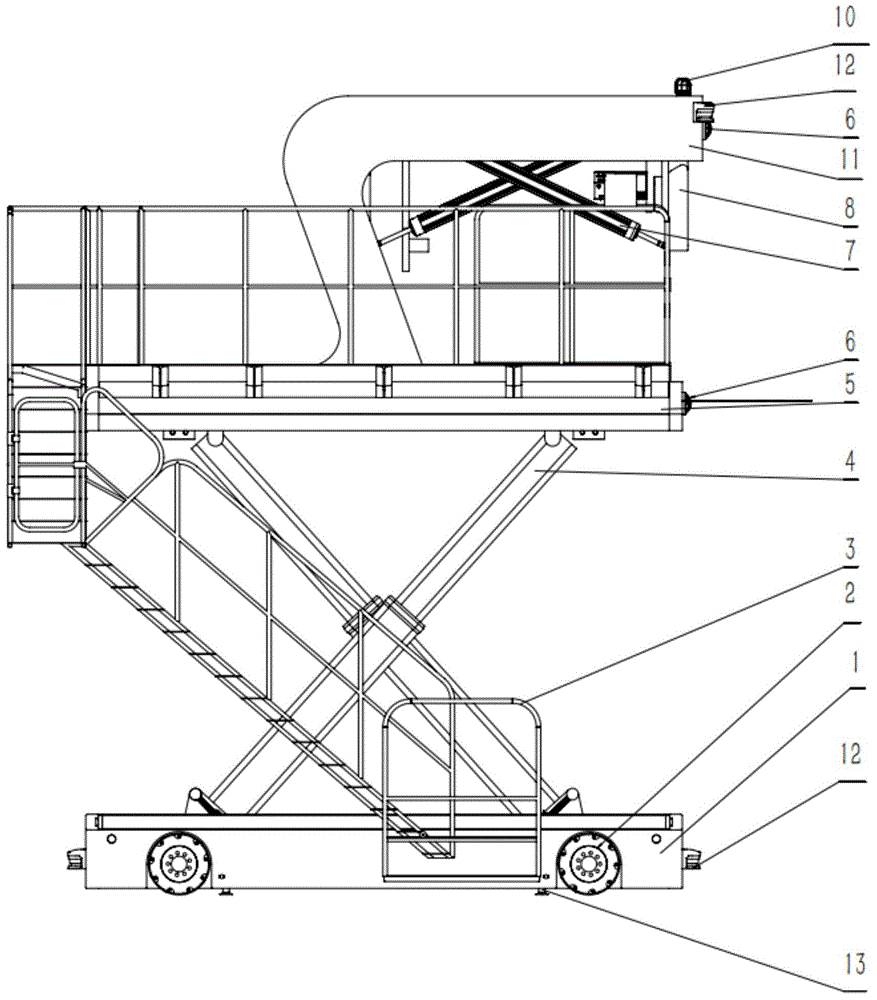

Omni-directional automatic transporter

The invention discloses an all-round automatic transport vehicle that can realize the automated process of picking up goods and loading goods in a narrow space. The omnidirectional automatic transport vehicle includes an omnidirectional motion mechanism, a lifting mechanism, a telescopic mechanism and a control system; the omnidirectional motion mechanism is composed of four omnidirectional Mecanum wheels; the lifting mechanism is composed of a bevel gear mechanism, a ball screw pair and a scissor mechanism Composition; the telescopic mechanism consists of electric push rods, roller slides and connecting rod support structures. The control system drives the mecanum wheel to realize the forward and backward movement, left and right movement, diagonal movement and zero-radius turning of the transport vehicle; the movement of the bevel gear transmission mechanism makes the scissors move to realize the lifting and lowering of the platform; the electric push rod moves to make the platform extend and retract.

Owner:CHANGCHUN UNIV OF SCI & TECH

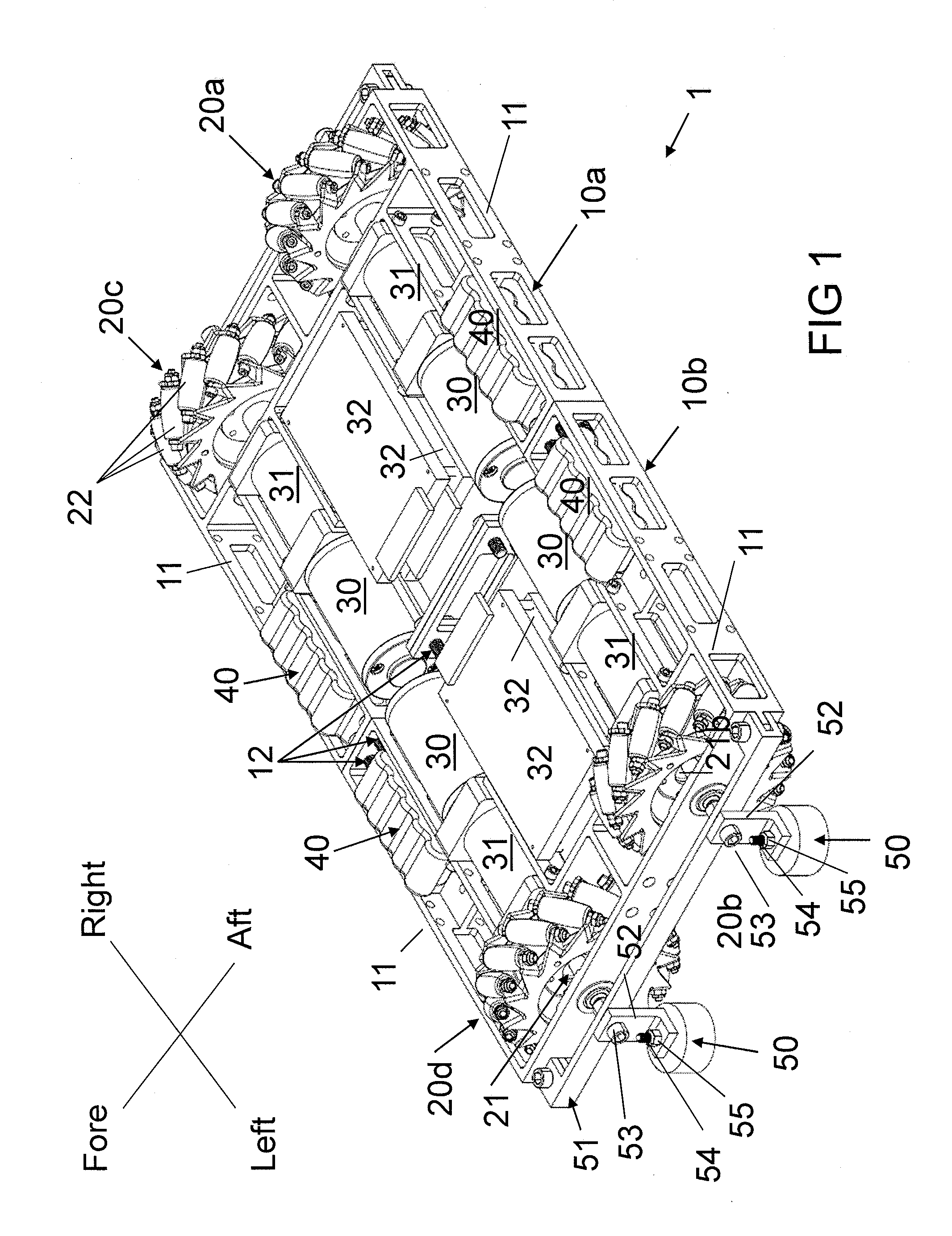

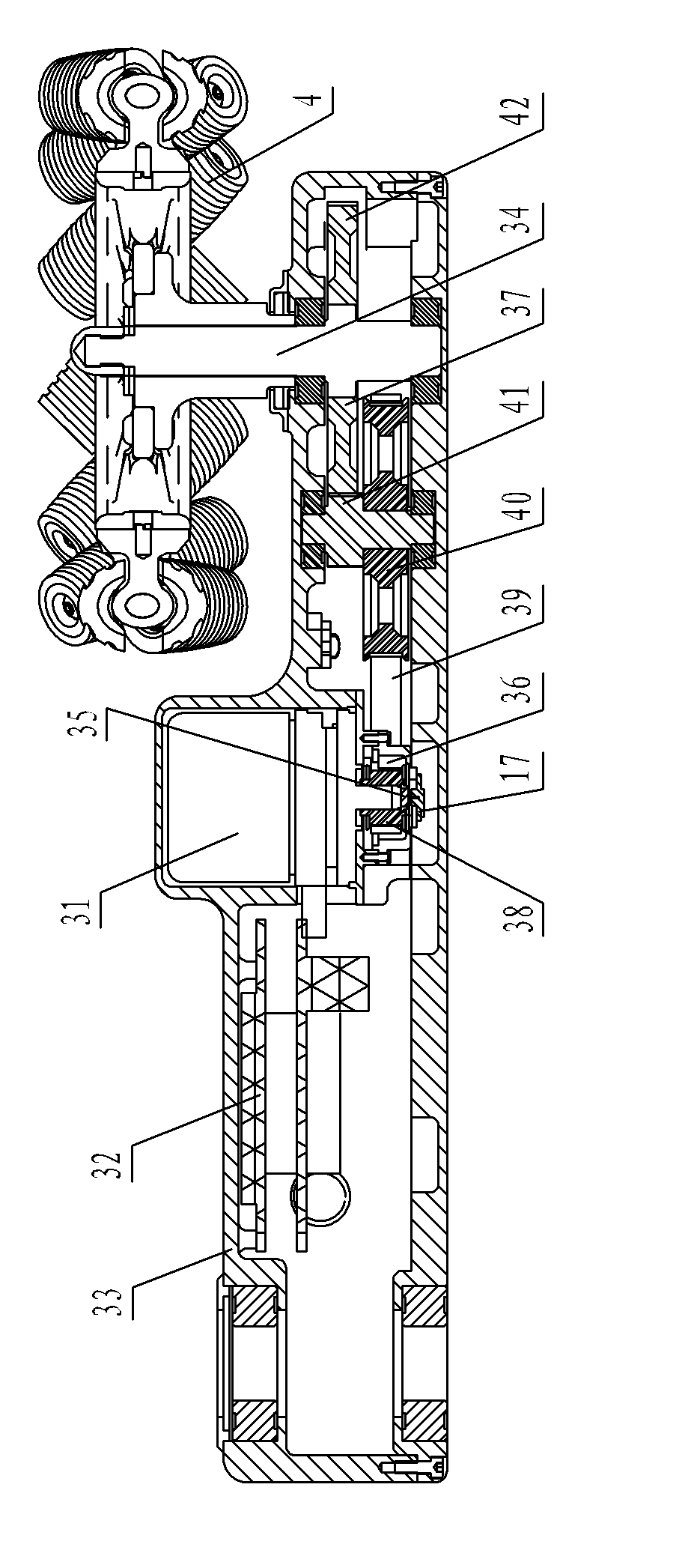

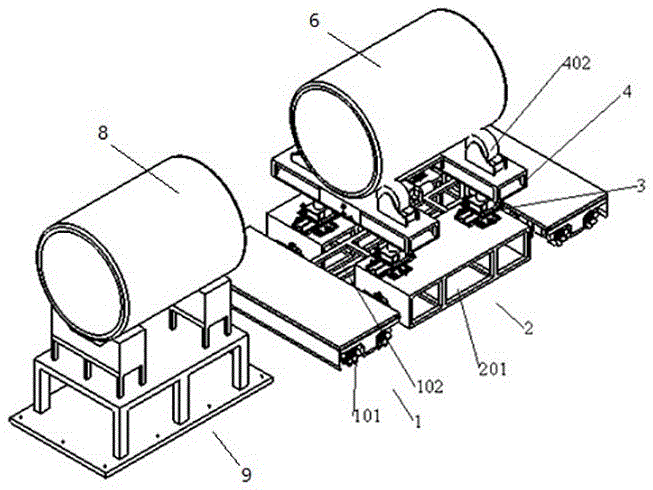

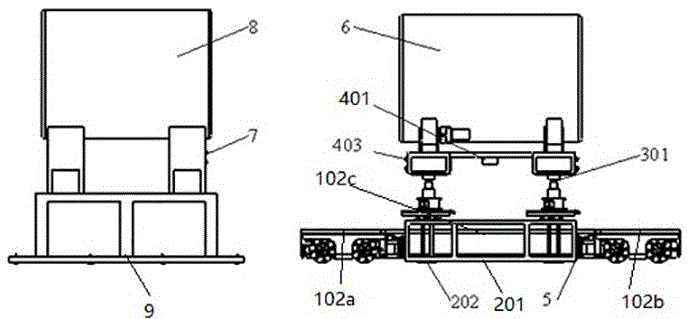

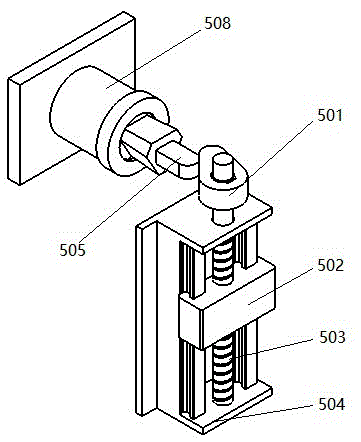

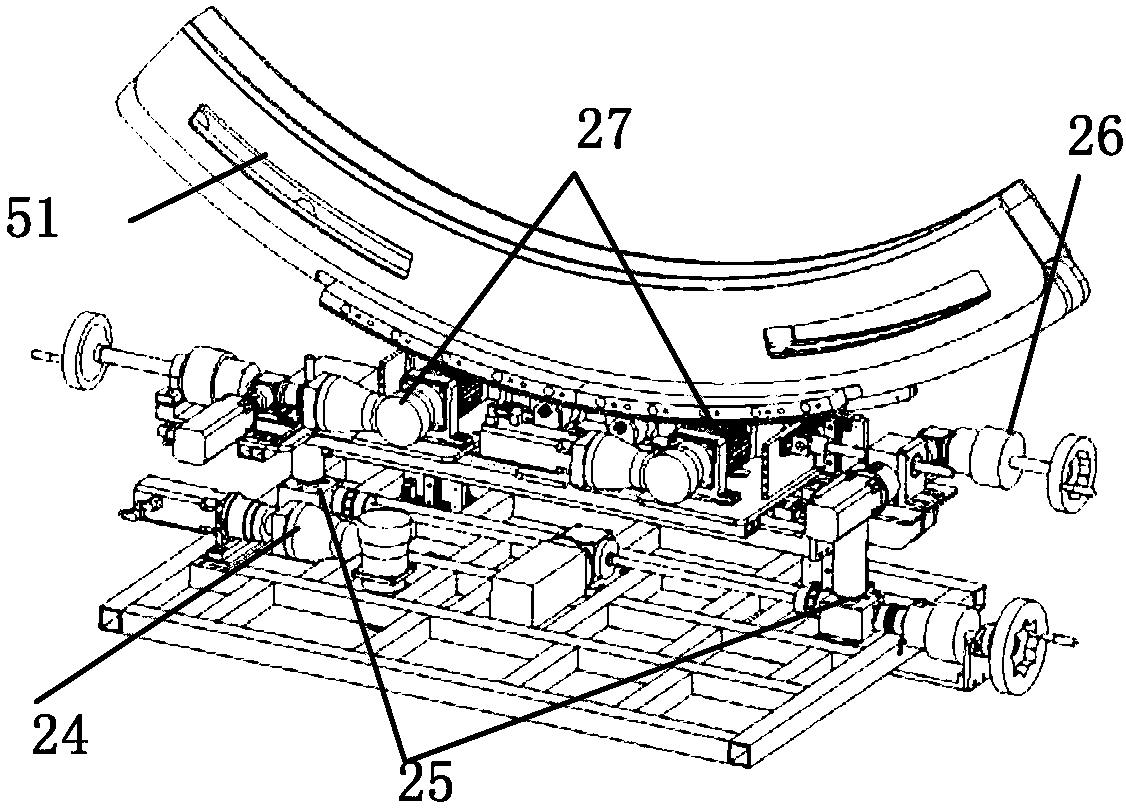

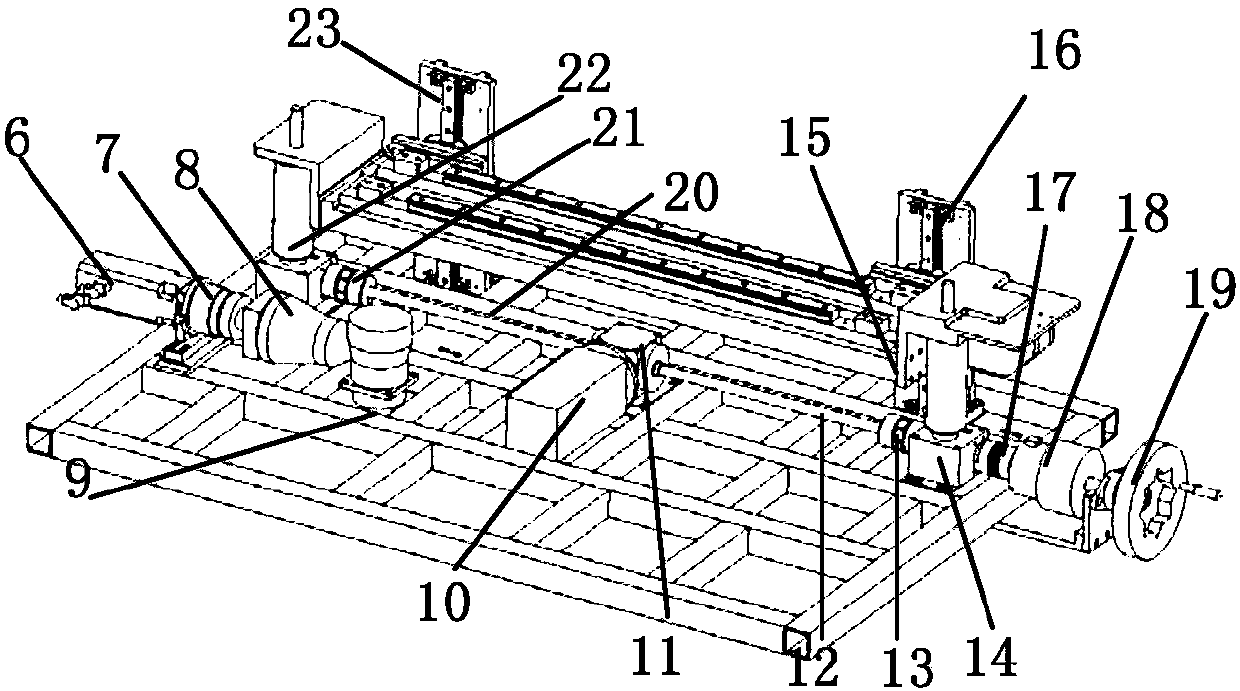

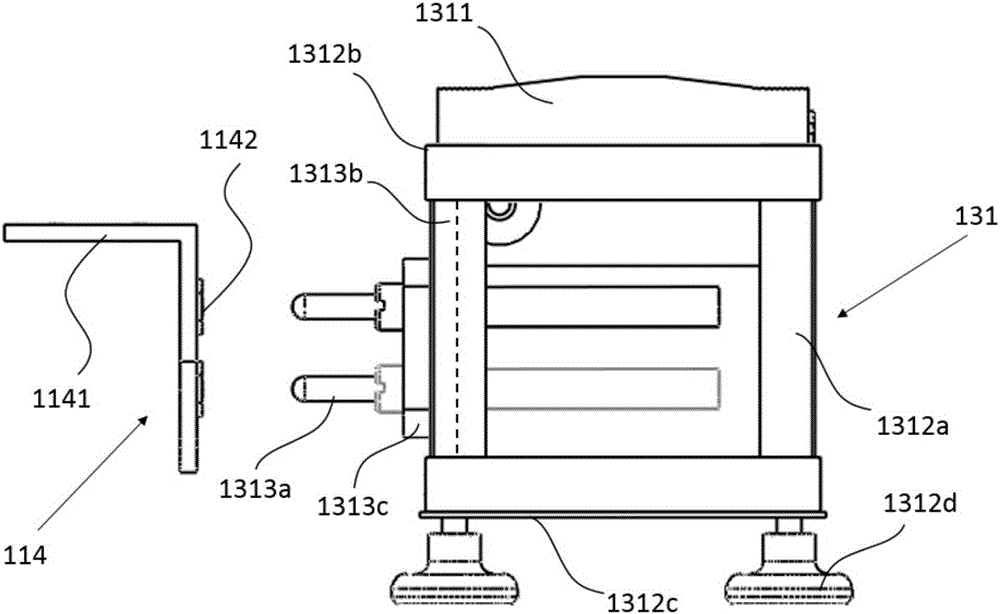

Carrying and docking assembly for large-size heavy-load cylindrical workpieces

ActiveCN105479129AImprove stabilitySimplify the measurement partMetal working apparatusLaser rangingButt joint

The invention discloses a carrying and docking assembly for large-size heavy-load cylindrical workpieces, comprising a carrying platform, a posture adjusting and docking assembly and a support assembly, wherein the carrying platform comprises a Mecanum wheel omni-directional platform and an air cushion platform which are connected with each other by a connecting assembly and can displace up and down; the posture adjusting and docking assembly comprises four groups of triaxial mobile locating devices, a bracket, laser distance measuring sensors, a controller and a bracket; the three laser distance measuring sensors in triangular arrangement are arranged on the bracket; three target balls are arranged on the support assembly; and the controller is used for receiving data measured by scanning the target balls with the laser distance measuring sensors and controlling the triaxial mobile locating devices to act to achieve butt joint of an active butt joint workpiece and a passive butt joint workpiece. The docking device is suitable for mobile carrying and assembly butt joint of large-size heavy-load cylindrical workpieces by utilizing flexibility of the Mecanum wheel omni-directional platform and loading characteristics of the air cushion platform and simplifying the setting of the sensors by adopting a method of determining a plane with three points.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

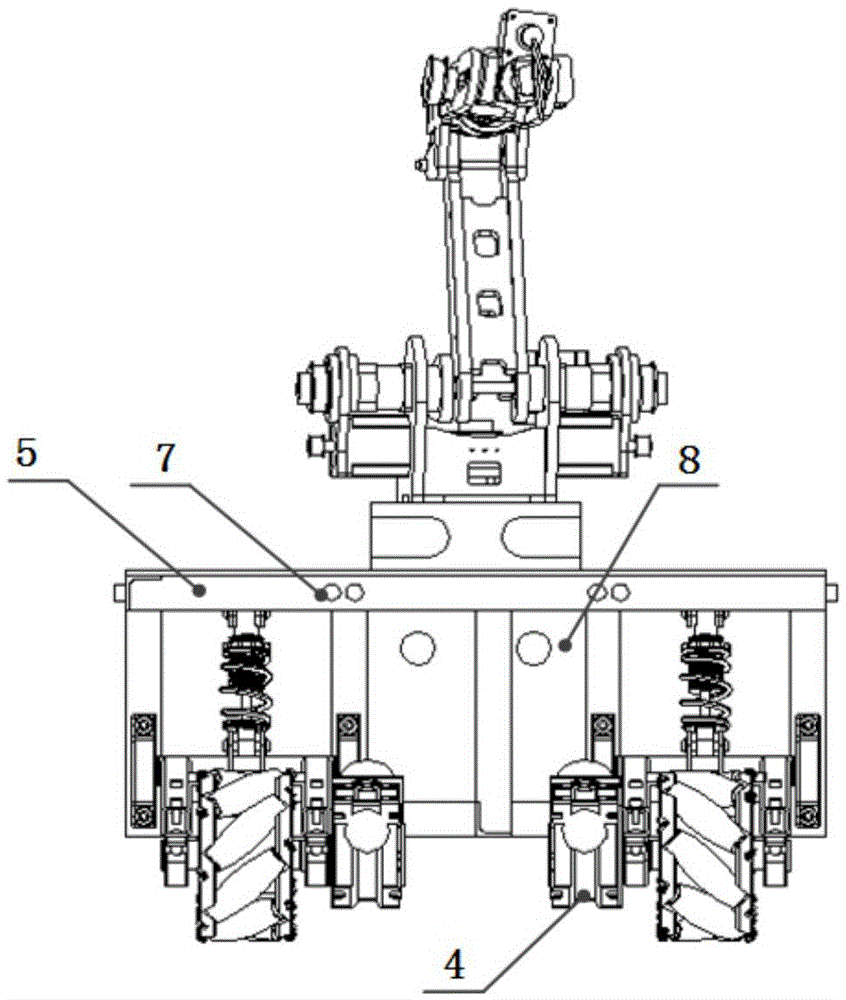

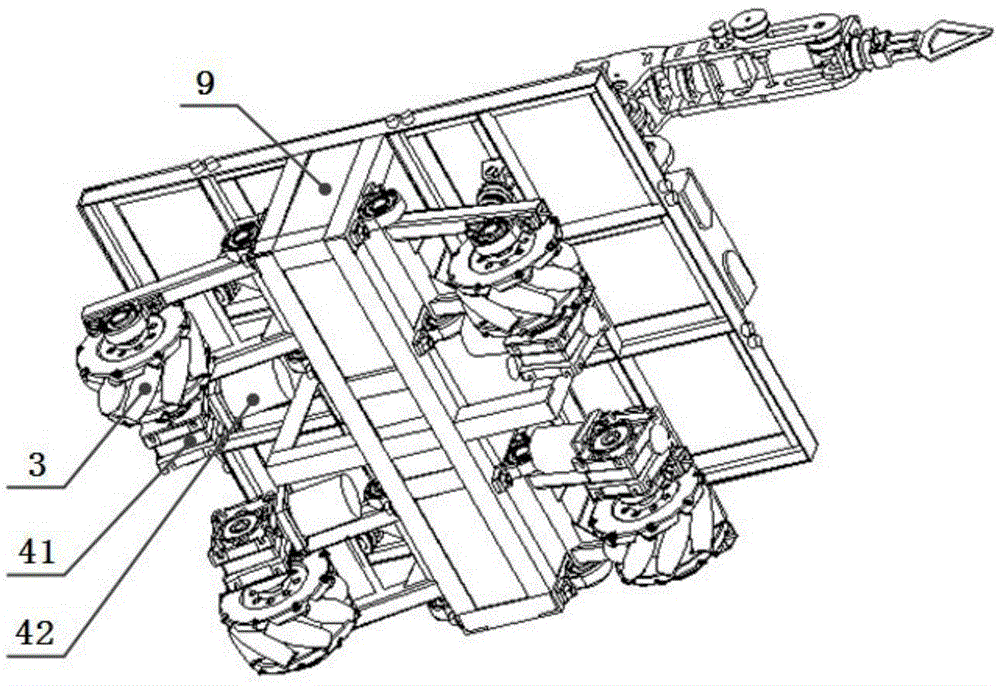

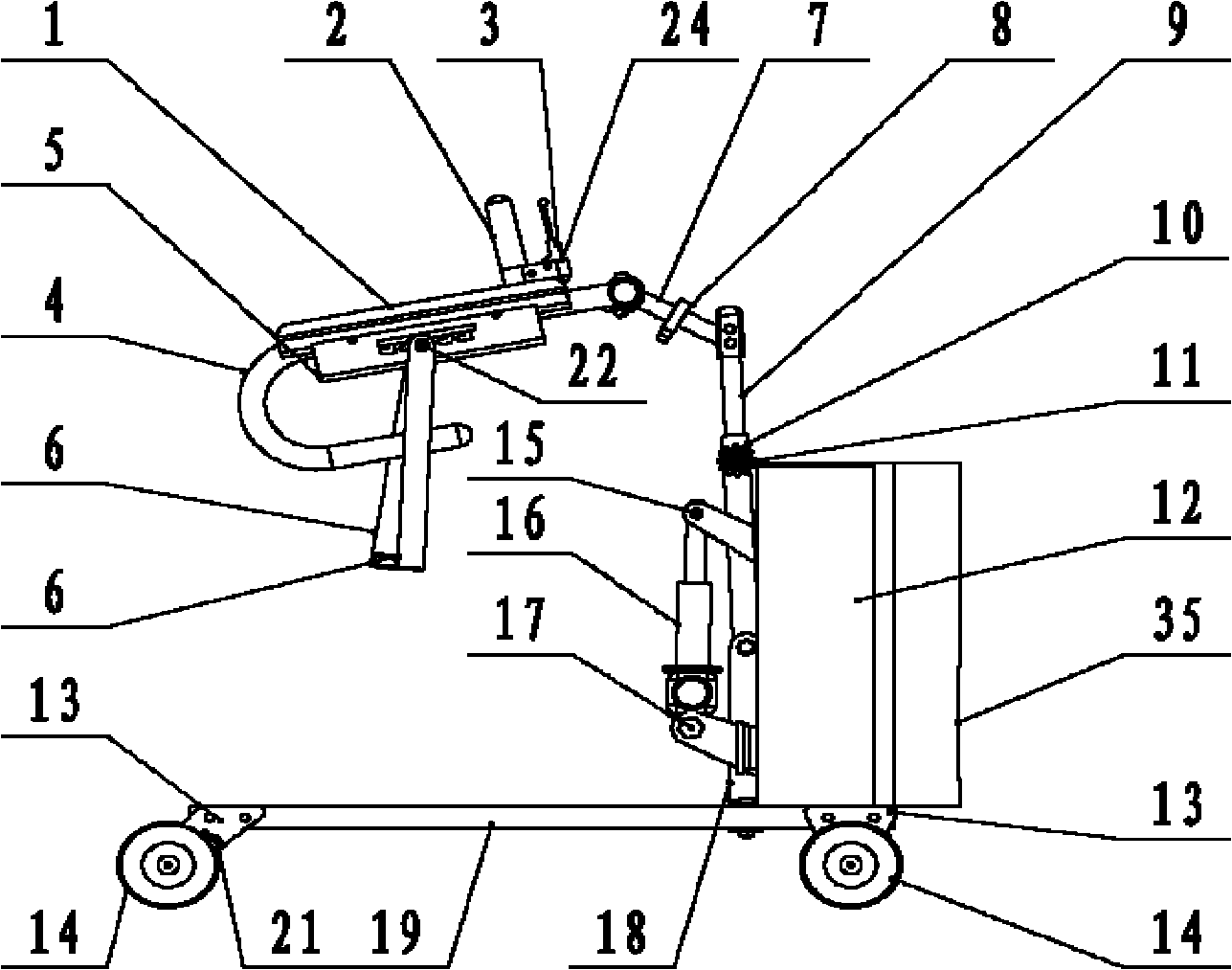

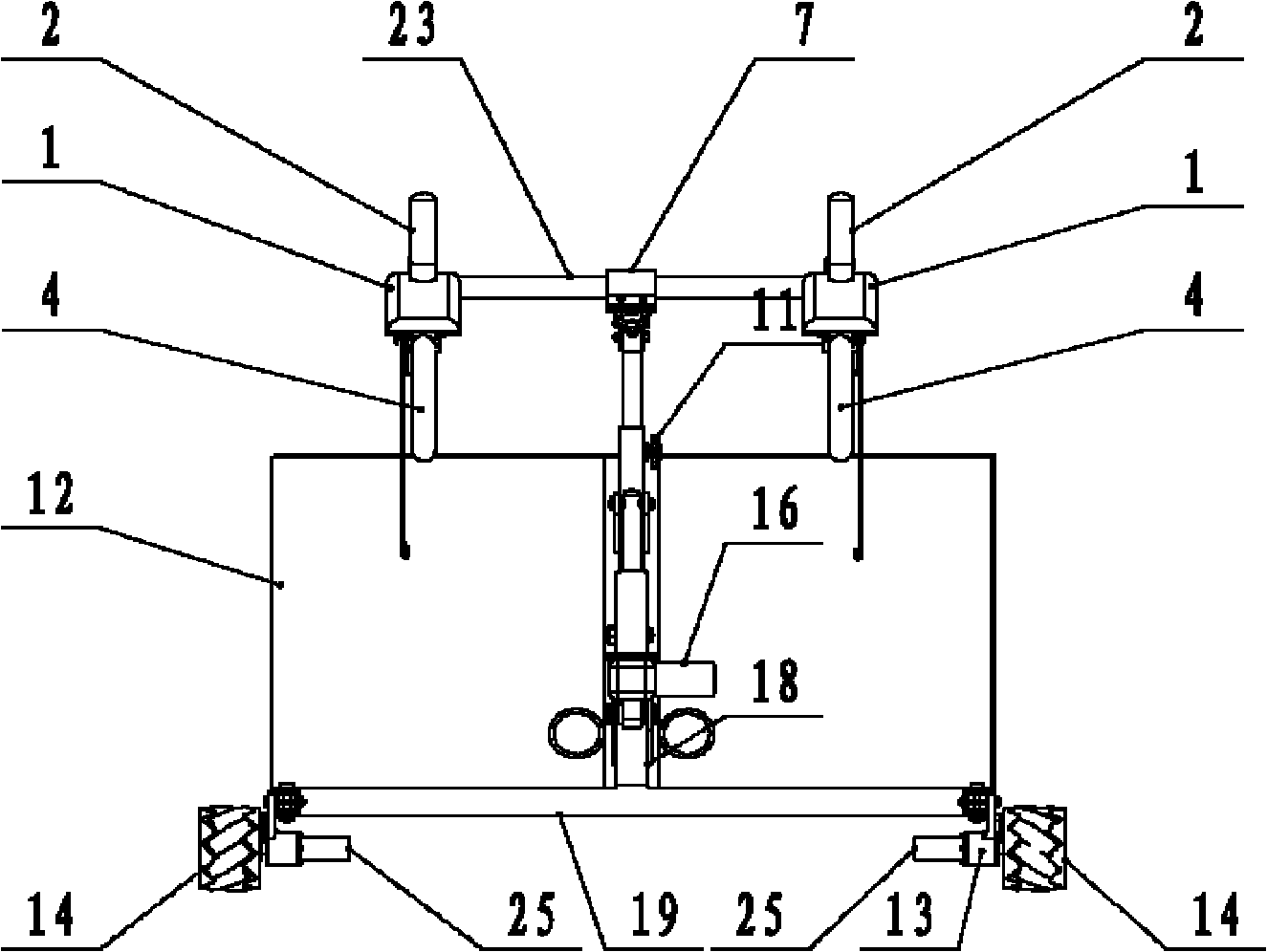

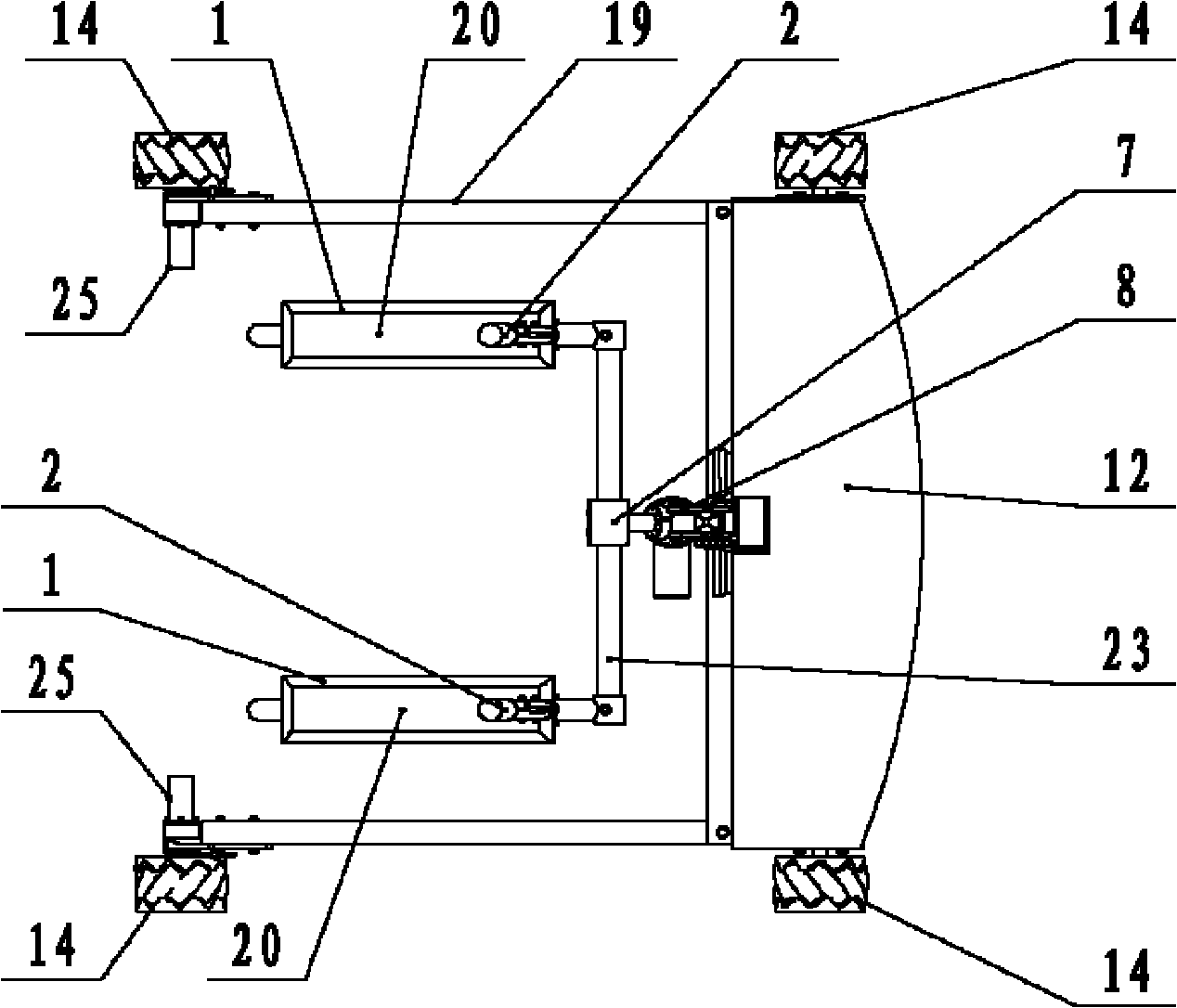

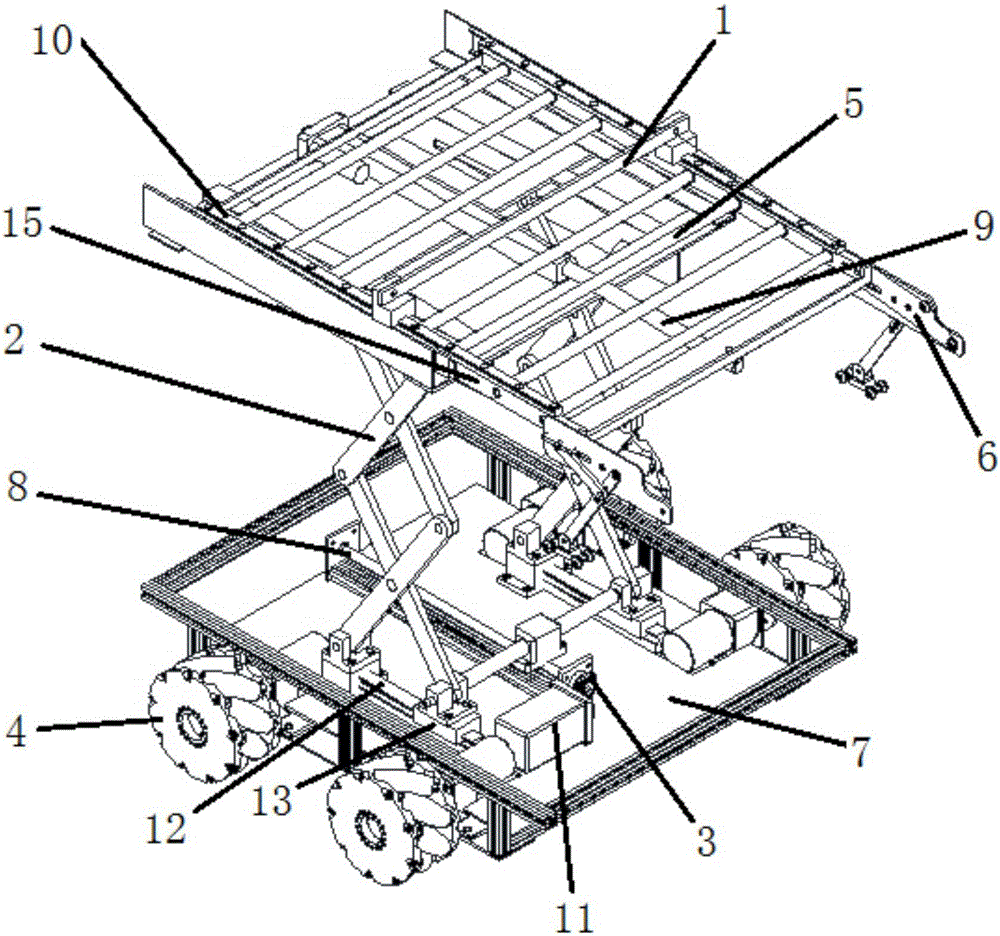

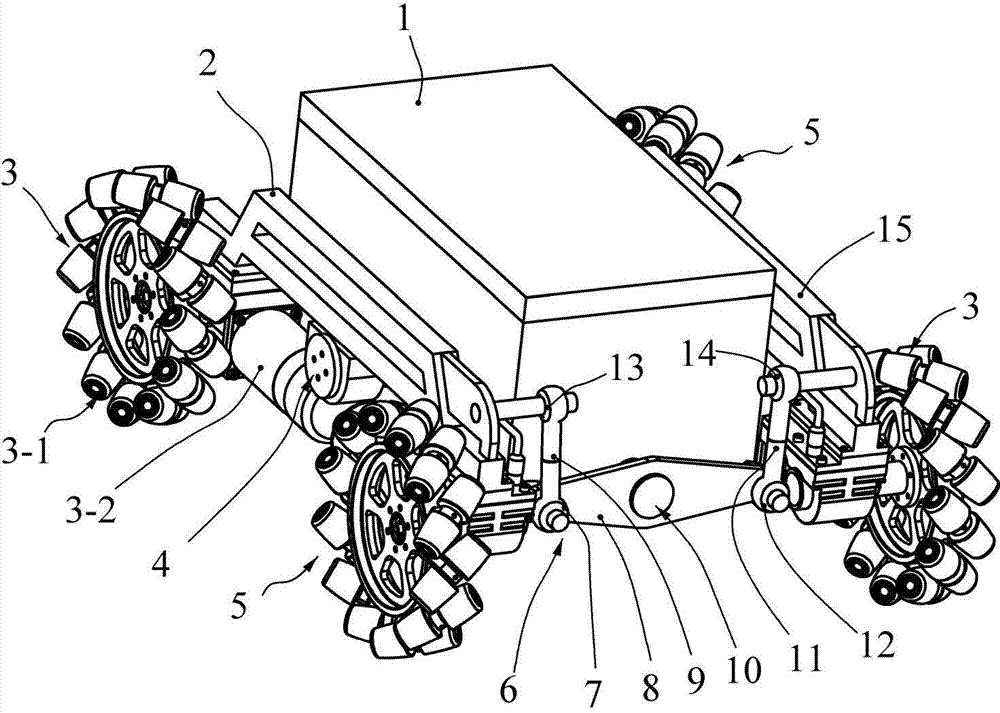

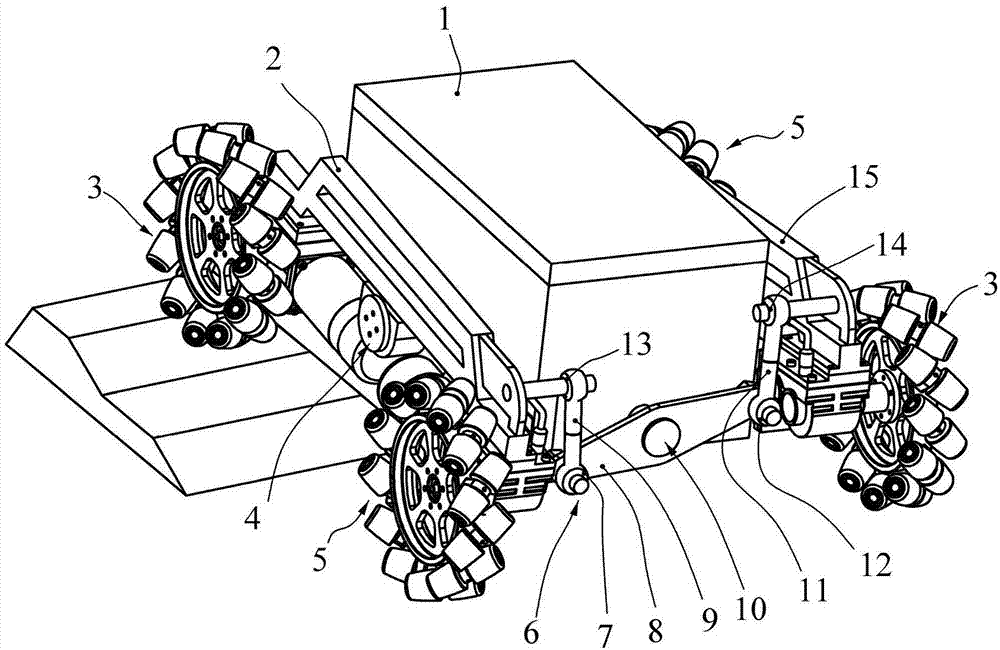

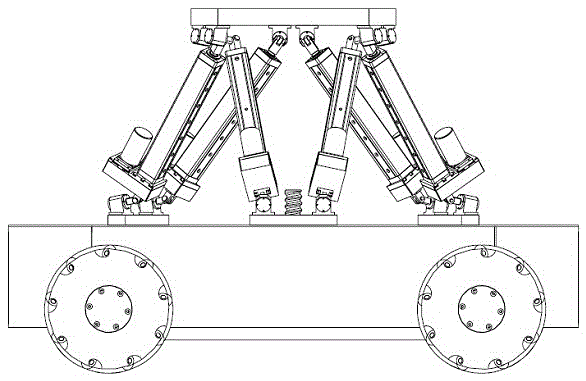

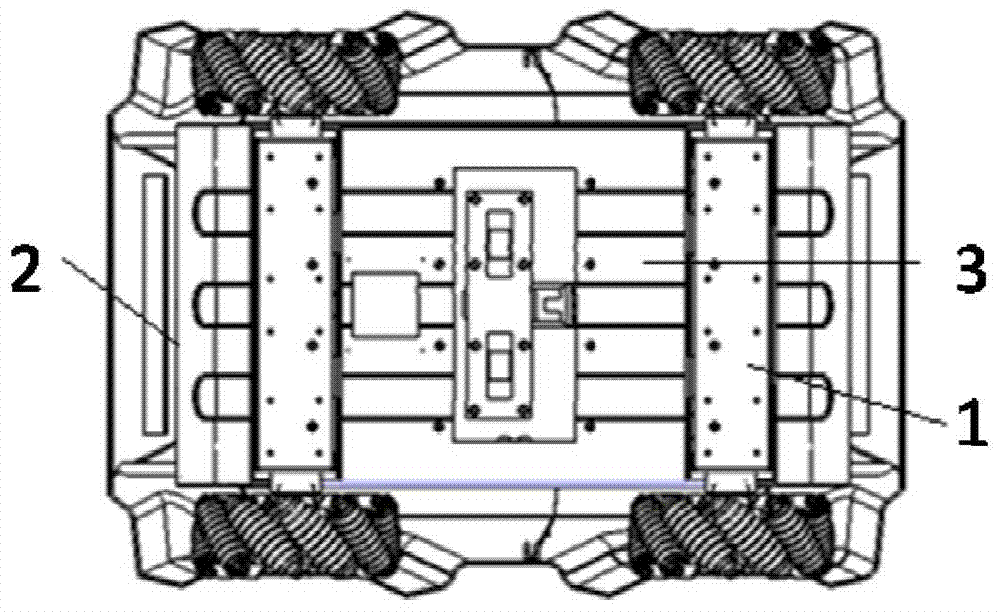

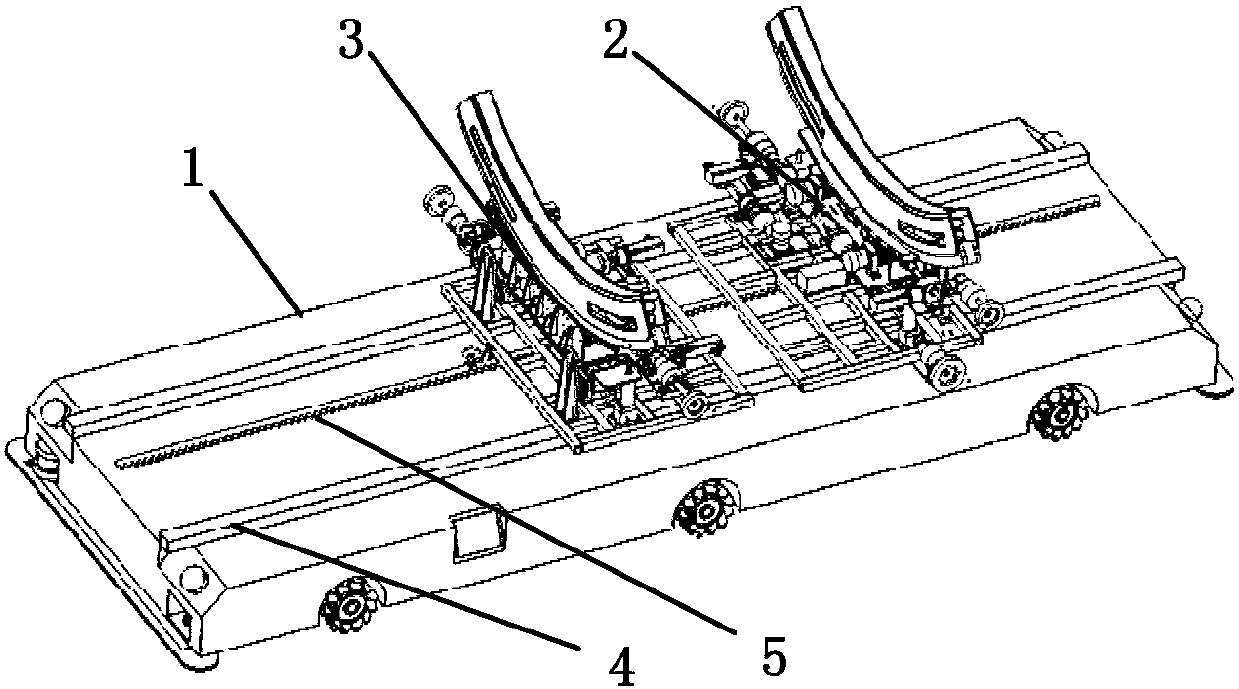

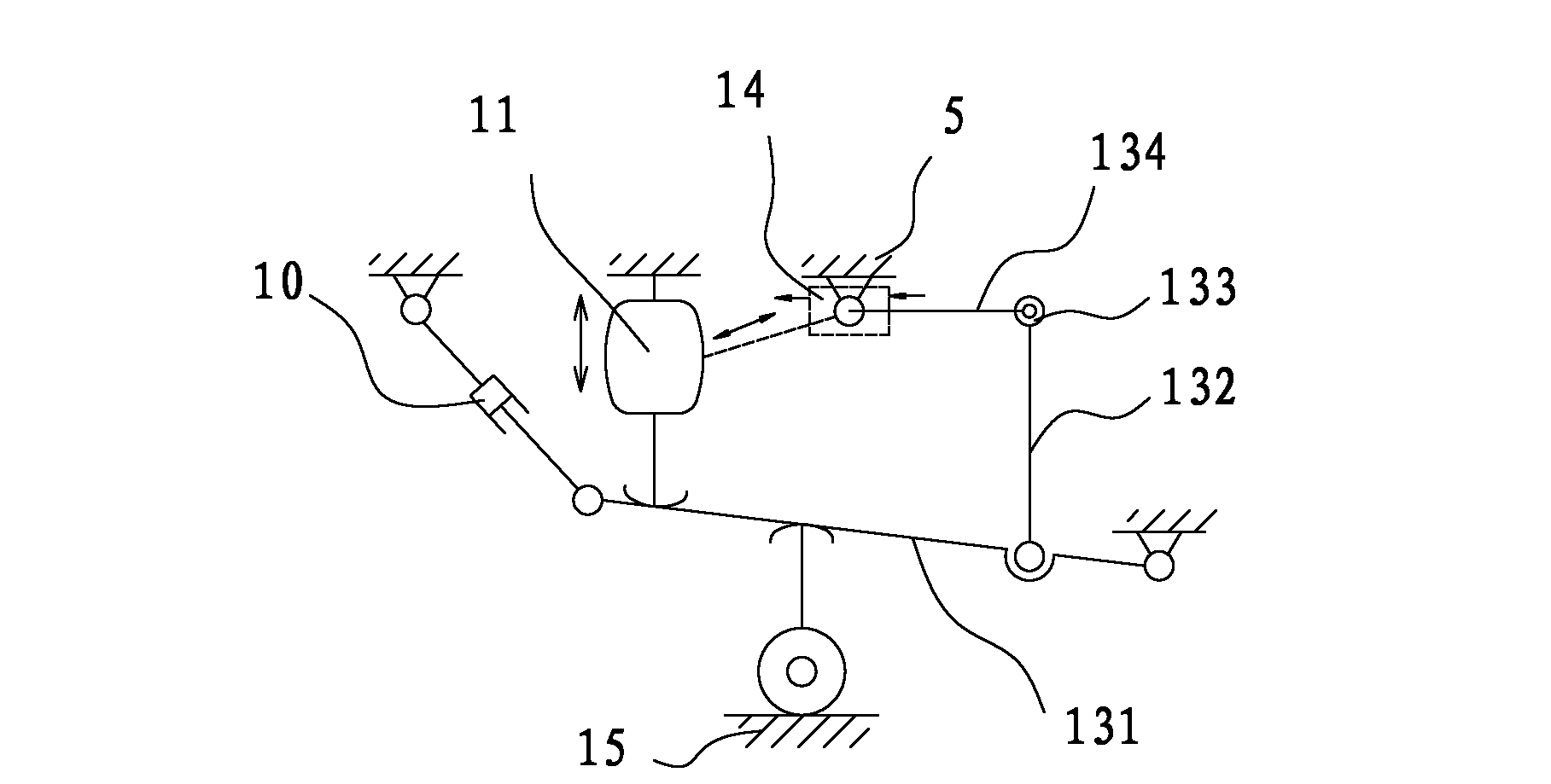

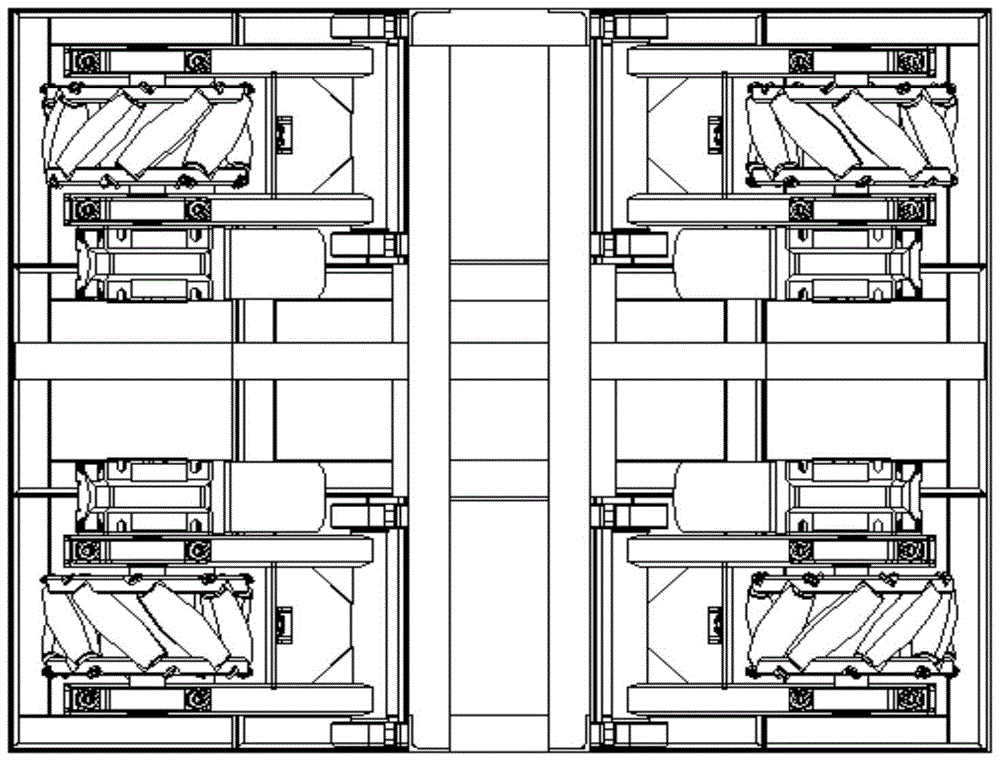

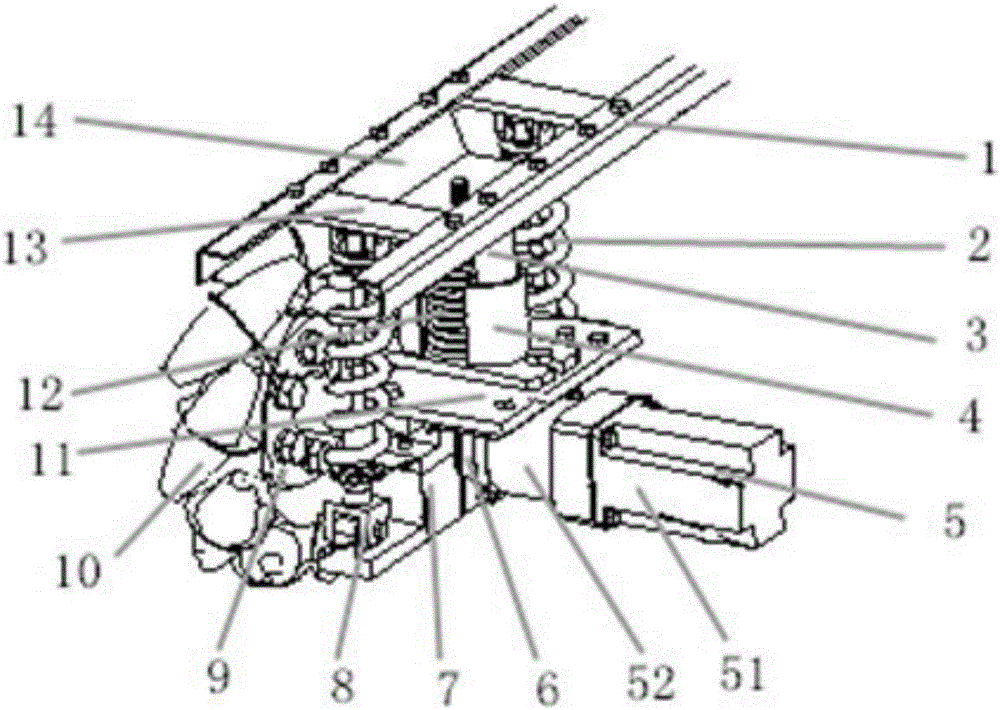

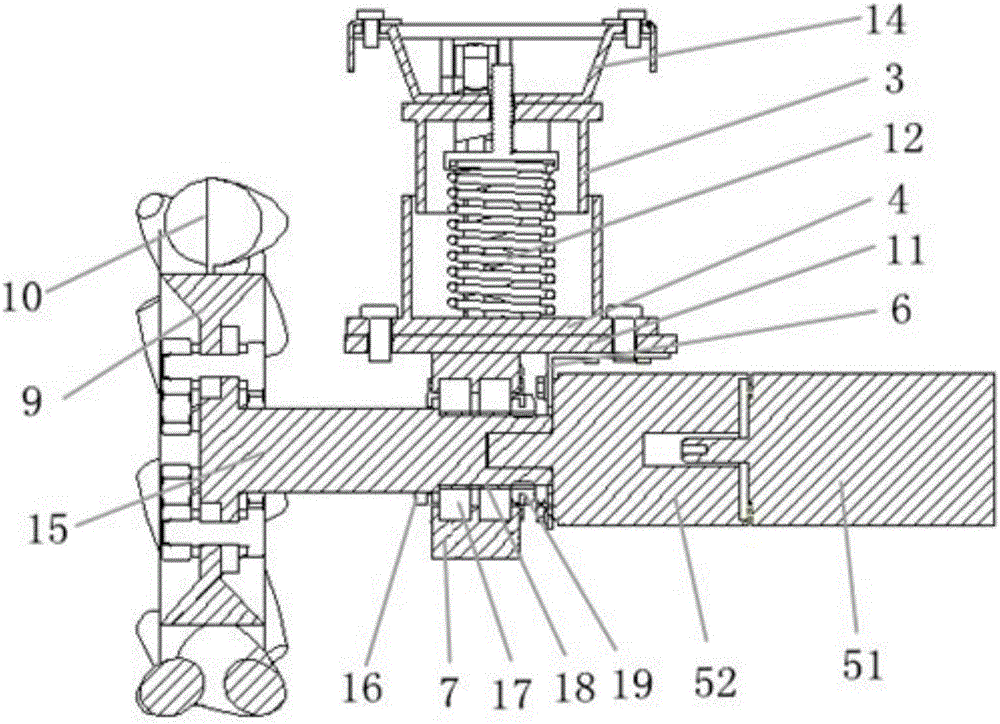

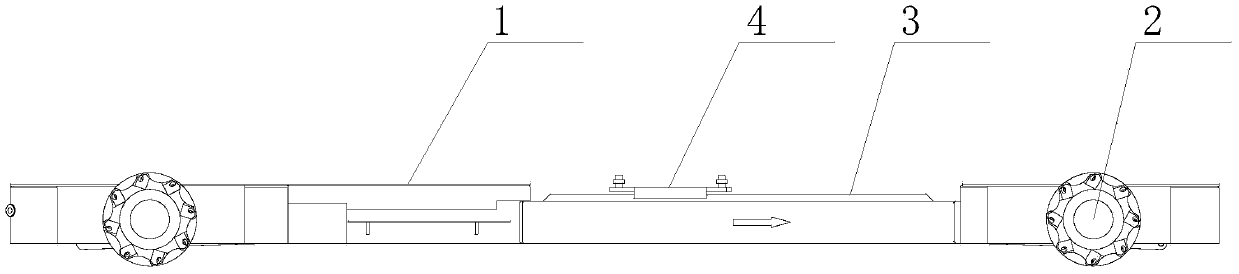

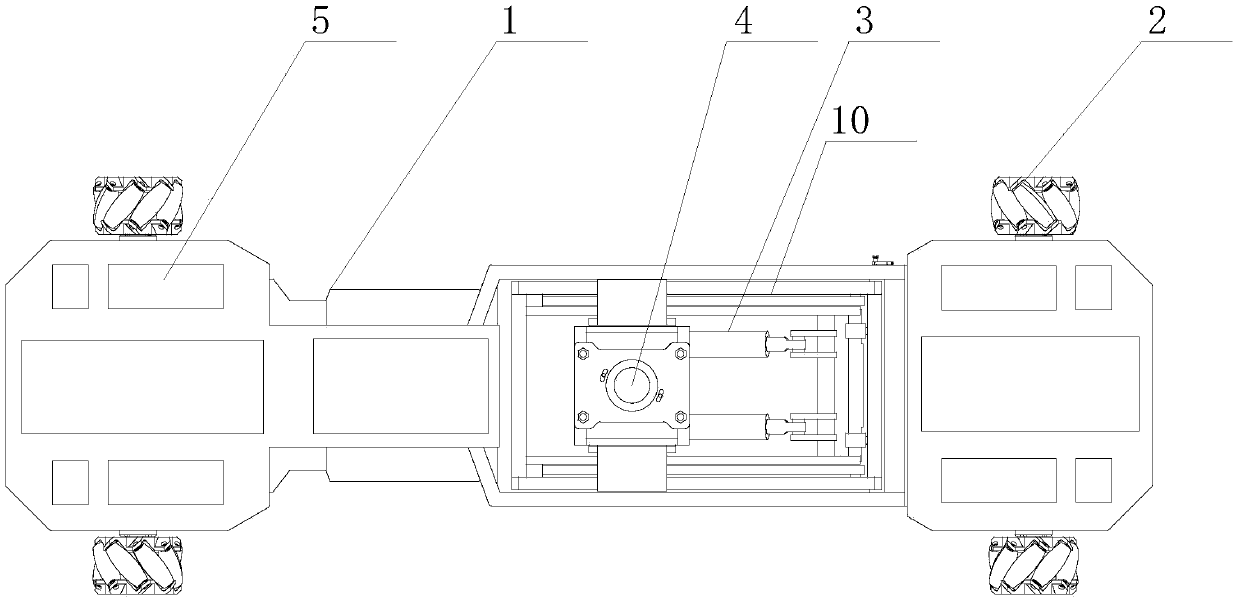

Mecanum wheel-based rocker omnidirectional mobile platform

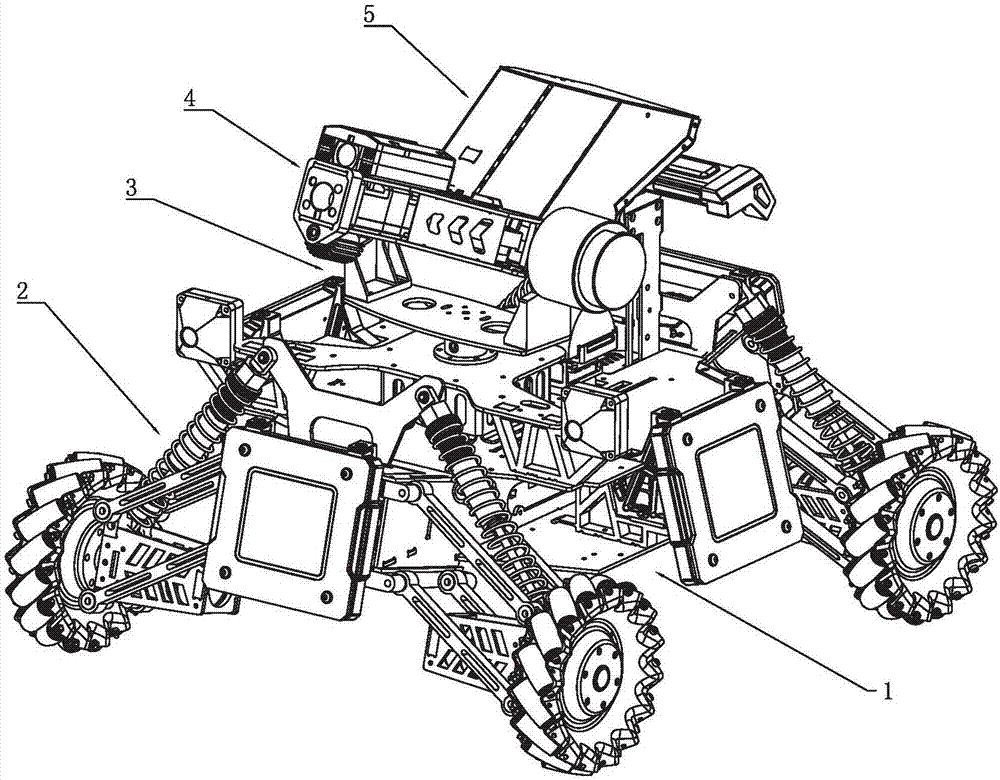

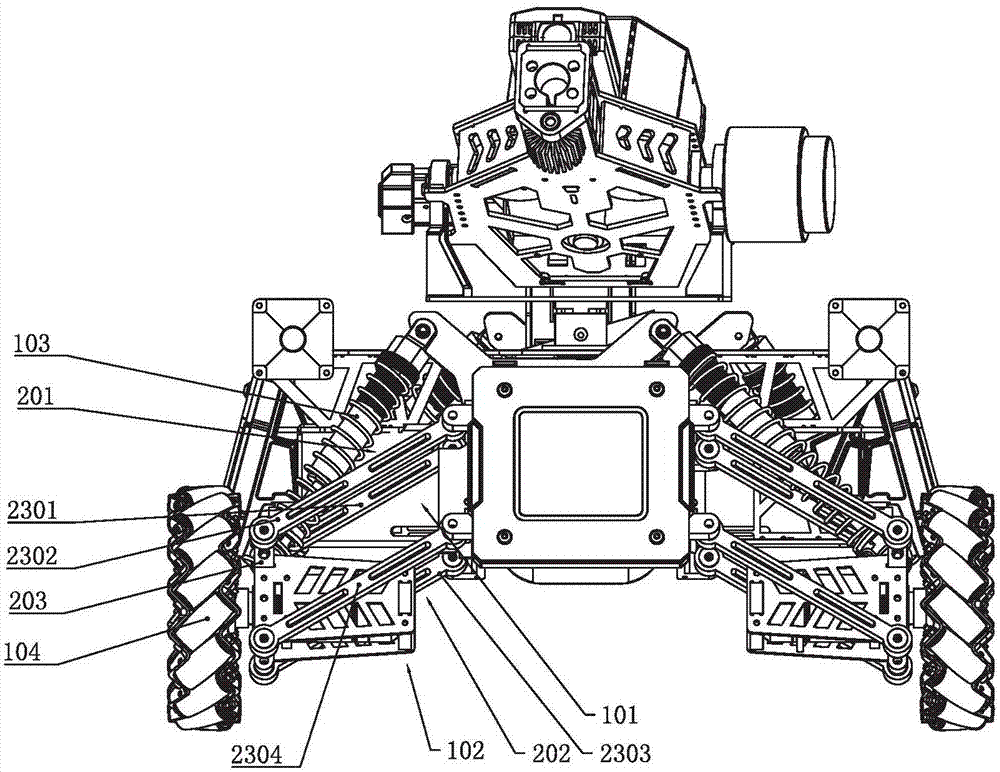

ActiveCN104494721AImprove terrain adaptabilityEasy to controlInterconnection systemsVehiclesTerrainEngineering

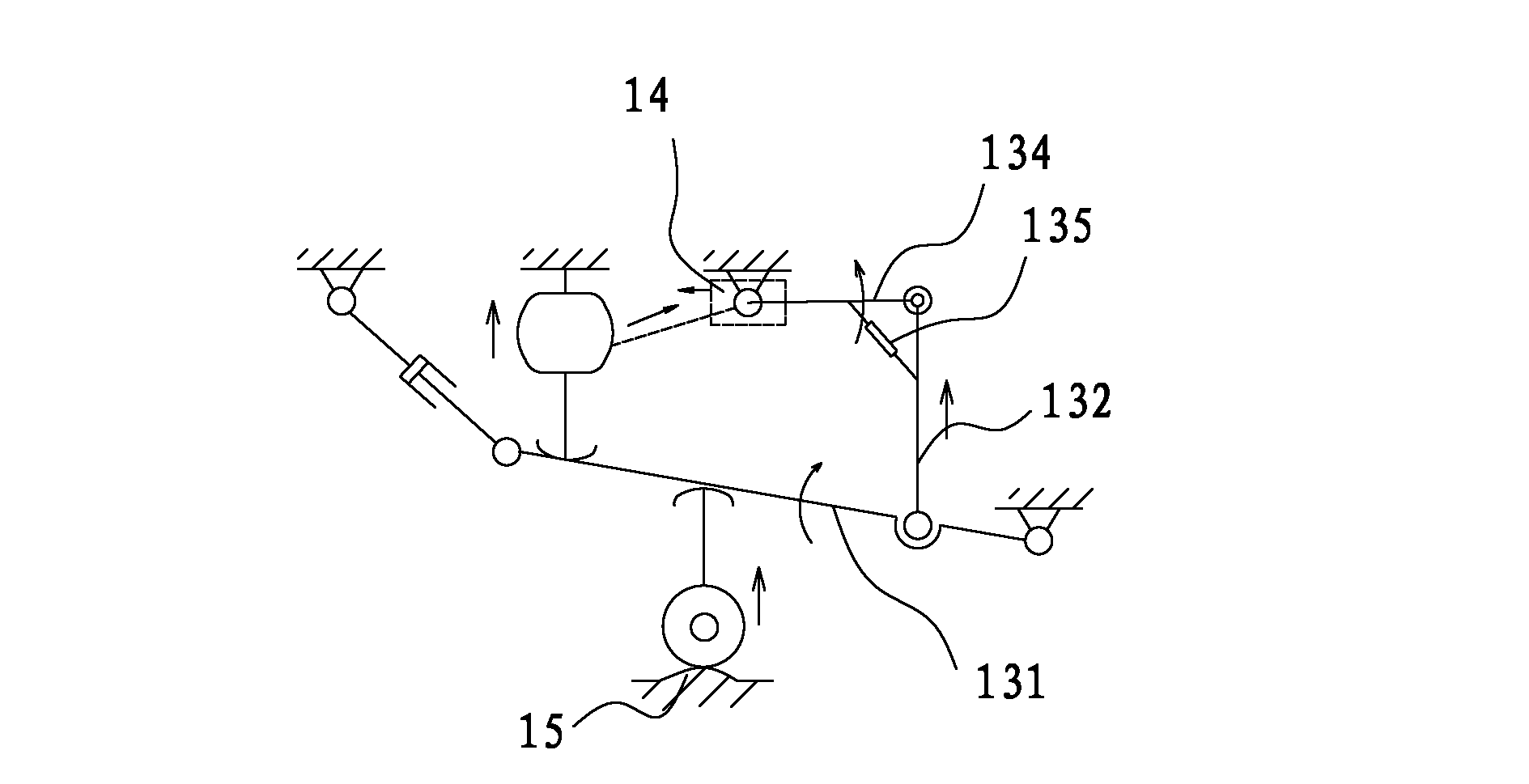

A Mecanum wheel-based rocker omnidirectional mobile platform comprises a main body (1), leftwards-rotating Mecanum wheel assemblies (3), rightwards-rotating Mecanum wheel assemblies (5), a rocker suspension I (2), a rocker suspension II (15) and a balancing mechanism (6); the middle parts of the rocker suspension I and the rocker suspension II are hinged to the left and right sides of the main body through revolute joints symmetrically; the middle part of a transverse rocker (8) of the balancing mechanism and one end of the main body are hinged by a revolute joint (10); one end of a side connecting rod I (9) and one end of a side connecting rod II (11) of the balancing mechanism are hinged to the left and right ends of the transverse rocker by spherical joints, and the other end of the side connecting rod I (9) and the other end of the side connecting rod II (11) of the balancing mechanism are hinged to the rocker suspension I and the rocker suspension II by spherical joints; two Mecanum wheel assemblies with different rotation directions are fixed to the two ends of each rocker suspension, and the Mecanum wheel assemblies at the same ends of the rocker suspension I and the rocker suspension II are opposite in rotation directions. According to the invention, wheels are always in contact with the ground and the load is shared, so that the Mecanum wheel-based rocker omnidirectional mobile platform has better motion controllability and terrain trafficability.

Owner:CHINA UNIV OF MINING & TECH

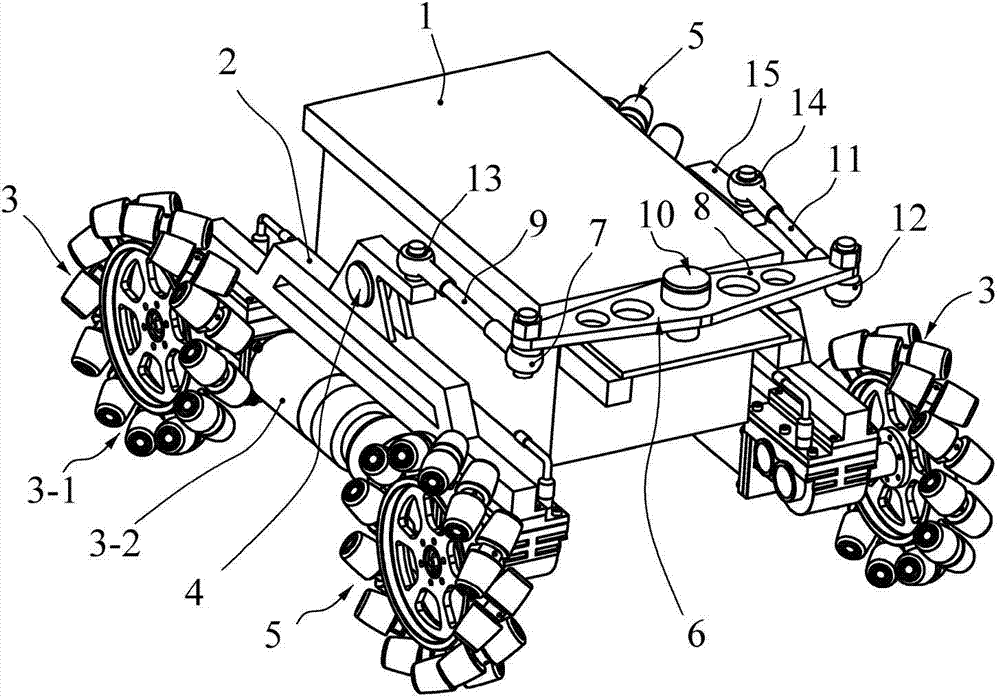

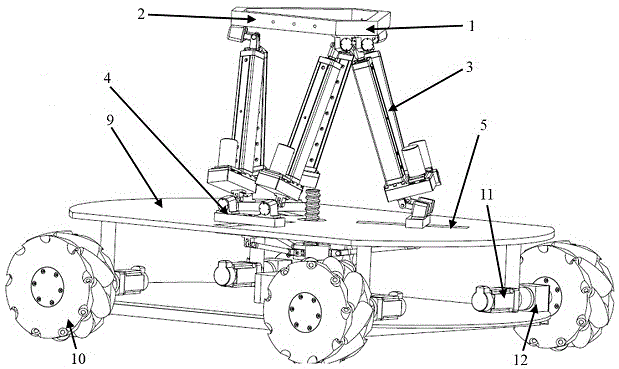

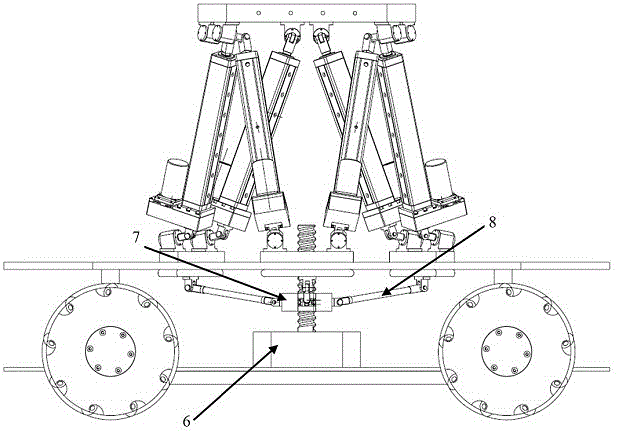

Structural dimension parameter adjustable Mecanum wheel type mobile robot

The invention discloses a structural dimension parameter adjustable Mecanum wheel type mobile robot. The robot is composed of a structural dimension parameter adjustable Stewart platform and a Mecanum wheel type mobile platform, wherein the Stewart platform comprises a Stewart movable platform, a Stewart static platform and a linkage mechanism. The Stewart platform is a parallel robot which has six freedom degrees and is applicable to heavy load; the Mecanum wheel type mobile platform has the characteristics of heavy load and all-direction movement; a mobile parallel robot formed by combination of the Mecanum wheel type mobile platform and the Stewart platform has the characteristics of being movable in all directions, high in positioning precision, capable of being heavily loaded and flexible in adjustment of tail end posture, and is applicable to industrial demands of flexible processing, overloading transportation and the like. By respectively changing the structural dimension parameters of the Stewart movable platform and the Stewart static platform, the robot disclosed by the invention is correspondingly changed in overall height, tail end motion space range and bearing capacity so as to adapt to work demands, so the applicability of the Mecanum wheel type mobile parallel robot is improved.

Owner:SHANGHAI UNIV

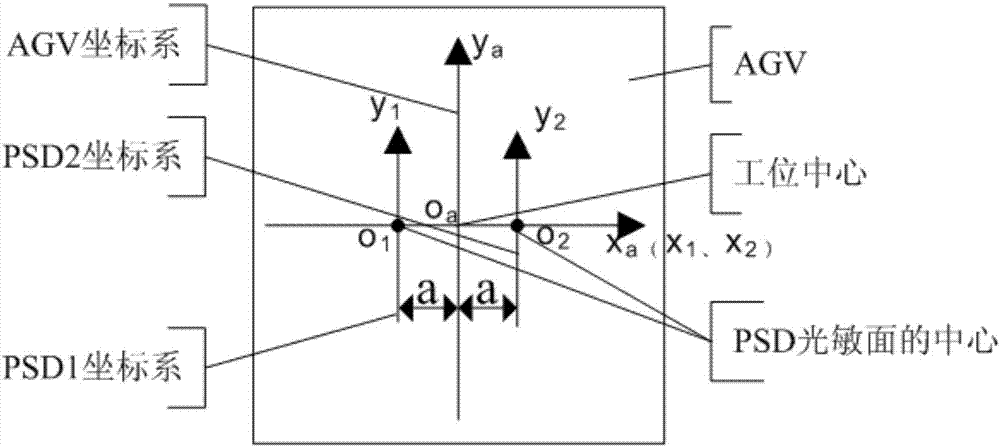

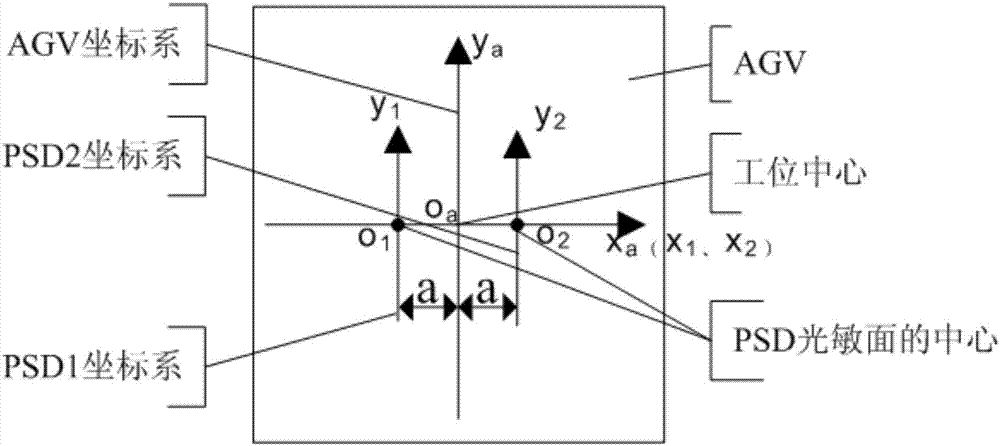

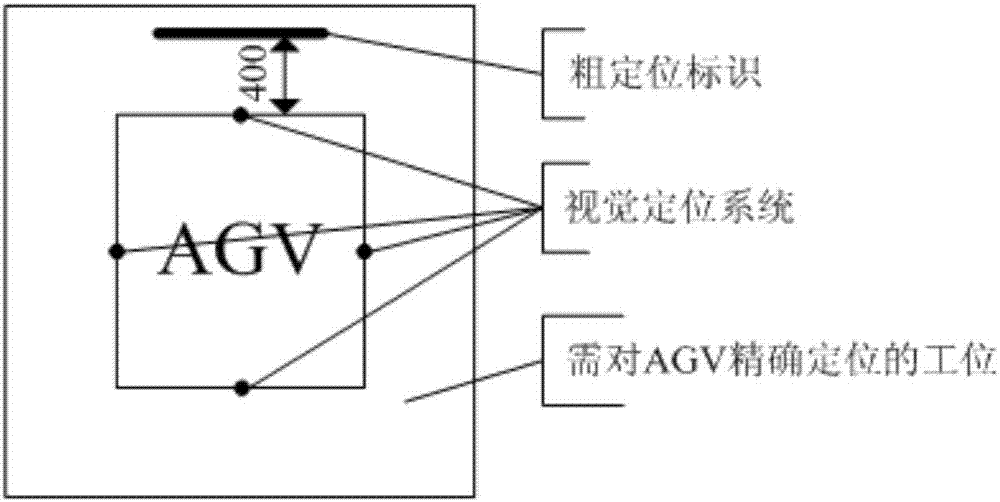

PSD range finding-based AGV accurate positioning method

ActiveCN106940183AGuaranteed accuracyHigh positioning accuracyNavigational calculation instrumentsNavigation by terrestrial meansOffset distanceAutomated guided vehicle

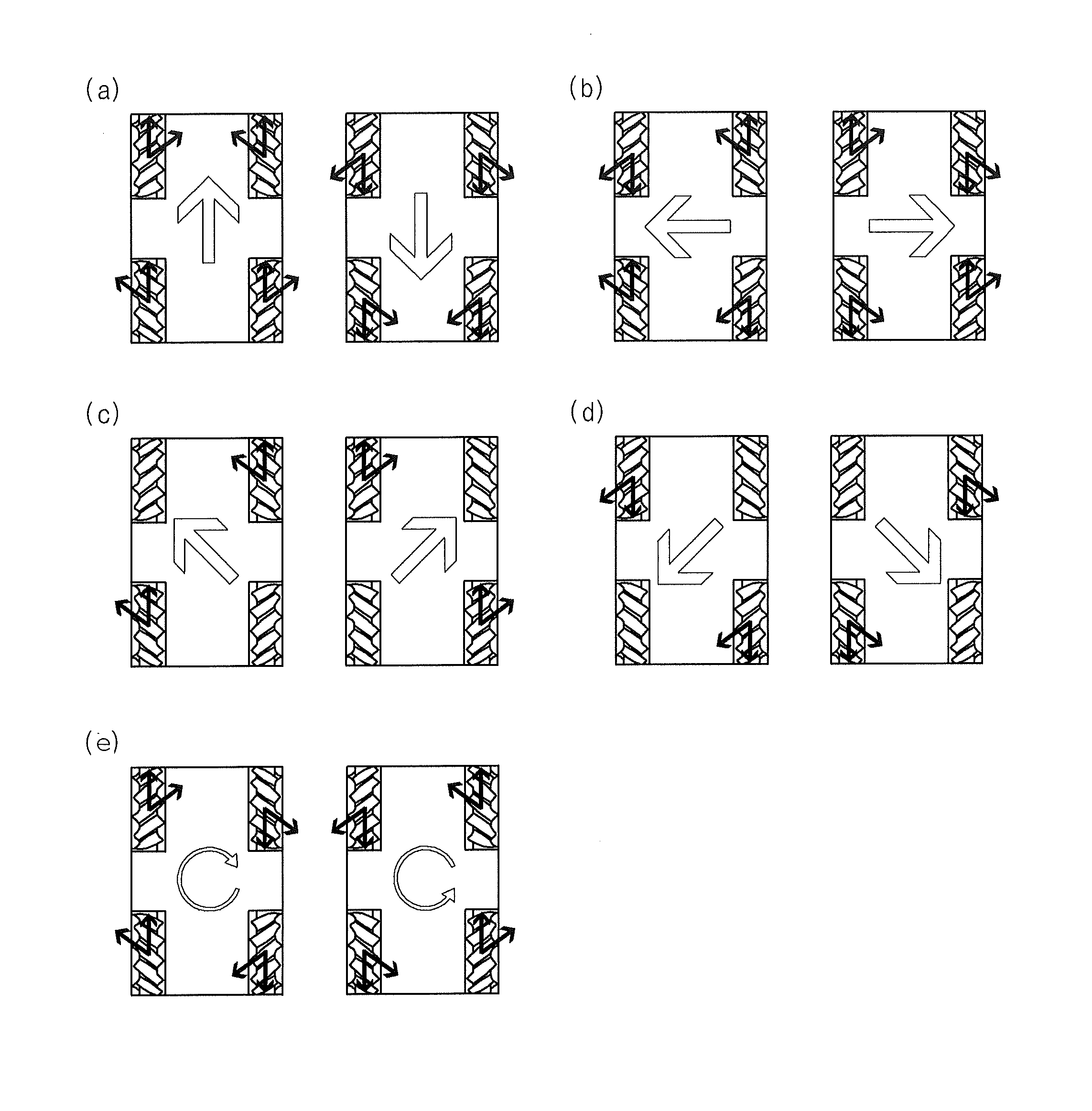

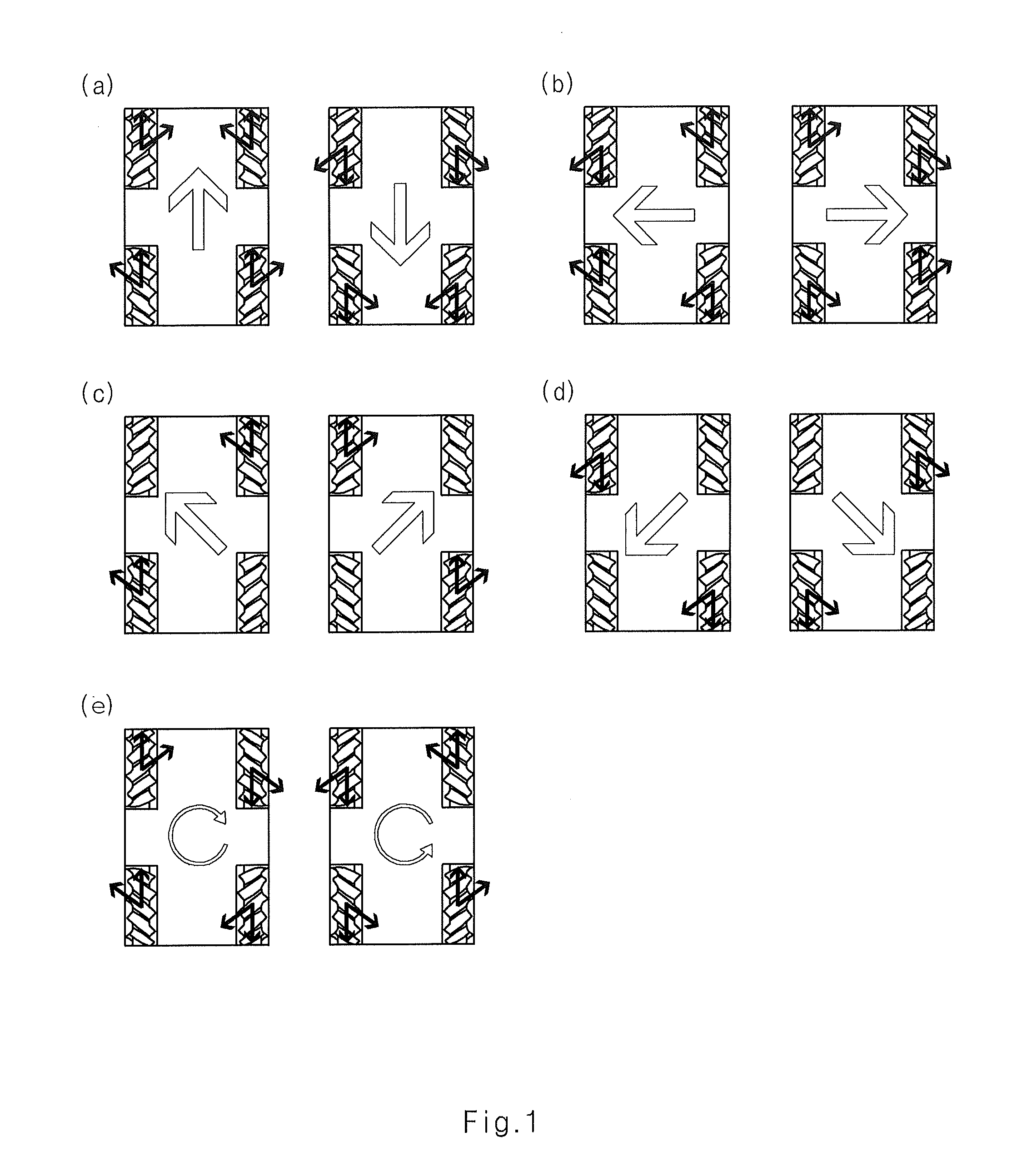

A PSD (position sensitive detector) range finding-based AGV (automated guided vehicle) accurate positioning method comprises the following steps: (1) allowing the positioning precision of the AGV to be in + / - 10 mm in a visual guidance manner; (2) using PSD range finding to measure the coordinates of two reference points after the coarse positioning of the AGV is completed, and determining the current transverse and longitudinal offset distance and the offset angle of the AGV according to a linear equation in order to obtain the current pose of the AGV; (3) inputting the current pose and the target pose of the AGV, establishing the motion equation of the AGV, and calculating the yaw angle and the rotating angle of the AGV; (4) realizing the pose adjustment through the Mecanum wheel-based omnidirectional movement (forward and backward straight movement, leftward and rightward traverse movement, oblique movement at any angle, 0-revolution radius in-place rotation, and combination of all above movements) of the AGV; and (5) resolving the pose of the AGV in real-time in the AGV pose adjustment process until the positioning accuracy reaches up to + / - 0.3mm. The method has the advantages of high positioning accuracy, simplicity in calculation, and easiness in engineering realization.

Owner:BEIJING SATELLITE MFG FACTORY

Mecanum wheel omni-directional mobile inspection robot

InactiveCN104714550ATake advantage ofTo achieve the effect of multi-directional monitoringPosition/course control in two dimensionsVideo monitoringOmni directional

The invention relates to a Mecanum wheel omni-directional mobile inspection robot. The Mecanum wheel omni-directional mobile inspection robot comprises a movable chassis, a movable vehicle body, a monitoring device and a remote control device, wherein the movable chassis comprises a driving device, a navigation positioning device, a control device, a power supply and a charging device, the driving device comprises vehicle wheels and a transmission device, the navigation positioning device comprises a magnetic field sensor and a radio frequency identification reader-writer, the control device comprises a control mainboard and a communication device, the power supply is electrically connected with the control device and used for supply power to the movable chassis, the charging device is electrically connected with the power supply and used for charging the power supply; the movable vehicle body is fixed on the movable chassis; the monitoring device is arranged on the movable vehicle body and comprises a video monitoring device and a monitoring sensing device. The Mecanum wheel omni-directional mobile inspection robot can achieve actions such as start and stop or track transformation according to the set requirements in any position so that the comprehensive inspection of electrical equipment within the inspection range can be achieved.

Owner:WUHAN HANDY ROBOTICS TECH

Ventilation pipeline cleaning robot with variable structure

InactiveCN106862195ASmooth rotationIncrease flexibilityHollow article cleaningMulti degree of freedomEngineering

The invention relates to a ventilation pipeline cleaning robot with a variable structure. The ventilation pipeline cleaning robot comprises a car body, a walking driving device, a pipe diameter self-adaption adjustment device, a cleaning device, a detecting device, a walking assisting device and a main control box. The main control box is in line connection with the walking driving device, the pipe diameter self-adaption adjustment device, the cleaning device, the detecting device and the walking assisting device and controls the walking driving device, the pipe diameter self-adaption adjustment device, the cleaning device, the detecting device and the walking assisting device to move. The ventilation pipeline cleaning robot has the beneficial effects that a cleaning range is increased through a cleaning arm with multiple degrees of freedom; a cloud platform is favorable for rotation of a camera, so that a visual range is increased; Mecanum wheels are independently driven, so that moving in any direction is realized, and the flexibility and obstacle avoidance ability of the robot are improved; by arranging the self-adaption adjustment device, the ability of adapting to pipe diameter change of the robot is improved, and the walking assisting device mounted on the car body in a matched mode more effectively guarantees the stability of walking; and a vision sensor and a distance measuring sensor guide the robot to complete detection and cleaning tasks, so that the intellectualization degree is high.

Owner:CHANGZHOU UNIV

Railless automatic transfer butt joint platform

ActiveCN108098710AOmnidirectional mobilityAdjust position and attitudeWork benchesButt jointGear wheel

The invention discloses a railless automatic transfer butt joint platform. The railless automatic transfer butt joint platform comprises a transfer platform, a gesture adjusting mechanism a, a gestureadjusting mechanism b, a linear guide rail a and a rack; the rack and the linear guide rail a are mounted in parallel; the gesture adjusting mechanism a and the gesture adjusting mechanism b are mounted on slide blocks on the linear guide rail a; the transfer platform is driven by adopting multiple pairs of Mecanum wheels; the gesture adjusting mechanism a comprises a front-back moving mechanism,a lifting mechanism, a left-right translation mechanism, a gap elimination rolling mechanism and a diameter adjusting tool; the front-back moving mechanism comprises a motor a, a clutch a, speed reducer a and a straight gear a; when a motor of the gesture adjusting mechanism a moves front and back, the clutch a is closed, and the motor a drives the speed reducer a through the clutch a, so that the straight gear a is rotated and engaged with a rack of the transfer platform to drive the gesture adjusting mechanism a to advance along the linear guide rail a; and when the gesture adjusting mechanism a manually advances, the clutch a is off, and the gesture adjusting mechanism a is manually pushed to advance.

Owner:BEIJING AEROSPACE INST FOR METROLOGY & MEASUREMENT TECH +1

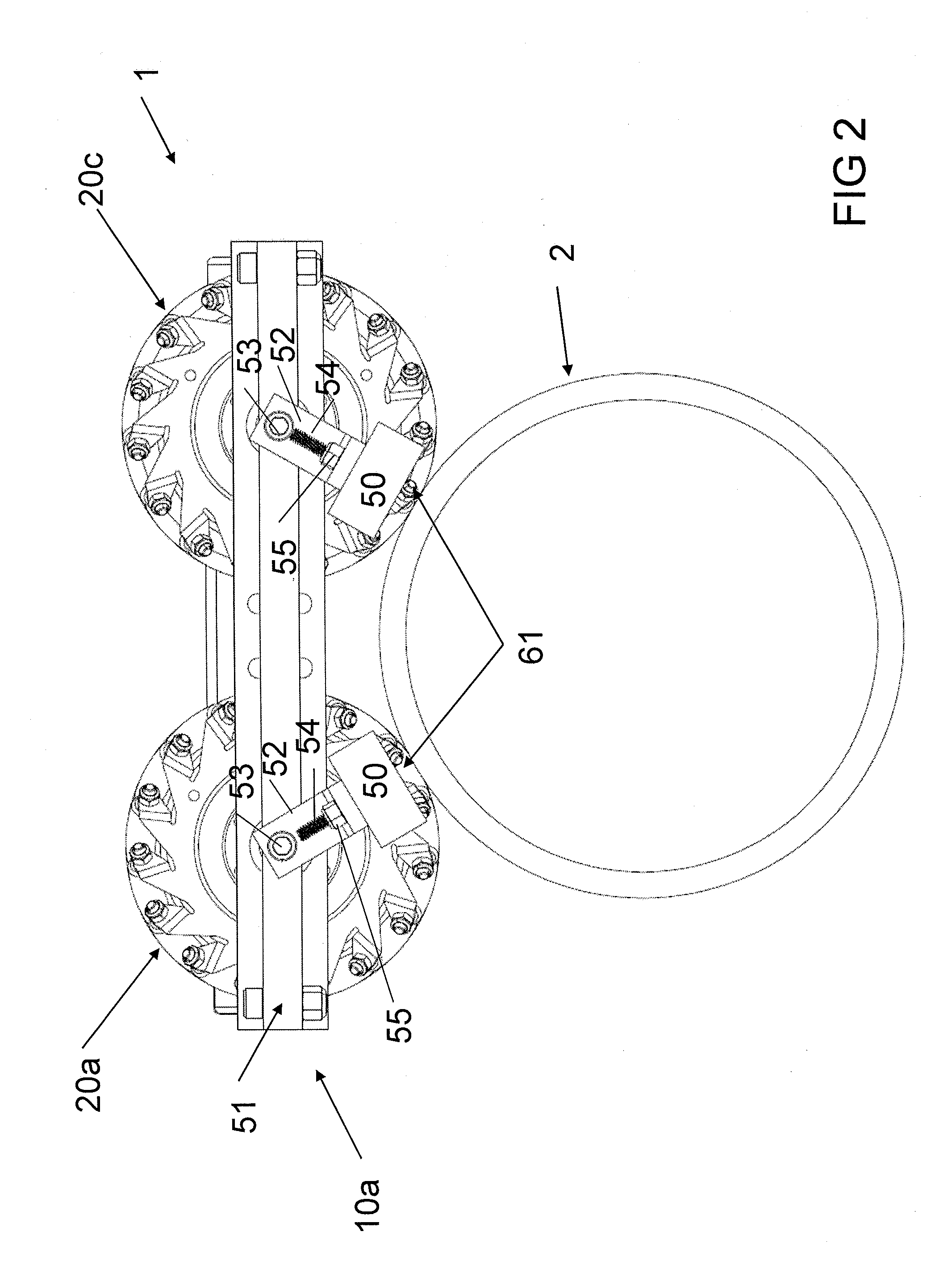

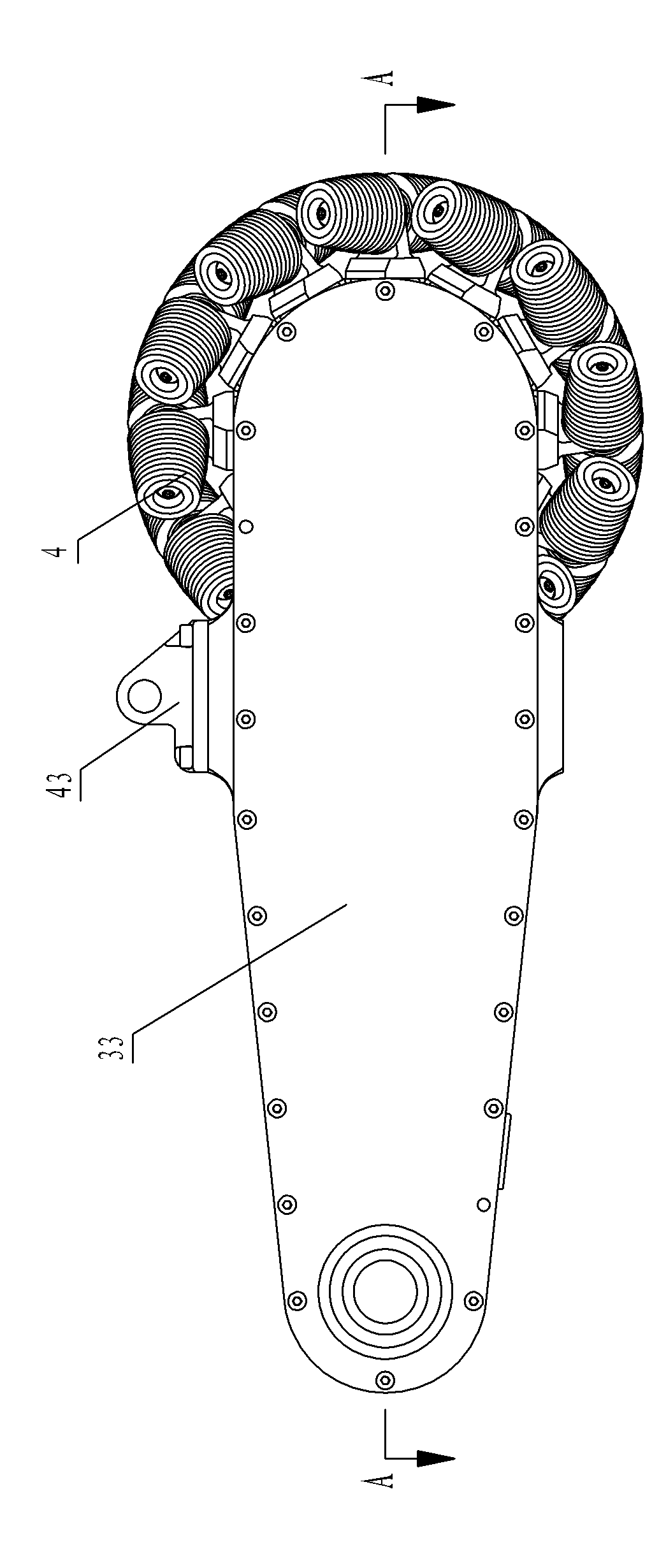

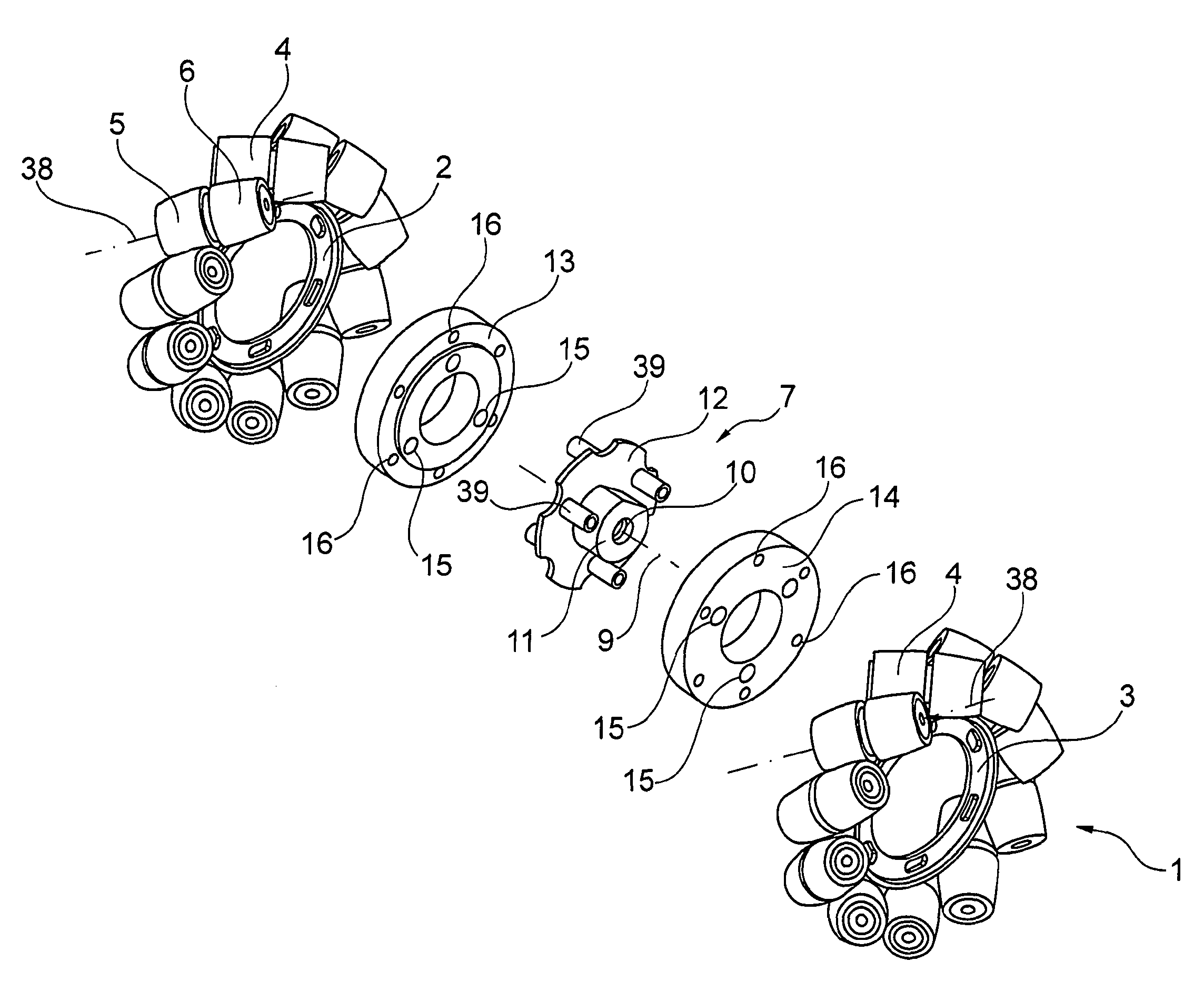

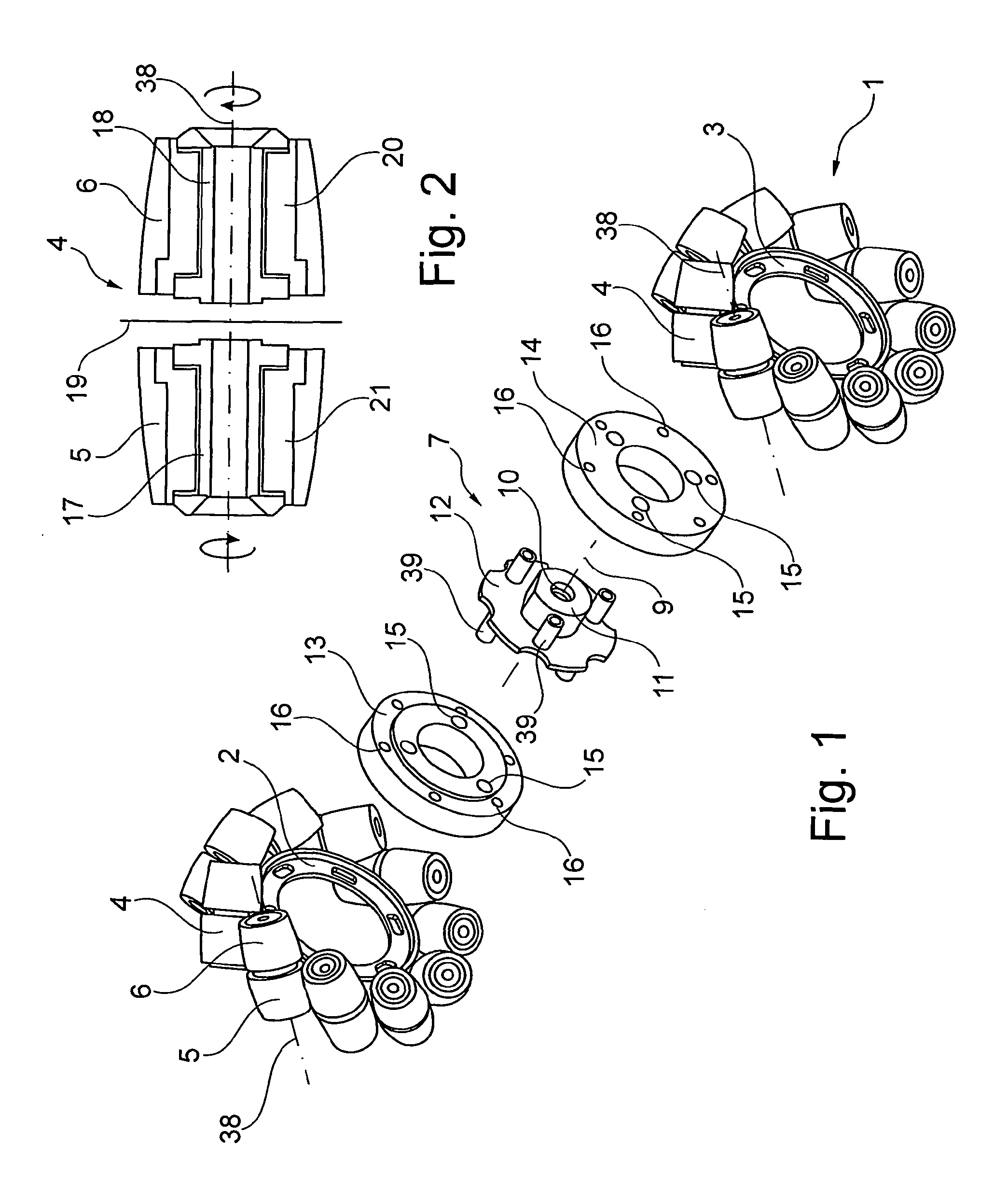

Mecanum wheel and mecanum-wheeled vehicle

A Mecanum wheel having a first wheel rim (2) which bears a multiplicity of rollers (4) which are arranged adjacent to one another in a circumferential direction and which are in each case mounted so as to be rotatable about a roller axis of rotation (38) arranged at an angle with respect to a first wheel rim axis of rotation (24), wherein said Mecanum wheel is characterized by a second wheel rim (3) which can be driven together with the first wheel rim (2) by means of a common drive shaft (33) and which bears a multiplicity of rollers (4) which are arranged adjacent to one another in a circumferential direction and which are in each case mounted so as to be rotatable about a roller axis of rotation (38) arranged at an angle with respect to a second wheel rim axis of rotation (25), which second wheel rim is connected to the first wheel rim (2) via damping means (7) formed so as to permit a limited relative movement of the first and the second rim (3) relative to one another. It is provided according to the invention that the damping means (7) are formed so as to permit a damped, limited relative movement between the first and the second wheel rim (2, 3) in the circumferential direction and / or perpendicular to a Mecanum wheel axis of rotation (9) and / or perpendicular to the first and / or to the second wheel rim axis of rotation (25) and / or at a tilt angle relative to one another.

Owner:OMNIROLL

Nursing robot and motion control system

The invention discloses a nursing robot and a motion control system. The nursing robot comprises a hardware platform and the motion control system. The hardware platform comprises an omni-directional moving chassis, a body skeleton structure, an autonomous charging module, a binocular vision module, a mechanical arm module and a display screen module. According to the motion control system, a generalized matrix is used for conducting positive and athwart kinematics analysis on the moving chassis with four Mecanum wheels being distributed in a rectangular mode, and closed-loop control and feedback of the center speed of the chassis are achieved; obstacle avoidance control over the chassis is achieved based on ultrasonic sensors in the four directions of the chassis and a speed value linear mapping set threshold value. The motion control system achieves the functions of flexible omni-directional movement, autonomous obstacle avoidance, autonomous charging and the like of the nursing robot. The nursing robot is an intelligent indoor moving robot, and the diversified demands for life assisting of the old are met.

Owner:BEIHANG UNIV

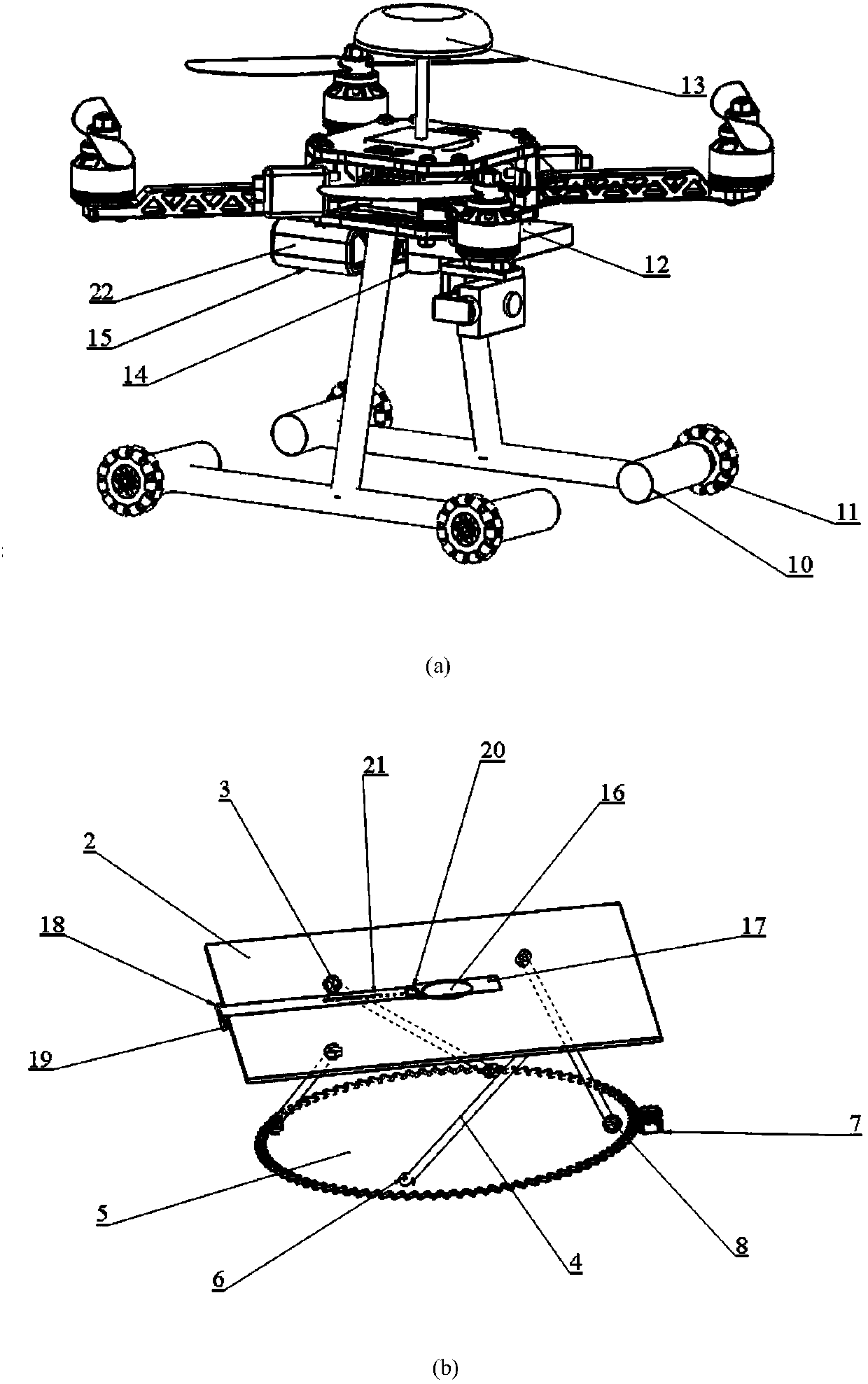

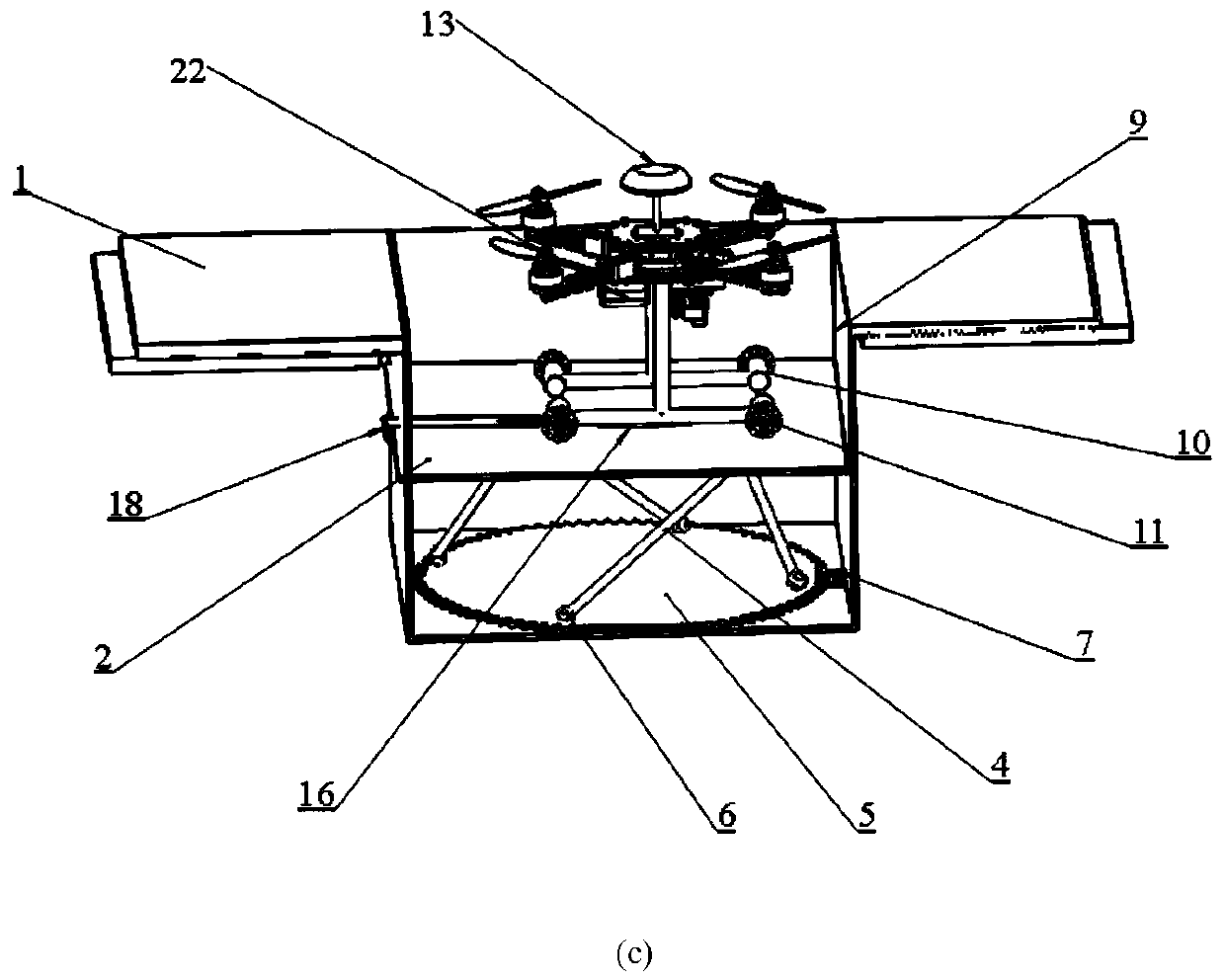

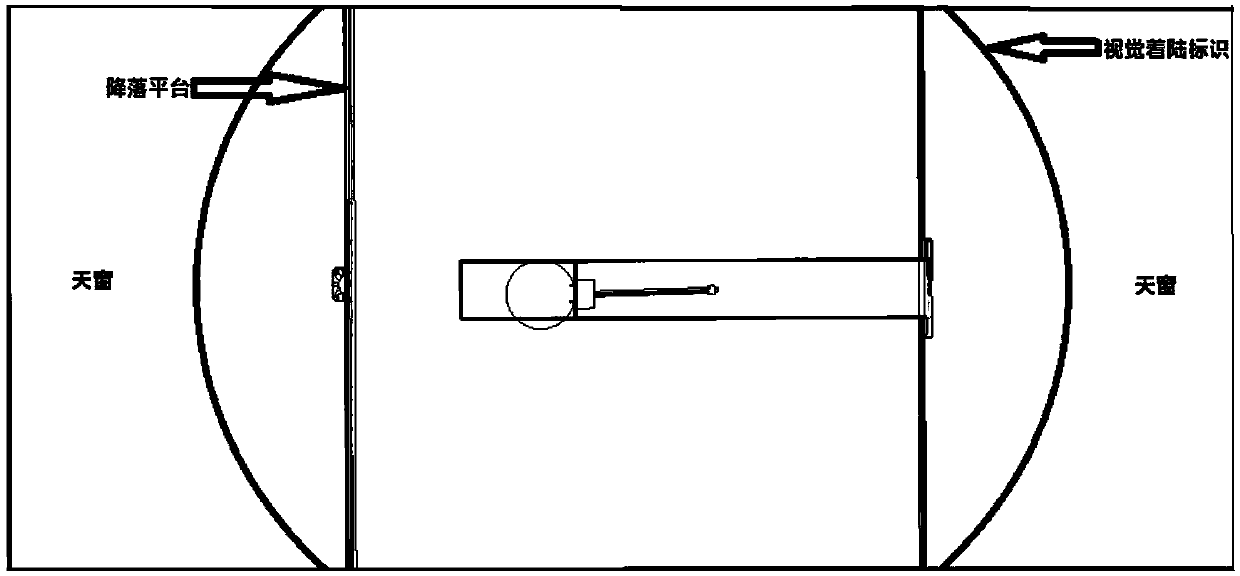

Pickup truck type vehicle-mounted unmanned aerial vehicle intelligent take-off and landing and autonomous endurance system

ActiveCN108622432ASolve the problem of accurately landing on the predetermined position of the intelligent lifting platformAchieve omnidirectional movementCharging stationsElectric vehicle charging technologyMecanum wheelAerospace engineering

The invention discloses a pickup truck type vehicle-mounted unmanned aerial vehicle intelligent take-off and landing and autonomous endurance system and belongs to the technical field of unmanned aerial vehicle design. The system comprises three parts of a lifting platform device, an unmanned aerial vehicle automatic charging device and algorithms of the landing algorithm and the omnidirectional positioning algorithm, wherein the landing algorithm and the omnidirectional positioning algorithm are based on the visual sense and Mecanum wheels. The four Mecanum wheels are installed at the bottomof an undercarriage of an unmanned aerial vehicle, and the purpose of omnidirectional movement of the unmanned aerial vehicle on a platform can be achieved through cooperation with a visual camera ofthe unmanned aerial vehicle and an omnidirectional movement algorithm based on the Mecanum wheels. Through a mechanical transmission principle, the lifting platform is designed to be of a space connecting rod lifting structure with sliding rails, and the structure can achieve conversion between rotating motion on the plane and rectilinear motion perpendicular to the plane. Only driven by gear motors, a lower rotating face rotates at a certain angle, the unmanned aerial vehicle landing platform can be correspondingly lifted up or lowered, rotation of the rotating face is then locked through thegear motors, and therefore it can be guaranteed that the height obtained after adjustment is unchangeable.

Owner:INNER MONGOLIA UNIV OF TECH

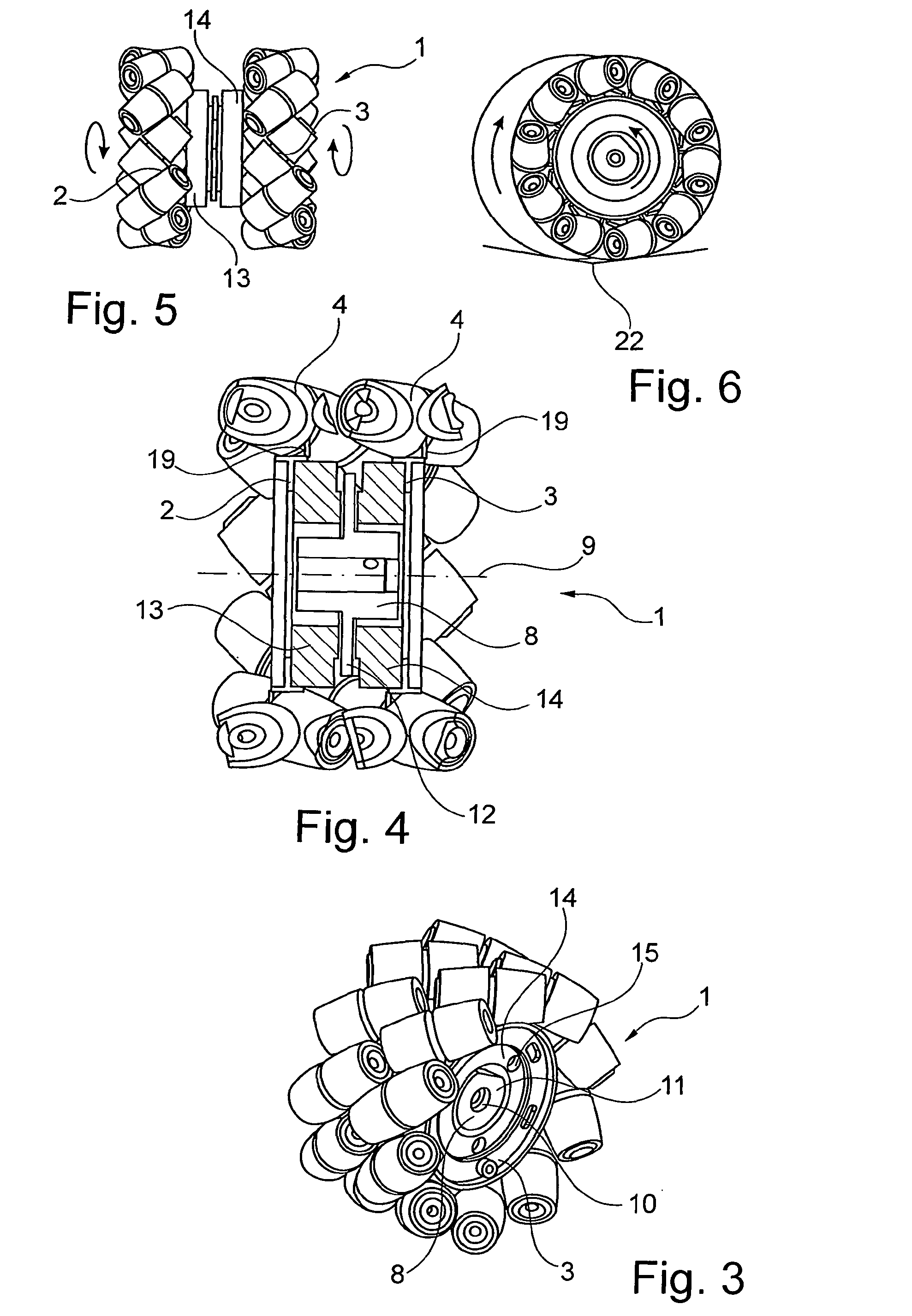

Mecanum wheel omnidirectional mobile vehicle and working method thereof

The invention provides a Mecanum wheel omnidirectional mobile vehicle and a working method of the Mecanum wheel omnidirectional mobile vehicle, relates to an omnidirectional mobile vehicle provided with a Mecanum wheel and a working method of the omnidirectional mobile vehicle which are particularly applicable to realizing omnidirectional movement of the vehicle in a narrow space, and provides the Mecanum wheel omnidirectional mobile vehicle with four wheels uniformly grounded and having capability of keeping a frame horizontal to the greatest extent and the working method of the Mecanum wheel omnidirectional mobile vehicle. The Mecanum wheel omnidirectional mobile vehicle comprises a frame, a power supply, a controller and Mecanum wheels, wherein the Mecanum wheels are connected to the bottom of the frame through an air bag suspending device; the air bag suspending device comprises a damper, an air bag, an air supply, an air valve and a height adjusting device; tops of the damper andthe air bag are fixedly connected to the bottom of the frame; an axle of the Mecanum wheels is connected to the bottom ends of the damper and the air bag; and the air bag is connected with the air supply through the air valve. According to the Mecanum wheel omnidirectional mobile vehicle, closed-loop control is performed over the horizontality of the frame and the distance from the frame to the wheels, so that the wheels provided by the invention are adaptable to the application requirements of special industry.

Owner:YANGZHOU WANFANG ELECTRONICS TECH

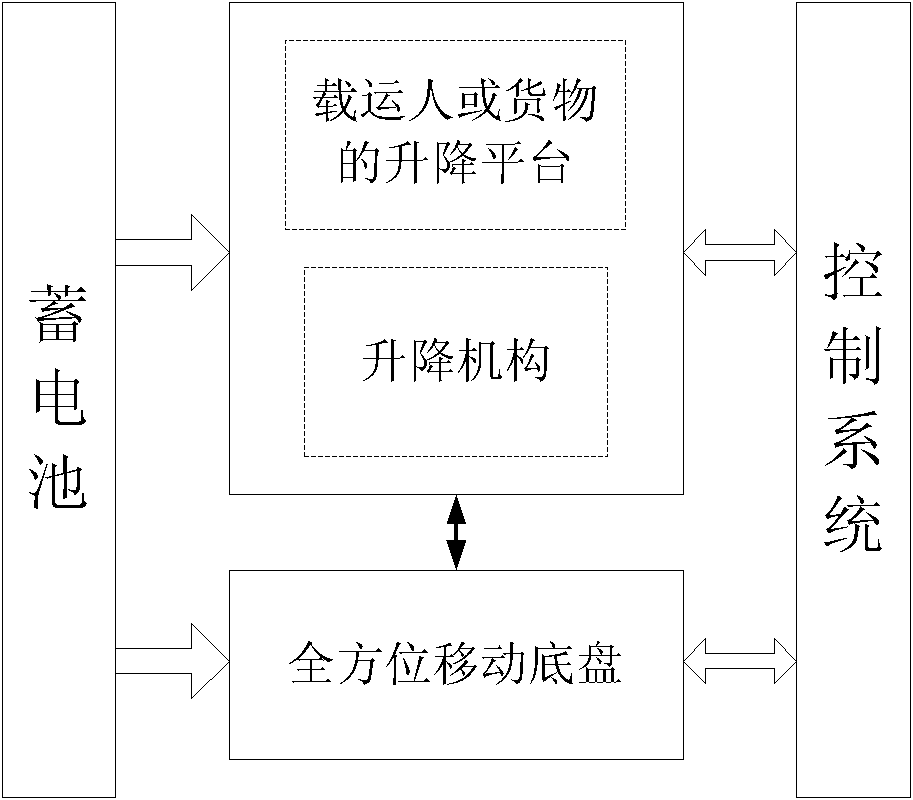

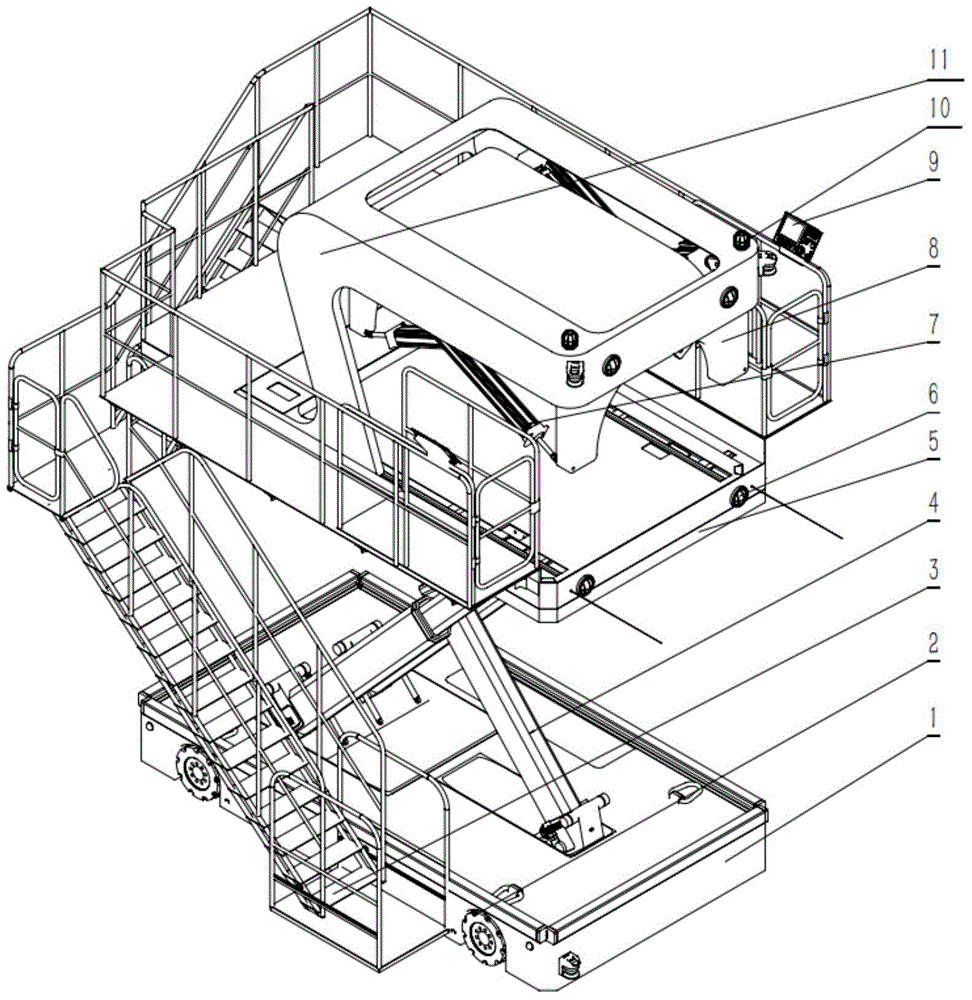

Electric omnidirectional mobile lift

InactiveCN102040176AAccurate spatial positioningIncrease flexibilityLifting devicesMotor depositionEngineeringMecanum wheel

The invention discloses an electric omnidirectional mobile lift. The lift comprises an omnidirectional mobile chassis, a lift platform which is arranged on the omnidirectional mobile chassis through a lift system and used for carrying people or cargo; and four independent driving Mecanum wheel assemblies are arranged at the bottom of the omnidirectional mobile chassis. The electric omnidirectional mobile lift has higher flexibility, maneuverability and accurate positioning capability, and can be applied to butt assembly of large and important equipment and special application situations so as to save at least half the time.

Owner:MILITARY TRANSPORTATION UNIV PLA

Heavy-load automated guided vehicle

The invention discloses a heavy-load automated guided vehicle. Mecanum wheel drive mechanisms are installed on the bottom of a frame and drive the frame to move in an all-dimensional mode; a lifting mechanism is installed on the frame, and a work table is installed on the lifting mechanism; a magnetic navigation sensor is installed on the bottom of the frame, detects ground magnetic stripes and drives the frame to drive along the magnetic stripe; an RFID landmark sensor is installed on the bottom of the frame, recognizes the landmark information for obtaining the position coordinates and implements the starting action, the stopping action and the turning action according to commands; a vehicle-mounted power source supplies power to the Mecanum wheel drive mechanisms, the lifting mechanism, the magnetic navigation sensor, the RFID landmark sensor and a PLC, and the PLC controls the Mecanum wheel drive mechanisms, the lifting mechanism, the magnetic navigation sensor and the RFID landmark sensor to work. The heavy-load automated guided vehicle can transfer material efficiently, accurately and flexibly, realizes logistics automation, improve the production efficiency and lower the production cost.

Owner:XIAMEN AEROSPACE SIERT ROBOT SYST CO LTD

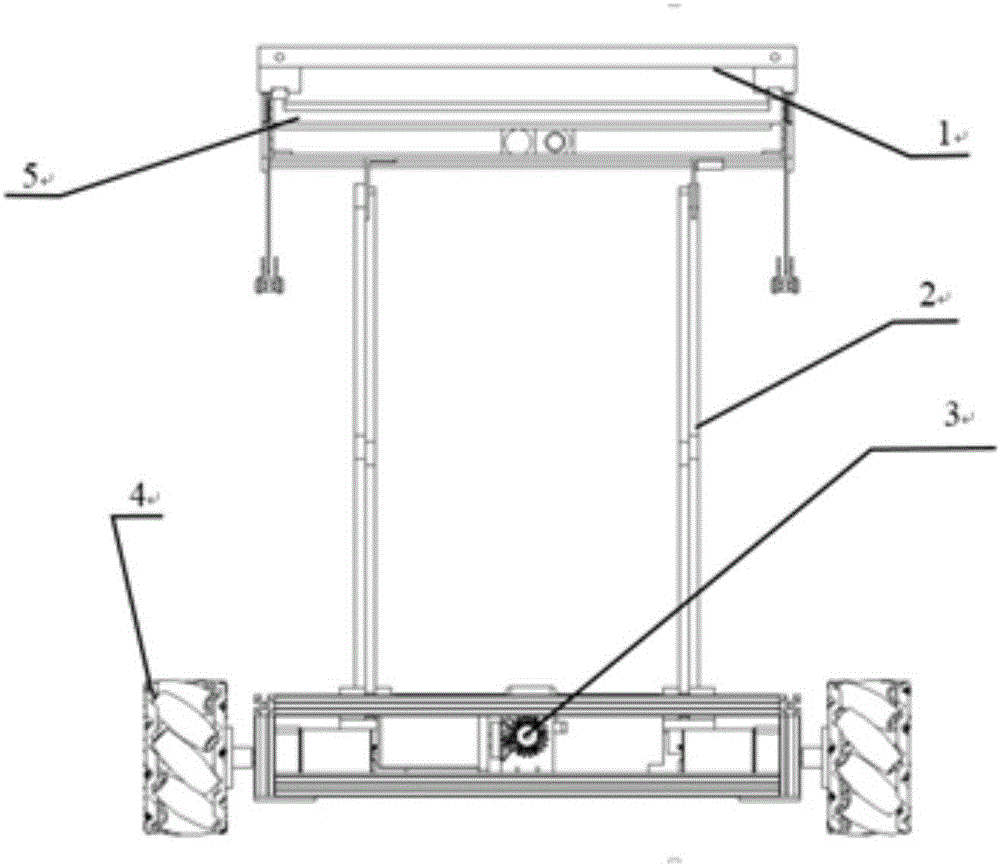

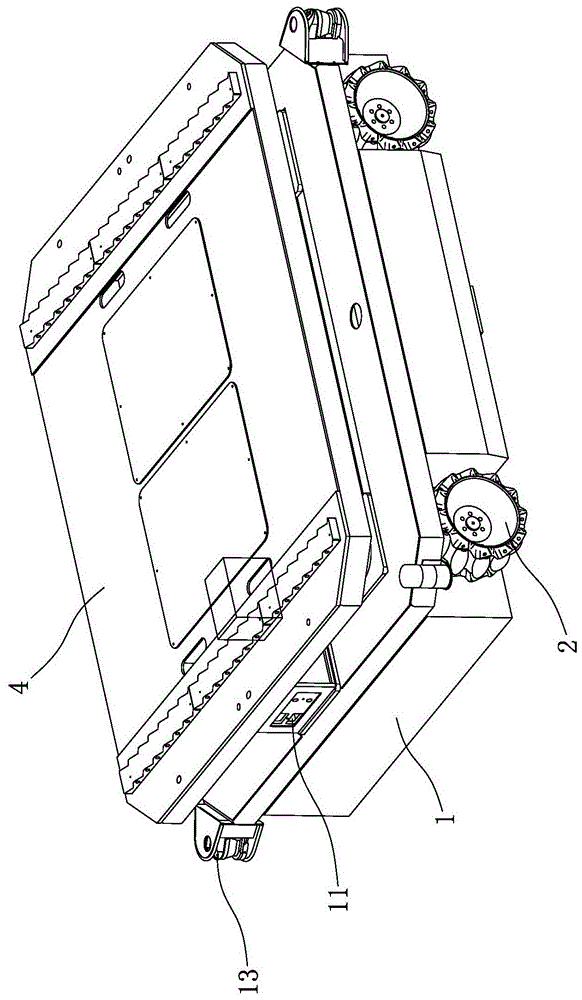

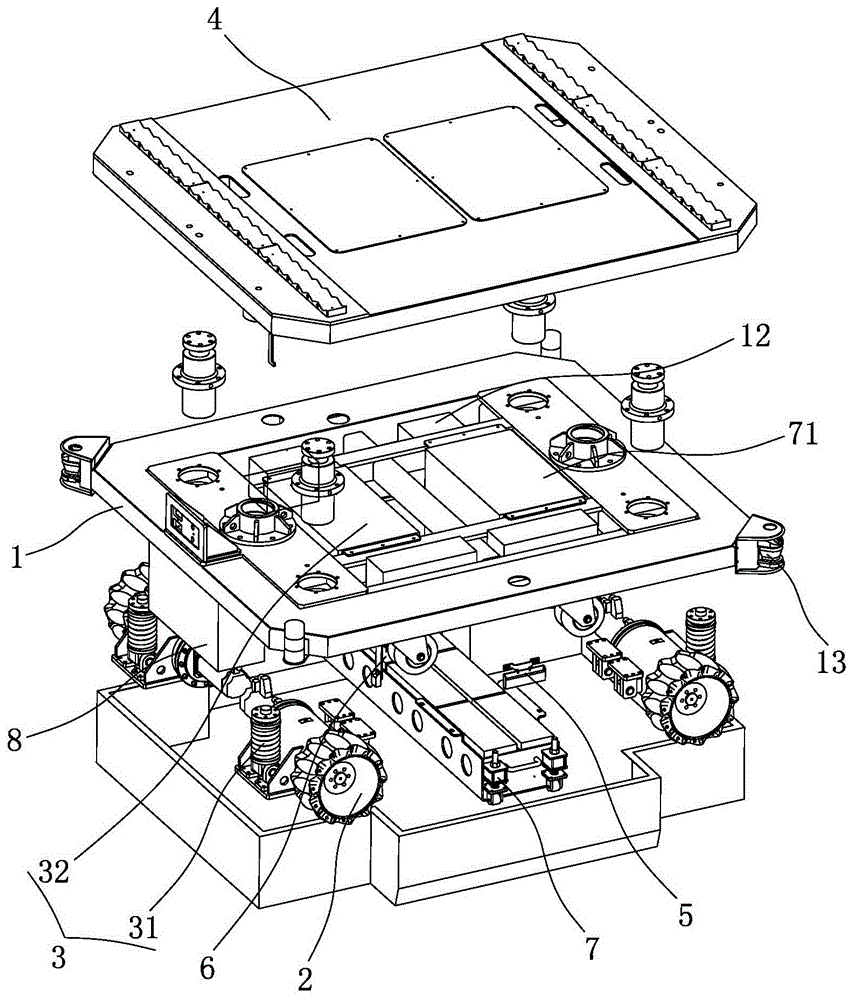

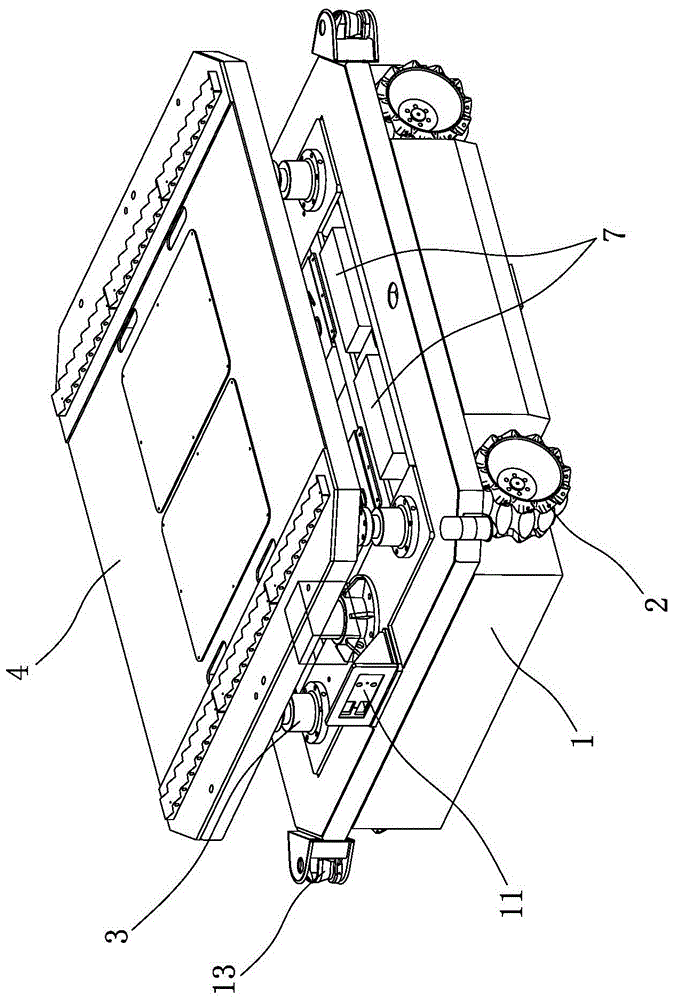

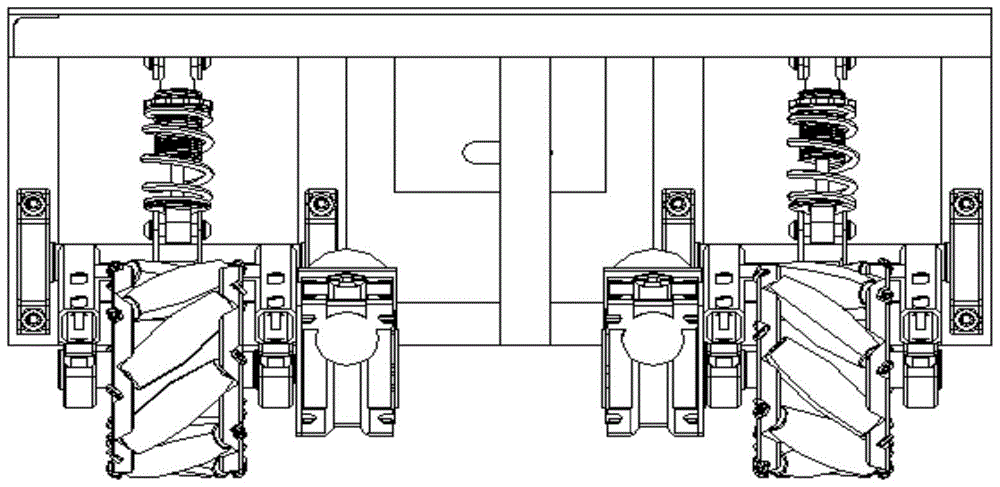

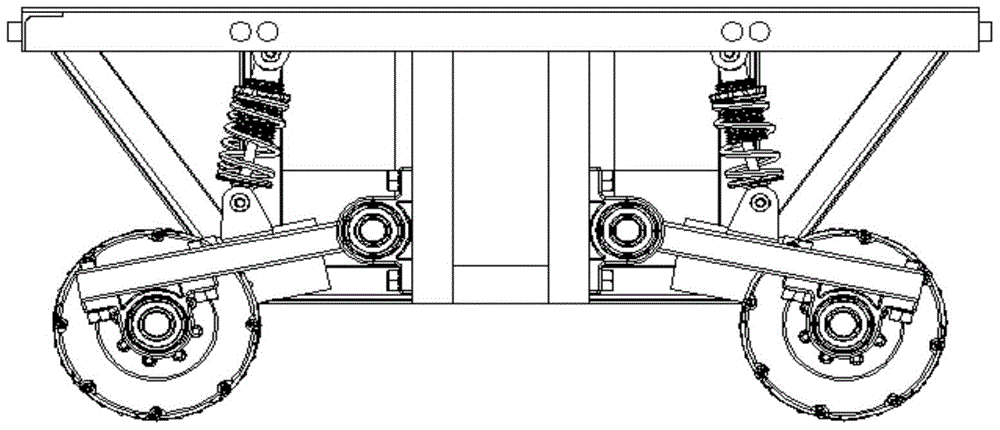

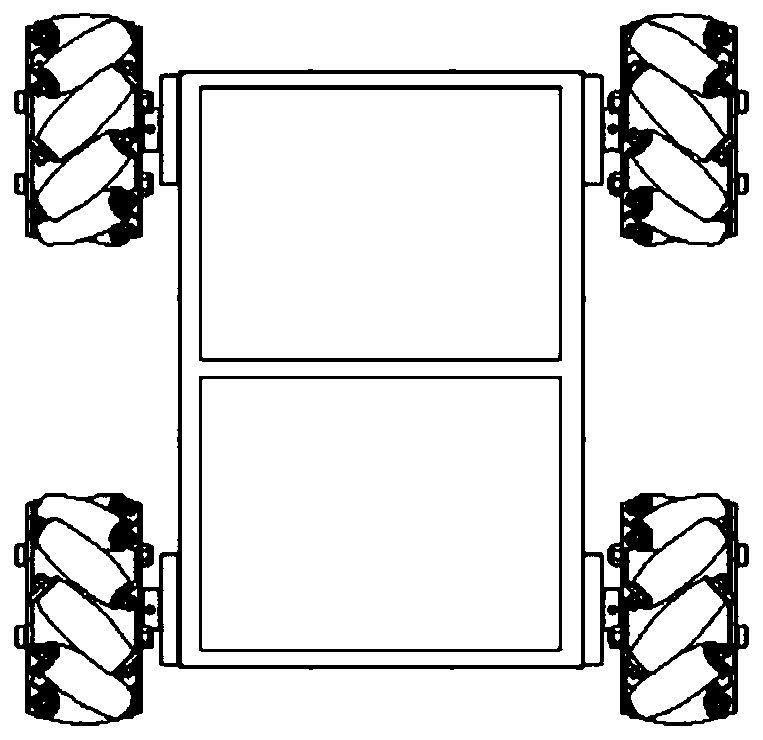

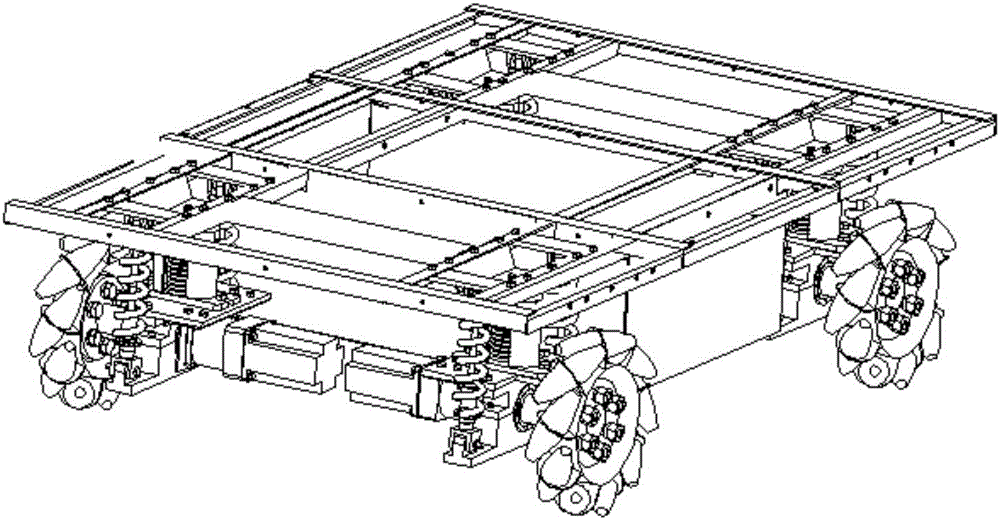

Omnidirectional mobile platform for Mecanum wheels

ActiveCN105667632AImprove motor flexibilityPlay the role of cushioning and shock absorptionMotor depositionResilient suspensionsVehicle frameDrive shaft

The invention discloses an omnidirectional mobile platform for Mecanum wheels. The omnidirectional mobile platform comprises a frame, the Mecanum wheels, independent suspension modules, power transmission devices, a master control box and a battery pack. Each Mecanum wheel is arranged below the frame through the corresponding independent suspension module. The master control box can cooperatively control the rotation speeds and steering of all the Mecanum wheels. Each independent suspension module comprises two cantilevers arranged in parallel, a connecting board fixedly connecting the two cantilevers and a damper; one end of each damper is connected with the corresponding connecting board, and the other end of each damper is connected with the frame; and one end of each of every two cantilevers is connected with a transmission shaft through bearings with seats, wherein each transmission shaft is sleeved with the corresponding Mecanum wheel. After the structure is adopted, the omnidirectional movement can be flexibly achieved in the plane, the structure is simple and reliable, the overall bearing capacity is high, it can be guaranteed that the Mecanum wheels can make full contact with the ground, and the operation stability and control accuracy of the mobile platform are improved; and meanwhile the mobile platform has the beneficial effects of being compact in structure, high in applicability and suitable for popularization.

Owner:JIANGSU UNIV OF SCI & TECH

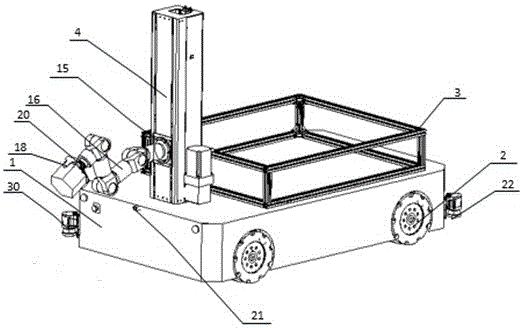

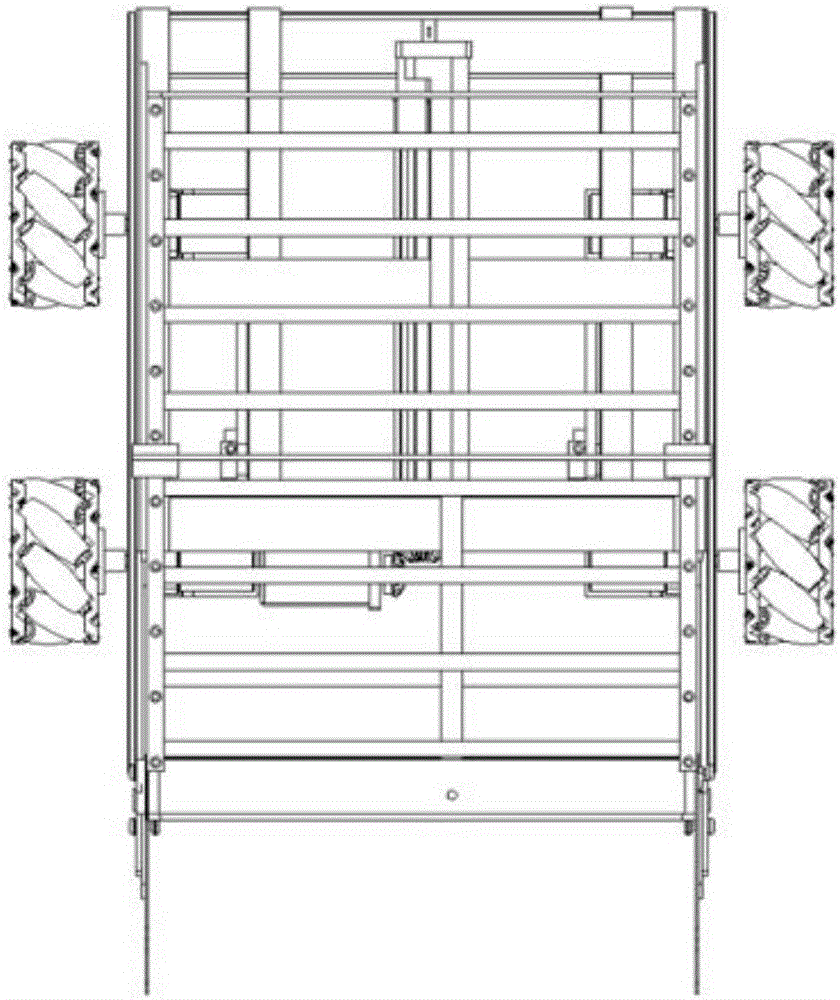

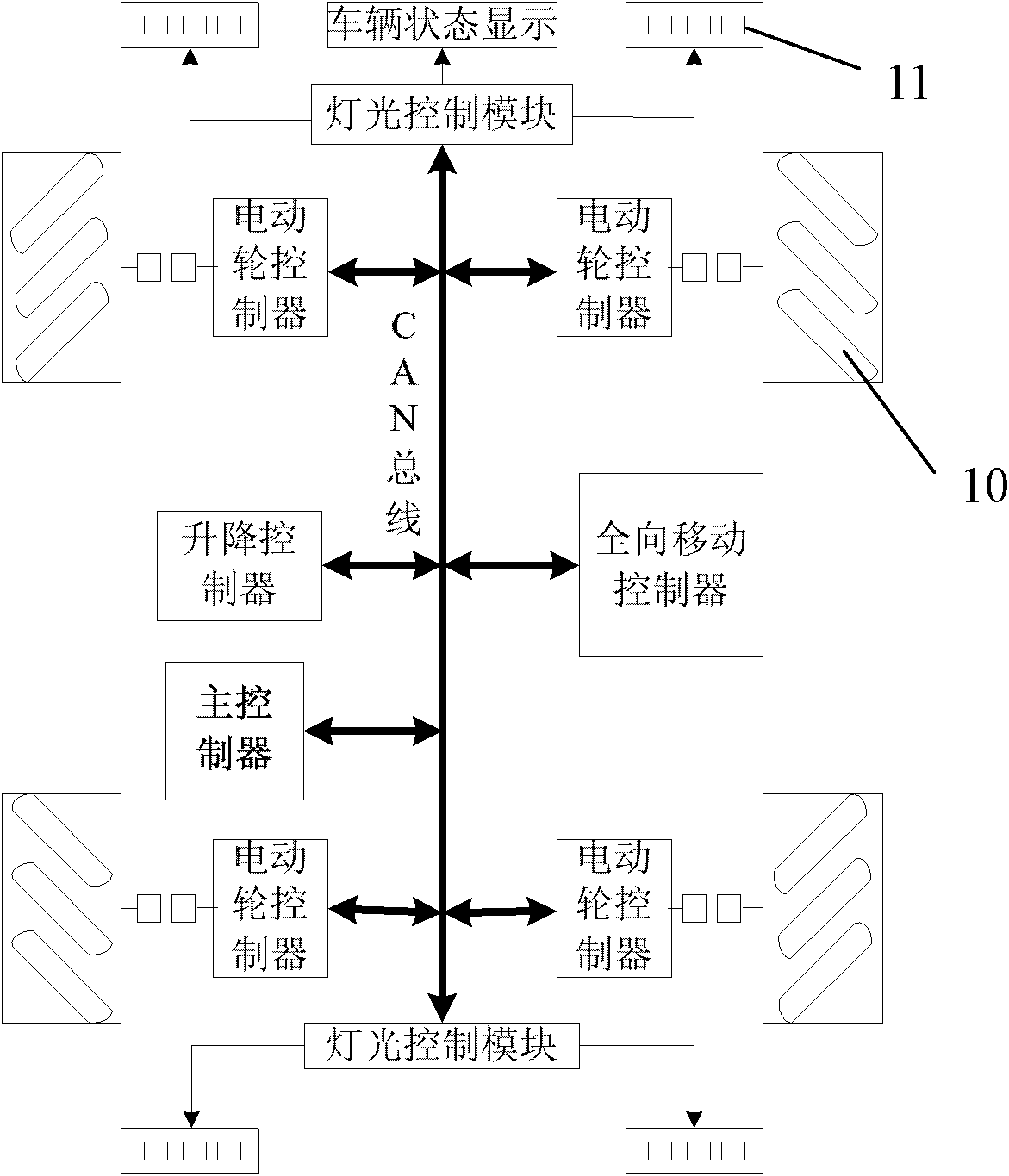

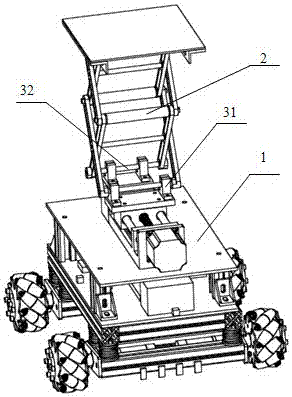

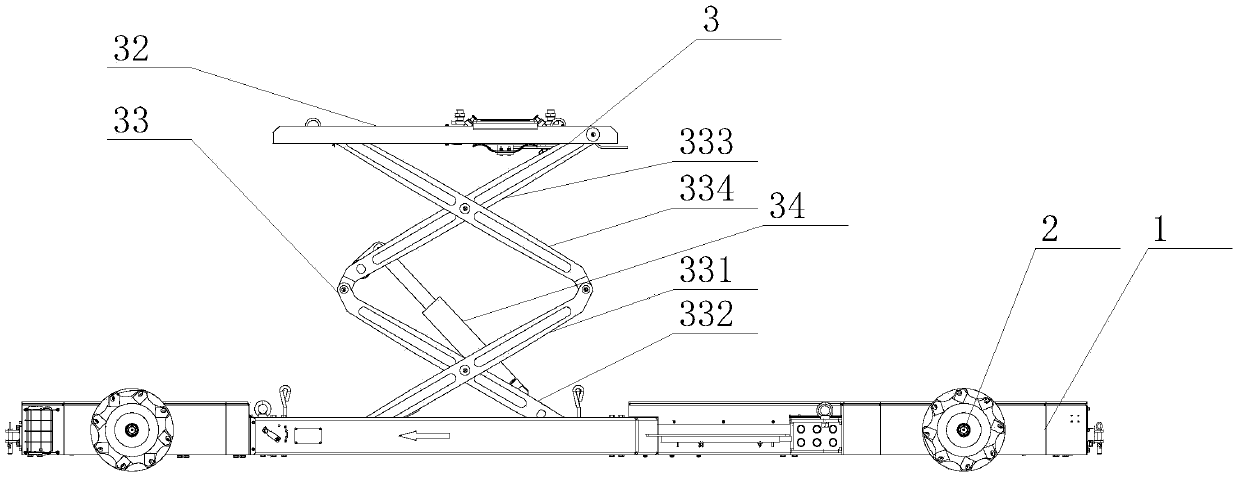

Omni-directional mobile transportation robot

PendingCN107020614AReduce the impact of stabilityGuaranteed uptimeManipulatorMotor driveVehicle frame

The invention discloses an omni-directional mobile transportation robot. The omni-directional mobile transportation robot comprises a shear type lifting mechanism and a car body, wherein the shear type lifting mechanism is fixed on the car body and comprises a transportation table, a screw sliding table, a stepping motor and a shear type support, and the stepping motor drives the screw sliding table to move and then controls the transportation table to lift and drop; the car body comprises a frame, a walking mechanism and a lower panel; the walking mechanism comprises Mecanum wheels, wheel motors, suspensions and motor mounting plates; a storage battery, a control panel, a brushless DC motor drivers, a Bluetooth expansion board, a voice sensor, an obstacle avoidance sensor and a stepping motor driver are fixed on the lower panel; tracking sensors are arranged on the walking mechanism. The transportation robot can realize omni-directional movement, transports objects flexibly, has a transportation table lifting function and can select and switch a control mode according to different working environments and transportation requirements, and therefore, adaptability and working efficiency of the transportation robot can be improved.

Owner:NANJING INST OF TECH

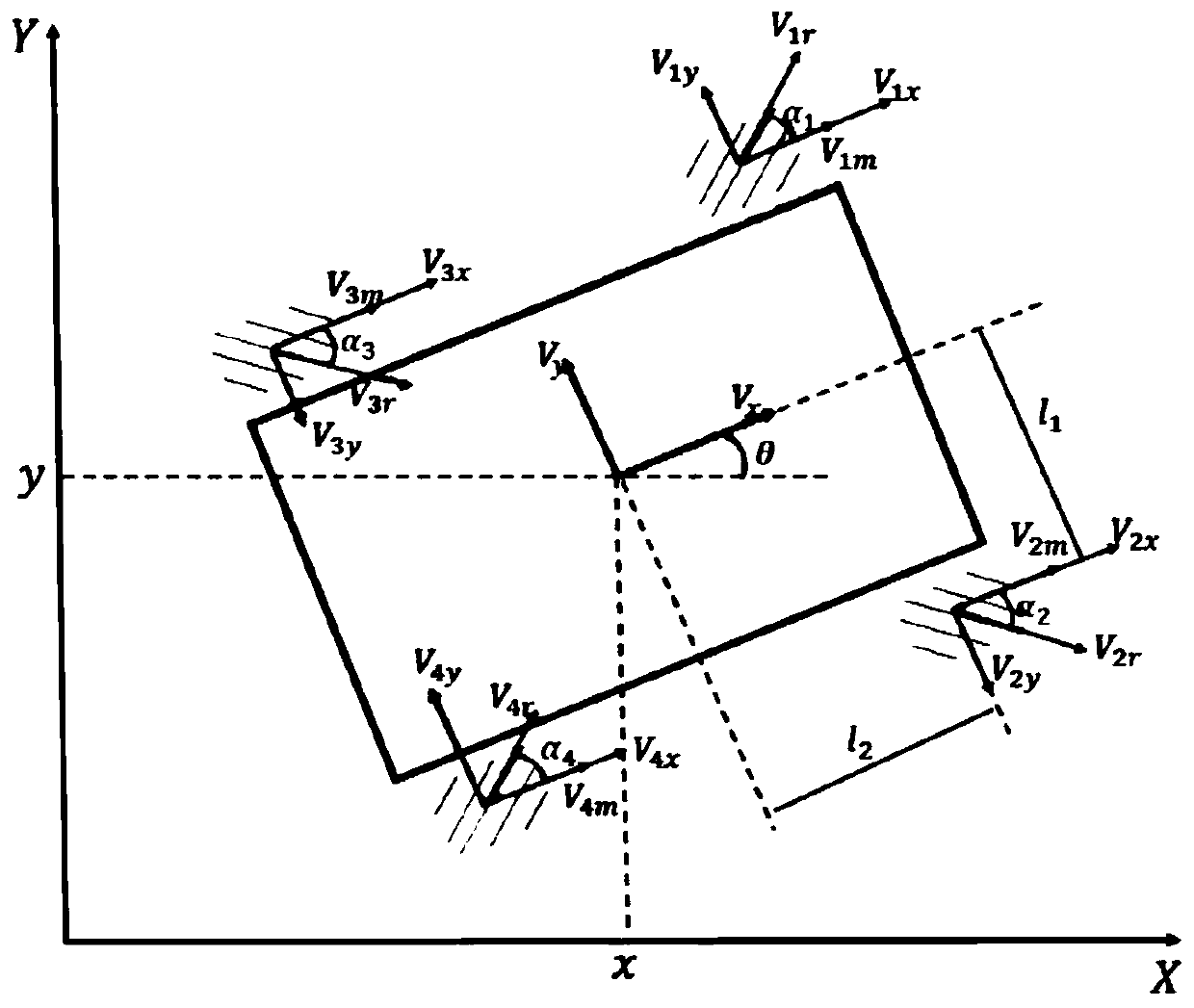

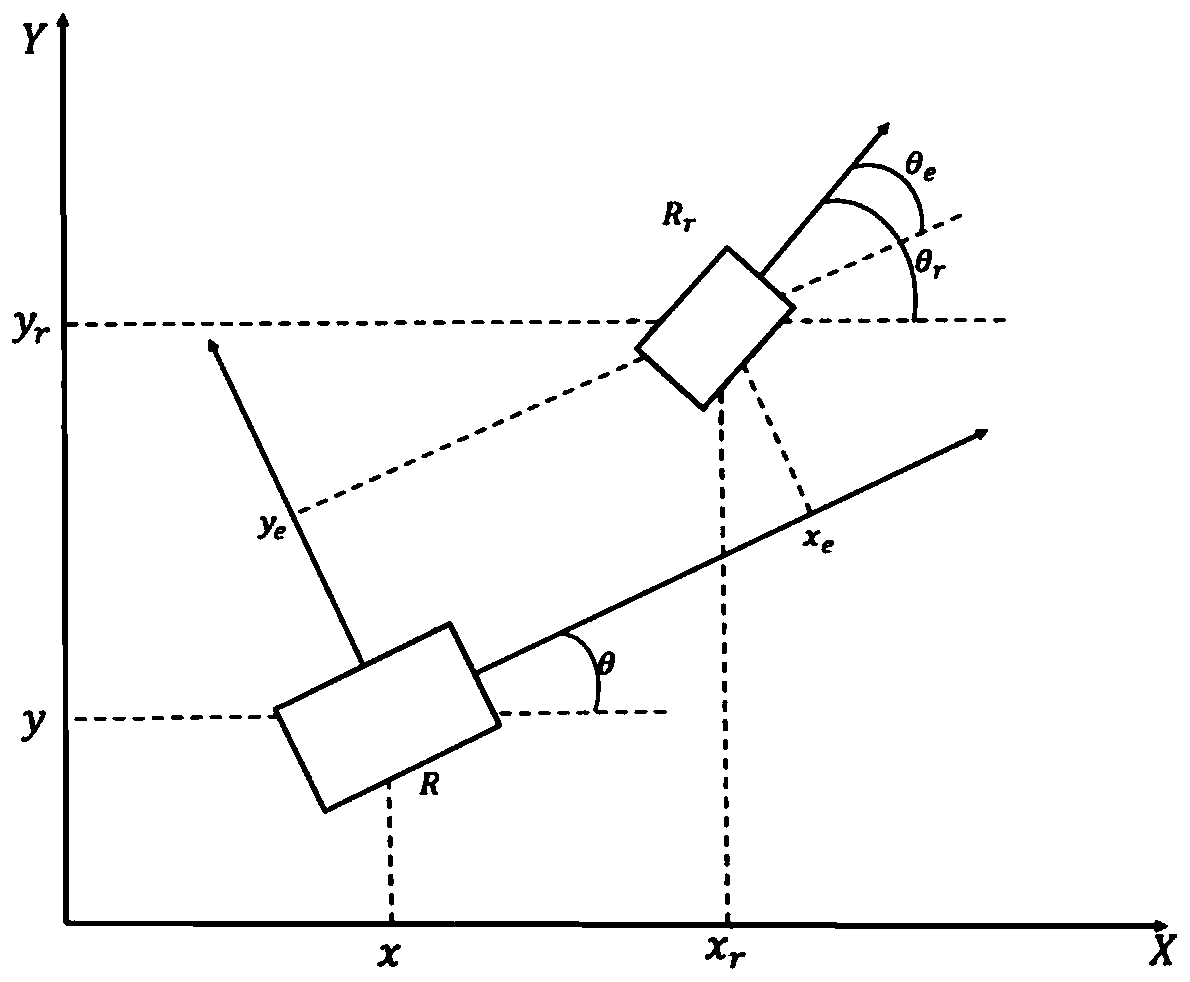

Error model predictive control method based on kinematics modeling of omnidirectional mobile robots

ActiveCN109885052ASolve the speed constraint problemFull rangePosition/course control in two dimensionsPosition/direction controlPredictive controllerOmnidirectional mobile robot

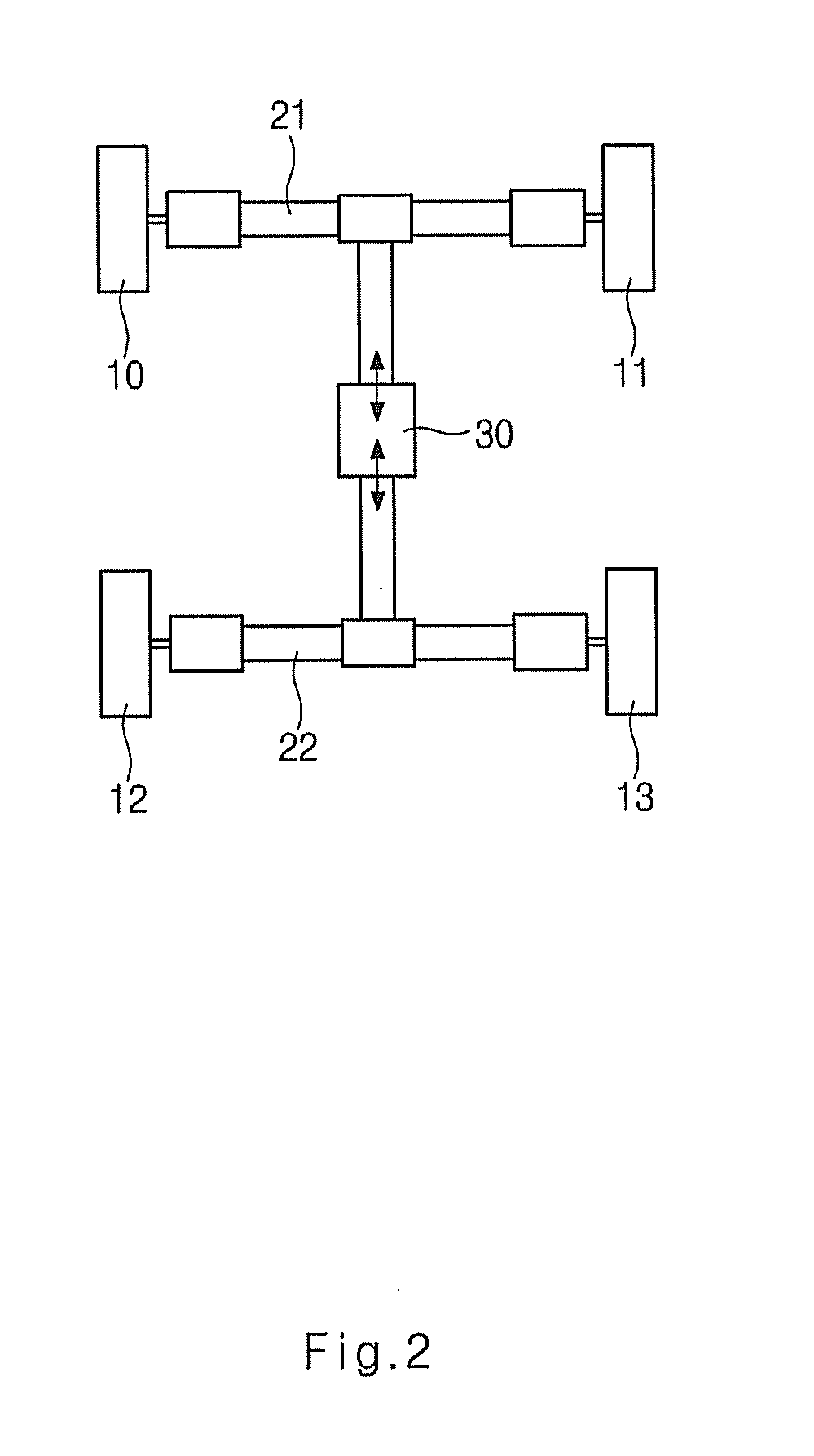

The invention discloses an error model predictive control method based on kinematics modeling of omnidirectional mobile robots. The error model predictive control method comprises the following stepsthat S11, a velocity constraint kinematics model is established between FM-OMR four Mecanum wheels; S12, a tracking error kinematics model of a FM-OMR is established; S13, aiming at the trajectory tracking problem of the FM-OMR and the tracking error kinematics model, an error model predictive controller combined with a velocity constraint equation is designed; and S14, according to the error model predictive controller, effective trajectory tracking parameters between the omnidirectional mobile robots are controlled so as to enable tracking errors between the omnidirectional mobile robots toremain unchanged. According to the error model predictive control method based on the kinematics modeling of the omnidirectional mobile robots, the error model predictive control method based on the trajectory tracking error kinematics modeling is provided aiming at the omnidirectional mobile robots with the four Mecanum wheels, the non-holonomic constraint problem of the effective trajectory tracking control is solved, and the accuracy and the validity are realized.

Owner:SOUTH CHINA UNIV OF TECH

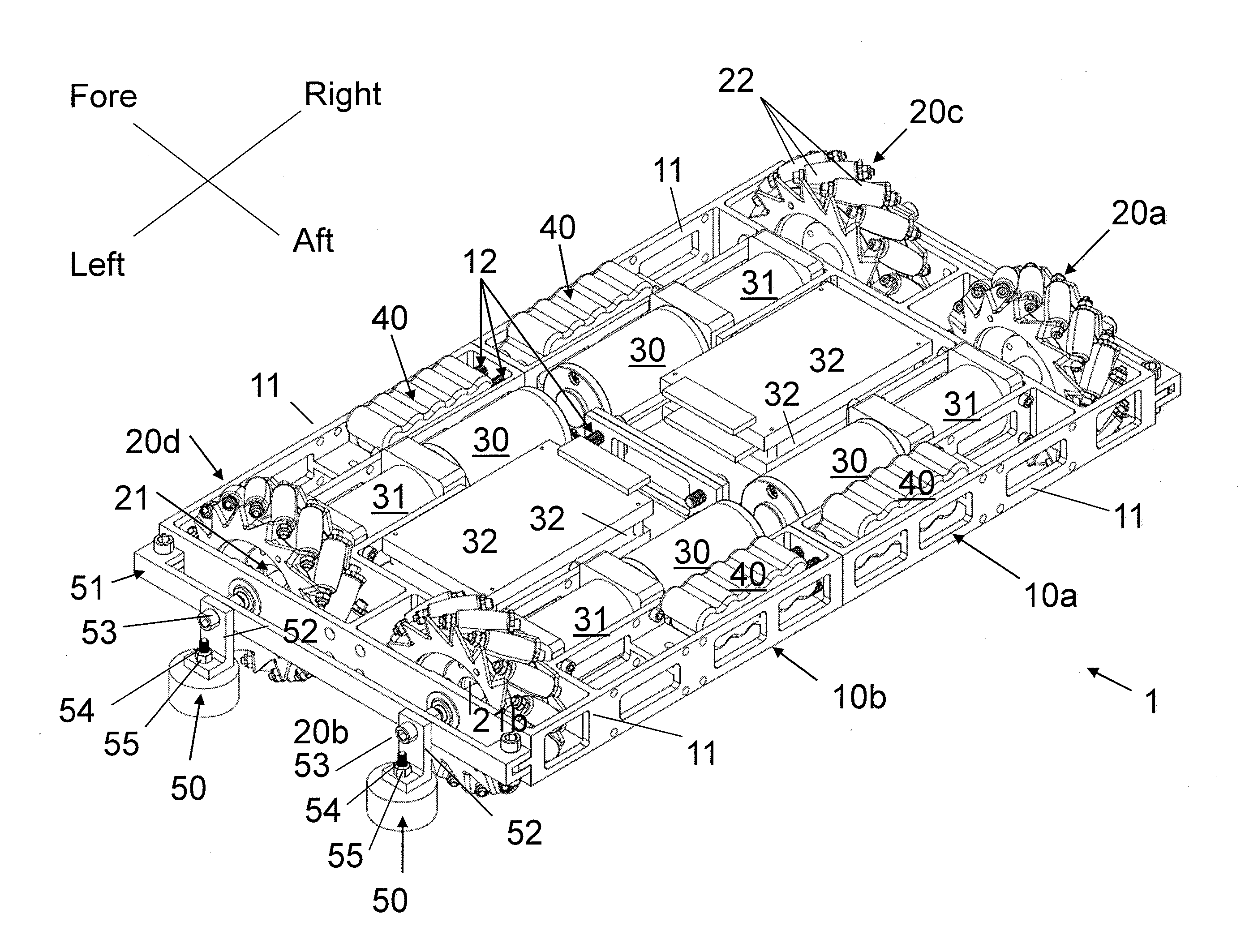

Omni-directional mobile platform with damping devices

InactiveCN106183681AGuaranteed contact at all timesVibration DissipationResilient suspensionsVehicle springsTerrainVehicle frame

The invention discloses an omnidirectional mobile platform with a shock absorbing device, which belongs to the field of omnidirectional mobile platforms. The omnidirectional mobile platform with a shock absorbing device includes a vehicle frame, a mecanum wheel and a motor drive mechanism. The frame is provided with a motor seat for fixing the motor drive mechanism, and the output end of the motor drive mechanism is provided with a hub for fixing the mecanum wheel, and it is characterized in that the frame and the motor seat A shock absorber is arranged between them, and the shock absorber includes a damping spring and a pair of shock absorbers installed symmetrically with respect to the damping spring. The invention can passively adapt to uneven terrain, ensure that all mecanum wheels can touch the ground and share the load of the omni-directional mobile platform, improve the controllability and obstacle-surpassing ability of the omni-directional mobile platform, and at the same time reduce the Vibration during exercise.

Owner:SHANDONG JIANZHU UNIV

Width variable structure of moving and transport means using mecanum wheels

A width variable structure of a moving and transport means using mecanum wheels is provided, which includes a plurality of mecanum wheels, a plurality of links connecting the mecanum wheels, and motors mounted on the mecanum wheels to transfer driving forces to the links, respectively. Since the width of the moving and transport means in the horizontal and vertical directions can be adjusted using the driving forces of the mecanum wheels, components such as actuators are omitted from the present invention in the overall assembly.

Owner:HYUNDAI MOTOR CO LTD

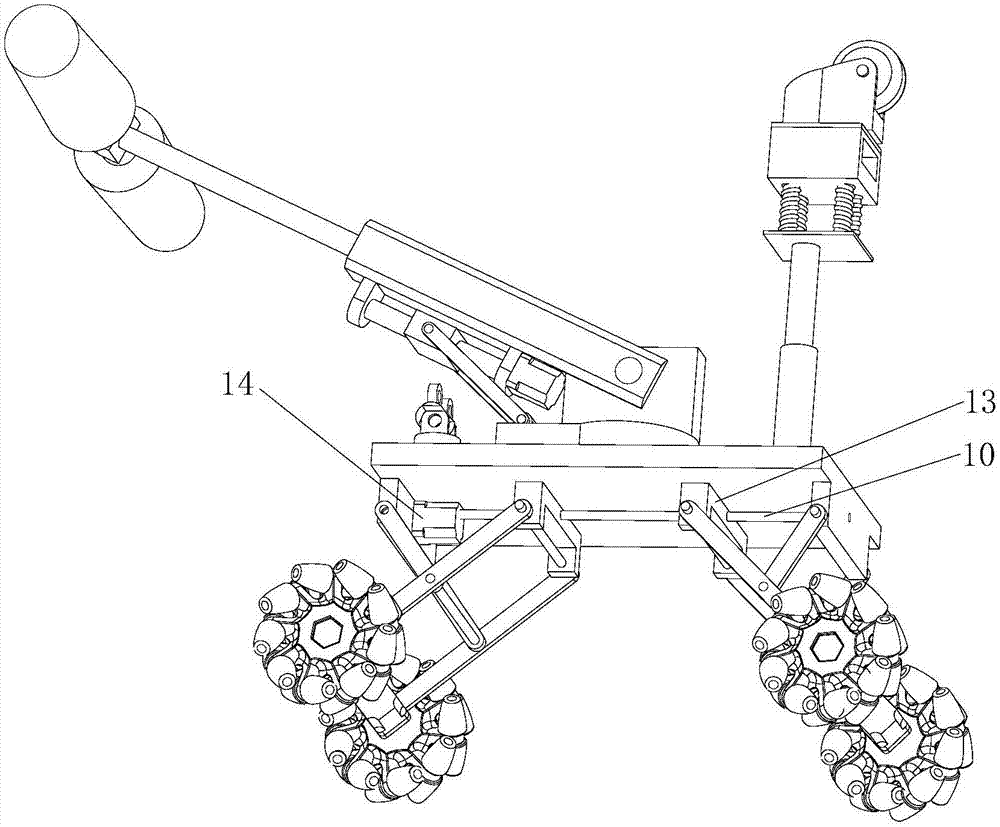

Material shooting robot

ActiveCN107253201AMeet job requirementsEasy to controlSighting devicesManipulatorMotor driveEngineering

The invention discloses a material shooting robot. The material shooting robot comprises a movable chassis. The chassis is provided with a deck device, a launching device and a dialing device from bottom to top in sequence. The dialing device is used for dialing materials to the launching device. The launching device is used for launching the materials to a target location. The deck device drives the launching device to rotate horizontally. The front part and the back part of the chassis are correspondingly provided with hanging systems. Each hanging system comprises a connecting module, a power module, a damper and a Mecanum wheel. A deck motor is installed on the chassis. The deck motor is connected with the deck device through a coupler. A launching motor is installed on the deck device. The launching motor drives the launching device to rotate up and down. The material shooting robot has the beneficial effects that the material shooting robot is driven by the Mecanum wheels, omni-directional moving is achieved, and the speed is high; and ball-shaped materials are rotationally launched out through a friction launching wheel of the side of a launching pipe, the control is convenient, and the shooting precision is high.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Novel ammunition suspending vehicle

ActiveCN104192320AEasy to adjustImprove stabilityFreight handling installationsSUSPENDING VEHICLEMecanum wheel

The invention relates to a novel ammunition suspending vehicle and relates to the field of military equipment. The vehicle comprises a vehicle body and two pairs of Mecanum wheels which are arranged at two ends of the vehicle body; the vehicle further comprises a lifting mechanism, a holding mechanism and four walking drive mechanisms; the four walking drive mechanisms are arranged in the vehicle body, are connected to the Mecanum wheels respectively and are used for driving the Mecanum wheels; the middle of the vehicle body is provided with a square hole used for accommodating a lifting mechanism, and the side walls of the square hole are provided with a pair of first sliding grooves along the length of the vehicle body; the lifting mechanism comprises a sliding rod, an ejecting seat, two parallel crossing rod groups and a lifting drive mechanism; the holding mechanism comprises a base plate, a pitching platform, a horizontal moving platform, a hanger tray, an adjusting handle, two tensioning hand wheels, two pairs of pitching and adjusting bolts and a plurality of stretching springs. The vehicle has the advantages of fine using effect and high operation reliability.

Owner:YANGZHOU WANFANG ELECTRONICS TECH

Mecanum wheel universal projectile robot

InactiveCN106091814AAchieve omnidirectional movementThe method is simple and reliableLaunching weaponsFixed frameMecanum wheel

The invention discloses a Mecanum wheel universal projectile robot. The Mecanum wheel universal projectile robot comprises a Mecanum wheel moving platform, a holder and a launching mechanism; the holder is fixed at the top of the Mecanum wheel moving platform; and the launching mechanism is fixed on the holder. The holder includes a Yaw shaft rotating frame, a Yaw shaft motor, a Pitch shaft motor and a pitching frame; the Yaw shaft motor is fixed at the top of the Mecanum wheel moving platform; an output shaft of the Yaw shaft motor is fixedly connected with the bottom surface of the Yaw shaft rotating frame through a connecting piece; the top of the Yaw shaft rotating frame is rotationally connected with the pitching frame to form a launching mechanism fixed frame; the launching mechanism is fixed in the launching mechanism fixed frame; and the Pitch shaft motor is fixed on the Yaw shaft rotating frame, and an output shaft thereof is fixedly connected with the pitching frame. The Mecanum wheel universal projectile robot can perform universal movement, and can emit bullets; and the carried holder can rotate around horizontal and vertical axles to adjust aiming of the launching mechanism.

Owner:NANJING UNIV OF SCI & TECH

Aeroengine installation vehicle

Owner:上海汇聚自动化科技有限公司

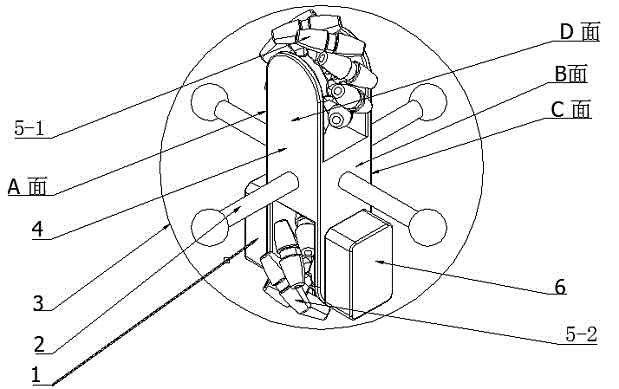

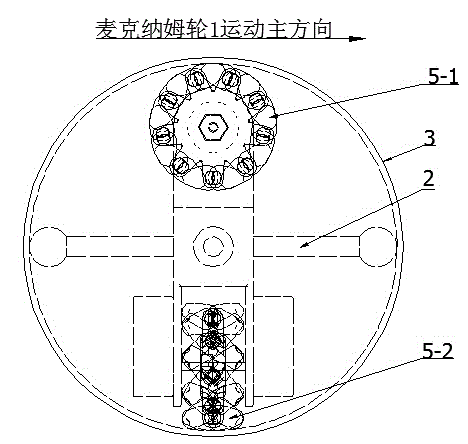

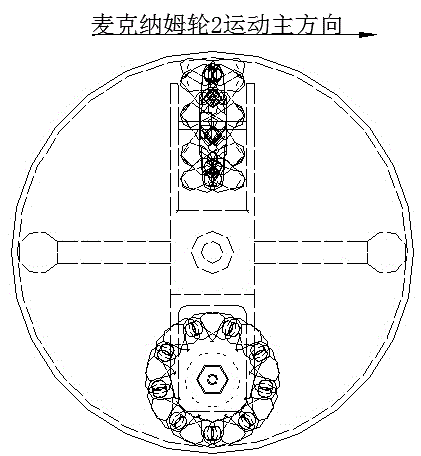

Mecanum-wheel-driven type spherical mobile robot

InactiveCN104097706AImprove practicalitySimplify the charging processVehiclesEngineeringMecanum wheel

The invention discloses a Mecanum-wheel-driven type spherical mobile robot. The robot comprises a rigid spherical shell, four automotive pneumatic rods serving as struts, a rack, two Mecanum wheels, hub motors inside the Mecanum wheels, a power supply module, a wireless charging device of the power supply module, and a main control module. The two Mecanum wheels provide two perpendicular driving forces by being symmetrically fixed on the rack and being orthogonally arranged; one ends of the four struts are fixedly connected with the rack and the other ends of the four struts are in contact with the inner surface of the spherical shell; moreover, the four pneumatic rods are uniformly distributed in the same plane vertical to the plane where the wheels are positioned and a six-point stable supporting structure is formed by the four pneumatic rods and the two wheels. The control module, a battery and the other devices are all fixed on the rack and the integral internal structure is simplified to the greatest extent. According to the invention, the internal structure of the spherical robot is simplified and energy loss of contact drive is reduced.

Owner:SHANGHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com