Mecanum wheel-based rocker omnidirectional mobile platform

A technology of all-round movement and mecanum wheels, which is applied in the direction of motor vehicles, interconnection systems, suspensions, etc., can solve the problem of poor obstacle-surpassing performance and terrain adaptability, suspension of wheels, and inability to obtain mobile platforms with mecanum wheels Good control and other issues to achieve good terrain adaptability and smooth operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

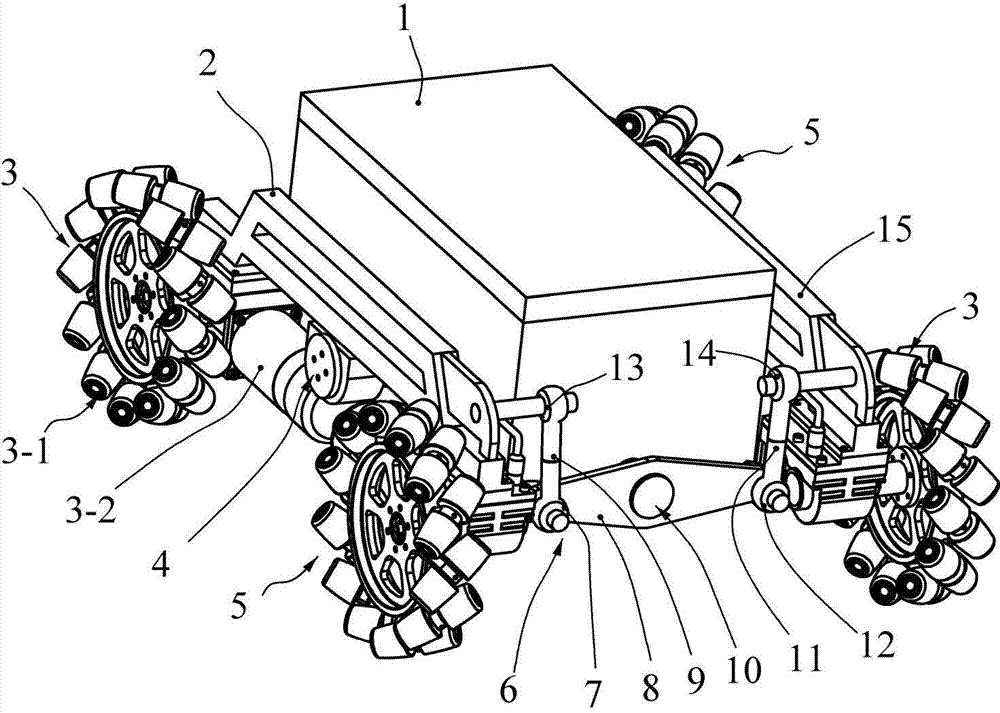

[0025] Refer to attached figure 1 , 2 :

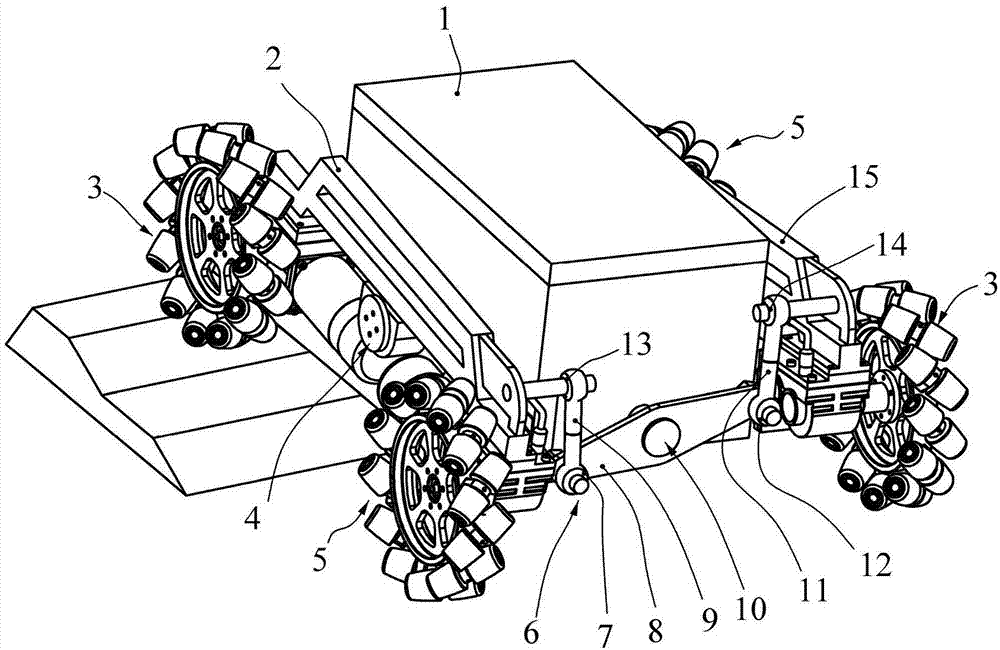

[0026] figure 1 It is a perspective view of Embodiment 1 of the present invention. In this embodiment, the structures of rocker suspension 1 2 and rocker suspension 2 15 are left-right symmetrical, and they are symmetrically arranged on the left and right sides of main vehicle body 1. On the side, the rocker suspension one 2 is hinged with the left side of the main vehicle body 1 by a rotating pair 4, and the rocker suspension two 15 is also hinged with the right side of the main vehicle body 1 by a rotating pair, And the two rotating pairs are coaxial. The axis of the rotating pair 10 formed by the middle part of the roll bar 8 of the balance mechanism 6 and the main vehicle body 1 is perpendicular to the front view projection plane of the main vehicle body 1; the side link one 9 and the side link two 11 are up and down Direction setting, the lower end of side link one 9 is hinged with one end of roll bar 8 by ball pair 7, and the...

Embodiment 2

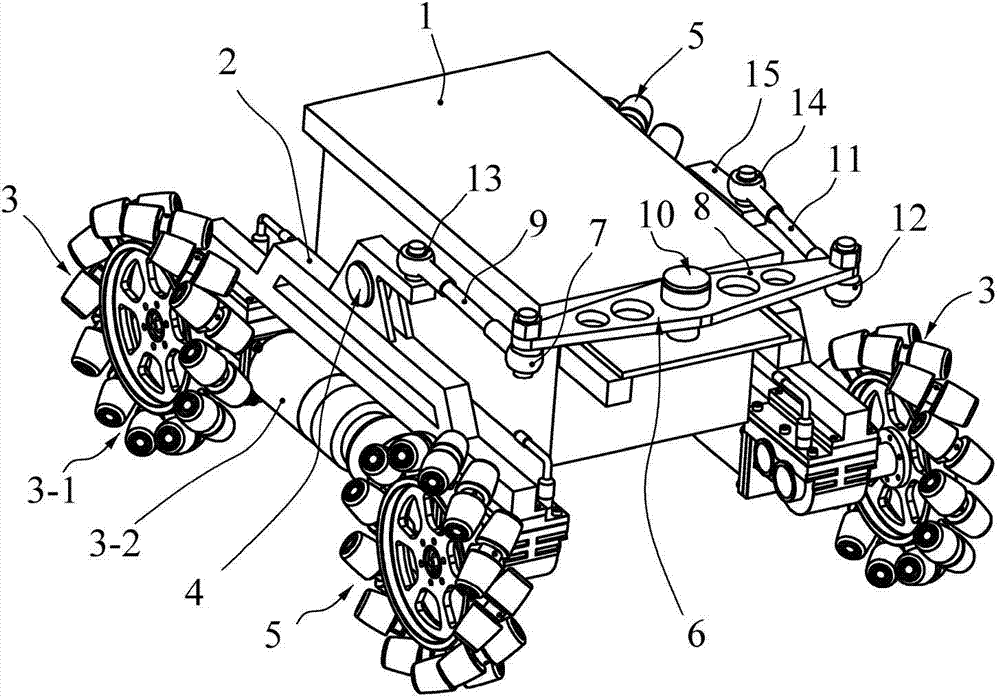

[0029] Refer to attached image 3 , 4 :

[0030] image 3 It is a perspective view of Embodiment 2 of the present invention. The difference from Embodiment 1 is that the axis of the rotating pair 10 formed by the middle part of the roll bar 8 of the balance mechanism 6 and the main vehicle body is perpendicular to the main vehicle body 1 The top view projection plane of , the side link one 9 and the side link two 11 are arranged in the front and back directions, and the position of the ball pair 13 hinged between the side link one 9 and the rocker suspension one 2 is the same as that of the rocker suspension one 13 The axis of the revolving pair 4 in the middle has a certain offset in the vertical direction of the rocker suspension one 13; The connection structure of suspension one and two is symmetrical. Embodiment two and figure 2 The working principle of the first embodiment shown is similar, Figure 4 It is a state diagram of Embodiment 2 of the present invention wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com