Material shooting robot

A robot and material technology, applied in the field of robots, can solve the problems of low shooting accuracy, cumbersome control, cumbersome manipulation, etc., and achieve the effects of high manoeuvrability, precise control, and convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

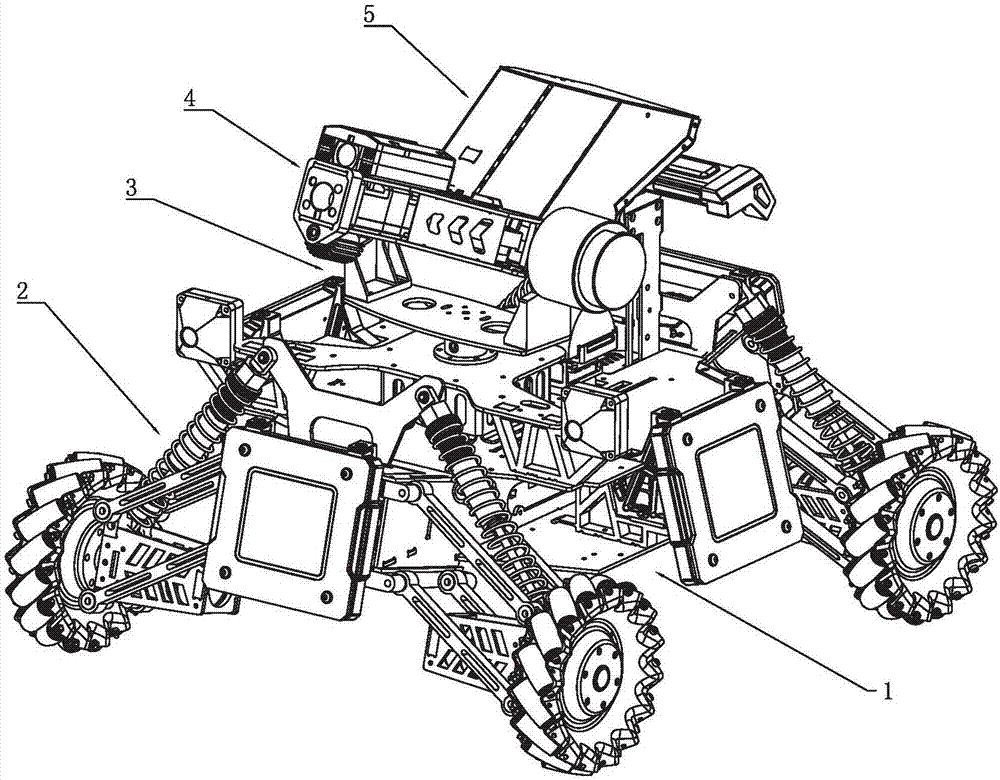

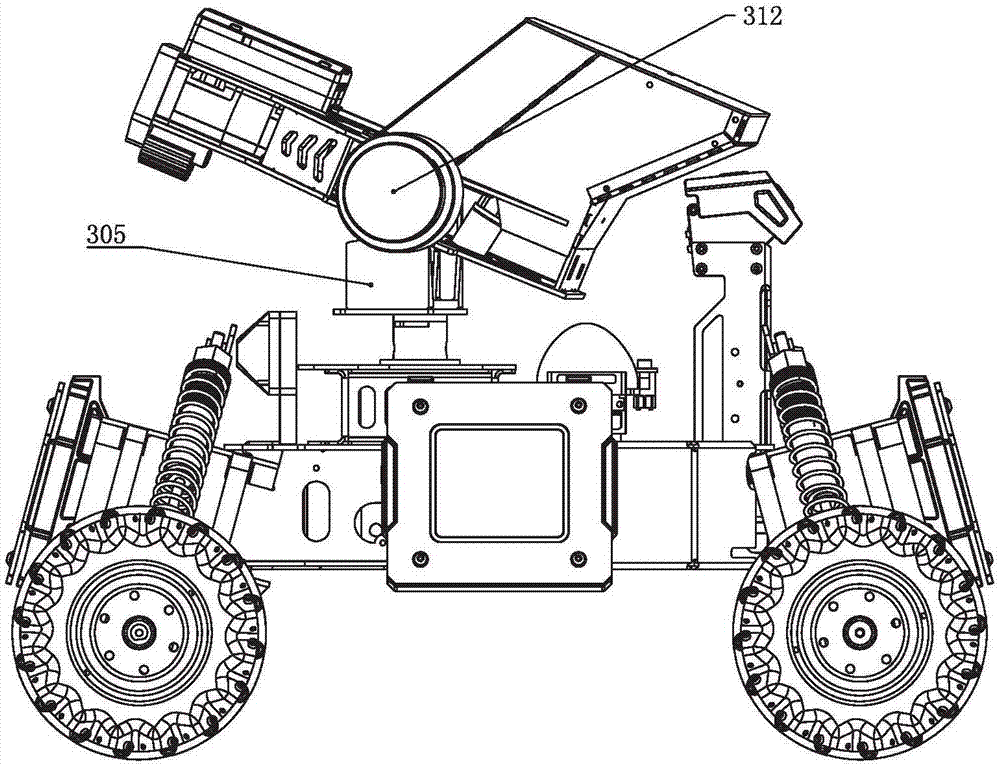

[0035] like figure 1 As shown, the material shooting robot provided by the present invention includes a movable chassis 1, on which a pan-tilt device 3, a launching device 4, and a plucking device 5 are installed sequentially from bottom to top, and the plucking device 5 is used to move the material Dial into the launcher 4, the launcher 4 is used to project the material to the target position, and the pan-tilt device 3 drives the launcher 4 to rotate horizontally.

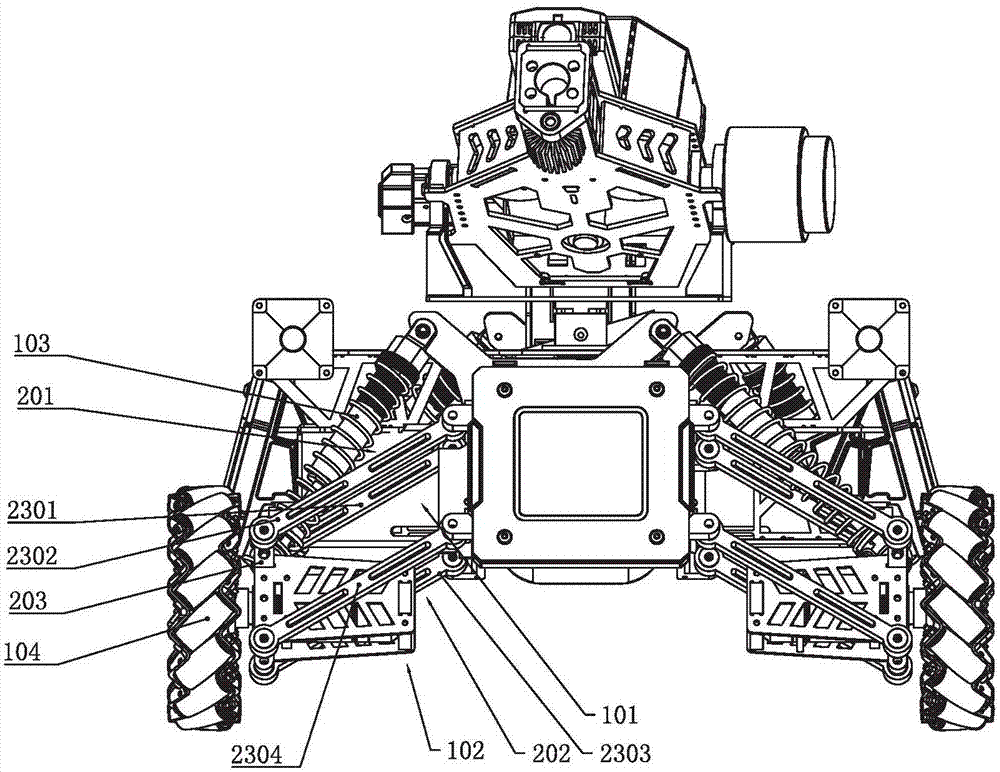

[0036] like figure 1 and figure 2 As shown, the front and rear parts of the chassis 1 are respectively provided with a suspension system 2, the suspension system 2 includes a connecting module 101, a power module 102, a shock absorber 103 and a mecanum wheel 104, and the connecting module 101 includes an upper connecting arm 201 and The lower connecting arm 202, one end of the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com