Magnetorheological torsion damper and automotive seat with same

A car seat, magnetorheological technology, applied in the direction of vehicle seats, shock absorbers, shock absorbers, etc., can solve the problems of inapplicability, inability to suppress vibration, limited damping force, etc., to achieve compact structure and wide use. The effect of large range and elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

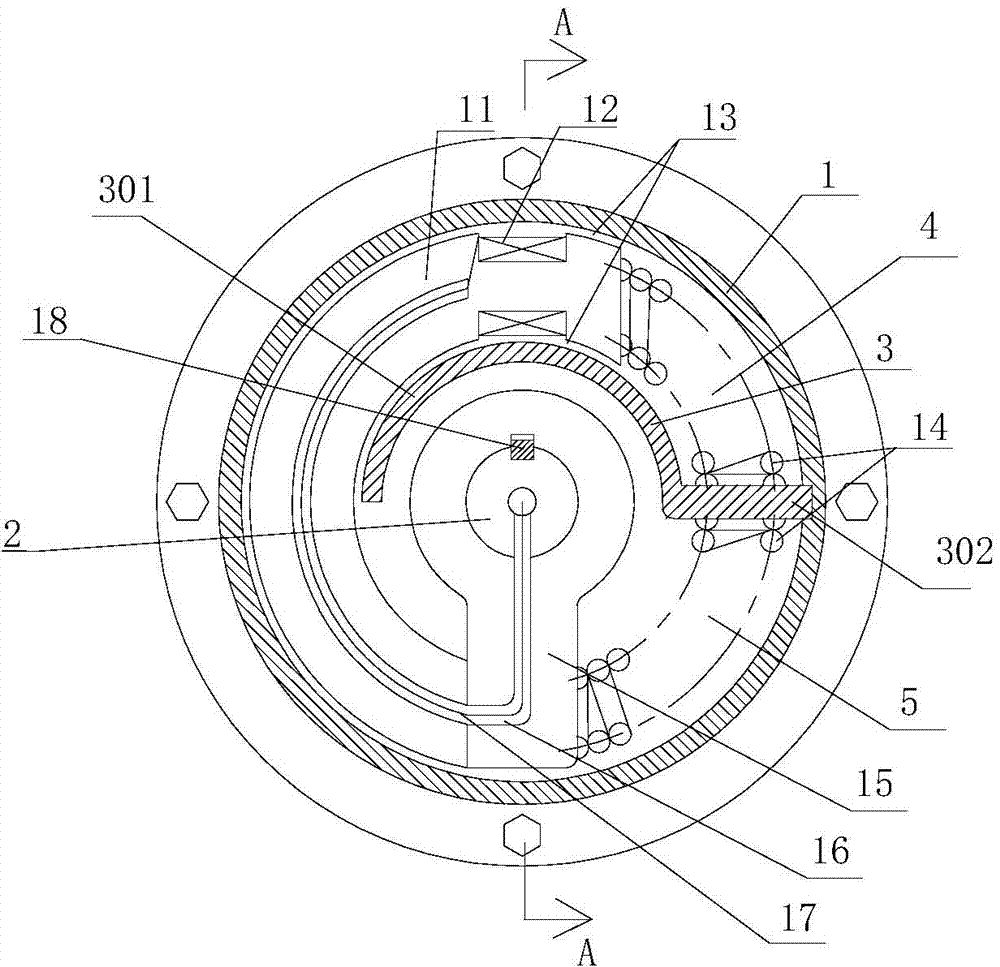

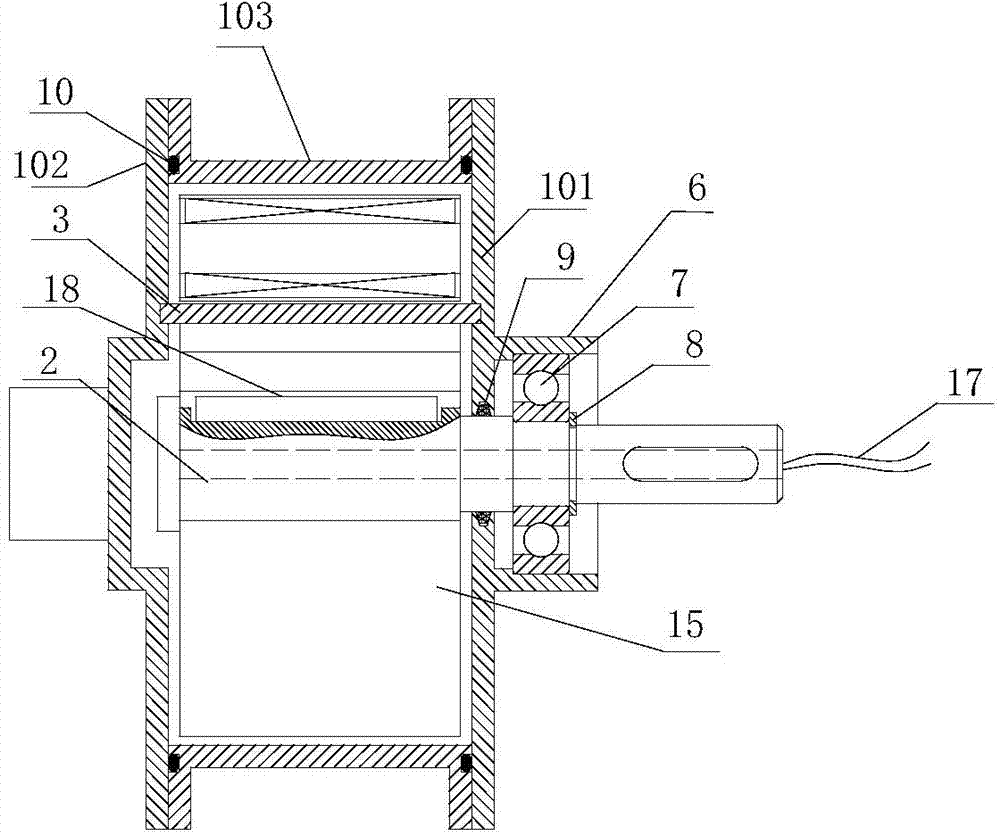

[0017] figure 1 It is a schematic diagram of the structure of the present invention, figure 2 for figure 1 A-A direction view, as shown in the figure: the magnetorheological torsional damper of this embodiment includes a cylinder body 1 with a cavity inside and a rotating shaft 2 that penetrates from the cavity and is rotatably matched and sealed with the cylinder body 1. The longitudinal section of the cavity is circular; it also includes a cavity frame 3, an arc-shaped piston 11 and an electromagnetic coil 12 all placed in the cavity. The cavity frame 3 is arc-shaped concentric with the inner wall of the cylinder body 1 and one end is radially outward. It is extended to form a connection part that is fixedly connected to the cylinder body 1. One end of the arc-shaped piston is connected with the rotating shaft 2. The piston, the cavity frame 3 and the cylinder body 1 jointly form the sub-cavity I4 and the sub-cavity II5, and the radial sides of the arc-shaped piston are a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com