Consumable chip and its data resetting method, consumable container

A consumable chip and data technology, applied in the field of consumable containers, can solve problems such as affecting the work of the toner cartridge laser printer, unable to cover the toner remaining data in time, etc., and achieve the effect of ensuring timeliness and accuracy and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

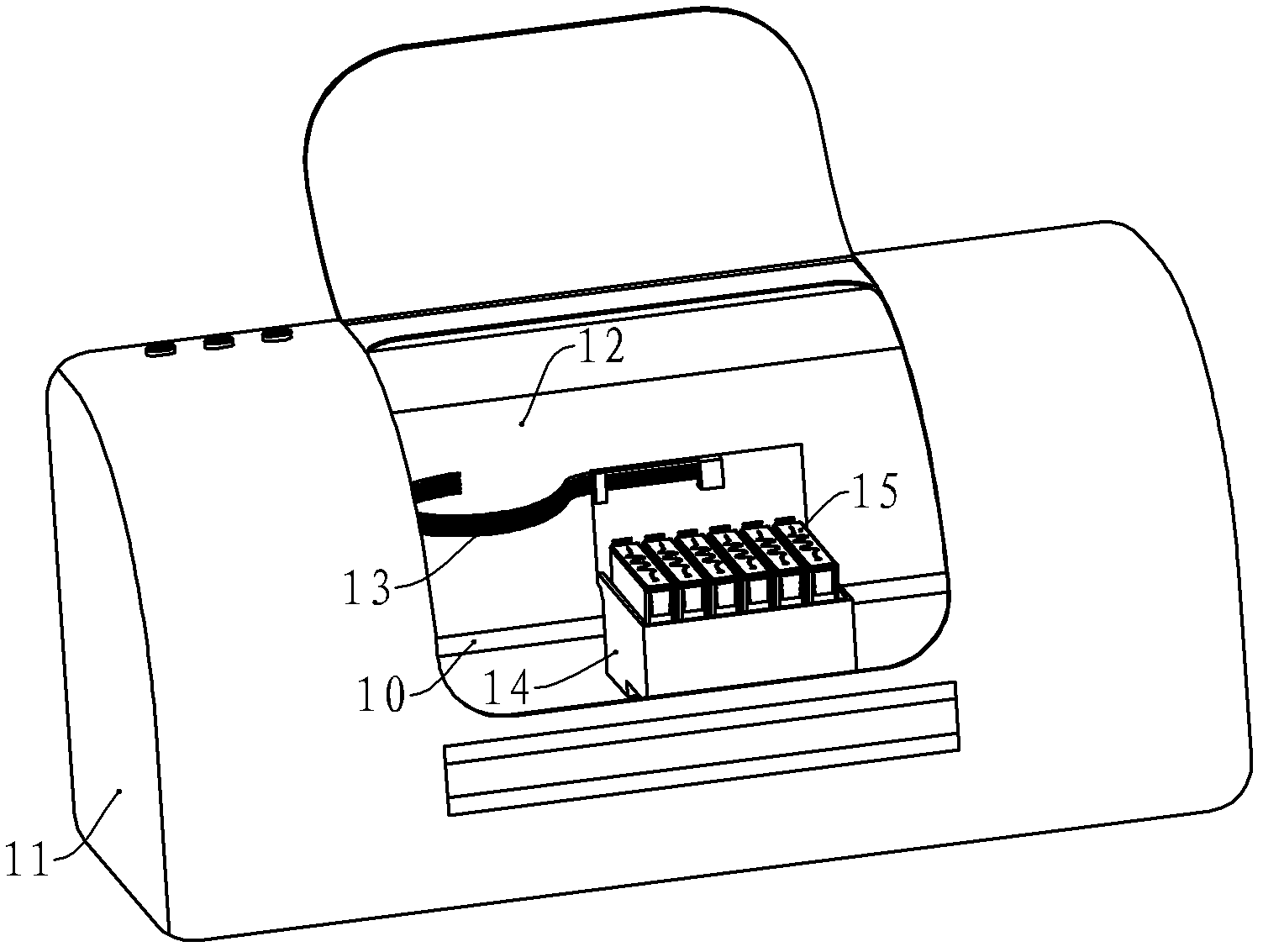

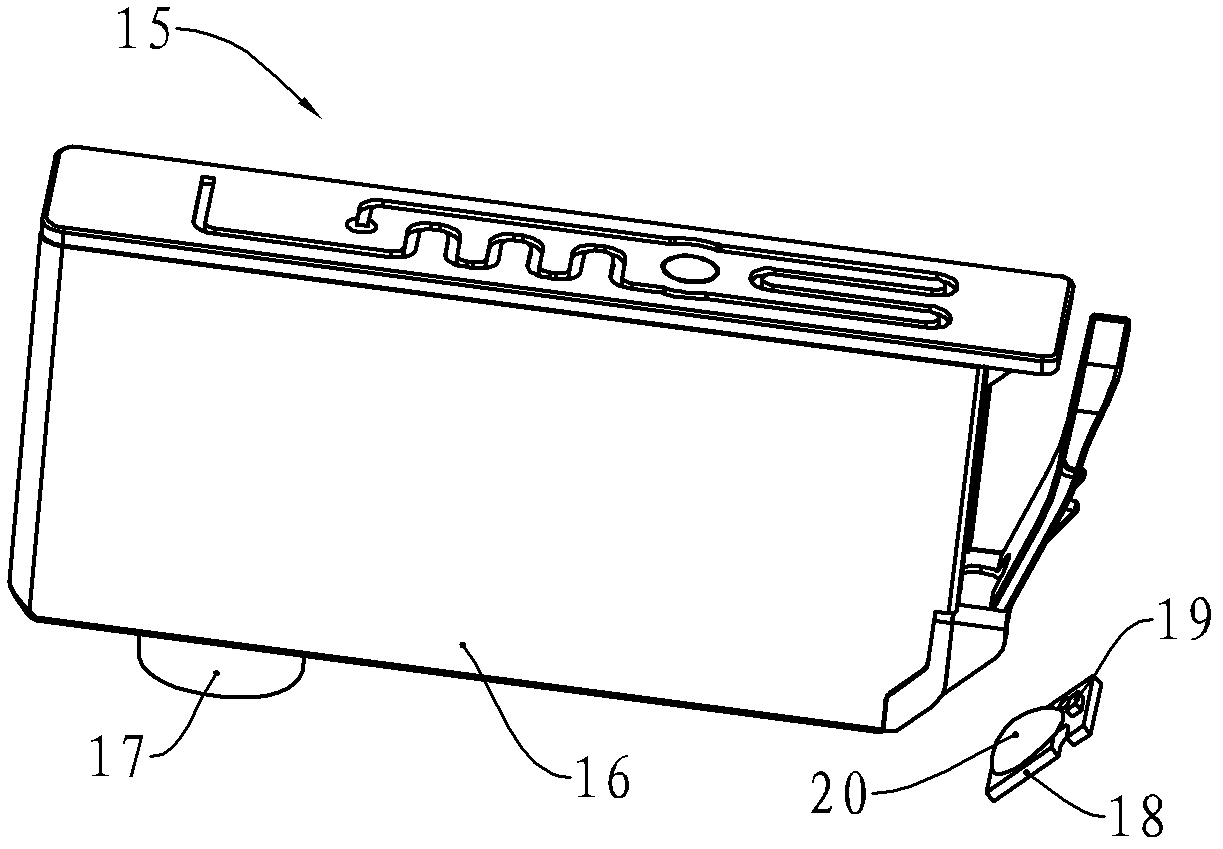

[0040] The consumable chip in this embodiment is an ink cartridge chip installed in an ink cartridge for an inkjet printer, which has a substrate, and one side of the substrate is provided with a plurality of electrical contacts as a communication unit for connecting with the electrical contacts of the inkjet printer. Of course, if the inkjet printer and the chip of the consumables communicate wirelessly, the communication unit is an antenna for wireless communication. On the other side of the substrate, there are electronic modules and light-emitting diodes connected to electrical contacts. The electrical schematic diagram of the connection between the electronic modules and the light-emitting diodes is as follows Figure 5 shown.

[0041] The electronic module 40 is provided with a control unit 41 , a memory 42 and a counter 48 , wherein the memory 42 is provided with a first storage area 43 and a second storage area 44 . The first storage area 43 stores data related to ink...

no. 2 example

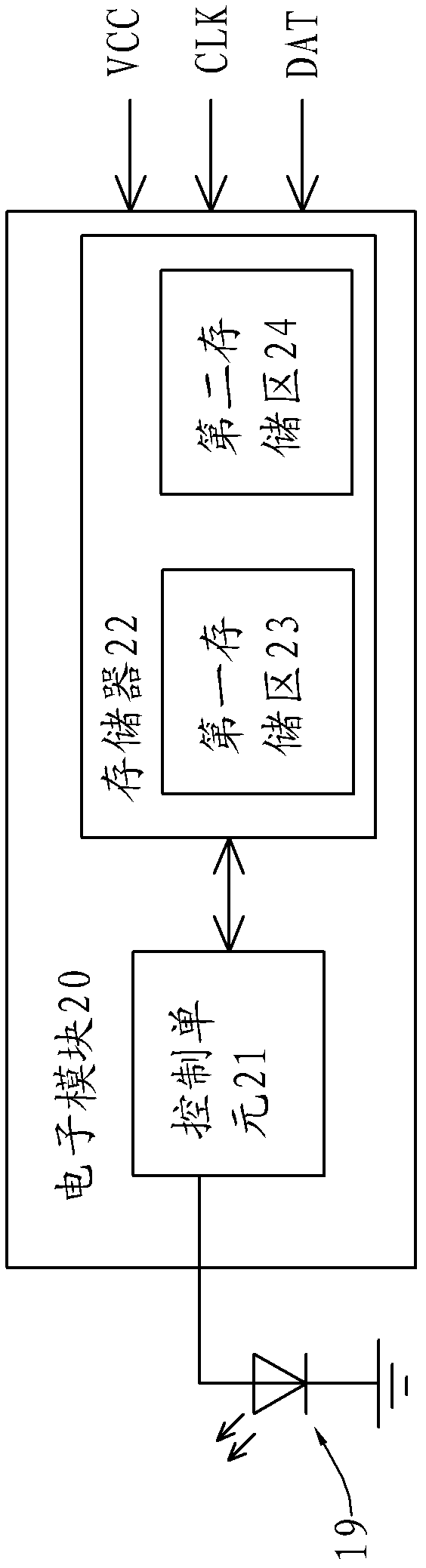

[0050] This embodiment has a substrate on which electrical contacts, electronic modules, and light-emitting diodes are arranged. The electrical schematic diagram of the connection between the electronic module and the light-emitting diodes is as follows Figure 6 shown. The electronic module 50 is provided with a control unit 51 and a memory 52. The memory 52 has a first storage area 53 and a second storage area 54. The first storage area 53 stores ink remaining data, and the second storage area stores a predetermined ink remaining value. data. The anode of the LED 56 is connected to the electronic module 50 and the cathode is grounded.

[0051] The control unit 51 receives signals from the inkjet printer, including a clock signal CLK, a data signal DAT, and the like. In addition, the control unit 51 also receives a control signal from the inkjet printer, and sends an on-off signal SCK to the anode of the light-emitting diode 56 . When the inkjet printer is working normal...

no. 3 example

[0057] This embodiment is also provided with a substrate, and the substrate is provided with electrical contacts, electronic modules, and light-emitting diodes. The electrical schematic diagram of the connection between the electronic module and the light-emitting diodes in this embodiment is the same as that of the second embodiment, and will not be repeated here.

[0058] In this embodiment, when the inkjet printer is working normally, the frequency of the on-off signal sent by the control unit to the light-emitting diode is relatively low, and when the ink remaining data is judged to be low, the frequency of the on-off signal is relatively high. larger. Therefore, when the counter judges that the count value is greater than the threshold value, the first signal sent to the control unit is a data reset signal. After the control unit receives the data reset signal, it will write the predetermined value data of the remaining ink level stored in the second storage area. Go to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com