Can cap multi-level composite air pressure reverse mold and forming method

A technology for forming molds and can lids, applied in the field of cold stamping molds, can solve the problems of local material thinning, waste of processing procedures, and high processing costs, and achieve the effects of less material deformation, convenient processing, and low material costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

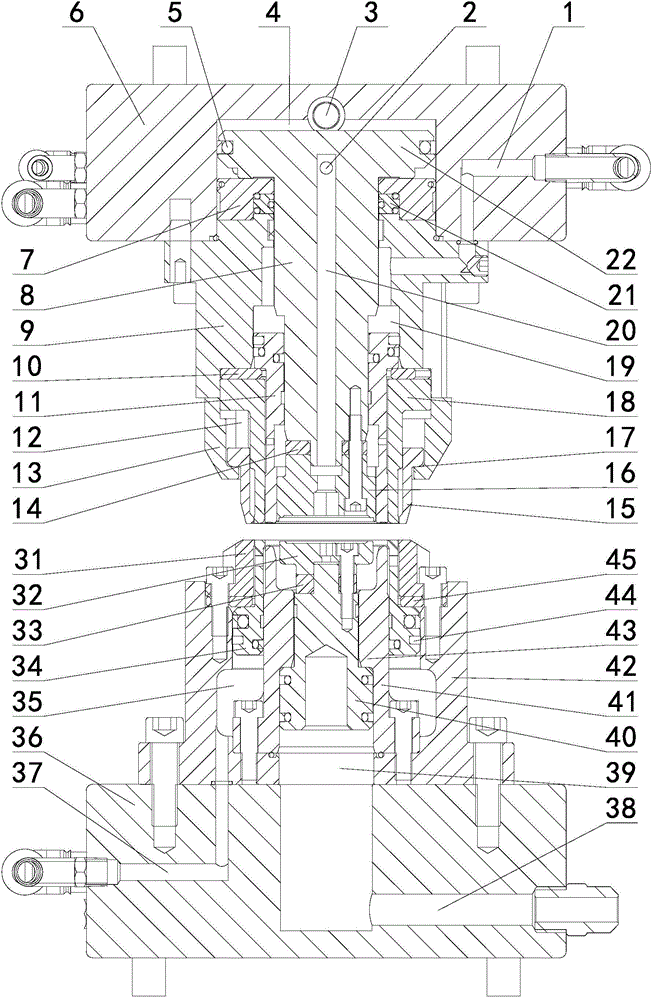

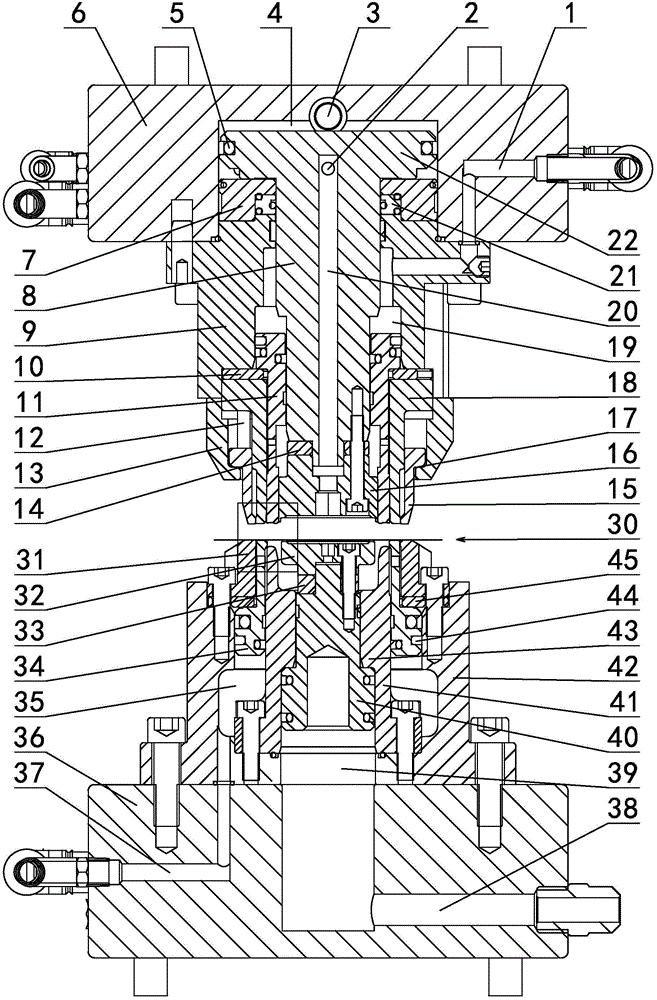

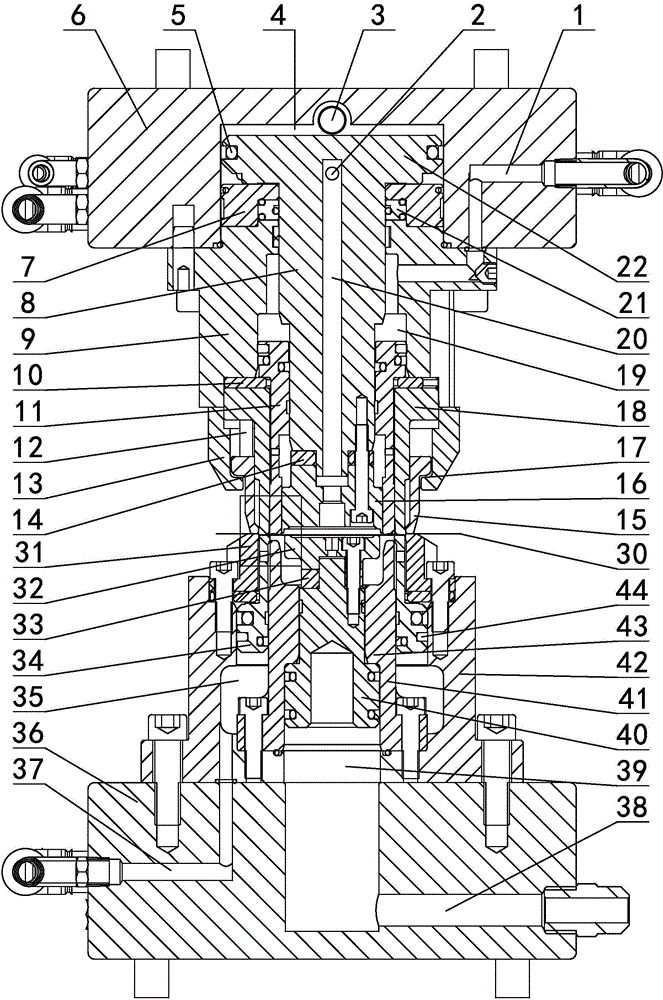

[0044] in such as figure 1 In the shown embodiment 1, a multi-stage composite air pressure reverse forming mold for a tank cover includes an upper mold and a lower mold, and the upper mold and the lower mold are a combined structure of a plurality of ring-shaped single molds concentrically stacked inside and outside. Described patrix comprises patrix 6, and patrix is provided with the cylindrical patrix cavity of opening downward, is provided with piston body 22 in patrix cavity, and patrix 9 is fixed on the opening of patrix cavity, patrix The upper end of the seat is provided with a shaft hole, and the lower end of the piston body extends downwards to form an upper mold core fixed shaft 8. The upper mold core fixed shaft passes through the shaft hole, and the upper mold core 16 is fixed on the upper mold core. The lower end of the shaft and the upper mold cavity at the upper end of the piston body form the upper mold high-pressure air chamber 4, and the upper mold high-pre...

Embodiment 2

[0058] exist Figure 14 In the shown embodiment 2, a vibrating device 46 is fixed on the bottom of the inner core seat of the lower mold, and the vibrating device is a small vibrator, and the rest are the same as in the embodiment 1.

[0059] In the can lid molding method of Example 2, when the lower high-pressure air chamber is inflated to push the inner core of the lower mold to rise, the vibration device works, and the axial vibration force is applied to the inner core of the lower mold through the inner core seat of the lower mold, and the high-pressure air chamber of the lower mold stops During air intake, the vibrating device stops working, and all the other are identical with embodiment 1.

[0060] When the multi-stage compound air pressure reverse molding die for the can lid of the present invention is working, the upper mold high-pressure air chamber, the binder air chamber and the blank holder air chamber are fed into the initial position, and the upper mold moves do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com