Composite synthetic air compressor oil

A technology for air compressor oil and olefin oil, which is used in the petroleum industry, lubricating compositions, base materials, etc. to achieve excellent high-temperature oxidation stability, excellent low-temperature start-up performance, and extended service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Butyloctyldiphenylamine 0.3%

[0058] 2.6 di-tert-butyl-p-cresol 1.0%

[0059] Tricresyl Phosphate 1.8%

[0060] Barium Dialkylnaphthalene Sulfonate 0.5%

[0061] Benzotriazole 0.06%

[0062] Methyl silicone oil 10ppm

[0063] Synthetic polyalphaolefin 6.0%

[0064] Different (C 6~13 ) Alkyl straight chain dibasic acid ester 18.0%

[0065] Diisoalkyl (C 8~13 ) phthalates balance.

[0066] Mix all raw materials and stir evenly to obtain the product.

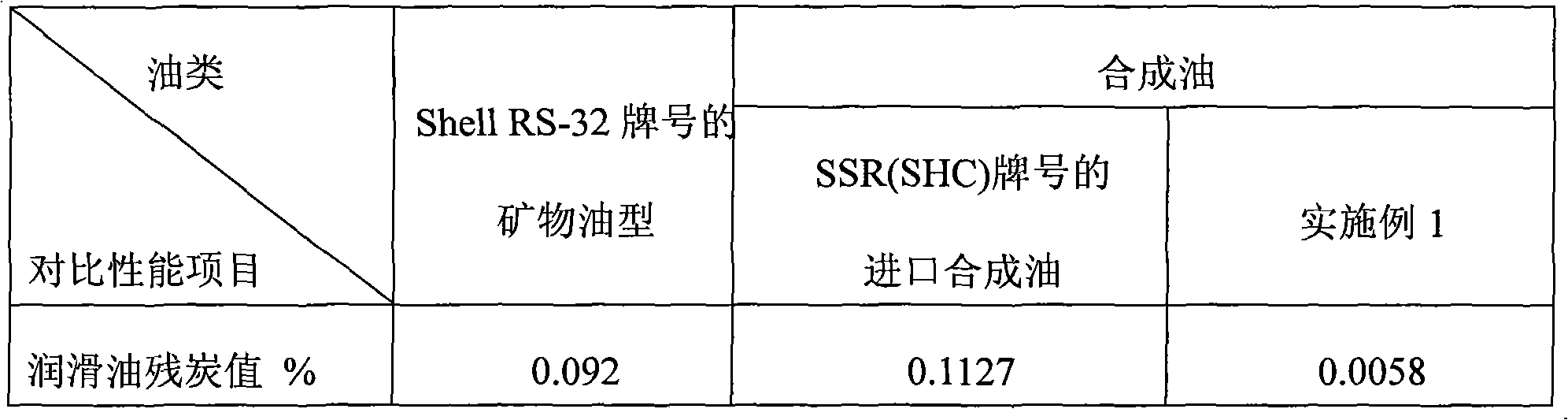

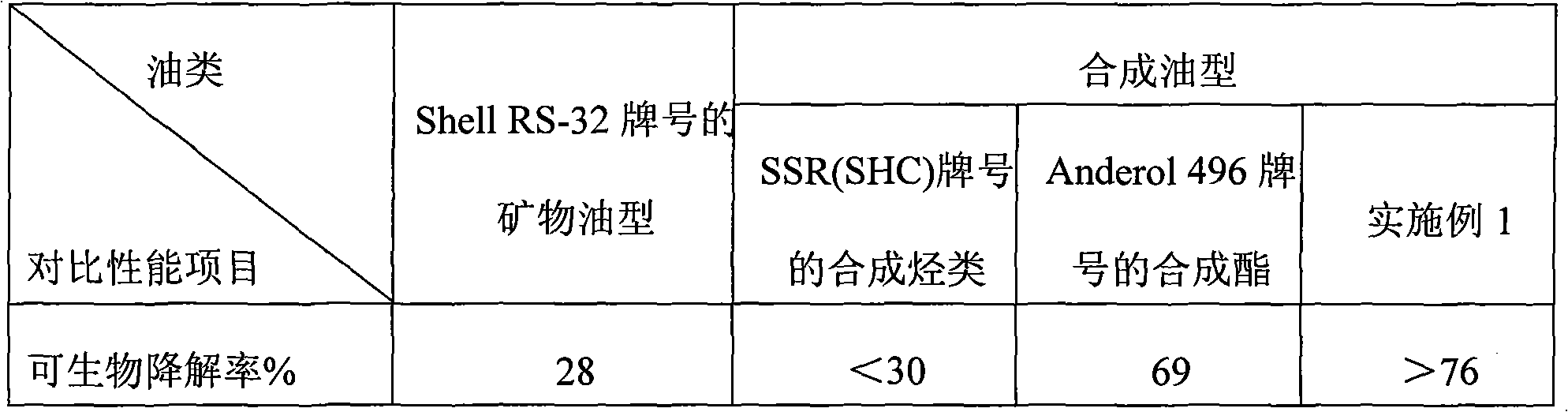

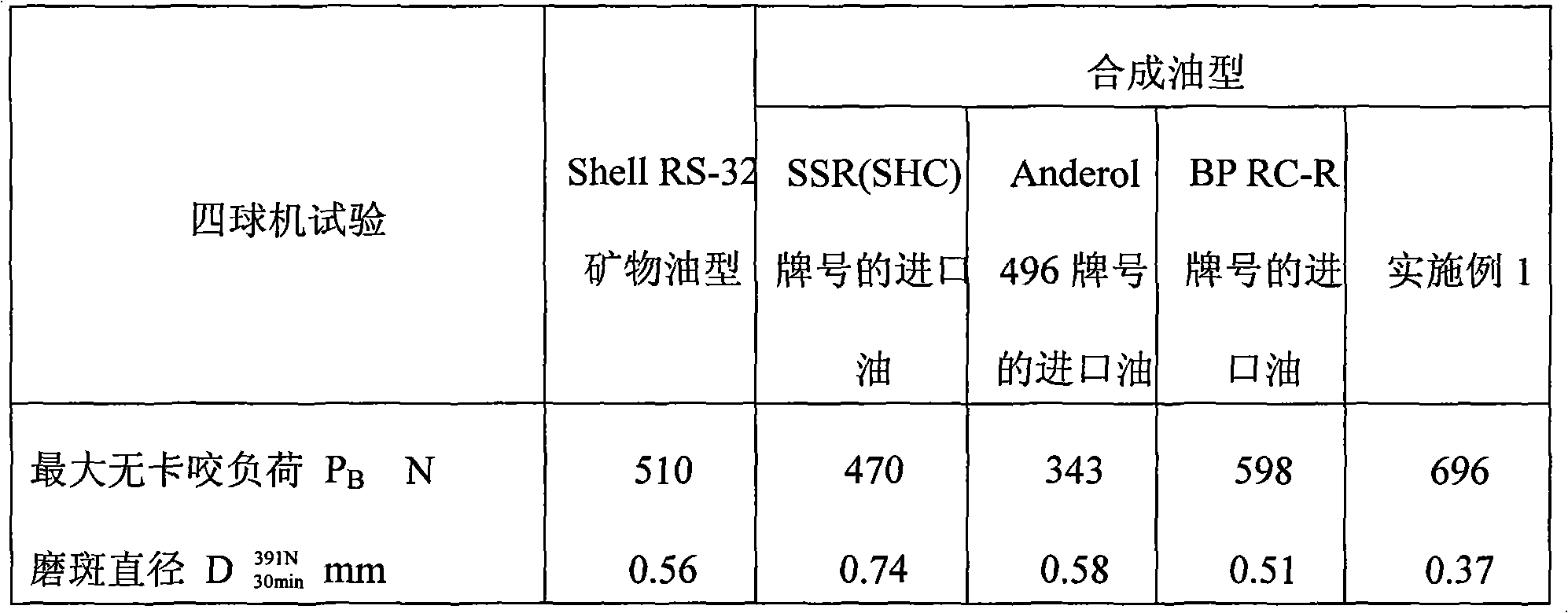

[0067] The above-mentioned synthetic compressor oil was tested and the results are as follows:

[0068] project

technical indicators

Test results

experiment method

Kinematic viscosity(40℃)mm 2 / s

(100℃)mm 2 / s

28.8~35.2

Measured

32.79

5.08

GB / T265

Acid value mgKOH / g≤

0.5

0.087

GB / T264

Flash point (opening)℃≥

200

219

GB / T3536

Pour point ℃≤

-30

-35

GB / T3535

An...

Embodiment 2

[0077] Butyloctyldiphenylamine 0.8%

[0078] 2.6 di-tert-butyl-p-cresol 0.5%

[0079] Tricresyl Phosphate 1.2%

[0080] Barium Dialkylnaphthalene Sulfonate 0.3%

[0081] Benzotriazole 0.1%

[0082] Methyl silicone oil 20ppm

[0083] Synthetic polyalphaolefin 8.0%

[0084] Different (C 6~13 ) Alkyl straight chain dibasic acid ester 16.0%

[0085] Diisoalkyl (C 8~13 ) phthalates balance.

[0086] Mix all raw materials and stir evenly to obtain the product.

[0087] The above-mentioned synthetic compressor oil was tested and the results are as follows:

[0088] project

technical indicators

Test results

experiment method

Kinematic viscosity(40℃)mm 2 / s

(100℃)mm 2 / s

28.8~35.2

Measured

34.2

5.38

GB / T265

Acid value mgKOH / g≤

0.5

0.1

GB / T264

Flash point (opening)℃≥

200

220

GB / T3536

Pour point ℃≤

-30

-36

GB / T3535

Anti-e...

Embodiment 3

[0097] Butyloctyldiphenylamine 1.0%

[0098] 2.6 di-tert-butyl-p-cresol 0.3%

[0099] Tricresyl Phosphate 1.5%

[0100] Barium Dialkylnaphthalene Sulfonate 0.2%

[0101] Benzotriazole 0.15%

[0102] Methyl silicone oil 40ppm

[0103] Synthetic polyalphaolefin 9.0%

[0104] Different (C 6~13 ) Alkyl straight chain dibasic acid ester 14.0%

[0105] Diisoalkyl (C 8~13 ) phthalates balance.

[0106] Mix all raw materials and stir evenly to obtain the product.

[0107] The above-mentioned synthetic compressor oil was tested and the results are as follows:

[0108] project

[0109] .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com