Railless automatic transfer butt joint platform

A docking platform and automatic technology, applied in the direction of workbench, manufacturing tools, etc., can solve the problems of difficult to meet the docking accuracy requirements, the limited positioning accuracy of the trackless system, and the large change of the docking station of the trackless system, so as to prevent free movement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

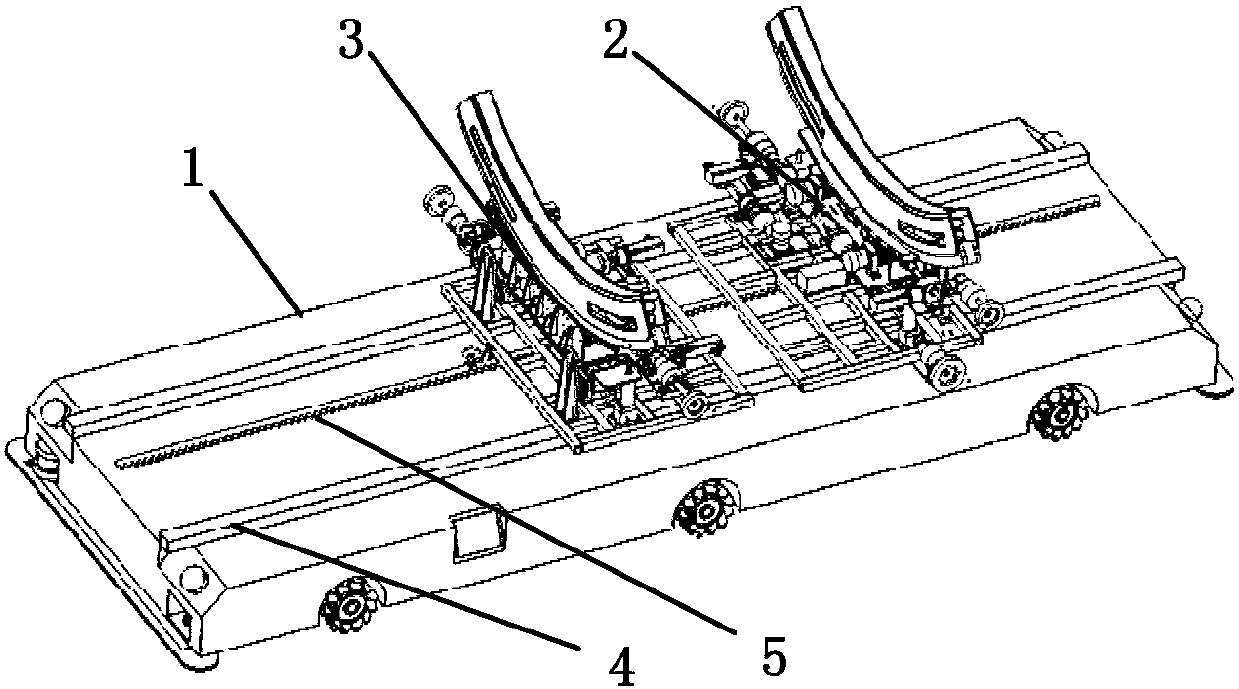

[0024] A trackless automatic transfer docking platform, comprising a transfer platform 1, an attitude adjustment mechanism a2, an attitude adjustment mechanism b3, a linear guide rail a4, and a rack 5, the rack 5 is installed in parallel with the linear guide rail a4, and the attitude adjustment mechanism a2, the attitude adjustment mechanism b3 is installed on the slider of linear guide rail a4;

[0025] The transfer platform 1 is driven by several pairs of mecanum wheels, which can realize omnidirectional movement in the horizontal plane, and realize automatic transfer of sections through geomagnetic navigation and other control methods.

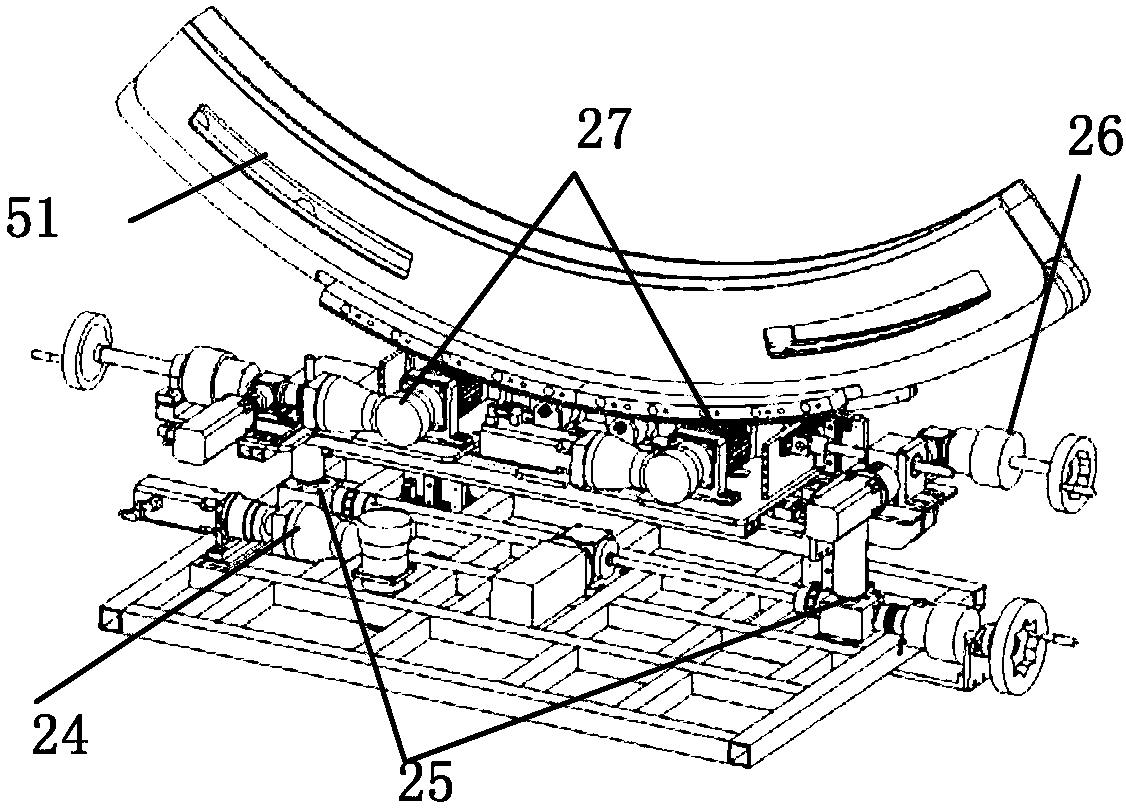

[0026] The attitude adjustment mechanism a2 includes a forward and backward moving mechanism 24 , a lifting mechanism 25 , a left and right translation mechanism 26 , an anti-backlash rolling mechanism 27 and a diameter adjusting tool 51 .

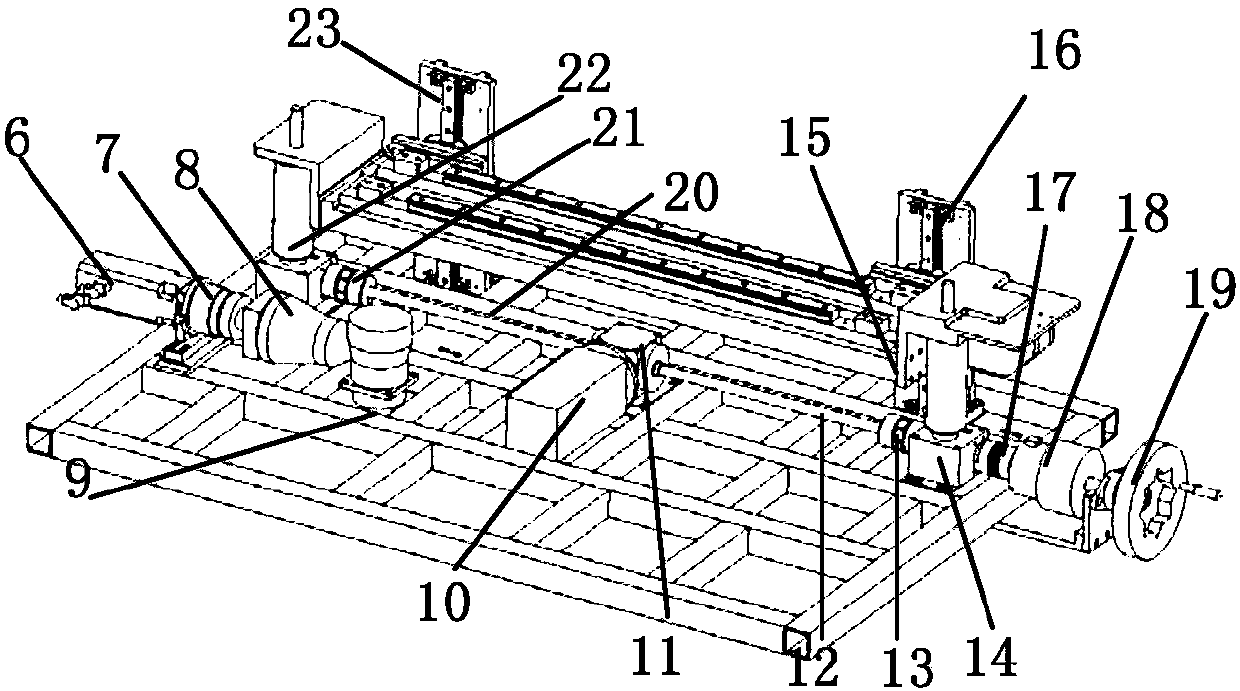

[0027] Mechanism 24, lifting mechanism 25 such as image 3 As shown, the front and rear moving mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com