Patents

Literature

78results about How to "Precise pick and place" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

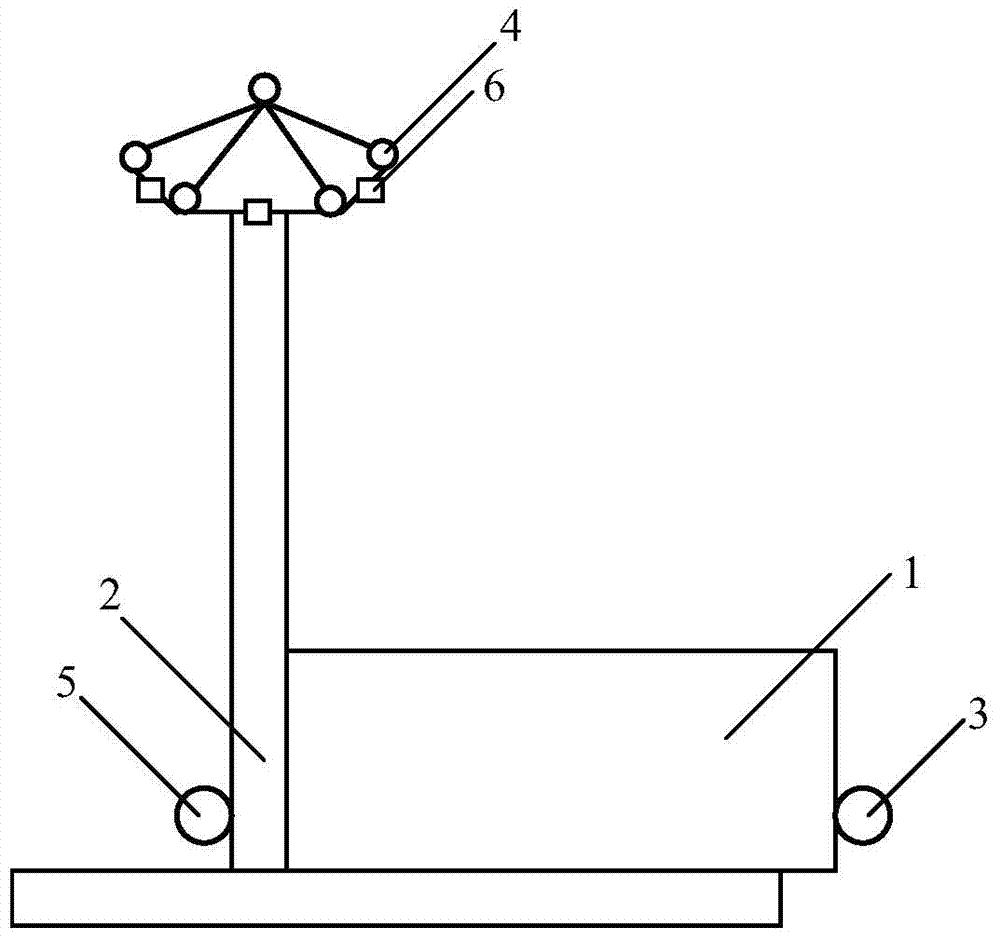

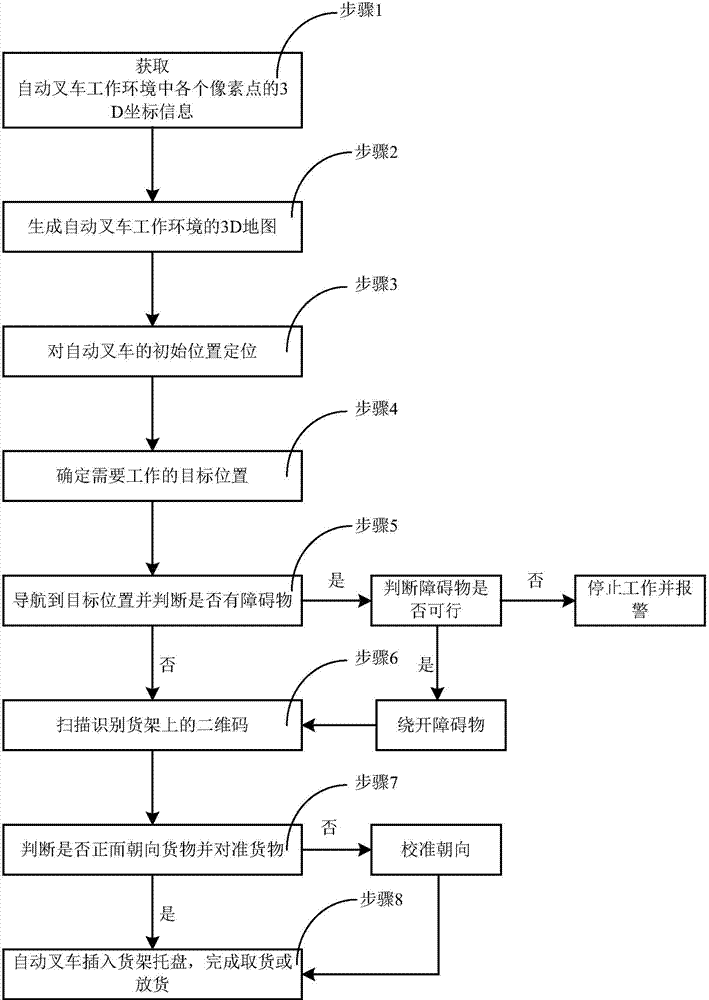

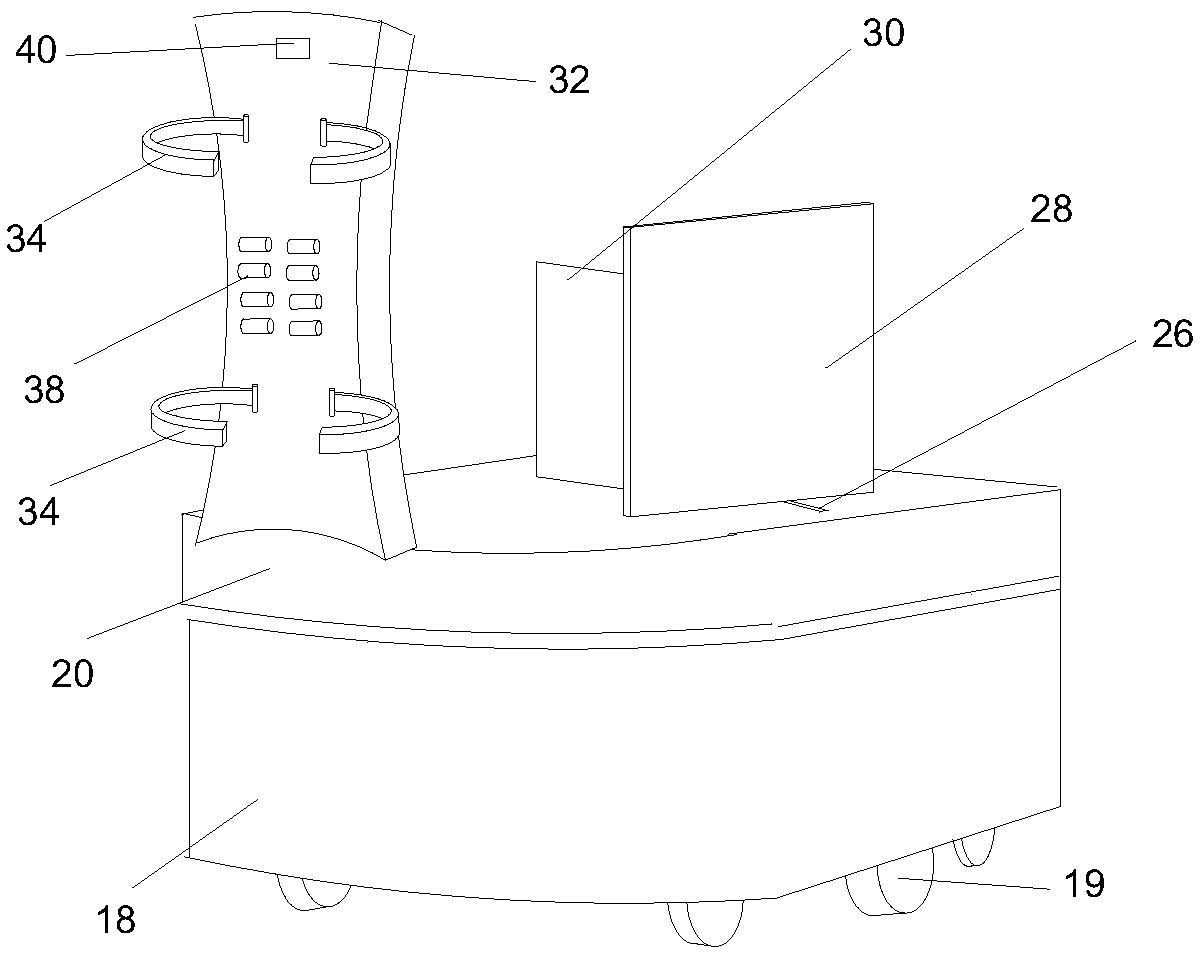

Omni-directional automatic forklift and 3D stereoscopic vision navigating and positioning method

InactiveCN104777835APrecise pick and placeFlexible planningPosition/course control in two dimensionsRadarWorking environment

The invention discloses an omni-directional automatic forklift and a 3D stereoscopic vision navigating and positioning method. The 3D stereoscopic vision navigating and positioning method comprises the following steps: acquiring information of a 3D coordinate in the working environment of the automatic forklift; generating a 3D map; acquiring real-time images and positioning an initial position according to the 3D map; determining a target position; navigating to the target position and judging whether encountering barriers; scanning and identifying two-dimensional codes on a goods shelf; judging whether the automatic forklift is over against the goods and is aligned with the goods; enabling the automatic forklift to insert into a goods shelf tray and completing taking the goods and putting the goods. The omni-directional automatic forklift and the 3D stereoscopic vision navigating and positioning method have the benefits that the 3D map of the working environment is built by a plurality of binocular stereo cameras, the automatic forklift is capable of effectively and accurately positioning, taking the goods and putting the goods with combination of a speedometer, a laser radar and a front camera, three-freedom-degree omni-directional movement on the plane is implemented by Mecanum wheels, the automatic forklift is capable of taking the goods and putting the goods on the same goods shelf without steering, any barriers in the working environment can be effectively avoided in tine by the laser radar and an infrared sensor, and the automatic forklift can be automatically charged by communication between an upper computer and a charging box.

Owner:WUHAN HANDY ROBOTICS TECH

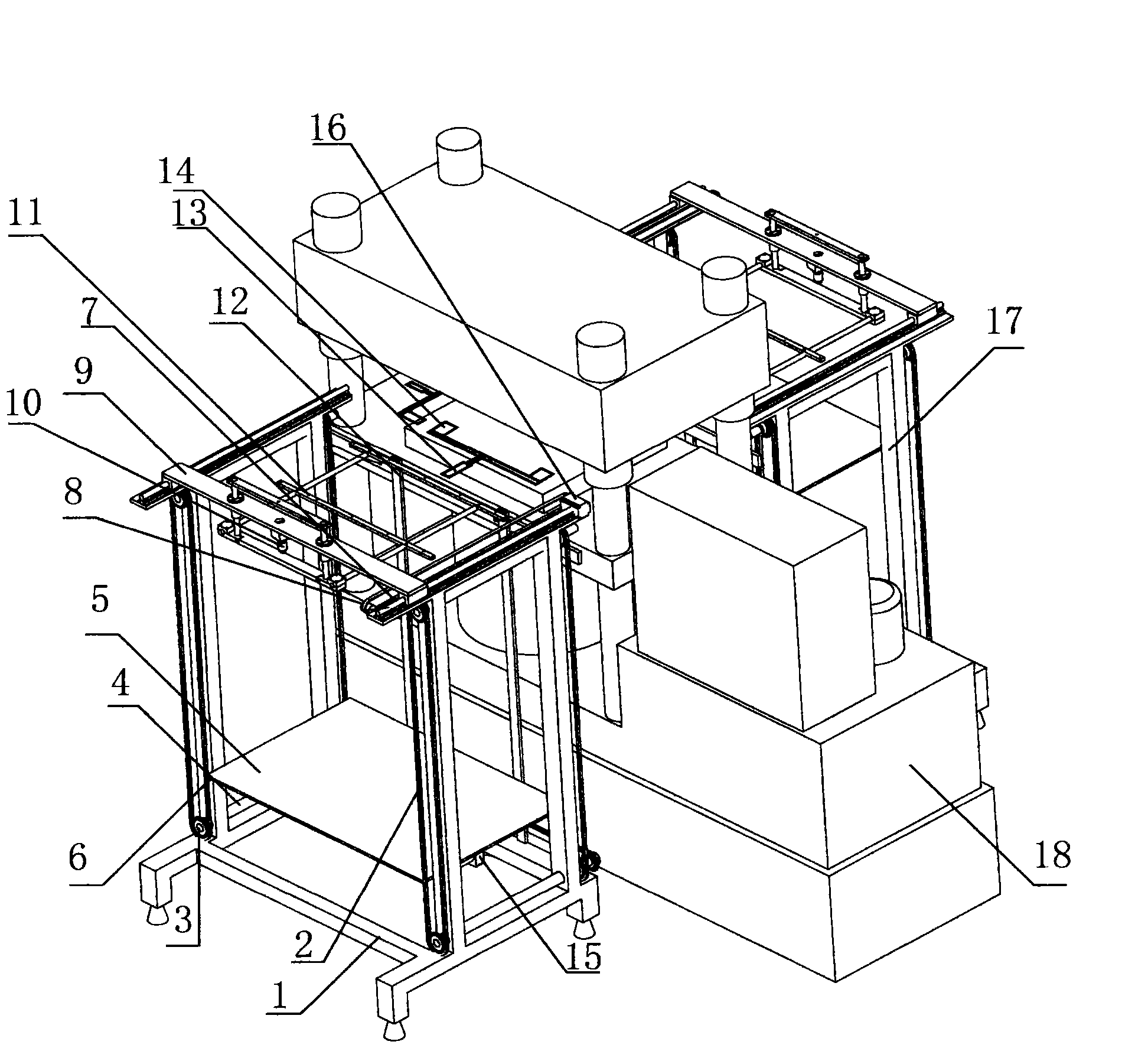

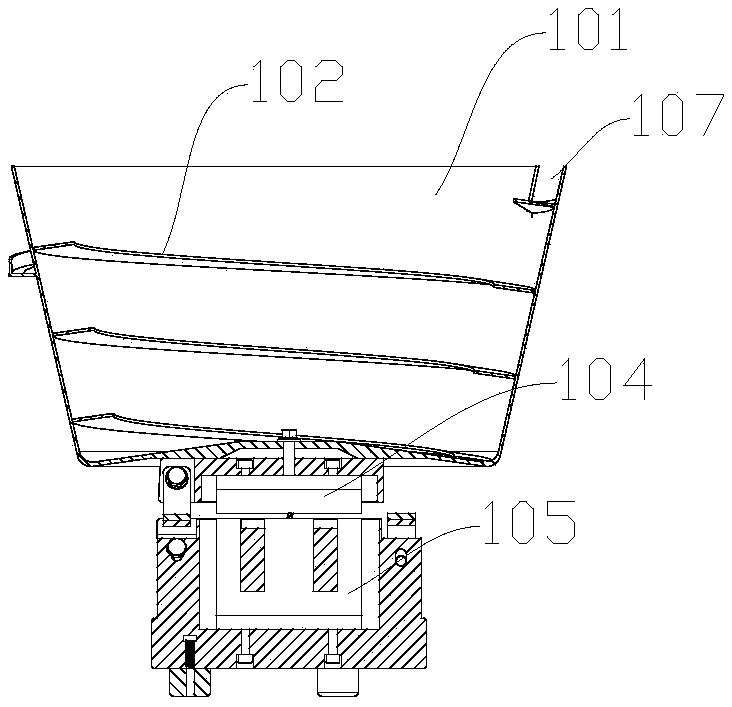

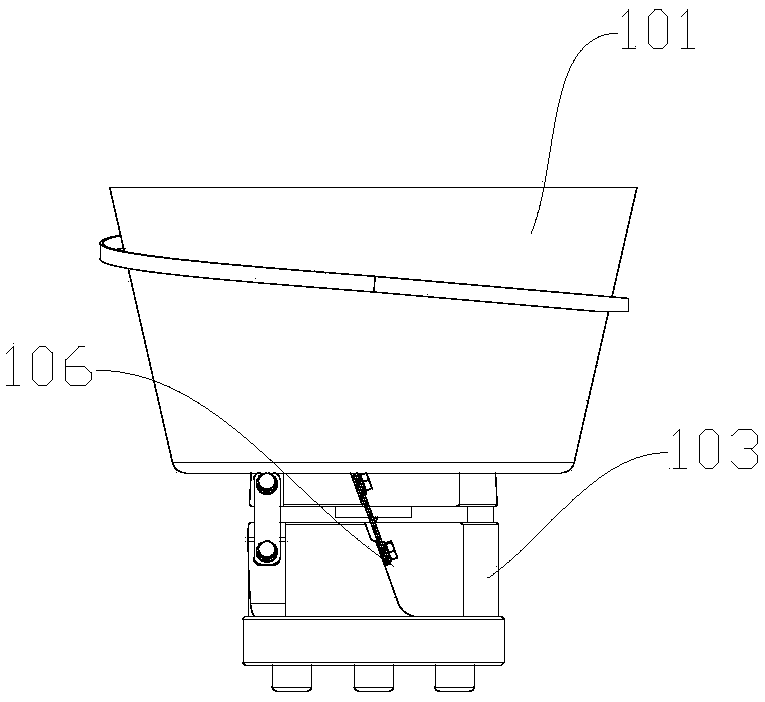

Automatic loading and unloading mechanism of hydraulic machine

The invention relates to an automatic loading and unloading mechanism of a hydraulic machine, wherein a loading stand and an unloading stand are respectively arranged at two sides of the hydraulic machine, an up-down cylinder is arranged at the upper part of the loading stand, a retainer plate is parallel to the middle part of a frame body, and a gear motor is arranged at the lower end of the retainer plate; the upper side of the up-down cylinder is connected with a suction tray frame sliding plate which is connected with a guide rod sliding rail of a frame body at the lateral end in a slidingway and connected with a drag chain in series; and a suction tray is respectively arranged at the rear side of the up-down cylinder and the frame body thereof. In the invention, the material productto be processes just needs to be put on the retainer plate at will and is conveyed into the hydraulic machine under the control of a power switch of a pneumatic motor and an induction switch of a stepping motor by adopting a way of synchronously and translationally loading and unloading by the automatic ascending and descending matching of the retainer plate, and the product to be processed is moved to a specific position by a guiding device, thereby the product can be put in and taken out quickly and accurately; and the invention has the unmatched advantages any conveying machines or mechanical arms can not reach, can effectively avoid potential safety hazards and improves the production efficiency in the packaging process of paper boxes.

Owner:林定亮

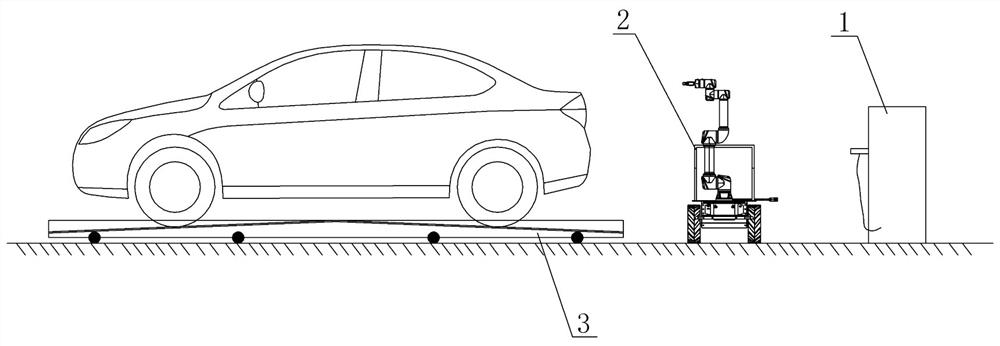

Intelligent charging device for electric automobile

PendingCN111619388APrecise pick and placeAccurate insertionCharging stationsElectric vehicle charging technologyRobot handControl system

An intelligent charging device for an electric automobile is provided with a charging pile, a parking frame used for parking the automobile and a movable robot, and a control system, a vision system,a positioning system, a camera and a plurality of sensors are installed on the robot. After the automobile is parked in the parking frame, the robot moves to the charging pile, takes out the charginggun by utilizing a manipulator mounted on the robot, and then drives the charging gun to be inserted into an automobile charging port; in the charging process of the automobile, the robot can leave and provide services for other automobiles; and after the automobile is charged, the robot moves to the automobile again, takes out the charging gun and puts the charging gun back to the charging pile.According to the intelligent charging device for the electric vehicle, the arrangement convenience and utilization rate of the charging pile and the parking frame can be improved; meanwhile, the adjusting mechanism is arranged on the parking frame and used for adjusting the position of the automobile so as to be matched with the robot, the working accuracy can be improved, the use requirements ofvarious automobiles can be met, and therefore the application range of the charging device is widened.

Owner:孙旭阳

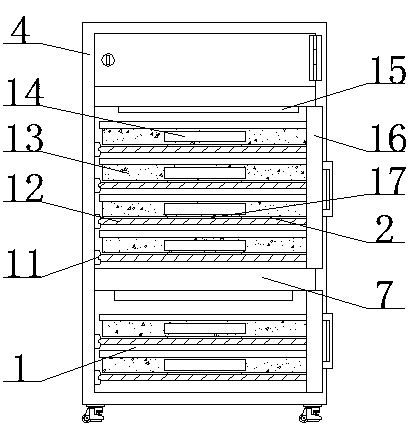

A drug access system

ActiveCN102259744AImprove efficiency and accuracyEasy to assemble and repairStorage devicesDrug accessBiomedical engineering

The invention relates to a medicine access system for hospitals, in particular to a medicine workstation of medicines and consumables in operating rooms. The medicine access system can be used for realizing automatic medicine access registration and effective data tracking; in addition, based on the design of a single access door, all drawers, medicine boxes and internal equipment can be maintained and changed only after a rear cabinet door is opened, moreover the cabinet door has a function of state memory and can record the open state of the cabinet without being electrified, therefore the safety of medicine and equipment management and convenience of equipment maintenance can be improved.

Owner:HUAXING RONGTAI

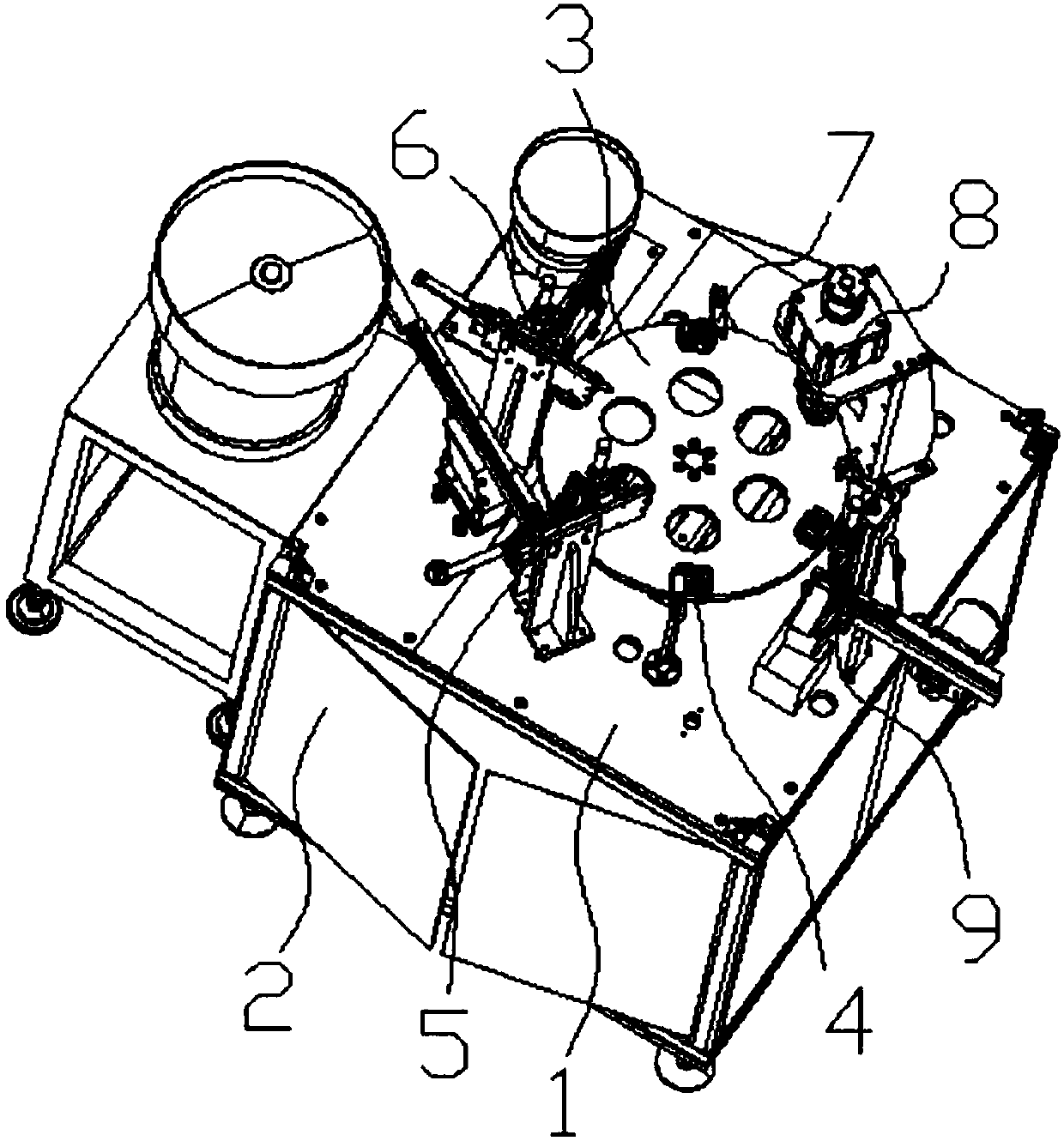

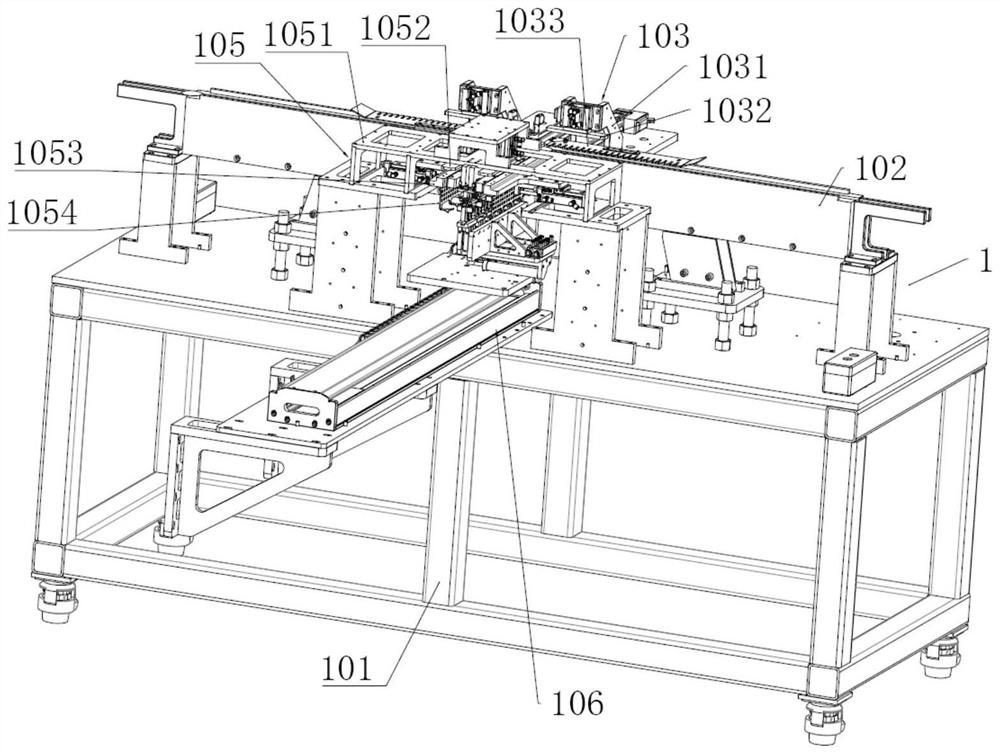

Continuous automatic assembly machine of lug plate elastic piece

ActiveCN107553107AGuaranteed accuracyAvoid elastic deformationMetal working apparatusDistribution controlButt joint

The invention relates to a continuous automatic assembly machine of a lug plate elastic piece. The continuous automatic assembly machine comprises a rack, a power distribution control box, a rotary disc and carriers. A lug plate feeding mechanism, an elastic piece feeding mechanism, a press-fitting mechanism and a discharging mechanism are arranged on the rack. Each carrier comprises a carried material mounting seat embedded into the rotary disc. A carried material seat lifting block penetrating the rotary disc is arranged in each carried material mounting seat. A vertical carried material seat composite spring is arranged between each carried material seat lifting block and the lower portion of the corresponding carried material mounting seat. A carried material seat cooperating with a product is arranged above each carried material seat lifting block. A press-fitting device comprises a press-down device cooperating with the products on the carriers and a carried material seat jackingdevice which is located below the press-down device and cooperates with the carried material seat lifting blocks. According to the continuous automatic assembly machine, the carried material seat lifting blocks and the press-down device can be in butt joint precisely, meanwhile, pressing assembly of a lock piece and a lug plate can be achieved, it can be ensured that the press-down portion is a flat plate between two elastic piece mounting columns, the press-fitting precision is ensured, elastic deformation of the elastic pieces is avoided, and meanwhile continuous automatic machining is achieved.

Owner:CHONGQING TECH & BUSINESS UNIV

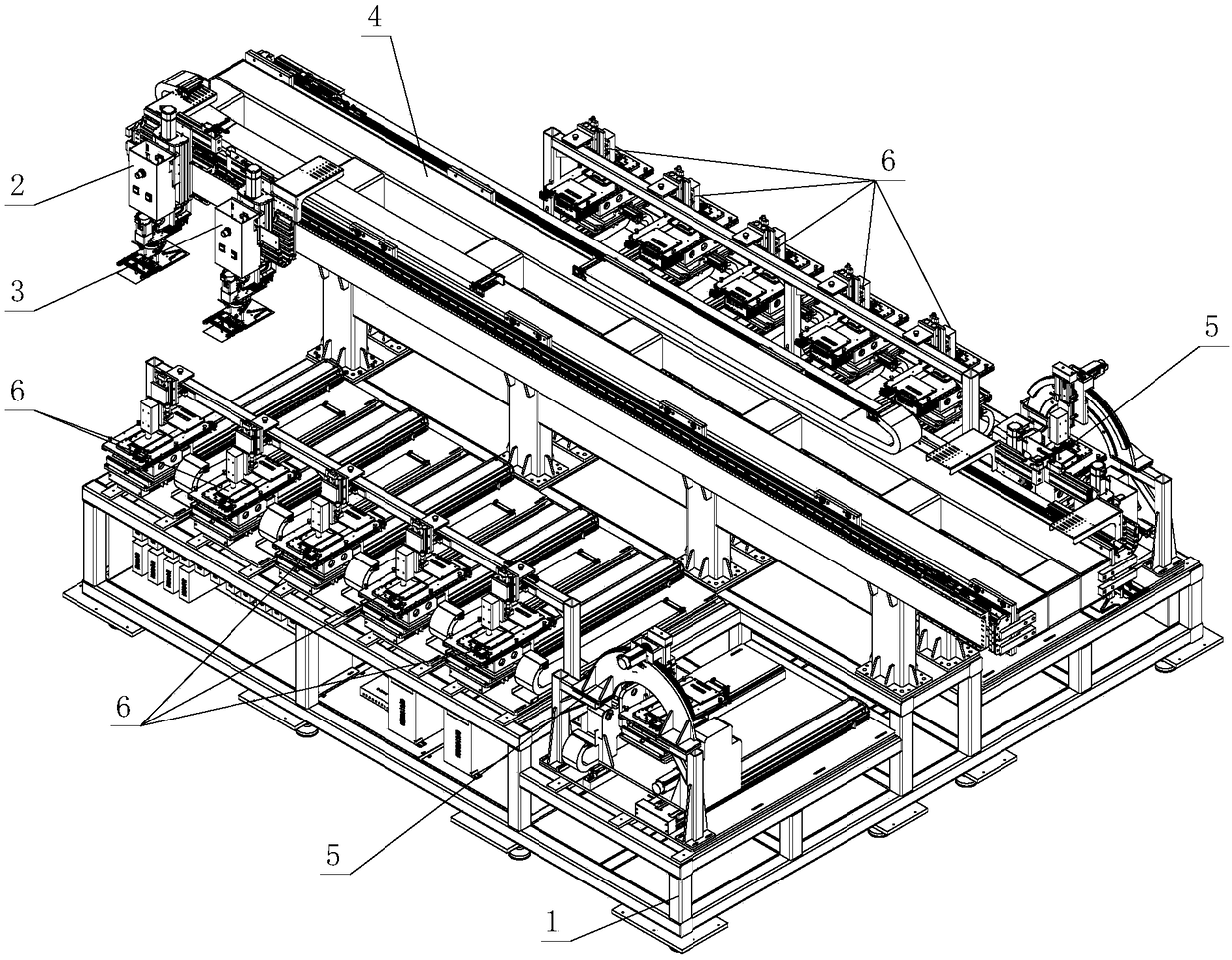

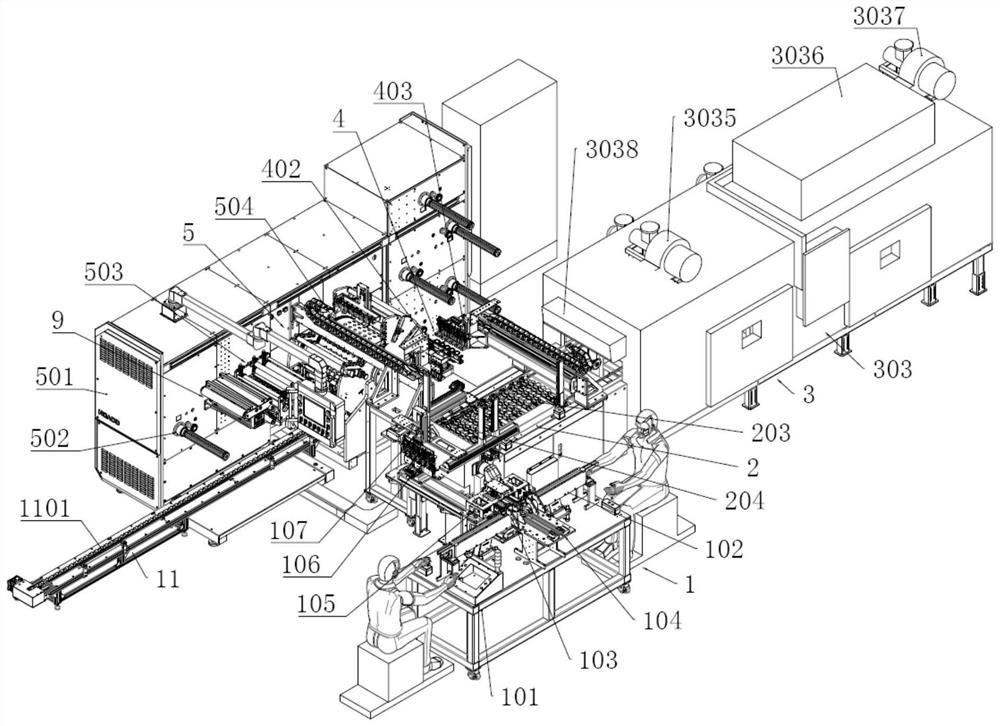

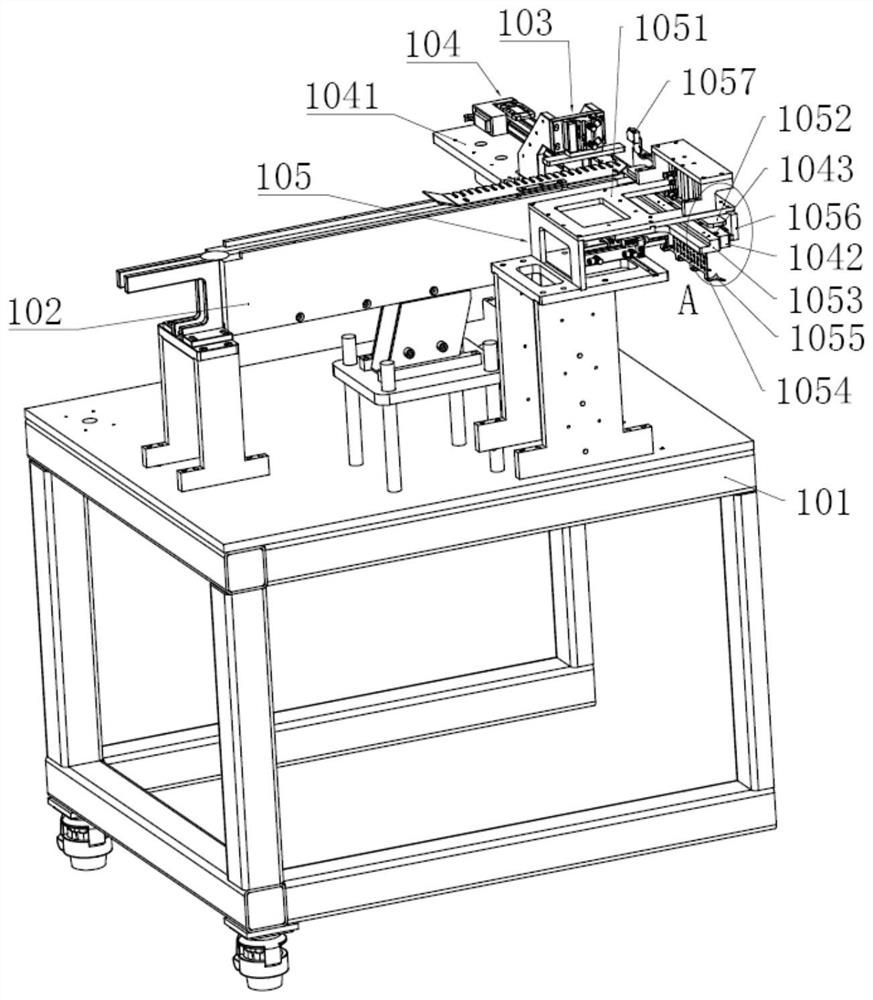

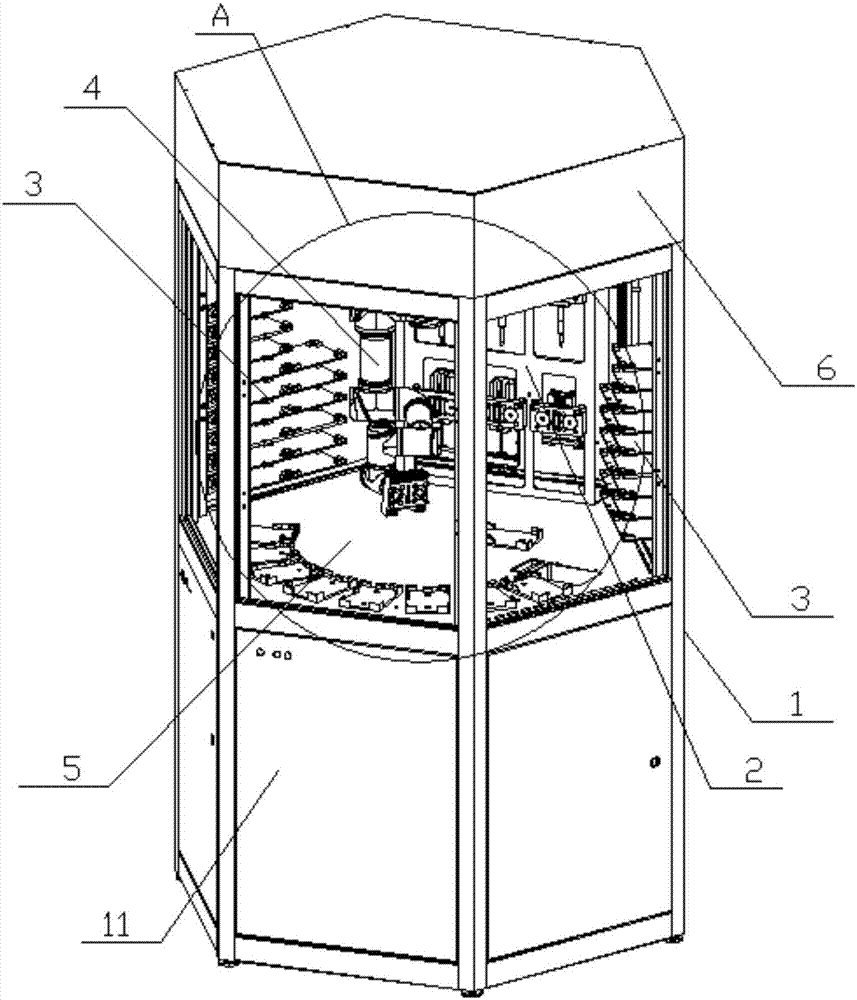

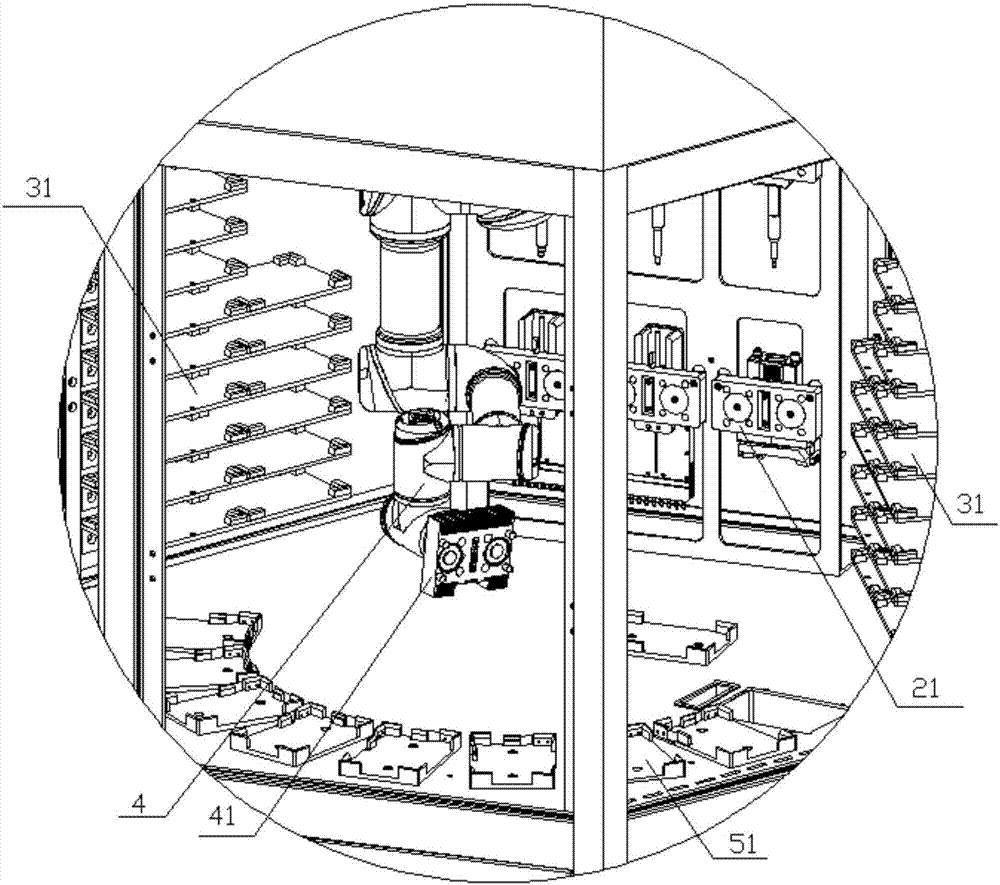

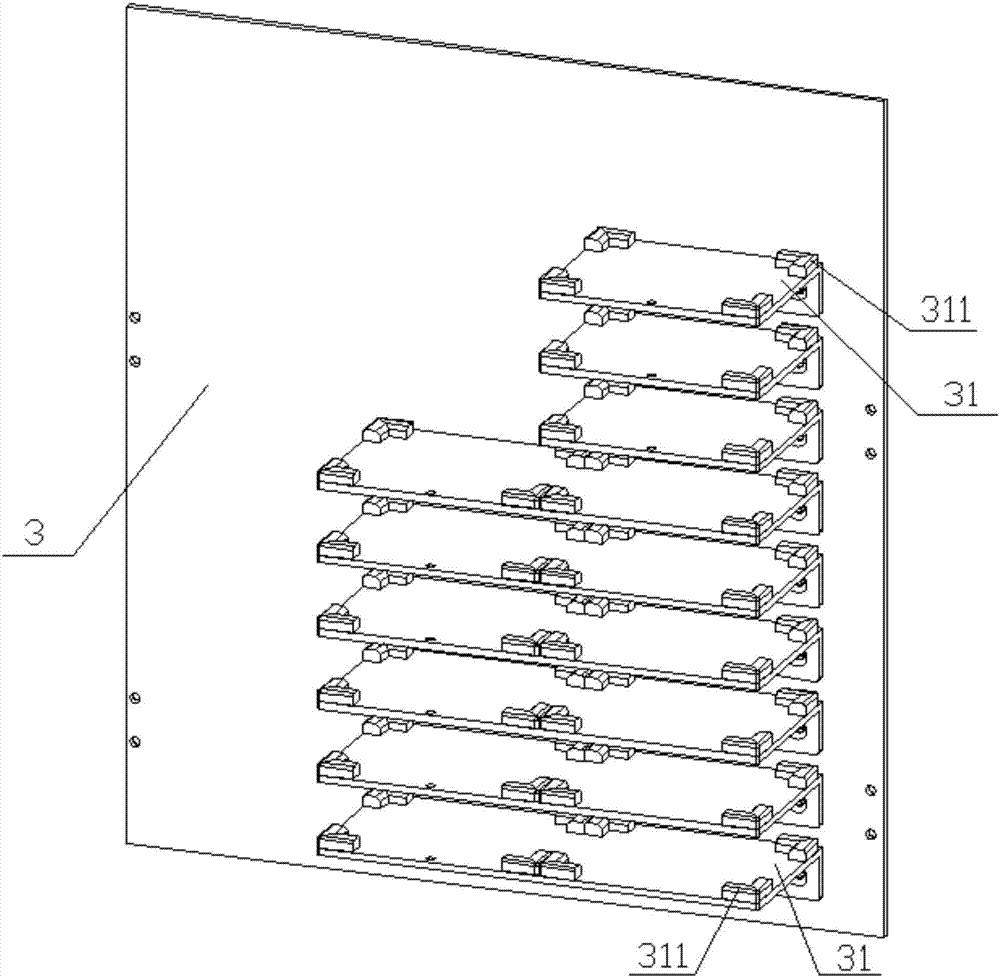

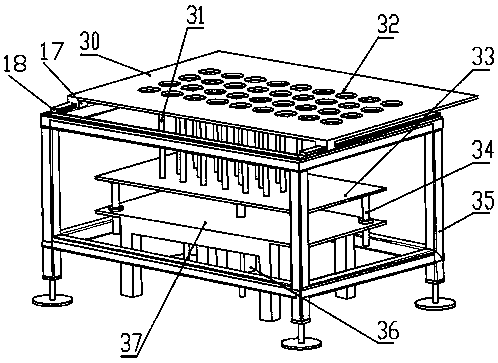

Automatic display panel Gamma detection platform

PendingCN108761868AReasonable layoutImprove detection efficiencyNon-linear opticsEngineeringSurface plate

The invention relates to the technical field of display panel detection techniques and in particular relates to an automatic display panel Gamma detection platform which comprises a machine body, a transferring device, Gamma burning detection devices, Gamma casual inspection devices, a taking device and a discharge device, wherein the transferring device is arranged in the middle of the machine body; the Gamma burning detection devices and the Gamma casual inspection devices are arranged in a straight line arrangement manner on both sides of the machine body; a display panel to be detected isplaced on the Gamma burning detection devices or the Gamma casual inspection devices for detection through the taking device; the detected display panel is taken down from the Gamma burning detectiondevices or the Gamma casual inspection devices through the discharge device and is placed on a downstream working table. The whole detection platform is reasonable in arrangement and high in detectionefficiency, the Gamma casual inspection devices have functions of automatic and manual modes, a casual inspection function can be achieved while the display panel is detected, and relatively accuratedetection results can be achieved.

Owner:WUHAN JINGCE ELECTRONICS GRP CO LTD

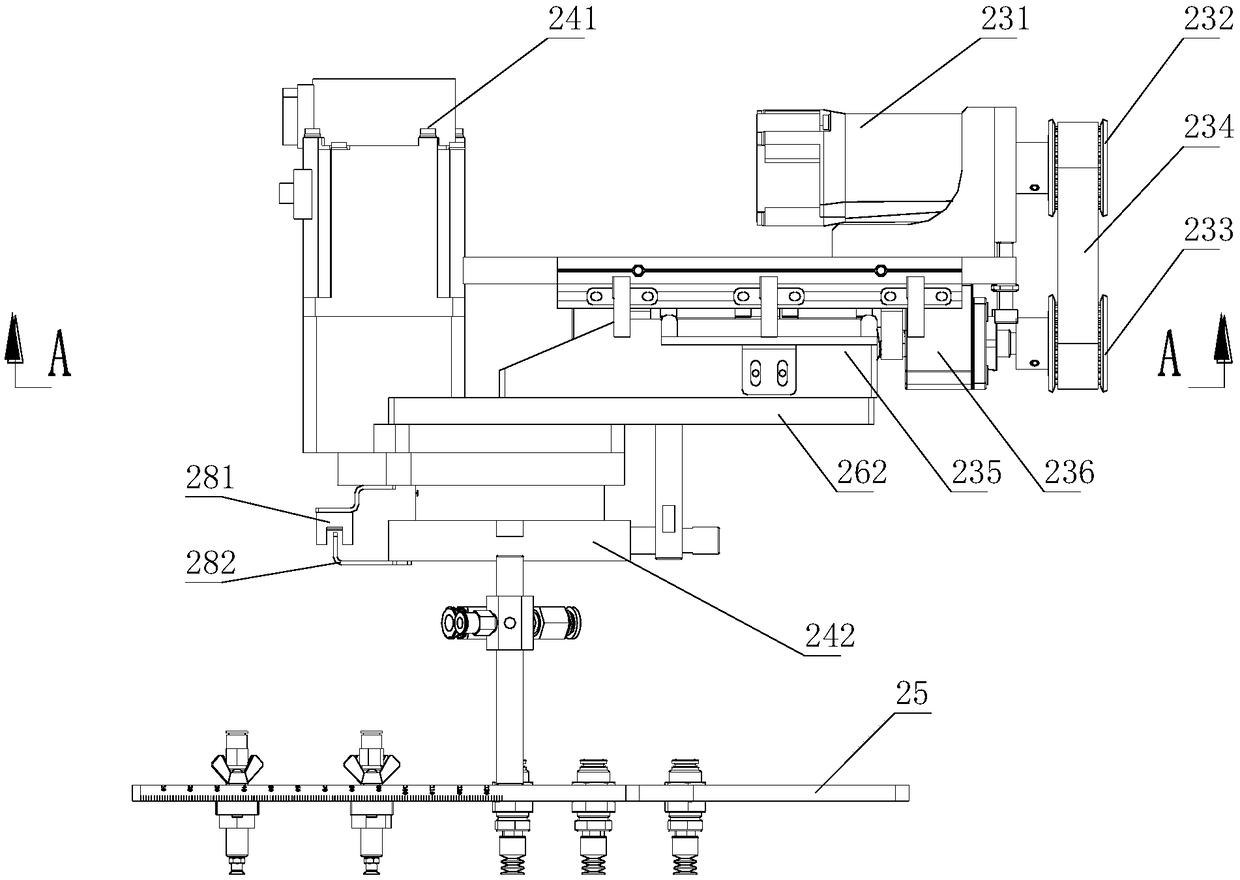

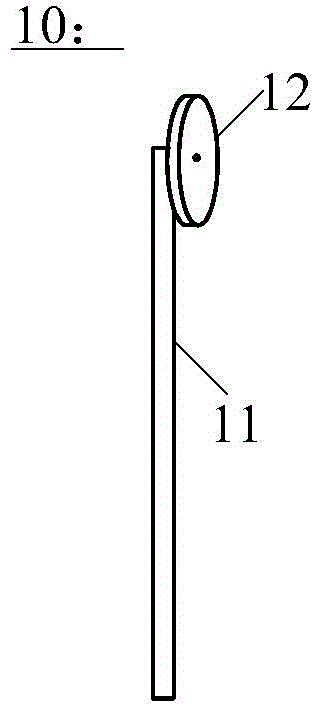

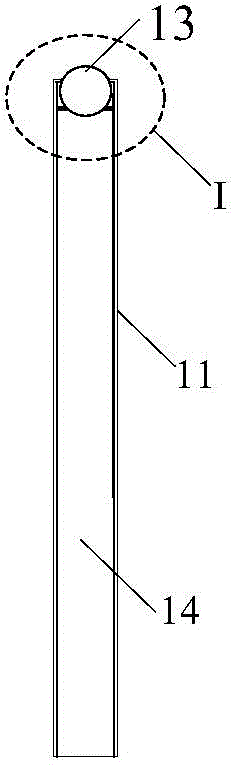

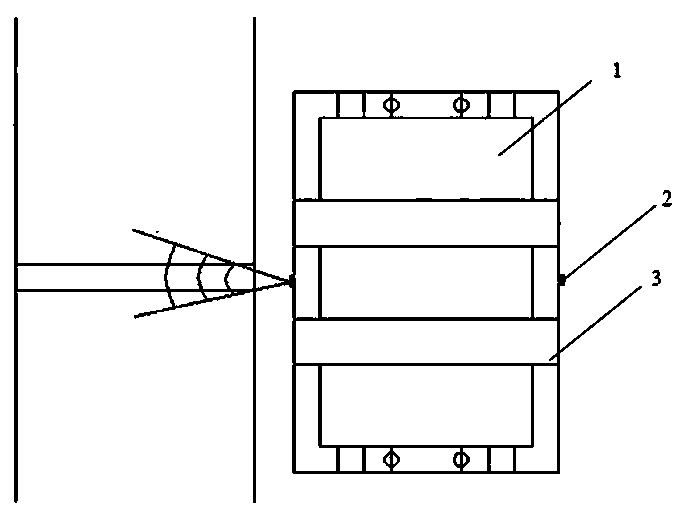

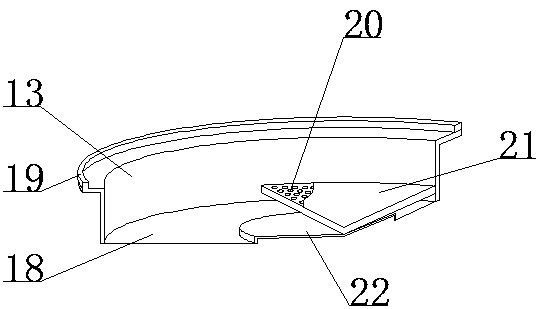

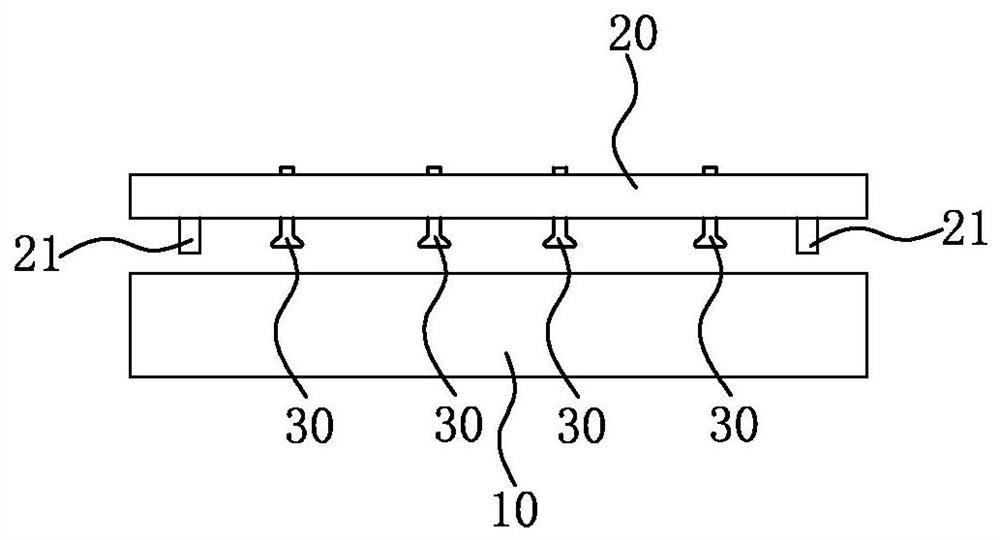

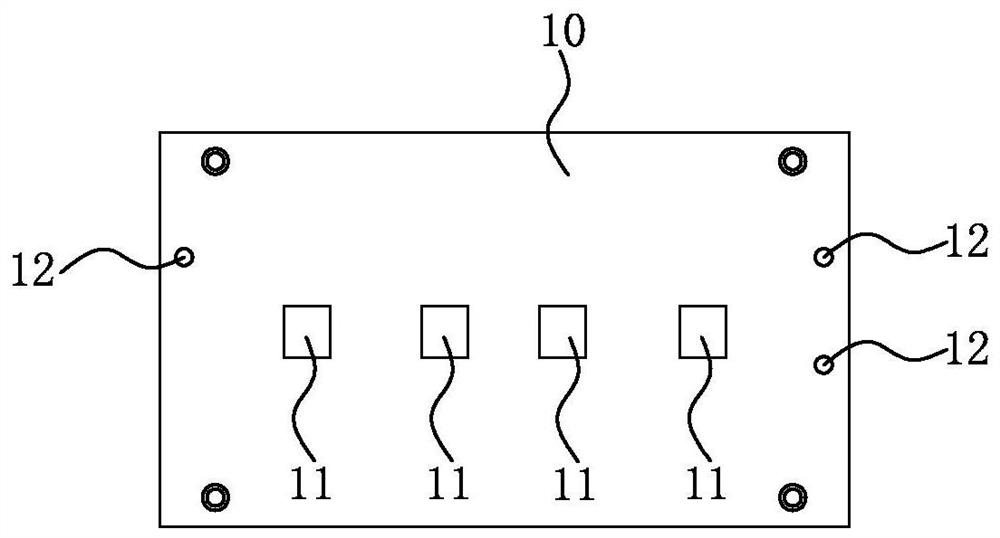

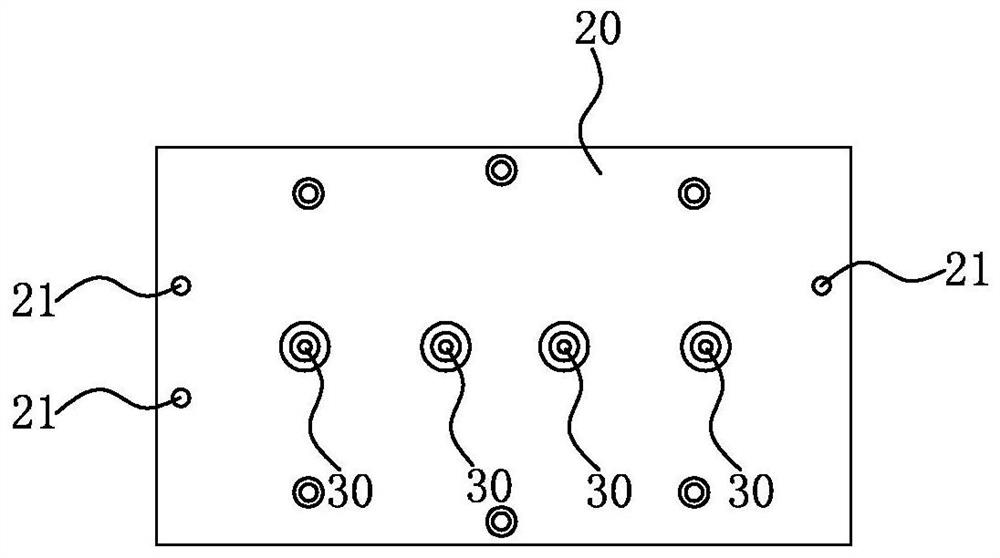

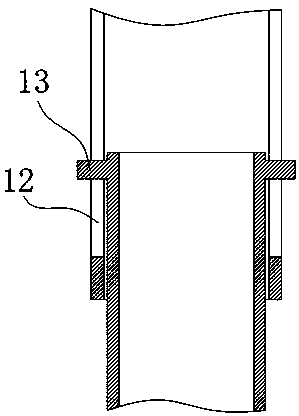

Substrate supporting needle, substrate supporting device and substrate picking and placing system

ActiveCN104658959APrecise pick and placeAvoid damageSemiconductor/solid-state device manufacturingState of artEngineering

The invention provides a substrate supporting needle, a substrate supporting device and a substrate picking and placing system, wherein the substrate supporting needle is used for supporting a substrate and comprises a rod body; and a rotating piece is arranged at the supporting end of the rod body and can roll along the surface of the substrate. Compared with the prior art, the substrate supporting needle, the substrate supporting device and the substrate picking and placing system have the advantage that the damage to the substrate can be reduced.

Owner:HEFEI BOE OPTOELECTRONICS TECH +1

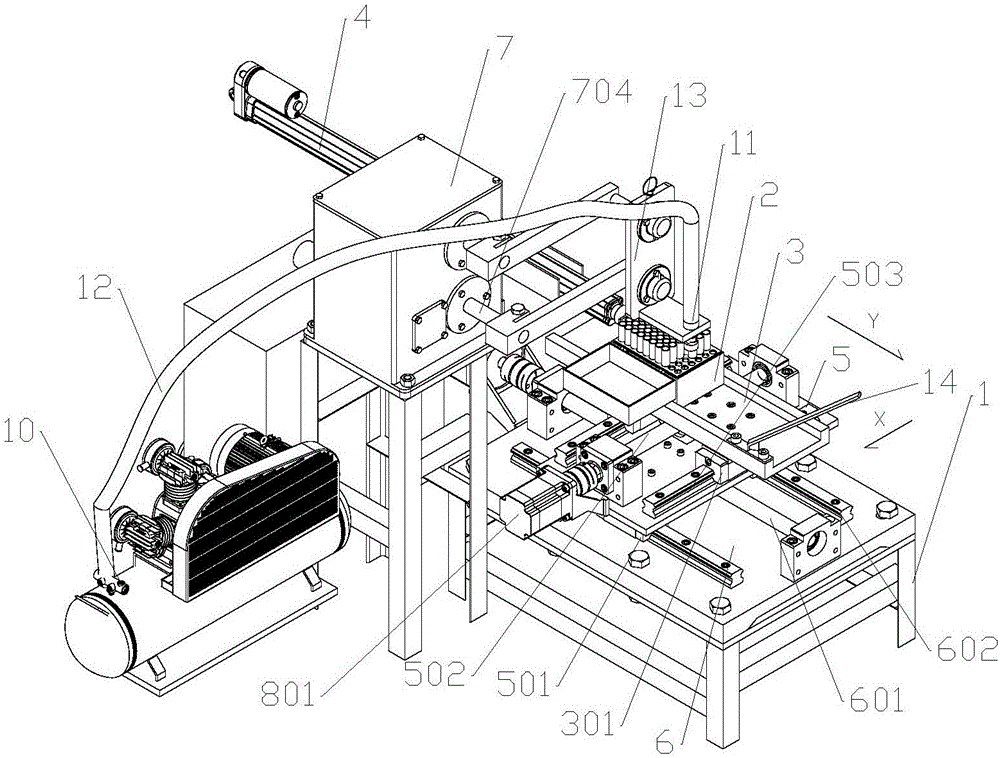

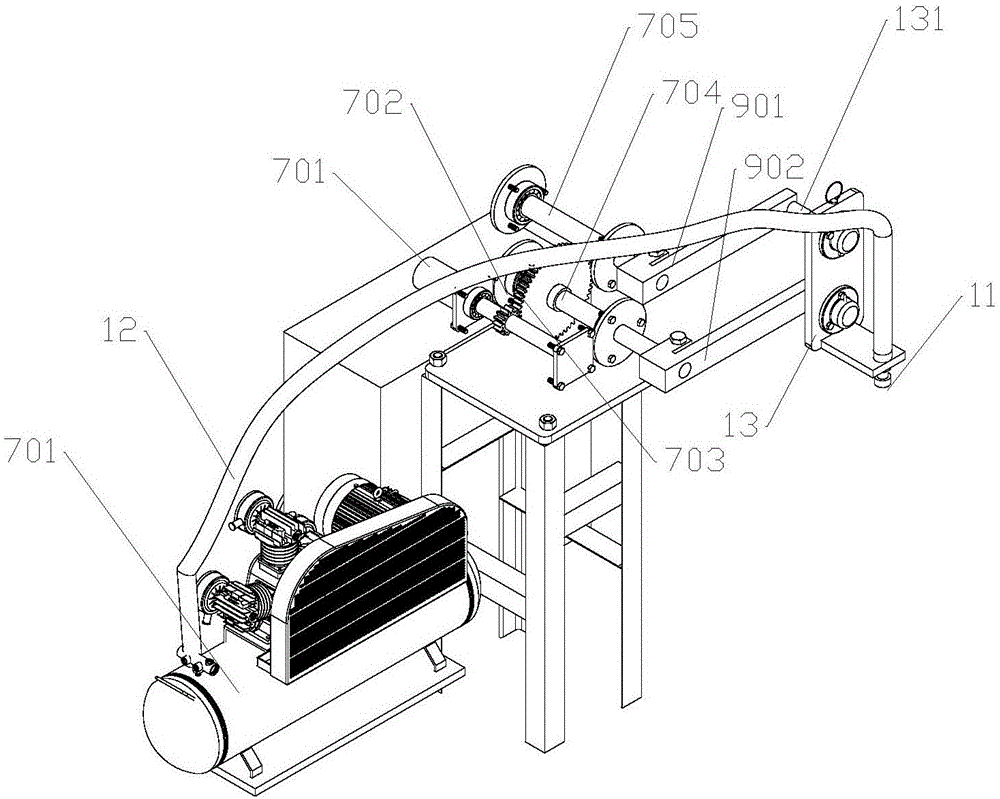

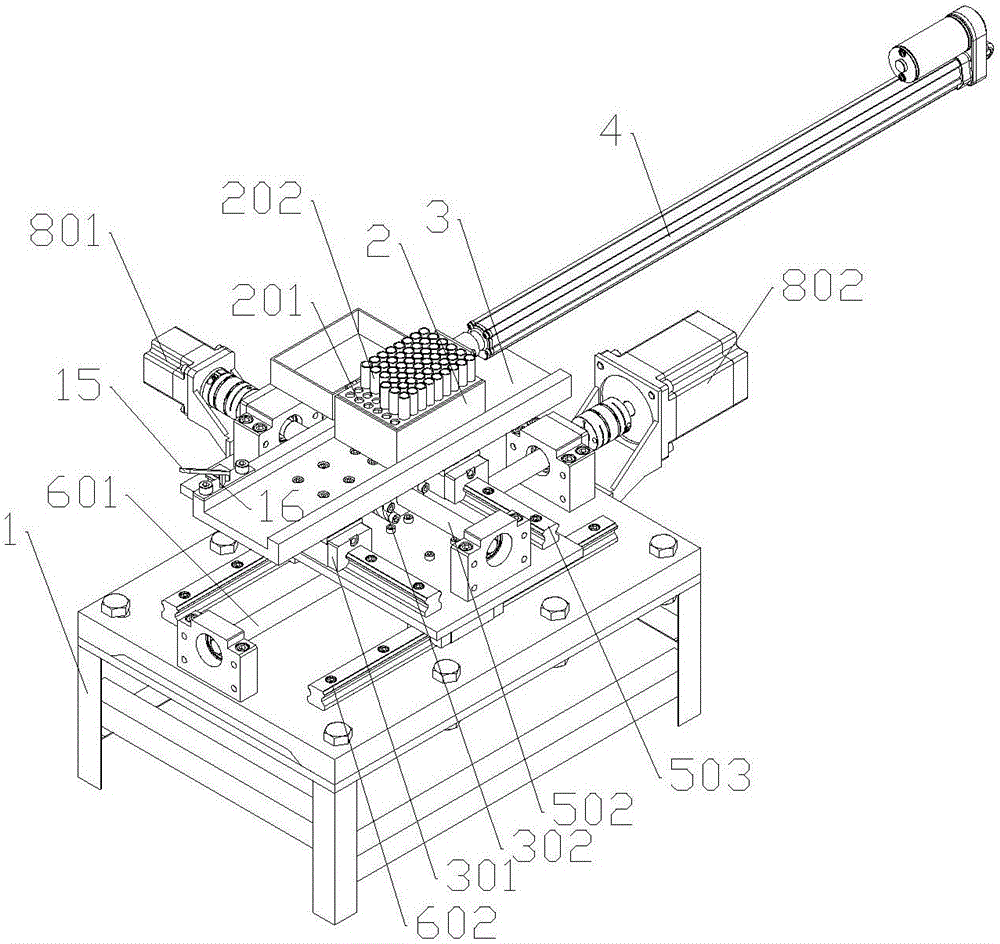

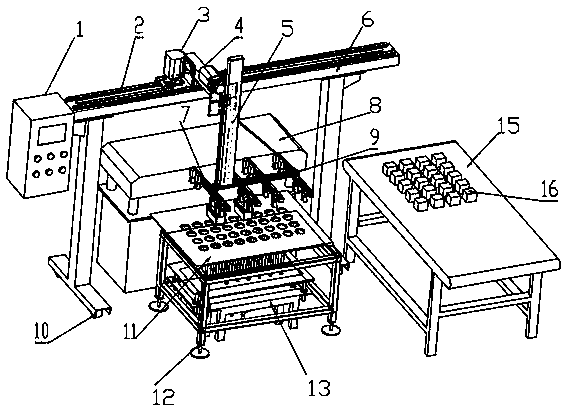

Box packing system of liquid transfer gun head

The invention provides a box packing system of a liquid transfer gun head. The box packing system of the liquid transfer gun head comprises a box packing mechanism, and a conveying mechanism for conveying the liquid transfer gun head. The box packing mechanism comprises a gun head fetching mechanism, a gun head box platform, an electric push rod, and a horizontal workbench used for carrying the gun head box platform and capable of driving the gun head box platform to move in two vertical directions. The gun head fetching mechanism comprises a gun head acquiring device and a control mechanism. A cover buckling mechanism for buckling a box cover is arranged at the end, away from the electric push rod, of the edge of the gun head box platform. The cover buckling mechanism comprises a cover buckling strip installed on a work platform, and the cover buckling strip is inclined towards the inner side and the upper portion of the gun head box platform in the pushed direction of a gun head box. The liquid transfer gun head box packing complete flow operation of fetching the liquid transfer gun head, placing the liquid transfer gun head and automatically buckling the box cover of the gun head box after the liquid transfer gun head is subjected to box packing can be completed. In the integrated box packing process, manual intervention is not needed, and the box packing efficiency of the liquid transfer gun head can be improved.

Owner:QINGDAO AGRI UNIV

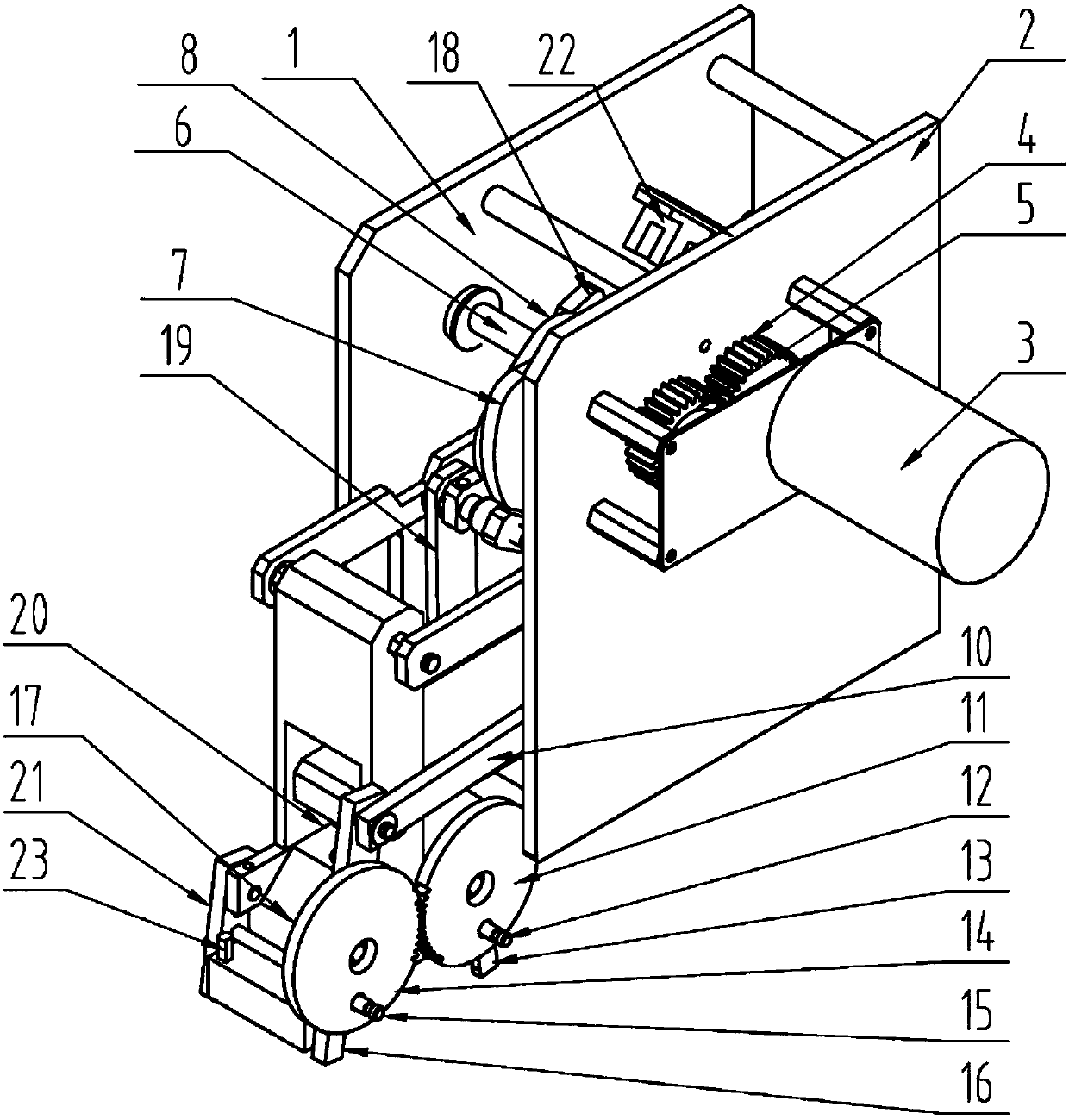

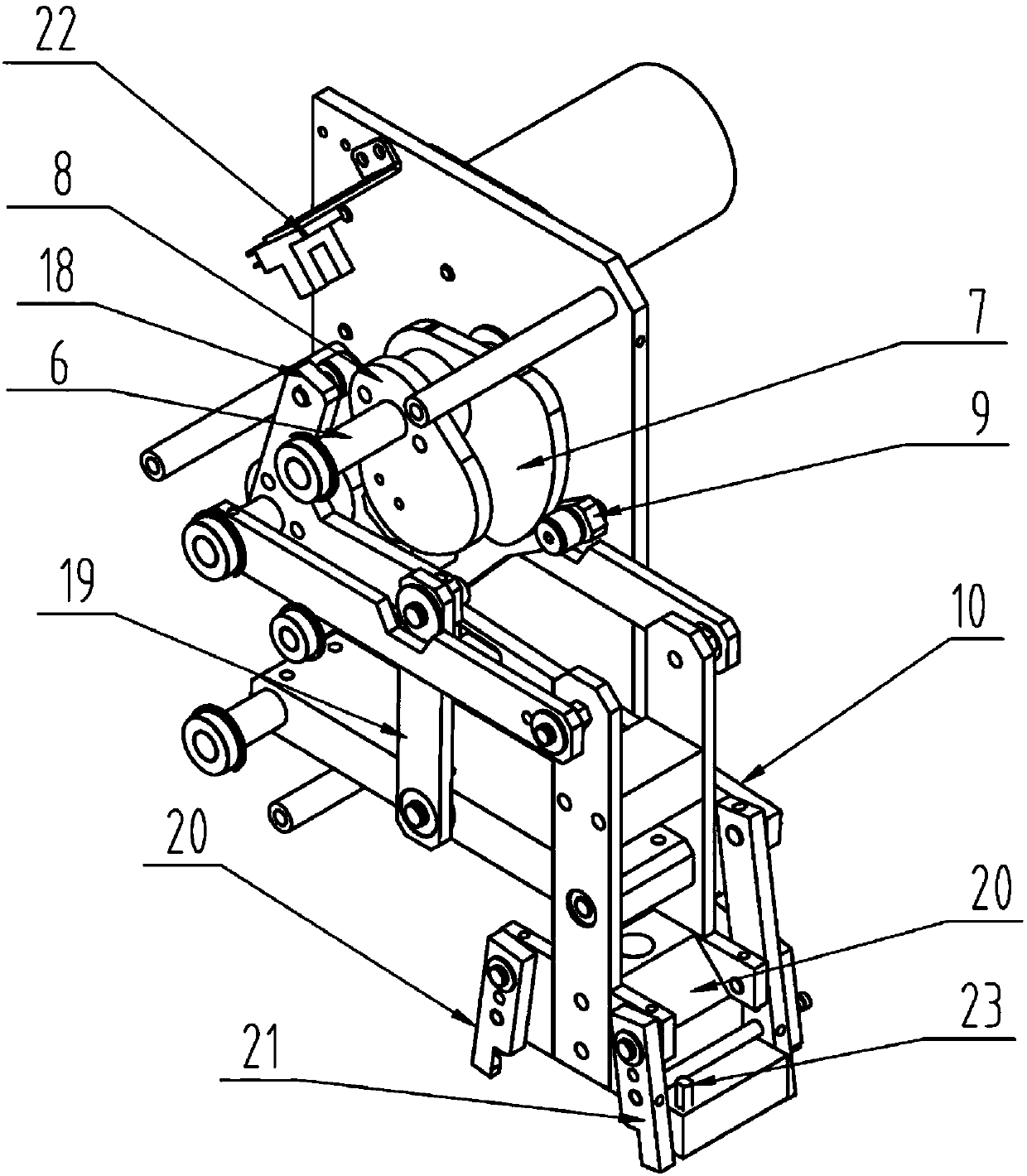

Moving device of tube gripper of spinning machine

ActiveCN101864628AMeet the needs of the production siteFlexible translationTextiles and paperYarnTextile mill

The invention relates to a moving device of a tube gripper of a spinning machine, which comprises a riser, a supporting plate, a cylinder seat, a cylinder, a push plate, an aluminum tube seat, a yarn holder, the tube gripper, a rolling linear guide rail pair, a support, a long connecting rod, a short connecting rod and a hanger. The rolling linear guide rail pair is arranged on the supporting plate, the aluminum tube seat is arranged on a slide block of the rolling linear guide rail pair, the yarn holder is fixed on the aluminum tube seat, the tube gripper is arranged on the yarn holder, the support is rotationally connected with one end of the long connecting rod, the middle part of the long connecting rod is rotationally connected with one end of the short connecting rod, the other end of the short connecting rod is rotationally connected on the hanger, the other end of the long connecting rod is glidingly connected in the hanger, and the hanger is fixedly connected on a wall board in the spinning machine. A connecting point of the support and the long connecting rod and a connecting point of the short connecting rod and the hanger are on the same vertical line. By using the technical scheme of the invention, the moving device has the advantages of simple operation, flexible translation, accurate tube gripping and placement and small occupied space, and fully meets the requirement of a textile mill production site.

Owner:NANTONG JINCHI MECHANICAL ELECTRIC

Plunger paste production line and production process

ActiveCN113955395AEasy to transportEasy to dipLiquid surface applicatorsConveyorsMaterial transferIndustrial engineering

The invention relates to the technical field of plunger paste production, and provides a plunger paste production line and a production process. The plunger paste production line comprises a rotary conveying device, the rotary conveying device is connected with a gum dipping and drying device, the gum dipping and drying device is connected with a material transferring device, and the material transferring device is connected with a plunger paste assembling device; the rotary conveying device comprises a rotary conveying frame, a rotary chain and a positioning jig; the gum dipping and drying device comprises a gum dipping mechanism, a gum homogenizing mechanism and a drying box body; the material transferring device comprises a material transfer table, a material transfer mechanism and a material taking and placing mechanism; and the plunger paste assembling device comprises an assembling frame, and an axial adjusting type material shaft, a slotting assembly, a satellite type rotating assembly, a finished product taking mechanism and a multi-action material moving mechanism are arranged on the assembling frame. The production process of automatic feeding of plunger paste semi-finished products, gum dipping, drying, transferring, plunger paste assembling and attaching, and automatic discharging and collection of finished plunger paste in the plunger paste production process is achieved, and the plunger paste production efficiency is greatly improved.

Owner:SHANDONG HOACO AUTOMATION TECH

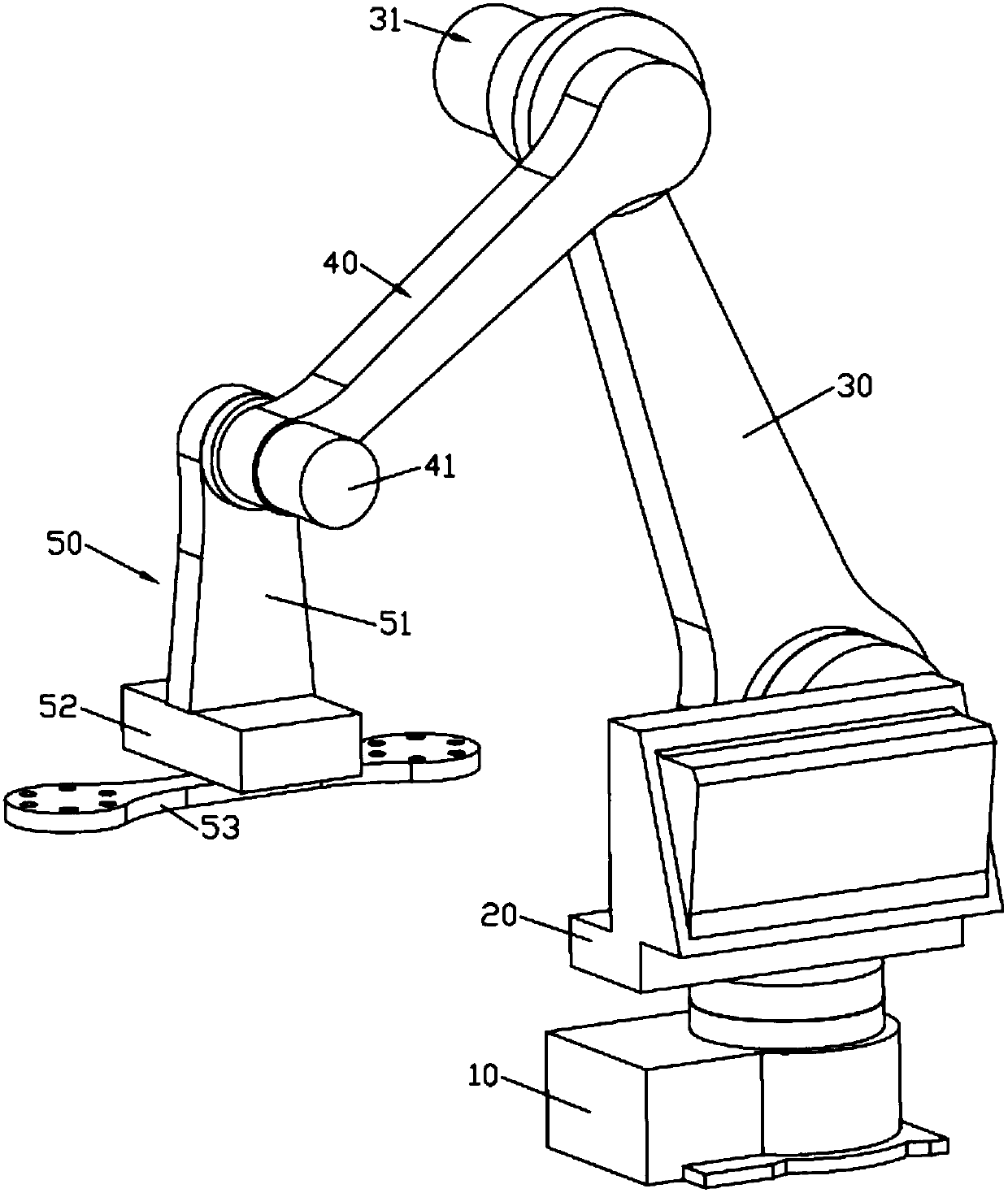

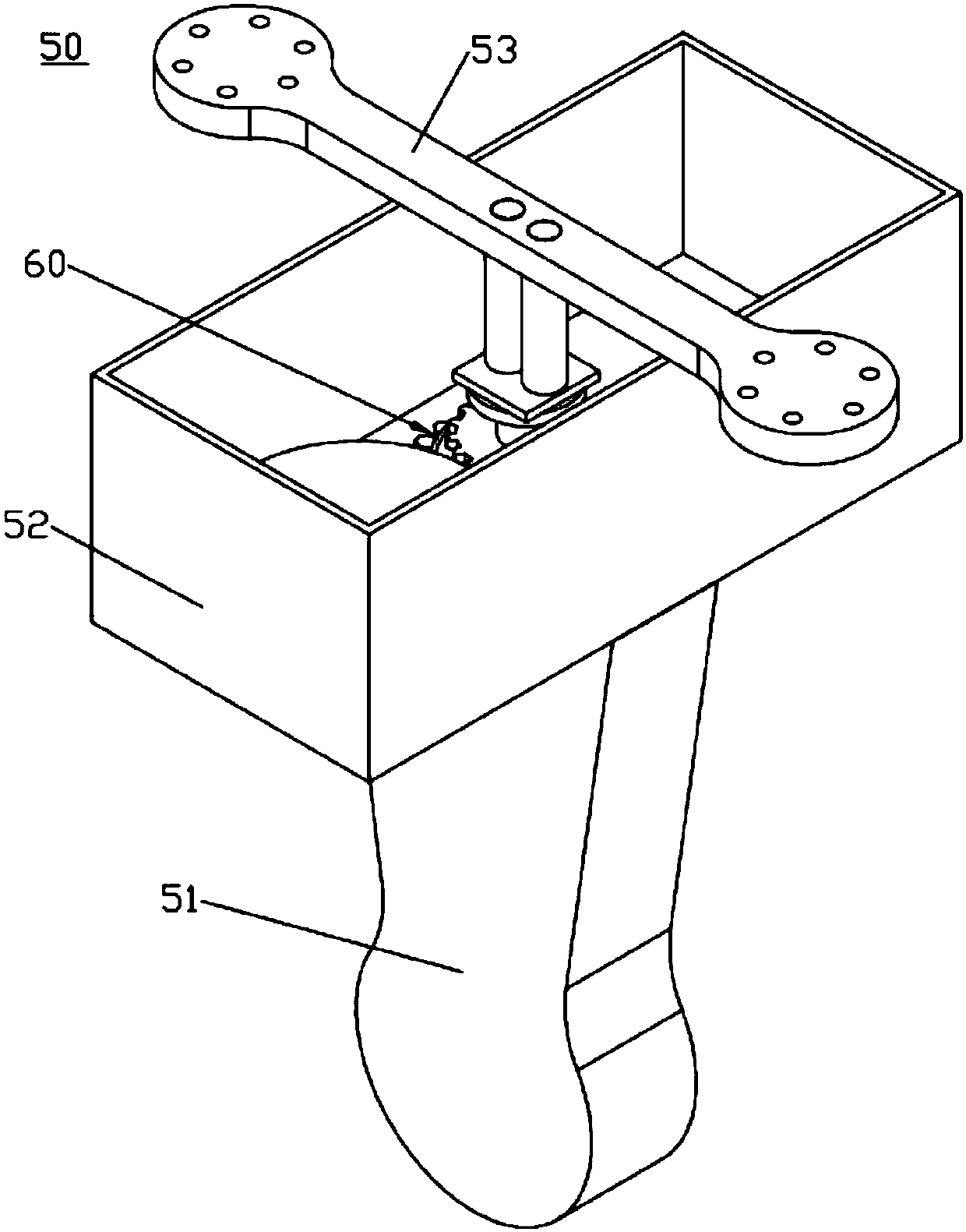

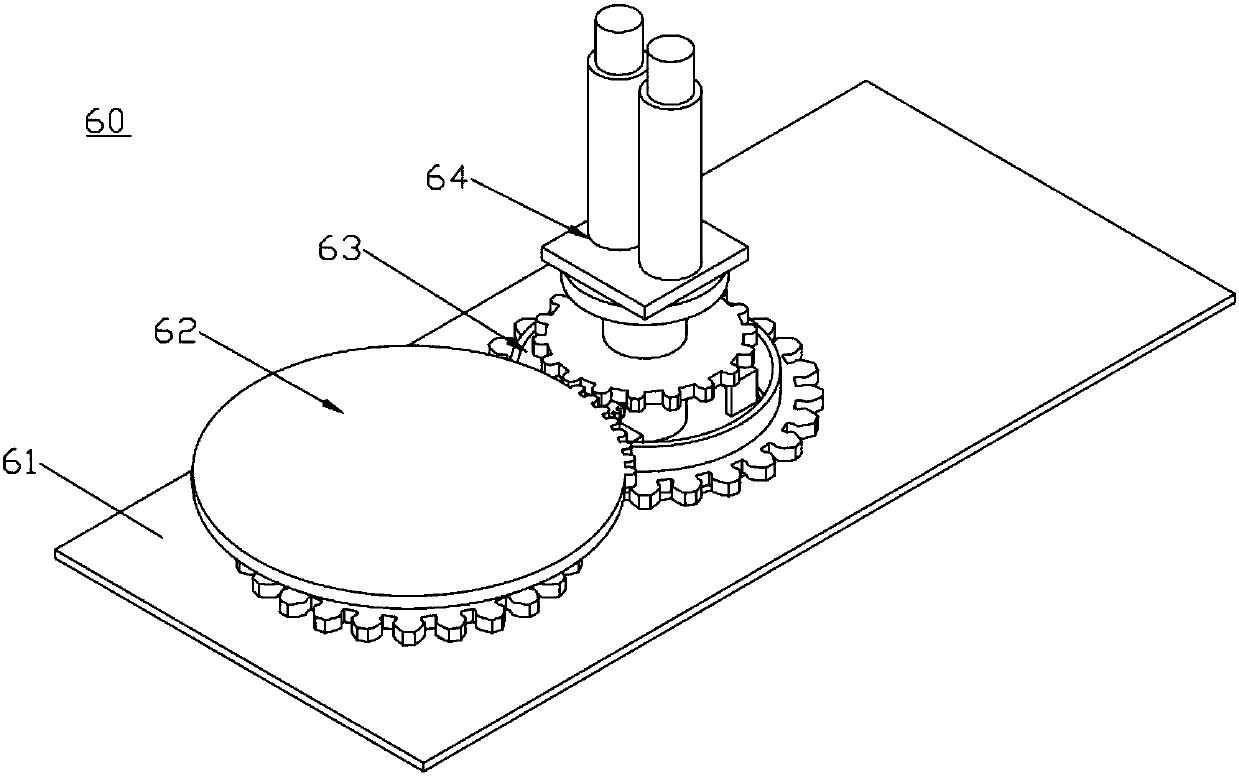

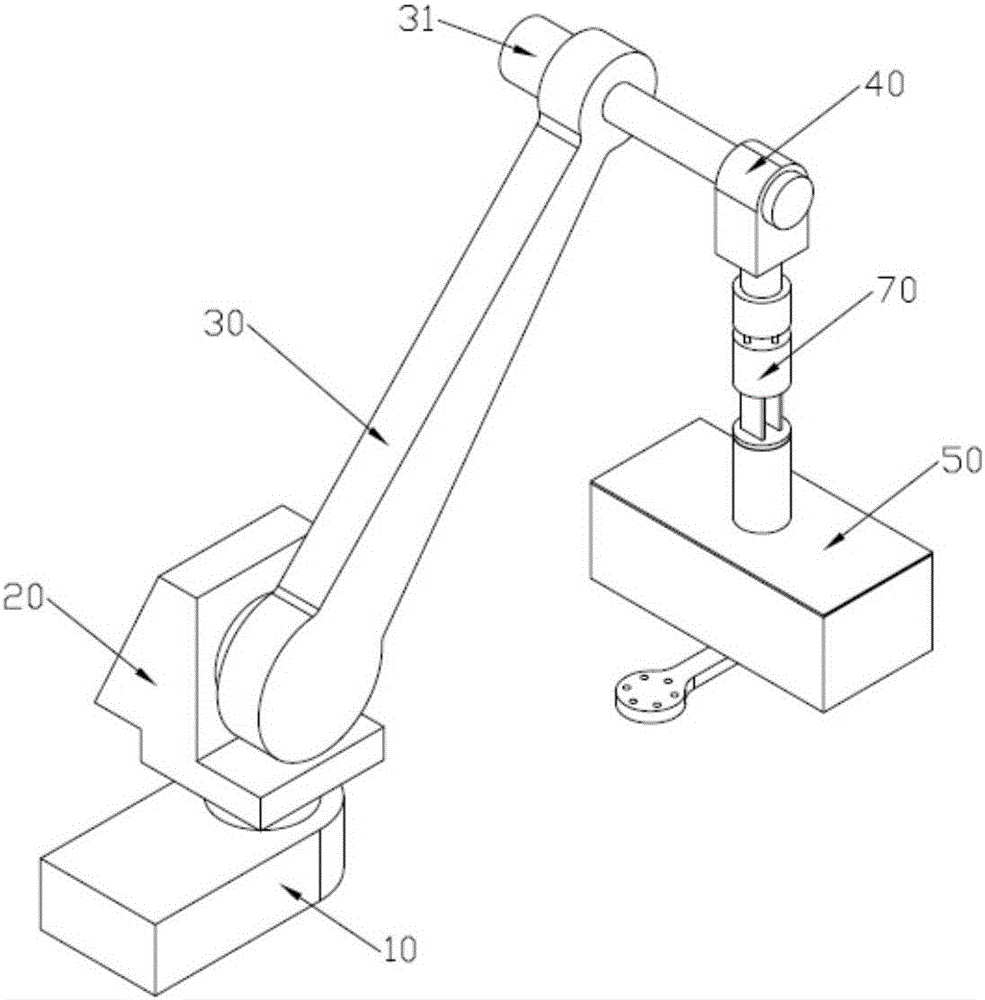

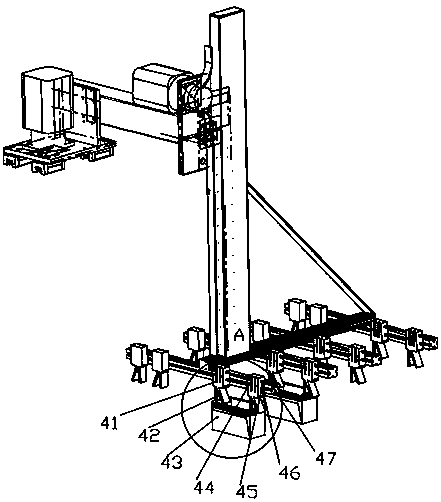

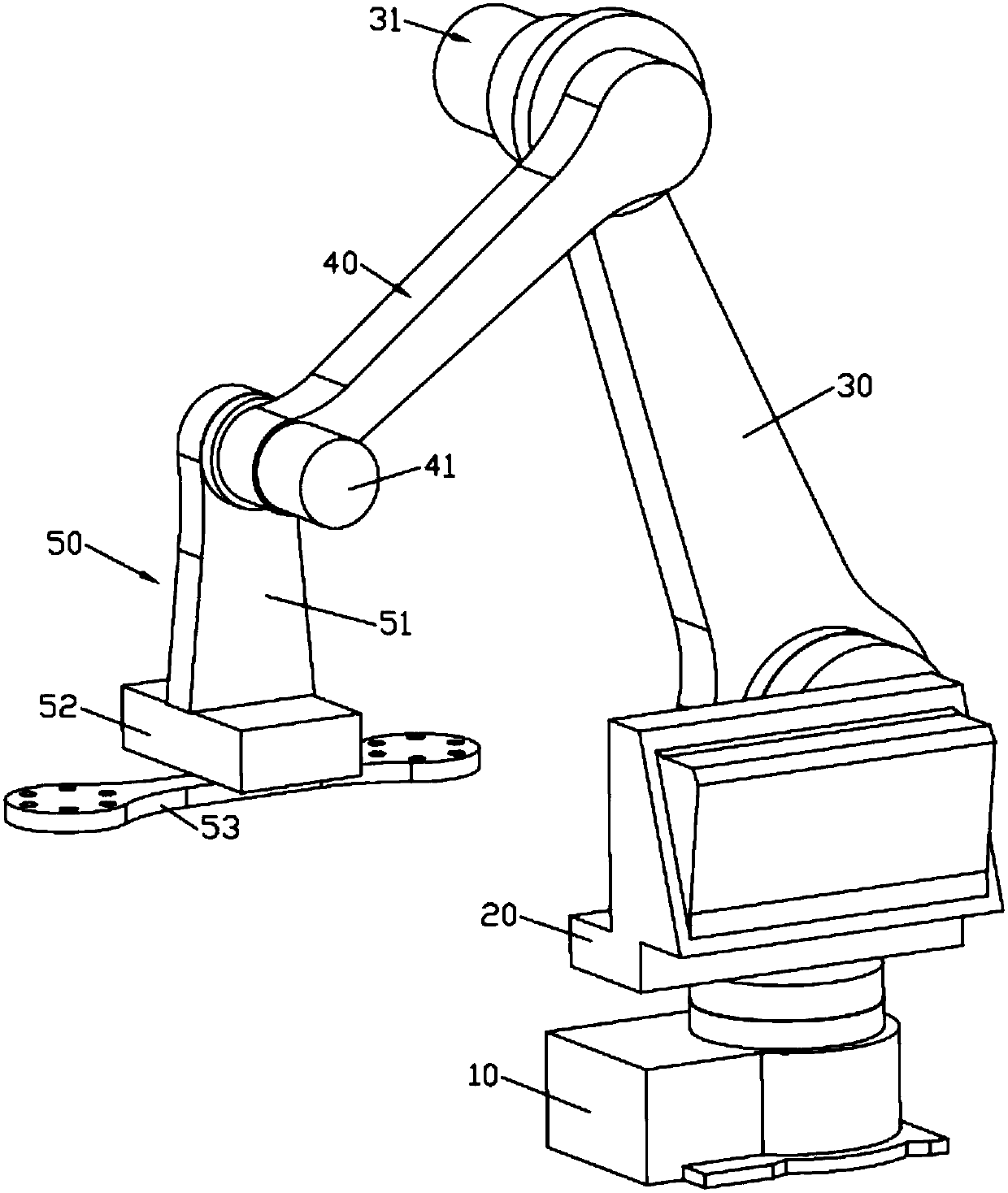

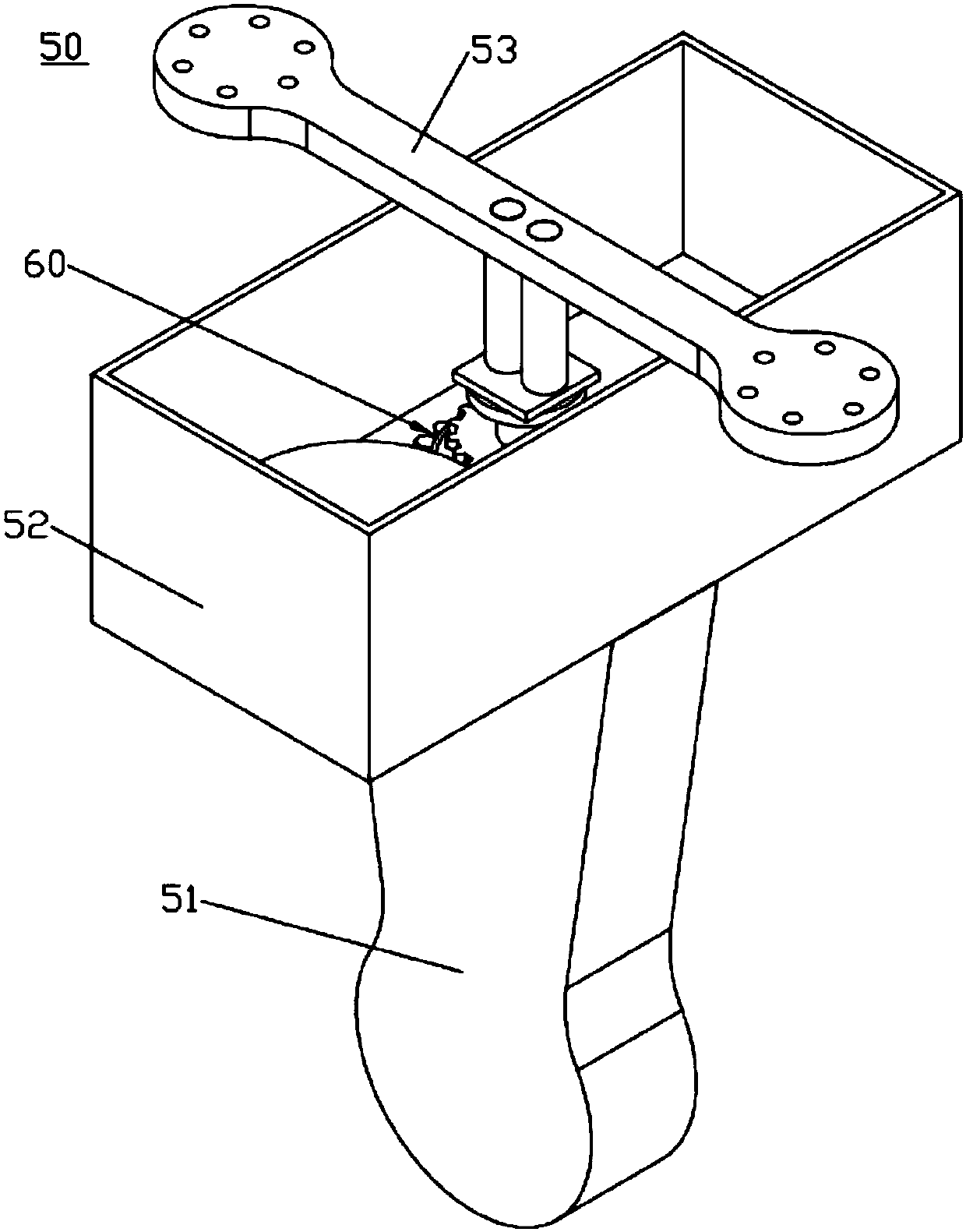

PCB plate handling robot capable of taking and placing materials accurately

ActiveCN105945936APrecise rotationPrecise pick and placeProgramme-controlled manipulatorGripping headsManipulatorSmall arms

The invention discloses a PCB plate handling robot capable of taking and placing materials accurately. The robot comprises a pedestal body, a waist rotating component pivoted on the pedestal body, a big arm pivoted on the waist rotating component, a small arm pivoted on the big arm and a manipulator mounted on the small arm; the waist rotating component rotates around the pedestal body; the big arm rotates around the waist rotating component; and the small arm rotates around the big arm. The manipulator comprises a pair of suction disc groups and a driving mechanism for driving the pair of suction disc groups; the driving mechanism comprises a base, a rotating assembly, a rotating driving device and a locking assembly. In the invention, the driving assembly which moves in a circle can remove the restriction of the locking assembly to the rotating assembly and drive the rotating assembly to rotate 180 degrees, and the pair of suction discs rotates 180 degrees along with the rotating assembly. The driving mechanism of the invention can enable the two suction discs on the manipulator to rotate 180 degrees accurately to take and place materials accurately.

Owner:永州菲斯特电子科技有限公司

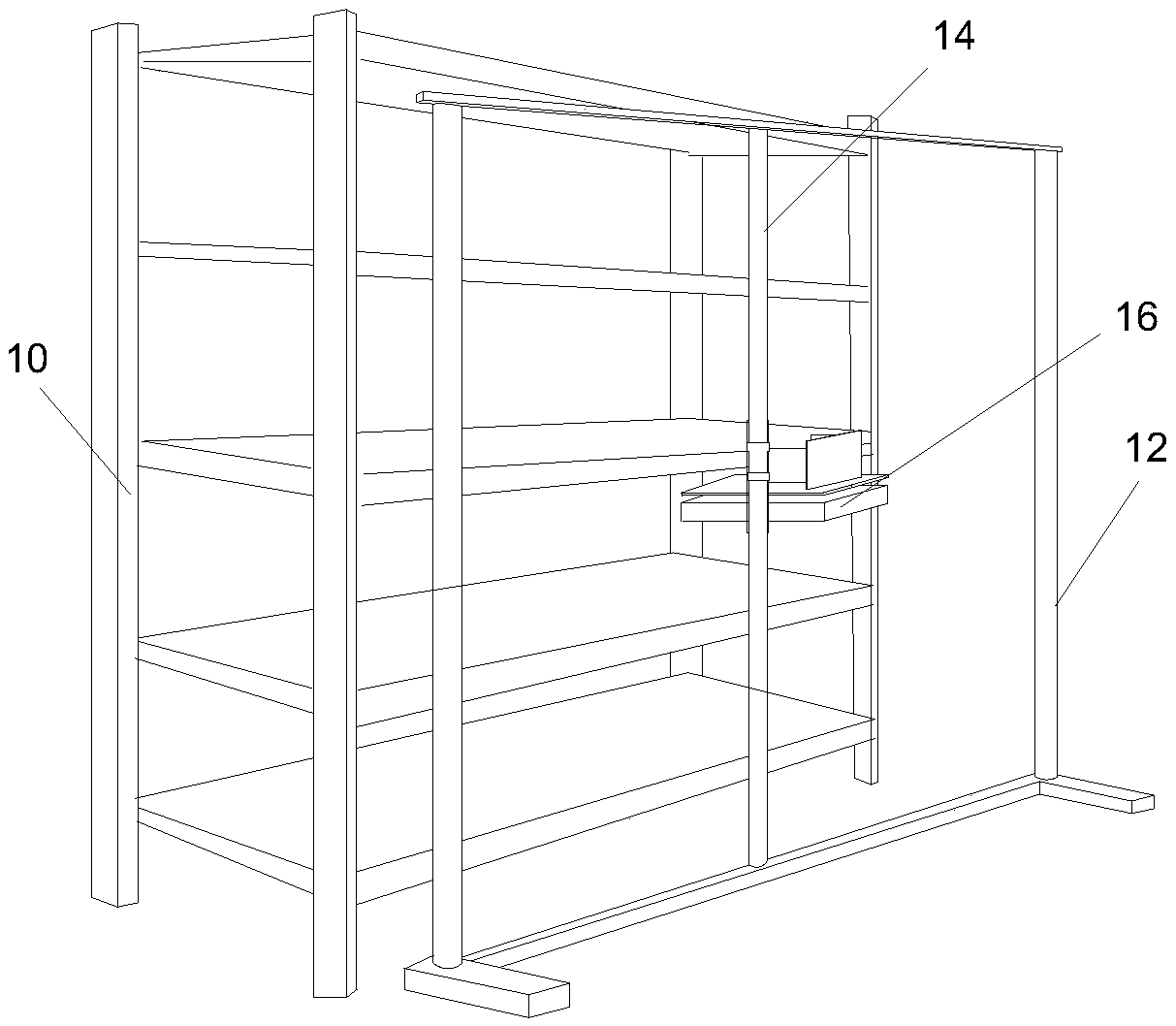

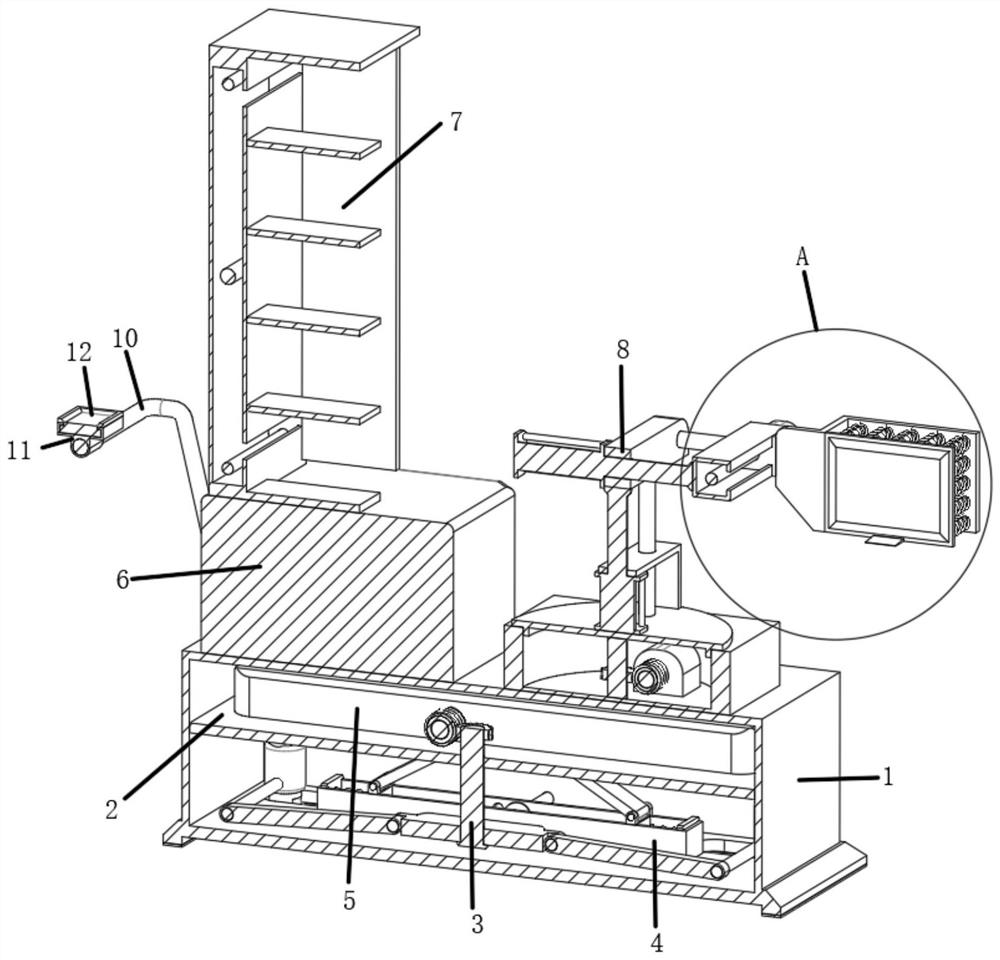

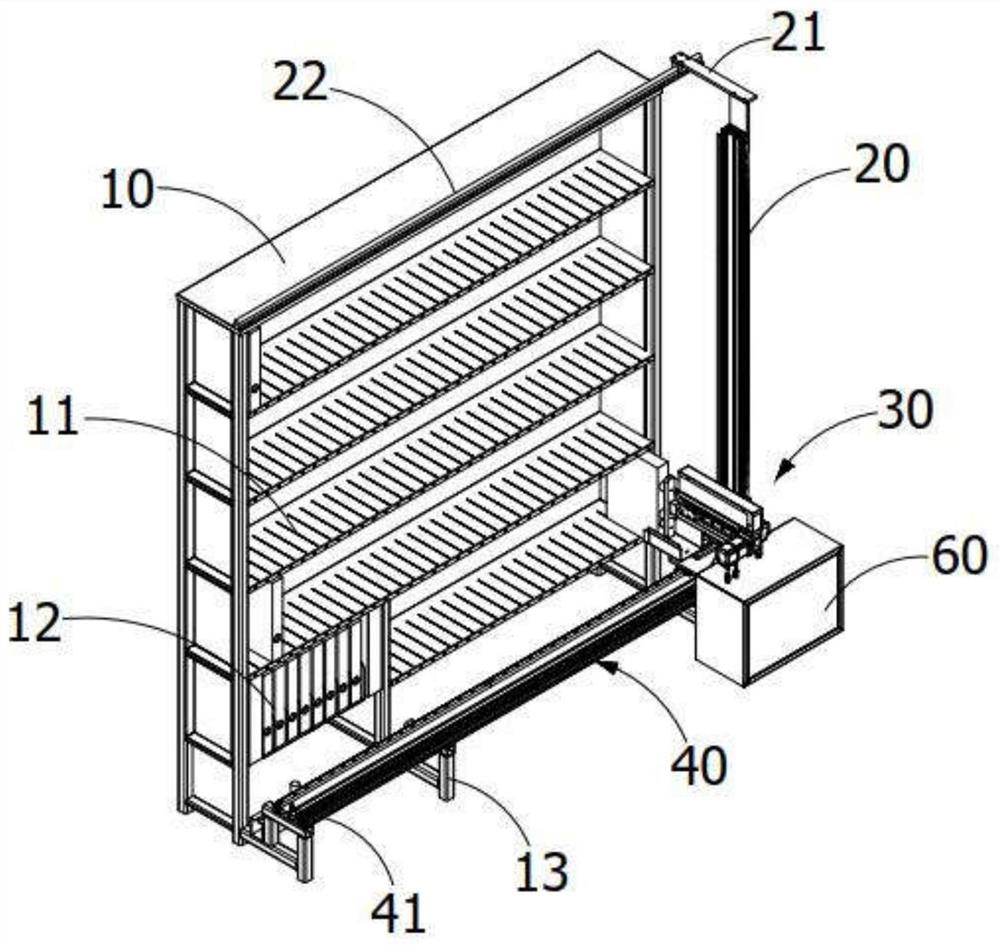

Intelligent warehouse based on robots

The invention discloses an intelligent warehouse based on robots. The intelligent warehouse based on the robots comprises a plurality of goods shelves arranged in the warehouse and a computing centerstoring information of goods on the goods shelves and further comprises a rod frame which is arranged in front of the goods shelves, and the rod frame is provided with at least one guide rod perpendicular to the ground. The intelligent warehouse based on the robots further comprises the multiple robots which can move in the warehouse and can ascend or descend along guide rails. Each robot comprises a base, wherein the base is movably provided with a fixture which is used for taking the goods on and putting the goods from the goods shelves, walking wheels or caterpillar bands are arranged belowthe base, and the computing center and the robots carry out data interaction through wireless communication. According to the intelligent warehouse based on the robots, the robots which can climb thegoods shelves are used for taking and putting the goods, precise goods taking and putting can be achieved through the robots, the relatively large investment generated by using a manipulator or othermanners is also avoided, and meanwhile the space is also saved.

Owner:SUZHOU DELTA LOGISTICS

Shoe cabinet with multiple lighting devices

InactiveCN102462189AEnergy savingQuick pick and placeWardrobesLighting elementsEngineeringControl switch

The invention relates to a shoe cabinet with multiple lighting devices. The shoe cabinet with of the multiple lighting devices is characterized by comprising a cabinet body, wherein a disinfection zone and a storage zone are arranged in the cabinet body, the lighting devices are arranged in the disinfection zone and the storage zone and connected with corresponding door control switches, and the lighting devices can work independently. The shoe cabinet with the multiple lighting devices, disclosed by the invention, has the advantages that: (1) the lighting devices are also arranged in the storage zone in the cabinet body, so that the people can take the needed shoes rapidly and accurately; meanwhile, the door control switches are arranged in the shoe cabinet, so that the lighting devices can be automatically powered off when a door is closed, and the lighting devices can start working when the door is opened; and (2) LED (Light-Emitting Diode) lamps are arranged in the shoe cabinet, so that the advantages of environmental friendliness and the like of the LED (Light-Emitting Diode) are utilized to save the energy effectively.

Owner:江苏金世康电器科技有限公司

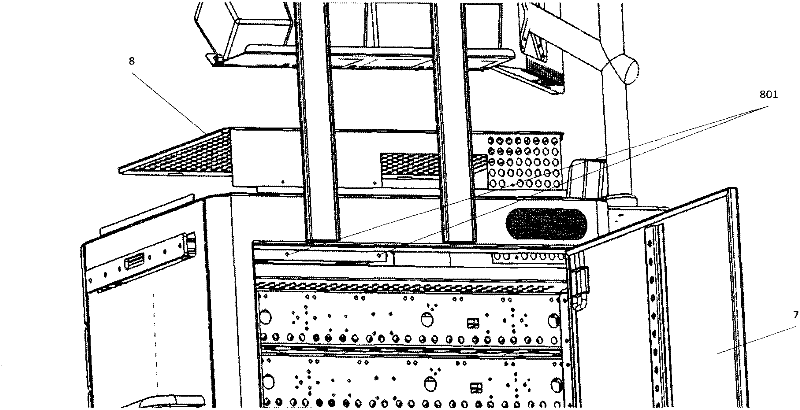

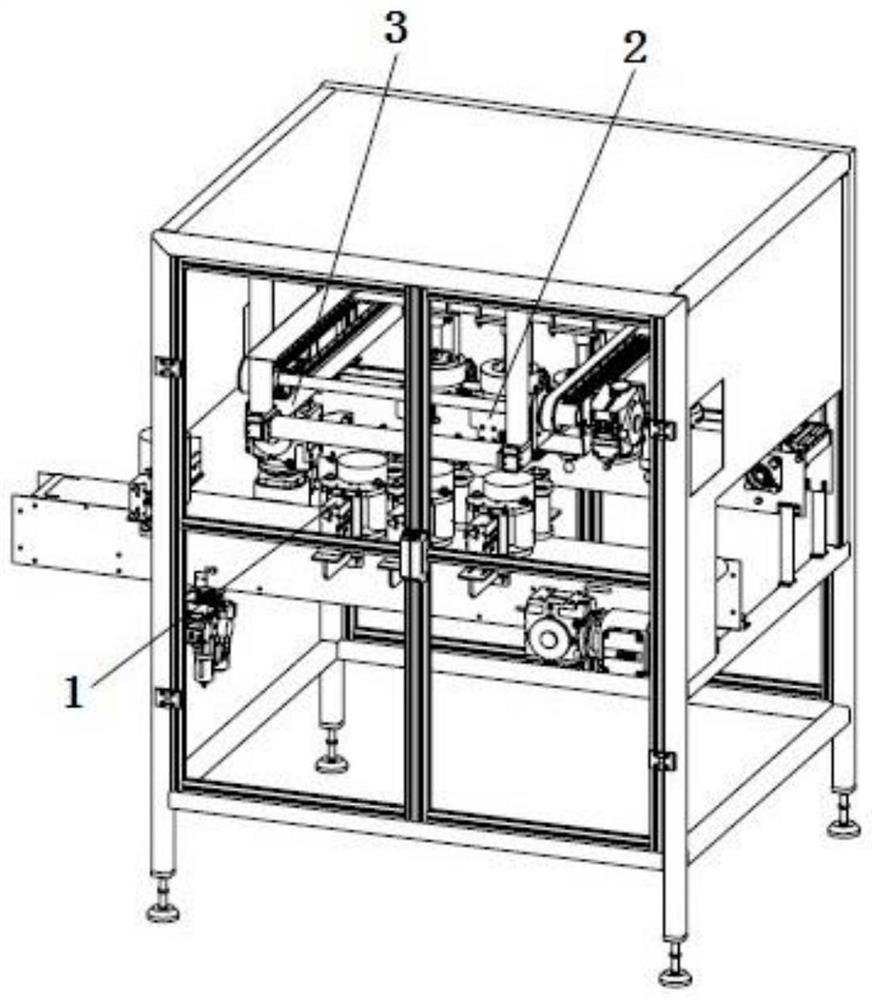

Biological experiment workstation

ActiveCN107377034ACompact structureImprove space utilizationProgramme-controlled manipulatorEnclosures/chambersInterior spaceMedicine

The invention relates to the technical field of biological medicine test equipment and particularly relates to a biological experiment workstation. The biological experiment workstation comprises a cabin and a mechanical arm arranged in the cabin, wherein a workbench panel which is used for separating the inner space of the cabin into upper and lower parts is arranged in the cabin; a detachable upper lateral plate component is arranged on the upper part of the cabin in an encircling manner; a working chamber is formed by the upper lateral plate component and the space above the workbench panel; a lower lateral plate component is arranged on the lower part of the cabin in an encircling manner; a storage chamber is formed by the lower lateral plate component and the space under the workbench panel. The workstation has the beneficial effects that the structure layout is compact, the space utility rate is increased, the motion of the mechanical arm along various directions is beneficial to the flexible application of various test operations, the operation is more convenient, the time and the labor are saved, the labor intensity is reduced and the working efficiency is improved.

Owner:CHONGQING WAVELET BIOLOGICAL TECH CO LTD

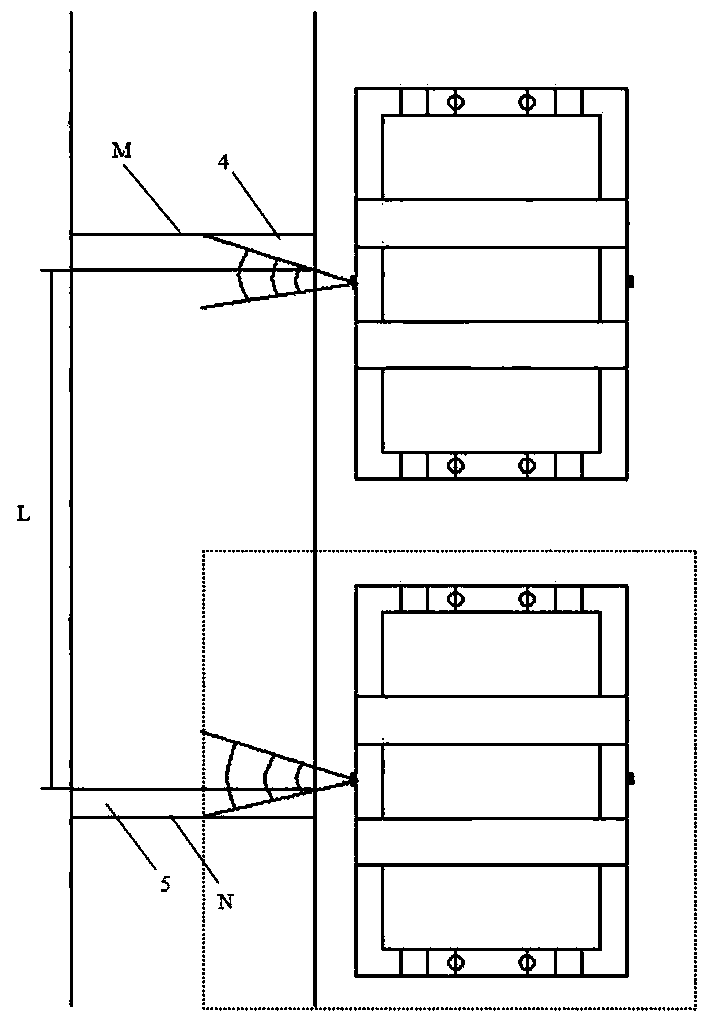

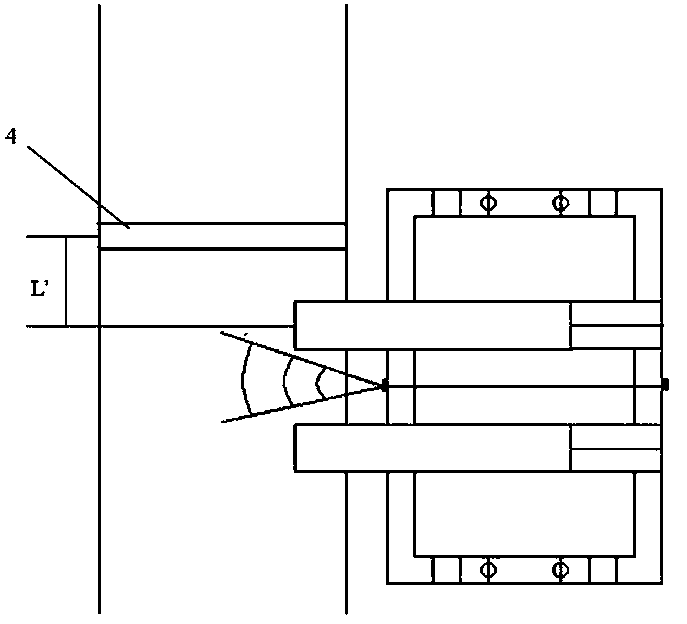

Automatic measurement method for data of stacking machine

ActiveCN103759640AFacilitate accurate pick and placePrecise pick and placeUsing optical meansElectrical controlEngineering

The invention discloses an automatic measurement method for the data of a stacking machine. The automatic measurement method comprises the method for measuring the distance of the radiation angle of goods-detecting photoelectricity. The method comprises the steps: firstly, the stacking machine walks to the first position, then the goods-detecting photoelectricity detects a first vertical column, and an electrical control system records the walking distance data of the stacking machine; the stacking machine walks to the second position, then the goods-detecting photoelectricity detects a second vertical column, and the electrical control system records the walking distance data of the stacking machine; the distance data from the first vertical column to the second vertical column is measured actually; the electrical control system carries out rear portion operation to obtain the distance of the radiation angle of the goods-detecting photoelectricity. According to the automatic measurement method for the stacking machine, the distance of the radiation angle of the goods-detecting photoelectricity is measured and calculated, the distance of the radiation angle of the goods-detecting photoelectricity is subtracted from or added to the data measured in the subsequent walking process of the stacking machine, and therefore the effect that a fork takes and places trays accurately is achieved.

Owner:南京音飞储存设备(集团)股份有限公司

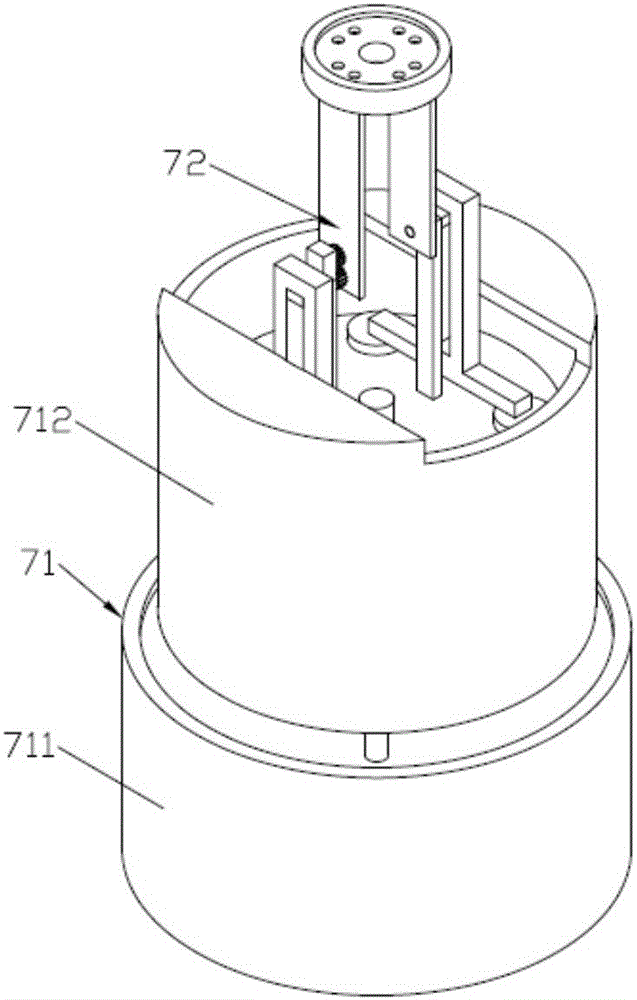

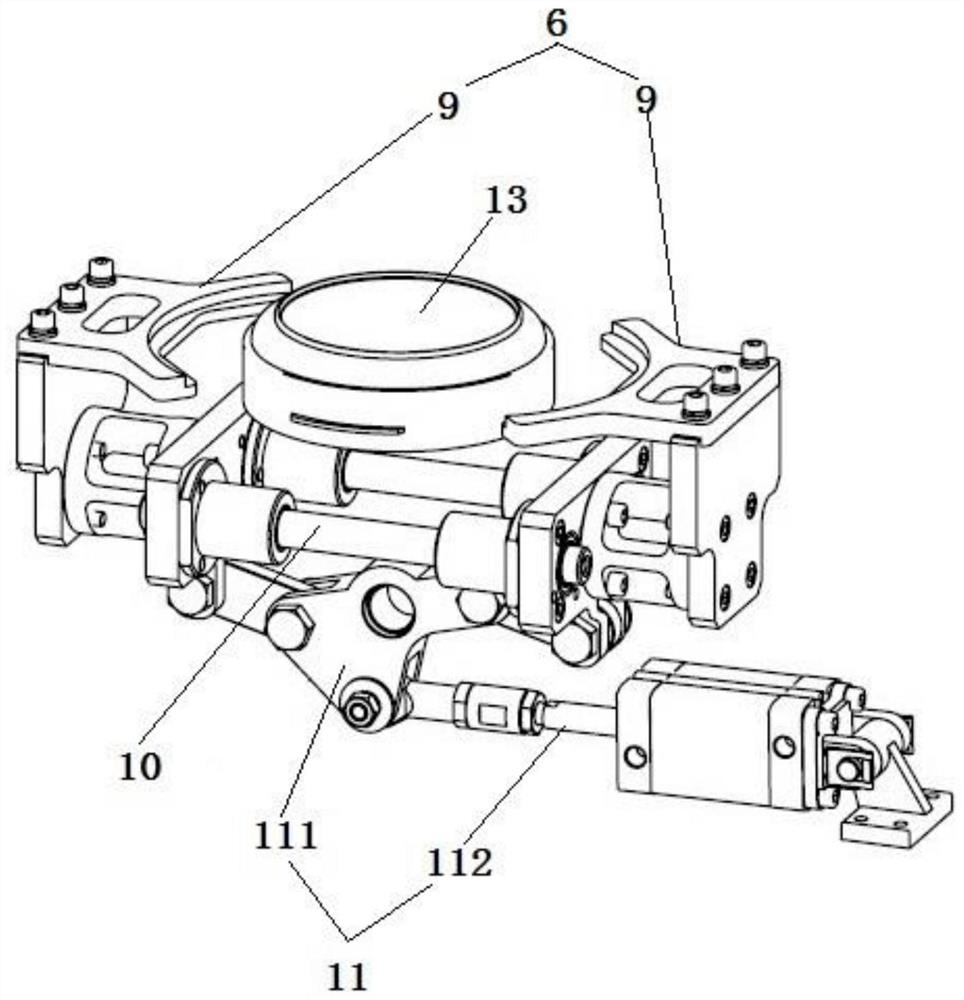

Robot provided with fixed rotating angle execution end

ActiveCN106078712ALengthen or shorten the overall lengthPrecise pick and placeProgramme-controlled manipulatorGripping headsEngineeringManipulator

The invention discloses a robot provided with a fixed rotating angle execution end. An extending arm is arranged on a small arm of the robot and comprises a support body fixedly connected with the small arm, a first telescopic mechanism mounted on the support body, a sliding mechanism fixed to the first telescopic mechanism, a swing mechanism mounted on the sliding mechanism and a reset device mounted on the swing mechanism. A rotating mechanical hand is fixed to the front end of the extending arm and comprises a pair of suction cup sets and a drive mechanism for driving the pair of suction cup sets to rotate. The drive mechanism comprises a base, a rotating assembly, a rotating drive device and a lock catch assembly. The first telescopic mechanism of the robot can stretch or shorten the extending arm and can increase or decrease the total length of the small arm and the extending arm so as to adapt to various working conditions; the swing mechanism can swing by a certain amplitude relative to a swing drive mechanism, that is, the small arm has a bending function; and two suction cups on the rotating mechanical hand can accurately rotate by 180 degrees.

Owner:TIANJIN HUIZHI IOT TECH CO LTD

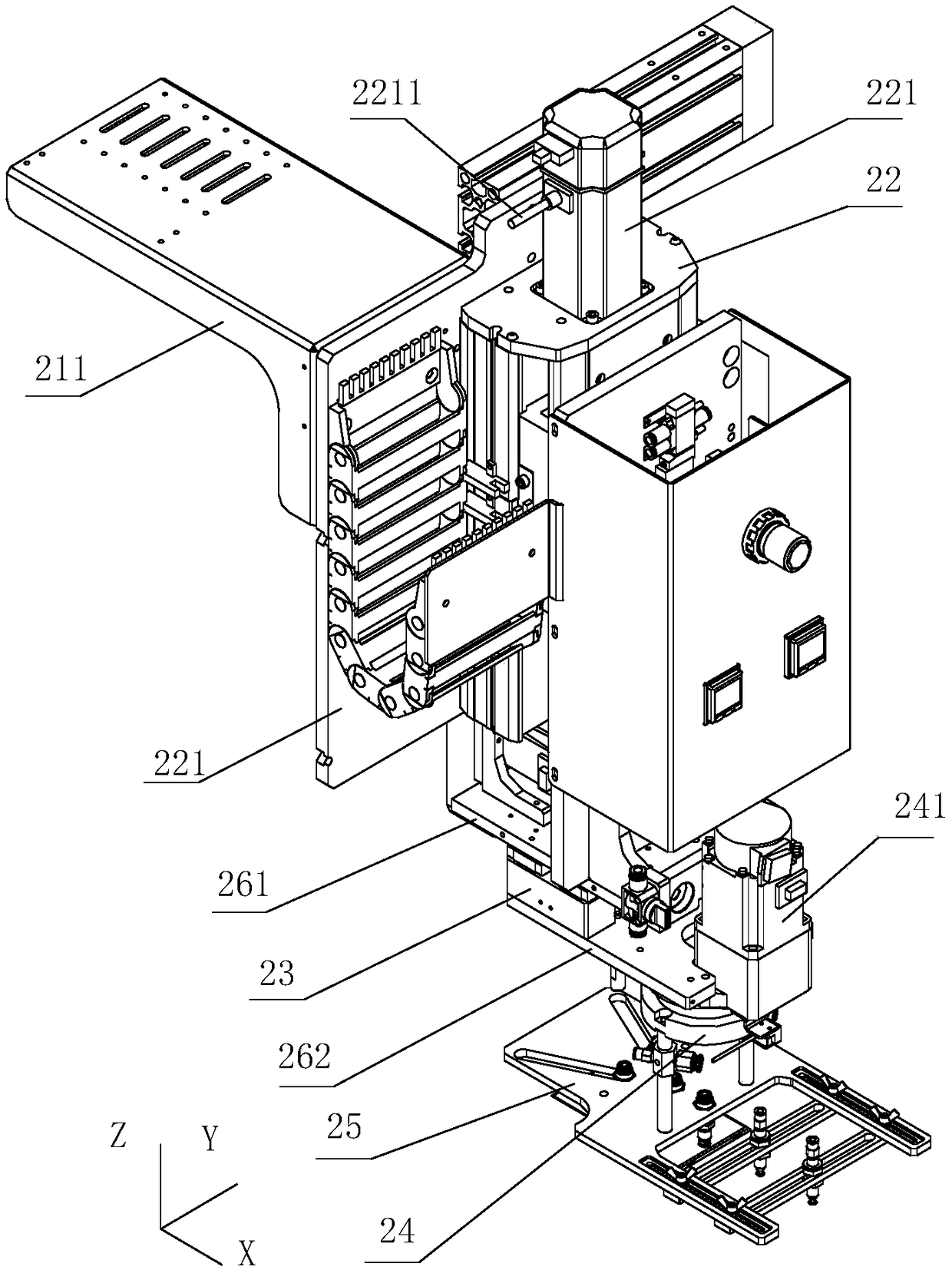

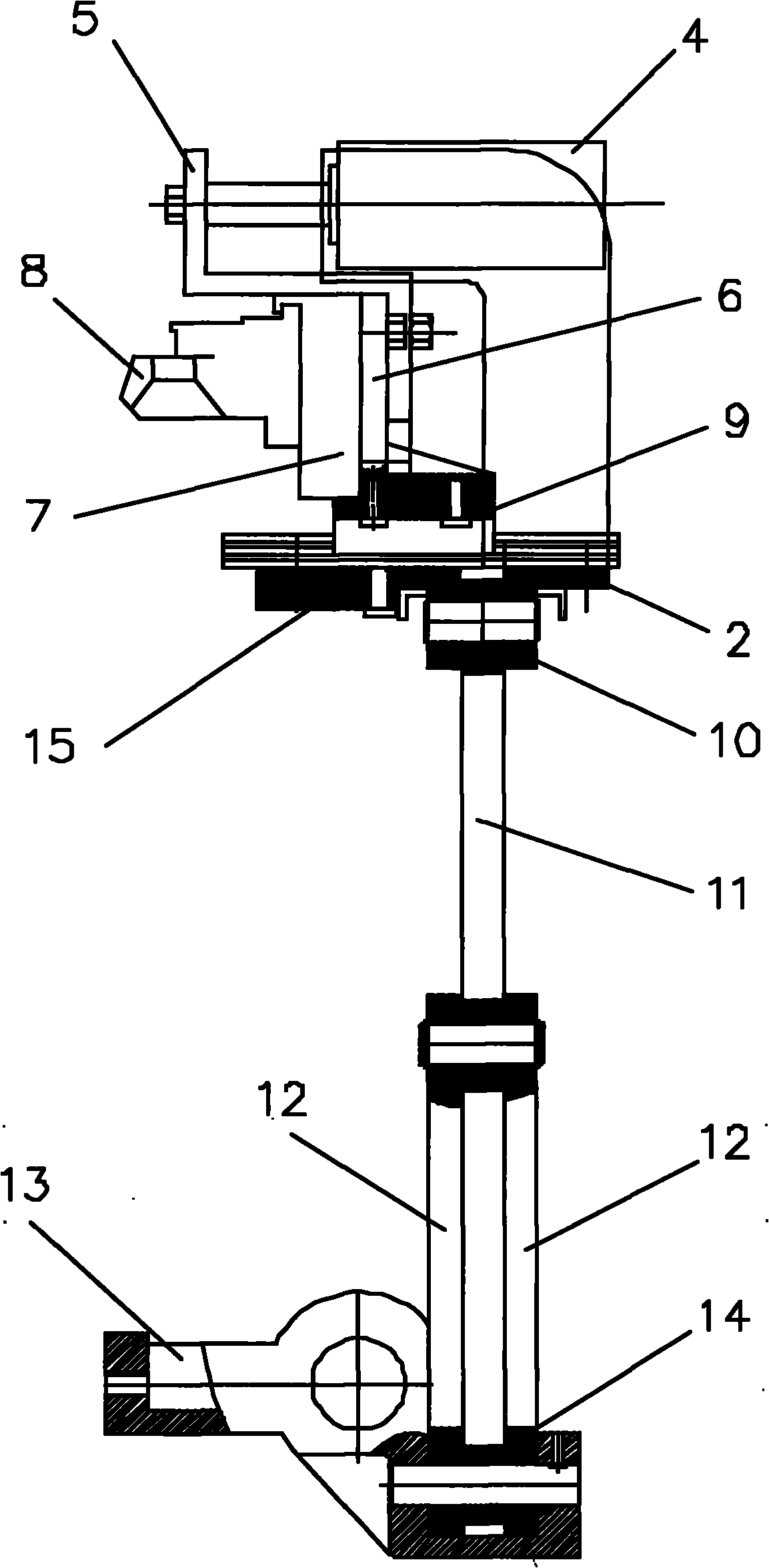

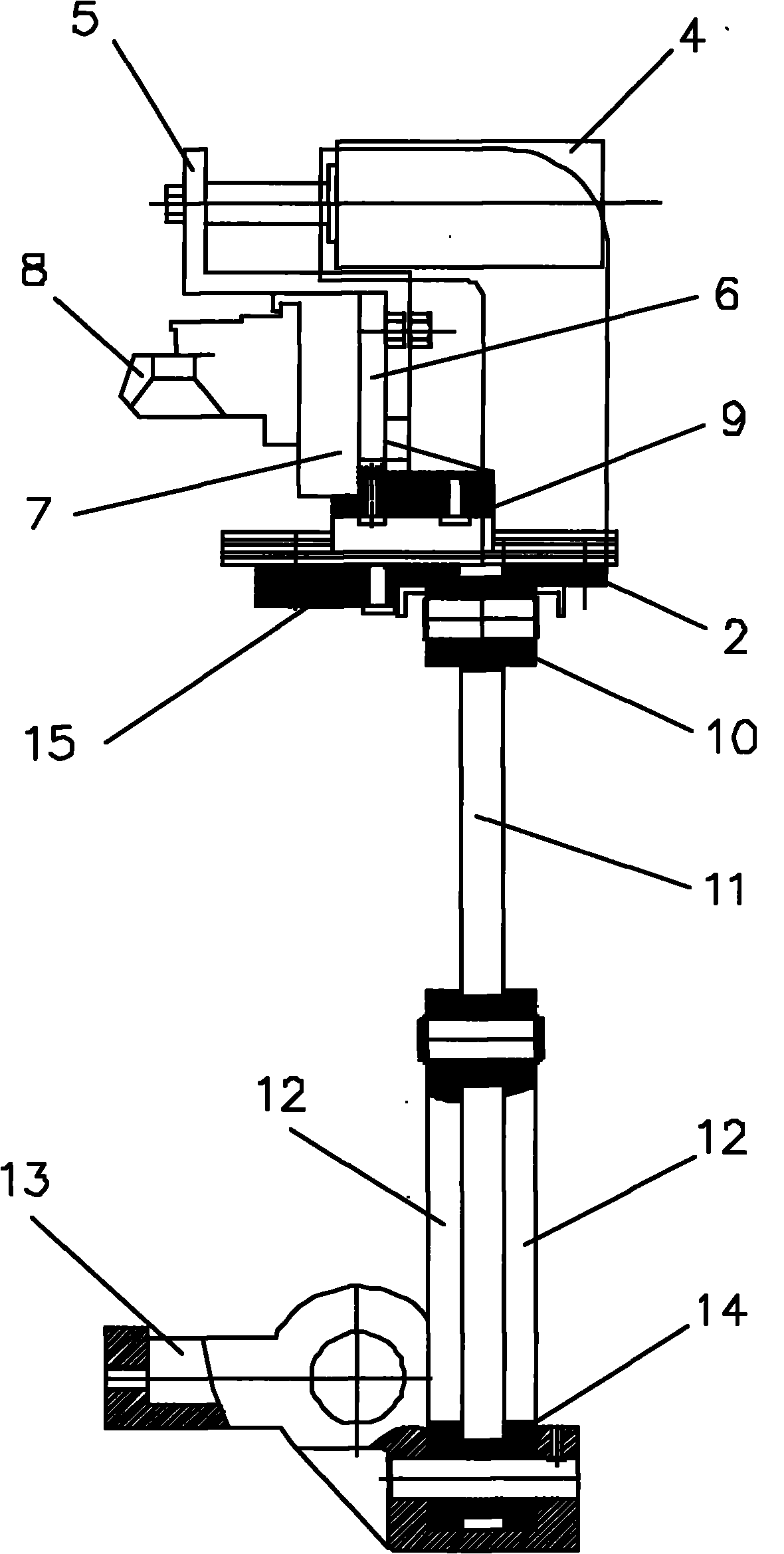

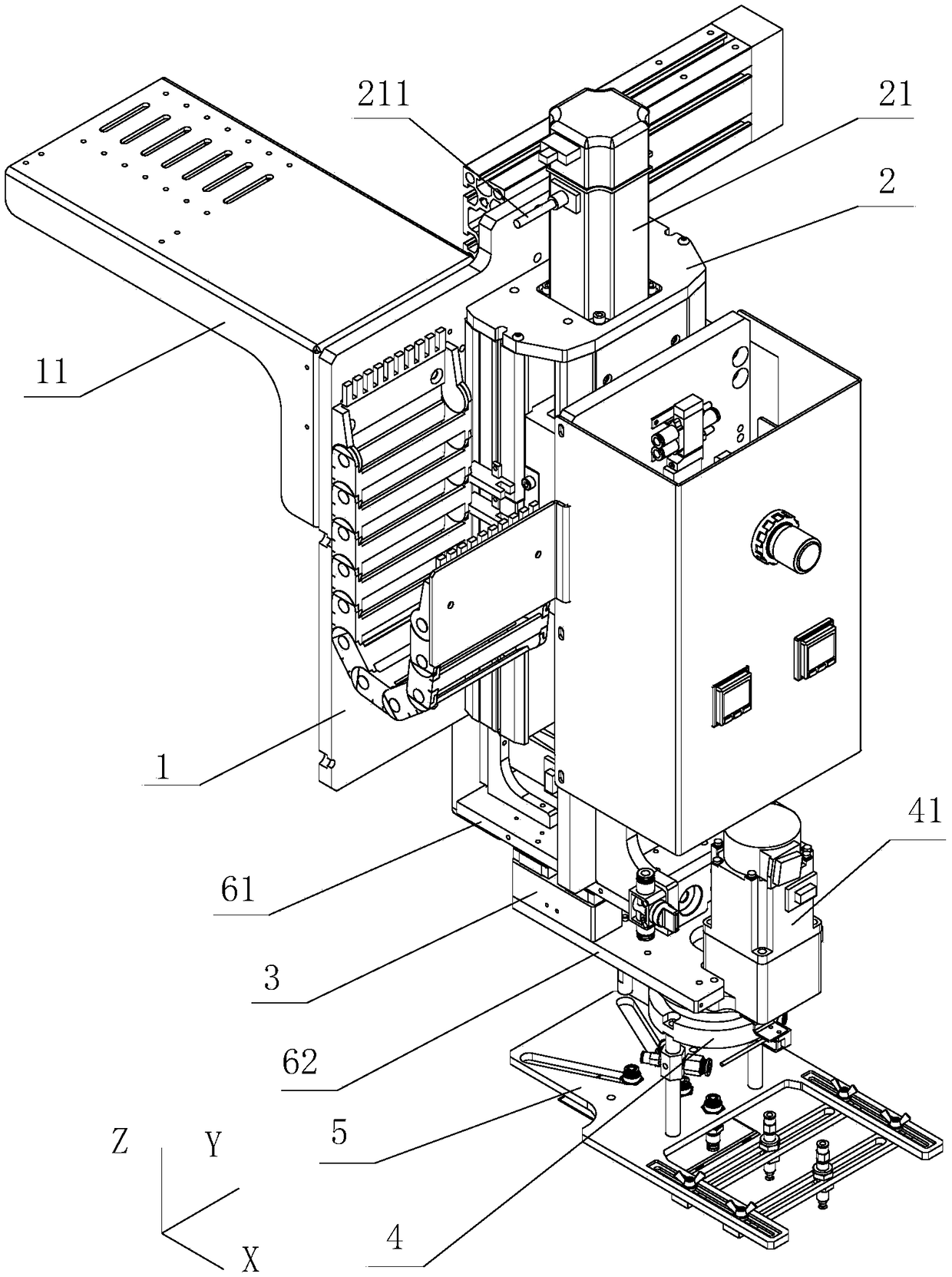

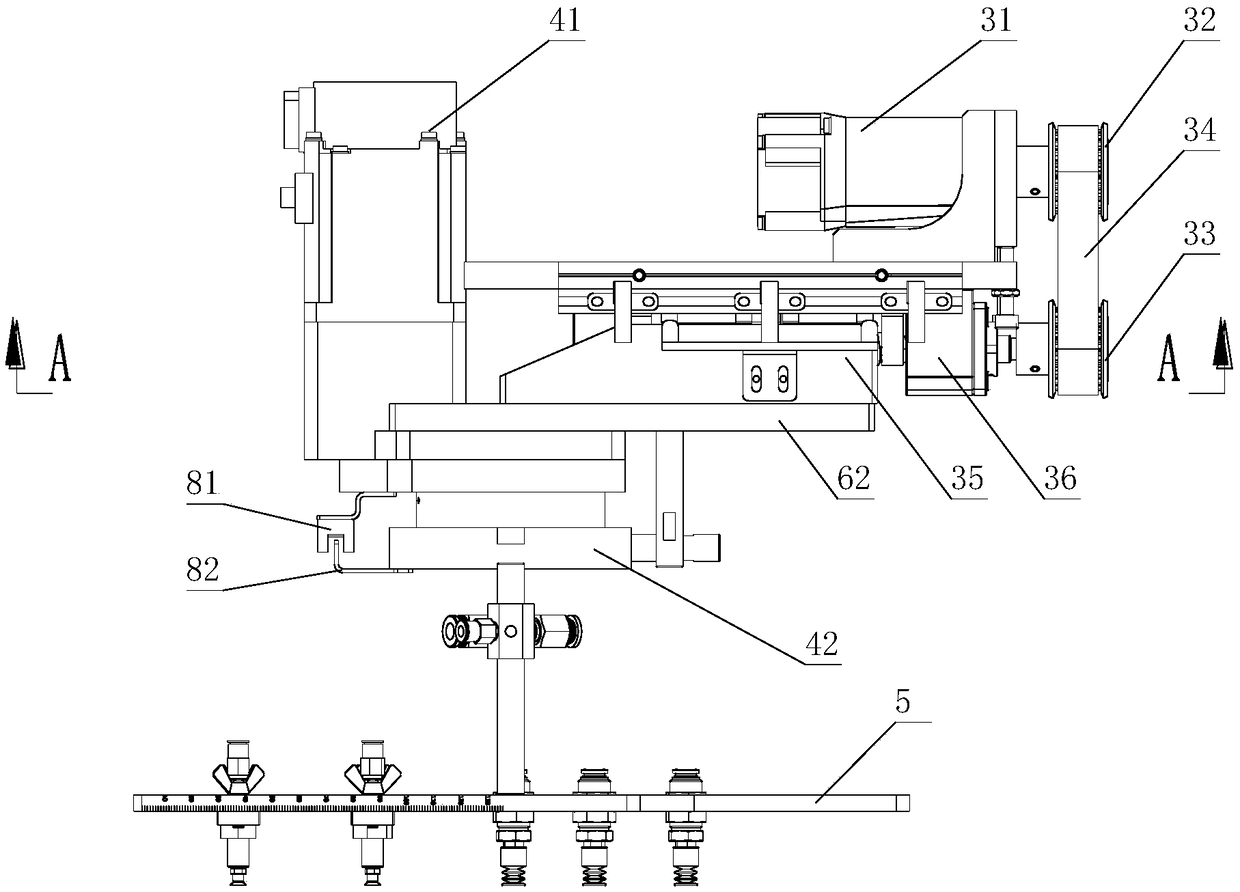

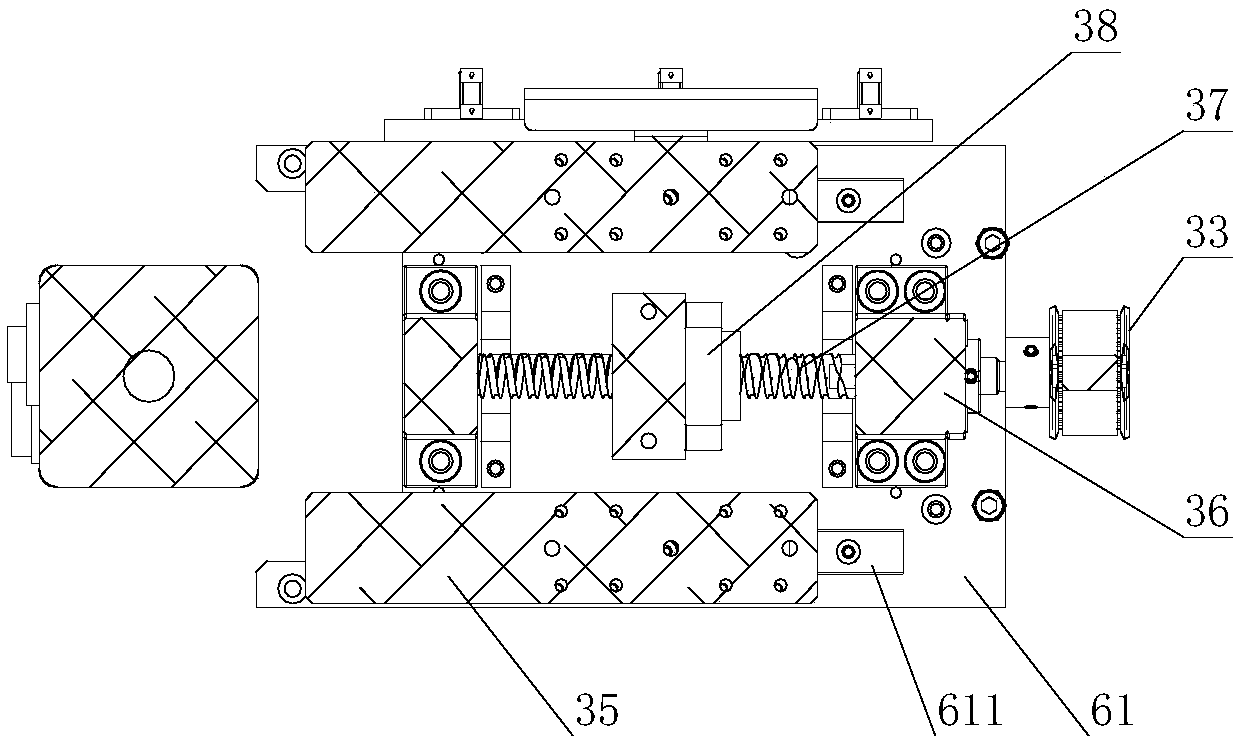

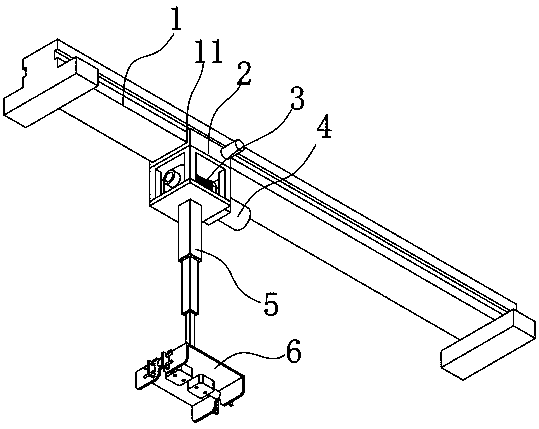

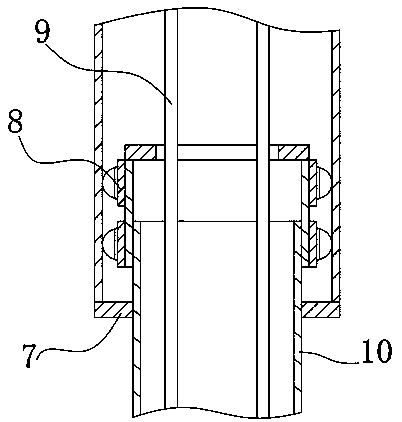

Display panel taking and placing device

PendingCN109019008APrecise pick and placeMeet pick and place requirementsConveyor partsUtilization rateElectrical and Electronics engineering

The invention relates to the technical field of display panel detection, in particular to a display panel taking and placing device. The display panel taking and placing device comprises a lifting mechanism, a translation mechanism, a rotating mechanism and a sucker. According to the display panel taking and placing device, the overall upward and downward movement of the device in the direction Zis realized through the lifting mechanism, the translation mechanism is used for realizing translational movement of the device in the direction X, the rotation movement of the sucker on the horizontal plane is realized through the rotating mechanism, and the combined action of the lifting mechanism, the translation mechanism and the rotating mechanism is achieved, and accurate taking and placingof the display panel can be realized; and an inclined slide groove and a straight slide groove are formed in the sucker, the position of the sucker adsorption display panel can be effectively adjusted, and the requirement for taking and placing the size of the multi-specification display panel is met. The device is compact in structure, high in space utilization rate, accurate in positioning and good in safety performance.

Owner:WUHAN JINGCE ELECTRONICS GRP CO LTD

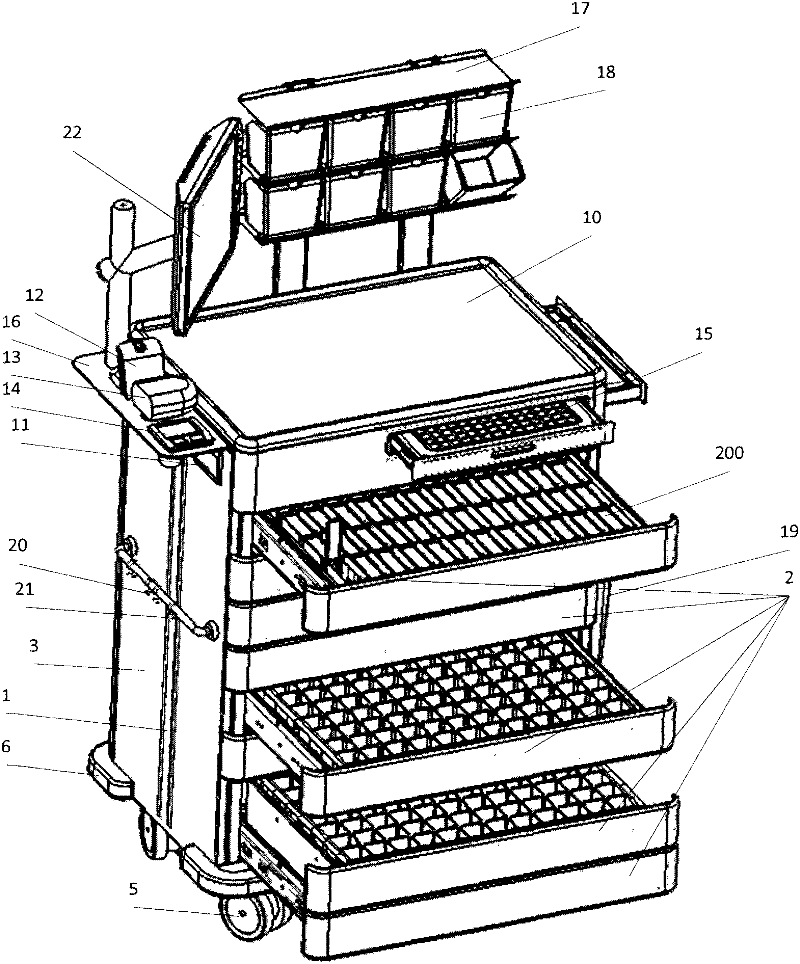

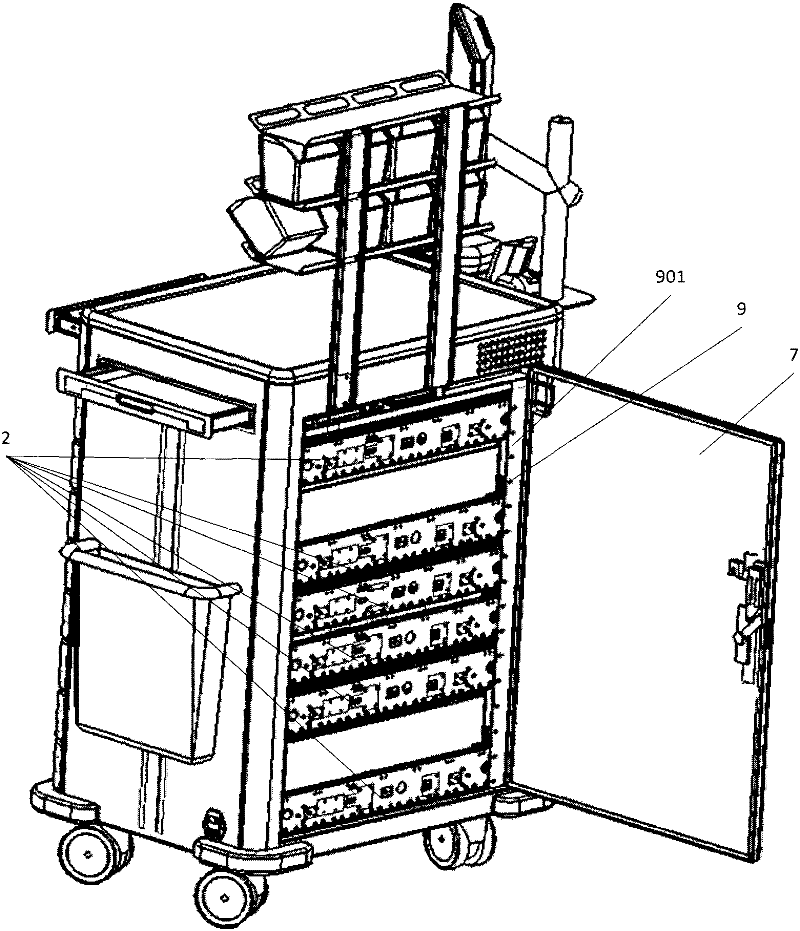

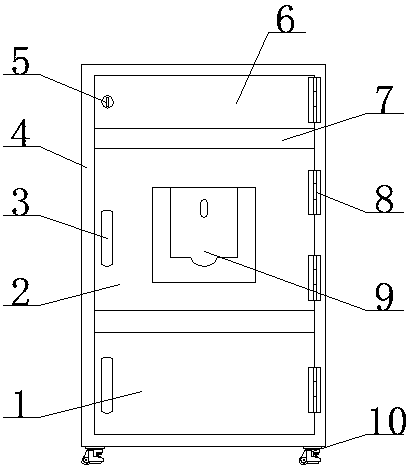

Equipment for disinfecting medical apparatuses

InactiveCN107551301APrecise pick and placePrecise managementLavatory sanitoryChemicalsBiomedical engineeringCaster

The invention discloses equipment for disinfecting medical apparatuses. The equipment comprises a cabinet, an ozone generating cabinet, a supporting plate chute and a disinfecting disc. A horizontal adjusting trundle is arranged on the lower side surface of the cabinet; a lower disinfecting cabinet is arranged below the inner side of the cabinet; an upper disinfecting cabinet is arranged on the upper side of the lower disinfecting cabinet; a cabinet door handle is arranged in the middle position of the left side of the upper disinfecting cabinet; a file placing clamp is arranged on the right side of the cabinet door handle; an apparatus taking and placing register list clamp is arranged on the cabinet door of the equipment, multiple layers of apparatus disinfecting discs labeled with classification labels are arranged in the cabinet, and the disinfecting discs are designed in rotary discs, so that staff takes and places and manages apparatuses accurately, quickly and conveniently. In addition, a drain plate is arranged in each of the disinfecting discs, so that the apparatuses with water placed in the disinfecting discs can be still dried, and therefore, the disinfecting reliability of the apparatuses in the disinfecting cabinet is ensured.

Owner:南京思齐环保仪器有限公司

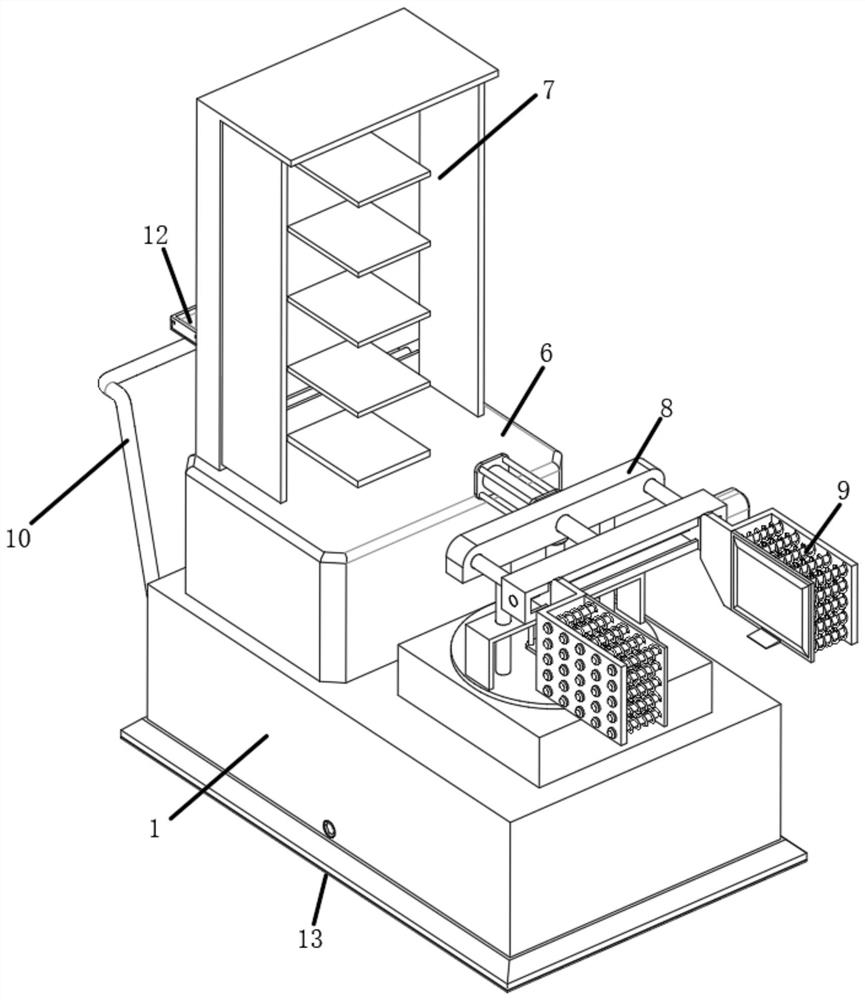

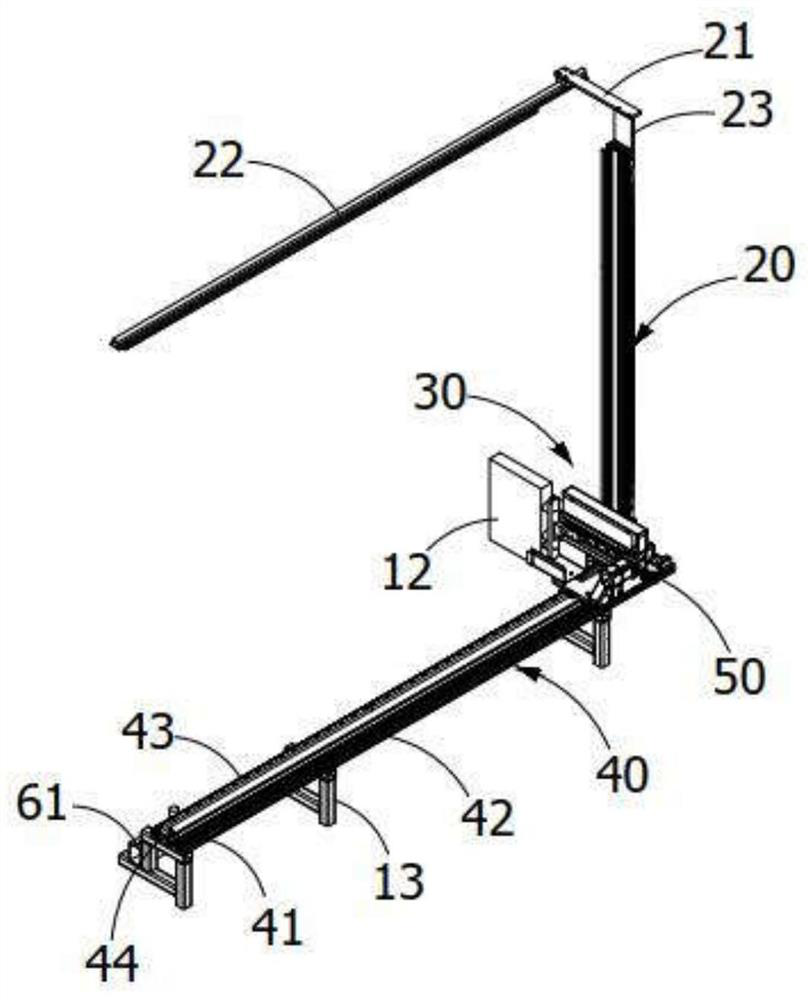

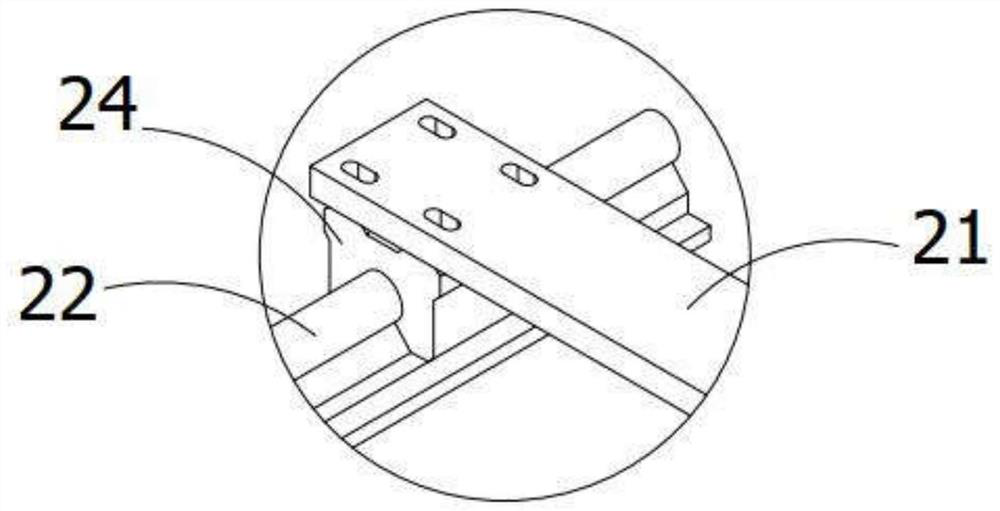

Automatic multi-layer blister material taking machine

InactiveCN110759084APrecise pick and placeReduced areaStacking articlesDe-stacking articlesRobot handProcess engineering

The invention discloses an automatic multi-layer blister material taking machine comprising a mechanical hand, a portal frame and a hollowed-out feeding platform. The mechanical hand comprises a mechanical hand moving mechanism and a mechanical hand rising and falling mechanism. One end of the mechanical hand moving mechanism is connected with the mechanical hand rising and falling mechanism, andthe other end of the mechanical hand moving mechanism is movably connected with the top of the portal frame. During work, a control electric cabinet can control operation of a cutting machine and themechanical hand through an internal PLC, manual movement is not needed, higher intellectualization is achieved, and the work efficiency is higher. Manual feeding, hand-operated cutting, manual material taking, manual material stacking and manual counting in the traditional blister industry are replaced, the problems that an existing mechanical hand is large in land occupation and low in flexibility are solved, and the problem that traditional suction cup mechanical hands can only take single-layer blister cut products is solved. By means of the automatic multi-layer blister material taking machine, multi-layer blister cut products can be clamped and taken out at a time. Applicable blister types are wide, the production efficiency is greatly improved, and time and labor are saved.

Owner:蔡锡涛

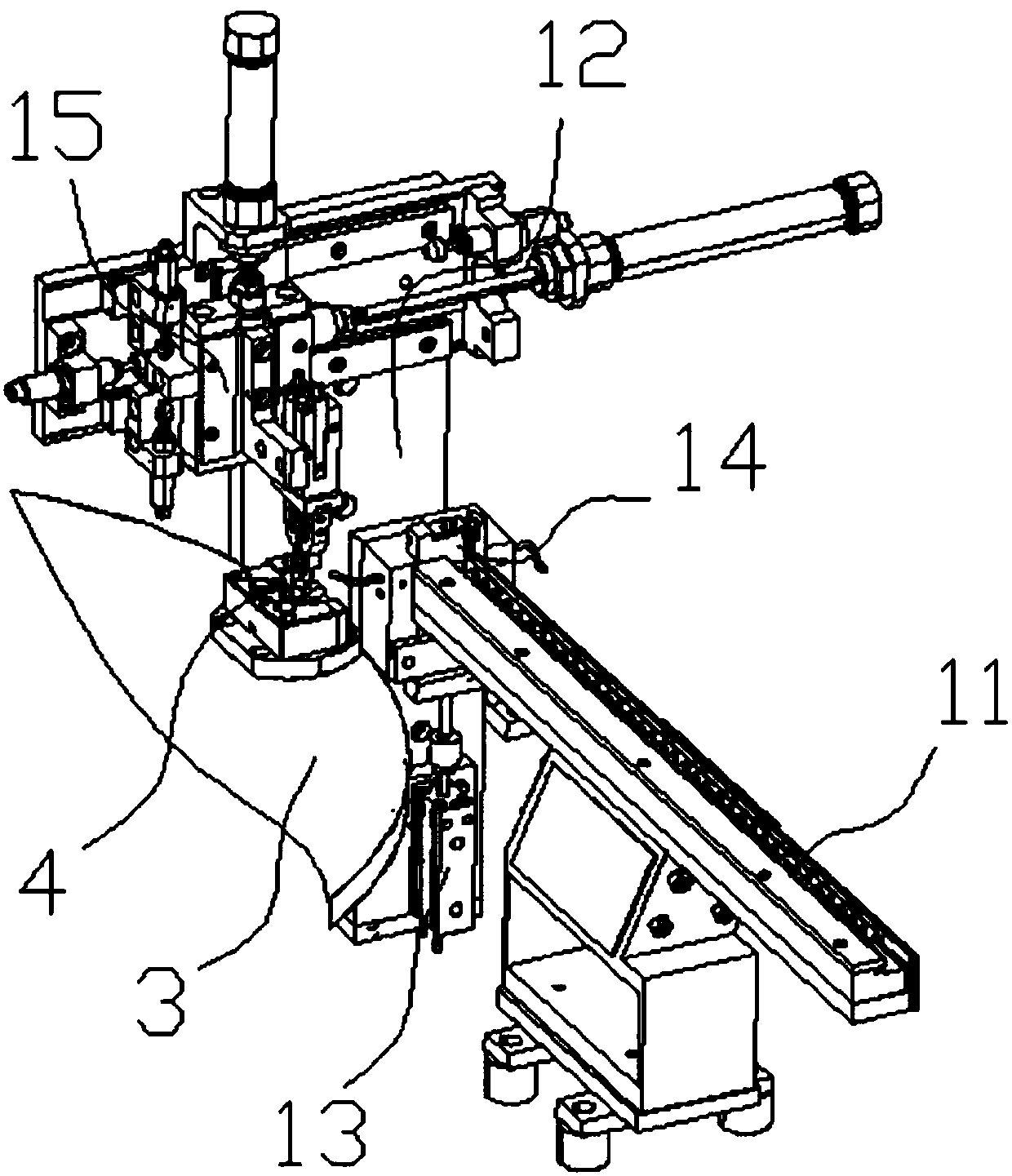

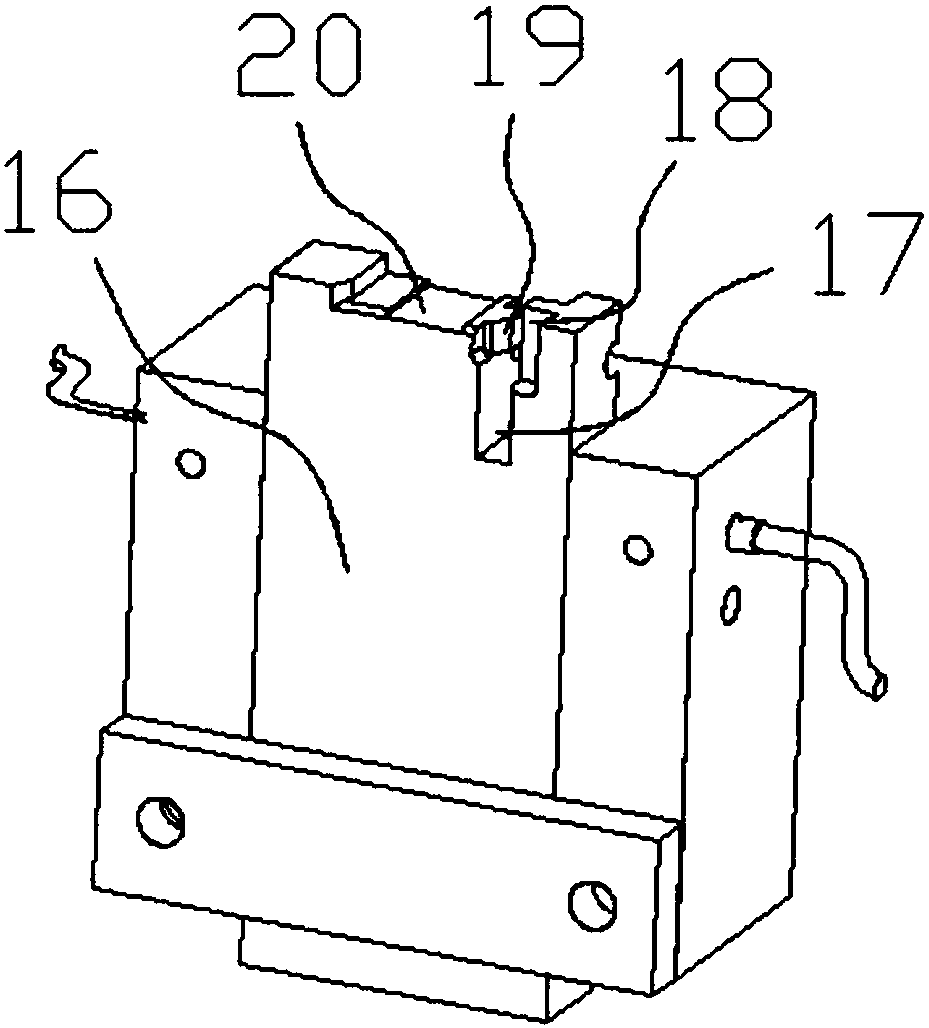

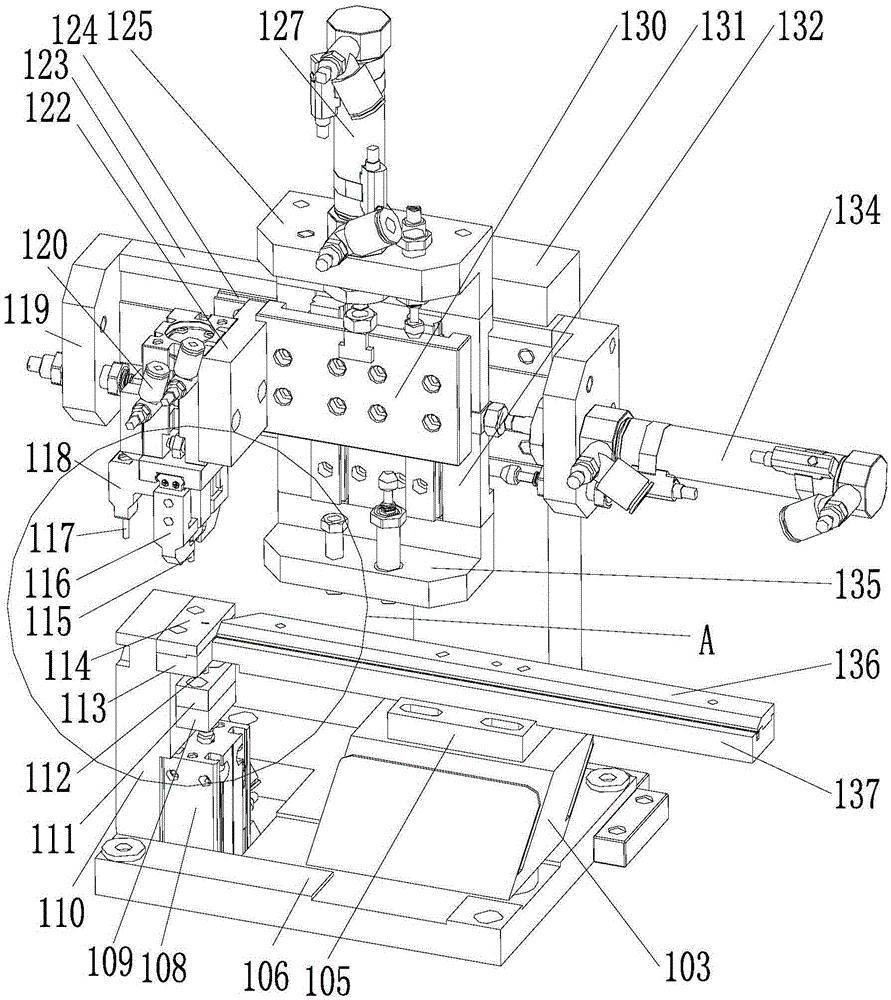

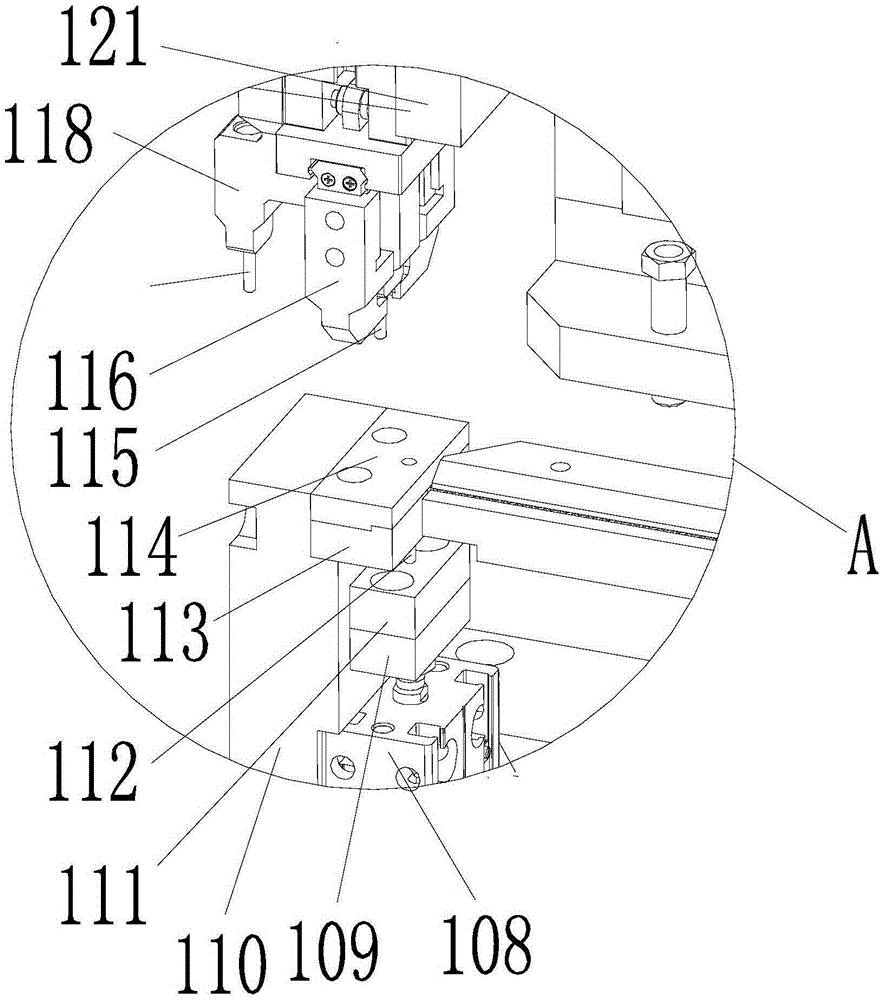

Taking device used in contact riveting process

InactiveCN105414935ARealize pick and placePrecise pick and placeMetal working apparatusEngineeringAutomation

The invention relates to a taking device used in a contact riveting process. The taking device comprises a support structure and a transverse material channel, wherein the transverse material channel is formed in the support structure, a top material channel plate is arranged on the top end of the transverse material channel, and a material vibrating disk is connected to the tail end of the transverse material channel; a top material channel cover plate is arranged above the top material channel plate, an upward ejector pin is arranged below the top material channel plate, and an upward air cylinder is installed on the support structure; a lifting mounting support and a translational air cylinder are arranged on the support structure; a finger air cylinder mounting support and a lifting air cylinder are arranged on the lifting mounting support; a finger air cylinder is arranged on the left end of the finger air cylinder mounting support, left and right clamping jaws and a prepressing ejector pin mounting plate are arranged on the finger air cylinder, and a downward ejector pin is arranged on the prepressing ejector pin mounting plate. According to the taking device, the problems of low degree of automation and production efficiency and high labor cost caused by manually taking a contact and putting on a to-be-riveted product first and then riveting in an existing contact riveting process can be effectively solved.

Owner:昌辉汽车电器(黄山)股份公司

Positioning transfer jig

PendingCN111745557ARealize movingPrecise pick and placeWork holdersEngineeringMechanical engineering

Owner:MITAC PRECISION TECH(KUNSHAN) CORP

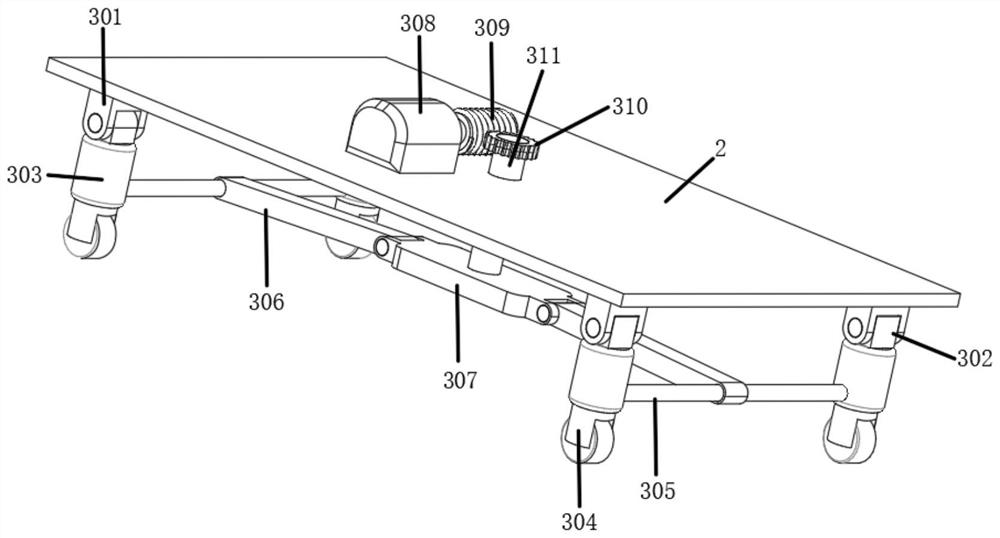

Battery carrying device in new energy battery detection process

PendingCN113353132AEasy to placeEasy remote controlSupporting partsHand carts with multiple axesNew energyEngineering

The invention relates to the technical field of new energy, in particular to a battery carrying device in a new energy battery detection process. The device comprises a base, a mounting plate is arranged in the base, and a lifting moving assembly is fixedly arranged between the mounting plate and the bottom of the inner wall of the base. A plurality of buffer assemblies are fixedly arranged between the lower surface of the mounting plate and the bottom of the inner wall of the base, a storage battery holder is fixedly arranged on one side of the upper surface of the base, a placing assembly is fixedly arranged on the upper surface of the storage battery holder, a clamping assembly is arranged at one side of the base, a position adjusting assembly enabling the clamping assembly to move is fixedly arranged between the clamping assembly and the base, and an anti-skid rubber pad is fixedly arranged on the lower surface of the base. On the basis of a common carrying device, lifting, buffering, moving, driving, clamping and placing devices are arranged, and the carrying efficiency, the protection performance, the convenience and the stability are improved.

Owner:SUZHOU GUANKE IND EQUIP CO LTD

Novel cover pressing mechanism

InactiveCN112225145APrecise pick and placeIncrease the level of automationConveyorsControl devices for conveyorsSmall footprintConveyor belt

The invention discloses a novel cover pressing mechanism, and aims to provide the novel cover pressing mechanism which is compact in structure, small in floor space, high in automation level and highin cover and jar pressing accuracy. The novel cover pressing mechanism comprises a jar conveying assembly, a cover conveying assembly and a cover pressing assembly, wherein the jar conveying assemblycomprises a first color mark sensor, a jar holding part and a jar rotating part for driving a jar to rotate in situ; the cover conveying assembly comprises a conveyor belt, a second color mark sensorand a cover holding part for hooping a cover in the horizontal direction; the cover pressing assembly comprises a cover pressing air cylinder and a cover sucking head; the upper end of the cover sucking head is connected with the cover pressing air cylinder; the lower end of the cover sucking head is used for sucking the cover; the jar holding part is positioned below the cover holding part; and when a pushing rod of the cover pressing air cylinder moves downwards to the lowest position, the cover is pressed with a jar body opening in the jar holding part. With the adoption of the design, thejar can automatically rotate by a corresponding angle according to a deviation position of the cover, so that pressing accuracy between the jar and the cover is higher.

Owner:HANGZHOU WAHAHA PRECISION MACHINERY

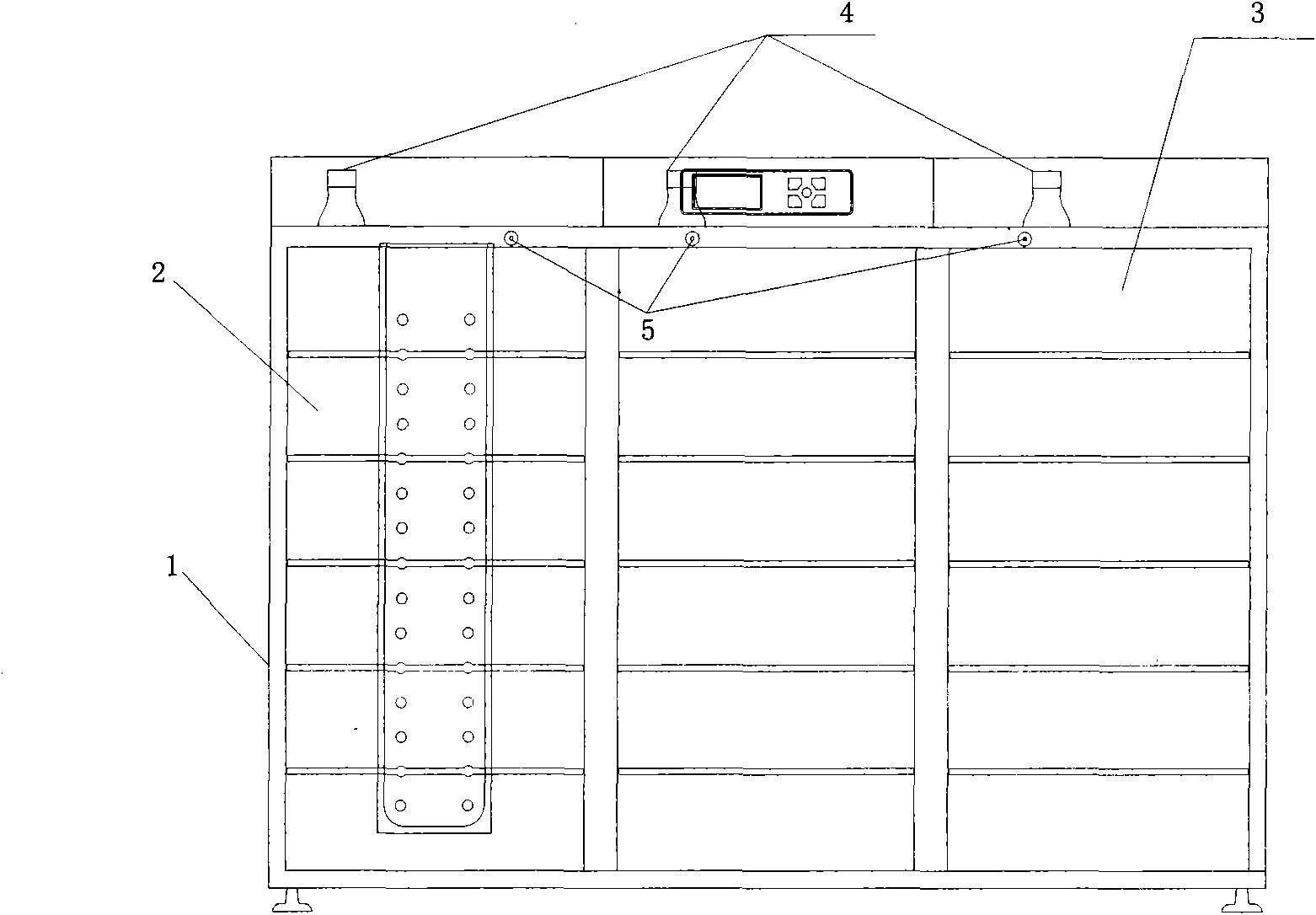

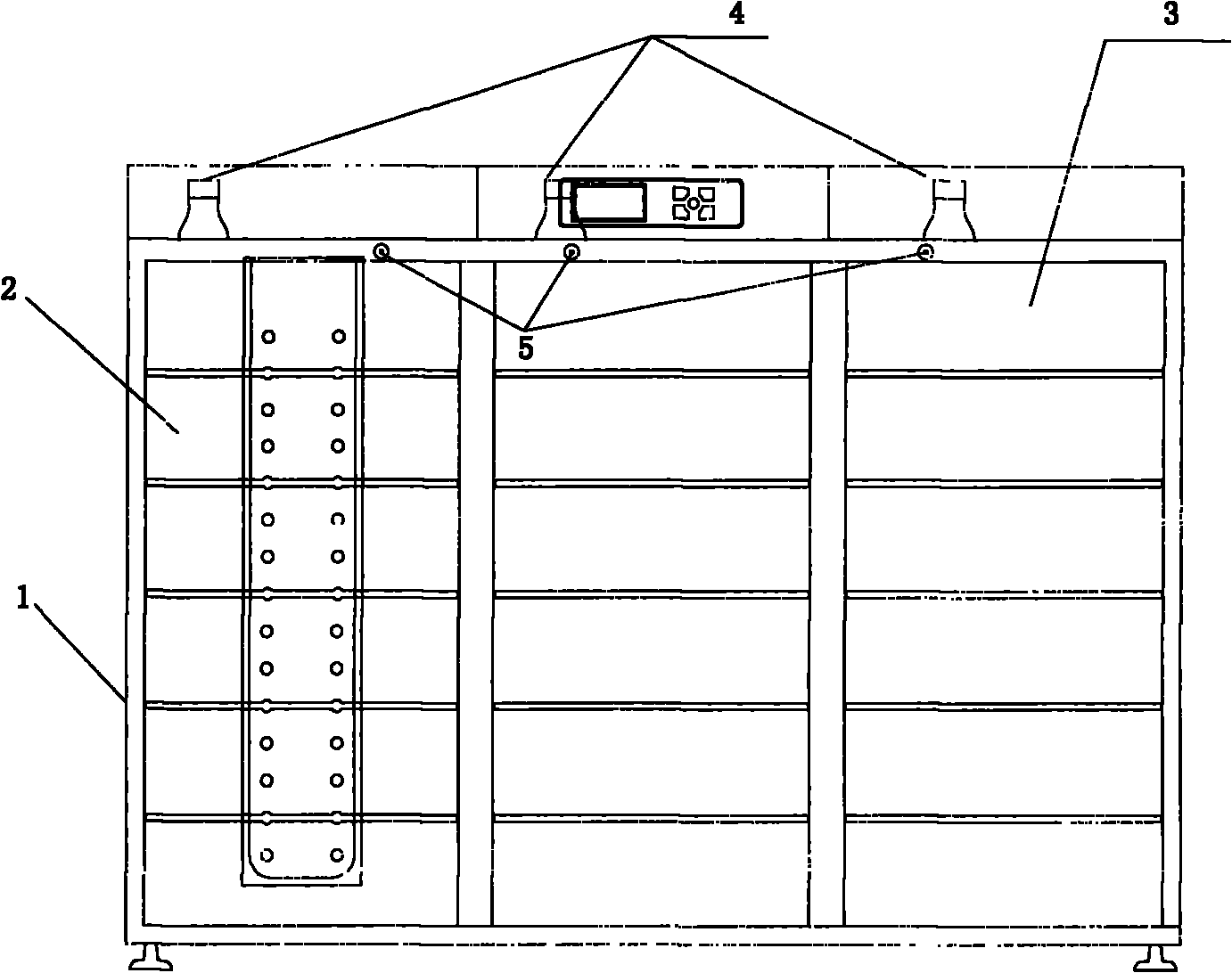

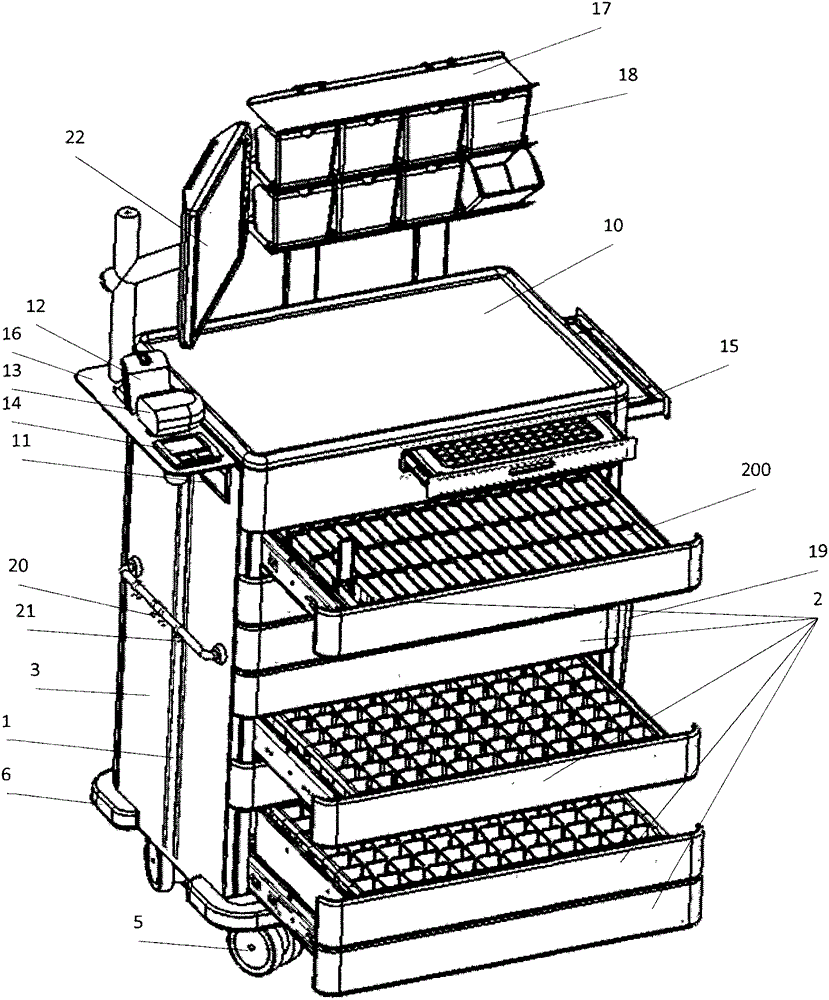

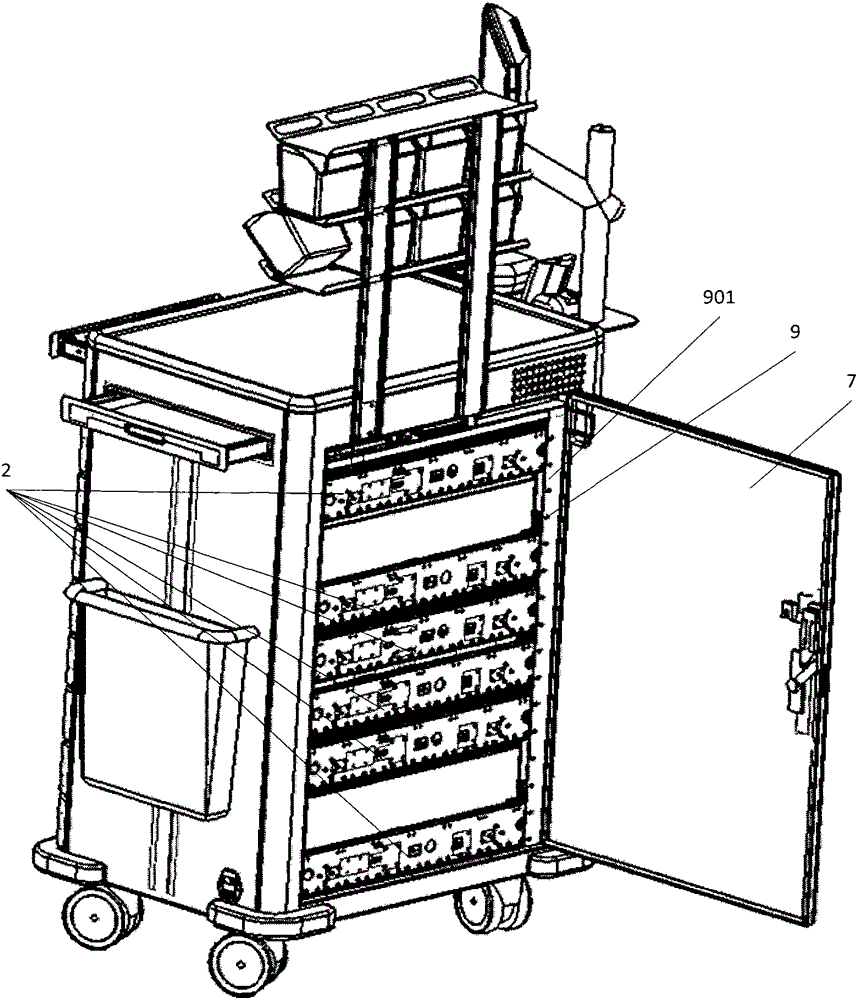

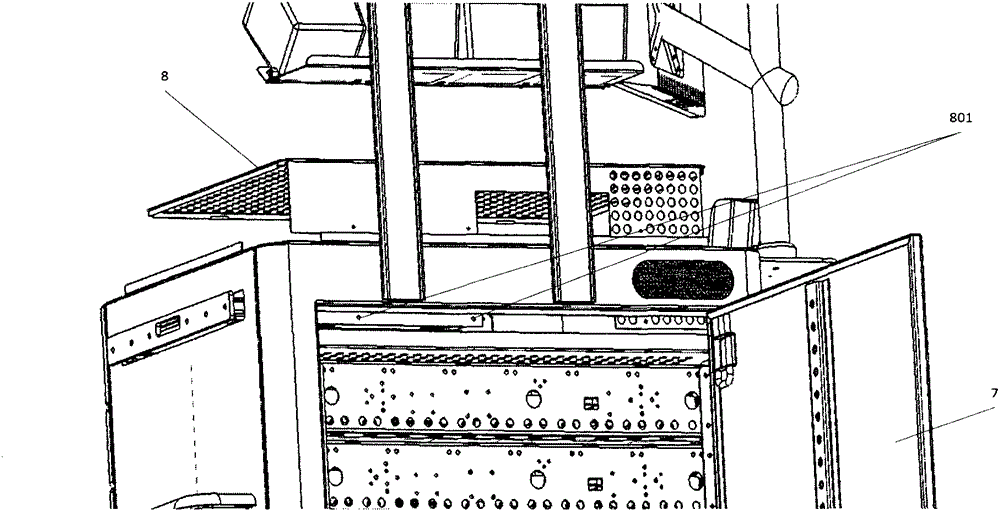

Medicine access system

InactiveCN102259744BImprove inventory efficiencyImprove accuracyStorage devicesDrug productWorkstation

The invention relates to a medicine access system for hospitals, in particular to a medicine workstation of medicines and consumables in operating rooms. The medicine access system can be used for realizing automatic medicine access registration and effective data tracking; in addition, based on the design of a single access door, all drawers, medicine boxes and internal equipment can be maintained and changed only after a rear cabinet door is opened, moreover the cabinet door has a function of state memory and can record the open state of the cabinet without being electrified, therefore the safety of medicine and equipment management and convenience of equipment maintenance can be improved.

Owner:HUAXING RONGTAI

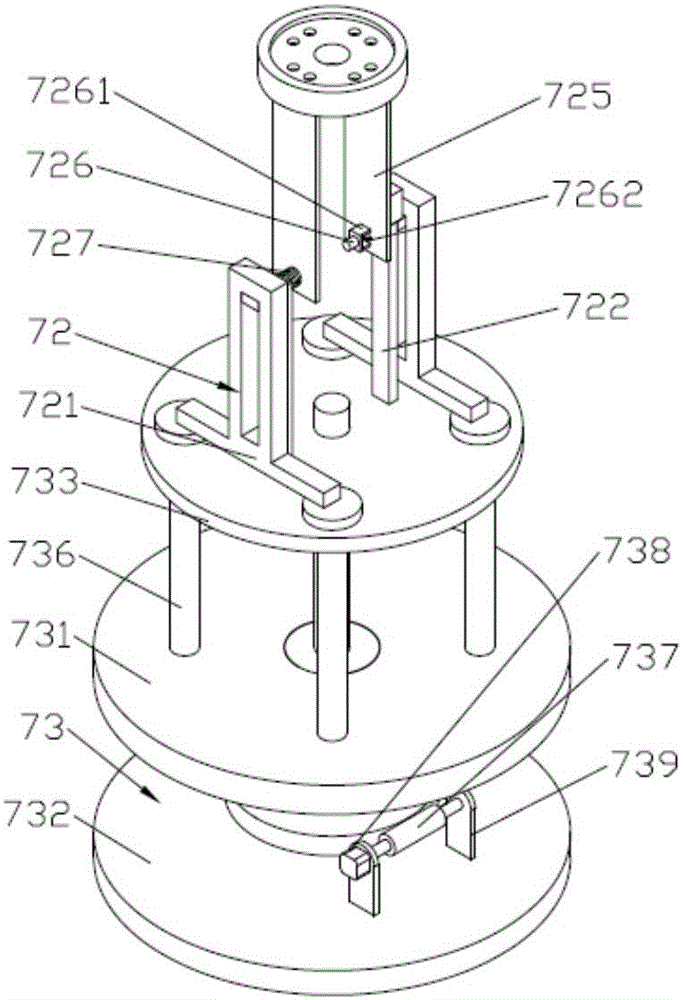

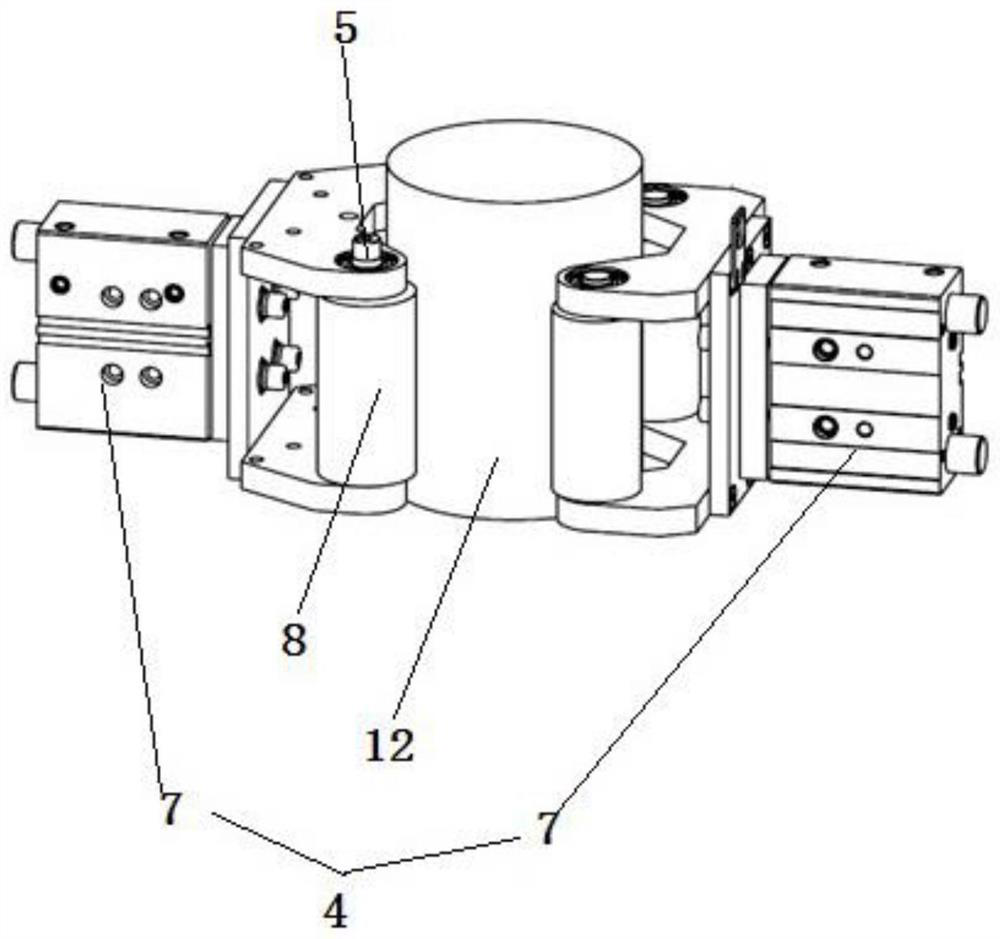

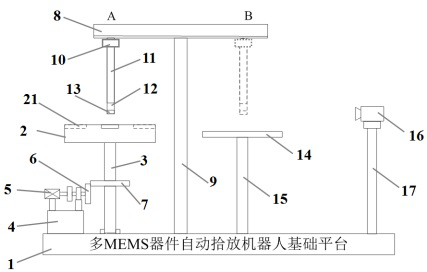

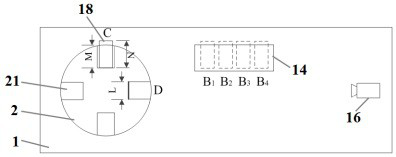

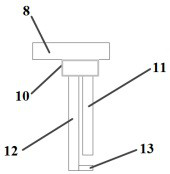

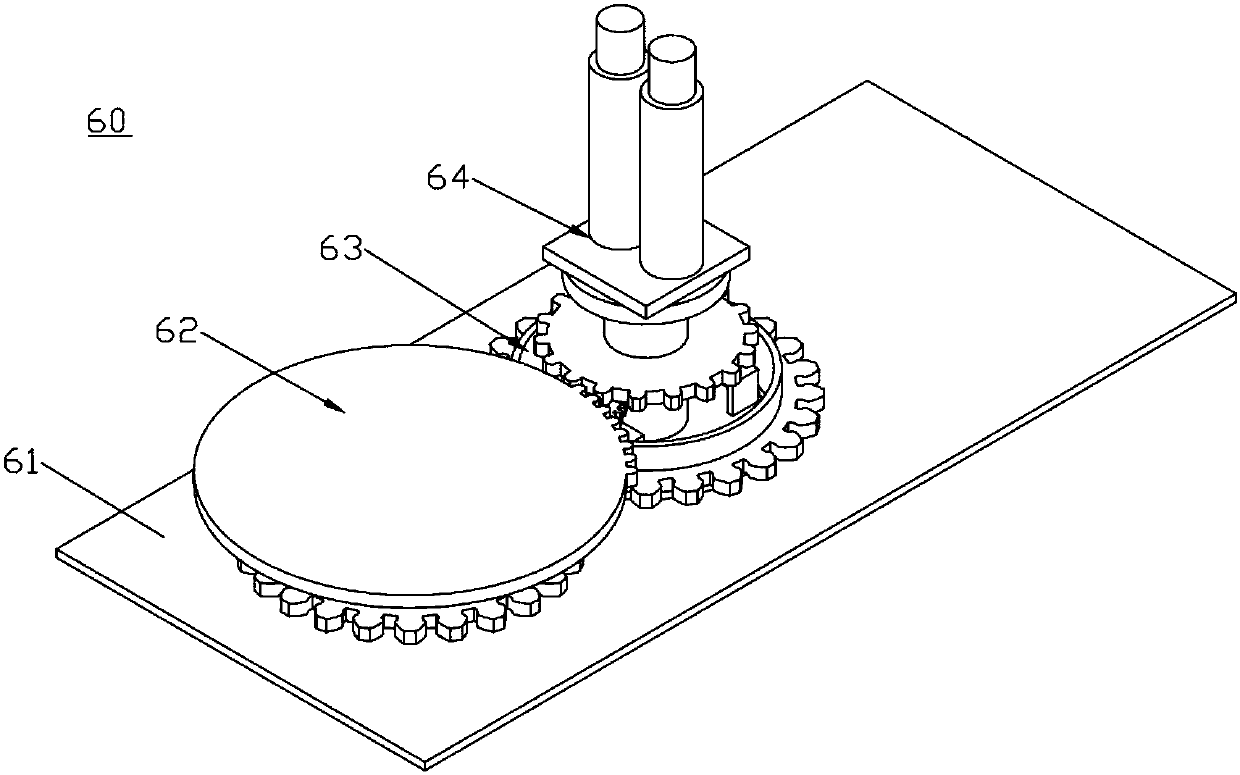

Image feedback multi-MEMS device piezoelectric automatic pick-and-place robot and control method thereof

ActiveCN111646196AAvoid damageReduce uncertaintyTelevision system detailsColor television detailsControl engineeringImage detection

The invention belongs to the field of a micro-electromechanical integration technology and a micro-nano technology, and particularly relates to an image feedback multi-MEMS device piezoelectric automatic pick-and-place robot and a control method thereof. The robot comprises a base platform, wherein a circumferential rotation unit, an automatic pick-and-place device, a piezoelectric adjustable sample table and a liftable image detection unit are sequentially fixed on the base platform from left to right, the automatic pick-and-place device can smoothly pick up MEMS devices arranged on the circumferential rotation unit through cooperation among the circumferential rotation unit, the automatic pick-and-place device, the piezoelectric adjustable sample table and the liftable image detection unit, the MEMS devices are transferred to the piezoelectric adjustable sample table, and the robot has the advantages of automation in operation, high pick-and-place precision and high efficiency.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

File grabbing device based on electromagnetic type

InactiveCN113001524AAvoid accidentsReduce manual laborProgramme-controlled manipulatorGripping headsEngineeringElectrical and Electronics engineering

The invention discloses a file grabbing device based on an electromagnetic type, and belongs to the technical field of file management.The device comprises a displacement control assembly, wherein the displacement control assembly is arranged at the front end of a file rack body, the displacement control assembly comprises a vertical moving assembly, a transverse moving assembly and a longitudinal moving assembly, a horizontally-placed first sliding rail is arranged at the top of the file rack body, the first sliding rail is parallel to the moving track of the transverse moving assembly, a first sliding block is arranged on the first sliding rail in a matched mode, the upper end of the first sliding block is connected with one end of a second auxiliary connecting plate which is perpendicularly staggered with the first sliding rail, and the other end of the second auxiliary connecting plate is connected with the upper end of the perpendicular moving assembly which is perpendicularly arranged. According to the scheme, intelligent file taking and placing are achieved, the taking and placing process is efficient and quiet, meanwhile, taking and placing of files of different specifications, especially small or heavy files, can be coped with, taking and placing errors do not occur after the device is used for a long time, personnel or light rays are not needed for assisting in taking and placing of the files, labor force is reduced, and energy consumption is reduced.

Owner:浙江仰天云信息技术有限公司

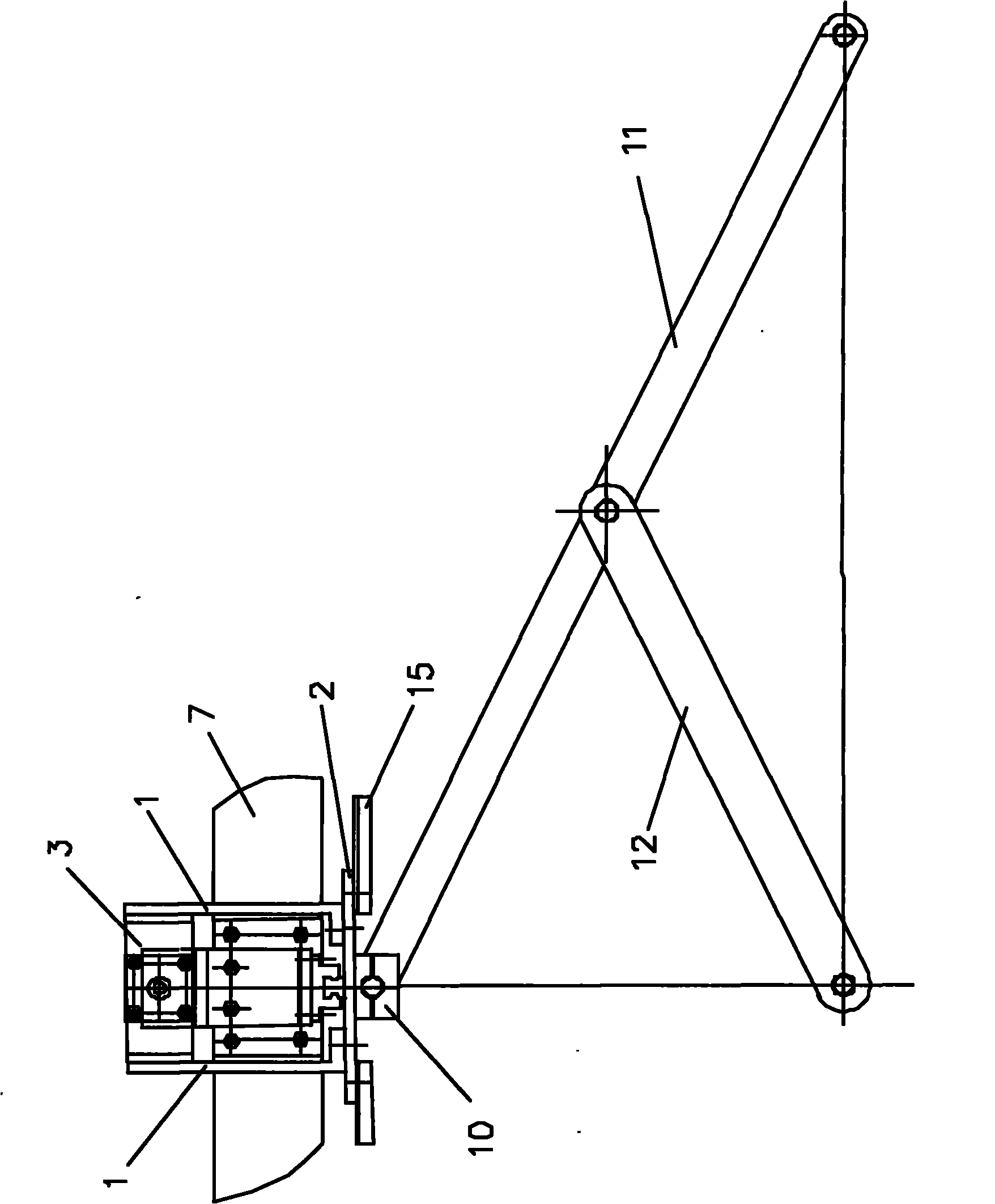

Automatic fishing rod type hoisting device

The invention relates to an automatic fishing rod type hoisting device. The automatic fishing rod type hoisting device comprises a cross beam and a walking trolley, wherein the cross beam is horizontally arranged on the cross beam, and the walking trolley is arranged on the cross beam and moves along the cross beam. A vertical telescopic sleeve is arranged at the bottom of the walking trolley, thetelescopic sleeve is composed of a plurality of hollow pipes which are connected end to end, the last hollow pipe is inserted into the top of each hollow pipe, a lifting tool is arranged at the bottoms of the hollow pipes at the bottommost part of the telescopic sleeve, a winch is arranged on the walking trolley, a lifting rope is arranged on the winch in a wound mode, and the free end of the lifting rope is connected with the hollow pipes at the bottommost part of the telescopic sleeve. According to the automatic fishing rod type hoisting device, lifting of the lifting tool is realized by utilizing the winch, the travel is long, the size of equipment is small, and the cost is low; the lifting tool can be effectively prevented from shaking by the aid of the telescopic sleeve, the stability in the hoisting process is guaranteed, the defect of shaking in the hoisting process of the winch can be overcome effectively, and the cargos can be conveniently placed more accurately; and the telescopic sleeve can stretch and contract in the hoisting process, so that interference between the telescopic sleeve and adjacent equipment can be effectively prevented.

Owner:苏州勃朗科技股份有限公司

Single motor driving lifting high-precision grabbing and releasing mechanical hand and control method thereof

PendingCN108015756ASimplify power configurationPrevent malfunctionProgramme-controlled manipulatorMotor driveGear wheel

The invention relates to a single motor driving lifting high-precision grabbing and releasing mechanical hand. The single motor driving lifting high-precision grabbing and releasing mechanical hand comprises a driving module, an execution module and a control module, wherein the driving module uses a single motor as a unique power device; the execution module comprises a mechanical hand part and amechanical hand movement mechanism; the mechanical hand part comprises four arms; the four arms are pairwise connected by limiting shafts in parallel; the linkage of the four arms is realized throughsprings and two engaged semi-gears; the mechanical hand movement mechanism comprises a cam unit and multiple levers; the cam unit comprises two disc cams which are coaxially arranged and are parallelto each other; a large cam (7) is used for driving the multiple arms to simultaneously carry out inward clamping and outward stretching; a small cam (8) is used for driving the hand part to drop andlift; and the control module comprises two sensory feedback devices which are respectively used for positioning the lifting position of the mechanical hand part and judging whether an object is grabbed by the mechanical hand part. The single motor driving lifting high-precision grabbing and releasing mechanical hand is simple in structure, easy to control, is accurate in grapping and releasing andhas high reliability.

Owner:NCS TESTING TECH

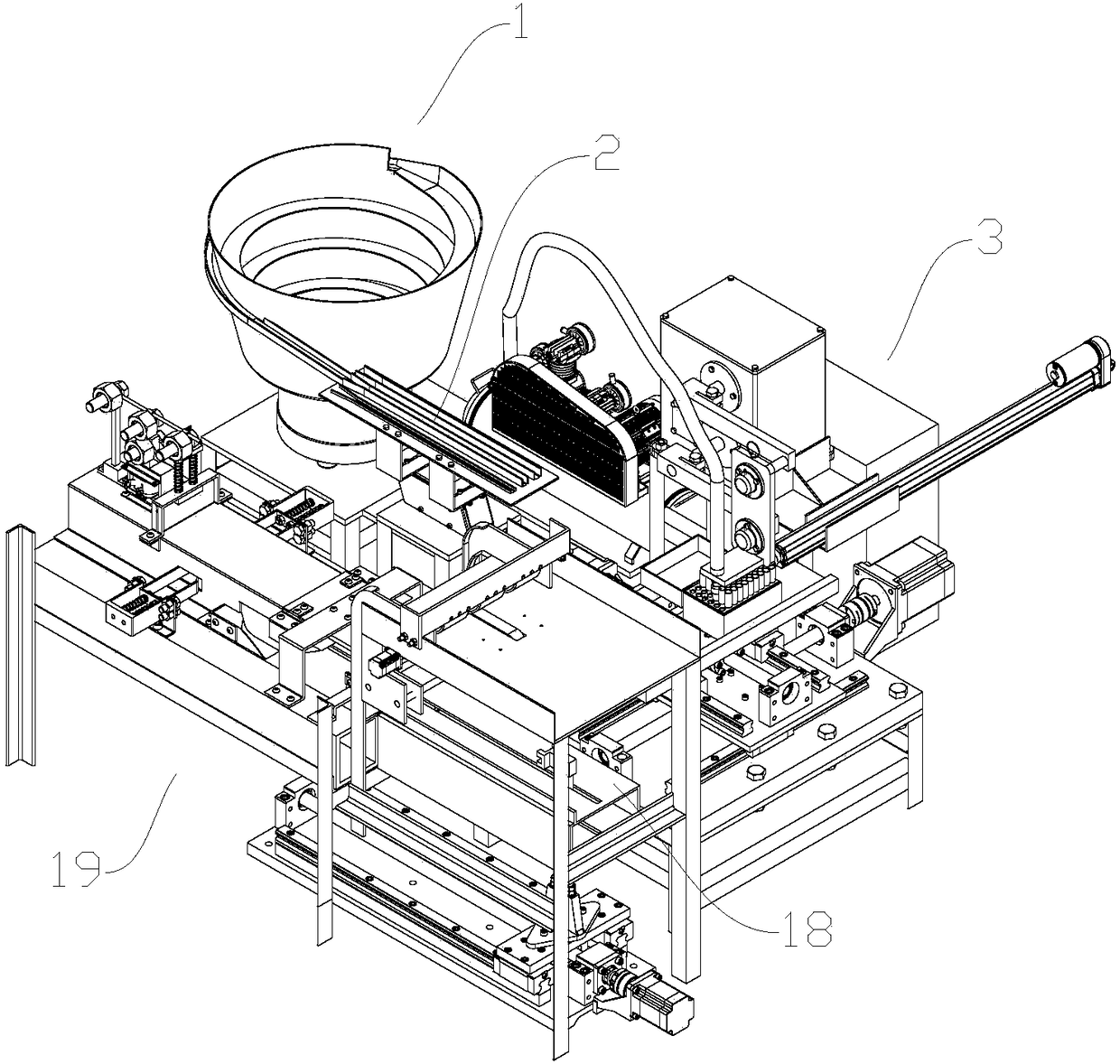

Pipette Tip Sealing Machine

ActiveCN106394991BImprove operational efficiencyRealize the whole process packagingPackagingConveyor partsPipetteEngineering

A liquid relief gun head packaging machine comprises a loading mechanism and further comprises a feeding mechanism and a boxing mechanism; the boxing mechanism comprises a gun head taking mechanism used for taking gun heads from the position of the feeding mechanism, a gun head box platform used for containing a gun head box, an electric pushing rod used for pushing the gun head box to move on the gun head box platform, and a horizontal workbench used for carrying the gun head box platform and capable of driving the gun head box to move in two perpendicular directions; and a cover buckling mechanism is arranged on the edge of the gun head box platform. The loading mechanism completes one-by-one loading of the liquid relief gun heads; the feeding mechanism further conveys the loaded liquid relief gun heads; the gun head taking mechanism takes the liquid relief gun heads from the position of the feeding mechanism and places the liquid relief gun heads in the gun head box one by one; the electric pushing rod completes pushing of the gun head box; and the cover buckling mechanism completes cover buckling in the process. The invention provides a liquid relief gun head automatic packaging system integrating the conveying, boxing and packaging functions, manual intervention is not needed in the boxing and packaging process, and the liquid relief gun head boxing operation efficiency can be greatly improved.

Owner:QINGDAO AGRI UNIV

A handling robot equipped with a rotating manipulator

The invention discloses a handling robot with a rotary manipulator. The handling robot with the rotary manipulator comprises a base body, a waist turning part pivoted onto the base body, a big arm pivoted onto the waist turning part, a small arm pivoted on the big arm, and the manipulator arranged on the small arm. The waist turning part rotates around the base body; the big arm rotates around the waist turning part; the small arm rotates around the big arm. The manipulator comprises a pair of sucking disc groups, and a driving mechanism for driving the pair of sucking disc groups to rotate; the driving mechanism comprises a base, a rotating assembly, a rotation driving device and a lock catch assembly. According to the handling robot with the rotary manipulator provided by the invention, a driving assembly making the annular circular motion can unlock the restriction of the lock catch assembly on the rotating assembly so as to drive the rotating assembly to rotate at 180 degrees, and the pair of sucking discs are rotated at 180 degrees along with the rotating assembly. The two sucking discs on the manipulator can be accurately rotated at 180 degrees through the driving mechanism provided by the invention, so that the manipulator can accurately pick and place materials.

Owner:ZHEJIANG AOCHUAN HYDRAULIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com