Patents

Literature

439 results about "Robot manipulator" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A robot manipulator is a robotic arm-like mechanism that is designed to manipulate or move materials, tools, and parts without direct human contact.

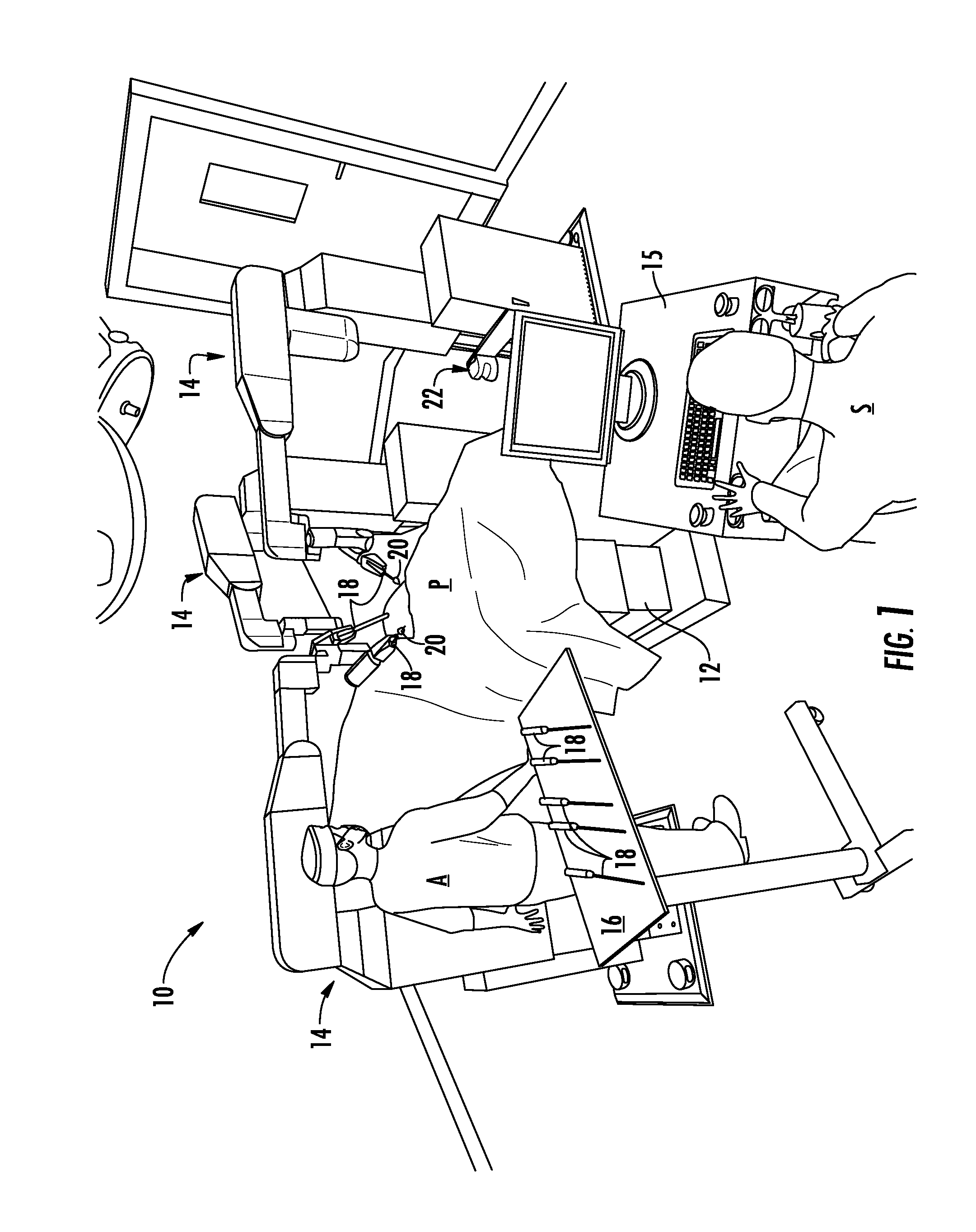

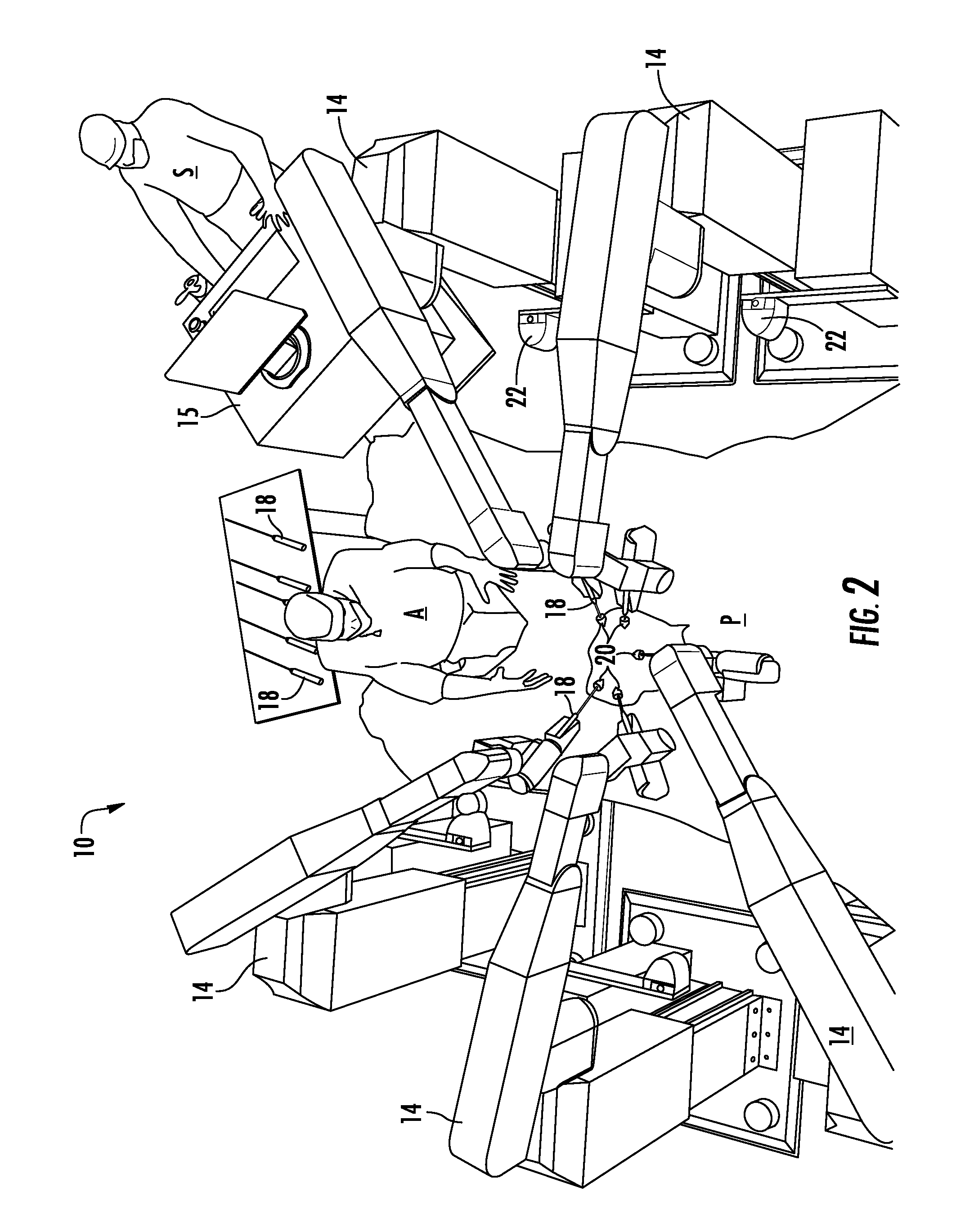

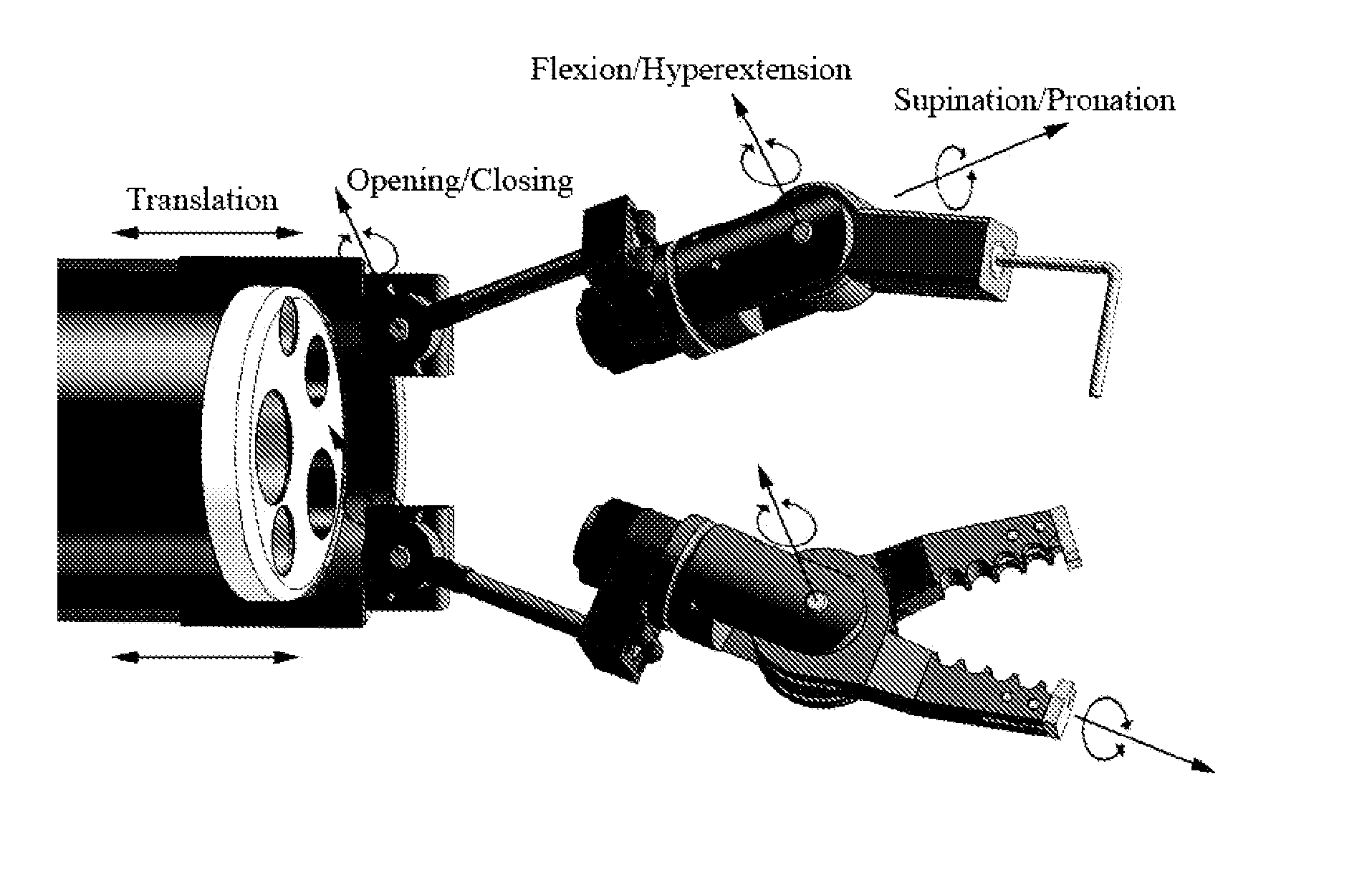

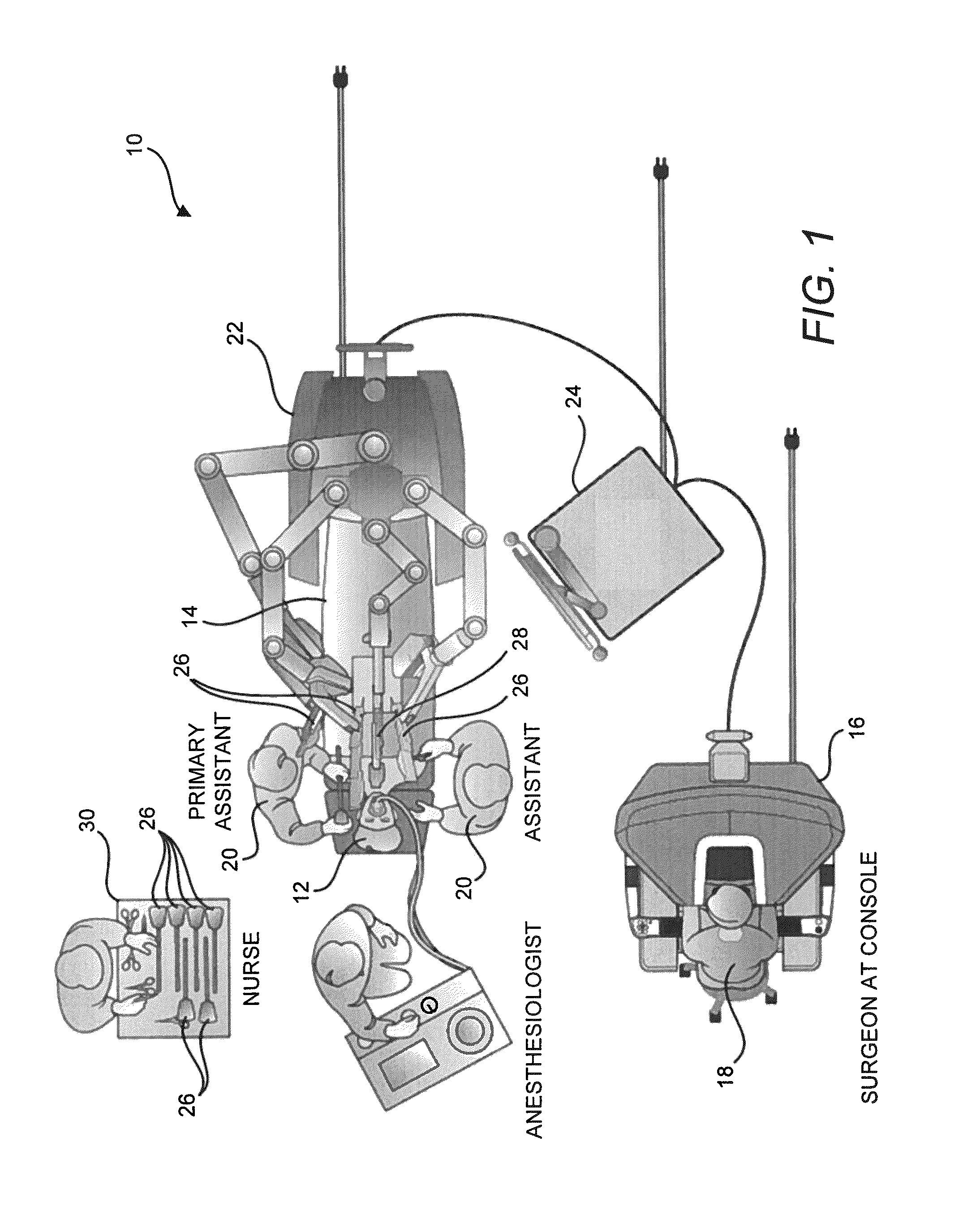

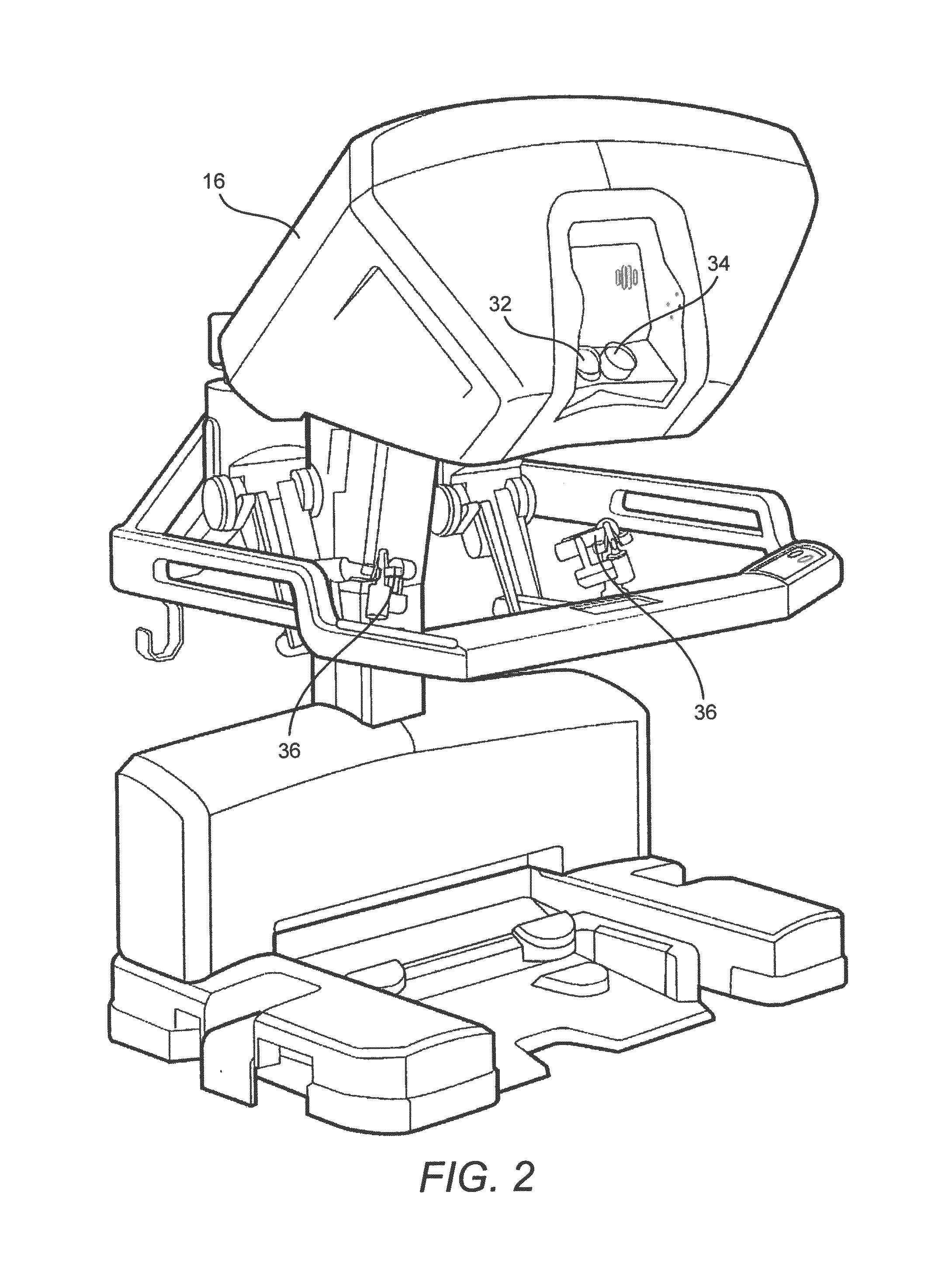

Robotic surgical system for performing minimally invasive medical procedures

ActiveUS8506555B2Level of manoeuvrabilityAccurate feedbackProgramme-controlled manipulatorDiagnosticsAccelerometerWrist support

Owner:EURO ATOMIC ENERGY COMMUNITY (EURATOM)

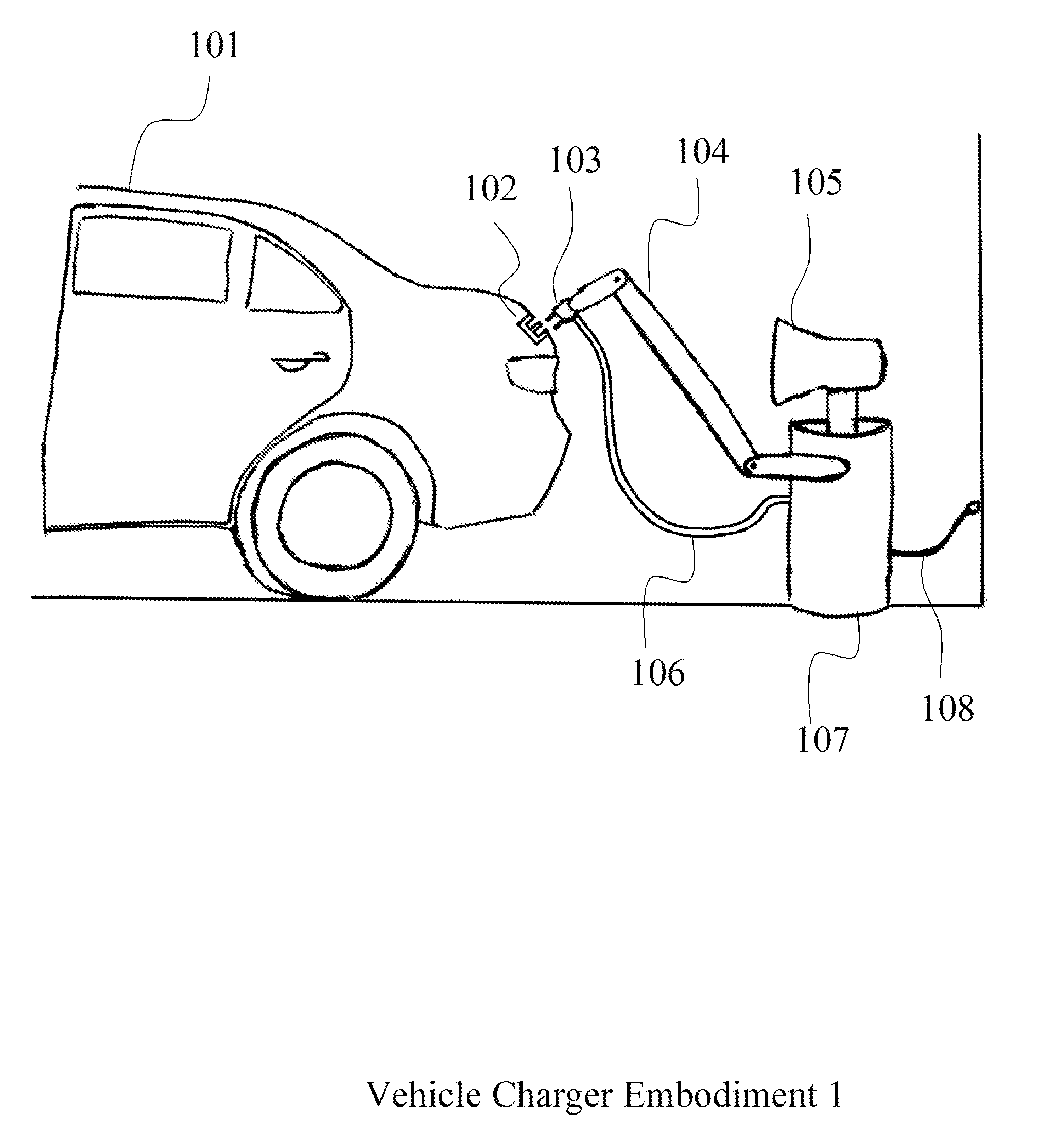

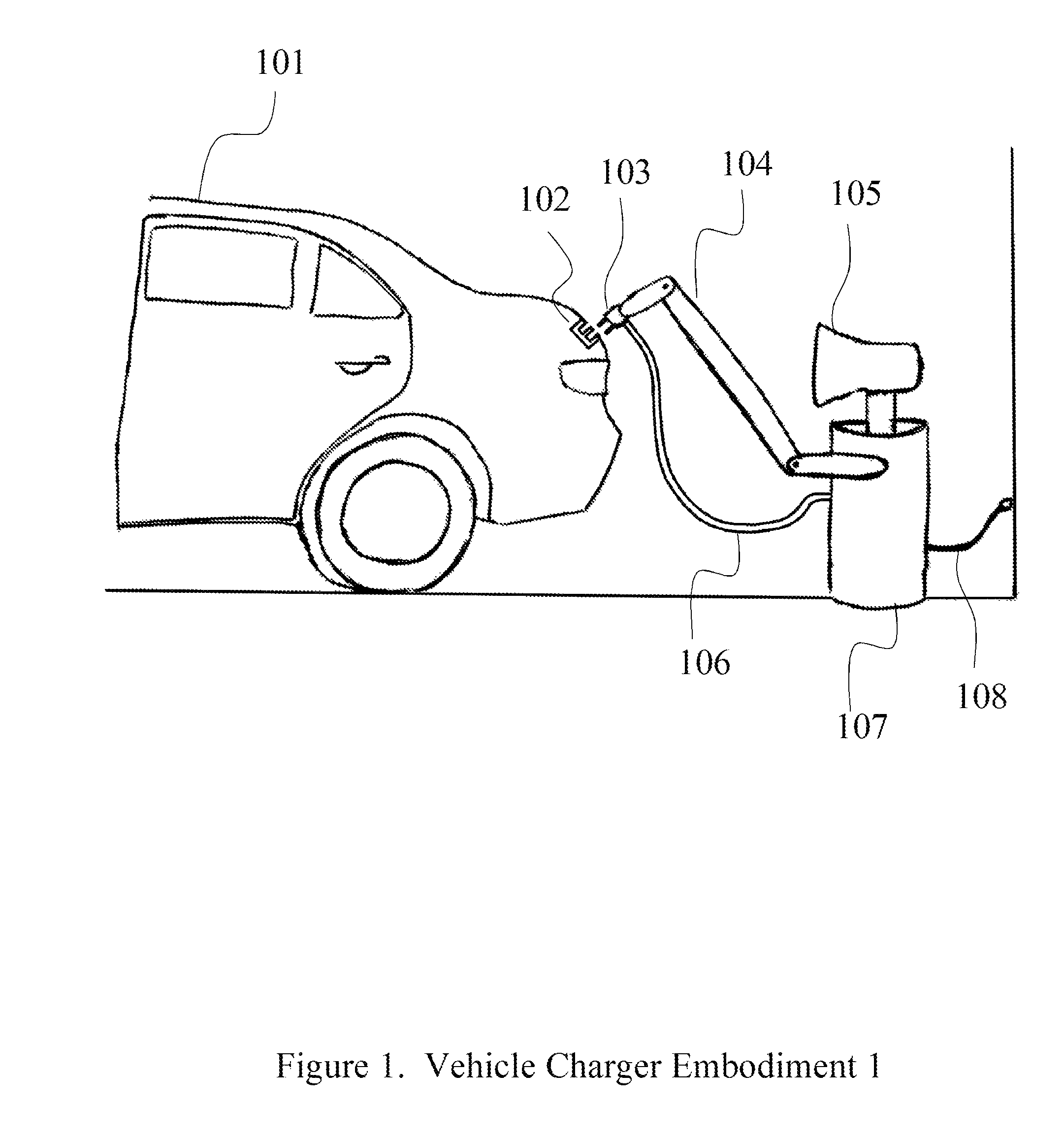

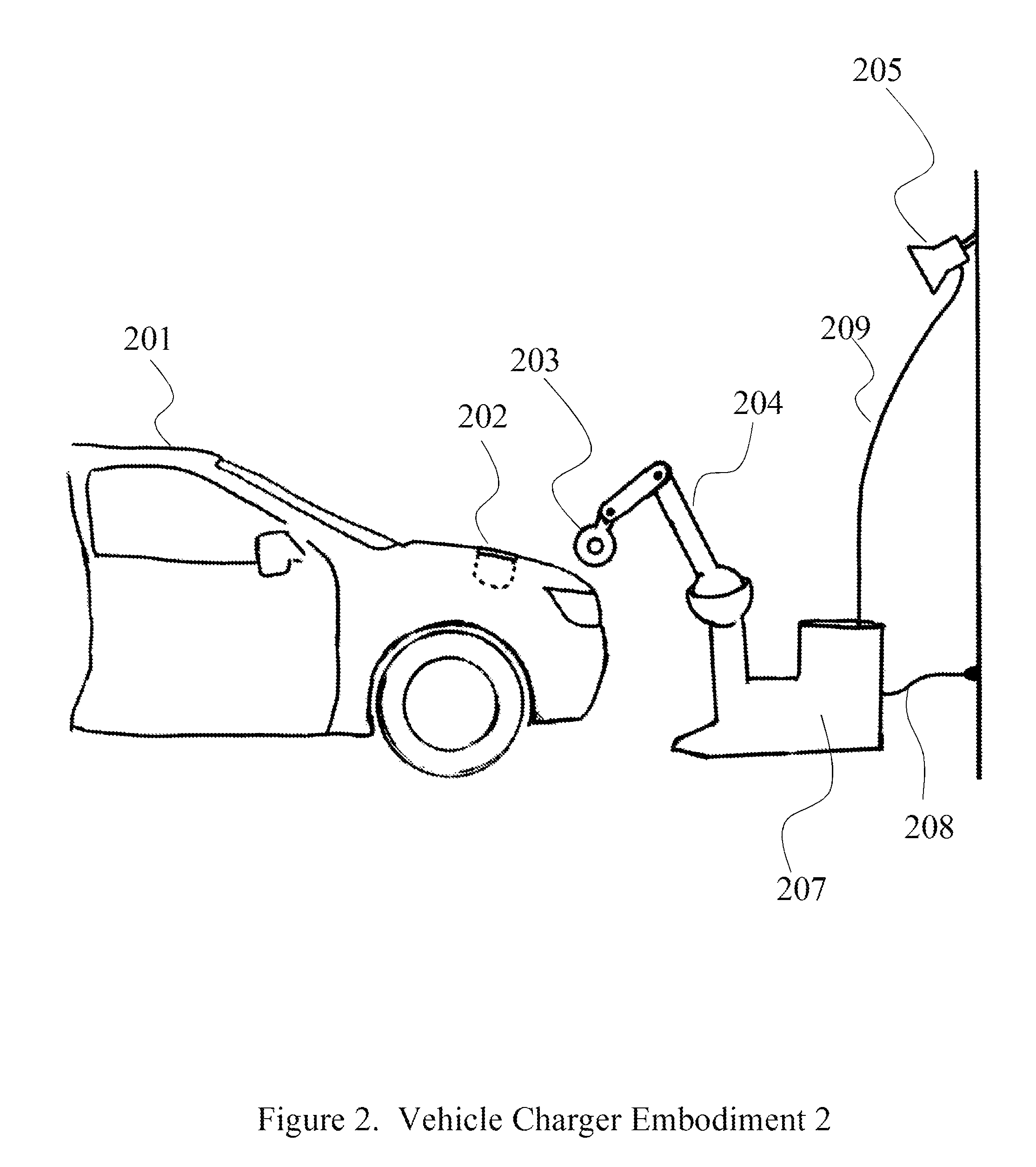

System to automatically recharge vehicles with batteries

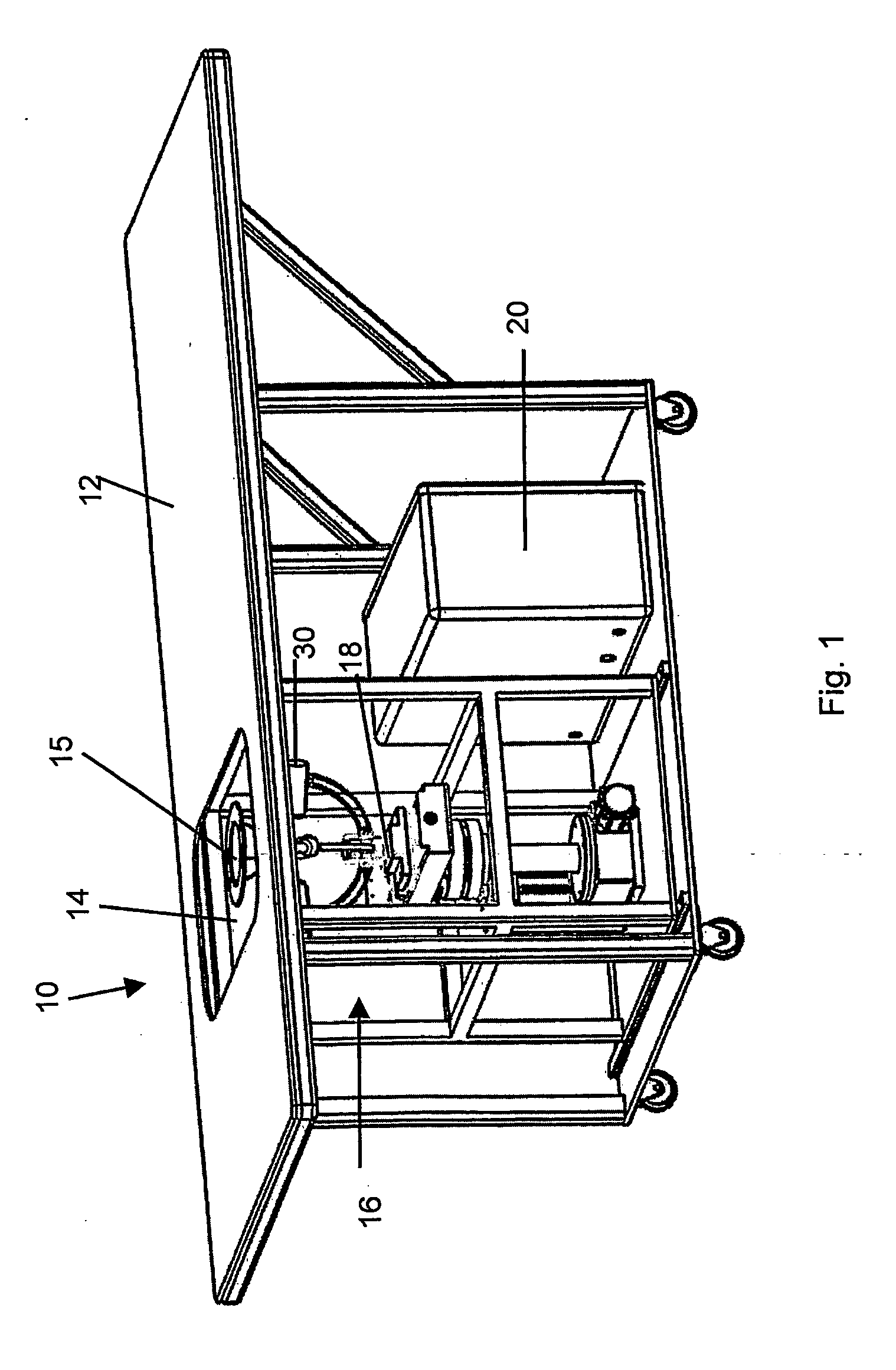

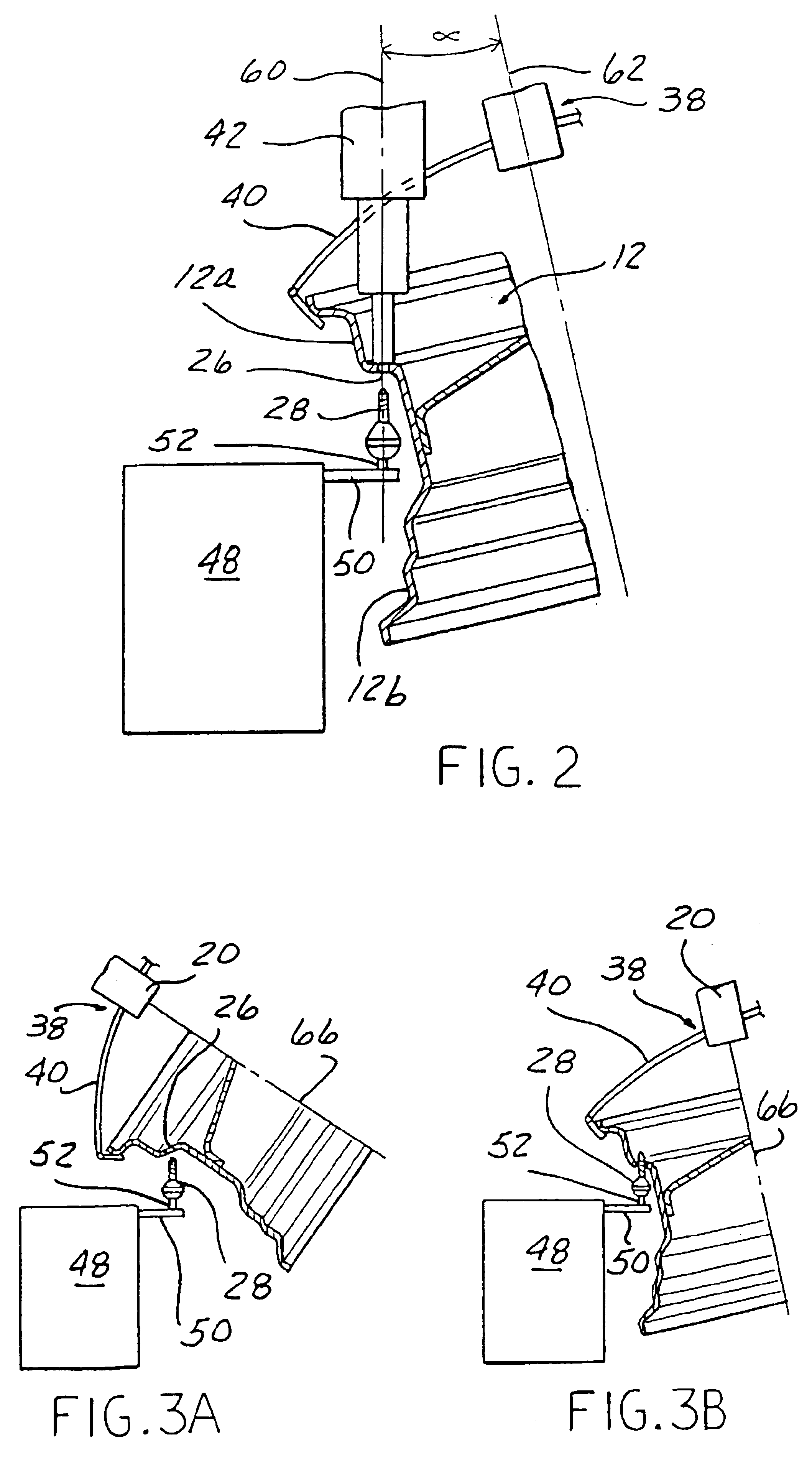

A plug-in hybrid electric vehicle (PHEV) is an automobile which can use either electricity or gasoline. With high gasoline prices, electricity is becoming a promising alternative to power next generation automobiles. One advantage of the PHEV and the BEV (battery electric vehicle) is that charging can be done at home. However, the small battery capacity of PHEV's may require recharging the batteries almost daily. It would be convenient for an owner of a car with batteries to not have to plug in the battery each and every day that charging is required. Our invention is a system that plugs the power automatically into the vehicle with minimal human intervention using an automated docking system. The system is composed of a robotic manipulator with a camera and a processing unit. The system uses the camera and vision processing to identify the vehicle's position, and consequently, the location of the vehicle's charging receptacle. The robotic manipulator then directs the charging cord's plug into the receptacle of the vehicle. Once charging is complete, the robotic manipulator removes the plug from the vehicle.

Owner:SEVENTHDIGIT CORP

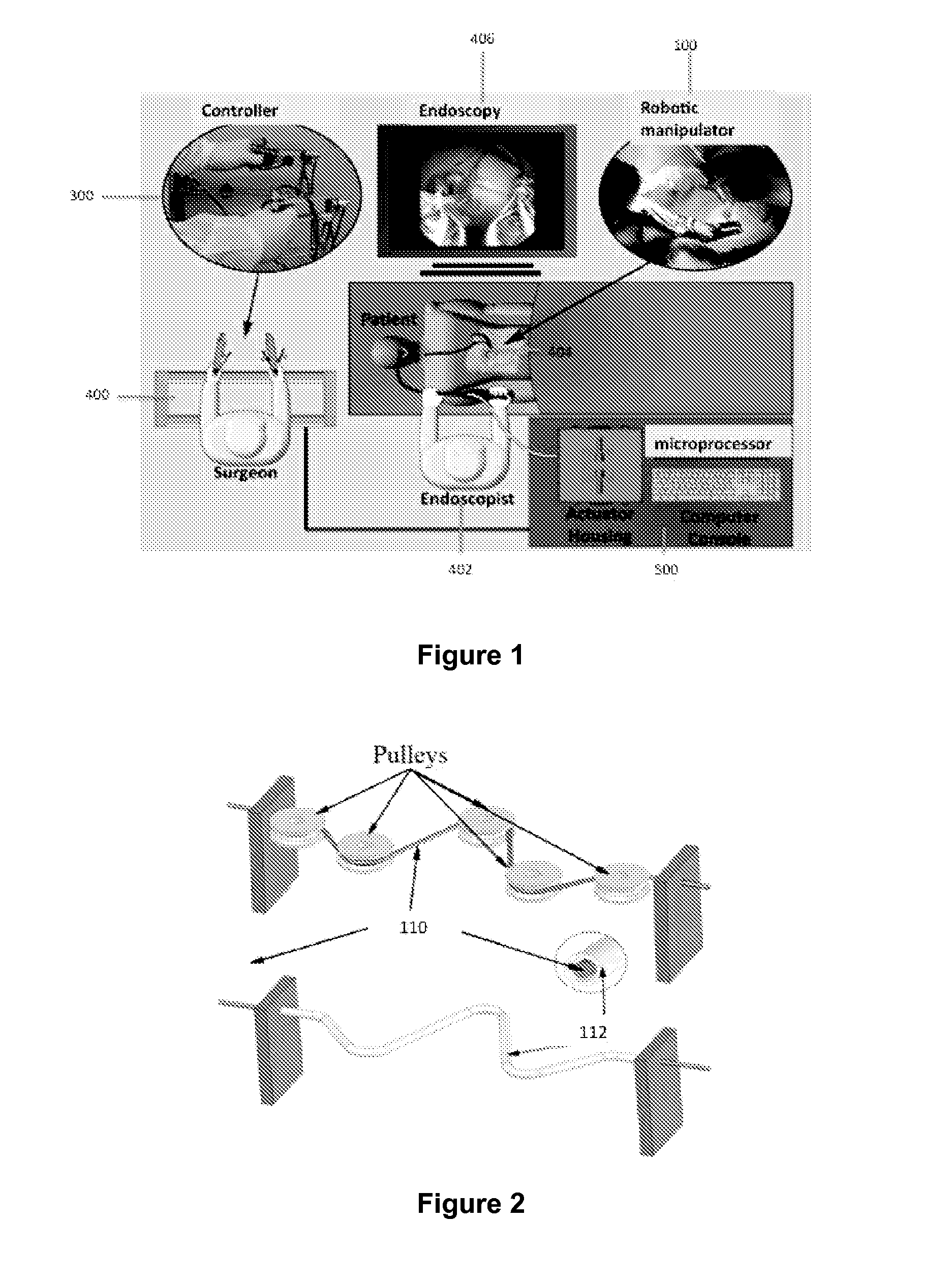

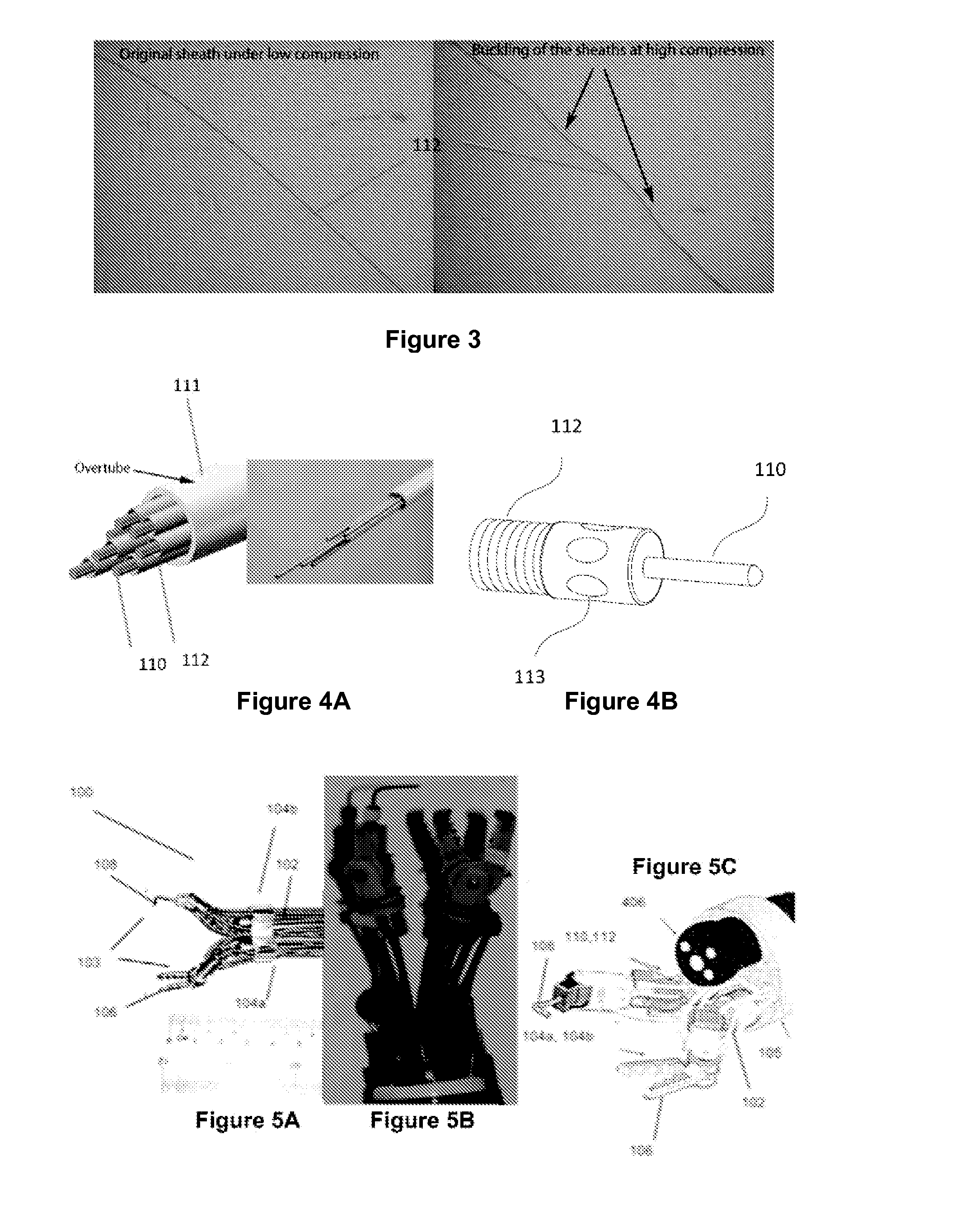

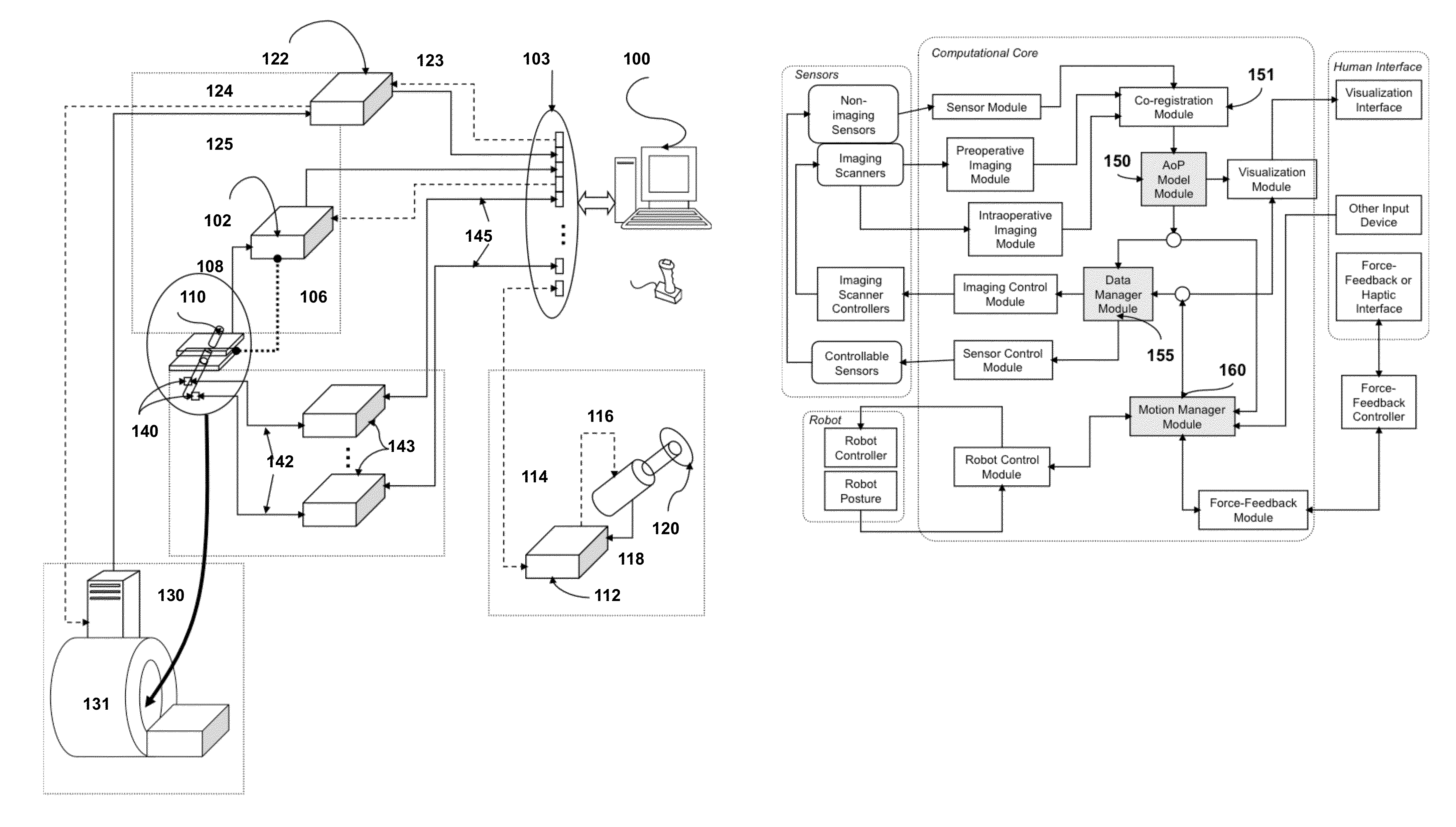

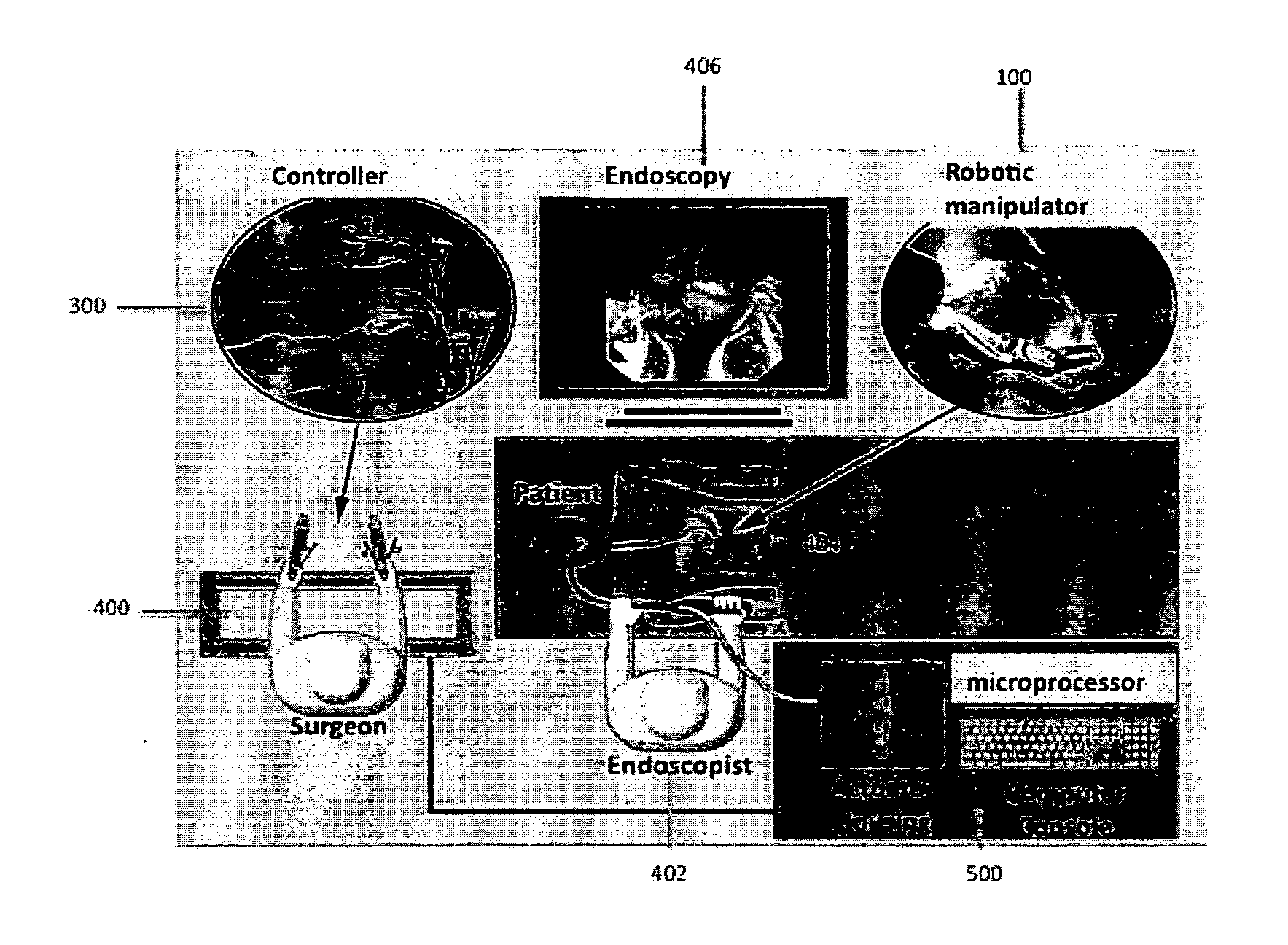

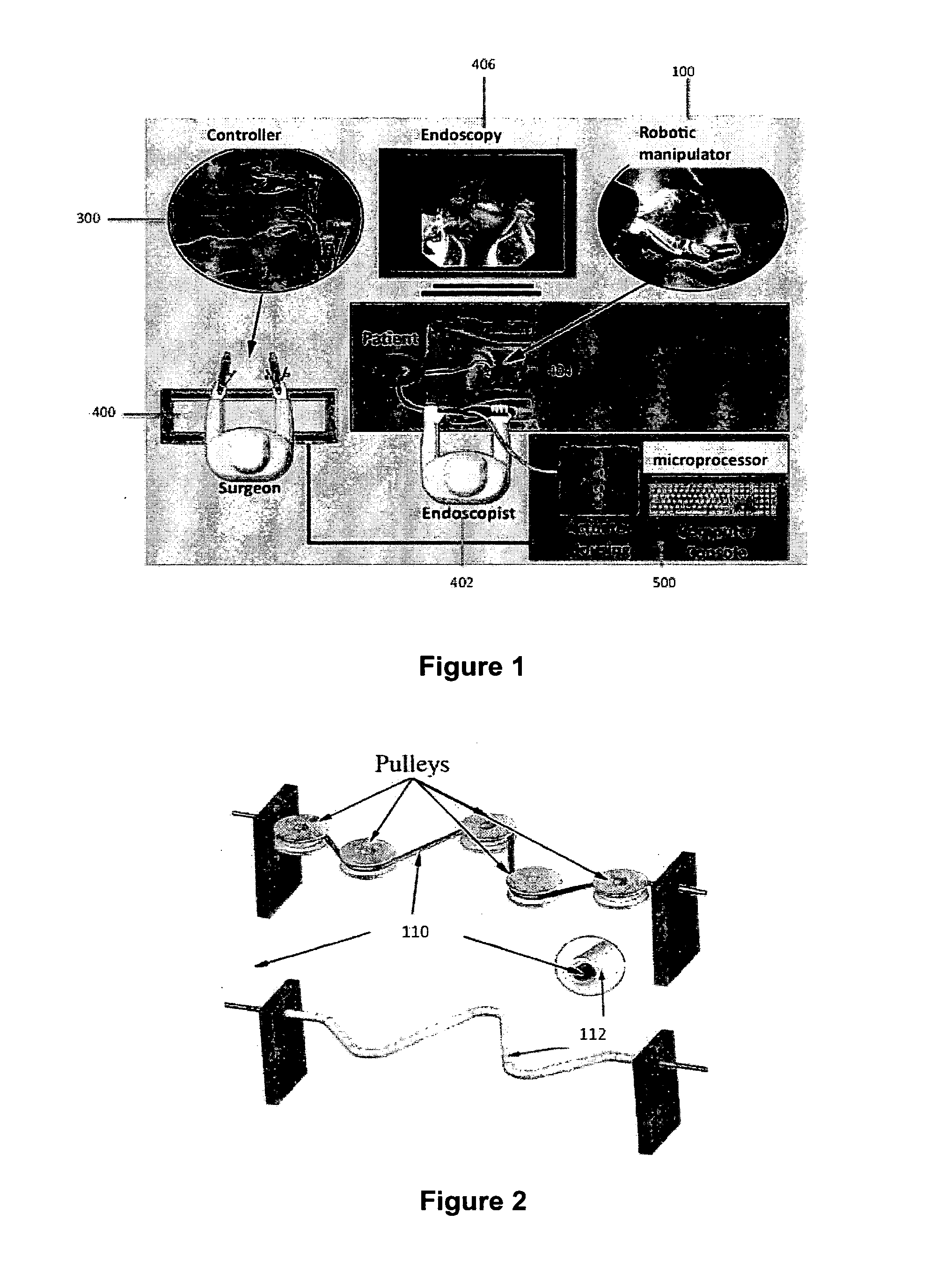

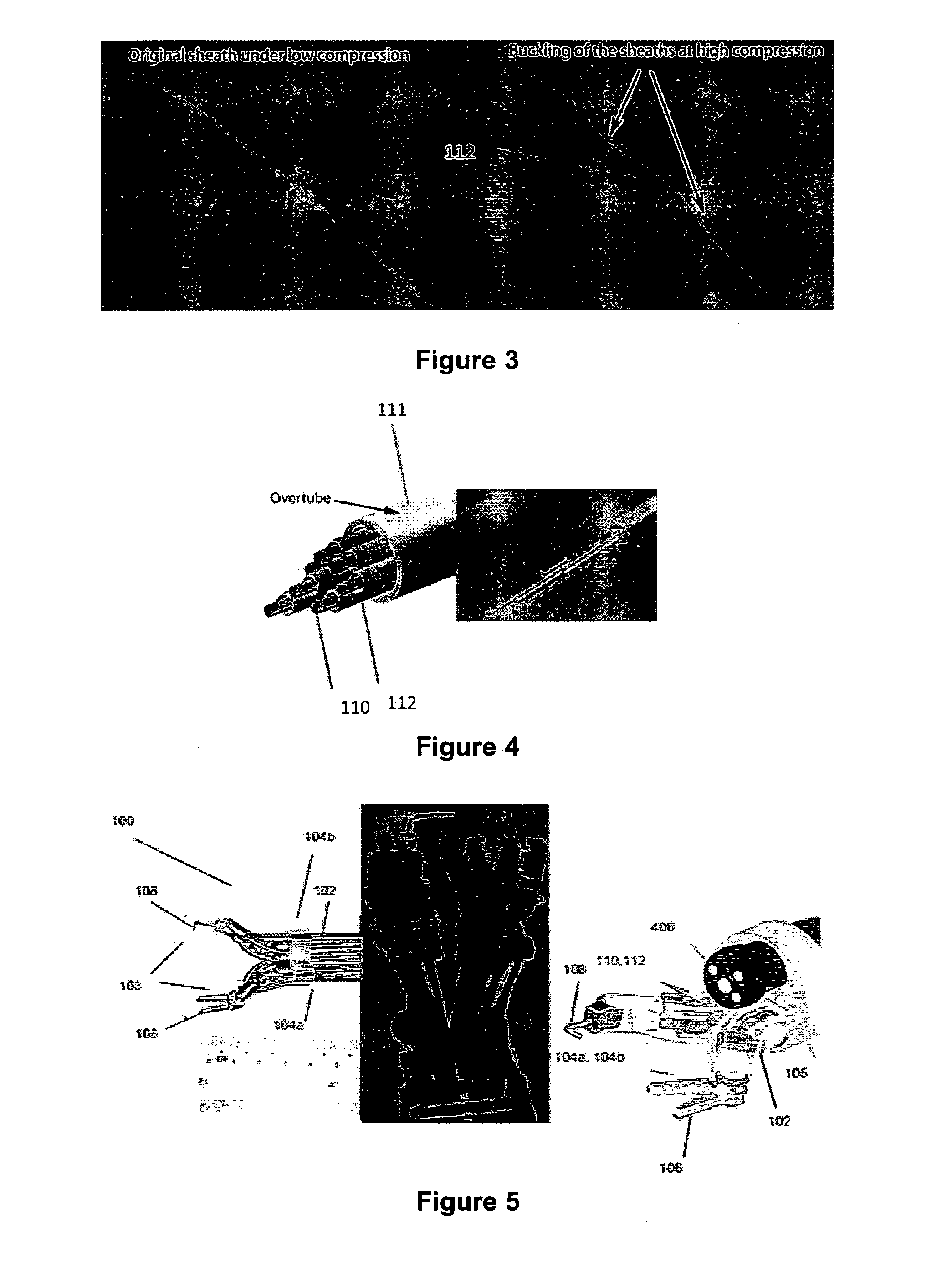

Robotic system for flexible endoscopy

InactiveUS8882660B2Intricate and precise surgical interventionRemove scarsEndoscopesSurgical instruments for heatingFlexible endoscopyRobotic systems

A robotic manipulator controller and system for use in flexible endoscopy, the manipulator comprising a flexible member configured to be coupled to an endoscope, and an arm connected to and movable by the flexible member, wherein the flexible member has a first end connected to the arm and a second end connectable to the controller to allow a physical movement of the arm to be controllable by a physical movement of the controller.

Owner:NANYANG TECH UNIV +1

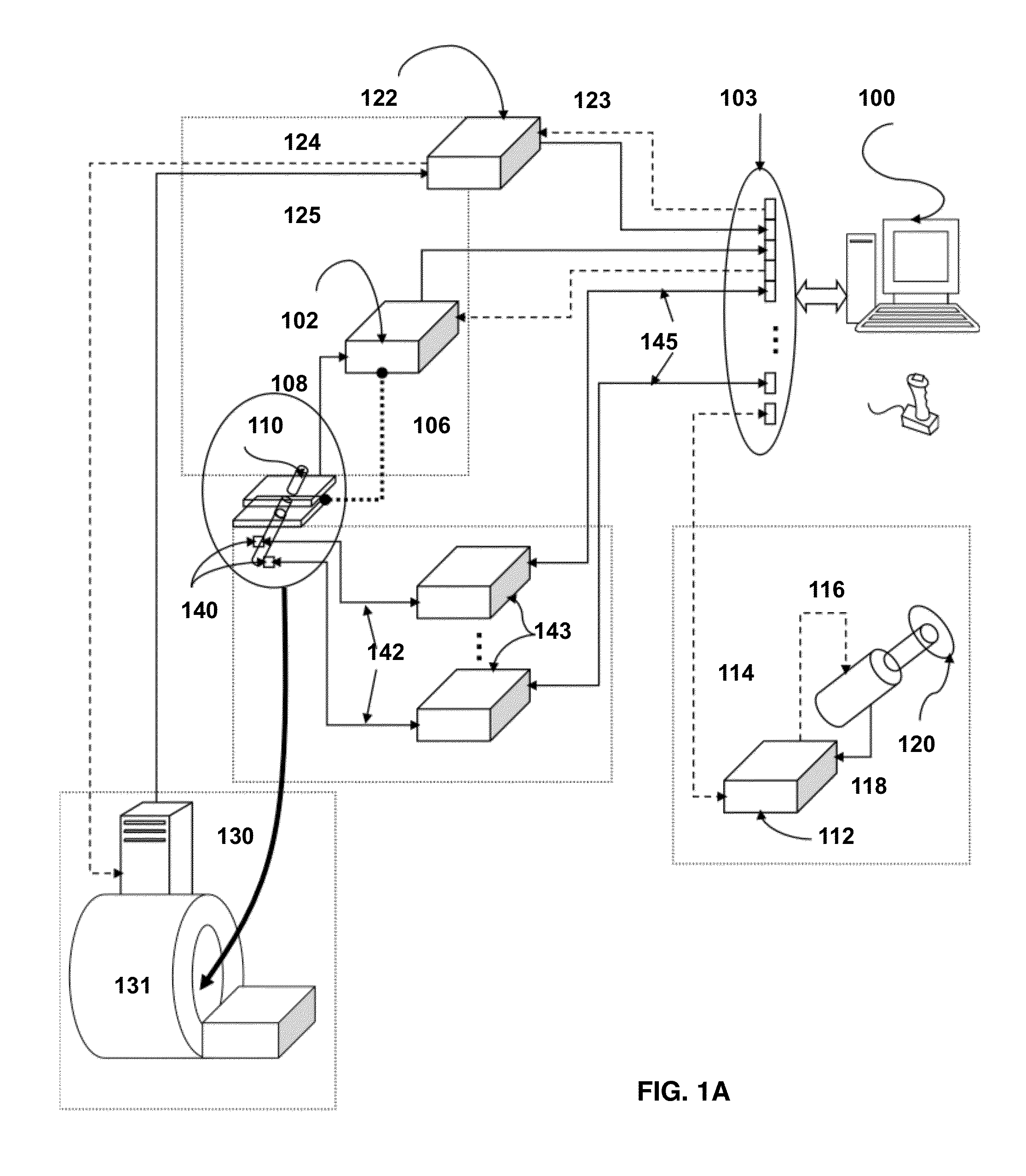

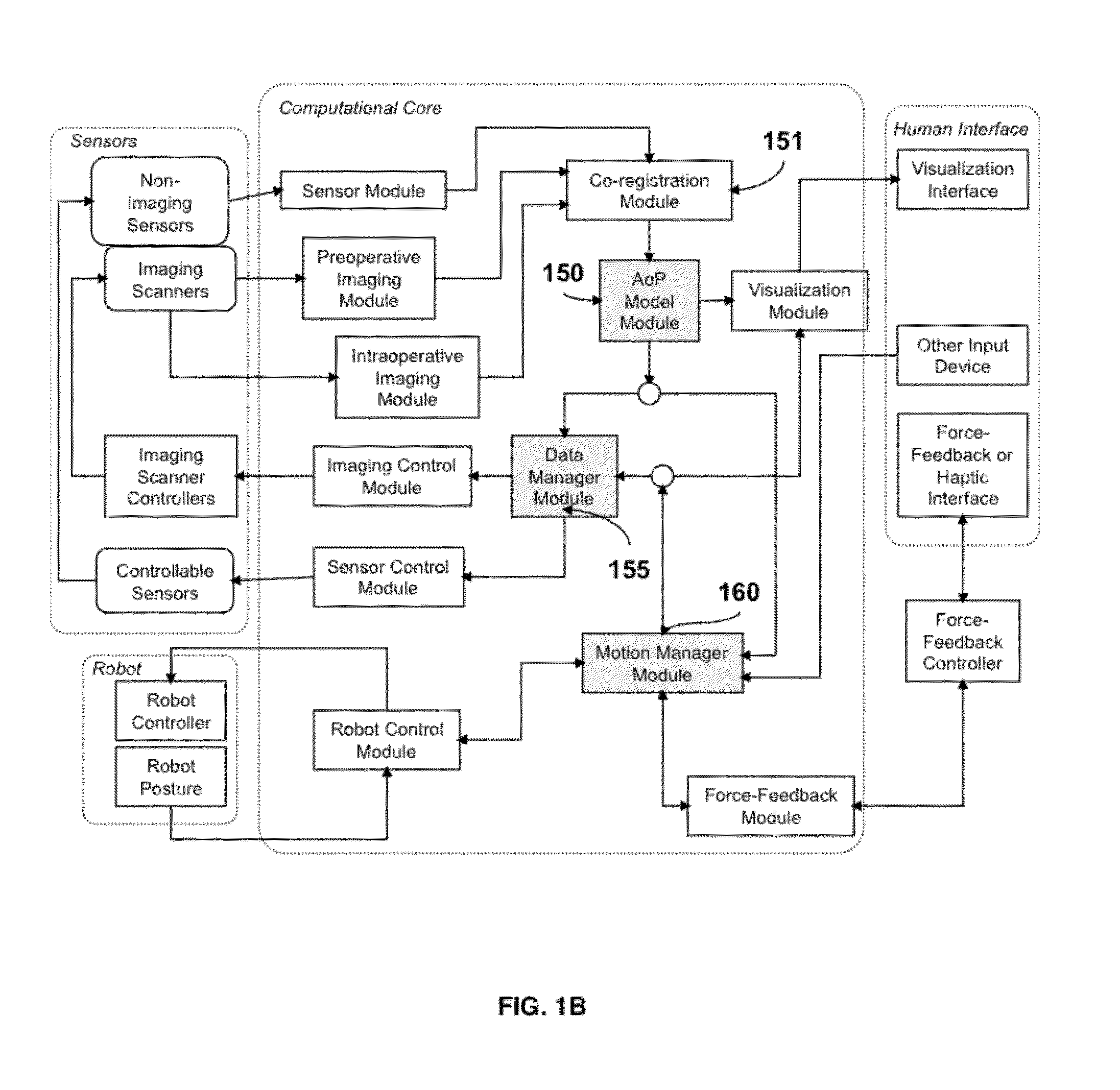

Robotic Device and Systems for Image-Guided and Robot-Assisted Surgery

Provided herein are robotic systems, for example, MRI guided robots, for image-guided robot-assisted surgical procedures and methods for using the same to perform such surgical procedures on a patient. The robotic systems comprise a robotic manipulator device or global positioner, means for actuating the robotic manipulator or global positioner that is mechanically linked thereto and a computer having a memory, a processor and at least one network connection in electronic communication with the robotic system. The actuating means comprises at least one transmission line having a flexible component comprising a displaceable medium, a rigid component comprising rigid pistons or a combination through which actuation is transmitted to the robotic manipulator or global positioner. The computer tangibly stores in memory software modules comprising processor-executable instructions to provide interfaces between the robotic system, an imaging system and an operator and to control operation thereof.

Owner:UNIV HOUSTON SYST

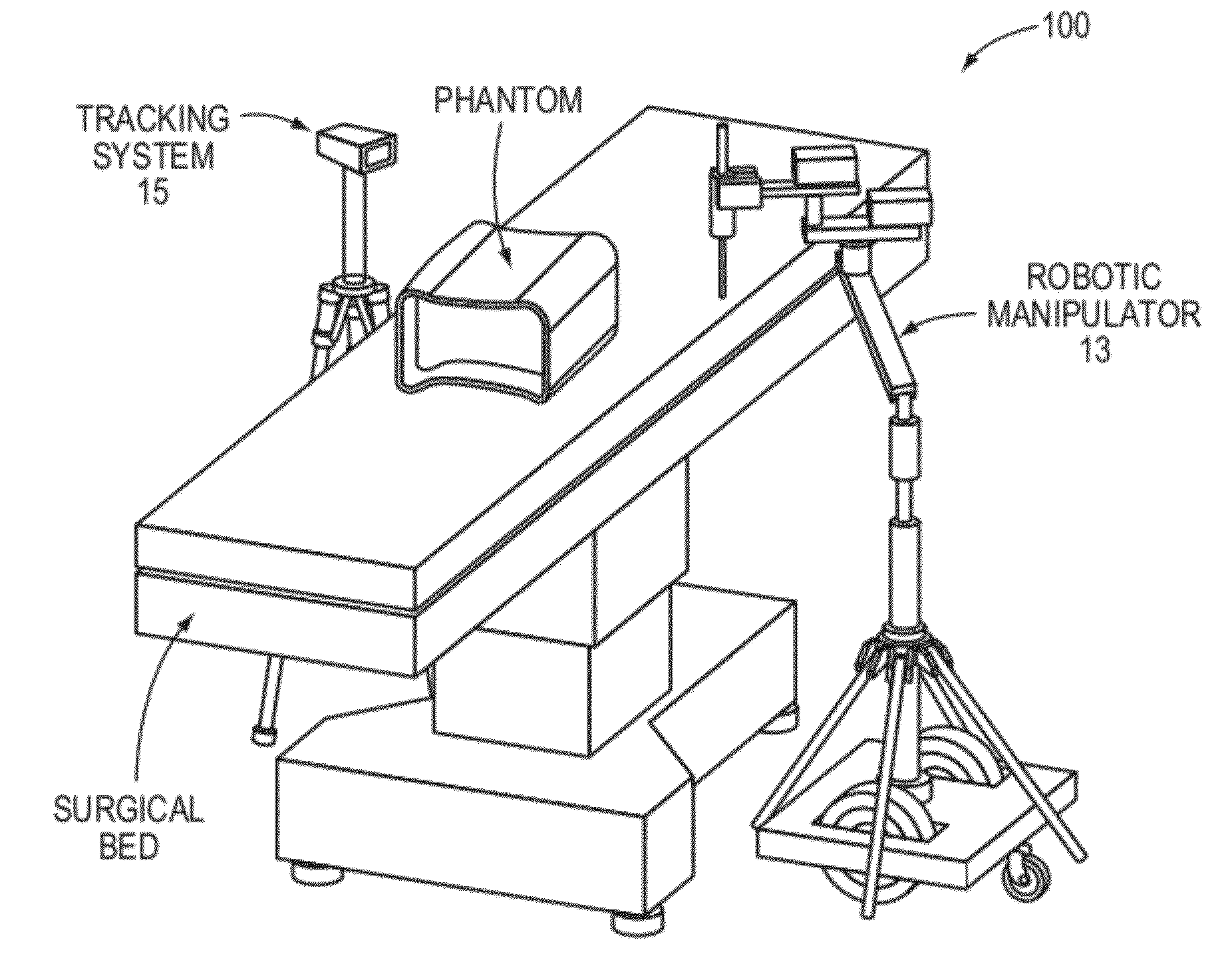

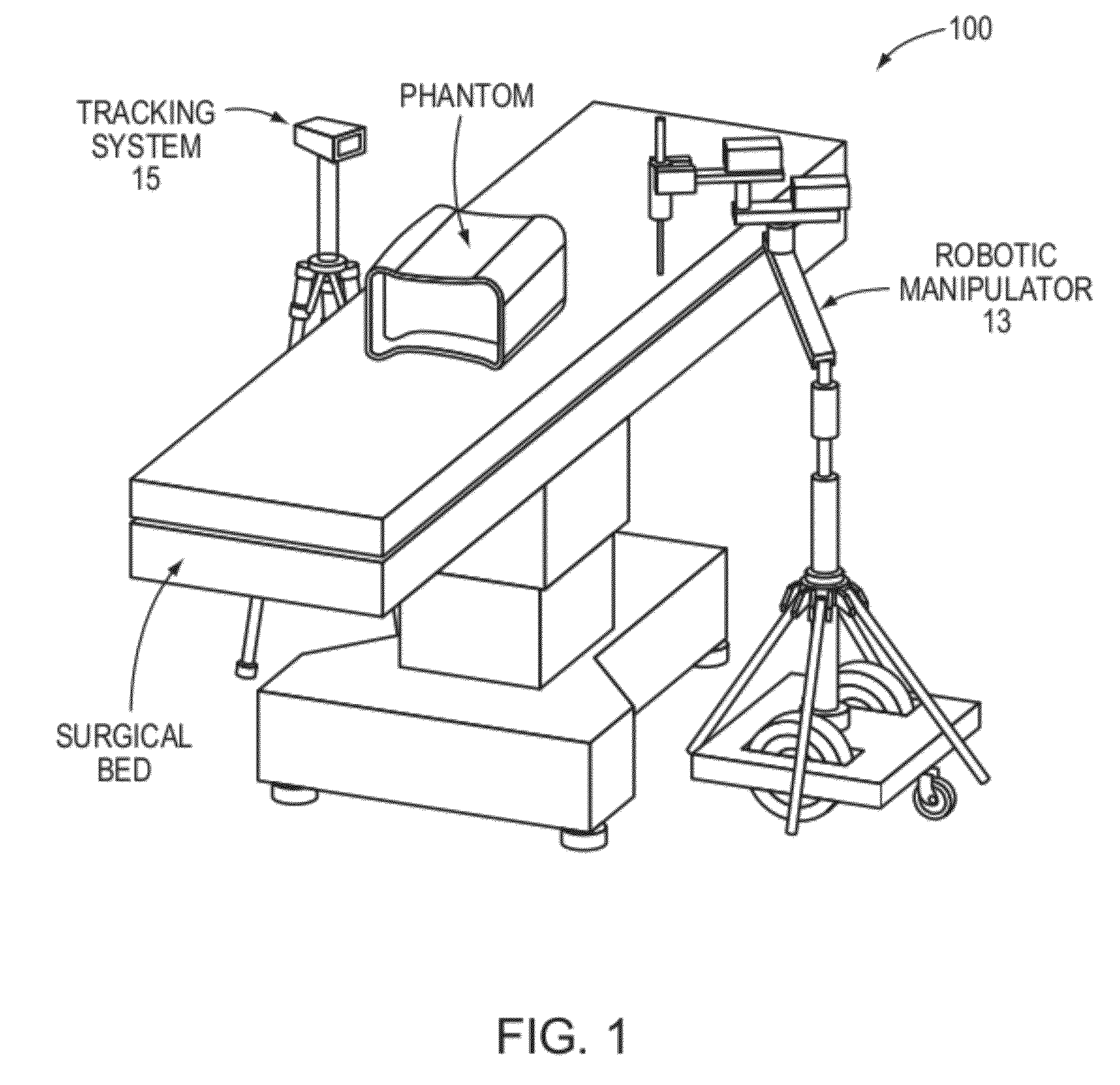

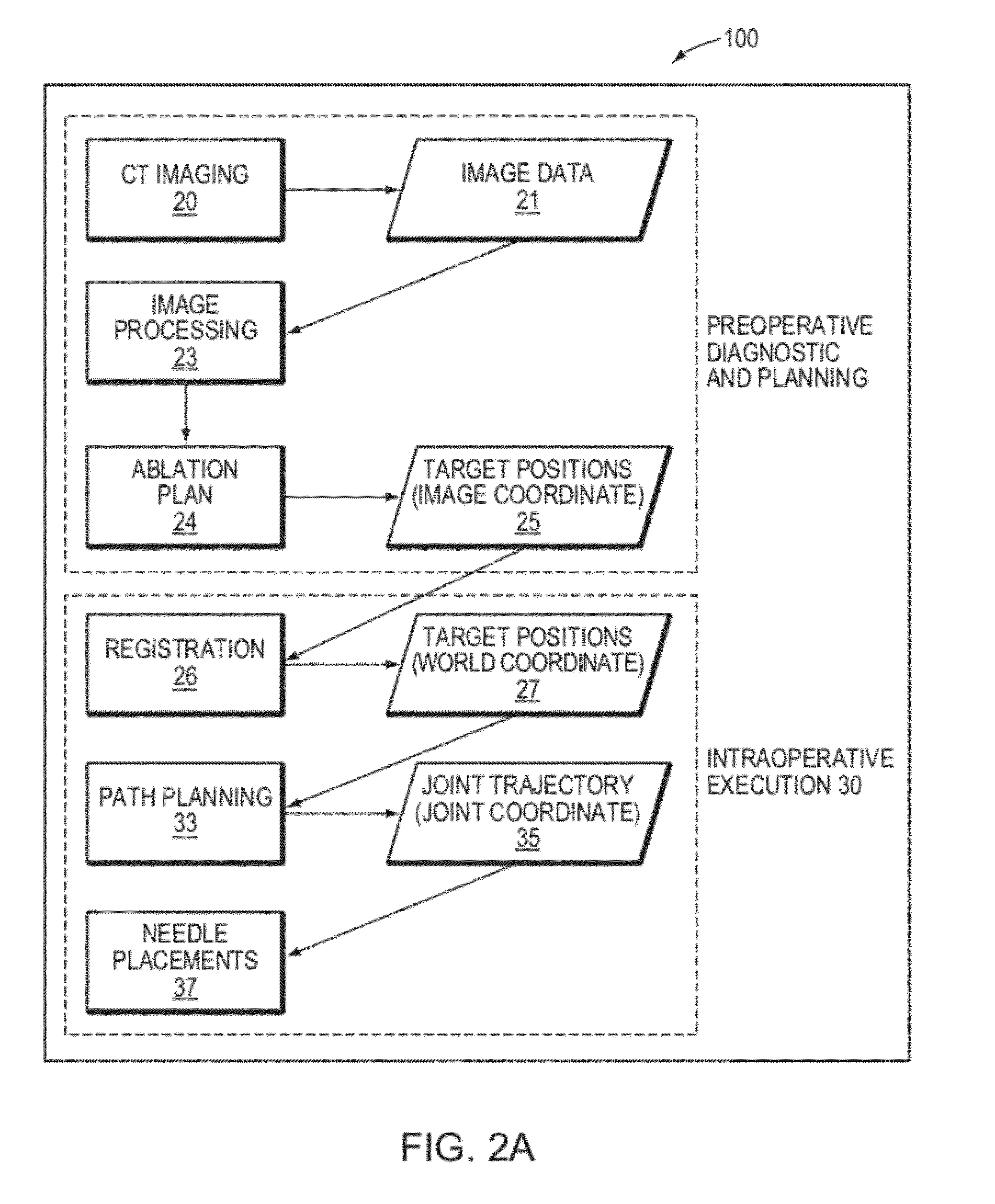

Transcutaneous robot-assisted ablation-device insertion navigation system

InactiveUS20120226145A1Easy to operateFacilitates potential expansionUltrasonic/sonic/infrasonic diagnosticsSurgical needlesRadiofrequency ablationControl system design

A robotic system for overlapping radiofrequency ablation (RFA) in tumor treatment is disclosed. The robot assisted navigation system is formed of a robotic manipulator and a control system designed to execute preoperatively planned needle trajectories. Preoperative imaging and planning is followed by interoperative robot execution of the ablation treatment plan. The navigation system combines mechanical linkage sensory units with an optical registration system. There is no requirement for bulky hardware installation or computationally demanding software modules. Final position of the first needle placement is confirmed for validity with the plan and then is used as a reference for the subsequent needle insertions and ablations.

Owner:NAT UNIV OF SINGAPORE

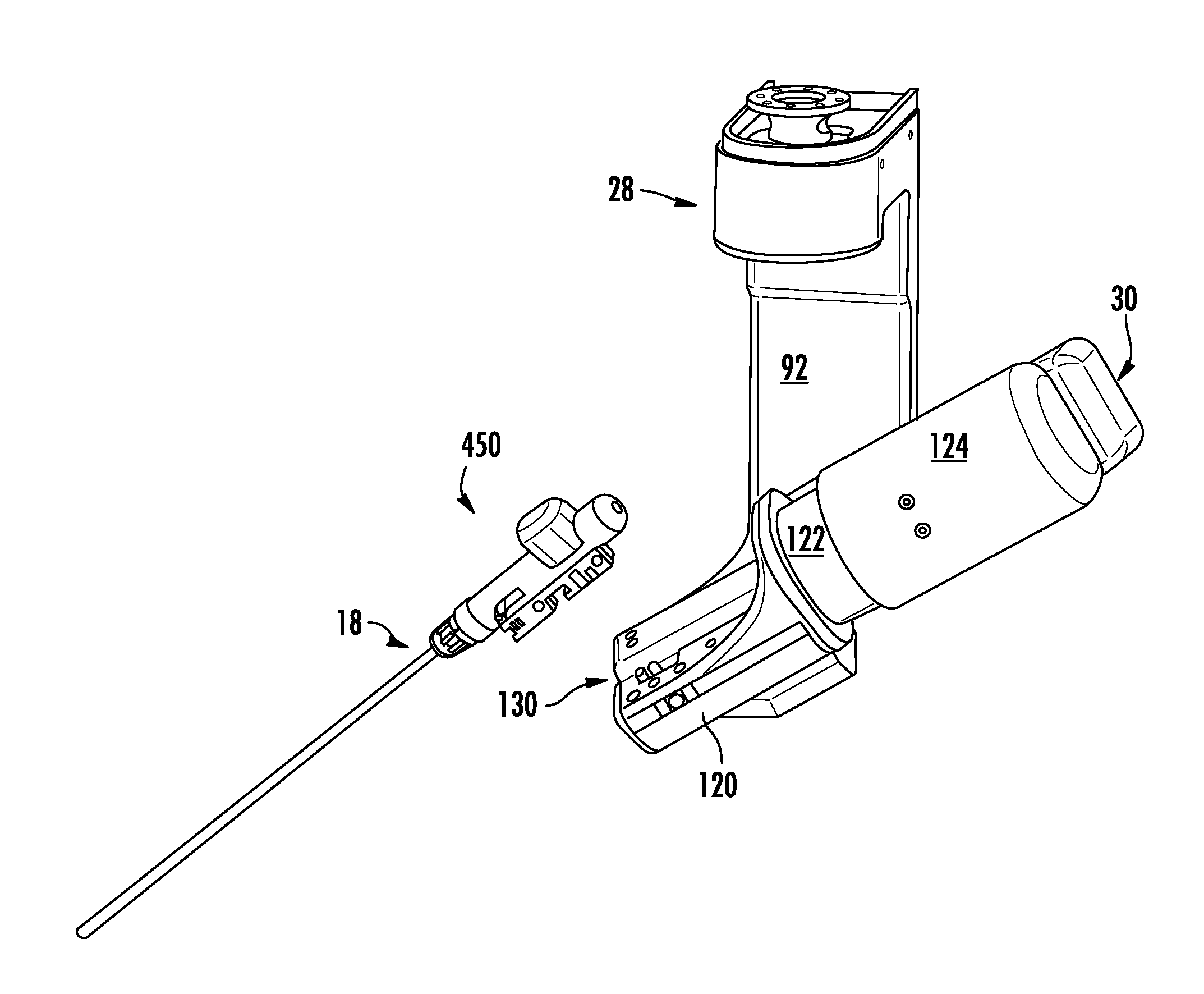

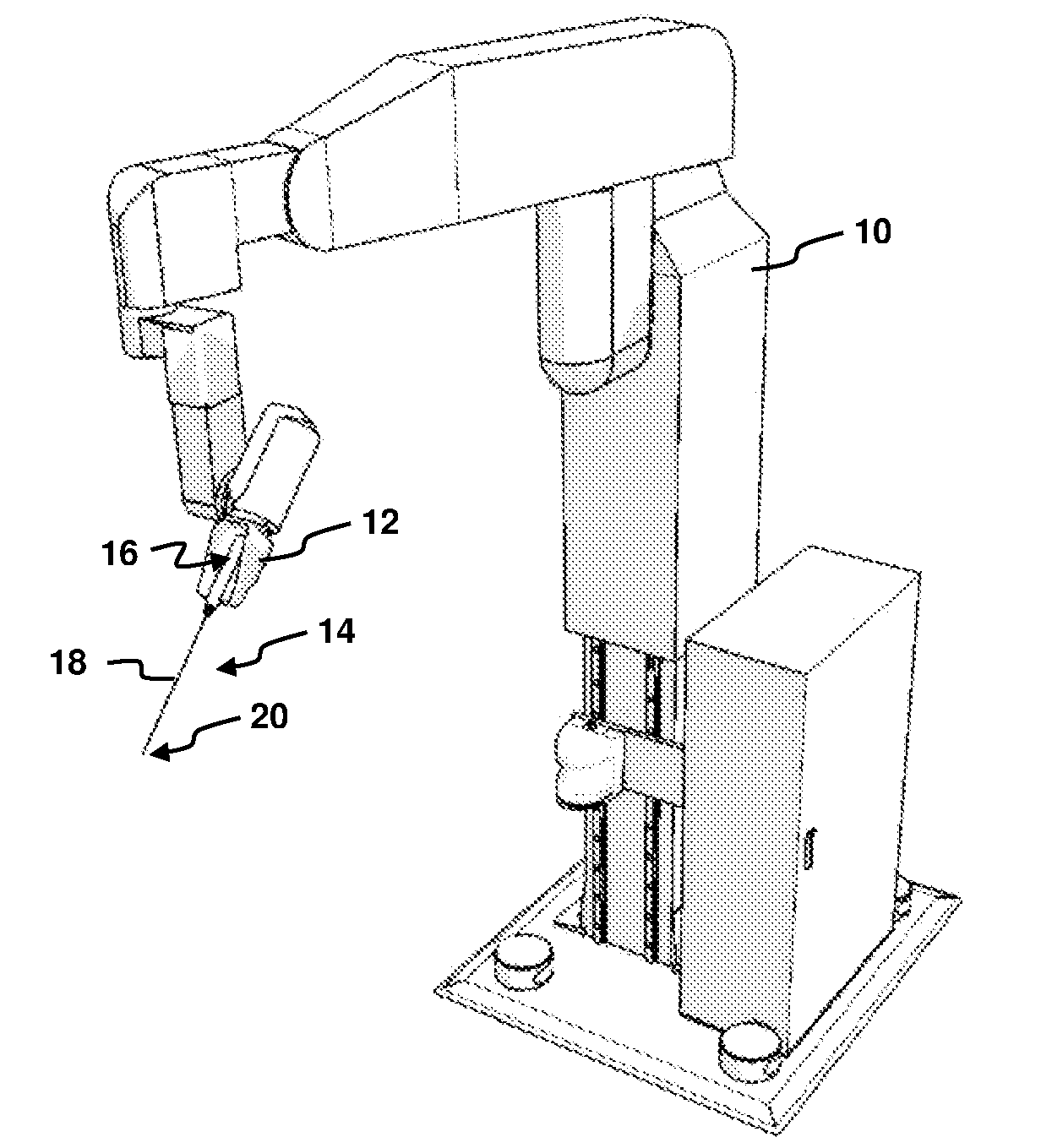

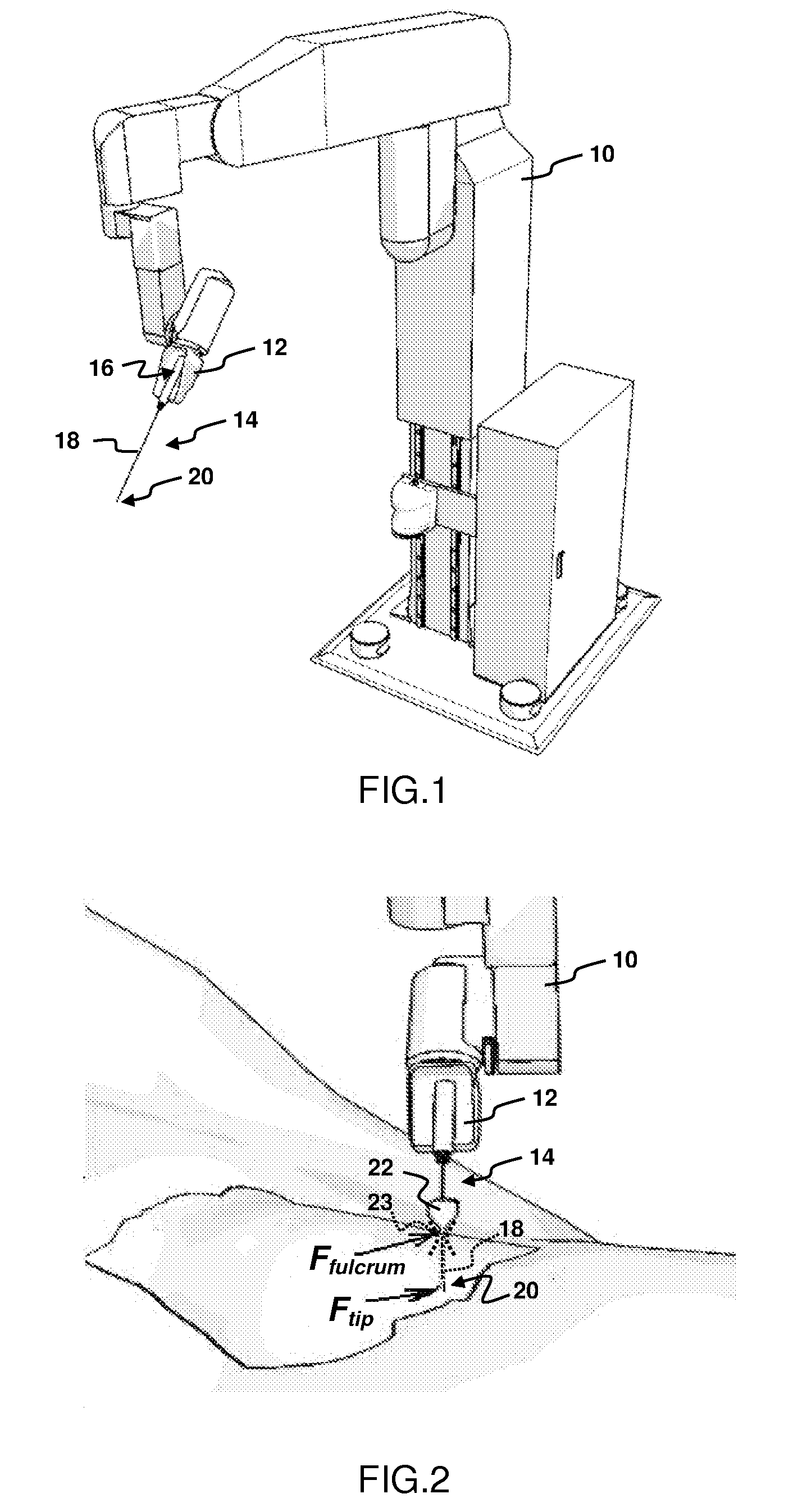

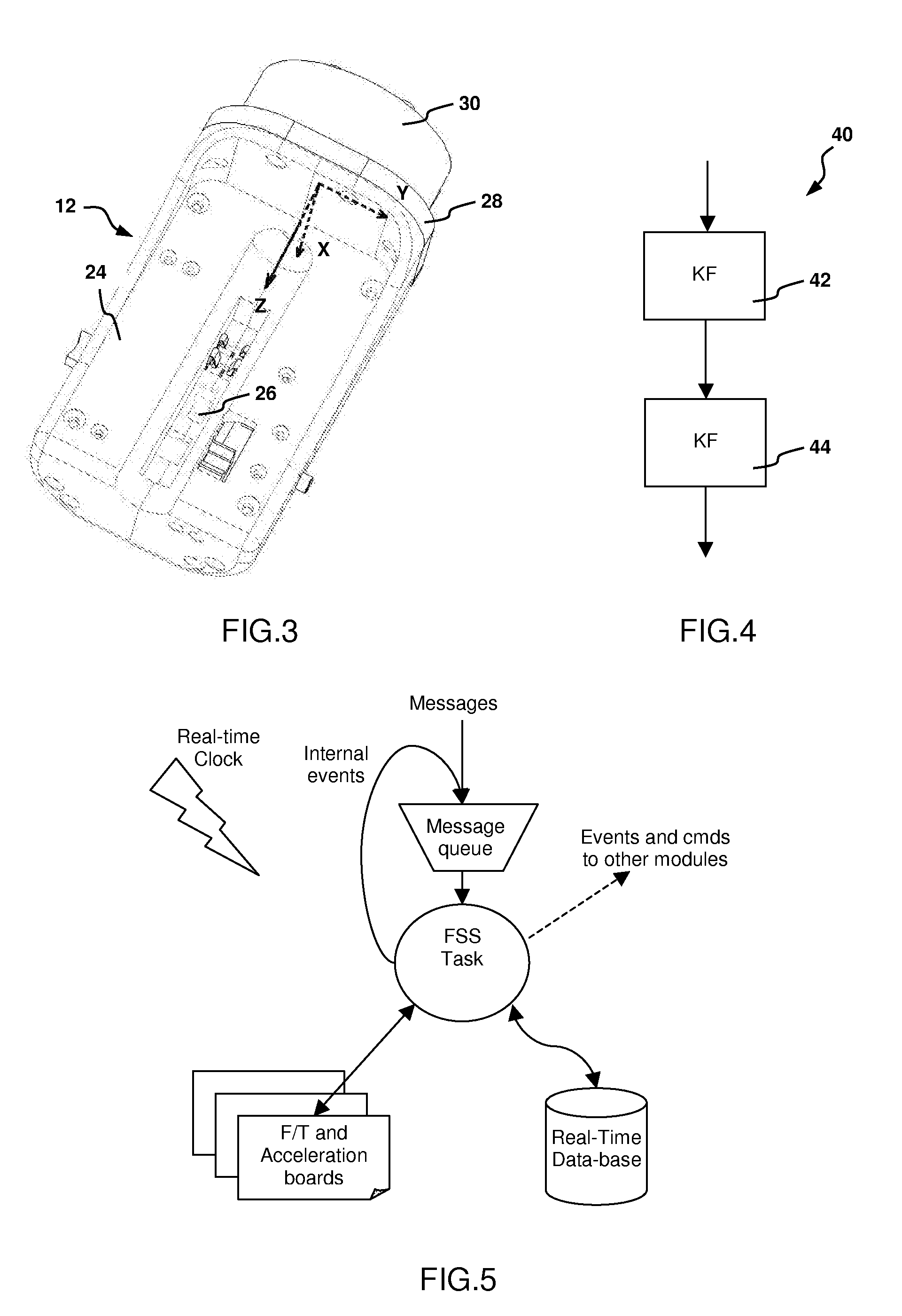

Force estimation for a minimally invasive robotic surgery system

ActiveUS20100094312A1Efficient and cost-effectiveAvoid the needProgramme-controlled manipulatorAcceleration measurement using interia forcesDegrees of freedomEngineering

A method of force estimation for a minimally invasive medical system comprising a robot manipulator (10). The manipulator has an effector unit (12) equipped with a 6-degrees-of-freedom (DOF) force / torque sensor and is configured to hold a minimally invasive instrument (14) having a first end (16) mounted to the effector unit and a second end (20) located beyond an external fulcrum (23) that limits the instrument in motion, usually to 4 DOF. The method comprising the steps: —determining a position of the instrument relative to the fulcrum; —measuring by means of the 6-DOF force / torque sensor a force and a torque exerted onto the effector unit by the first end of the instrument; and —calculating by means of the principle of superposition an estimate of a force exerted onto the second end of the instrument based on the determined position, the measured force and the measured torque.

Owner:EURATOM

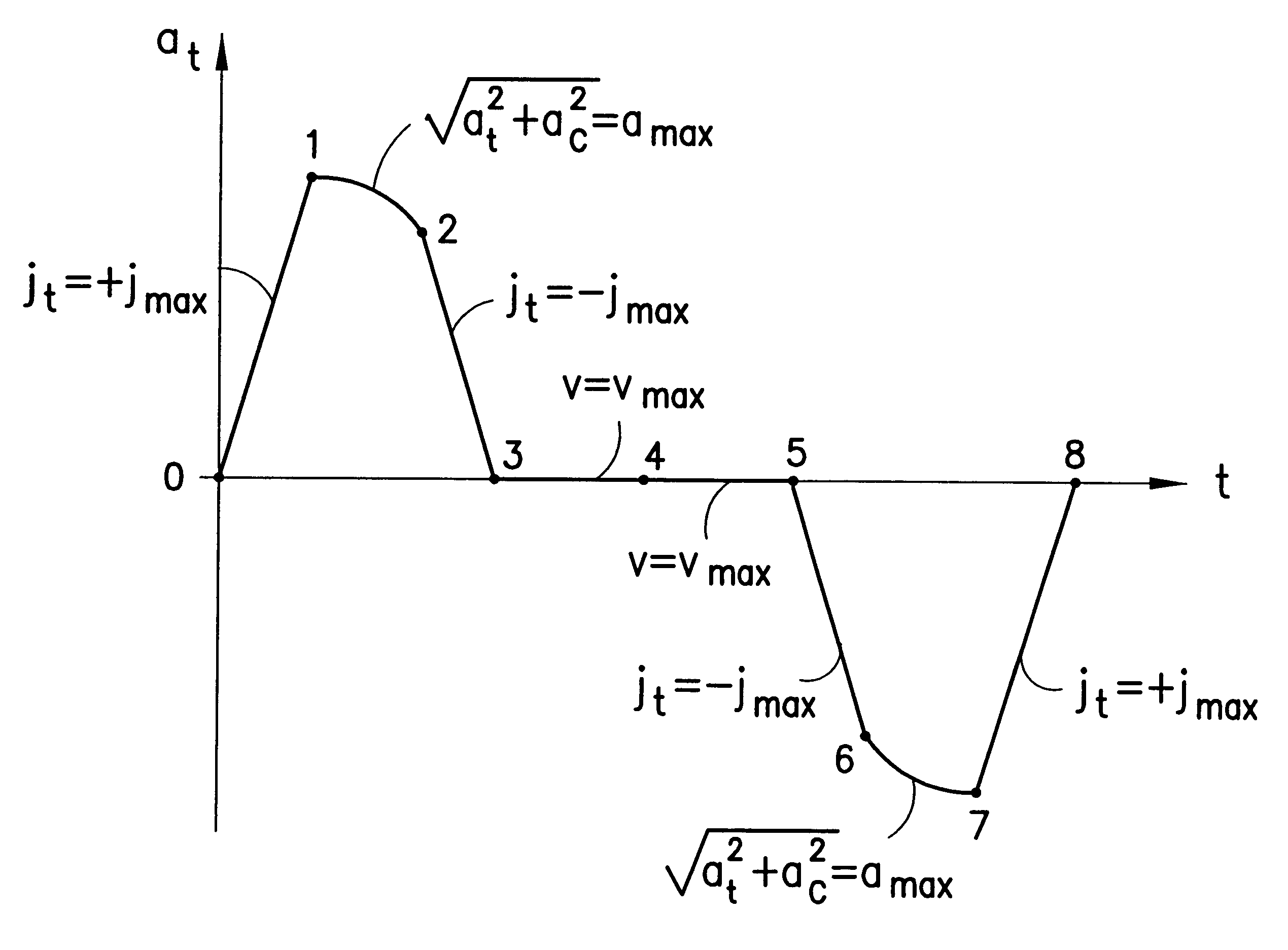

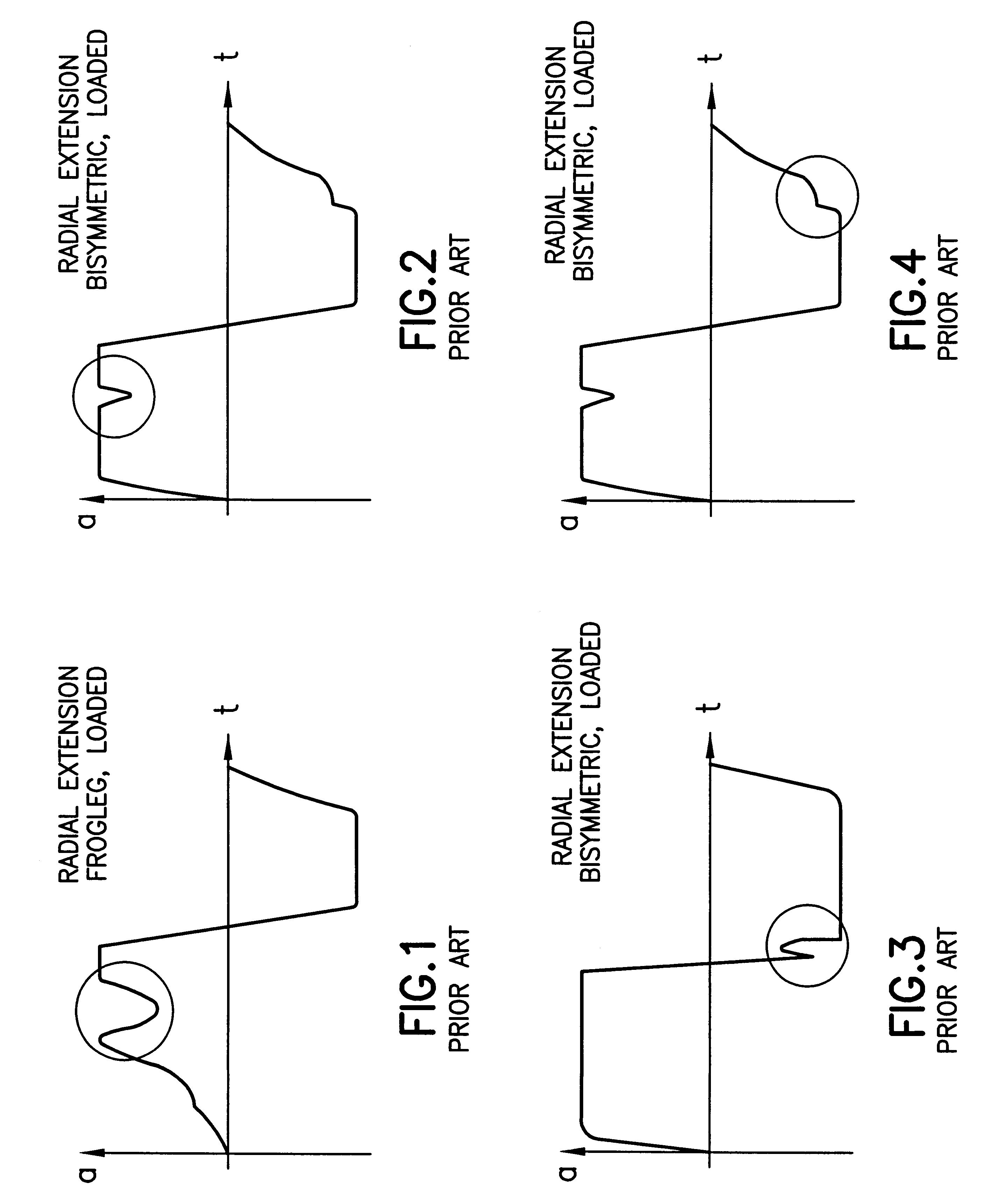

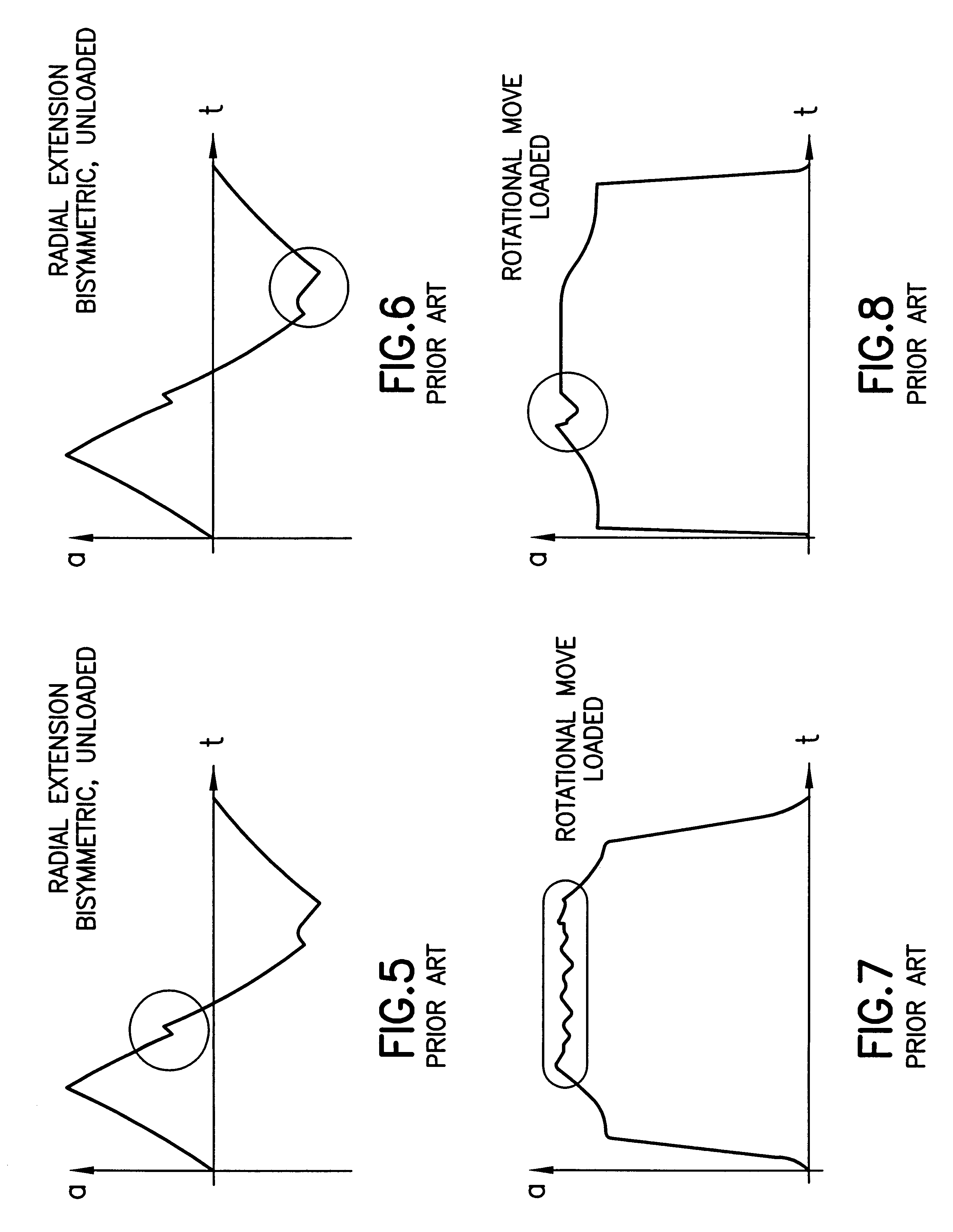

System of trajectory planning for robotic manipulators based on pre-defined time-optimum trajectory shapes

InactiveUS6216058B1Elimination of all typeShort travel timeProgramme-controlled manipulatorComputer controlEngineeringTrajectory planning

A system for providing the reliable and numerically efficient generation of time-optimum trajectories with easy-to-track or continuous acceleration profiles for simple and blended moves of single- and multi-arm robotic manipulators, such as an extension and retraction move along a straight line or a rotary move following a circular arc, with velocity, acceleration, jerk, and jerk rate constraints. A time-optimum trajectory is the set of the position, velocity, and acceleration profiles which describe the move of a selected end effector along a given path in the shortest time possible without violating given constraints, with a special case being an optimum abort trajectory, which brings the moving arm into complete rest in the shortest time. The invention involves firstly identifying the set of fundamental trajectory shapes which cover all possible combinations of constraints for a given category of moves, e.g., a move along a straight line or along a circular arc; next, decomposing the fundamental shapes into segments where a single constraint is active; and, then, determining the time optimum paths in the segments. As a result, a unique design of time-optimum trajectories is produced based on a set of pre-defined trajectory shapes. The invention also involves the blending of simple moves into a single trajectory by decomposing trajectories of the individual moves into their orthogonal components and overlapping them for a given time interval, which results in a non-stop move along a smooth transfer path.

Owner:BOOKS AUTOMATION US LLC

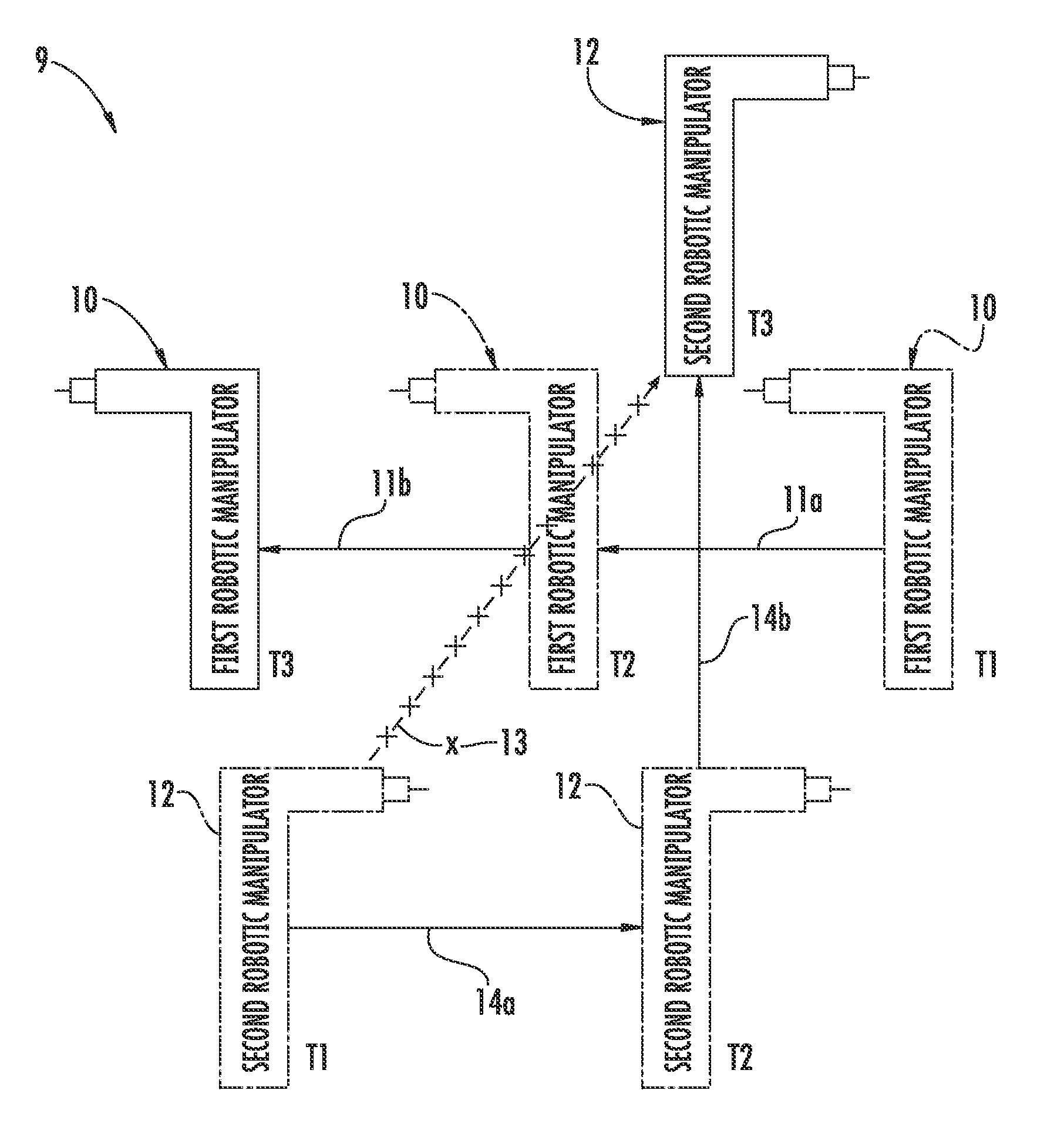

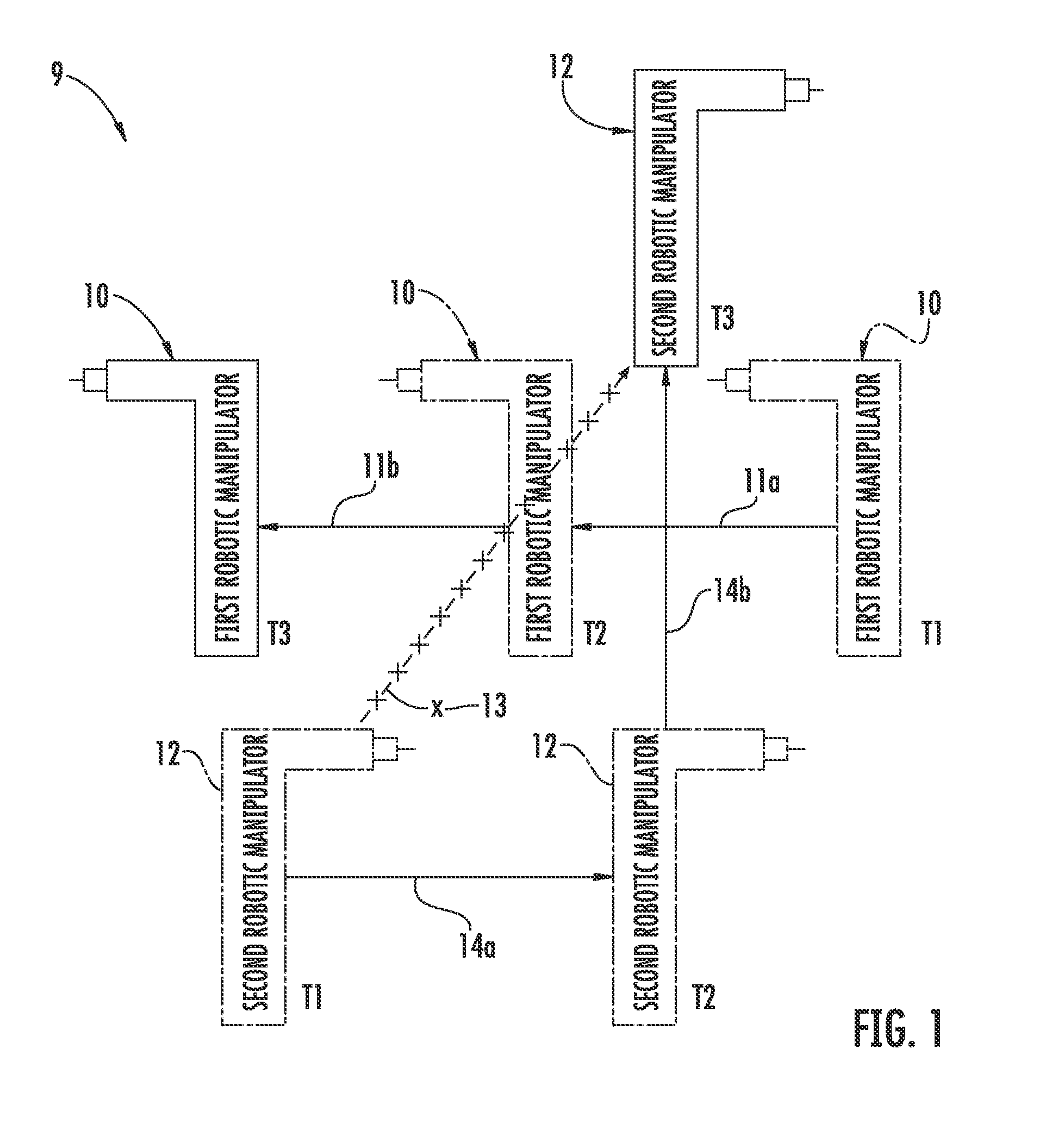

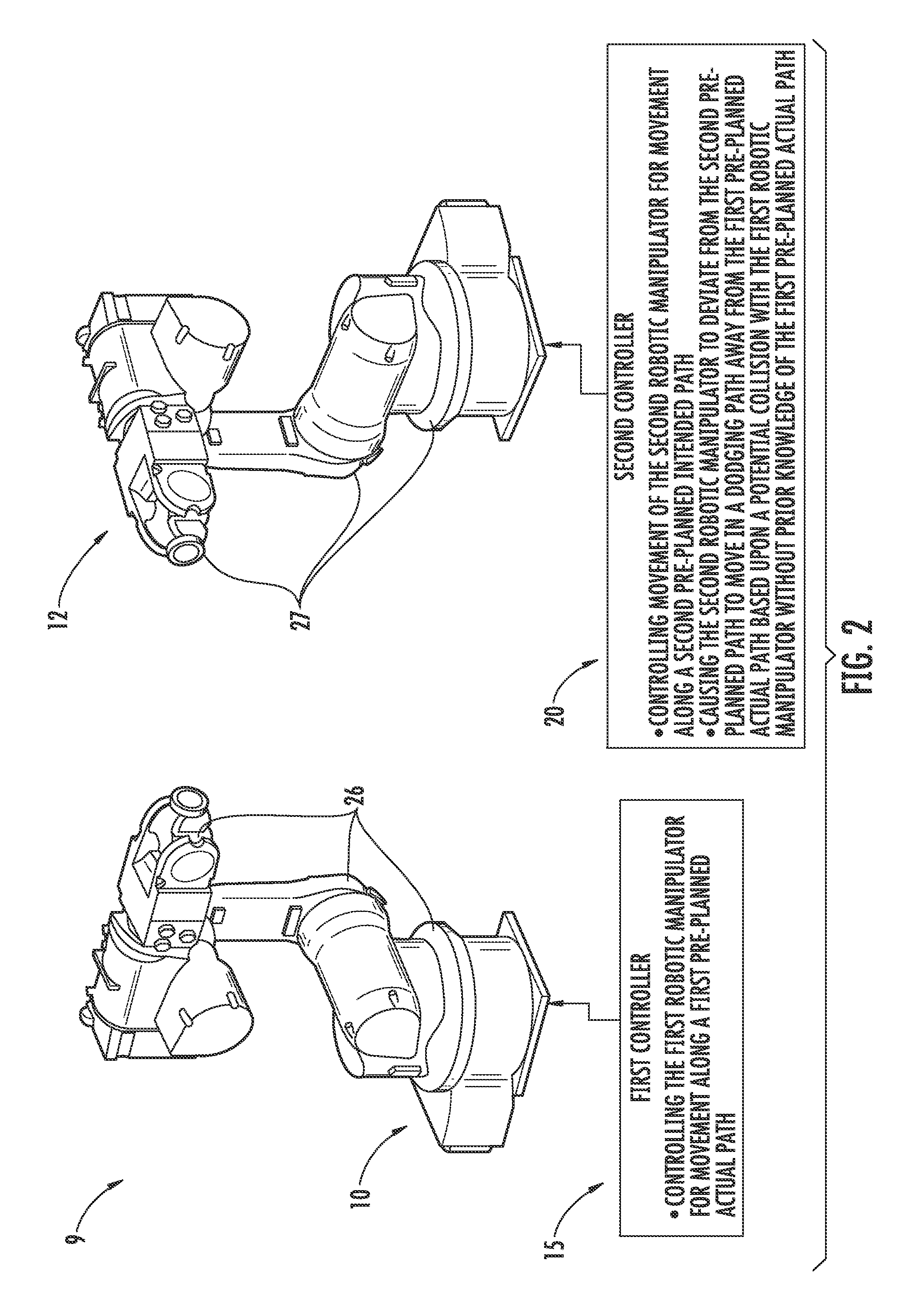

Robotic apparatus implementing collision avoidance scheme and associated methods

ActiveUS20110066282A1Shorten the timeLess processing powerProgramme-controlled manipulatorComputer controlRobotic systemsRobot manipulator

A robotic system implements a collision avoidance scheme and includes a first robotic manipulator and a first controller configured to control the first robotic manipulator for movement along a first pre-planned actual path. A second controller is configured to control movement of a second robotic manipulator for movement along a second pre-planned intended path and deviating therefrom to move in a dodging path away from the first pre-planned actual path based upon determining a potential collision with the first robotic manipulator without prior knowledge of the first pre-planned actual path.

Owner:HARRIS CORP

Low cost robot manipulator

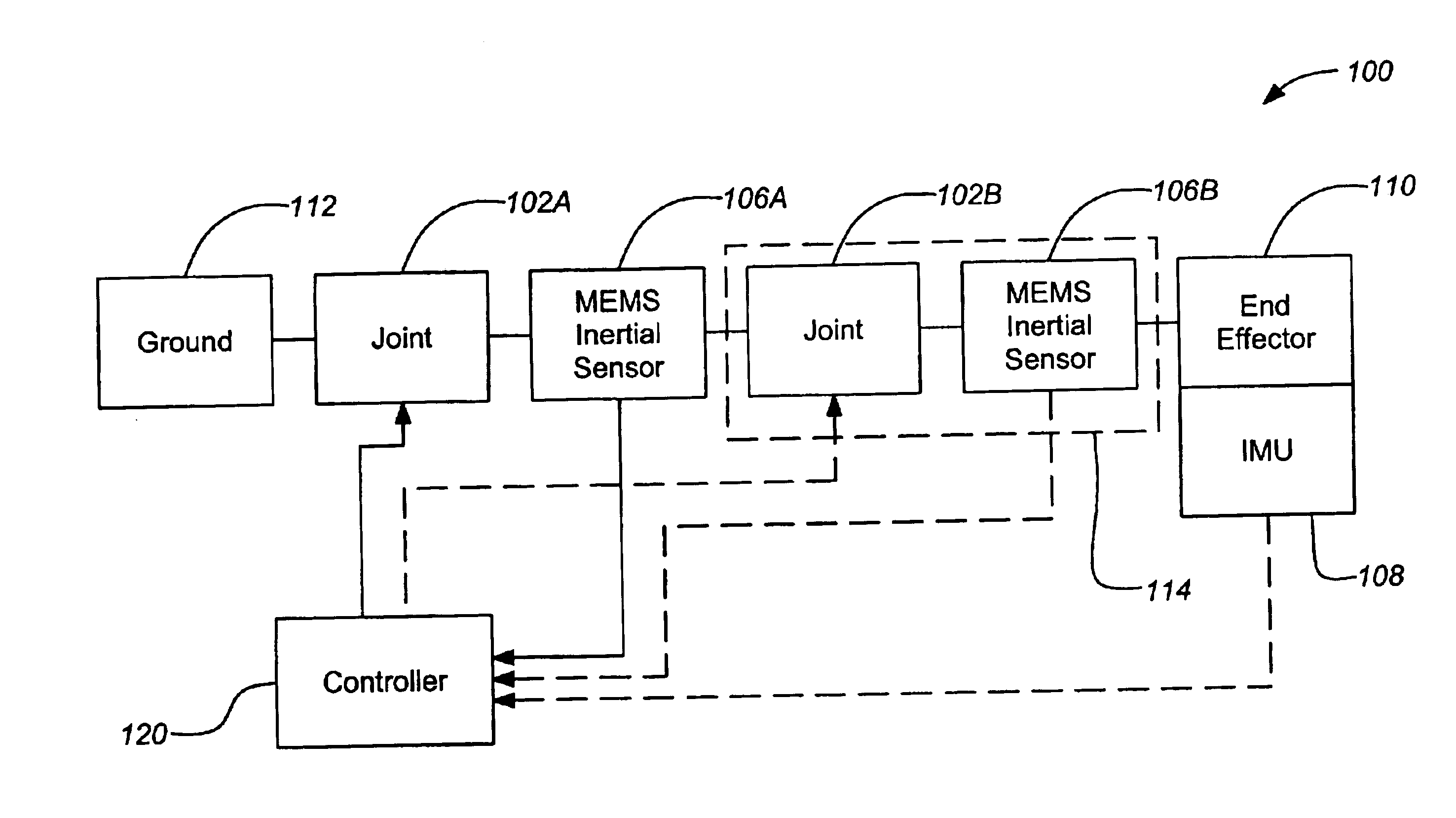

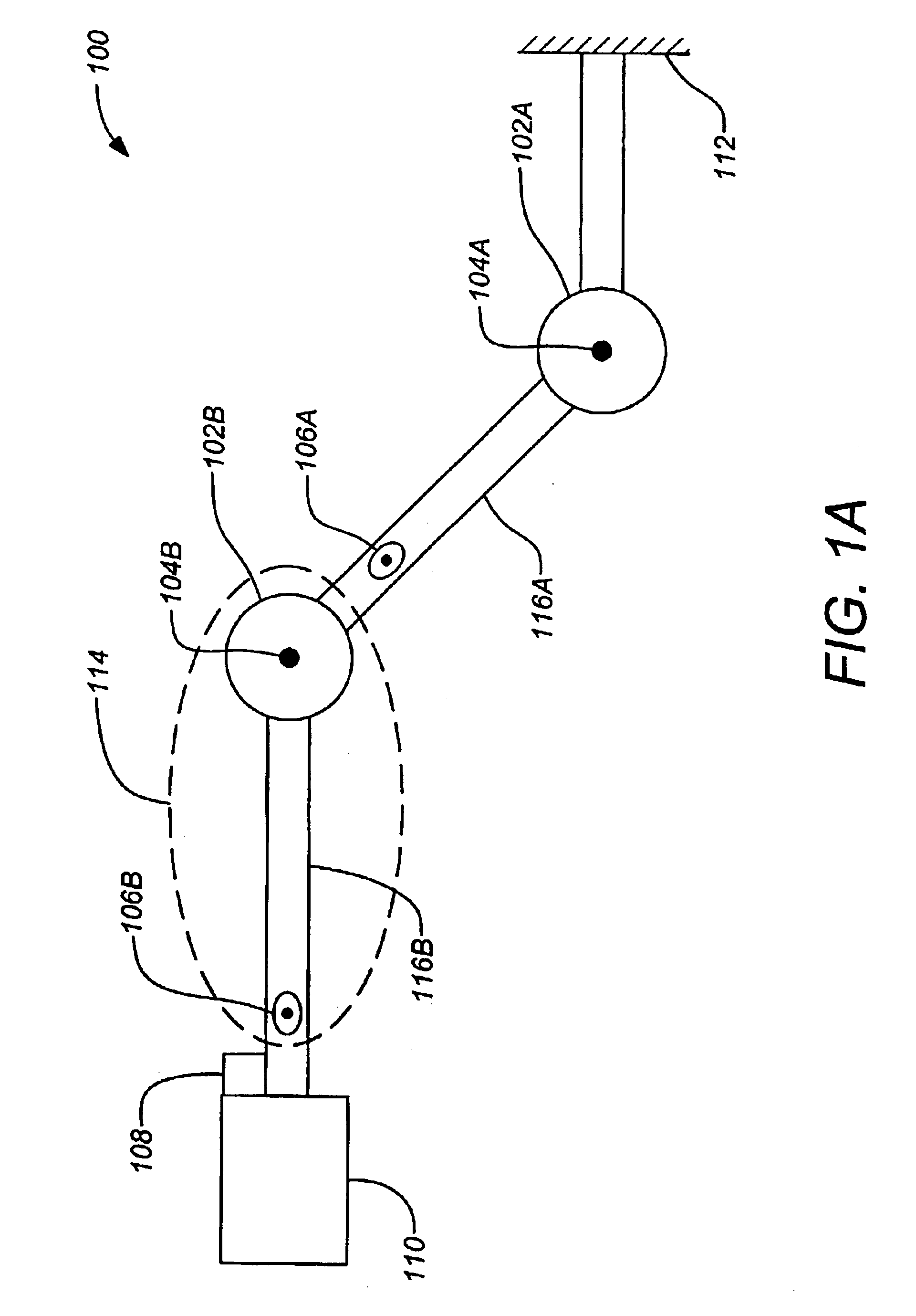

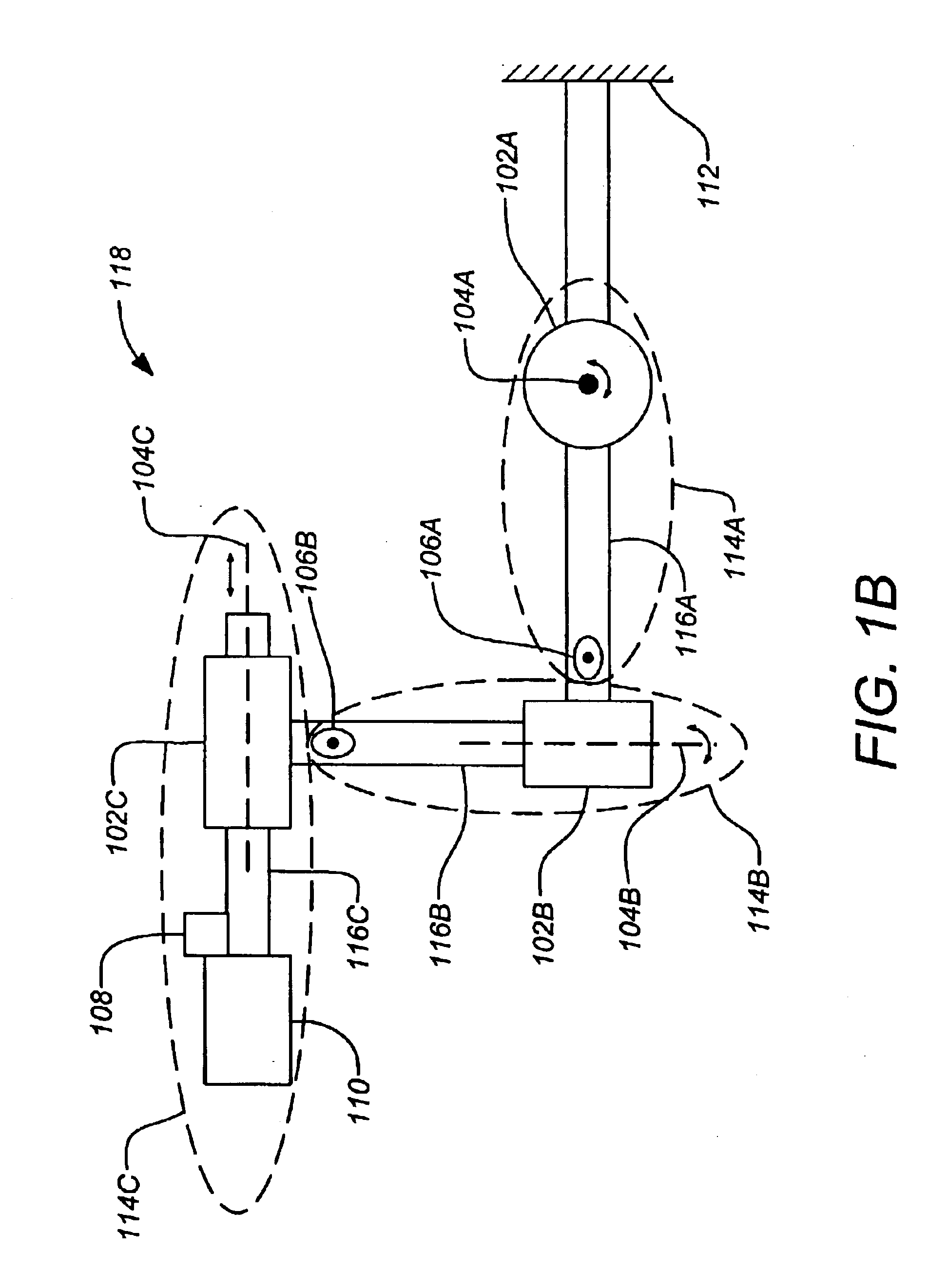

InactiveUS6995536B2Reduce business operating costsRobust servo controlProgramme-controlled manipulatorSafety arrangmentsEngineeringMems sensors

The present invention discloses a robotic manipulator, comprising at least one joint, each joint having a drive axis and at least one microelectromechanical system (MEMS) inertial sensor aligned with at least one drive axis providing sensing of a relative position of the drive axis. The robotic manipulator can include an inertial measurement unit (IMU) coupled to the robotic manipulator for determining the end effector position and orientation. A controller can be used, receiving a signal from at least one MEMS inertial sensor and controlling at least one joint drive axis in response to the signal to change the relative position of the joint drive axis. Rate information from MEMS sensors can be integrated to determine the position of their respective drive axes.

Owner:THE BOEING CO

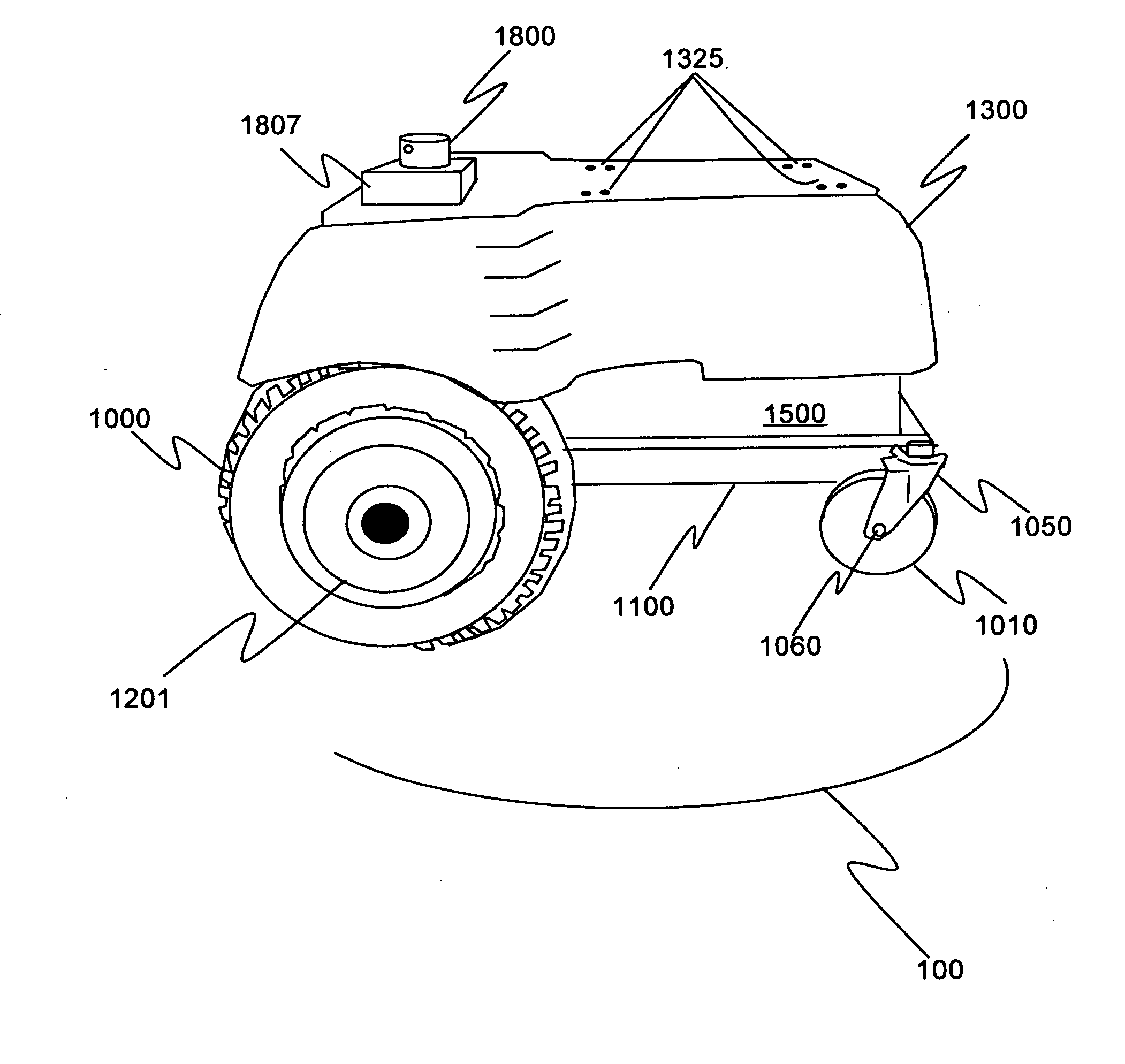

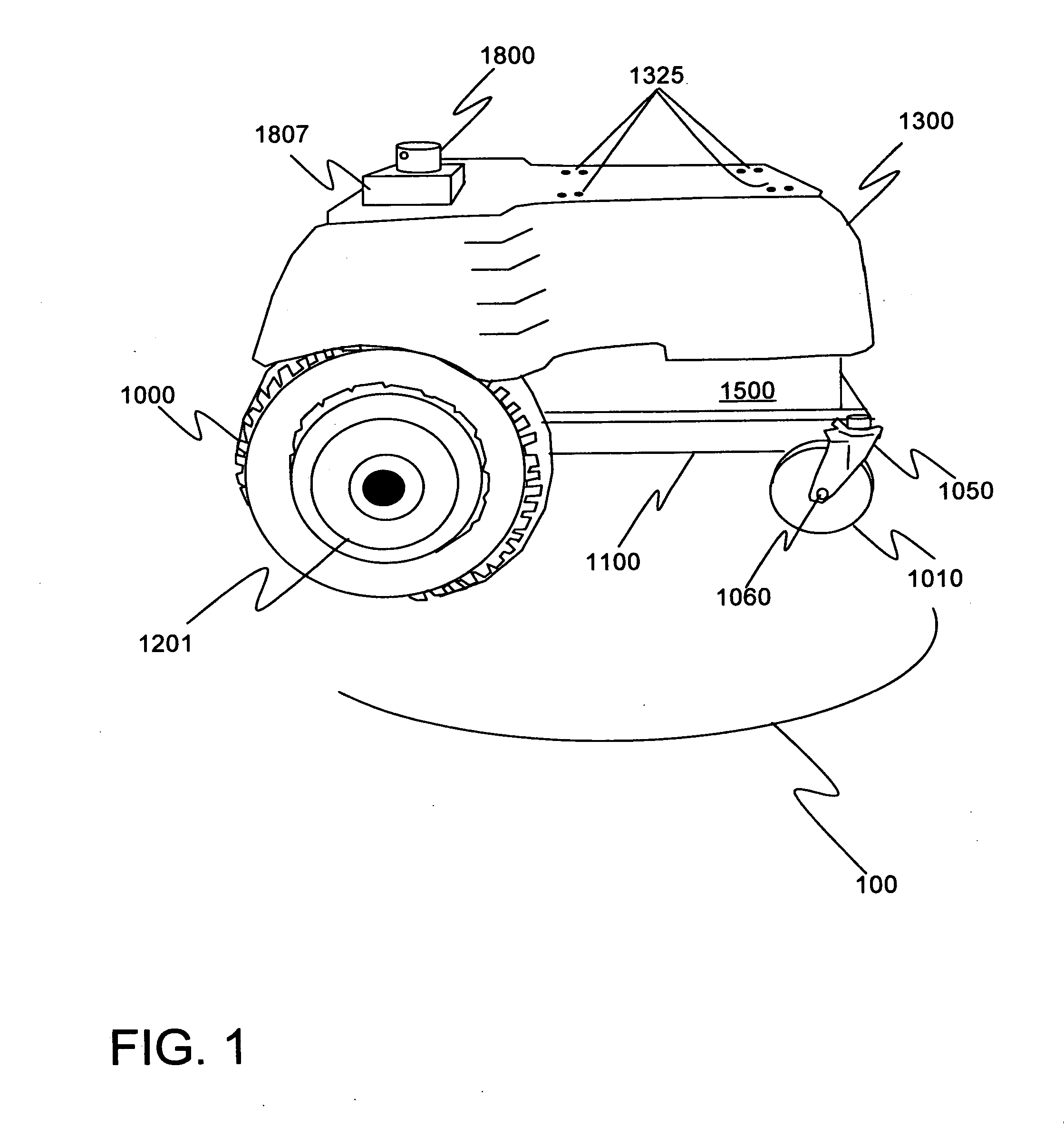

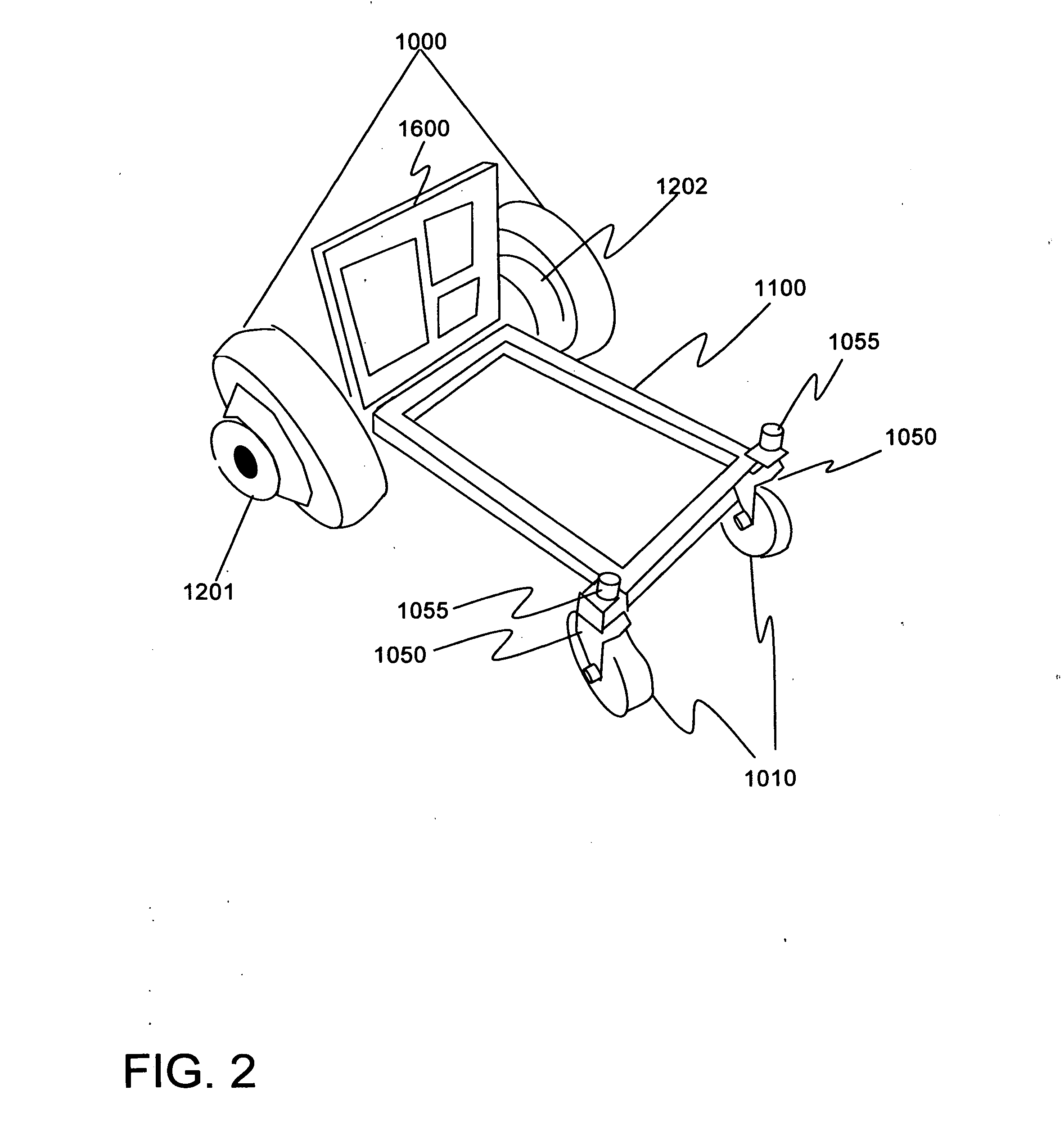

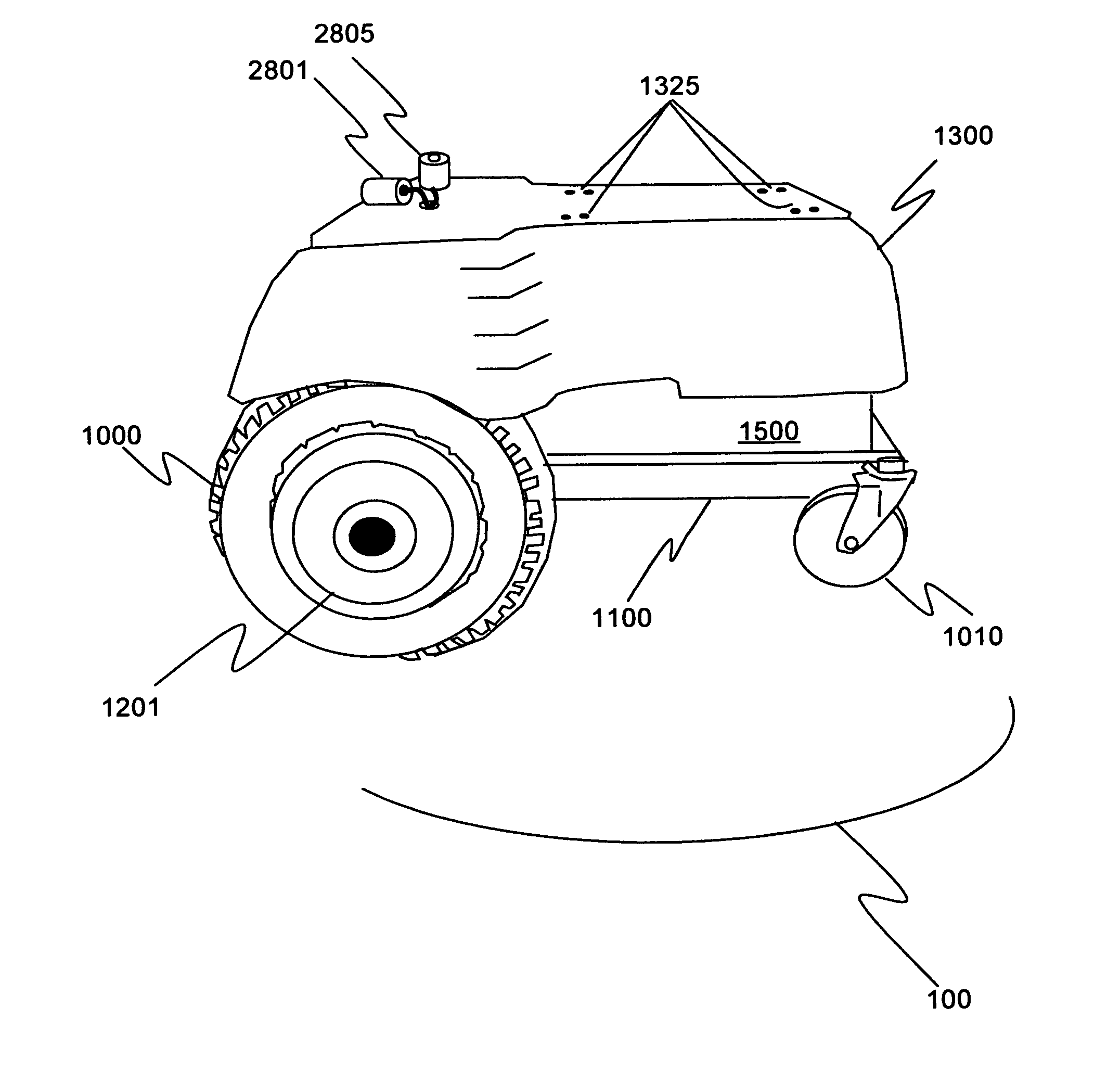

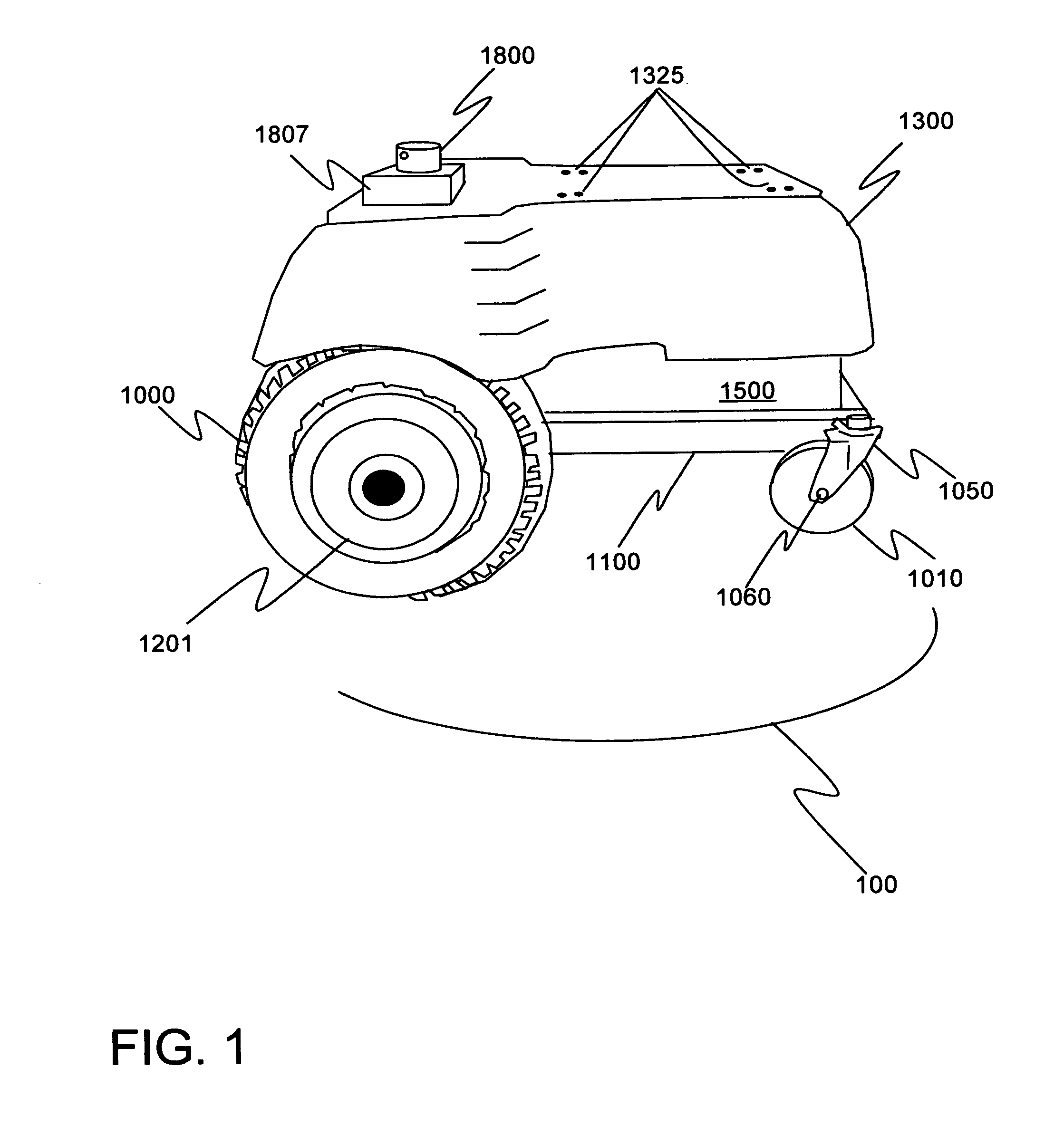

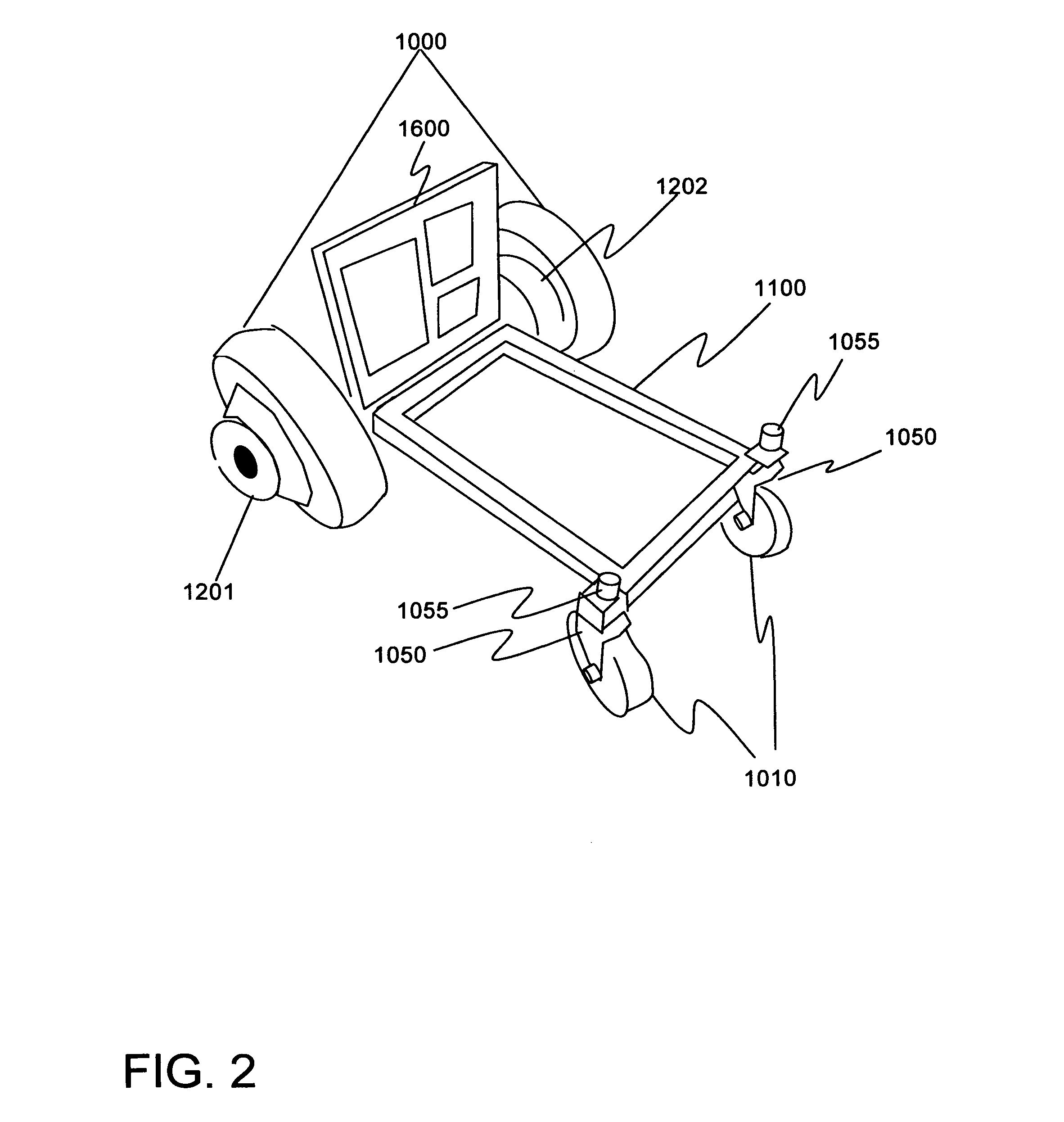

Autonomous mobile platform for service applications

The invention disclosed with this application is a autonomous mobile system comprising: a means of achieving mobility, a means of navigating, a means of providing autonomous power, and a means of providing general purpose computing.In some embodiments, the system comprises a base unit capable of sensing its environment and computing navigation instructions to direct the system to move to particular locations and execute particular functions, as directed by a set of programmed instructions.In some embodiments, a coupling exists on the base unit to attach additional structures and mechanisms. These structures may comprise a means for carrying packages or other items, robotic manipulators that can grab and move objects, interactive audio and video displays for telepresence applications, a means for serving food and drink, etc. These extensions may be designed to be detachable and interchangeable, or may be designed to be permanently attached to the base unit.

Owner:UBIQUITY ROBOTICS INC

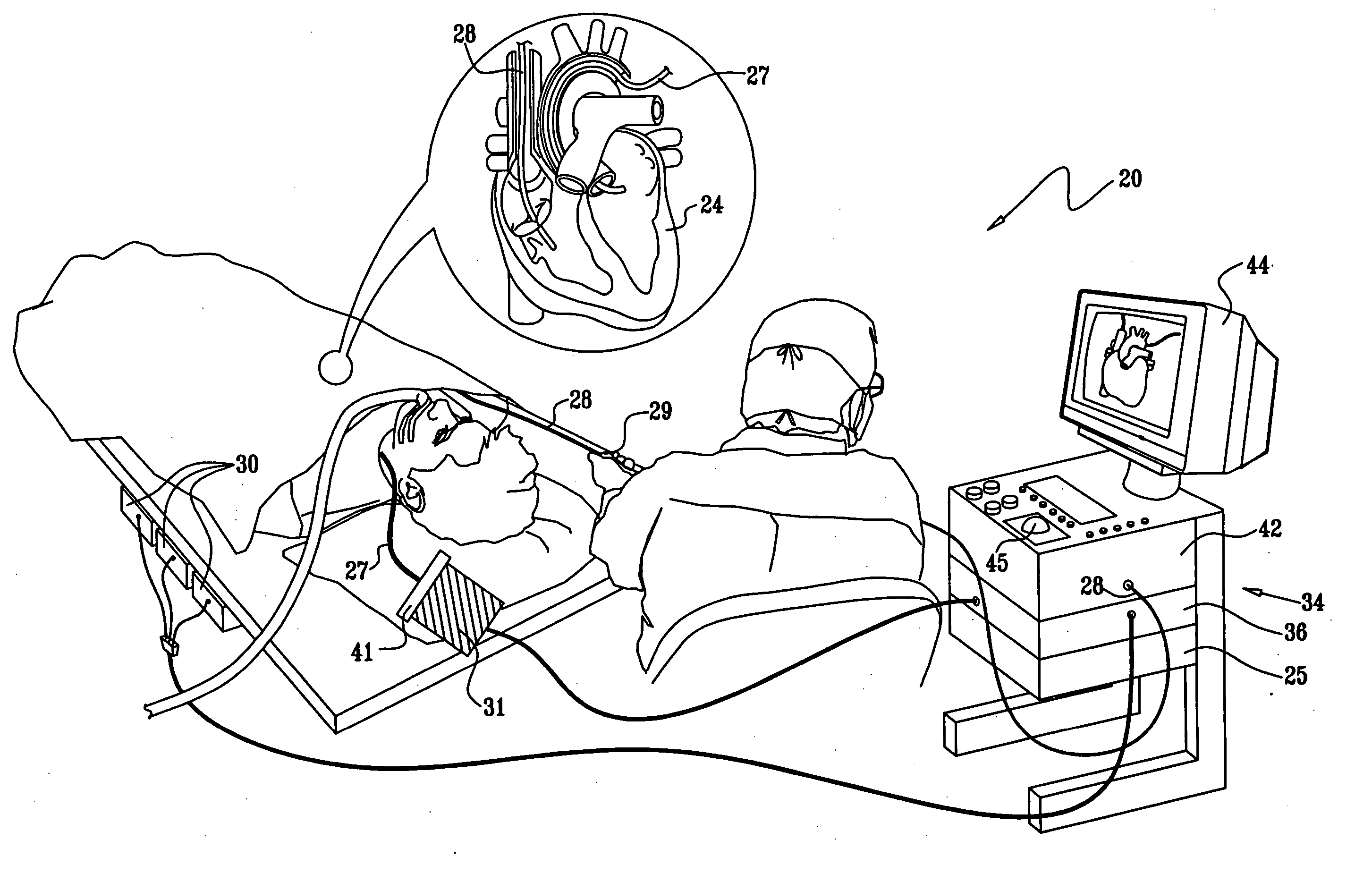

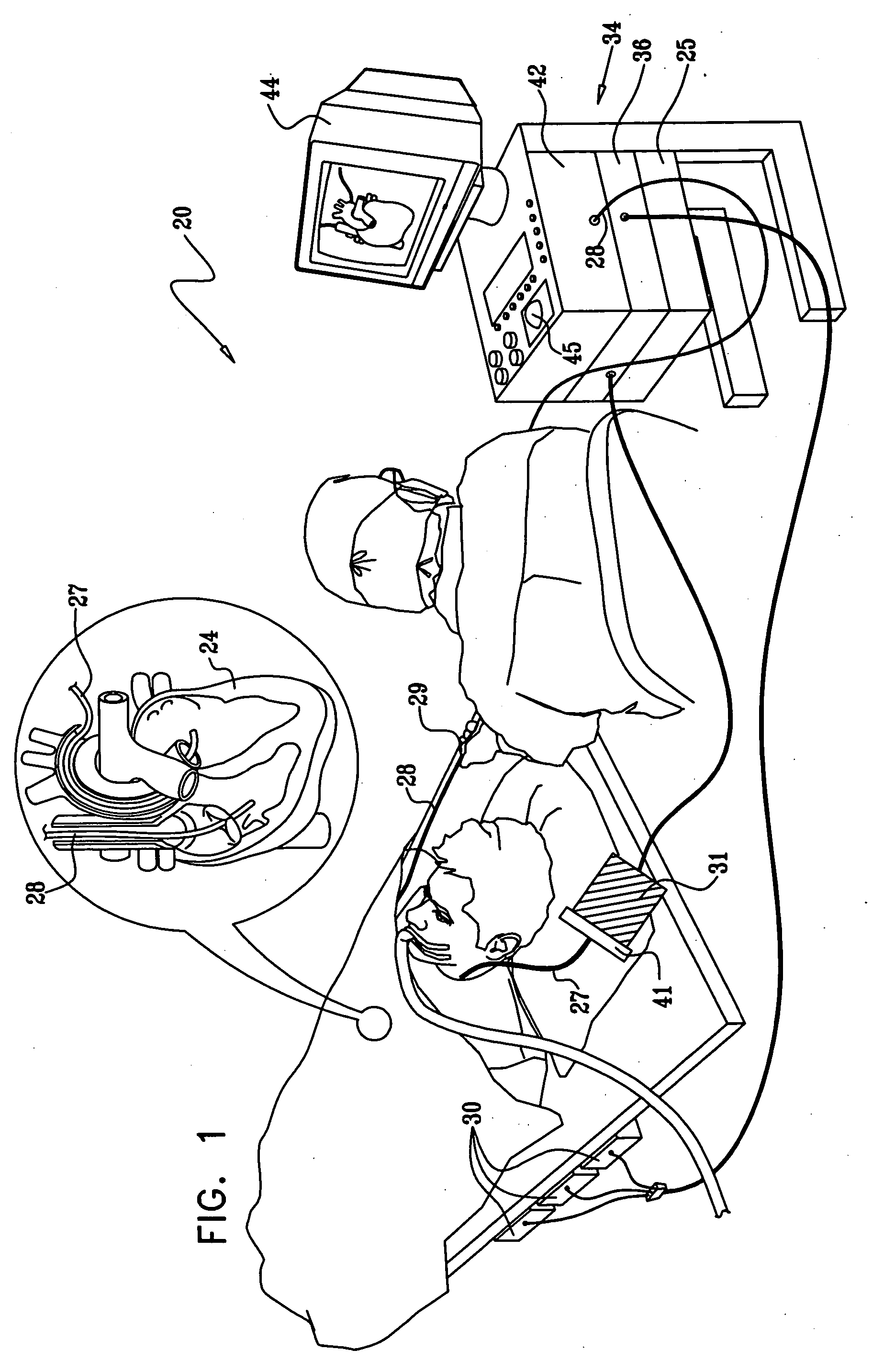

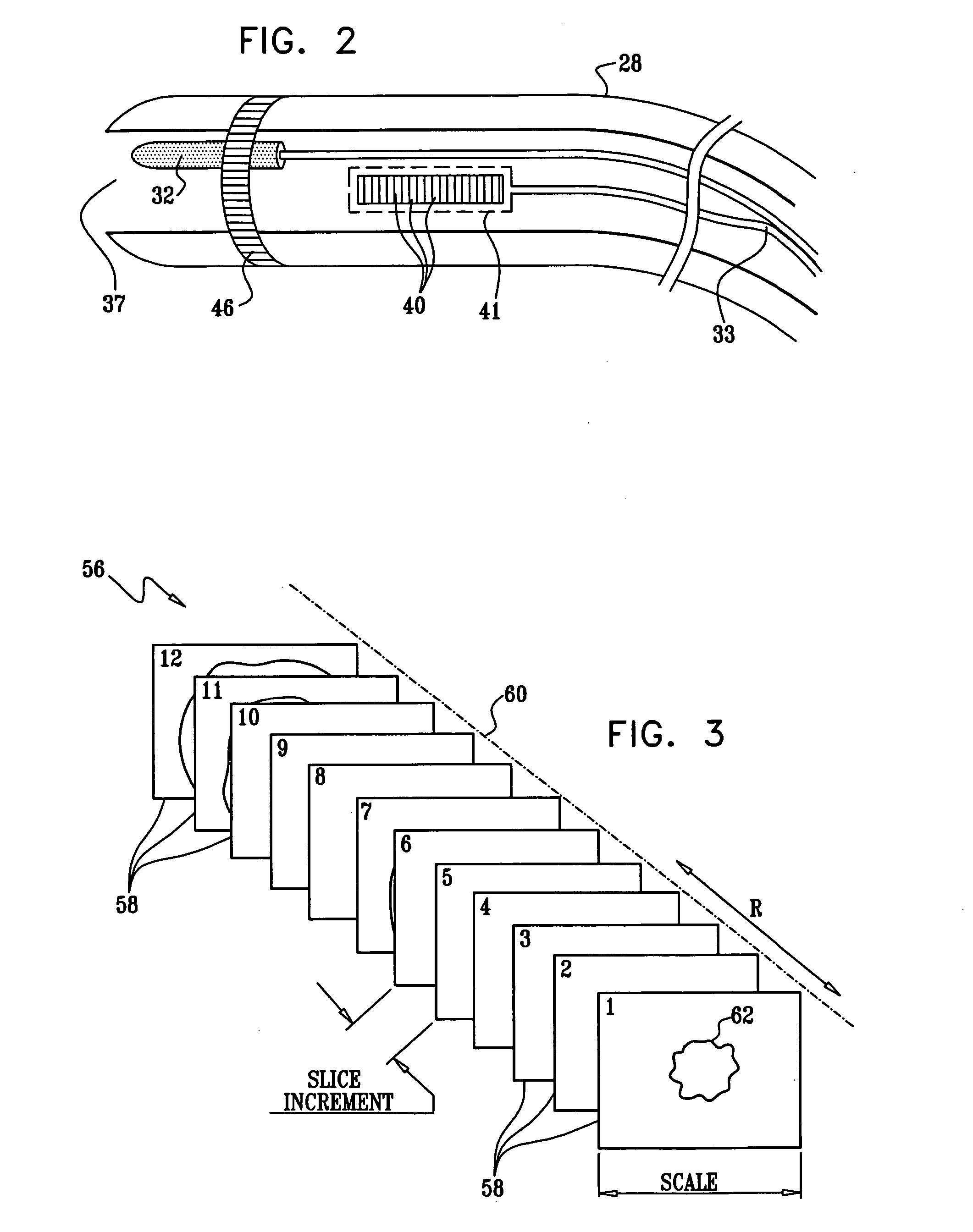

Controlling direction of ultrasound imaging catheter

InactiveUS20070106147A1Structure be loseImprove executionUltrasonic/sonic/infrasonic diagnosticsSurgical navigation systemsUltrasound imagingControl ultrasound

The position of an imaging catheter in a body structure such as the heart is automatically controlled by a robotic manipulator such that its field of view at all times includes the distal end of a second catheter that is employed to effect a medical procedure. A processor receives signals from position sensors in the catheters. The processor utilizes the information received from the sensors and continually determines any deviation of the second catheter from the required field of view of the imaging catheter. The processor transmits compensation instructions to the robotic manipulator, which when executed assure that the imaging catheter tracks the second catheter.

Owner:BIOSENSE WEBSTER INC

Robotic system for flexible endoscopy

InactiveUS20120078053A1Reduce inertiaExtreme environmental conditionEndoscopesSurgical instruments for heatingFlexible endoscopyRobotic systems

A robotic manipulator controller and system for use in flexible endoscopy, the manipulator comprising a flexible member configured to be coupled to an endoscope, and an arm connected to and movable by the flexible member, wherein the flexible member has a first end connected to the arm and a second end connectable to the controller to allow a physical movement of the arm to be controllable by a physical movement of the controller.

Owner:NANYANG TECH UNIV +1

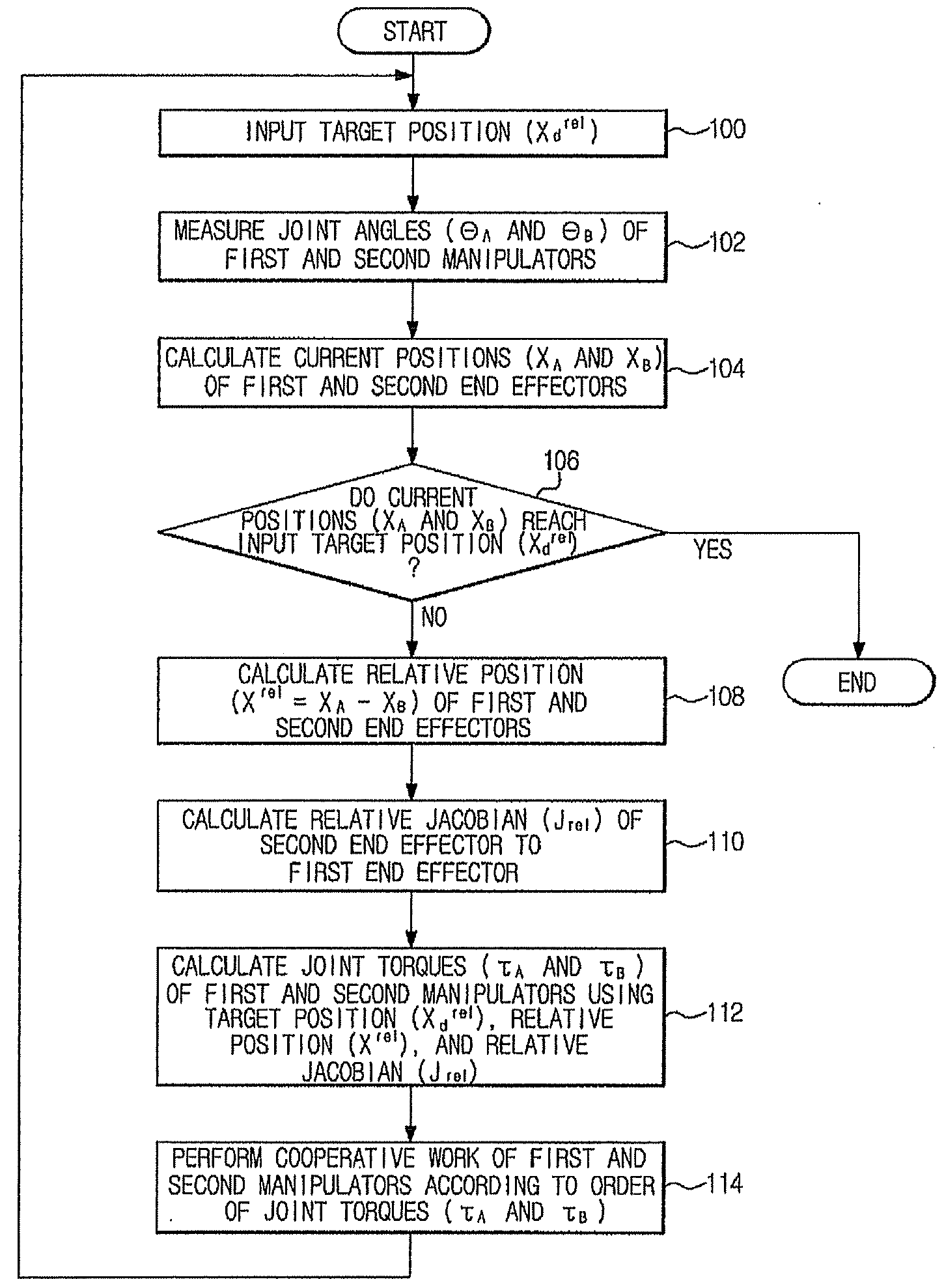

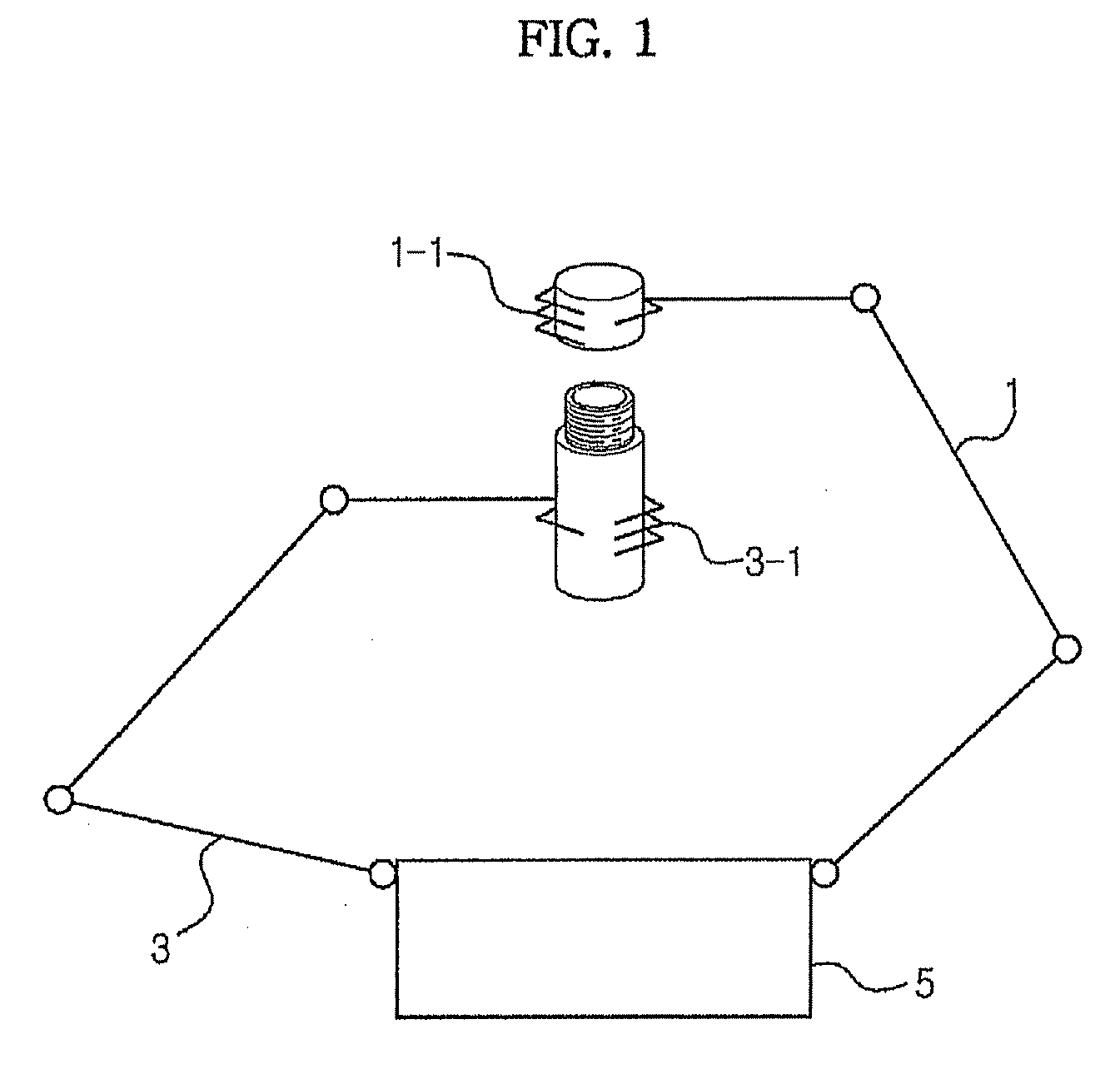

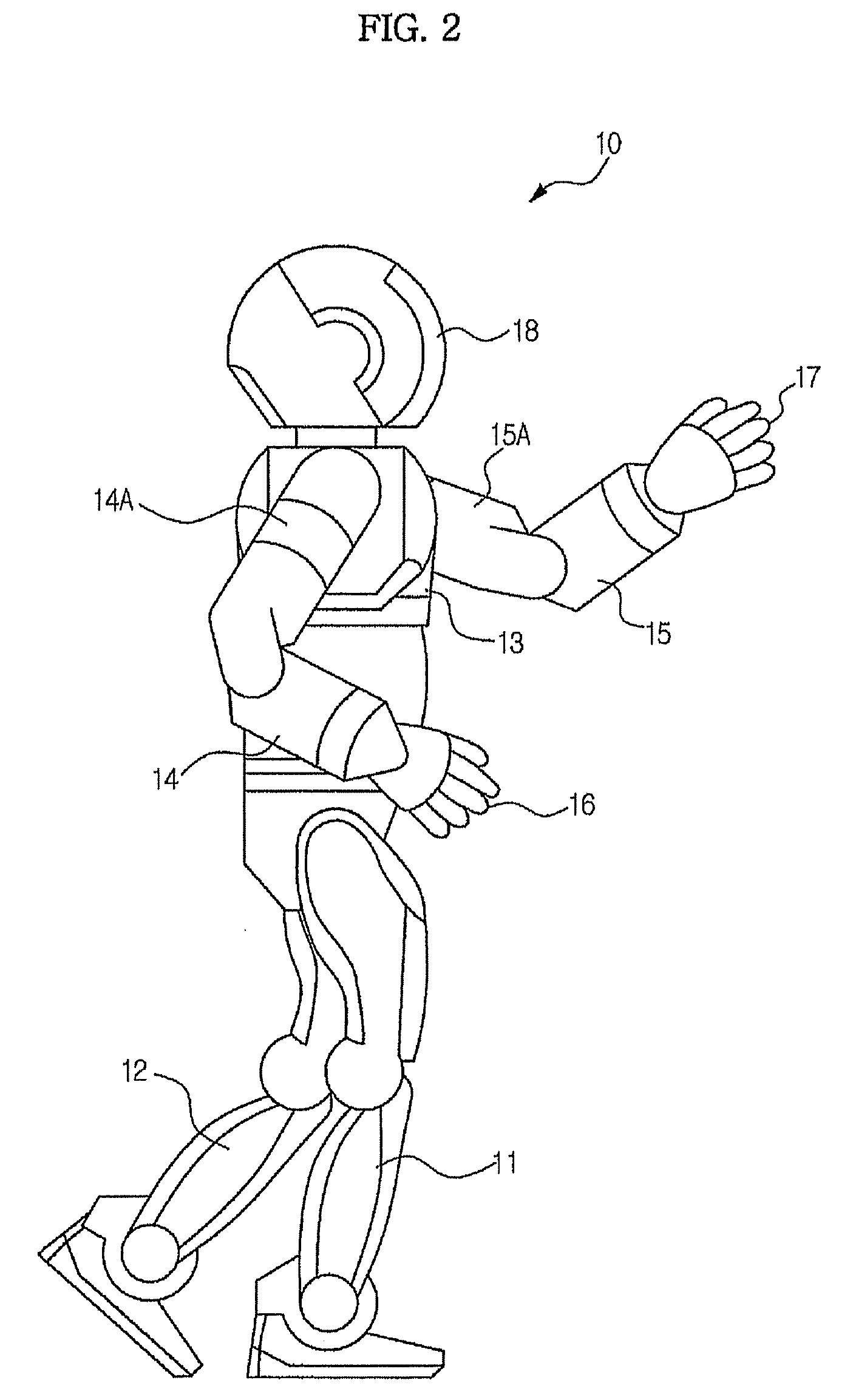

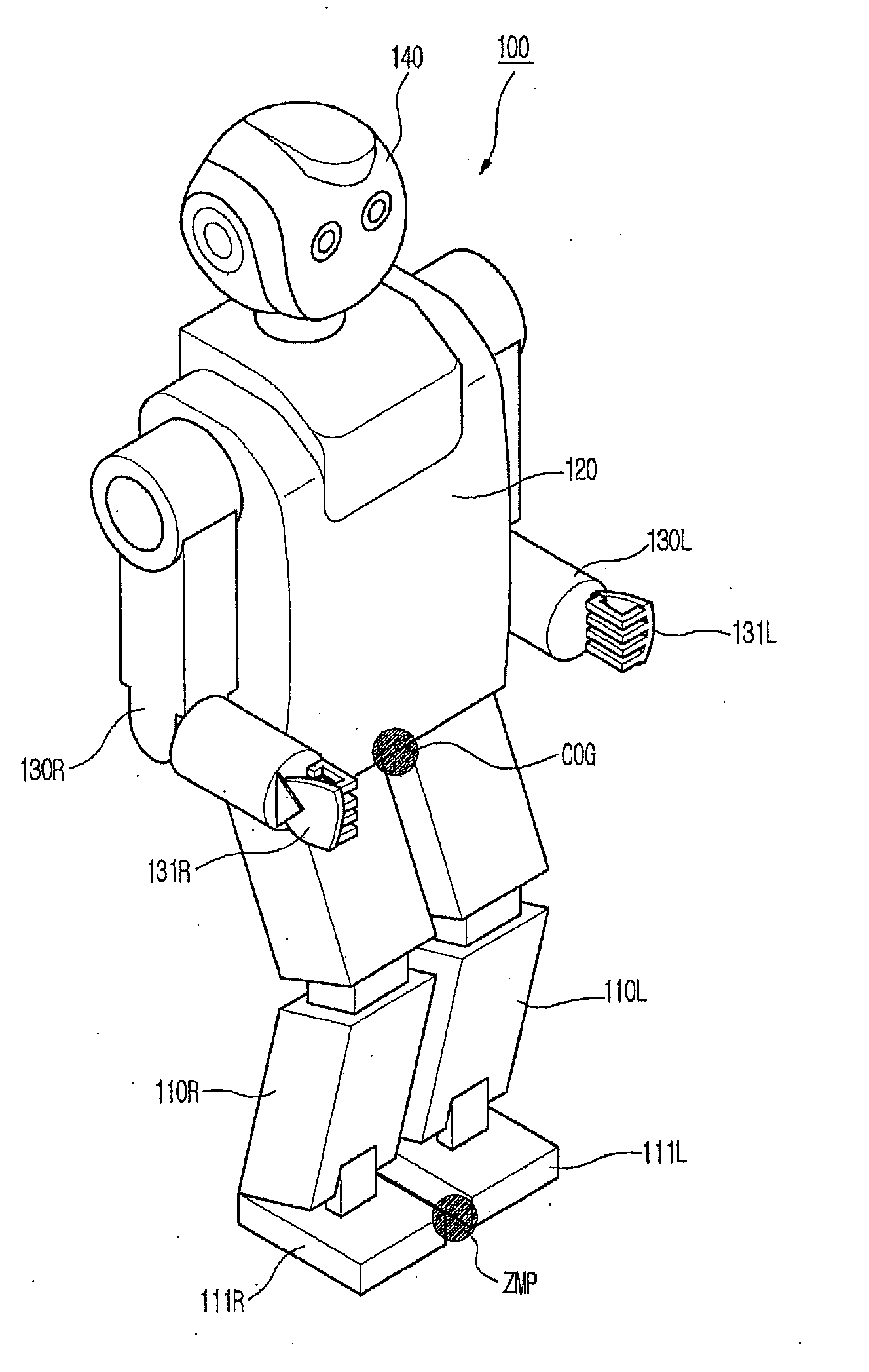

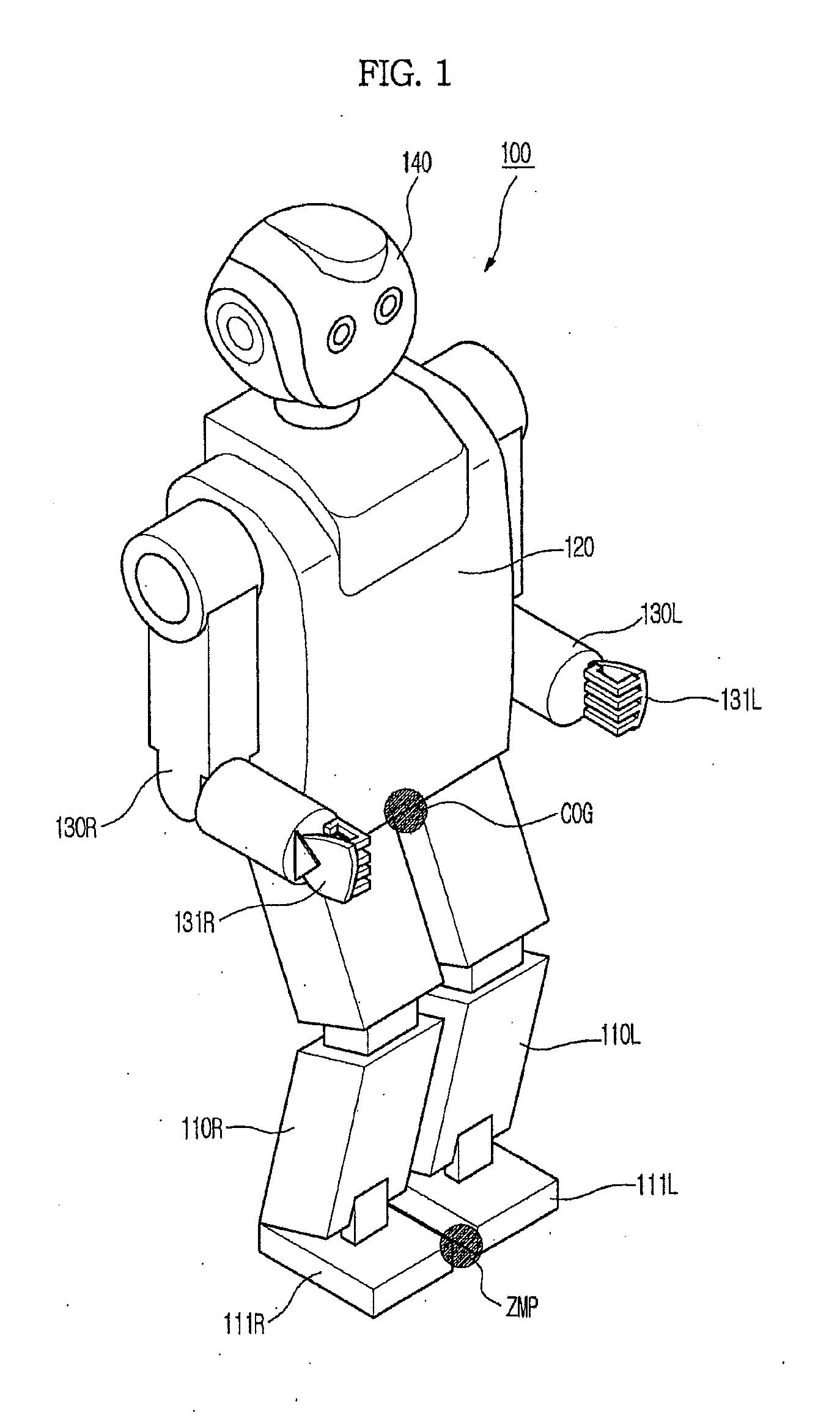

Robot and method of controlling cooperative work thereof

InactiveUS20090287354A1Without limitationProgramme-controlled manipulatorComputer controlSimulationActuator

Disclosed are a robot, which performs cooperative work with a plurality of robot manipulators through impedance control, and a method of controlling cooperative work of the robot. The method includes calculating absolute coordinate positions of end effectors, respectively provided at a plurality of manipulators to perform the work; calculating a relative coordinate position from the absolute coordinate positions of the end effectors; calculating joint torques of the plurality of manipulators using the relative coordinate position; and controlling the cooperative work of the plurality of manipulators according to the joint torques.

Owner:SAMSUNG ELECTRONICS CO LTD

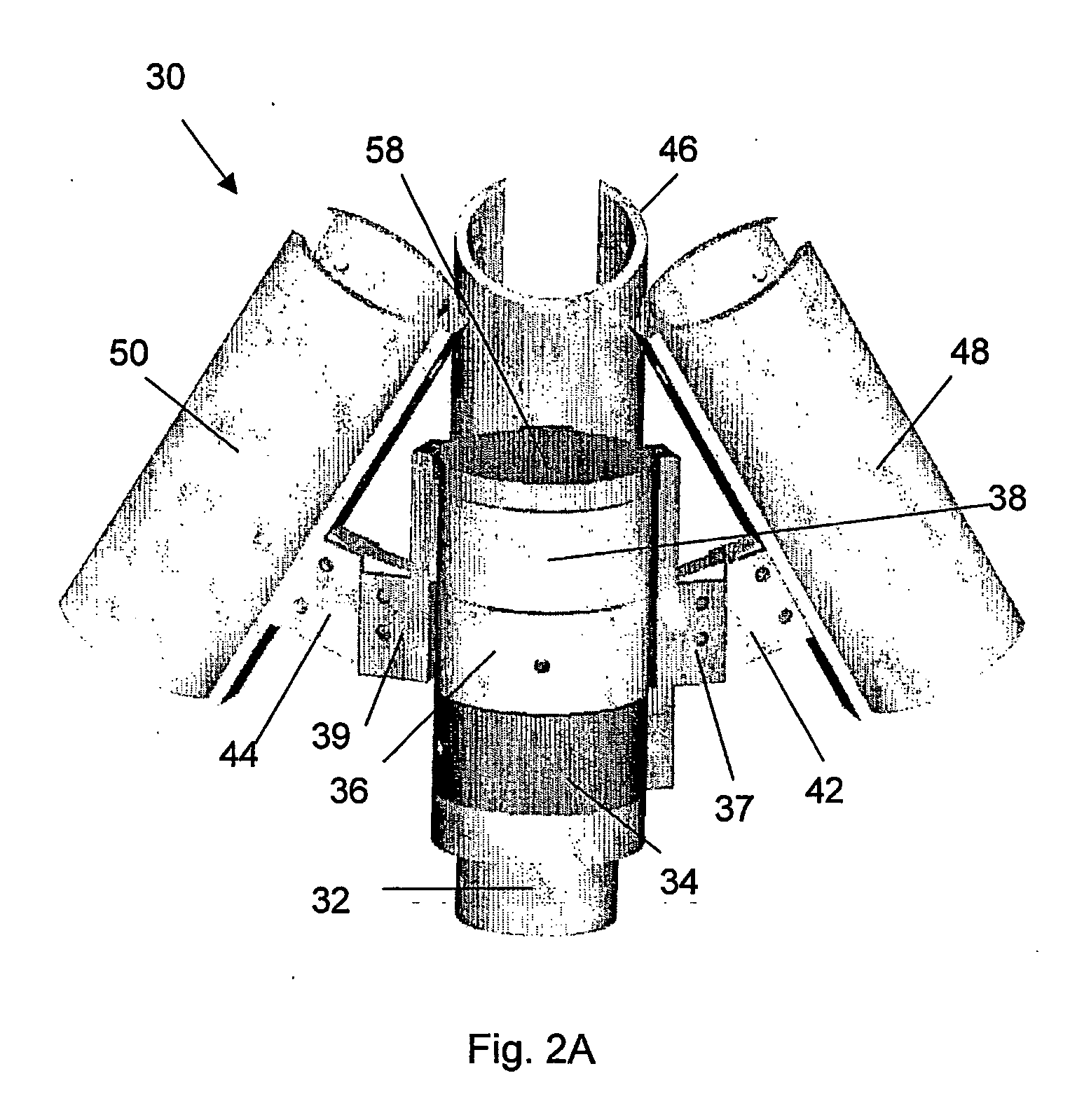

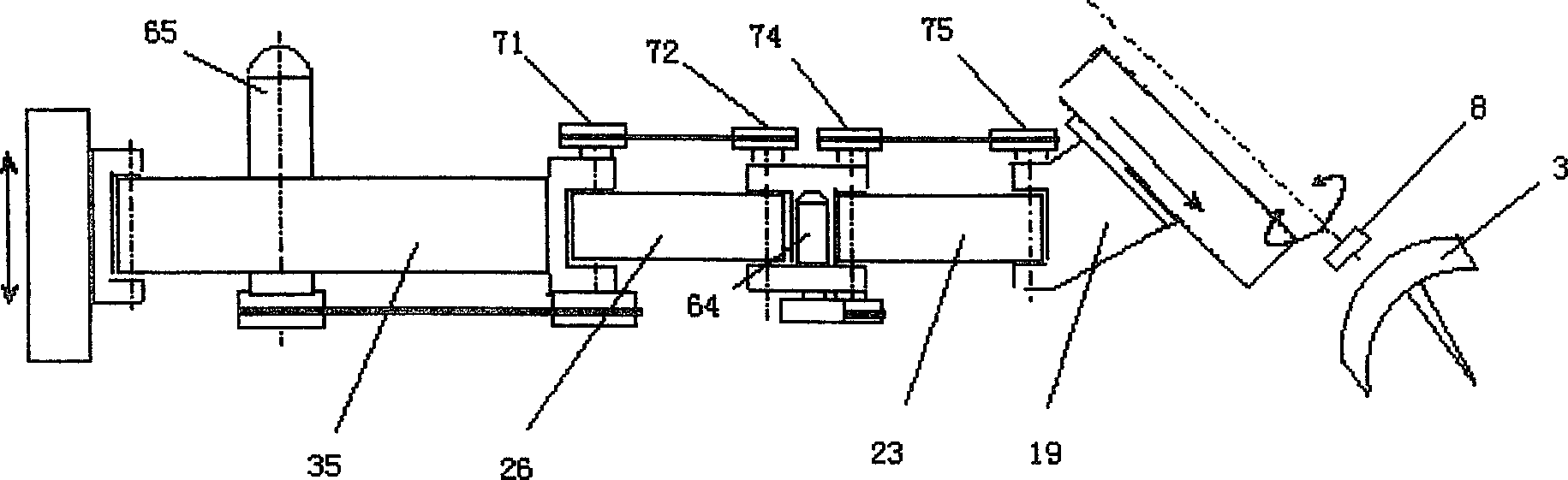

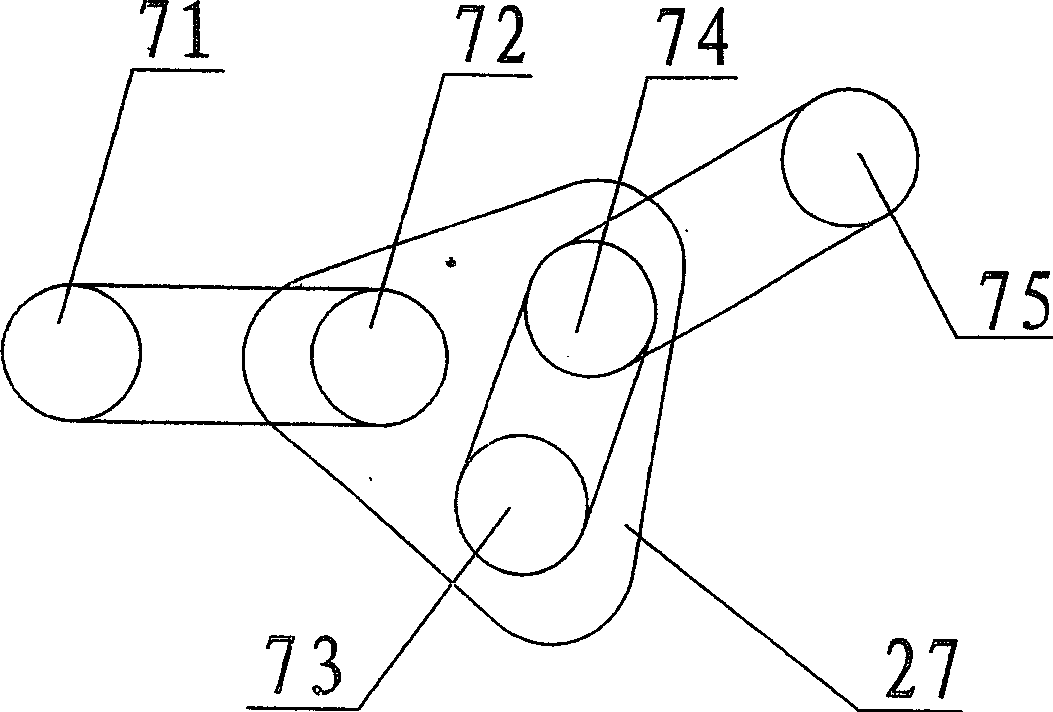

Ultrasonic treatment of breast cancer

InactiveUS20050038339A1Ultrasonic/sonic/infrasonic diagnosticsUltrasound therapyEarly breast cancerWilms' tumor

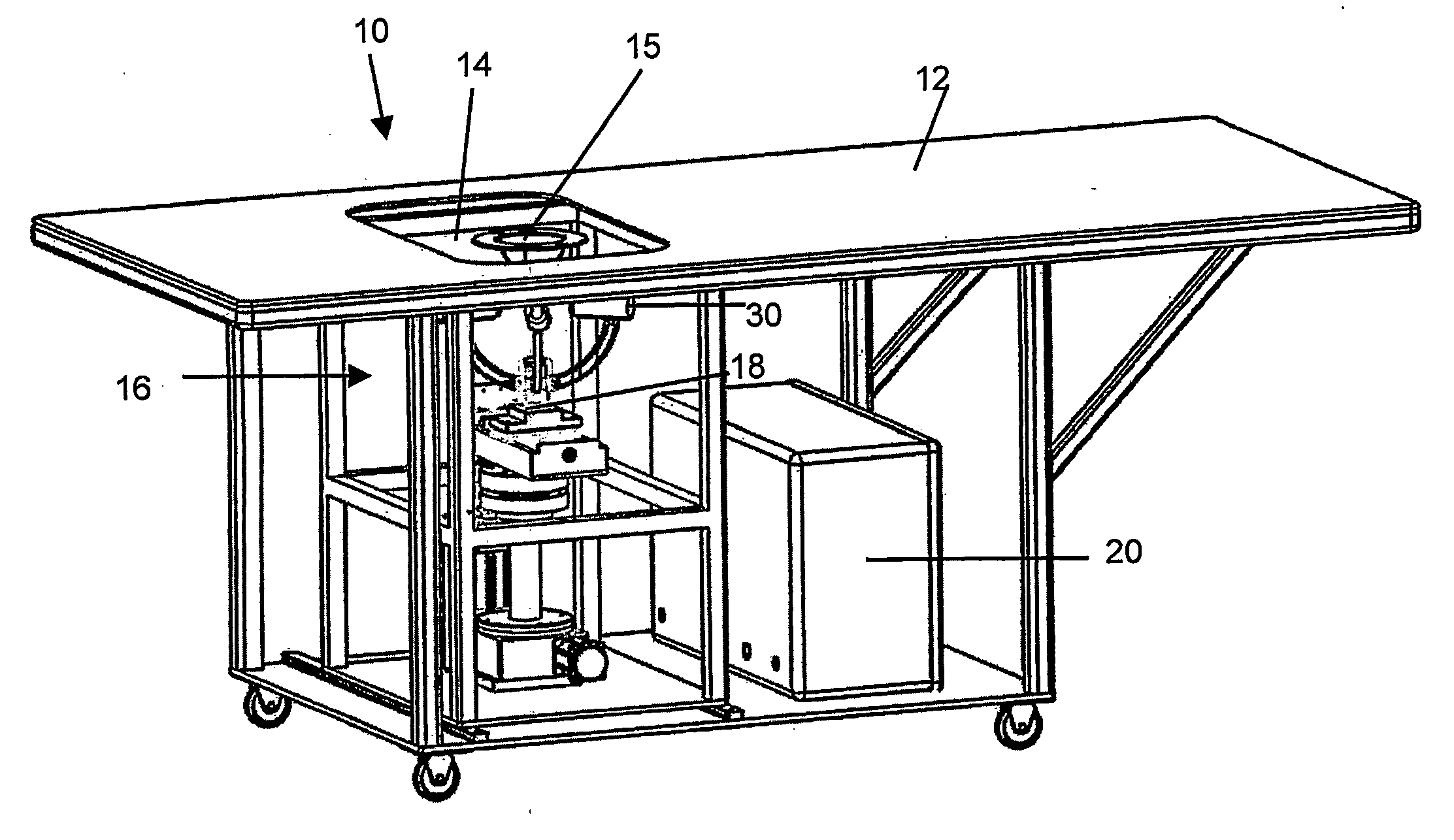

A method of treatment, clinical treatment assembly, robotic manipulator and controlling arrangements for the treatment of cancers are described. The invention has particular application in the treatment of breast cancer. A robotic manipulator (18) carries a jig assembly (30). The jig assembly (30) includes an array of treatment probes (52, 54, 56) and a single identification / diagnostic probe (58). The probes can be moved by the robotic manipulator (18) in three directions (x, y, θ). A subject breast tissue is received in a tank (16) through an operating window (14), and the robotic manipulator (18) is to firstly determine the site of a tumour in the breast tissue. Once the tumour has been located by use of the identification / diagnostic probe (58), the treatment probes (52, 54, 56) are used to ablate the tumour by the superposition of ultrasonic waves at a focal region. A series of such lesions may be performed in sequence to traverse the full extent of the tumour.

Owner:NANYANG TECH UNIV

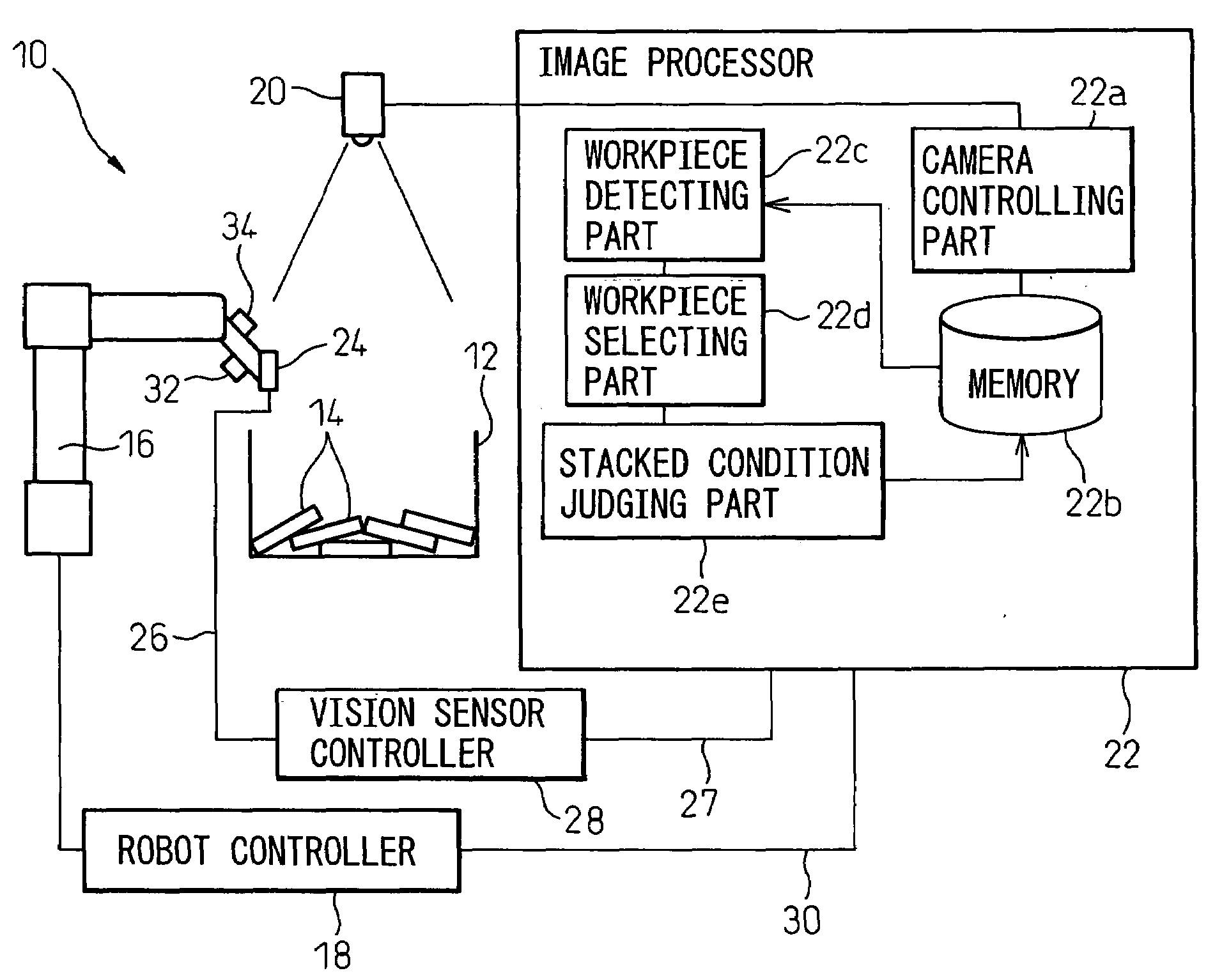

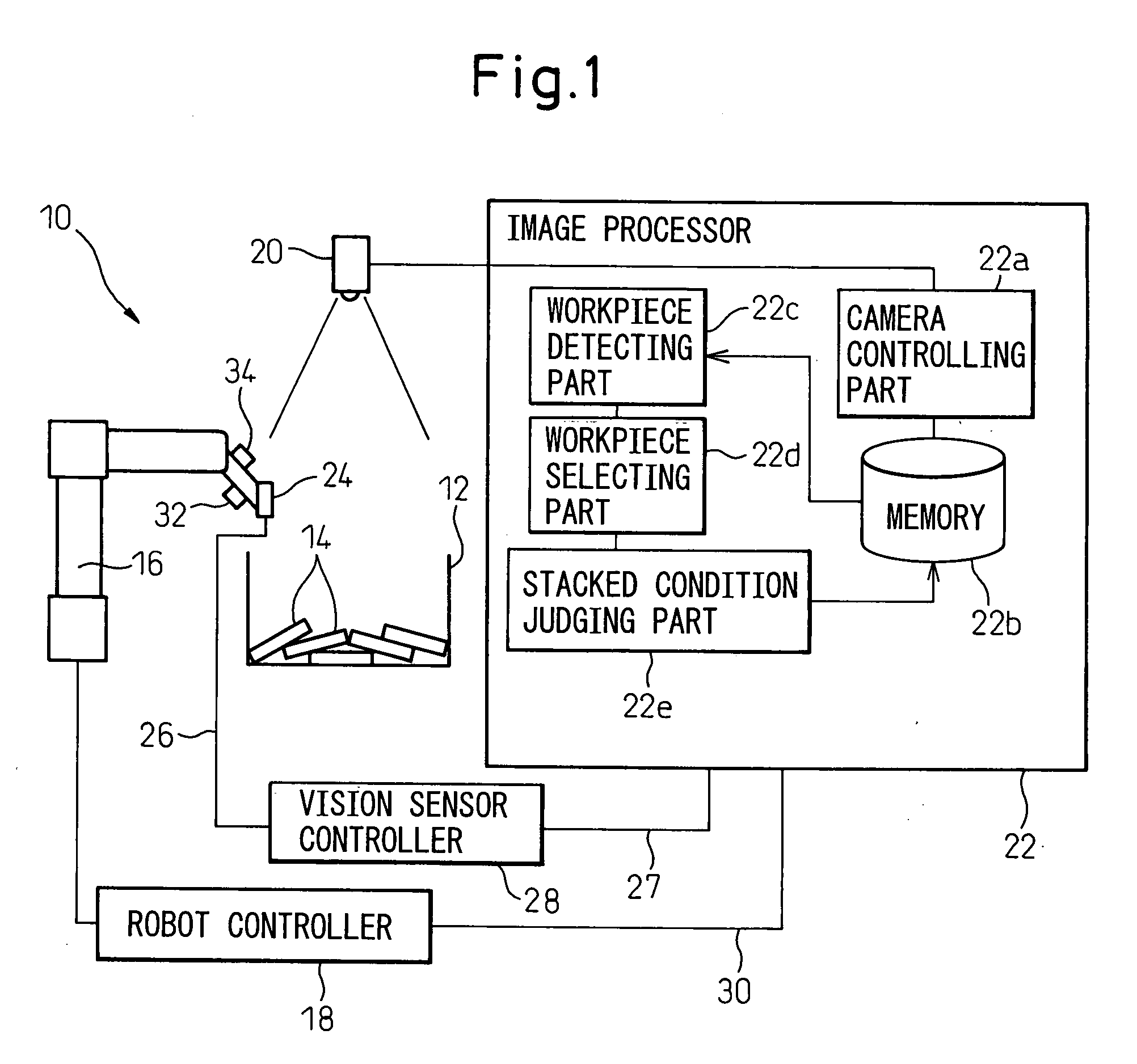

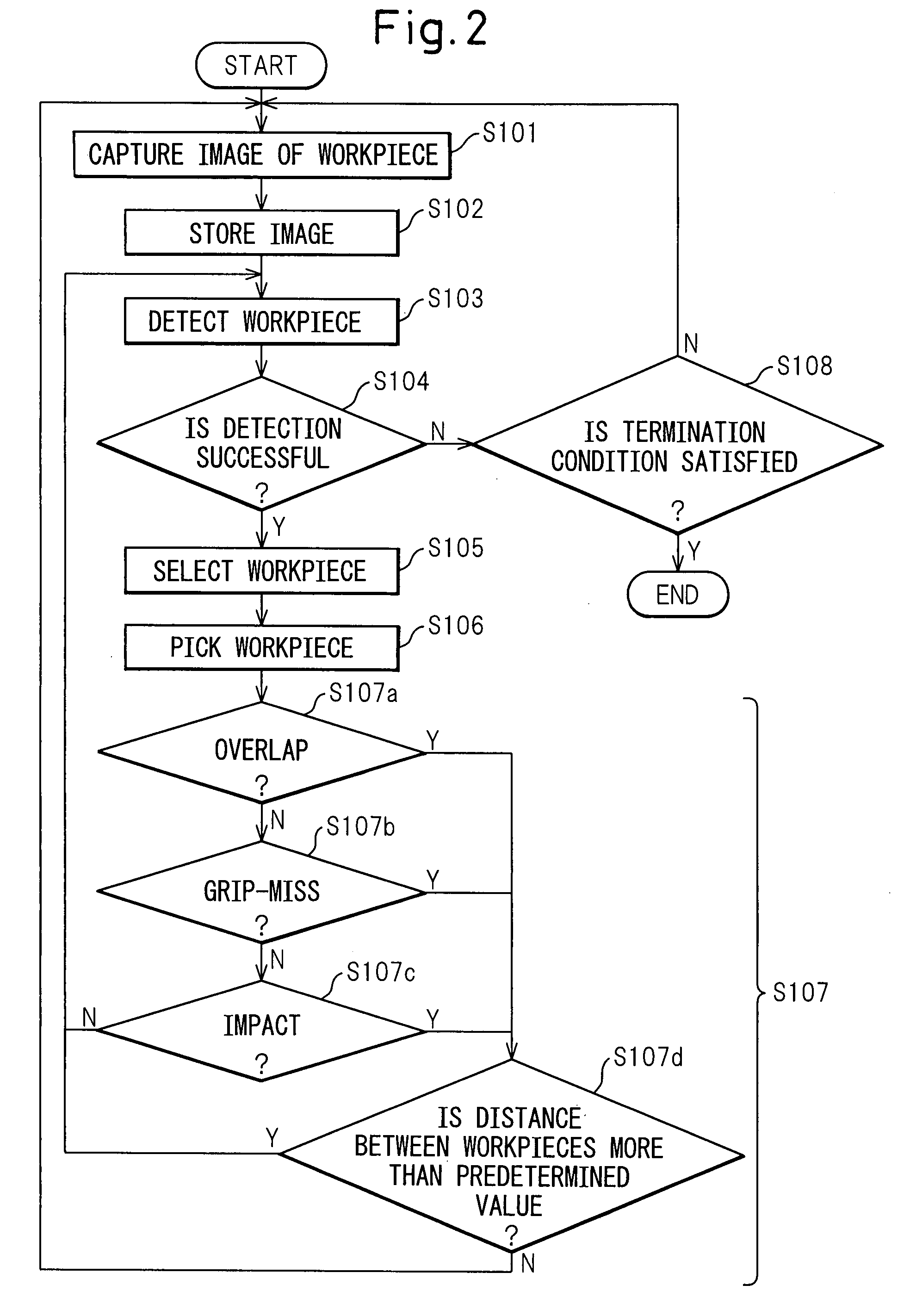

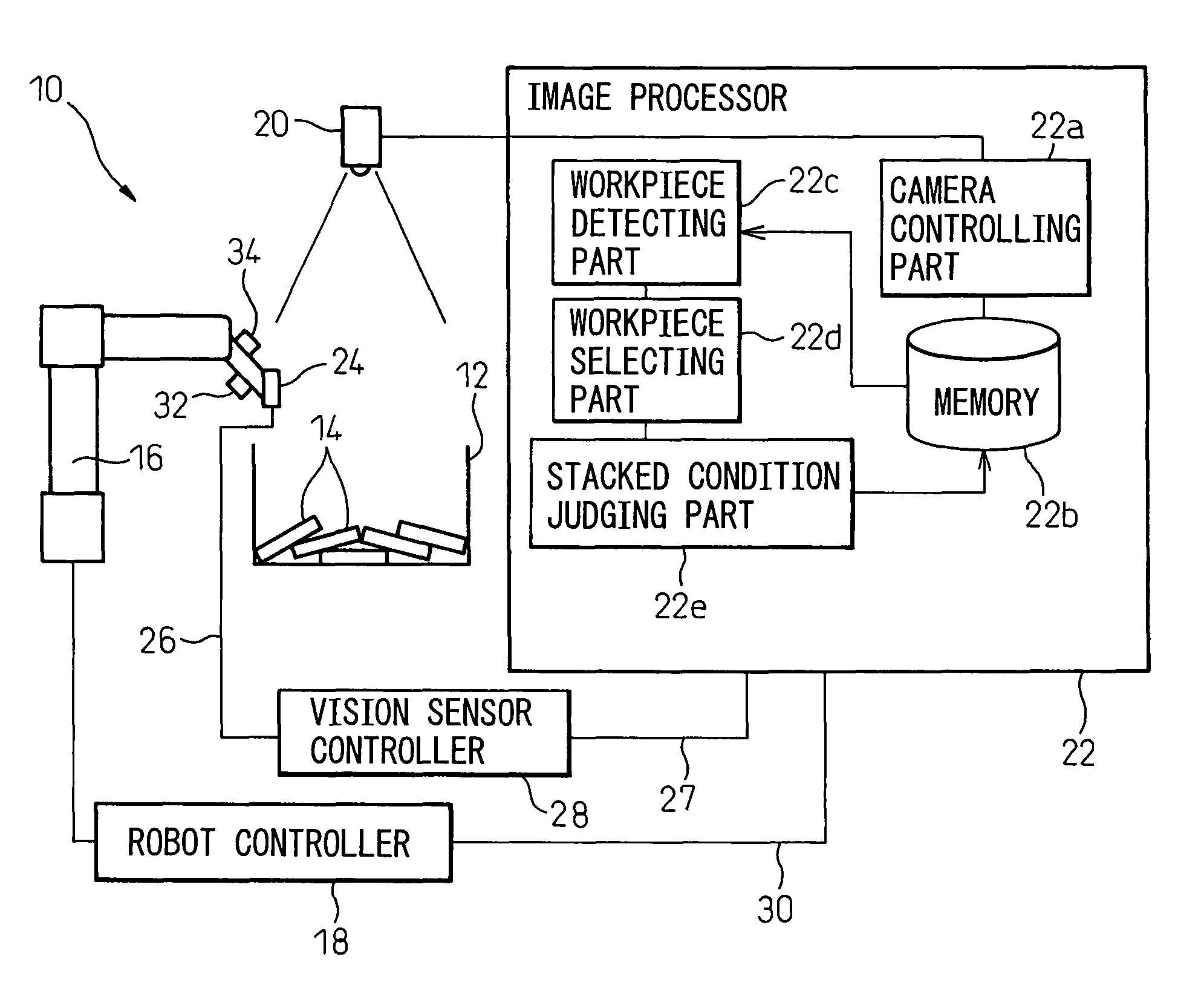

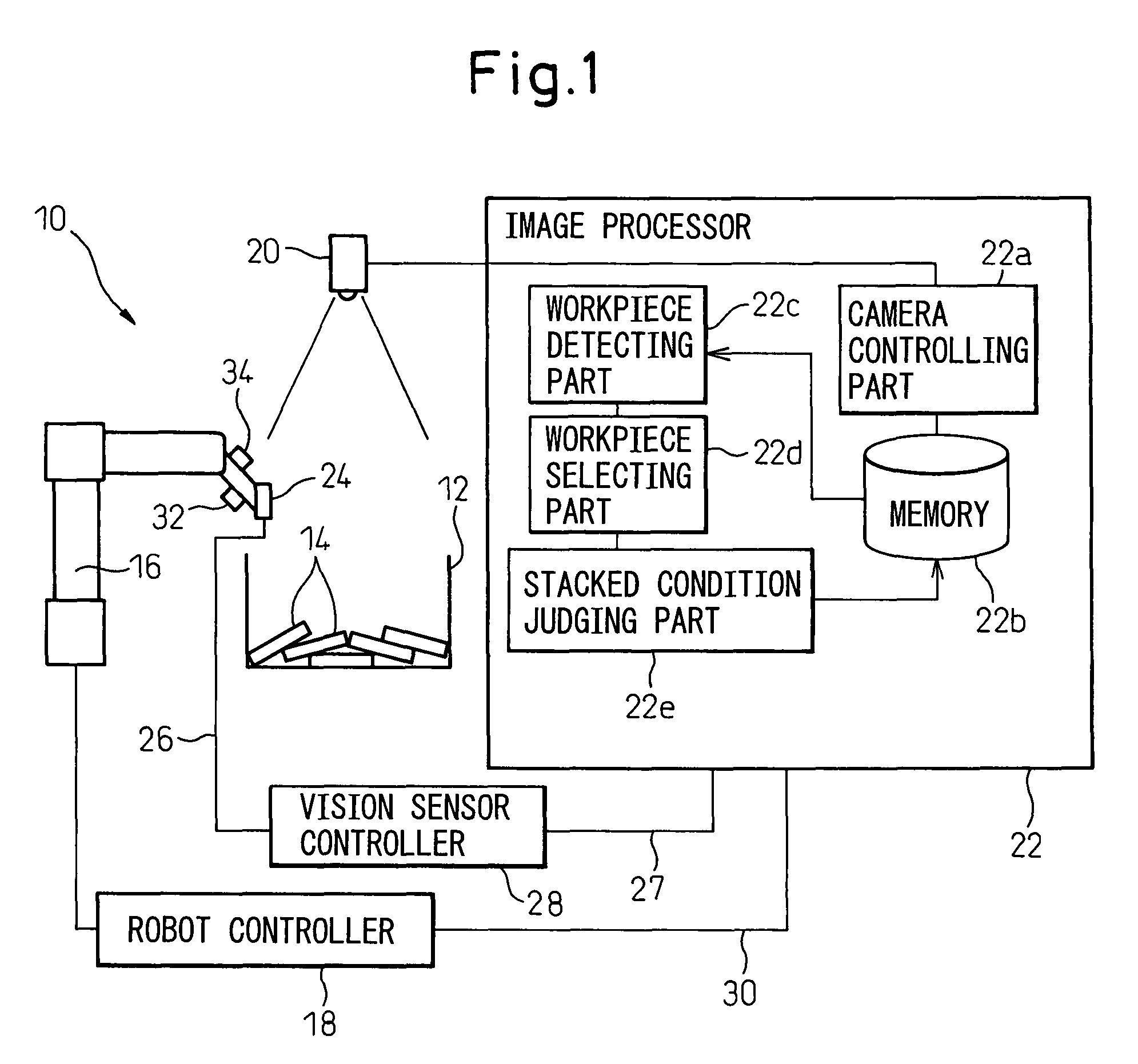

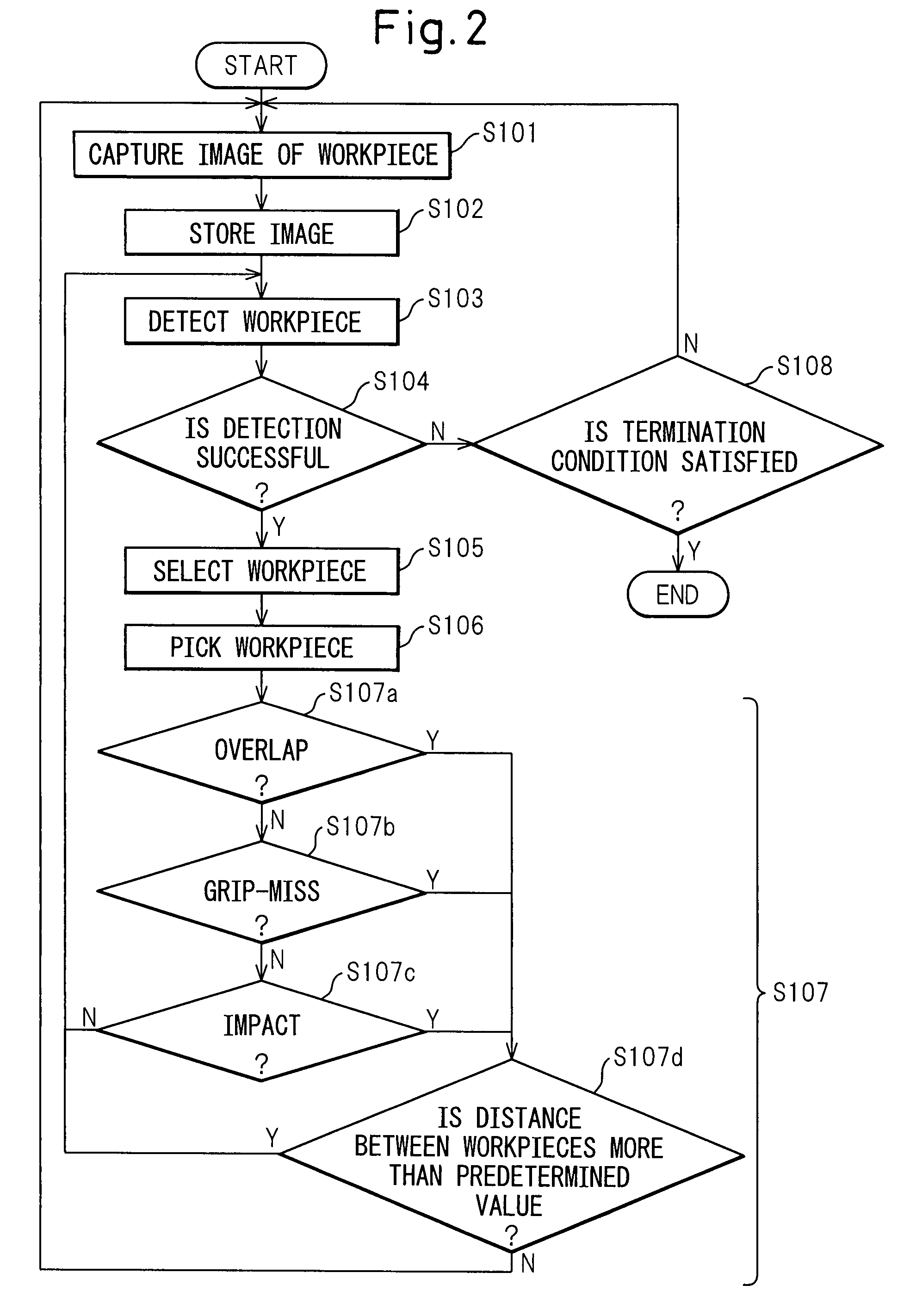

Workpiece picking device and method

InactiveUS20070274812A1Short cycleProgramme controlProgramme-controlled manipulatorCamera controlCycle time

A workpiece picking device and method for reducing the cycle time of a picking operation of workpieces, by omitting or reducing the movement of a robot manipulator when an image of the workpieces is captured. An image processor of the picking device includes a camera controlling part for reading image data from a camera, a memory for storing the image data, a workpiece detecting part for extracting one or more images from the memory and detecting one or more workpieces in the image, and a workpiece selecting part for selecting a workpiece to be picked among the workpieces detected by the workpiece detecting part. The image processor further includes a stacked condition judging part for determining whether the condition of the stacked workpieces in a container is changed.

Owner:FANUC LTD

Autonomous mobile platform for service applications

The invention disclosed with this Application is a autonomous mobile system comprising: a means of achieving mobility, a means of navigating, a means of providing autonomous power, and a means of providing general purpose computing.In some embodiments, the system comprises a base unit capable of sensing its environment and computing navigation instructions to direct the system to move to particular locations and execute particular functions, as directed by a set of programmed instructions.In some embodiments, a coupling exists on the base unit to attach additional structures and mechanisms. These structures may comprise a means for carrying packages or other items, robotic manipulators that can grab and move objects, interactive audio and video displays for telepresence applications, a means for serving food and drink, etc. These extensions may be designed to be detachable and interchangeable, or may be designed to be permanently attached to the base unit.

Owner:UBIQUITY ROBOTICS INC

Robust impedance-matching of manipulators interacting with unknown environments

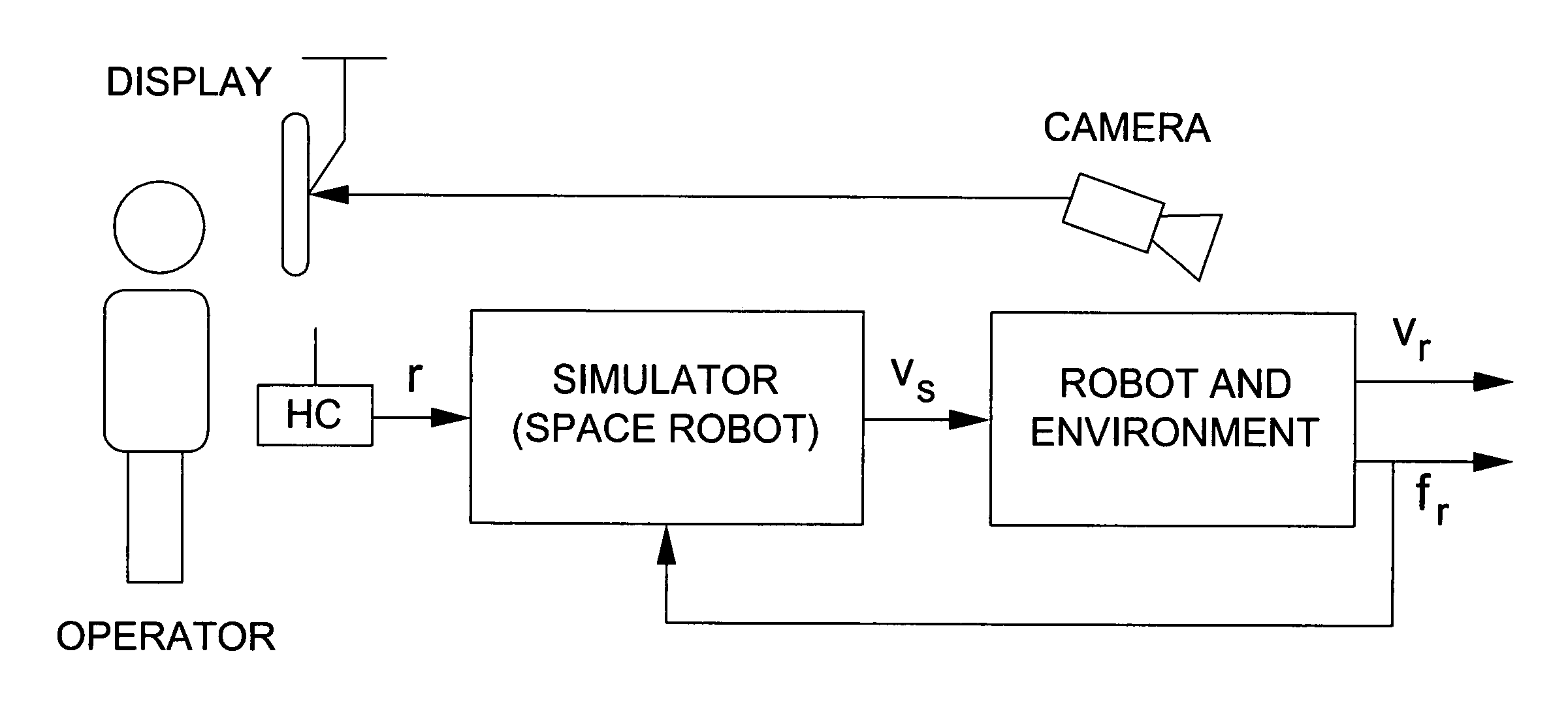

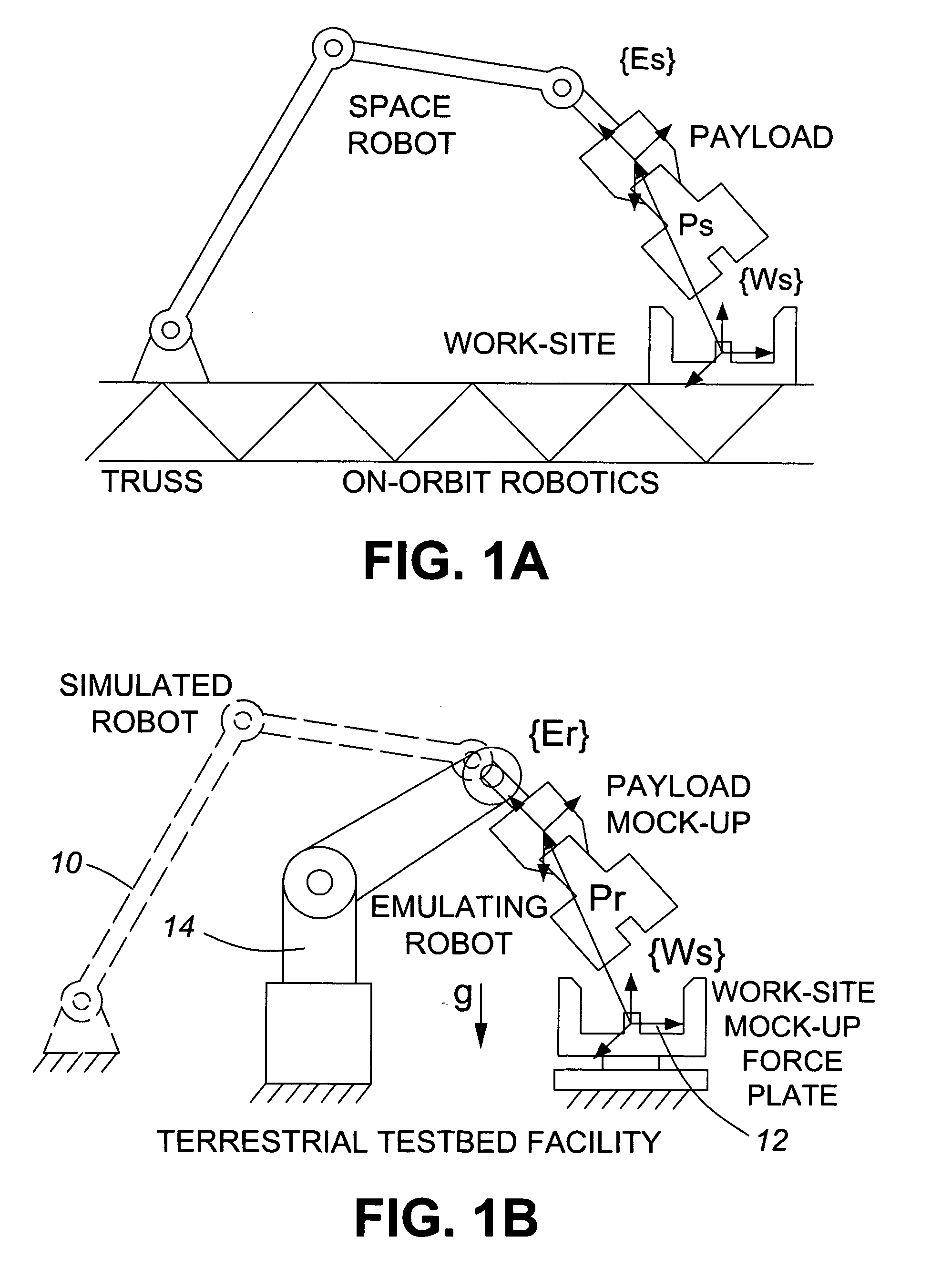

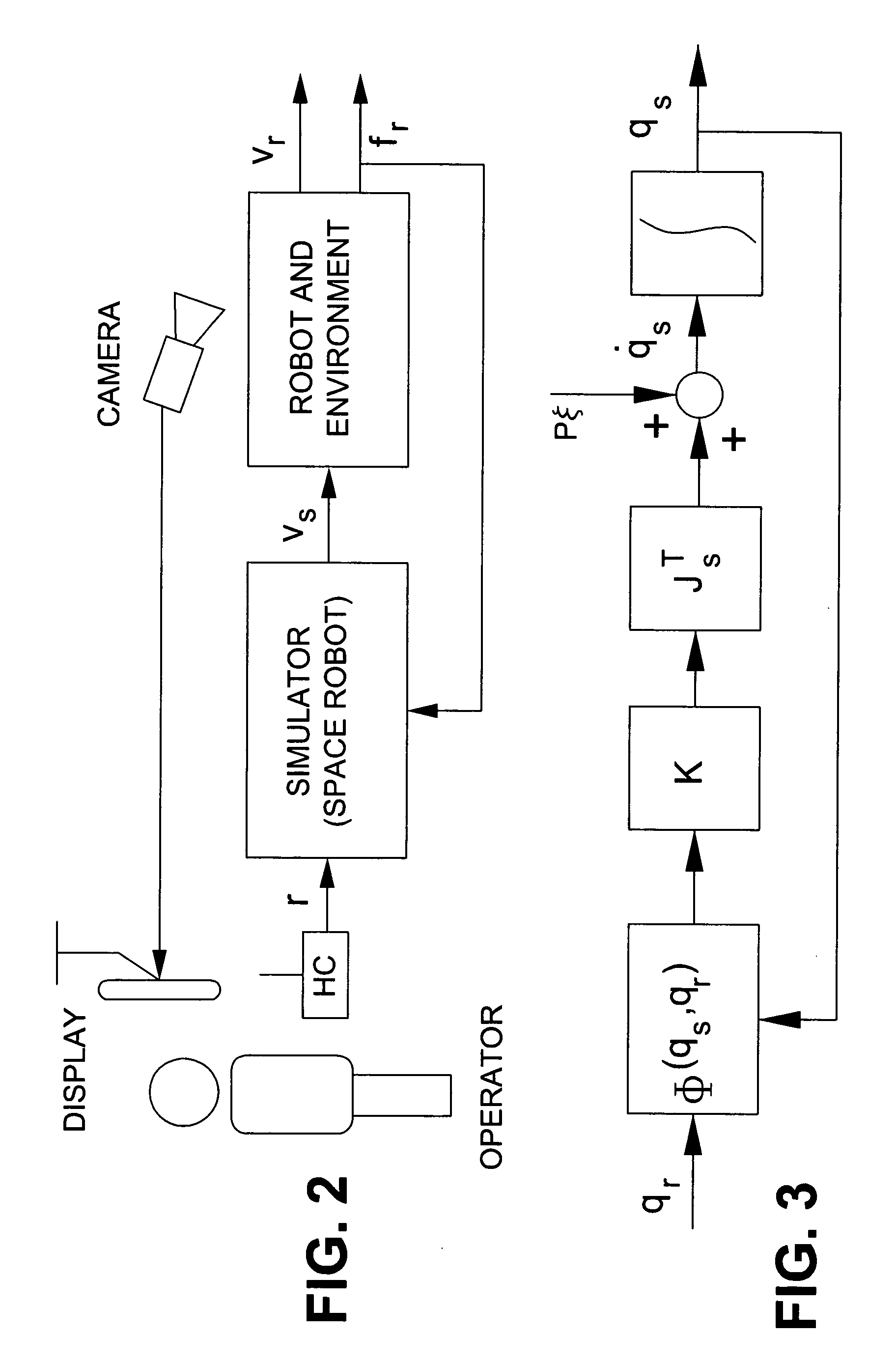

InactiveUS20070073442A1Minimizes disturbance sensitivityMore sensitivityProgramme-controlled manipulatorComputer controlMock upsSimulation

A system for replicating the behavior of a target robotic manipulator with respect to a payload and worksite, has a real-time simulator capturing the dynamics of the target robot manipulator; a mock-up of the payload and worksite; and an emulating robotic manipulator for interacting with said payload and worksite. The emulating robotic manipulator is controlled by the real-time simulator in a control loop to replicate the dynamical behavior of said target robotic manipulator in its environment by matching the impedance of the emulating robotic manipulator with that of the target robotic manipulator.

Owner:CANADIAN SPACE AGENCY

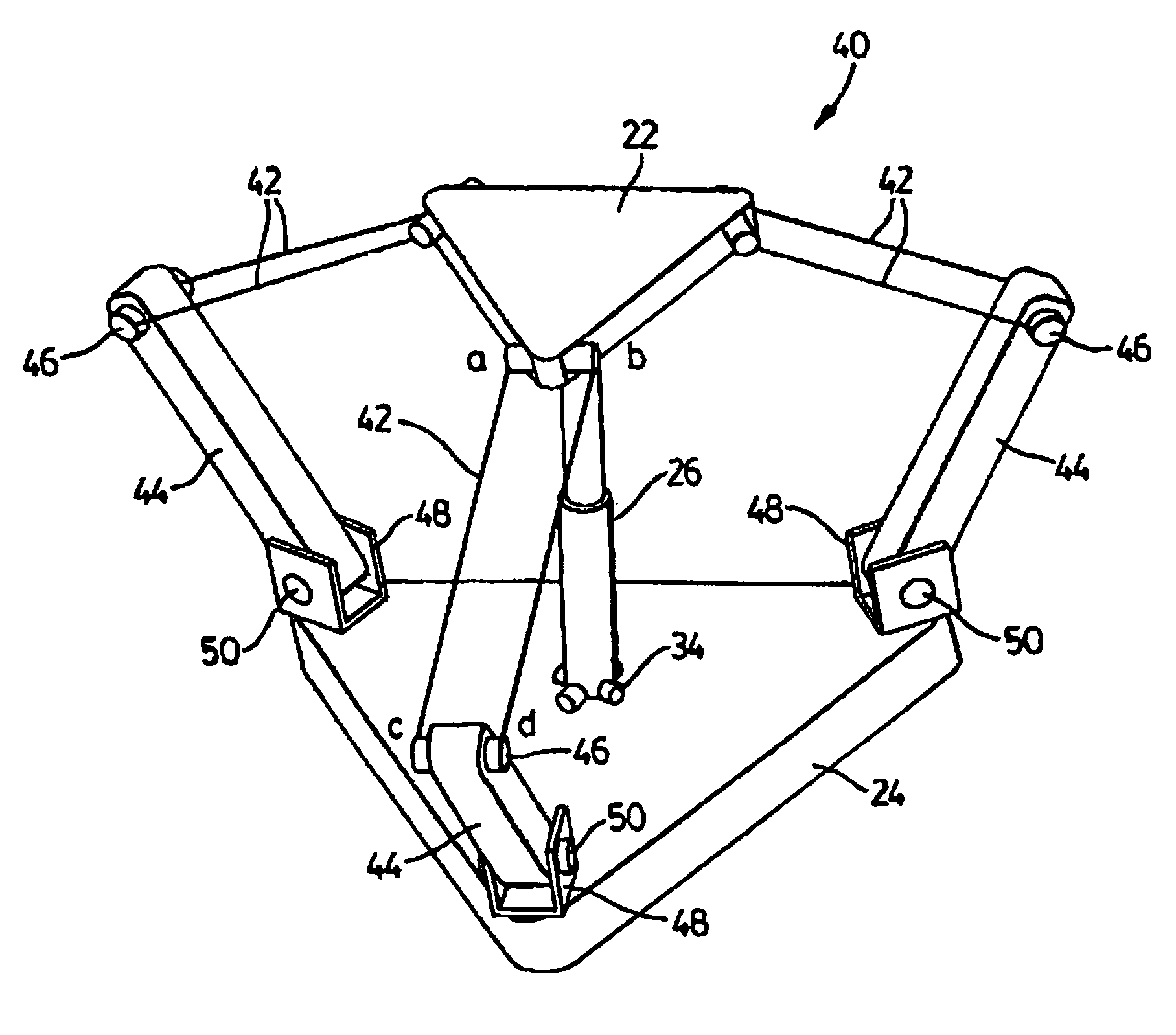

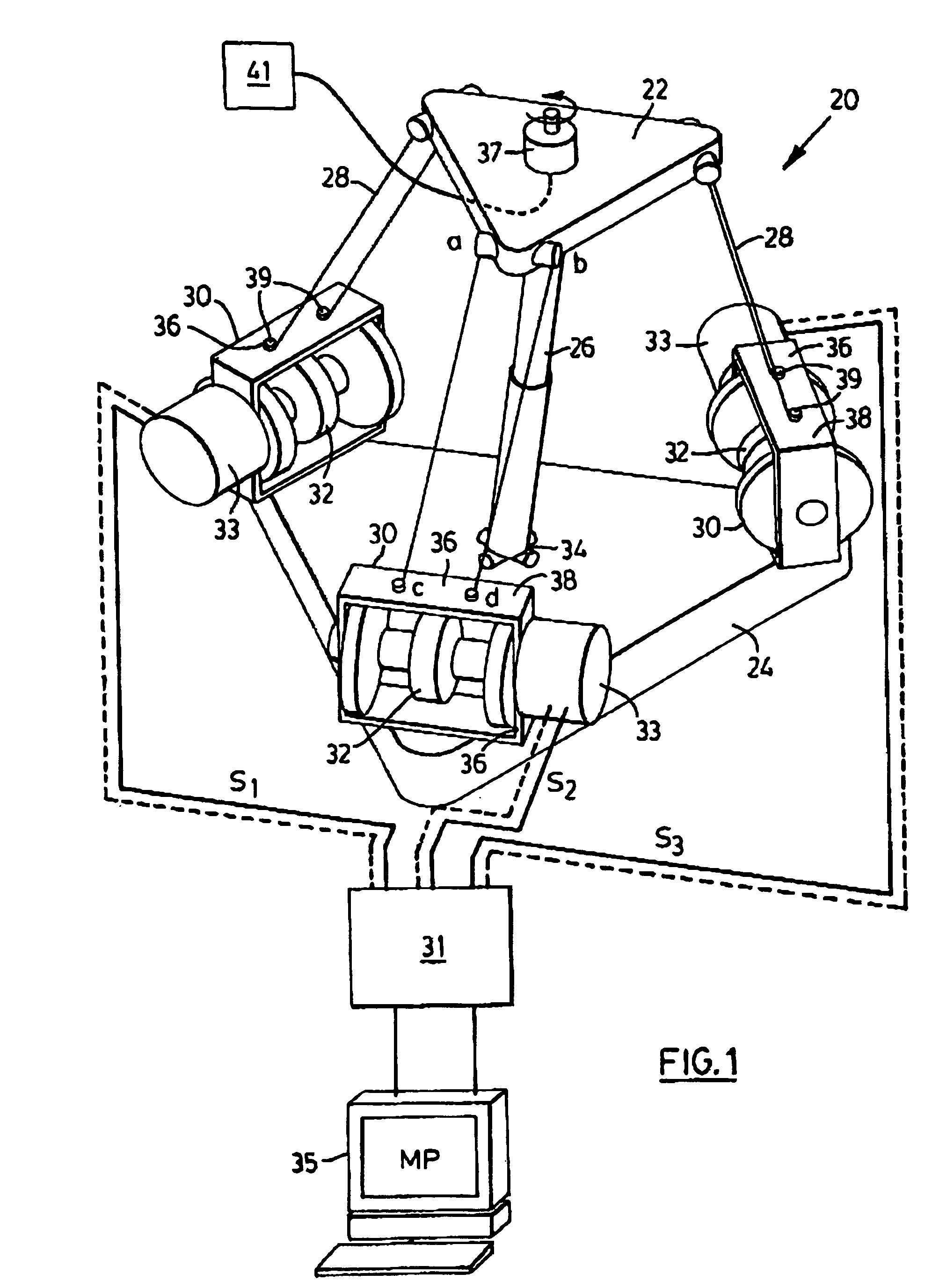

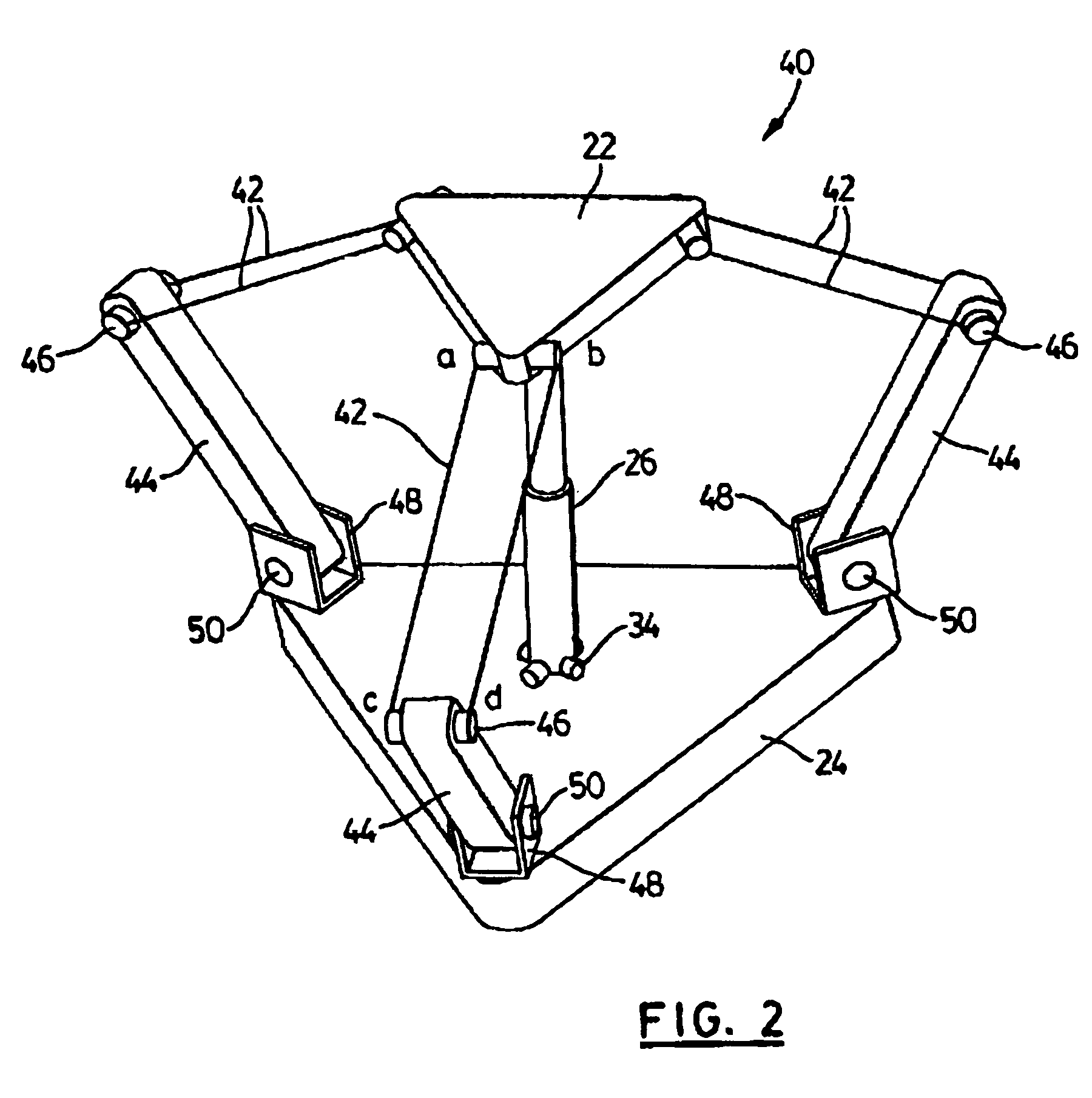

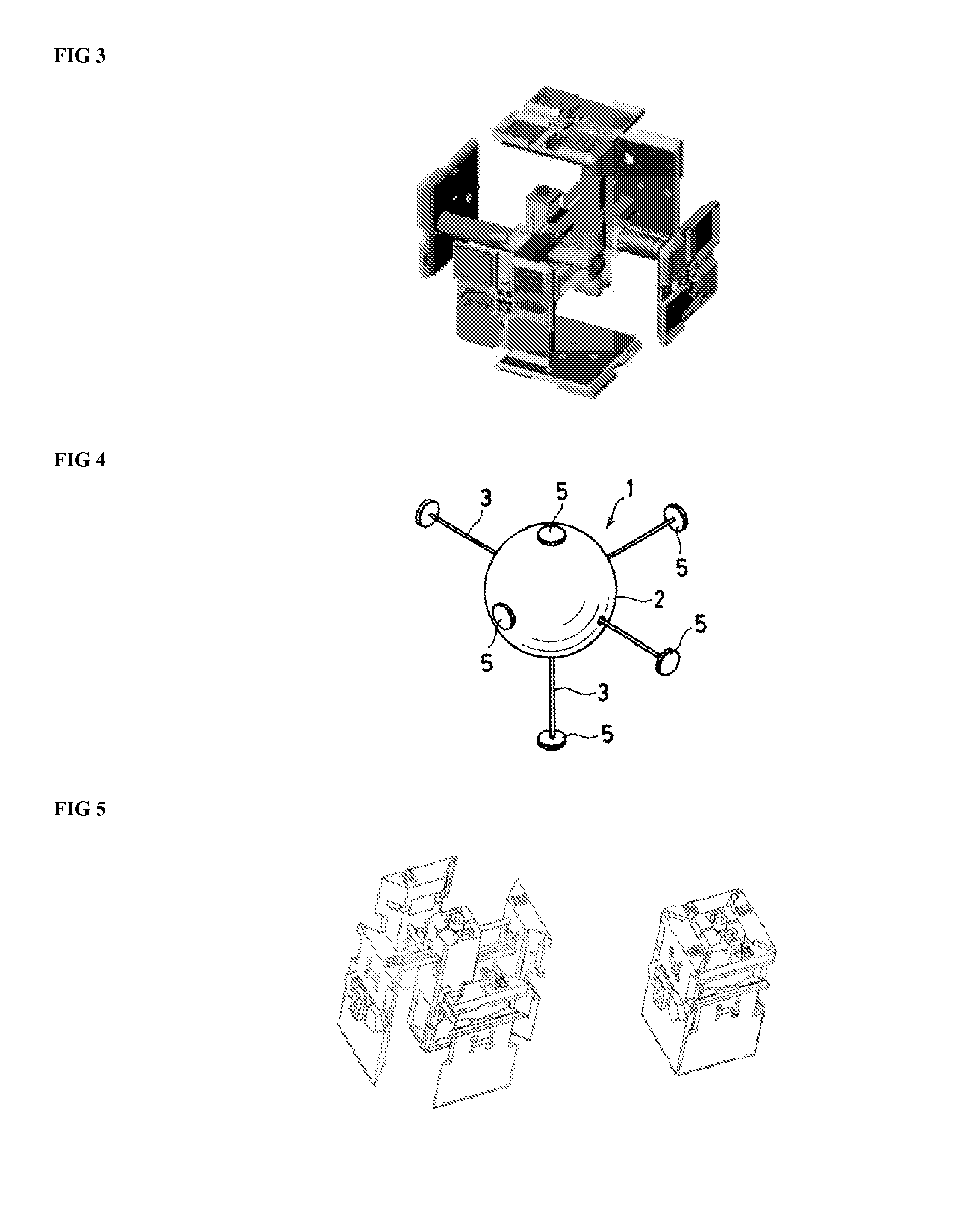

Light weight parallel manipulators using active/passive cables

ActiveUS7172385B2Simple processMaximize the benefitsProgramme-controlled manipulatorMechanical apparatusUltra high speedCost effectiveness

The present invention provides parallel, cable based robotic manipulators, for use in different applications such as ultra high-speed robots or positioning devices with between three to six degrees of freedom. The manipulators provide more options for the number of degrees of freedom and also more simplicity compared to the current cable-based robots. The general structure of these manipulators includes a base platform, a moving platform or end effector, an extensible or telescoping central post connecting the base to moving platform to apply a pushing force to the platforms. The central post can apply the force by an actuator (active), or spring or air pressure (passive) using telescoping cylinders. The robotic manipulators use a combination of active and passive tensile (cable) members, and collapsible and rigid links to maximize the benefits of both pure cable and conventional parallel mechanisms. Different embodiments of the robotic manipulators use either active cables only, passive cables only, or combinations of active and passive cables. An active cable is one whose length is varied by means of a winch. A passive cable is one whose length is constant and which is used to provide a mechanical constraint. These mechanisms reduce the moving inertia significantly to enhance the operational speed of the robots. They also provide a simpler, more cost effective way to manufacture parallel mechanisms for use in robotic applications.

Owner:KHAJEPOUR AMIR +3

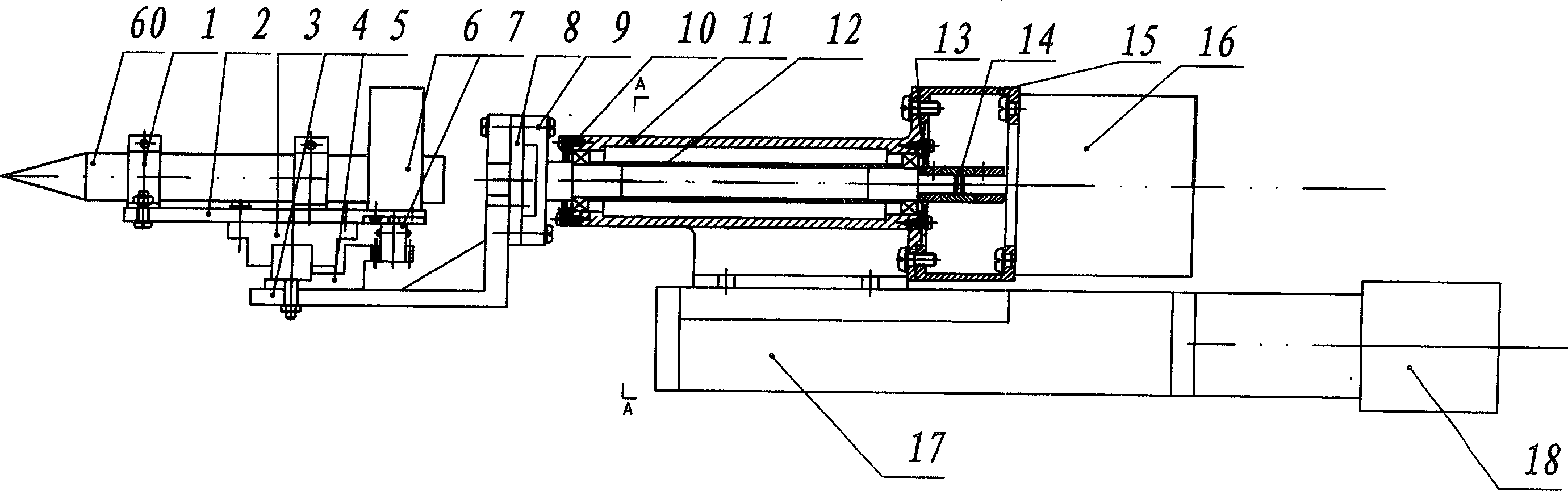

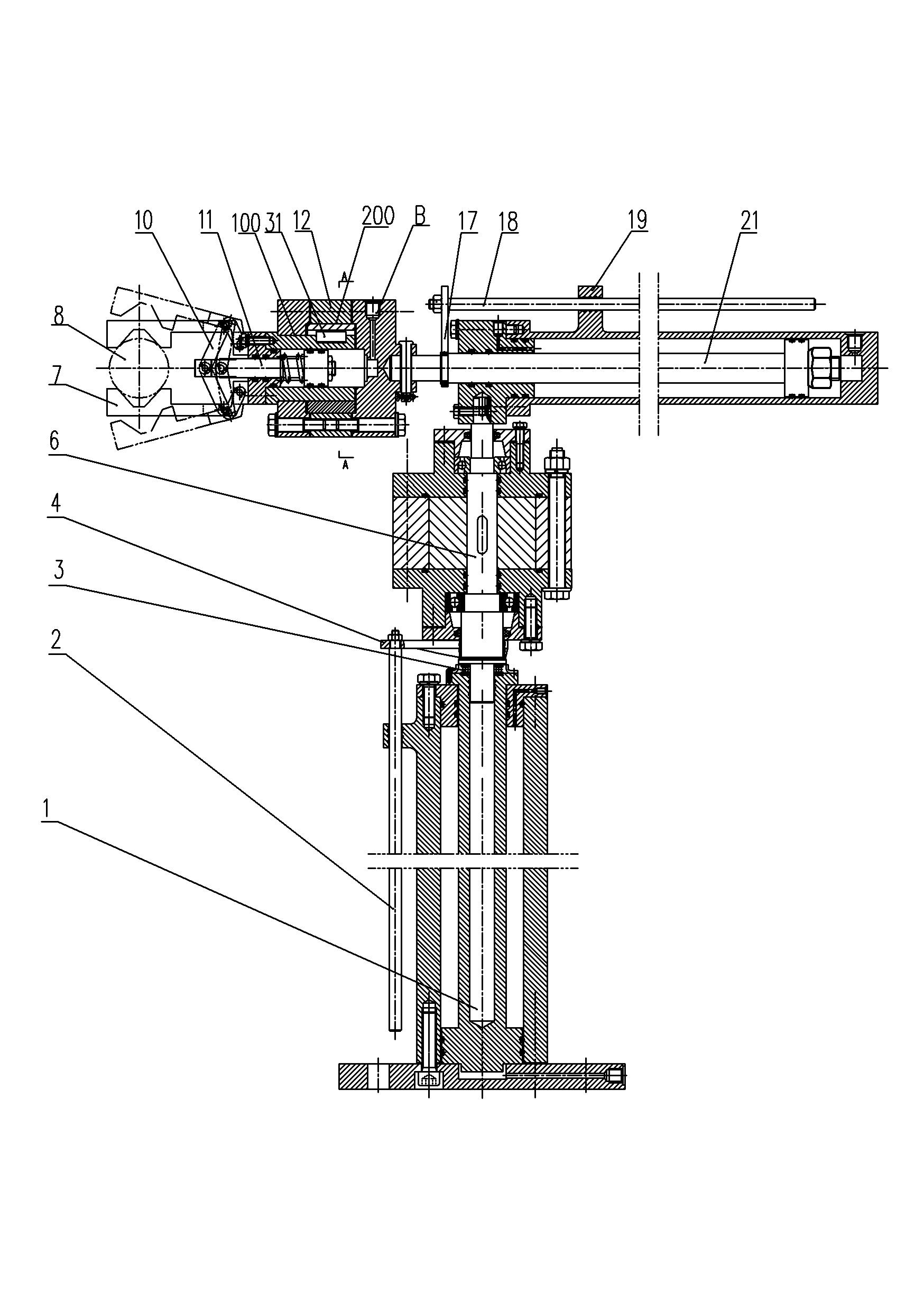

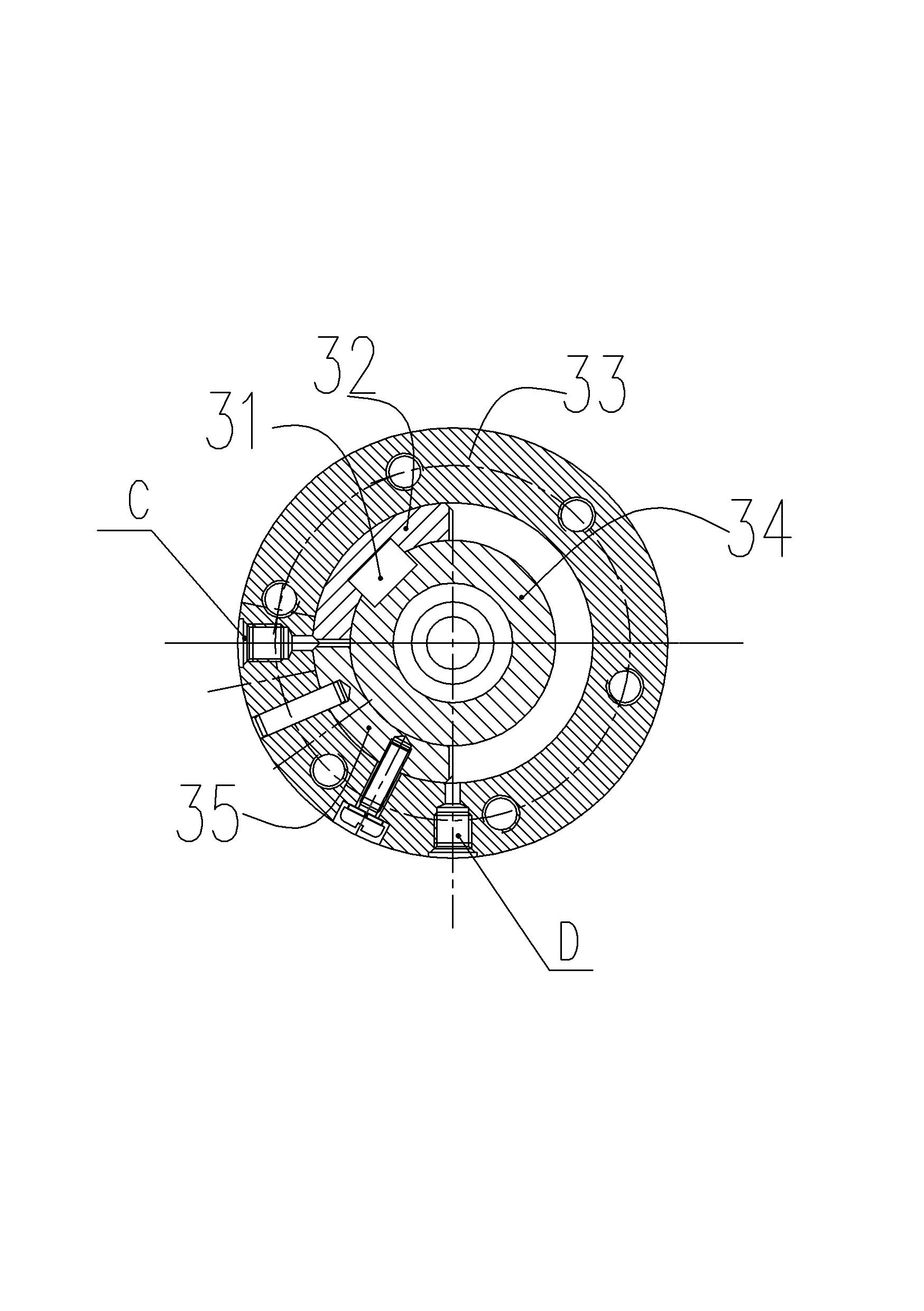

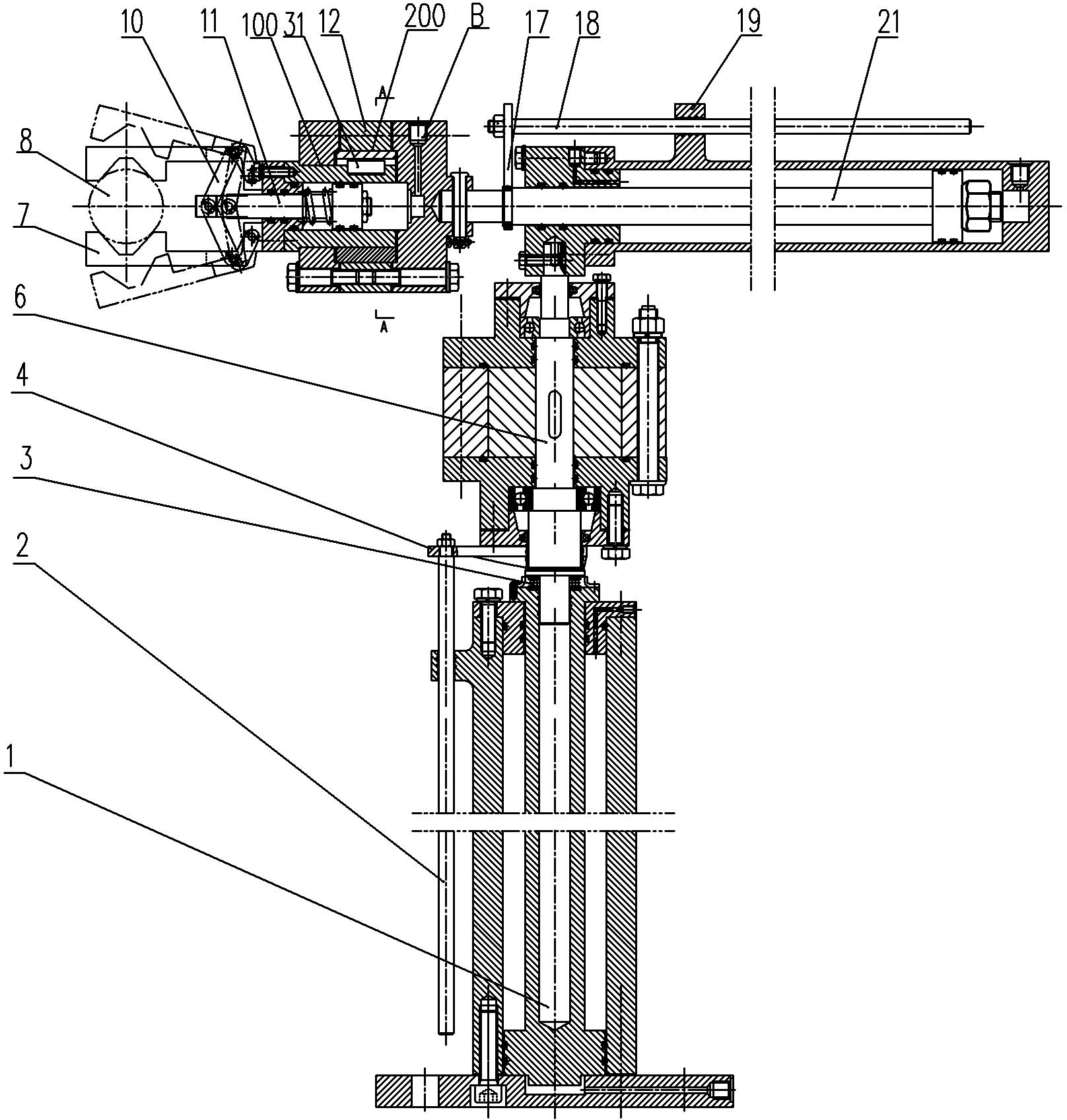

Secondary manipulator of surgery operation robot

ActiveCN1654174AEasy and flexible operationRealize mechanical structure uncouplingJointsDiagnosticsBlood vesselRobot manipulator

The servo actuated robot manipulator for surgical operation has fingers in the most front end as well as finger circularly moving joint mechanism, arc guide rotating joint mechanism, inclined guide straight motion joint mechanism, the first small arm rotating joint mechanism, the second small arm rotating joint mechanism, large arm rotating joint mechanism, vertical position regulating mechanism and sync toothed belt wheel mechanism. The present invention is used mainly in micro wound surgical operation, eye operation, orthopaedics operation, etc., especially in blood vessel stitching and other microscopic surgical operations.

Owner:TIANJIN UNIV

Workpiece picking device and method

InactiveUS7996114B2Short cycleProgramme controlProgramme-controlled manipulatorCamera controlCycle time

A workpiece picking device and method for reducing the cycle time of a picking operation of workpieces, by omitting or reducing the movement of a robot manipulator when an image of the workpieces is captured. An image processor of the picking device includes a camera controlling part for reading image data from a camera, a memory for storing the image data, a workpiece detecting part for extracting one or more images from the memory and detecting one or more workpieces in the image, and a workpiece selecting part for selecting a workpiece to be picked among the workpieces detected by the workpiece detecting part. The image processor further includes a stacked condition judging part for determining whether the condition of the stacked workpieces in a container is changed.

Owner:FANUC LTD

Path planning apparatus of robot and method and computer-readable medium thereof

ActiveUS20110106307A1Improves path planning performanceImprove performanceHybrid vehiclesProgramme-controlled manipulatorMomentumEngineering

An apparatus, method and computer-readable medium planning a path of a robot by planning an optimal path while satisfying a dynamic constraint. In a process of searching for a motion path from a start point to a goal point while extending a tree from a start point of a configuration space to generate a path, along which a manipulator of the robot is moved in order to perform a task, an optimal path is generated responsive to the dynamic constraint of the manipulator of the robot to generate stable motion satisfying momentum and Zero Moment Position (ZMP) constraint. Accordingly, path planning performance is improved and a path satisfying a kinematic constraint and a dynamic constraint is rapidly obtained.

Owner:SAMSUNG ELECTRONICS CO LTD

Bionic manipulator

InactiveCN102672713ASimple structureCompact structureProgramme-controlled manipulatorBionicsEngineering

The invention discloses a bionic manipulator, which comprises a main body lifting cylinder, which extends along a vertical direction, wherein a main body rotating cylinder capable of rotating around a central axis of the main body lifting cylinder is fixedly arranged on the output end of the main body lifting cylinder, an arm telescopic cylinder, which extends along a horizontal direction, is fixedly arranged on the output end of the main body rotating cylinder, an artifice rotating cylinder, which rotates around the central axis of the arm telescopic cylinder, is fixedly arranged on the arm telescopic cylinder, and a paw part used for grabbing articles is arranged on a rotating output part on the artifice rotating cylinder. When used, materials are grabbed by the paw part firstly, and then the paw part is moved and adjusted to a proper position through a telescopic action of the arm telescopic cylinder, a rotating action of the main body rotating cylinder and a lifting action of the main body lifting cylinder according to actual requirements, when the paw is moved in place, the materials are put down by the paw part, so that the materials can be conveyed without manual work.

Owner:HENAN UNIV OF SCI & TECH

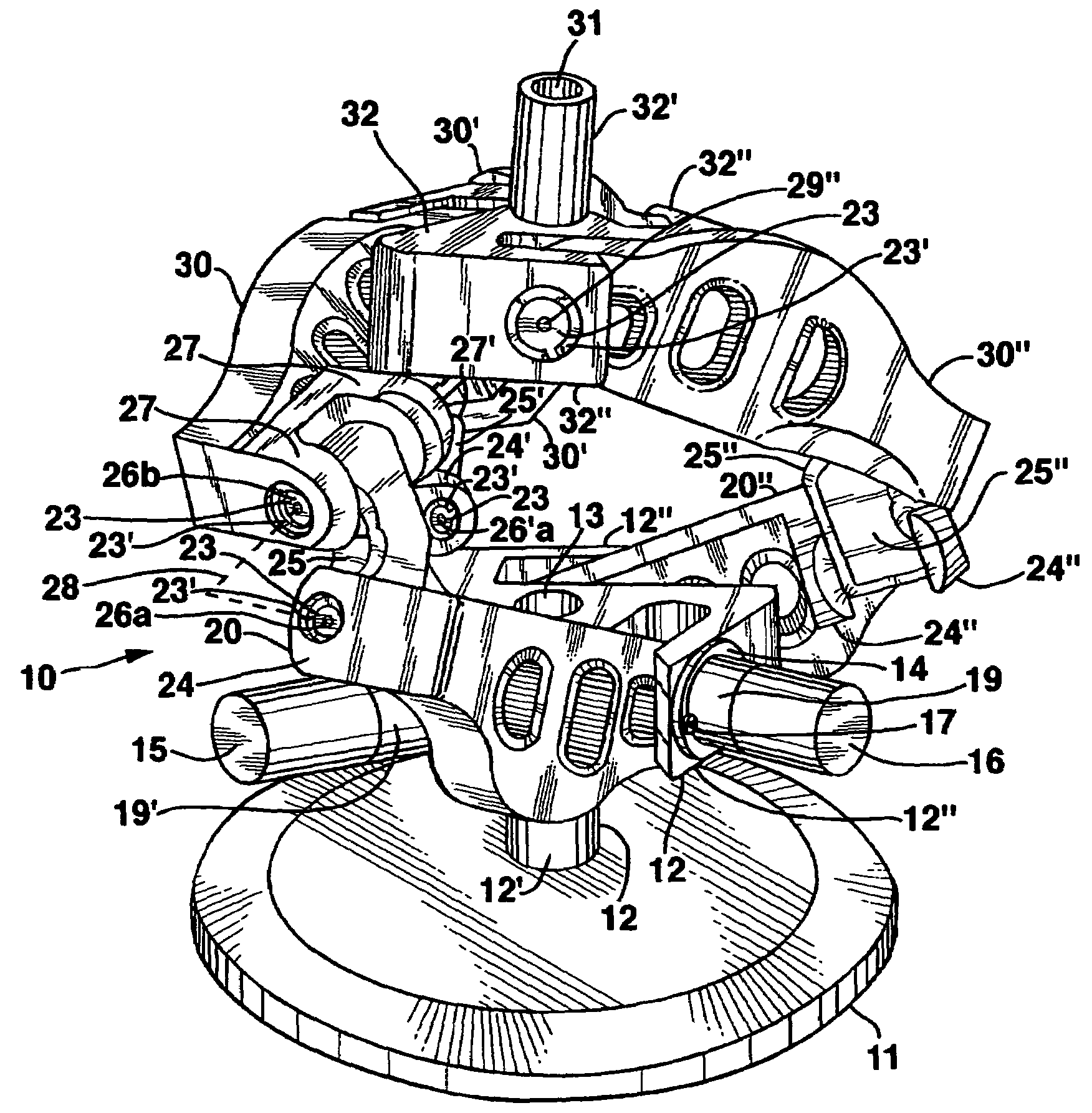

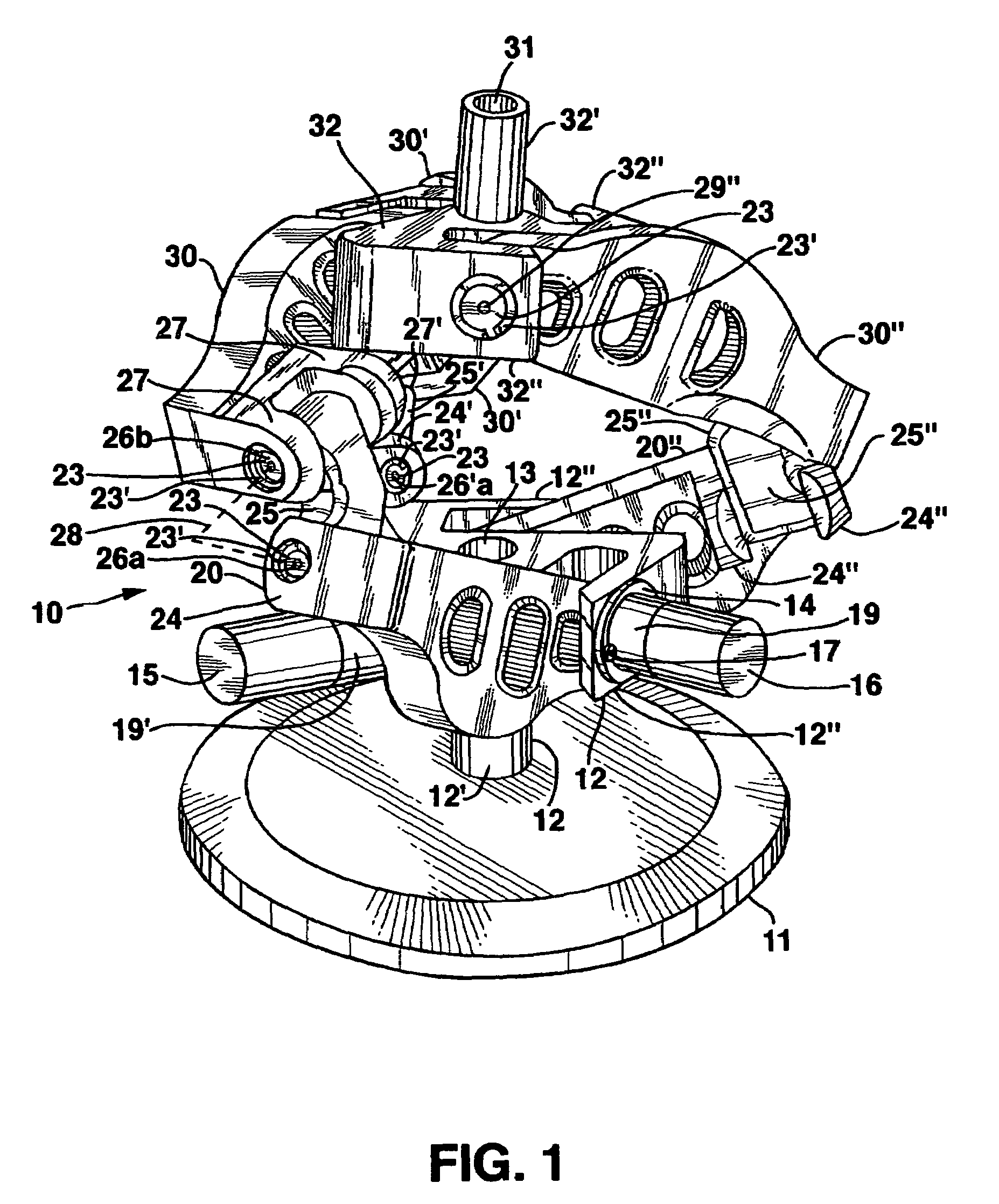

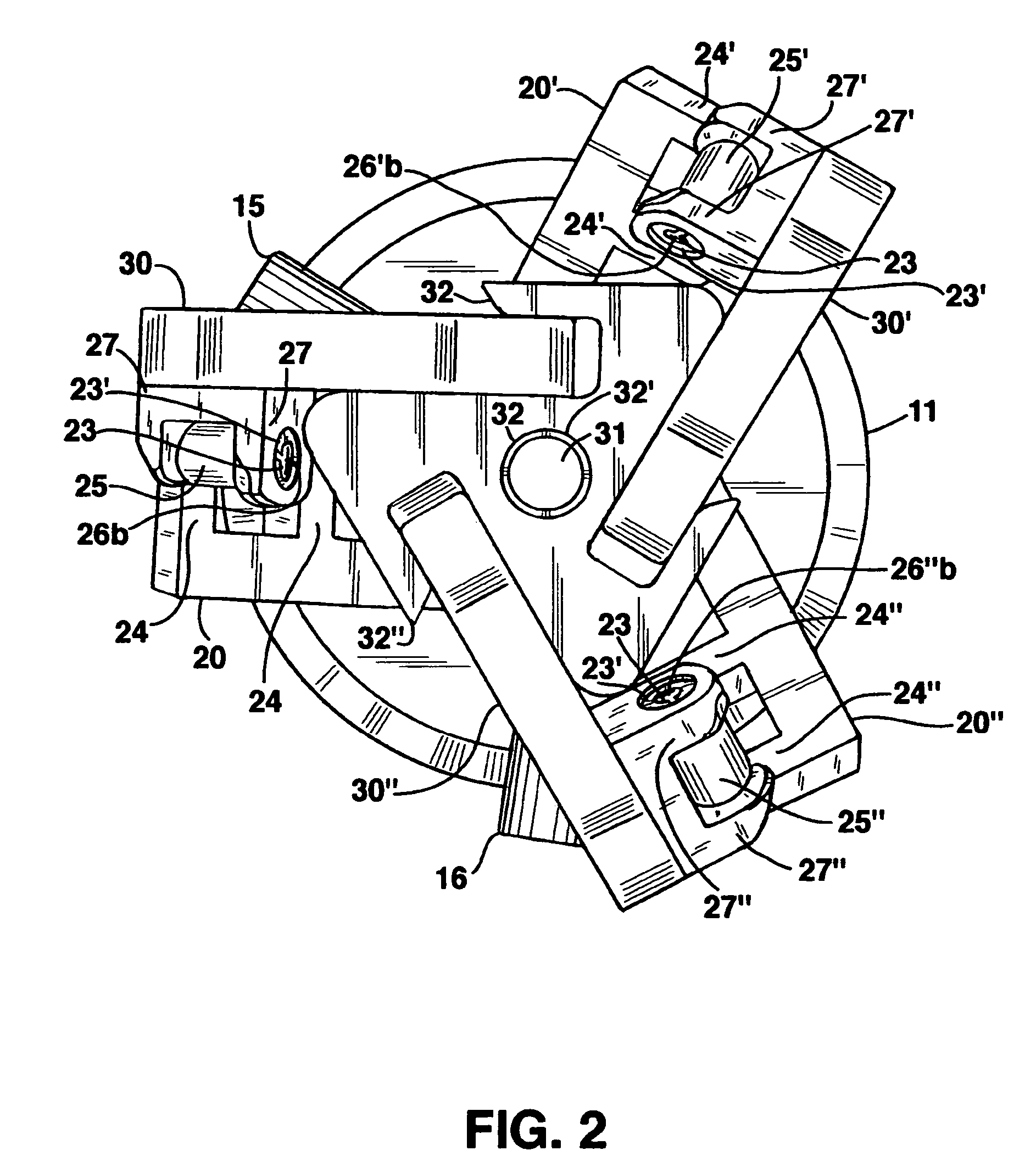

Robotic manipulator

A controlled relative motion system comprising a base support, a pivot holder and a plurality of pivoting links with the pivoting links rotatably coupled to both the base support and to members of the pivot holder to rotate about axes which extend in different directions for each of these rotatable couplings in a link, typically in accord with specific geometrical arrangements, and in different directions from similar axes in another of such links. The foregoing various rotatable couplings are provided by insertable bearings or bushings in the supports and links. The pivoting links have larger portions thereof outside of the interior of the manipulator parts of which can extend outside in different directions. Such systems can incorporate a variety of force imparting members to control movements of various ones of the pivoting links or pivot holder members.

Owner:ROSS HIME DESIGNS

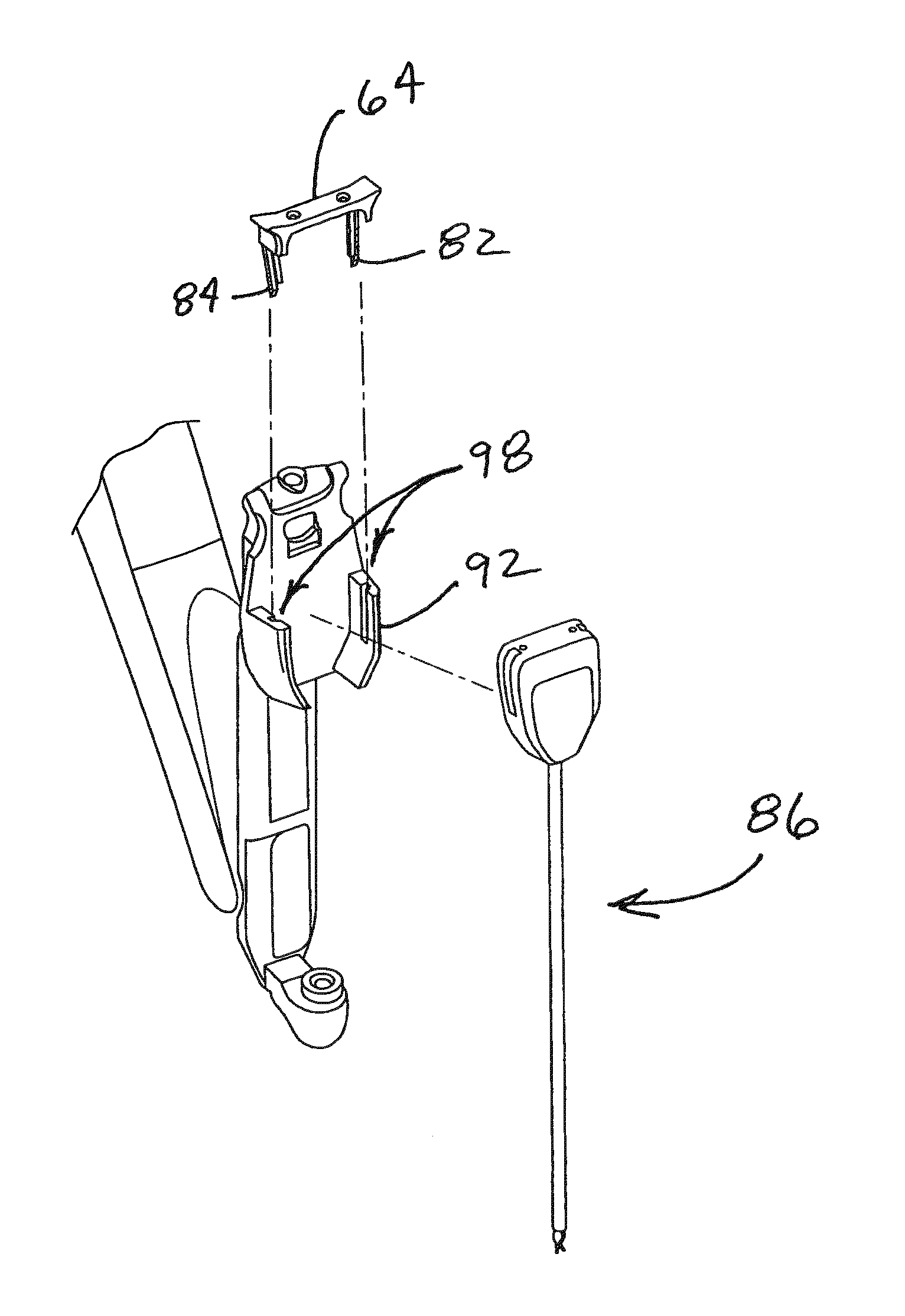

Alternate instrument removal

Minimally invasive robotic surgical instruments and related methods are disclosed. A surgical instrument includes an interface fitting that couples a proximal chassis of the instrument with a holding fixture of a robotic manipulator. A securing feature releasably prevents relative axial sliding between the interface fitting and the chassis. In response to binding of the surgical instrument within a minimally invasive surgical site so as to inhibit removal of the surgical instrument from the surgical site and inhibit disengagement of the interface fitting from the holding fixture, the securing feature can be released to allow relative axial sliding between the interface fitting and the chassis, thereby allowing the holding fixture and the interface fitting to be separated from the rest of the surgical instrument and repositioning of the robotic manipulator out of the way.

Owner:INTUITIVE SURGICAL OPERATIONS INC

System, method and computer program for autonomously emulating robot manipulators of continuously-varying configurations

ActiveUS20140222198A1Continuous reconfigurabilityRecovery functionProgramme-controlled manipulatorComputer controlKinematicsSimulation

The invention is a modular and autonomously reconfigurable manipulator system which introduces a new dimension to the versatility of robot manipulation for diverse tasks. The hardware component is a redundant mechanism which can lock any number of its joints at any relative position to form a particular configuration with a certain number of degrees of freedom and specific values for kinematic, dynamic and control parameters, optimum for a given task to be performed. The process of identifying the optimum configuration for a given task and implementing it on the manipulator is done autonomously through the system software. Therefore, no manual interaction is required to form a new configuration most suitable for a given task. The kinematic, dynamic and control parameters of the system can vary continuously enabling the manipulator to form virtually an infinite number of configurations.

Owner:EMAMI MOHAMMAD REZA +1

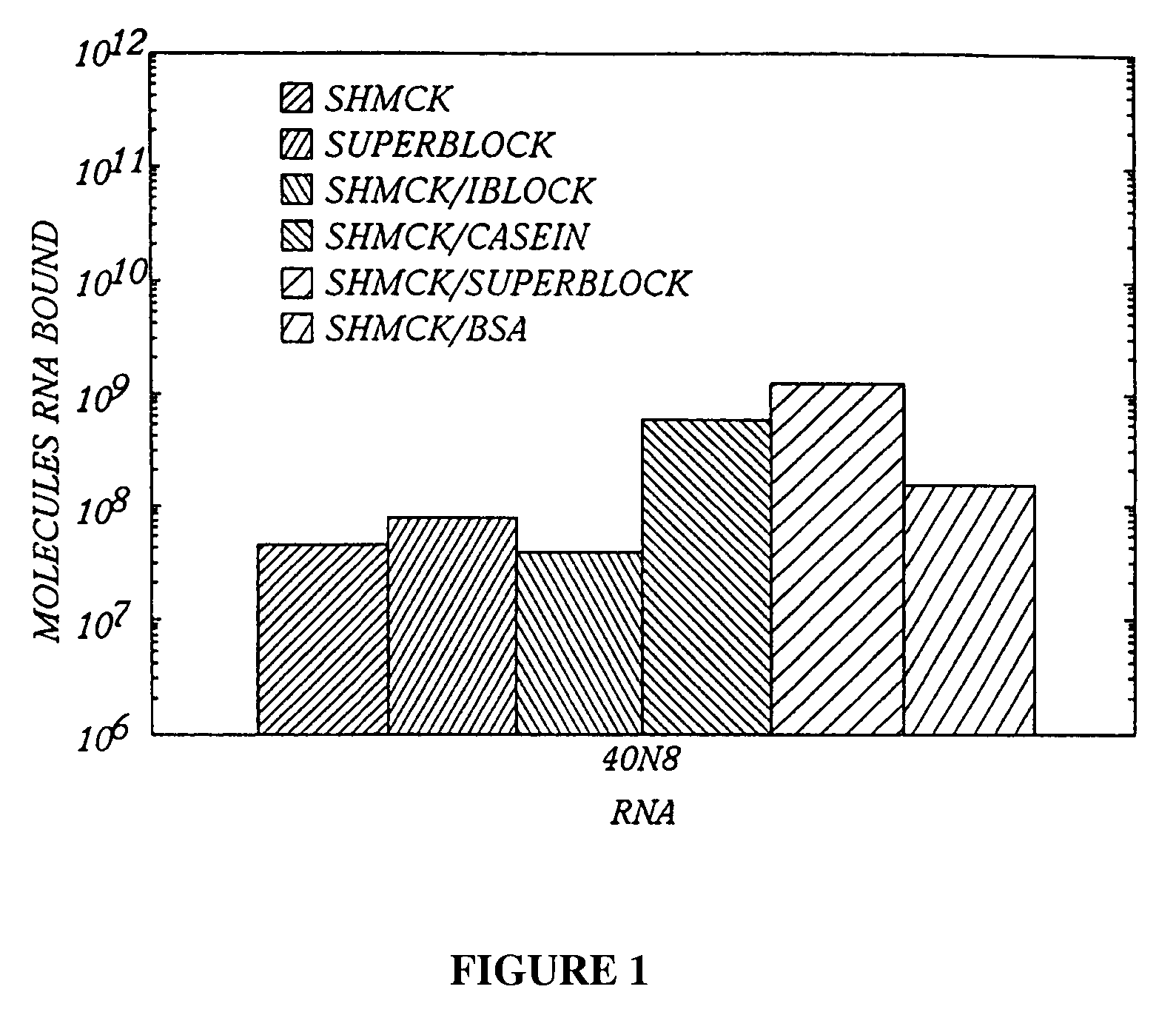

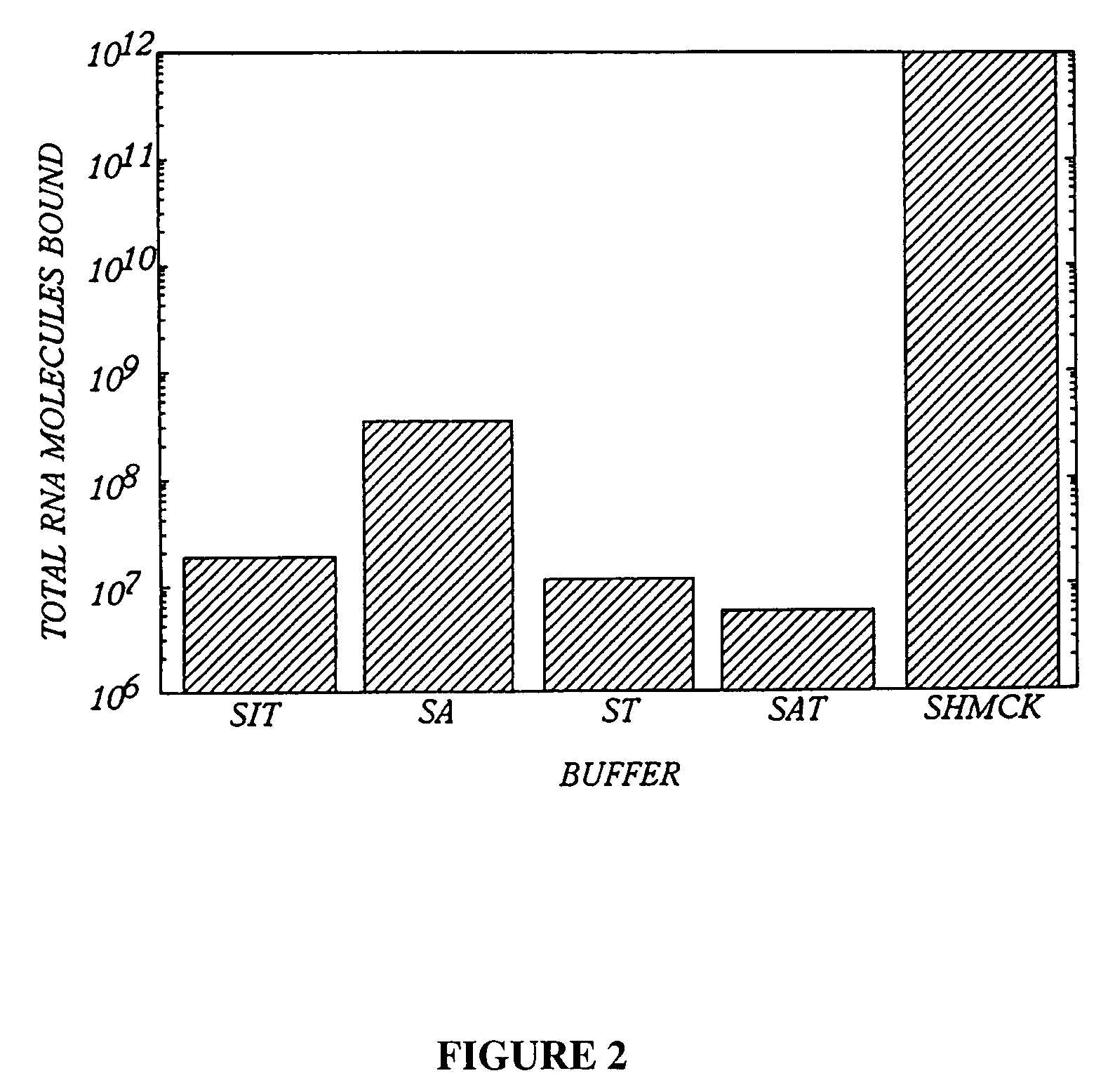

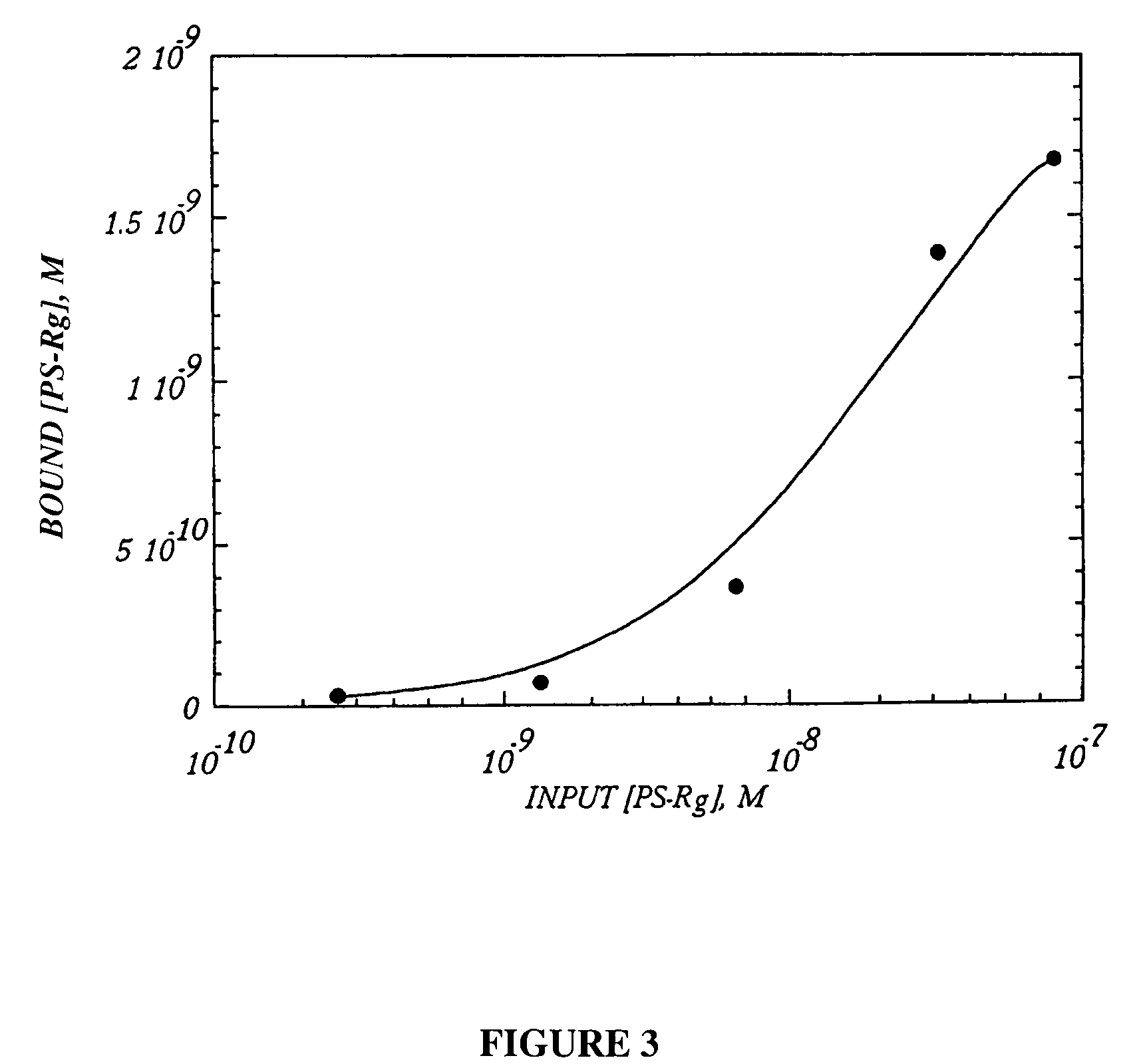

Method and apparatus for the automated generation of nucleic acid ligands

InactiveUS7629151B2Time-consuming and difficult to automateReduce frequencyBioreactor/fermenter combinationsBiological substance pretreatmentsFractionationWorkstation

The present invention includes a method and device for performing automated SELEX. The steps of the SELEX process are performed at one or more work stations on a work surface by a robotic manipulator controlled by a computer. The invention also includes methods and reagents to obviate the need for size-fractionation of amplified candidate nucleic acids before beginning the next round of the SELEX process.

Owner:SOMALOGIC INC

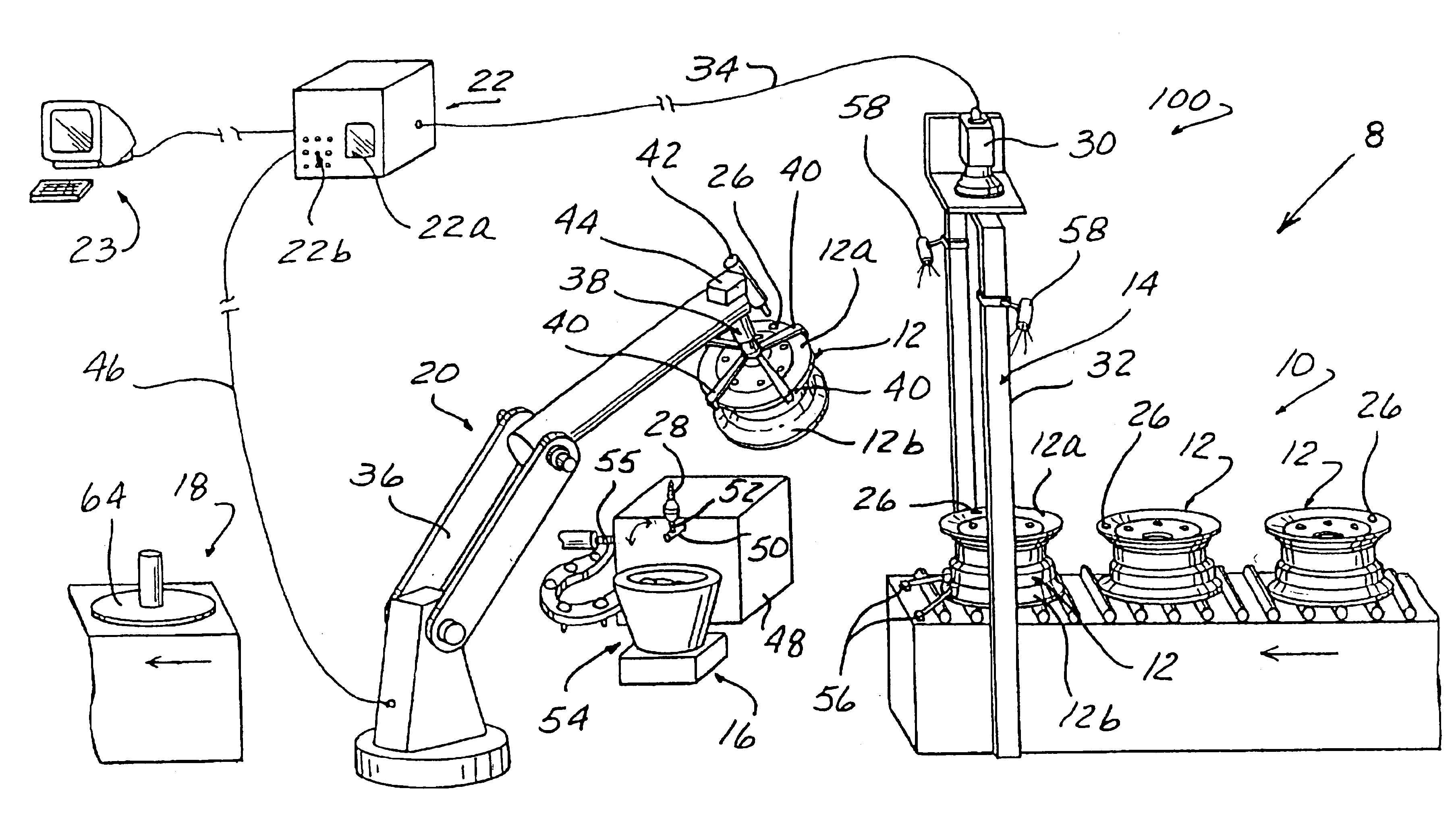

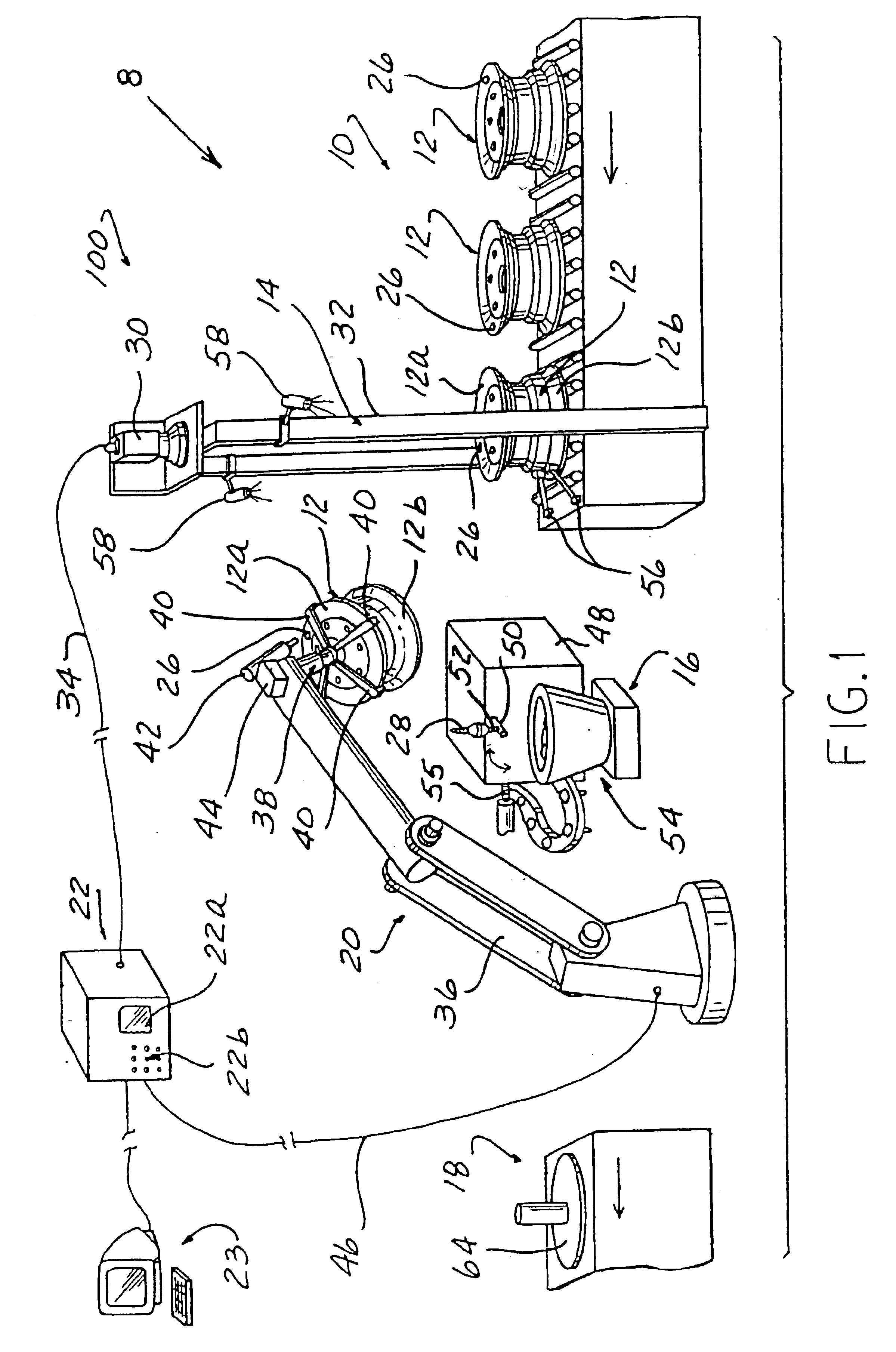

Robotic apparatus and method for mounting a valve stem on a wheel rim

InactiveUS6886231B2Accurate insertionIncrease volumeProgramme-controlled manipulatorAutomatic control devicesRotary stageElectronic control system

An apparatus and method for mounting a valve stem to the rim of an automotive vehicle wheel includes rims being supplied in series by a conveyor to a gauging station where the type and / or size of the rim and the location and alignment of an aperture for receiving the valve stem is determined by a machine vision system. An electronic control system directs a robotic manipulator to grasp either the valve stem or the rim, move the valve stem or the rim to a mounting station, position the valve stem or the rim with respect to the other such that the aperture in the rim is in coaxial alignment with the valve stem, and insert the valve stem through the aperture in the rim. If necessary, a power-actuated nut runner, mounted on the robotic manipulator or adjacent the mounting station, is used to tighten a nut over the valve stem. As an alternative to the machine vision system, the gauging station can use a rotating table which rotates the wheel about a central axis, and an “electric eye” optical sensor directing a beam of infrared light onto the rim. As the rim rotates through the beam, the presence or lack of a reflection of the light beam is used to detect the location of the aperture, and rotation of the table is stopped when the aperture is in alignment with the beam. A probe mounted on the gauging station can be extended to project into the aperture to confirm that the aperture is at the desired position and reposition the rim slightly to provide a precise positioning of the aperture.

Owner:BURKE E PORTER MACHINERY

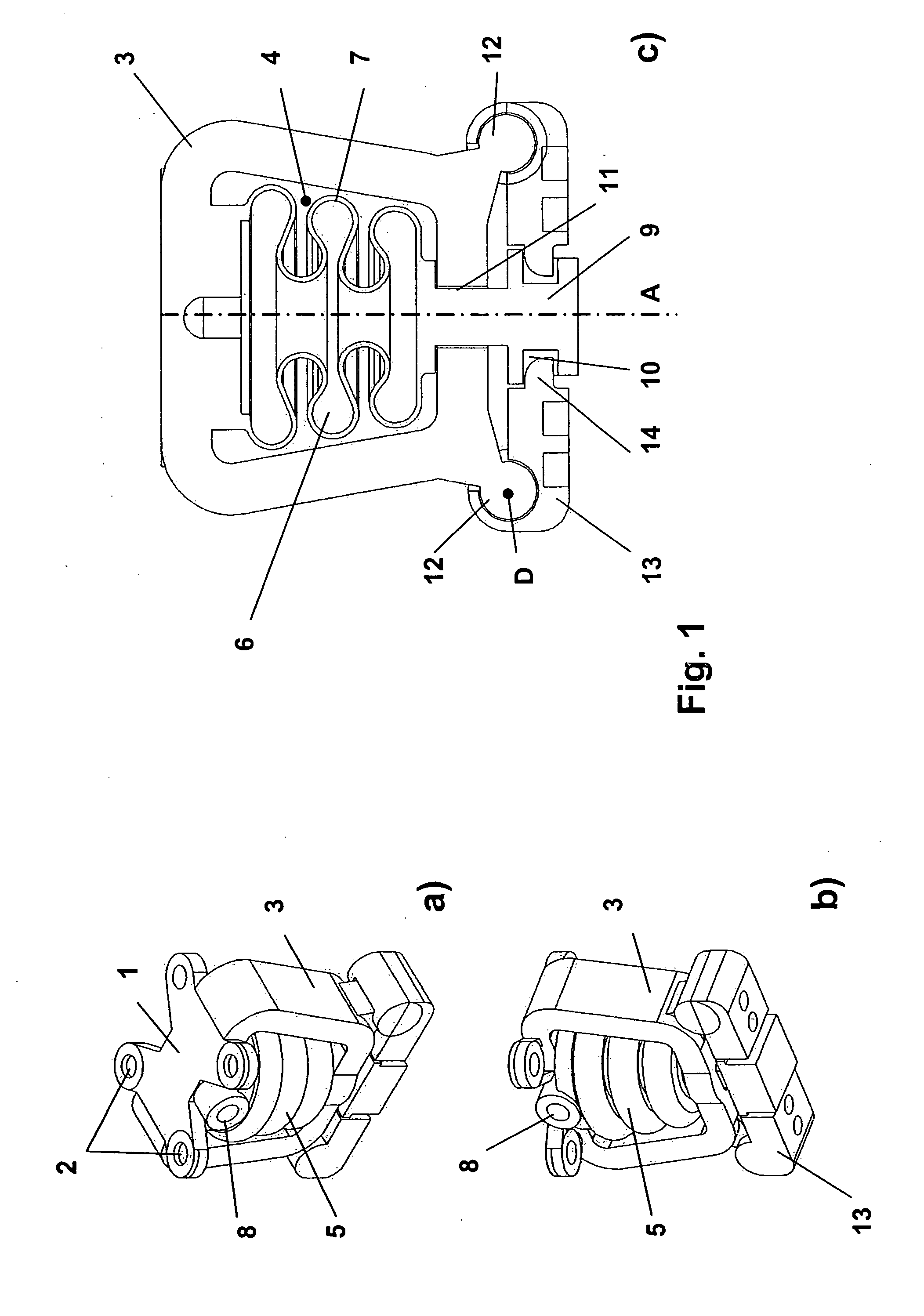

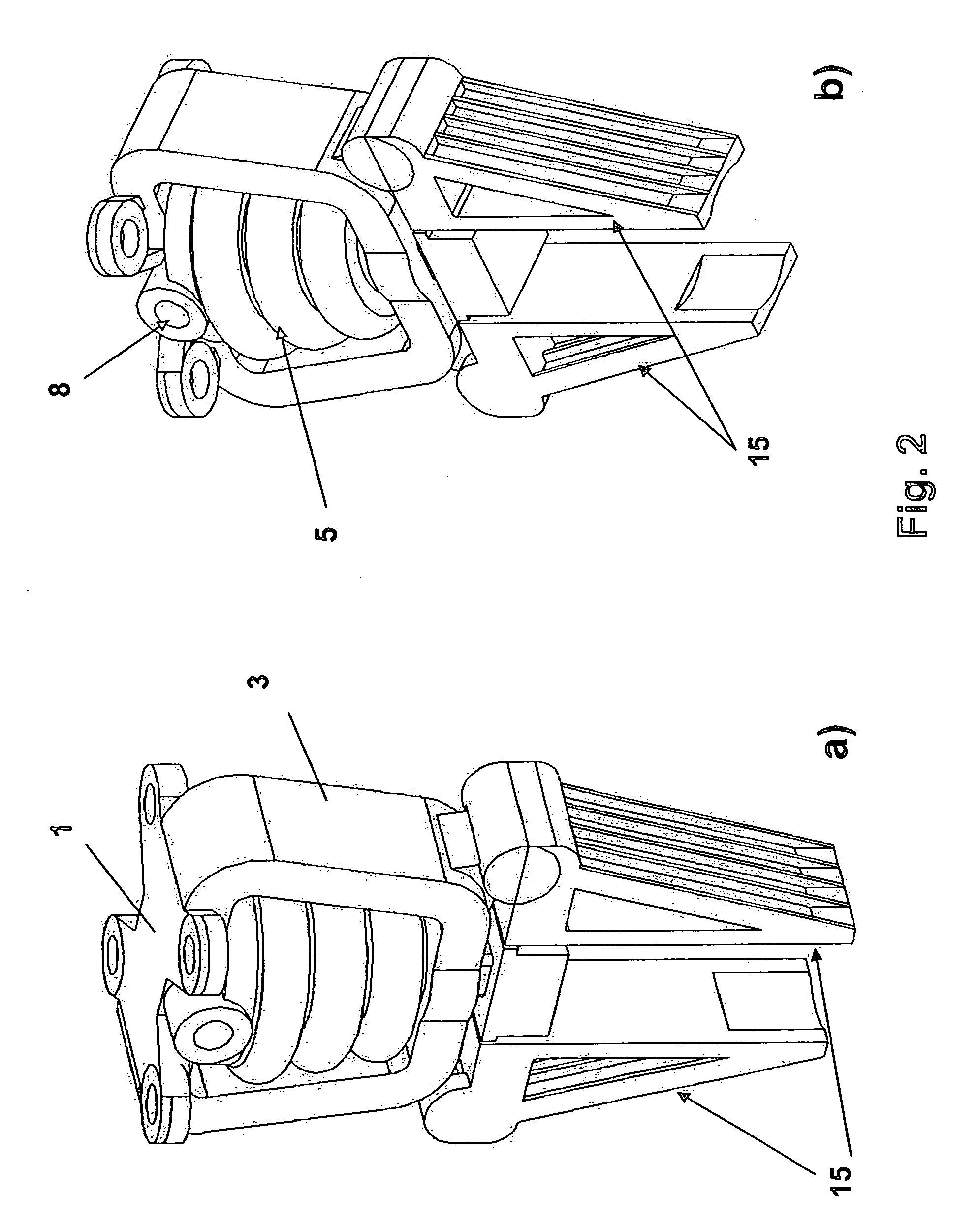

Robot Gripper and Method for Its Manufacture

ActiveUS20090108605A1Compromise functionalityWeight optimizationProgramme-controlled manipulatorAdditive manufacturing apparatusEngineeringActuator

The invention relates to a robot gripper having a fixing flange for detachably attaching it to a robot manipulator arm, and at least one actuator element which is supported in a frame, that actuates at least two gripper jaws indirectly or directly kinematically via at least one articulated unit. At least the fixing flange, the frame and the actuator element are manufactured integrally using a generative manufacturing method, and the actuator element is in the form of a bellows, enclosed an internal volume, which can be filled with a medium via at least one opening, and is capable of expanding, when filled with a medium, along a linear axis predetermined by the bellows design of the actuator element and of contracting, when the volume is emptied, in the opposite direction.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

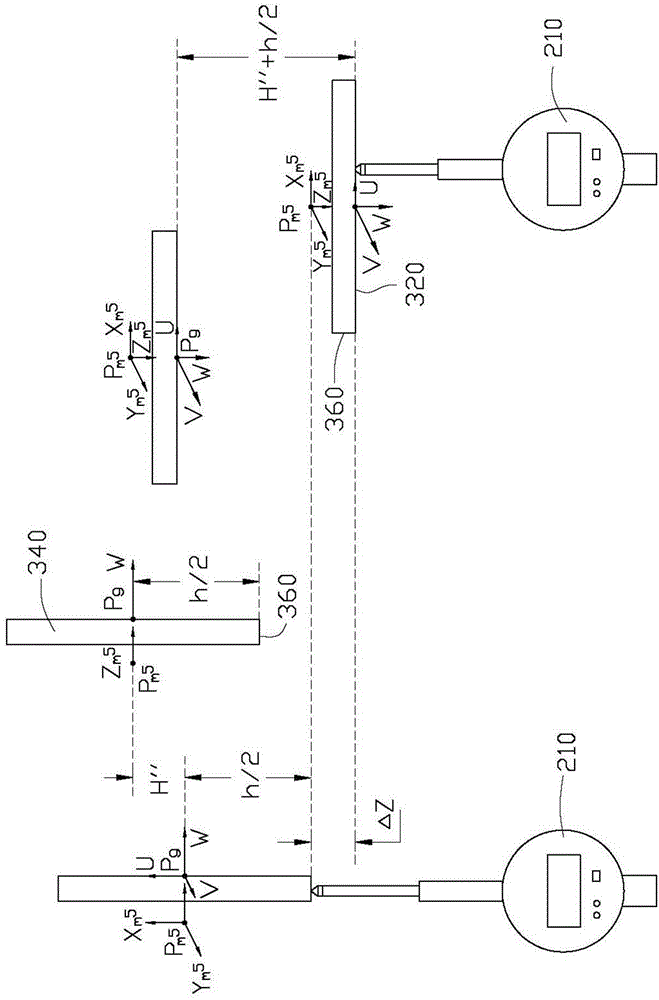

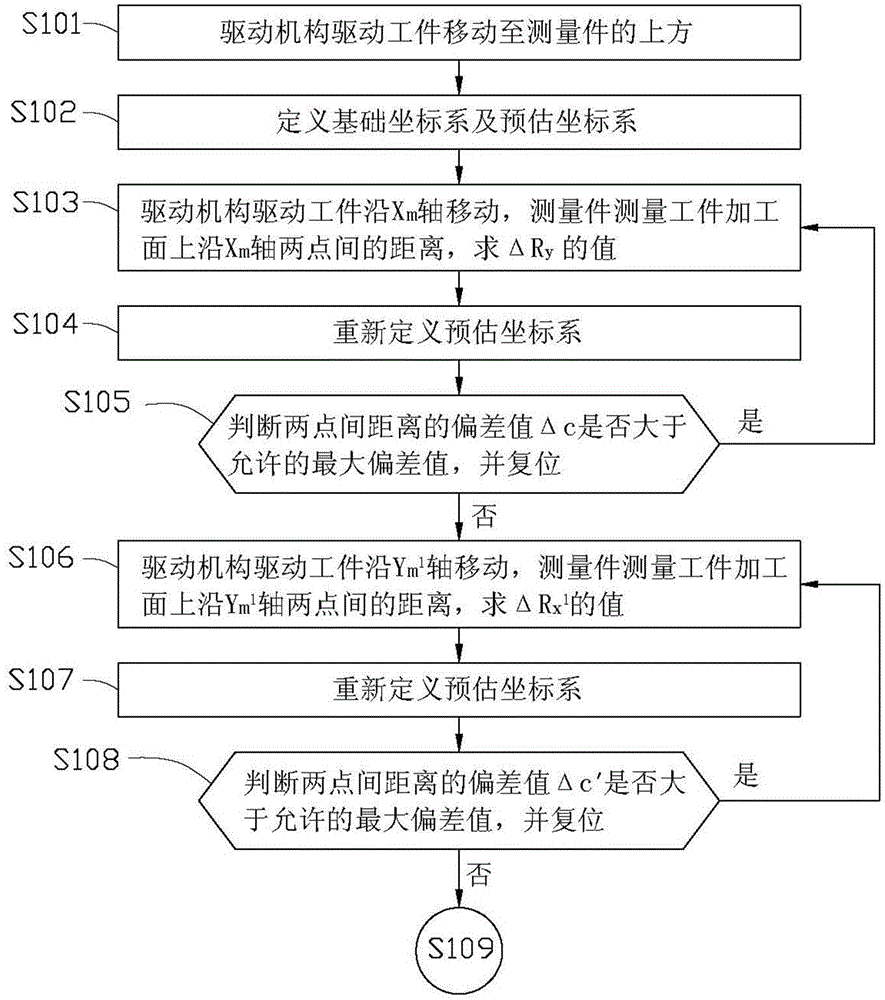

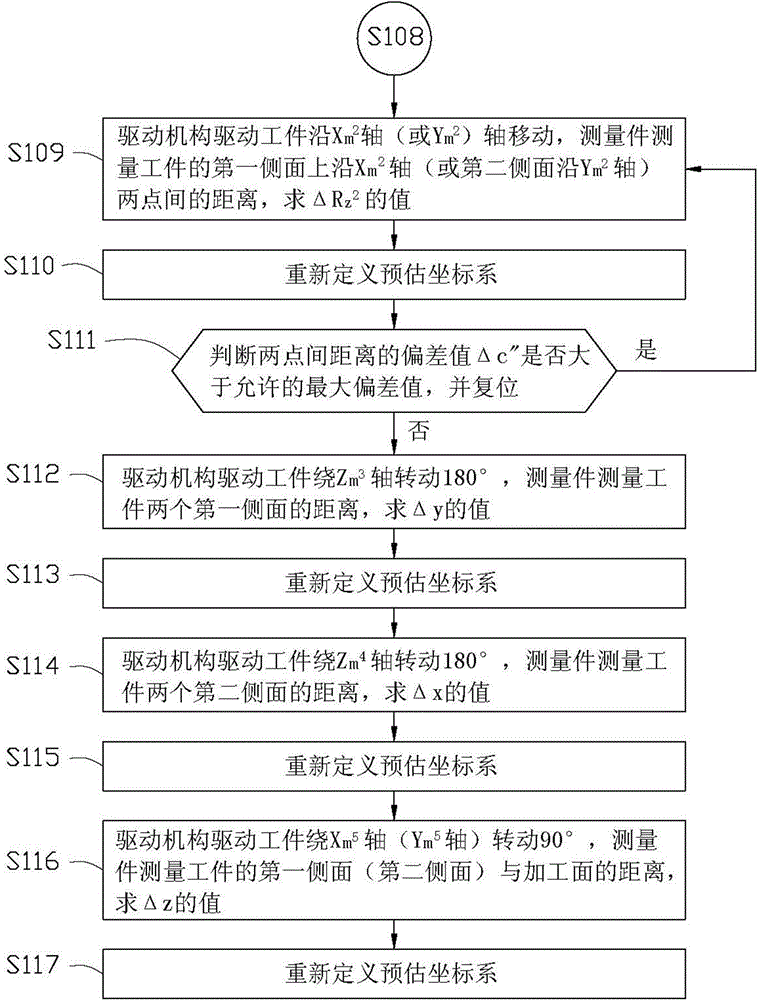

Robot tool coordinate system correction method

ActiveCN105091807AImprove calibration accuracyThe calibration method is simpleProgramme controlProgramme-controlled manipulatorEngineeringPosition error

A calibration method for a coordinate system of a workpiece held by a robot manipulator, which includes the following steps: setting a predicted coordinate system on the workpiece; controlling the drive mechanism to drive the workpiece to move a specific distance along a coordinate axis in the predicted coordinate system and measuring the distance change of the workpiece in a direction perpendicular to the move; using the measured distance change to determine an orientation error between the predicted coordinate system and the actual coordinate system; correcting the orientation parameters of the predicted coordinate system; controlling the drive mechanism to drive the workpiece to rotate by a specific angle around a coordinate axis of the predicted coordinate system and measuring the distance change after being rotated; using the measured distance change to determine a position error; correcting the position parameters of the predicted coordinate system.

Owner:SHENZHENSHI YUZHAN PRECISION TECH CO LTD

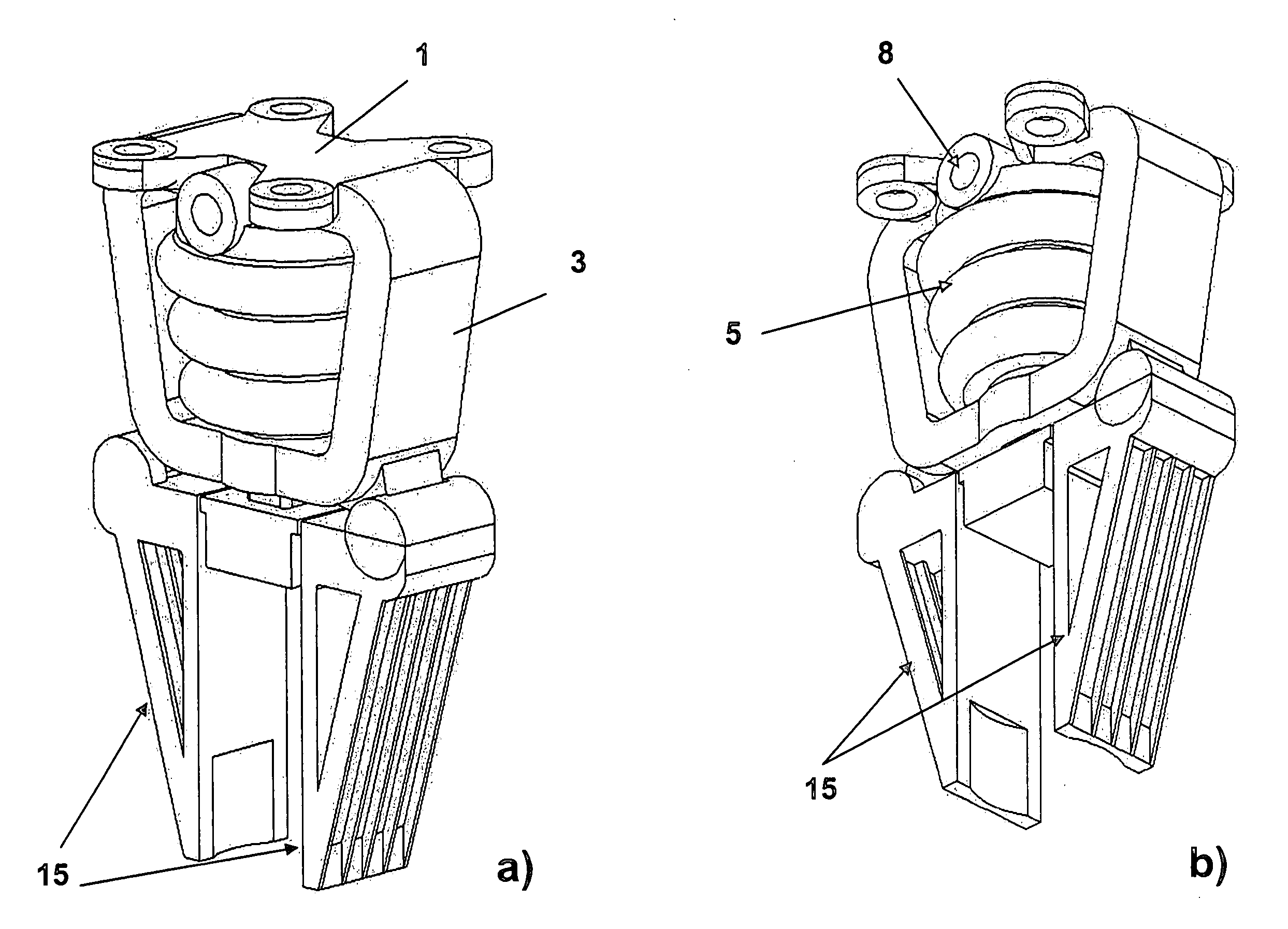

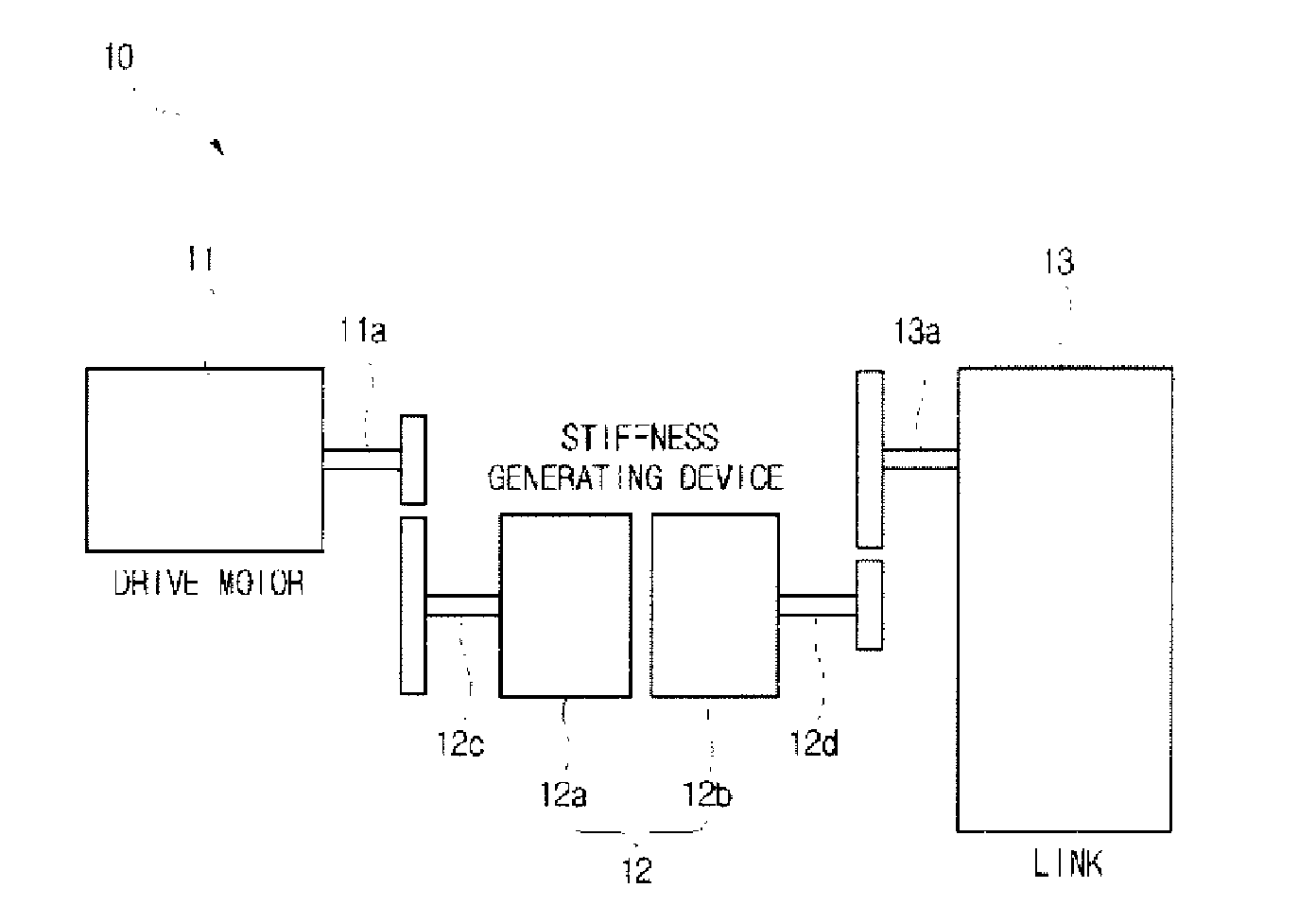

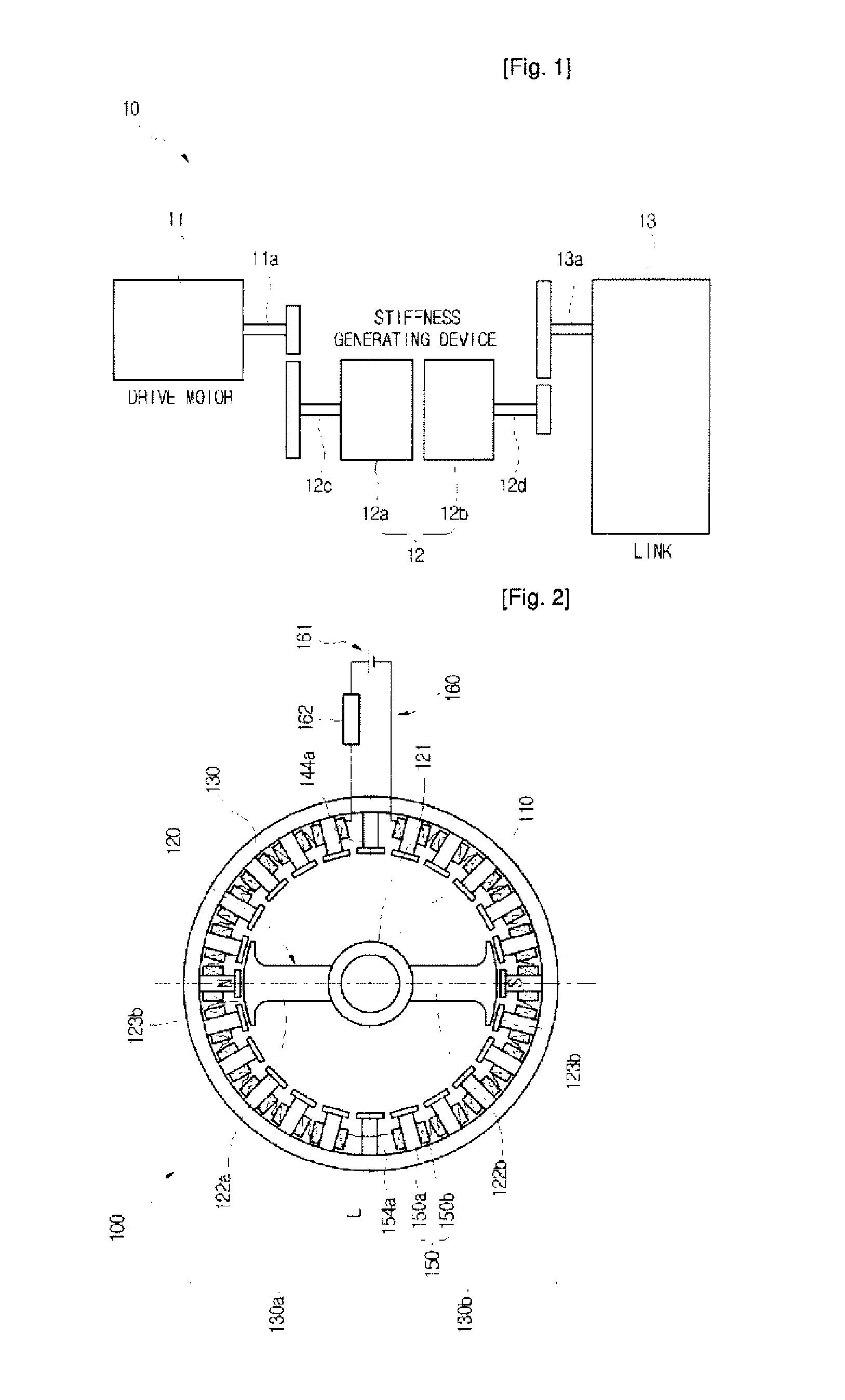

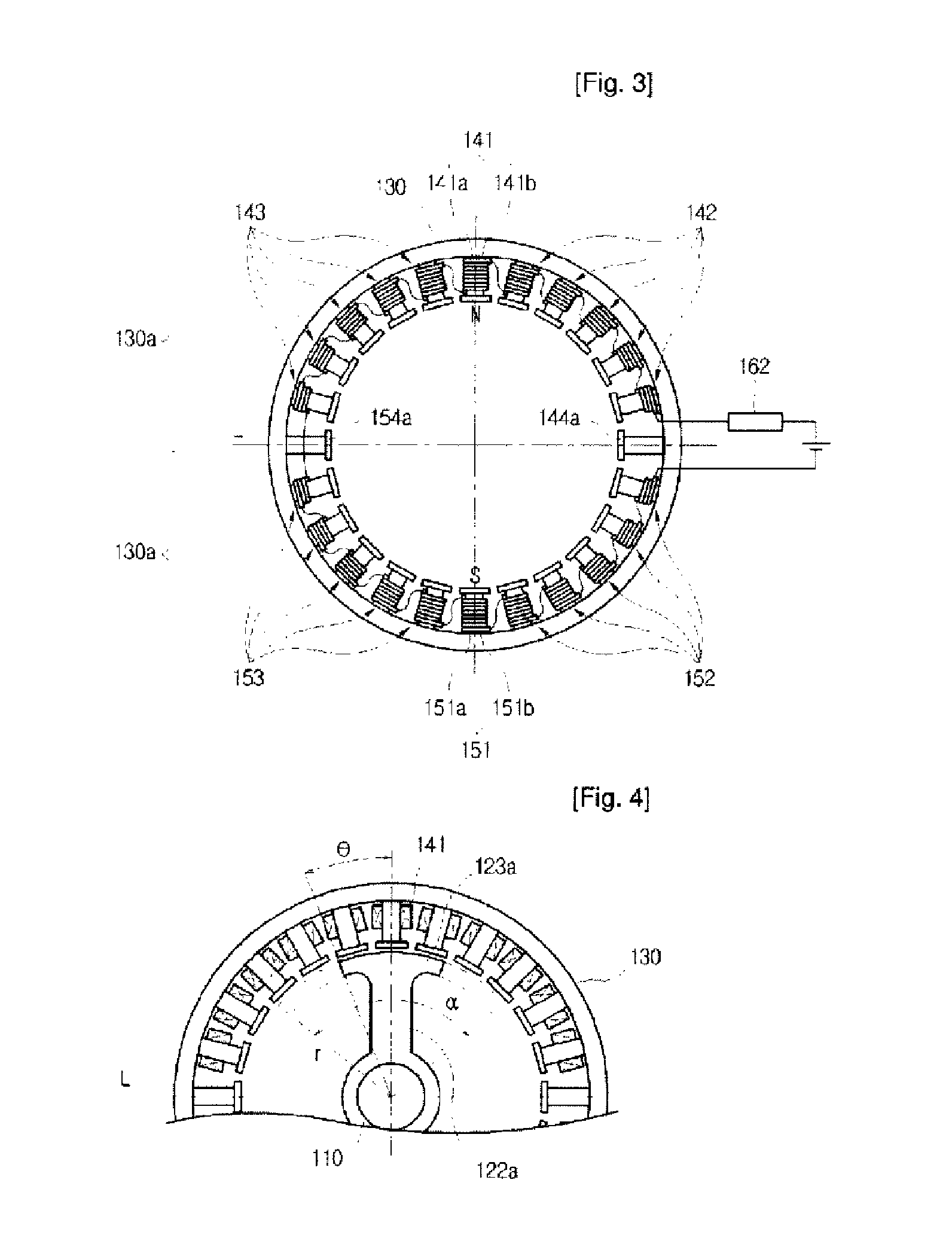

Device for generating stiffness and joint of robot manipulator comprising the same

ActiveUS7965006B2Simple constitutionGenerate stiffnessSynchronous generatorsDynamo-electric brakes/clutchesDrive motorRobot manipulator

Owner:KOREA INST OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com