Patents

Literature

68results about How to "The calibration method is simple" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

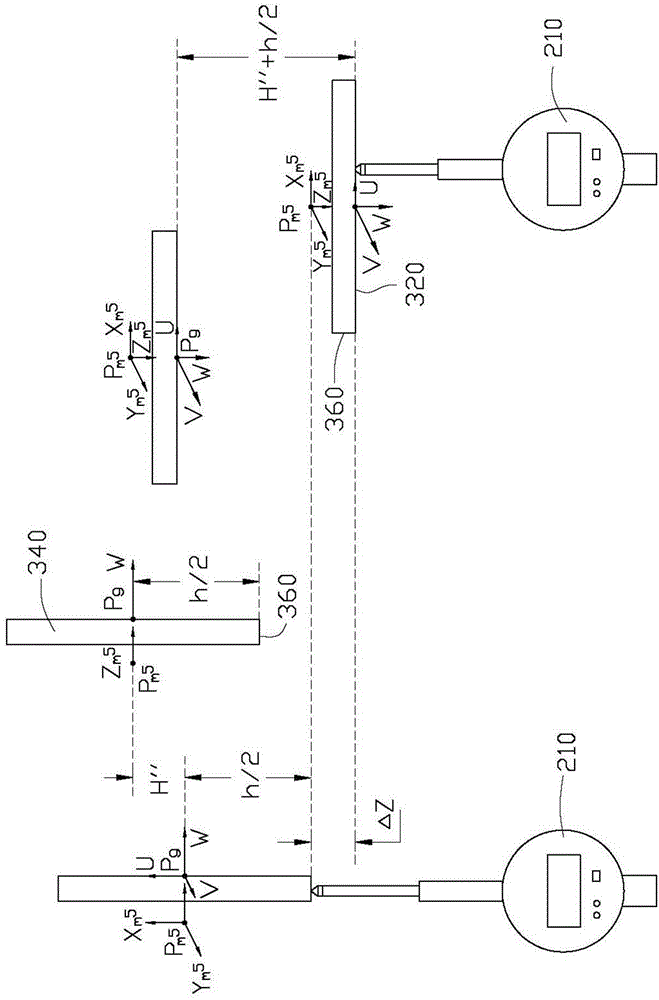

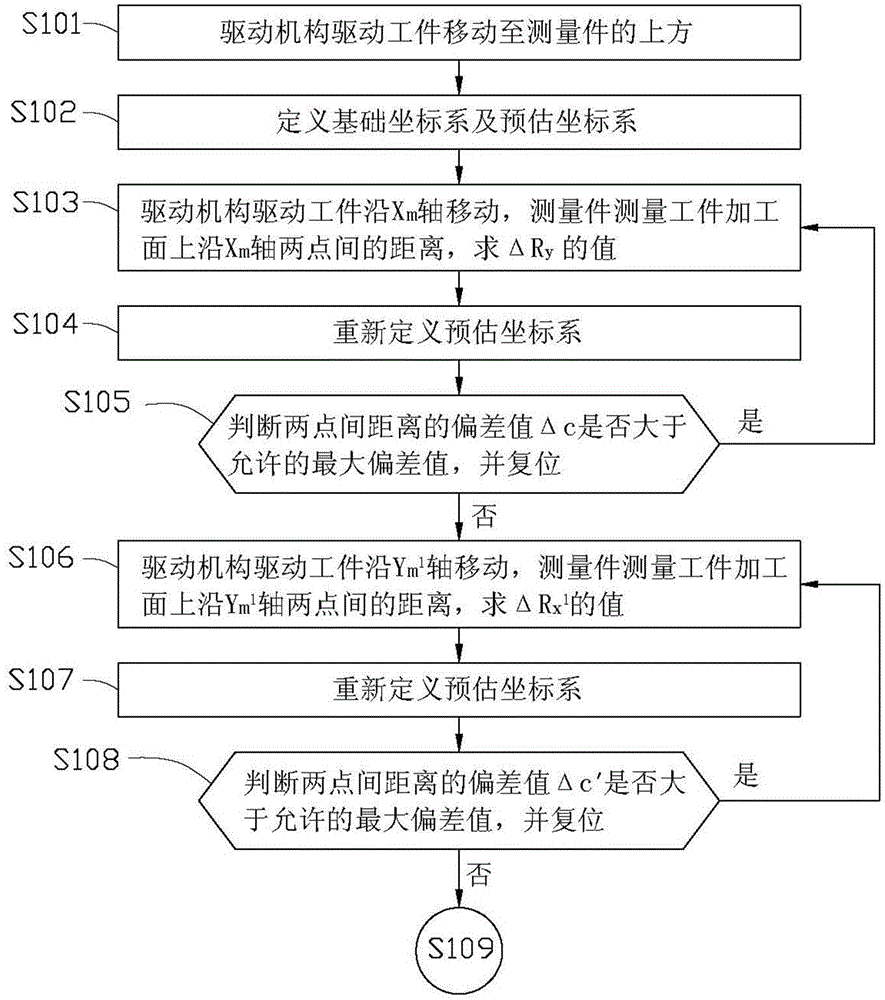

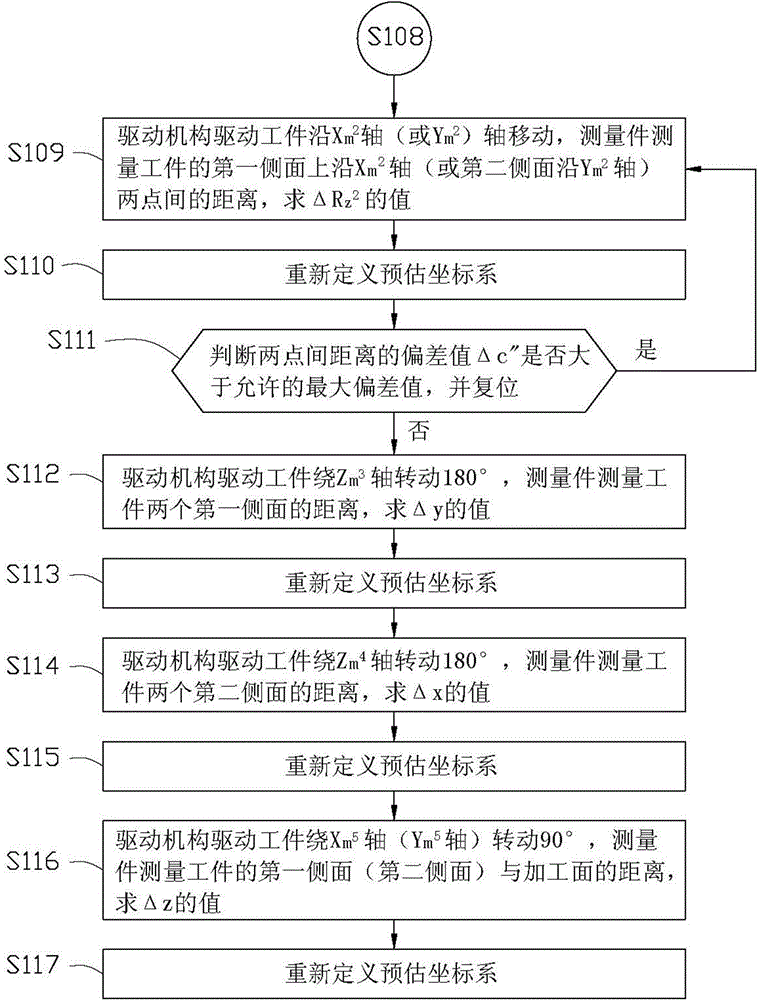

Robot tool coordinate system correction method

ActiveCN105091807AImprove calibration accuracyThe calibration method is simpleProgramme controlProgramme-controlled manipulatorEngineeringPosition error

A calibration method for a coordinate system of a workpiece held by a robot manipulator, which includes the following steps: setting a predicted coordinate system on the workpiece; controlling the drive mechanism to drive the workpiece to move a specific distance along a coordinate axis in the predicted coordinate system and measuring the distance change of the workpiece in a direction perpendicular to the move; using the measured distance change to determine an orientation error between the predicted coordinate system and the actual coordinate system; correcting the orientation parameters of the predicted coordinate system; controlling the drive mechanism to drive the workpiece to rotate by a specific angle around a coordinate axis of the predicted coordinate system and measuring the distance change after being rotated; using the measured distance change to determine a position error; correcting the position parameters of the predicted coordinate system.

Owner:SHENZHENSHI YUZHAN PRECISION TECH CO LTD

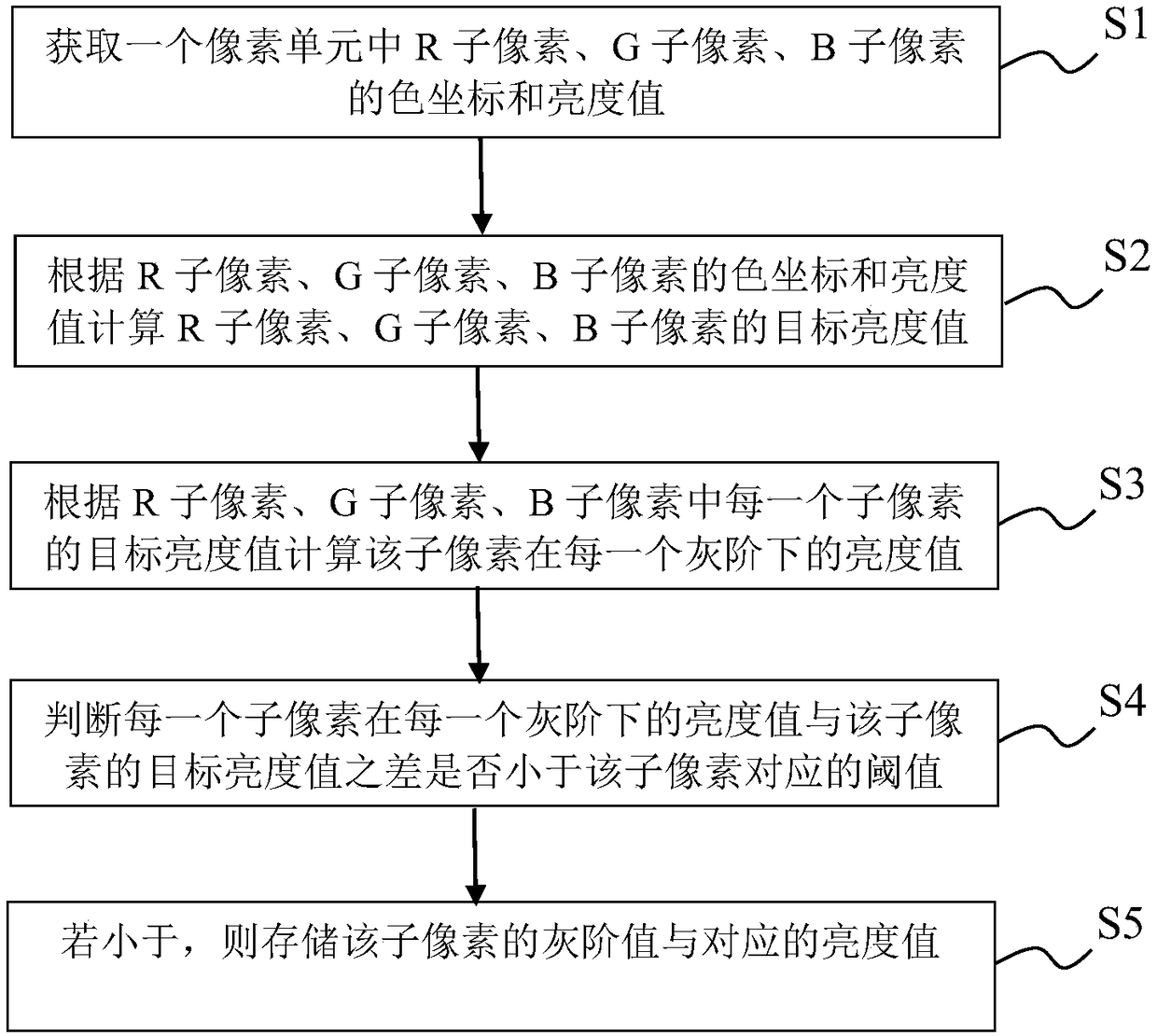

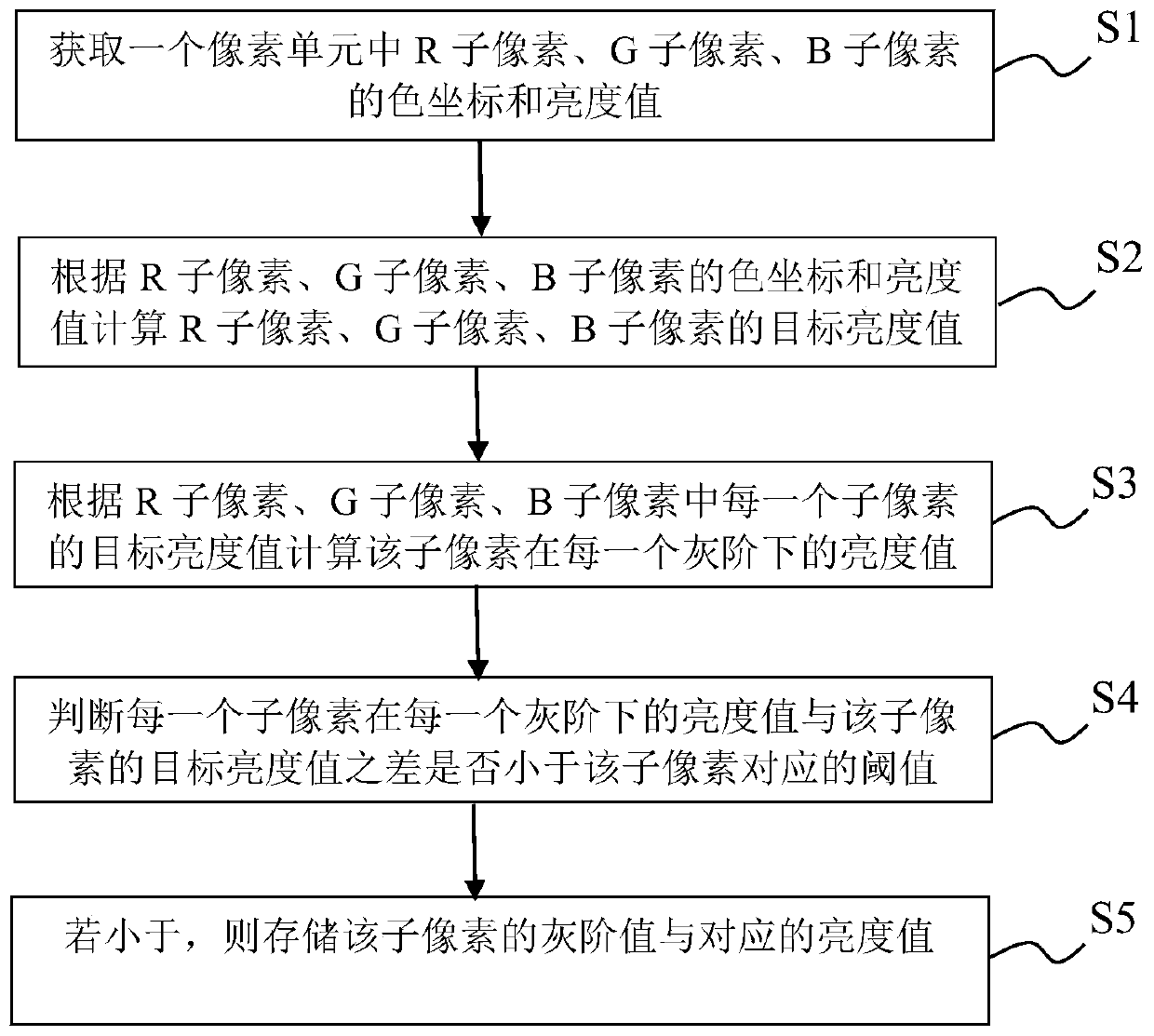

Gamma correction system and gamma correction method

ActiveCN108182914ASimple methodReduce calibration timeStatic indicating devicesGray levelBrightness perception

The invention provides a gamma correction system and a gamma correction method. The gamma correction method includes: acquiring the color coordinates and the brightness values of a R sub-pixel, a G sub-pixel, and a B sub-pixel; calculating the target brightness values of the R sub-pixel, the G sub-pixel, and the B sub-pixel according to the color coordinates and the brightness values of the R sub-pixel, the G sub-pixel, and the B sub-pixel, and calculating the brightness value of each sub-pixel at each grayscale according to the brightness value of each of the R sub-pixel, the G sub-pixel, andthe B sub-pixel; determining whether a difference between the brightness value of each sub-pixel of the R sub-pixel, the G sub-pixel, and the B sub-pixel at each grayscale and the target brightness value of each sub-pixel is smaller than a threshold corresponding to the sub-pixel; if so, storing the grayscale value and corresponding brightness value of the sub-pixel. The gamma correction method saves storage resources, greatly shortens correction time and improves correction efficiency.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

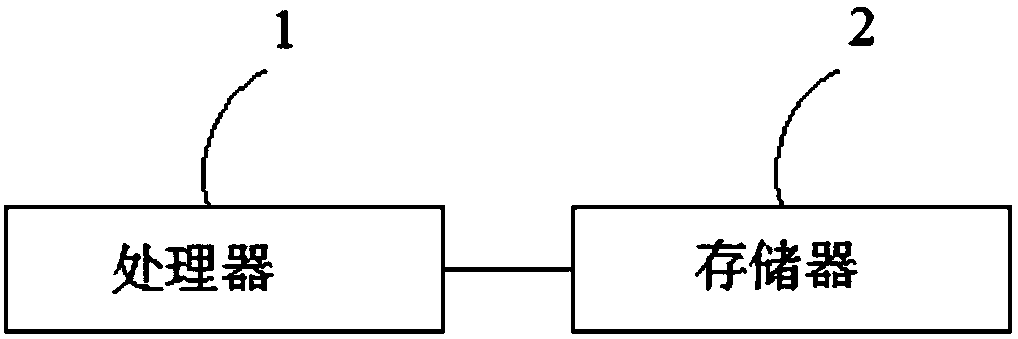

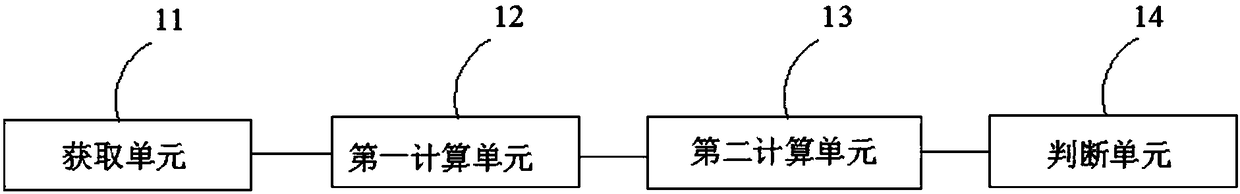

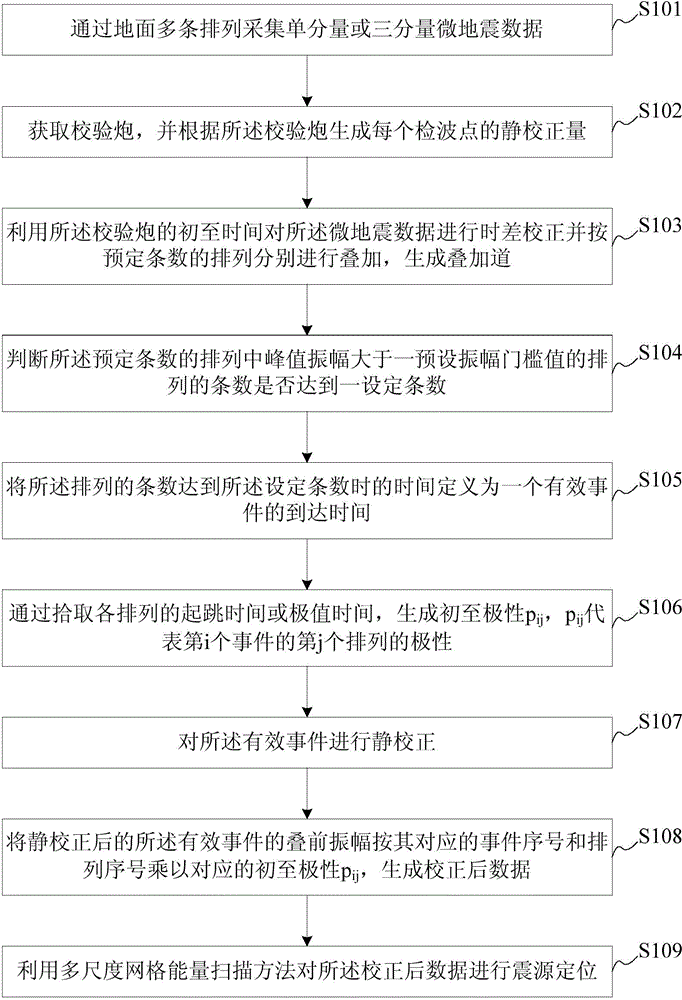

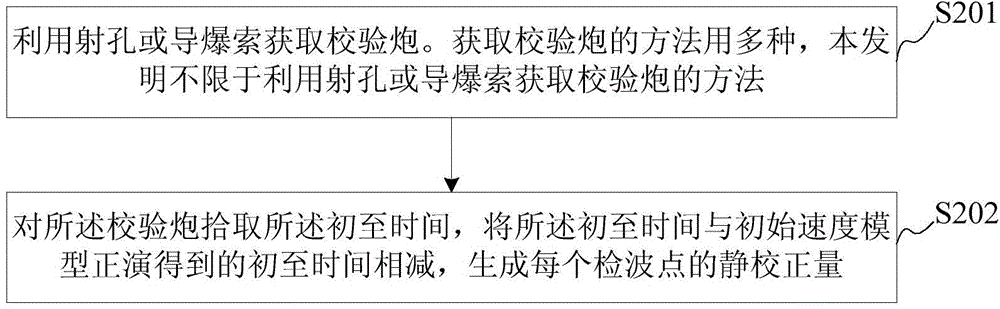

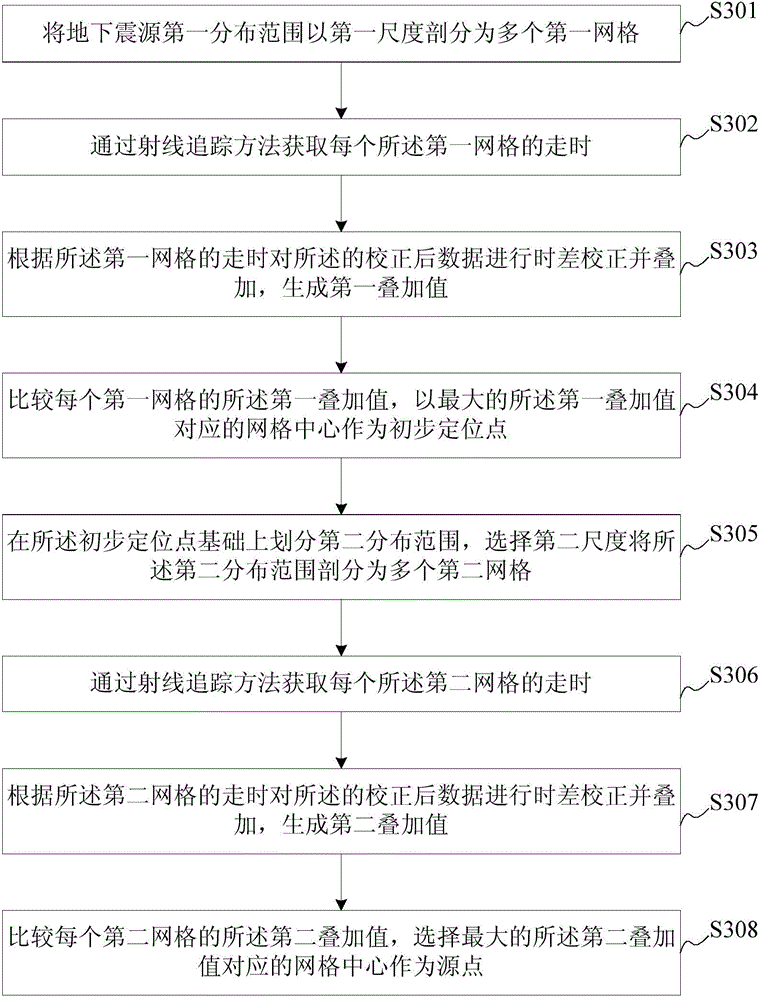

Microseism event scanning positioning method and device

ActiveCN104133246AThe calibration method is simpleAdaptableSeismic signal processingMicroseismGeophone

The invention discloses a microseism event scanning positioning method and device. The microseism event scanning positioning method includes the steps of collecting simple-component or three-component microseism data; obtaining a check shot, and generating static correction values of geophone points according to the check shot; carrying out time difference correction on the microseism data with the first-break time of the check shot, and respectively carrying out stacking to generate stacked tracks; judging whether the number of arrays, with peak amplitudes larger than a preset amplitude threshold value, in arrays with the preset number reaches a set number or not; if the number of the arrays, with the peak amplitudes larger than the preset amplitude threshold value, in the arrays with the preset number reaches the set number, defining the time when the number of the arrays reaches the set number to be arrival time of one effective event; generating first-break polarity pij by picking up take-off time or extreme value time of the arrays; carrying out static correction on the effective events, multiplying pre-stack amplitudes of the effective events obtained after static correction by the corresponding first-break polarity pij according to event numbers and array numbers corresponding to the effective events to generate corrected data; carrying out seismic focus positioning on the corrected data with a multi-scale mesh energy scanning method.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

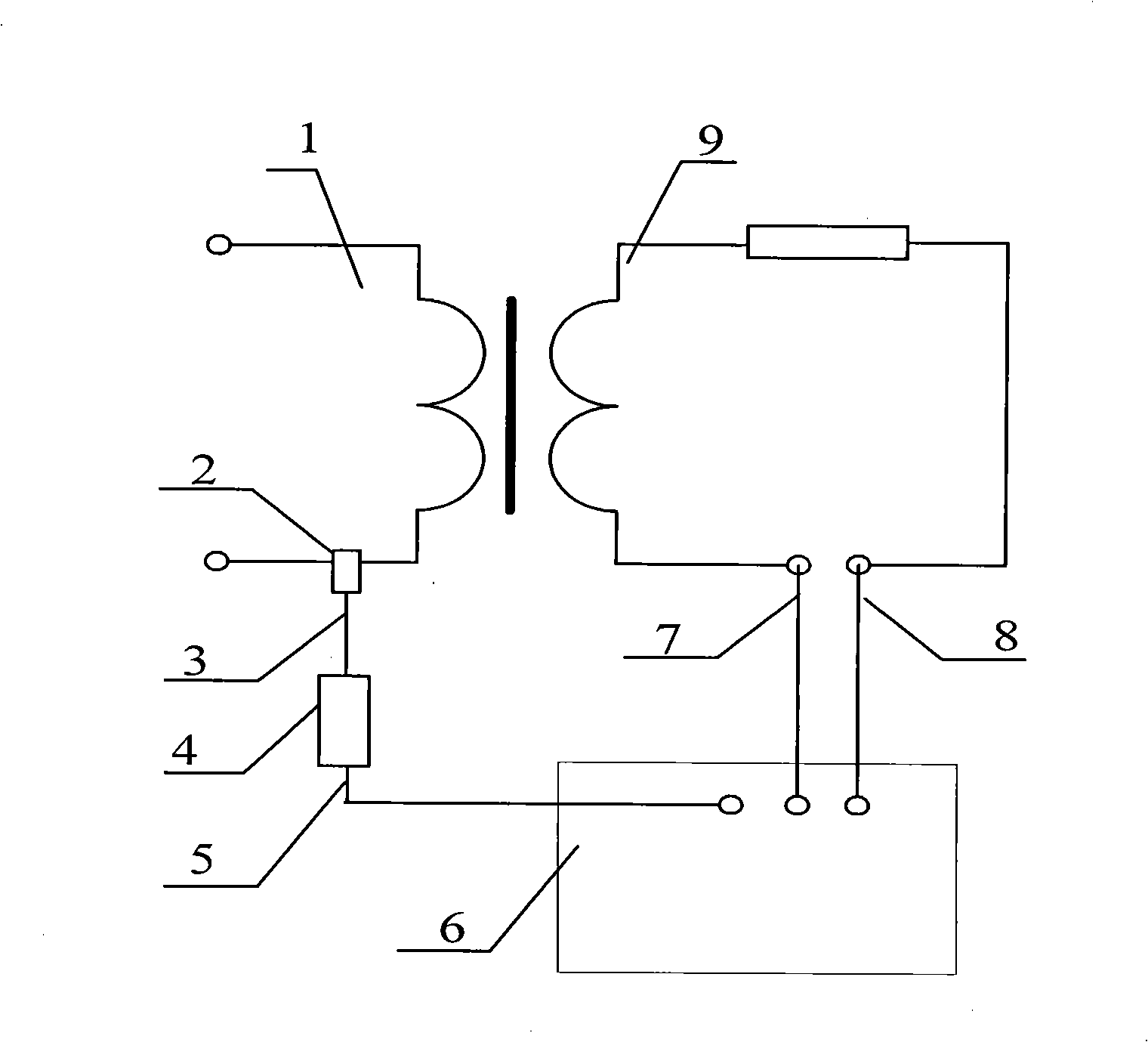

Method of electrified checkout of current mutual inductor

InactiveCN101408597ACalibration equipment simplifiedSimple methodElectrical measurementsAngular differenceInductor

The invention provides a current transformer electrification correcting method. In the method, a current signal is sampled at the primary side and the secondary side of a transformer in on-line operation, the sampled analog signal is converted into a digital signal, the digital signal is processed by an arithmetic unit by applying error formula of the transformer, finally the actual current value, ratio and angular difference of the current transformer are obtained, thus realizing the electrification correction of the transformer. The invention has the advantages that the electrification correction of the current transformer is realized; the devices such as a standard current transformer, an upwash device, a load box and the like are not required, thus the correcting device is simplified and is lightweight and portable, and the correcting method is simple; high insulating safe measuring is realized; capacity of resisting disturbance in the measuring process is improved; and the measuring precision is improved.

Owner:红相电力(上海)有限公司

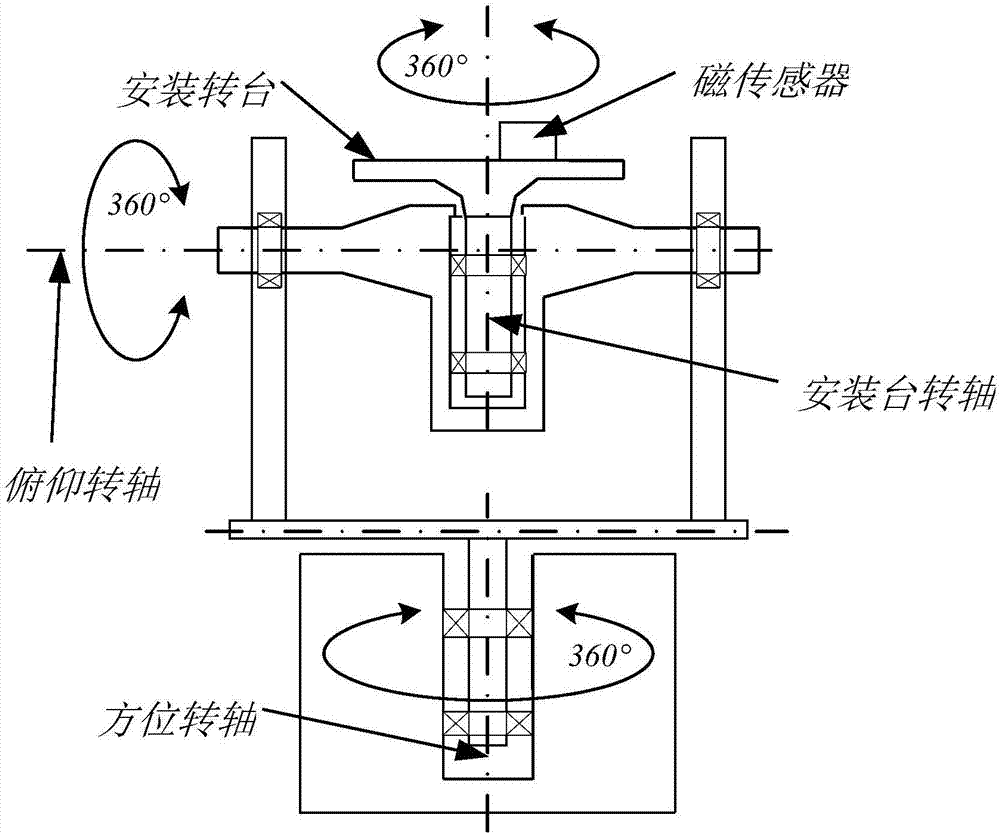

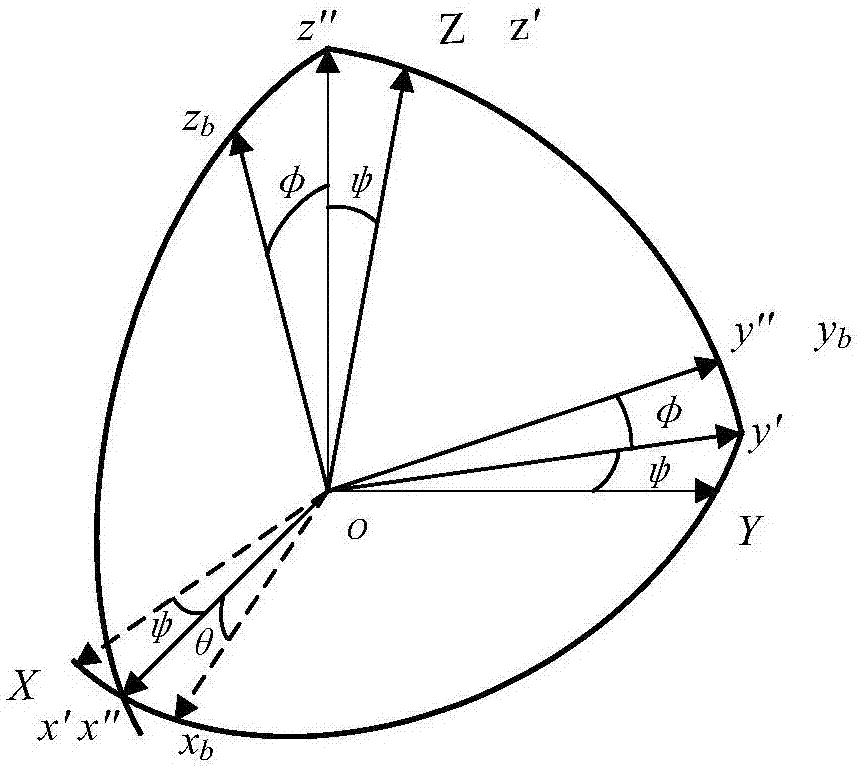

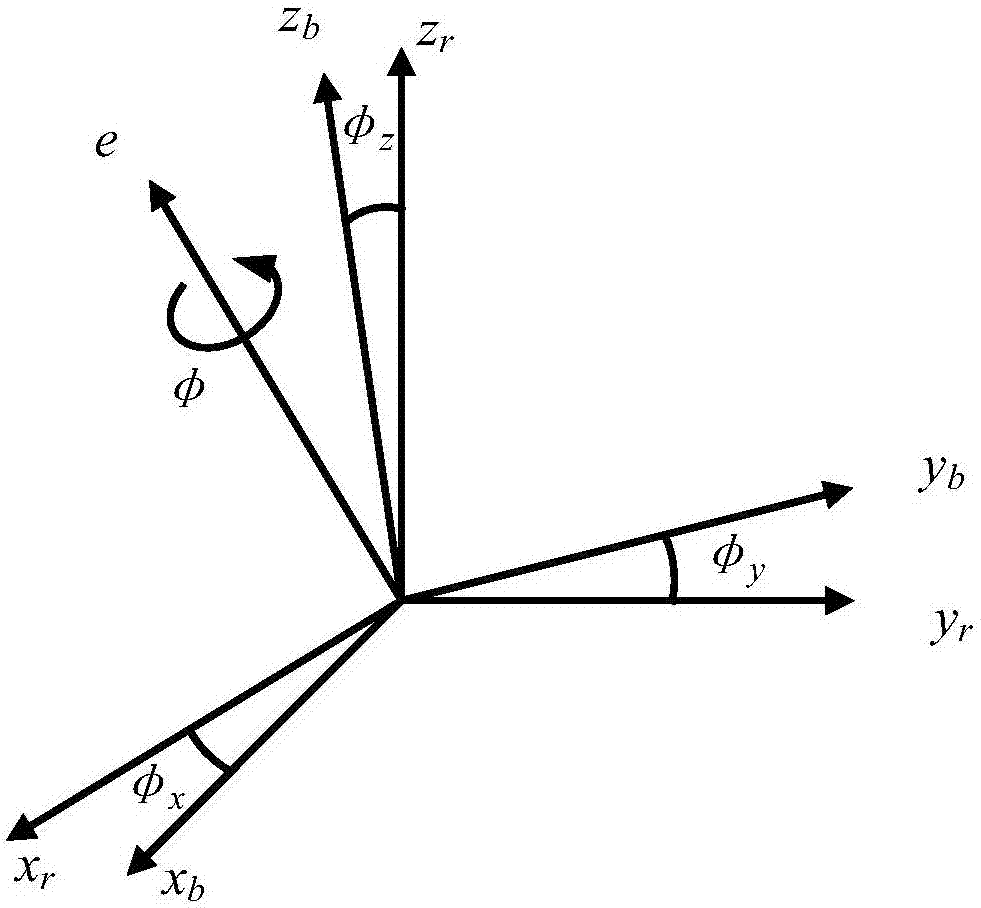

Error correction method for measuring datum and structural benchmark of tri-axial magnetic sensor

InactiveCN107121707AFast access to error correction matrixQuick and easy error correctionElectrical measurementsElectric/magnetic detectionRepeatabilityCorrection method

The invention provides an error correction method for a measuring datum and a structural benchmark of a tri-axial magnetic sensor. With a digital correction method, errors among a measuring datum, a structural benchmark, and a mounting benchmark of a tri-axial magnetic detector are eliminated. Under the circumstance that the structure precision and the assembling precision are not improved, the tri-axial magnetic sensor can reach high precision and accuracy. Different types of tri-axial magnetic sensors can be controlled at high precision levels and the performance consistency is guaranteed. The provided correction method is simple and effective; and the repeatability and correction precision are high.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN

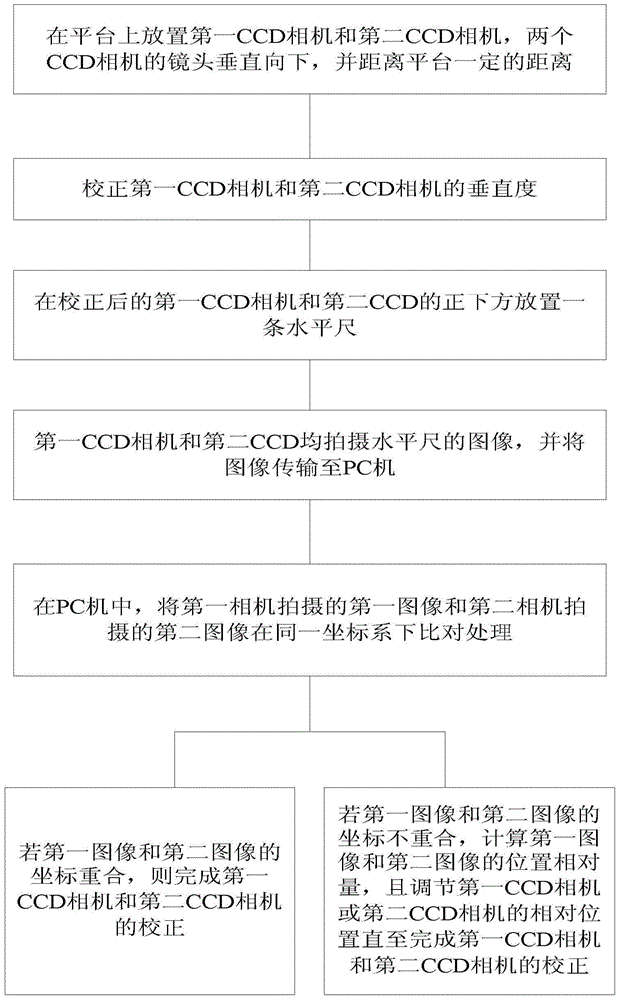

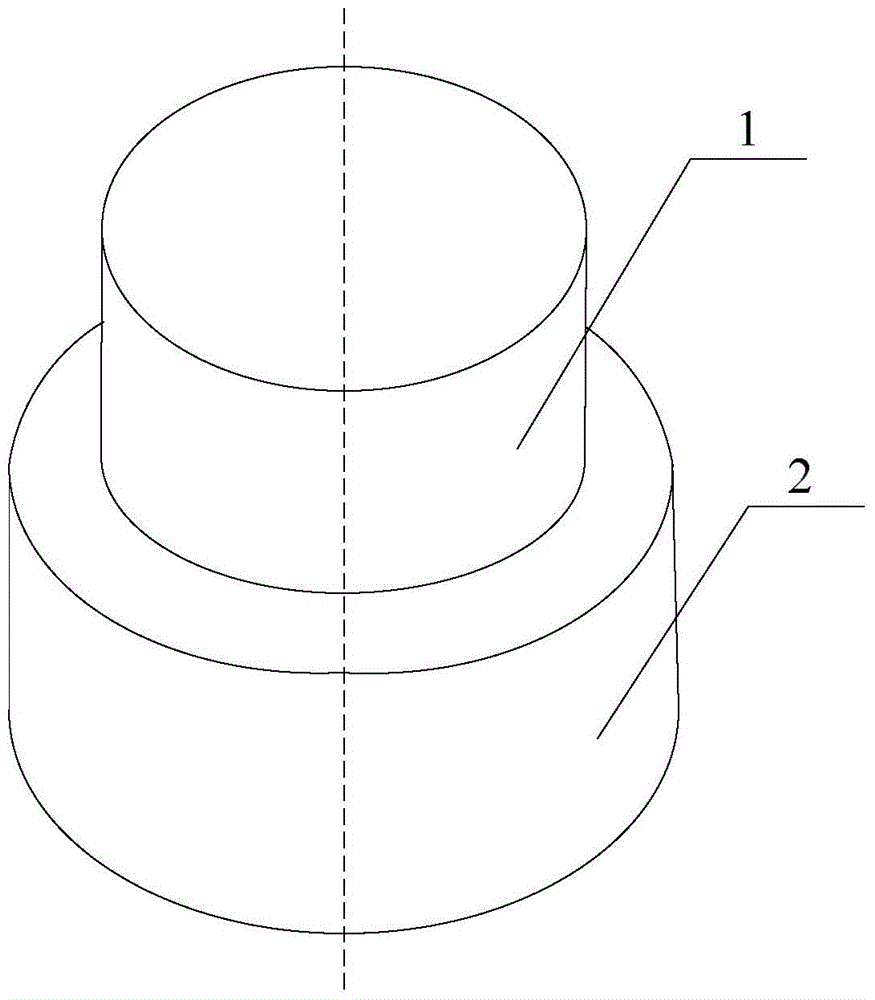

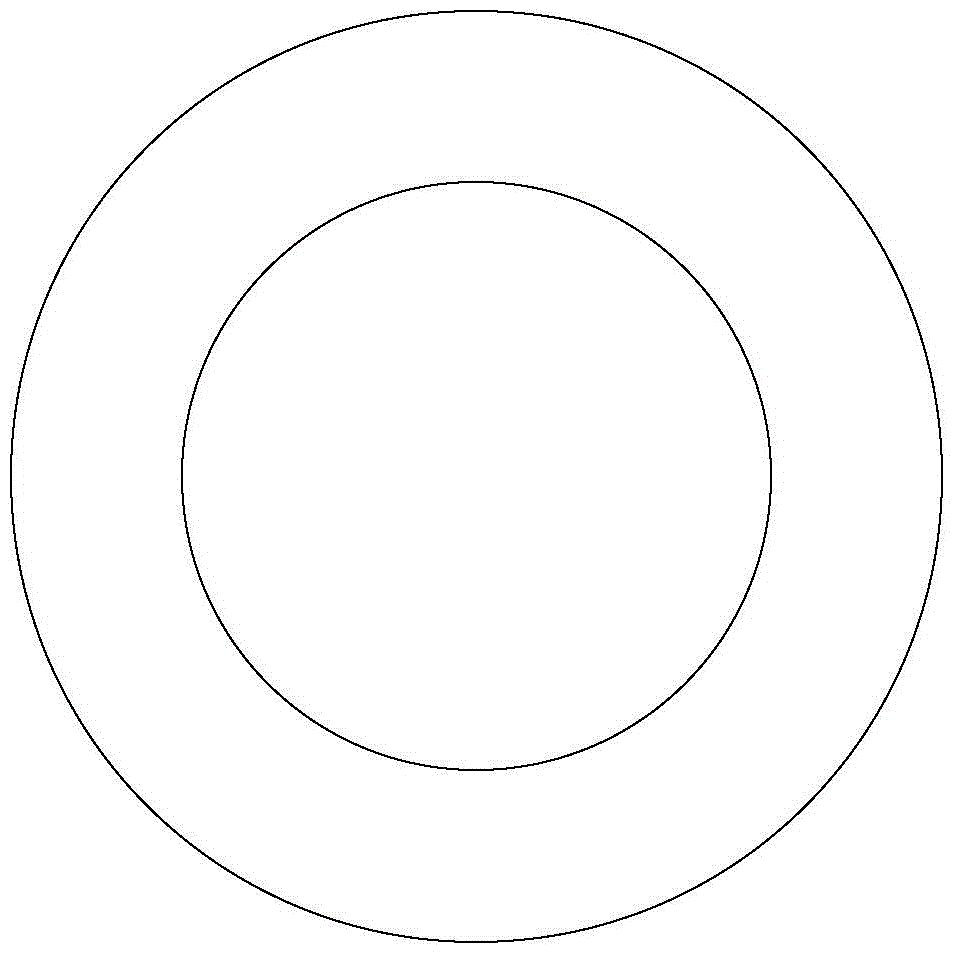

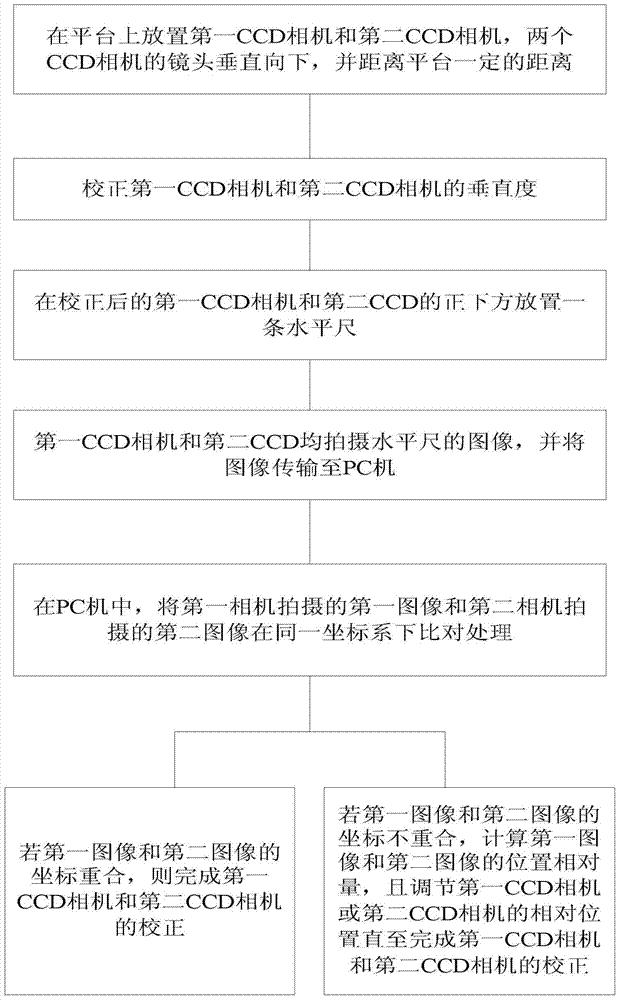

Reference positioning method of CCD (Charge Coupled Device) cameras

ActiveCN104820978ADatum Positioning AchievementAchieve positioningImage analysisCamera lensImage transfer

The invention provides a reference positioning method of CCD (Charge Coupled Device) cameras. The method comprises the steps of simultaneously correcting the two CCD cameras, placing the first CCD camera and the second CCD camera on a platform, allowing lenses of the first CCD camera and the second CCD camera to be perpendicularly downward and have certain distances from the platform, correcting the perpendicularity of the first CCD camera and the second CCD camera, horizontally placing a leveling rod under the first CCD camera and the second CCD camera, allowing the first CCD camera and the second CCD camera to shoot images of the leveling rod, transmitting the images to a PC (Personal Computer) for processing, and adjusting a position of the first CCD camera or the second CCD camera according to a processing result until correction of a relative position of the first CCD camera and the second CCD camera is completed. The reference positioning method is simple and high in accuracy.

Owner:SHANXI DIMAI WOKE PHOTOELECTRIC IND CO LTD

Self-correction method for detecting carbon dioxide concentration by adopting non-dispersive infrared technology

InactiveCN103175803AEliminate concentration instabilityEliminates factors in measurement accuracyColor/spectral properties measurementsData acquisitionData treatment

The invention relates to the field of a method for detecting gas concentration by adopting a non-dispersive infrared technology, and specifically relates to a self-correction method for detecting carbon dioxide concentration by adopting the non-dispersive infrared technology. According to the method, detection is performed by adopting an non-dispersive infrared detector, the non-dispersive infrared detection part comprises an infrared source, a single-window detector, a gold-plating gas chamber and a data acquirer, wherein a temperature sensor is arranged in the single-window detector, and a buffer area and a register are arranged in the data acquirer. The self-correction method is characterized by performing the steps of preparing, self-correction data processing and temperature compensating in sequence. The method provided by the invention is precise and reliable to measure, strong in interference resistance, and good in long-time working stability.

Owner:SHANGHAI YIHUA V&A INSTR

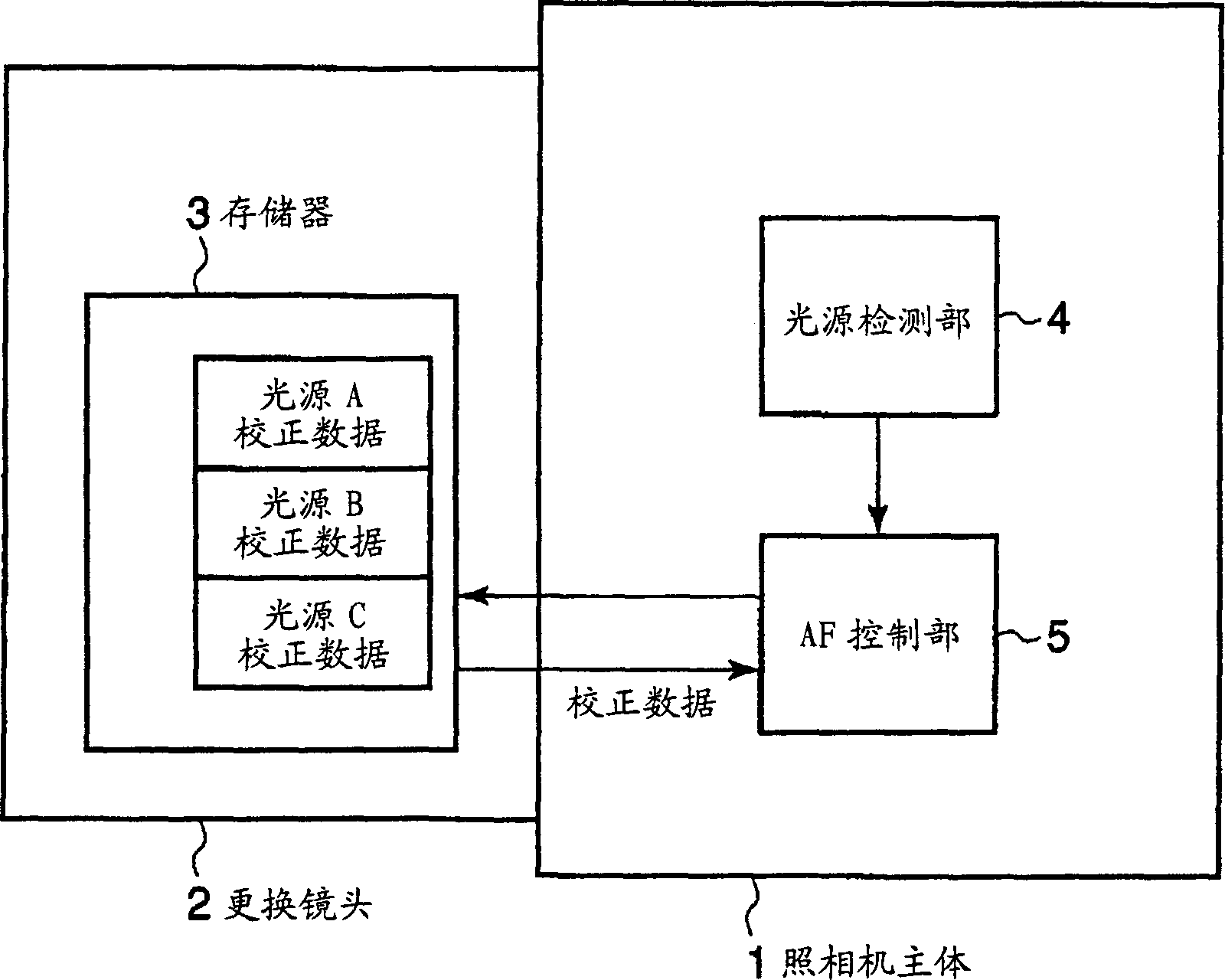

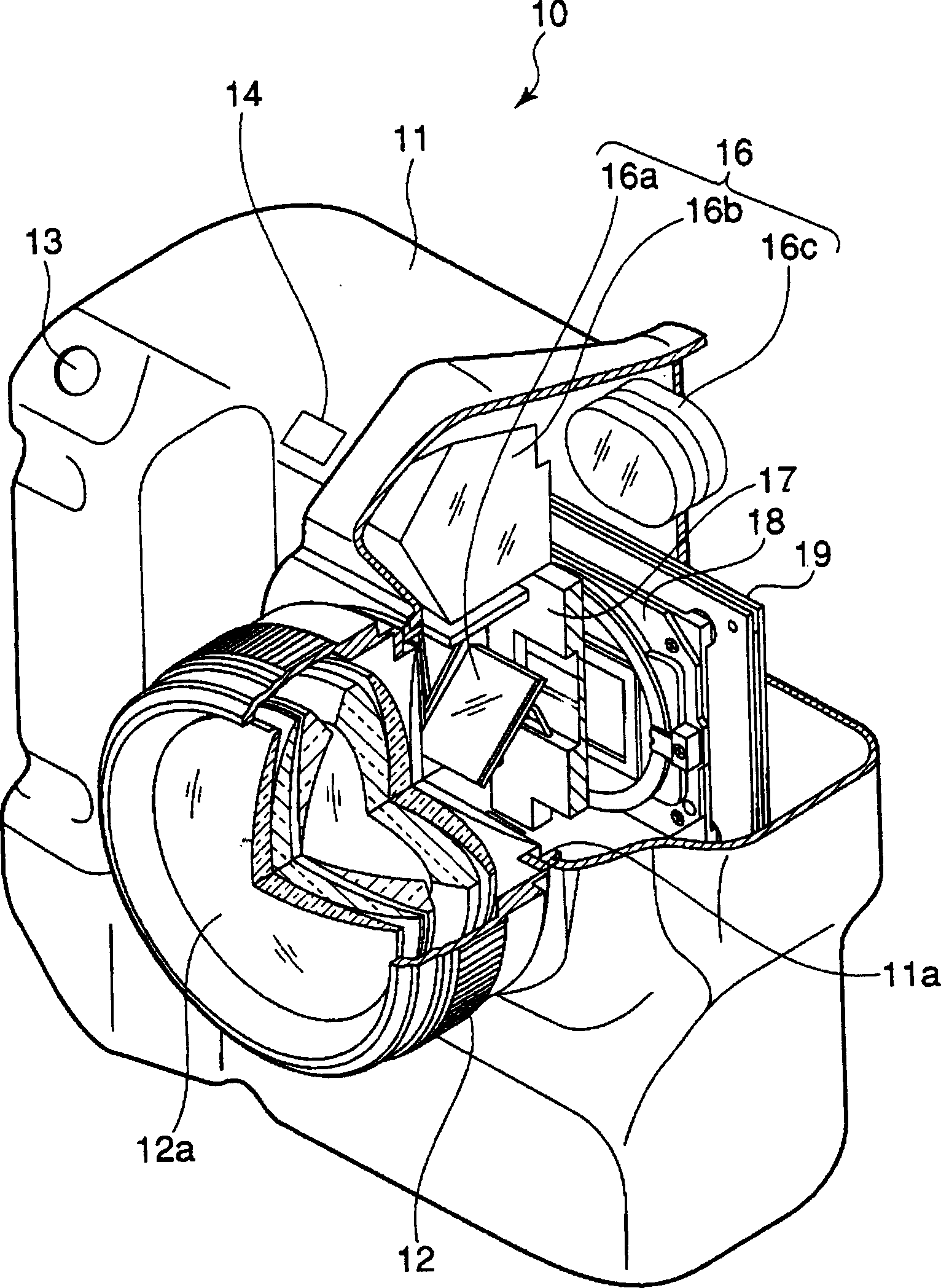

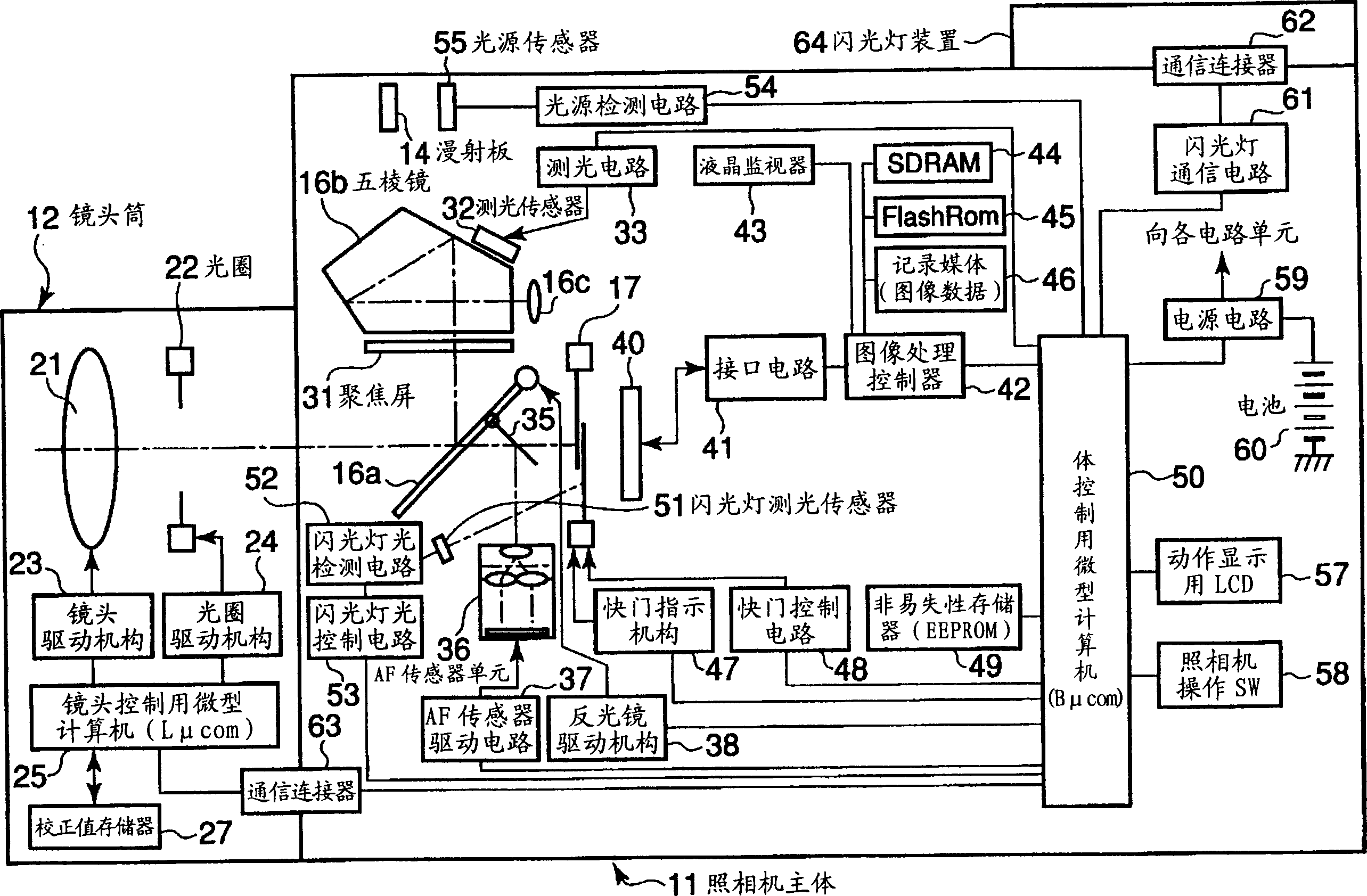

Camera and focus detection device

InactiveCN1645181AThe calibration method is simpleHigh-precision focus offset correctionMountingsFocusing aidsCamera lensCorrection method

The object of the invention is to reduce the cost of an interchangeable lense, camera or the like by simplifying a correction method thereby downsizing a memory and a processing circuit, and to provide the camera and a focus detecting device which can correct the out of focusing highly precisely. When a light source illuminating a subject is detected by a light source detection part 4 in a camera body 1, a signal corresponding to the light source is outputted from the light source detection part 4. In addition, a correction value for correcting defocus according to the type of the light source, which is stored in a memory 3, is read as correction data. Based upon the signal from the light source detection part 4 and the correction data read from the memory 3, an AF control part 5 performs the focus detection.

Owner:OLYMPUS CORP

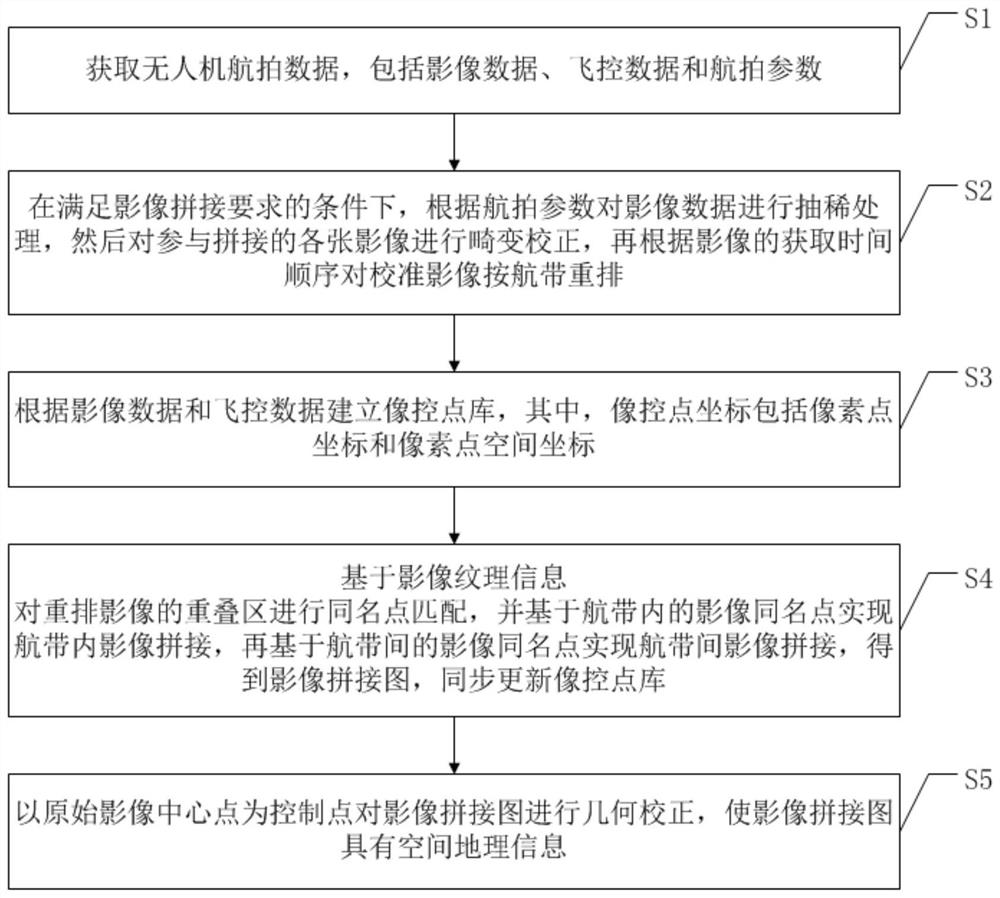

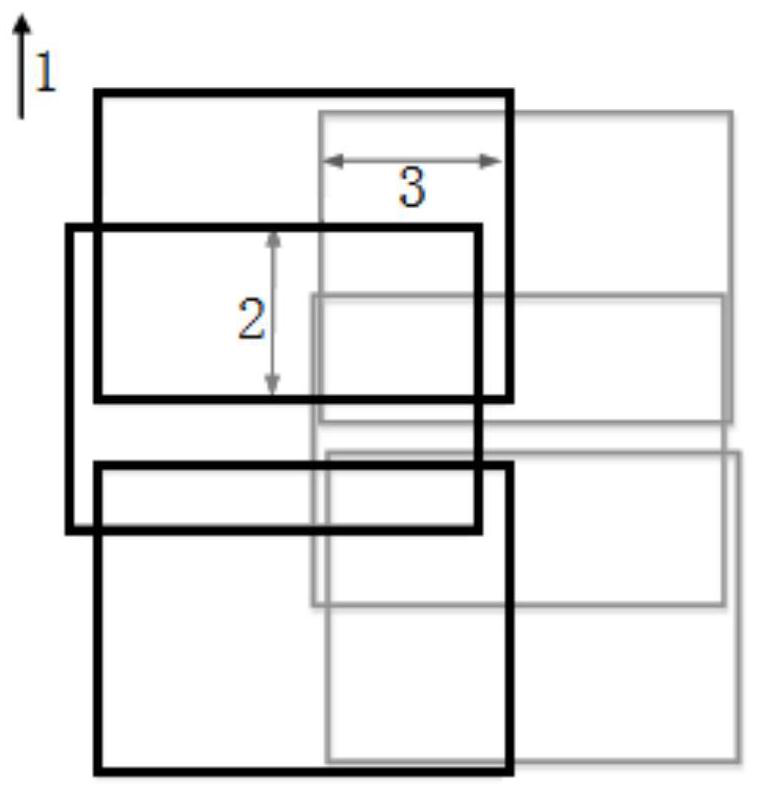

Method for quickly splicing aerial images of unmanned aerial vehicle in emergency rescue activities

PendingCN112330537AQuick stitchingReduce overlapImage enhancementGeometric image transformationEmergency rescueComputer graphics (images)

The invention relates to the field of image splicing and particularly relates to a method for quickly splicing aerial images of an unmanned aerial vehicle in emergency rescue activities. The method comprises the following steps of acquiring aerial data of the unmanned aerial vehicle; thinning the number of the images, and then performing distortion correction and image rearrangement on each imageparticipating in splicing; air strip image splicing being carried out based on the image texture, and then air strip splicing being carried out; and finally, geometrically correcting the spliced imageby taking the central point of the original image as a control point so that the image has geographic space information. According to the method, by reducing the image data and simplifying the data processing process, image splicing can be rapidly carried out, meanwhile, the image data has measurability, splicing efficiency of aerial images of the unmanned aerial vehicle is greatly improved, andthe obtained image splicing image can meet the requirement for emergency rescue command in precision.

Owner:AEROSPACE INFORMATION RES INST CAS +1

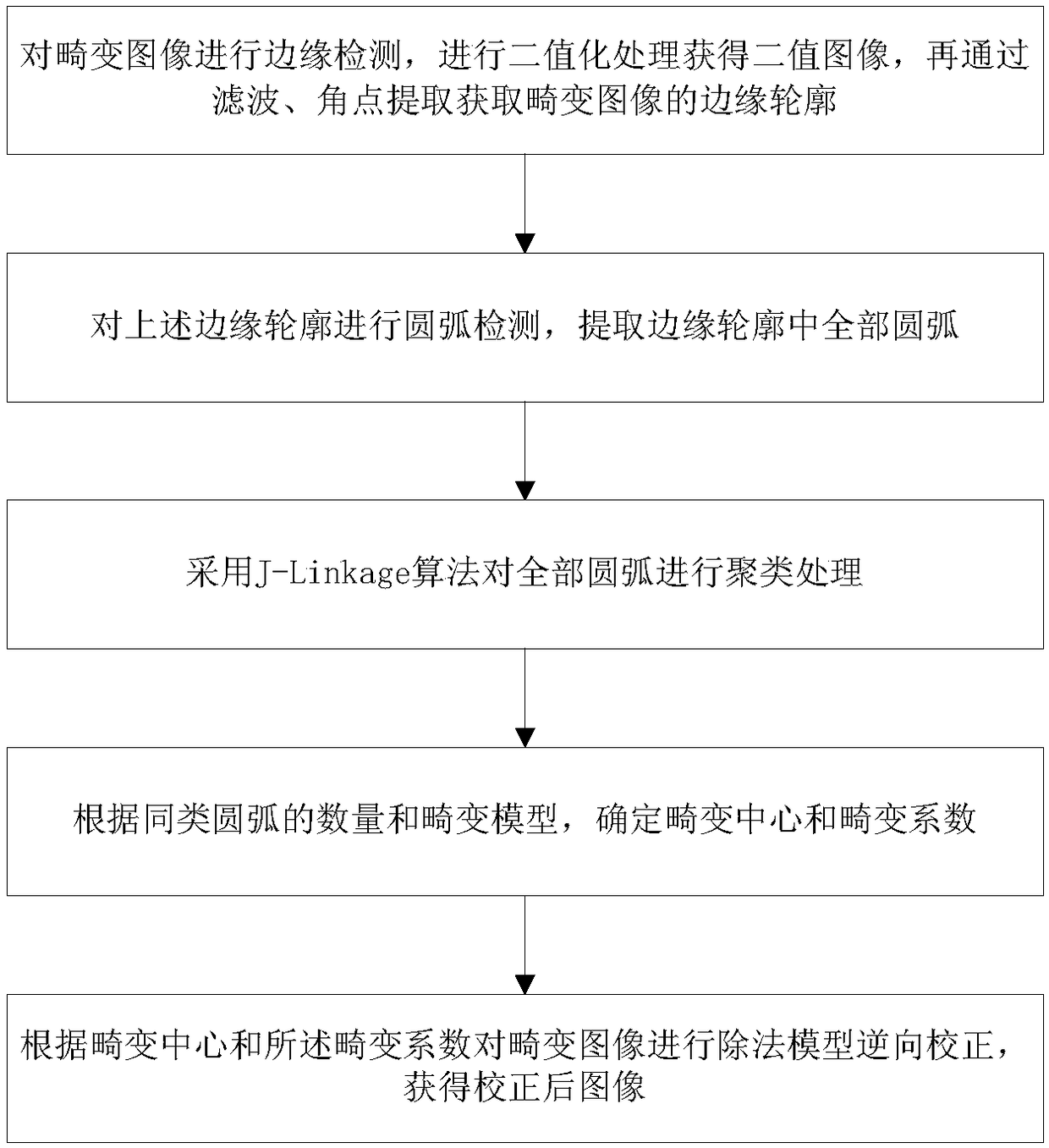

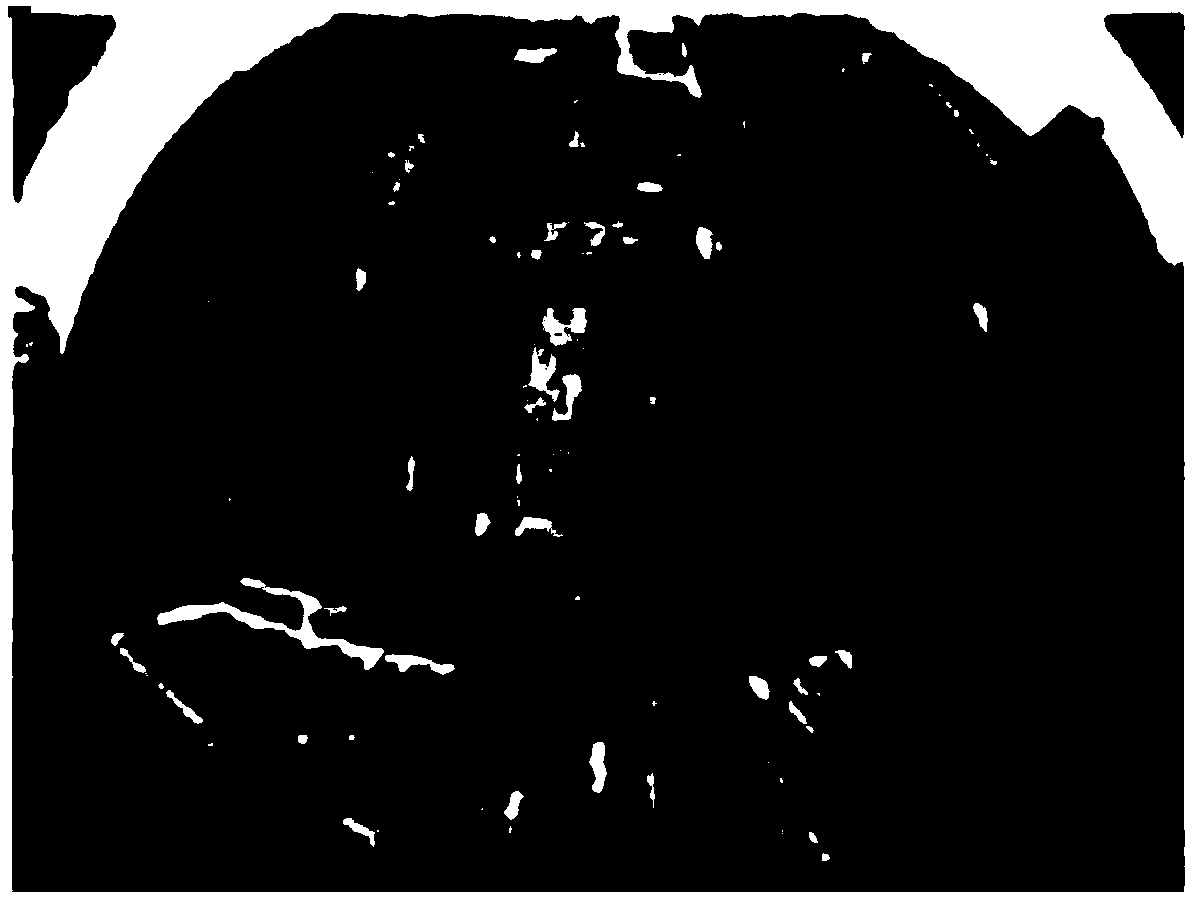

Lens radial distortion correction method

ActiveCN108492263ANo voidsThe calibration method is simpleImage enhancementImaging processingAlgorithm

The invention provides a lens radial distortion correction method, and belongs to the technical field of image processing. The invention can correct the obvious radial distortion of a short focal length lens, is simple in correction method, is good in correction effect, and has strong robustness. In the present invention, the J-Linkage algorithm is used to perform automatic clustering by using theJachard distance, the number of model instances does not need to be given in advance, and parameter debugging can be avoided; in the invention, according to the number of similar arcs and different distortion models, three methods are proposed to calculate the distortion center and a distortion coefficient. In the invention, the inverse model correction algorithm can avoid holes of the correctedimage, and successfully avoids additional operations such as interpolation; and a better correction effect and better real-time performance can be obtained.

Owner:ANSTEEL GRP MINING CO LTD

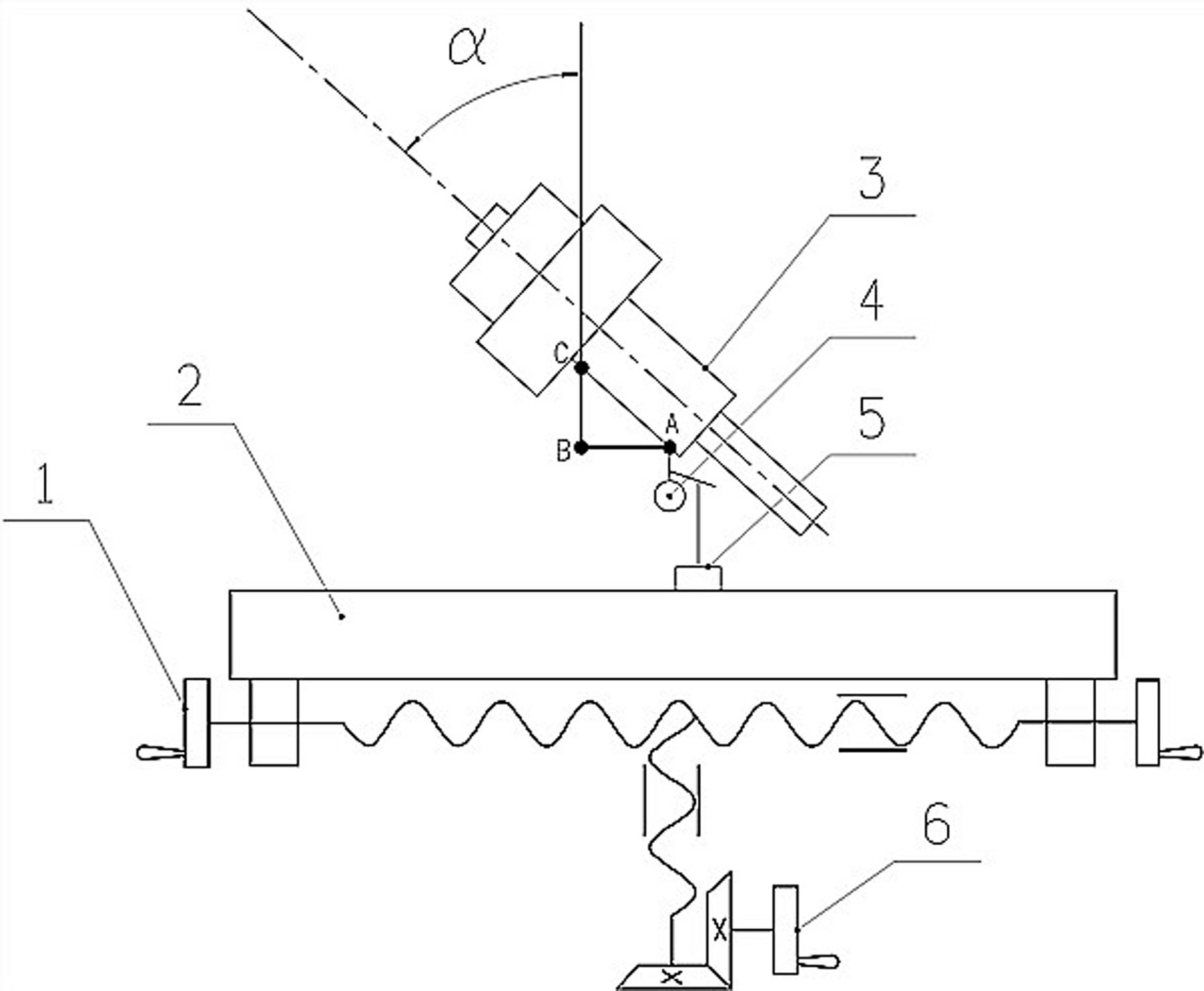

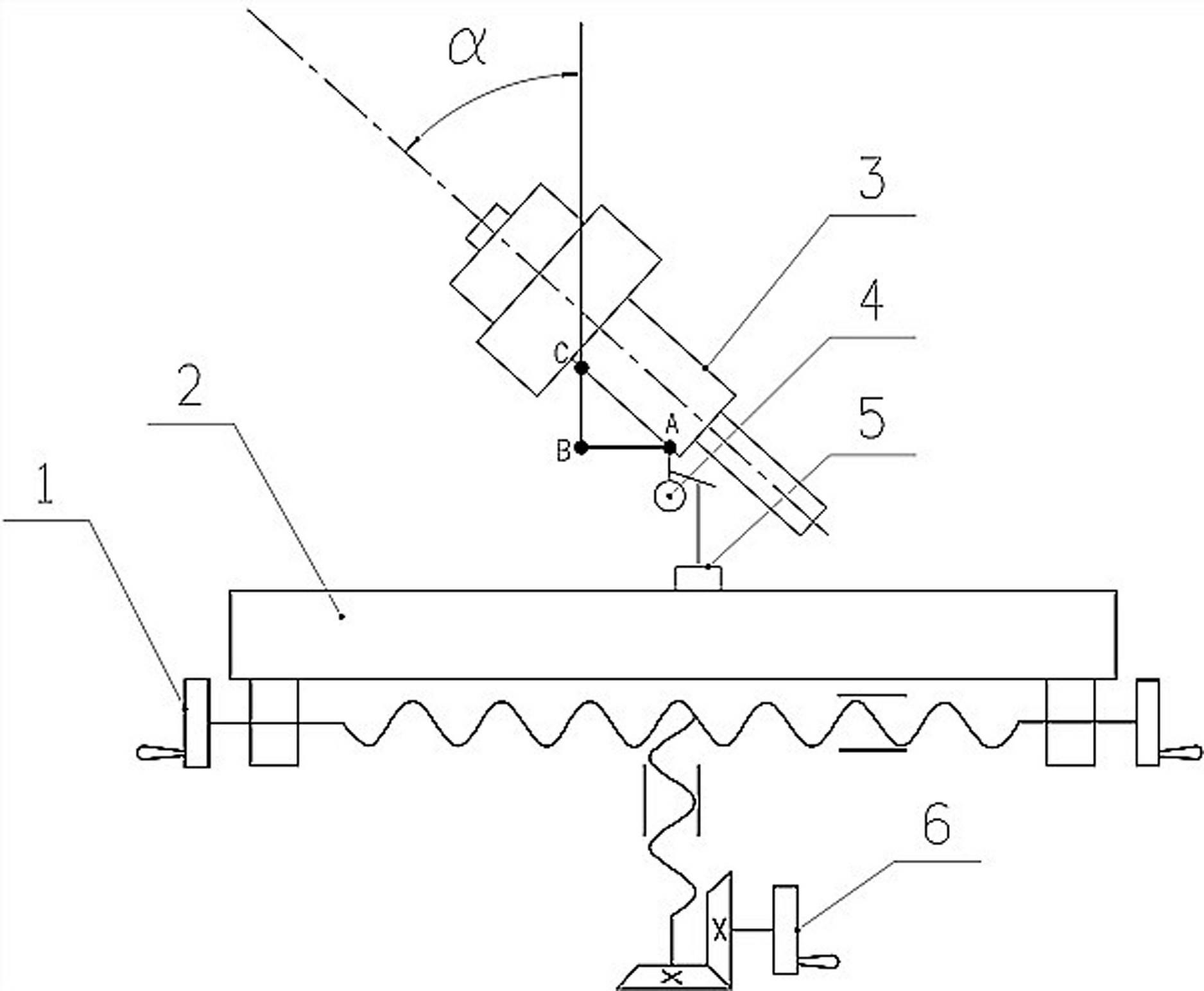

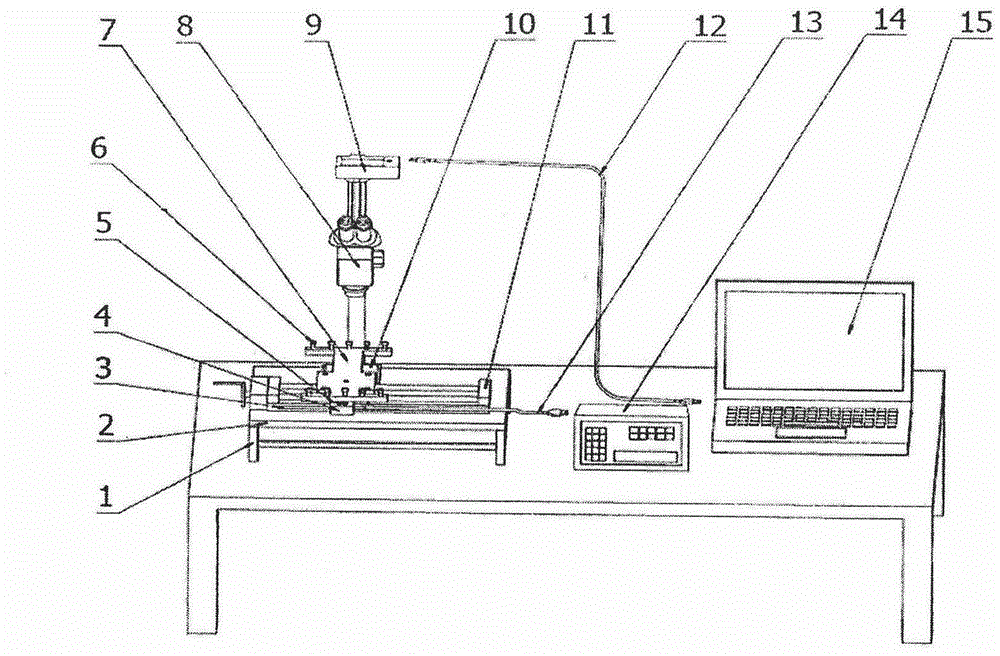

Method for accurately calibrating inclination of vertical milling head of milling machine by using dialgauge

InactiveCN102091971AThe calibration method is simpleThe calibration method is accuratePrecision positioning equipmentMilling equipment detailsEngineeringDeflection angle

The invention discloses a method for accurately calibrating the inclination of a vertical milling head of a milling machine by using a dialgauge. In the method, after the vertical milling head deviates an angle according to an inclined plane or inclined hole of a workpiece to be machined, the dialgauge is fixed on a workbench, a horizontal distance and a vertical distance between two points on the outer wall of a part, which is arranged on the vertical milling head and coaxially extends with the vertical milling head, and has an outer surface parallel to the axis of the vertical milling head,are measured by the dialgauge, the data obtained through measurement is calculated, the deviation between the actual deflection angle and the set deflection angle of the vertical milling head is compared, and the vertical milling head is regulated to a right place according to the deviation. By the method, the inclination of the vertical milling head of the milling machine can be accurately calibrated, the production period of the product is shortened, the production cost is reduced, and the method has high promotion and application value.

Owner:LUOYANG INST OF ELECTRO OPTICAL EQUIP OF AVIC

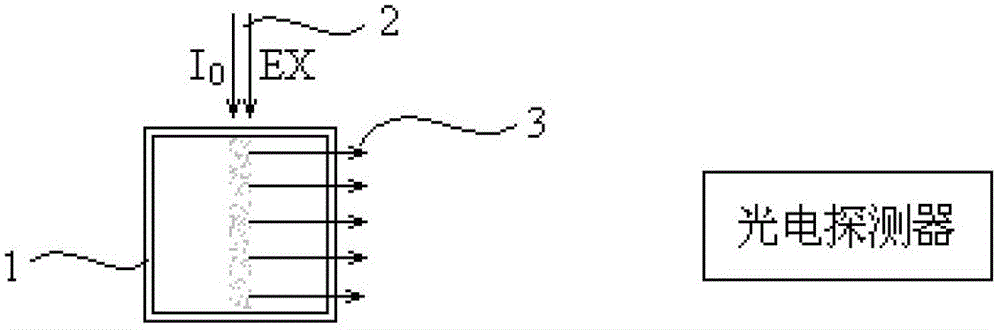

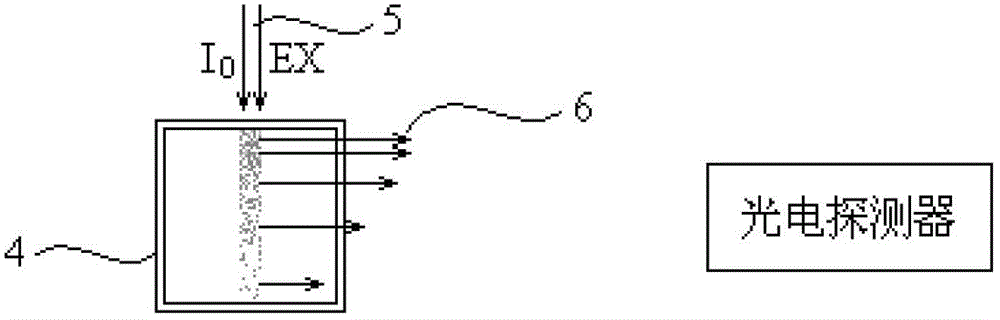

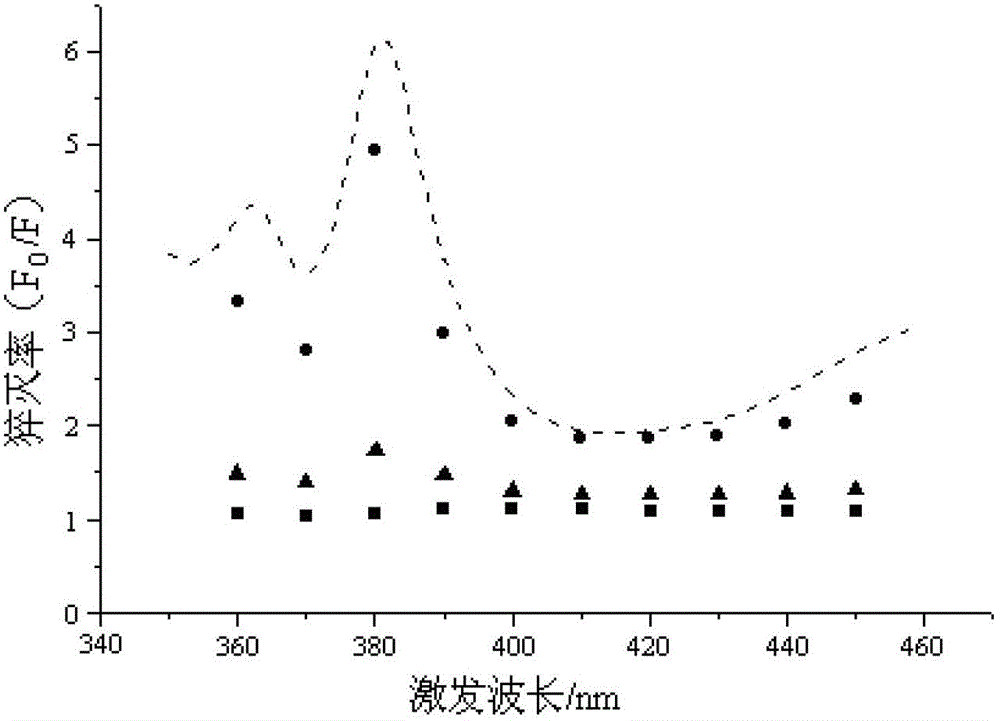

Accurate correction method of fluorescence quenching rate in inner filtering efficiency process of fluorescence quenching system

InactiveCN102914529AAccurate correctionThe calibration method is simpleFluorescence/phosphorescenceLighting spectrumCorrection method

The invention discloses an accurate correction method of a fluorescence quenching rate in an inner filtering efficiency process of a fluorescence quenching system, and the method is characterized by comprising the following steps of: firstly, correcting influences of competitive absorption on a light spectrum; then, correcting the influences of absorption on the light spectrum; and correcting the influences of absorption distribution on the light spectrum. The method disclosed by the invention can be used for carrying out combined correction on the influences caused by a fluorescence inner filtering efficiency and absorption distribution, so as to ensure that the light spectrum of the quenching system is accurately corrected; and the fluorescence quenching rate in the quenching process is really reflected.

Owner:HEFEI UNIV OF TECH

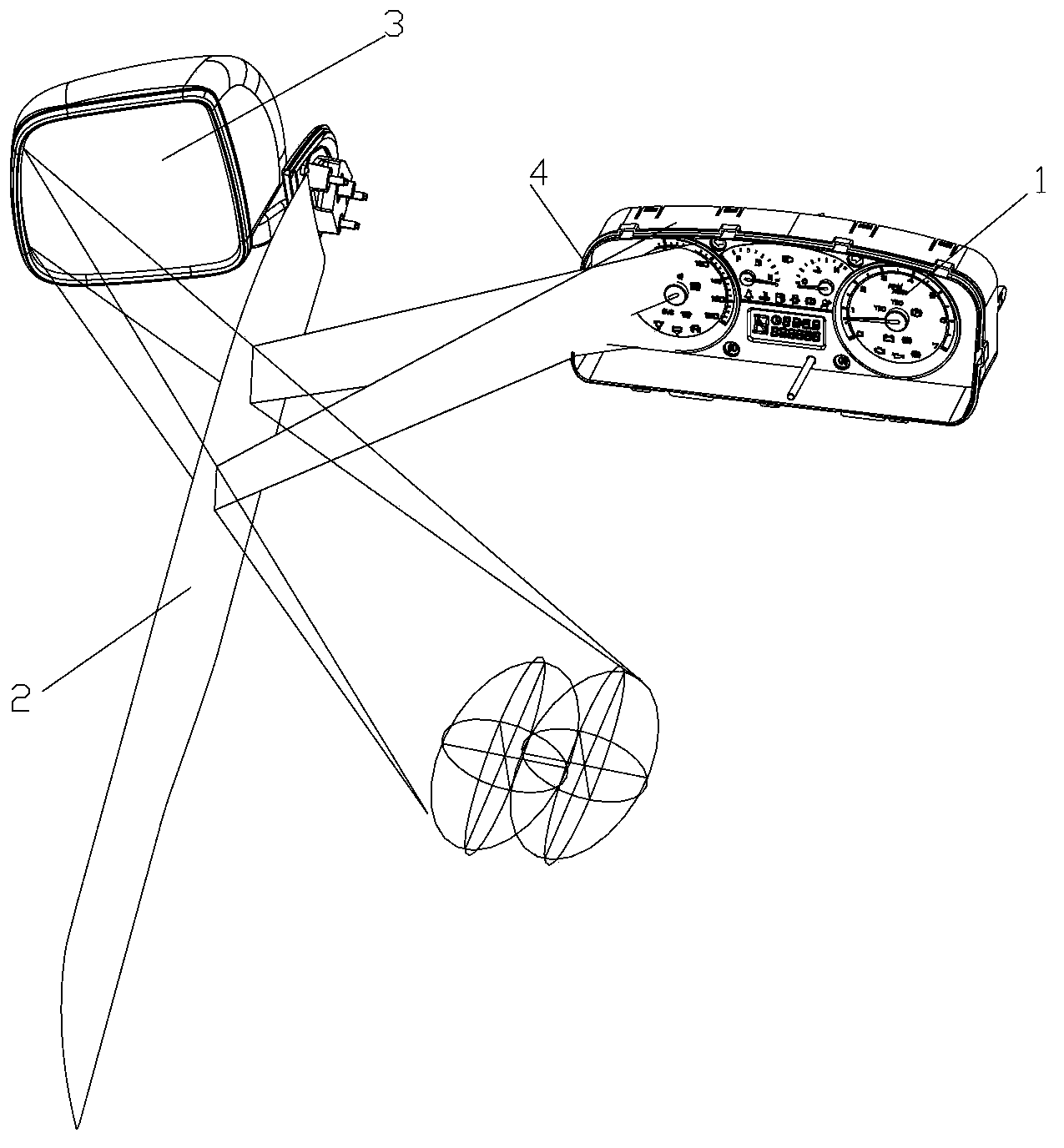

Automobile, checking method for reflected light of instrument panel of automobile on front door glass and manufacturing method for automobile

The invention discloses a checking method for the reflected light of an instrument panel of an automobile on front door glass. The method comprises the steps that an eye ellipse is made; tangents of the eye ellipse are made through a point on the mirror surface of a rearview mirror; front door glass acts as a reflecting surface, and reflection lines of all the tangents are made; and when all the reflection lines are not intersected with an indication surface of the instrument panel or all the reflection lines are not intersected with the indication surface of the instrument panel due to the fact that the reflection lines are blocked by a light blocking part, the reflected light of the instrument panel on front door glass does not influence visual lines of a driver for observing the rearview mirror. The invention also provides a manufacturing method for the automobile and the automobile. The aforementioned checking method is simple and easy to operate, and the reflected light of the instrument panel on front door glass can be checked in the design process of the automobile so that optimization can be timely performed in the design process, the situation that the reflected light of the instrument panel on front door glass influences the visual lines of the driver for observing the rearview mirror of the side at night is prevented, driving comfort degree is facilitated for the driver and driving safety is enhanced.

Owner:BEIQI FOTON MOTOR CO LTD

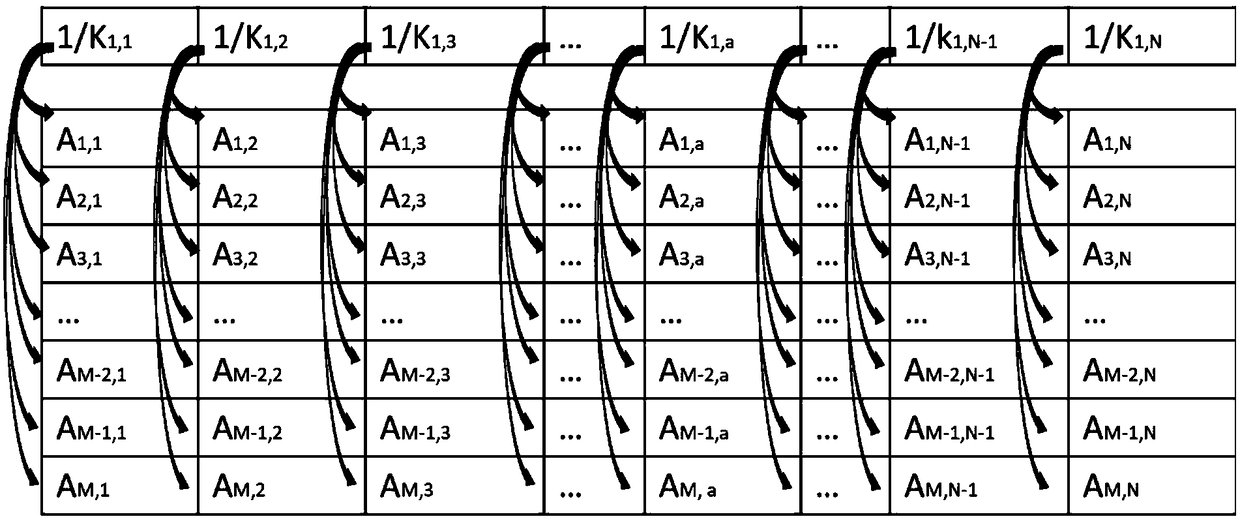

A flat-field calibration method of a linear array camera

ActiveCN108986170AImprove adaptabilityImprove Calibration AccuracyImage analysisWorking environmentComputer science

The invention discloses a flat field correction method of a linear array camera suitable for field working conditions. The method includes: obtaining an original correction coefficient matrix by shooting an initial gray value matrix of an initial row of a screen to be inspected; obtaining an original gray value matrix by scanning and photographing the gray value image of the screen to be inspectedby the linear array camera; multiplying the original gray value matrix by the original correction coefficients of the corresponding columns to obtain a preliminarily corrected gray value matrix; dividing the gray value of each pixel in the preliminarily corrected gray value matrix by the median value of the row to determine the pixel response non-uniformity coefficient of the initial row in the pixel matrix of the screen to be inspected; obtaining effective flat-field correction coefficients to correct the gray-scale image taken by the linear array camera. The method of the technical scheme of the invention aims at the problems that the current flat field correction method of the linear array camera is difficult to adapt to the difference of the working environment and the precision is not high, and under the actual working condition, the flat field correction of the linear array camera is carried out through the combination of the optics and the algorithm, which has good adaptabilityand high precision.

Owner:WUHAN JINGCE ELECTRONICS GRP CO LTD

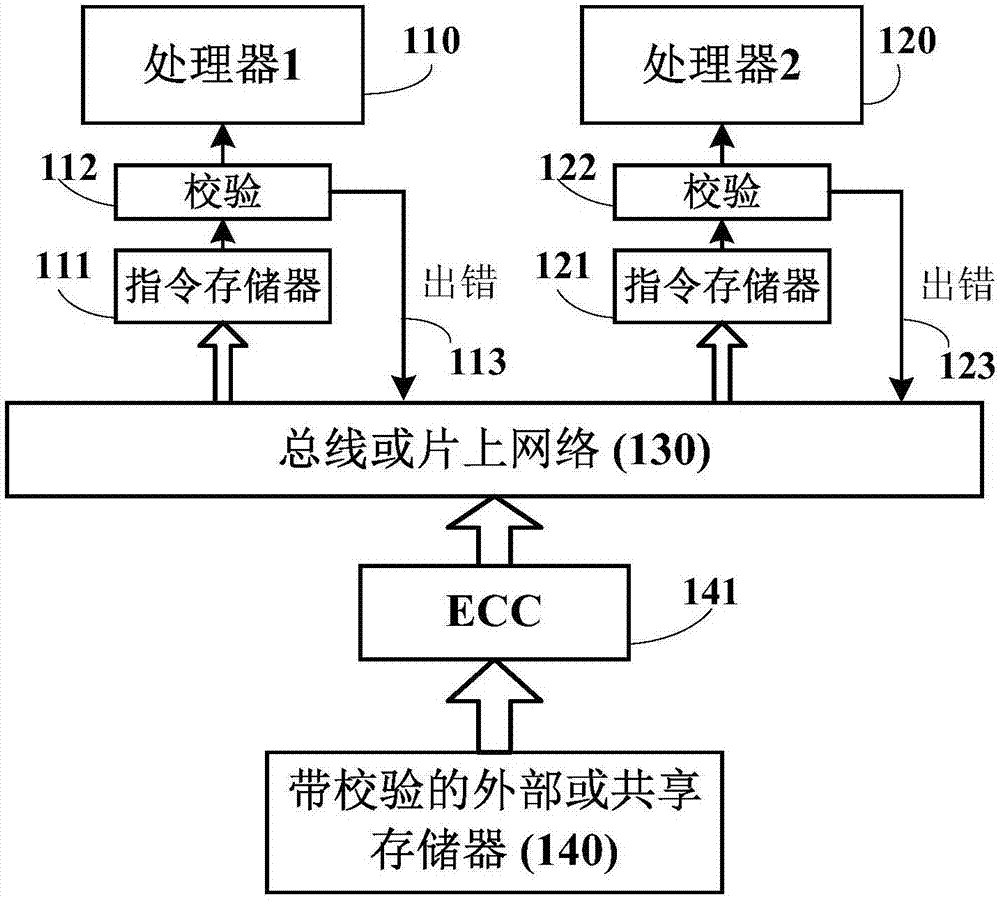

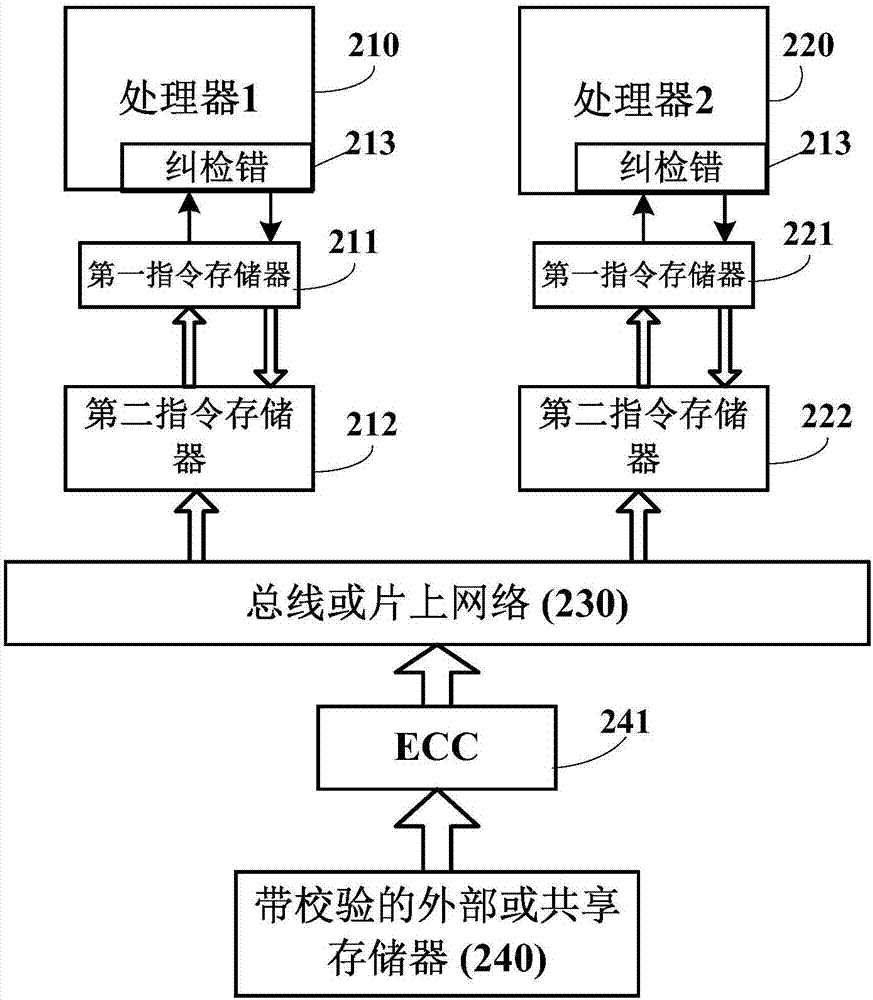

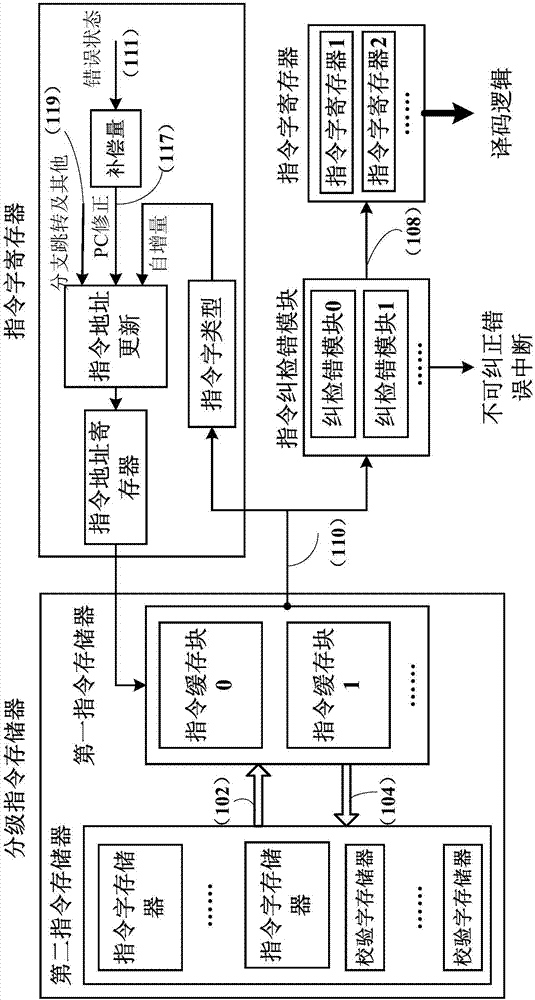

Method and device for fault tolerance of grading instruction memory structure capable of actively writing back

ActiveCN107885611AGuaranteed reliabilityImprove reliabilityNon-redundant fault processingInstruction memoryFault tolerance

The invention provides a method and a device for fault tolerance of a grading instruction memory structure capable of actively writing back. The device comprises a grading instruction memory, an instruction fault correcting and checking module, an instruction character register, and an instruction address register. The method comprises: 1, starting and operating a processor; 2, taking out instruction character data from the grading instruction memory; 3, sending the instruction character data to the instruction fault correcting and checking module; 4, determining a fault correcting and checking result to have no fault or have a correctable fault; if yes, continuing to perform a step 5; if no, jumping to step 10; 5, writing an instruction character to the instruction character register; 6,updating the instruction address register; 7, determining whether a correctable fault occurs; if yes, continuing to perform a step 8; if no, jumping to a step 9; 8, writing the instruction character data back to the grading instruction memory; 9, ending processing; jumping to the step 2, processing the address of the next instruction; 10, when the instruction character data has uncorrectable fault, suspending the processor. The method and the device realize fault tolerance of instructions and the instruction memory, and have relatively low hardware cost.

Owner:XIAN MICROELECTRONICS TECH INST

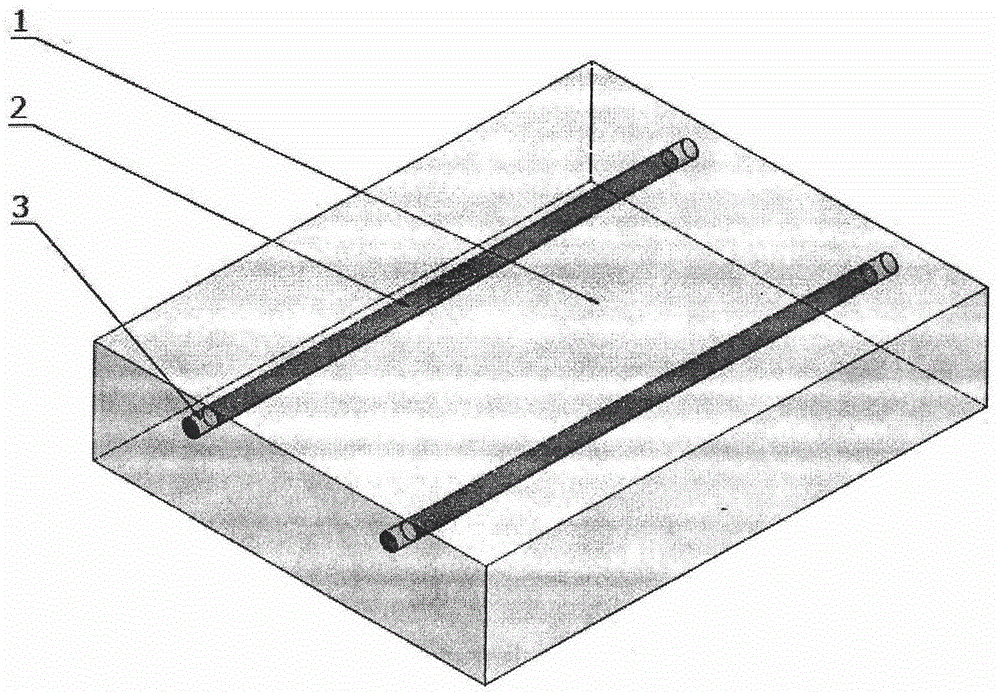

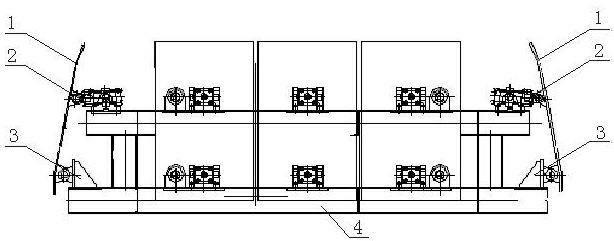

Electromagnetic sensing principle based inspection component of concrete reinforcement detector

InactiveCN104613859AImprove machining accuracyThe calibration method is simpleUsing electrical meansElectrical/magnetic diameter measurementsWaxRebar

The invention provides an electromagnetic sensing principle based inspection component of a concrete reinforcement detector. The inspection component is manufactured from organic glass. The inspection component is manufactured by the steps of manufacturing an organic glass component, and manufacturing a standard reinforcement bar. The organic glass component is manufactured by the steps of a) blanking, namely, cutting into blocks as requirement through a portable electric saw; b) roughly planing, namely, roughly planing the organic glass blocks through a numerical control milling machine, wherein the rough planing precision is + / -0.0.2mm; c) drilling a hole, namely, drilling reinforcement preset aperture in the roughly planed organic glass plate through a drilling machine according to the design aperture position, wherein the drilling precision is +0.02mm; d) polishing the aperture, namely, polishing the aperture through a zinc bar and a polishing machine, wherein a nylon fabric coils the zinc bar, and polishing wax is coated on the nylon fabric, and about 0.02mm diameter is increased after polishing; e) polishing the surface, namely, polishing the organic glass surface through a diamond polishing machine. The standard reinforcement bar is manufactured by the steps of milling an HRB400 reinforcement through a machine tool, wherein the processing precision is -0.02mm, the length is 20mm less than that of the organic glass, and 10mm is reserved in two ends of the standard reinforcement bar; sealing through curing glue.

Owner:RES INST OF HIGHWAY MINIST OF TRANSPORT

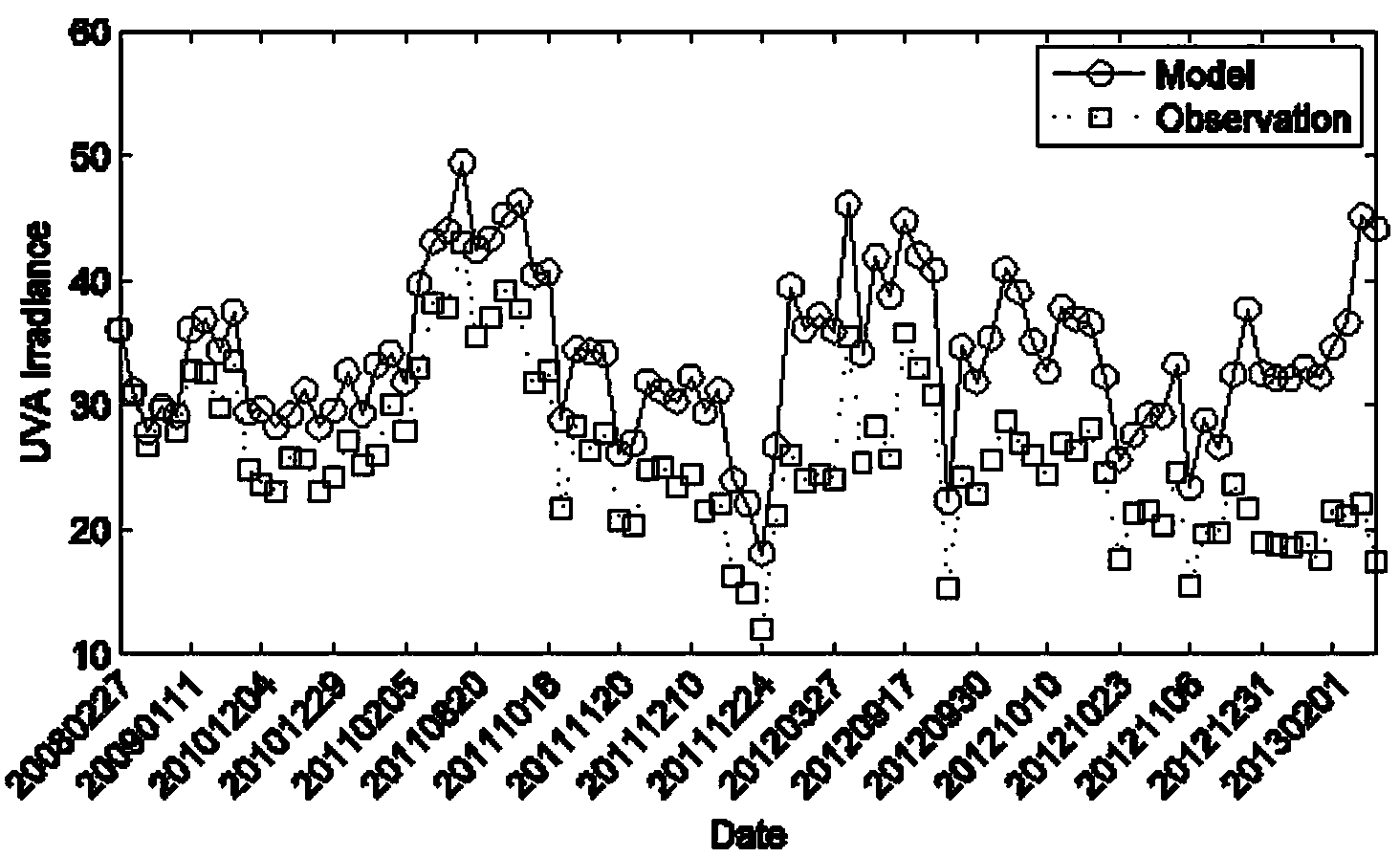

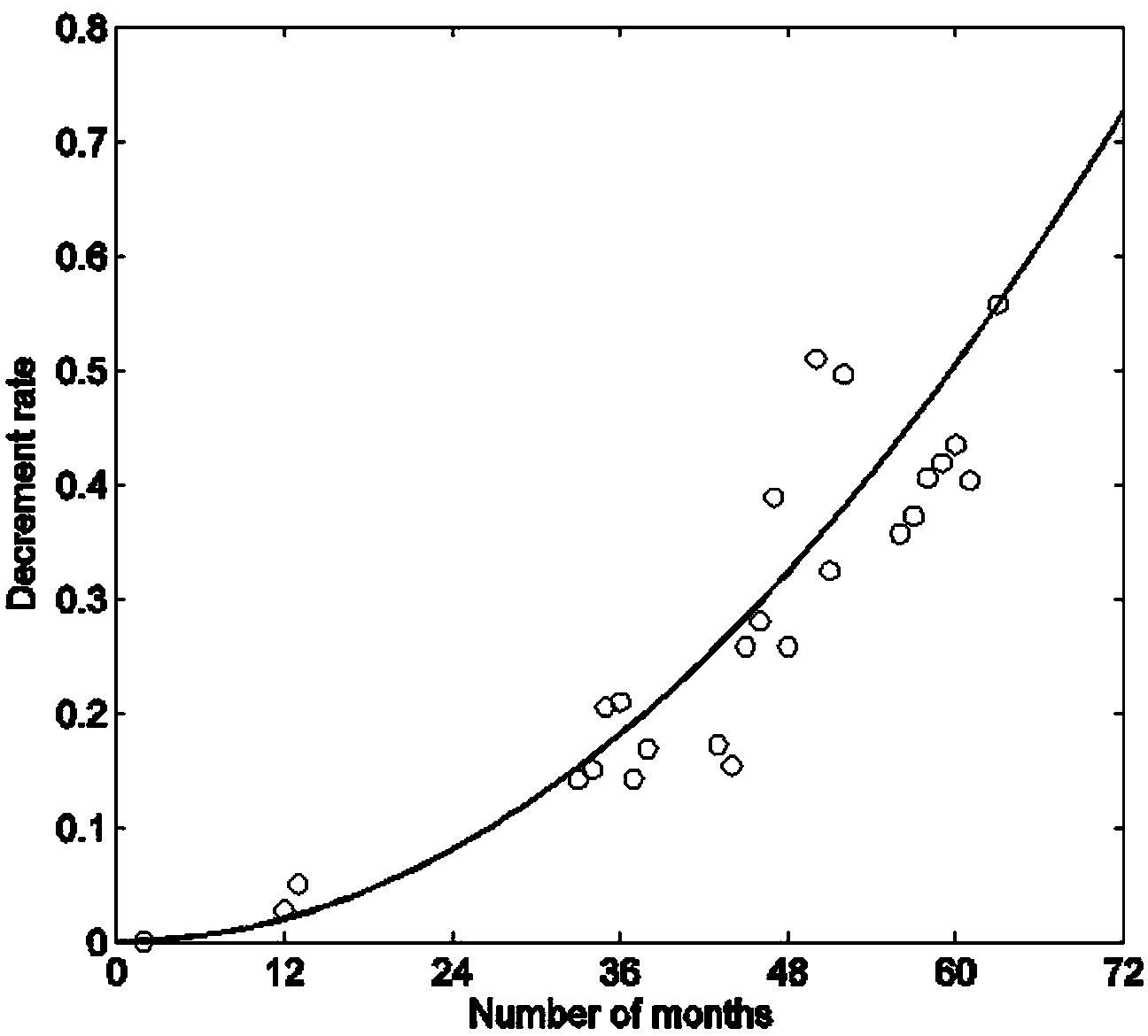

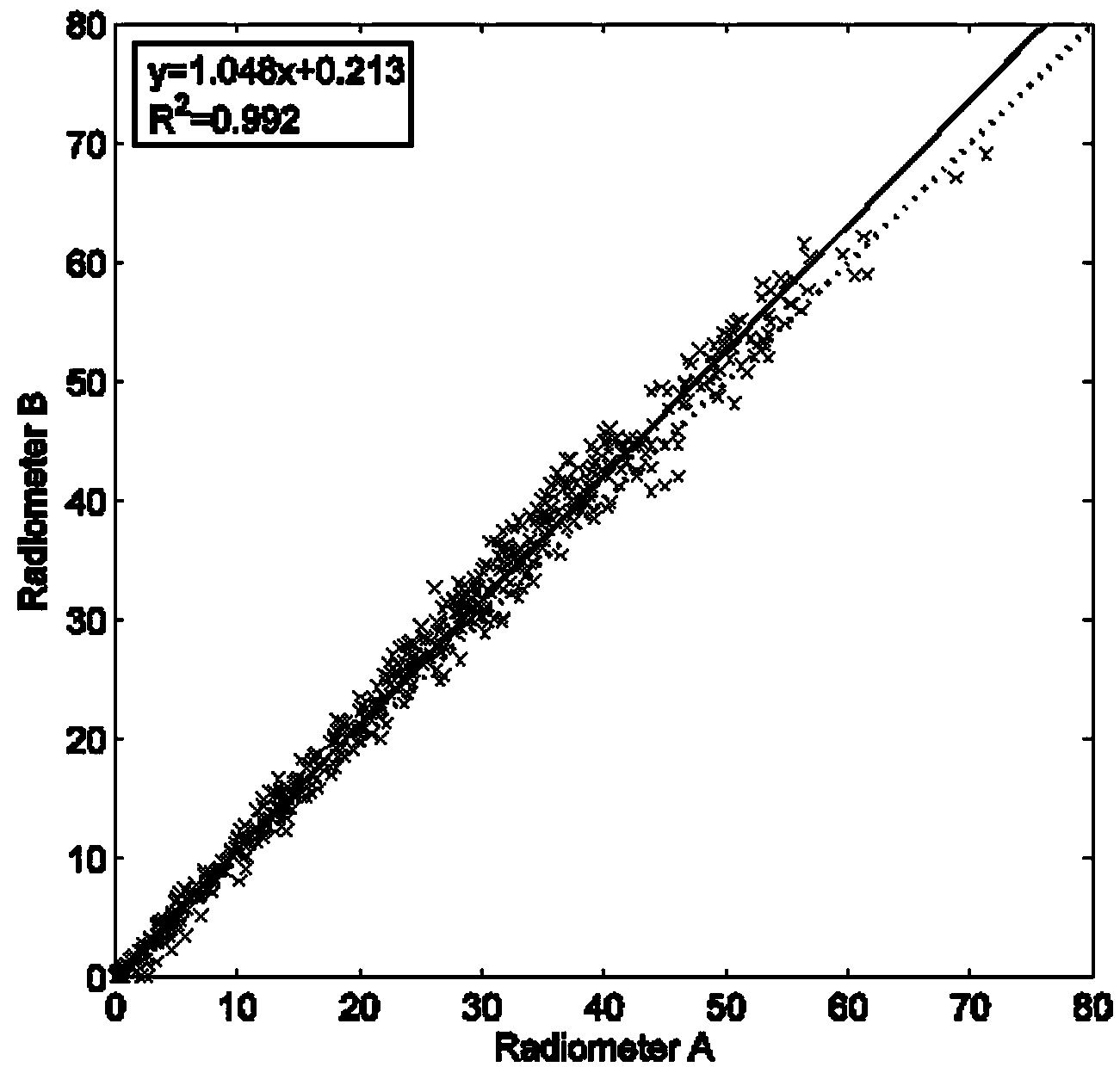

Calibration correcting method for ultraviolet radiation meter

InactiveCN104297816AReduce use costThe calibration method is simpleInstrumentsPhysicsCorrection method

The invention discloses a calibration correcting method for an ultraviolet radiation meter. The calibration correcting method comprises the steps that the real ultraviolet irradiance reaching the ground at a point is expressed as F(lambda), the ultraviolet irradiance output by a model is expressed as F[m] (lambda), and then the formula F(lambda)=F[m] (lambda) is obtained; the ultraviolet irradiance observed by an aged ultraviolet radiation meter is expressed as F[ab] (lambda), and then attenuation rate can be expressed as the formula D=1- , and the attenuation rate D is a function related to time, namely, D=F(t), wherein D is the monthly attenuation rate, t is the number of service months of the meter; 85 fine cloudless days are selected, and the ultraviolet irradiances of 106 time points are adopted; the time series of D is obtained according to the formula, the attenuation rate of all the months are averaged, so that the monthly average attenuation rate D[mean] is obtained, fitting is conducted on the monthly average attenuation rate D[mean] and t, the attenuation rate obtained after fitting changes exponentially along with time, the relevance (R<2>) reaches 0.96, and please see the fitting equation in the equation (4); the attenuation rate of the ultraviolet radiation meter gradually becomes larger within short time, namely D=0.00116t<2>, and then a calibration correcting formula F'(t)= is obtained. The calibration correcting method is simple and economical and reduces the use cost of the meter.

Owner:广东省东莞市气象局

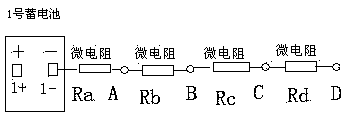

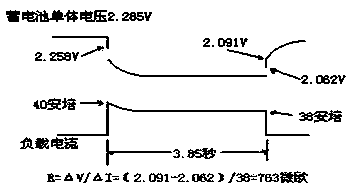

Method for correcting internal resistance measurement accuracy of valve regulated sealed lead acid storage battery

ActiveCN104035060AEasy to compareThe calibration method is simpleElectrical measurementsFloating chargeInternal resistance

The invention provides a method for correcting internal resistance measurement accuracy of a valve regulated sealed lead acid storage battery. The method mainly comprises the first step that a storage battery set is in a float charging state after equalizing charging is carried out on the storage battery, the second step that a storage battery internal resistance measurement procedure is started, high-current discharge is carried out on the storage battery, a corresponding voltage is generated, the voltage is measured, the specific value of the voltage and the discharging current is calculated, and the internal resistance of the storage battery can be obtained, and the third step that a standard micro resistance string is connected to a negative electrode column of the storage battery in series, the relative error of the internal resistance is calculated, and the relative error of the internal resistance is within a credible range.

Owner:STATE GRID CORP OF CHINA +3

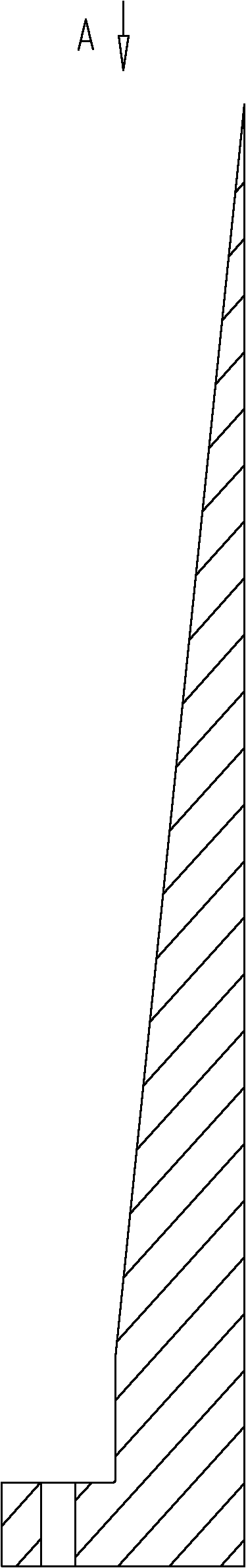

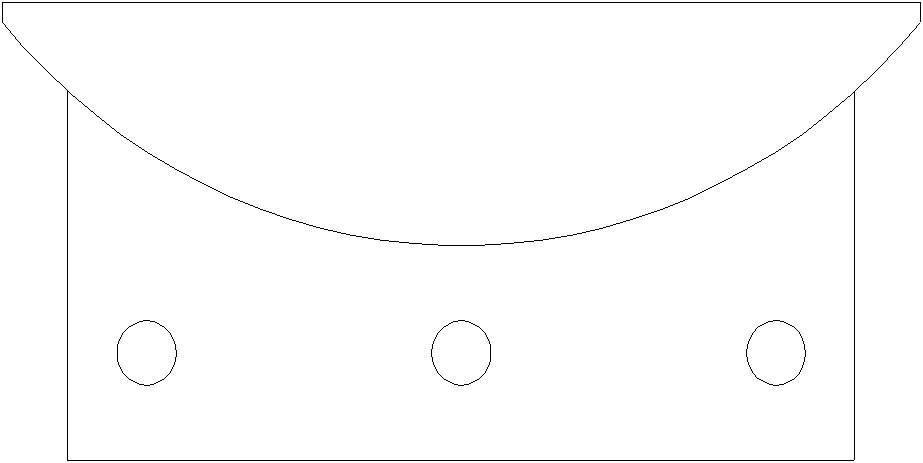

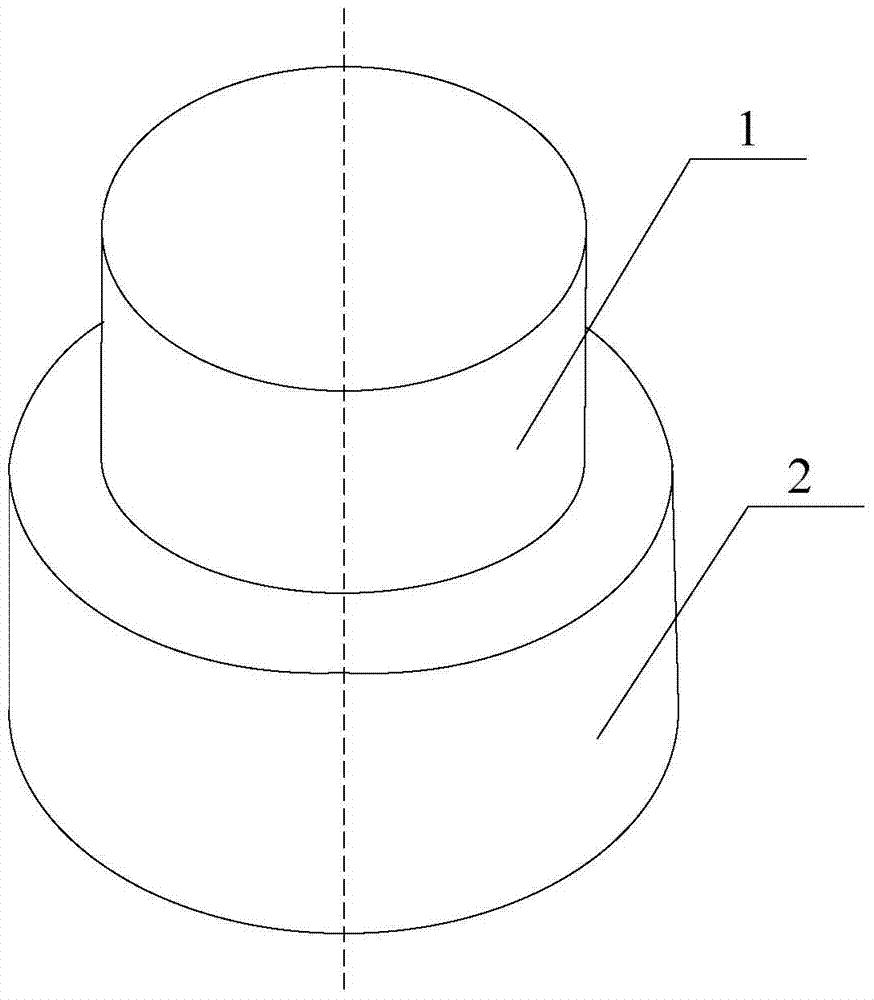

Processing method for conical surface of inclined base plate of aluminum extruder and correcting tool for conical surface of inclined base plate

ActiveCN102463443ASimple processing methodEasy to operatePositioning apparatusMetal-working holdersConical surfaceAluminium

The invention discloses a processing method for a conical surface of an inclined base plate of an aluminum extruder. A correcting tool for the conical surface of the inclined base plate is used for processing the conical surface of the inclined base plate of the aluminum extruder. The processing method comprises the following steps of: firstly, fixedly connecting two to-be-processed inclined base plates with the correcting tool for the conical surface of the inclined base plate; secondly, roughly processing the conical surfaces of the inclined base plates on a boring mill; and thirdly, finely processing the conical surfaces of the inclined base plate workpieces on a vertical vehicle. In the invention, the method for correcting and processing the conical surface of the inclined base plate of the aluminum extruder is simplified and the processing efficiency for the inclined base plate is greatly increased. The invention also discloses the correcting tool for the conical surface of the inclined base plate.

Owner:上海电气上重碾磨特装设备有限公司 +1

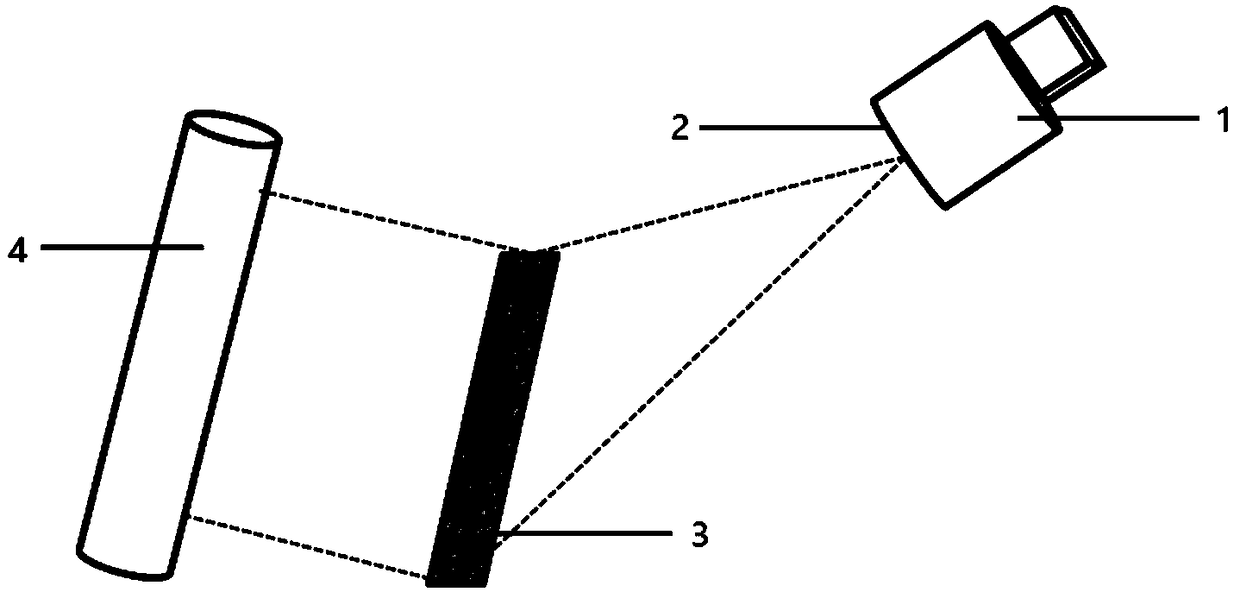

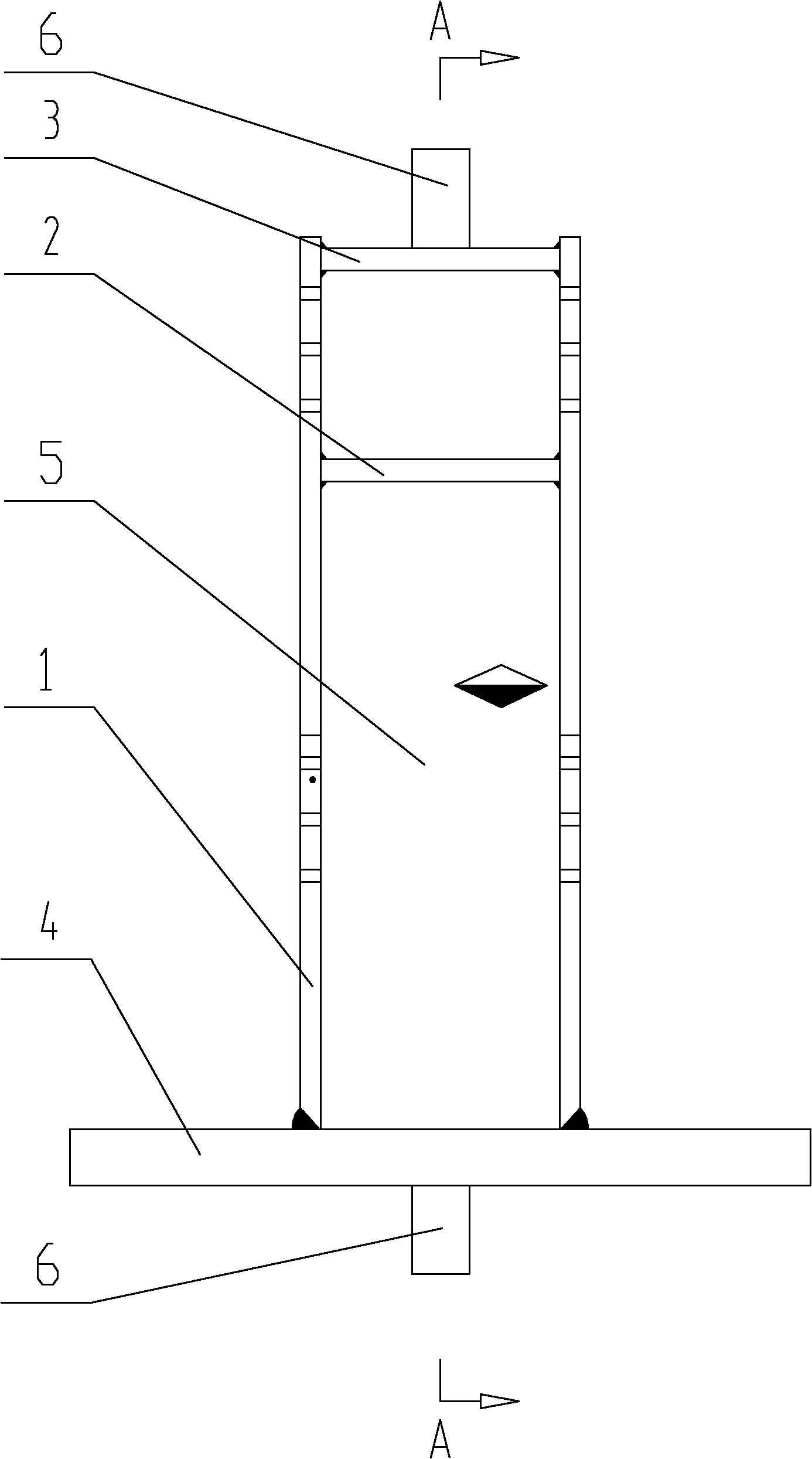

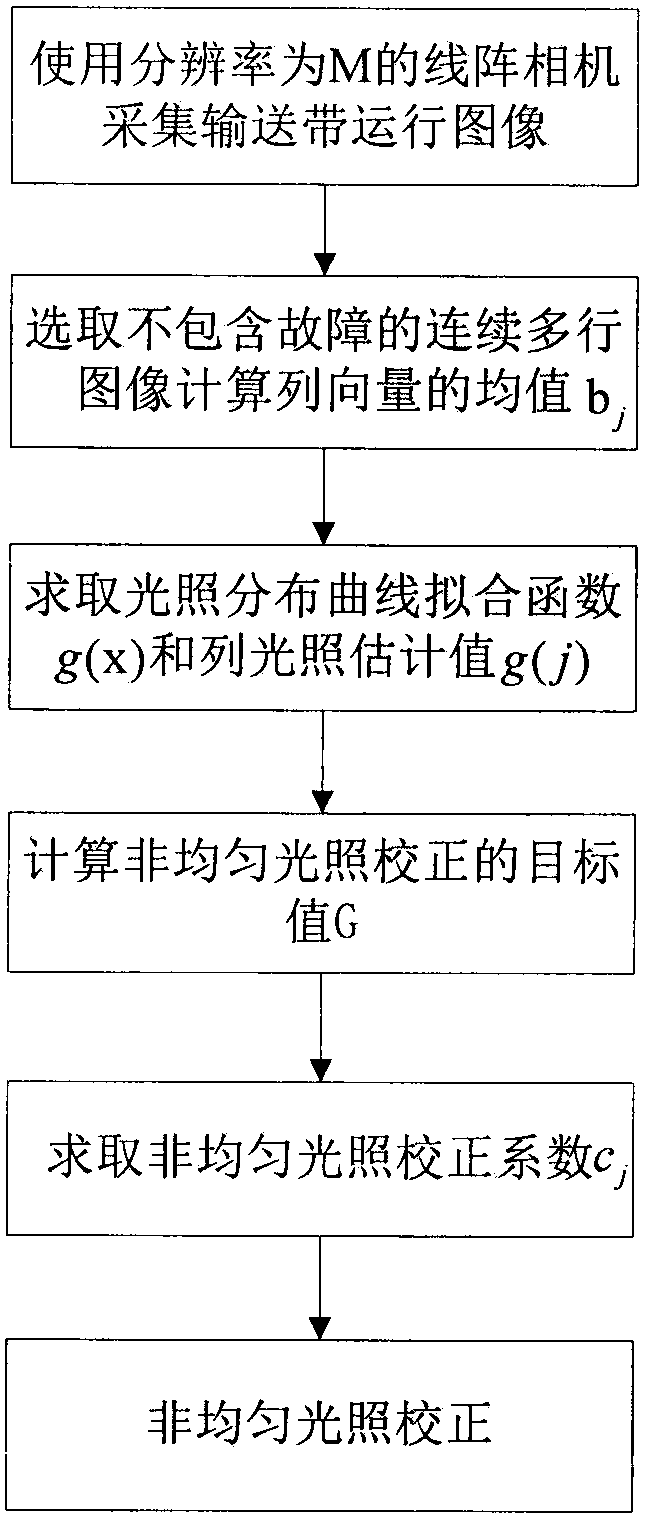

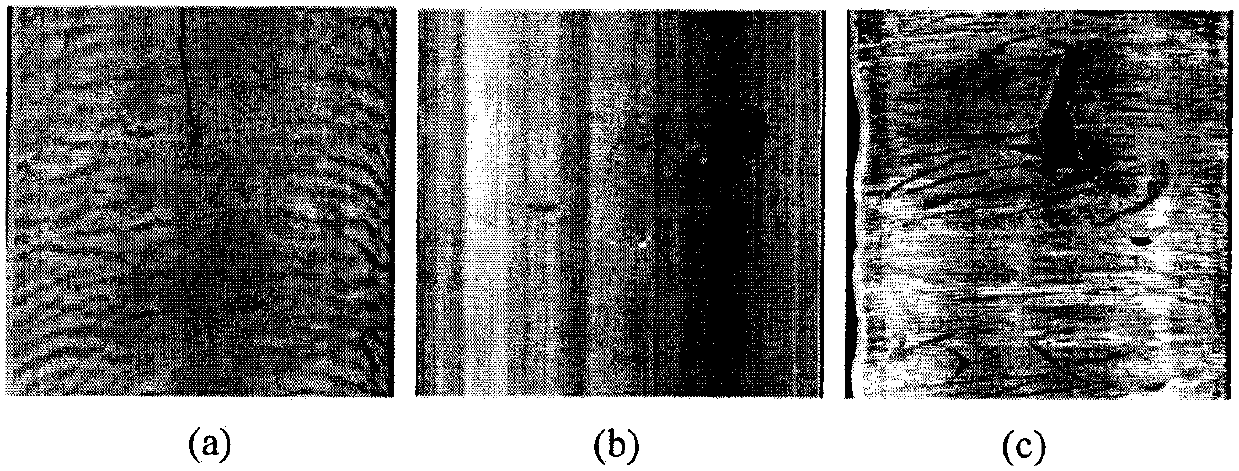

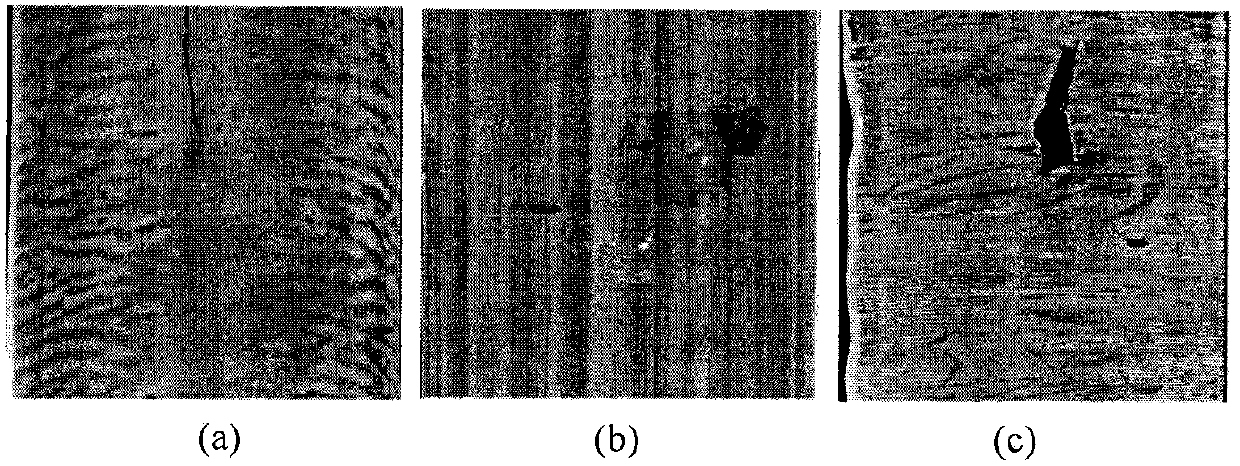

Correction method of non-uniform illumination images of online detection of conveyor belt faults

PendingCN107610116AThe calibration method is simpleReliable completionImage analysisFalse detectionCorrection method

The invention discloses a correction method of non-uniform illumination images of online detection of conveyor belt faults, and belongs to the field of fault detection. The method solves technical problems that illumination of the collected images is not uniform, image quality is poor, fault detection is impacted and missed detection or false detection of the faults is liable to be caused due to factors of conveyor belt surface geometry, light source lighting differences, light source placement positions, complex on-site environments and the like in online detection of the conveyor belt faults. According to the method, a linear-array camera is used to collect the conveyor belt running images, images, which does not contain the faults, of successive multiple rows are selected to calculate amean value of column vectors, then an illumination distribution curve fitting function and column illumination evaluation values are calculated, then a target value of non-uniform illumination correction and non-uniform illumination correction coefficients are calculated, and finally, non-uniform illumination correction is completed. The method of the invention is simple and fast, is suitable forfast correction of the non-uniform illumination images detected online by adopting the linear-array camera, and facilitates highly efficient and reliable completion of online detection of the conveyor belt faults.

Owner:TIANJIN POLYTECHNIC UNIV +1

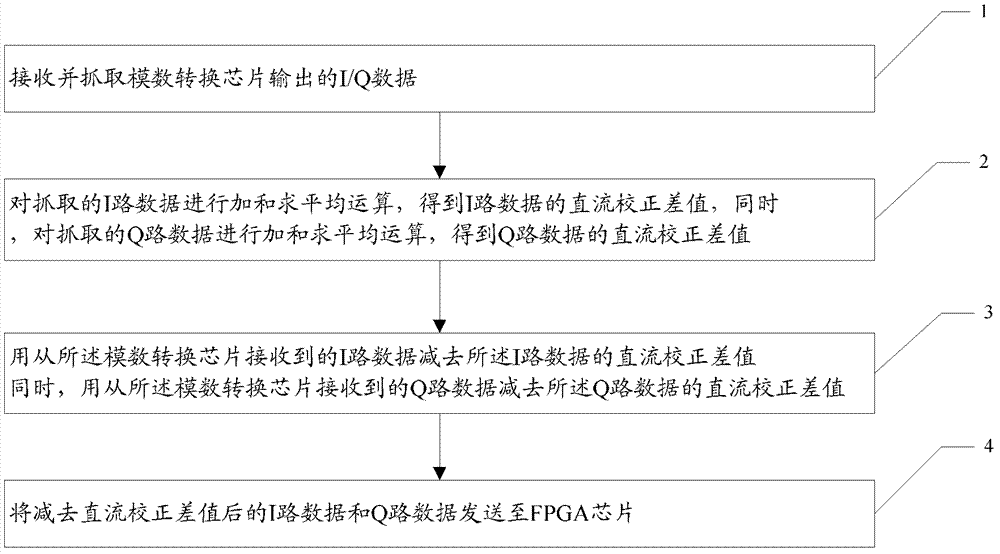

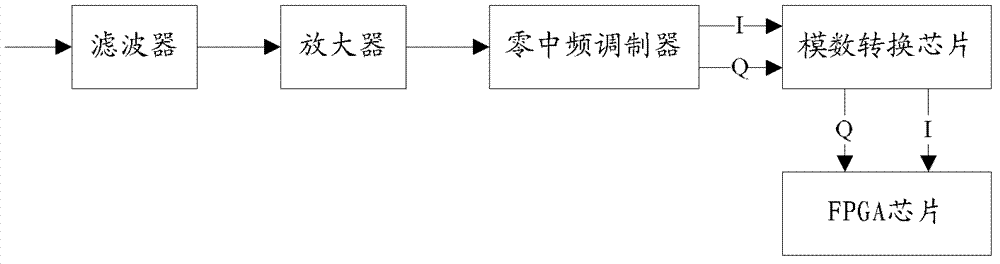

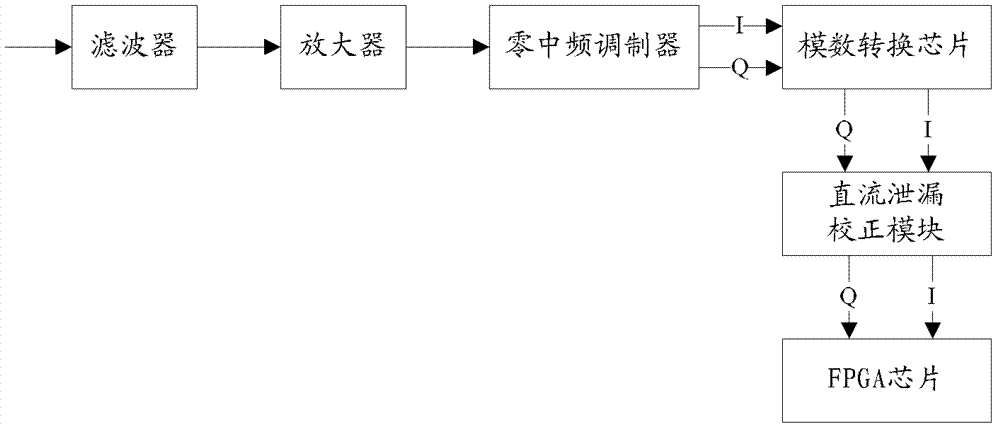

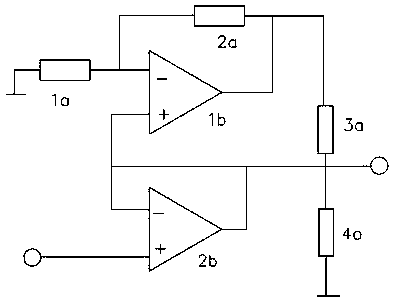

Zero intermediate frequency receiver and direct current leakage suppression method thereof

InactiveCN103095320AStrong real-timeThe calibration method is simpleDc level restoring means or bias distort correctionIntermediate frequencyCorrection method

The invention discloses a zero intermediate frequency receiver and a direct current leakage suppression method thereof. The zero intermediate frequency receiver direct current leakage suppression method includes: respectively grabbing I route data and Q route data output by a digital-to-analogue conversion (DAC) chip, then respectively computing weighted average values of the grabbed I route data and Q route data to obtain direct current leakage rectifying differences of the I route and the Q route, subtracting respective direct current leakage rectifying differences from the received I route data and Q route data, and namely finishing direct current leakage rectifying of the I / Q data. The rectifying difference values are calculated according to received data in real time and the real-time received data is rectified according to the rectifying difference values, so that the zero intermediate frequency receiver and the direct current leakage suppression method thereof are strong in real time, and the rectifying method is simple and effective.

Owner:COMBA TELECOM SYST CHINA LTD

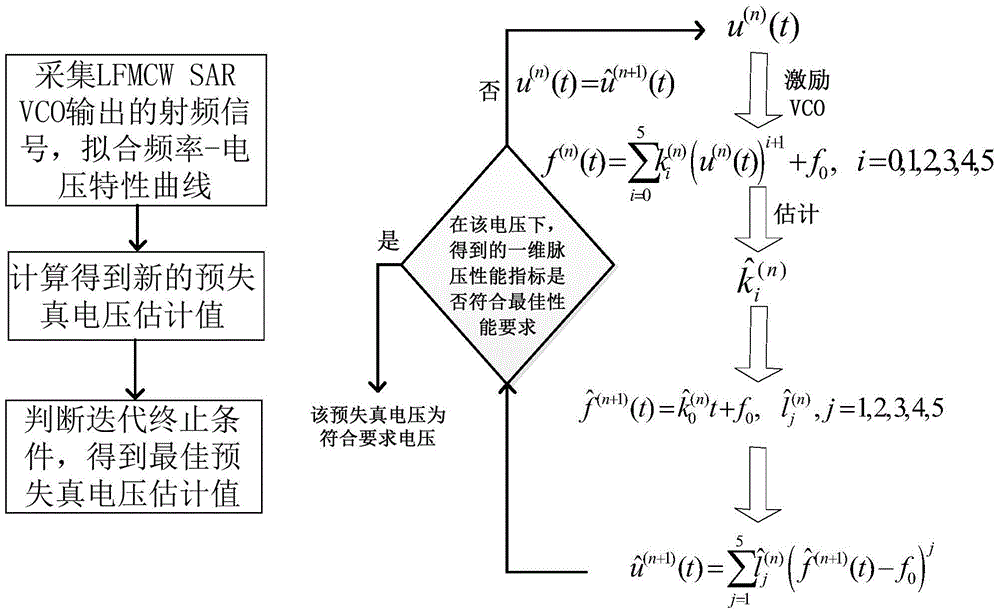

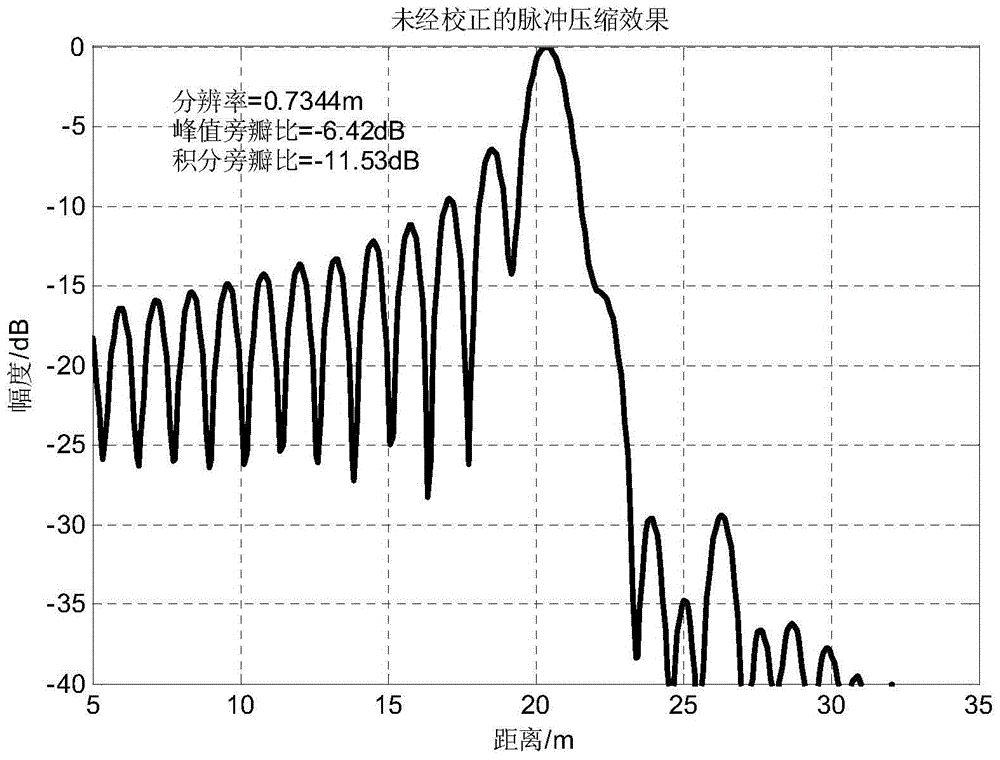

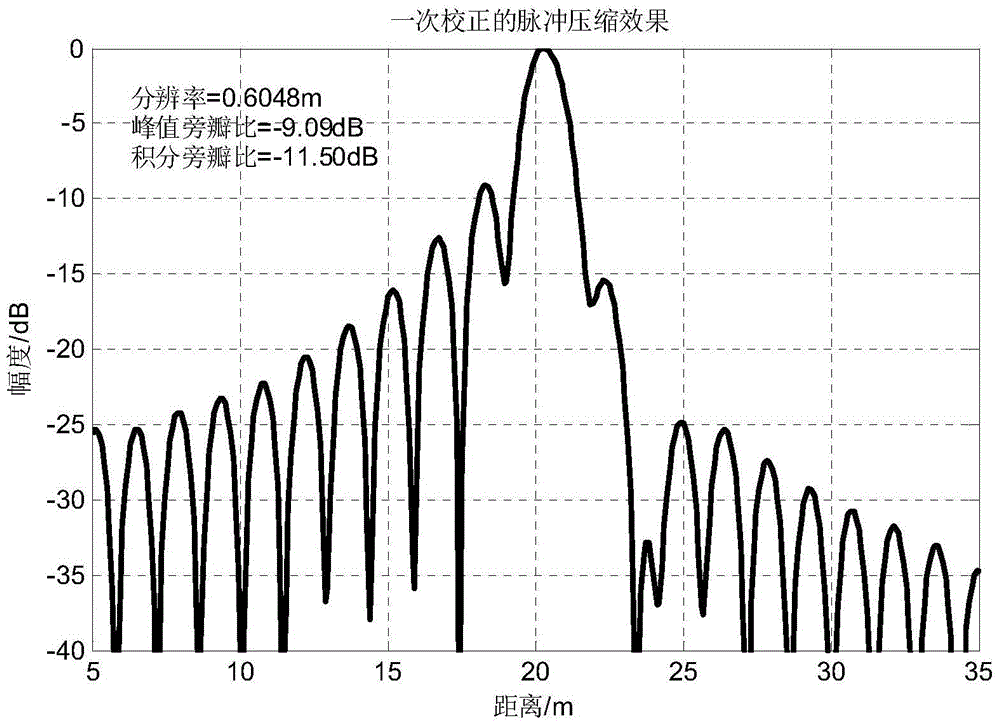

Open loop correction method for LFMCW SAR nonlinear error

ActiveCN104459653AEasy to implementReduce computationWave based measurement systemsLinearity errorError coefficient

The invention provides an open loop correction method for an LFMCW SAR nonlinear error. According to the technical scheme, an LFMCW SAR VCO signal containing the frequency modulation nonlinear error is collected and subjected to frequency modulation nonlinear analysis, in other words, fitting is performed on all-order error coefficients, the all-order error coefficients having been subjected to fitting are substituted into a frequency modulation nonlinear error correction model, and therefore corrected pre-distortion voltage data can be obtained, and whether pre-distortion voltage is optimal pre-distortion voltage or not can be judged by judging the iteration stopping condition. The correction method is easy to implement, computation burden of an algorithm is low, and pulse compression performance is remarkably improved after correction.

Owner:NAT UNIV OF DEFENSE TECH

Gamma correction system and gamma correction method

ActiveCN108182914BSave storage resourcesThe calibration method is simpleStatic indicating devicesGray levelComputer science

The invention provides a gamma correction system and a gamma correction method. The gamma correction method includes: acquiring the color coordinates and the brightness values of a R sub-pixel, a G sub-pixel, and a B sub-pixel; calculating the target brightness values of the R sub-pixel, the G sub-pixel, and the B sub-pixel according to the color coordinates and the brightness values of the R sub-pixel, the G sub-pixel, and the B sub-pixel, and calculating the brightness value of each sub-pixel at each grayscale according to the brightness value of each of the R sub-pixel, the G sub-pixel, andthe B sub-pixel; determining whether a difference between the brightness value of each sub-pixel of the R sub-pixel, the G sub-pixel, and the B sub-pixel at each grayscale and the target brightness value of each sub-pixel is smaller than a threshold corresponding to the sub-pixel; if so, storing the grayscale value and corresponding brightness value of the sub-pixel. The gamma correction method saves storage resources, greatly shortens correction time and improves correction efficiency.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

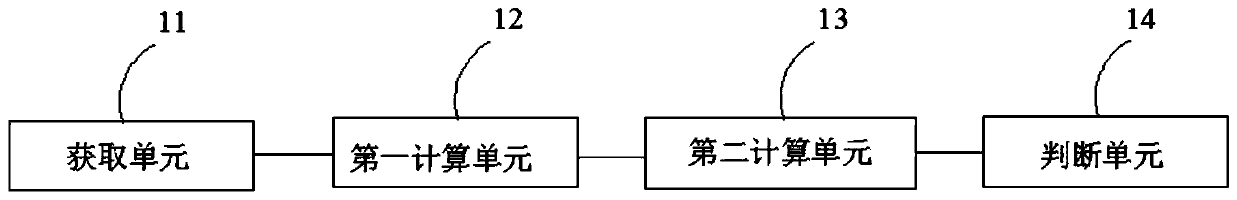

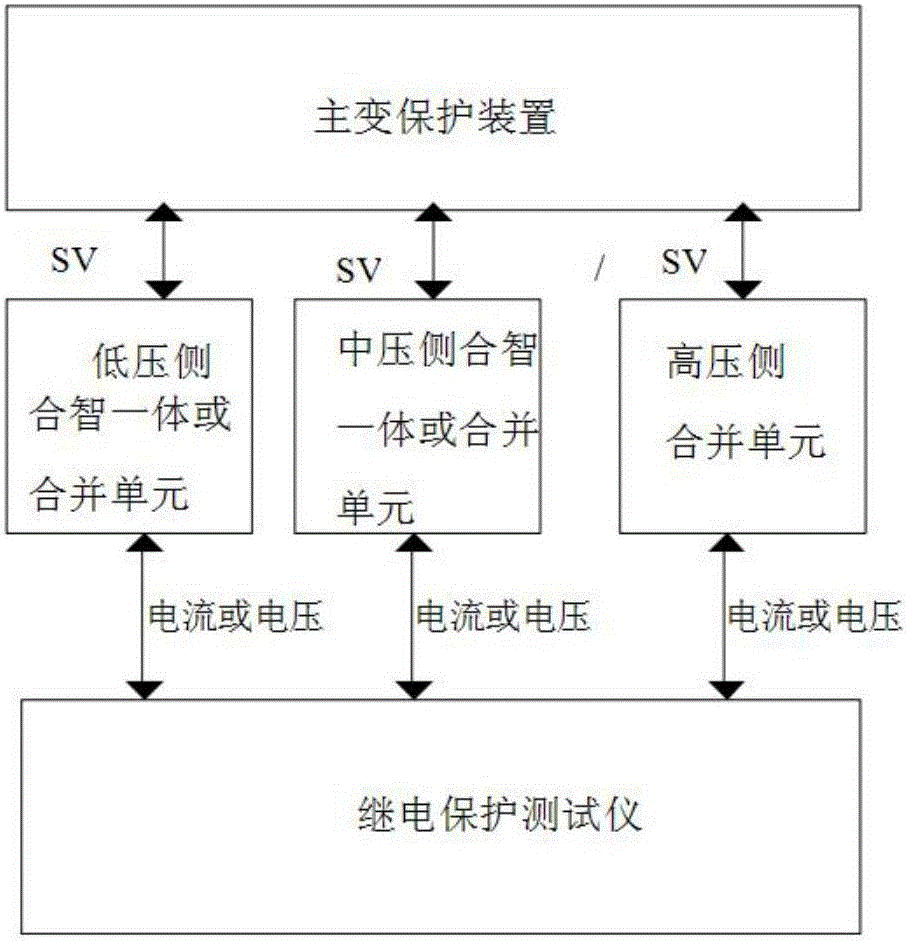

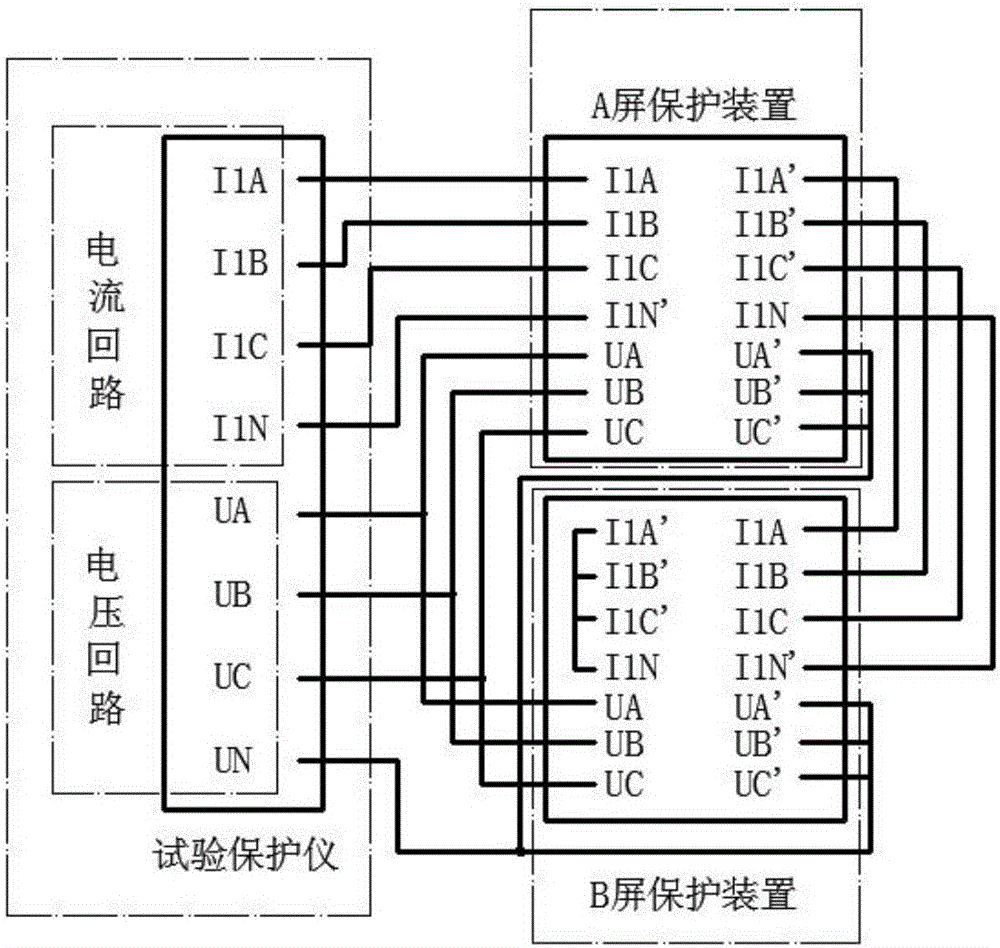

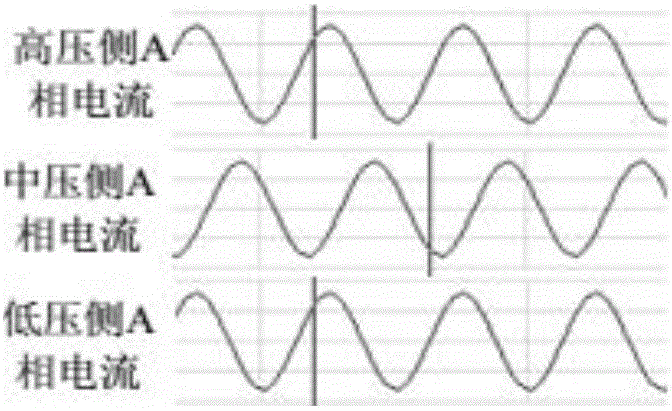

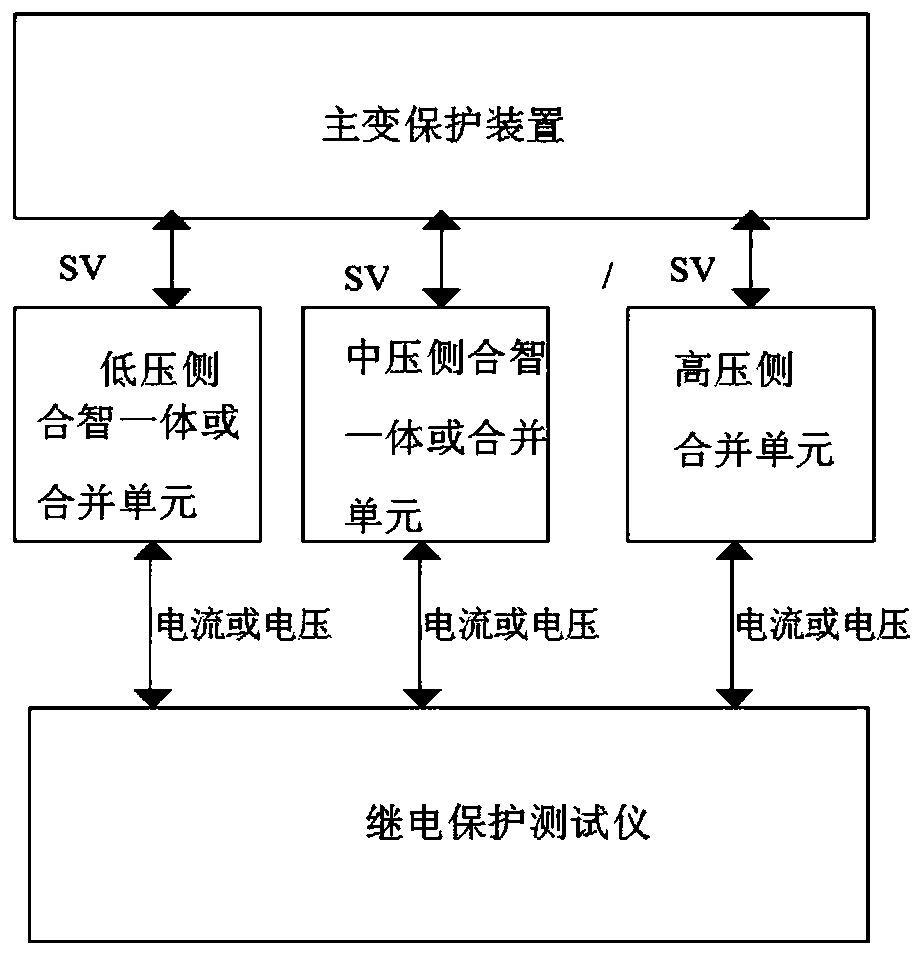

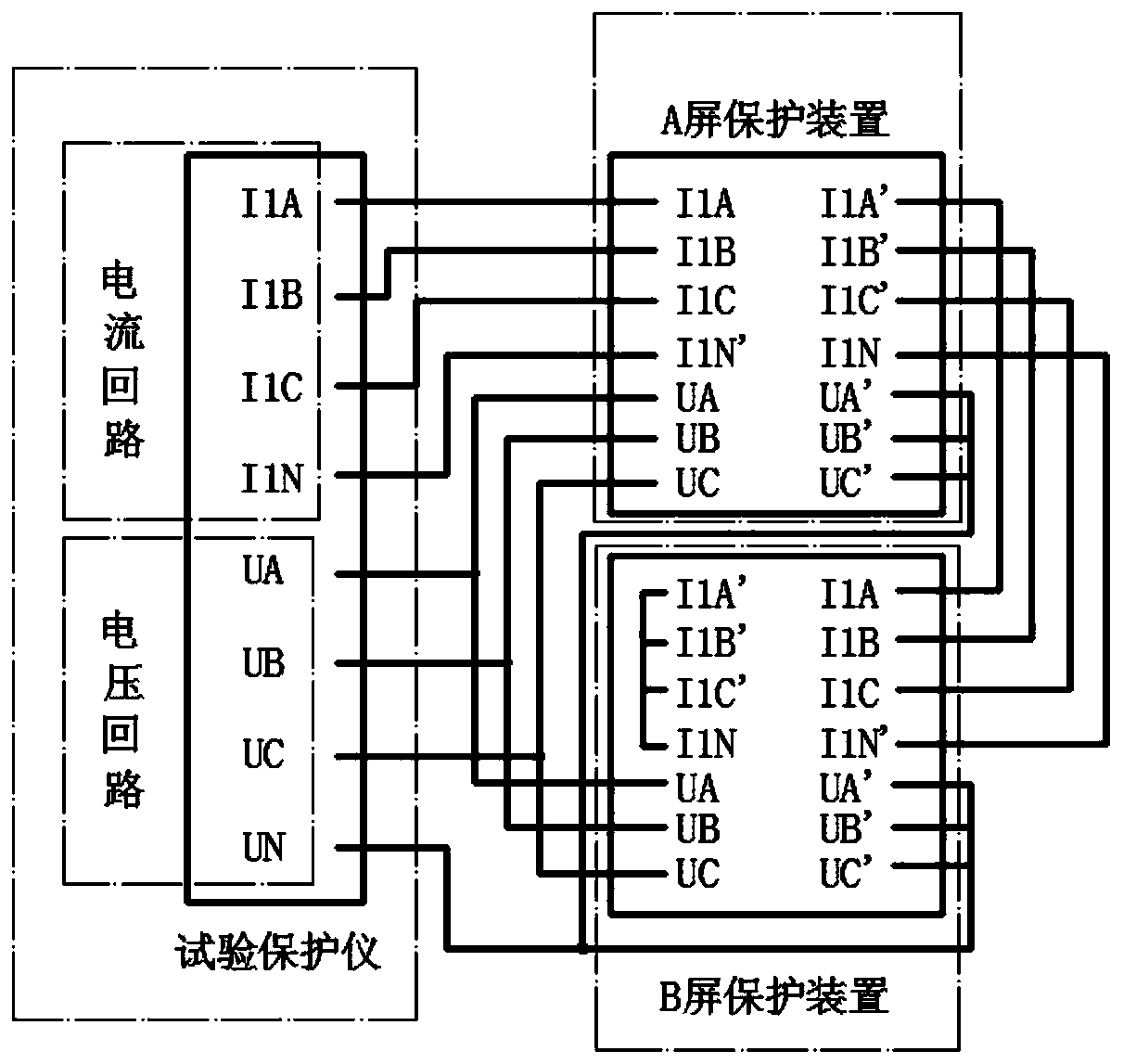

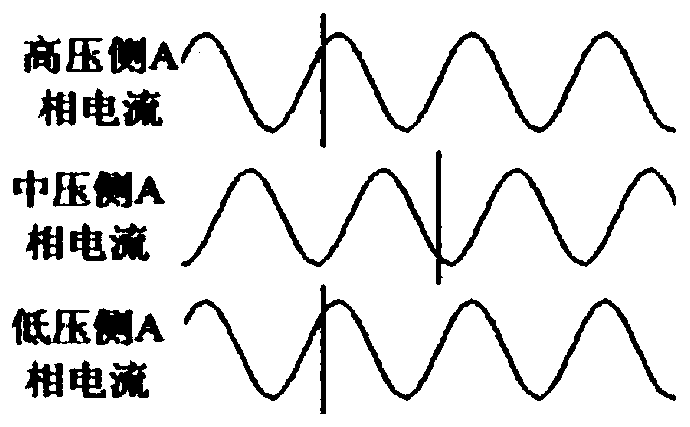

Site calibration method for solving delay problem among different combination units of intelligent substation

ActiveCN106451323AImprove stability and reliabilityGuaranteed correctnessEmergency protective arrangement detailsMethod of undetermined coefficientsSmart substation

Owner:TIANJIN ELECTRIC POWER TRANSMISSION & TRANSFORMATION ENG CORP +1

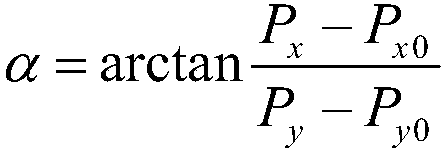

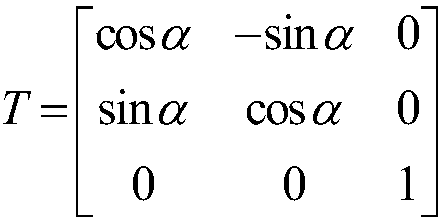

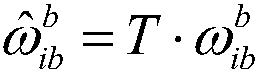

Walking micro-inertial navigation device azimuth installation deviation correcting method

ActiveCN109387220AImprove navigation and positioning accuracyEasy to operateMeasurement devicesAccelerometerInstallation Error

The invention belongs to the technical field of micro-inertial navigation systems, and specifically discloses a walking micro-inertial navigation device azimuth installation deviation correcting method, which comprises: after setting initial static conditions, determining the horizontal attitude information of a walking micro-inertial navigation device through the information of an accelerometer;carrying out state correcting on the walking micro-inertial navigation device; determining azimuth installation deviation; compensating the sampling value of the walking micro-inertial navigation device to obtain positioning error accumulation caused by the azimuth installation error, ie., the lateral displacement, such that the azimuth installation error is estimated; and correcting before inertial navigation solution. According to the present invention, the operation method is simple, the azimuth installation error is estimated accurately, the correcting method is easy to perform, and the navigation positioning precision of the walking micro-inertial navigation device can be effectively improved.

Owner:BEIJING AUTOMATION CONTROL EQUIP INST

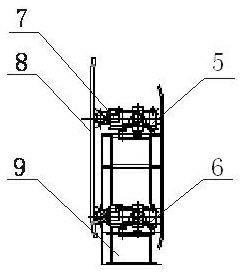

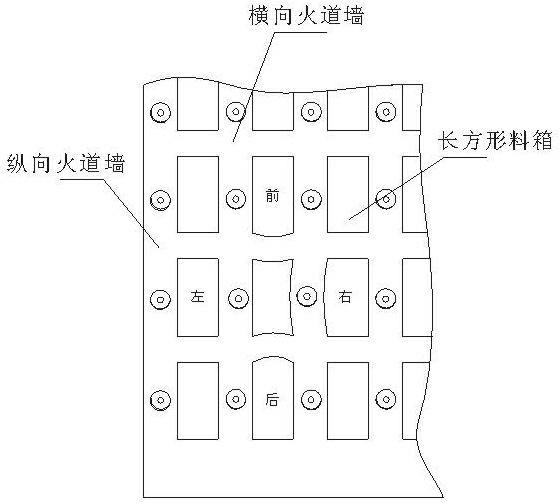

Method for correcting deformed fire path wall of roasting furnace

InactiveCN102435071APrevent springbackEliminate deformation stressFurnace componentsCorrection methodEngineering

The invention discloses a method for correcting a deformed fire path wall of a roasting furnace. The correcting method performs completely correction for the deformed area of the fire path wall on the basis of a designed wall-correcting machine. The wall-correcting machine consists of a cross wall pushing plate (1), a horizontal hydraulic cylinder (2), a hinge support seat (3), a machine frame (4), a longitudinal wall pushing plate (5), a lower longitudinal hydraulic cylinder (6), an upper longitudinal hydraulic cylinder (7), a wall protection plate (8) and a balancing weight (9), wherein the longitudinal wall pushing plate and the cross wall pushing plate of the wall-correcting machine are aligned to a convex surface of the deformed fire path wall and not aligned to a concave surface of the deformed fire path wall, therefore, a rectangular material box located by the convex surface of the deformed fire path all is the place where the wall-correcting machine is mounted; the interior of the rectangular material box is provided with two layers of carbon anode blocks and is uniformly paved with auxiliary materials in a layered manner; and the concave surface of the deformed fire path wall must be an empty box so as to contribute to correcting the deformed fire path wall. The method is simple and practical, has good effect, does not influence normal work, does not damage the deformed fire path wall and can obtain greater economic benefits to a user.

Owner:王国强 +1

A benchmark positioning method for ccd camera

ActiveCN104820978BDatum Positioning AchievementAchieve positioningImage analysisCamera lensCcd camera

The invention provides a reference positioning method for a CCD camera. The method corrects two CCD cameras at the same time. The first CCD camera and the second CCD camera are placed on a platform, and the lenses of the first CCD camera and the second CCD camera are perpendicular to each other. downward, and a certain distance from the platform; correct the verticality of the first CCD camera and the second CCD camera; place a horizontal ruler directly below the first CCD camera and the second CCD camera after correcting the verticality; Both a CCD camera and a second CCD camera capture the images of the spirit level, and transmit the images to a PC for processing, and adjust the position of the first CCD camera or the second CCD camera according to the processing results until the first CCD camera and the second CCD camera are completed. Correction of the relative positions of the two CCD cameras. The reference positioning method of the invention is simple and has high accuracy.

Owner:SHANXI DIMAI WOKE PHOTOELECTRIC IND CO LTD

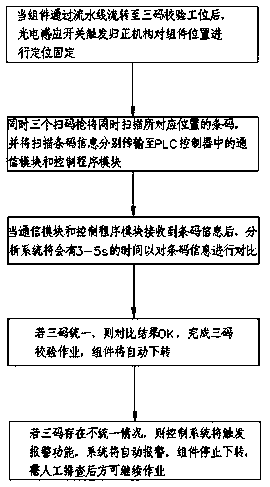

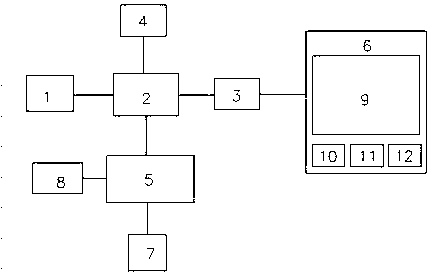

Photovoltaic module three-code automatic verification method

InactiveCN108649895AThe calibration method is simpleAvoid missing detectionPhotovoltaic monitoringPhotovoltaic energy generationHuman powerAssembly line

The invention discloses a photovoltaic module three-code automatic verification method. The photovoltaic module three-code automatic verification method comprises the following steps A, after a moduleis transferred to a three-code verification station through an assembly line, a photoelectric induction switch triggers a restoration mechanism to perform positioning and fixing on the module position; B, meanwhile, three code-scanning guns scan bar codes of the corresponding position at the same time, and transmit the bar code information to a communication module and a control program module ina PLC controller separately; and C, after the communication module and the control program receive the bar code information, an analysis system takes 3-5 seconds to perform bar code information comparison. The verification method disclosed in the invention is simple and capable of replacing manual examination and verification, avoiding leak detection, realizing 100% of examination and verification and ensuring unification of three codes of each module, meanwhile, improving operational automation, saving manpower, improving operation efficiency and achieving an excellent verification effect.

Owner:格润智能光伏南通有限公司

A method for calibrating a vehicle weighing system

ActiveCN110857883BRealize automatic calibrationDetect abnormalities in timeWeighing apparatus testing/calibrationWeight changeSimulation

The invention relates to a method for calibrating a driving weighing system, comprising: returning to zero, weighing at an initial position, weighing at a verification position, and weight compensation. The method for calibrating the weighing system of the traveling crane provided by the present invention utilizes the characteristic that the weight change of the steel wire rope used in the hook of the traveling crane has a linear relationship with the height to realize the automatic calibration of the weighing system of the traveling crane. The calibration method is simple and fast, It has high efficiency and does not affect production. It can detect the abnormality of the weighing system in time, and adjust it by human intervention in time to ensure the accuracy of the weighing system.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

An on-site verification method to solve the delay problem between different merging units in smart substations

ActiveCN106451323BGuaranteed correctnessImprove stabilityEmergency protective arrangement detailsSmart substationComputer science

The invention relates to a site calibration method for solving delay problem among different combination units of an intelligent substrate. The site calibration method comprises the steps of (1) analyzing a differential current size when delay is not consistent and analyzing influence of protection; (2) selecting a calibration method according to a delay analysis result, wherein the calibration method comprises a calibration method for that the delay difference of different combination units is a non-integer multiple of cycle wave and a calibration method for that the delay difference of different combination units is an integer multiple of cycle wave. By the method, the inconsistent conditions of the combination units at each side are classified and separately discussed, a new calibration method for inconsistent delay of the combination units at each side and a calibration method of a dual-configuration protection device, which are corresponding to different conditions, are proposed on the basis, and the method has the characteristics of high practicability, simplicity and the like, and is easy to operate.

Owner:TIANJIN ELECTRIC POWER TRANSMISSION & TRANSFORMATION ENG CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com