Method for correcting deformed fire path wall of roasting furnace

A calibration method and fire channel wall technology, which are applied to furnaces, furnace components, lighting and heating equipment, etc., can solve the problems of multiple corrections of deformed fire channel walls, high labor intensity, and low user acceptance, and achieve the calibration method. Simple and practical, good effect, great economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The invention relates to a method for correcting the deformed flue wall of a roasting furnace.

[0025] Before narrating the correcting method of the present invention, the relevant nouns involved in the roasting furnace are defined as follows:

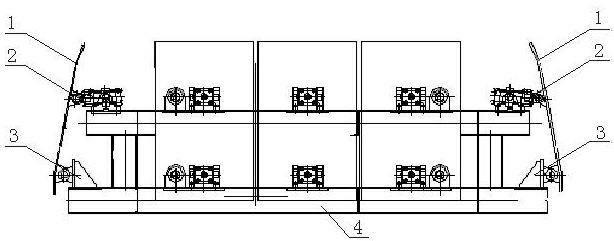

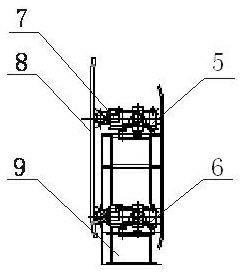

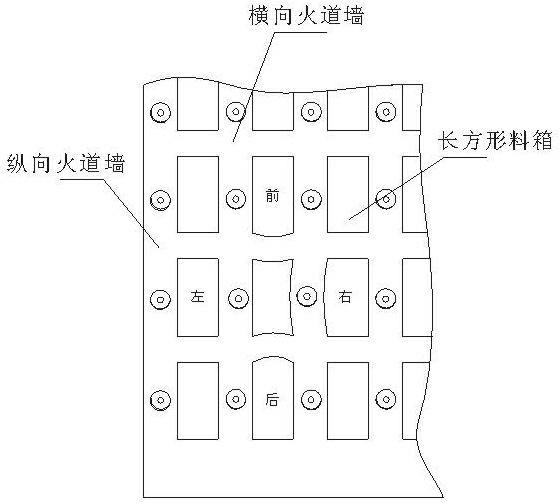

[0026] combine image 3and Figure 4 , the roasting furnace is equipped with N (N is a natural integer) longitudinal flue walls with equal intervals and parallel to each other. From left to right, the distance between the first longitudinal flue wall and the second longitudinal flue wall is called fire Road, the second longitudinal fire path wall and the third longitudinal fire path wall are divided into several rectangular material boxes with equal volume by two parallel and equal length horizontal fire channel walls, the long side of the rectangular material box is set is C meters, the short side of the rectangular material box is set as K meters, and the depth or height of the rectangular material box is set as G meters. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com