Patents

Literature

126 results about "Cross wall" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A cross-wall is an interior dividing wall of a castle. It may be an external wall dividing, for example, the inner and outer wards, or it may be a wall internal to a building such as the keep.

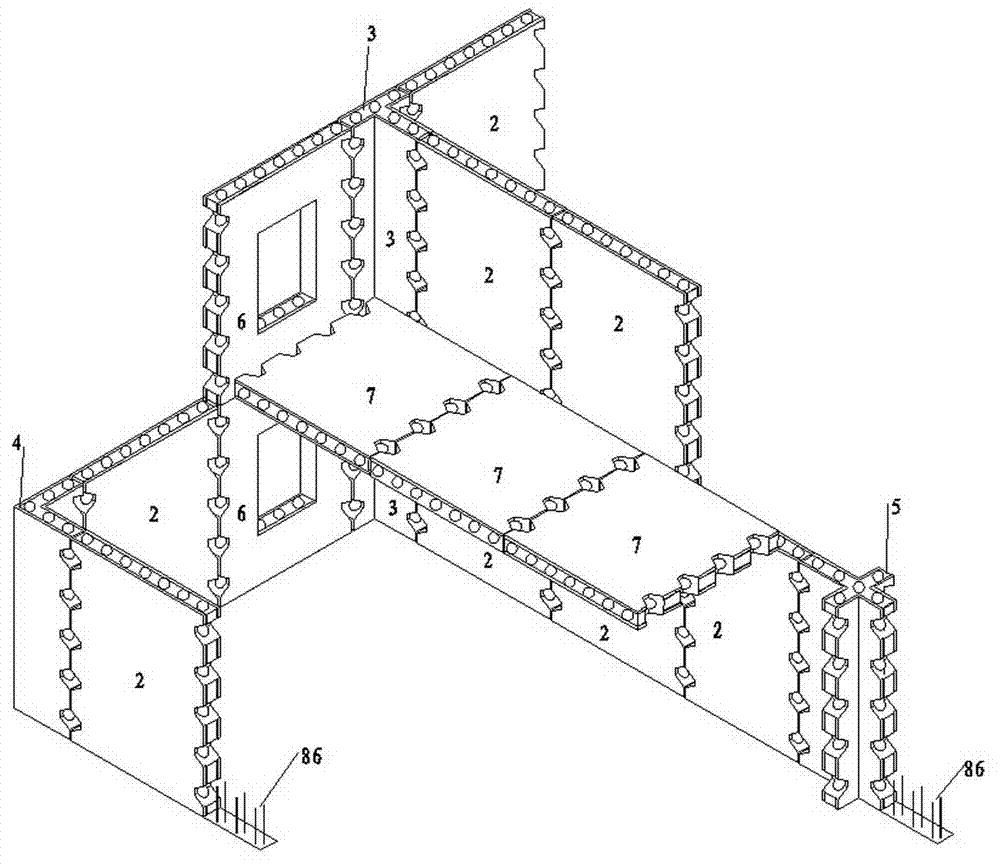

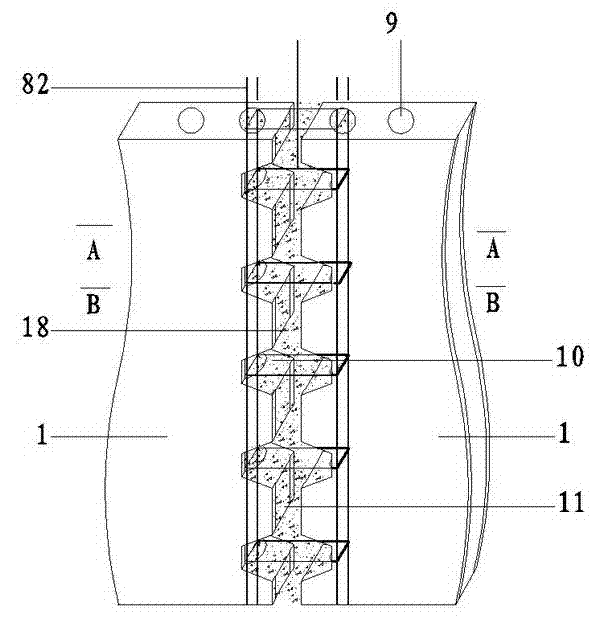

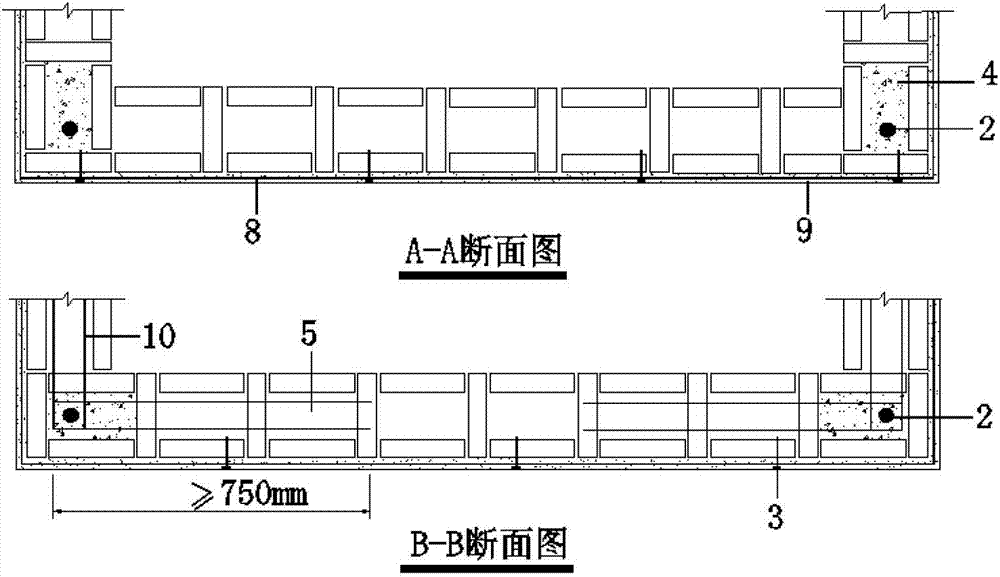

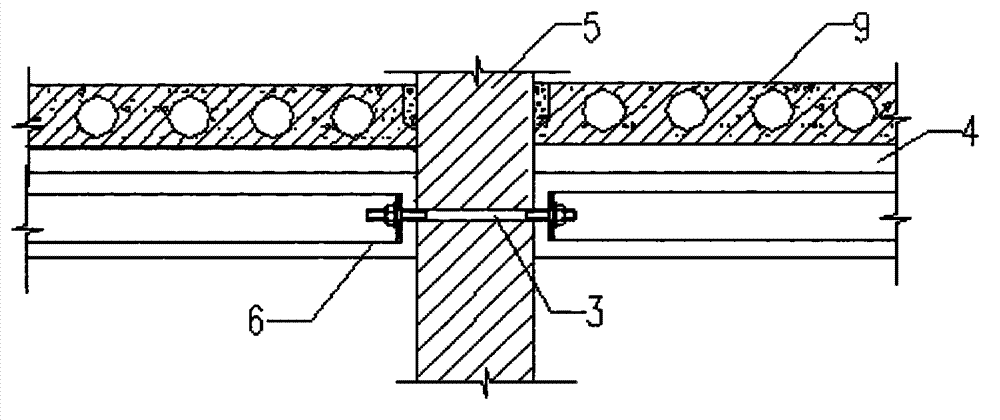

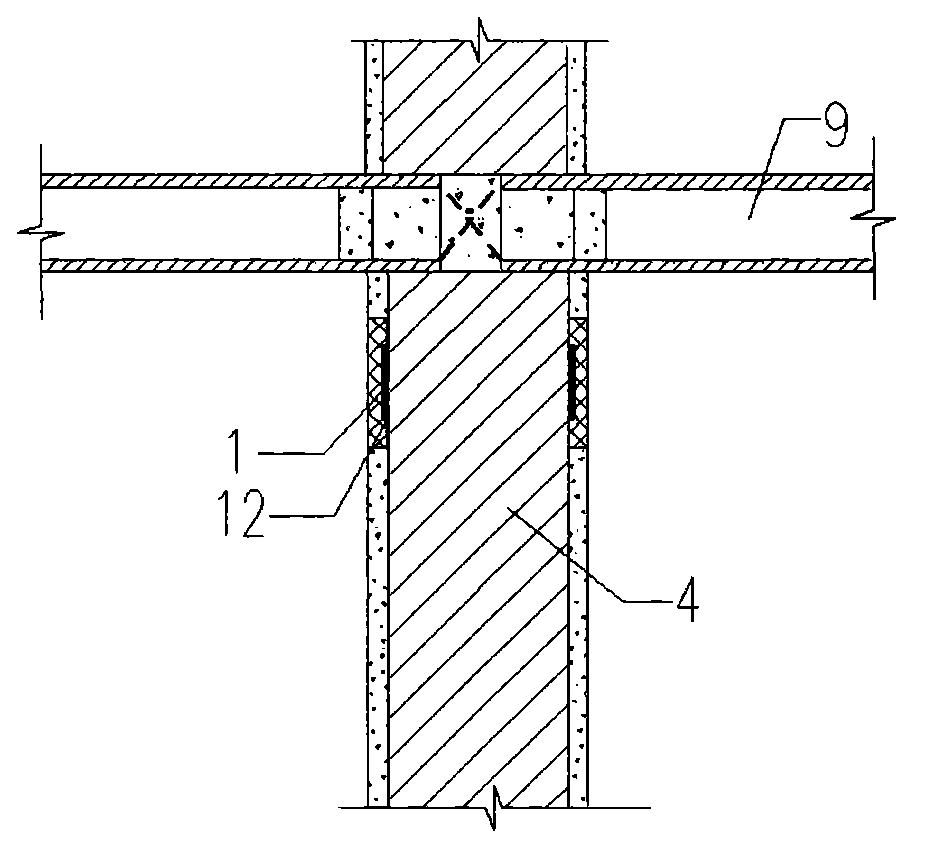

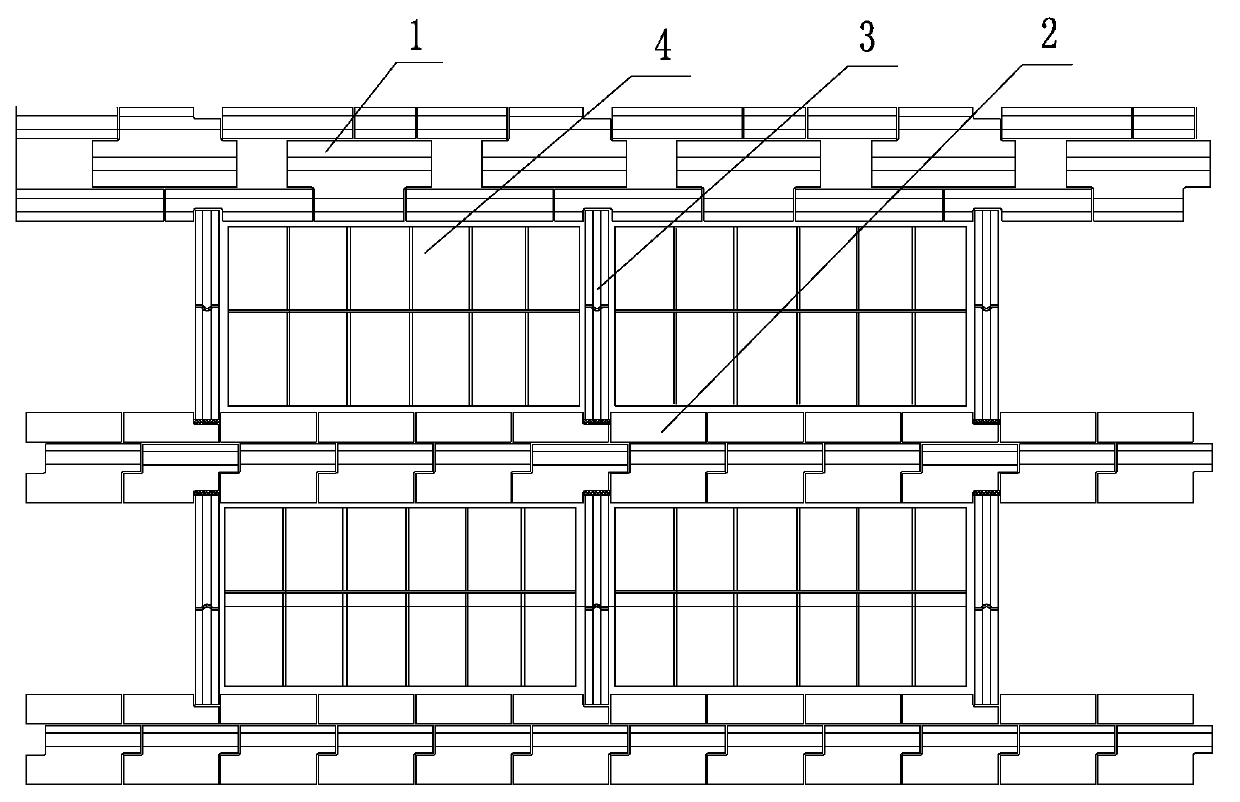

Assembled monolithic shear wall building structure and construction method thereof

InactiveCN102808450AImprove the level of industrializationIncrease productivityConstruction materialWallsTransverse grooveCross wall

The invention relates to an assembled monolithic shear wall building structure and a construction method thereof, and belongs to the technical field of buildings and construction thereof. The assembled monolithic shear wall building structure is formed by connecting prefabricated concrete members which comprise a prefabricated wall plate member, a floor member, a T-shaped wall column member, an L-shaped wall column member, a cross wall column member and a wall member with an opening. The structure is characterized in that a plurality of longitudinal through holes which are parallel to the surface are formed in each prefabricated concrete member; transverse grooves crossed with at least one longitudinal hole are formed on the longitudinal edge at intervals; transverse anchoring steel bars are arranged at the transverse grooves among different prefabricated members; longitudinal anchoring steel bars are arranged in the longitudinal holes; a layer of structural unit or a single-layer building structure is formed by filling concrete in the longitudinal holes and the transverse grooves; and a plurality of structural units are connected to form a multi-layer or high-rise assembled monolithic shear wall structure. The structure can be used in a multi-layer or high-rise shear wall building structure and a frame-shear wall building structure, the industrial level of the building structure can be improved, stress performance is improved, and resources are saved.

Owner:初明进

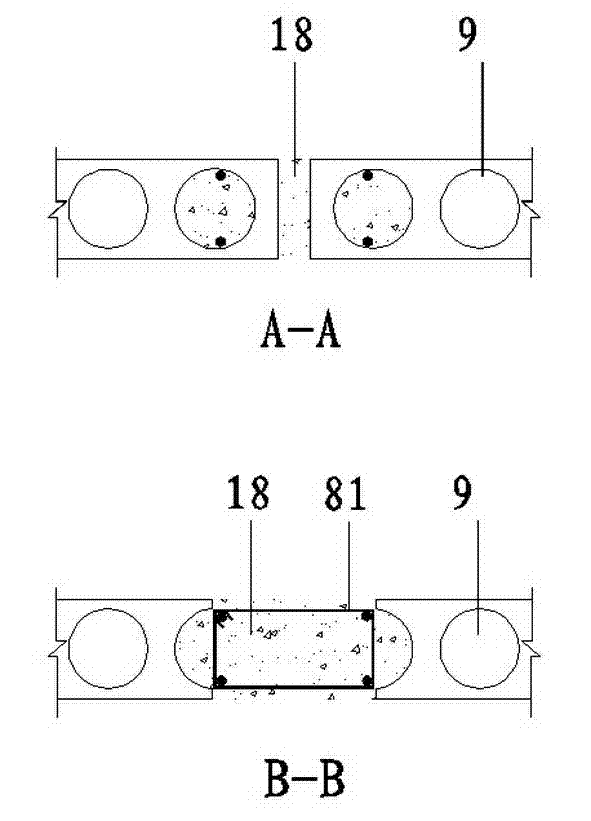

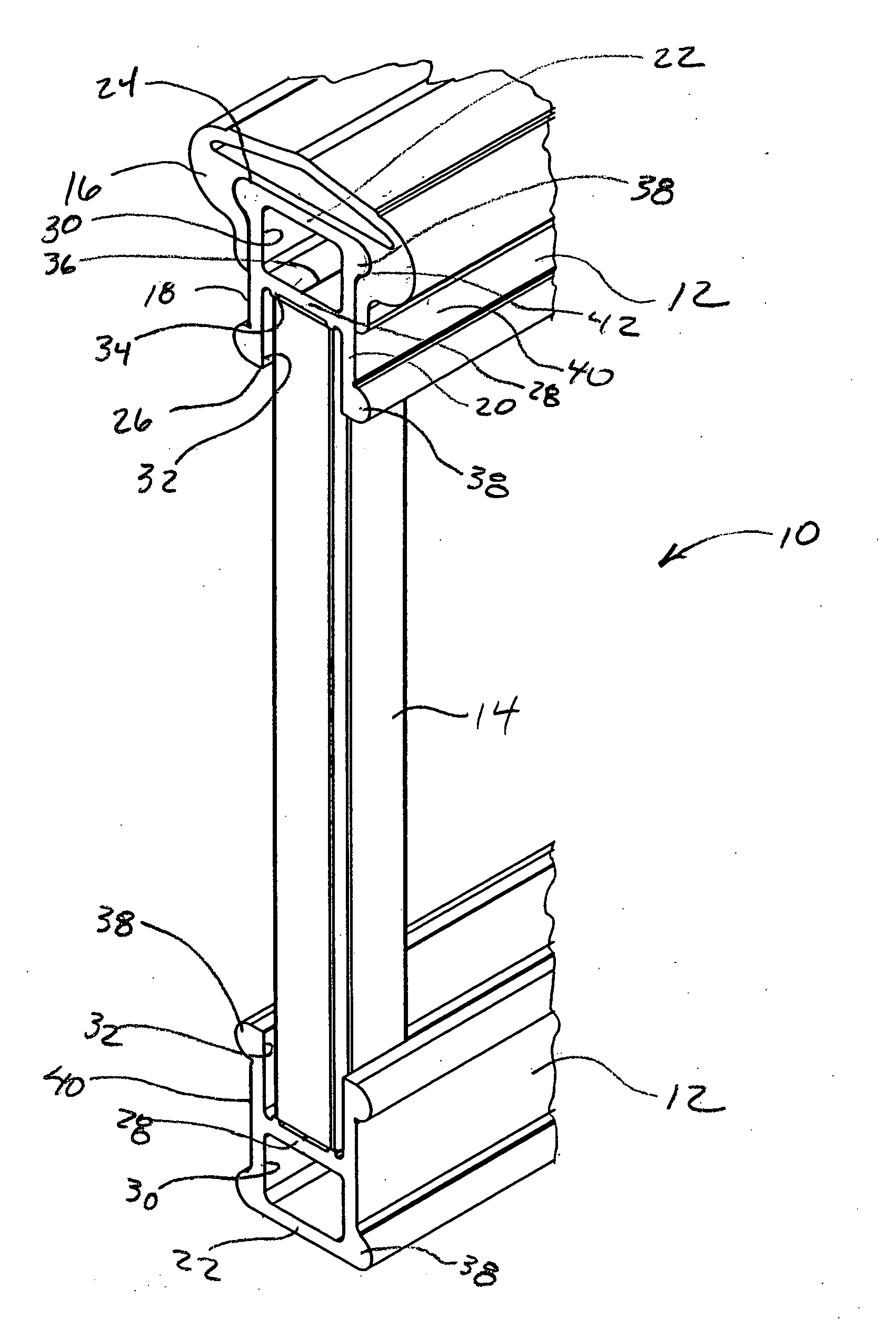

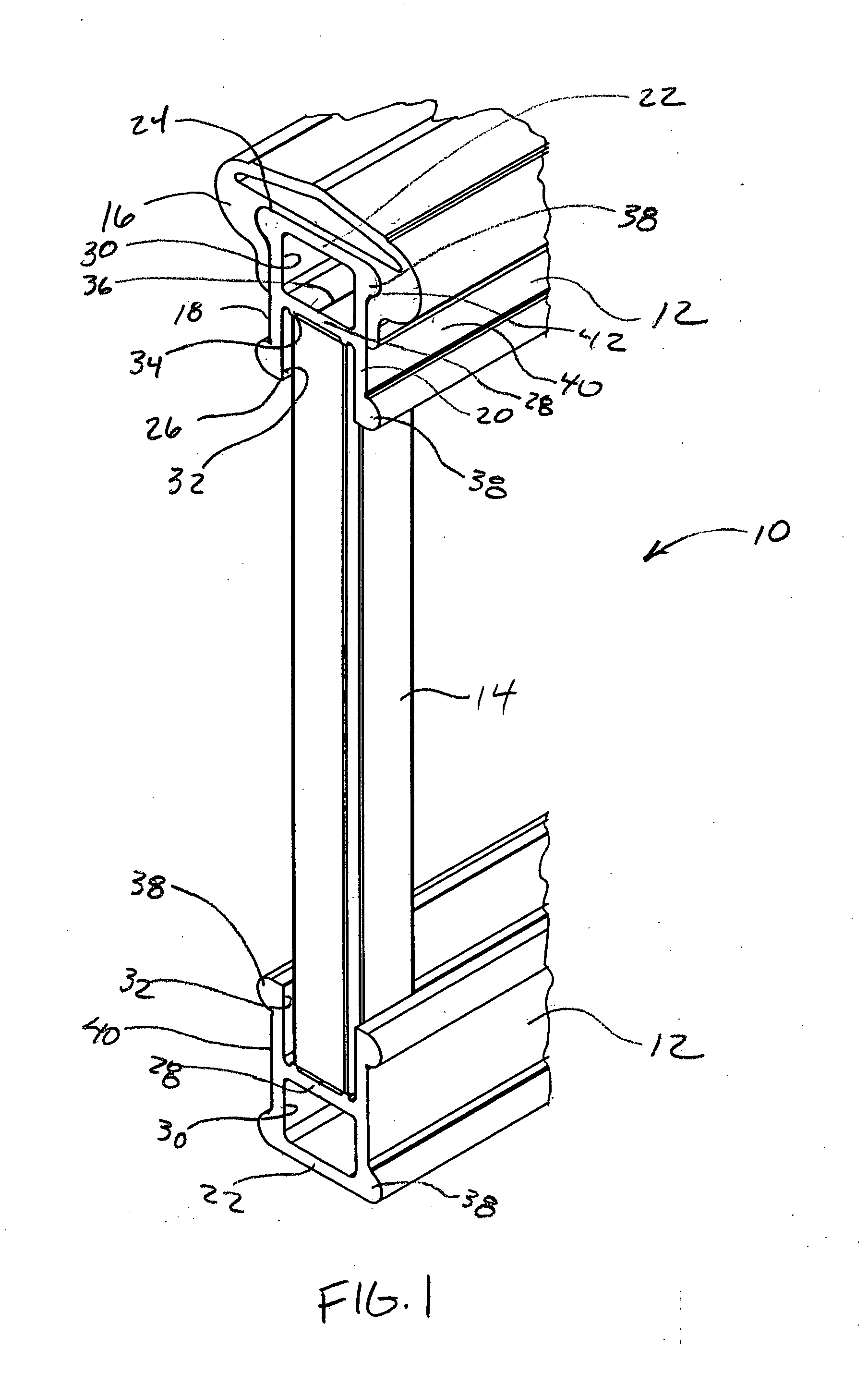

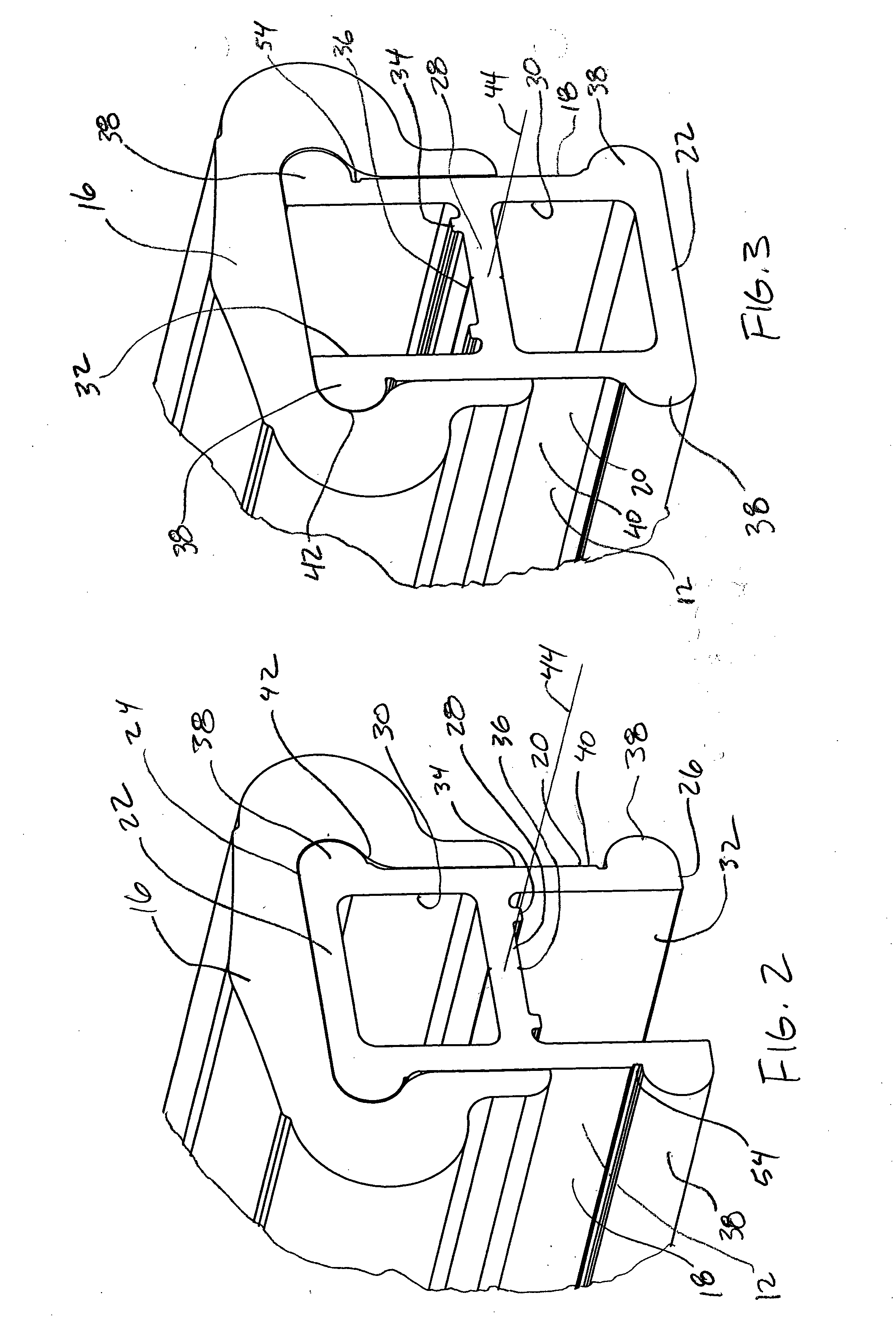

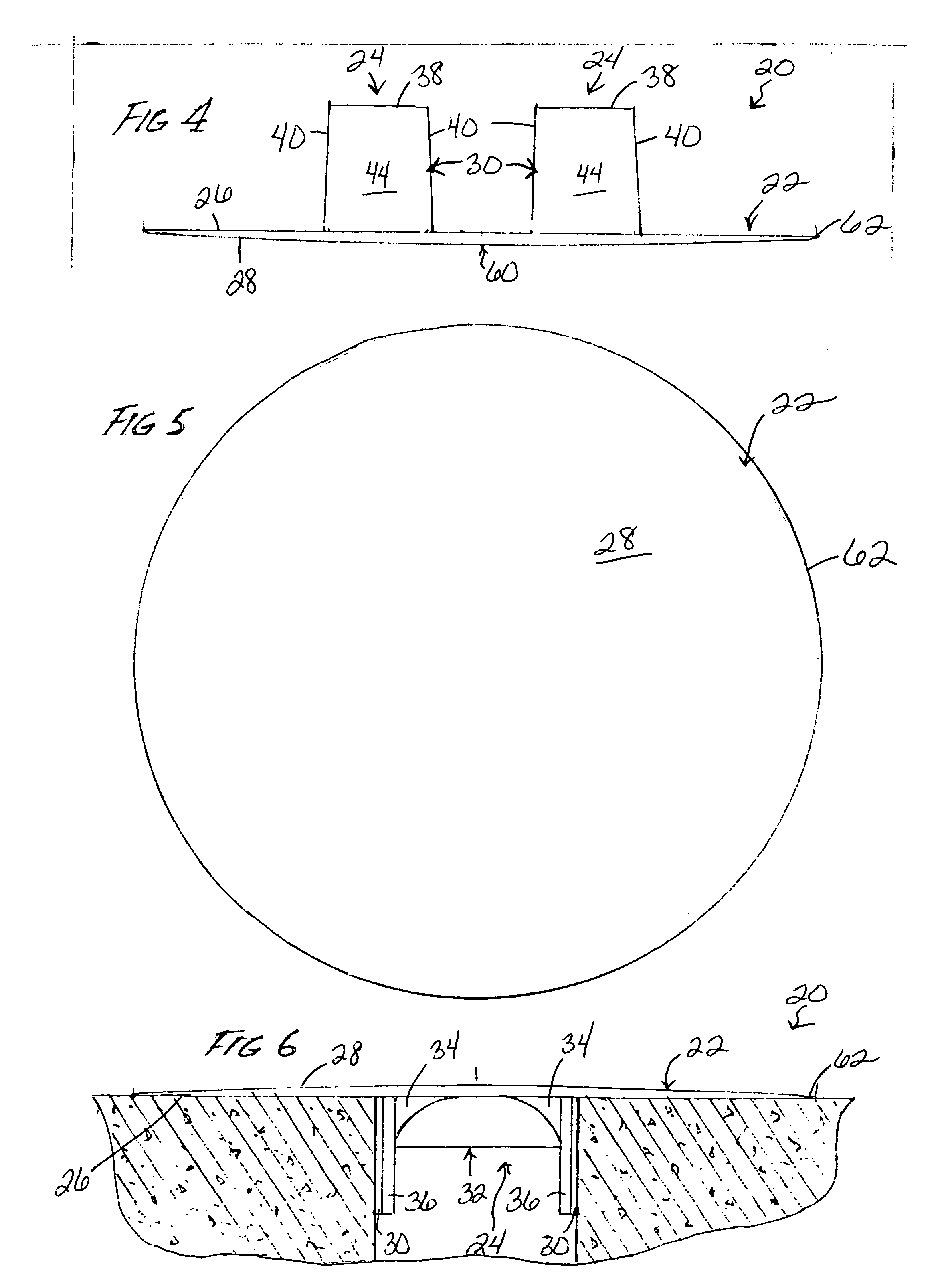

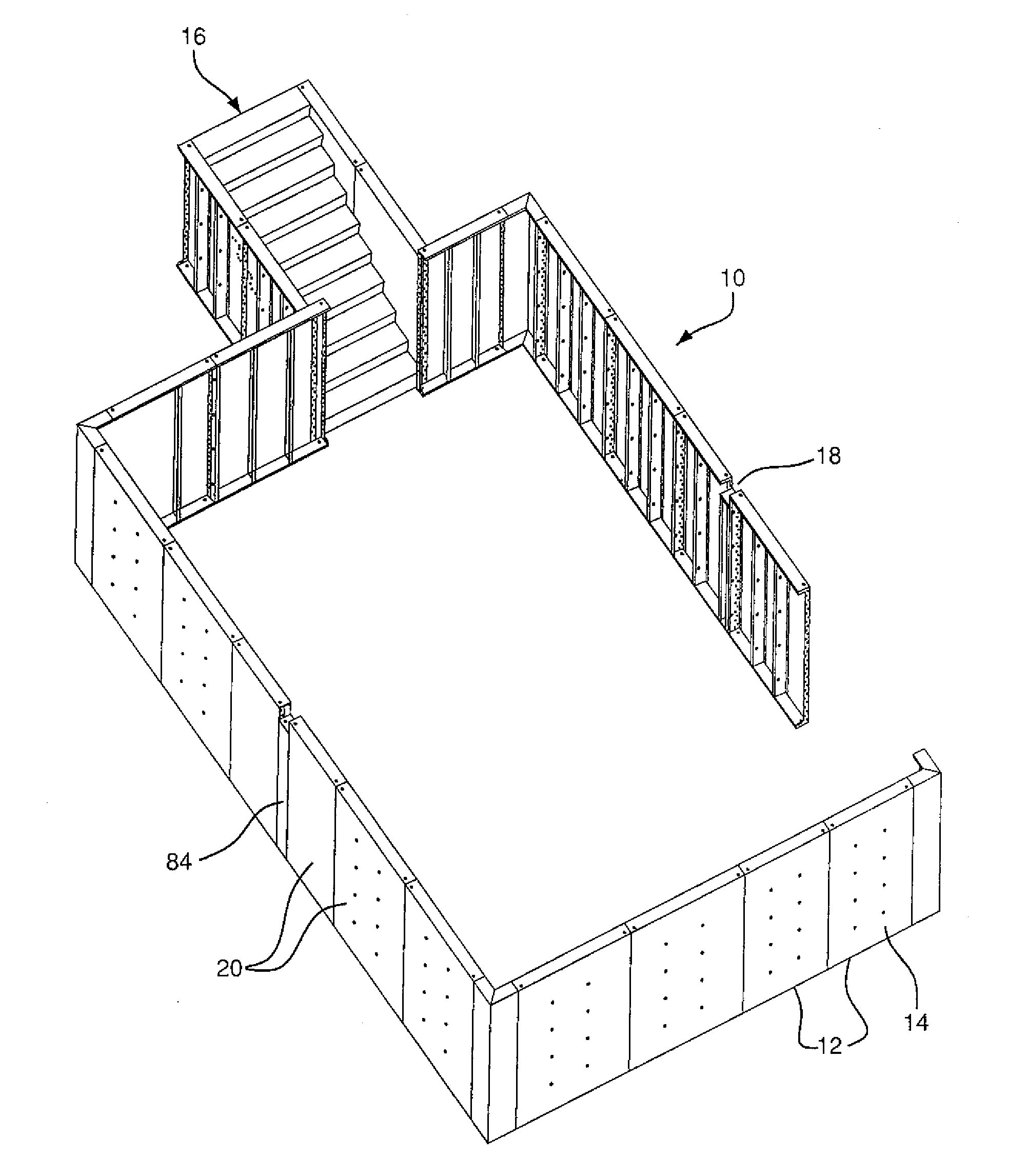

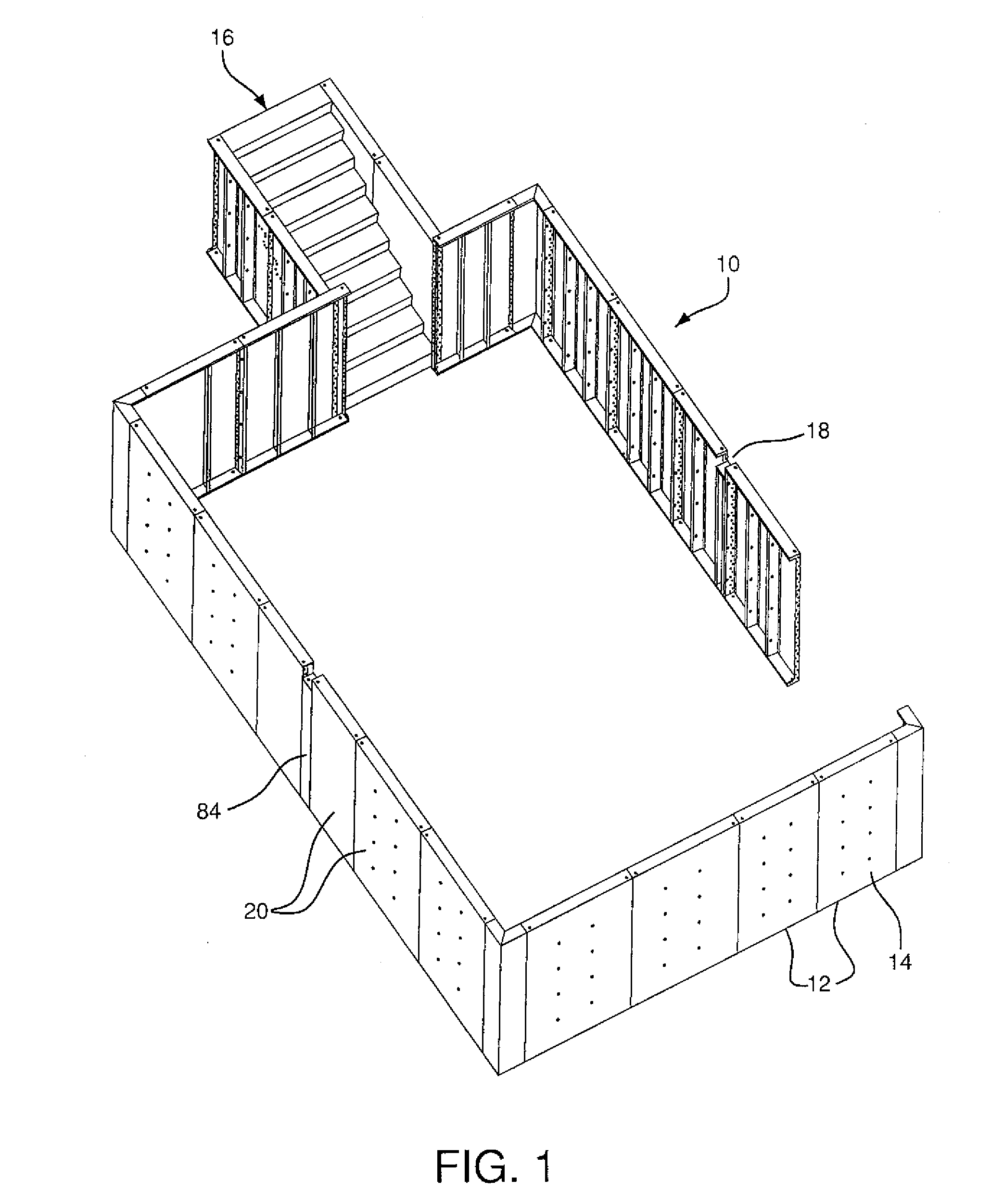

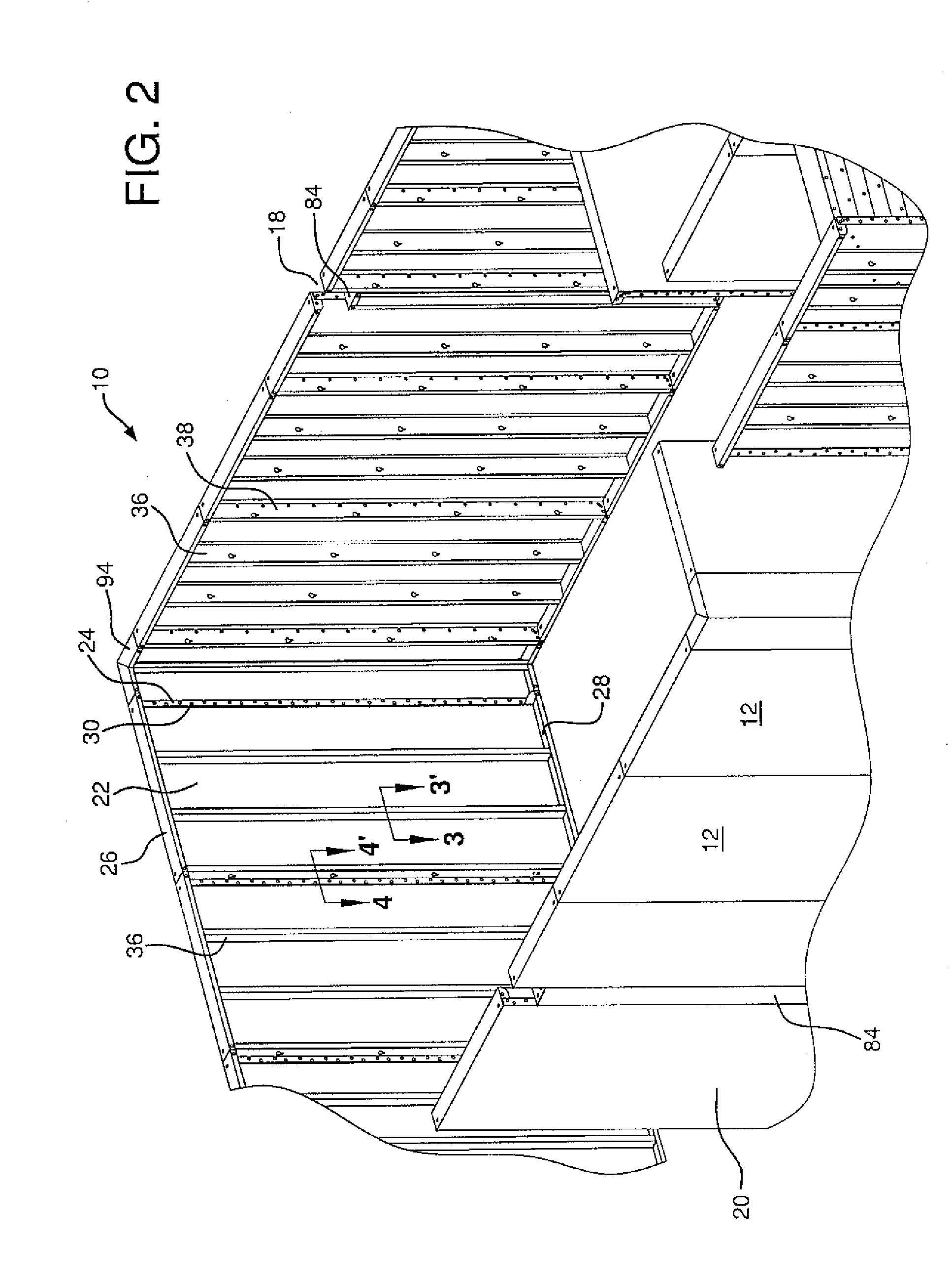

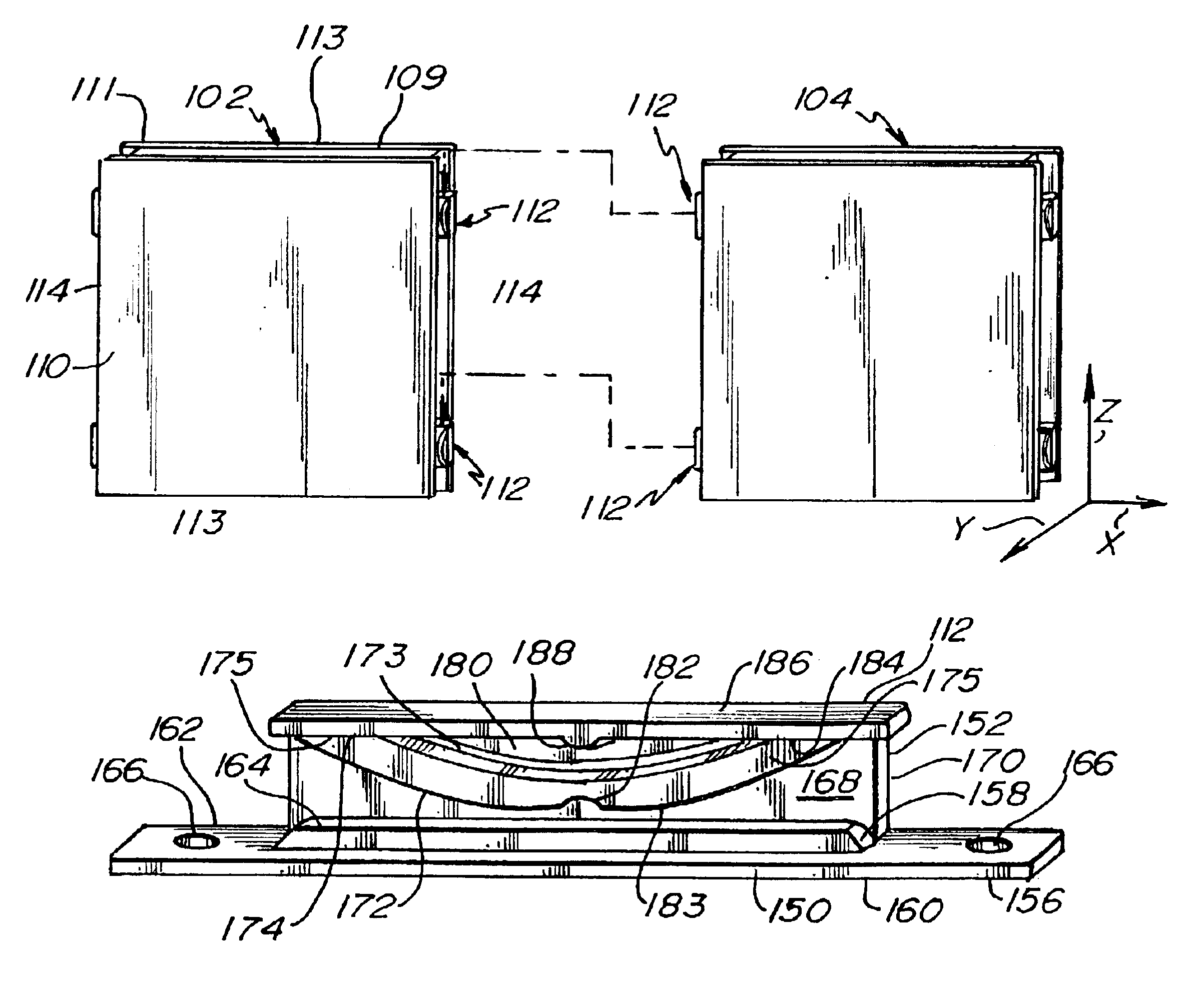

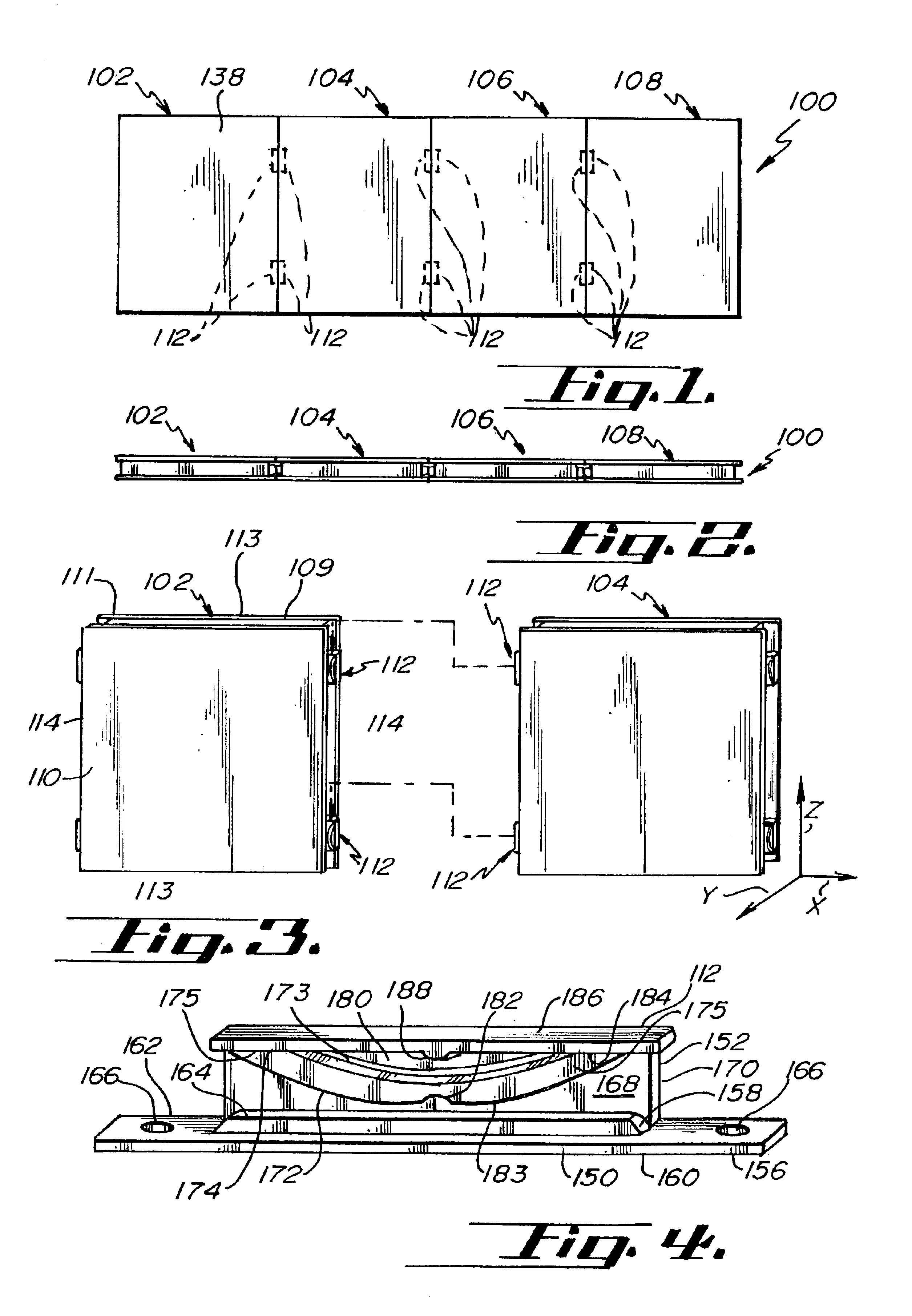

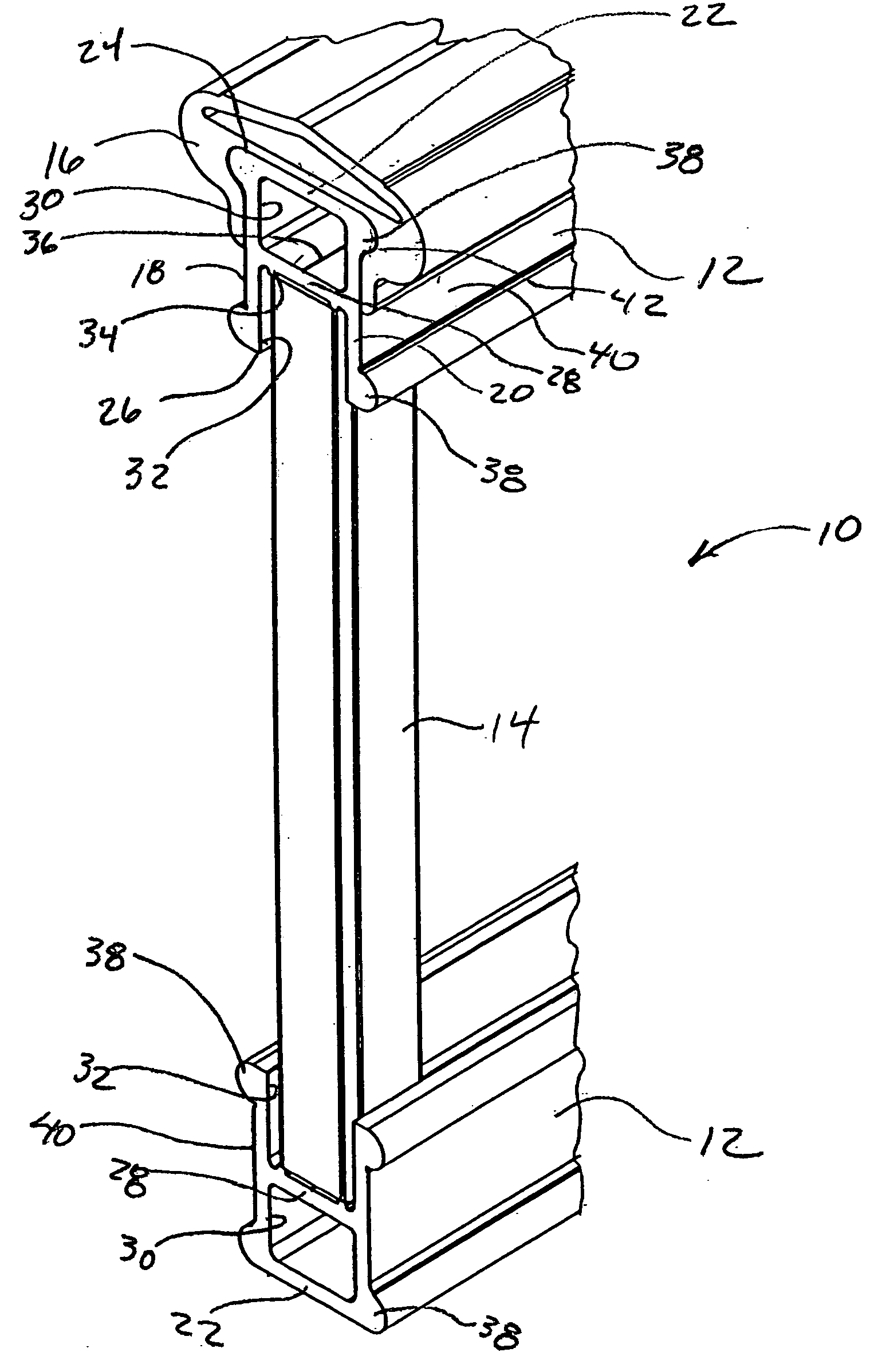

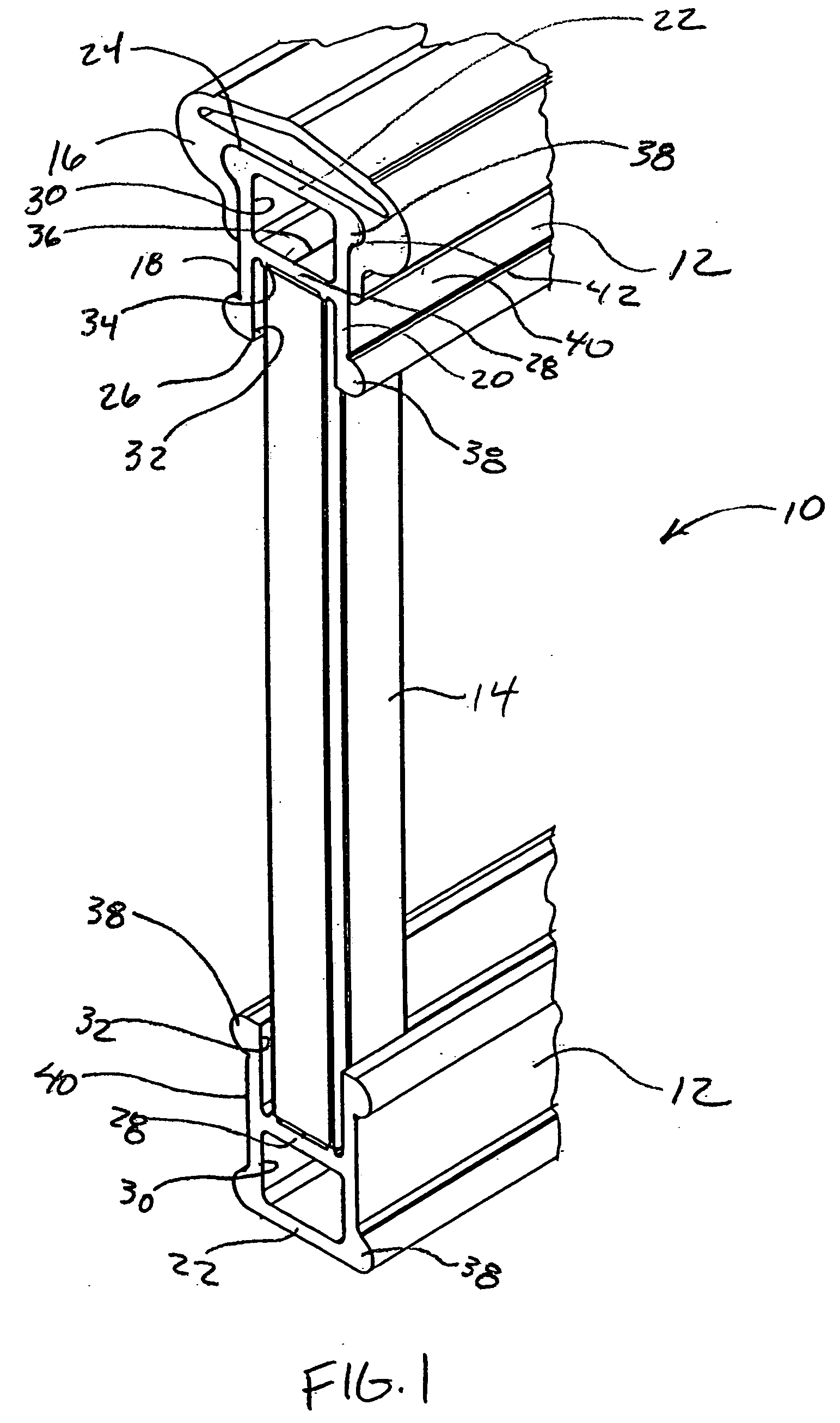

Multi-position rail for a barrier

A rail is disclosed for use in forming a barrier system, such as a railing for a deck, porch, walkway or fence. The rail has a versatile configuration in that either a top or bottom side of the rail may be received in a rail cover. The rail may have side walls and a cross wall on the top or bottom side of the rail. A channel may be formed on the side of the rail opposite the cross wall. Upright members, such as pickets, planks, balusters, or walls may be received in either the top side or the bottom side of the rail, in the channel or through the cross wall. A cap having openings for receiving the upright member may be placed on the channel. The rail may be positioned on the top or bottom of the barrier system and the rail may be symmetrical to provide an aesthetically pleasing appearance.

Owner:KROY BUILDING PROD

Cover for pockets in precast concrete panels

ActiveUS7441375B2Provide supportImprove adhesionFoundation engineeringForms/shuttering/falseworksCross wallPrecast concrete

Owner:MEADOW BURKE

Ceramic armor and method of making by encapsulation in a hot pressed three layer metal assembly

Owner:BAE SYST ADVANCED CERAMICS

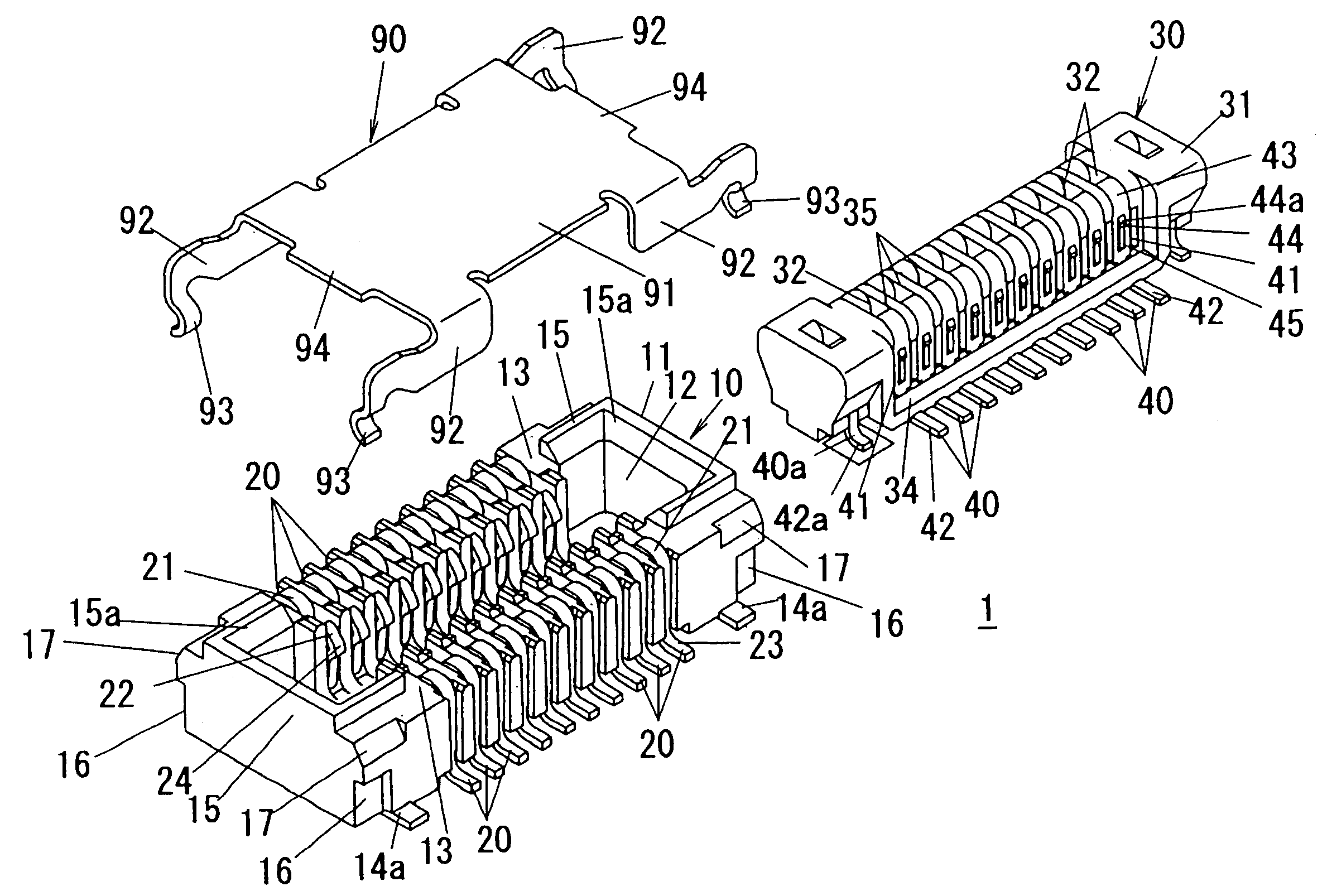

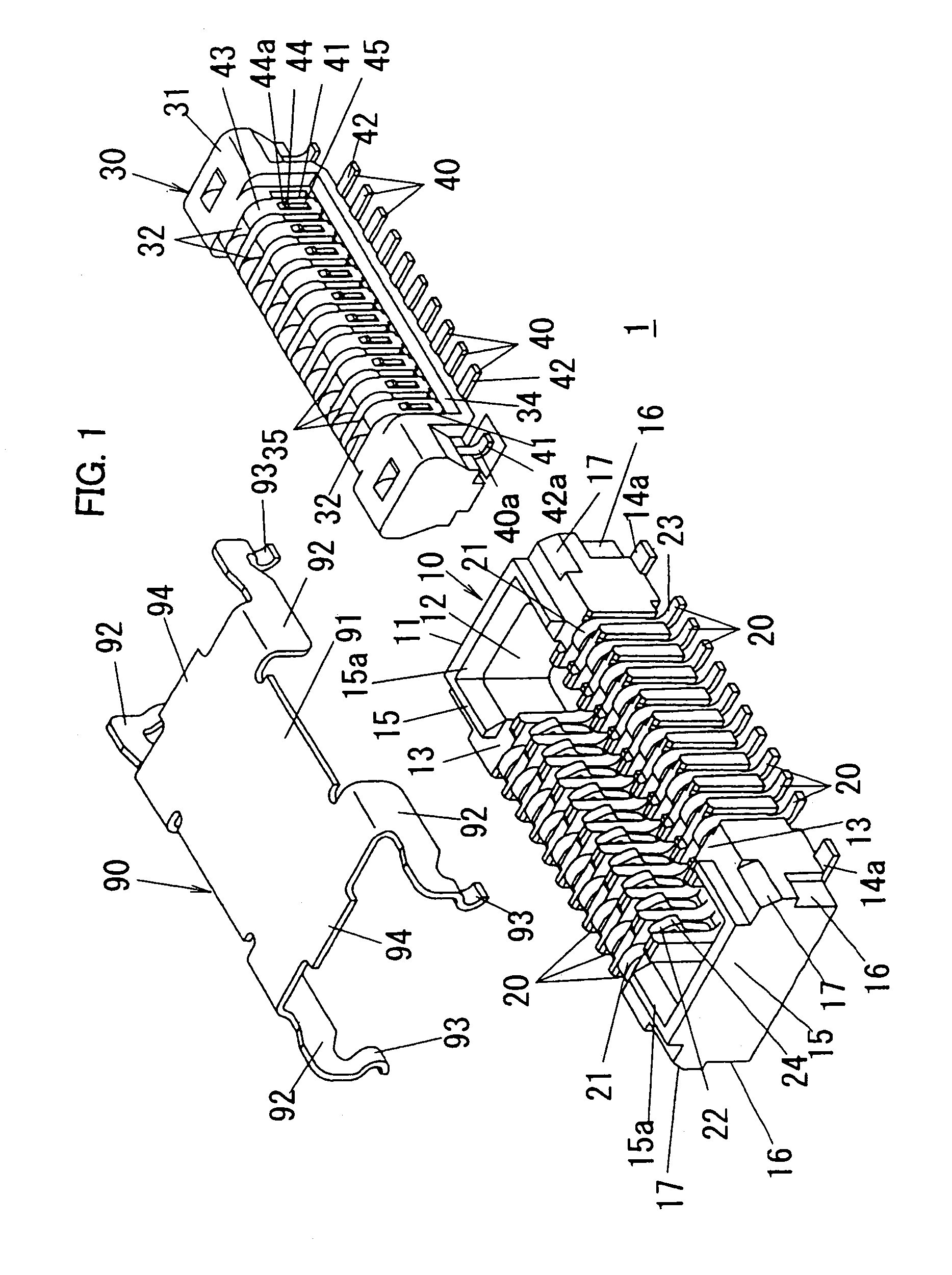

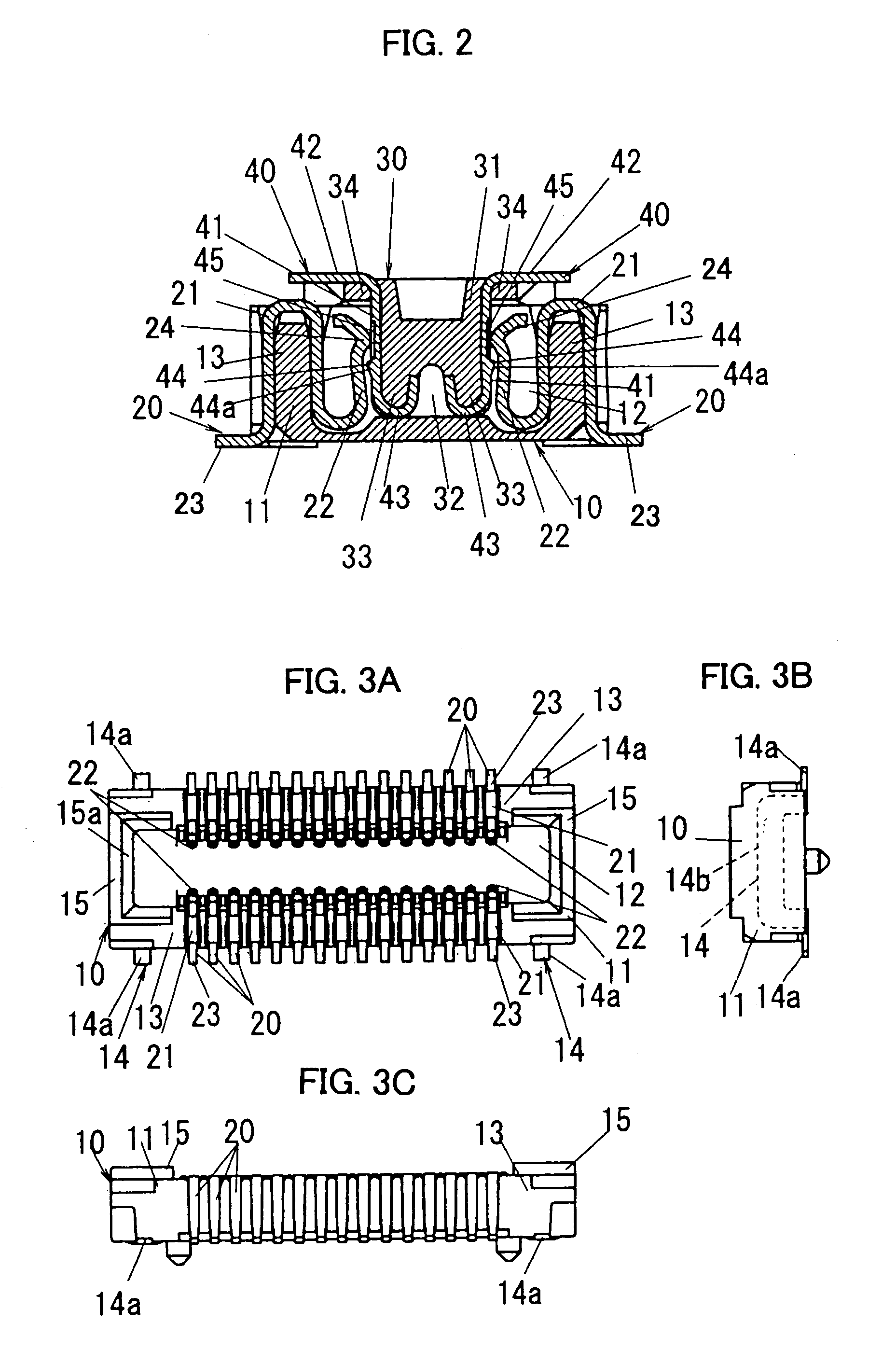

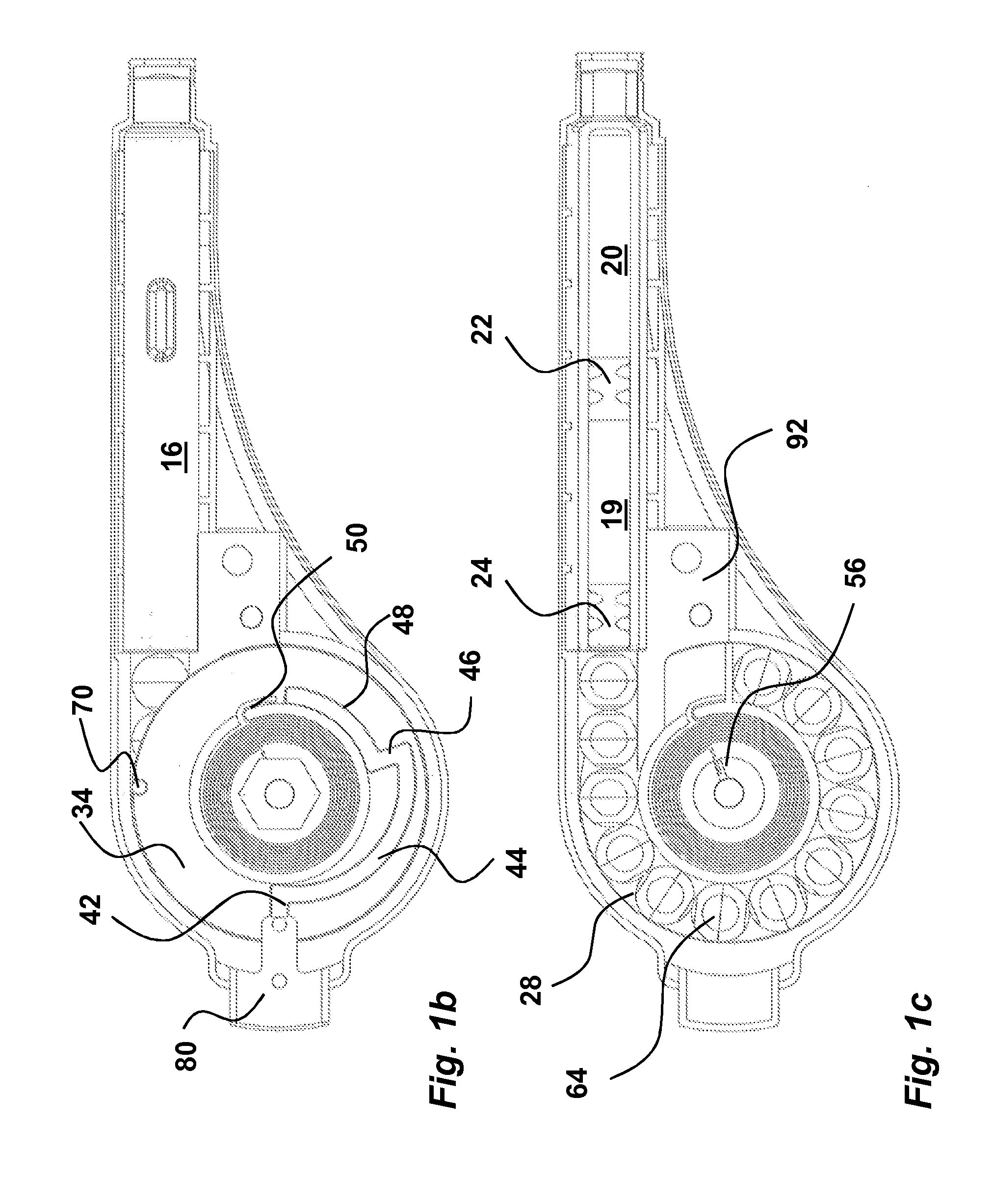

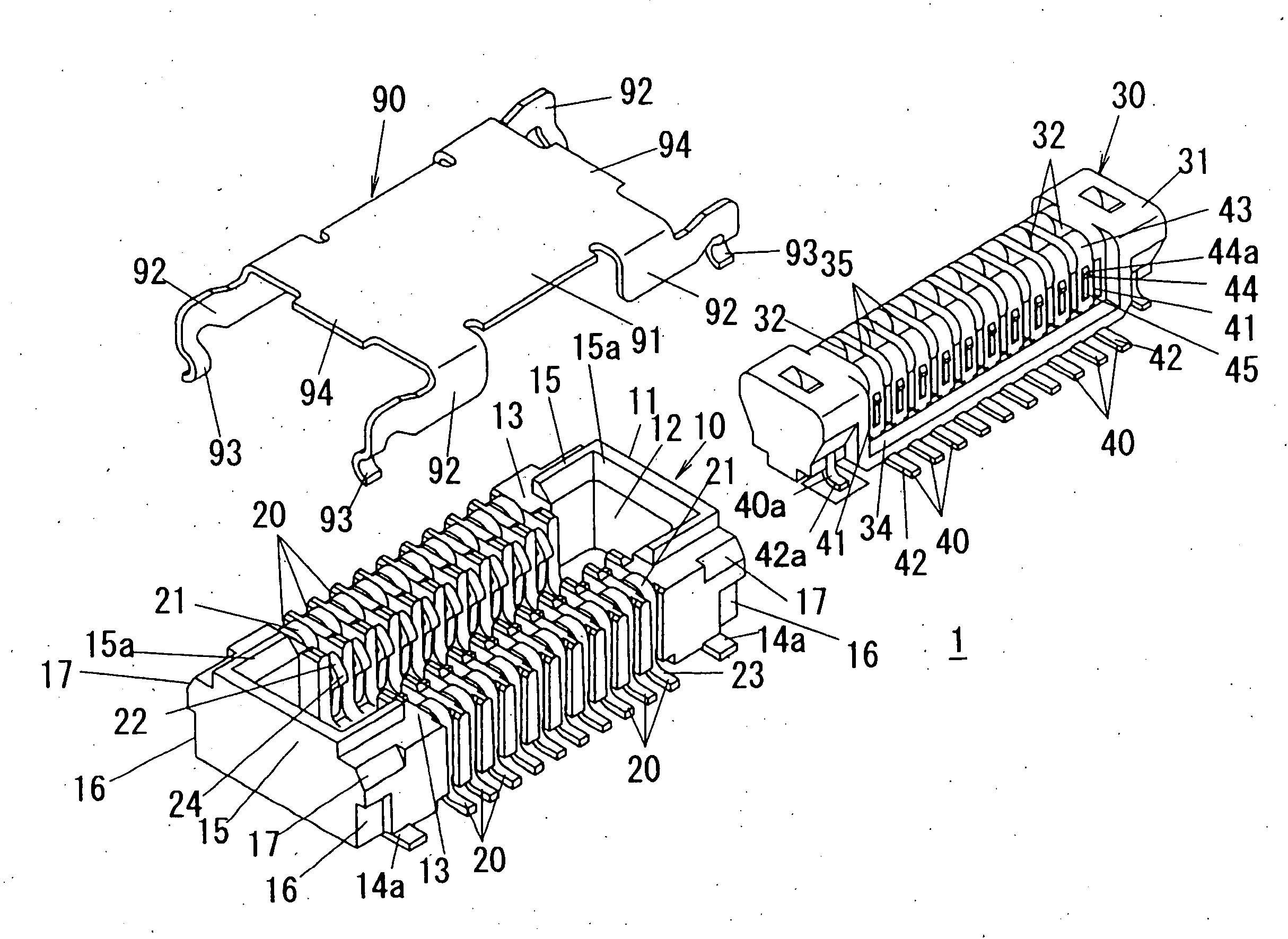

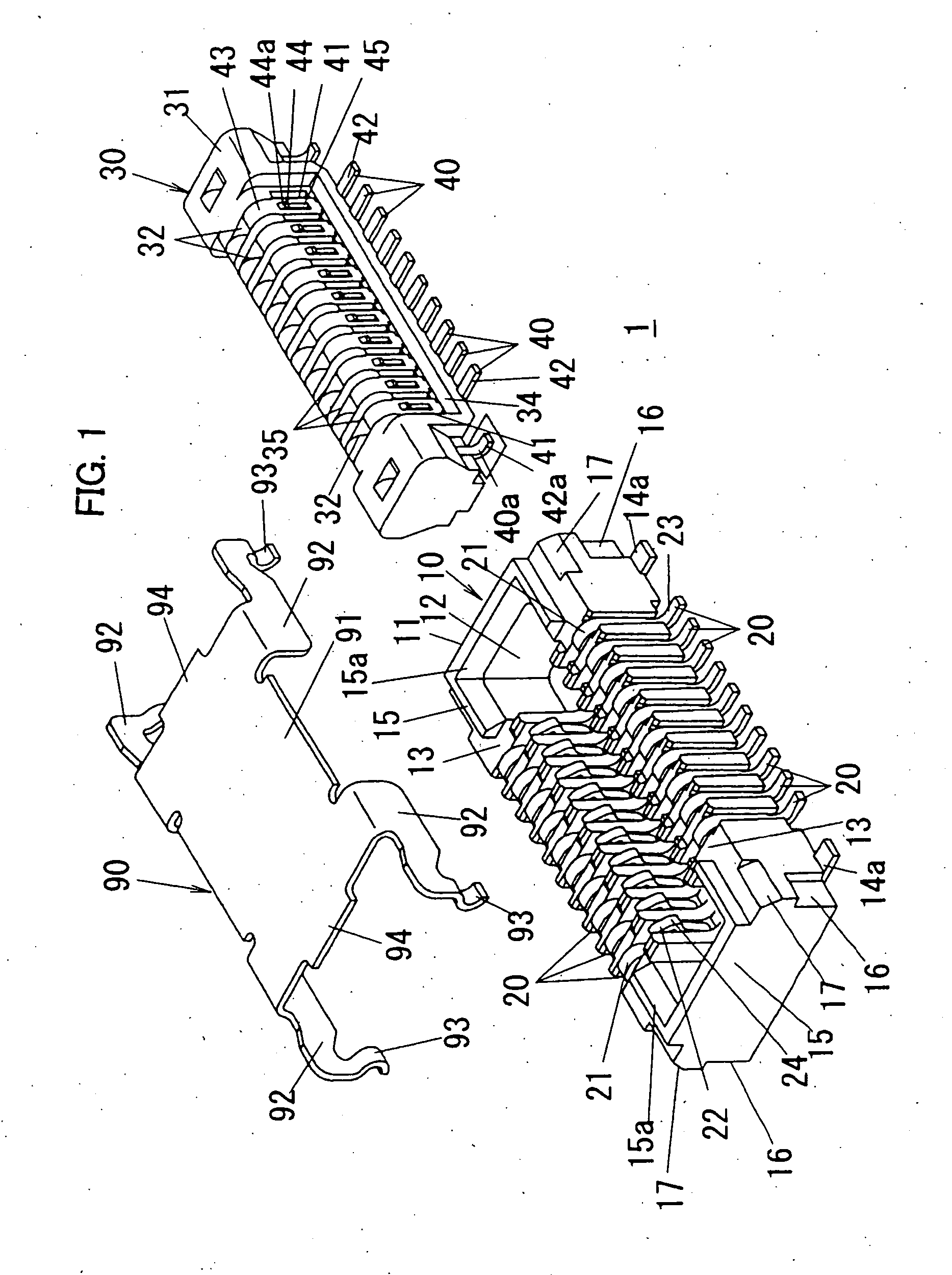

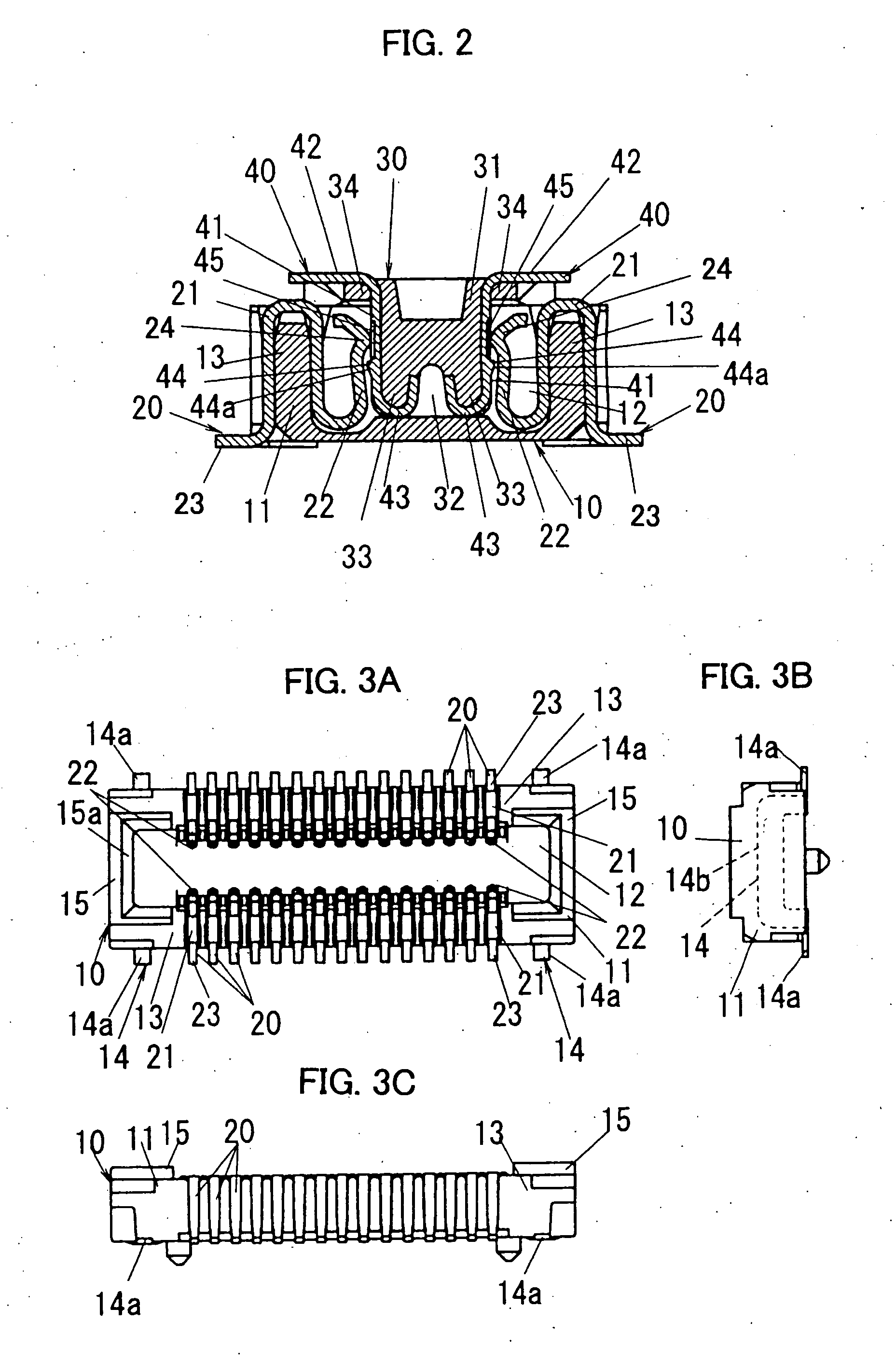

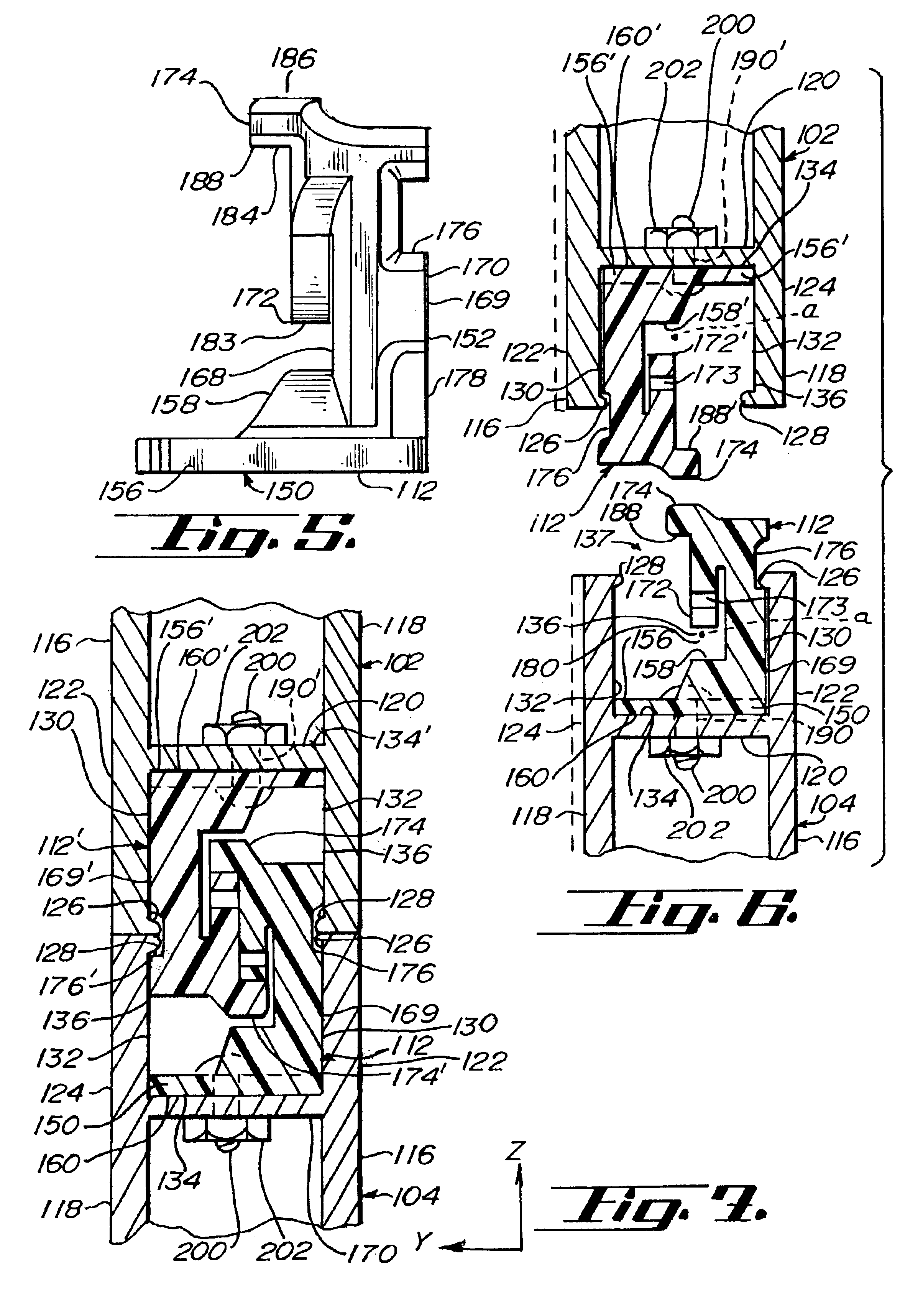

Connector for electrically connecting electronic components

ActiveUS7232317B2Flaking of the header post from the header body can be preventedInhibit flakingVehicle connectorsContact member cases/bases manufactureCross wallEngineering

A protruding table which was conventionally provided in a center portion of a socket body is eliminated, so that a dimension of a socket in widthwise direction is reduced. When the socket is mounted on a circuit board, an adsorption cover is attached to the socket, and the socket is adsorbed by and held on an adsorption nozzle via the adsorption cover. On the other hand, with respect to a header, gaps between header posts arranged in longitudinal direction are separated by cross walls, so that concave portions are formed between the cross walls. Under a state that an adsorption face of the adsorption nozzle is contacted with the header so that a suction opening of the adsorption nozzle face the concave portion, an enclosed space is formed by at least two cross walls, a bottom face of the concave portion and the adsorption face of the adsorption nozzle. When air in the enclosed space is sucked from the suction opening of the adsorption nozzle, negative pressure occurs, so that the header is adsorbed by and held on the adsorption nozzle. Consequently, it enables the adsorption and holding by the adsorption nozzle, and enables to reduce a dimension of the socket in widthwise direction.

Owner:MATSUSHITA ELECTRIC WORKS LTD

Modular Panel Wall Assemblies

A modular wall panel have a wall face, a top cap, a bottom pan and two side framing studs at the perimeter sides extending vertically from the bottom pan to the top cap are all constructed integrally. The side framing studs also define a surface for at attaching finishing strips that extend from the base pan to the top cap. A foundation wall is constructed from a plurality of modular wall panels. The wall panels may also have interior vertical reinforcing studs with surfaces for attaching finishing strips at regular intervals. The panels may include a support column for a cross wall beam or for a support beam over a door frame opening. The panels may be used for upper floor exterior walls

Owner:HARIG CHRISTOPHER W +1

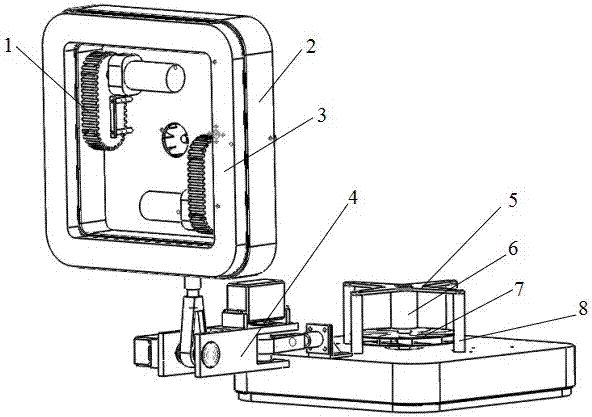

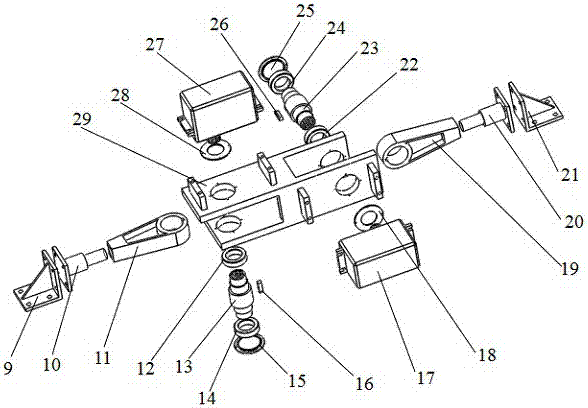

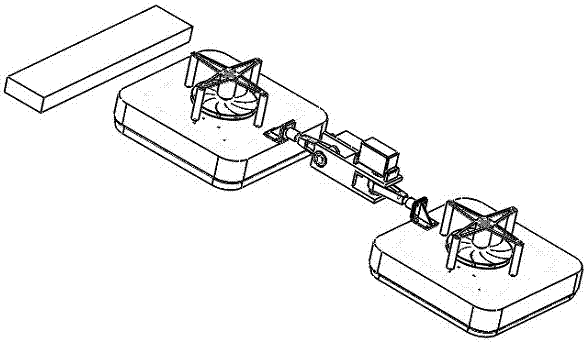

Obstacle-crossing wall-climbing robot with wall surface converting function

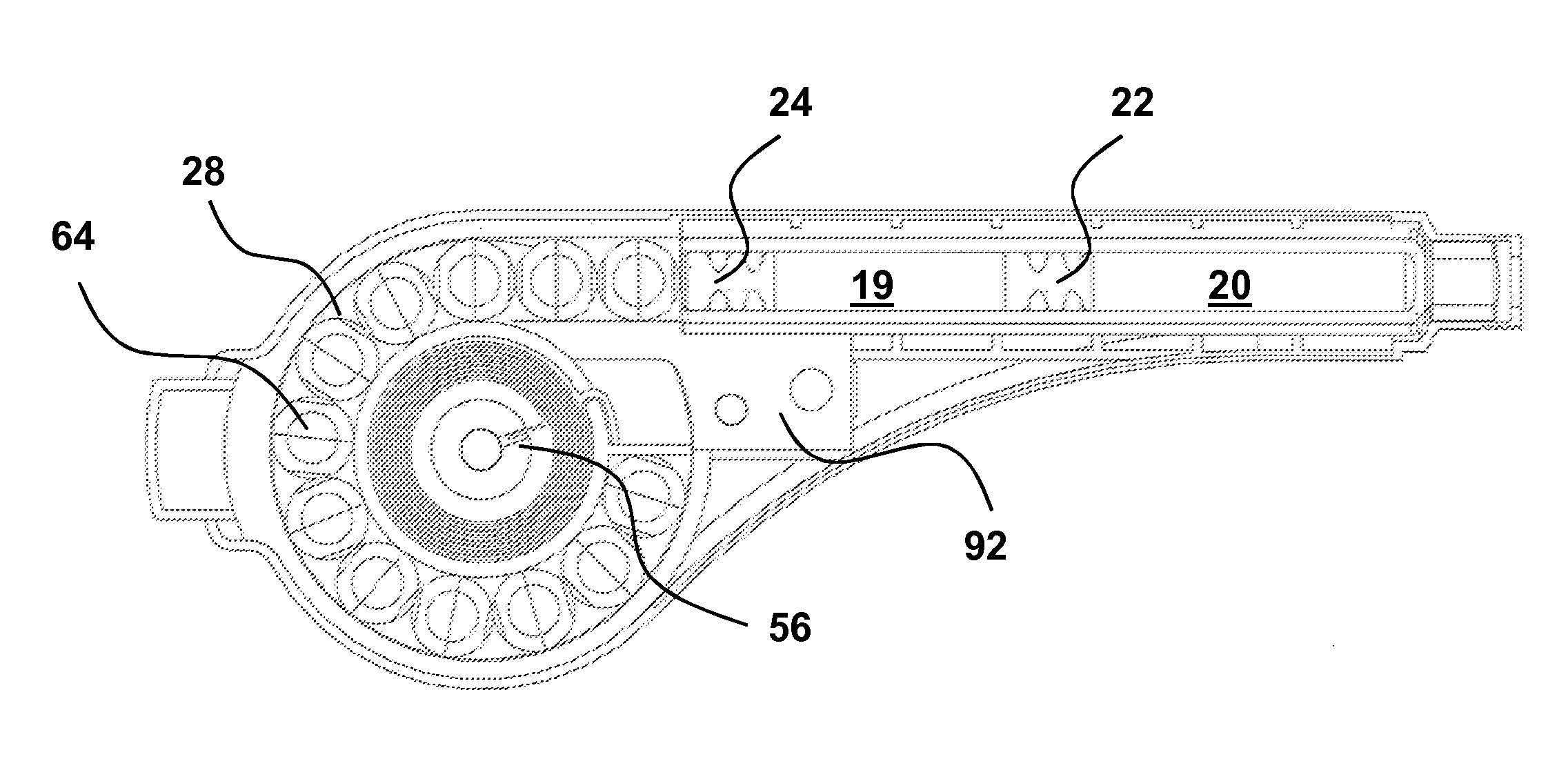

InactiveCN106945739AStrong load to weight ratioExpand the scope of activitiesVehiclesBrushless motorsRange of motion

The invention discloses an obstacle-crossing wall-climbing robot with a wall surface converting function. The obstacle-crossing wall-climbing robot comprises two single wall-climbing robot bodies and a pitching deflection mechanism; the two single wall-climbing robot bodies are connected through the pitching deflection mechanism in the middle; each single wall-climbing robot body comprises a brushless motor, a motor base, a motor supporting frame, centrifugal fan blades, a robot shell body, motion mechanisms and a sealing gasket. The brushless motors drive the centrifugal fan blades to rotate to pump out air inside the robot shell bodies, so that negative pressure is formed inside the robot shell bodies, and accordingly the robot bodies are adsorbed on the wall. The pitching deflection mechanism can assist the robot bodies to cross obstacles and turn. The double-body wall-climbing robot can move flexibly on the surface of the wall and can cross grooves and large protruding obstacles in the wall and complete conversion between the adjacent wall surfaces, so that the motion range of the wall-climbing robot is effectively increased.

Owner:SHANGHAI UNIV

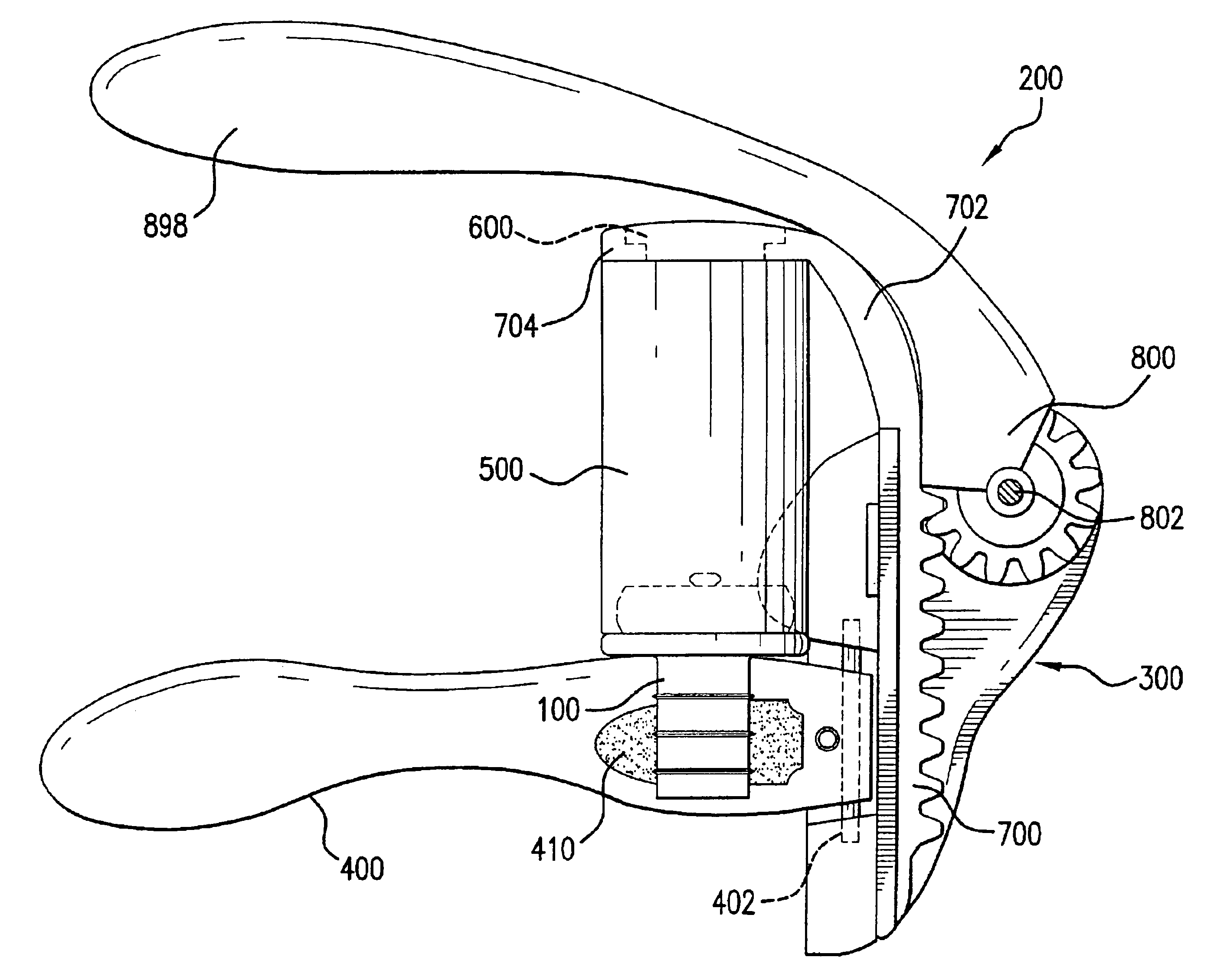

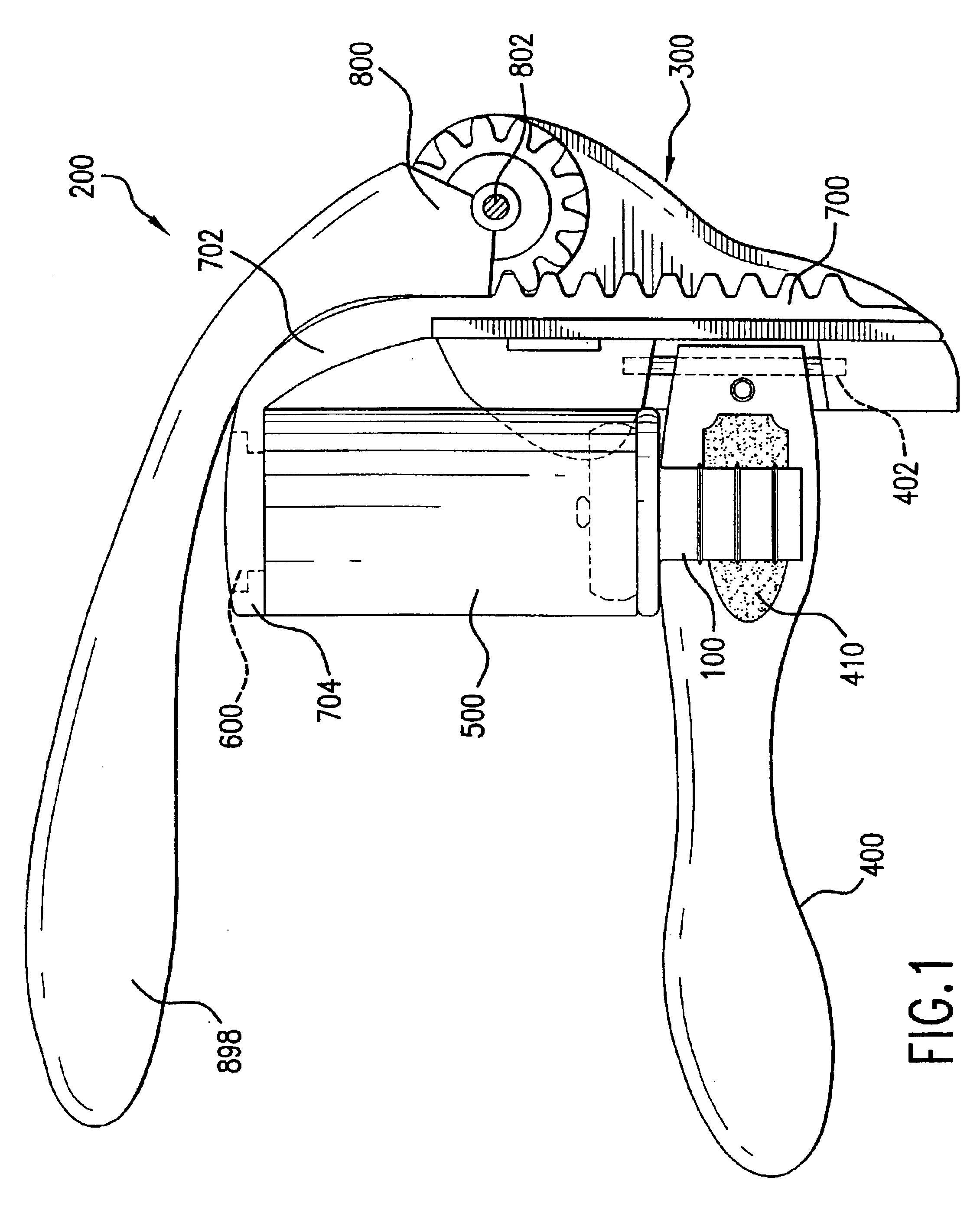

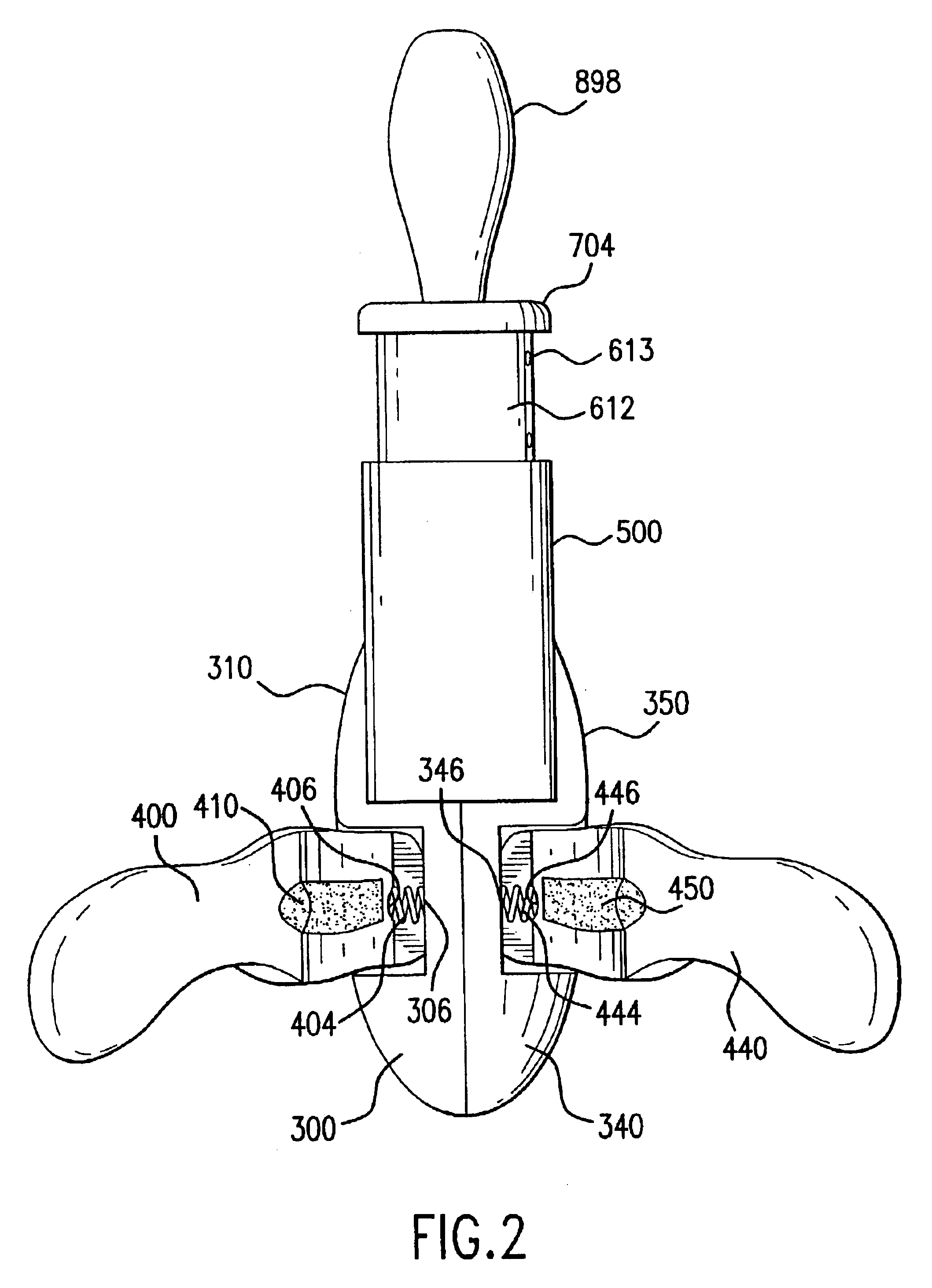

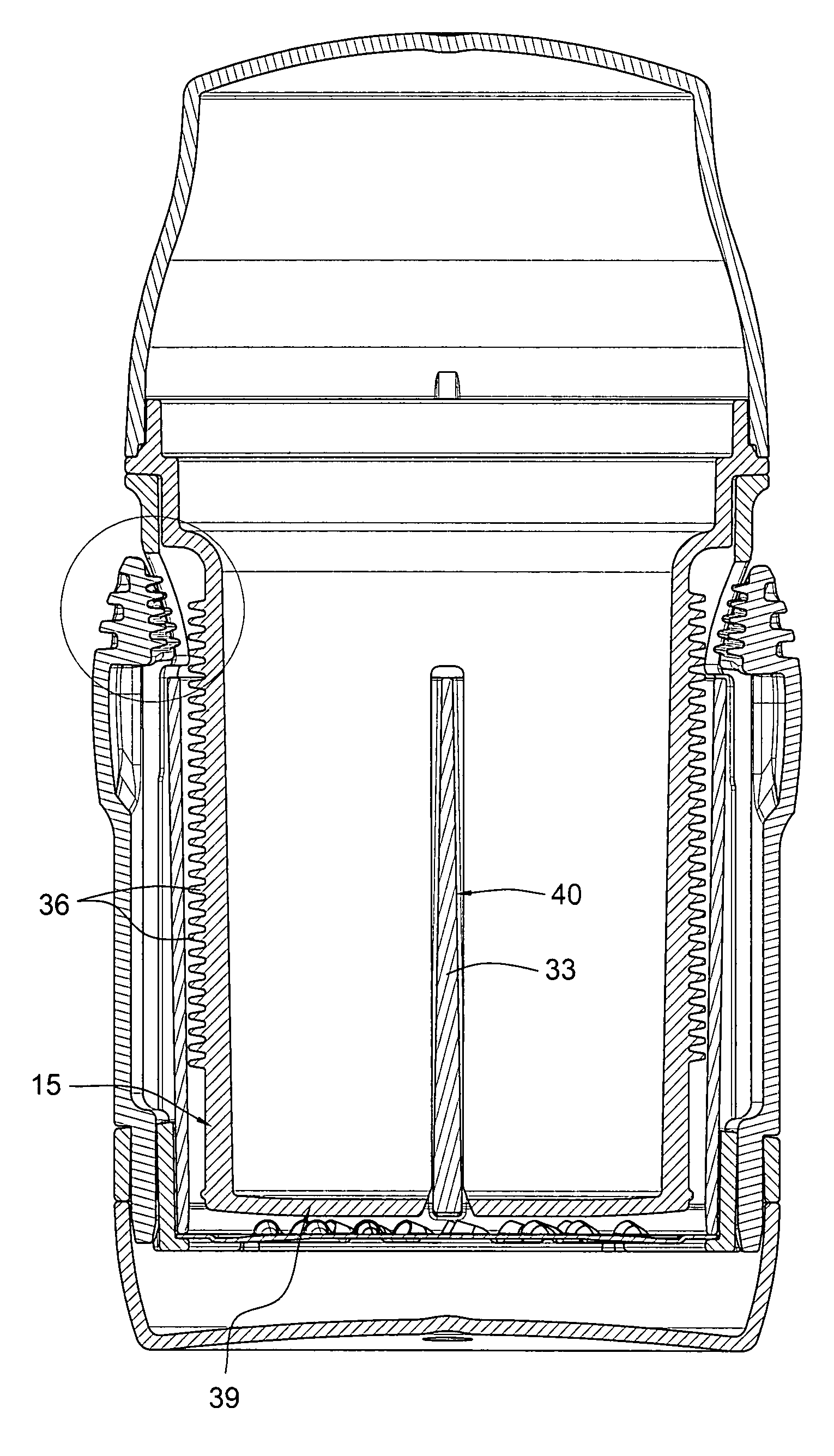

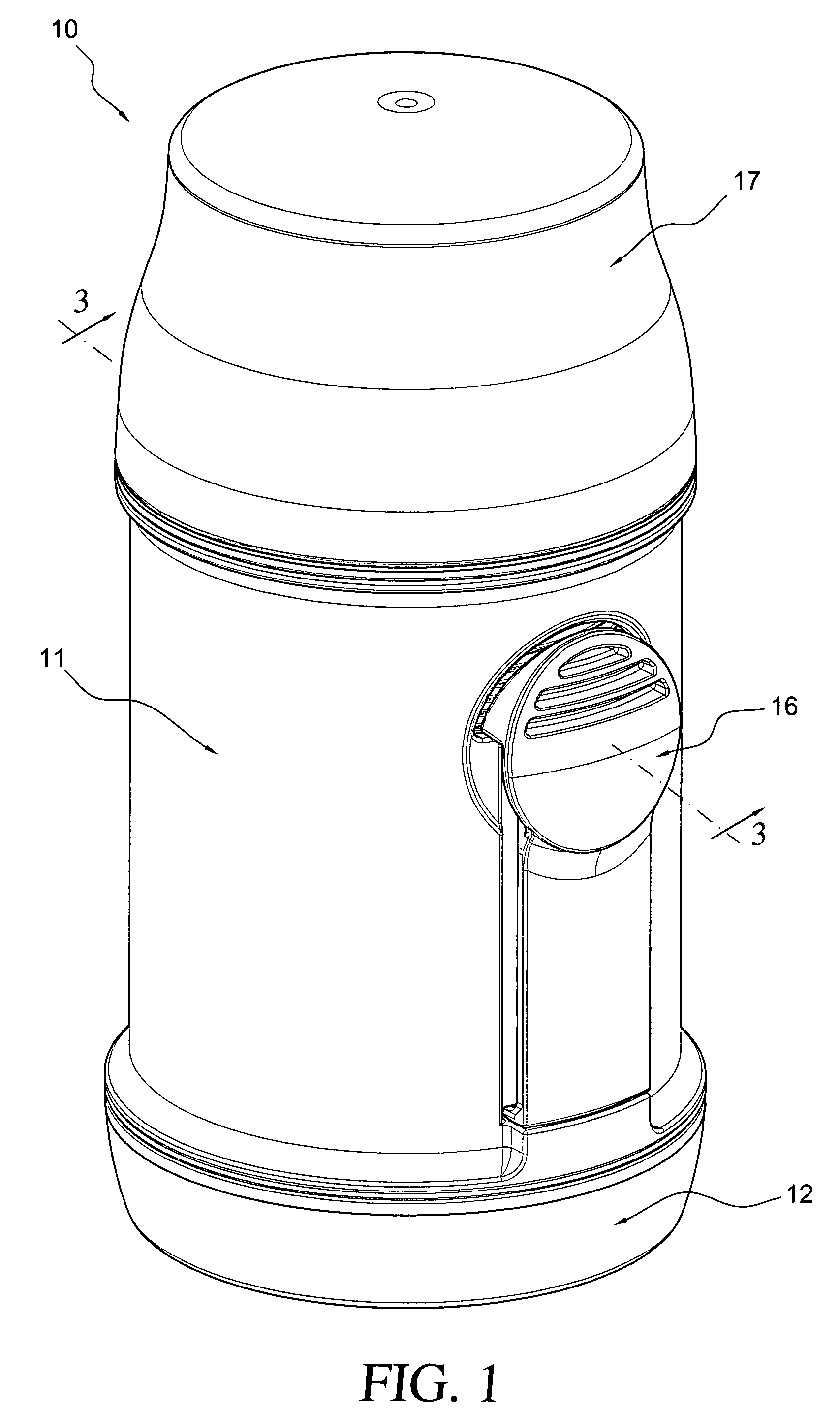

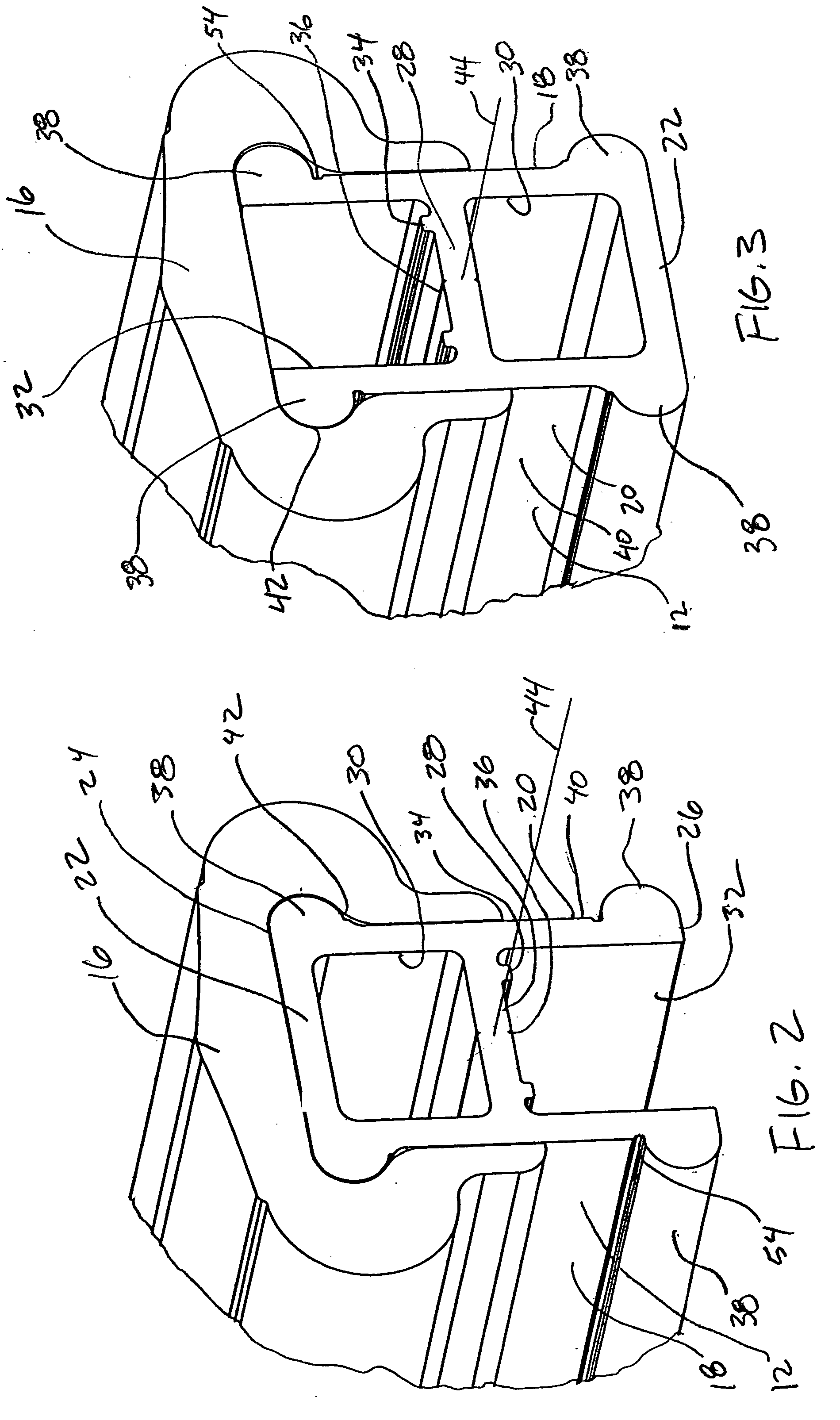

Wine saver machine and stopper

A machine includes a body, a hollow cylinder fixedly attached to the body, a piston assembly slidable within the hollow cylinder, and a lever handle pivotally attached to the body. The hollow cylinder has a sealing end, and the sealing end is capable of engaging with and sealing to a stopper. The piston assembly includes a cross wall at a first end. The lever handle is coupled to the piston assembly so as to be capable of sliding the piston assembly in the hollow cylinder.

Owner:TAYLOR PRECISION PROD

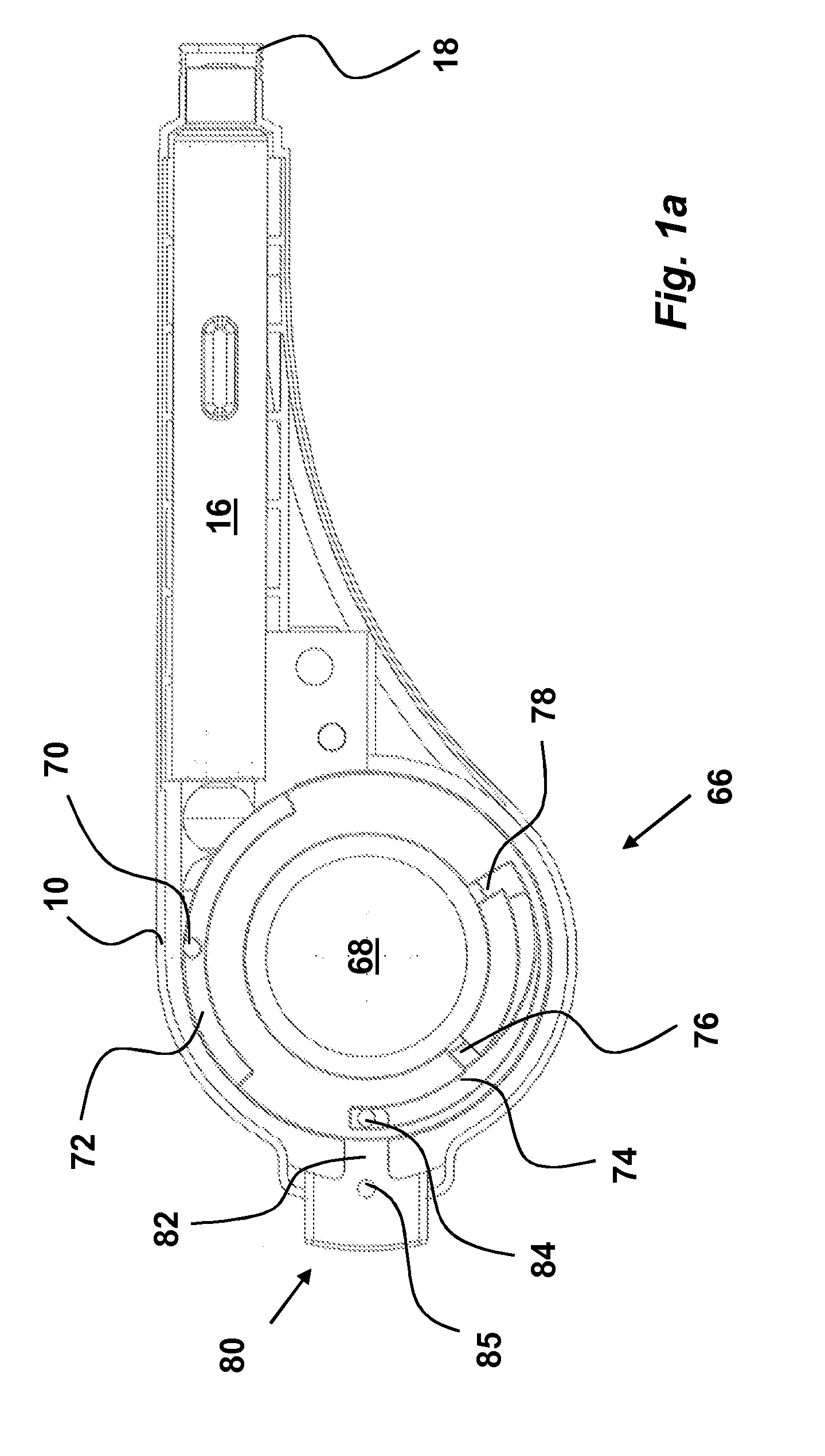

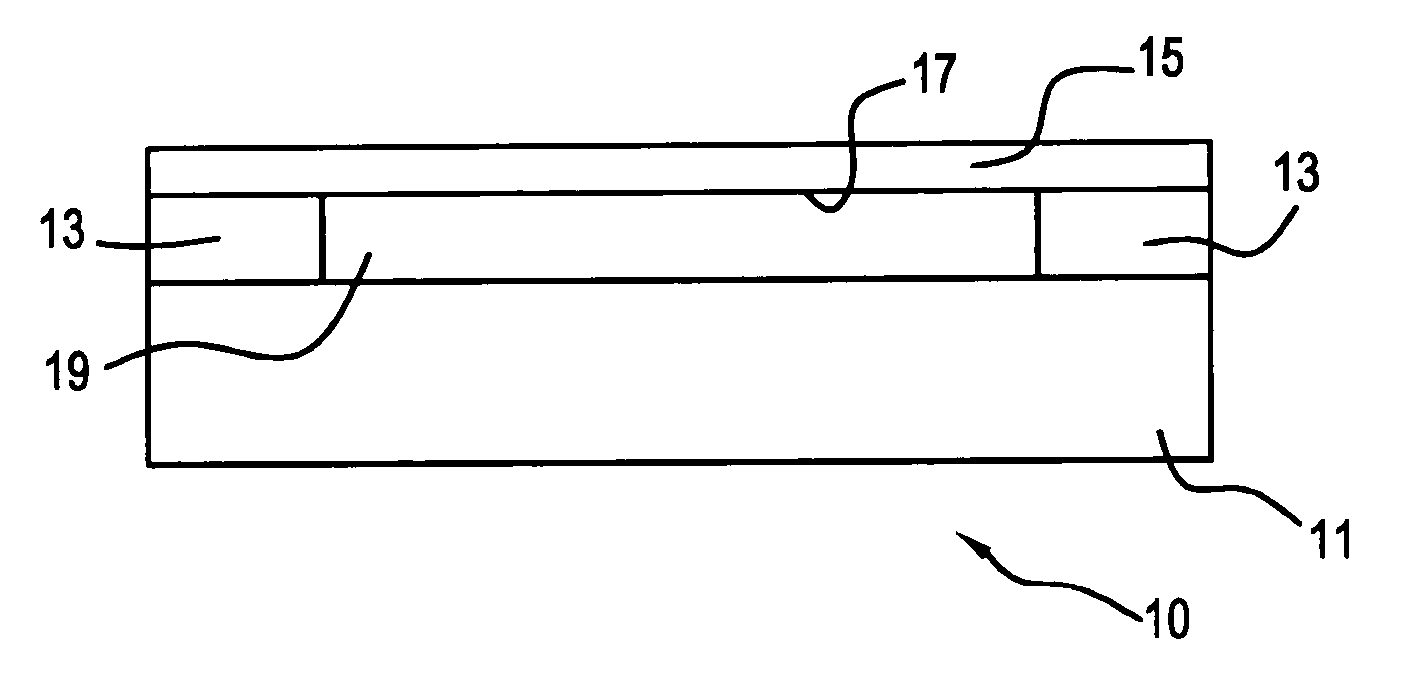

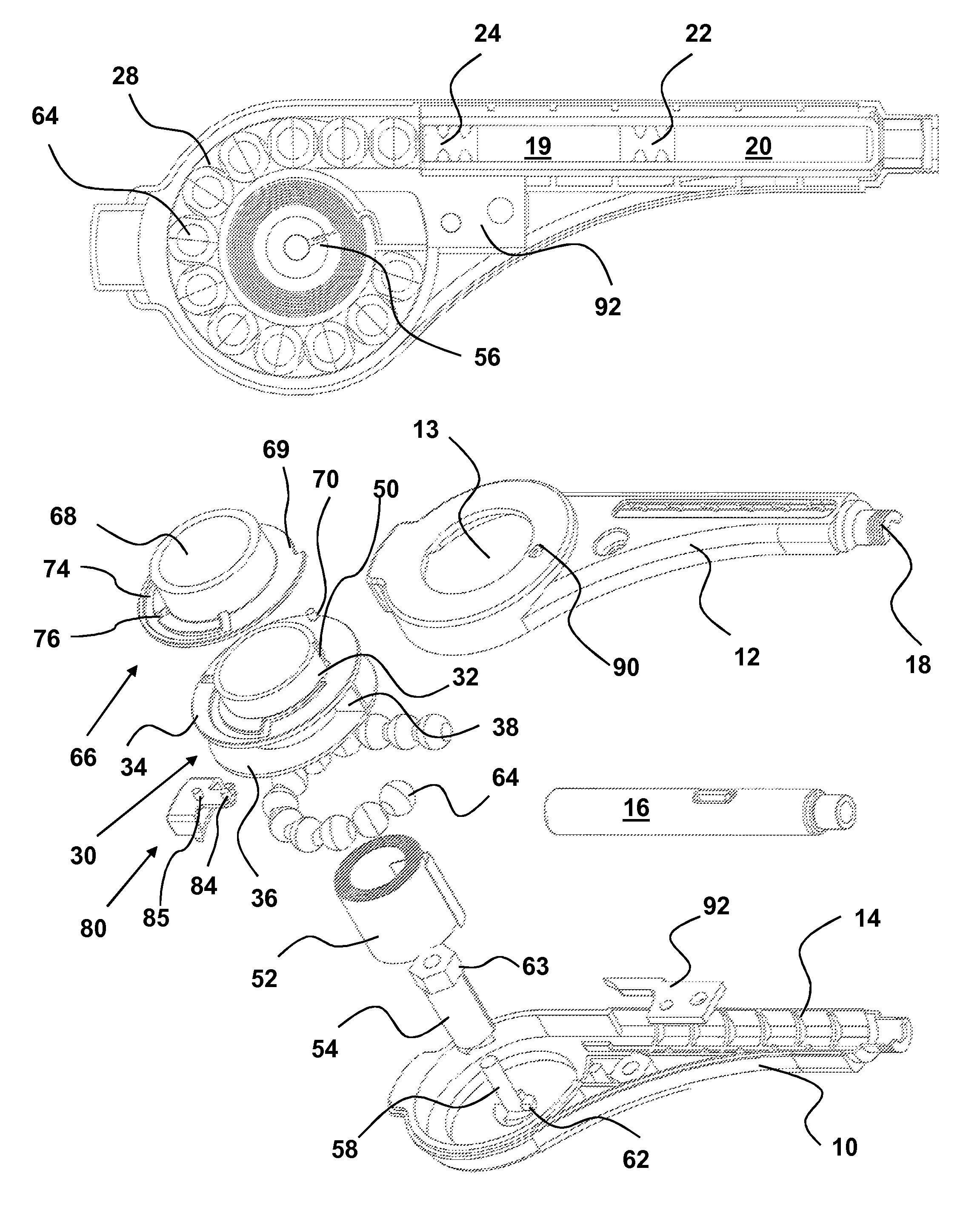

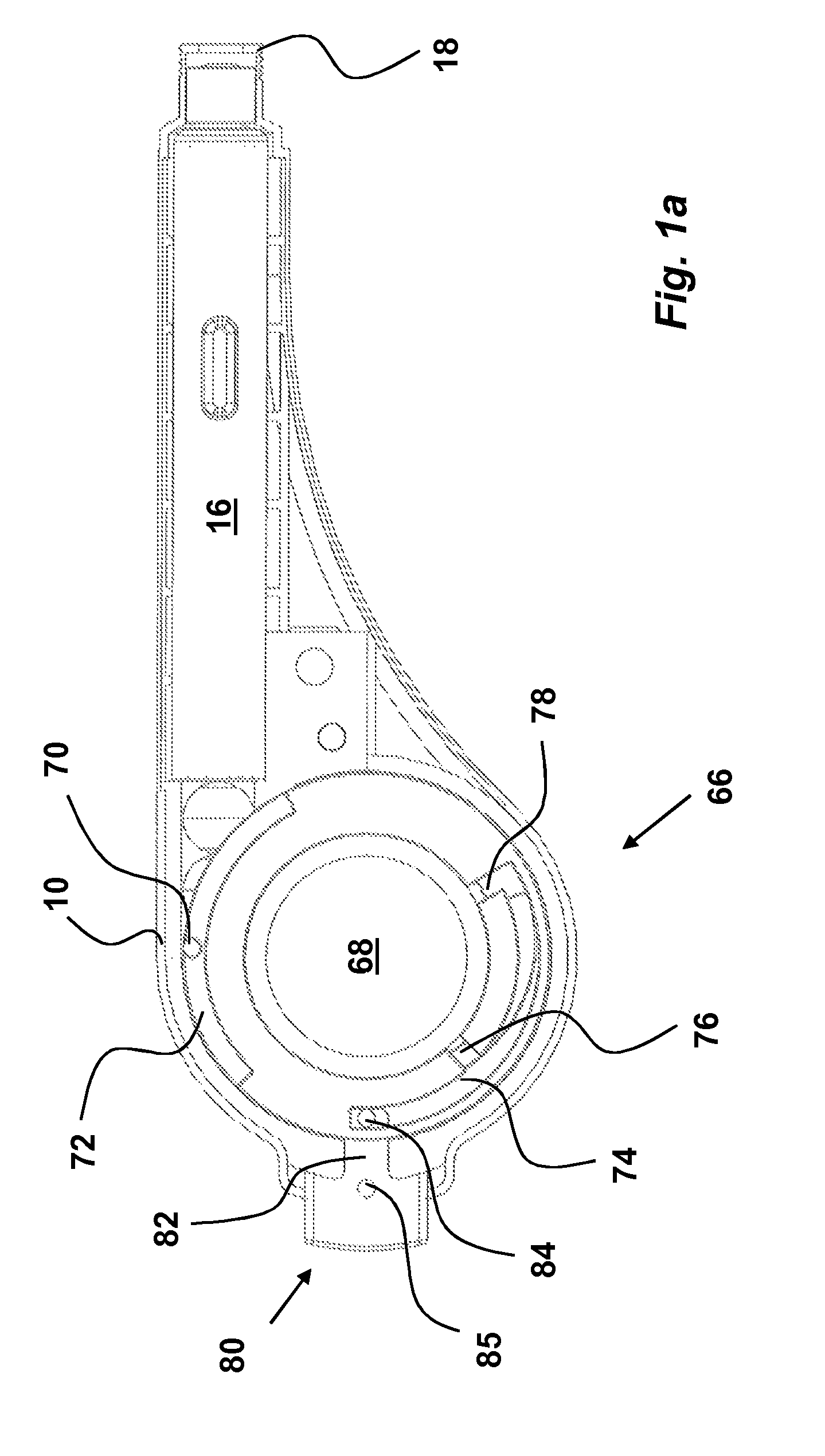

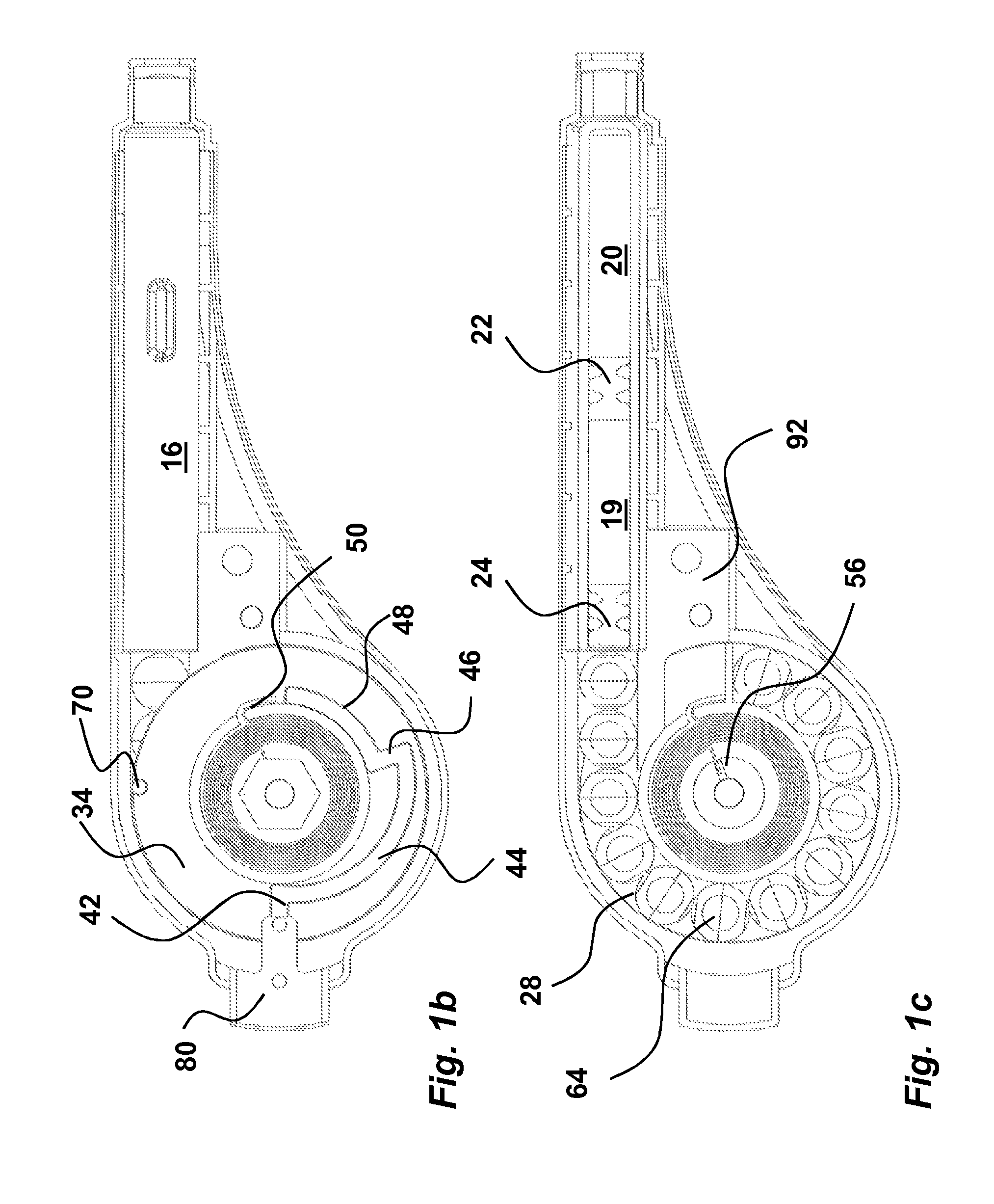

Medicament Delivery Device

ActiveUS20130096495A1Reduce component countReduce device sizeAutomatic syringesMedical devicesCross wallAbutment

A medicament delivery device includes a housing with a circle-segment-shaped compartment for a drive unit that moves at least one stopper in a medicament container and that includes a support wheel and central hub on which first and second parallel disks are fixedly attached and interconnected by an abutment cross-wall; spherical members between the abutment wall and adjacent the stopper; a clock spring within the hub with an outer end connected to the hub and an inner end connected to a one-direction-rotatable tubular hub coaxially arranged around a shaft fixedly attached to a housing part; and an activation member connected to the first disk by a hold-and-release mechanism. When the activation member is not depressed, the wheel and spring are held in a tensioned static state, and when the activation member is depressed, the spring and wheel are released and the spherical members are forced against the stopper.

Owner:SHL MEDICAL AG

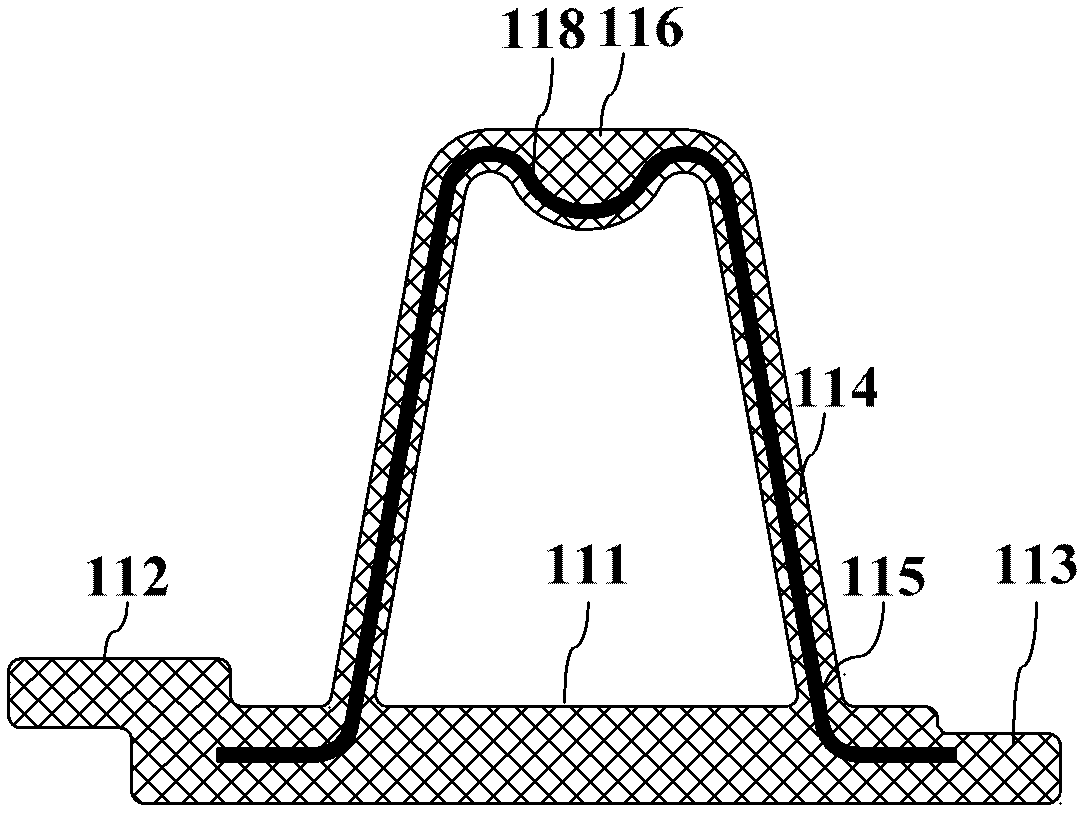

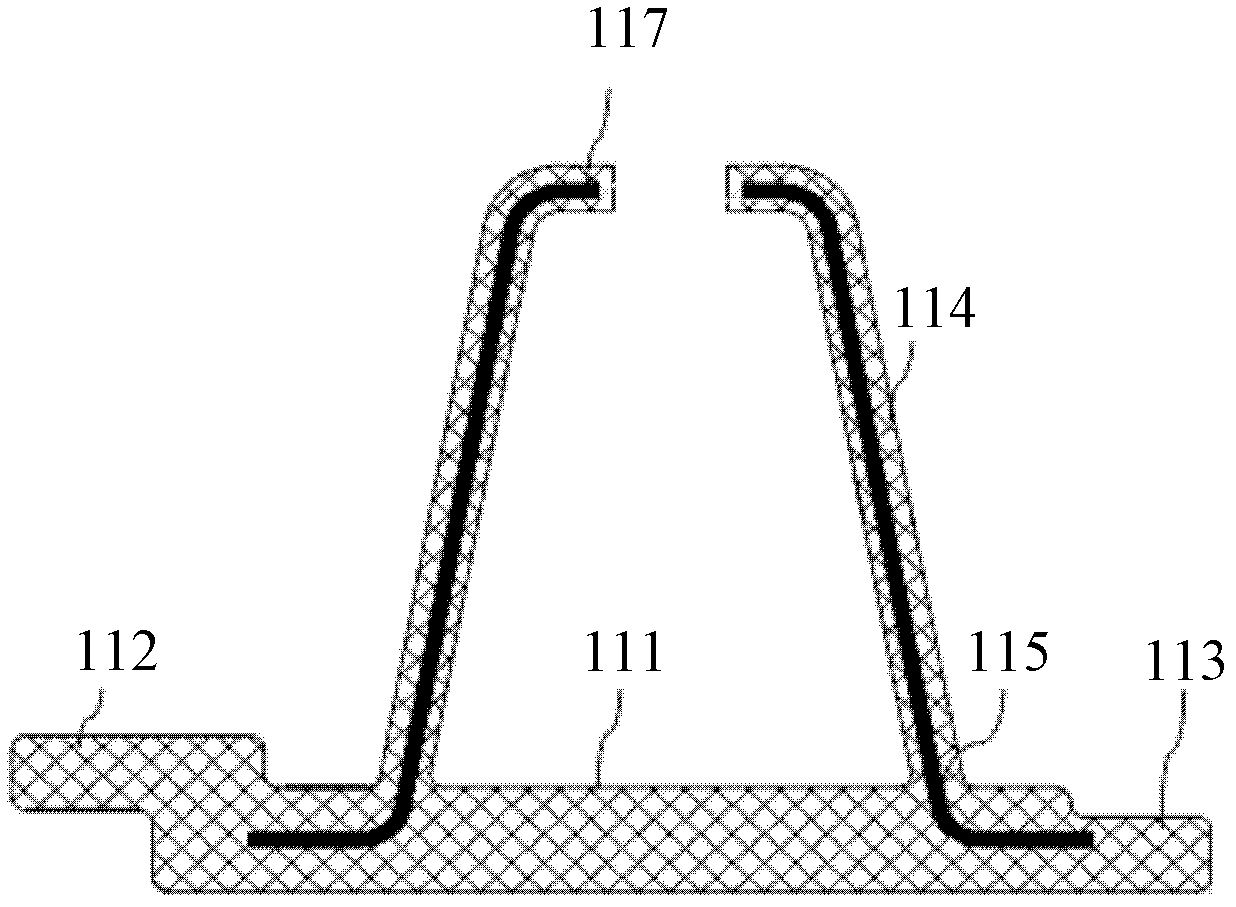

Reinforced thermoplastic composite structure wall pipe and strip and complete-set production device thereof

InactiveCN102322551AReduce consumptionLow costFlexible pipesRigid pipesComposite constructionCross wall

The invention discloses a reinforced thermoplastic composite structure wall pipe strip, which comprises a substrate, at least one corrugated reinforcing rib forming a whole together with the substrate as well as a reinforcing section, wherein the reinforcing section forms a whole together with the corrugated reinforcing rib or forms a whole together with the substrate and the corrugated reinforcing rib simultaneously; the corrugated reinforcing rib is protruded towards the same direction from one side of the substrate and extends along the length direction of the substrate; and the corrugated reinforcing rib consists of two adjacent reinforcing wall boards and a reinforcing cross wall. According to the reinforced thermoplastic composite structure wall pipe strip disclosed by the invention, by using the composite reinforcing section, the ring stiffness of the pipe can be remarkably improved and the consumption of raw materials can be remarkably reduced. The invention also discloses a reinforced thermoplastic composite structure wall pipe adopting the reinforced thermoplastic composite structure wall pipe strip. The reinforced thermoplastic composite structure wall pipe is provided with a smooth and flat inner wall and an outer wall of the reinforced thermoplastic composite structure, which is spirally encircled at intervals. The invention further discloses a reinforced thermoplastic composite structure wall pipe complete-set production device for producing the reinforced thermoplastic composite structure wall pipe, which is used for realizing continuous production and improving the production efficiency.

Owner:SHENZHEN JIN HONG MASCH CO LTD

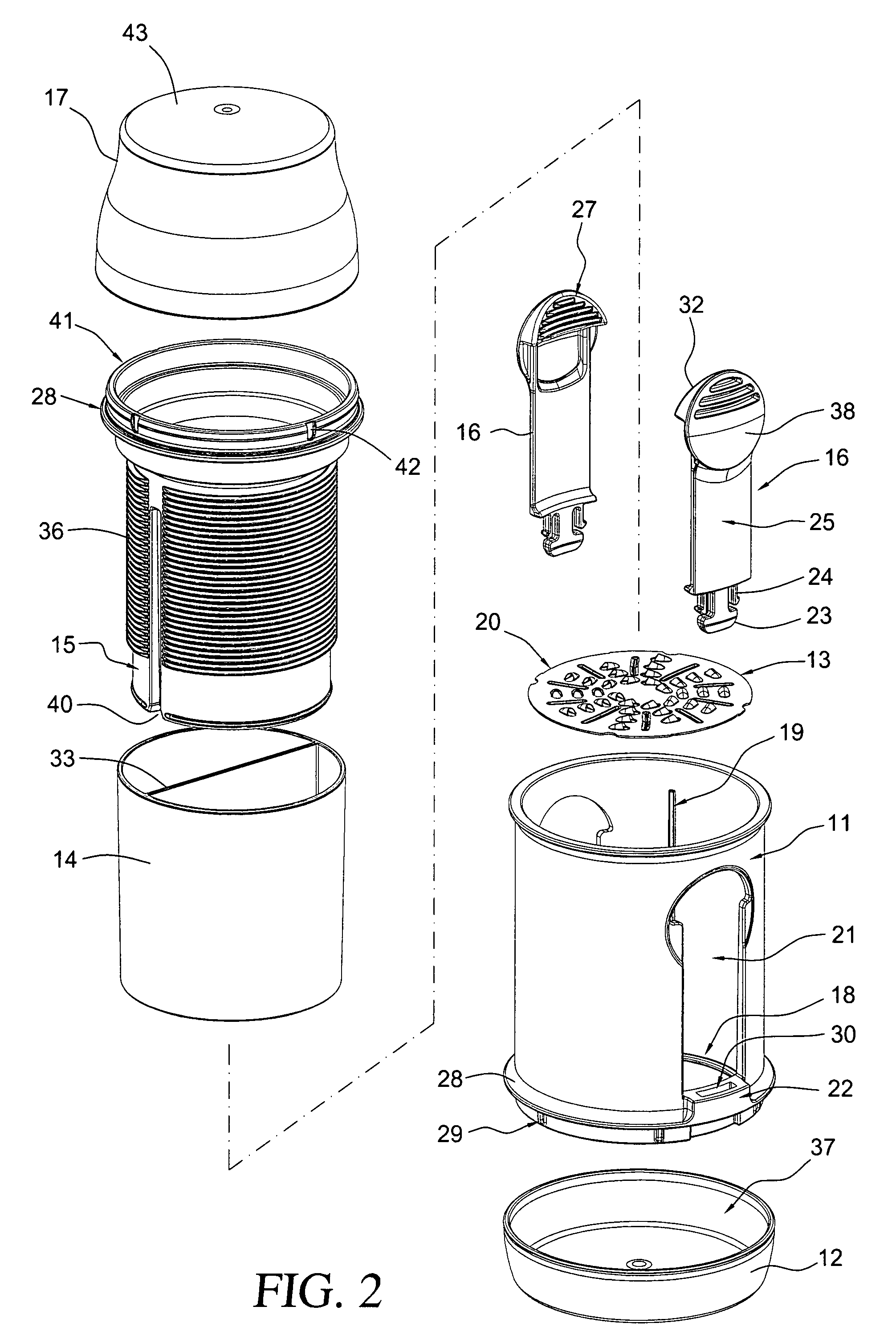

Cheese grater

The invention provides a food grater assembly comprising a base; an external cylindrical portion removably attached to the base; a grater disc disposed within and removably attached to the lower end of the outer cylindrical portion; an inner divider having a cross wall dividing the inner space of the inner cylindrical portion in two equal portions; said divider being able to rotate freely within the external cylindrical portion; a plunger disposed within the divider, said plunger having a plurality of annular ridges disposed along a portion of its length; said plunger portion having a closed bottom wall and a slot defined axially and longitudinally along a portion of is length; a pair of engaging strips flexibly attached to and disposed in the wall of the external cylinder, each of said engaging strips having horizontal ridges along a portion of the inner surface thereof for engaging and disengaging the horizontal ridges of the plunger; and a cap disposed on the upper end of the inner plunger portion.

Owner:DART IND INC

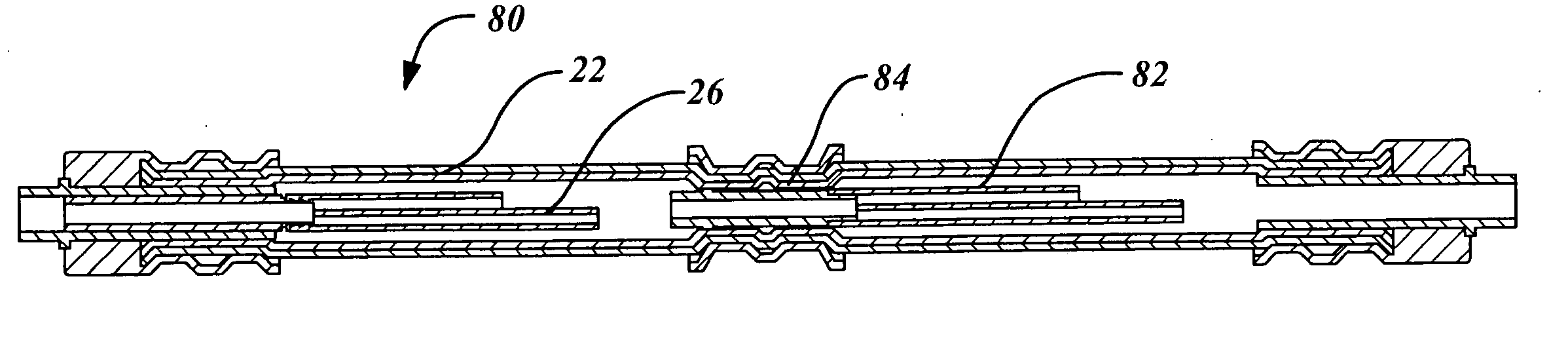

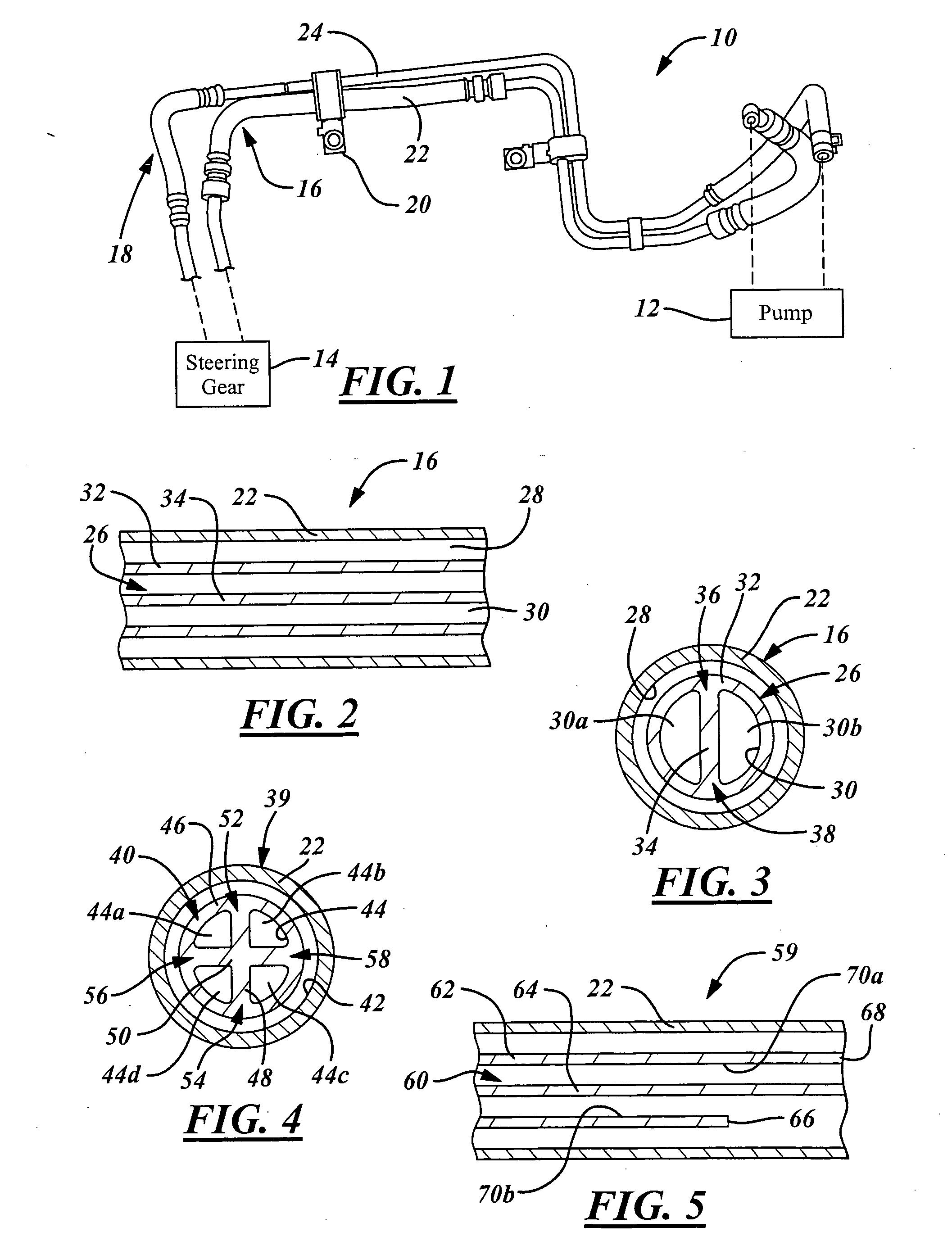

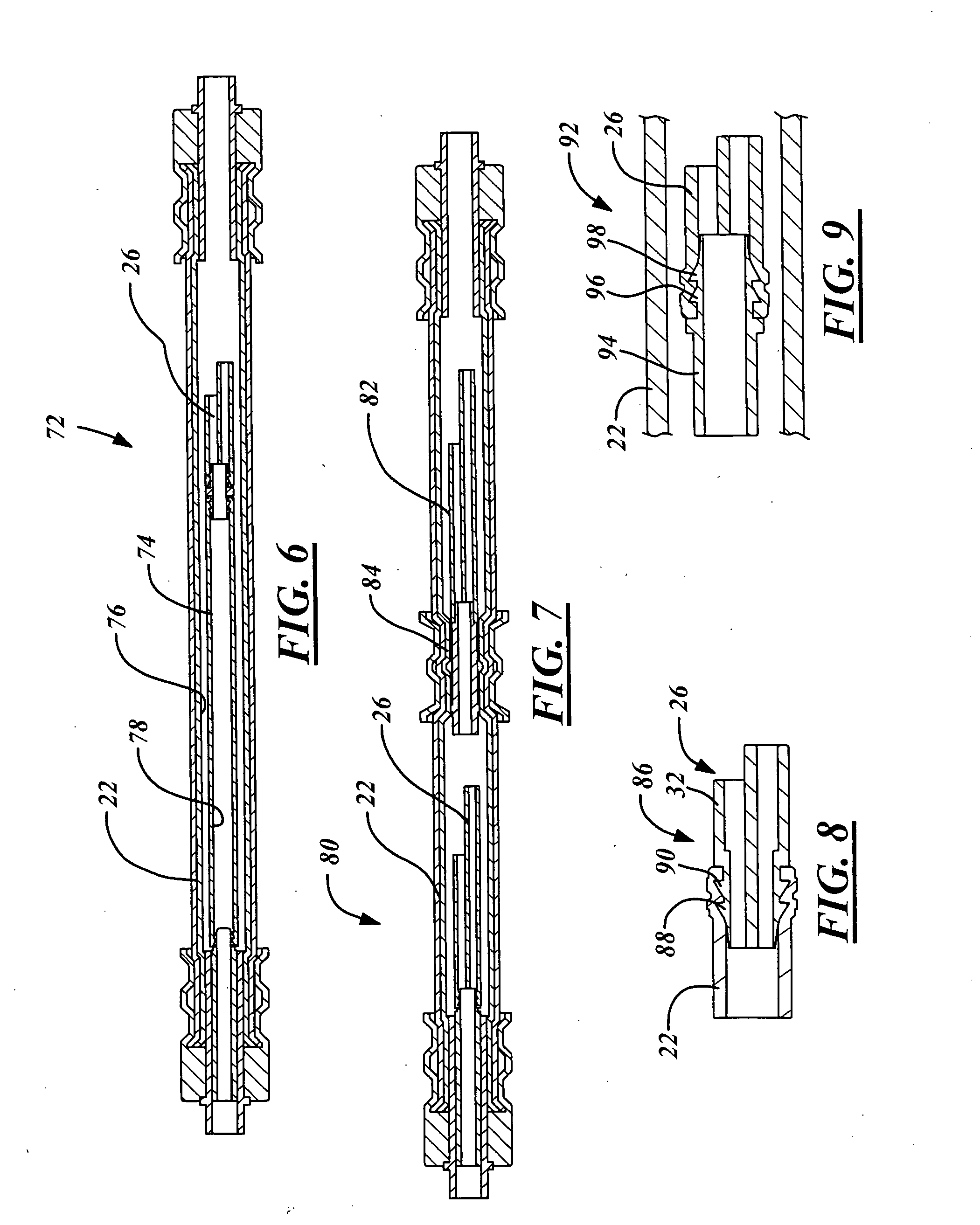

Multiple channel conduit hydraulic noise attenuation device

The present invention provides a hose assembly for attenuating noise from fluid pressure pulses in a power steering assembly. The assembly includes a hose disposed between a fluid pump and power steering gear and a tuning conduit disposed within the hose that defines concentric outer and inner fluid passages within the hose. The conduit includes an annular wall and one or more integral cross walls extending between points on the annular wall to subdivide the inner fluid passage into a plurality of parallel, longitudinally extending fluid passages allowing tuning over a broader frequency range.

Owner:COUPLED PRODS

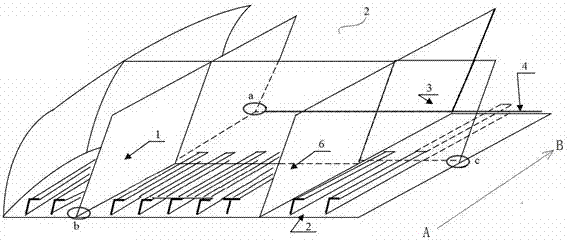

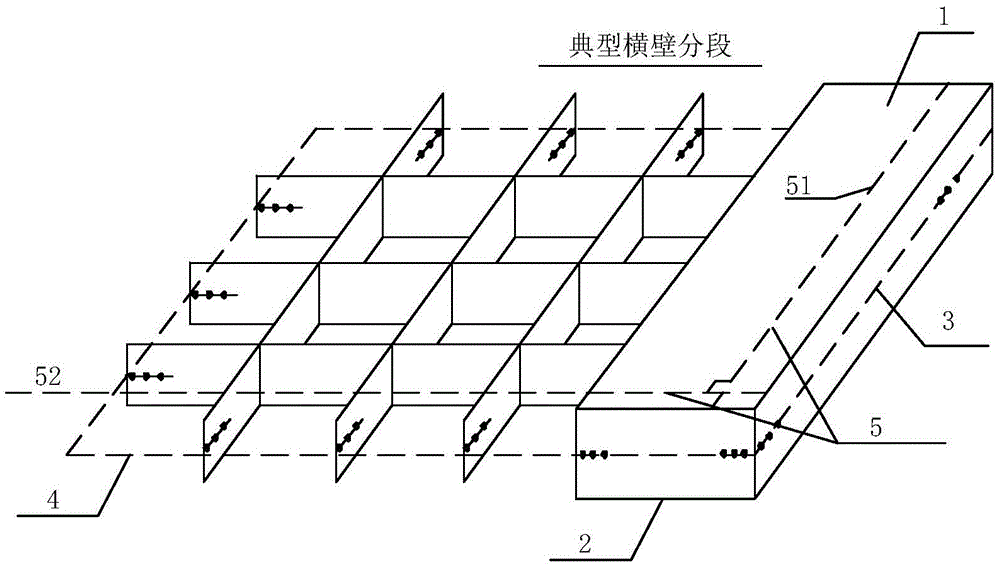

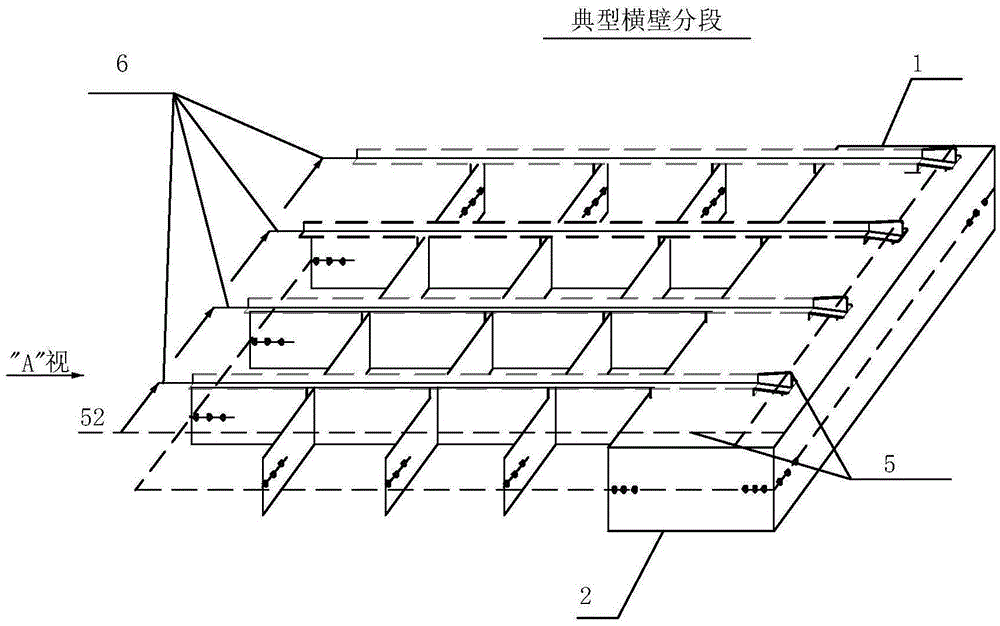

Design method for reference lines for mounting outfitting piping system in inverse segment of cabin surface

InactiveCN107264724AEasy to installMeet the process requirementsVessel partsCross wallThree dimensional measurement

The invention discloses a design method for reference lines for mounting an outfitting piping system in an inverse segment of a cabin surface. The method comprises the following steps: the first step, establishing a three-dimensional reference, the intersection point of a shipboard side wall and the bow of a deck, and the intersection point of the shipboard side wall and a stern of the deck serve as the first management reference point a and the second management reference point b separately, and the intersection point of a cross wall and the midship of the deck serves as the third management reference point c; the second step, drawing waterline marks, drawing deck minus 1000mm waterline marks on the shipboard side wall, the cross wall and a longitudinal bulkhead by using a gradienter; the third step, based on the segment standard three-dimensional measurement data report, drawing corresponding half-width reference lines from the shipboard side wall to the midship by 200mm and 10m straight thatching line auxiliary reference lines on the framework surface of the deck, and drawing bow-end and stern-end frame plus or minus 200mm end reference lines on the corresponding positions. By adopting the design method, the outfitting piping system can be highly precisely mounted in the segment of the cabin, and the purposes of cancelling joining and correcting pipes on site are realized for most of the segments. The design method is high in precision and the piping system can be highly precisely mounted in the segment of the cabin.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

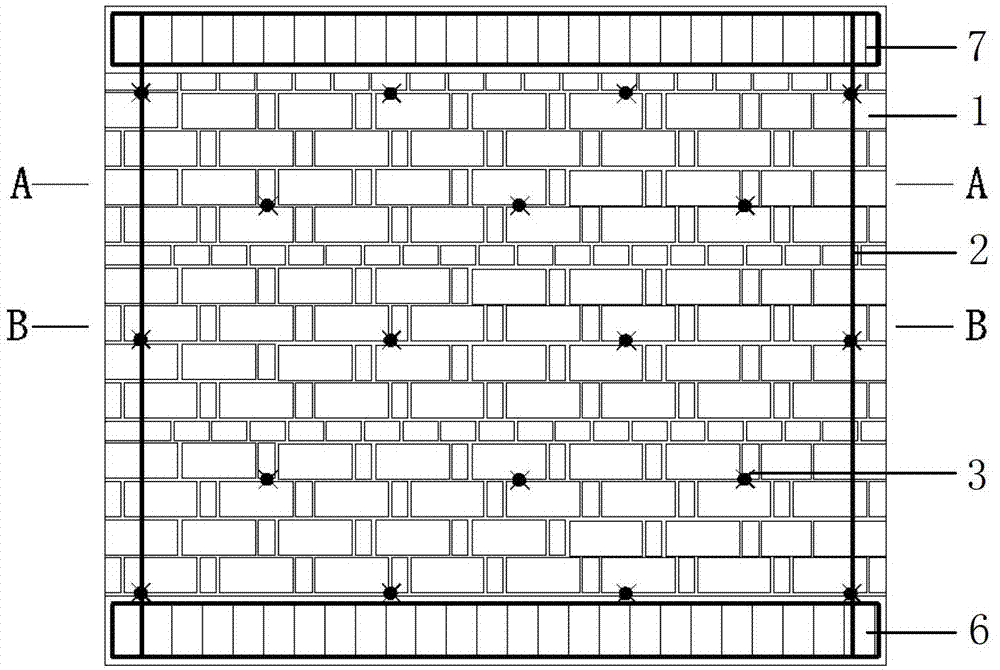

Insulating mortar strengthening layer rowlock wall with steel wire mesh for setting hose tooth constructional column and manufacturing method thereof

The invention relates to an insulating mortar strengthening layer rowlock wall with steel wire mesh for setting a hose tooth constructional column and a manufacturing method thereof, belonging to building field. The rowlock wall comprises a hose tooth constructional column, a reinforced concrete ring beam, transverse tie-reinforcement ribs, a wall body and an exterior wall insulating mortar composite galvanized steel fabric sheet; the wall body is bricked up to form a cavity by concrete through horizontal bricking, side bricking or vertical bricking; vertical holes with indenting are bricked at the joints of longitudinal and cross walls and interior and exterior walls; a vertical constructional rib is arranged at the center of the vertical hole and concrete is poured to form the hose tooth constructional column; the lower end of the vertical constructional rib is anchored inside a foundation beam, the upper end of the vertical constructional rib is fixed inside the reinforced concrete ring beam, and a floor slab is made of cast-in-place concrete; the transverse tie-reinforcement ribs are distributed inside the wall body and are tie-reinforced with the vertical constructional ribs, and are pressed inside the wall body at a certain length; when wall bricking, steel nails are pre-buried along the exterior wall, a layer of insulating mortar is firstly plastered after the exterior wall is bricked, the galvanized steel fabric sheet is hung on the pre-buried steel nail, and then a layer of insulating mortar is plastered. The rowlock wall has the characteristics of being material-saving, good in insulation, good in anti-seismic performance and the like.

Owner:BEIJING UNIV OF TECH

Connector

ActiveUS20060258227A1Inhibit flakingDownsizeVehicle connectorsContact member cases/bases manufactureCross wallClosed space

A protruding table which was conventionally provided in a center portion of a socket body is eliminated, so that a dimension of a socket in widthwise direction is reduced. When the socket is mounted on a circuit board, an adsorption cover is attached to the socket, and the socket is adsorbed by and held on an adsorption nozzle via the adsorption cover. On the other hand, with respect to a header, gaps between header posts arranged in longitudinal direction are separated by cross walls, so that concave portions are formed between the cross walls. Under a state that an adsorption face of the adsorption nozzle is contacted with the header so that a suction opening of the adsorption nozzle face the concave portion, an enclosed space is formed by at least two cross walls, a bottom face of the concave portion and the adsorption face of the adsorption nozzle. When air in the enclosed space is sucked from the suction opening of the adsorption nozzle, negative pressure occurs, so that the header is adsorbed by and held on the adsorption nozzle. Consequently, it enables the adsorption and holding by the adsorption nozzle, and enables to reduce a dimension of the socket in widthwise direction.

Owner:MATSUSHITA ELECTRIC WORKS LTD

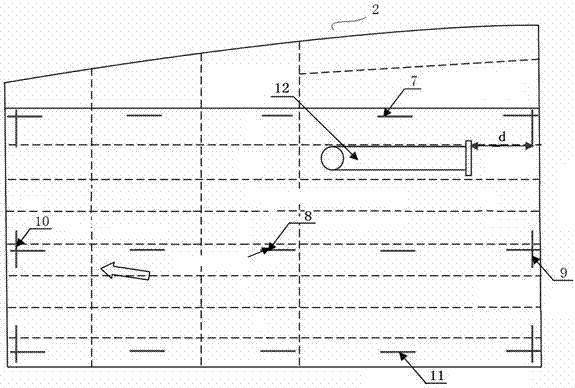

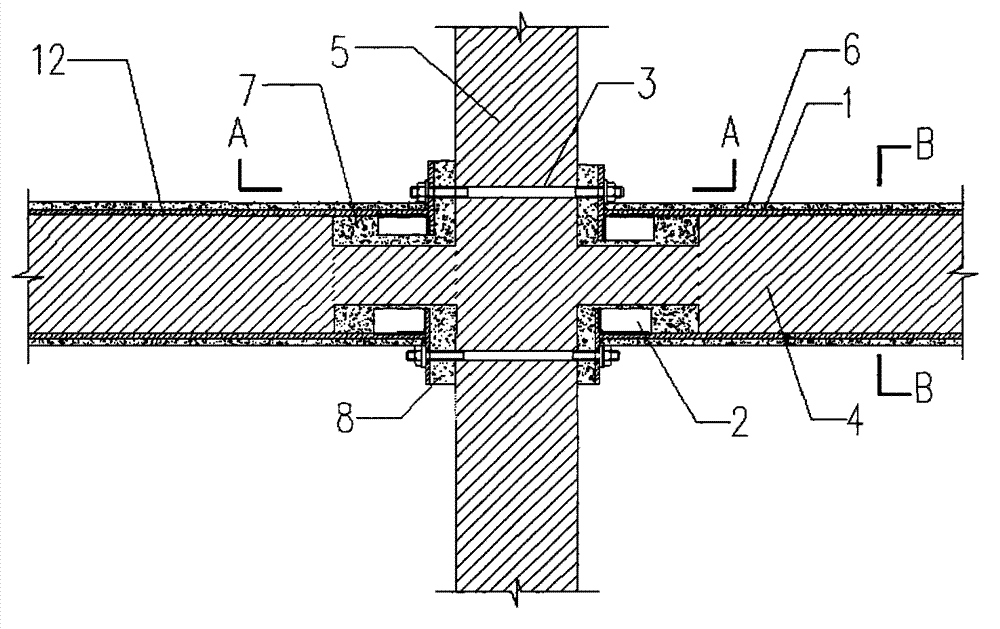

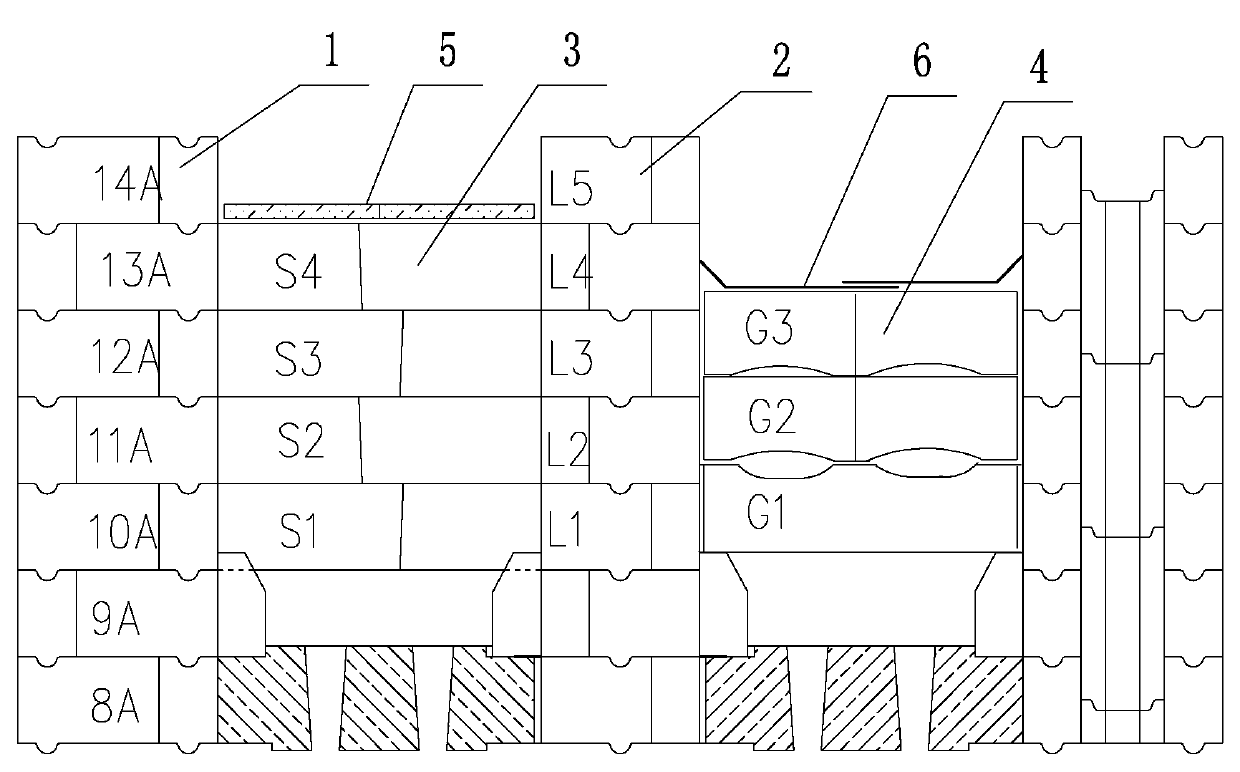

System and method for reinforcing masonry structure by using cross wall and flat steel draw bar

InactiveCN102926550AGuarantee collaborative workReduce stress hysteresisBuilding repairsShock proofingFloor slabPre stress

The invention relates to a system and a method for reinforcing a masonry structure by using a cross wall and flat steel draw bars, and belongs to the field of seismic resistant reinforcement. An upper floor plate of the cross wall or the lower side of a roof board (close to the wall surface) is horizontally provided with the flat steel draw bars; two ends of the flat steel draw bars are respectively provided with flat steel supports; and the flat steel supports at two ends are respectively arranged in open slots at two ends of the cross wall, and are symmetrically pulled and combined through tension bolts. According to the structure system and the method thereof provided by the invention, the flat steel draw bars are utilized for replacing the steel draw bars in the conventional binding-type reinforcing method, flat steel is laid close to the walls and are protected by stainless mortar, and the defect that the steel draw bars are easy to rust is overcome; especially prestress tension is applied to the flat steel, so that the cooperative operation of the flat steel draw bars and a wall body is ensured, and the stress hysteresis phenomenon is reduced; and the flat steel draw bars have greater tension force than that of steel draw bars, so that the seismic resistant reinforcement effect is played relatively effectively.

Owner:江西省坤泽建筑工程有限公司

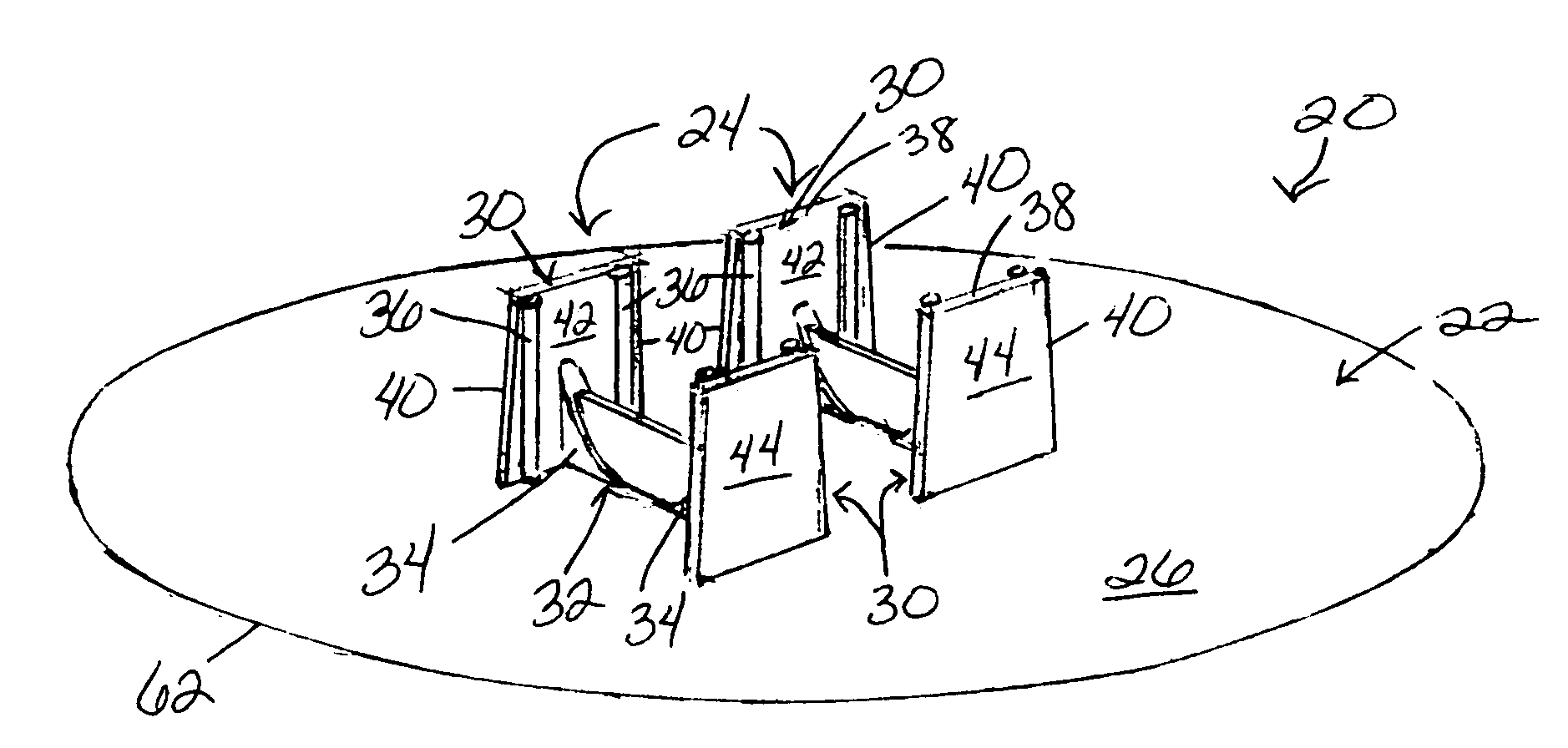

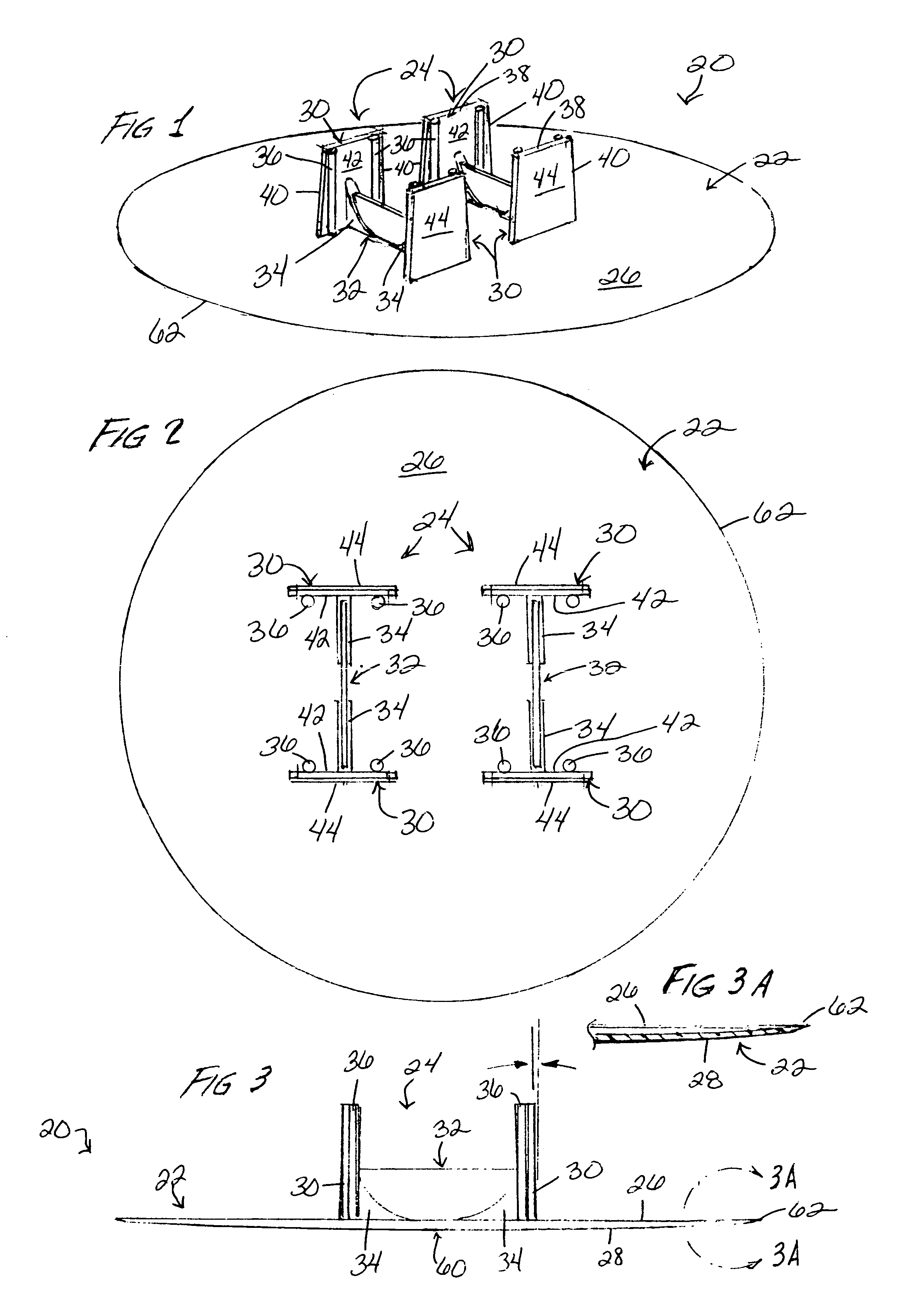

Panel connector system

A panel connector system is provided and includes a plurality of panels and panel connectors. Each panel includes panel sidewall extensions, lips extending from the sidewall extensions, and cross-walls. The sidewall extensions, lips, and cross-walls define outwardly opening edge channels. The panel connectors include a base and a member extending generally transversely from the base. The base includes a base plate and a contact element. The arm portion includes a generally longitudinal slot, a ledge or protruding portion and a spring portion. A male seating surface extends from the ledge and a female seating surface is present on the spring portion. The clip base plate is fastened to the panel cross-wall and one of the lips is disposed in the clip slot when the clip is attached within the edge channel. Two panels are reversibly connected by raising one of the panels and vertically aligning and lowering one of the edges of the raised panel with one of the edges of the other panel, thereby slidably and vertically mating the fastened connectors. When the connectors are mated, the biasing elements are slidingly resiliently biased toward the connector ledges, the male seating surfaces is disposed on the female seating surface, and adjacent lips of joined panels are disposed in the connector slot.

Owner:SKYLINE DISPLAY LLC

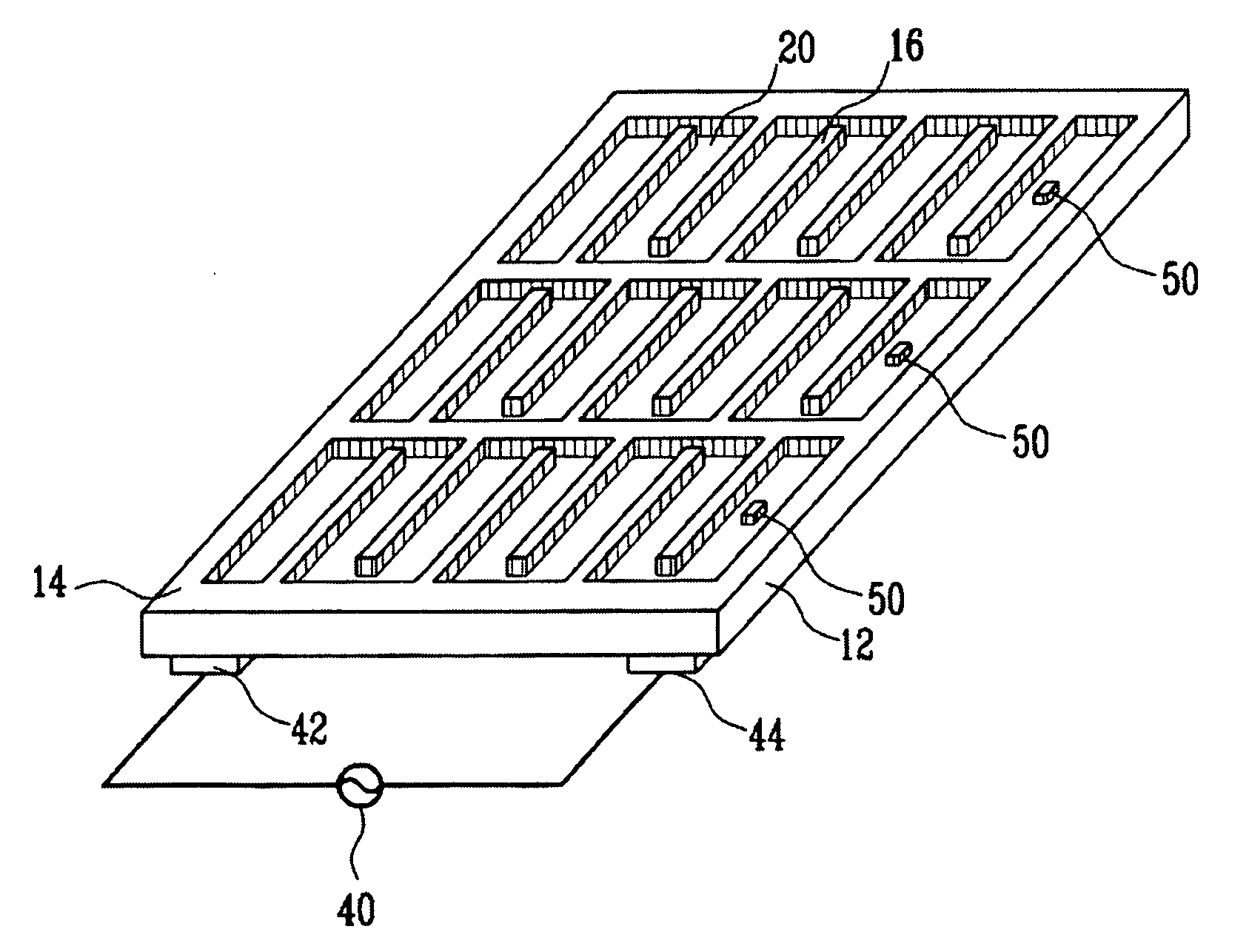

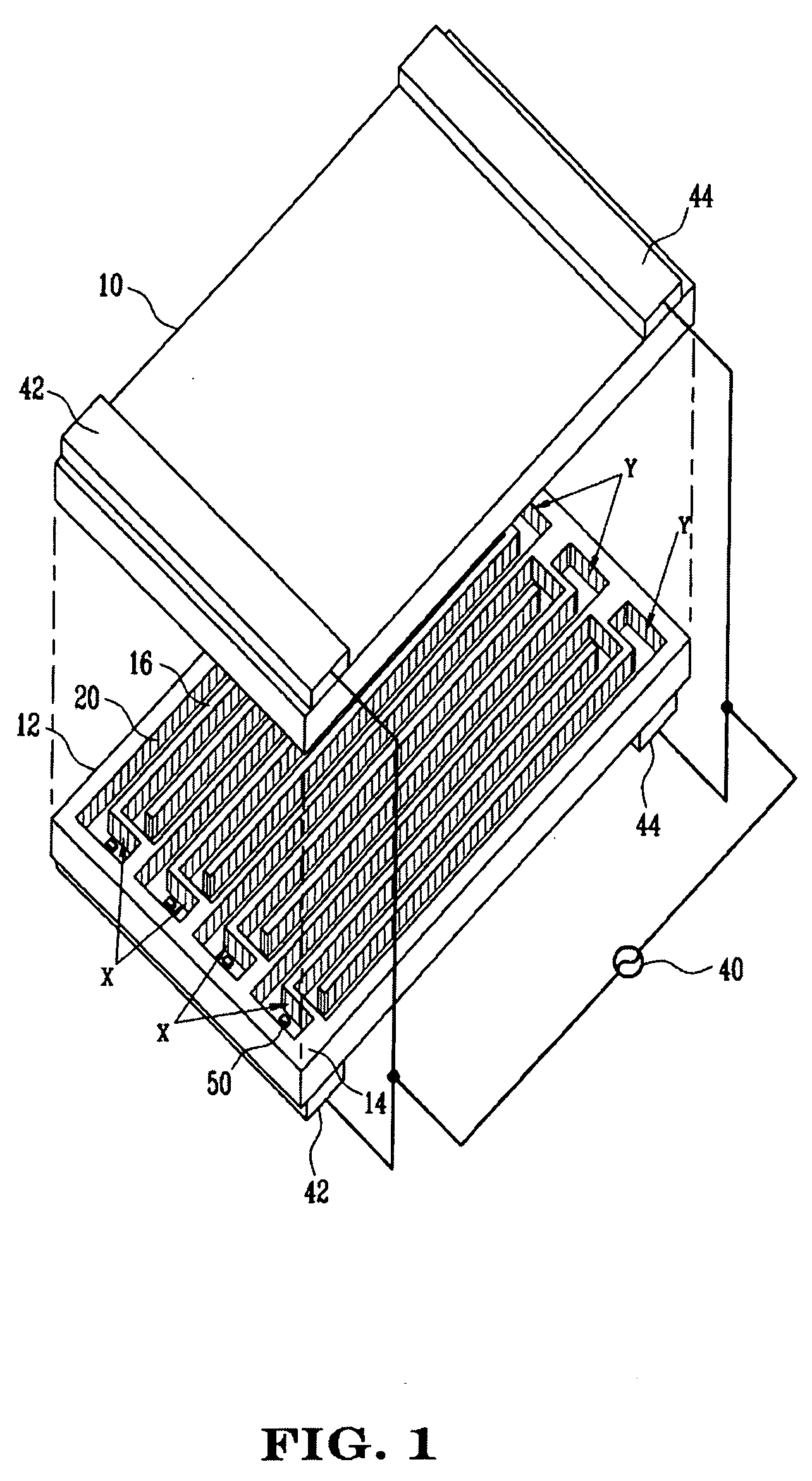

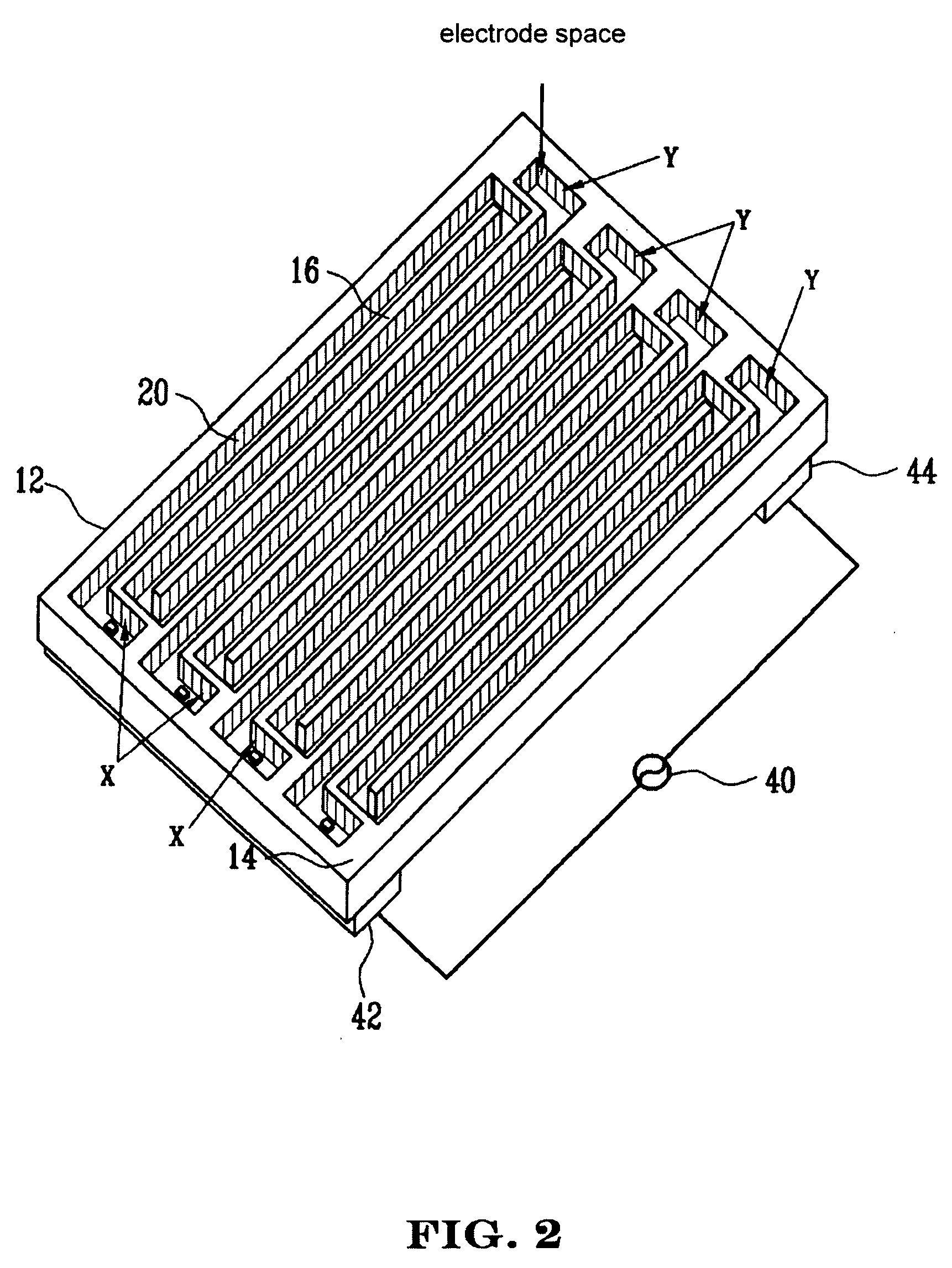

Flat fluorescent lamp improving discharge efficiency

InactiveUS20060017392A1Increase brightnessReduce voltageStatic indicating devicesGas discharge lampsDischarge efficiencyCross wall

The present invention discloses a flat fluorescent lamp which can improve discharge efficiency and luminance by increasing a current density per discharge channel by forming a plurality of independent meandering discharge channels on a rear substrate, lowering a discharge initiation voltage by auxiliary electrodes and internal and external discharge electrodes, and minimizing non-luminescent regions by the external electrodes. A sidewall is installed to form an airtight space between front and rear substrates, cross walls for forming a plurality of independent meandering discharge channels are installed on the rear substrate, and discharge electrodes are disposed at both sides of the starting and terminating ends of the plurality of meandering discharge channels, for discharging the meandering discharge channels in parallel.

Owner:LS TECH

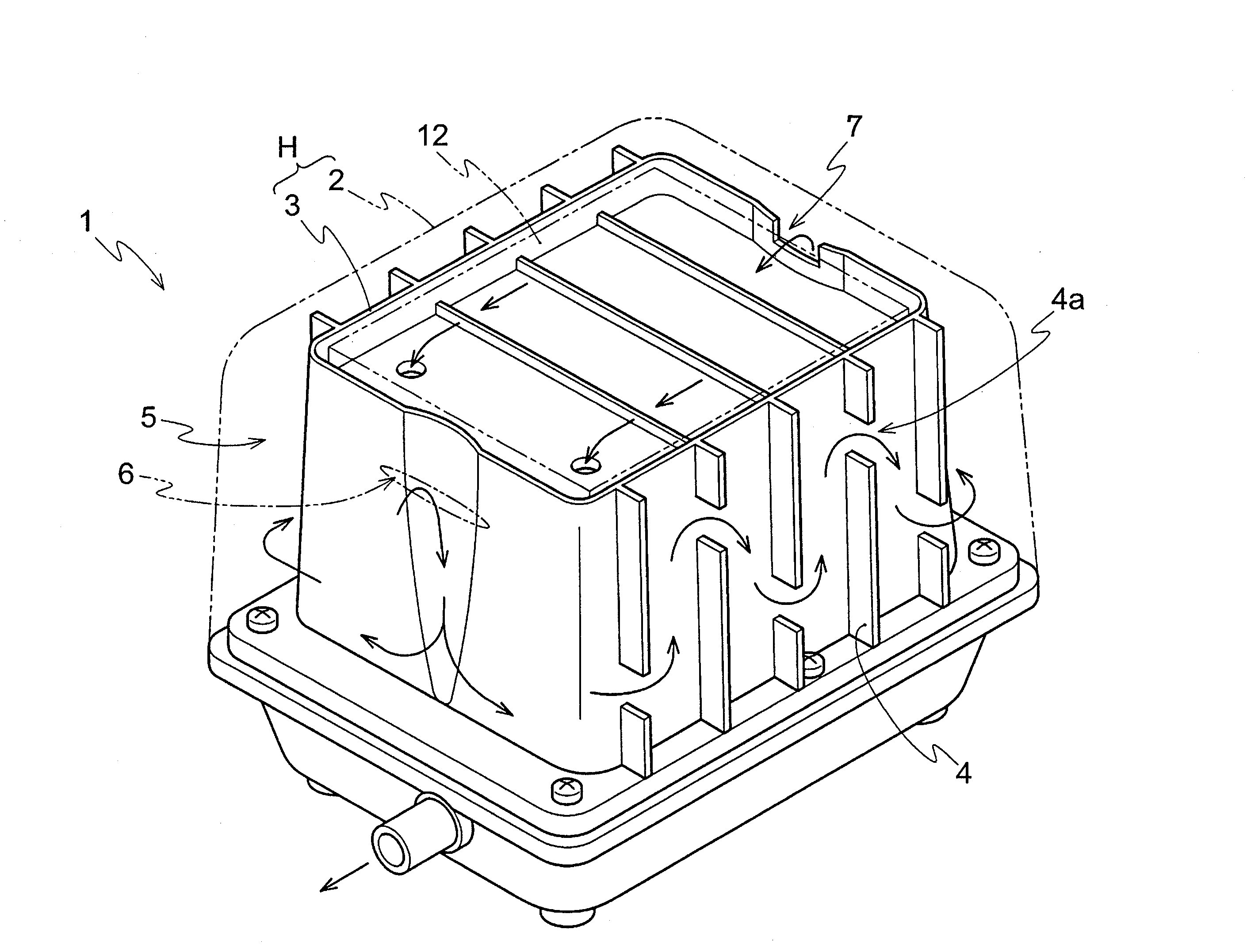

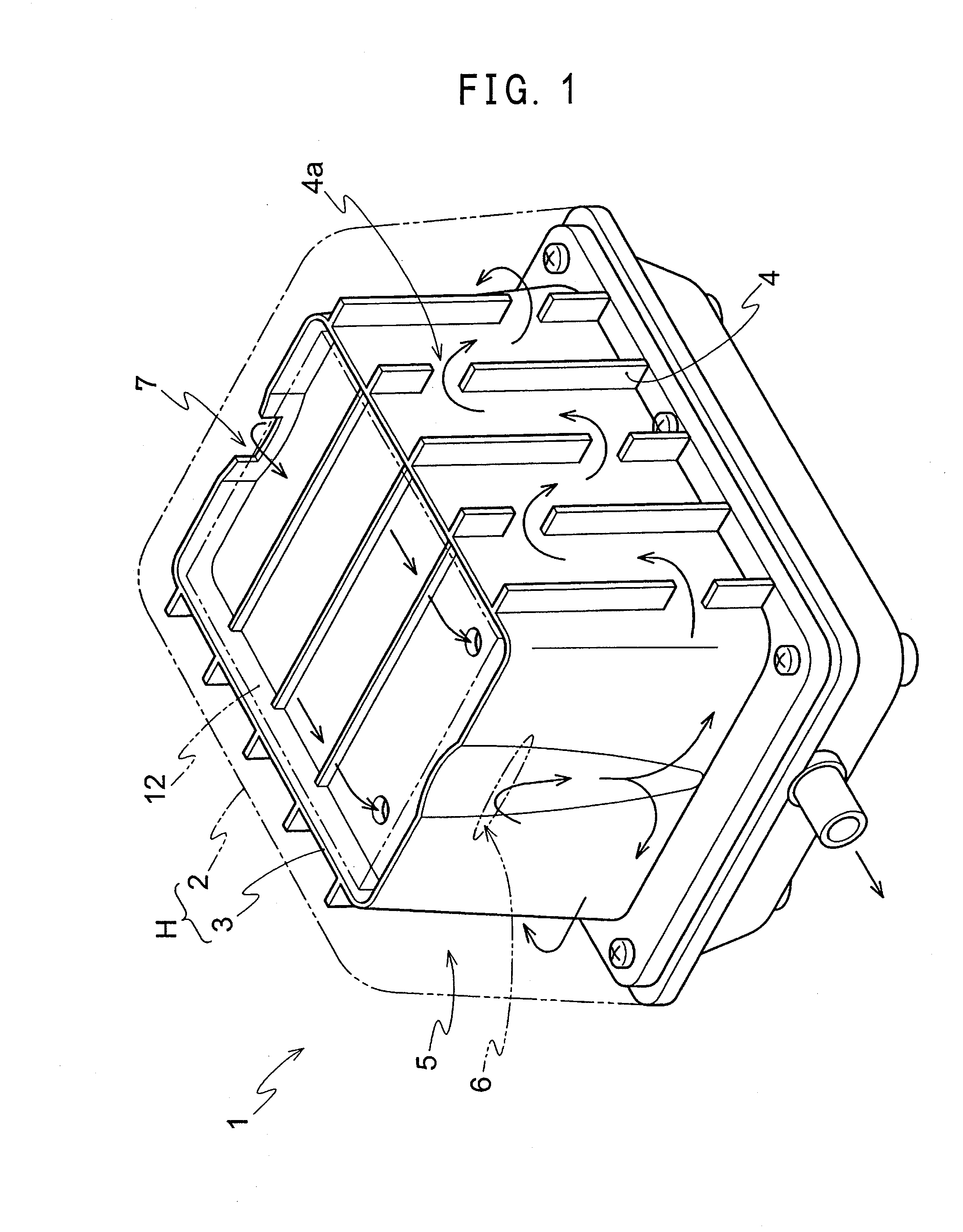

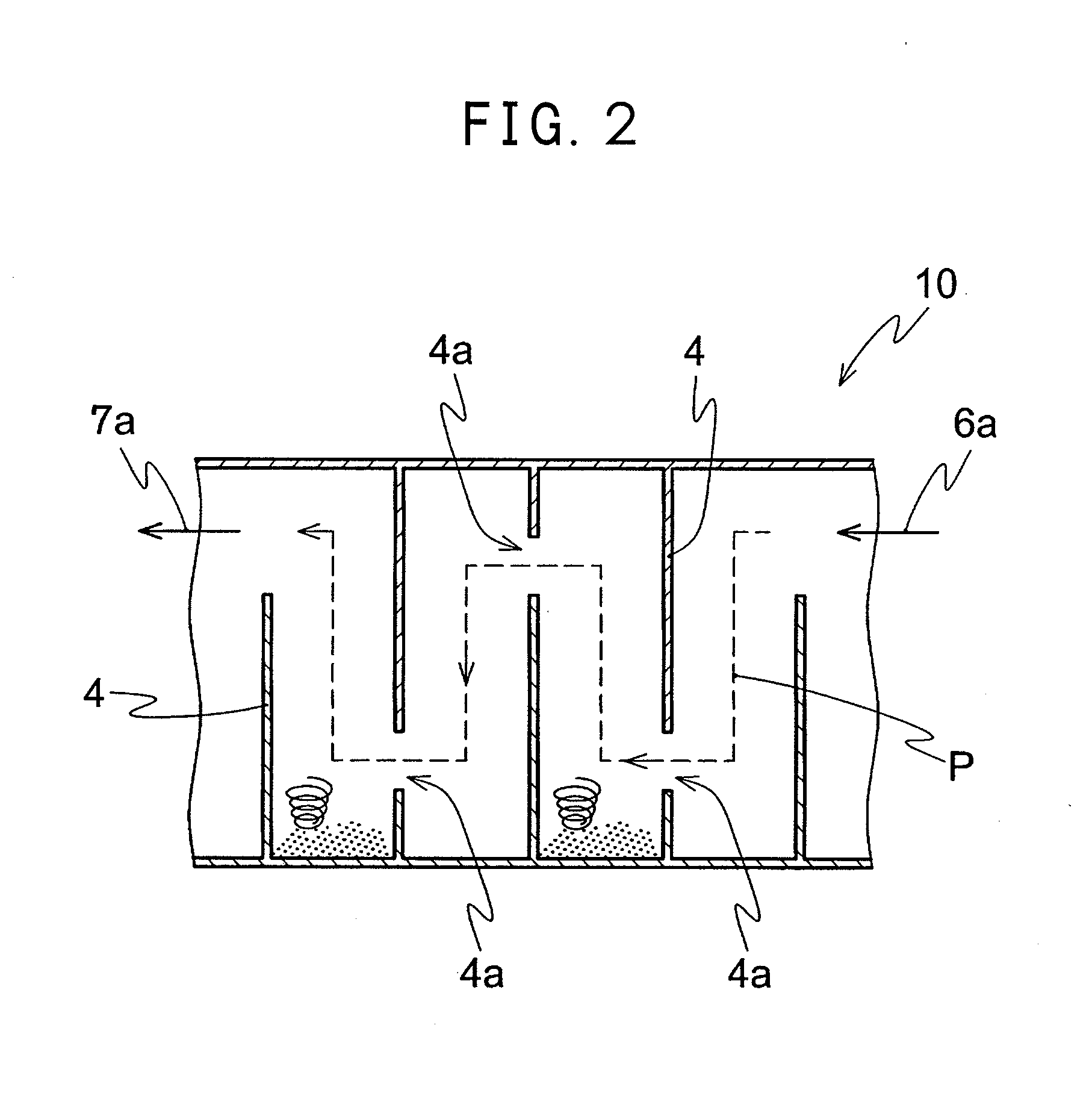

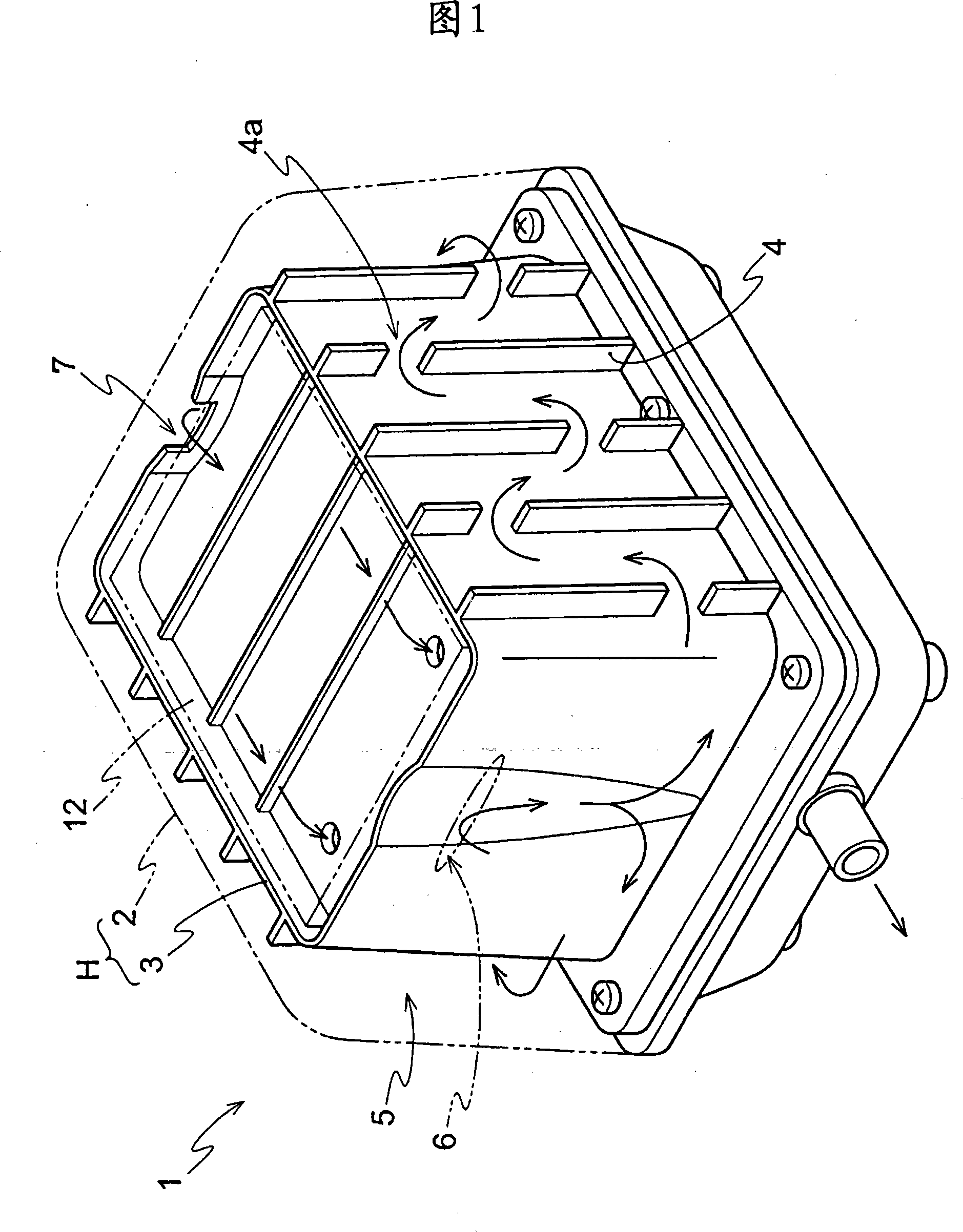

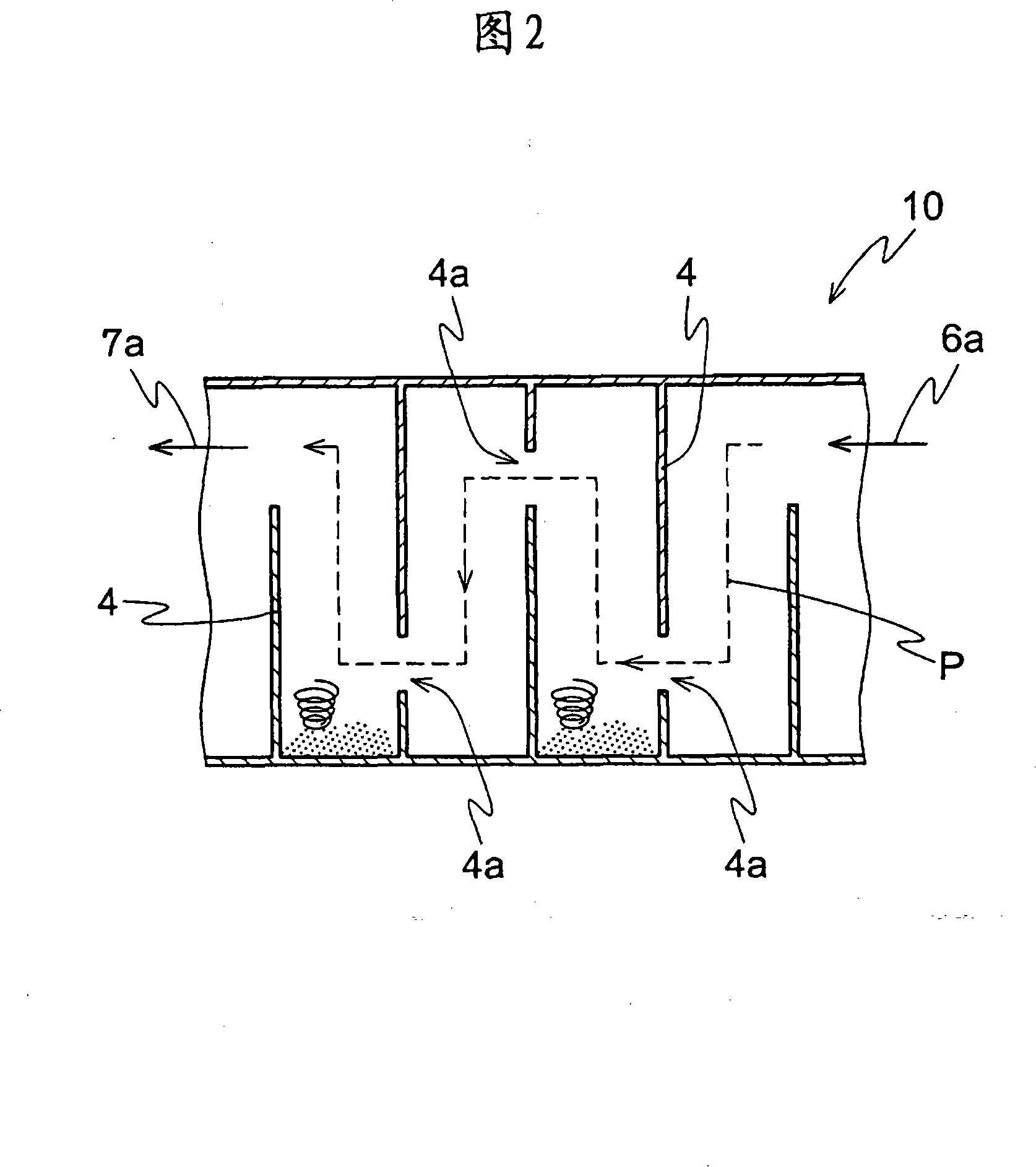

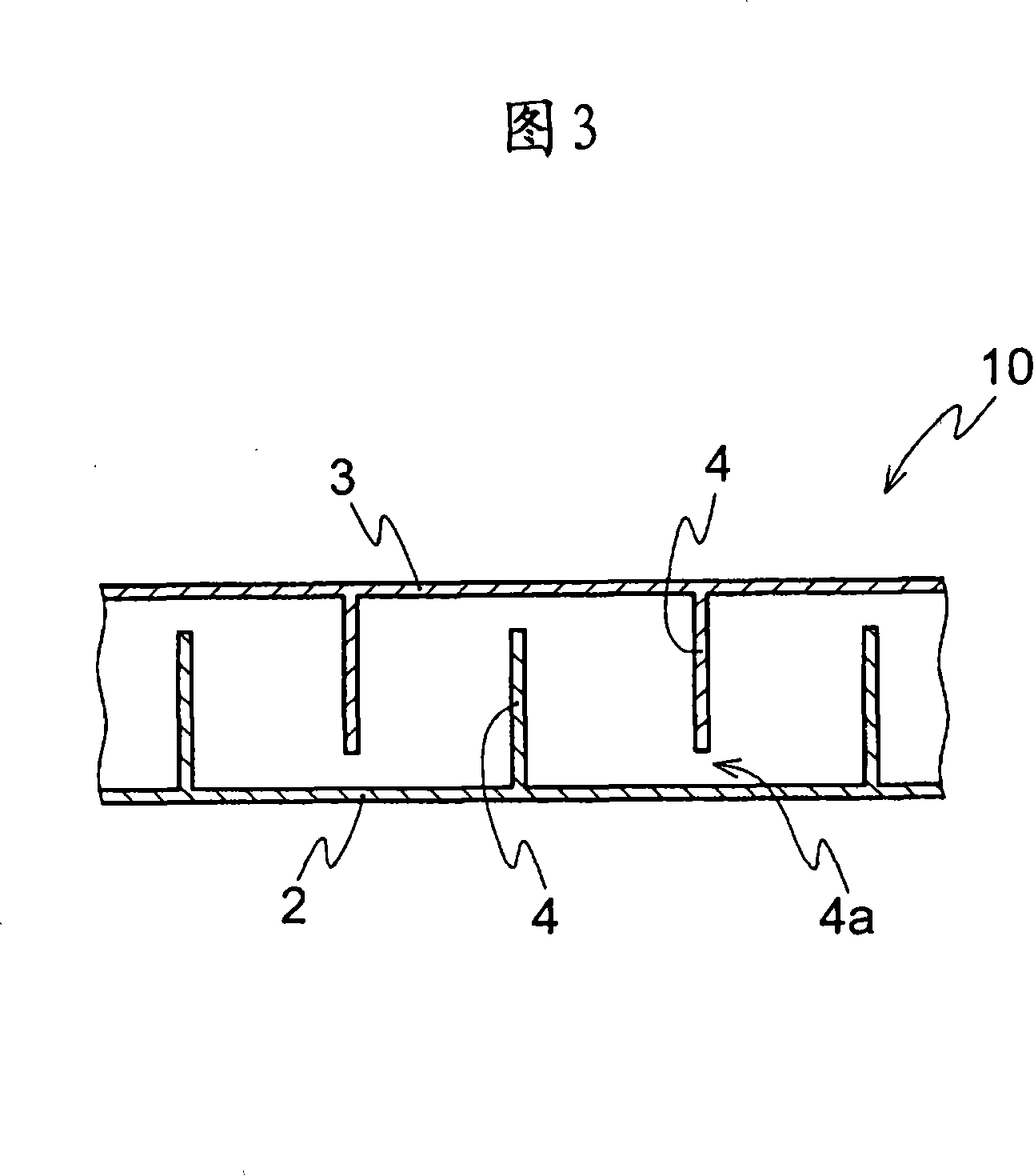

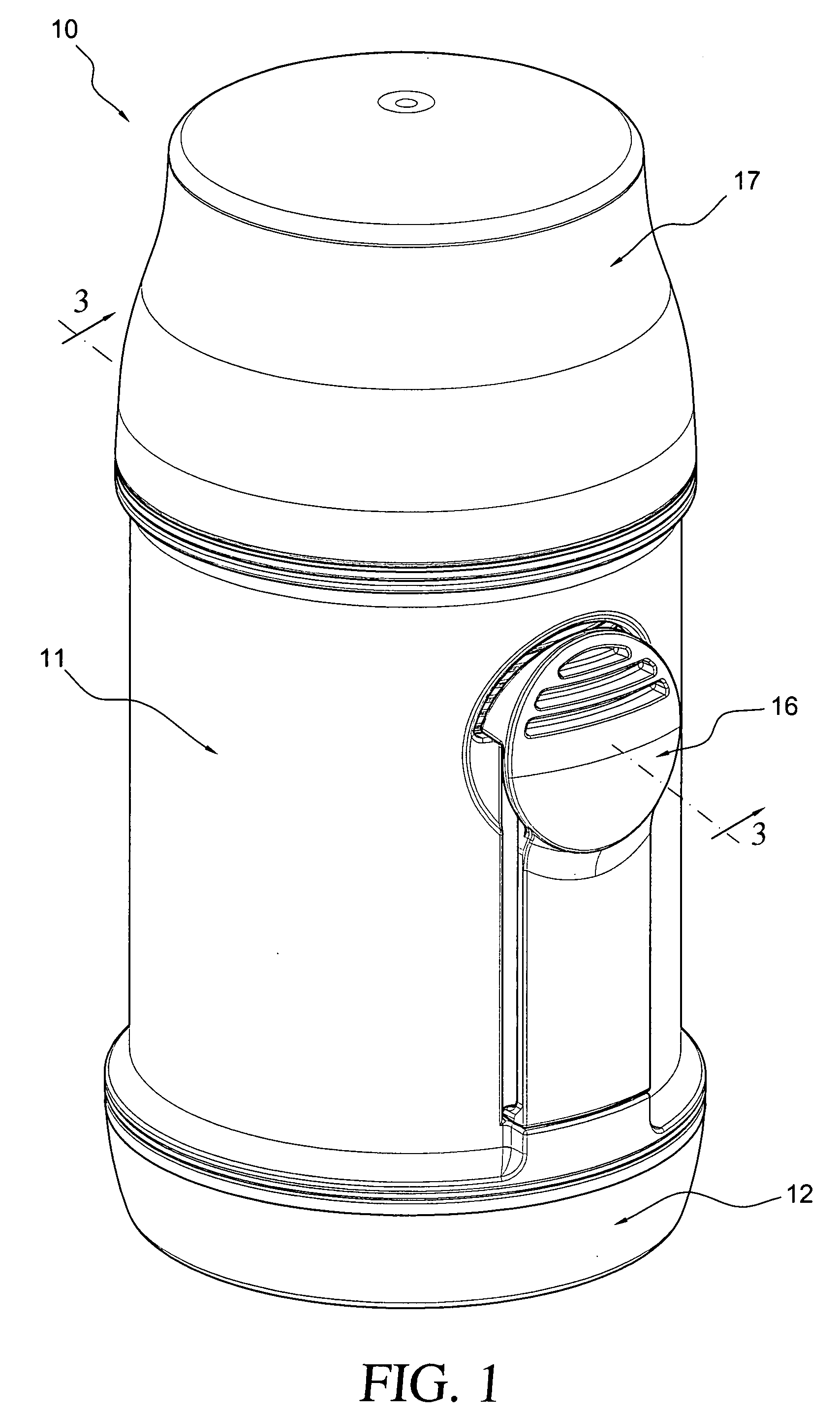

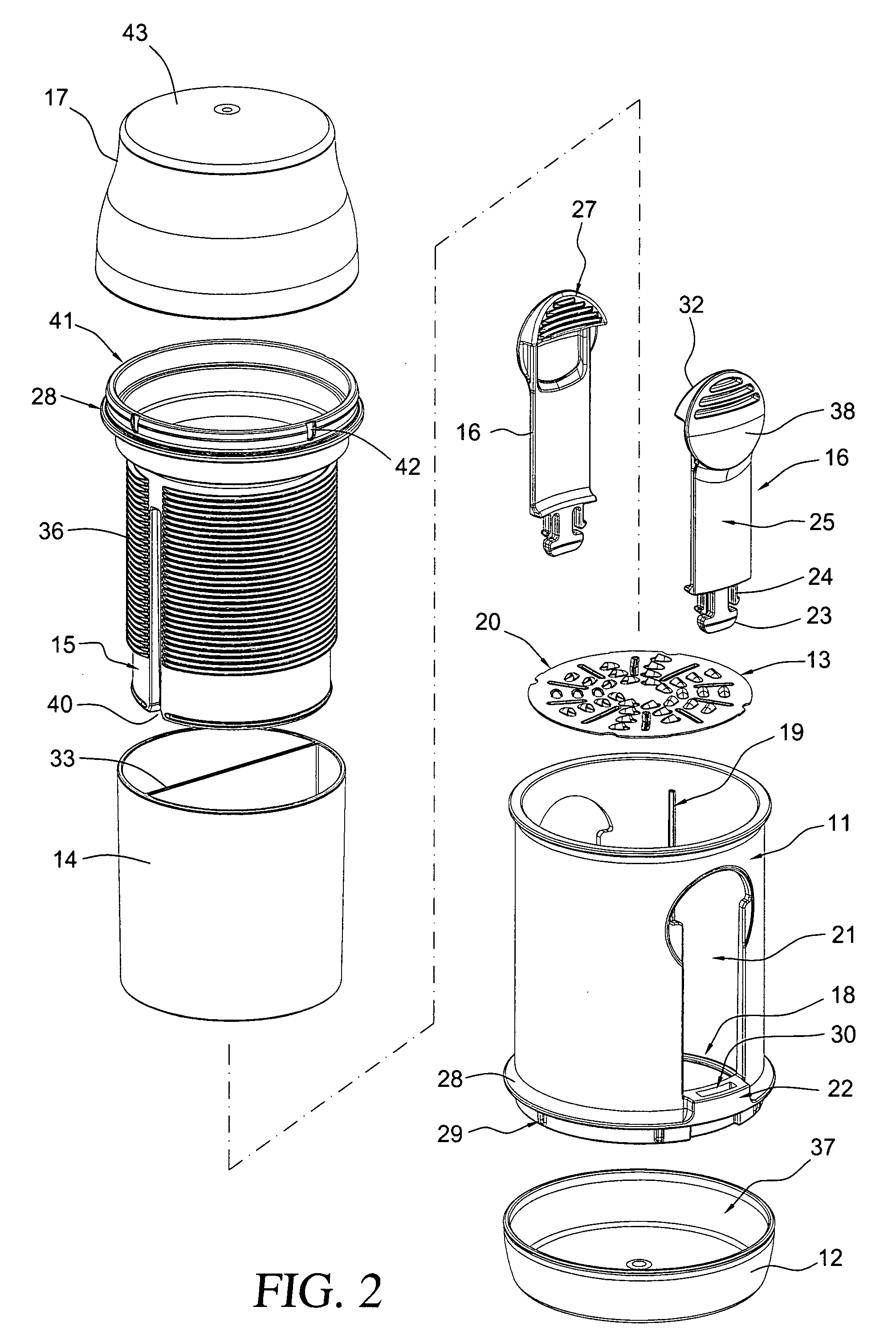

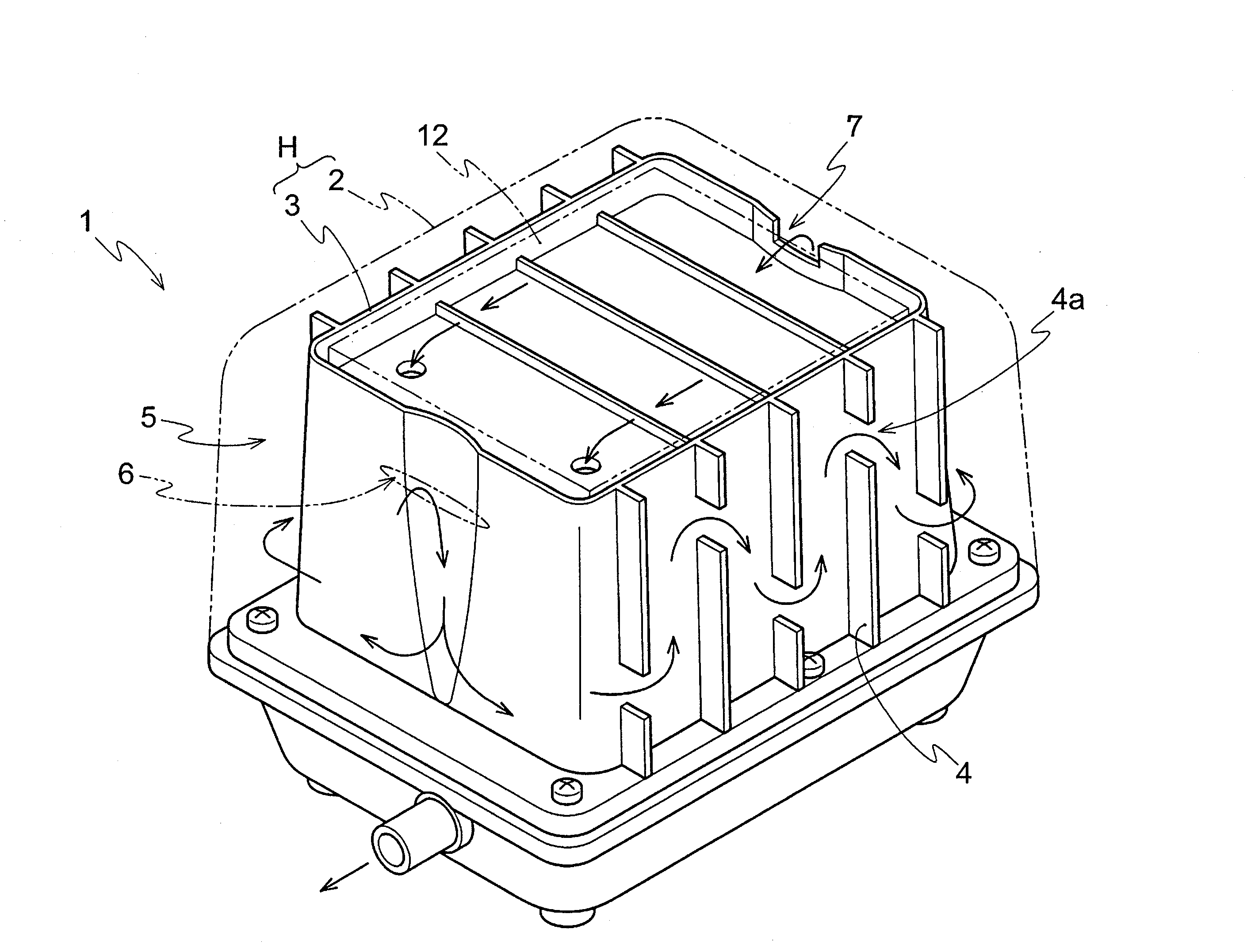

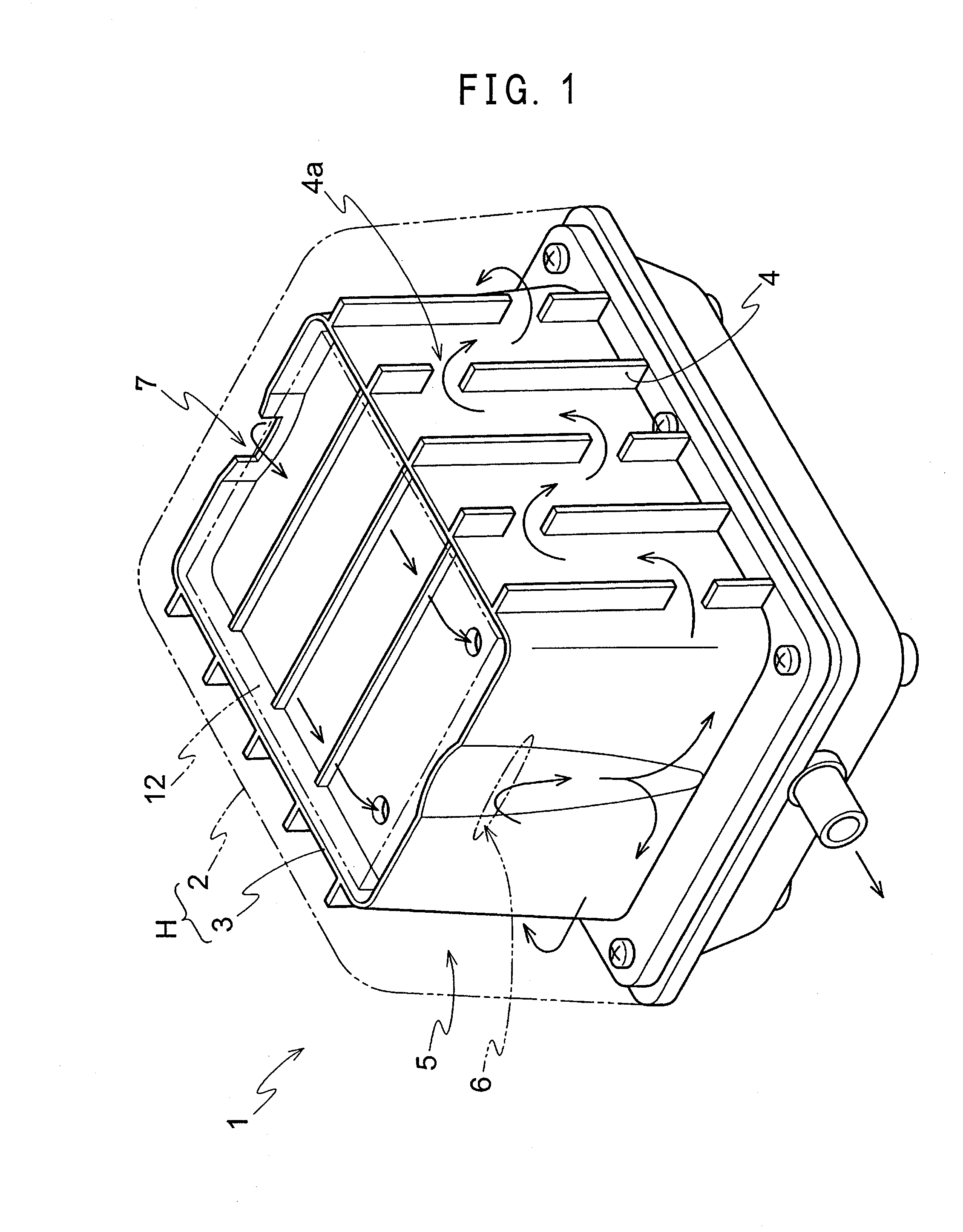

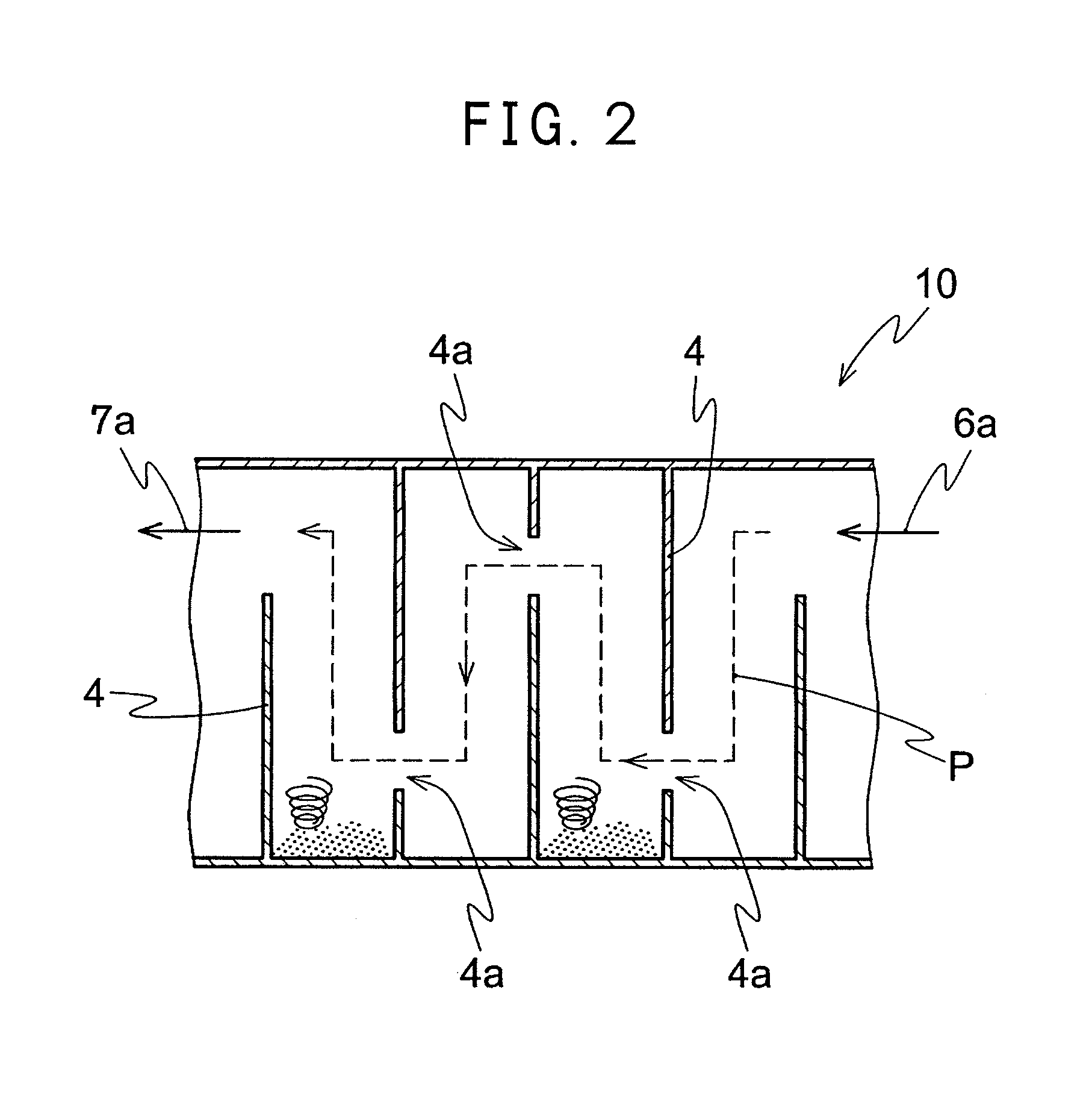

Dust Collecting Mechanism

InactiveUS20080236116A1Efficiency of collecting abilitySimple in assembly work and maintenanceCombination devicesAuxillary pretreatmentCross wallAir pump

A dust collecting mechanism for an air pump, in particular, an electromagnetic vibrational pump having a compact structure, capable of realizing the efficiency of dust collecting ability is disclosed. The mechanism is simple in assembly work. An inlet and an outlet for fluid are provided in the mechanism at a barrier chamber of the mechanism provided in at least one portion of a housing. A plurality of cross walls at which 1 or 2 or more of vent holes are provided are arranged in the mechanism. At least the position of the vent hole of the adjacent cross wall is different among a plurality of the cross walls.

Owner:TECHNO TAKATSUKI

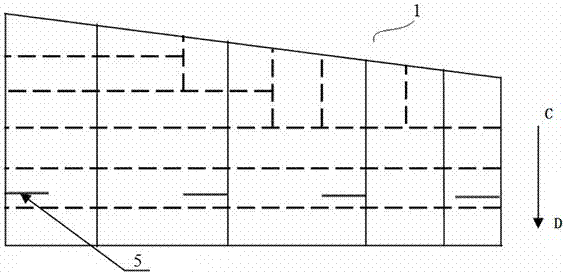

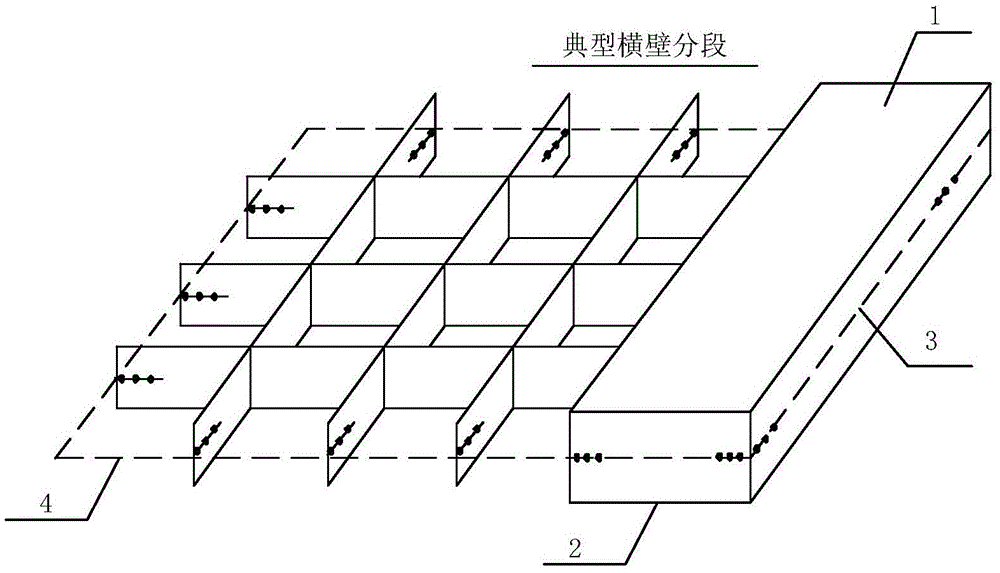

Cross wall segment guide rail bracket installation method

ActiveCN105644715AAccurately determine the installation position in the distanceGuaranteed squarenessVessel partsCross wallEngineering

The invention provides a cross wall segment guide rail bracket installation method. According to the cross wall segment guide rail bracket installation method, the references such as a central datum line, a cross-shaped datum line and a datum marker post are arranged according to a uniform datum, and in the installation process of each guide rail bracket, scribing is conducted for installation with the references as the datum; and meanwhile, the operation, such as combining and welding, is conducted based on the references. According to the cross wall segment guide rail bracket installation method, the installation squareness and installation perpendicularity of the guide rail brackets are guaranteed, distortion is avoided, and positioning is more accurate; uniform datum points are adopted from beginning to end, and thus the positioning precision and installation precision of the guide rail brackets are further guaranteed; and when cross wall segments are combined, positioning and combining are conducted with the central datum line as the datum, and thus the cross wall positioning precision can be further improved.

Owner:DALIAN SHIPBUILDING IND

Dust collecting mechanism

InactiveCN101153588AGet dust collectionPrevent intrusionPositive displacement pump componentsFlexible member pumpsAir pumpCross wall

An object of the present invention is to provide a dust collecting mechanism for an air pump, in particular, an electromagnetic vibrational pump having a compact structure, capable of realizing the efficiency of dust collecting ability and simple in assembly work. The present invention is characterized in that the inlet and outlet of fluid are provided at a barrier chamber provided in at least one portion of a housing, a plurality of cross walls at which 1 or 2 or more of vent holes are provided are arranged, and at least the position of the vent hole of the adjacent cross wall is different among a plurality of the cross walls.

Owner:TECHNO TAKATSUKI

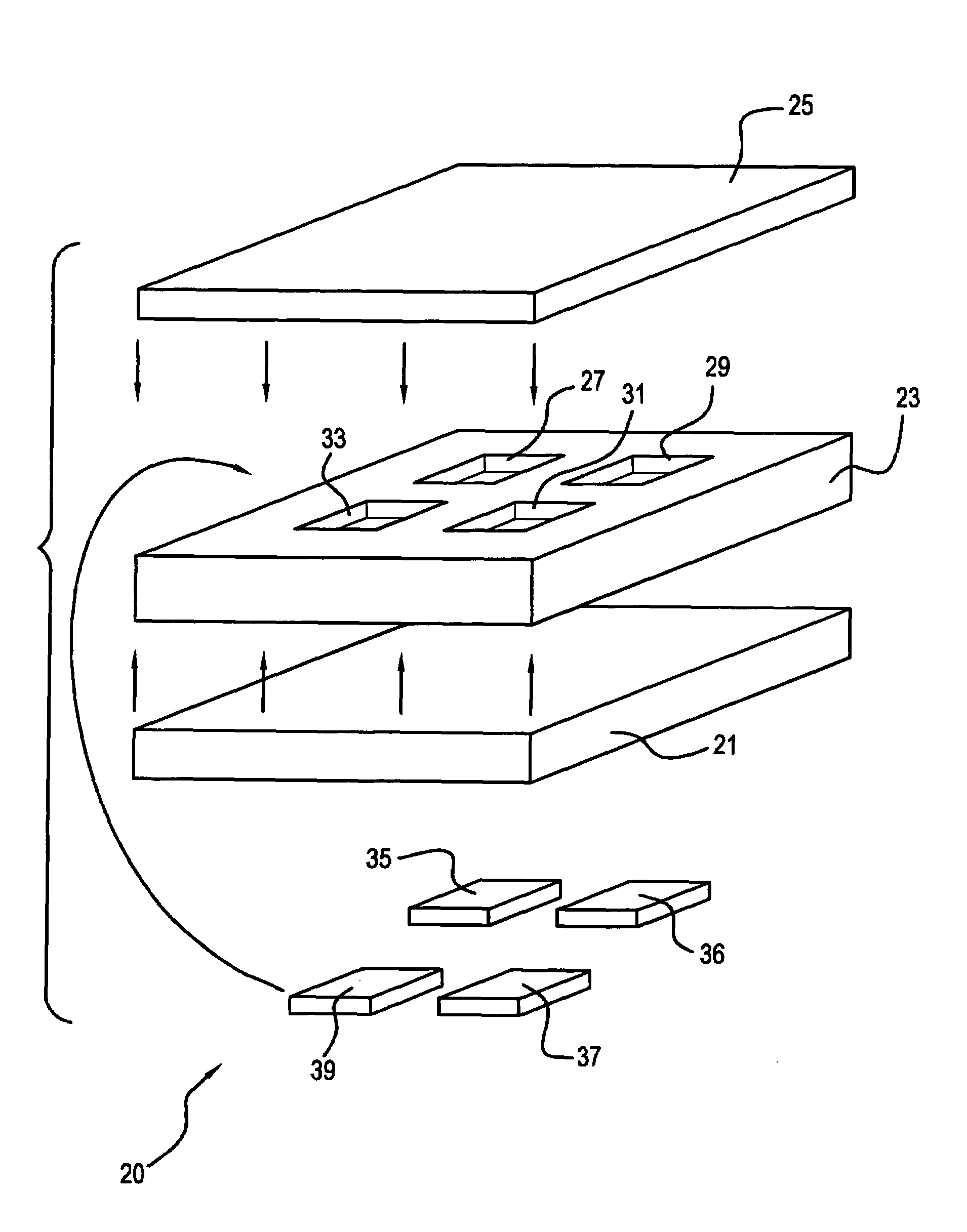

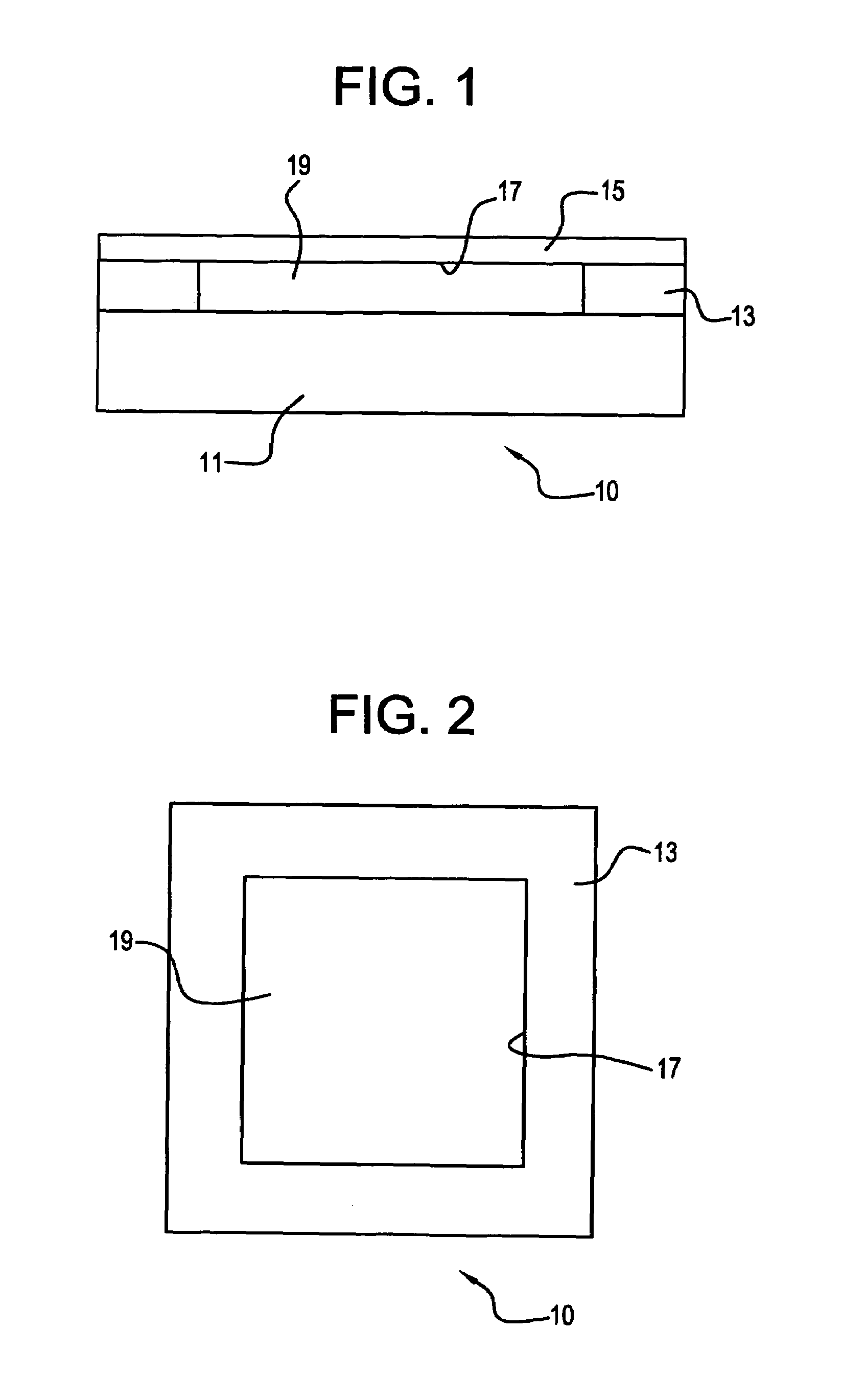

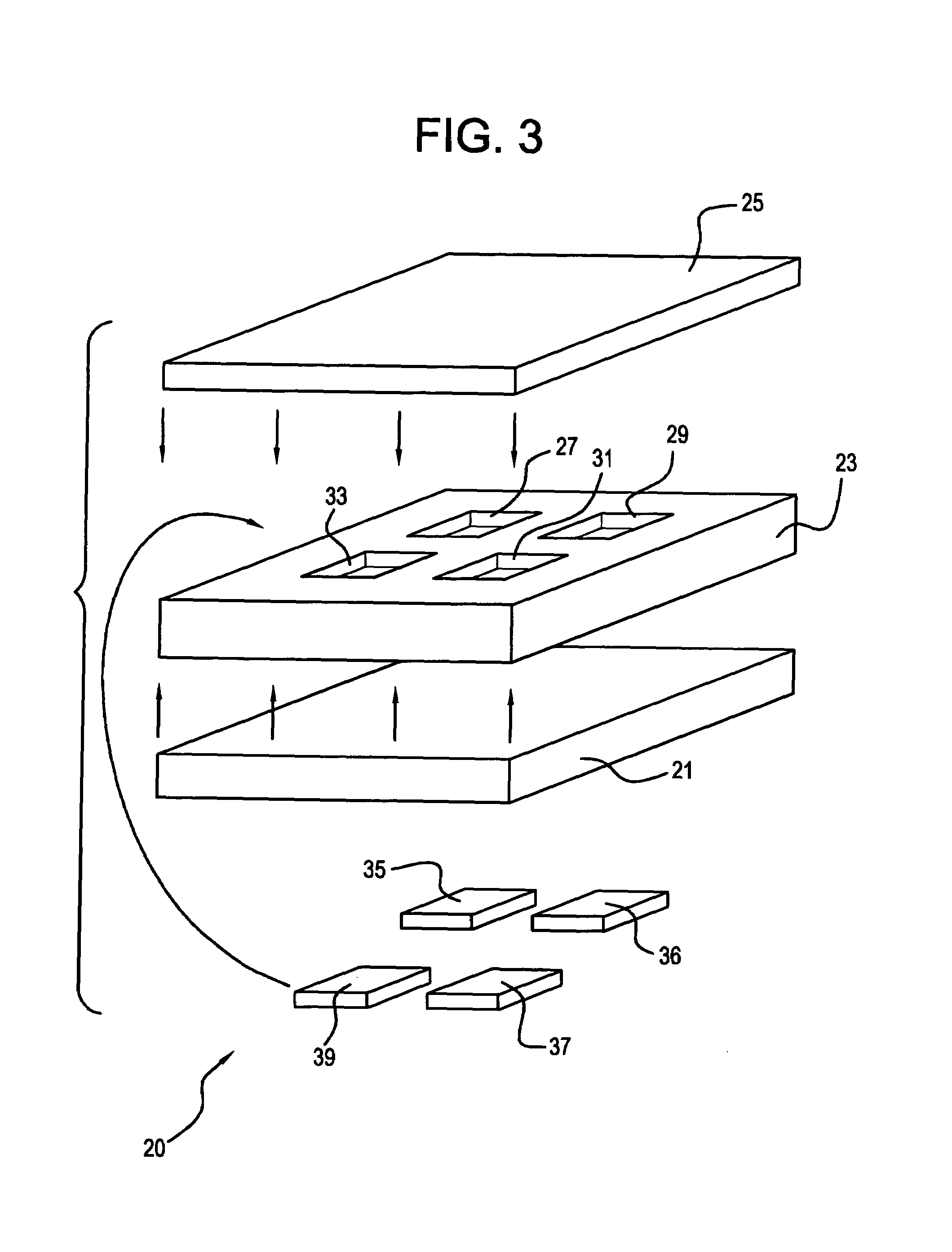

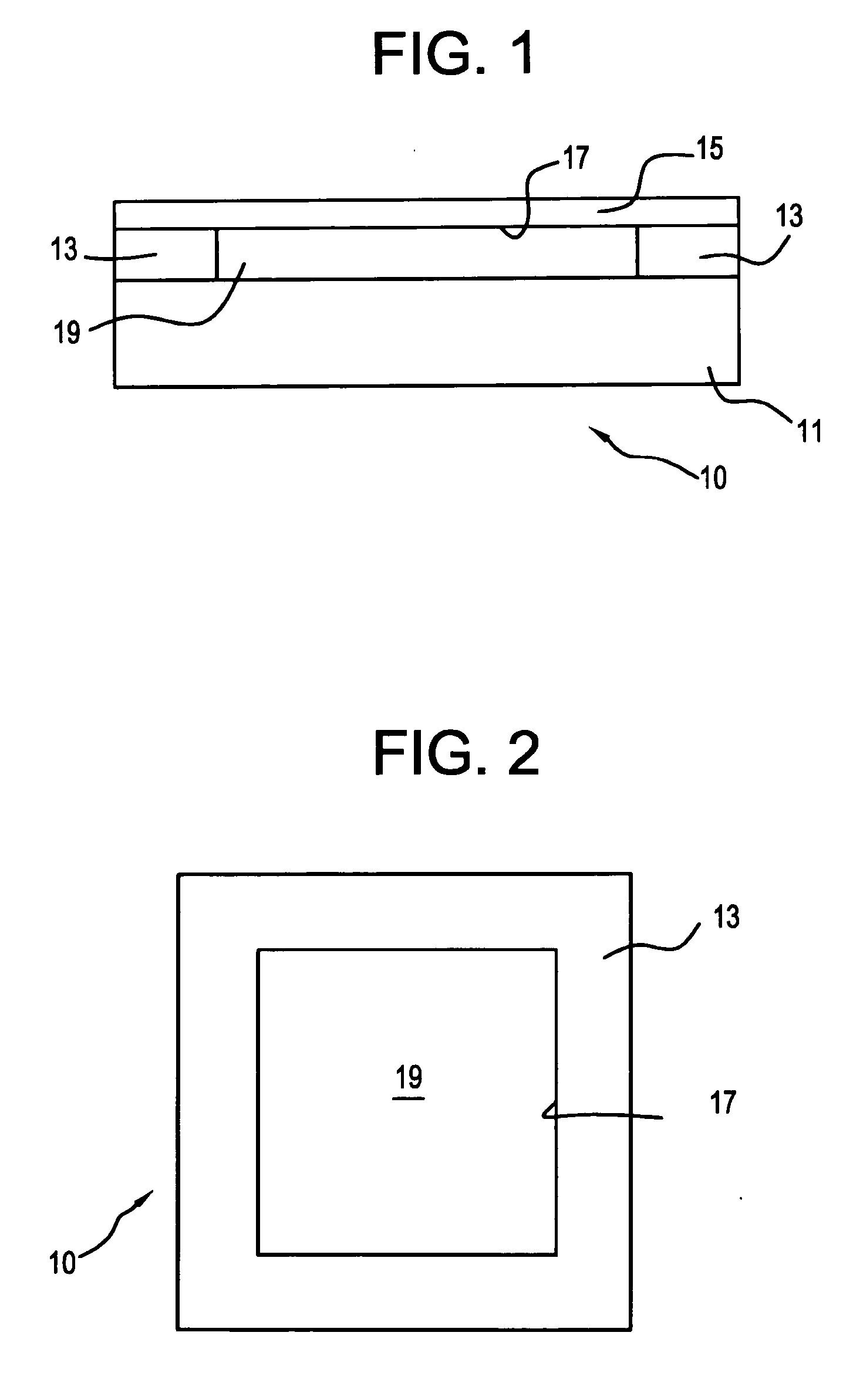

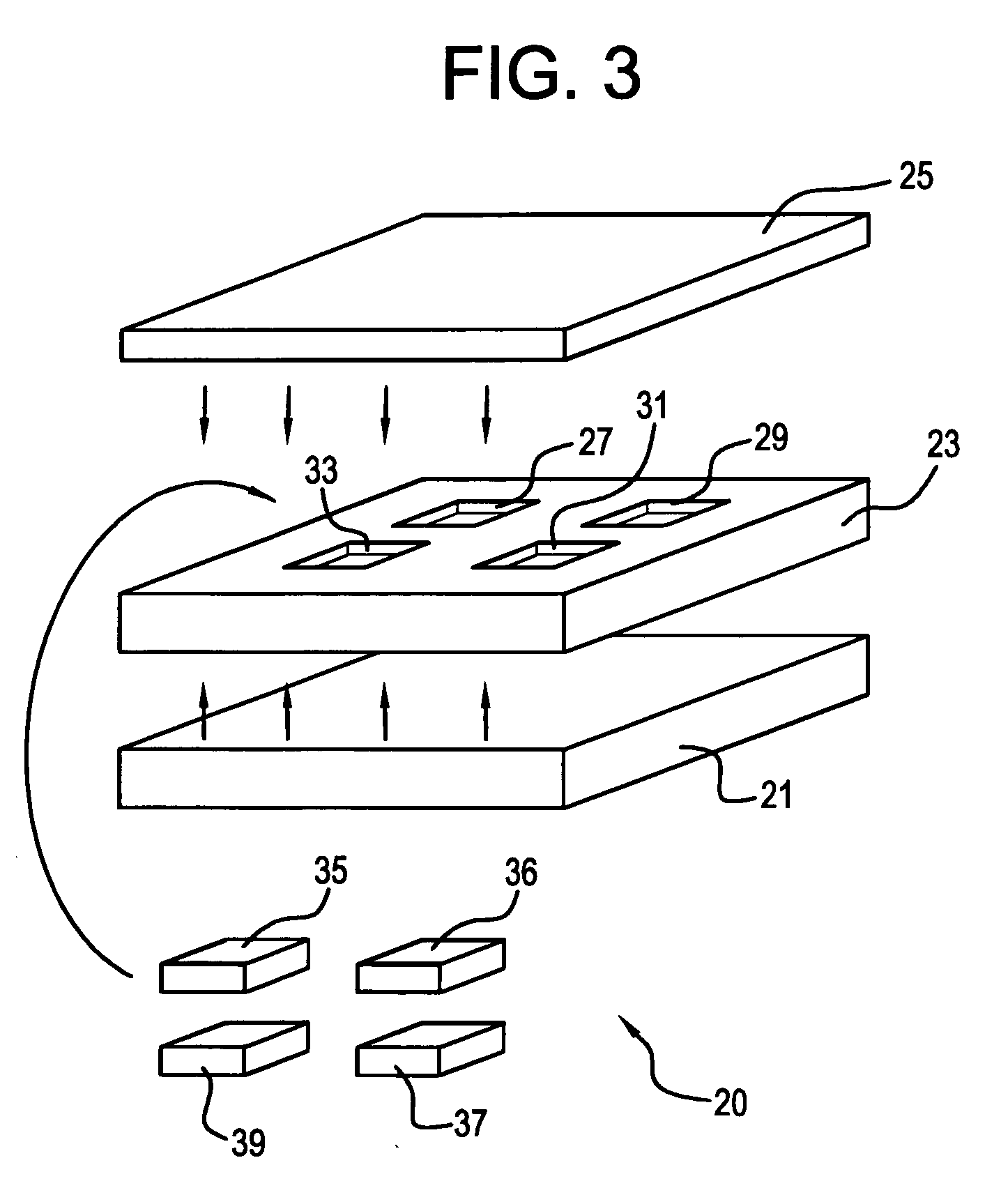

Ceramic armor and method of making by encapsulation in a hot pressed three layer metal assembly

InactiveUS20060105184A1Plastically deformArmourWelding/cutting media/materialsMetal frameworkBoron carbide

A ceramic armor is disclosed in several embodiments. In a first embodiment, a metal base plate has a metal frame assembled on it having a central opening into which the ceramic material is placed. A cover plate is placed over the frame to enclose the ceramic material on all sides. In a second embodiment, the frame has an open central area that has two crossing walls that define four sub-chambers. Four pieces of ceramic material are placed in the respective sub-chambers and a covering plate is placed over it. In a further embodiment, the frame has a plurality of cavities mechanically formed in it. A ceramic tile or plate is placed in each cavity and a cover plate is placed over the frame. The metal used to encapsulate the ceramic material may, if desired, comprise a Titanium alloy such as Ti-6Al-4V, and the ceramic material may comprise Silicon Carbide, Boron Carbide, Tungsten Carbide, Titanium Diboride or Aluminum Nitride. A hot pressing procedure is carried out on the armor to cause the metal to plastically deform about the encapsulated ceramic material.

Owner:BAE SYST ADVANCED CERAMICS

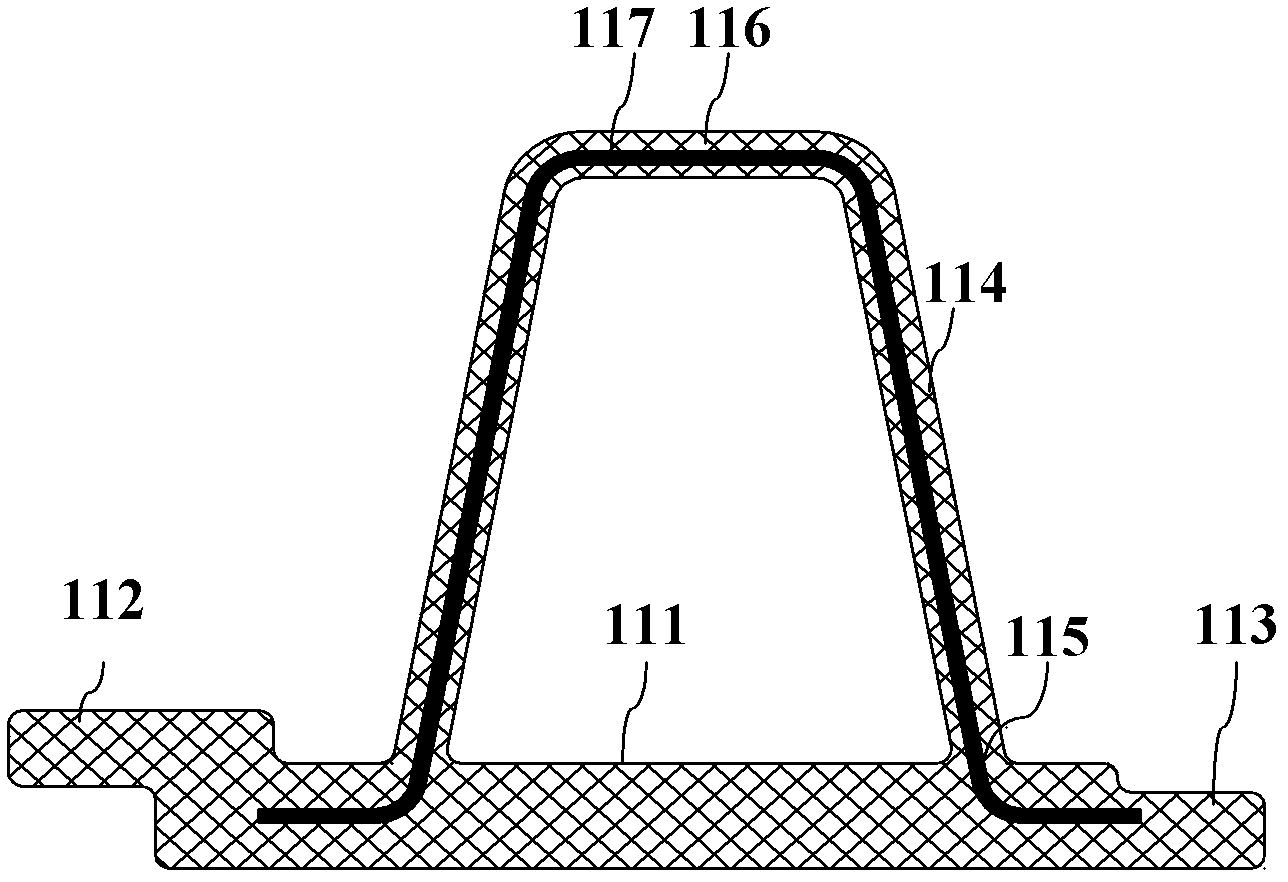

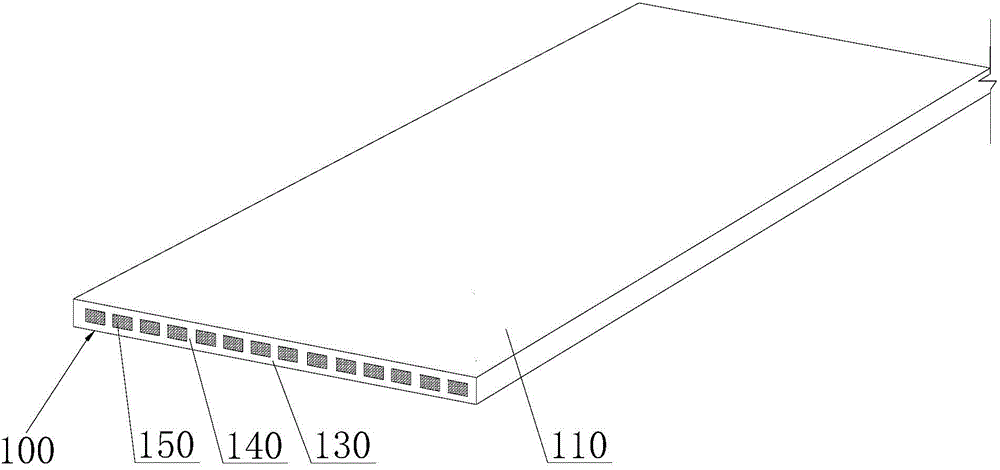

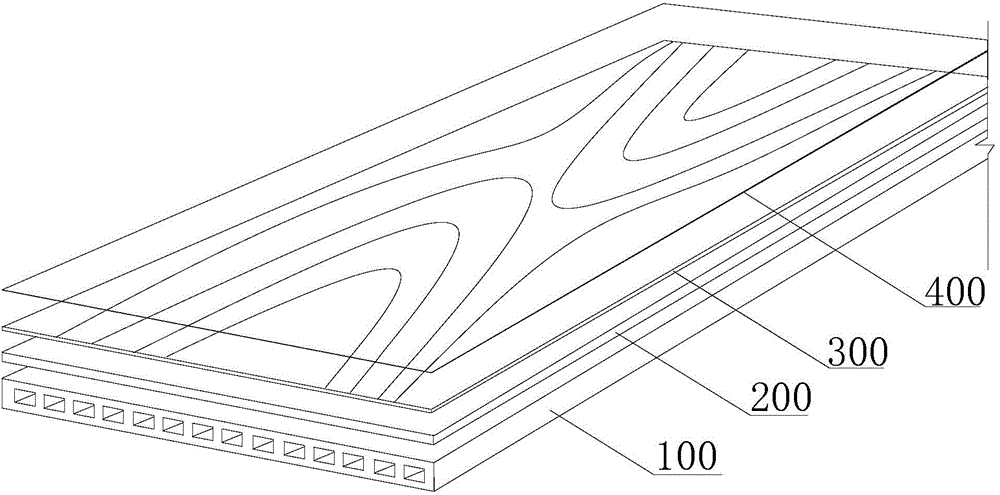

Hollow board and composite board

InactiveCN104403233AIncrease market shareGuarantee product qualitySynthetic resin layered productsLaminationWear resistantColor film

The embodiment of the invention discloses a hollow board. According to the hollow board, uniformly mixed PVC (polyvinyl chloride) composite materials are fused and is processed by a mouth mold of a plastic extruding machine to obtain extrudate; the extrudate is cooled and shaped to obtain a board-shaped body; a strip hole array is formed inside the board-shaped body; the wall thicknesses of upper and lower cross walls of the strip hole array and rib thicknesses of vertical ribs between the adjacent strip holes can ensure strength of the board-shaped body. The embodiment of the invention also discloses a composite board which comprises a light-transmitting and waterproof wear-resistant layer, a color film layer with a decorative pattern and a base layer formed by the hollow board, wherein the light-transmitting and waterproof wear-resistant layer, the color film layer and the base layer are sequentially combined from top to bottom. The hollow board and the composite board which are disclosed by the embodiment of the invention have good waterproofness and mute effect and can be used as floors, ceilings, door plates, wall decoration boards and the like.

Owner:ZHEJIANG TIANZHEN BAMBOO & WOOD DEV

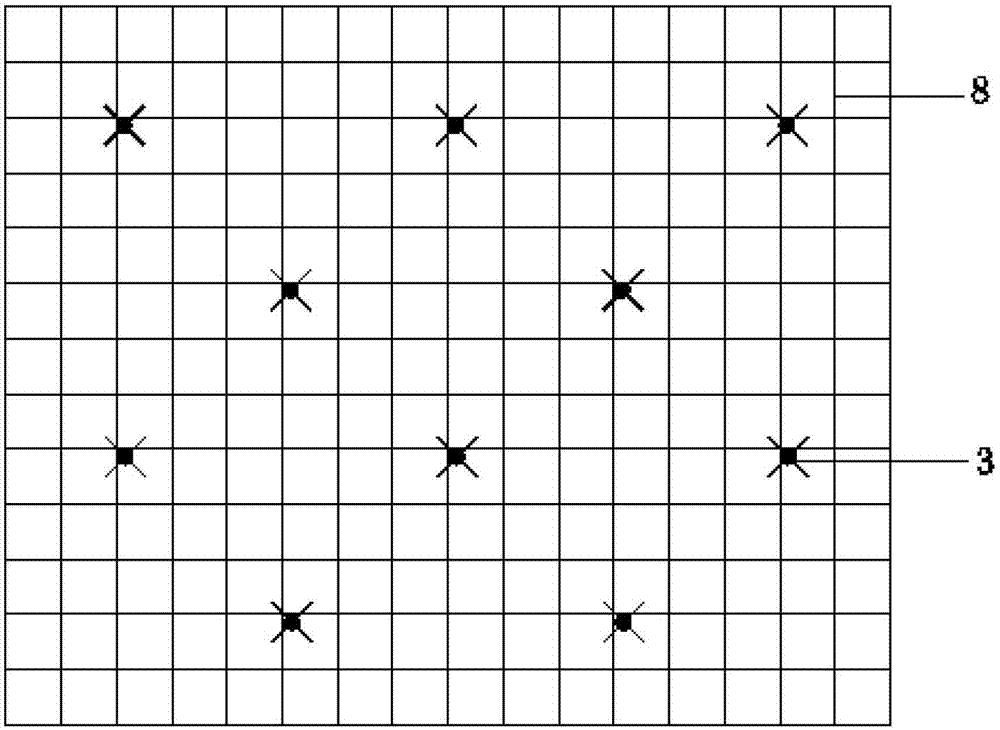

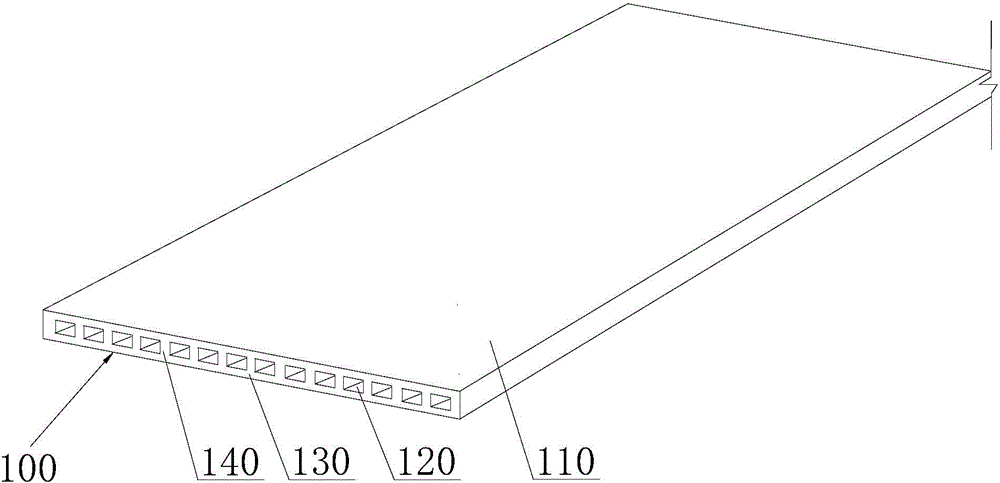

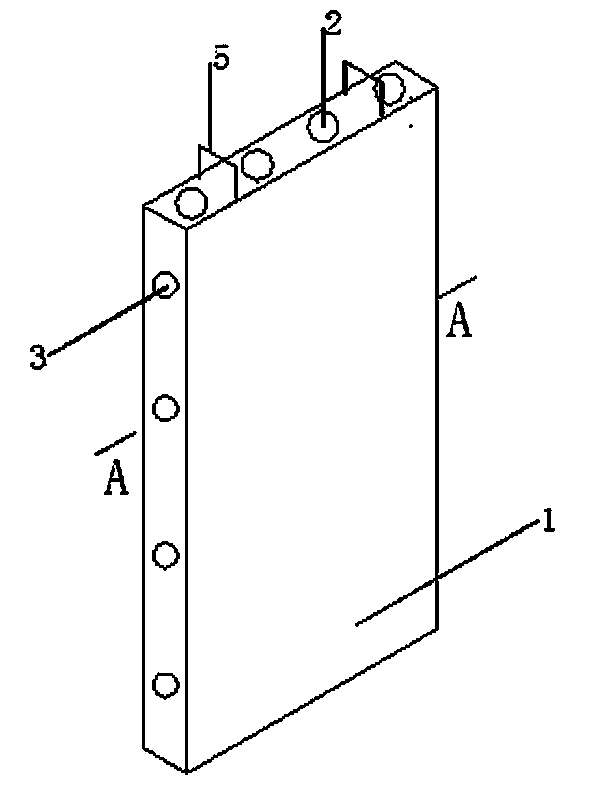

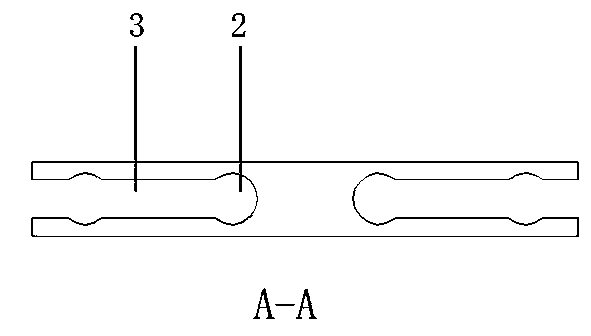

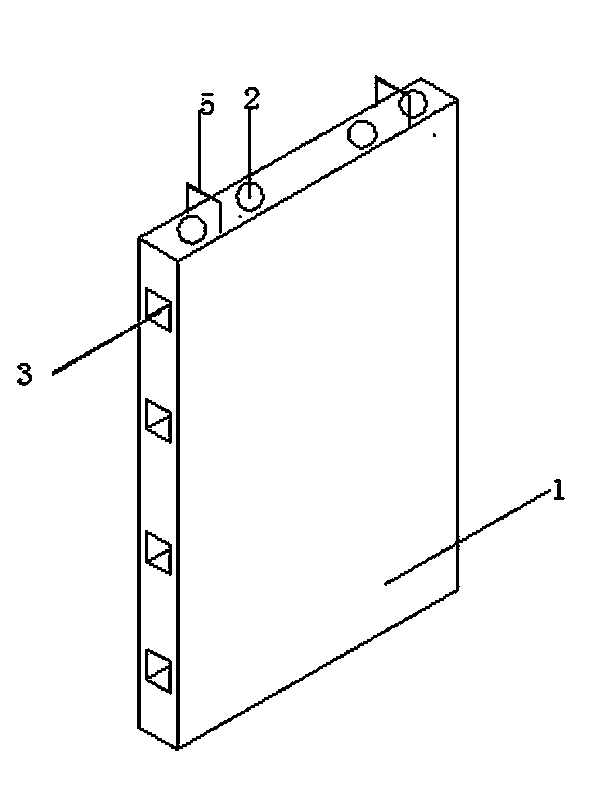

Precast concrete hollow component, and manufacturing method thereof

InactiveCN103628618AImprove the level of industrializationIncrease productivityStrutsConstruction materialReinforced concreteCross wall

The invention relates to a precast concrete hollow component, and a manufacturing method thereof, and belongs to the technical field of precast reinforced concrete structural components. The precast concrete hollow component comprises a precast wall plate component, a floor component, a T-shaped wall post component, an L-shaped wall post component, a cross wall post component and a wall body component provided with a hole; the precast concrete hollow component is internally provided with a plurality of longitudinal through holes along the length direction, and a plurality of horizontal non-through holes communicated with the longitudinal through holes along the width direction, wherein the longitudinal through holes are arranged parallelly to each other, and the horizontal non-through holes are arranged parallelly to each other. The manufacturing method comprises following steps: combining templates, such as a bottom die, a top die, a side die, a steel pipe inner die and the like, on a production field of precast slabs; arranging reinforcing meshes; then pouring concrete; drawing out a steel pipe after the strength of the concrete reaches to a certain degree; and dismounting the templates after the concrete reaches to an expected strength degree. The precast concrete hollow component can be used in multilayered, high-rise shear wall and frame-shear wall building structures, thus improving industrial level of the building structures, improving structural behaviors and saving sources.

Owner:初明进

Method of forming a barrier

Owner:KROY BUILDING PROD

Cheese grater

The invention provides a food grater assembly comprising a base; an external cylindrical portion removably attached to the base; a grater disc disposed within and removably attached to the lower end of the outer cylindrical portion; an inner divider having a cross wall dividing the inner space of the inner cylindrical portion in two equal portions; said divider being able to rotate freely within the external cylindrical portion; a plunger disposed within the divider, said plunger having a plurality of annular ridges disposed along a portion of its length; said plunger portion having a closed bottom wall and a slot defined axially and longitudinally along a portion of is length; a pair of engaging strips flexibly attached to and disposed in the wall of the external cylinder, each of said engaging strips having horizontal ridges along a portion of the inner surface thereof for engaging and disengaging the horizontal ridges of the plunger; and a cap disposed on the upper end of the inner plunger portion.

Owner:DART IND INC

Method for building cellular regenerative chamber of coke oven

The invention discloses a method for building a cellular regenerative chamber of a coke oven. The method is characterized by comprising the following steps of: a, building a main wall and a single wall of the regenerative chamber; b, building a small cross wall of the regenerative chamber; c, building lattice bricks; d, placing rubber skins and wood boards for protection; and e, repeating the steps a-d until the building design height of the cellular regenerative chamber of the coke oven is reached. The method for building the cellular regenerative chamber of the coke oven, disclosed by the invention, has the advantages of being reasonable in construction step design and simple in operation, changing a conventional building method, being large in construction space and orderly in management of refractory materials, being capable of immediately monitoring the building quality, being safe and reliable in project quality, increasing labor efficiency, greatly reducing the construction period and lowering the project cost.

Owner:MCC5 GROUP CORP SHANGHAI

Dust collecting mechanism

InactiveUS7803208B2Efficiency of collecting abilitySimple in assembly work and maintenanceCombination devicesAuxillary pretreatmentCross wallAir pump

A dust collecting mechanism for an air pump, in particular, an electromagnetic vibrational pump having a compact structure, capable of realizing the efficiency of dust collecting ability is disclosed. The mechanism is simple in assembly work. An inlet and an outlet for fluid are provided in the mechanism at a barrier chamber of the mechanism provided in at least one portion of a housing. A plurality of cross walls at which 1 or 2 or more of vent holes are provided are arranged in the mechanism. At least the position of the vent hole of the adjacent cross wall is different among a plurality of the cross walls.

Owner:TECHNO TAKATSUKI

Medicament delivery device

A medicament delivery device includes a housing with a circle-segment-shaped compartment for a drive unit that moves at least one stopper in a medicament container and that includes a support wheel and central hub on which first and second parallel disks are fixedly attached and interconnected by an abutment cross-wall; spherical members between the abutment wall and adjacent the stopper; a clock spring within the hub with an outer end connected to the hub and an inner end connected to a one-direction-rotatable tubular hub coaxially arranged around a shaft fixedly attached to a housing part; and an activation member connected to the first disk by a hold-and-release mechanism. When the activation member is not depressed, the wheel and spring are held in a tensioned static state, and when the activation member is depressed, the spring and wheel are released and the spherical members are forced against the stopper.

Owner:SHL MEDICAL AG

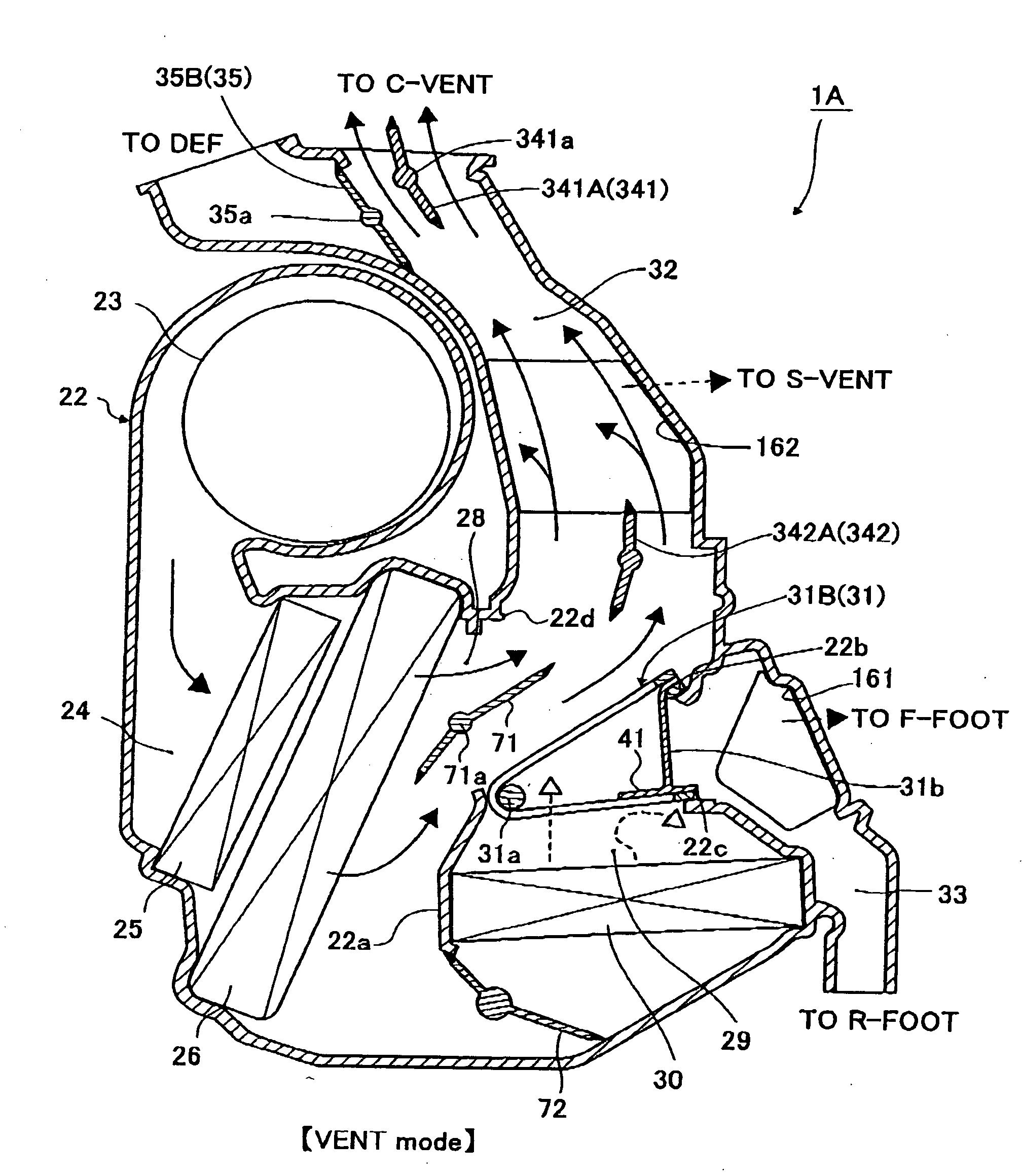

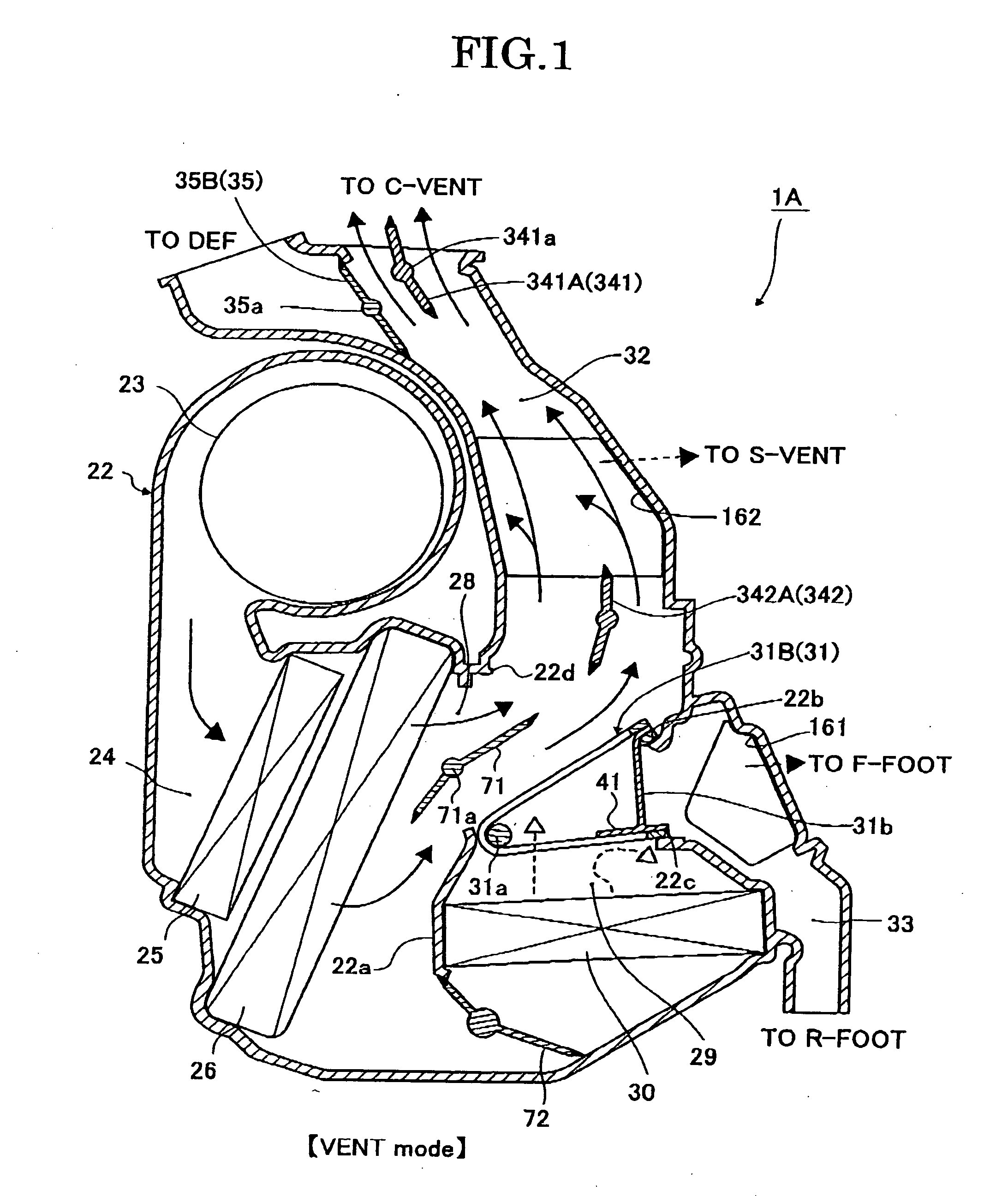

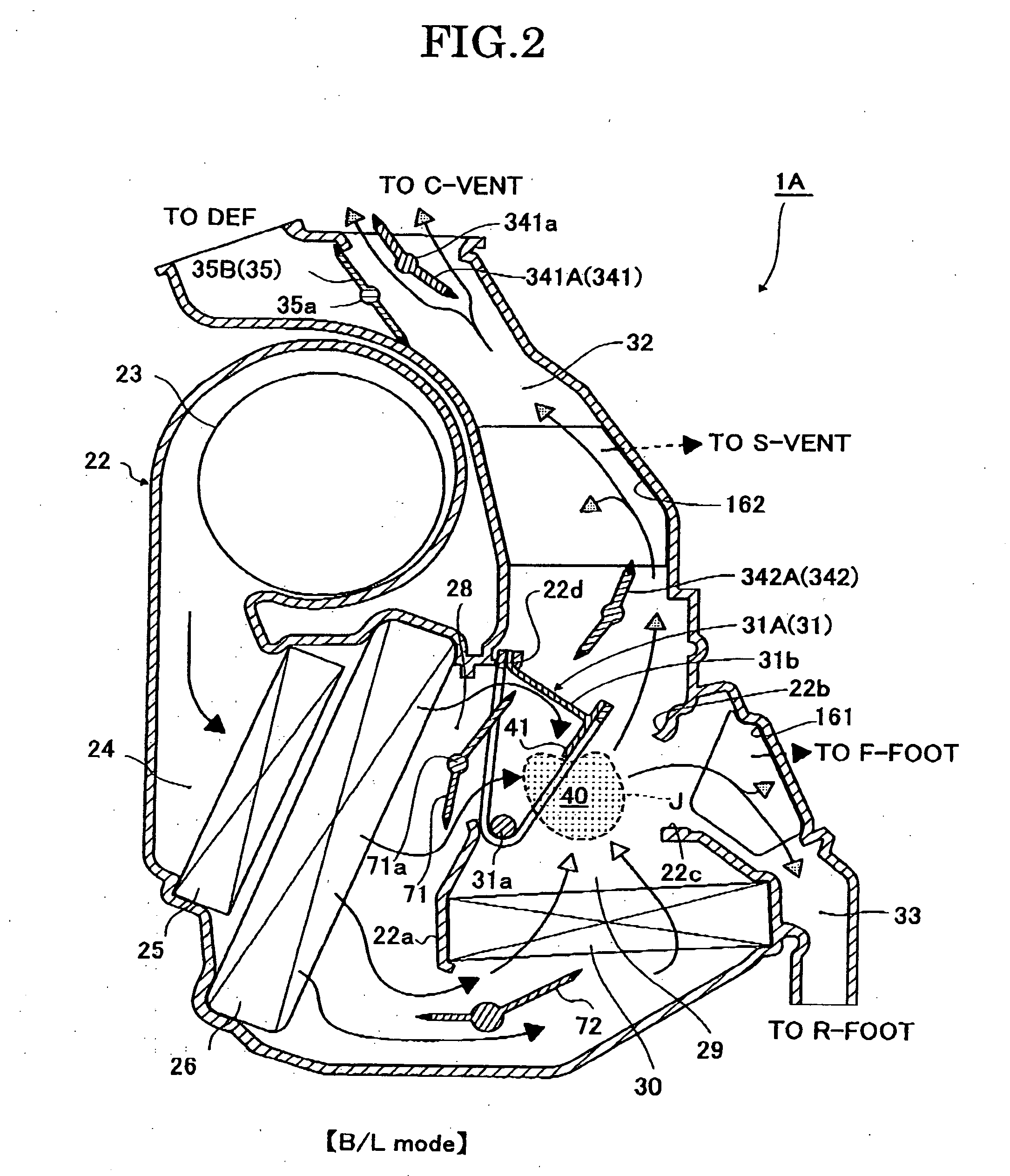

Automotive air conditioner

ActiveUS20090068939A1Improve performanceMeet demandAir-treating devicesVehicle heating/cooling devicesCold airDoor space

An automotive air conditioner includes an air-conditioning case in which air passageways having a cold air path via an evaporator, a warm air path via a heater core, and a plurality of discharge path systems communicating with outlets, respectively, are formed, an air mix door which distributes cold air and warm air by an opening degree to each of the discharge path systems via a junction region of the cold air and the warm air, and a rotary door having a cross wall, which is rotatably disposed in the junction region of the cold air and the warm air and blocks air flow from the junction region to the downstream side by the cross wall in an advanced position, the rotary door and the air mix door including an overlap layout which uses a door space inside the cross wall of the rotary door in the advanced position as an opening and closing operation space of the air mix door.

Owner:HIGHLY MARELLI JAPAN CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com