Design method for reference lines for mounting outfitting piping system in inverse segment of cabin surface

A technology for installation and design of pipe systems, applied in transportation and packaging, ship parts, ships, etc., can solve problems such as increased construction costs, poor precision, and scrapping of finished closed pipes, achieving high-precision installation, clear interface, and simple form Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

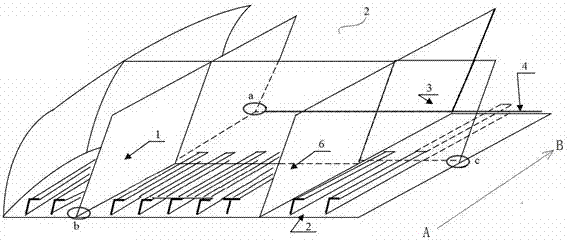

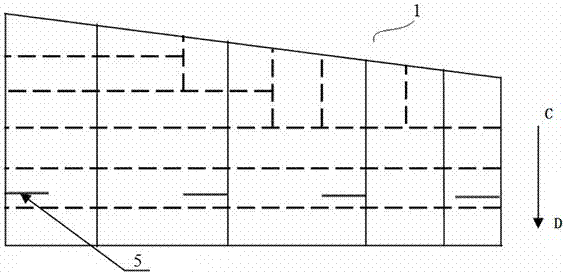

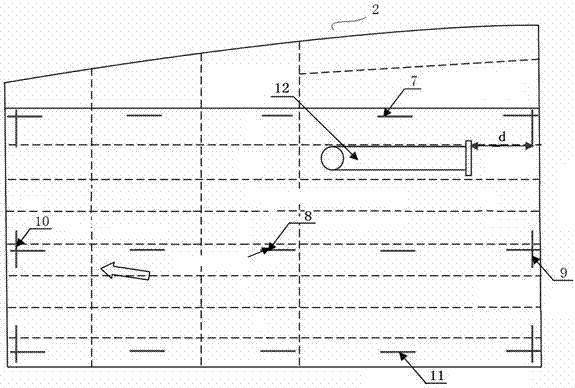

[0017] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, the baseline design method for the installation of the outfitting piping system in the anti-state section of the curved surface of the nacelle in this embodiment includes the following steps:

[0018] The first step is to establish a three-dimensional datum. The intersection points of the side longitudinal wall 1 and the bow and stern of the deck 2 are respectively the first management reference point a and the second management reference point b, and the intersection point of the transverse bulkhead 3 and the midship of the deck 2 is the third The management reference point c constitutes a three-dimensional benchmark for segmented horizontal data analysis and management. The intersection of the side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com