Method for building cellular regenerative chamber of coke oven

A regenerator and masonry technology, which is applied in the field of coke oven masonry, can solve the problems of poor control of furnace body masonry quality, large number of refractory bricks, and narrow construction space, so as to achieve safe and reliable project quality and large construction space. The effect of large size and reasonable construction steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

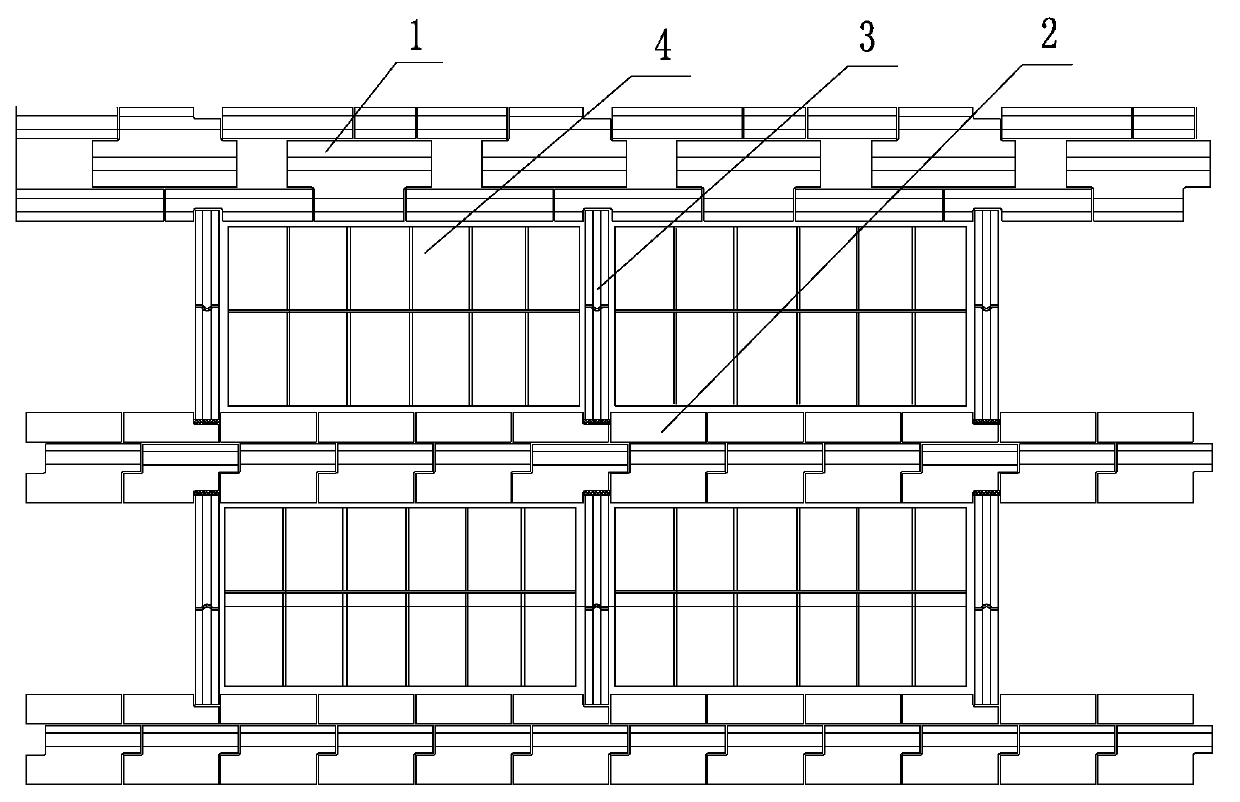

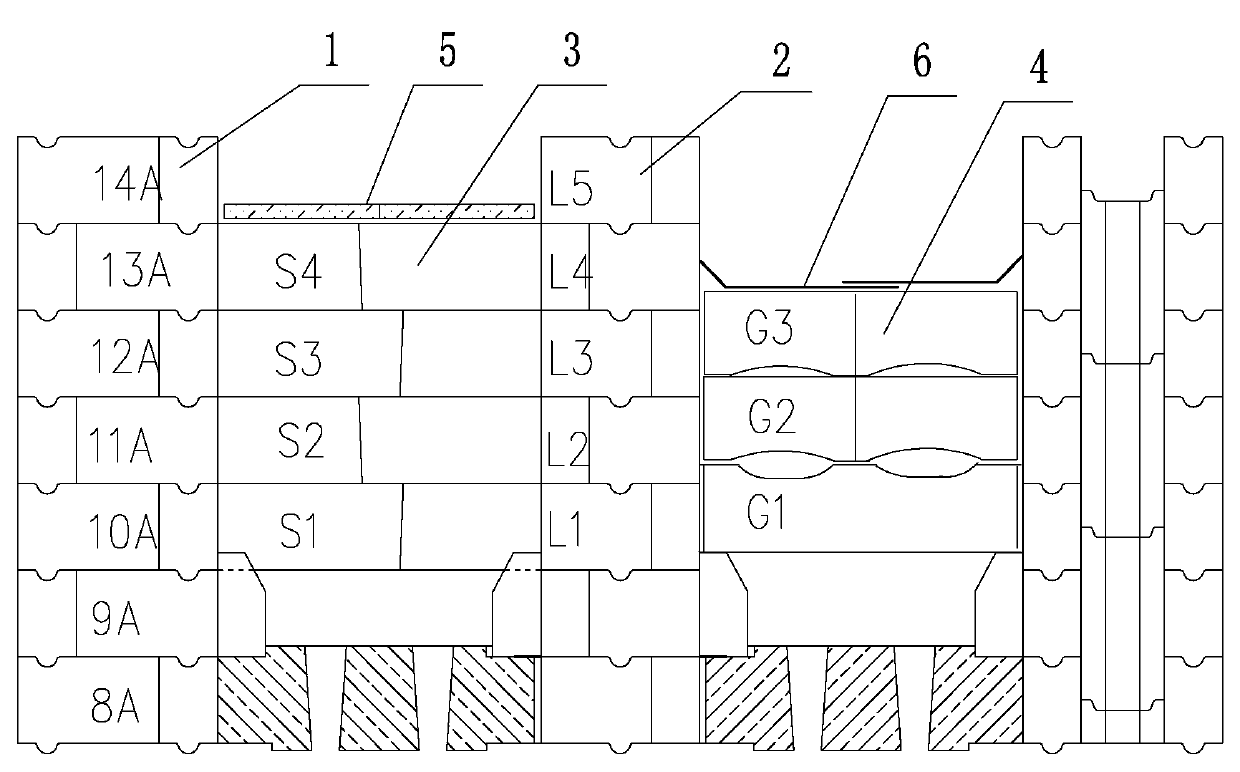

[0031] see now figure 1 with figure 2 , figure 1 It is a top view of the grid regenerator of the coke oven according to the embodiment of the present invention, figure 2 It is a sectional view of the coke oven gridded regenerator according to the embodiment of the present invention. As shown in the figure, the main wall and the single wall of the gridded regenerator of the 7-meter coke oven have a total of 25 floors, from the 10A to the 34A; 24 layers of lattice bricks, and 26 layers of small horizontal partition walls;

[0032] 1. The main construction sequence is:

[0033] Build the main wall of the coke oven grid regenerator and the 10A~14A floors of the single wall→build the 1st~5th layer of small transverse partition walls→build the 1st~3rd layer of lattice bricks and take protective measures→build heat storage The main wall and single wall of the room on the 15th to 19th floors → build the 6th to 10th floors A to 1 small transverse partition walls → build the 4th t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com