Patents

Literature

149results about How to "Engineering quality is safe and reliable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tank fabricating and welding method

ActiveCN102848087AControl welding deformationAdvantages of making welding methodsWelding apparatusStructural engineeringSeam welding

The invention discloses a tank fabricating and welding method, which is characterized by comprising the following steps of: a. fabricating and welding a tank soleplate, wherein the step comprises: (1) paving the soleplate, and (2) welding the soleplate; and b. fabricating and welding a tank wall board, wherein the step comprises: (1) paving the wall board, and (2) welding the wall board, and the step of welding the wall board comprises: 1) temporarily not welding 300mm of the lower edge of a longitudinal weld and welding the lower edge together with a circular seam after being paired with a next sine wall board; 2) when welding the circular seam, enabling welders to be uniformly distributed on the surrounding of the tank and welded in the same direction; 3) selecting the setting distance of an anti-deformation fixture according to the thickness of the wall board before welding the circular seam, the distance of the fixture of the wall board with delta equal to 6mm being 300mm; and 4) selecting an even number of welders when welding the wall board, the levels of the welders being close, and welding with the same vertical seam and circular seam welding parameters. The tank fabricating and welding method disclosed by the invention has the advantages of simple and convenient operation, strong maneuverability and the capability of effectively controlling the welding deformation of the tank.

Owner:MCC5 GROUP CORP SHANGHAI

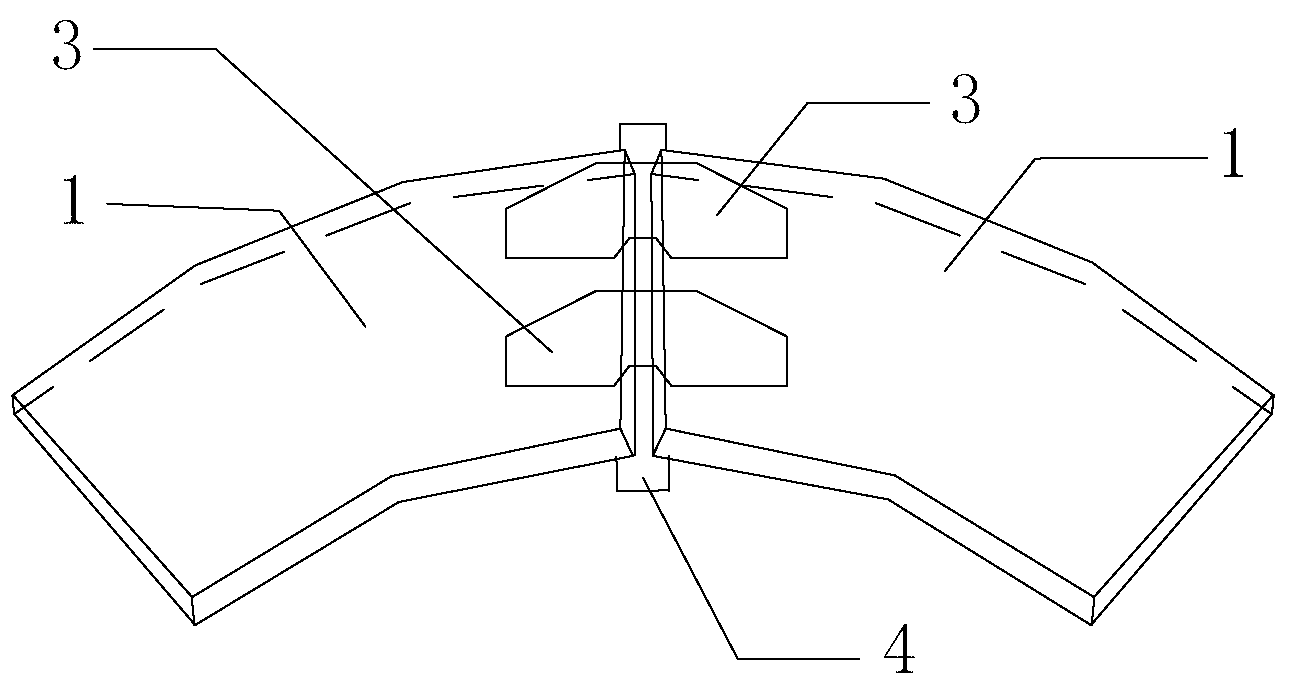

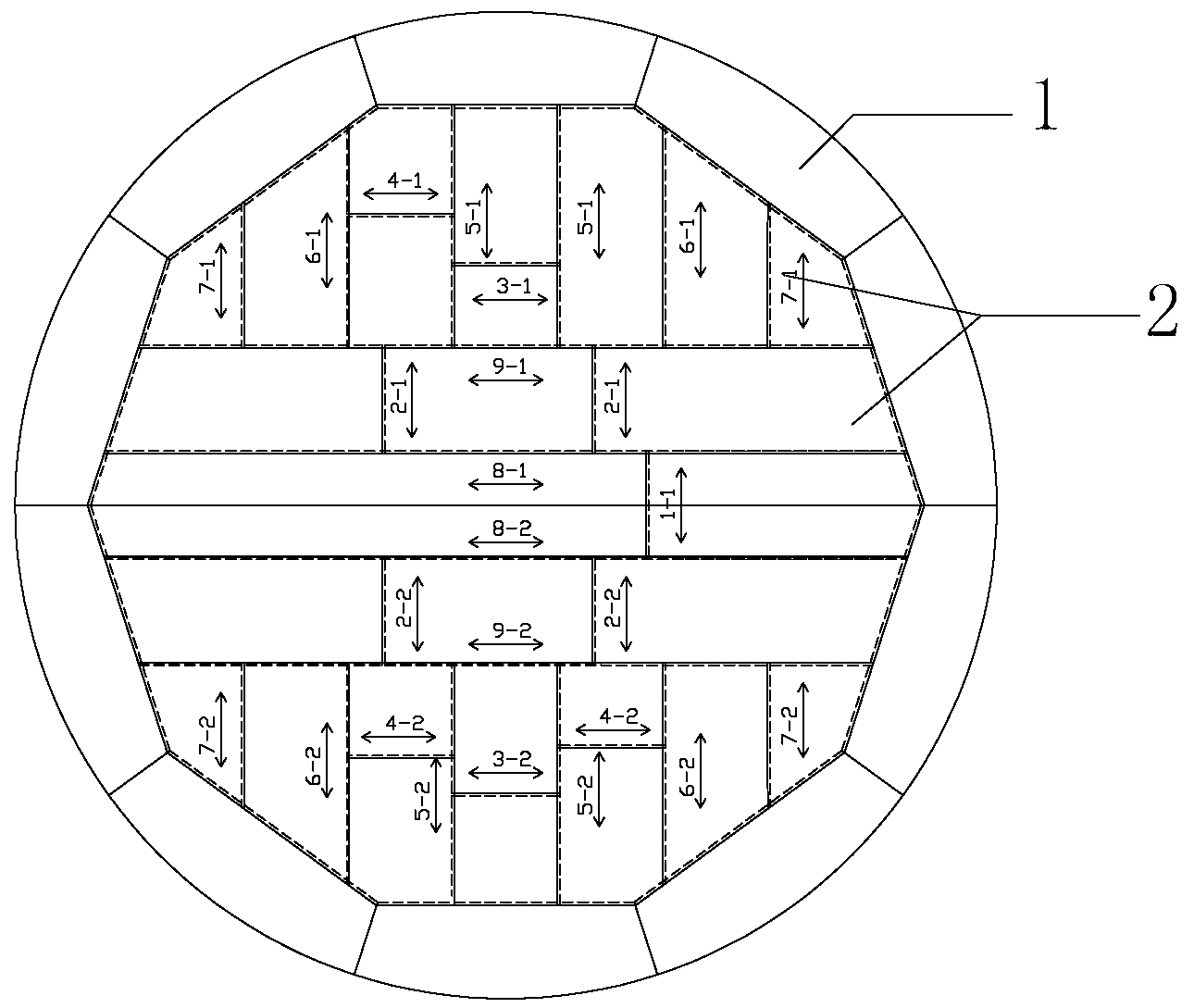

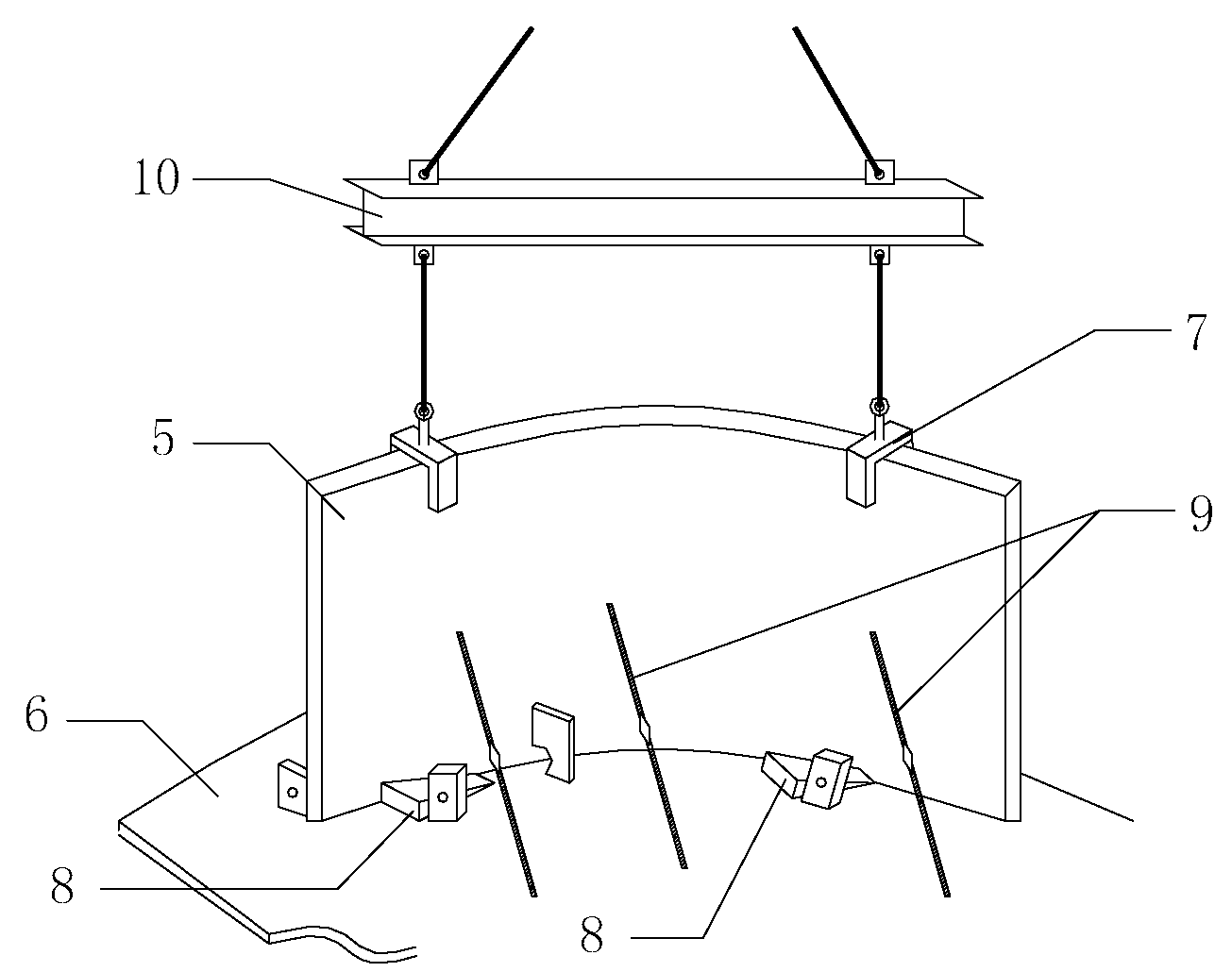

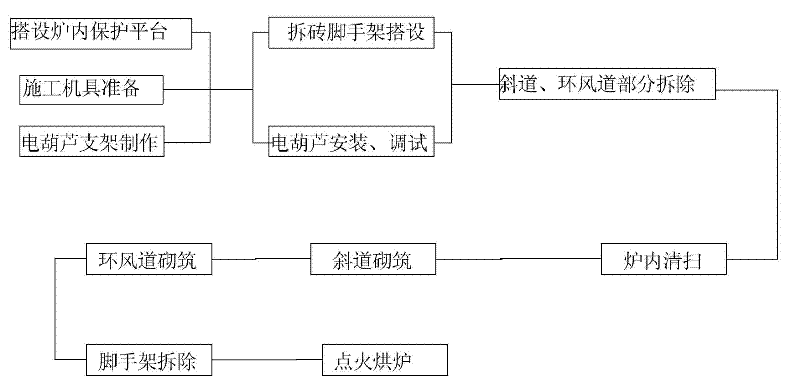

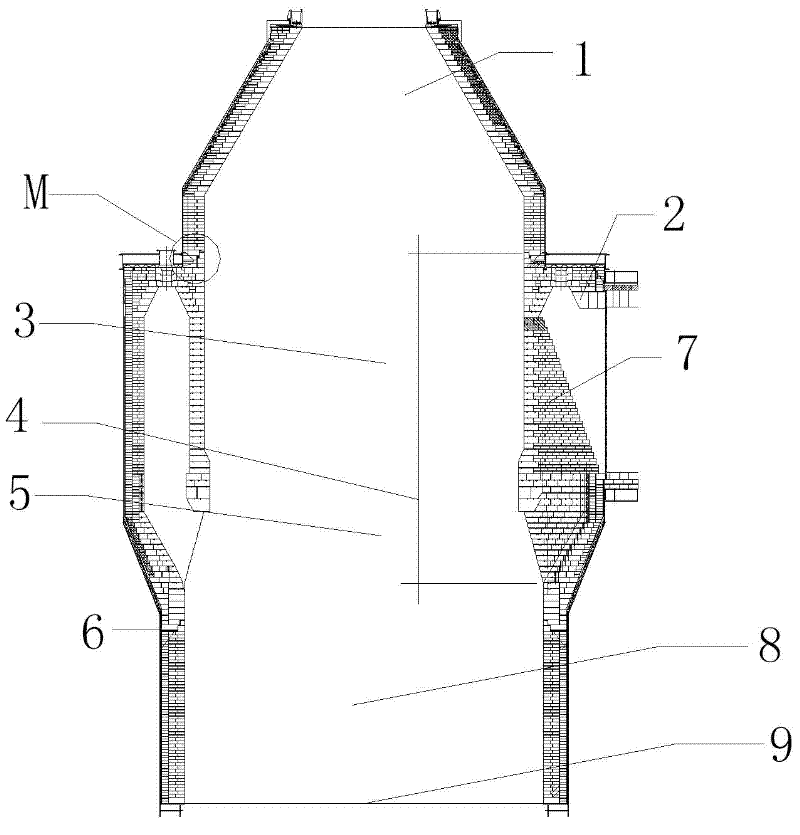

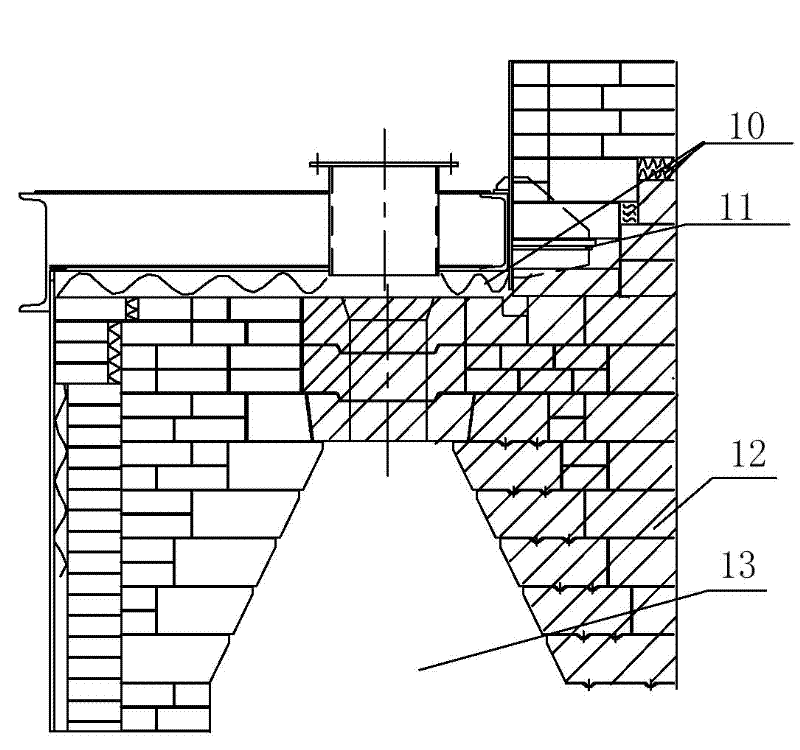

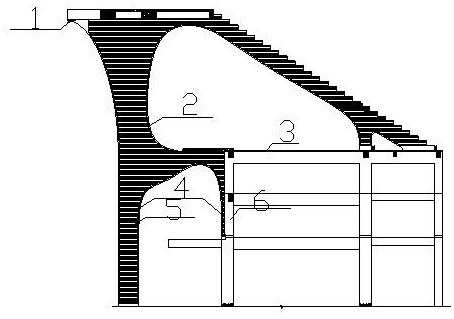

Method for overhauling fire-resistant material for annular air duct and chute in coke dry quenching furnace

The invention provides a method for overhauling a fire-resistant material for an annular air duct and a chute in a coke dry quenching furnace. A furnace body is divided into a pre-storage chamber, the annular air duct, a chute area and a cooling chamber; and brick supporting rib plates and expansion seams are arranged on a pre-storage section and the annular air duct. The method is characterized by comprising the following steps of: a, erecting a protection platform in the furnace and preparing construction equipment; b, erecting a scaffold for taking apart bricks; c, dismounting a part of the chute and the annular air duct; d, cleaning the furnace; e, constructing the chute; f, constructing the annular air duct; and g, dismounting the scaffold and igniting to bake the furnace. The method for overhauling the fire-resistant material for the annular air duct and the chute in the coke dry quenching furnace provided by the invention has the advantages of reasonable design of construction step, simplicity in operation, safe and reliable engineering quality, and reduction of the engineering construction cost.

Owner:CHINA MCC5 GROUP CORP

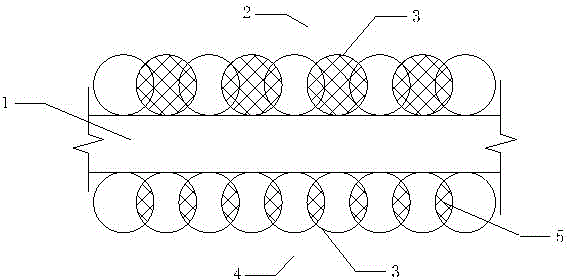

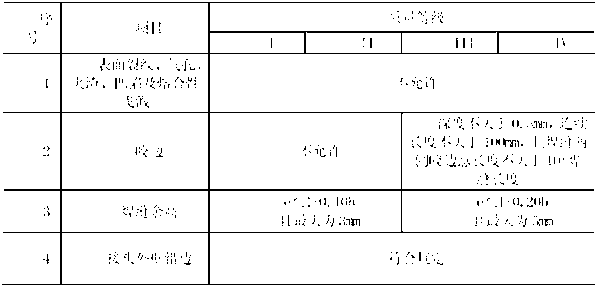

Construction method of basement roof polyvinyl chloride root thorn resistance waterproof roll

ActiveCN104695486AReasonable designEasy to operateProtective foundationBasementArchitectural engineering

The invention discloses a construction method of a basement roof polyvinyl chloride root thorn resistance waterproof roll. The construction method is characterized by comprising the steps of: (a) construction preparation; (b) base layer treatment of the root thorn resistance waterproof roll; (c) construction of a reinforced additional layer in a node; (d) large surface construction of the polyvinyl chloride root thorn resistance waterproof roll; (e) head shrinkage treatment of the polyvinyl chloride root thorn resistance waterproof roll; and (f) cleaning, checking and acceptance of the polyvinyl chloride root thorn resistance waterproof roll. The construction method of the basement roof polyvinyl chloride root thorn resistance waterproof roll has the advantages of reasonable design and simple operation in production of the additional layer of the polyvinyl chloride root thorn resistance waterproof roll, no influence on construction period, lower investment, safe and reliable engineering quality, improvement of once acceptance pass percent, in particular prominent improvement of root thorn and water resistant in the node and elimination of subsequent node leakage hidden danger of a basement roof, and wide promotion and application prospect.

Owner:MCC5 GROUP CORP SHANGHAI

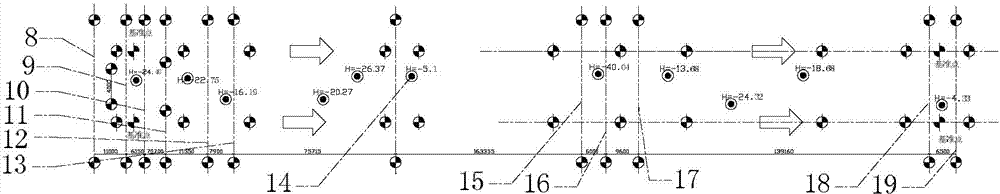

Method for mounting continuous production line of non-oriented silicon steel

ActiveCN102950464AImprove installation efficiencyShorten the construction periodOther manufacturing equipments/toolsProduction lineEconomic benefits

A method for mounting a continuous production line of non-oriented silicon steel is characterized by including the steps of a, manufacturing and mounting a gantry frame steel structure; b, mounting single equipment online; mounting a horizontal continuous annealing furnace; and d, mounting process pipelines, including mounting of an industrial pipeline and an inter-unit pipe. The method for mounting the continuous production line of non-oriented silicon steel has the advantages that mounting efficiency is improved, and time limit is shortened; and construction process is simplified and compact, labor and construction cost are economized greatly, project quality is safe and reliable, and economic benefit is high.

Owner:MCC5 GROUP CORP SHANGHAI

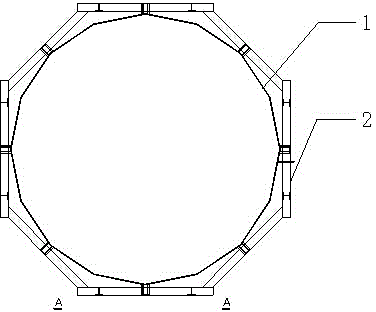

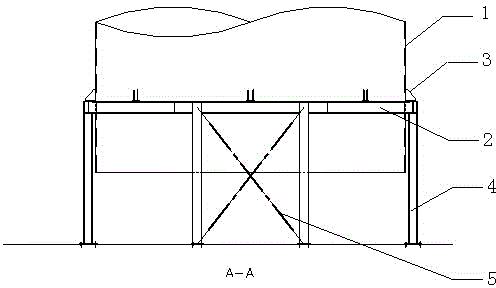

Airbag type inner framework form traveler and primary tunnel supporting shotcrete construction method

ActiveCN105507927ASimple structureEasy to processMining devicesUnderground chambersShotcreteArchitectural engineering

The invention discloses an airbag type inner framework from traveler and a primary tunnel supporting shotcrete construction method. The form traveler comprises a movable supporting framed bent, an inflatable formwork located on the outer side of the movable supporting framed bent, and a retractable supporting device for supporting the inflatable formwork, and the retractable supporting device is installed on the movable supporting framed bent and located on the inner side of the inflatable formwork. The construction method includes the steps: firstly, forwarding the airbag type inner framework from traveler in place; secondly, performing primary tunnel supporting shotcrete construction; thirdly, performing primary tunnel supporting shotcrete construction on a next tunnel section; fourthly, repeating the third step for multiple times till the primary tunnel supporting shotcrete construction process of all the tunnel sections is finished. The airbag type inner framework from traveler is reasonable in design, simple to construct and good in using effect, resilience rate of primary tunnel supporting shotcrete is effectively controlled through an airbag type inner framework, construction efficiency is high, construction period is short, construction quality is high, and zero resilience rate of primary tunnel supporting shotcrete can be realized.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

Method for manufacturing steel structure framework of benzene hydrogenation main device in benzene hydrogenation engineering

ActiveCN102465600AReasonable designEasy to operateArc welding apparatusBuilding material handlingBenzeneMetallurgy

The invention relates to a method for manufacturing a steel structure framework of a benzene hydrogenation main device in benzene hydrogenation engineering, and the method is characterized by comprising the following steps of: a, manufacturing parts; b, lofting, marking out, cutting and drilling; c, correcting the parts; d, assembling a steel column; e, welding the steel structure; and f, coating the steel structure. The method for manufacturing the steel structure framework of the benzene hydrogenation main device in the benzene hydrogenation engineering, provided by the invention, has the advantages of reasonable manufacturing step and design, simplicity in operation, safe and reliable engineering quality and low engineering cost.

Owner:MCC5 GROUP CORP SHANGHAI

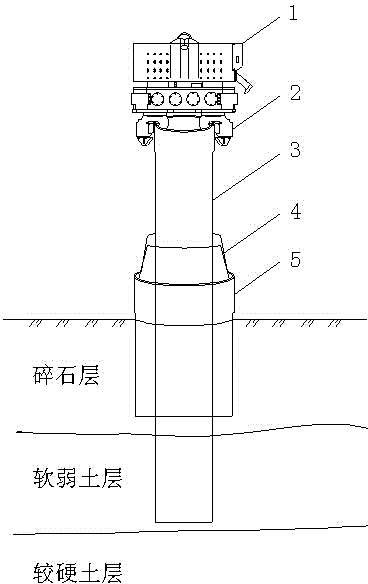

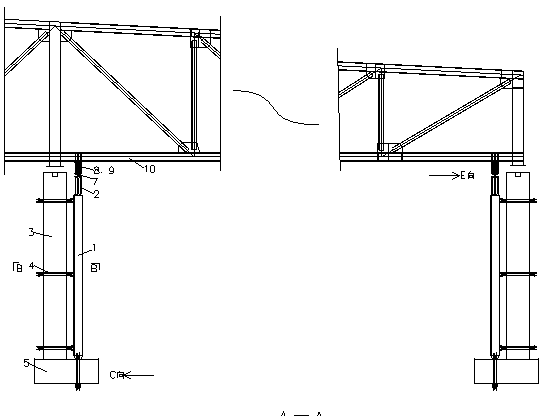

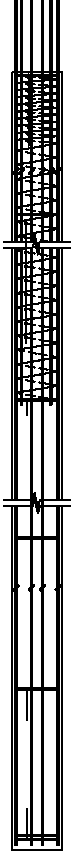

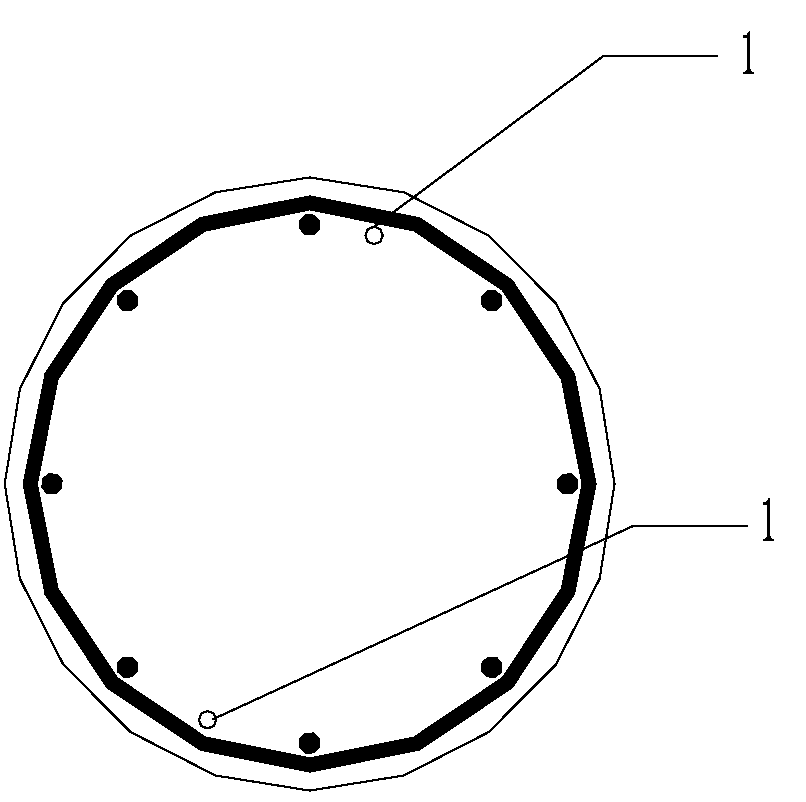

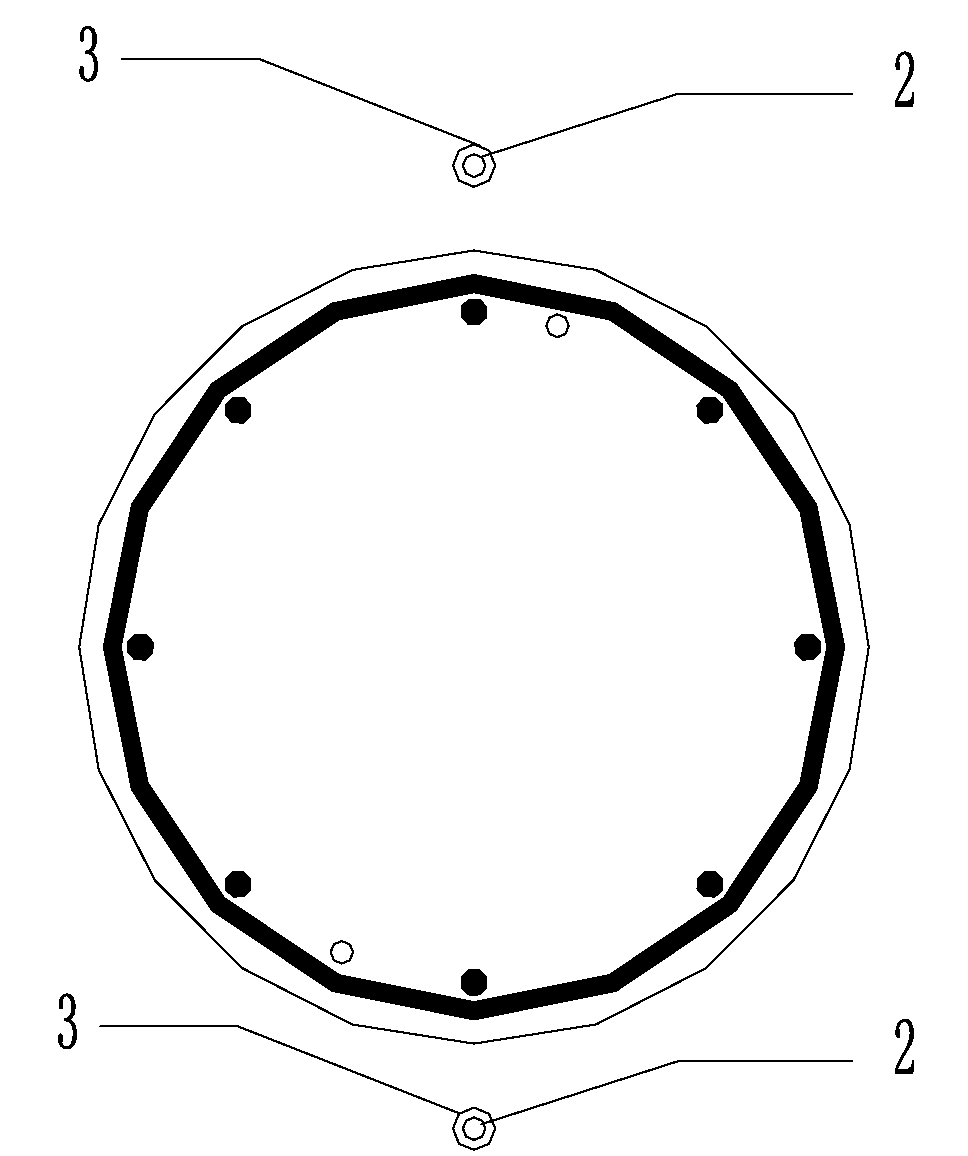

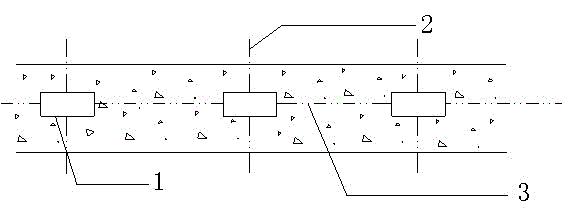

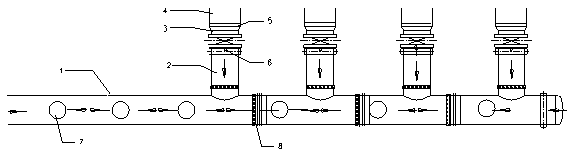

Cast-in-place pile construction method by adopting two retaining cylinders to transverse deep and thick gravel layer

InactiveCN106149683AEngineering quality is safe and reliableConducive to organization and constructionBulkheads/pilesRock coreEngineering

The invention discloses a cast-in-place pile construction method by adopting two retaining cylinders to transverse a deep and thick gravel layer. The cast-in-place pile construction method is characterized by comprising the following steps: a, clamping the groove part of an outer steel retaining cylinder (5) with a clamp (2) of a vibration hammer (1); b, completely extracting rock cores from the outer steel retaining cylinder (5) with a rotary drilling machine; c, hoisting an inner steel retaining cylinder (3) with the vibration hammer; d, clamping a hoisting lug (4) on the outer steel retaining cylinder (5) with the vibration hammer (1); e, extracting soil from the inner steel retaining cylinder (3) with the rotary drilling machine; f, putting down a steel reinforcement cage; g, pouring concrete; and h, pulling out the inner steel retaining cylinder (3) with the vibration hammer (1) to complete pouring of a cast-in-place pile. The cast-in-place pile construction method by adopting the two retaining cylinders to transverse the deep and thick gravel layer has the characteristics of being capable of constructing the cast-in-place pile with the two retaining cylinders on a complicated stratum without special equipment, being high in construction speed and being low in manufacturing cost.

Owner:MCC5 GROUP CORP SHANGHAI

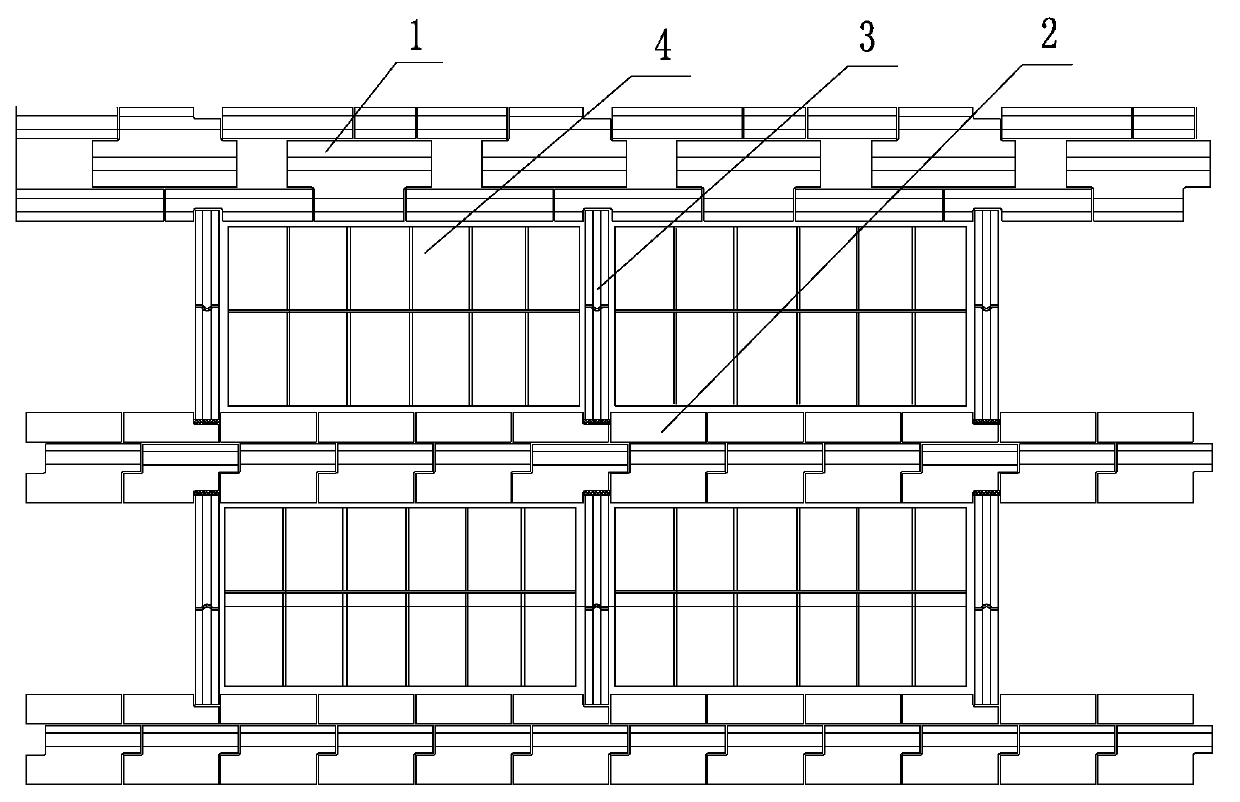

Method for building cellular regenerative chamber of coke oven

The invention discloses a method for building a cellular regenerative chamber of a coke oven. The method is characterized by comprising the following steps of: a, building a main wall and a single wall of the regenerative chamber; b, building a small cross wall of the regenerative chamber; c, building lattice bricks; d, placing rubber skins and wood boards for protection; and e, repeating the steps a-d until the building design height of the cellular regenerative chamber of the coke oven is reached. The method for building the cellular regenerative chamber of the coke oven, disclosed by the invention, has the advantages of being reasonable in construction step design and simple in operation, changing a conventional building method, being large in construction space and orderly in management of refractory materials, being capable of immediately monitoring the building quality, being safe and reliable in project quality, increasing labor efficiency, greatly reducing the construction period and lowering the project cost.

Owner:MCC5 GROUP CORP SHANGHAI

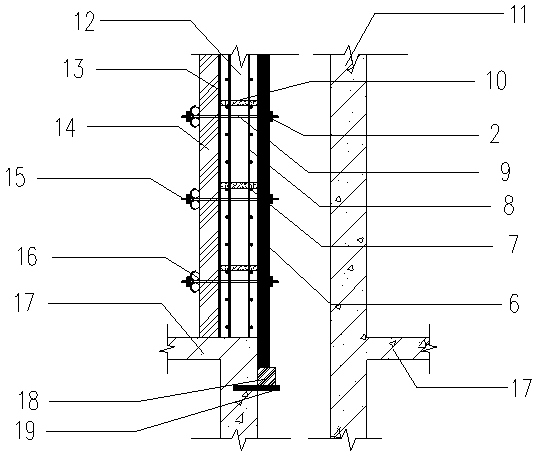

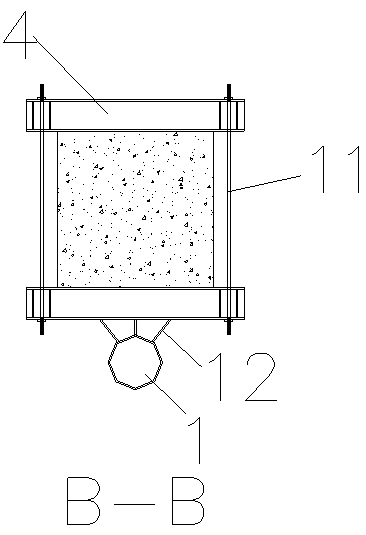

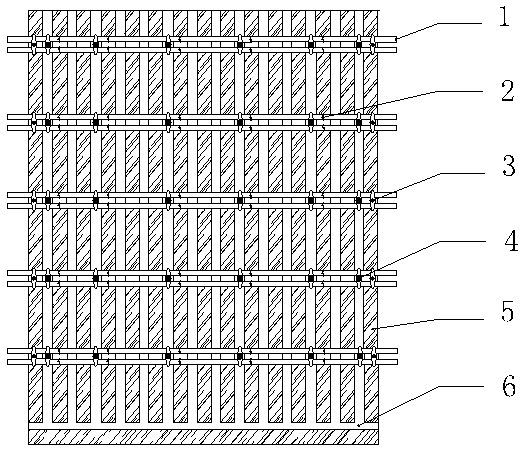

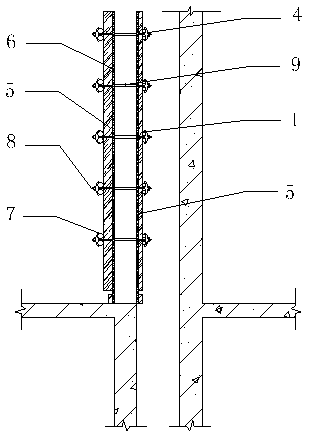

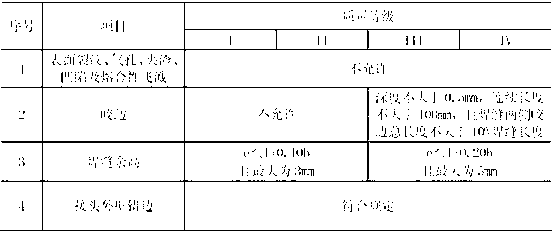

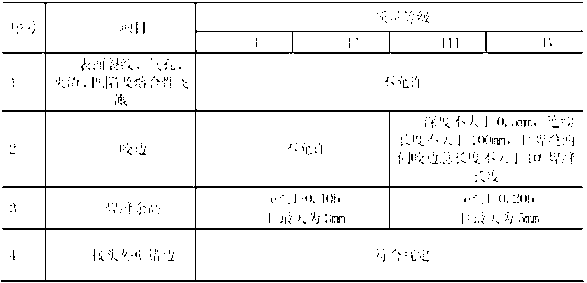

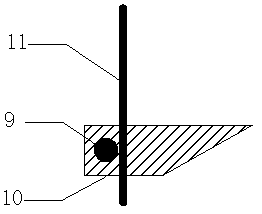

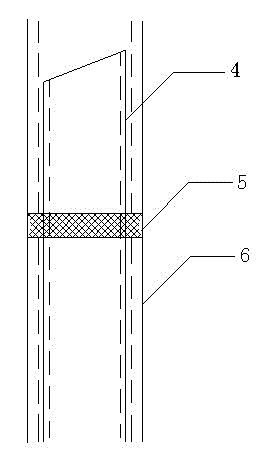

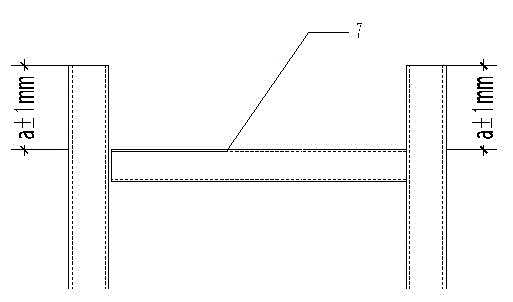

Construction method for shear wall setting steel framework bracing unidirectional fastening screw on deformation joint

The invention discloses a construction method for a shear wall setting steel framework bracing unidirectional fastening screw on a deformation joint. The construction method is characterized in comprising the following steps: a, according to a drawing, carrying out template sample refurbishment, and manufacturing a setting steel framework and a wood pattern used for a shear wall on the deformationjoint; b, after the vertical reinforcing steel bars of the shear wall finish binding acceptance check, installing a template; c, mutually contrasting an inner side timber formwork and an outer side steel framework to enable a split bolt to be penetrated; d, after the framework finishes being reinforced, carrying out framework acceptance check; e, pouring concrete. The construction method for theshear wall setting steel framework bracing unidirectional fastening screw on the deformation joint has the advantages of simple structure of the shear wall setting steel framework bracing device, convenience in manufacture and safe and reliable engineering quality, the integral rigidity of the shear wall framework on the deformation joint can be improved, the flatness and the perpendicularity of the shear wall framework on the deformation joint are guaranteed, the compactness of the concrete is guaranteed, engineering cost is lowered, concrete forming quality is guaranteed, and the functions of lowering cost and increasing effects are performed.

Owner:MCC5 GROUP CORP SHANGHAI

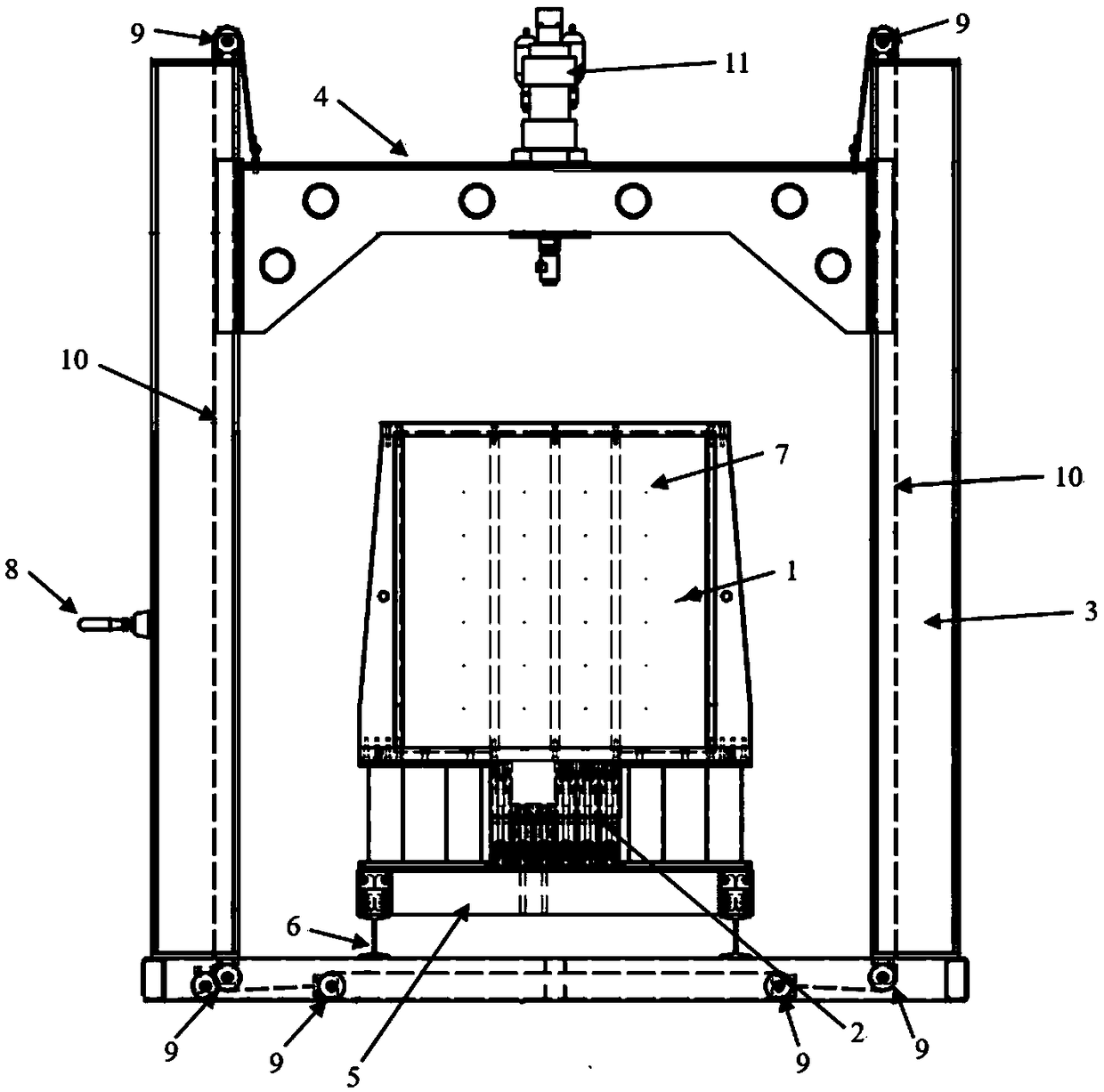

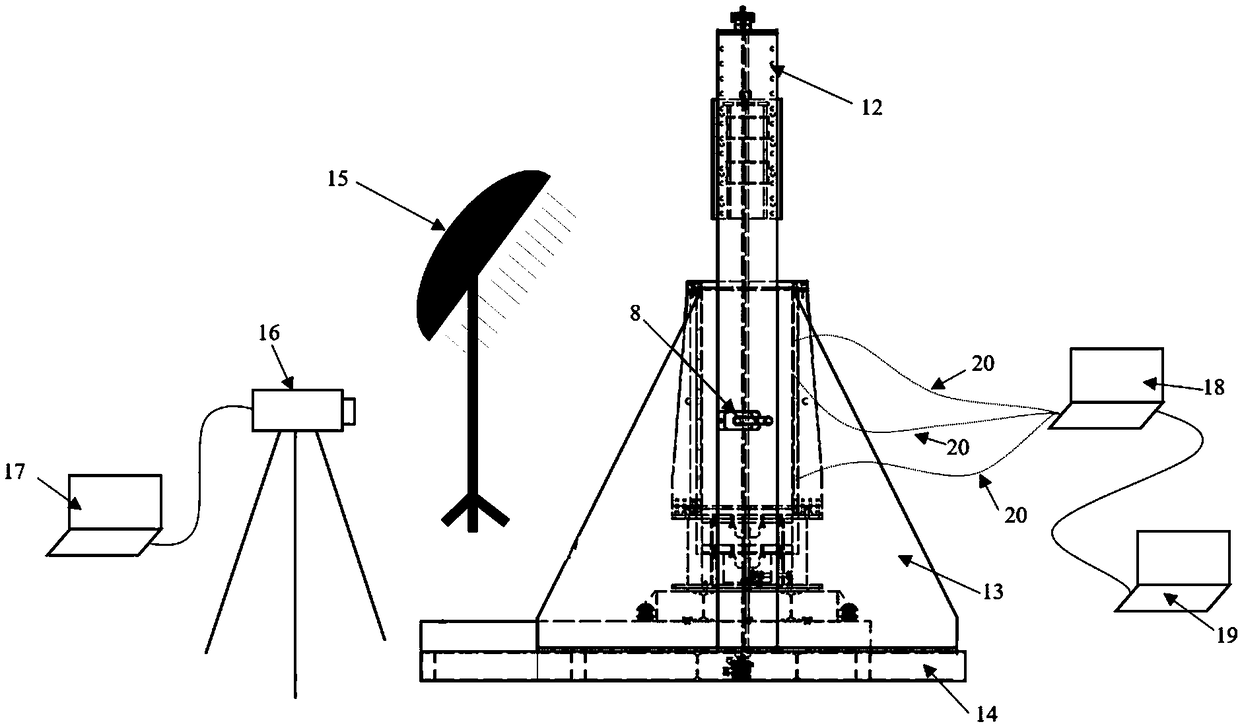

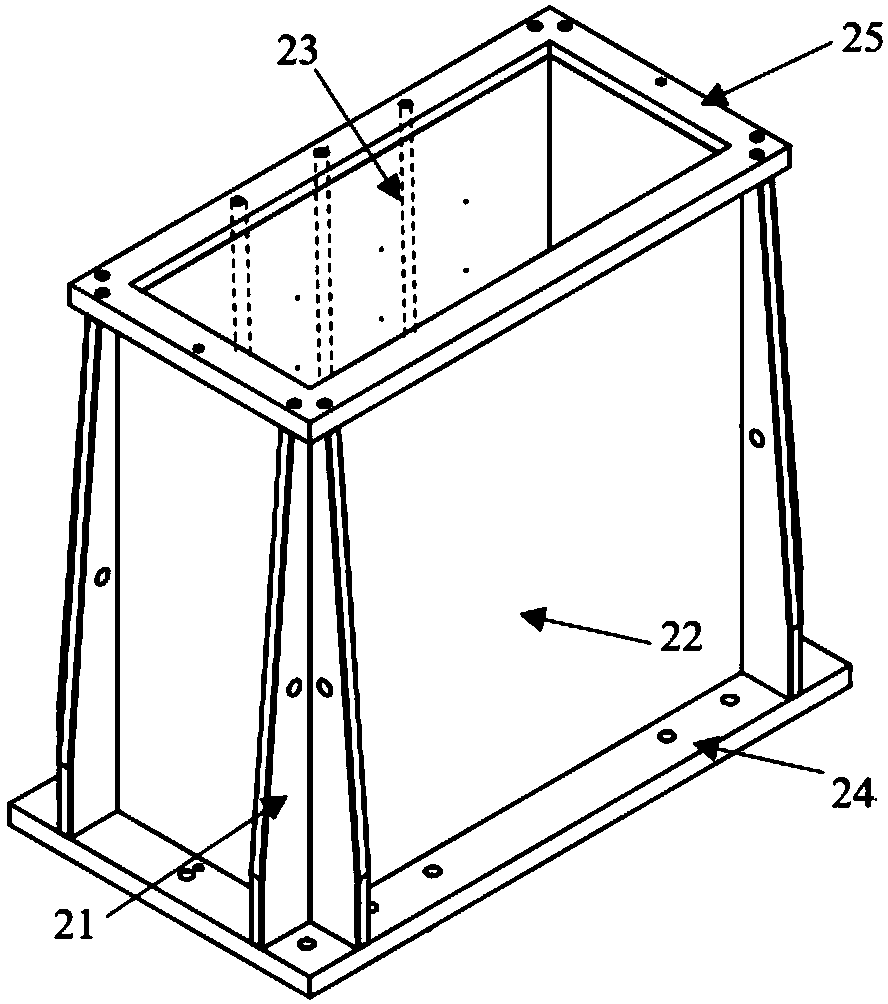

Test system for simulating degradation law of dynamic soil arching effects

InactiveCN108761032AAltitude changes at any timeImprove test accuracyEarth material testingSoil archingEngineering

The invention relates to a test system for simulating a degradation law of dynamic soil arching effects, the test system is composed of a loading device, an observation device, a testing device and anadjusting device. The loading device controls load loading on the adjusting device, and the observation device is arranged on one side of the adjusting device. The testing device is used for testing.Compared with the prior art, the test system can improve the testing of the dynamic soil arching effects, realize the simultaneous observation of different degrees of soil arching effects, stress fields and displacement fields, and realize the change of different levels of factors. The test system can improve the test accuracy and maintain the convenience of operation.

Owner:TONGJI UNIV

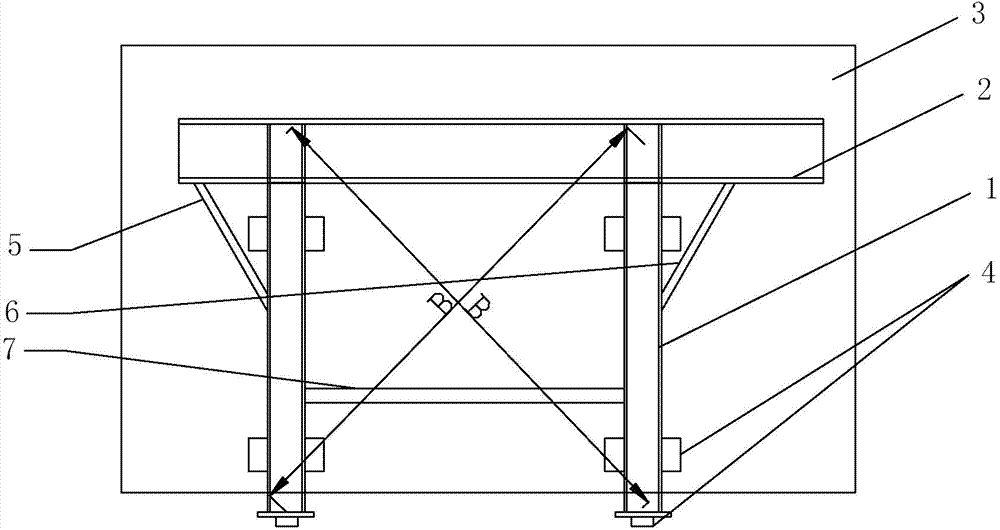

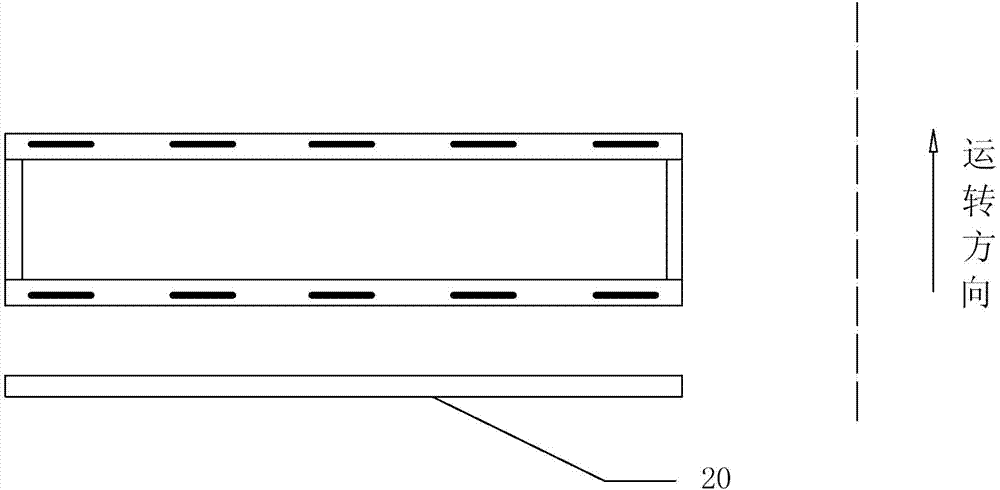

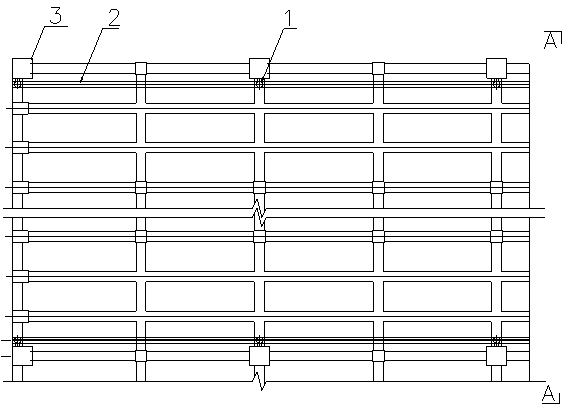

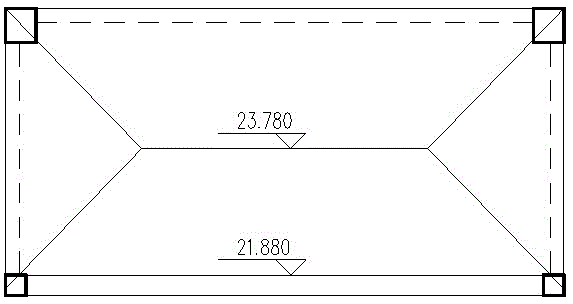

Large-span steel structure roof sliding method for electronic factory building

ActiveCN109653377ASimple structureEasy to manufactureBuilding roofsGirdersSpandrelBuilding construction

A large-span steel structure roof sliding method for an electronic factory building is characterized by including the following steps: a. arranging a steel pipe column 351*10mm in diameter beside theinner side of a two-layer concrete column at each roof steel structure truss base on each side of the plant span; b, connecting the bottom of each steel pipe column with a two-layer lattice beam through a hoop; c, arranging a sliding track beam at the tops of the steel pipe columns; d, placing a 43kg track in the middle of the top of the track beam; e, placing a sliding shoe at a position corresponding to a steel beam of a bottom cord of a roof steel structure truss and above the 43kg track; f, providing a crawler, and pushing the sliding shoe by the crawler; g, completing the entire roof sliding mounting by a roof steel structure truss sliding process. The large-span steel structure roof sliding method has the advantages that a sliding process device is simple in structure, the sliding construction quality is safe and reliable, the problem that two-layer boards of plants cannot be mounted by crawler cranes and roof steel structure sliding cannot be carried out by original design structures are solved, the construction time is shortened, and the construction cost is reduced.

Owner:MCC5 GROUP CORP SHANGHAI

Three axes agitating pile construction method capable of assisting in grooving of reinforced underground diaphragm wall

ActiveCN105696550AMature construction technologyEasy constructionExcavationsBulkheads/pilesSlurry wallInjection pressure

The invention discloses a three axes agitating pile construction method capable of assisting in grooving of a reinforced underground diaphragm wall. The construction method is characterized by comprising the following technological steps that a, the range of a reinforced target of three axes agitating piles is determined; b, the reinforcing depth of the three axes agitating piles is determined; c, the distance between an inner reinforcing pile body and an outer reinforcing pile body of the three axes agitating piles is determined; d, guide wall construction is conducted according to a construction technique of an ordinary underground diaphragm wall; e, the slurry proportion is adjusted properly; f, main quality control points of reinforcement of the three axes agitating piles are determined; g, the stability of a pile machine is checked; h, the perpendicularity control over a pile frame of the three axes agitating piles is strengthened; i, the water cement ratio, the stirring time and the slurry quality are controlled strictly, and the slurry injection pressure and the slurry injection speed during slurry injection are controlled; and j, the drilling speed and lifting speed of a drill pipe are controlled strictly. The construction method has the advantages that the technique is mature, construction is easy and convenient, the project quality is safe and reliable, the horizontal displacement and settlement amount of important structures are quite small, the requirements for economic benefits are met, and smooth implementation of a project is guaranteed.

Owner:MCC5 GROUP CORP SHANGHAI

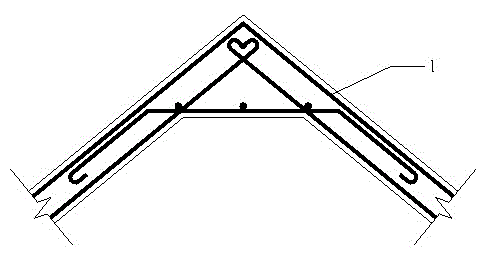

High-altitude cantilever structure formwork support and upper protection system construction method

InactiveCN113550578ASolve the problem of not being able to take rootSolve the problem of not being able to set up a reliable security protection systemForms/shuttering/falseworksScaffold accessoriesSupporting systemArchitectural engineering

The invention discloses a high-altitude cantilever structure formwork support and an upper protection system construction method. The high-altitude cantilever structure formwork support and the upper protection system construction method is characterized by comprising the following steps that a, construction positioning is conducted in advance along with a building main body structure, embedded parts are installed, and connecting bolts are reserved; b, cantilever girders and lower inclined struts are installed; c, the support bottom is closed; d, a high-altitude cantilever structure formwork support body is erected; e, acceptance and concrete pouring are conducted; and f, edge protection construction is conducted before modeling construction of an inclined roof on the upper portion of a roof, vertical rods on the outer side continue to be heightened in a staggered mode, the vertical rods on the outer side are connected with newly-added vertical rods above a cornice into a whole, temporary tying is conducted, and it is guaranteed that a protection system is stable and reliable. The high-altitude cantilever structure formwork support and the upper protection system construction method have the advantages that the problems that a high-altitude cantilever structure formwork support system cannot take roots and exert force, and a reliable safety protection system cannot be arranged in upper roof modeling construction are solved, and a large amount of profile steel is not needed; and factory processing is adopted, installation is convenient and fast, turnover use can be achieved, and quality guarantee and construction safety are achieved.

Owner:CHINA MCC5 GROUP CORP

Method for manufacturing high-voltage power cable terminal by benzene hydrogenation process

InactiveCN102377127AAdvantages of production methodReasonable designApparatus for removing/armouring cablesCable terminationsAnti stressPower cable

The invention discloses a method for manufacturing a high-voltage power cable terminal by a benzene hydrogenation process. The method is characterized by comprising the following steps of: a, stripping and cutting a cable; b, stripping a copper shielding layer; c, making gas chromatographic marks; d, stripping a semiconductor; e, cutting an anti-stress cone of each phase of an insulating layer of a core; f, crimping a terminal; g, removing the insulting layer; h, arranging an insulating tube; i, fixing the insulating tube and a gas chromatographic tube; and j, performing enveloping processing. The method for manufacturing the high-voltage power cable terminal by the benzene hydrogenation process has the advantages of rational manufacturing steps, simple operations, safe and reliable process quality, high electrical properties and reduction in process cost.

Owner:MCC5 GROUP CORP SHANGHAI

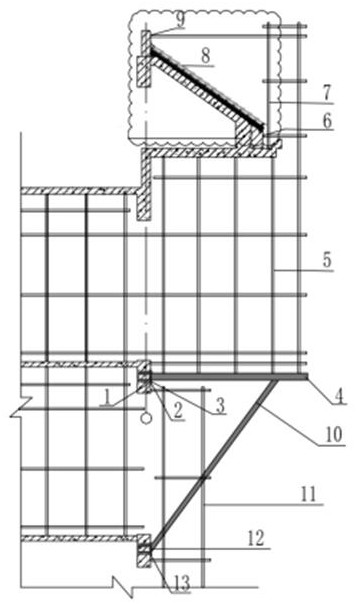

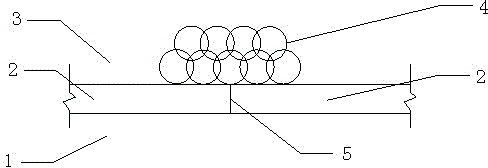

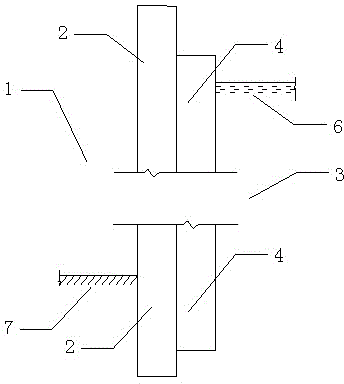

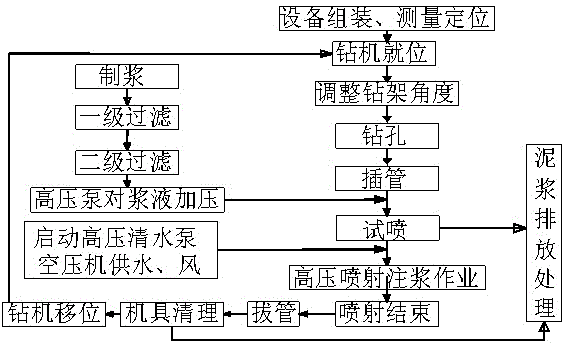

Construction method of high-pressure jet grouting pile used outside underground diaphragm wall joint for reinforcing seal waterstop

ActiveCN105986570AMature construction technologyEasy constructionBulkheads/pilesSlurry wallEconomic benefits

The invention relates to a construction method of a high-pressure jet grouting pile used outside an underground diaphragm wall joint for reinforcing a seal waterstop. The mature high-pressure jet grouting pile construction method is adopted, and the seal waterstop is strengthened and reinforced in the underground diaphragm wall joint weak link in a form of constructing the high-pressure jet grouting pile outside the underground diaphragm wall joint. The method is characterized by including the following technical steps of a, determination of construction parameters and selection of construction methods, b, jet material control, c, measurement and locating, d, pile test, e, technical control on jet process construction, f, grout return observation, g, recharge, h, observation of surroundings in the jet process, and i, abandoned slurry sewage discharge. The method has the advantages of the mature construction process of the high-pressure jet grouting pile, simpleness, convenience in construction, safety and reliability in construction quality, obvious effect on waterstop reinforcement of the underground diaphragm wall joint, capabilities of greatly lowering potential risk in foundation pit construction and meeting economic benefit of engineering construction.

Owner:MCC5 GROUP CORP SHANGHAI

Repair method of unqualified post-grouting bored concrete pile

A repair method of an unqualified post-grouting bored concrete pile is characterized by comprising the following steps: a, drilling a plurality of lead holes at the outer side of a bored concrete pile body; b, supplementing a post-grouting pipe at the outer side of the bored concrete pile; c, conducting post-grouting construction; and d, maintaining the bored concrete pile, and inspecting and accepting the bored concrete pile, wherein the posting-grouting construction includes the following steps: (1) providing raw materials of slurry, (2) preparing the slurry, (3) conducting preparation for grouting construction, (4) conducting the first round of grouting, (5) conducting the second round of grouting, and (6) controlling over stop of the grouting. The repair method of the unqualified post-grouting bored concrete pile has the advantages of being reasonable in design of construction steps, easy and convenient to operate, safe and reliable in construction quality, free from influencing the construction period, remarkable in economic benefit, and capable of guaranteeing that a project is implemented smoothly.

Owner:MCC5 GROUP CORP SHANGHAI

Deformation joint formwork erection construction method

InactiveCN108571166ASimple structureEasy to manufactureForms/shuttering/falseworksTower craneExpansion joint

A deformation joint formwork erection construction method is suitable for wall structure expansion joints, and is characterized by including the steps that a, the wall area at a construction joint isworked out according to a construction drawing, and meanwhile it is determined that timber formworks are used according to formwork materials supplied on site; b, the wall inner formwork is manufactured; c, the wall outer formwork is manufactured; d, formwork reinforcement is carried out; e, formwork installation is carried out, wherein the whole reinforced deformation joint formwork is hoisted tothe deformation joint through a tower crane and then is installed and fixed at the deformation joint by workers. The deformation joint formwork erection construction method has the advantages that the deformation joint formwork is simple in structure and convenient to manufacture, the overall laying mode is adopted for the deformation joint formwork, reinforcement measures for the deformation joint formwork are effective, the phenomena of formwork swelling, bottom grout leaking and the like will not occur, the construction quality is improved, and the construction cost is reduced.

Owner:MCC5 GROUP CORP SHANGHAI

Construction method for mounting benzene hydrogenation engineering pressure pipeline

ActiveCN102758966AEasy to operateEngineering quality is safe and reliablePipe laying and repairBenzeneEngineering

The invention discloses a construction method for mounting a benzene hydrogenation engineering pressure pipeline, which is characterized by comprising the following steps of: a, pipeline machining; b, pipeline welding; and c, pipeline mounting: (1) pipeline prefabrication; (2) pipeline prestretching; (3) heat tracking pipe and jacketed pipe mounting; (4) bracket and hanging bracket mounting; (5) valve mounting; (6) pipeline flange, spacer and flange fastener mounting; (7) pipeline compensation device mounting; and (8) electrostatic grounding mounting. The construction method for mounting the benzene hydrogenation engineering pressure pipeline, provided by the invention, has the advantages of reasonable operation step design, simplicity in operation, safe and reliable engineering quality and reduction of engineering construction cost.

Owner:MCC5 GROUP CORP SHANGHAI

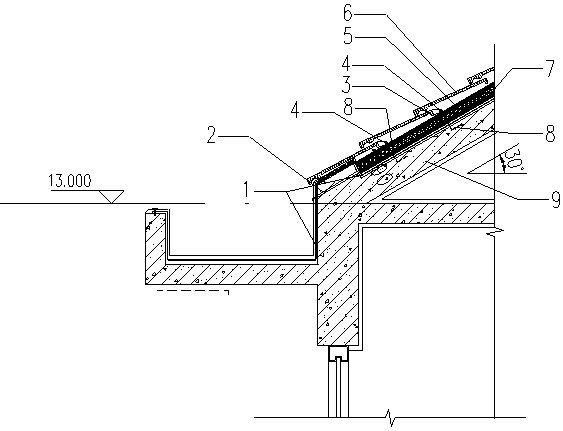

45-degree slope roof cast-in-place concrete construction method

ActiveCN104674998AAvoid leakage hazardsGuarantee molding qualityBuilding roofsBuilding material handlingEconomic benefitsEngineering

The invention discloses a 45-degree slope roof cast-in-place concrete construction method. The method is characterized by comprising the following steps: a, preparing concrete; b, arranging a steel wire mesh on a slope roof; c, setting the casting sequence of the concrete; d, curing the concrete and performing form removal. The 45-degree slope roof cast-in-place concrete construction method has the advantages that the leakage hidden trouble remained to the slope roof concrete structure in the existing construction is effectively overcome, the concrete forming quality is guaranteed, the engineering quality is safe and reliable, the delay of construction period and economic loss thereof caused by rework repair due to leakage of the structure are avoided, and the created potential economic benefit is far greater than the increased investment.

Owner:MCC5 GROUP CORP SHANGHAI

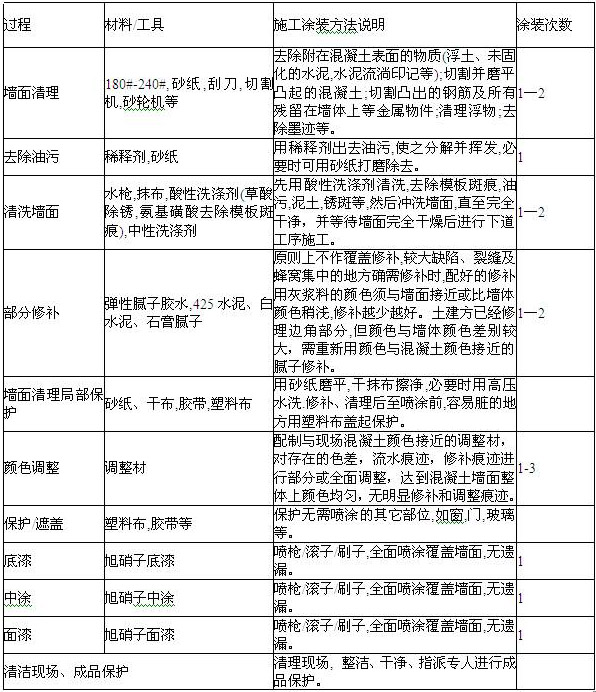

Method for repairing load-bearing structure bare concrete

InactiveCN112412091AEasy to operateGain a sense of scaleBuilding repairsArchitectural engineeringStructural safety

The invention discloses a method for repairing load-bearing structure bare concrete. The method is characterized by comprising the following steps of a, substrate treatment; b, bare concrete defect repairing; c, bolt hole plugging treatment; d, protective agent construction. The method has the advantages that the repairing steps are elaborately designed, scientific and reasonable, operability is high, engineering quality is safe and reliable, the facade effect is good, the bare concrete obtains the scale feeling and the rhythm feeling, the special effect of the bare concrete vision is presented, under the condition that structural safety is not damaged, the bare concrete is repaired in an economical manner, and the engineering cost is reduced.

Owner:SHANGHAI BAOYE GRP CORP

Mounting method of lightning protection and grounding equipment in benzol hydrogenation process

InactiveCN102403578AEngineering quality is safe and reliableGood electrical performanceCorona dischargeConnection contact member materialElectrical resistance and conductanceProcess quality

A mounting method of lightning protection and grounding equipment in the benzol hydrogenation process is characterized by including the following steps of a, mounting a manual grounding body, b, mounting an artificial grounding body, c, laying grounding main wires, d, mounting a lightning conductor, e, mounting a support, f, embedding lightning protection downleads, g, laying lightning protection downleads in an exposed manner, h, mounting a lightning conduction net, and i, testing resistivity values. The mounting method of the lightning protection and grounding equipment has the advantages of reasonable design of mounting steps, simplicity in operation, safety and reliability in process quality, excellent electric performance and lower process cost.

Owner:MCC5 GROUP CORP SHANGHAI

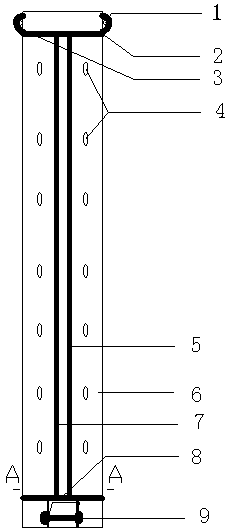

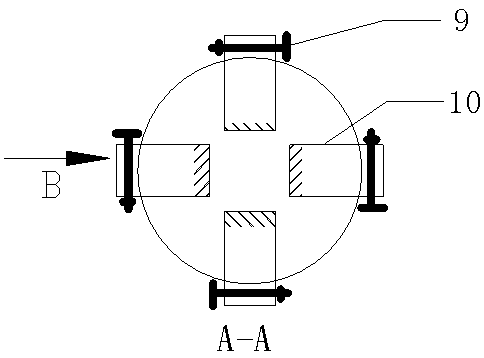

Pile extracting sleeve and using method thereof

InactiveCN108560551ASimple structureEasy to manufactureBulkheads/pilesArchitectural engineeringPiping

The invention relates to a pile extracting sleeve which is used for concrete prefabricated square pile pulling operation. The pile extracting sleeve comprises a steel pipe, four tongues, a water pipeand an air pipe, and is characterized in that a steel pipe body is a welding steel pipe with one end fixedly provided with lifting lugs in a welded manner, the four tongues are arranged at the other end of the steel pipe body, four square holes are formed in the steel pipe body in a quartering circumferential manner, two seat plates are fixedly welded to the outer walls of the square holes in parallel, a through hole is formed in the center of each seat plate, and a pin shaft is contained in each through hole; and when the steel pipe is upwards pulled, the four tongues are opened toward the center in the pipe at the same time, one side of each tongue tip abuts against a pile pipe, and the other sides of the tongue tips are lined at the positions, where the square holes are formed, on the wall of the steel pipe body. The pile extracting sleeve and a using method of the pile extracting sleeve have the advantages that the pile extracting sleeve device is simple in structure, convenient tomanufacture, high in pile pulling speed, safe and reliable in construction quality, simple in pile pulling process and convenient to construct and reduces the engineering cost.

Owner:MCC5 GROUP CORP SHANGHAI

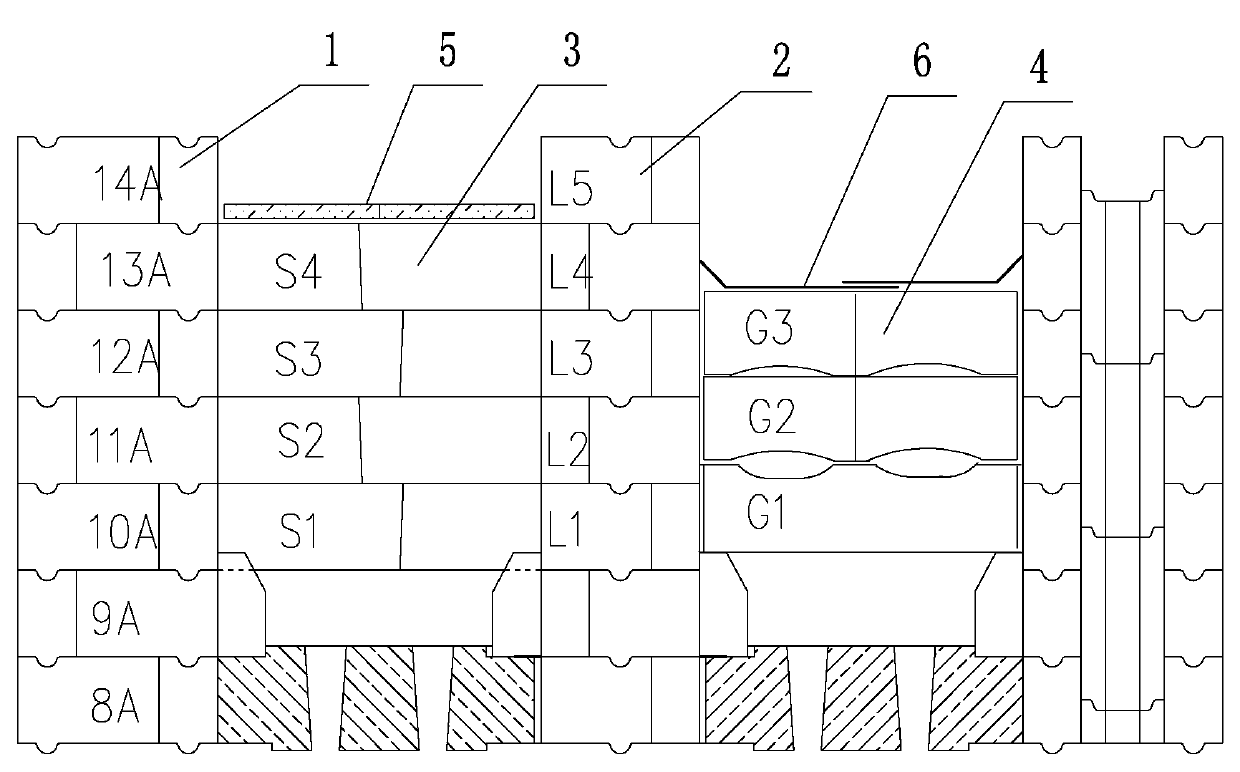

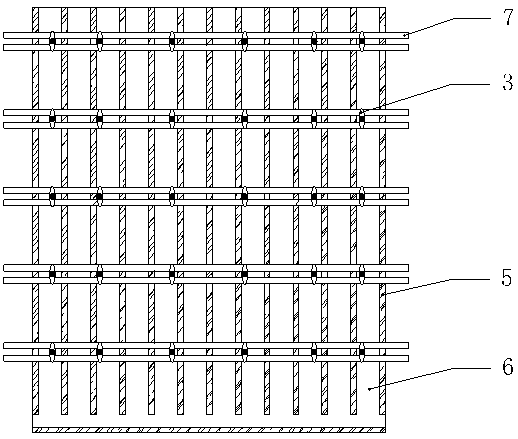

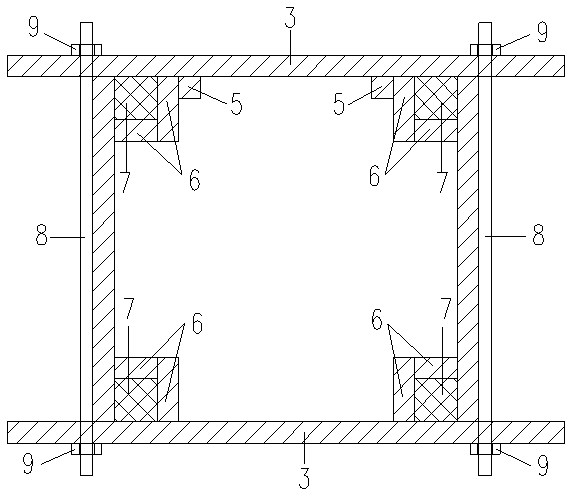

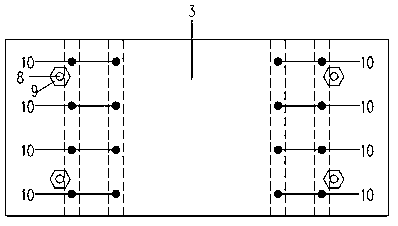

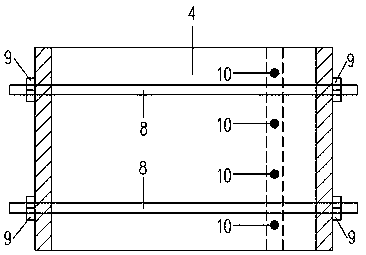

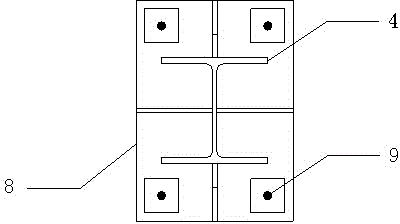

Mold device for manufacturing + type cavity concrete mold block and using method thereof

The invention discloses a mold device for manufacturing a + type cavity concrete mold block. The mold device comprises an outer mold, an inner mold and opposite-pull screws, and is characterized in that the outer mold is provided with two main clamping plate units (3) and two auxiliary clamping plate units (4), wherein the opposite-pull screws (8) at the two ends of the main clamping plate units penetrate through the main clamping plate units; the inner mold is provided with clamping plates (5), auxiliary clamping plates (6) and square timbers (7); the main clamping plate units, the auxiliaryclamping plate units, the clamping plates, the auxiliary clamping plates and the square timbers are spliced after cutting to form a wall with the same width size and the same thickness as the masonrywall; and the height size is the same as the height of bricks for masonry. The mold device changes a traditional formwork erecting mode, and has the advantages of further guaranteeing the constructionquality when improving the working efficiency, repeatedly recycling a shaping formwork for manufacturing the concrete mold block and reducing the engineering cost.

Owner:CHINA MCC20 GRP CORP

Desulphurizing tower bottom replacing method employing Jig frame bearing

A desulphurizing tower bottom replacing method employing Jig frame bearing is characterized by comprising the following steps: a, isolating a desulphurizing tower, and clearing away combustibles in the tower; b, manufacturing and welding a jig; c, welding reinforcing plates and corbels; d, arranging a hawser; e, arranging a *-shaped support in the tower; f, arranging positioning baffle plates; g, replacing the bottom of the desulphurizing tower. The desulphurizing tower bottom replacing method employing Jig frame bearing has the advantages as follows: a jig frame device is simple in structure, convenient to manufacture and good in using effect; the construction quality is safe and reliable; the difficulty in replacing the bottom of a large-sized tower and other non-standard equipment after bottom corrosion under the conditions that the environment is complex and a site is limited is overcome.

Owner:MCC5 GROUP CORP SHANGHAI

Construction method of exterior hidden frame supported glass curtain wall

InactiveCN105672656AAdvantages of construction methodReasonable design specificationsWallsBuilding material handlingKeelEconomic benefits

Provided is a construction method of an exterior hidden frame supported glass curtain wall. The glass of the exterior hidden frame supported glass curtain wall is installed outside a vertical keel and placed on a transverse keel. All vertical frameworks of a framework system are firmly connected with pre-buried iron accessories in structural concrete. The construction method is characterized by comprising following steps: a, examining a main body structure and pre-buried iron accessories; b, installing supports and columns; c, installing crossbeams; d, installing rock wool; e, installing glass press blocks; f, installing glass boards and g gluing and caulking. The construction method of the exterior hidden frame supported glass curtain wall has following advantages: the construction method is standardized and reasonable in design of construction steps, easy in operation, quick in construction speed, safe and reliable in engineering quality, short working period and valuable economic benefit.

Owner:MCC5 GROUP CORP SHANGHAI

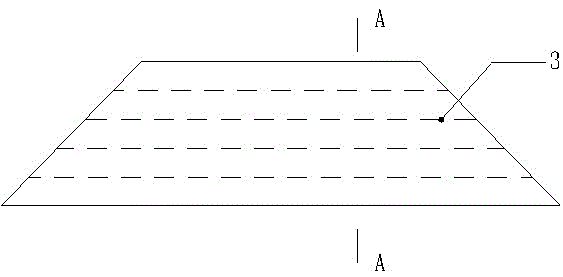

Fixing method for ceramic tile

InactiveCN108442617AAdvantages of fixed methodSimple structureRoof covering using tiles/slatesBuild-up roofsForeign matterCopper wire

Provided is a fixing method for a ceramic tile suitable for the range of inclination angles from 20 degrees to 45 degrees of a slope roof. The construction process follows the sequence of a pre-embedded steel bar in a structure layer, a water-proof layer, a heat-preserving layer, a leveling layer, a tile-laying layer, fixation of the ceramic tile and cleaning. The construction process comprises the following steps: a, laying the structure layer; b, laying the water-proof layer; c, laying the heat-preserving layer; d, laying the leveling layer; e, laying the tile-laying layer; f, fixing the ceramic tile; g, cleaning waste and foreign matter on the surface of a surface of the ceramic tile in order to keep the surface of the ceramic tile clean and bright. The fixing method for the ceramic tile has a fixing structure of the ceramic tile. The structure is simple and the ceramic tile is convenient to manufacture. A pre-embedded steel bar head is combined with a binding copper wire in order to fix the ceramic tile. The project quality is safe and reliable. The construction speed is high. The construction is simple and convenient. In addition, the ceramic tile is firmly fixed with a basiclayer in order to prevent the tile from falling down. The fixing method is advantaged by being excellent in waterproofness and helps reduce project cost.

Owner:MCC5 GROUP CORP SHANGHAI

Method for mounting process steel platform steel columns in project of mounting benzene hydrogenation steel structure

The invention discloses a method for mounting process steel platform steel columns in a project of mounting a benzene hydrogenation steel structure. The method is characterized by comprising the following steps of: a, hoisting steel columns; b, correcting the steel columns; c, measuring and controlling the steel columns during the mounting of a multilayer steel framework; d, mounting multiple layers of process steel platform steel beams; e, connecting the steel columns with framework webs and flanges, and f, mounting secondary beams and platform planks. The method for mounting the process steel platform steel columns in the project of mounting the benzene hydrogenation steel structure has the advantages of reasonable manufacturing step design, simpleness in operation, safe and reliable construction quality and low construction cost.

Owner:MCC5 GROUP CORP SHANGHAI

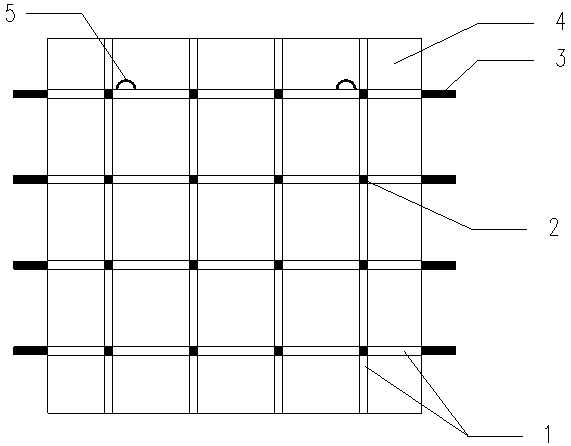

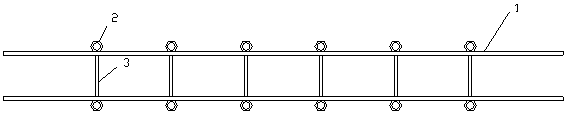

Ladder rib for controlling spacing of vertical reinforcement of shear wall and using method thereof

The invention discloses a ladder rib for controlling the spacing of vertical reinforcement of a shear wall. The ladder rib comprises two horizontal ladder ribs, a plurality of step ribs and a plurality of nuts. The ladder rib is characterized in that the two horizontal ladder ribs are arranged in parallel, the lengths of the two ladder ribs are the lengths of a wall section of the shear wall section plus 100mm. The multiple step ribs are fixedly welded between the inner sides of the two ladder ribs at equal intervals. A plurality of nut bodies are in a hexagonal shape, threaded holes are formed in nut bodies, the side walls of the nut bodies are fixedly welded on outer sides of horizontal ladder ribs at the welded joints of the two horizontal ladder ribs and the step ribs, and the verticalreinforcement can pass through the threaded holes of the nuts when the ladder rid is used. The ladder rib for controlling the spacing of the vertical reinforcement of the shear wall and a using method thereof have the advantages that a novel horizontal ladder rib device is simple in structure and convenient to use, the labor is saved, the construction is fast, the efficiency is high, the construction quality is safe and reliable, the installation quality of wall ribs are effectively ensured, materials are saved, environmental protection is achieved, the horizontal ladder ribs can be reused, and the construction cost is reduced.

Owner:MCC5 GROUP CORP SHANGHAI

Method for installing main body frame steel structure of benzene hydrogenation project

ActiveCN102465601AReasonable designEasy to operateBuilding material handlingSheet steelSteel columns

The invention relates to a method for installing a main body frame steel structure of a benzene hydrogenation project. The method is characterized by comprising the following steps of: a, dividing hoisting areas of frame steel structures, dividing hoisting areas of multi-layer and high-rise frame steel structures according to the operating range of a tower crane to ensure that steel members are hoisted sequentially and simultaneously in parallel, hoisting from the middle or a certain symmetrical panel of a plane, hoisting by taking a column grid of a panel as a hoisting unit according to the sequence of steel columns, steel beams and supports, and expanding towards the periphery; after a stable structure is formed from bottom to top in the vertical direction, installing minor structures layer by layer, namely arranging the minor structures on the steel members of each panel in each floor; b, measuring, correcting and performing initial screwing by using a high-strength bolt after the frame steel structures of a district are hoisted, measuring, correcting, performing the initial screwing by using the high-strength bolt and welding after the frame steel structures of several districts are installed, and hoisting the next section of the steel column; and c, hoisting, releasing and paving combined floor compression steel plates.

Owner:MCC5 GROUP CORP SHANGHAI

Rapid overhauling method for blast furnace hot air main pipe refractory lining

ActiveCN109735675AReasonable designEasy to operateBlast furnace detailsHeating stovesMaterials preparationRefractory

A rapid overhauling method for a blast furnace hot air main pipe refractory lining is characterized by comprising the following steps that a, building material preparing is conducted; b, cooling is conducted; c, holes are formed in the upper portion of a hot air main pipe; d, refractory lining dismounting is conducted; e, refractory lining building is conducted; and f, fire stop blind plate and fire stop wall dismounting is conducted. The rapid overhauling method for the blast furnace hot air main pipe refractory lining has the advantages that the dismounting step design is reasonable, the operability of the overhauling method is high, and simultaneous multi-point dismounting and building are conducted; and through the multi-point crossed construction manner, the project quality is safe and reliable, rapidness and convenience are achieved, the construction efficiency is improved, and the overhauling project cost is reduced.

Owner:MCC5 GROUP CORP SHANGHAI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com