Mold device for manufacturing + type cavity concrete mold block and using method thereof

A mold and cavity technology is applied in the field of mold devices for making +-type cavity concrete modules, which can solve the problems of wasting raw material resources, slurry leakage, and affecting quality, and achieve the effects of reducing engineering costs, safe and reliable quality, and convenient production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The mold device for making a +-shaped cavity concrete module of the present invention includes an outer mold, an inner mold, and a pull screw.

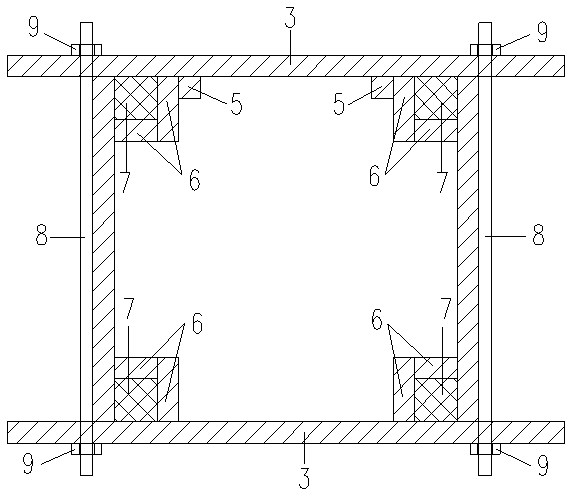

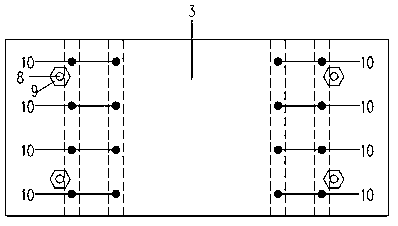

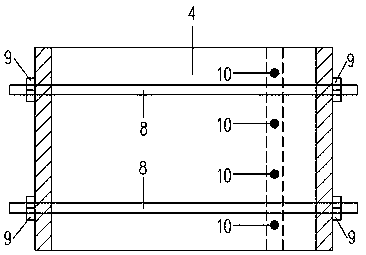

[0040] see now Figure 1-Figure 3 , figure 1 It is a schematic diagram of the mold structure for making concrete modules according to the embodiment of the present invention, figure 2 It is a schematic cross-sectional view of the front view direction of the outer mold of the embodiment of the present invention, image 3 It is a schematic cross-sectional view of the outer mold in the left view direction of the embodiment of the present invention. As shown in the figure, the outer mold is provided with two main splint units 3 and two auxiliary splint units 4, through the main splint unit through the pull screw 8 at both ends of the main splint unit, and the two auxiliary splint units are clamped A well-shaped mold frame is formed at both ends of the main splint unit, the main splint unit is a template with a thickness of 20 m...

Embodiment 2

[0044] The method for using the mold device for making the + type cavity concrete module of the present invention comprises the following steps:

[0045] a. Mold clamping in the well-shaped mold frame: each component of the inner mold and the outer mold is evenly coated with a thin layer of release agent, and cooperate with each other to generate the maximum static friction to achieve the assembly, so that the assembly forms a + shape mold;

[0046] b. The outer mold 1 connects the main splint unit 3 and the clamping plate 5 with rivets 10 evenly distributed in the interval, and the main splint unit 3 and the sub-splint unit 4 are connected with the rivets 10 in the even distribution of the interval. The two splint units 3 of the main splint use Tighten and lock the pulling screw 8 and the nut 9, square wood 7 and auxiliary splint 6 are evenly distributed in the interval of rivets 10 at the inner corner of the well-shaped mold frame, and are connected with the main splint unit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com