45-degree slope roof cast-in-place concrete construction method

A construction method and concrete pouring technology, which is applied to roofs, building components, buildings, etc., can solve the problems of uncompacted concrete pouring, leakage, inconvenience, etc., to ensure the quality of concrete molding, overcome hidden dangers of leakage, and increase economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

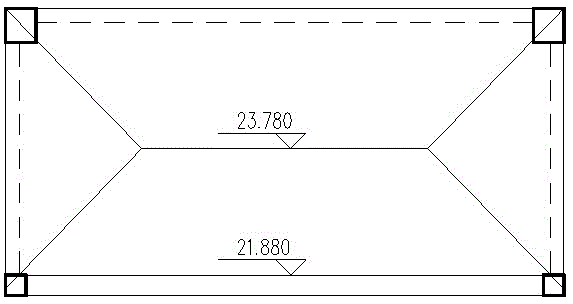

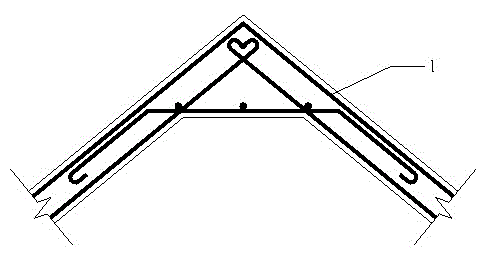

[0034] see now figure 1 , figure 1 It is a schematic plan view of a sloping roof structure according to an embodiment of the present invention, figure 2 It is a schematic diagram of roof folded plate reinforcement according to an embodiment of the present invention. 45 ° slope roof cast-in-place concrete construction method of the present invention is characterized in that comprising the following steps:

[0035] a. Prepare concrete

[0036] To prepare concrete, since it is very difficult to pour concrete on sloped roofs, the slump of concrete is required to be 120-150 mm; the automobile concrete boom pump is used as a vertical transportation tool to ensure the continuity and mobility of concrete pouring;

[0037] b. Steel wire mesh is set on the sloping roof

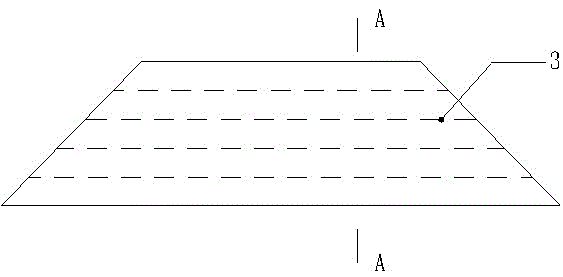

[0038] image 3 It is a schematic diagram of the steel wire mesh of the embodiment of the present invention, Figure 4 for image 3 Sectional view of A-A in Fig. Set the concrete formwork 2 for the sloping roof...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com