Welding process for suction and exhaust pipe of liquid accumulator

A welding process and liquid reservoir technology, applied in welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of high overall welding cost, low welding efficiency, and high overall cost, and achieve the effect of eliminating hidden leaks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

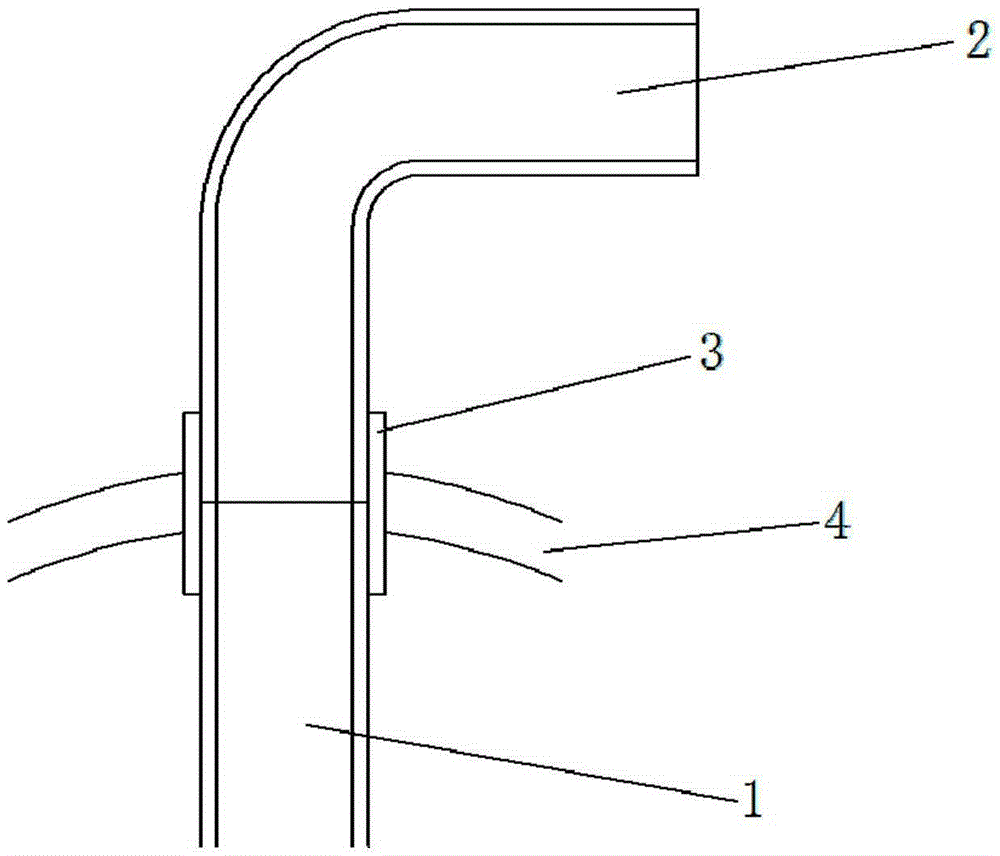

[0041] A welding process for the suction and exhaust pipes of a liquid reservoir, comprising a liquid reservoir, a small steel pipe and a copper bend, characterized in that a sleeve is provided at the connection between the small steel pipe and the copper bend, and the sleeve is stuck in the liquid reservoir At the through hole, the soldering process includes the following steps:

[0042] 1) Pre-welding treatment, including grinding and cleaning;

[0043] 2) Assembling the parts, clamping the ends of the small steel pipe and the copper elbow respectively in the casing to form a weldment;

[0044] 3) Welding;

[0045] 4) Clamp the sleeve of the weldment on the through hole of the reservoir for welding.

[0046] In the present embodiment, in step 1), grinding is performed on the small steel pipe and the copper elbow welding area and at least 20 mm around the area, grinding until metallic luster appears, removing oil stains and oxide films, and ensuring that the surface of the ...

Embodiment 2

[0056] A welding process for the suction and exhaust pipes of a liquid reservoir, comprising a liquid reservoir, a small steel pipe and a copper bend, characterized in that a sleeve is provided at the connection between the small steel pipe and the copper bend, and the sleeve is stuck in the liquid reservoir At the through hole, the soldering process includes the following steps:

[0057] 1) Pre-welding treatment, including grinding and cleaning;

[0058] 2) Assembling the parts, clamping the ends of the small steel pipe and the copper elbow respectively in the casing to form a weldment;

[0059] 3) Welding;

[0060] 4) Clamp the sleeve of the weldment on the through hole of the reservoir for welding.

[0061] In the present embodiment, in step 1), grinding is performed on the small steel pipe and the copper elbow welding area and at least 20 mm around the area, grinding until metallic luster appears, removing oil stains and oxide films, and ensuring that the surface of the ...

Embodiment 3

[0071] A welding process for the suction and exhaust pipes of a liquid reservoir, comprising a liquid reservoir, a small steel pipe and a copper bend, characterized in that a sleeve is provided at the connection between the small steel pipe and the copper bend, and the sleeve is stuck in the liquid reservoir At the through hole, the soldering process includes the following steps:

[0072] 1) Pre-welding treatment, including grinding and cleaning;

[0073] 2) Assembling the parts, clamping the ends of the small steel pipe and the copper elbow respectively in the casing to form a weldment;

[0074] 3) Welding;

[0075] 4) Clamp the sleeve of the weldment on the through hole of the reservoir for welding.

[0076] In the present embodiment, in step 1), grinding is performed on the small steel pipe and the copper elbow welding area and at least 20 mm around the area, grinding until metallic luster appears, removing oil stains and oxide films, and ensuring that the surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com