Construction method of inverted roof

An upside-down roofing and construction method technology, applied in the direction of roofing, roof covering, building roof, etc., can solve the problems of high construction cost, affect the quality, can not be drained, etc., to optimize the waterproof performance of the roof, the construction method is simple and feasible, The effect of reducing leakage hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

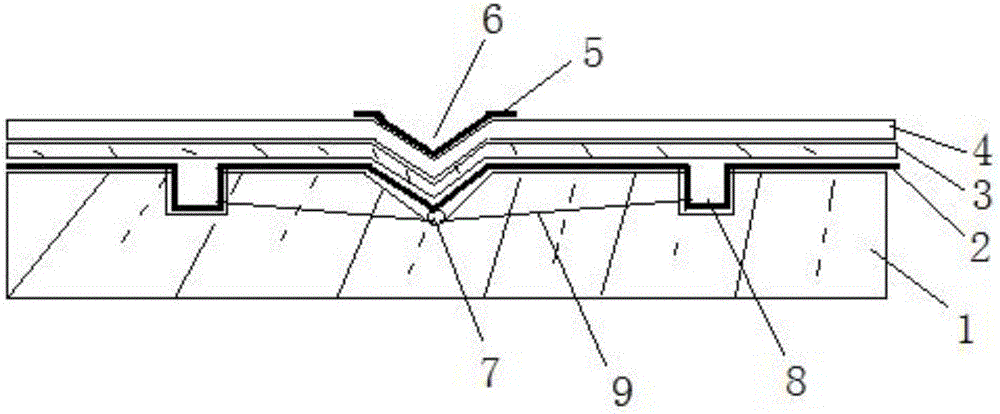

[0022] A construction method for an inverted roof, comprising a constructed structural layer 1, the construction steps of which are as follows:

[0023] (1) carry out slope finding setting to the outer surface of structure layer 1, make its slope be 2-3%;

[0024] (2) V-shaped drains 6 arranged from the center to the surroundings are spaced apart on the outer surface of the structural layer 1, and built-in drains 7 arranged along its length are arranged at the bottom of the V-shaped drains 6; A drainage hole 8 is reserved on the structural layer 1 between the glyph drainage ditch 6, so that the depth of the drainage hole 8 is not greater than one-third of the thickness of the structural layer 1, and the depth of the V-shaped drainage ditch 6 is greater than the depth of the drainage hole 8; The bottom of the drainage hole 8 is communicated with the built-in drainage pipe 7 through the pipeline 9;

[0025] (3) Clean up the sundries and garbage on the surface, and level off and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com