Bidirectional intensively ribbed mold clamp wall body

一种模卡、墙体的技术,应用在墙、建筑构件、建筑材料等方向,能够解决没有很好地解决冷桥、墙体施工工艺复杂、不能共同抵御地震等问题,达到良好节能效果、增强承重、简单施工工艺的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

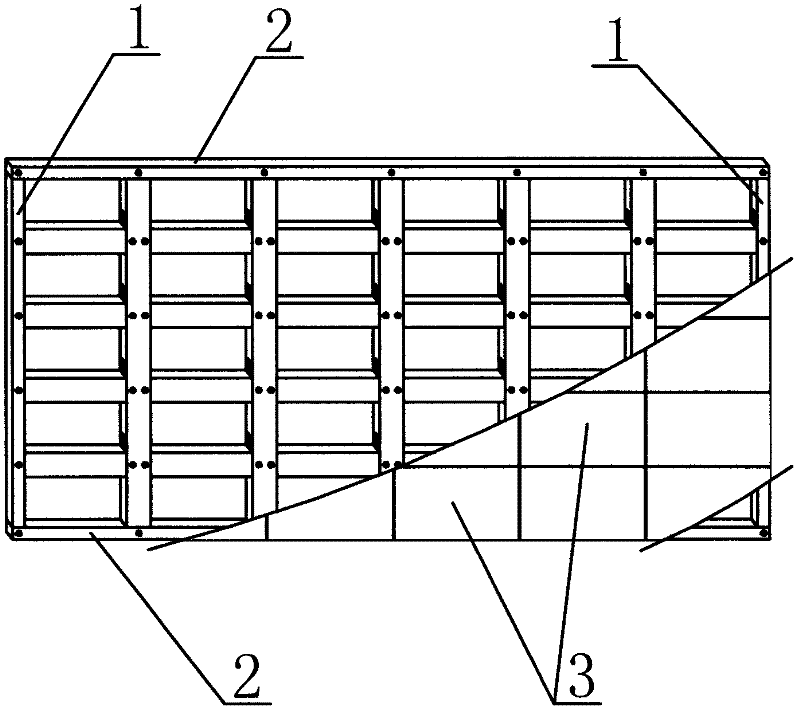

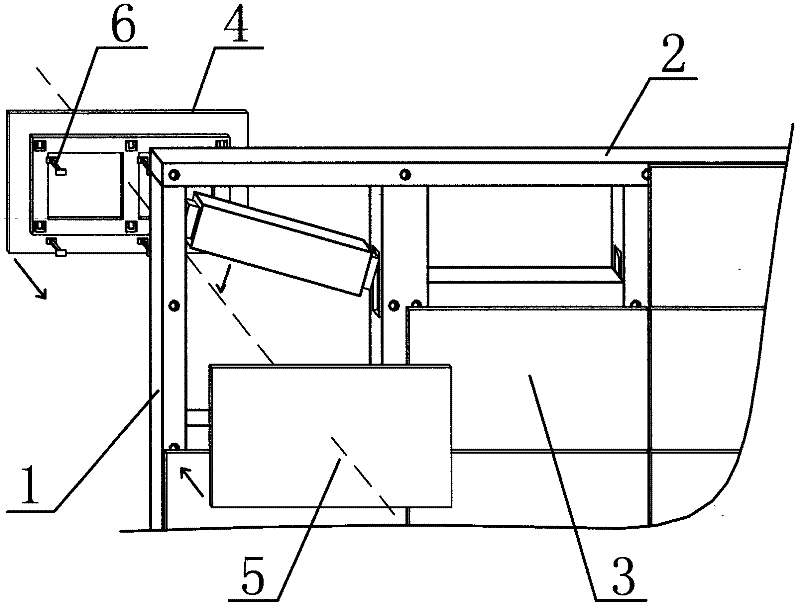

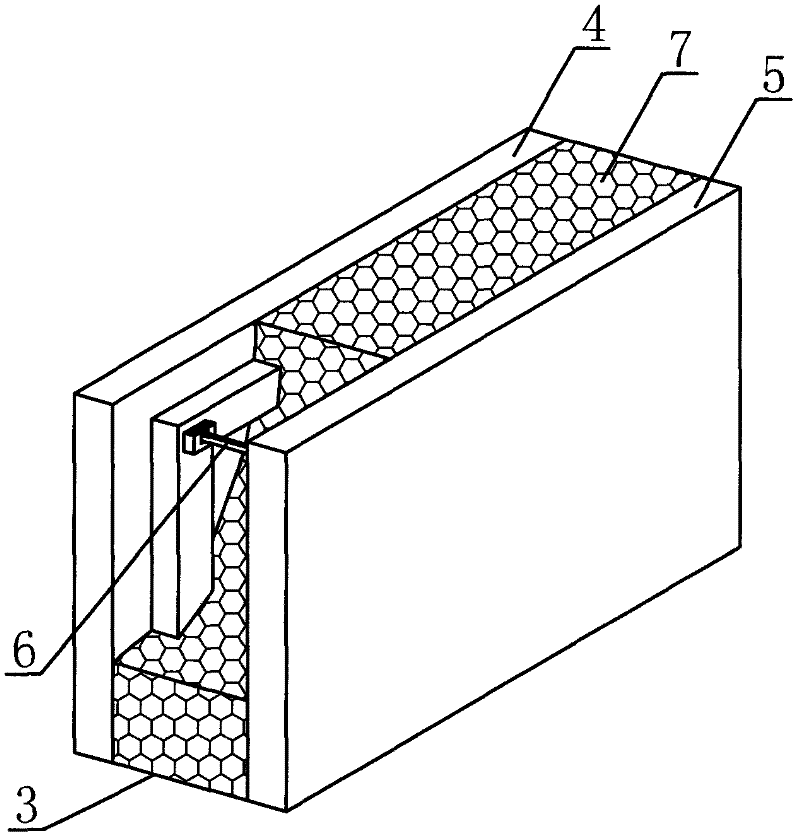

[0065] Below in conjunction with accompanying drawing, the present invention is further described: in each accompanying drawing, numbering is identical, and its description is identical. In the figure, 1 is the rib column, 2 is the rib beam, 3 is the modular block, 4 is the outer panel, 5 is the inner panel, 6 is the connector, 7 is the insulation layer, 8 is the heat insulation layer, and 9 is the flexible shock absorption 10 is the tongue and groove, 11 is the male and female tenon, 12 is the protrusion, 13 is the gap, 14 is the side rib column, 15 is the middle rib column, 16 is the upper and lower rib beam, 17 is the middle rib beam, and 18 is flexible Airtight layer, 19 is a channel, 20 is an outlet hole, 21 is a groove, 22 is a "one"-shaped insert, 23 is a "T", "Y" or "+"-shaped insert, 24 is a hole, 25 26 is a connecting rod, 27 is a connecting piece, 28 is an injection hole, 29 is a movable hole cover, 30 is a main structural column, and 31 is a main structural beam. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com