Method for controlling floor heave of dynamic pressure tunnel

A technology of roadway and bottom drum, which is applied in tunnels, tunnel lining, earthwork drilling, etc., can solve the problems of insufficient anchoring force, insufficient extension, complicated construction procedures, long time, etc., and achieves simple construction methods, significant economic benefits, and installation efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

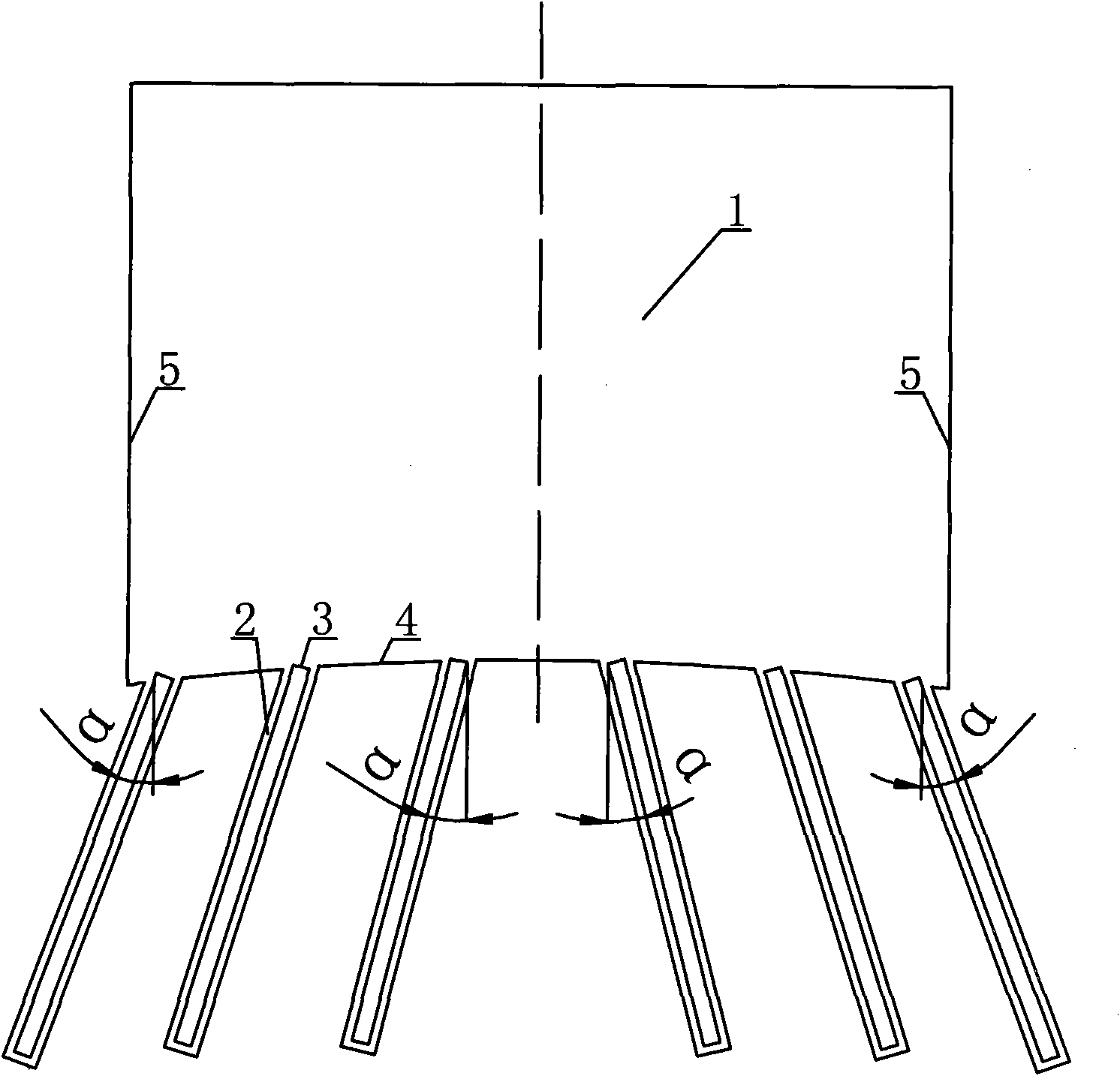

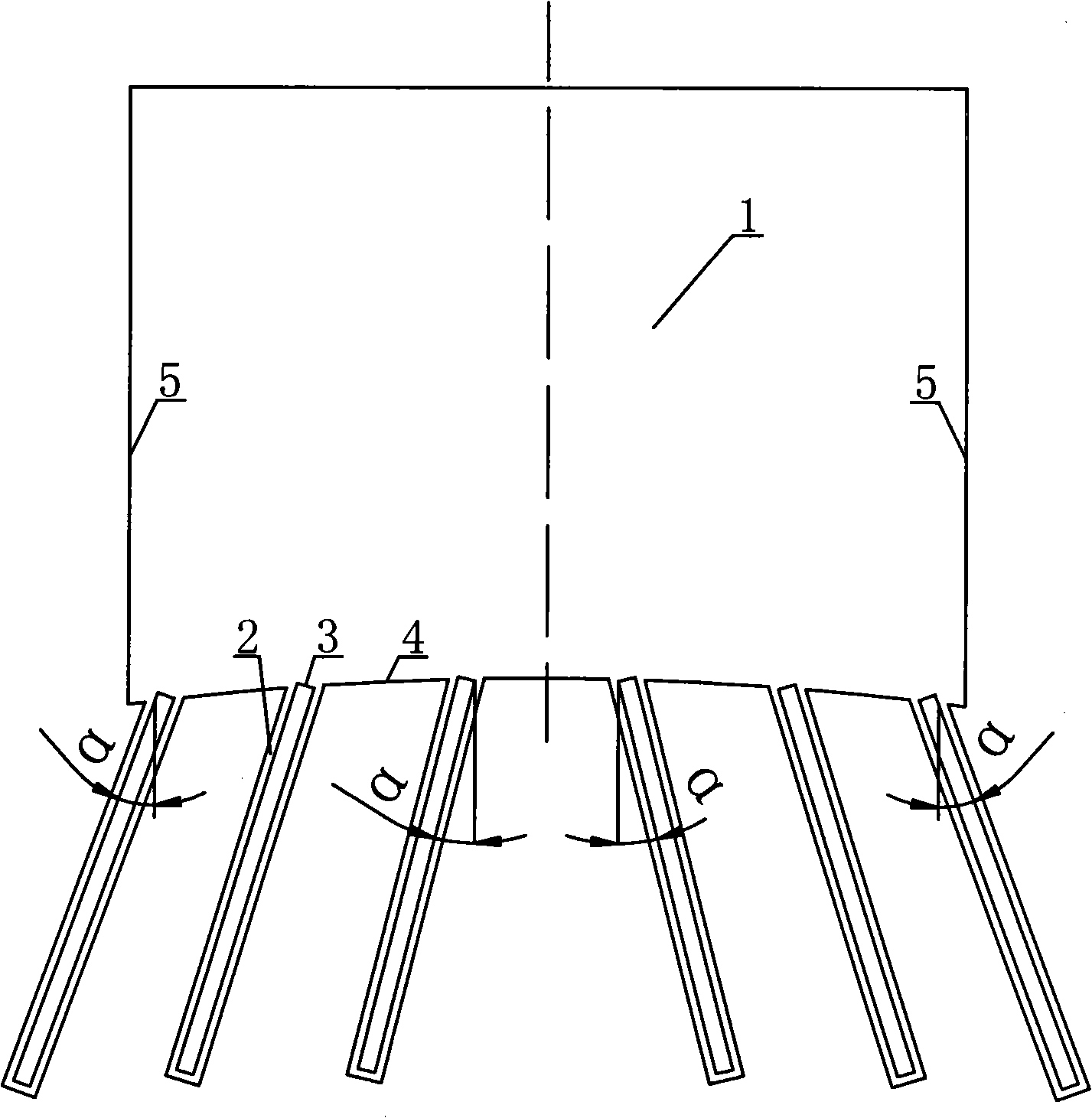

[0017] figure 1 As shown, the rectangular roadway 1 is taken as an example. The method of controlling the bottom drum of the dynamic pressure roadway in a certain mine is based on the actual situation on site. Install the hydraulic expansion bolt 3 on the roadway floor 4 according to different longitudinal clamps α, and then inject water to prevent The development of the plastic zone of the floor and the control of post-peak fracture expansion and shear displacement deformation of the floor rock mass realize the control of the floor heave of the dynamic pressure roadway. Specific steps are as follows:

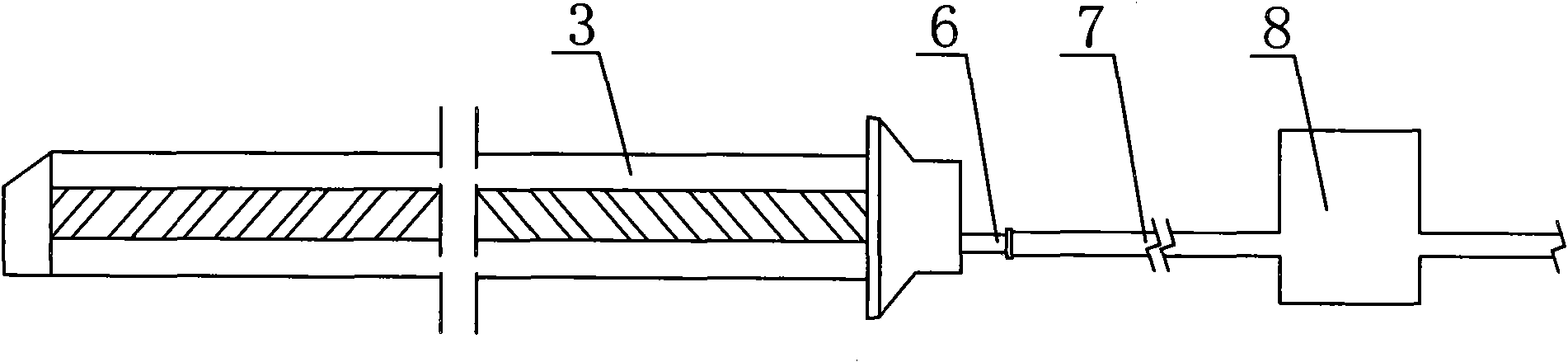

[0018] 1. Drilling: on the floor 4 of the roadway where the roadway bottom drum is prone to occur in the high-stress environment of mining, the longitudinal angle α in the direction of the two sides 5 is symmetrically bounded by the center of the cross-sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com