Patents

Literature

159results about How to "Reduce the risk of leakage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

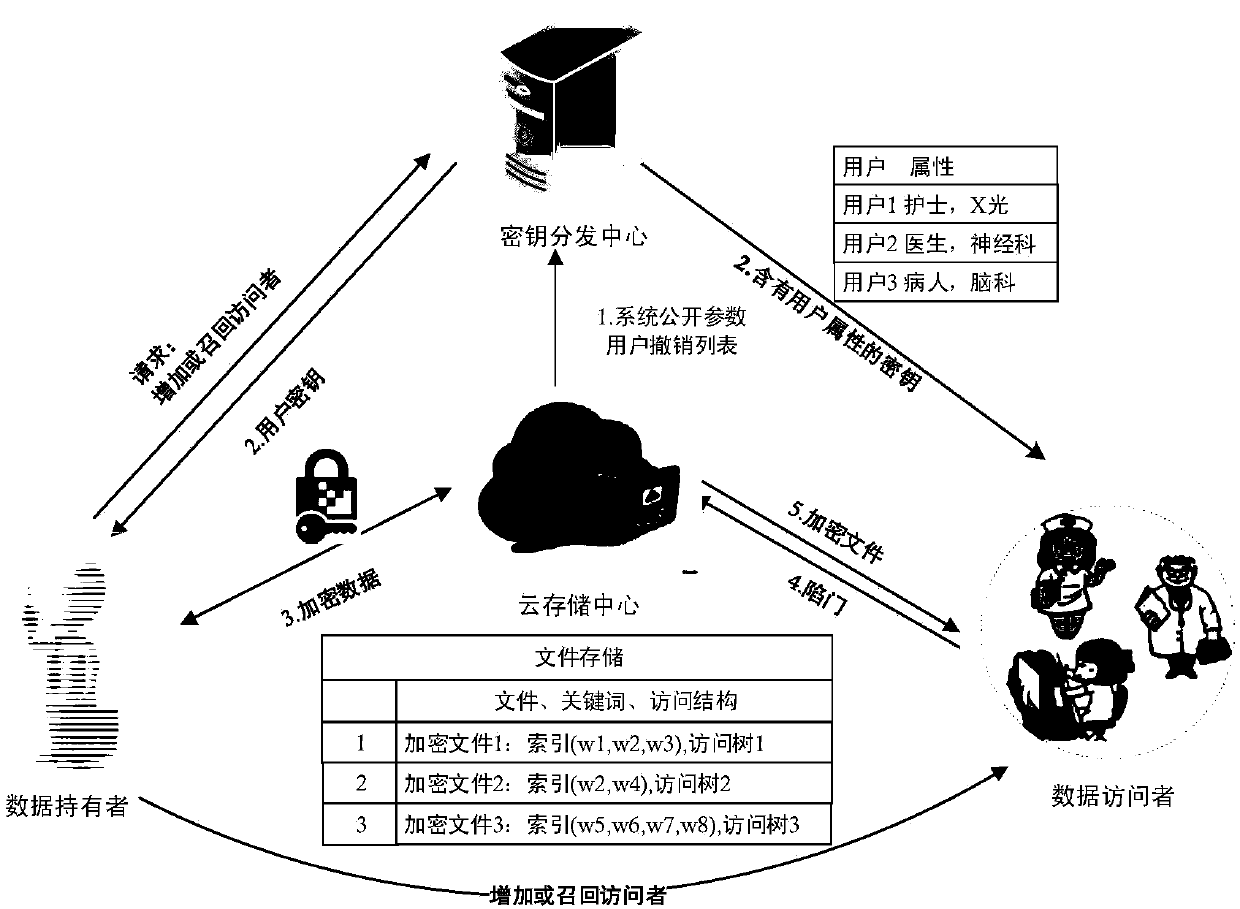

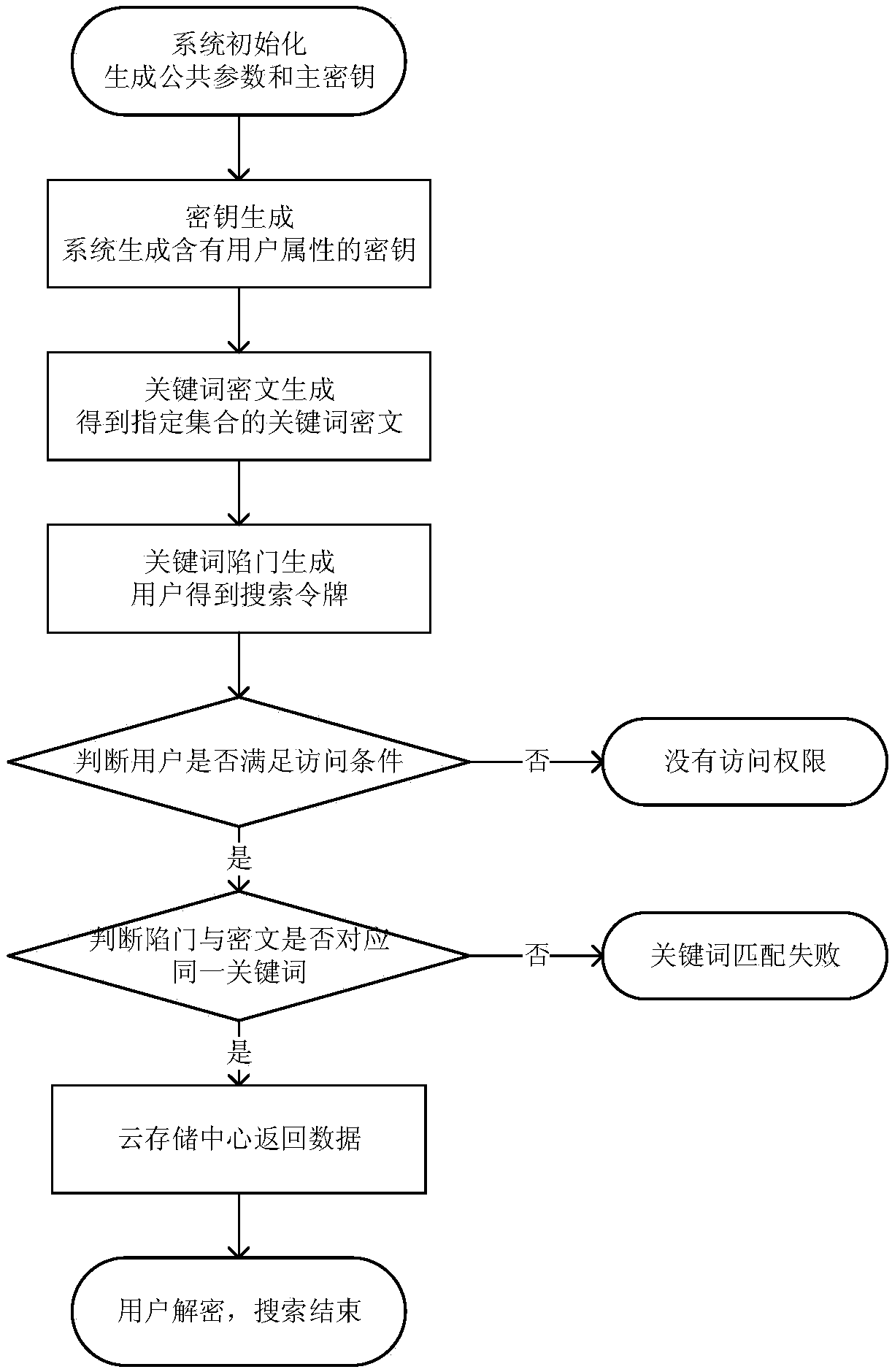

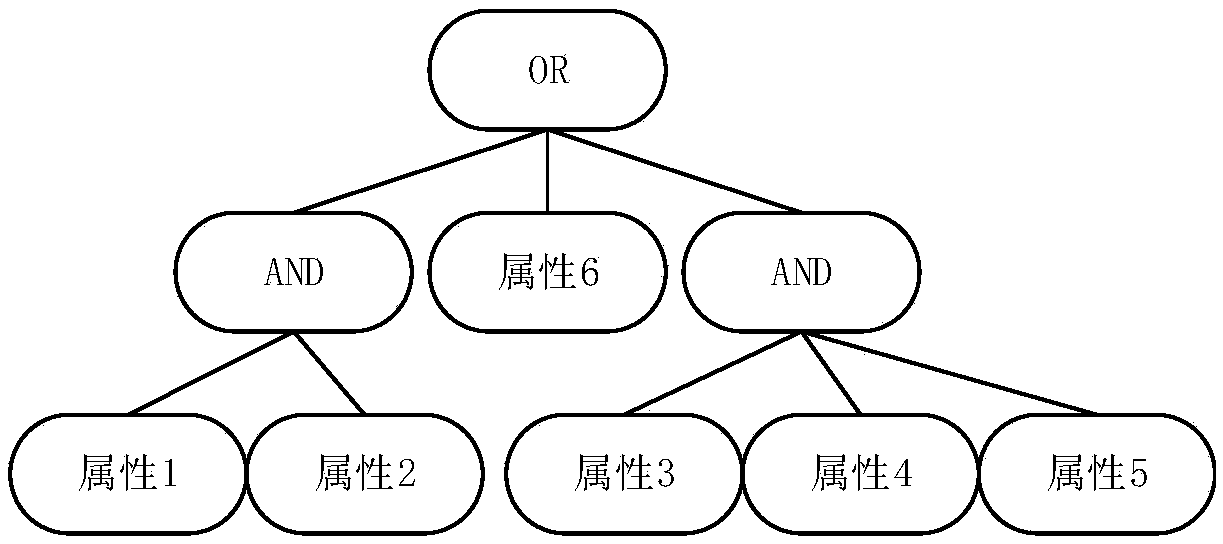

Attribute-based searchable encrypted electronic medical record system and encryption method

InactiveCN107634829AReduce computing requirementsReduce computational complexityKey distribution for secure communicationSpecial data processing applicationsMedical recordCiphertext

The invention discloses an attribute-based searchable encrypted electronic medical record system and an encryption method. The system comprises a key distribution center and a cloud storage center, wherein the key distribution center generates public parameters and a master key to initialize the system; the key distribution center generates and distributes keys containing user attributes to users;a data owner sets an access strategy before uploading medical record data, encrypts the data, and then uploads the data to the cloud storage center; a data visitor generates a trap door according tokeywords and the keys, and provides a query request to the cloud storage center; and after receiving the query request, the cloud storage center determines to return corresponding encrypted data to the data visitor according to the trap door and keyword ciphertexts. According to the scheme of the invention, the difficulty of key management in a multi-user environment can be reduced, data users canbe supported to accurately query the keywords of the ciphertexts, guessing attacks of the keywords can be resisted, and the leakage of privacy data can be effectively prevented.

Owner:NANJING UNIV OF SCI & TECH

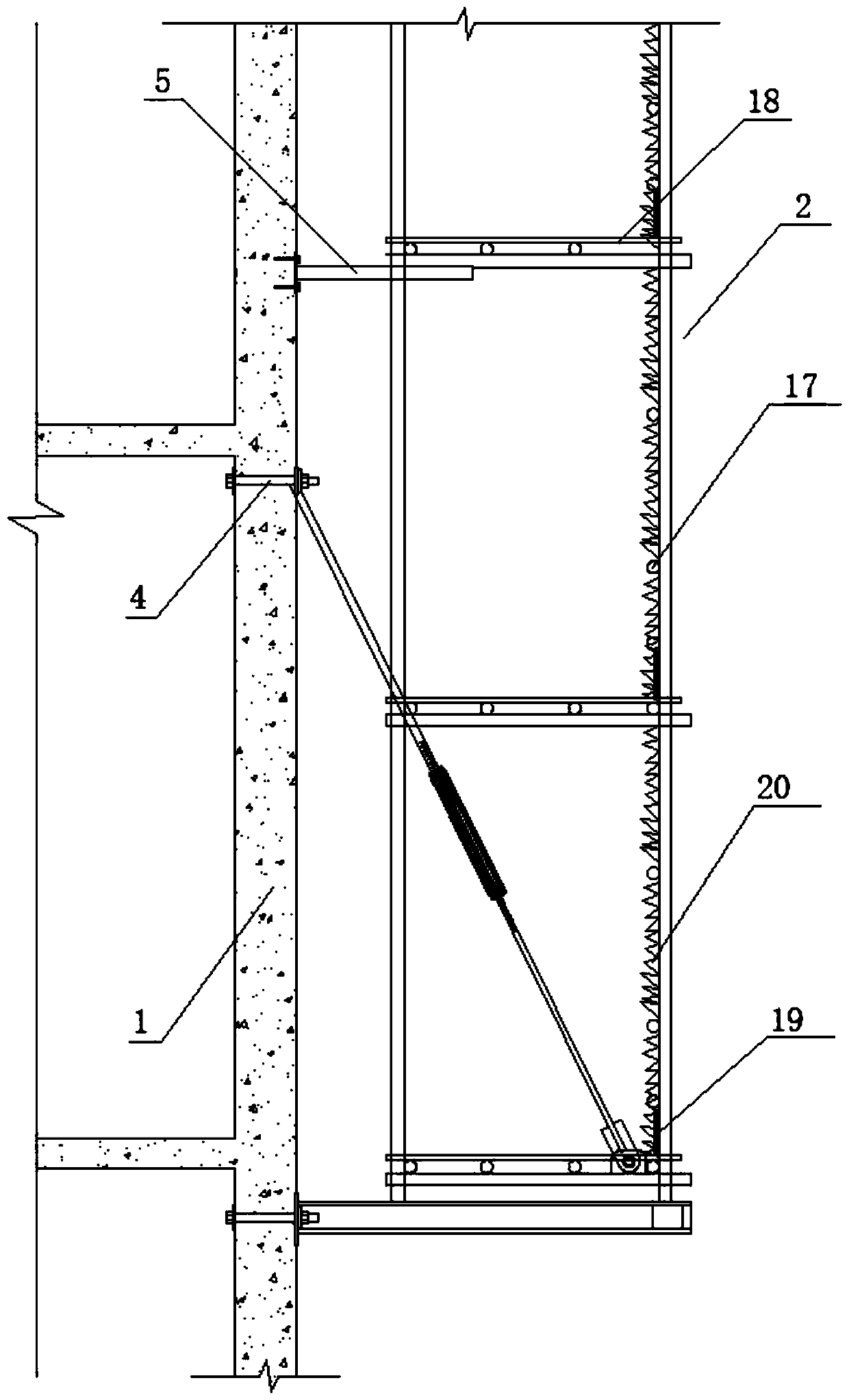

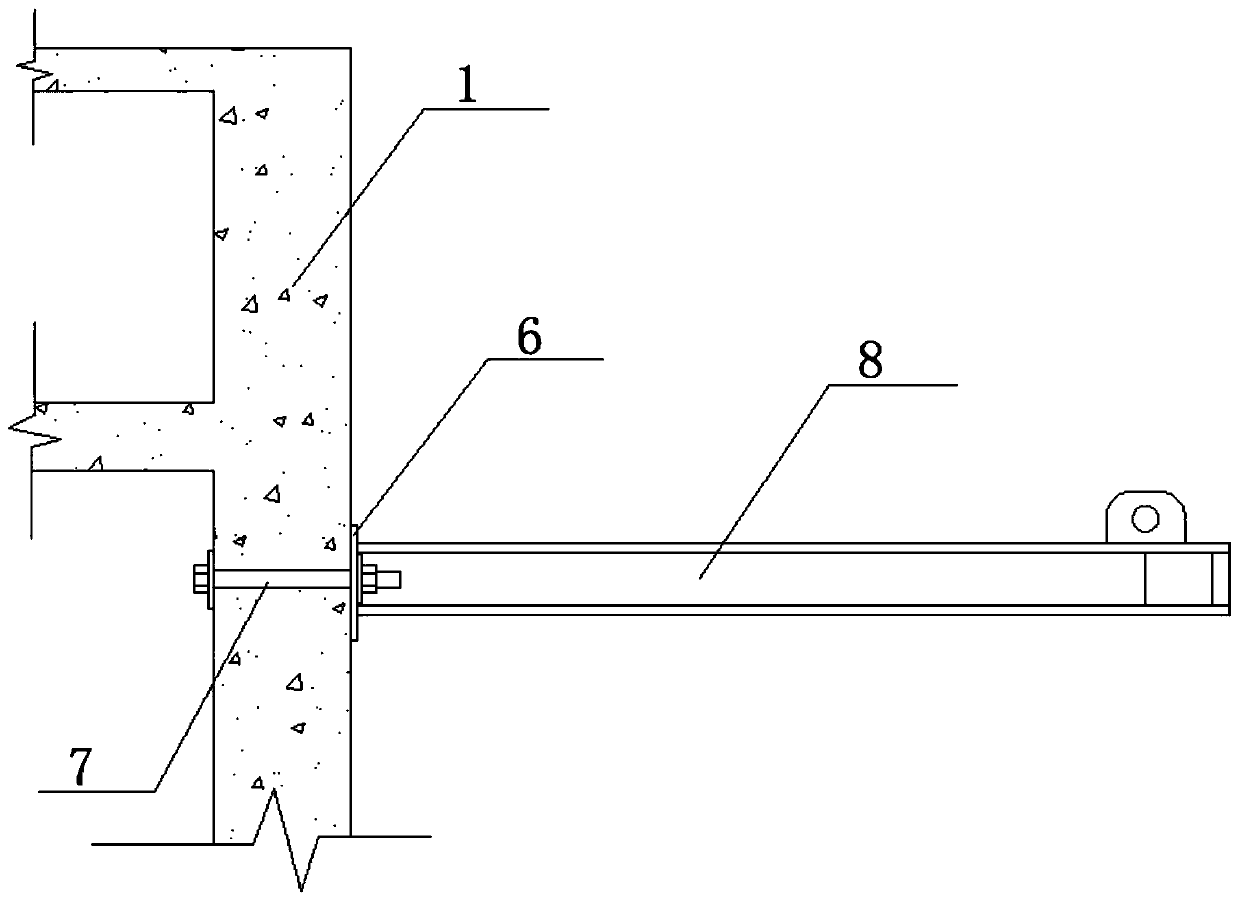

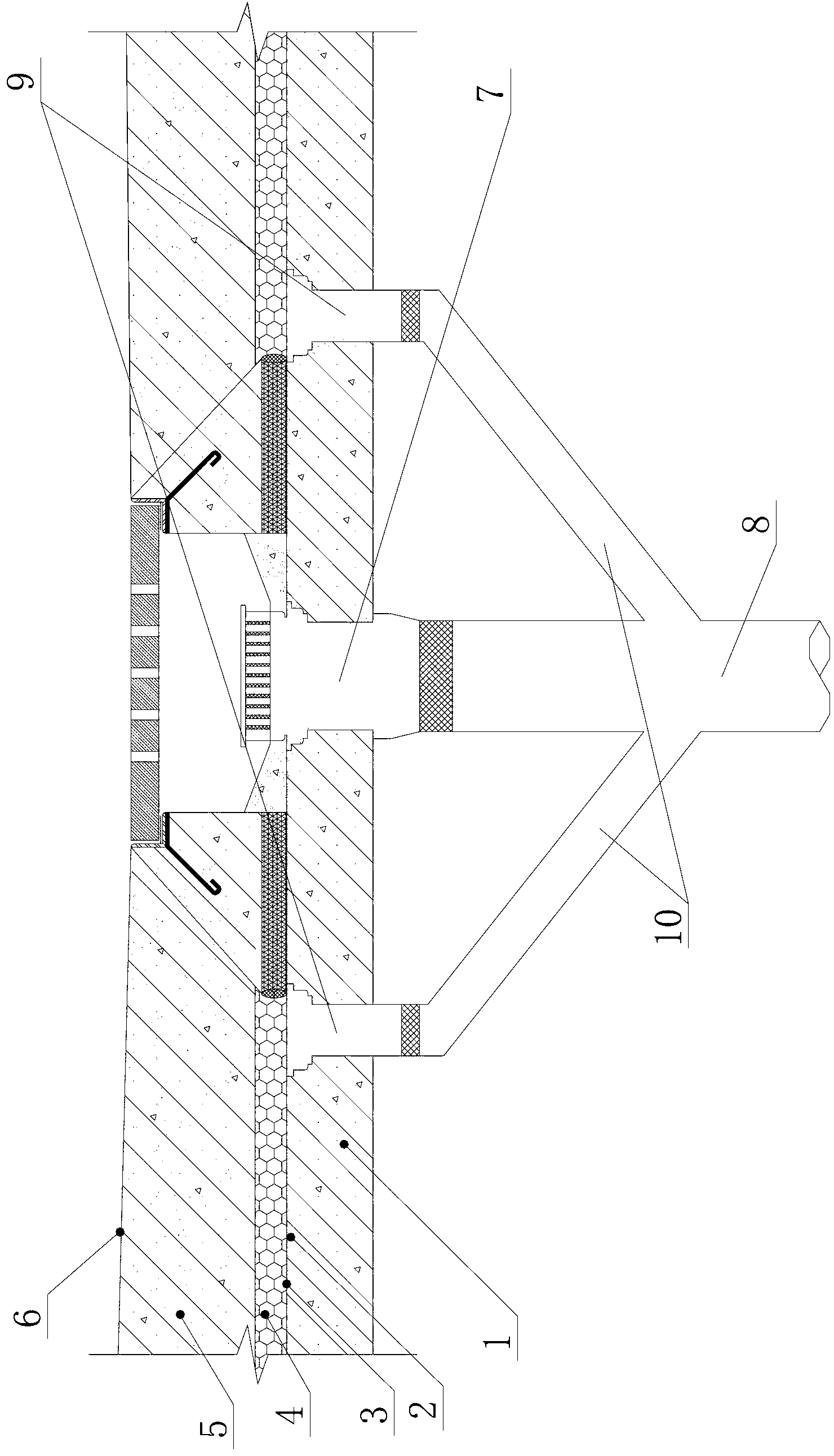

Overhanging type outer scaffold and construction method

InactiveCN109779225AAvoid the problem of uncontrollable parallelismReduce construction costsScaffold accessoriesBuilding support scaffoldsFalseworkSheet steel

The invention provides an overhanging type outer scaffold which comprises an outer scaffold body, the outer scaffold body is fixed to the outer side of a building outer wall through wall connecting pieces, and the wall connecting pieces comprise a first wall connecting piece, a second wall connecting piece and a third wall connecting piece. Compared with a traditional overhanging scaffold construction technology, the construction method has the advantages that by means of the construction method of embedded connecting steel plates on beams and fixing I-shaped steel, the problems that the overhanging scaffold has large requirements for I-shaped steel materials, and an embedded wall connecting rod is difficult to control on the aspect of parallelism and construction hole residues are solved.The embedded connecting steel plates do not affect masonry construction, the hidden danger of leakage caused by the fact that holes are reserved during masonry and the potential safety hazard causedby the fact that wall connecting rods are dismantled during worker construction are reduced, and the influence on the building structure is small. An overlong I-shaped steel material does not need tobe arranged to be fixed in a building, materials are saved, and the construction cost is saved. The problem that the parallelism of the embedded wall connecting rods is difficult to control is avoided, the construction efficiency is improved, and the construction period is shortened.

Owner:CHINA MCC17 GRP

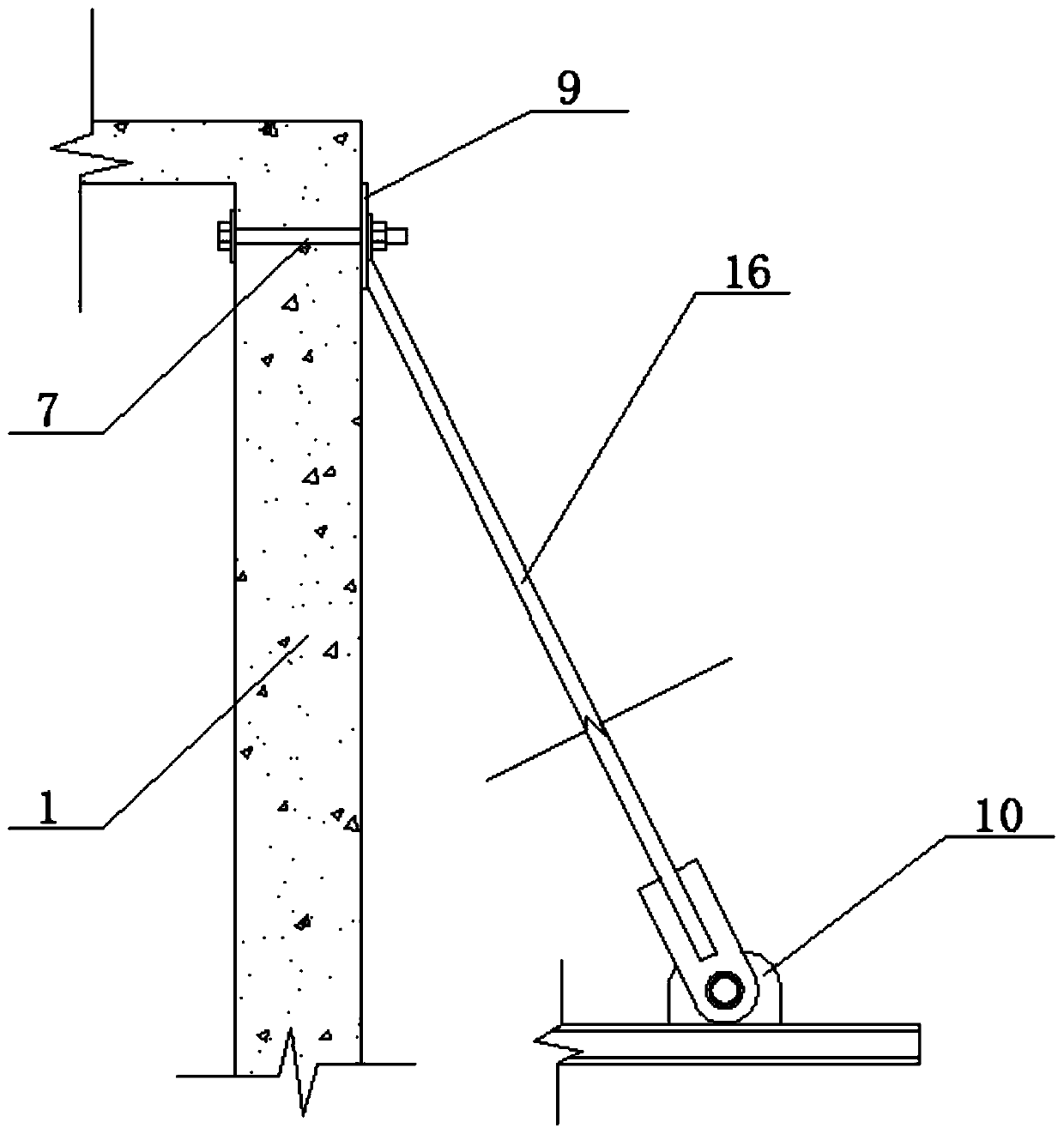

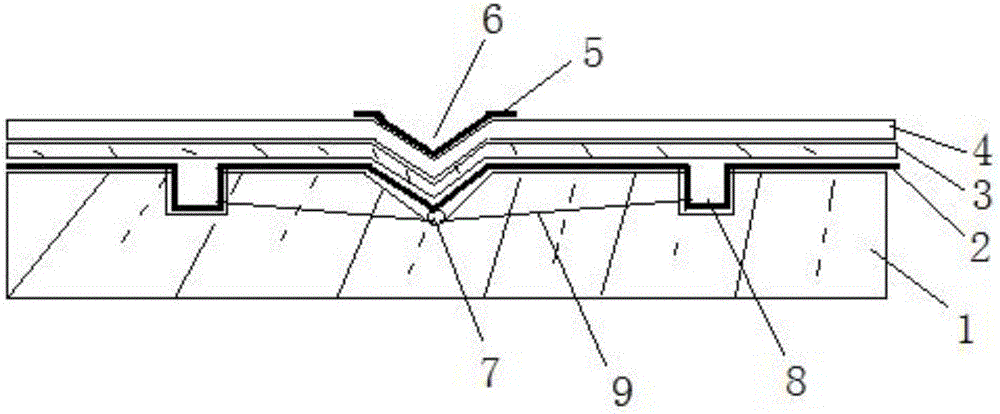

Building waterproof heat-preservation exhaust compound system and construction method thereof

InactiveCN101624859ADischarge in timeReduce hidden dangersLighting and heating apparatusBuild-up roofsArchitectural engineeringCompound system

The invention relates to a building waterproof heat-preservation exhaust compound system, which comprises a heat-preservation layer, a waterproof layer, a waterproof protective layer and an exhaust passage, and is characterized in that the heat-preservation layer comprises paved heat-preservation boards, the lower surfaces of the heat-preservation boards are provided with exhaust grooves, the exhaust grooves of all the heat-preservation boards are connected into the exhaust passage, one end of the exhaust passage is connected into a flue through a connecting pipe, and the waterproof layer and the waterproof protective layer are covered on the heat-preservation layer in turn. The building waterproof heat-preservation exhaust compound system has the following advantages that: the system is a heat-preservation waterproof moisture-proof exhaust system for roofs and the floors, which uses a JWG-M type to seal and resist water for EPS and XPS heat-preservation boards, is communicated with the flue through the exhaust grooves of the EPS and XPS heat-preservation boards, and exhausts moist air in time by the pipeline effect of the flue so as to achieve waterproof heat-preservation exhaust integral roofs. Simultaneously, the system removes the vertical exhaust pipes arranged on the roofs and reduces the hidden danger of seepage, and the roofs are smooth to prevent frost heave and gas heave so that the deserved effective service life of the waterproof and heat-preservation roofs is achieved. Besides, the system has good heat-preservation and waterproof effects.

Owner:刘铁刚

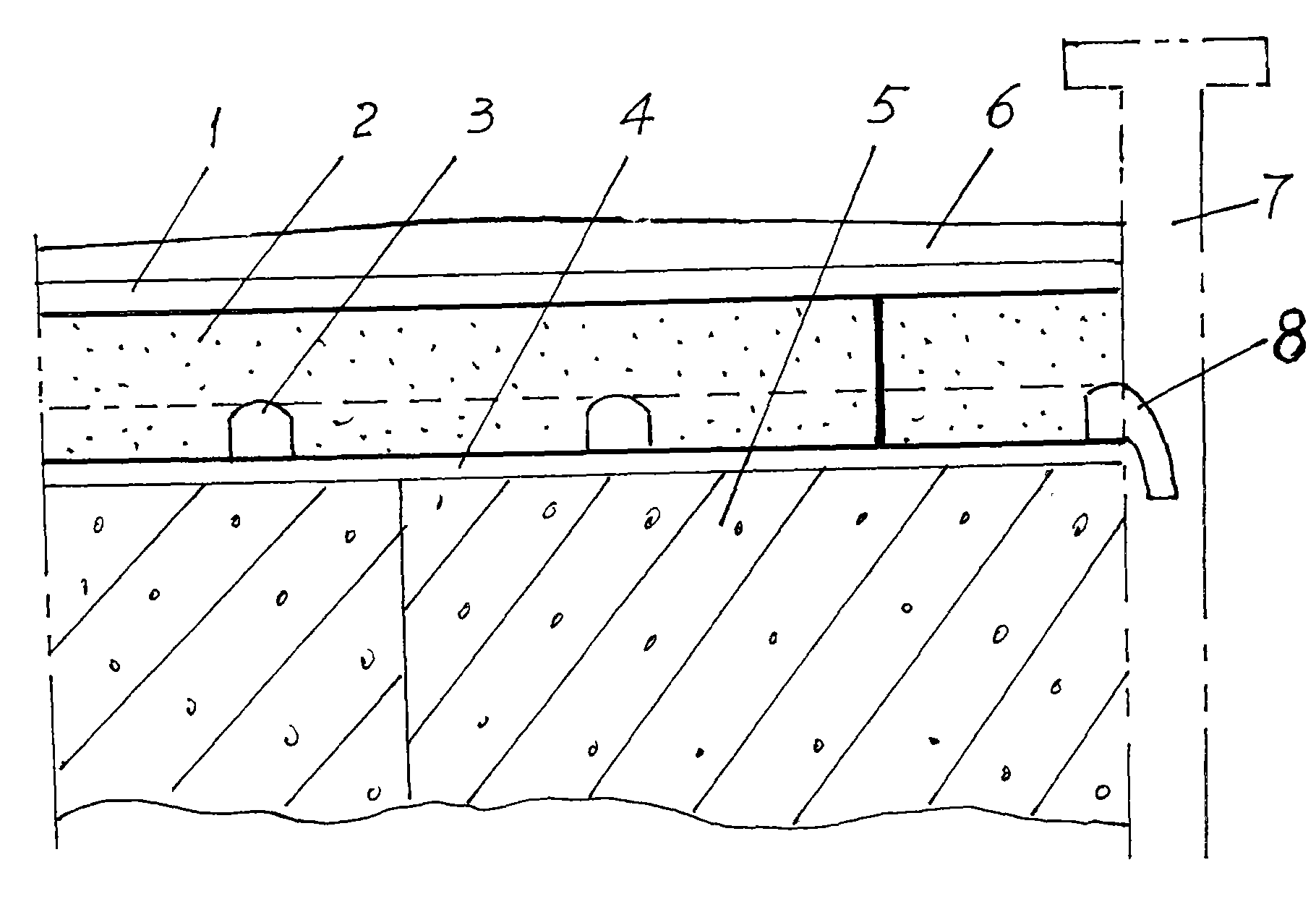

Low-NOx mixed burning system and method with coupling of pyrolyzing furnace and pulverized coal boiler

ActiveCN109578990AReduce the risk of leakageLow costCombustion using gaseous and pulverulent fuelCombustion apparatusChemical productsEngineering

The invention discloses a low-NOx mixed burning system and method with coupling of a pyrolyzing furnace and a pulverized coal boiler. The low-NOx mixed burning system comprises a coal pyrolyzing system formed by a raw coal cabin, a drying device, a coal pyrolyzing furnace, a semicoke collection device, a pyrolysis dust removal device and the like and a mixed burning system of pyrolyzing semicoke and bituminous coal; and the mixed burning system of pyrolyzing the semicoke and the bituminous coal is formed by a semicoke small material cabin, a coal mill, a desulfurization device and the like. For the low-NOx mixed burning system and method with coupling of the pyrolyzing furnace and the pulverized coal boiler, by putting the pyrolyzing furnace in front of the pulverized coal boiler, a semicoke large material and a semicoke small material obtained by pyrolyzing are separately stored and utilized, the semicoke large material is used as a chemical product, the semicoke small material is used as burning and bituminous coal for layering mixed burning, and a part of pyrolysis gas is used as a reburning fuel for a boiler to be sprayed into a furnace hearth for reburning. The low-NOx mixed burning system and method with coupling of the pyrolyzing furnace and the pulverized coal boiler lower production of NOx while solving resource waste of the semicoke small material and the pyrolysis gas and the various problems in the burning process, realizes full utilization of energy, is economic and environmentally friendly without improving the existing pulverized coal furnace, is wide in adaptability range and has a wide application prospect.

Owner:XI AN JIAOTONG UNIV

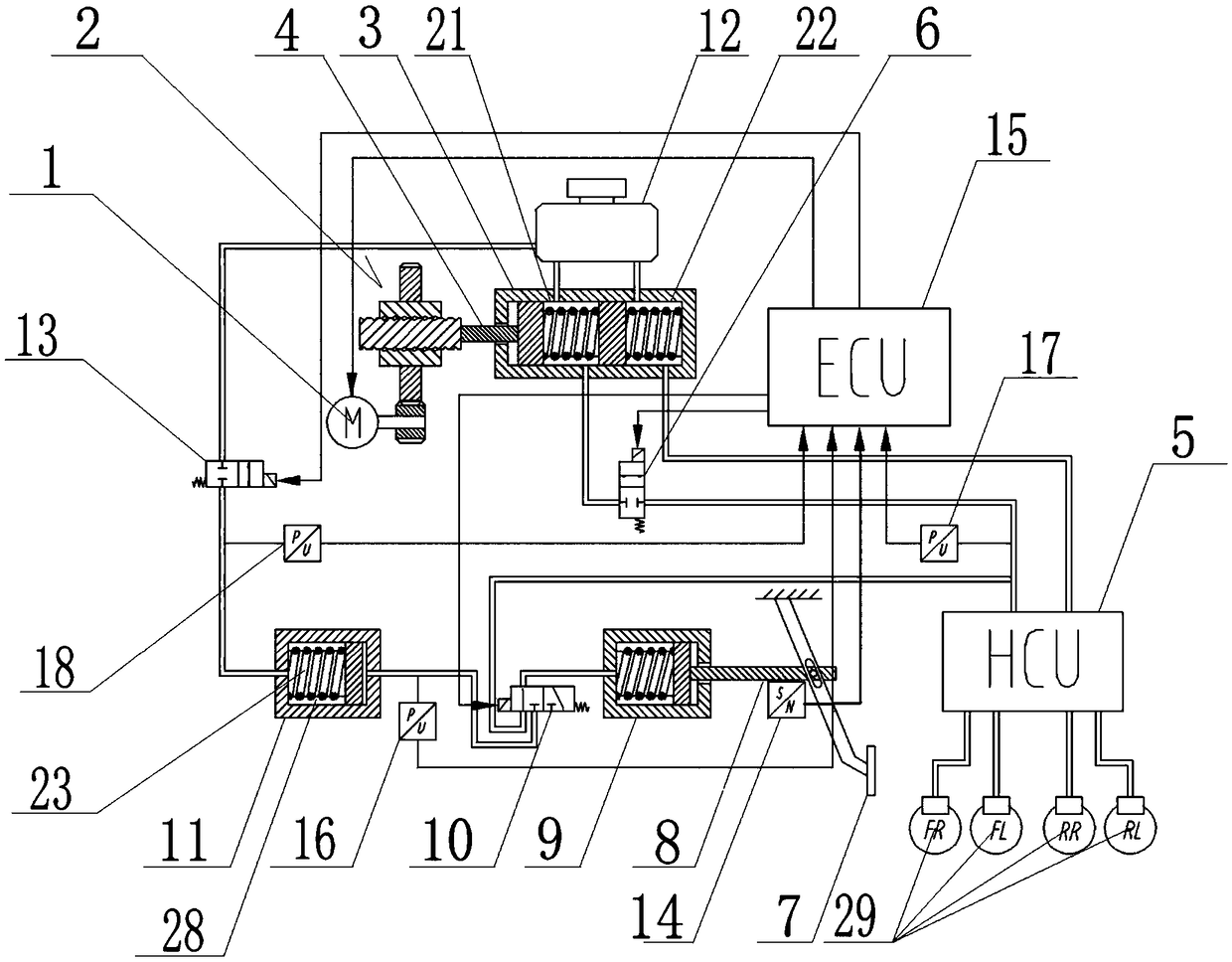

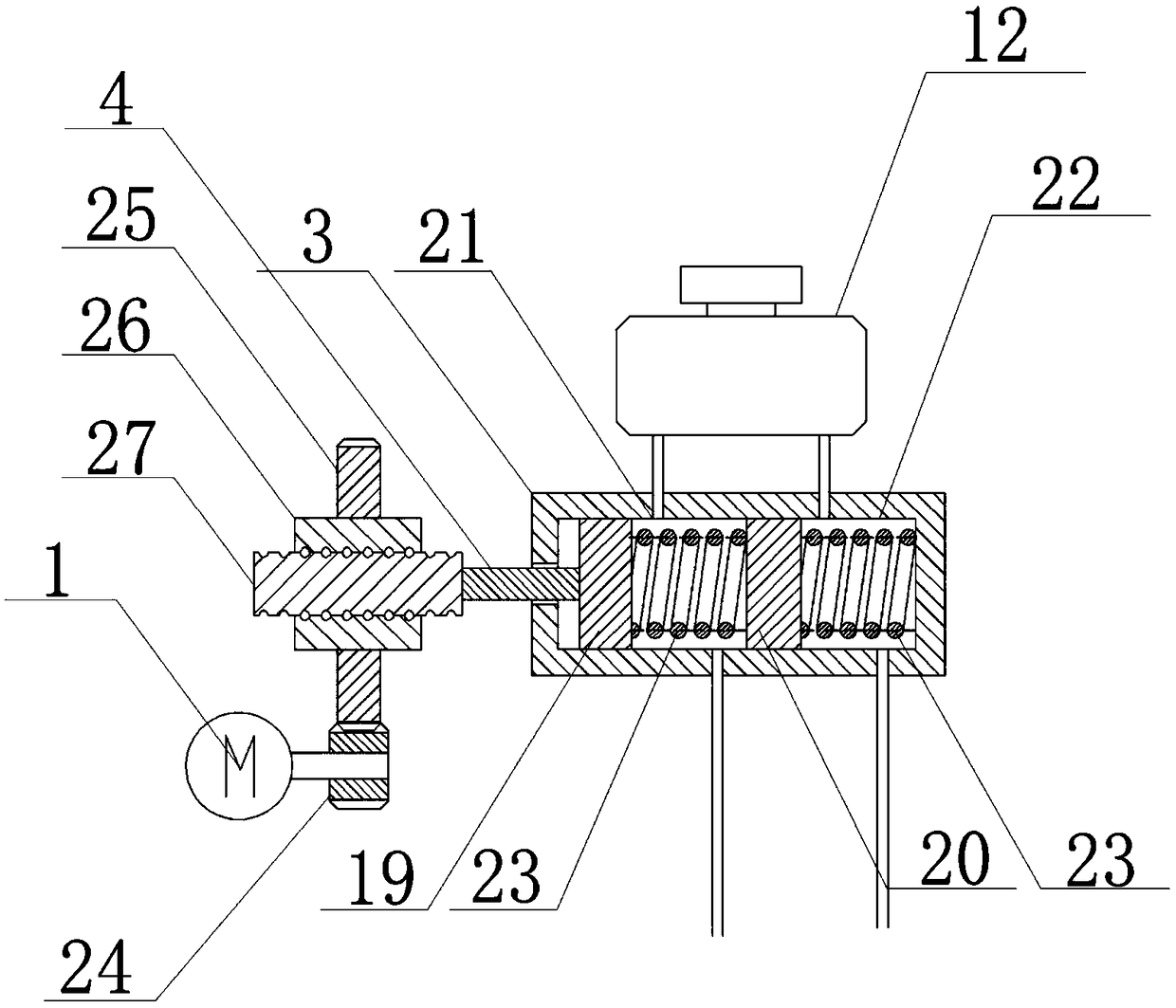

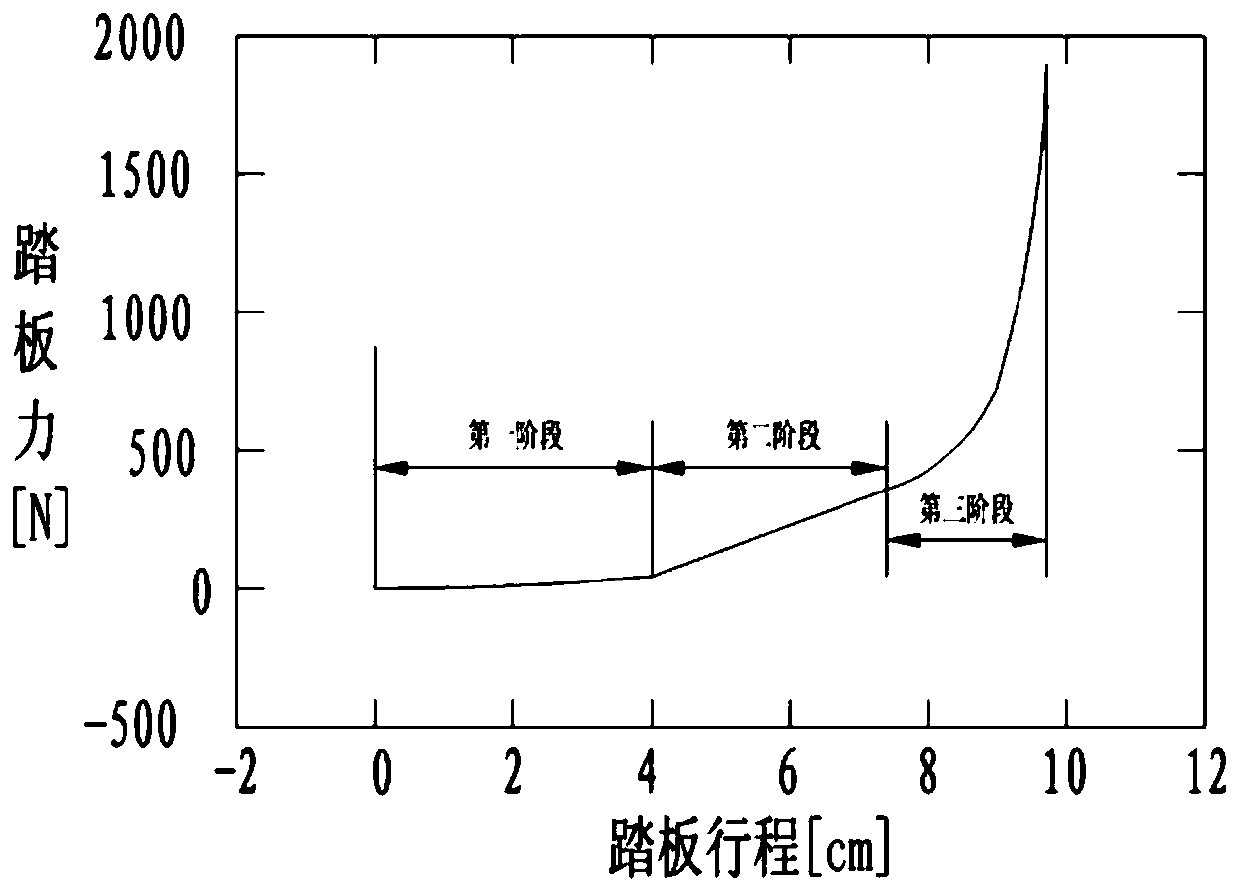

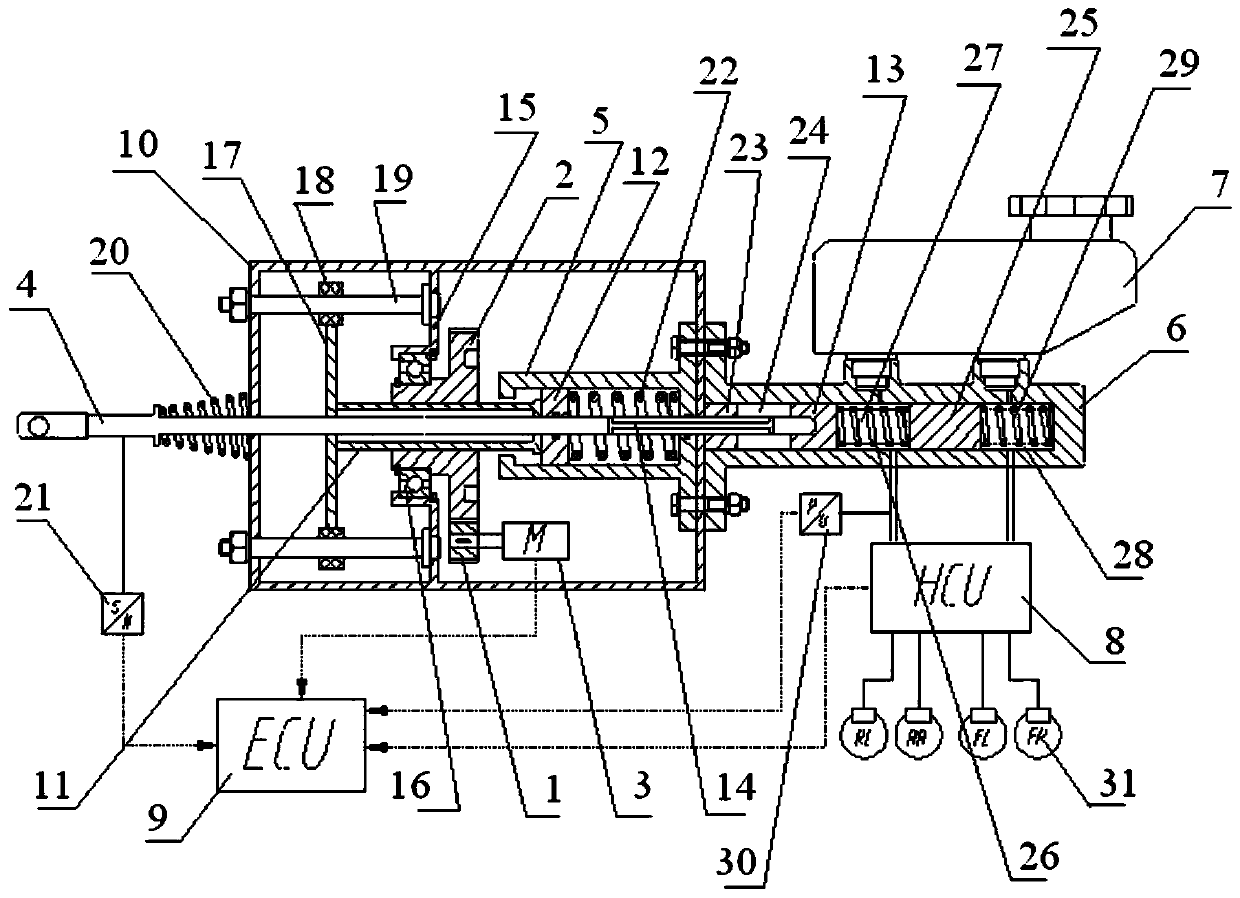

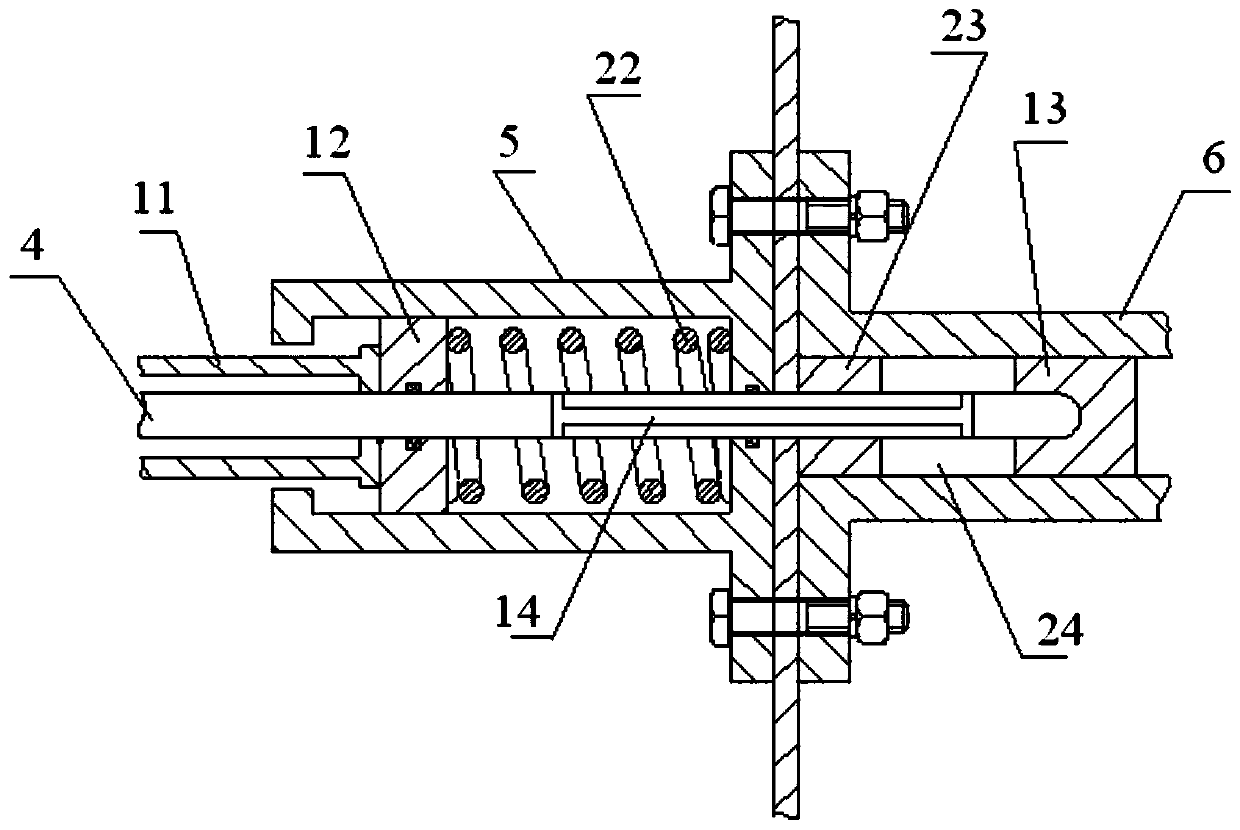

Fully decoupled electro-hydraulic brake system

InactiveCN109177945ASimple structureReduce the risk of leakageBraking action transmissionFoot actuated initiationsSolenoid valveHigh pressure

The present invention relates to a fully decoupled electro-hydraulic braking system, which comprises a booster motor, a booster transmission assembly, a brake master cylinder, a hydraulic control unitHCU, a normally closed solenoid valve A, a brake pedal, a pedal push rod, a human hydraulic cylinder, a two-position three-way solenoid valve, a pedal sensing simulator, a fluid reservoir, a normallyclosed solenoid valve B, a pedal stroke sensor and an electronic control unit ECU. The invention has three working modes of conventional braking, active braking and failure backup. The invention eliminates the structure of the high-pressure accumulator, adopts the motor driving and the mechanical structure driving, and has the advantages of simple structure, more reliable work, faster response speed, more accurate pressure control, and lower cost and maintenance cost. The invention adopts the scheme of complete decoupling, and can precisely control the hydraulic braking force through the booster motor, cooperate with the regenerative braking to recover the braking energy to the maximum extent, improve the range and comply with the development trend of the automobile electricization.

Owner:JILIN UNIV

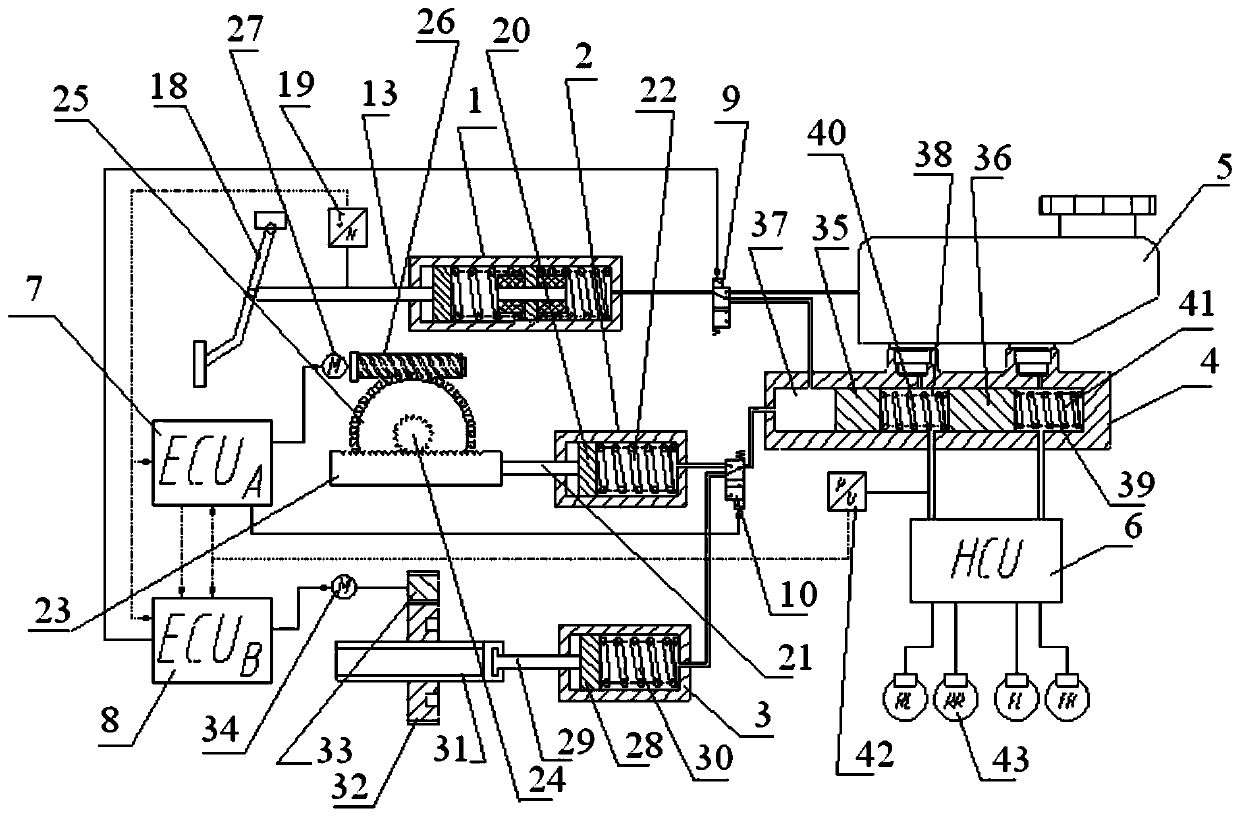

Completely decoupled dual-backup electronic hydraulic braking system

ActiveCN110155014ASimilar pedal feelImprove battery lifeBraking action transmissionCruise controlLiquid storage tank

The invention discloses a completely decoupled dual-backup electronic hydraulic braking system. The system comprises a pedal sense simulator, a first assisted pressure buildup cylinder, a second assisted pressure buildup cylinder, a brake master cylinder, a liquid storage tank, a hydraulic control unit, a first electronic control unit and a second electronic control unit, wherein the pedal sense simulator is communicated with the brake master cylinder and the liquid storage tank through pipelines respectively, a first electromagnetic valve is arranged on the communicating pipelines, connectedwith the second electronic control unit and controlled to work by the second electronic control unit, the brake master cylinder is communicated with the first assisted pressure buildup cylinder and the second assisted pressure buildup cylinder through pipelines respectively, and a second electromagnetic valve is arranged on the communicating pipelines, connected with the first electronic control unit and controlled to work by the first electronic control unit. The system has the beneficial effect as follows: functions of active braking, failure backup, brake energy recovery and the like can berealized, active control technologies such as ESP (electronic stability program), ACC (self-adaptive cruise control) and the like can also be effectively integrated, and intelligent control of vehicles is realized.

Owner:JILIN UNIV

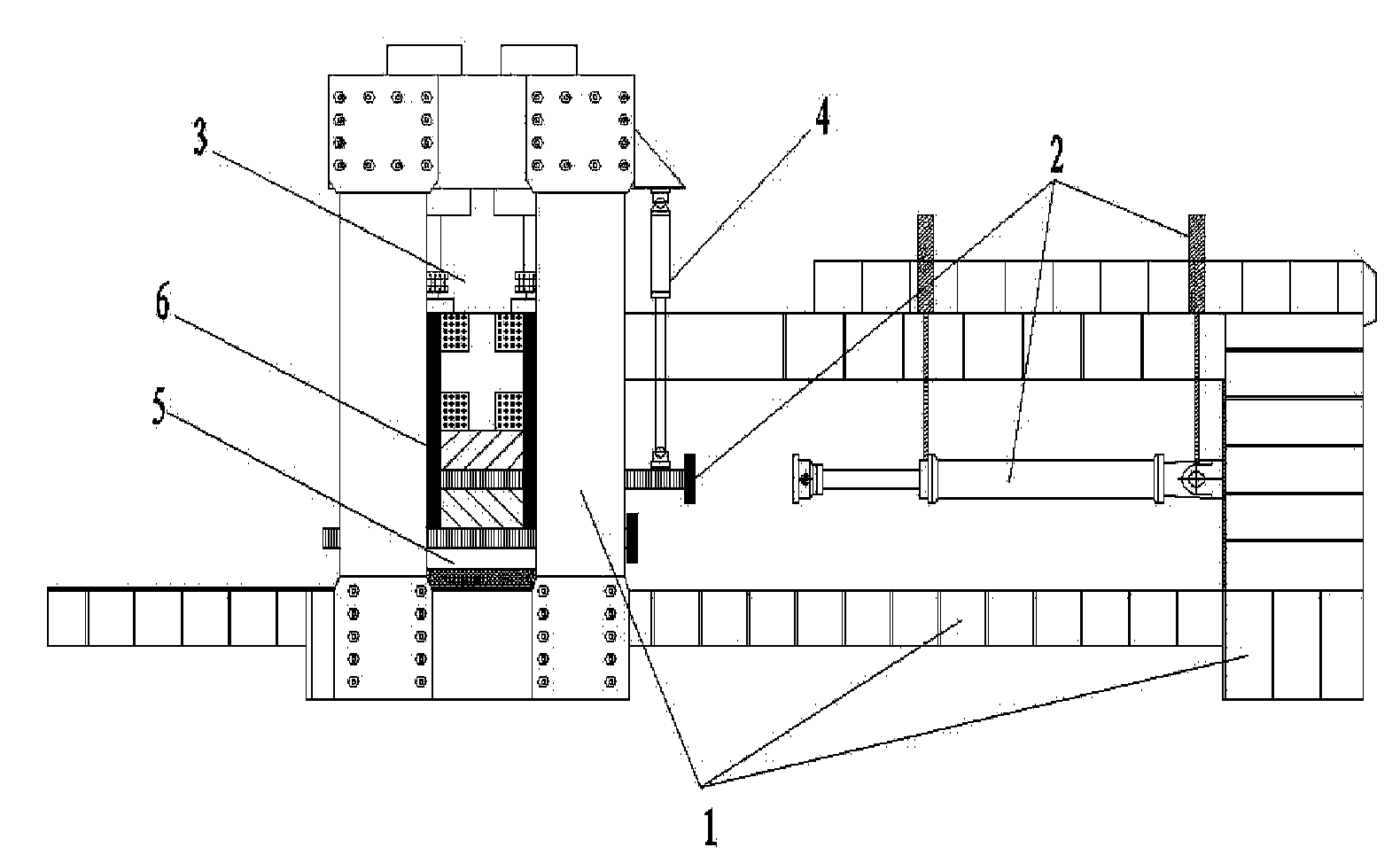

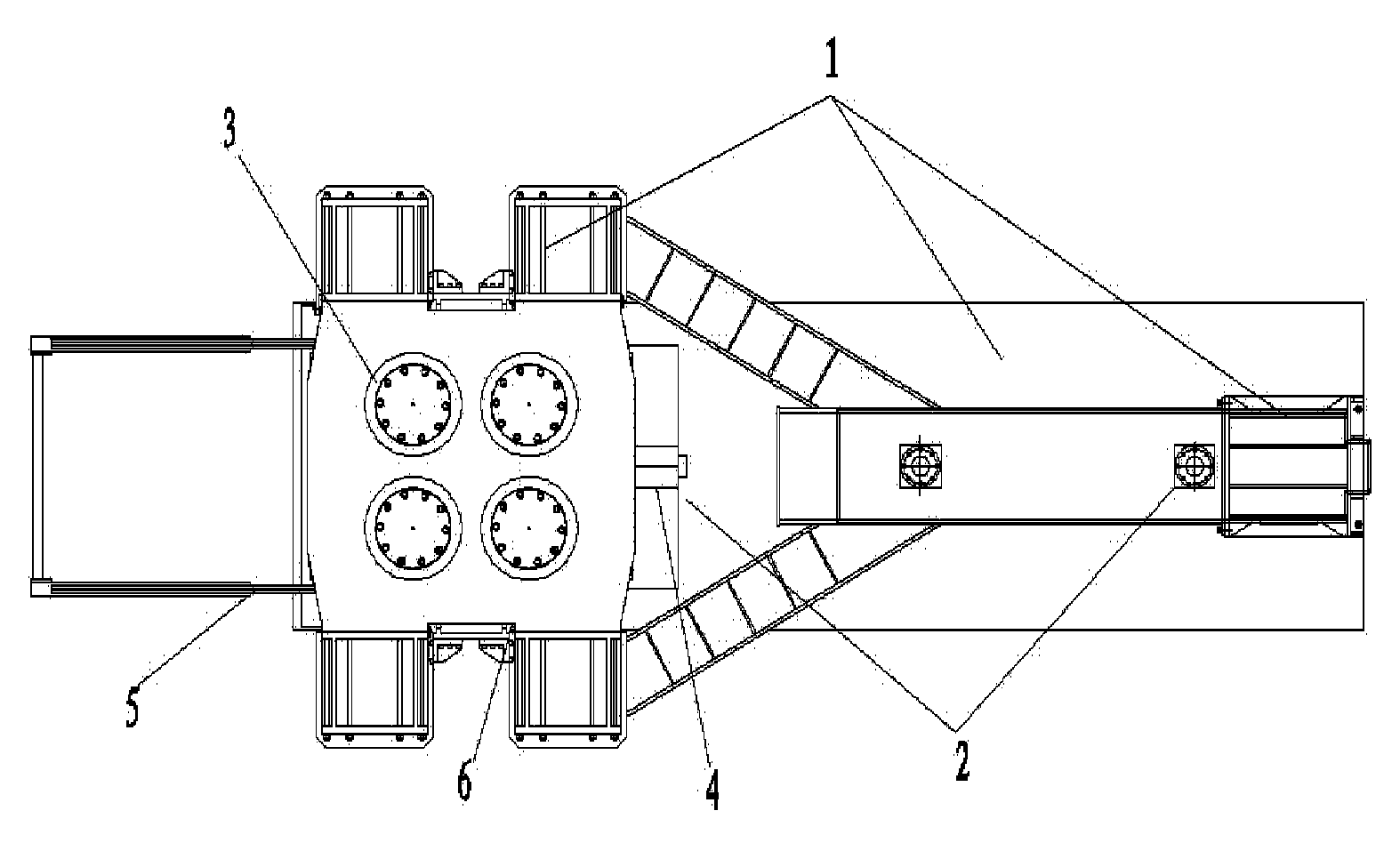

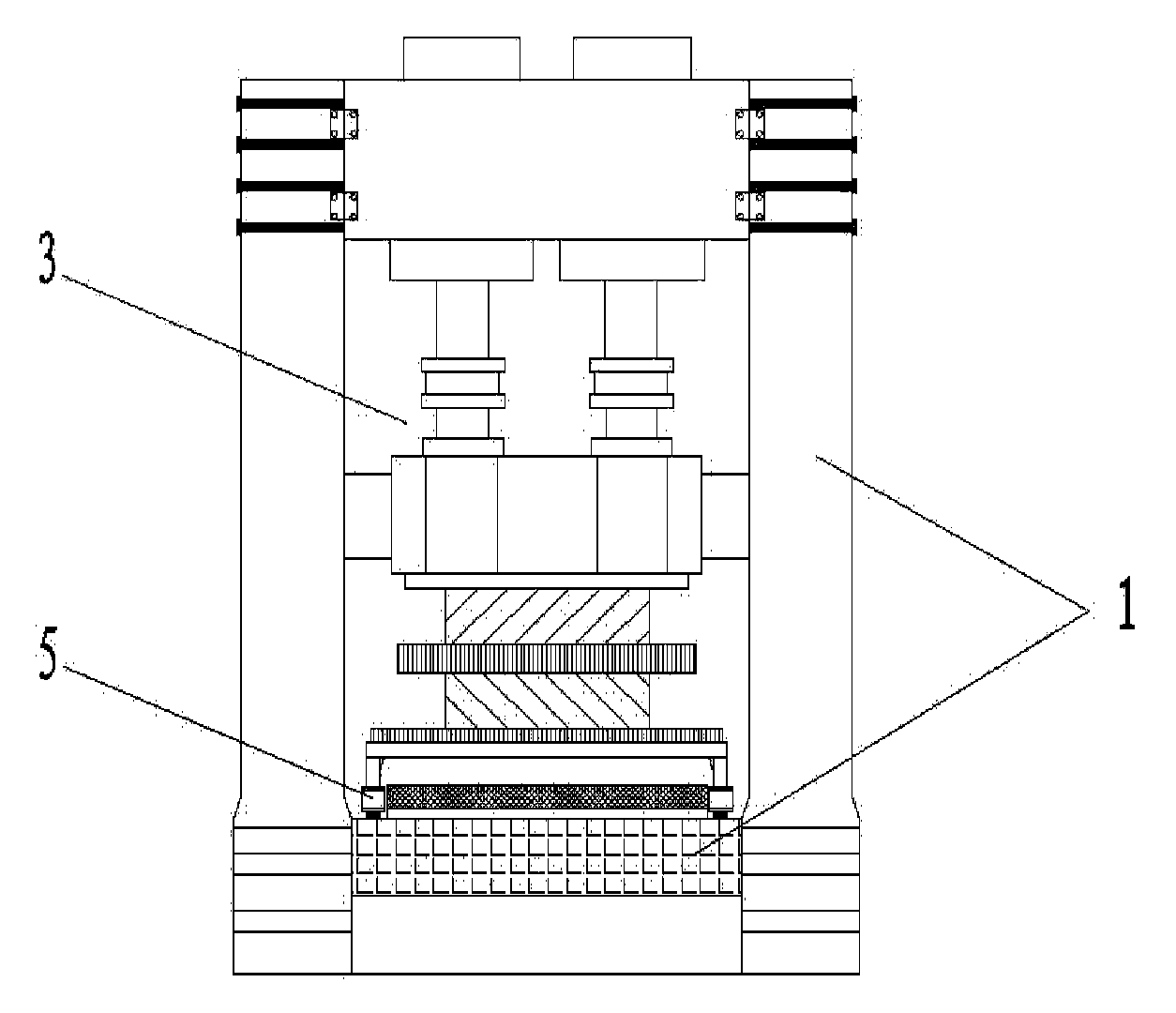

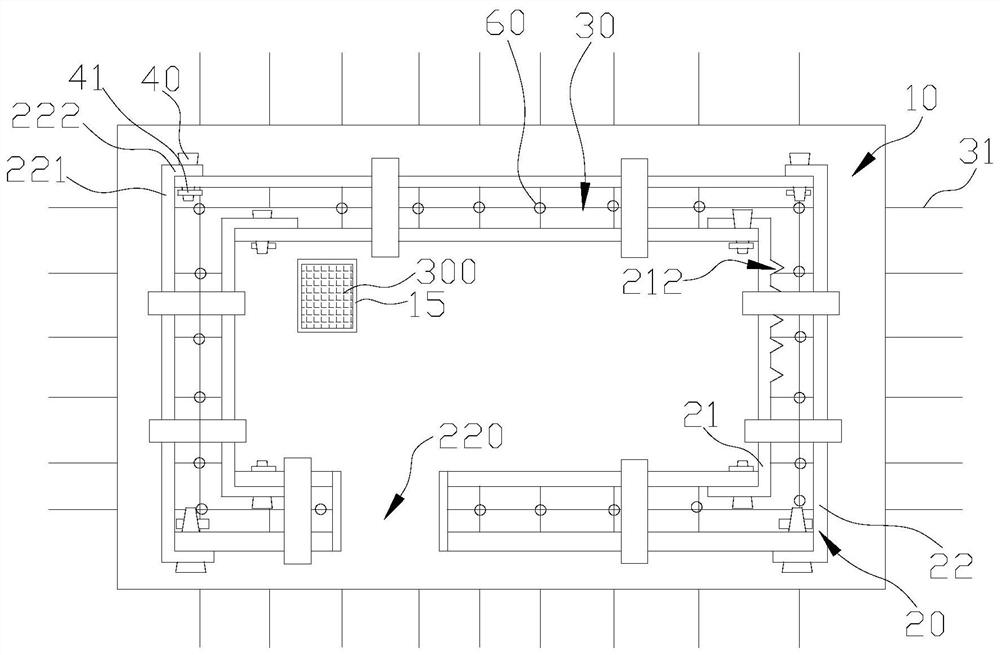

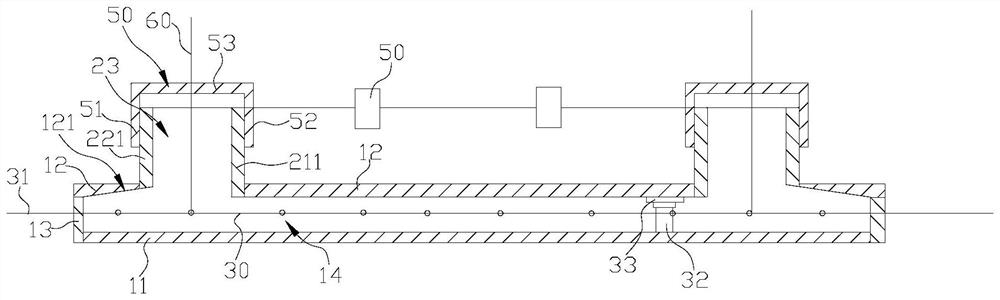

Device for carrying out static-dynamic force multifunction testing on support

ActiveCN103512740AReduce processingReduce the risk of leakageMachine part testingServo actuatorMultiple function

Owner:CCCC HIGHWAY BRIDNAT ENG RES CENT

Drainage structure for inverted roof and construction method of drainage structure

ActiveCN103276858AGuaranteed leak-proofImprove waterproof performanceBuild-up roofsRoof drainageSurface layerWater flow

The invention relates to a drainage structure for an inverted roof and a construction method of the drainage structure. The drainage structure comprises a roof structure layer, a local sloping layer, a leveling layer, a water-proof layer, an insulating layer, a rigid protection layer and a surface layer from bottom to top successively. A main rainwater port is formed in the surface layer, and a main rainwater pipe is communicated with the lower portion of the main rainwater port. The drainage structure is characterized in that concealed drainage ports are further formed under the insulating layer and communicated with concealed drainage pipes, and the concealed drainage pipes are communicated with the main rainwater pipe. The drainage structure and the construction method have the advantages that water flowing into the insulating layer and the water-proof layer through the surface layer or various gaps can be drained, hidden leakage troubles of inverted roofs are reduced greatly, and the roof water-proof performance is optimized.

Owner:TIANJIN TIANYI CONSTR GRP

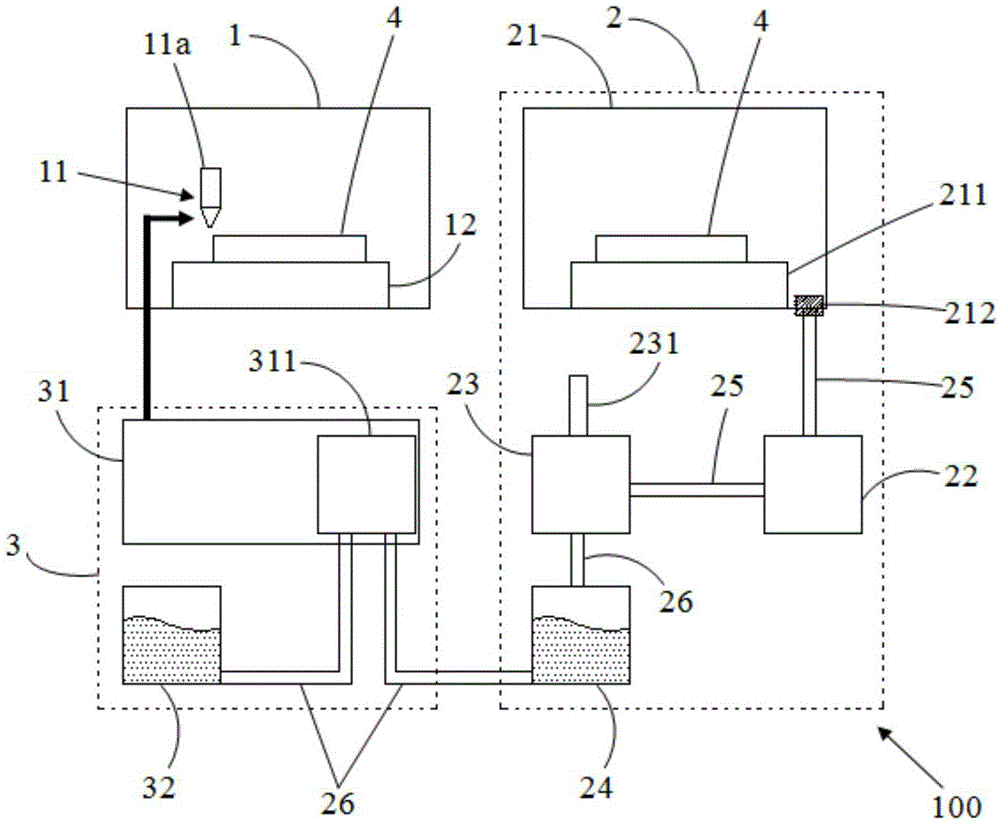

Photoresist coating device and lithography equipment

InactiveCN105242494AImprove protectionReduce exceptionPhotomechanical coating apparatusPhotomechanical exposure apparatusLithographic artistEvaporation

The invention discloses a photoresist coating device, comprising a coating unit, a drying unit and a cleaning unit. The coating unit comprises a spraying mechanism; the spraying mechanism is for spraying a photoresist material on a glass substrate; the drying unit comprises a drying chamber for evaporation and vaporization of a solvent in the photoresist material on the glass substrate; a vacuum pump is connected with the drying chamber and for discharging the vaporized solvent; a condenser is connected with the vacuum pump, and is used for condensing the liquefying gaseous solvent; a recycling container is connected with the condenser, and is for the storage of the liquefied solvent; the cleaning unit is connected between the recycling container and the coating unit; and solvent is obtained from the recycling container, and the solvent is used for cleaning the spraying mechanism. The invention also discloses lithography equipment containing the above photoresist coating device.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

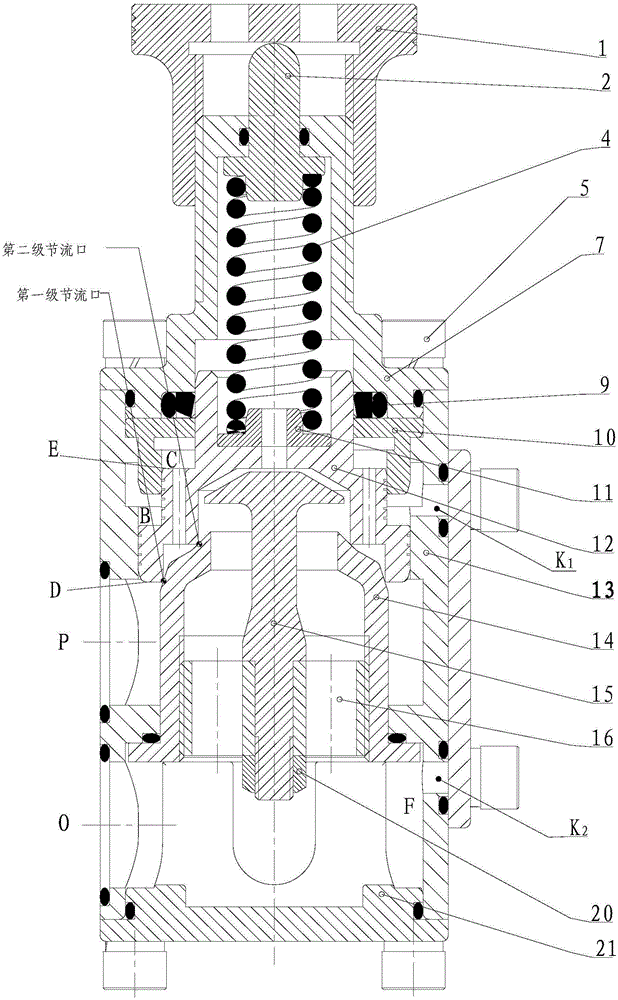

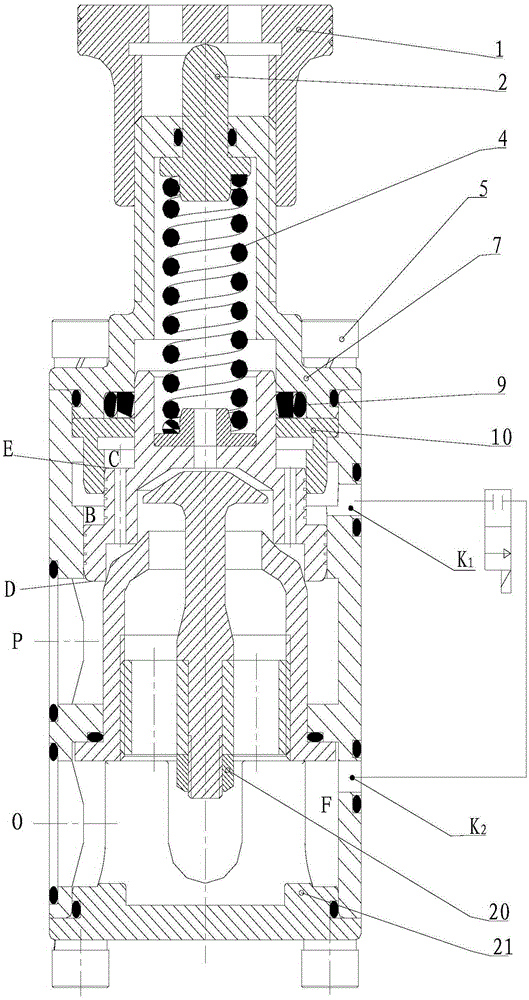

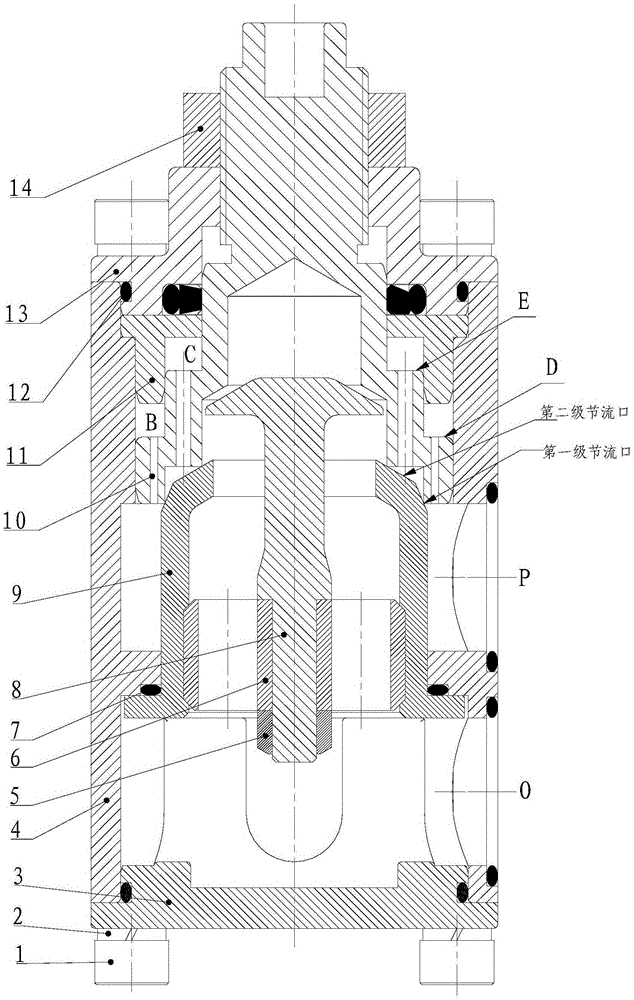

Movable valve seat type spring loaded type relief valve

InactiveCN105351582AReduce frictionExtended service lifeEqualizing valvesSafety valvesEngineeringPartial pressure

The invention discloses a movable valve seat type spring loaded type relief valve. The movable valve seat type spring loaded type relief valve comprises a valve body provided with a cavity body. A water inlet and a water outlet communicated with the cavity body are formed in the valve body. A valve core and a valve seat are arranged inside the cavity body of the valve body. A spring is arranged inside a cavity of the interior of a front end cover. A spring ejection rod is installed at the top of the spring, and a spring base is arranged at the bottom of the spring. One end of the spring abuts against the spring ejection rod, and the other end of the spring abuts against the spring base. The valve seat comprises a two-stage step structure. The ascending end of the step structure is in clearance fit with the valve body and a sleeve. According to the movable valve seat type spring loaded type relief valve, a valve core king-rod structure is designed in the position of an injection inlet where fluid enters the valve core through the valve seat, so that the fluid power of the sprayed fluid is conducted to the valve core through a valve core king-rod, and the impact force and the corrosion to the valve seat by the fluid power are reduced; in addition, the step structure part of the valve seat makes contact with the two-stage conical surfaces of the valve core, so that a two-stage throttling valve port structure is formed between the valve seat and the valve core, and the effective partial pressure can be achieved.

Owner:OCEAN UNIV OF CHINA

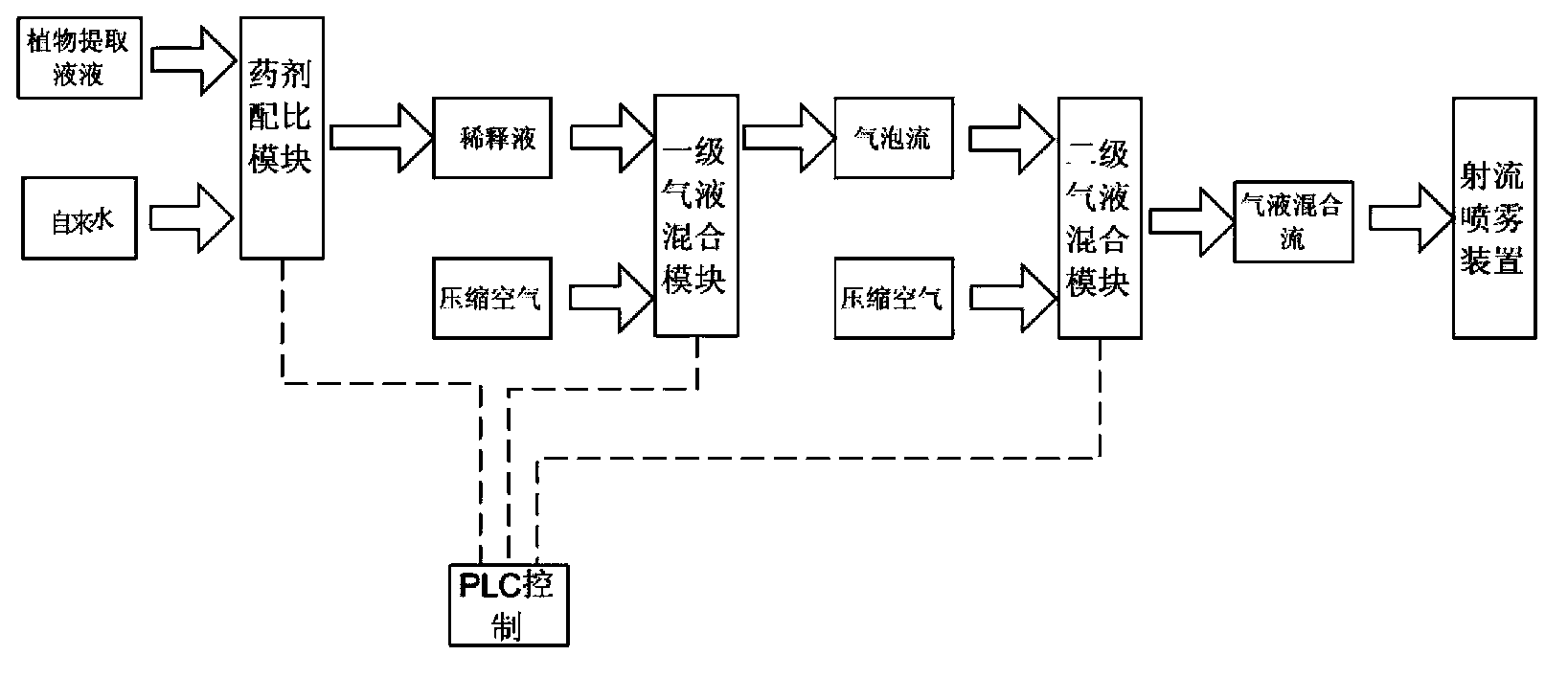

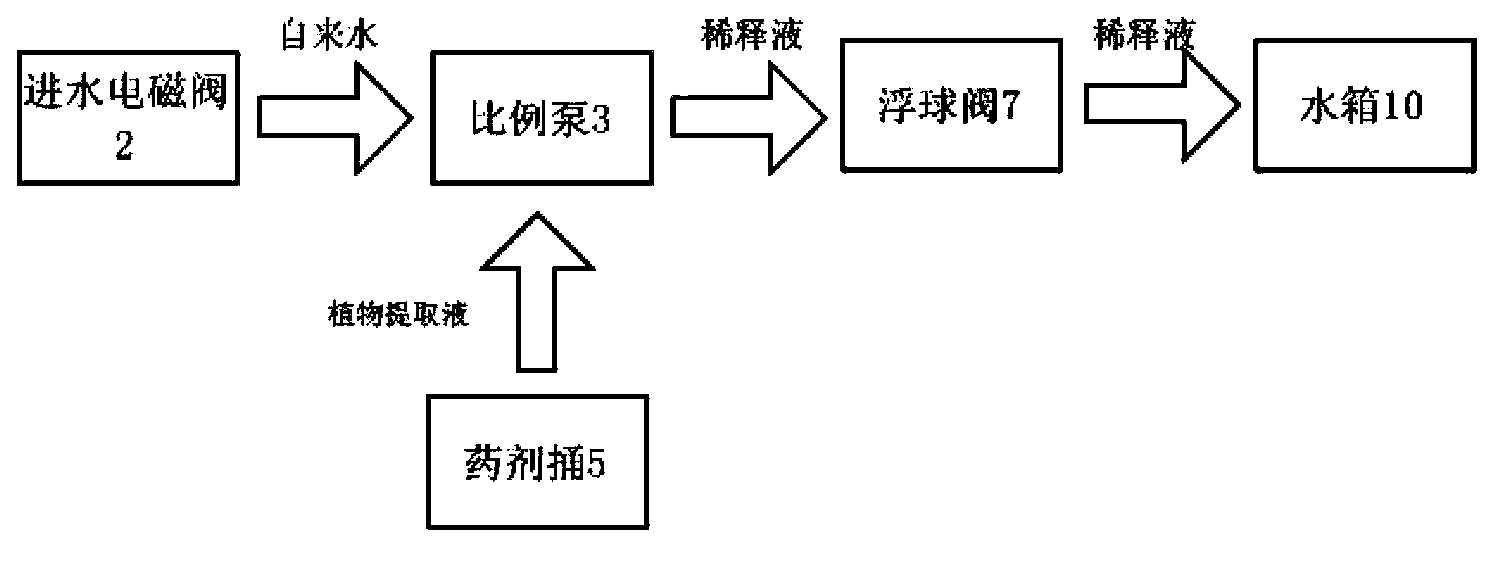

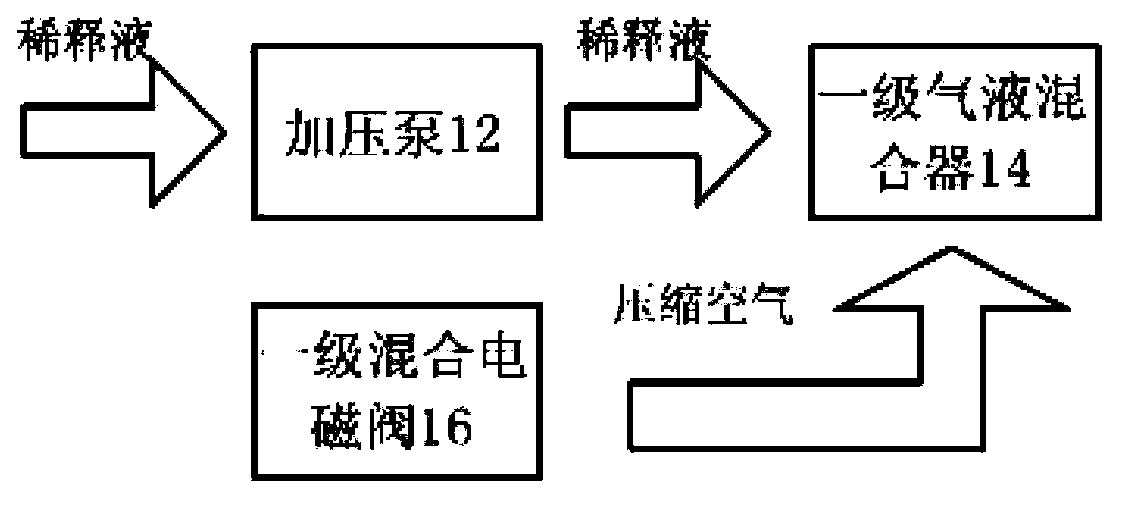

Method and system for carrying out atomization deodorization by adopting plant extract solution

ActiveCN104162353AReduce the risk of leakageReduce work stressDispersed particle separationAir quality improvementProcess engineeringElectromagnetic valve

The present invention provides a method and system for carrying out atomization deodorization by adopting a plant extract solution. The method comprises the steps that a water inlet electromagnetic valve is opened; a dosing pump sucks and mixes the plant extract solution; the obtained mixed solution enters a water tank and then enters a pressure pump; the solution flowing out from the pressure pump outlet and compressed air enter a first-stage gas-liquid mixer together to be mixed so as to form a gas-liquid two-phase flow; the gas-liquid two-phase flow and compressed air enter a second-stage gas-liquid mixer together to be mixed so as to form a gas-liquid mixing flow; and the gas-liquid mixing flow enters a jet spraying device so as to achieve atomization deodorization. The system comprises an agent matching module, wherein the agent matching module is sequentially connected with a first-stage gas-liquid mixing module, a second-stage gas-liquid mixing module and the jet spraying device, and the three modules are connected with a PLC control cabinet for controlling the total system. With the method and the system of the present invention, the plant extraction solution is subjected to high atomization at a low pressure state so that the working condition adaptability and the deodorization effect of atomization equipment are improved; the equipment maintenance and operation workload are reduced, and the safety is improved.

Owner:BAOSHAN IRON & STEEL CO LTD

Magnetic powder detection method for large cast valve

ActiveCN103076389AIncrease contrastUniform contrast backgroundMaterial magnetic variablesEngineeringVALVE PORT

The invention relates to a new technique method for magnetic powder detection of a large cast valve, which comprises the following steps: 1), processing the surface of the valve body; 2), uniformly spraying contrast sensitivity on the surface of the valve body; 3), detecting whether the equipment is in the check validity period or not; 4), configuring a magnetic suspending liquid with the concentration within 10-25g / L; 5), fixing a Al-30 / 100 sensitivity test piece in a detected part through a standard test piece fixing device so as to assess the comprehensive performance of a detecting system; 6), wetting the surface of the workpiece by the magnetic suspending liquid, magnetizing the surface of the workpiece, and detecting the valve body according to a special magnetized path graph for the valve body inspection via an AC magnetic yoke continuous method; 7), utilizing an air pressure type sprinkling can with a lighting function and suitable for magnetic powder detection, directly performing observation once magnetic marks are formed, and achieving that magnetization, magnetic suspending liquid spraying and observation are performed at the same time; 8), recording detection parameters and defect magnetic marks, grading the workpiece quality according to the detection technique standard based on the displayed defect magnetic marks, and then determining whether the workpiece is qualified or not according to the acceptance quality level. Moreover, in case of reinspection, the sensitivity of the detecting system is readjusted, and the workpiece is detected again until the requirements are met. The method can be effectively used for detecting the magnetic powder of the large valve.

Owner:STATE GRID HEBEI ELECTRIC POWER RES INST +2

Plastic composite tube

InactiveCN104961985AHigh compressive strengthEasy to installRigid pipesLow-density polyethylenePolymer science

The invention discloses a plastic composite tube. The plastic composite tube comprises the following raw materials by mass: 100 to 150 parts of low density polyethylene plastic, 100 to 150 parts of polystyrene plastic, 15 to 20 parts of polyacrylamide, 50 to 80 parts of polyvinyl chloride plastic, 30 to 40 parts of polyamide resin, 8 to 10 parts of aluminum powder, 5 to 10 parts of iron powder, 15 to 20 parts of nanometer silica powder, 3 to 5 parts of bisdodecanol ester and 5 to 8 parts of 2,6-tertbutyl-4-methylphenol. The plastic composite tube has high thermal conductivity, and heat transfer capacity per unit of the plastic composite tube is increased by more than 40% compared with a common plastic tube; and the plastic composite tube is convenient to construct and install, can reduce joints and hidden seepage thereof, and the advantages of high compressive strength, good hardness and dimensional stability, good cold and heat conduction diffusivity, etc.

Owner:张慧玲

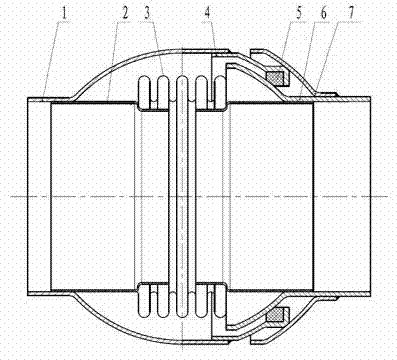

Corrugated pipe spherical joint

The invention belongs to the technical field of a joint for an airplane high-pressure guide pipe system, particularly relates to a corrugated pipe spherical joint and overcomes the problems of large weight, short service life and large leakage hidden danger of the existing metal corrugated expansion joint and the poor manufacturing manufacturability of the high-pressure guide pipe system. The corrugated pipe spherical joint comprises a corrugated pipe; two ends of the corrugated pipe are welded and connected with the inner end of a left connection pipe and the inner end of a right connection pipe respectively; an outer support is connected and welded with the outer end of the left connection pipe; an inner support is connected and welded with the outer end of the right connection pipe; the outside surface of a wear-resistant ring is fixedly connected to one end of a spherical hinge ring; the inside surface of the wear-resistant ring is an inner spherical surface and forms a spherical rotary pair with the inner support; the other end of the spherical hinge ring is welded and connected with the outer support; a limiting support is sleeved outside the spherical hinge ring and is connected and welded with the inner support. The corrugated pipe spherical joint has the characteristics of light weight, small size and long service life, so the leakage hidden danger of a pipeline is reduced, the reliability and maintainability are improved, the practicability is better, and the corrugated pipe spherical joint is easy for popularization and application and has larger practical value.

Owner:TAIYUAN AERO INSTR

Prefabricated toilet floor slab construction method

InactiveCN111827665AGood leak-proof and seepage-proof performanceAvoid destructionFloorsForms/shuttering/falseworksFloor slabArchitectural engineering

The invention provides a prefabricated toilet floor slab construction method, and relates to the technical field of fabricated toilets. The prefabricated toilet floor slab construction method comprises the steps of assembling and reinforcing a bottom plate pouring formwork and a reverse sill pouring formwork, arranging floor slab reinforcing steel bars on the bottom plate pouring formwork, installing positioning convex columns on the floor slab reinforcing steel bars, sleeving the positioning convex columns with water stop joints, pouring concrete to the bottom plate pouring formwork to form abottom plate, pouring concrete to the reverse sill pouring formwork to form a reverse sill, and dismantling the bottom plate pouring formwork and the reverse sill pouring formwork. The reverse sill pouring formwork comprises a reverse sill outer form and a reverse sill inner form, and a plurality of water supply and drainage pipeline groove pressing molds are arranged on the inner side of the reverse sill inner form at intervals. The floor slab reinforcing steel bars are provided with steel bar extending parts extending towards the periphery. The bottom plate and the reverse sill of the toilet floor slab are integrally poured and formed, so that the leakage-proof and seepage-proof performance is better, and the situation that the leakage-proof and seepage-proof performance of the toilet floor slab is affected by cold joints due to the fact that the bottom plate is poured firstly and then the reverse sill is poured on the basis of the bottom plate is avoided.

Owner:THE THIRD CONSTR CO LTD OF CHINA CONSTR THIRD ENG BUREAU

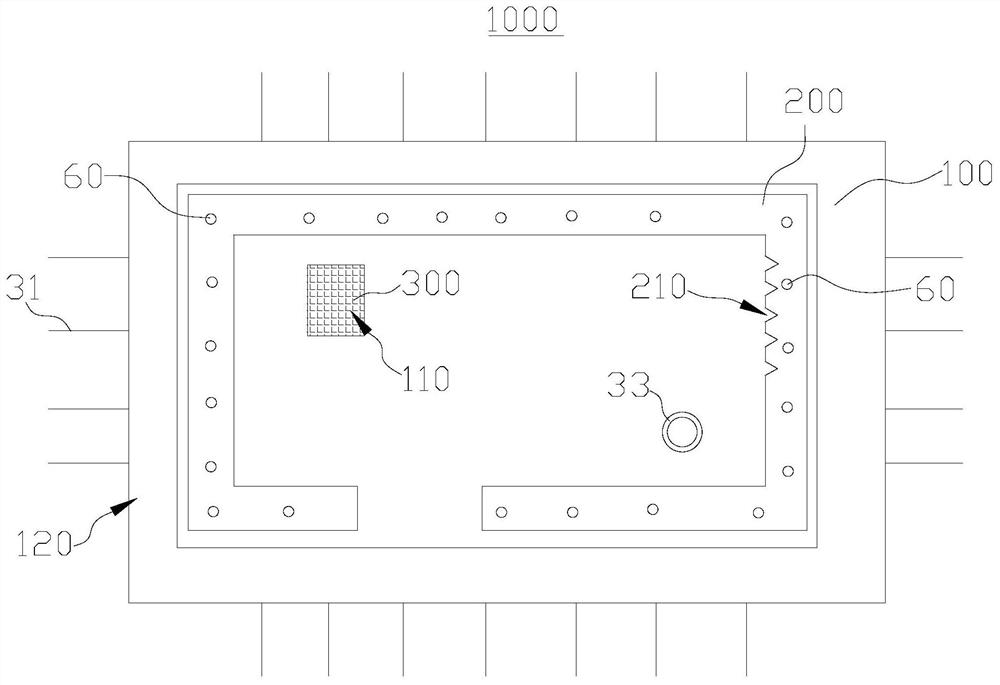

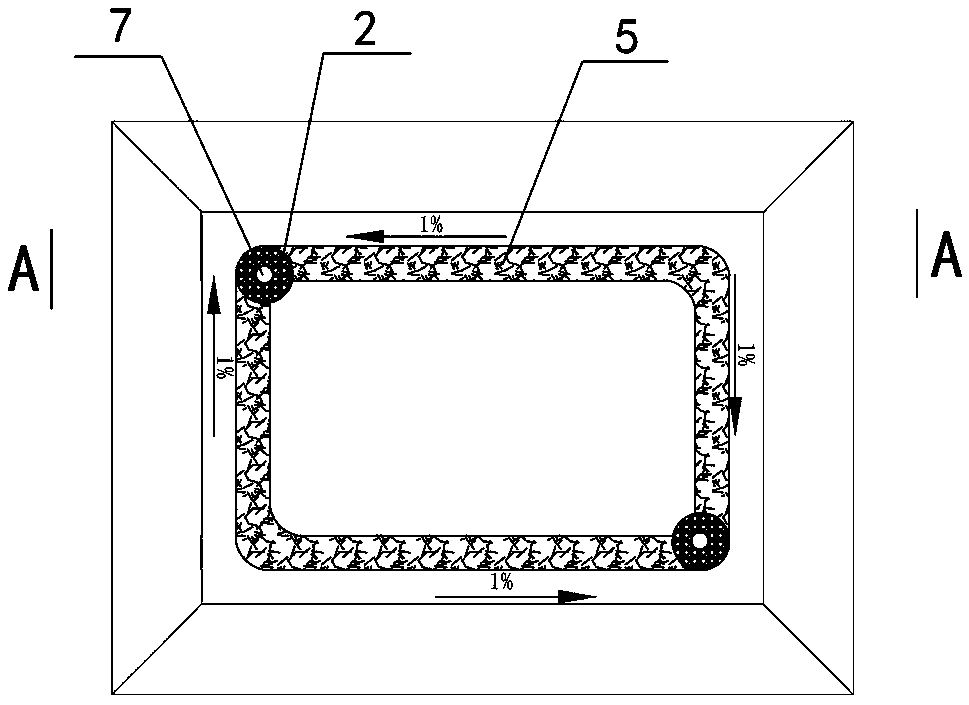

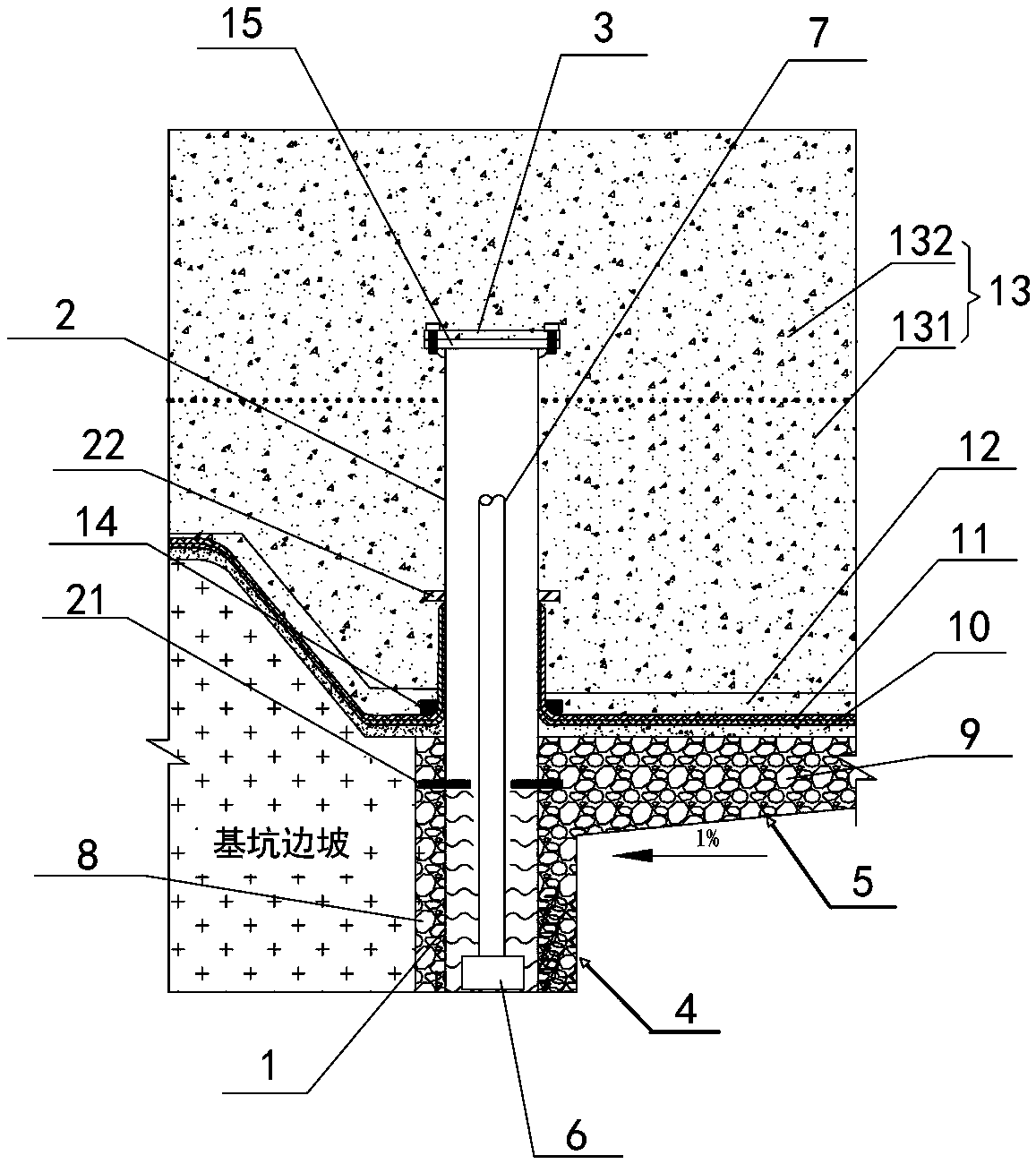

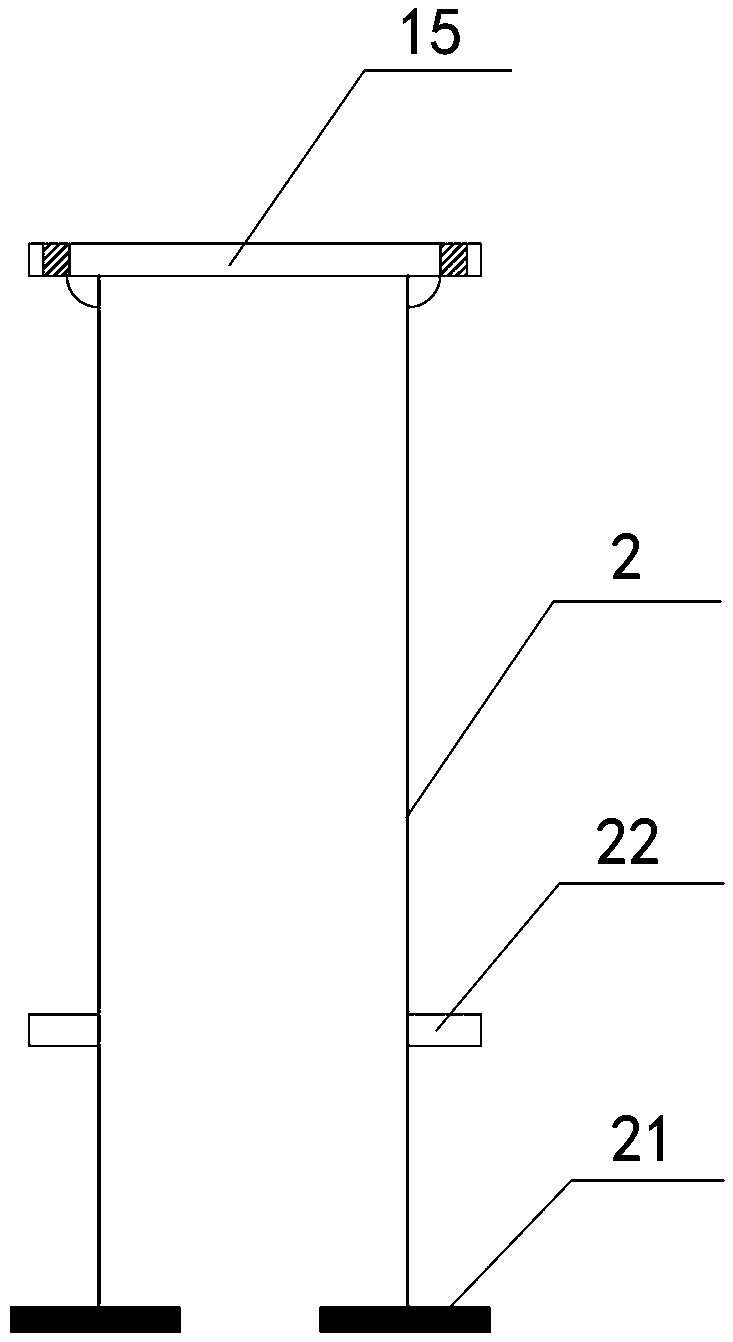

Raft built-in dewatering structure, sealing-well structure of dewatering well and sealing-well method

PendingCN109898533AAvoid secondary blockageMeet construction requirementsFoundation engineeringSurface waterProtection layer

The invention discloses a raft built-in dewatering structure, a sealing-well structure of a dewatering well and a sealing-well method, and relates to the technical field of the building construction.The raft built-in dewatering structure is arranged at the bottom of a foundation pit, and comprises a drainage ditch, a water collection pit, a well pipe, a water pump, an outer drainage pipe and electric wires, wherein the well pipe comprises a sand-free filter pipe and a water guide pipe, the sand-free filter pipe is embedded in the water collection pit, the top of the sand-free filter pipe is lower than the upper surface of the drainage ditch, the water guide pipe is arranged on the top of the sand-free filter pipe, the top of the water guide pipe exceeds the upper surface of the drainage ditch, and the top of the water guide pipe is provided with a cover plate in a covered mode. According to the raft built-in dewatering structure, the technical problems that the dewatering well is arranged at a local ponding position, sealing is conducted before concrete pouring of a base plate, then the base plate construction is conducted, if the surface water level is high and the water volume is large, the concrete pouring can not be conducted in time when sealing is conducted, resulting in a base plate cushion layer and a waterproof and protective layer being buoyed by the buoyancy of groundwater due to sealing, thus the base plate cushion and the waterproof and protective layer are destroyed are solved.

Owner:CHINA CONSTR FIRST GRP THE SECOND CONSTR +1

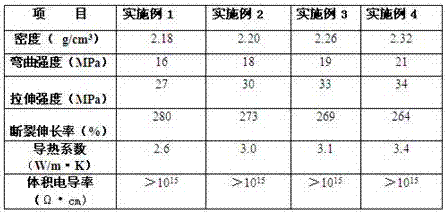

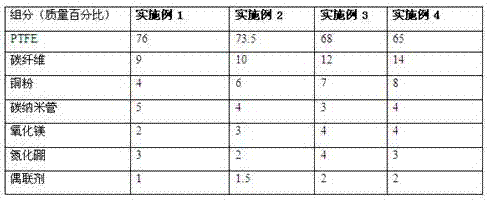

High-thermal-conductivity PTFE (polytetrafluoroethylene) resin composite for sealing strip in high-temperature region and preparation method of PTFE resin composite

The invention discloses a high-thermal-conductivity PTFE (polytetrafluoroethylene) resin composite for a sealing strip in a high-temperature region. The PTFE resin composite is prepared from components in percentage by mass as follows: 9%-14% of carbon fibers, 4%-8% of copper powder, 3%-5% of carbon nano tubes, 2%-4% of magnesium oxide, 2%-4% of boron nitride, 1%-2% of a coupling agent and the balance of PTFE. The invention further discloses a preparation method of the PTFE resin composite. By addition of the carbon fiber, tensile modulus, compression modulus and bending modulus of the material can be improved, a coefficient of thermal expansion is reduced, the thermal conductivity is increased, and friction heat is conducted out quickly; by addition of the copper powder and the carbon nano tubes, wear of the material can be reduced, creep is reduced, electrical conductivity is improved, accumulation of static charges produced by friction can be prevented, and the thermal conductivity of the material can be improved well by the carbon nano tubes; under the cooperation of magnesium oxide and boron nitride, the thermal conductivity and the wear resistance of the material can be enhanced effectively; the high-thermal-conductivity PTFE resin composite prepared from the materials and used for the sealing strip in the high-temperature region has high thermal conductivity and electrical conductivity.

Owner:NANJING COMPTECH COMPOSITES CORP

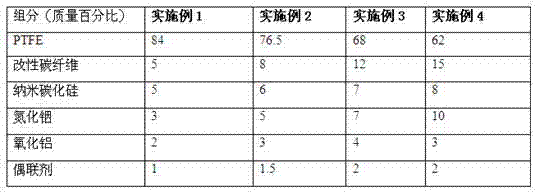

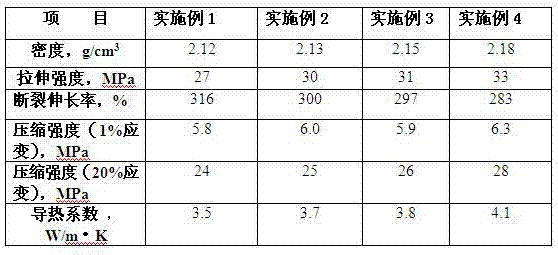

PTFE resin composite material of sealing ring with high thermal conductivity used for rotating shaft and preparation method thereof

InactiveCN107474452ASmall coefficient of thermal expansionReduce the risk of leakageHeat-exchange elementsThermal conductivityThermal transmittance

The invention discloses a PTFE resin composite material of a sealing ring with high thermal conductivity used for a rotating shaft. The PTFE resin composite material consists of the following components in percentage by mass: 5%-15% of carbon fiber, 5%-8% of nano-silicon carbide, 3%-10% of indium nitride, 2%-4% of alumina, 1%-2% of a coupling agent and the balance of PTFE. The invention also discloses a preparation method of the PTFE resin composite material. In the PTFE resin composite material and the preparation method disclosed by the invention, by adding the carbon fiber to the PTFE, the tensile, compressive and flexural moduli of the material can be increased, the thermal expansion coefficient can be decreased, and the potential hazard of leakage caused by expansion after the temperature rises can be reduced; meanwhile, the creep deformation can also be reduced, the hardness can be improved, and the thermal conductivity is increased simultaneously, so that friction heat can be quickly transferred out. The carbon fiber is subjected to modification treatment so as to be well dispersed in the PTFE. Through combination of nano-silicon carbide, alumina and indium nitride, the thermal conductivity of the material can be effectively improved, and the sealing ring with high thermal conductivity used for the rotating shaft made from the PTFE resin composite material disclosed by the invention has high thermal conductivity and can timely conduct out friction heat on the rotating shaft.

Owner:NANJING COMPTECH COMPOSITES CORP

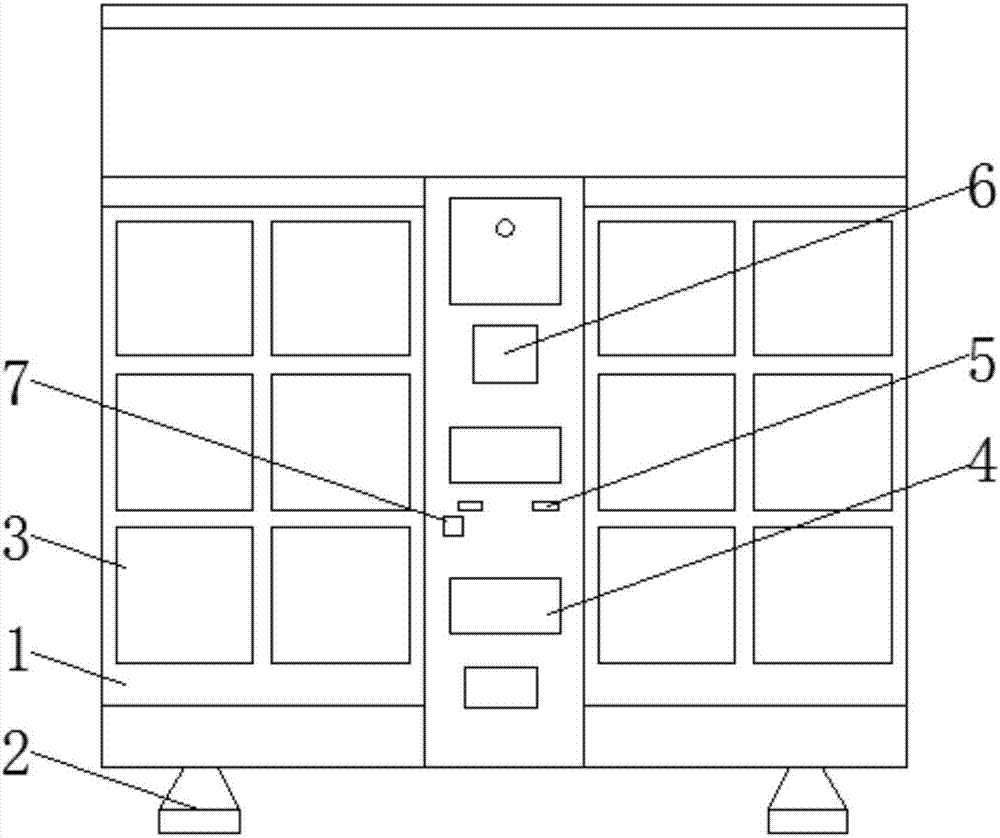

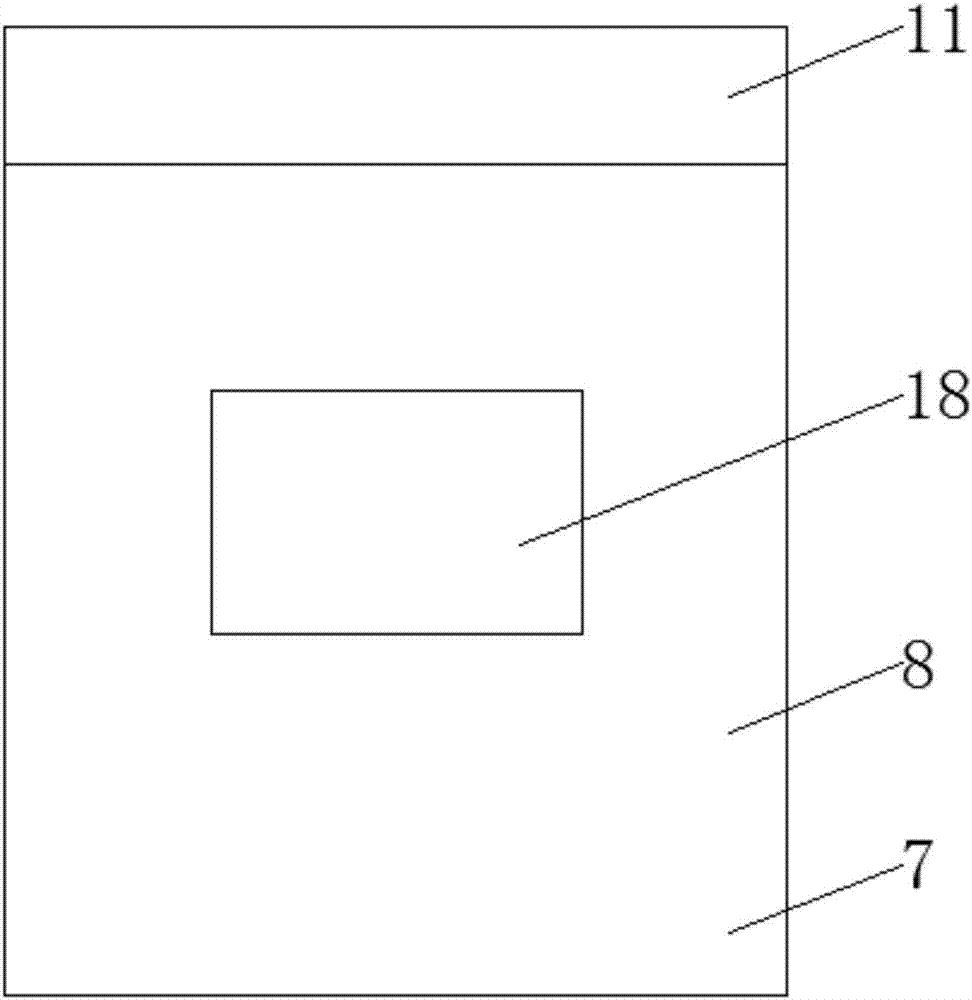

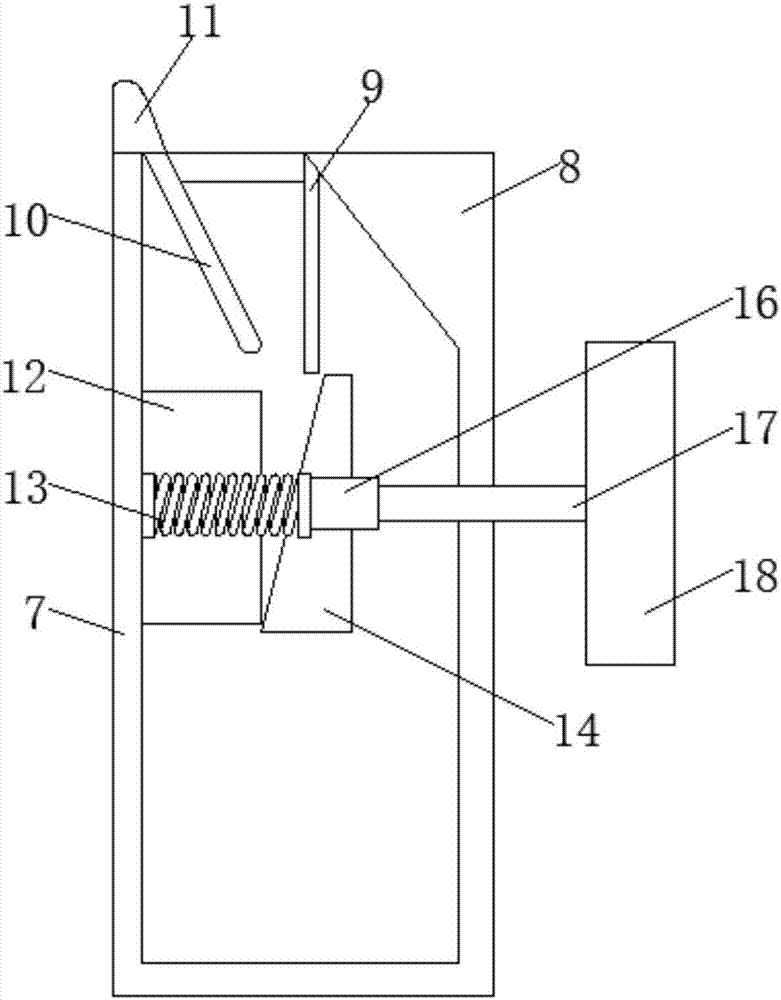

Intelligent fresh food cabinet for fresh food storage and refrigeration

InactiveCN107170136AEasy to put inEasy to collectCabinetsApparatus for meter-controlled dispensingFresh foodEngineering

The invention discloses an intelligent fresh cabinet for fresh storage and refrigeration, comprising a main body of the fresh cabinet, a support frame, an independent storage cabinet, a keyboard input terminal, a ticket outlet and a touch display screen, the support frame is fixedly installed At the bottom of the main body of the fresh food cabinet, the independent storage cabinet is fixedly installed on the front of the main body of the fresh food cabinet, and the keyboard input terminal, the ticket outlet and the touch screen are all fixedly installed in the middle of the front of the main body of the fresh food cabinet. The middle part of the front of the main body of the fresh food cabinet is also fixedly installed with a waste information list processing device. The intelligent fresh cabinet for fresh storage and refrigeration, through the cooperation between the above structures, achieves the advantages of being ready to collect waste information sheets, and can conveniently break the information sheets. While collecting waste information sheets, it also has the advantages of The effect of protecting user privacy.

Owner:ZHENGZHOU RUIQIANG EXPERIMENTAL EQUIP CO LTD

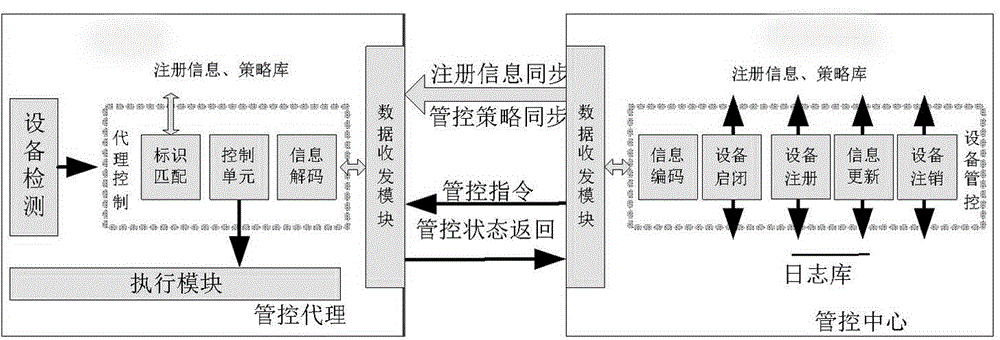

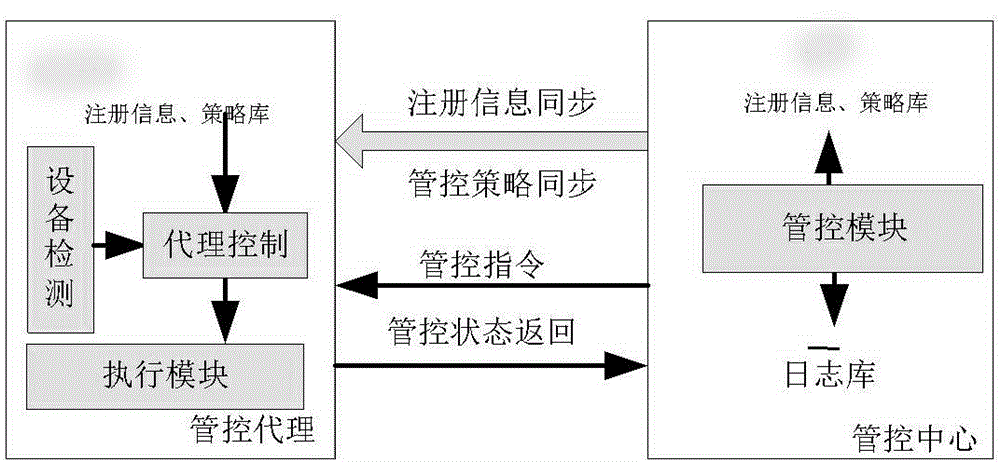

Domestic platform peripheral equipment management and control system and management and control method thereof

InactiveCN104598401AEasy to update and maintainConvenient and flexible management and controlElectric digital data processingControl systemWhitelist

The invention relates to a domestic platform peripheral equipment management and control system and a management and control method thereof. The domestic platform peripheral equipment management and control system and the management and control method thereof comprise a management and control center and a management and control agent, wherein the management and control center conducts peripheral equipment registering to establish a white list of peripheral equipment of a managed computer, establishes a corresponding peripheral equipment management and control strategy and transmits the peripheral equipment white list and the management and control strategy to the management and control agent; the management and control agent conducts corresponding peripheral equipment management and control operation according to the white list and the management and control strategy sent by the management and control center and conducts information synchronization of the peripheral equipment management and control strategy and the white list with the management and control center in real time. According to the domestic platform peripheral equipment management and control system and the management and control method thereof, it is guaranteed that only legally registered peripheral equipment can be used in an established management and control region, log recording is conducted, and the hidden danger of information leakage caused by the abuse of equipment is reduced; meanwhile, when a safety incident occurs, investigating and evidence collecting can be conducted conveniently through auditing the log, the safety management level of the domestic platform peripheral equipment is improved, and various safety threats caused by randomly connecting computers to the peripheral equipment without any control are solved.

Owner:THE PLA INFORMATION ENG UNIV

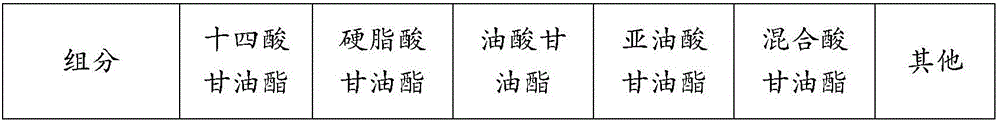

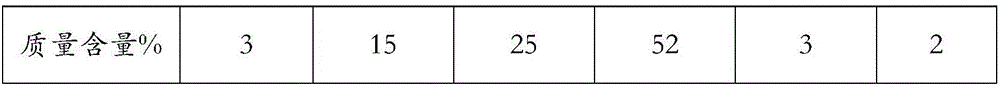

Flame-retardant degradable liquid insulating medium and application thereof

ActiveCN106590813AImprove heat resistanceImprove fire safetyLiquid organic insulatorsBase-materialsVegetable oilTransformer

The invention discloses a flame-retardant biodegradable liquid insulating medium. The flame-retardant biodegradable liquid insulating medium contains 90 mass% or more of glyceride, and the glyceride contains 10 mass% or less of C8-C14 fatty glyceride and 90 mass% or more of C1-C22 fatty glyceride. Raw materials of the insulating medium are mainly derived from vegetable oil, the biodegradation rate is up to 98% or above after 40 days, the flash point is higher than 300 DEG C, the breakdown voltage is higher than 60 kV, the pour point is lower than -20 DEG C, and the kinematic viscosity is less than 25 mm<2> / s. The provided liquid insulating medium has the advantages of being high in flash point, excellent in insulating property and environmentally friendly, can be widely applied in insulation of power equipment, such as the insulation and cooling of transformers, cables, switches and capacitors.

Owner:武汉泽电新材料有限公司

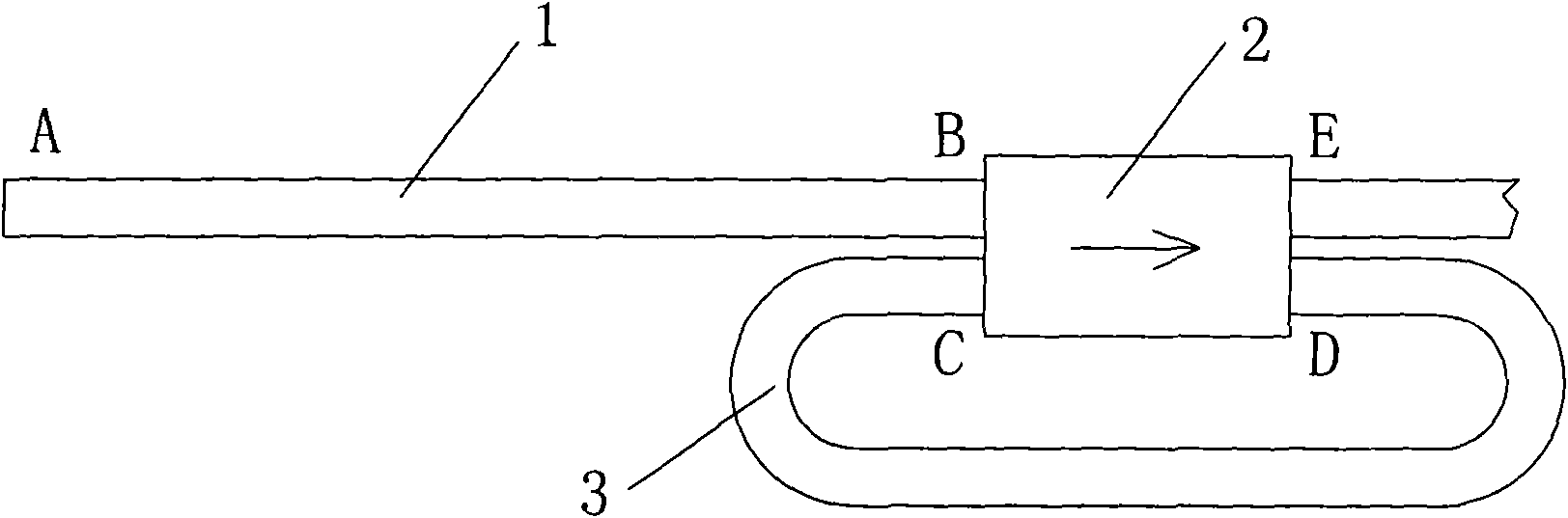

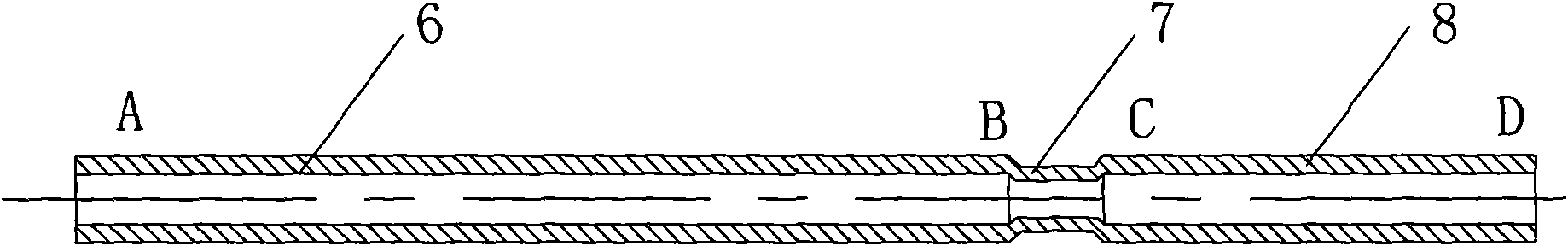

Welding process for suction and exhaust pipe of liquid accumulator

InactiveCN105234515AReduce the risk of leakageAvoid leakage hazardsSoldering apparatusEngineeringExhaust pipe

The invention discloses a welding process for a suction and exhaust pipe of a liquid accumulator. The liquid accumulator, a small steel pipe and a copper elbow pipe are included. A sleeve pipe is arranged at the joint of the small steel pipe and the copper elbow pipe, and the sleeve pipe is clamped at a through hole of the liquid accumulator. The welding process comprises the following steps of pre-welding processing including grinding and cleaning, component assembling, namely forming a weld assembly by clamping the end of the small steel pipe and the end of the copper elbow pipe in the sleeve pipe, and welding. As welding is carried out by clamping the sleeve pipe of the weld assembly at the through hole of the liquid accumulator, the potential hazards of leakage of a weld joint are reduced and eliminated; one-time welding or multi-time welding is carried out on copper pipes, iron pipes and other materials or structural products through different welding processes; the leakage rate is about hundreds of PPM through an existing conventional welding process; the leakage rate after improvement is about several PPM, and leakage is nearly eradicated.

Owner:WUHU SANHUA REFRIGERATION FITTINGS

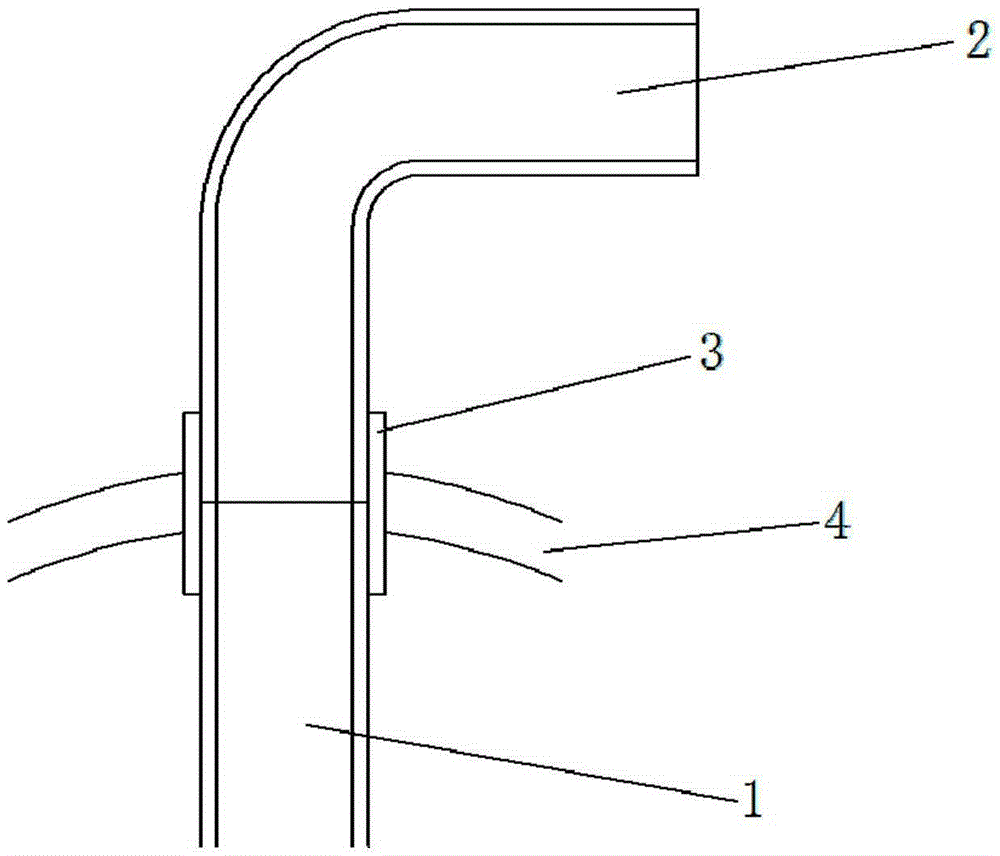

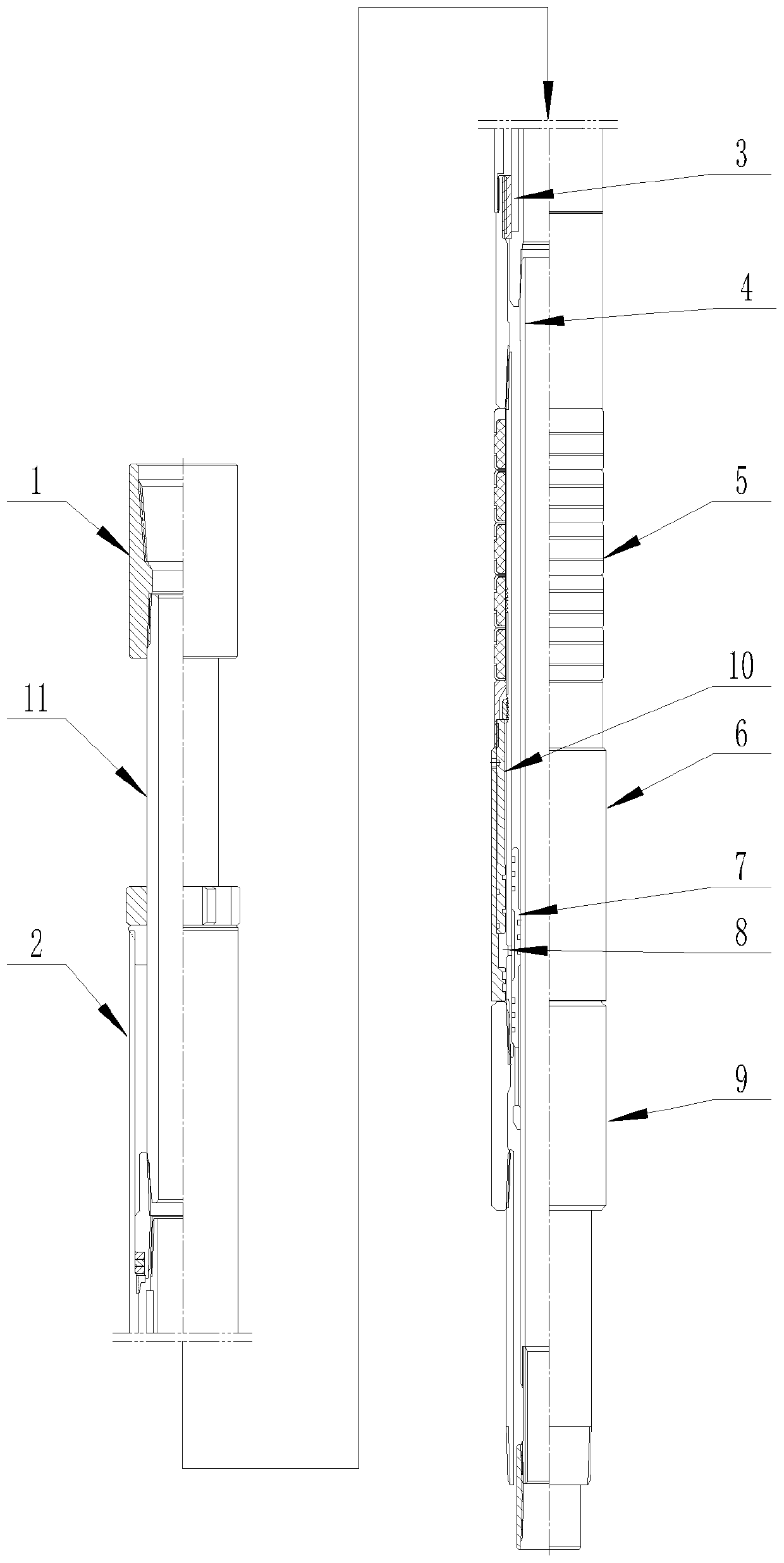

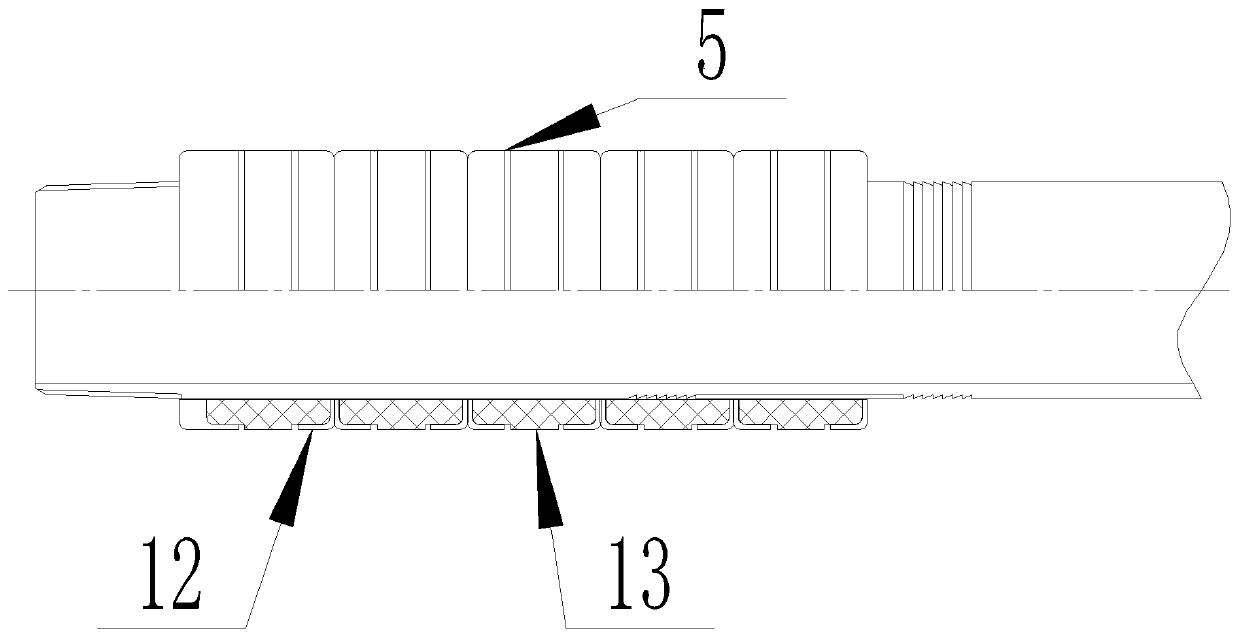

Drilling liner cementing tool with packer and cementing method

PendingCN111411917AIncrease success rateImprove cementing qualitySealing/packingMining engineeringWell drilling

The invention relates to the technical field of oil-gas well drilling completion technology, in particular to a drilling liner cementing tool with a packer and a cementing method. Hydraulic setting ofthe packer is carried out after a well is cemented through the drilling liner cementing tool, safety and reliability are achieved, the requirement of later underground increasing production operationis met, the drilling liner cementing tool with the packer is fed in the drilling rig in-well process, pumping circulation can be carried out in the whole process, circulating pressure is not limitedby pump pressure, and the sleeve lowering success rate is improved. Compared with a general hydraulic drilling liner hanger, an annular clearance of the drilling liner cementing tool and an upper sleeve is large in the cementing process, the circulation is reduced, the risk of leakage is reduced, the problems of dropout, borehole collapse and the like due to a ball seat of a general hanger generates surge pressure are solved, and the lowering success rate and the cementing quality of the whole drilling liner cementing tool are improved through the cementing method.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

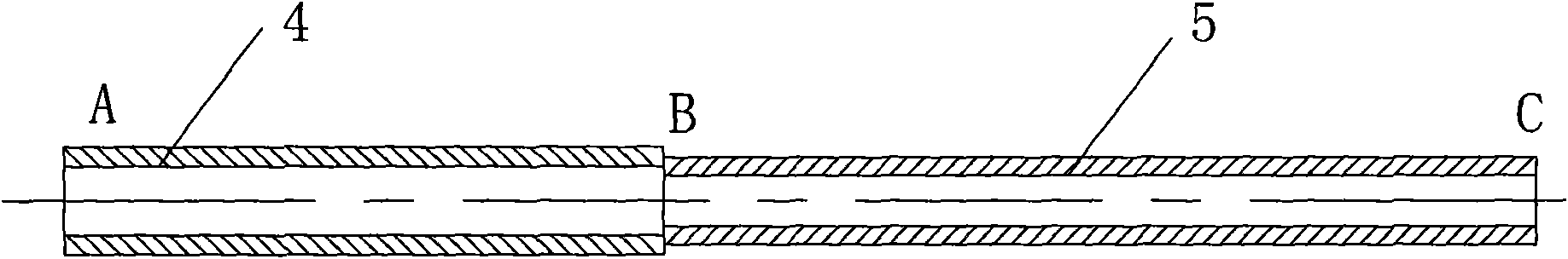

Single two-way throttling capillary tube

InactiveCN101684975AReduce manufacturing costReduce weld jointsFluid circulation arrangementHigh resistanceEngineering

The invention relates to a single two-way throttling capillary tube, which is characterized in that: the capillary tube comprises more than two capillary tubes with different tube inner diameters; twoadjacent capillary tubes are mutually communicated to form a single capillary tube; a refrigerant enters from an inlet A with low resistance when a refrigeration system refrigerates; and the refrigerant enters from an inlet C with high resistance during heating. The single two-way throttling capillary tube has the advantages of avoiding the use of a one-way valve, reducing production cost, reducing welded junctions, reducing hidden danger of leakage and completely avoiding vibration noise generated by the one-way valve.

Owner:SHUNDE POLYTECHNIC

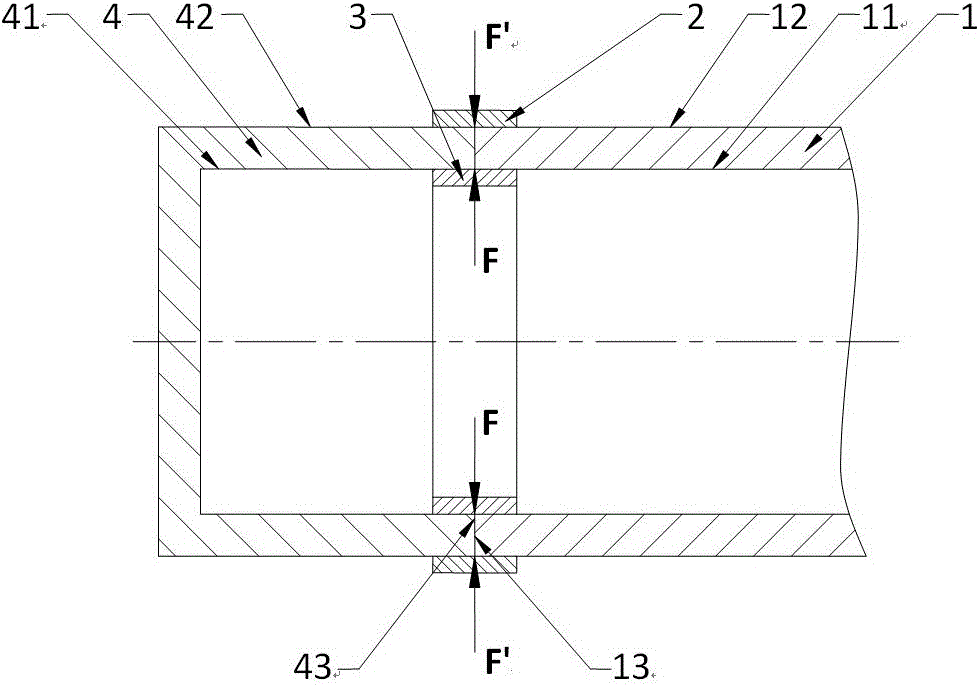

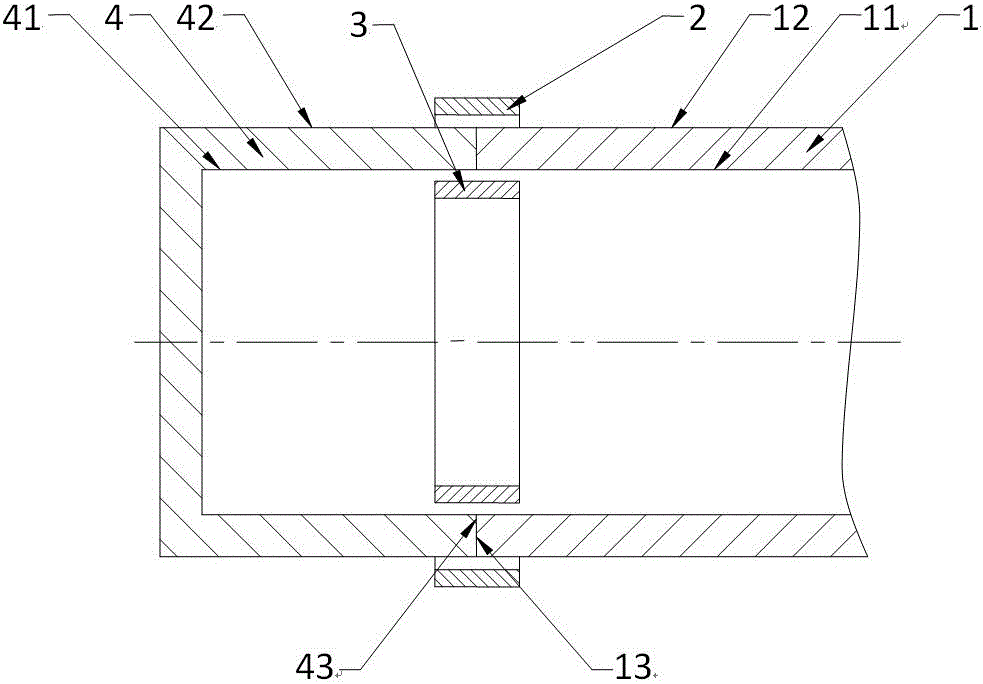

Memory alloy ring sealing device

InactiveCN106065948AExtended service lifeAvoid life aging problemsEngine sealsShape-memory alloyAlloy

The invention discloses a memory alloy ring sealing device which mainly comprises an outer cylinder, a memory alloy ring and an end cover, wherein the memory alloy ring is divided into an outer memory alloy ring and an inner memory alloy ring. During temperature raising phase change, the memory alloy ring turns into the shape of the high temperature phase, the shape of the outer memory alloy ring is shrunk on the whole, and the shape of the inner memory alloy ring is swelled on the whole, so that a sealing role can be played for a liquid or gas medium in the thin-wall outer cylinder device. During temperature reducing phase change, the memory alloy ring turns into the shape of the low temperature phase, the shape of the outer memory alloy ring is swelled on the whole, and the shape of the inner memory alloy ring is shrunk on the whole, so that the sealing device can be freely disassembled. In the sealing state, the theoretical resultant force value generated on the inner surface and the outer surface of the thin-wall outer cylinder by the outer memory alloy ring and the inner memory alloy ring is zero, so that leakage risk caused by single side load deformation of the thin-wall outer cylinder can be avoided. The memory alloy ring sealing device is long in sealing life, and the sealing effect on the medium in the thin-wall outer cylinder device cannot be reduced.

Owner:INST OF ELECTRONICS ENG CHINA ACAD OF ENG PHYSICS

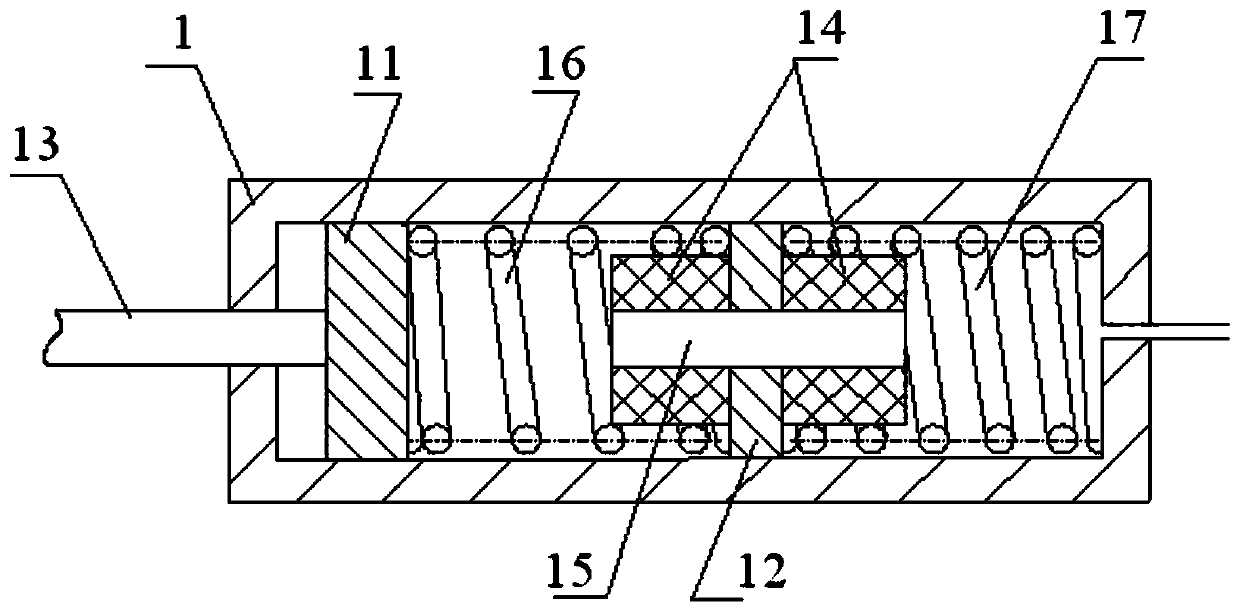

Integrated hydraulic pressure and mechanical force coupling electric power-assisted braking system

ActiveCN110155013AHigh degree of integrationRealize intelligent controlBraking action transmissionBrake safety systemsDriver/operatorElectric power system

The invention discloses an integrated hydraulic pressure and mechanical force coupling electric power-assisted braking system. The braking system comprises a first gear, a second gear, a power-assisted motor, a pedal push rod, a power-assisted pressure-building cylinder, a brake master cylinder, a hydraulic control unit and an electric control unit, wherein the first gear, the second gear, the power-assisted motor and the power-assisted pressure-building cylinder are assembled in a shell, the power-assisted motor is connected with the first gear and drives the first gear to rotate, the first gear is meshed with the second gear to drive the second gear to rotate synchronously, the middle of the second gear is connected with a screw rod in a threaded mode, the screw rod is of a hollow structure, and the screw rod is driven to move left and right in the rotating process of the second gear. The integrated hydraulic pressure and mechanical force coupling electric power-assisted braking system has the beneficial effects that the braking force of a driver and the braking force of the motor are simultaneously output and do not interfere with each other, the electric power-assisted brakingsystem can implement the functions of active braking, failure backup, braking energy recovery and the like, can achieve intelligent control of the vehicle, and can be used as a bottom layer actuator of an intelligent vehicle driving auxiliary system.

Owner:JILIN UNIV

Construction method of inverted roof

InactiveCN106013623ASimple construction methodReduce construction costsBuild-up roofsProtection layerNatural stone

The invention discloses a construction method for an inverted roof, which comprises the construction of a constructed structural layer, setting slope finding on the outer surface of the structural layer so that the slope is 2-3%; setting a V-shaped drainage ditch, built-in drainage pipes and Drainage holes; cleaning of layers; application of first waterproof coating; laying of insulation; pouring of protective layer; second application of waterproof coating in V-shaped drainage ditch; laying of natural stones or precast concrete blocks or loose paving pebble. The whole system achieves the best thermal insulation effect, and the water on the roof is discharged smoothly, so there will be no water accumulation on the roof, which greatly reduces the hidden danger of leakage and optimizes the waterproof performance of the roof.

Owner:CHINA COAL 72 ENG

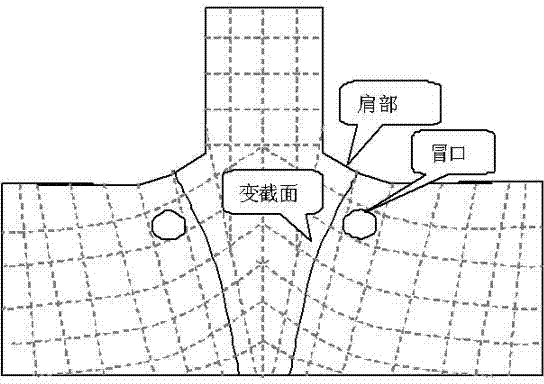

Cathode for dovetail groove type aluminum electrolytic cell

The invention relates to an improvement of an aluminum electrolytic cathode set structure, in particular to an improvement of a double-dovetail-groove or multi-dovetail-groove cathode set structure for large grooves, and discloses a cathode for a dovetail groove type aluminum electrolytic cell. The cathode structurally comprises a cathode carbon block and a cathode steel rod which are bonded through combined materials. The cathode is characterized in that the number of the cathode steel rod bonded through the combined materials in the cathode carbon block is one; the distance between the cathode steel rod and the side of the cathode carbon block is 50 mm-180 mm; and the distance between the cathode steel rod and the upper portion of the cathode carbon block is 150 mm-300 mm. Compared with the prior art, the cathode has the beneficial effect of greatly lowering voltage drop of ferric carbon; the limitation for electric conduction increasing through steel rod widening is broken through; quite remarkable functions for lowering furnace bottom voltage drop, lowering the horizontal current and reducing the furnace leakage risk are achieved; and meanwhile, the structure is simple, the manufacturing and running cost is low, and the production cost of electrolytic aluminum can be effectively reduced.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Movable valve seat type throttling valve

The invention discloses a movable valve seat type throttling valve. The throttling valve comprises a valve body with a cavity. A front end cover and a rear end cover are both fixedly connected with the valve body. The valve body is provided with a water inlet and a water outlet which are communicated with the cavity. A valve element and a valve seat are arranged in the cavity of the valve body, and the valve element is fixed into the cavity in the valve body through the rear end cover. The valve seat is embedded in a sleeve and the cavity in the valve body. The upper end of the valve seat stretches out of an axial through hole of the front end cover. The sleeve is in force fit with the front end cover and the valve body. The valve seat comprises a two-step structure, and the two steps have the same superficial area. According to the throttling valve, through the center rod structure of the valve element and the structure that two step surfaces have the same area, the function of compensating hydrodynamic force of fluid can be achieved, impact force and erosion to the valve seat are reduced, and the stability of manual adjustment of the valve seat is improved.

Owner:OCEAN UNIV OF CHINA

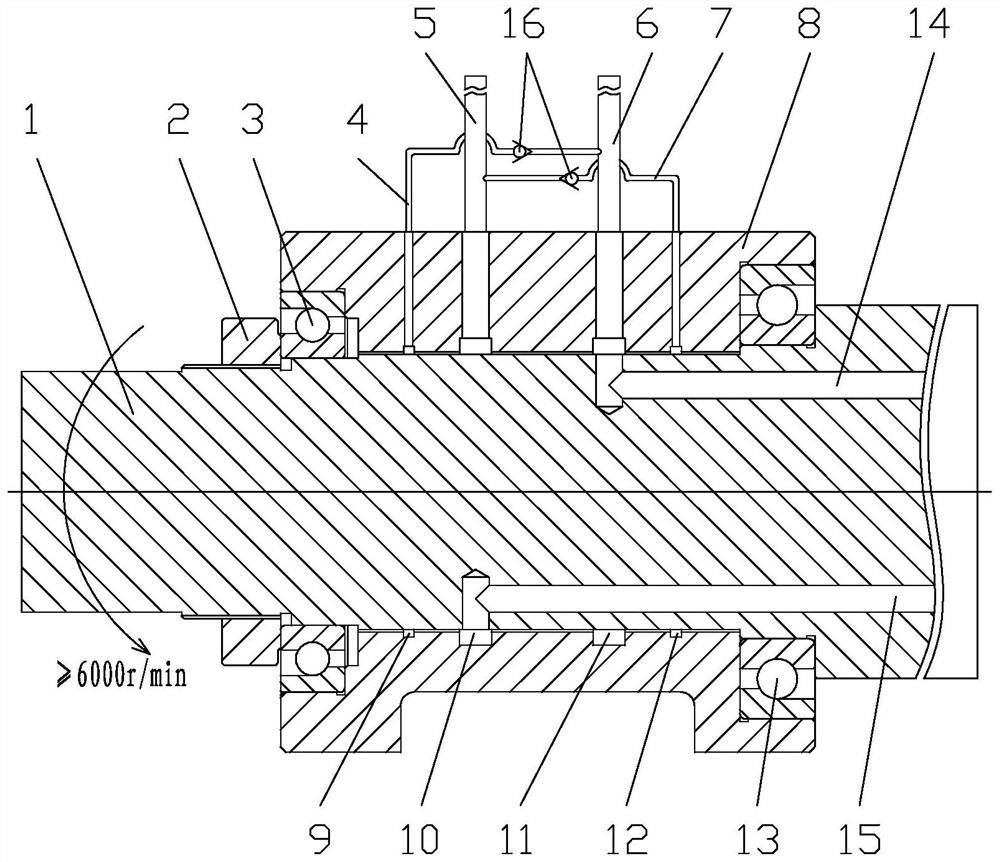

High-speed self-balancing spindle oil dividing structure of inertia friction welding machine

ActiveCN111843175ASimple structureExtended service lifeBearing unit rigid supportNon-electric welding apparatusFriction weldingRolling-element bearing

The invention discloses a high-speed self-balancing spindle oil dividing structure of an inertia friction welding machine. The high-speed self-balancing spindle oil dividing structure comprises a spindle and an oil dividing component, and an oil inlet connector and an oil return connector are formed in the oil dividing component. An oil inlet channel and an oil return channel extending in the axial direction of the spindle are arranged on the spindle. The oil dividing component is composed of an oil dividing ring of an annular structure, the oil dividing ring is rotationally arranged on the spindle through rolling bearings at the two ends, and a dynamic pressure bearing matching structure is formed between the oil dividing ring and the spindle and is located between the bearings at the twoends. The oil inlet channel and the oil return channel communicate with the corresponding oil inlet connector and oil return connector correspondingly through tow radial oil channels. The high-speedself-balancing spindle oil dividing structure has the advantages that hydraulic power can be reliably provided, spindle safety can be guaranteed through a ceaseless oil pressure self-balancing high-speed high-pressure oil film self-sealing structure, and a thrust bearing is allowed to be provided with a large end play; mounting difficulty is reduced, and damping is reduced; and the high-speed self-balancing spindle oil dividing structure is long in service life, and is especially suitable for high-speed heavy-load operation environments of 6000 r / min or above.

Owner:CHONGQING PULSAR TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com