Cathode for dovetail groove type aluminum electrolytic cell

The technology of aluminum electrolytic cell and dovetail cell is applied in the field of improvement of cathode group structure of double dovetail cell or multi-dovetail cell, which can solve the problems of small conductive area of cathode steel rod, large pressure drop of iron and carbon, leakage of furnace, etc. The effect of low operating cost, reduced iron and carbon pressure drop, and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

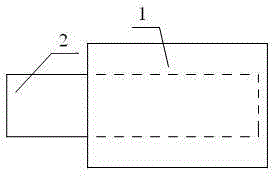

[0028] Such as figure 2 As mentioned above, the Q195 type steel is used as the steel rod, and the ordinary carbon block is used as the cathode carbon block. The entire cathode steel rod runs through the cathode carbon block. The buffer structure at the end of the rod is arc-shaped. Use tamping paste at the end position where the steel rod contacts the carbon block, and the two sides of the steel rod inside the carbon block adopt an arc-shaped concave shape. The cathode steel rod is 100mm from the side of the cathode carbon block, and the cathode steel rod is 250mm from the upper part of the cathode carbon block. Compared with the structure of the traditional cathode group, the voltage drop of this cathode group is reduced by 110mV, the horizontal current is reduced by 41%, and the power consumption per ton of aluminum can be reduced by 980kWh.

Embodiment 2

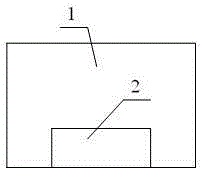

[0030] Such as image 3 As mentioned above, pure iron is used as the steel rod, and a semi-graphite carbon block is used as the cathode carbon block. There are 3 connection points at the position where the end of the cathode steel rod is connected to the peripheral busbar, and the cathode steel rods are distributed at both ends of the cathode carbon block. , the middle of the cathode steel rod is not connected, and the buffer structure at the end of the cathode steel rod is a triangle. A boss structure is used around the contact between the steel rod and the carbon block to increase the contact area and increase the strength. The cathode steel rod is 180mm from the side of the cathode carbon block, and the cathode steel rod is 200mm from the upper part of the cathode carbon block. Compared with the structure of the traditional cathode group, the voltage drop of this cathode group is reduced by 140mV, the horizontal current is reduced by 45%, and the power consumption per ton ...

Embodiment 3

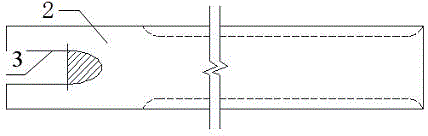

[0032] Such as Figure 4 As mentioned above, pure copper is used as the cathode conductive steel rod, and a fully graphitized carbon block is used as the cathode carbon block. There are two connection points at the position where the end of the cathode steel rod is connected to the peripheral busbar, and the entire cathode steel rod runs through the cathode carbon Blocks, steel rods adopt grooves around some steel rods inside the carbon block to increase contact strength. The cathode steel rod is 120mm from the side of the cathode carbon block, and the cathode steel rod is 280mm from the upper part of the cathode carbon block. Compared with the structure of the traditional cathode group, the voltage drop of this cathode group is reduced by 130mV, the horizontal current is reduced by 42%, and the power consumption per ton of aluminum can be reduced by 1000kWh.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com