Patents

Literature

165 results about "Contact strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

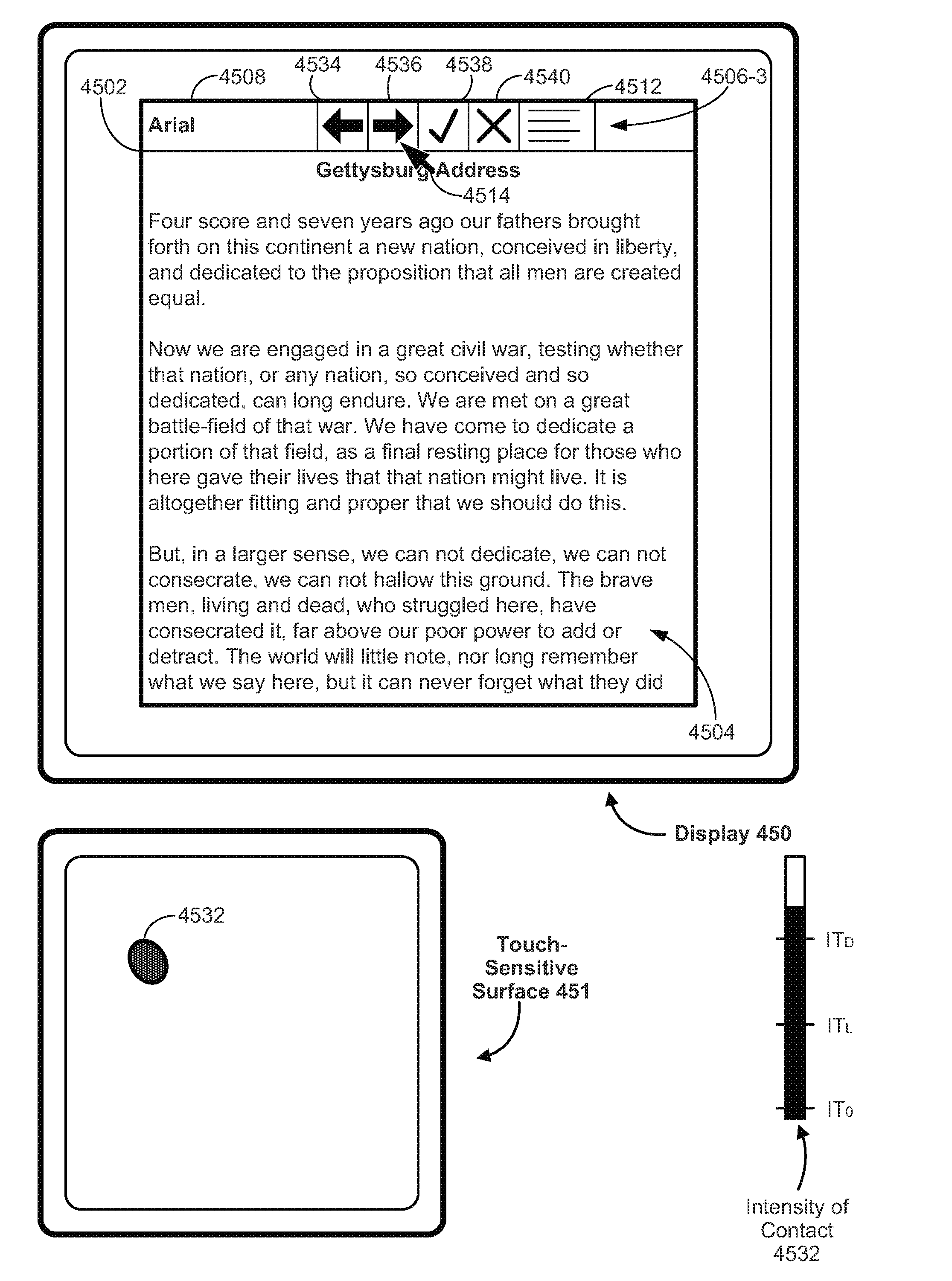

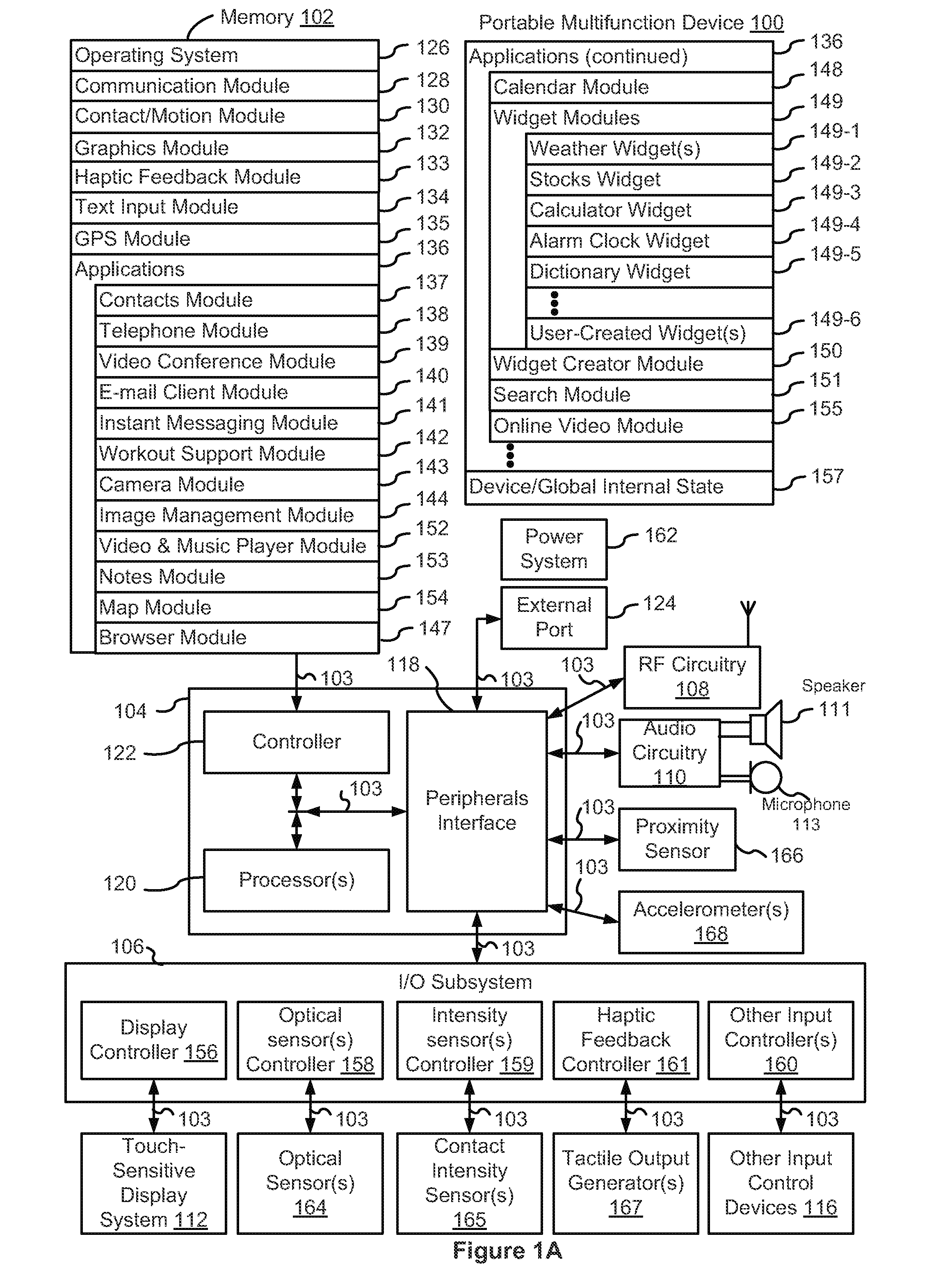

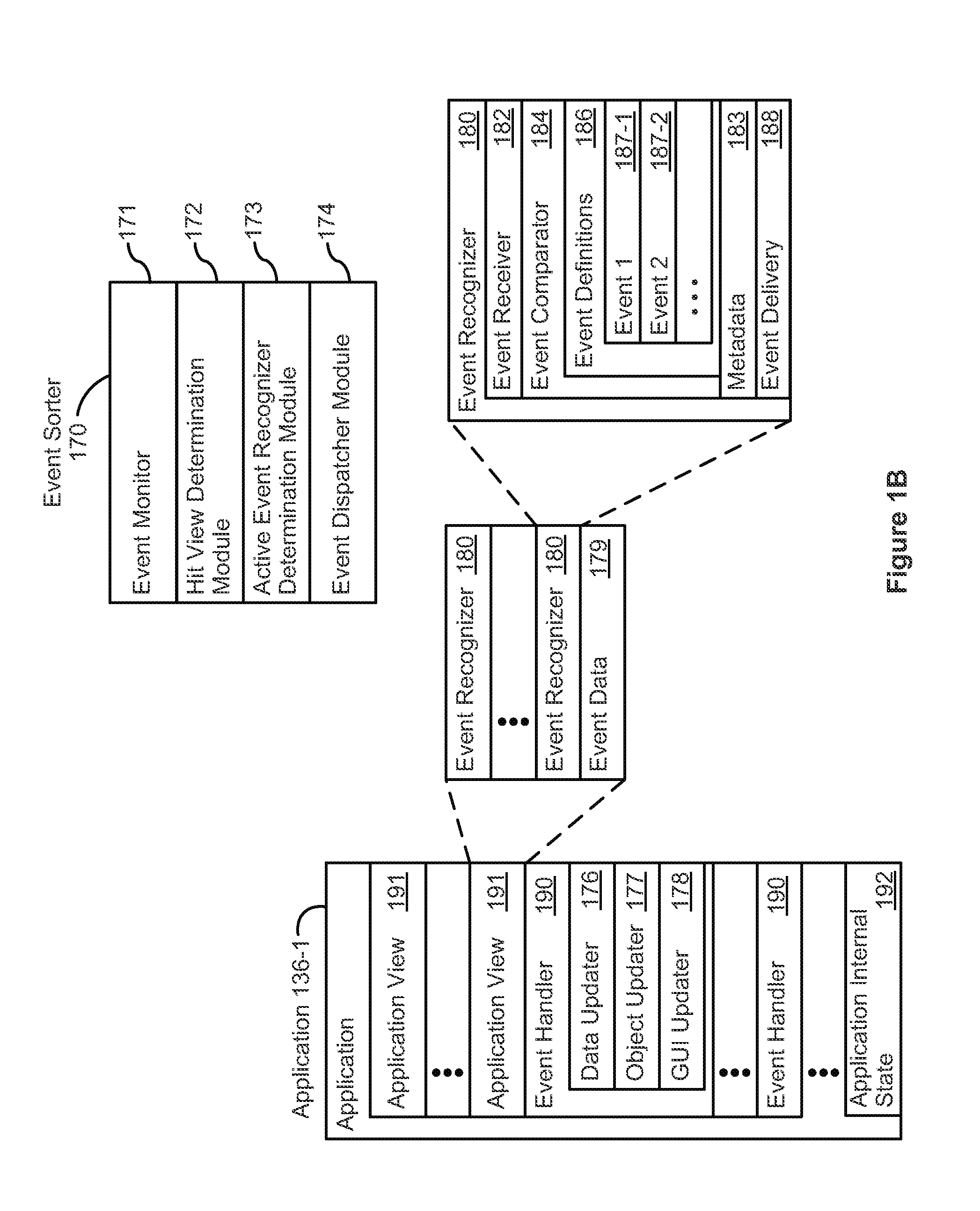

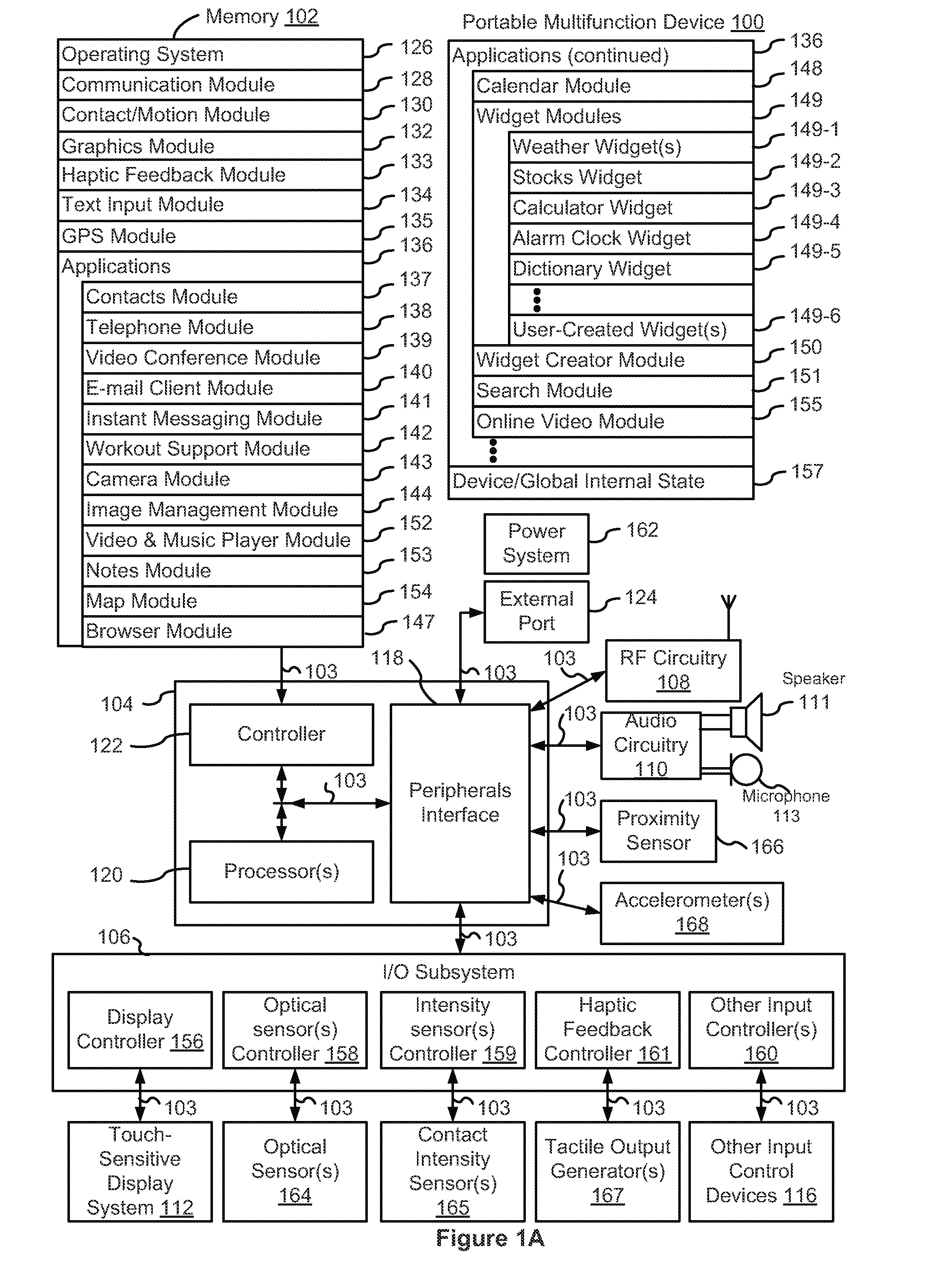

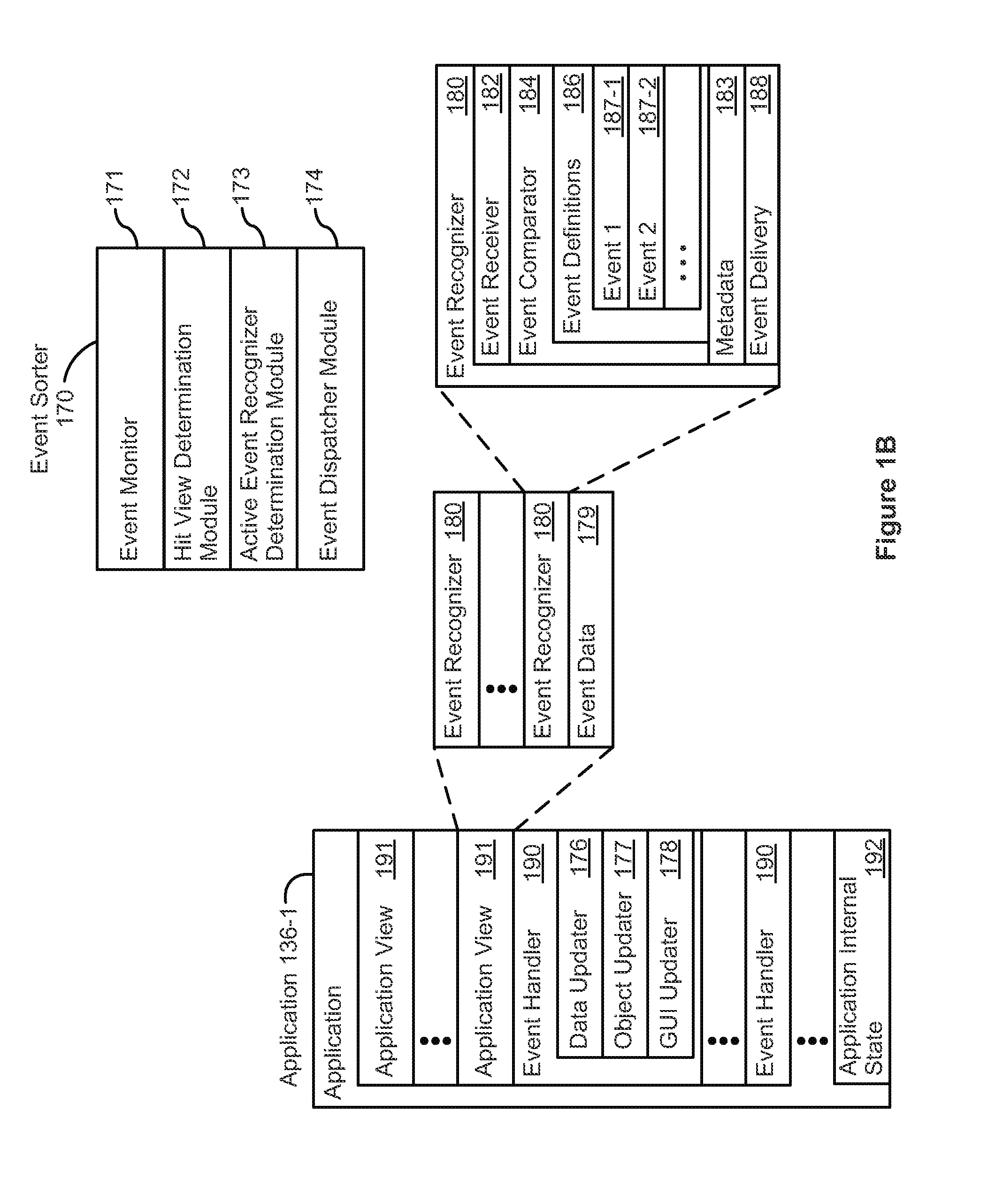

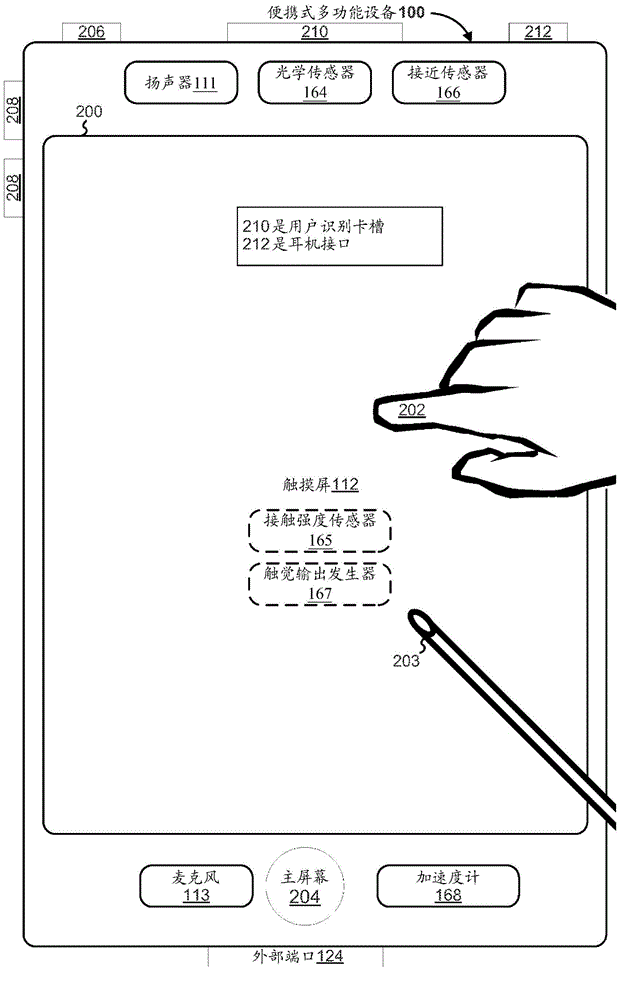

Device, Method, and Graphical User Interface for Facilitating User Interaction with Controls in a User Interface

ActiveUS20150067513A1Faster and efficient methodFaster and efficient and interfaceInput/output processes for data processingPictoral communicationGraphicsGraphical user interface

An electronic device, with a touch-sensitive surface and a display, includes one or more sensors to detect intensity of contacts with the touch-sensitive surface. The device displays, on the display, a first control for controlling a first operation. The device detects, on the touch-sensitive surface, a first input that corresponds to the first control; and in response to detecting the first input: in accordance with a determination that the first input meets first control-activation criteria but does not include a contact with a maximum intensity above a respective intensity threshold, the device performs the first operation; and in accordance with a determination that the first input includes a contact with an intensity above the respective intensity threshold, the device displays a second control for performing a second operation associated with the first operation.

Owner:APPLE INC

Device, Method, and Graphical User Interface for Forgoing Generation of Tactile Output for a Multi-Contact Gesture

ActiveUS20150149899A1Improve effectivenessImprove efficiencyInput/output for user-computer interactionPower supply for data processingGraphicsGraphical user interface

Owner:APPLE INC

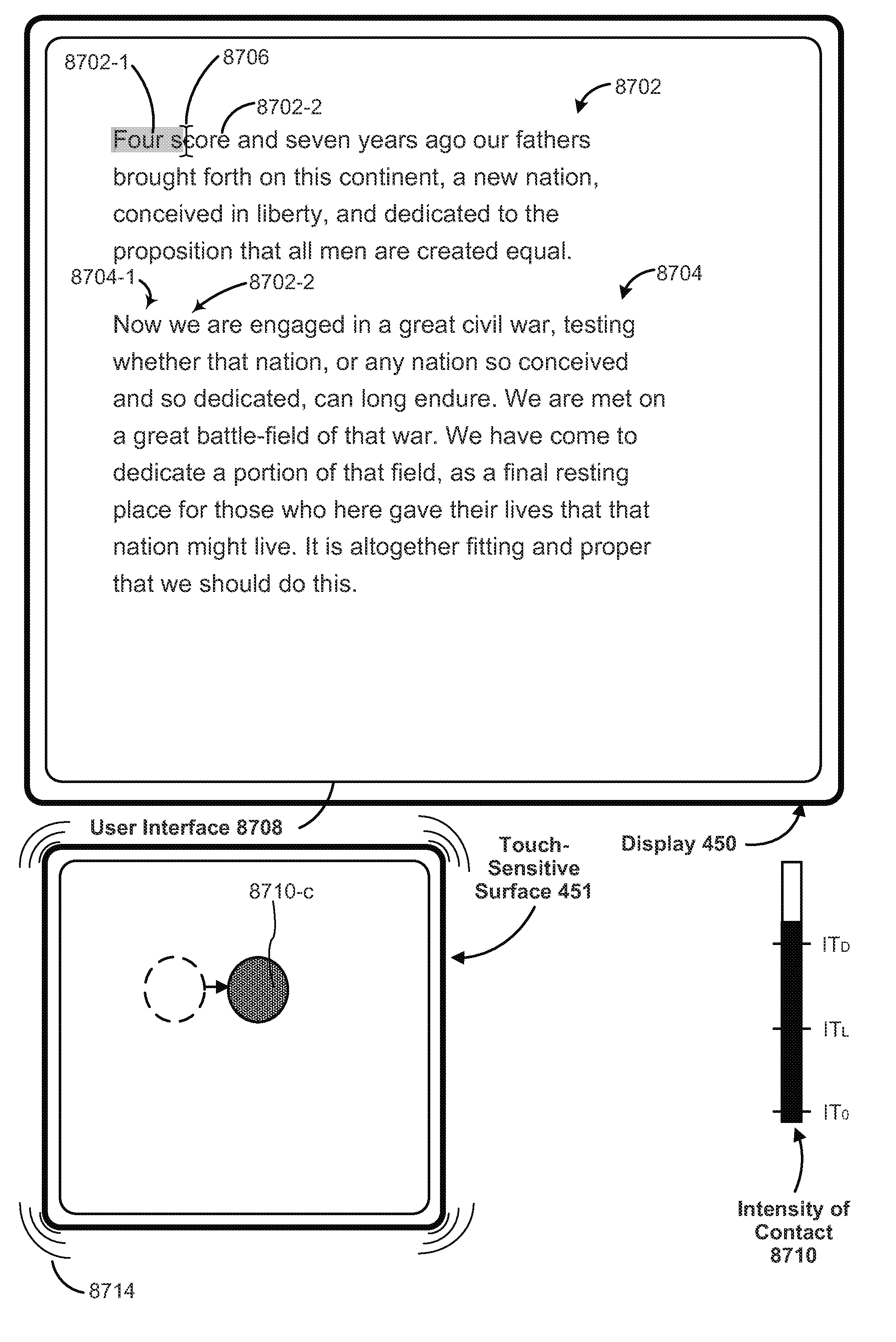

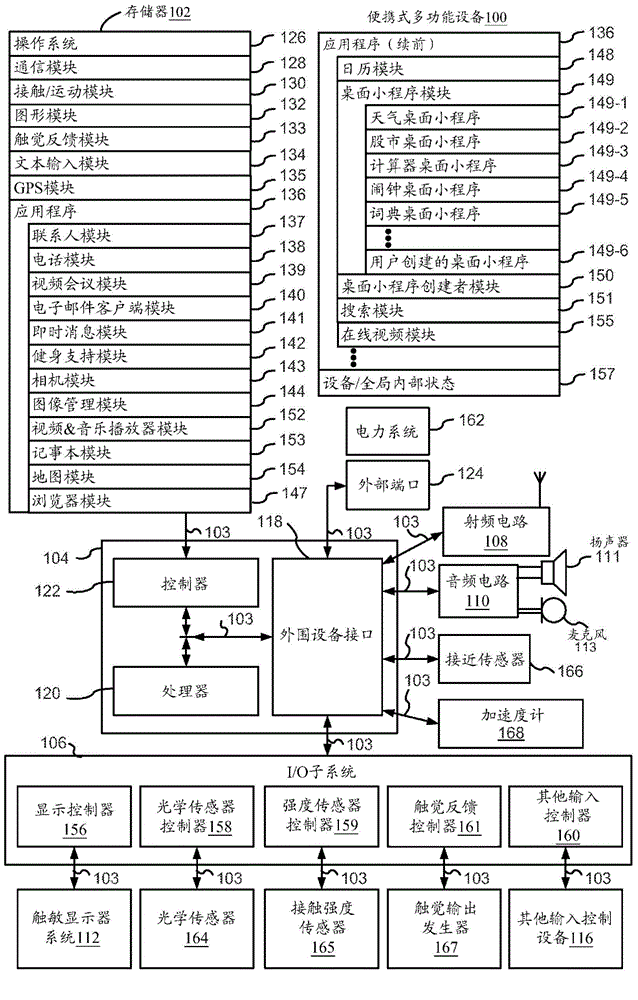

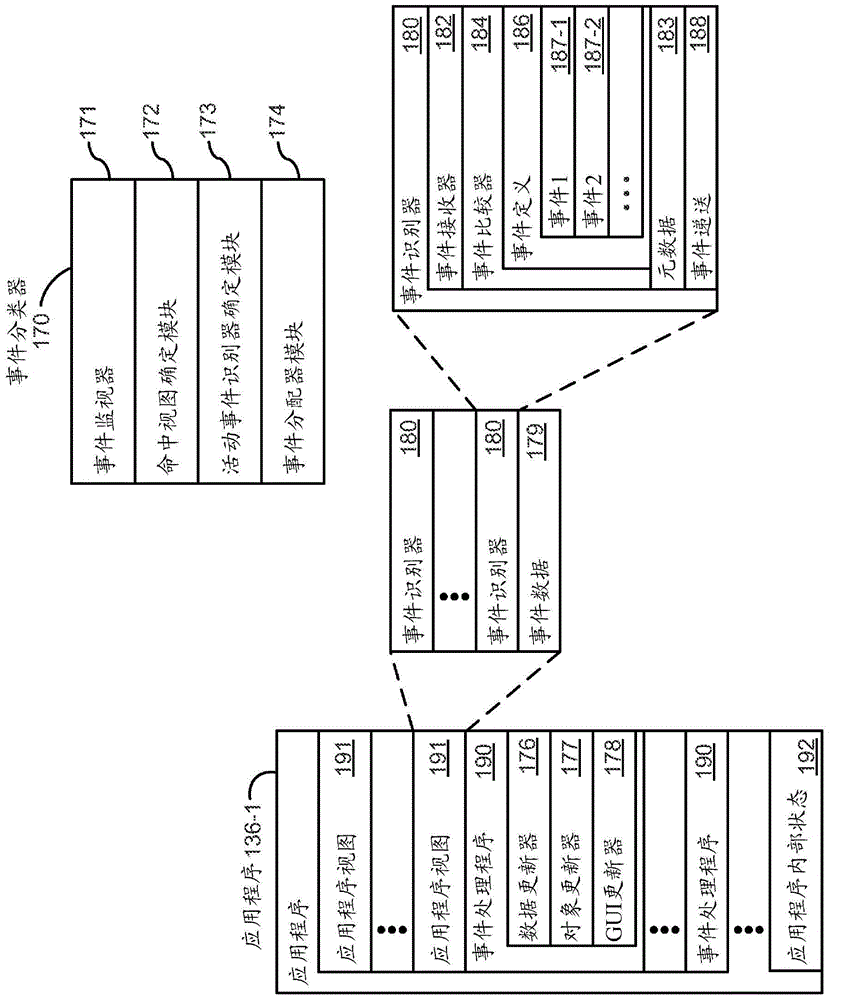

Device, method, and graphical user interface for transitioning between display states in response to gesture

ActiveCN104487928AImprove satisfactionFast wayInput/output processes for data processingGraphicsContinuation

An electronic device displays a user interface in a first display state. The device detects a first portion of a gesture on a touch-sensitive surface, including detecting intensity of a respective contact of the gesture. In response to detecting the first portion of the gesture, the device displays an intermediate display state between the first display state and a second display state. In response to detecting the end of the gesture: if intensity of the respective contact had reached a predefined intensity threshold prior to the end of the gesture, the device displays the second display state; otherwise, the device redisplays the first display state. After displaying an animated transition between a first display state and a second state, the device, optionally, detects an increase of the contact intensity. In response, the device displays a continuation of the animation in accordance with the increasing intensity of the respective contact.

Owner:APPLE INC

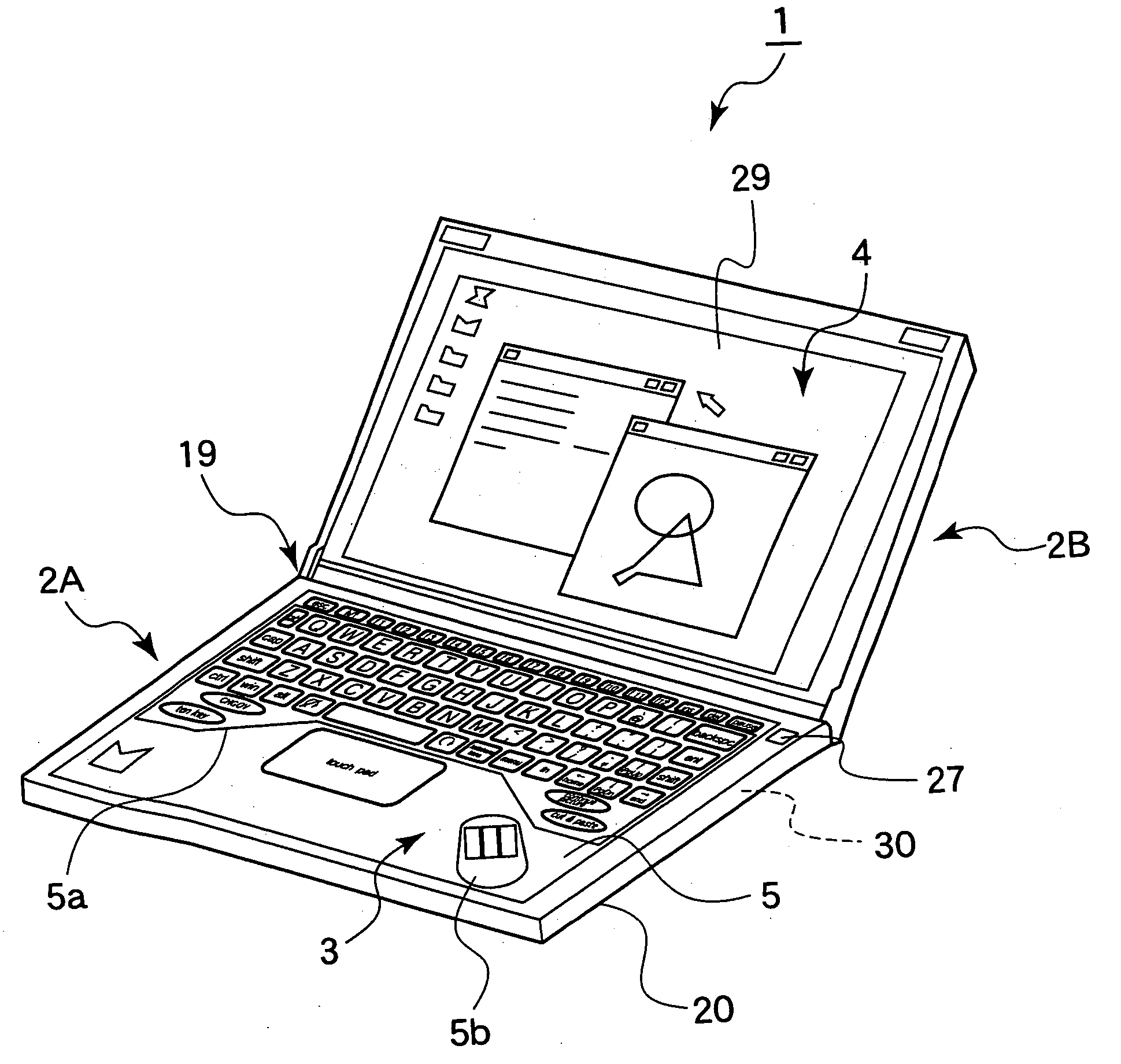

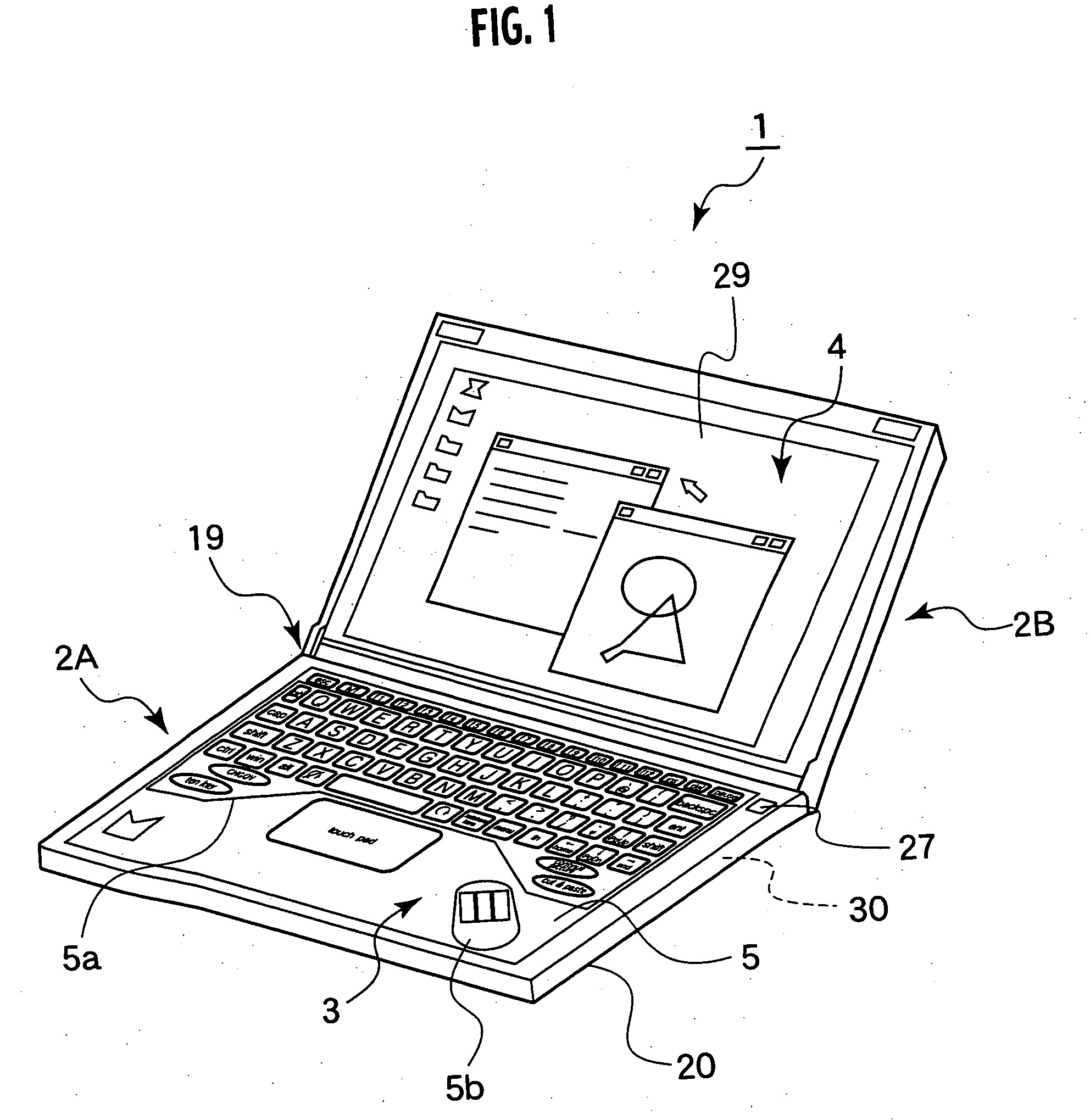

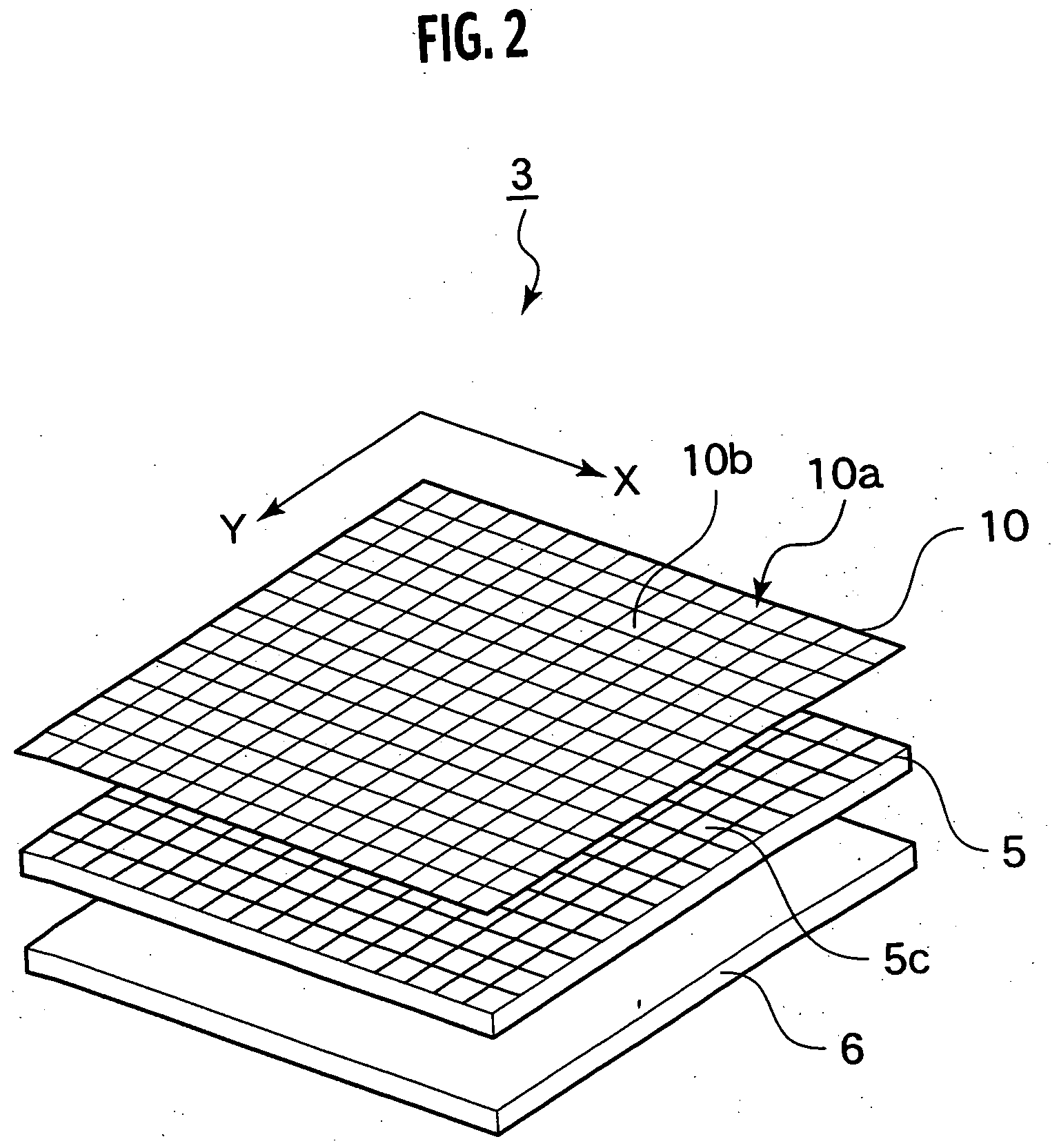

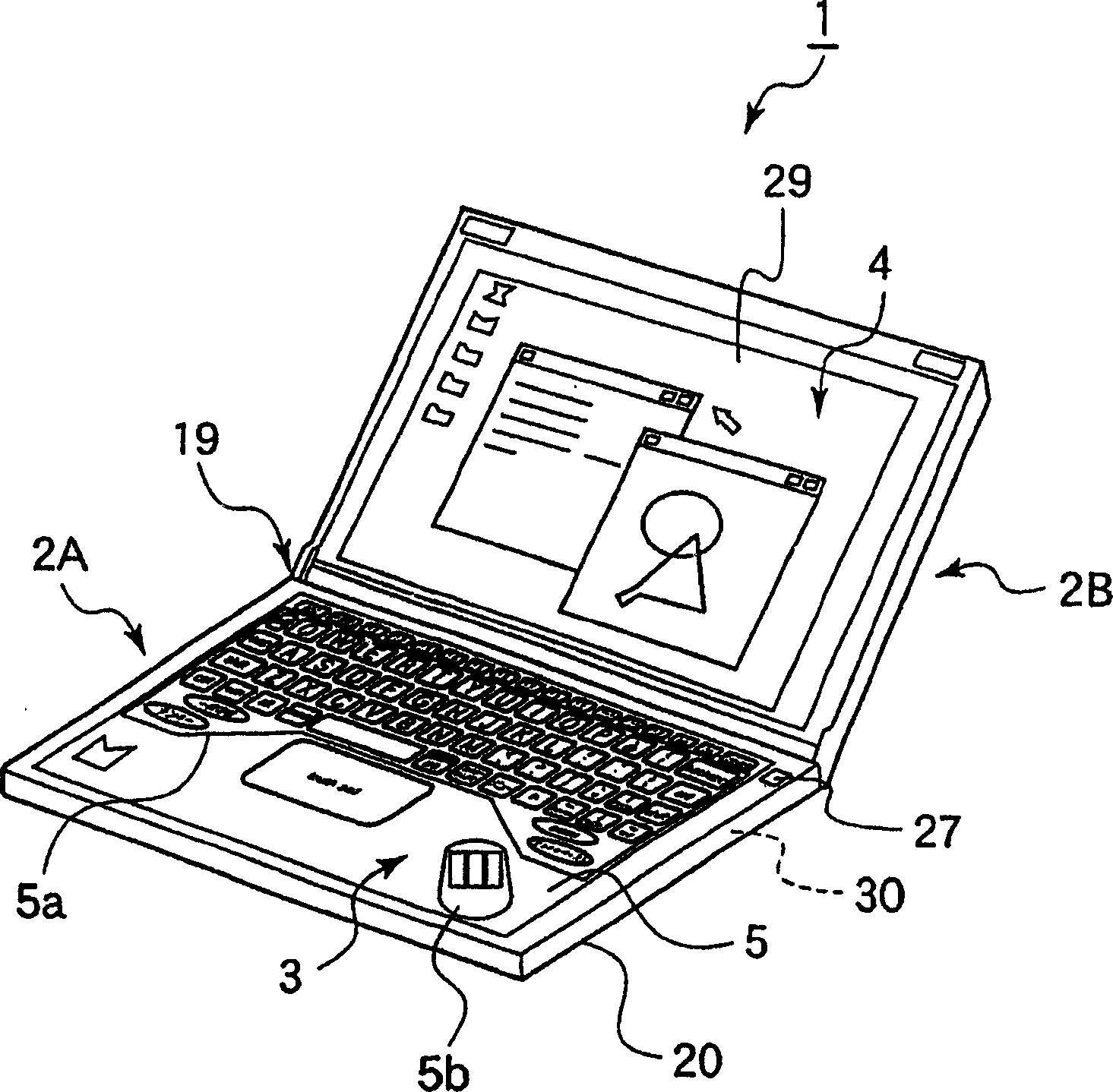

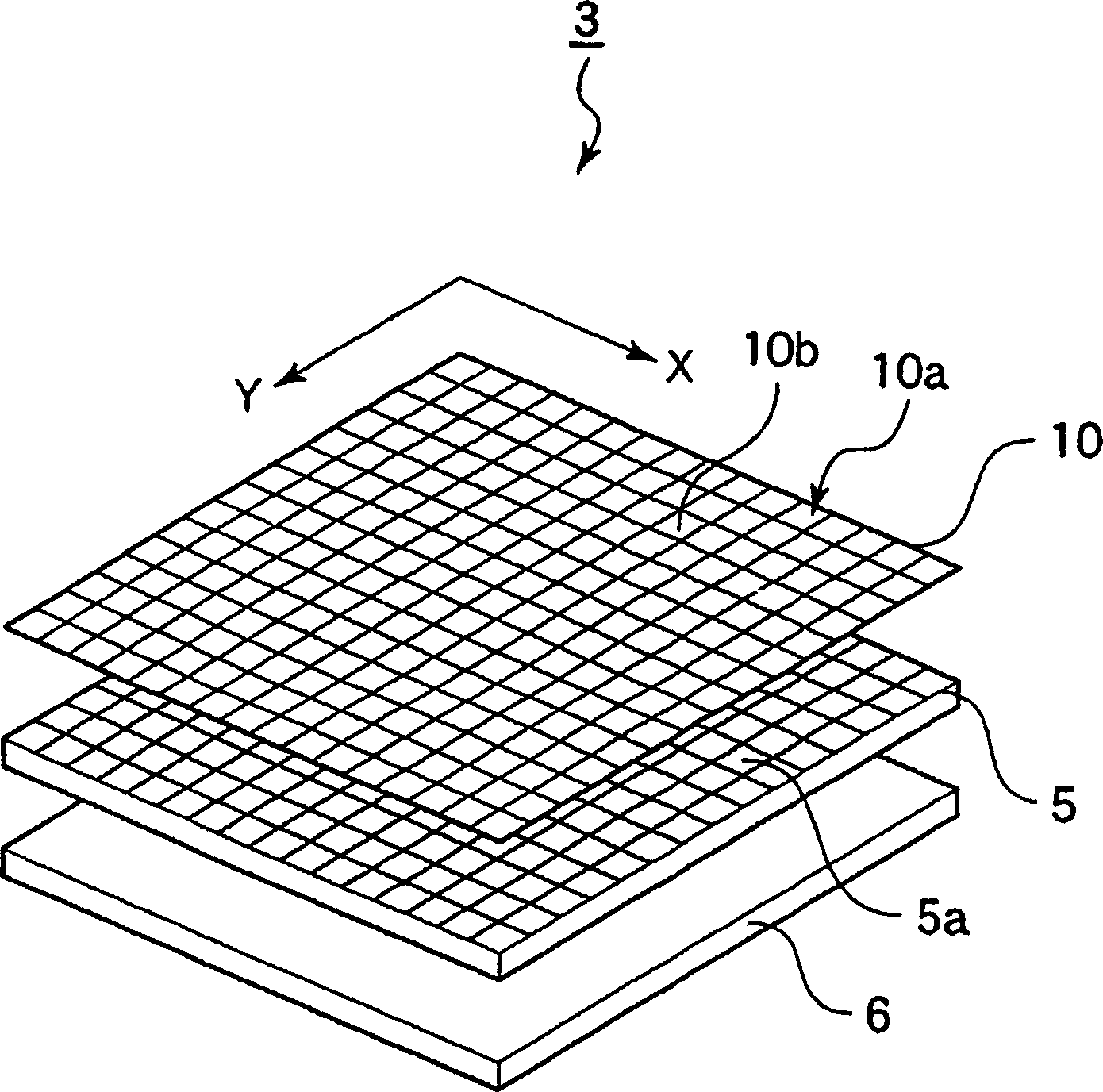

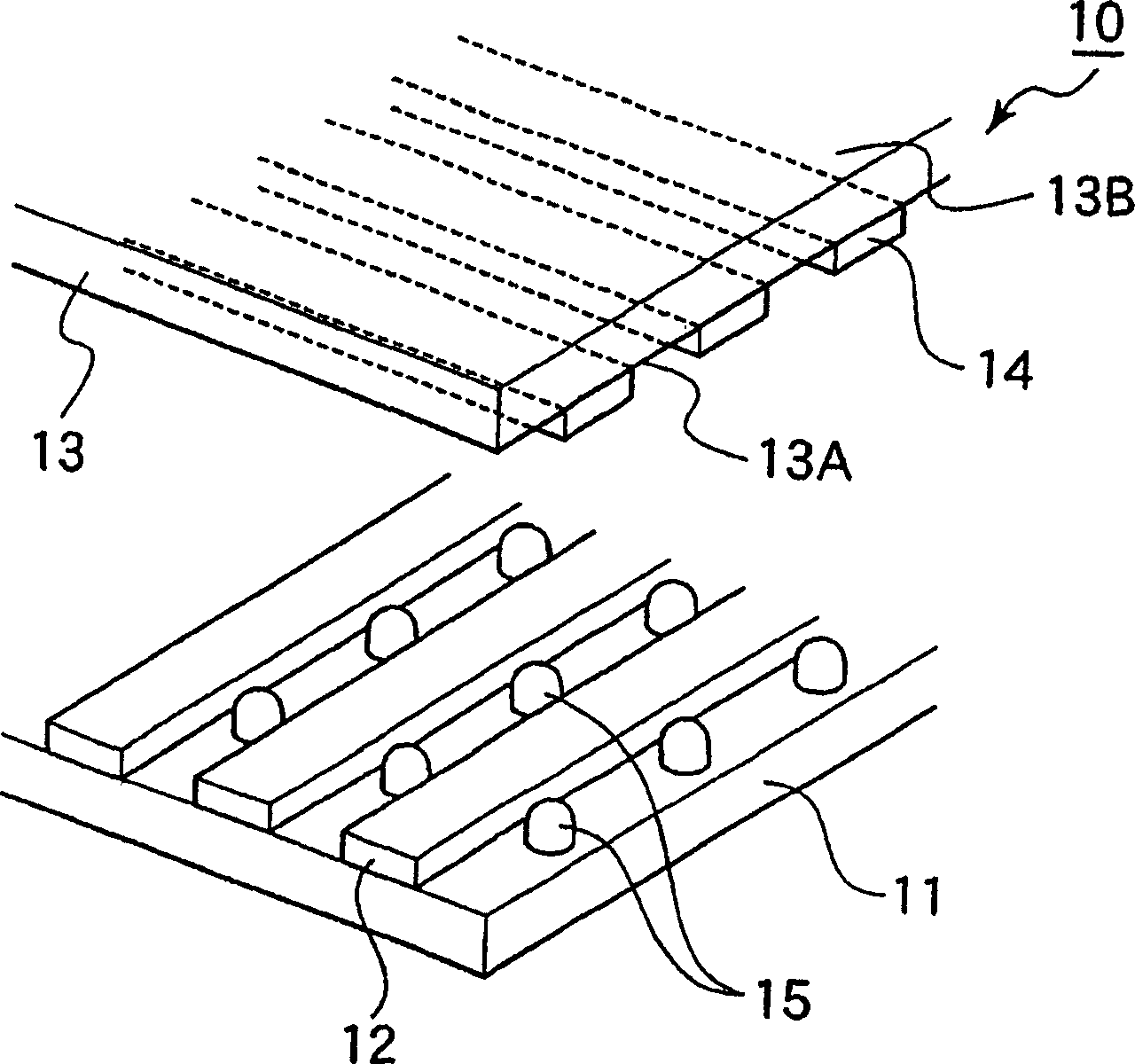

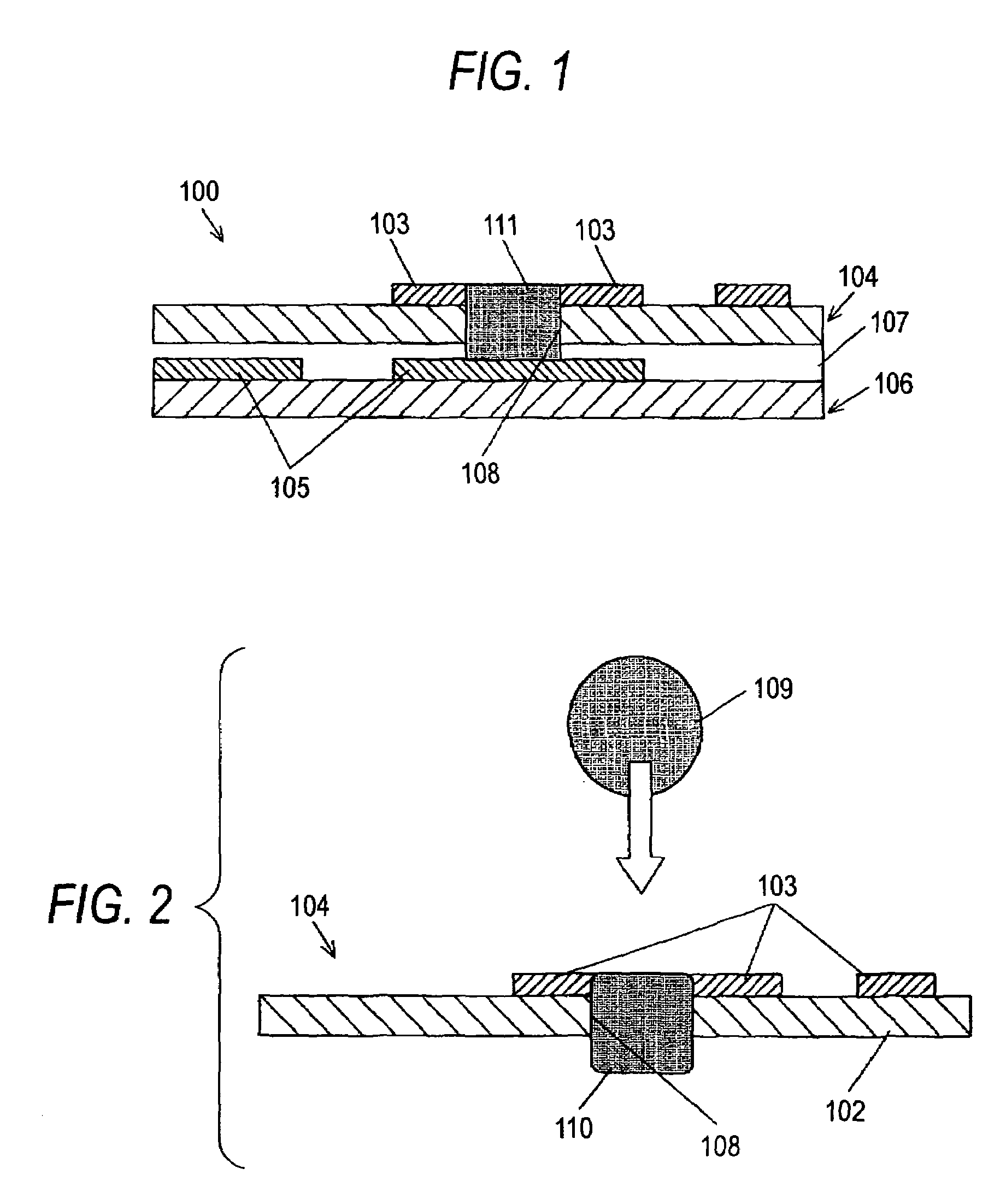

Input device

InactiveUS20060050062A1Cathode-ray tube indicatorsDetails for portable computersPattern recognitionContact position

An input device includes: a display unit indicating an image of an input position; a contact position detecting unit detecting a position of an object brought into contact with a contact detecting layer provided on a display layer of the display unit; a contact strength detecting unit detecting contact strength of the object brought into contact with the contact detecting layer; and a contact state determining unit which extracts a feature quantity of the detected contact strength, compares the extracted feature quantity with a predetermined threshold, and determines a contact state of the object.

Owner:KK TOSHIBA

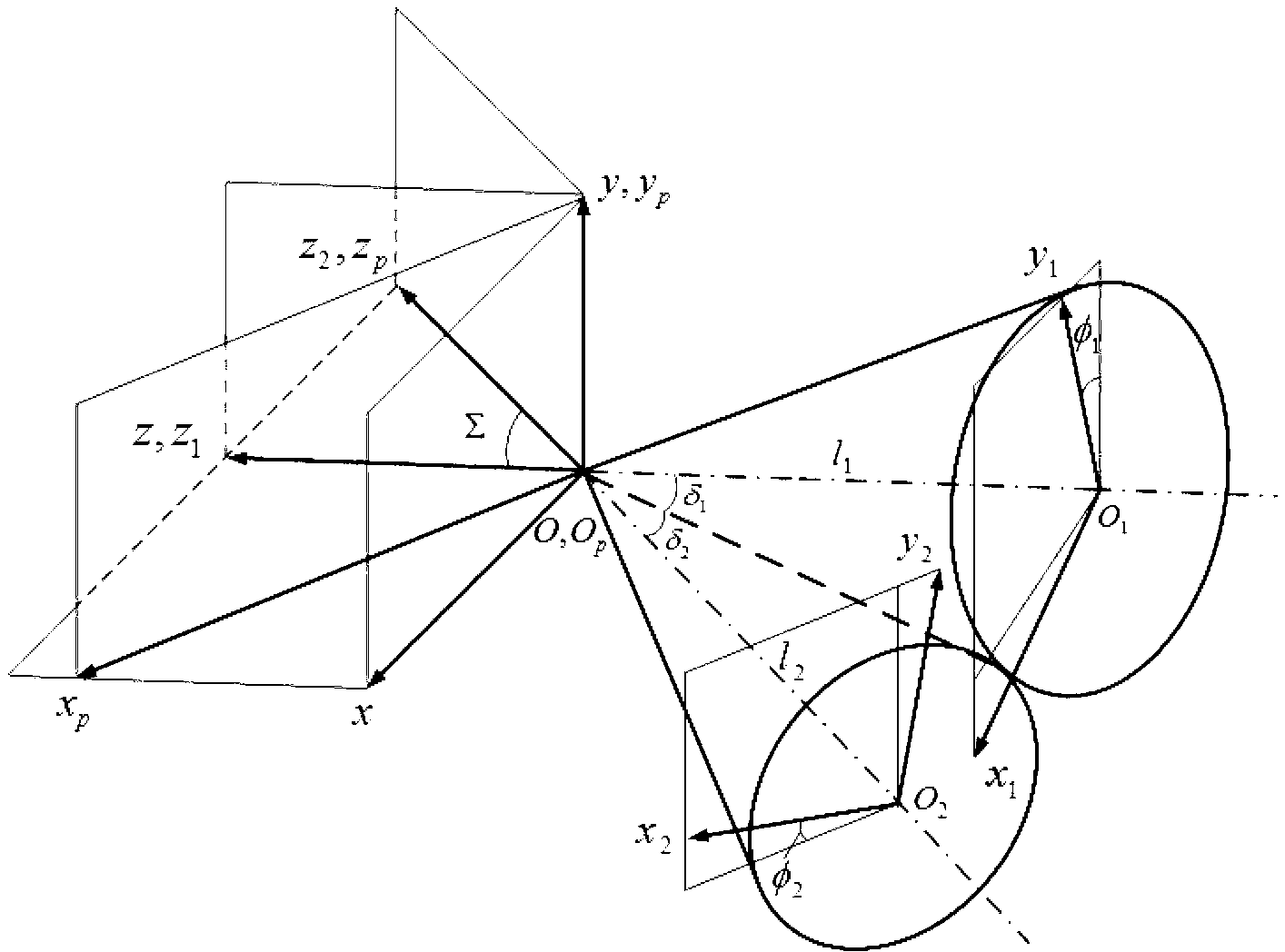

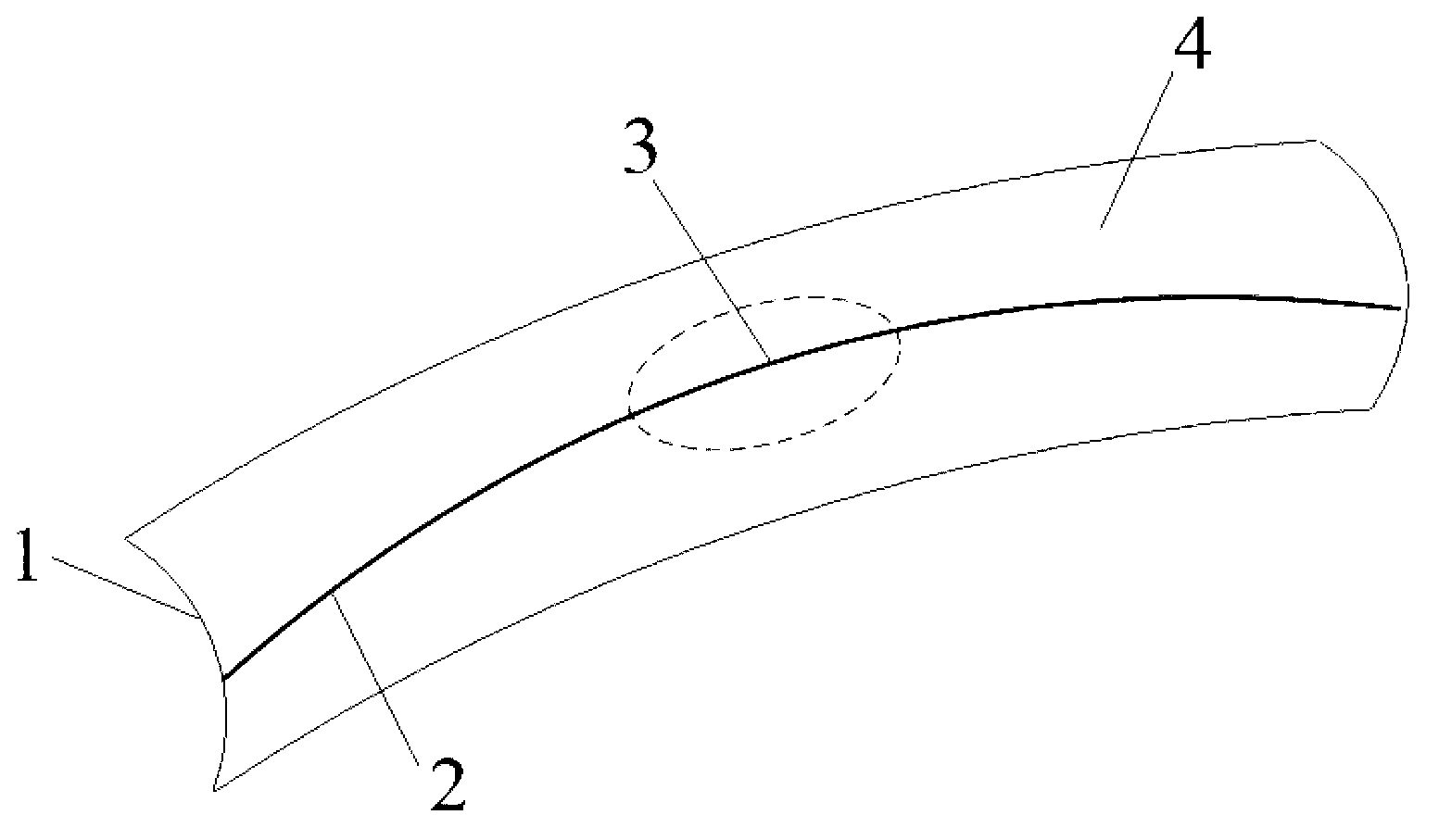

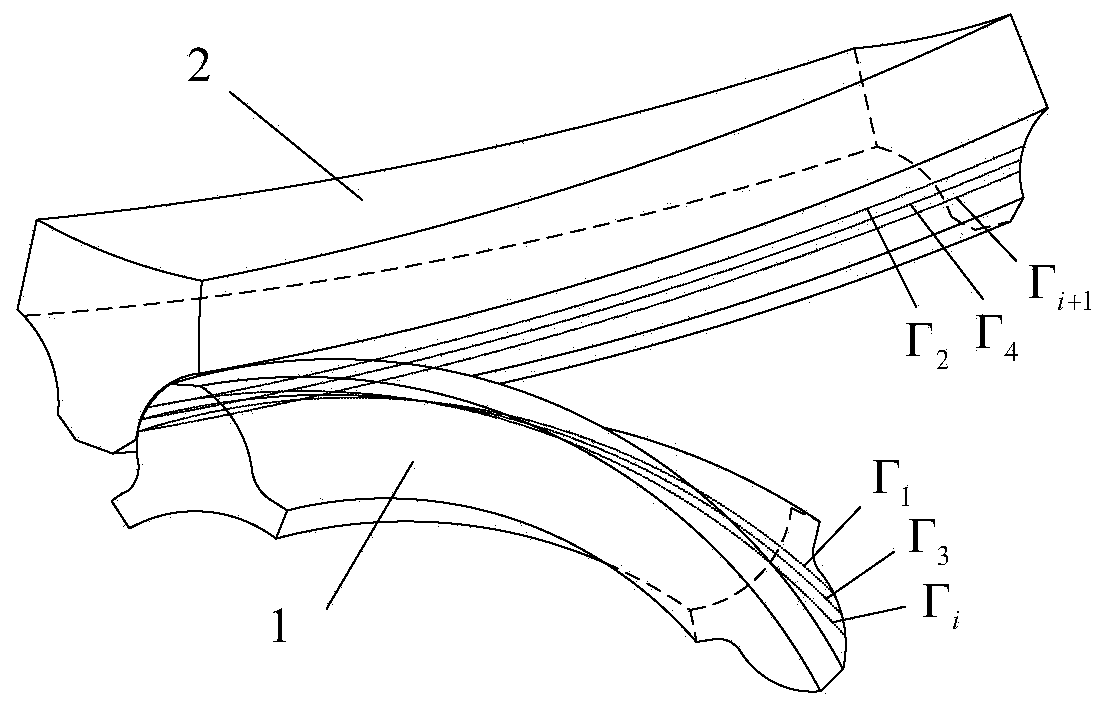

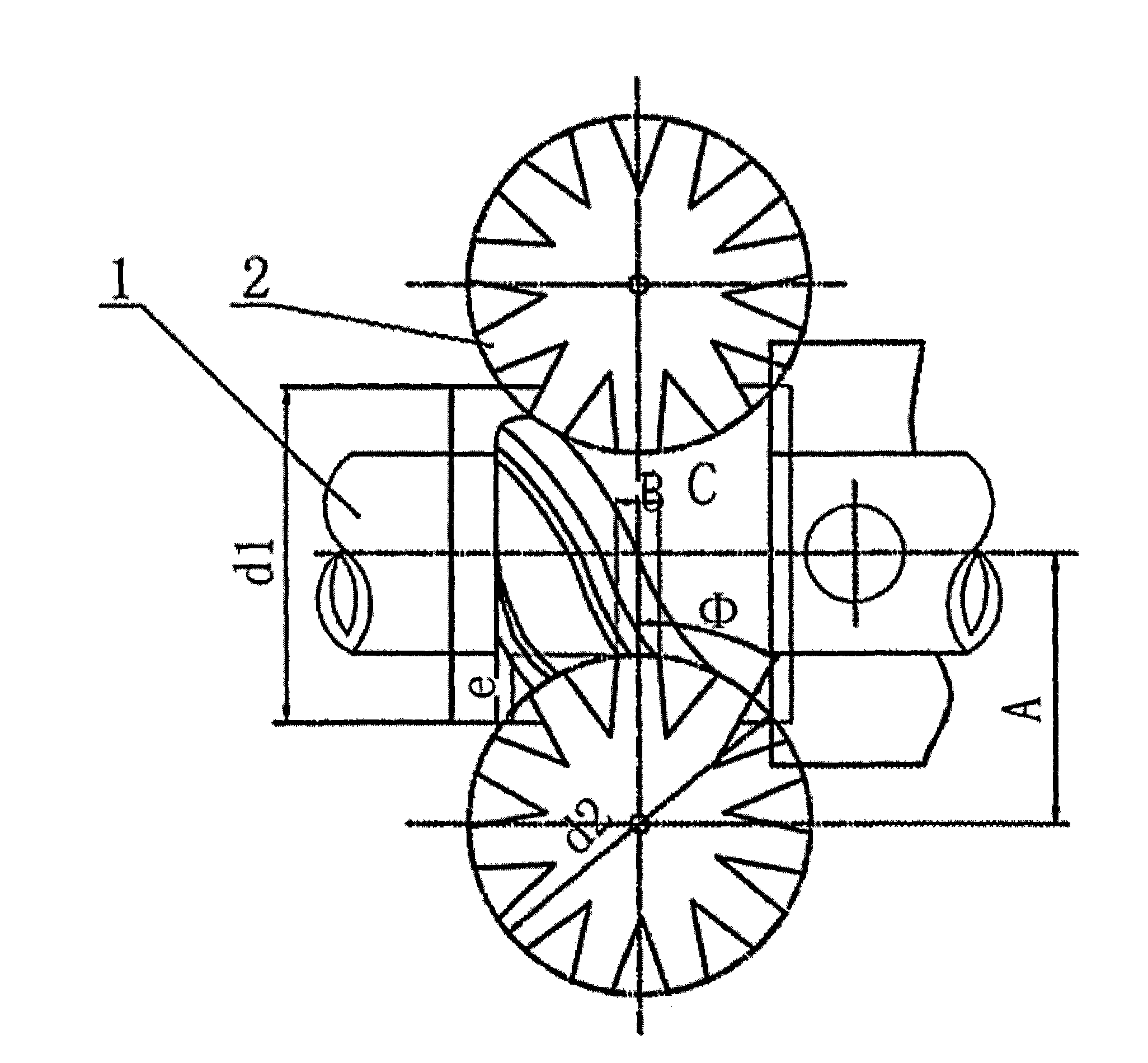

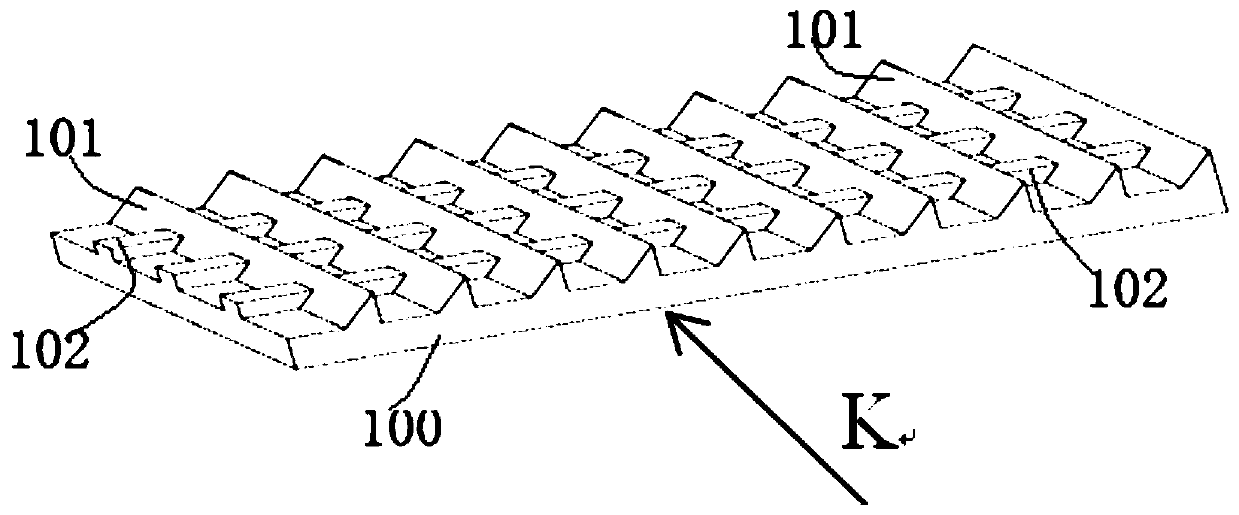

Bevel gear based on conjugate curves and meshing pair thereof

ActiveCN103075493AEasy to processImprove contact strengthToothed gearingsPortable liftingEngineeringContact Transmission

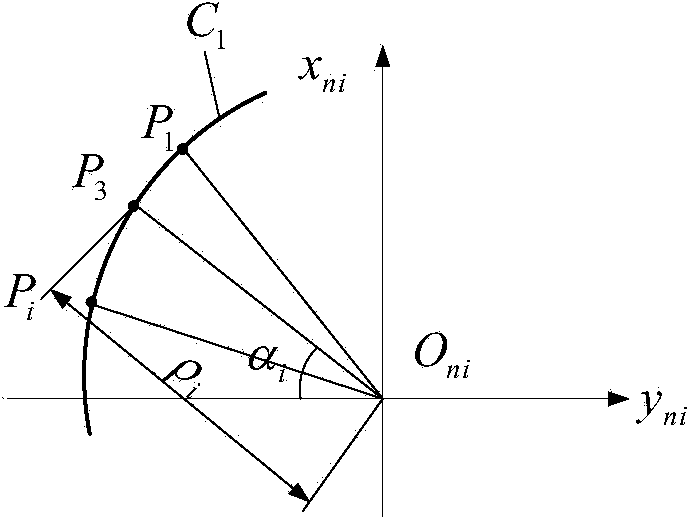

The invention discloses a bevel gear based on conjugate curves and a meshing pair thereof. The meshing pair comprises a bevel gear I and a bevel gear II which are mutually in point meshing and have arc tooth profile curves, and a contact curve gamma1 consisting of meshing points on the tooth profile curve of the bevel gear I and a contact curve gamma2 consisting of meshing points on the tooth profile curve of the bevel gear II are conjugate curves. According to the bevel gear transmission meshing pair based on the conjugate curves, the tooth profile curves of the mutually meshed bevel gear I and bevel gear II are respectively in an arc shape, the meshed tooth surfaces of the bevel gear I and the bevel gear II move along the conjugate curves, the meshing characteristics of the contact curves are succeeded, and the meshing of the contact curves between the tooth surfaces is high in contact strength; a contact transmission process is close to pure rolling along an axial direction, and the transmission efficiency is high; the tooth surfaces are easy to process and manufacture, transmission errors are small, and the service life is long; under the conditions of equivalent transmission ratio and center distance, the selection and determination of a small tooth number and a large modulus can be realized; and the transmission requirements of high speed, heavy load, large power and high efficiency can be met.

Owner:CHONGQING UNIV

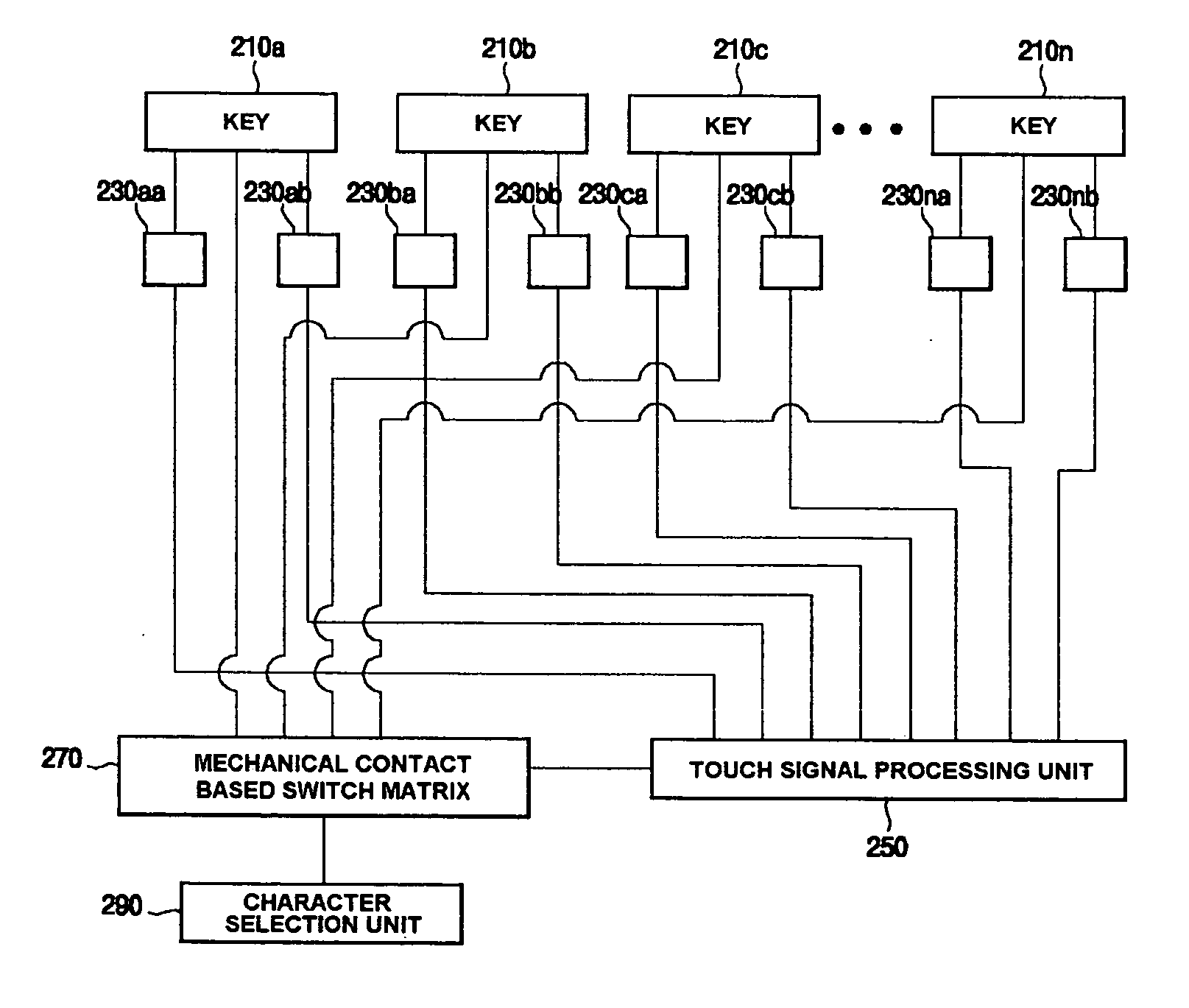

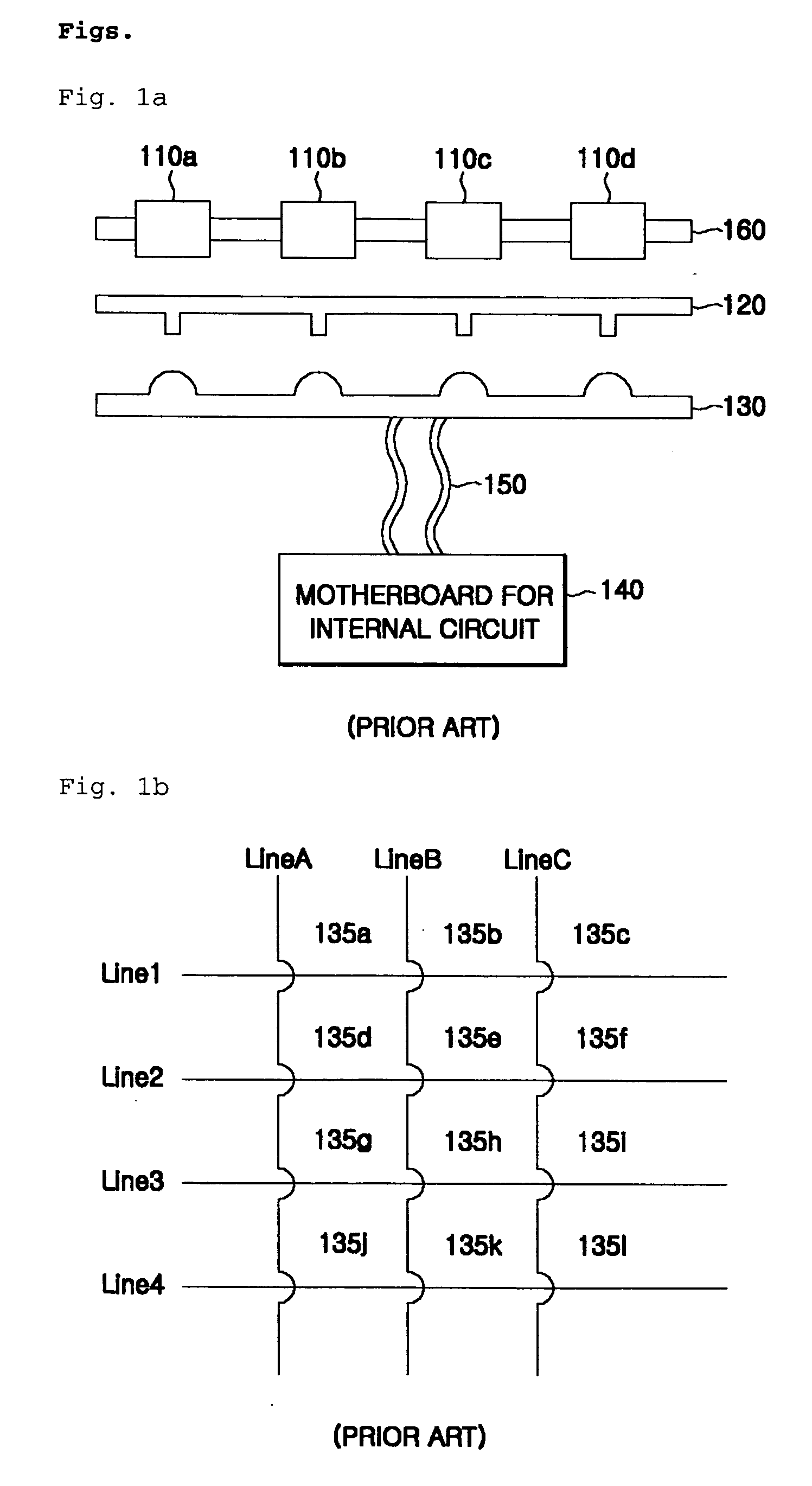

Keypad for enhancing input resolution and method for enhancing input resolution using the same

InactiveUS20060255971A1Increasing input resolutionIncrease inputElectronic switchingSwitch side locationImage resolutionContact strength

The present invention relates to a keypad with built-in touch sensors and touch signal processing units, and a method for increasing the input resolution of the keypad by evaluating a signal of the contact strength and eliminating a redundant signal, which enables a selection of a user's choice in an one-touch one-entry text input mode. The key pad in accordance with the present invention allows for a user to select the desired letter in a single step from a three by four keypad in a one-touch one-entry mode with a high speed and accuracy.

Owner:MCQUINT ELECTRONICS +1

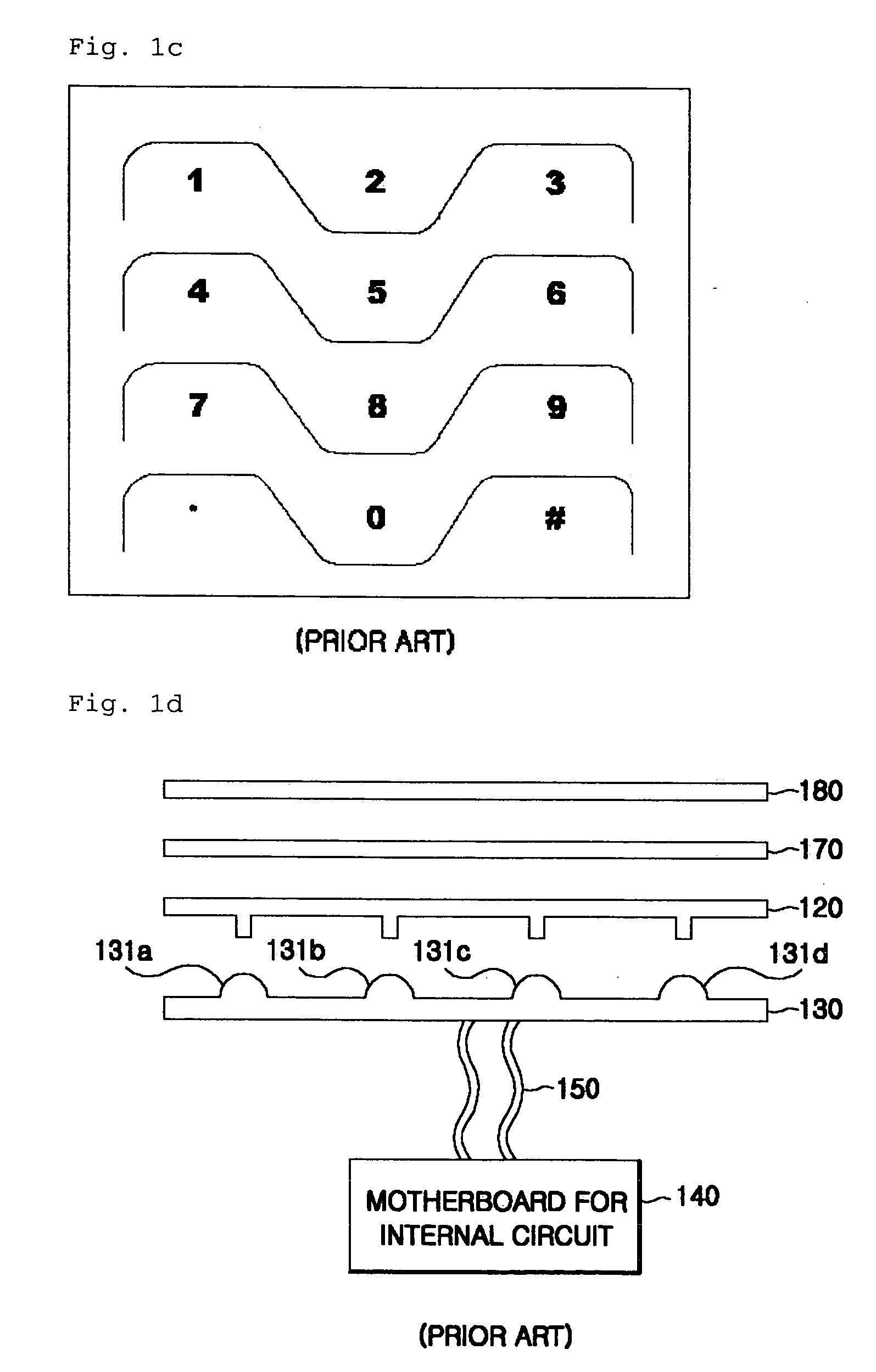

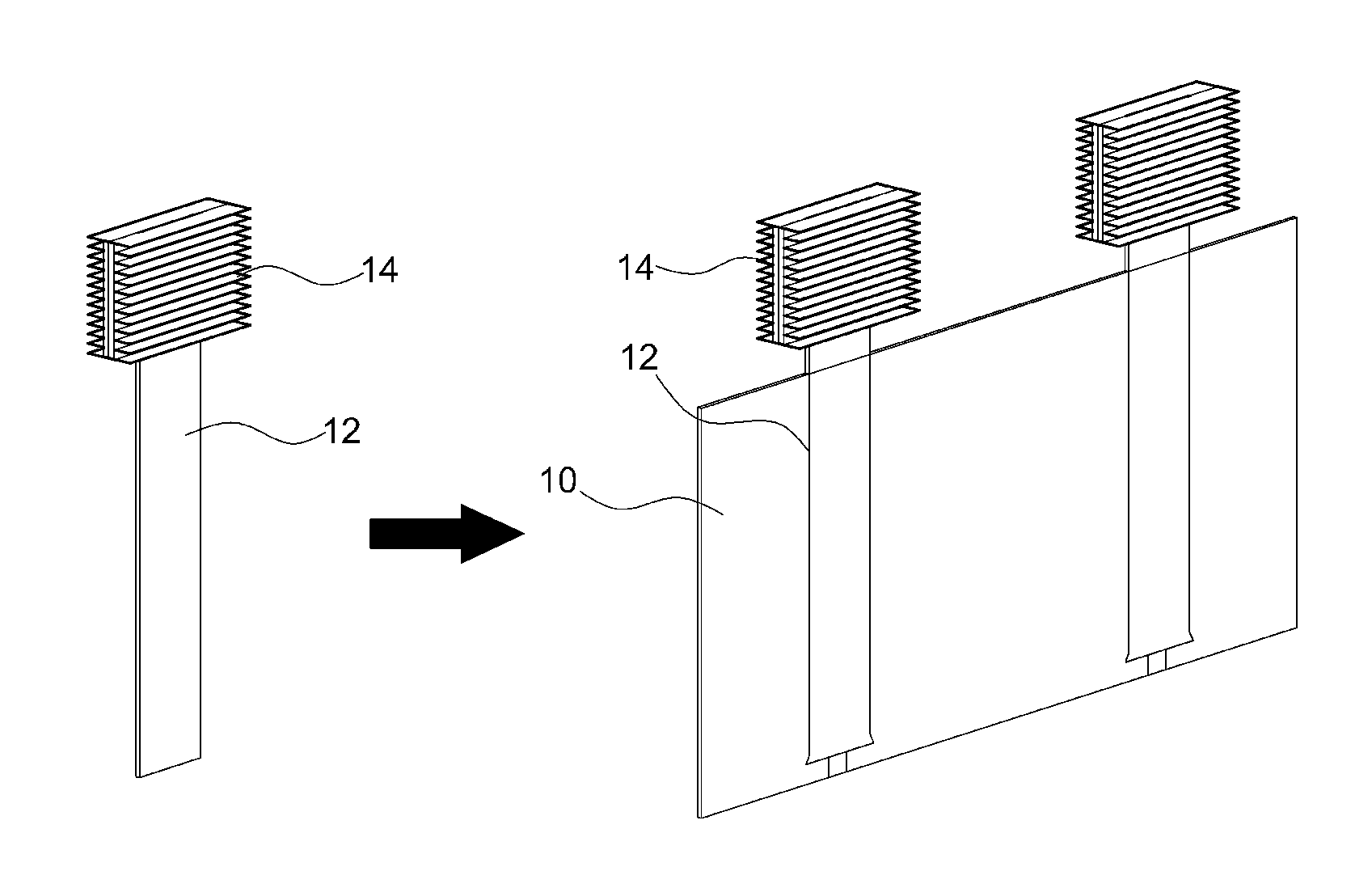

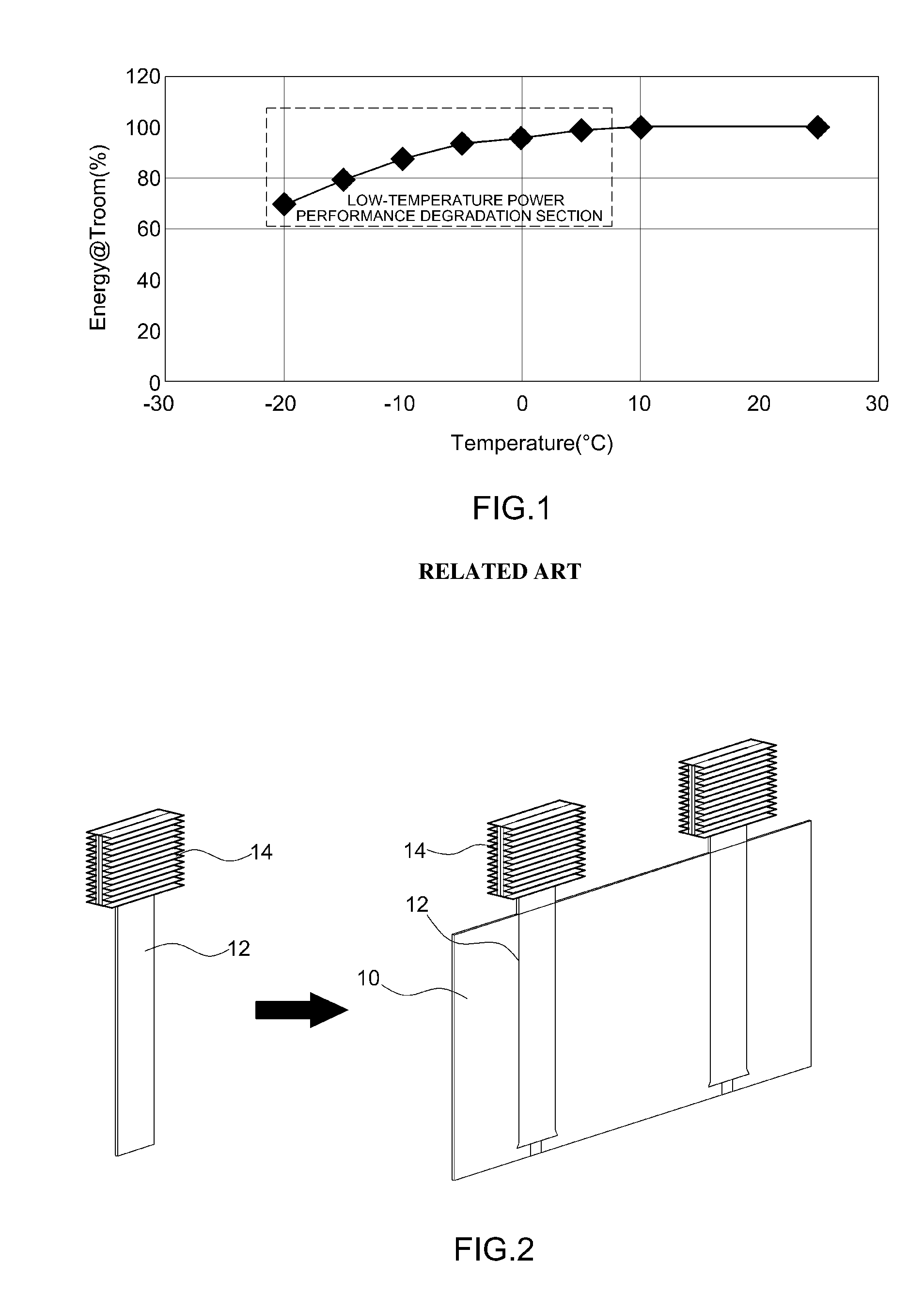

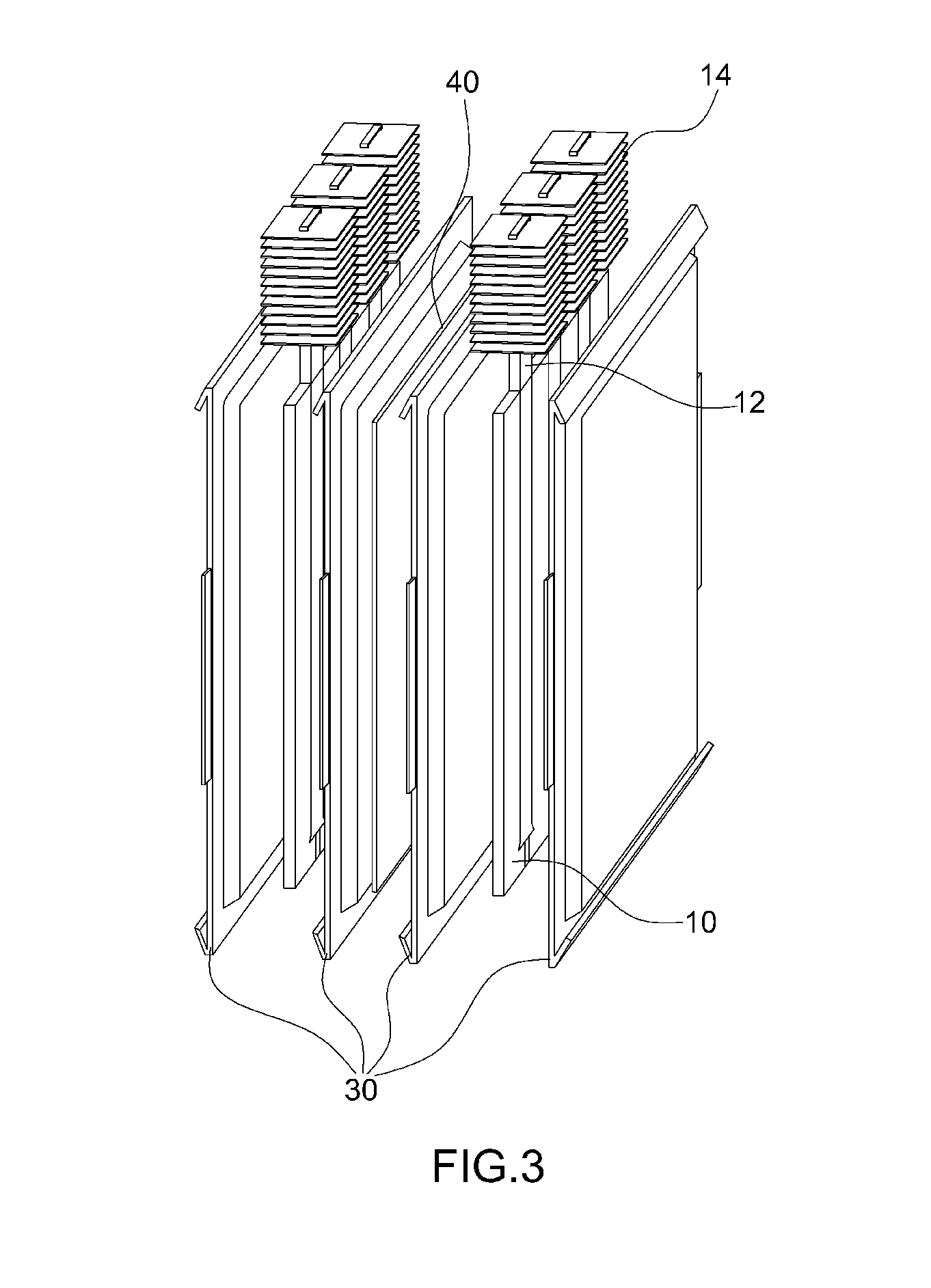

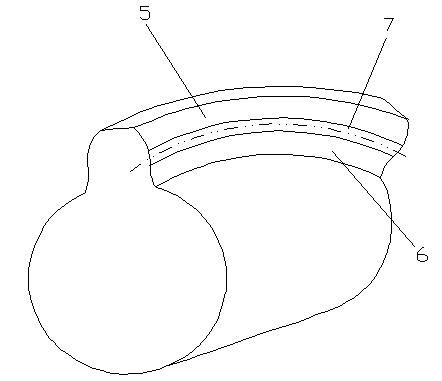

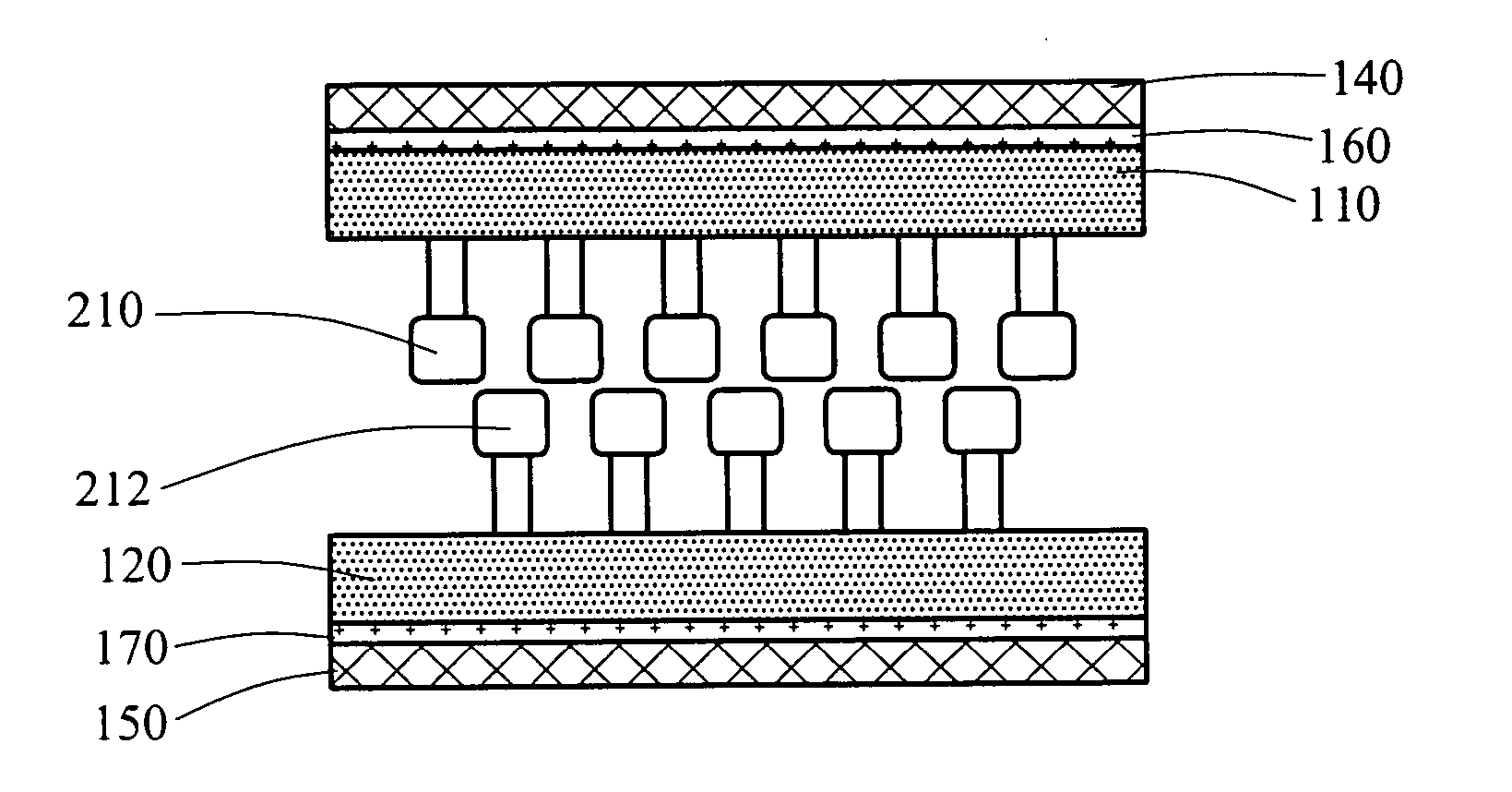

Device for indirectly cooling battery module of eco-friendly vehicle

ActiveUS20140318746A1Improve adhesionMaximizing heat-emission performance of batteryLiquid coolingCell temperature controlIn vehicleEngineering

A device for indirectly cooling a battery module of an eco-friendly vehicle is provided that cools the battery module using an interfacial plate into which a heat pipe is inserted to maximize battery heat emission performance and simultaneously prevent degradation of battery performance. A thermally-conductive interfacial plate in which a heat pipe is embedded by over-molding is disposed between battery cells and a heat sink, which is a condensation unit, integrally connected to an upper end of the heat pipe is disposed in a cooling air flow path to improve contact strength between the interfacial plate and the battery cells. A planar heat emitter is disposed between the battery cells where the interfacial plate is not disposed to heat the battery to a proper-level temperature in a cold-start environment and a low-temperature environment, thereby improving battery performance and preventing degradation in vehicle power.

Owner:HYUNDAI MOTOR CO LTD

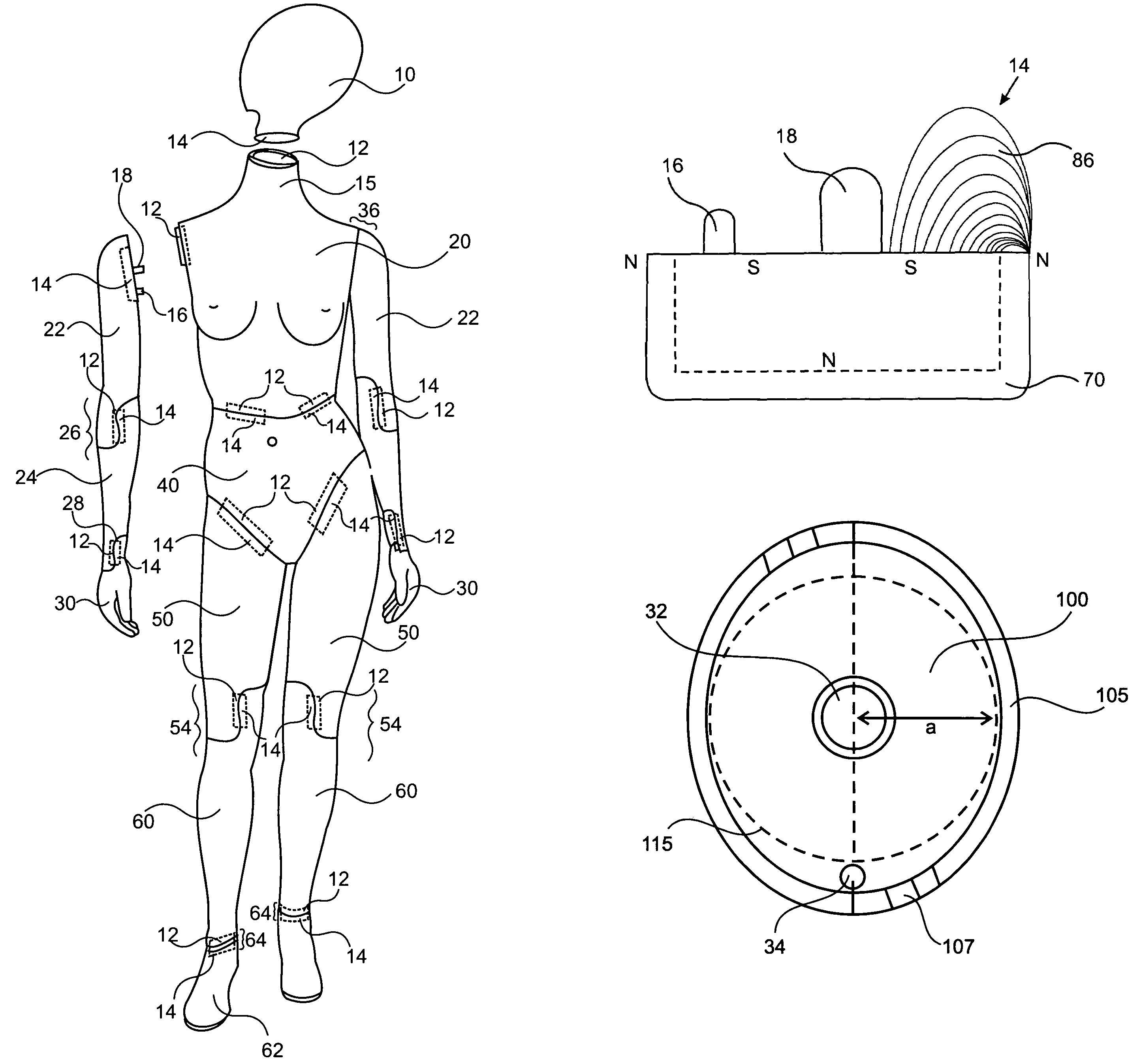

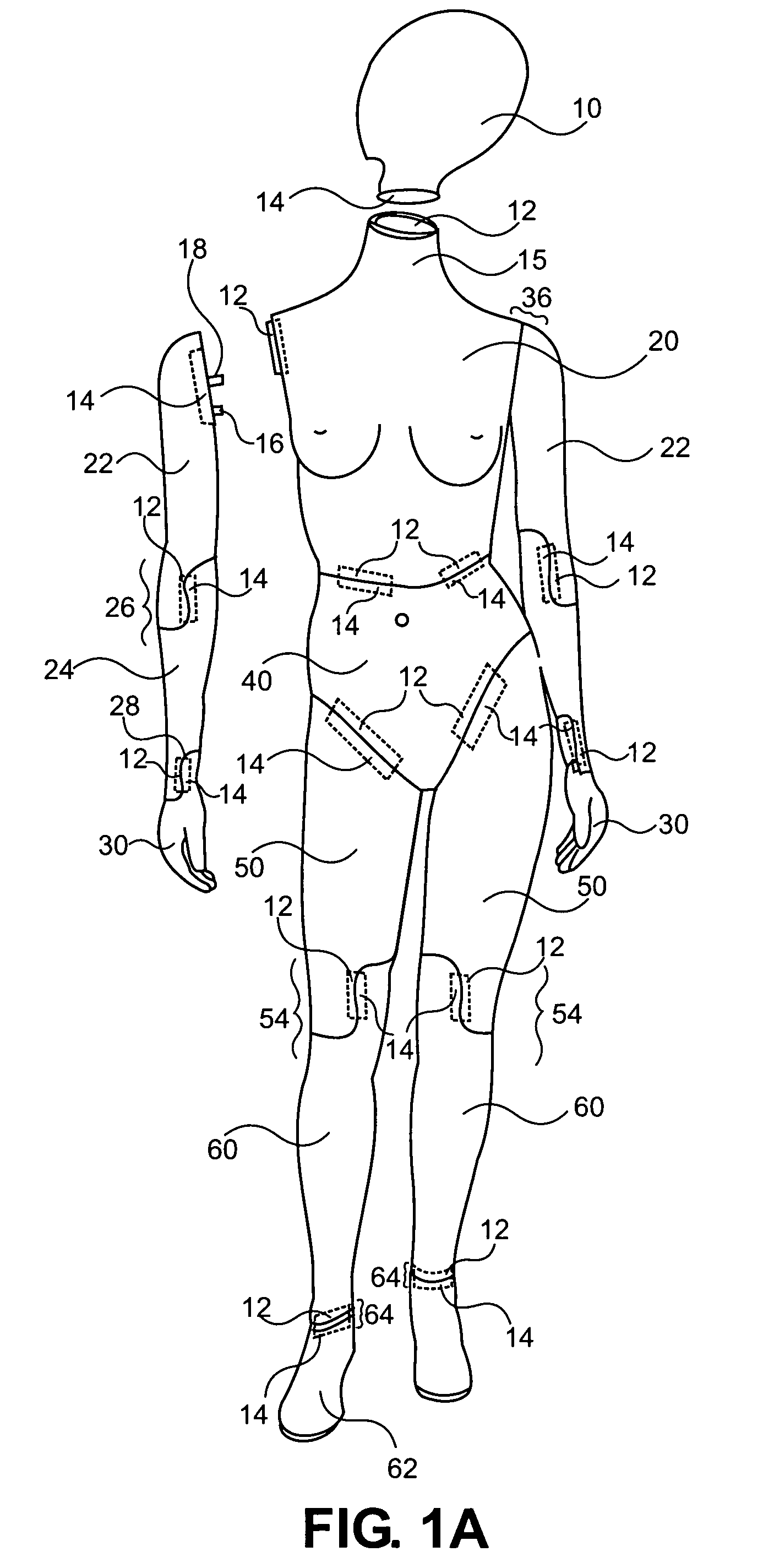

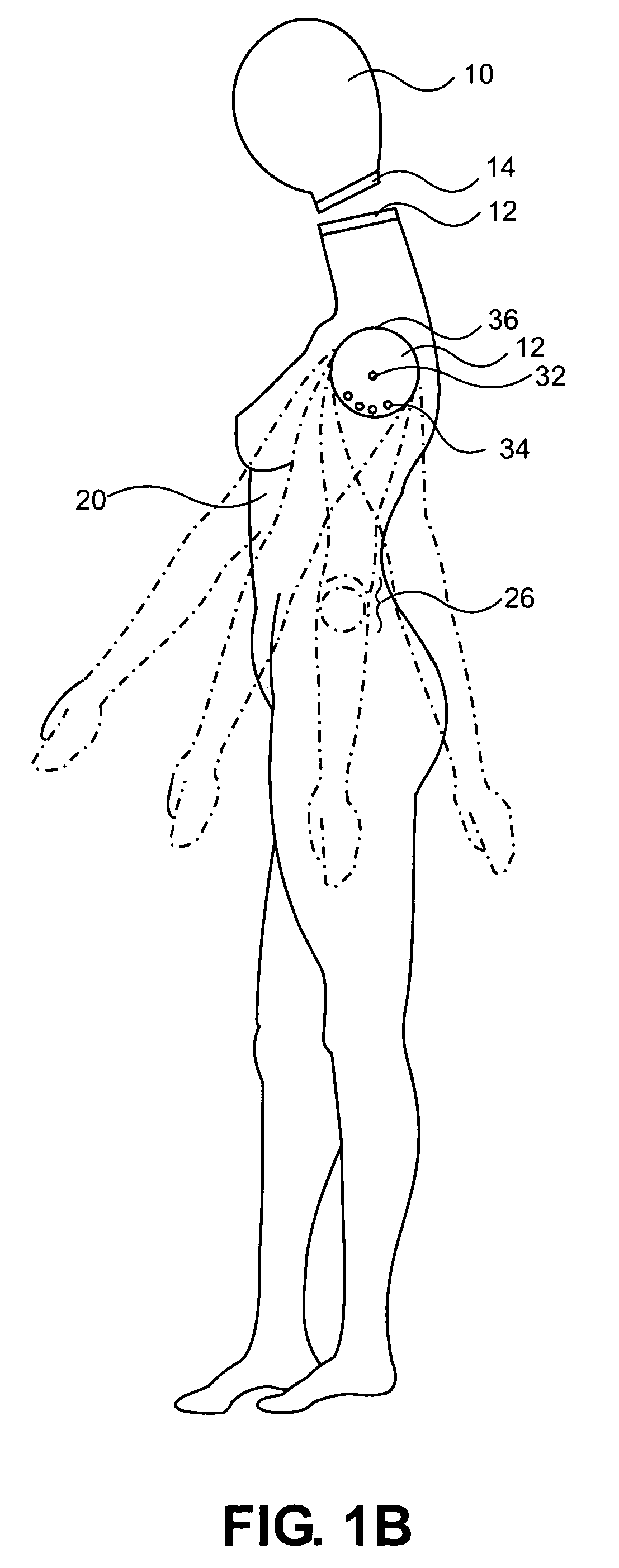

Display form having magnetically attachable parts

InactiveUS7144179B2Aid easeSave a lot of timeFurniture joining partsPivotal connectionsEngineeringUltimate tensile strength

Forms for display of clothing and the like with magnetically attachable parts are provided. The magnetic joints comprise a magnetic assembly with a depth-of-pull sufficient to cause the attachable part to begin to pull toward the form at a distance preferably greater than one-half inch, preferably about one inch. Preferably the magnetic assembly has a depth-of-pull of at least about 120 gauss at a distance of one inch. A metallic plate is arranged in mating configuration with the magnetic assembly. Mating pins may be provided, as well as indexing pins. If the manikin is knocked over, or if the attached part is pulled or bumped, it will come loose rather than breaking off; and the mating parts are self-seeking in use, so that they will come together in proper orientation even when being mated beneath clothes. A bump to the manikin sufficient to overcome the on-contact strength of the magnetic attachment may not result in detachment of the limb because of the depth-of-pull strength of the magnetic assembly. The indexing pins allow the limbs to be placed in a variety of positions.

Owner:NOA BRANDS AMERICA

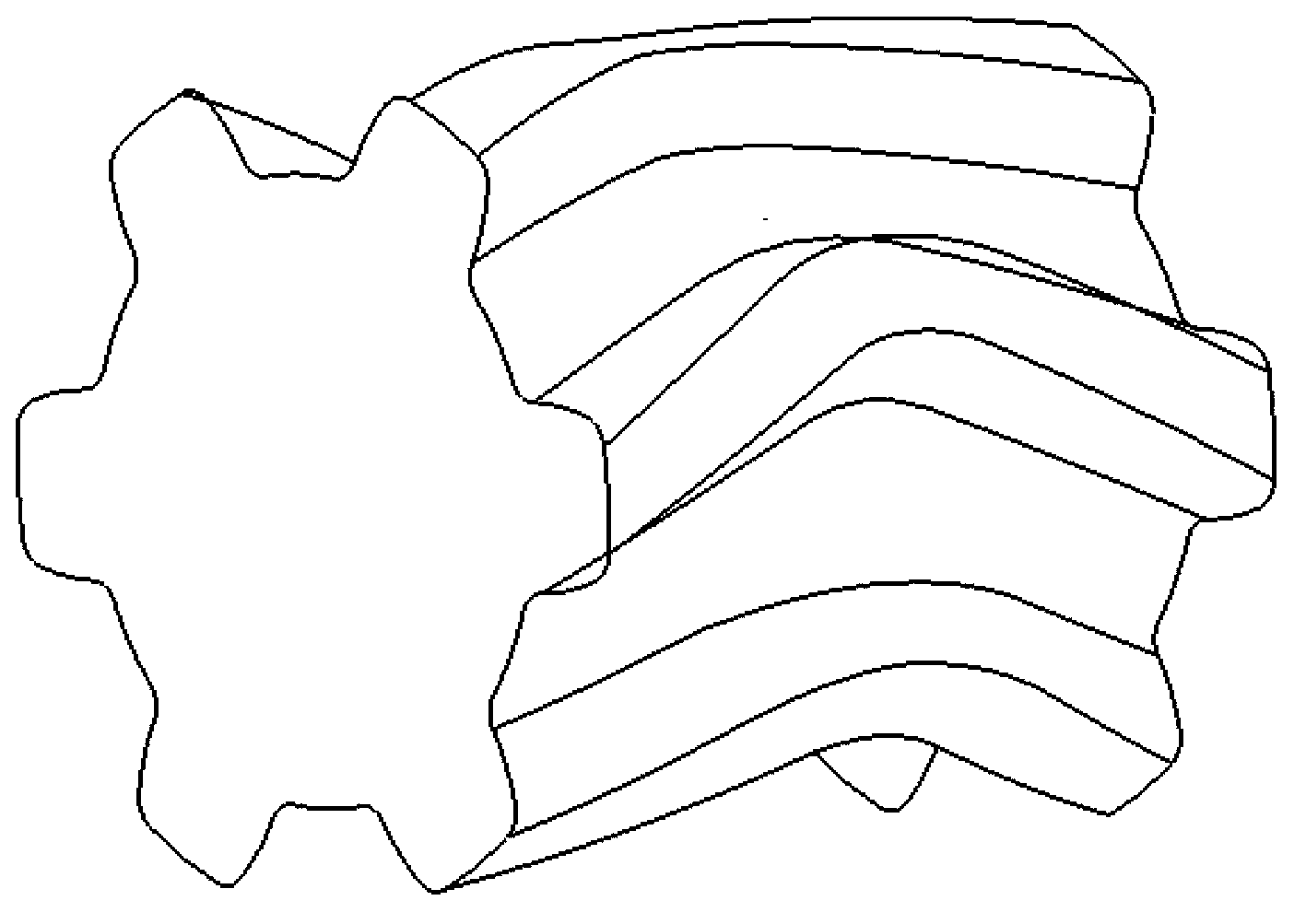

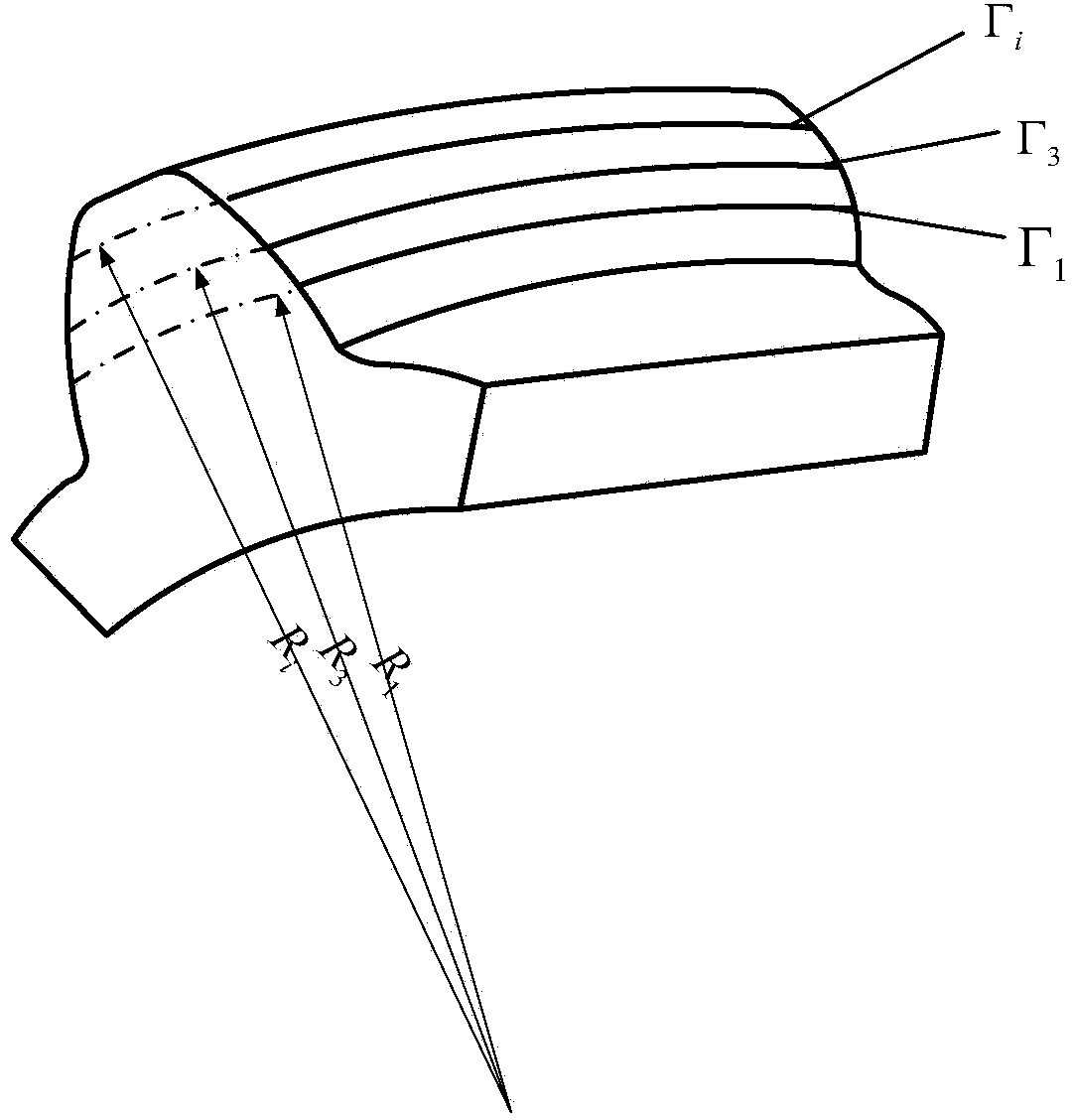

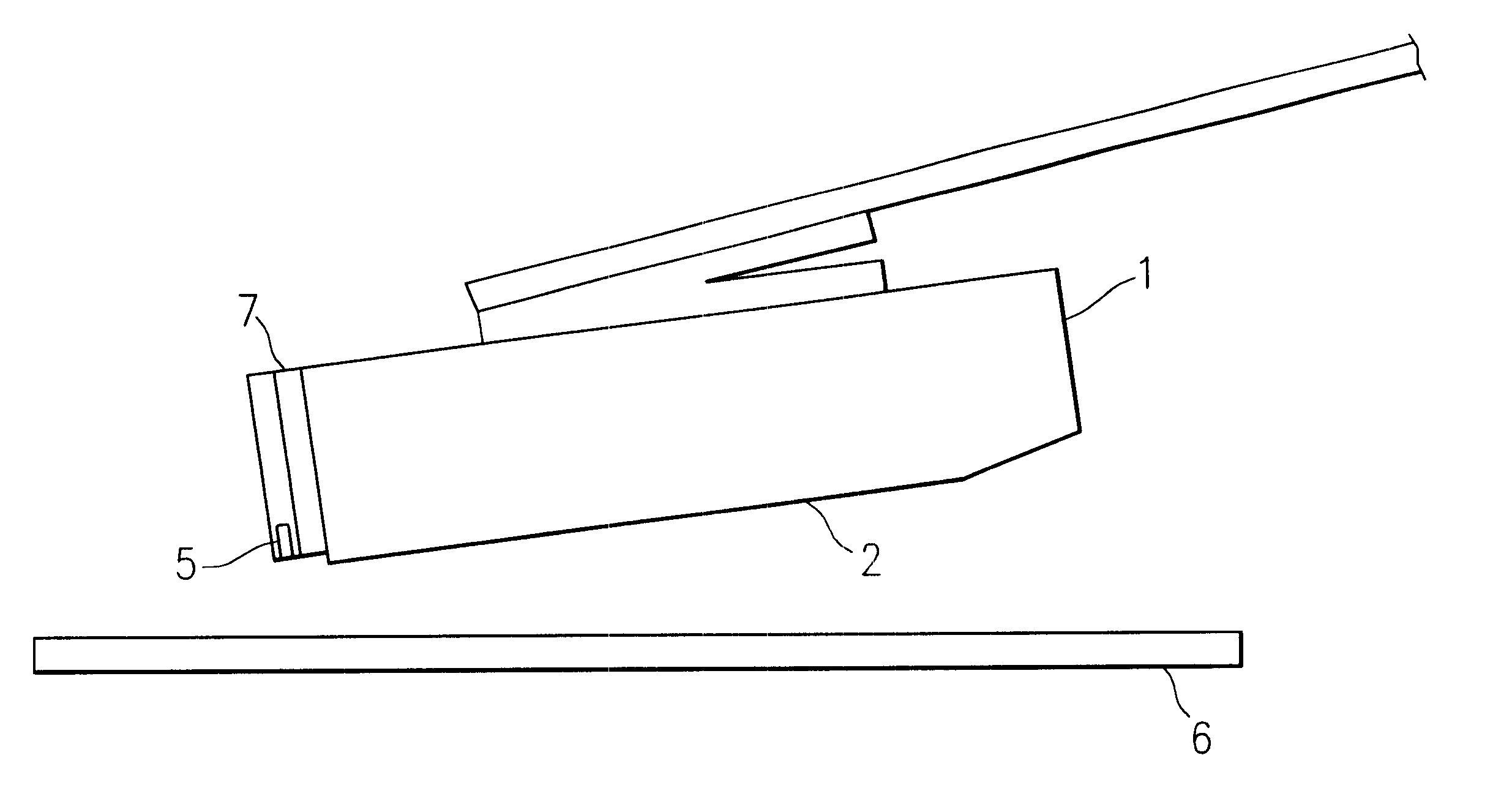

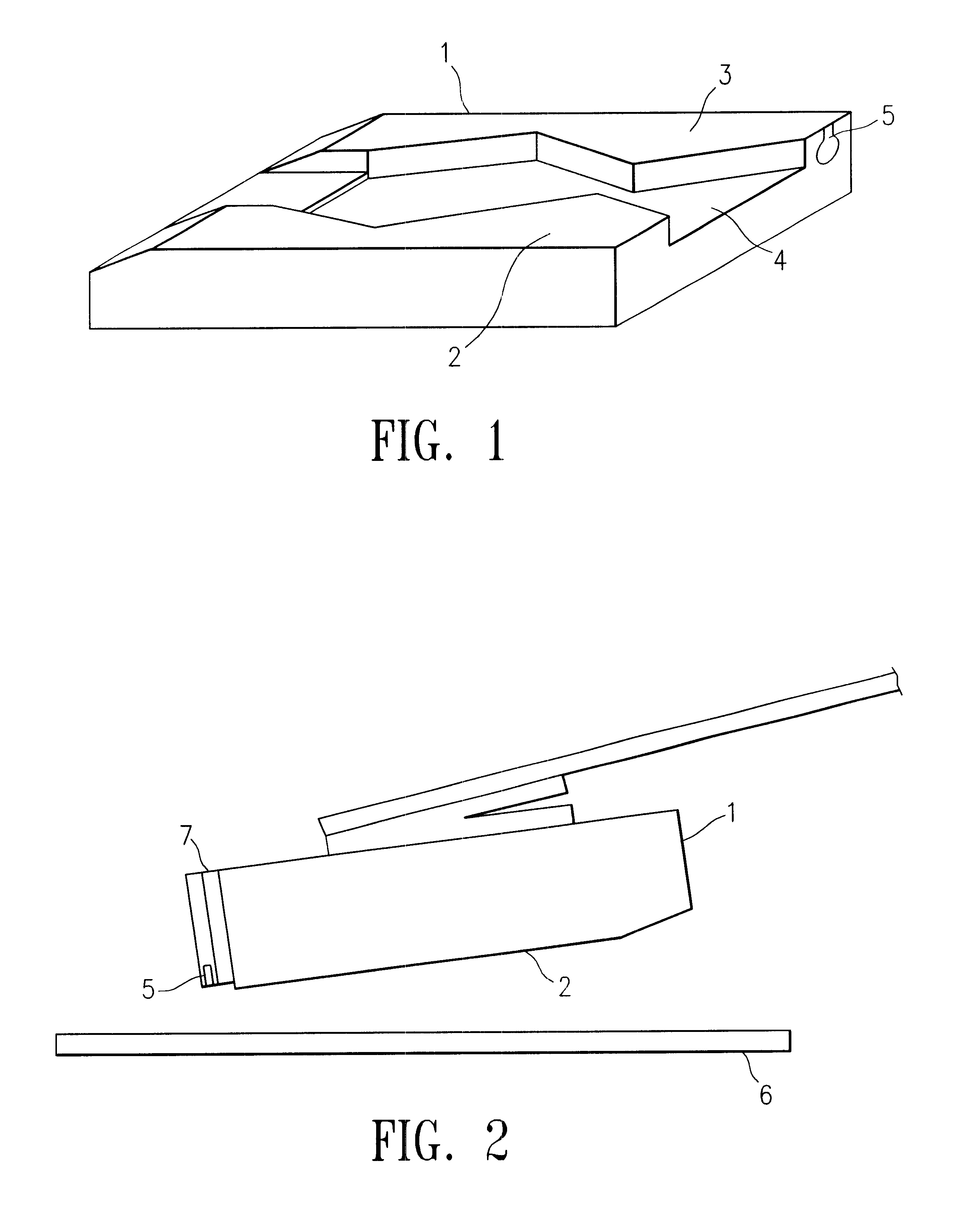

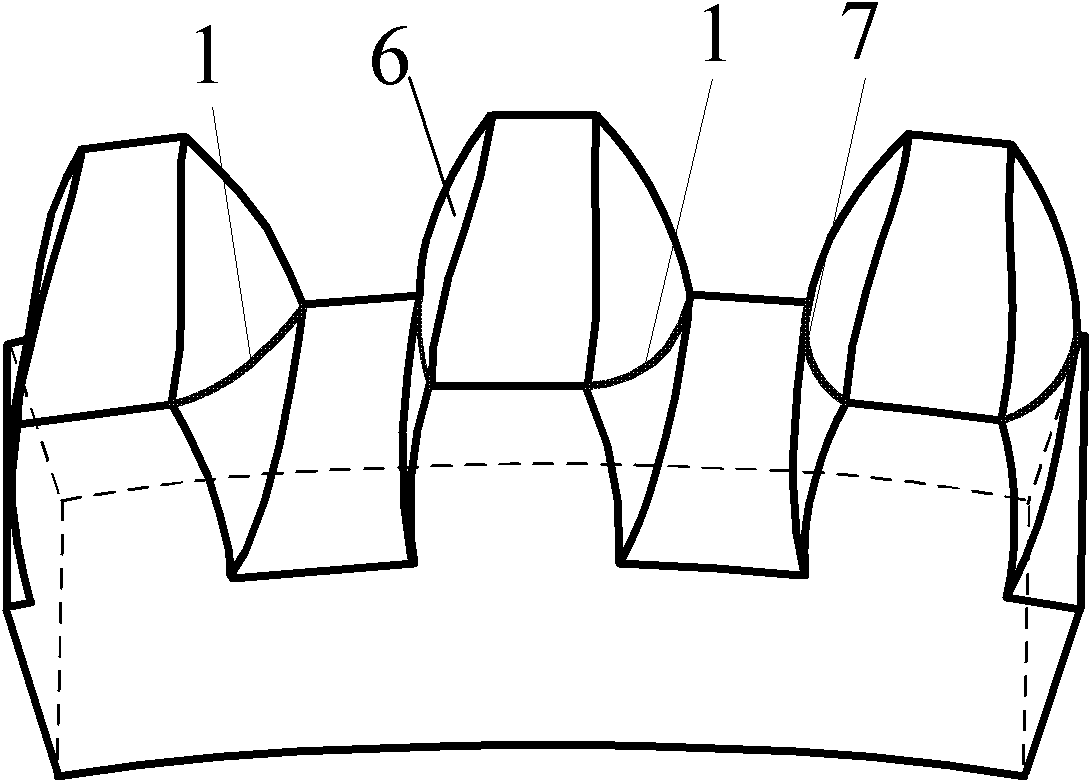

Curve conjugation based symmetrical cambered surface conjugate curve gears and engagement pair thereof

ActiveCN102853054AImprove contact strengthImprove transmission efficiencyPortable liftingGearing elementsSmall toothContact Transmission

The invention discloses curve conjugation based symmetrical cambered surface conjugate curve gears and an engagement pair thereof. The engagement pair comprises a gear I and a gear II, wherein the gear I and the gear II are engaged with each other in a point contact mode, and a contact curve gamma 1 which is composed of engagement points on a tooth profile cambered surface of the gear I and a contact curve gamma 2 which is composed of engagement points on a tooth profile cambered surface of the gear II are conjugate curves. According to the engagement pair of the curve conjugation based symmetrical cambered surface conjugate curve gears, the contact curve gamma 1 of the gear I and the contact curve gamma 2 of the gear II which form the engagement pair are conjugate curves, and engagement points between the gear I and the gear II move along contact curves; the engagement pair has the advantages of point contact engagement, tooth profiles of point contact have the high contact strength, the contact transmission process is close to pure rolling along the axial direction, and the transmission efficiency is high; and the selection and the determination of the small tooth number and the large modulus can be achieved on the conditions of the same transmission ratio and the same center-to-center distance, the transmission requirements of high speed, heavy load, high power and high efficiency can be met, and the engagement pair has broad application prospects.

Owner:CHONGQING UNIV

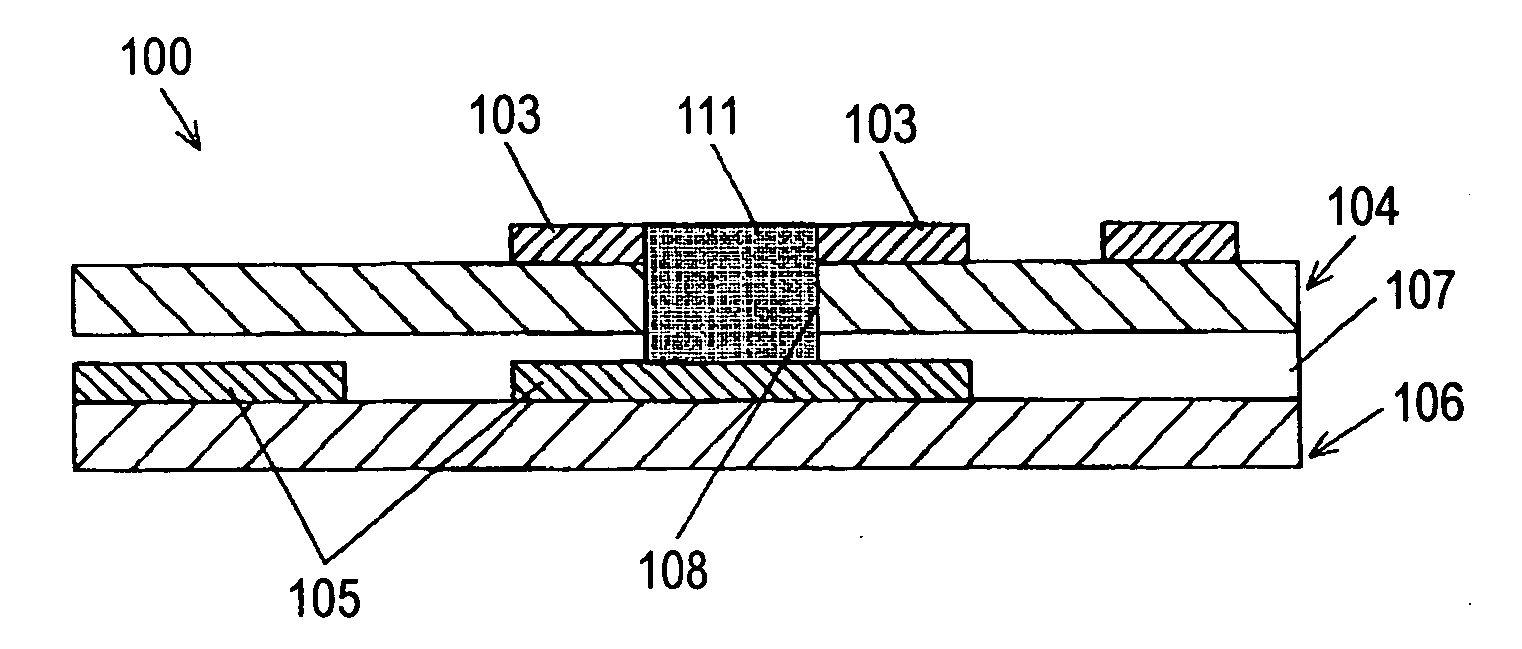

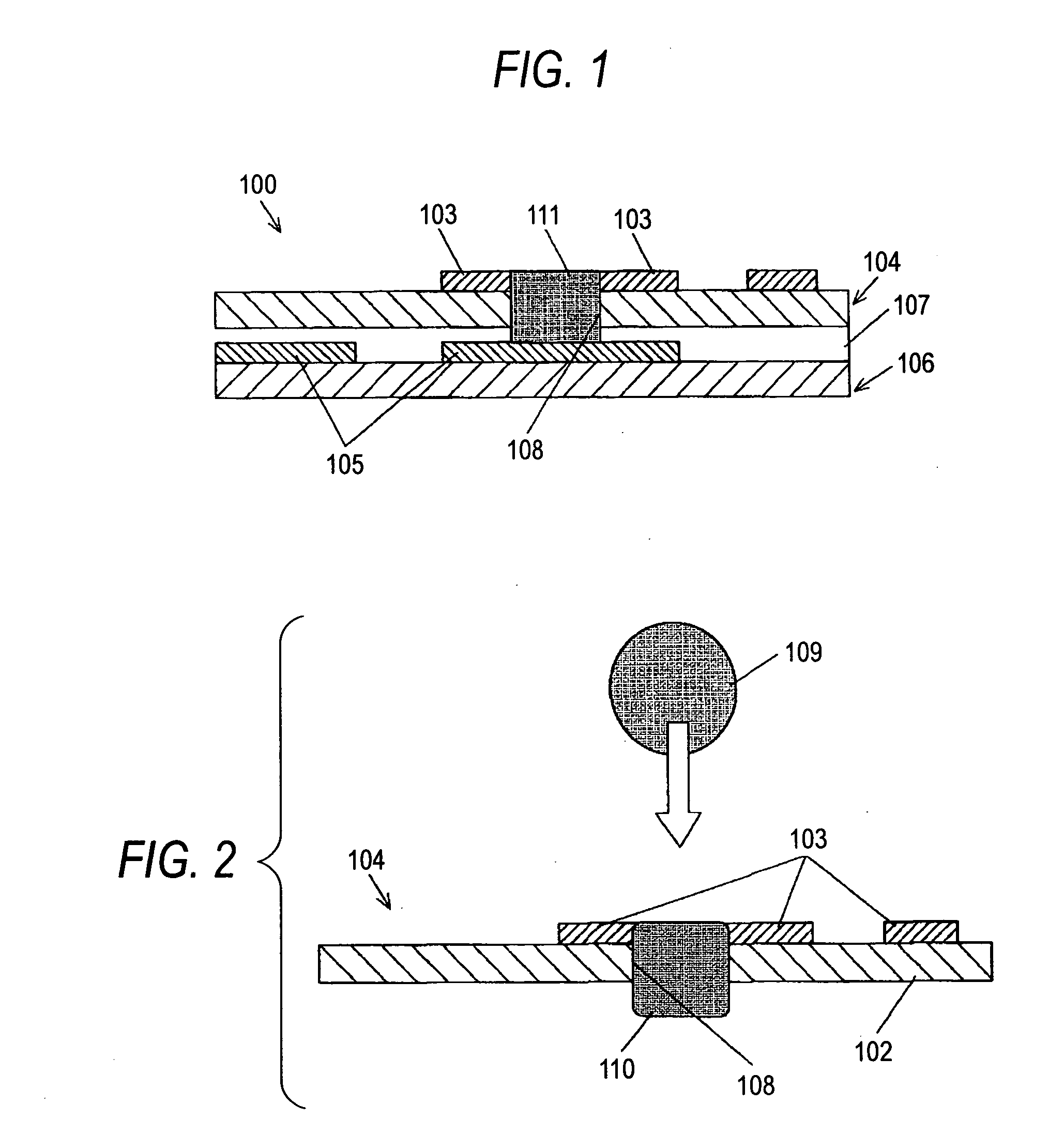

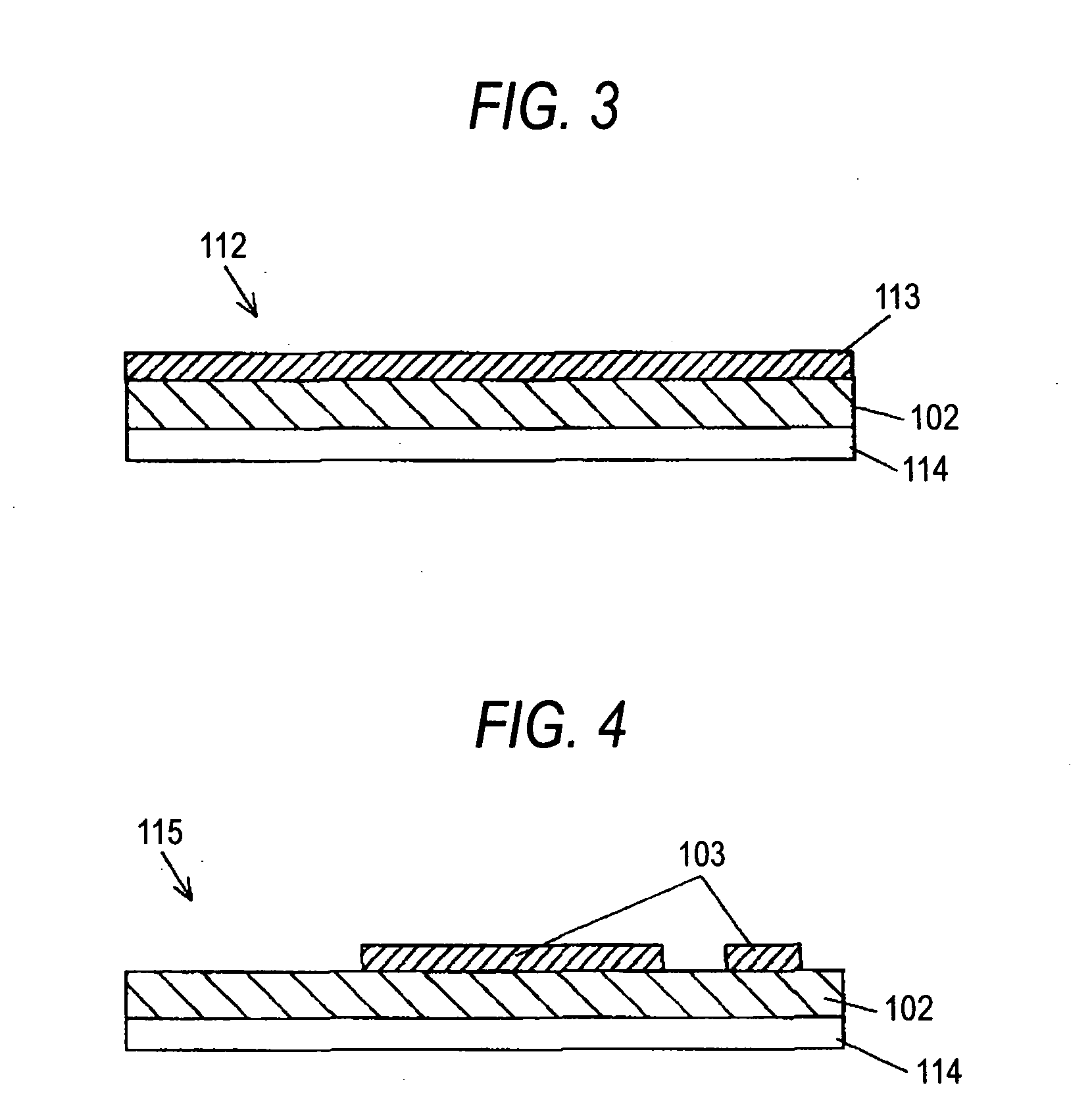

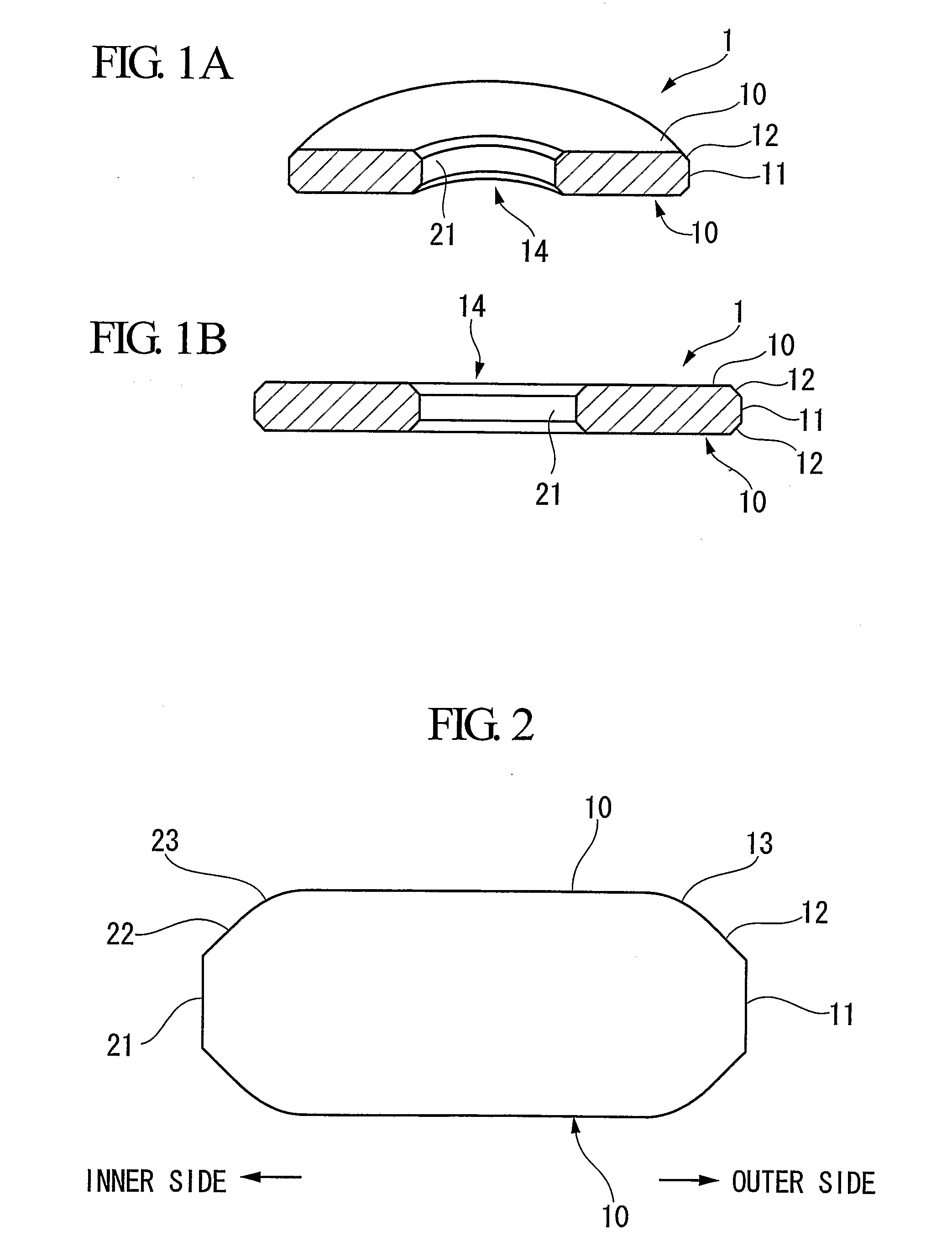

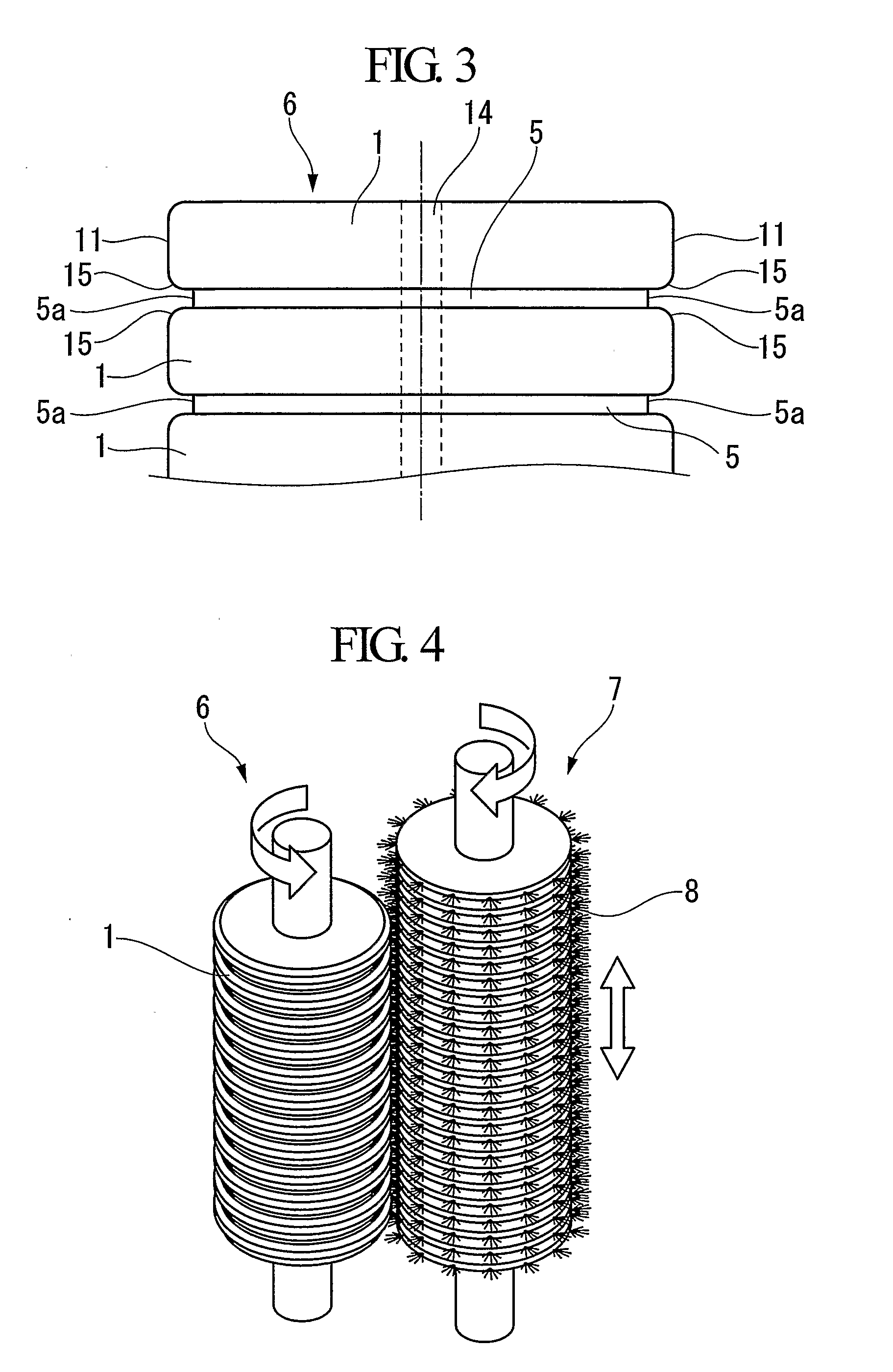

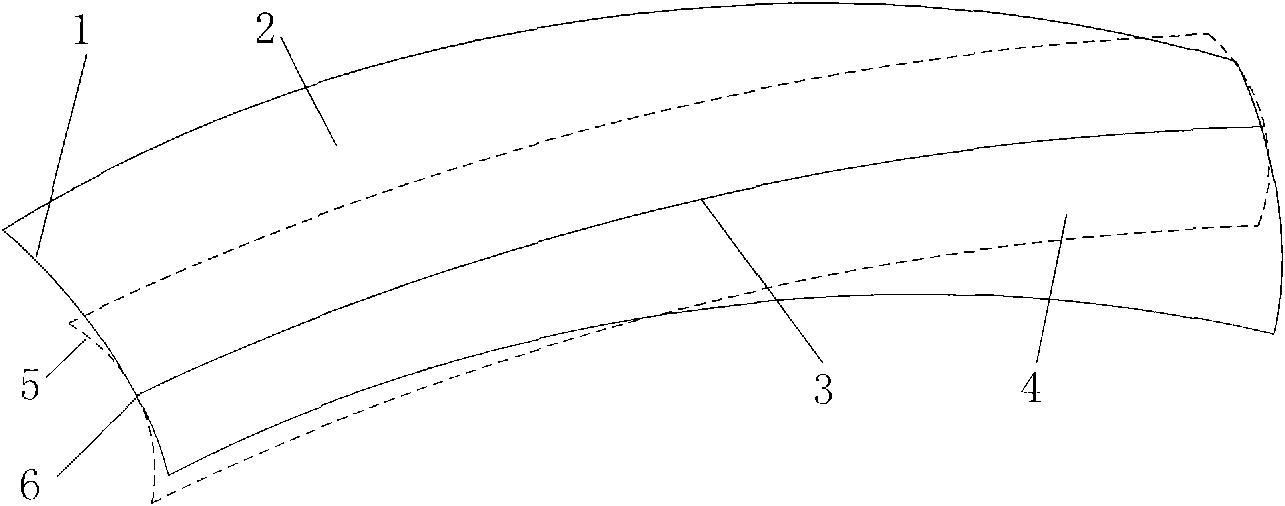

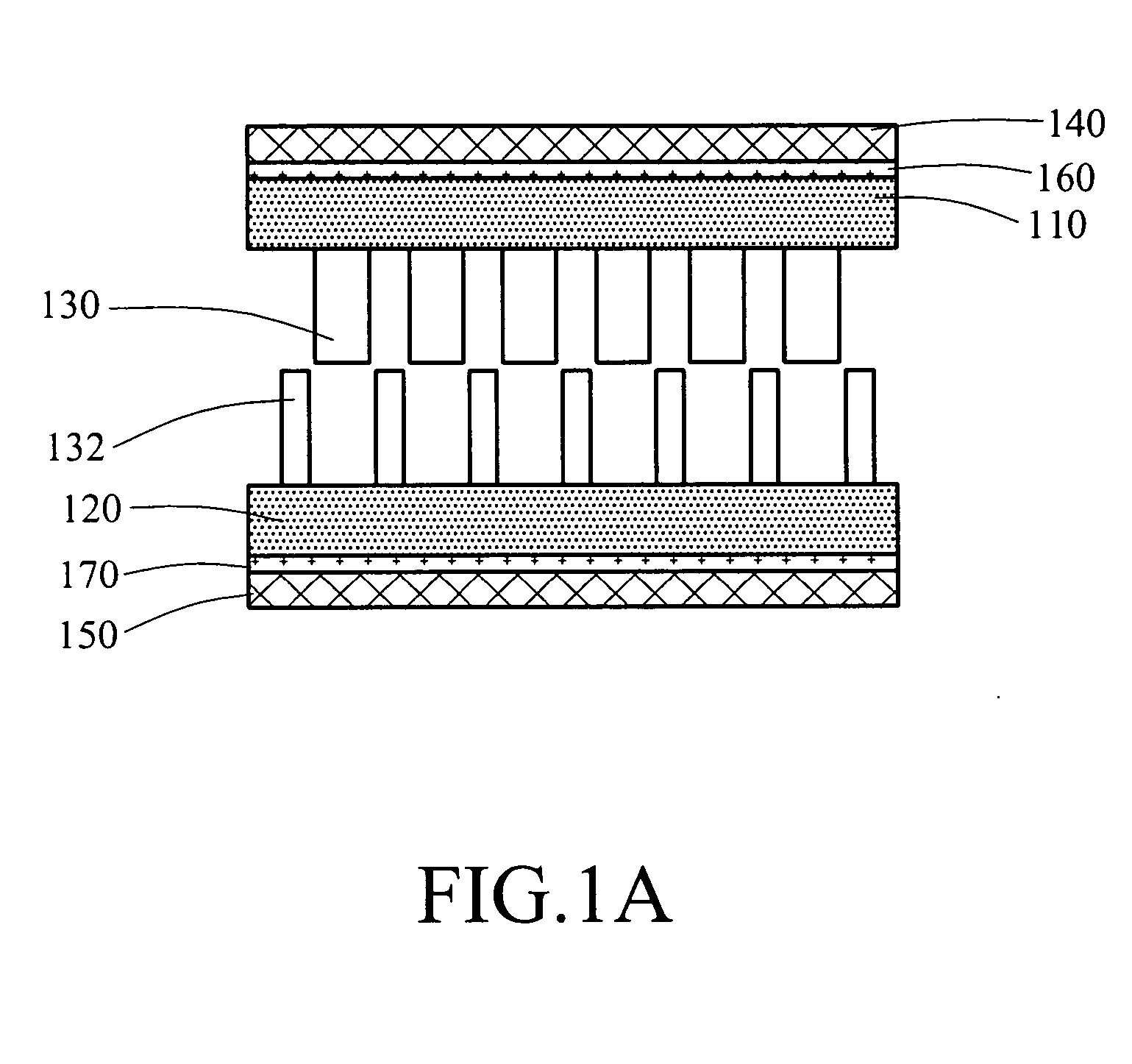

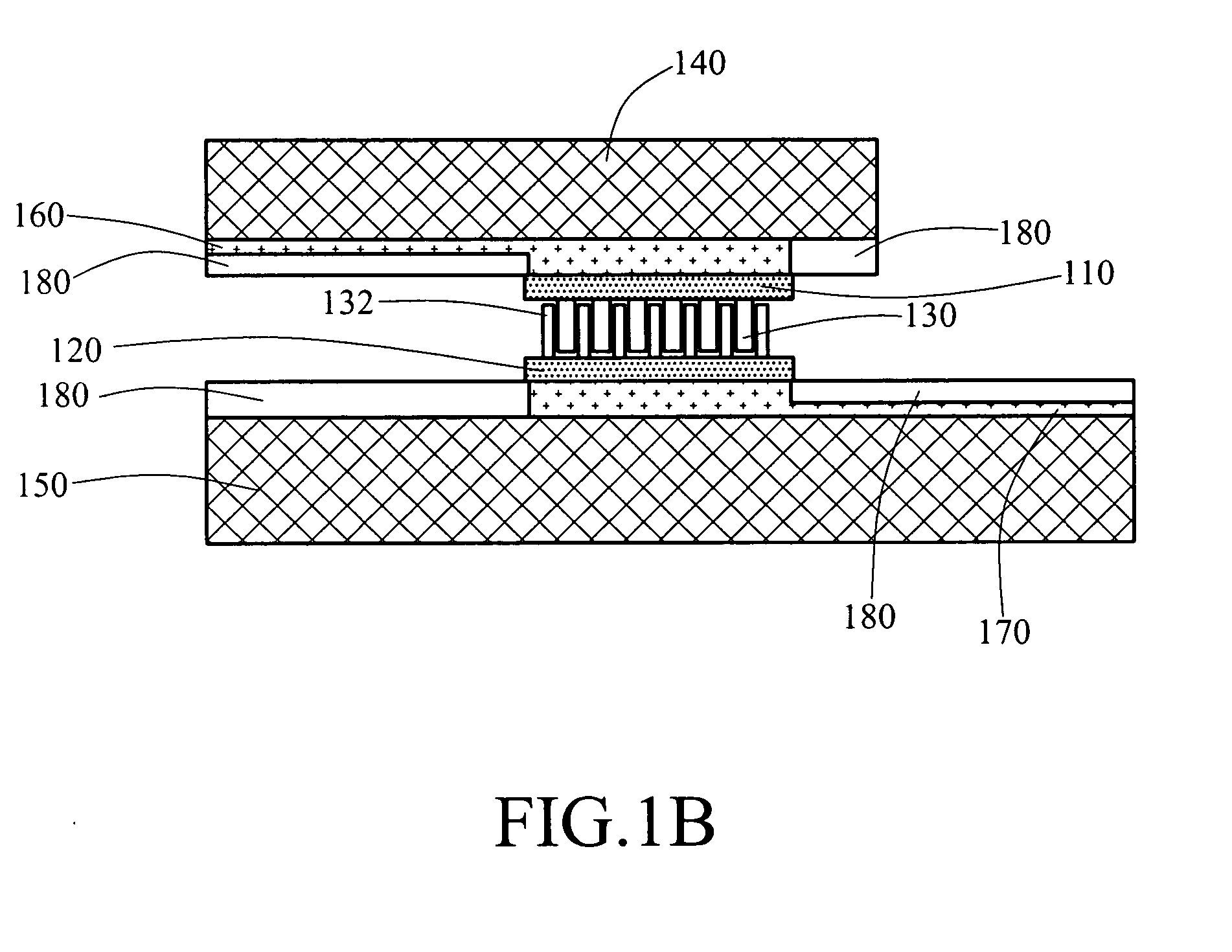

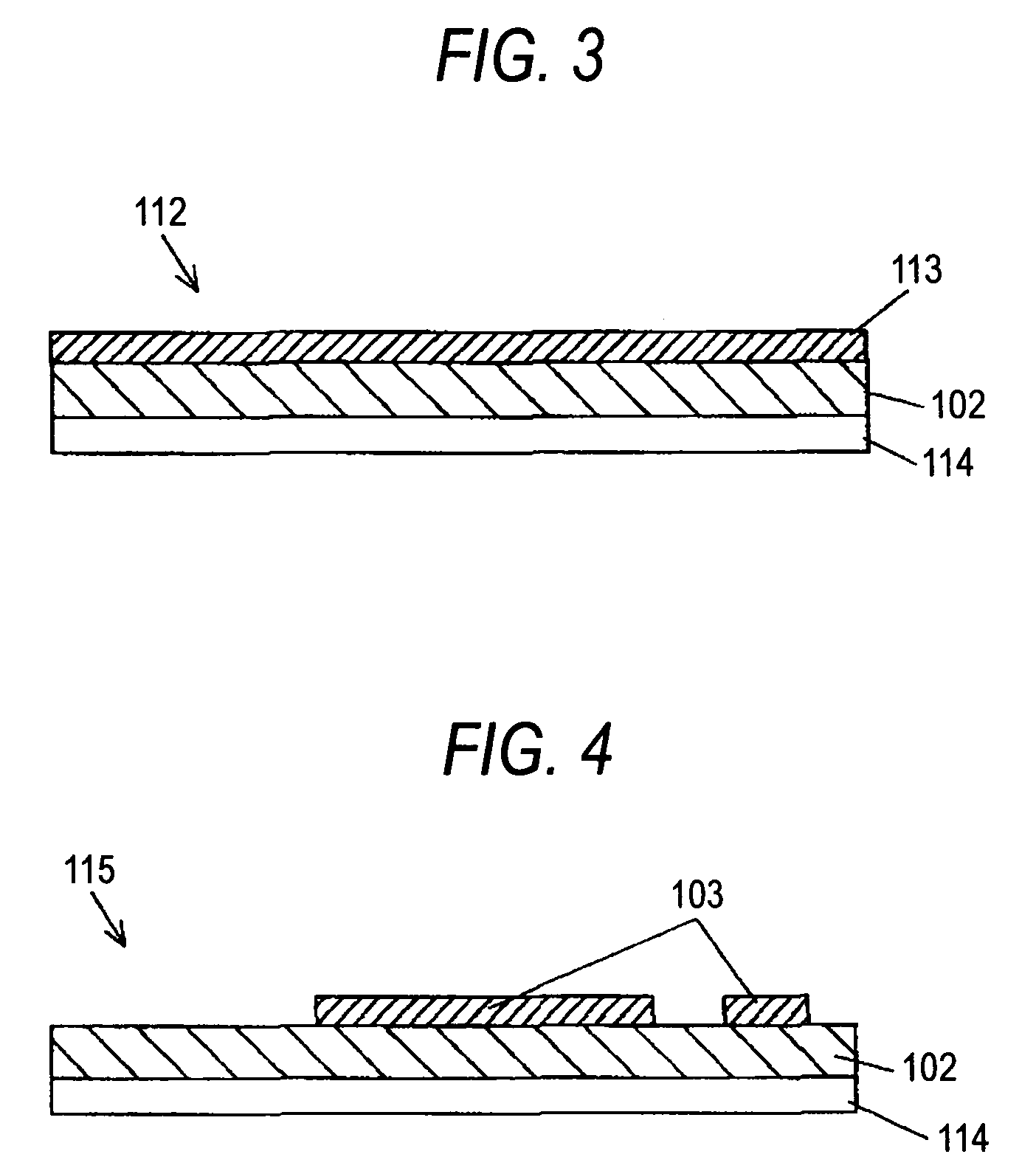

Multi-layered flexible print circuit board and manufacturing method thereof

InactiveUS20070148829A1Improve connection reliabilityImprove productivityPrinted circuit assemblingLine/current collector detailsElectrical conductorFlexible electronics

Provided is an FPC, which comprises an insulating layer 2, wiring layers 3 and 4 laminated above and under the insulating layer 2, and a layer connection for connecting the wiring layers 3 and 4 electrically. The layer connection is constituted to comprise: a conductor press-fit hole 5 of a cone shape extending through the insulating layer 2 and the upper and lower wiring layers 3 and 4 and expanded to the side of one wiring layer 3; and a conductor 6 filled and press-fitted without any clearance in the conductor press-fit hole such that it is jointed to the wiring upper layer 3 deformed into the cone shape of the conductor press-fit hole 5, and is protruded from the other wiring lower layer 4 to have its surface partially coated and jointed. As a result, the contact area between the wiring layers 3 and 4 and the conductor 6 filled in the conductor press-fit hole 5 can be enlarged to retain the contact strength between the wiring layers 3 and 4 and the conductor 6 sufficiently thereby to provide a high connection reliability for the layer connection.

Owner:PANASONIC CORP

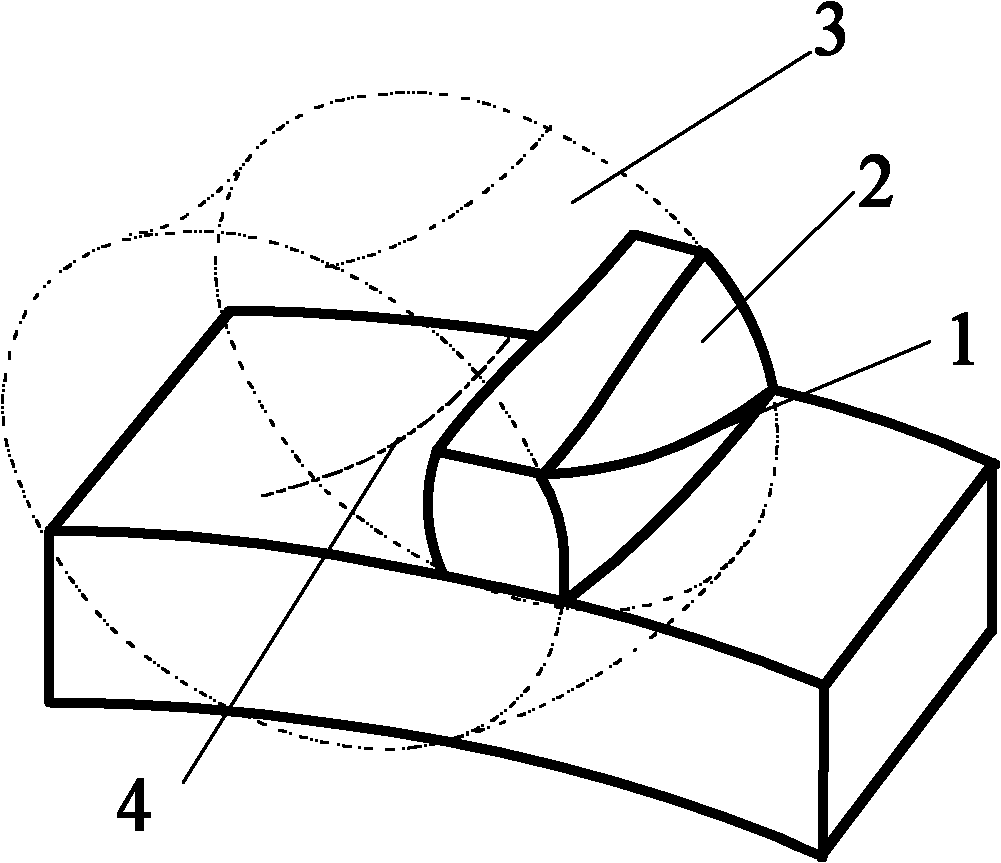

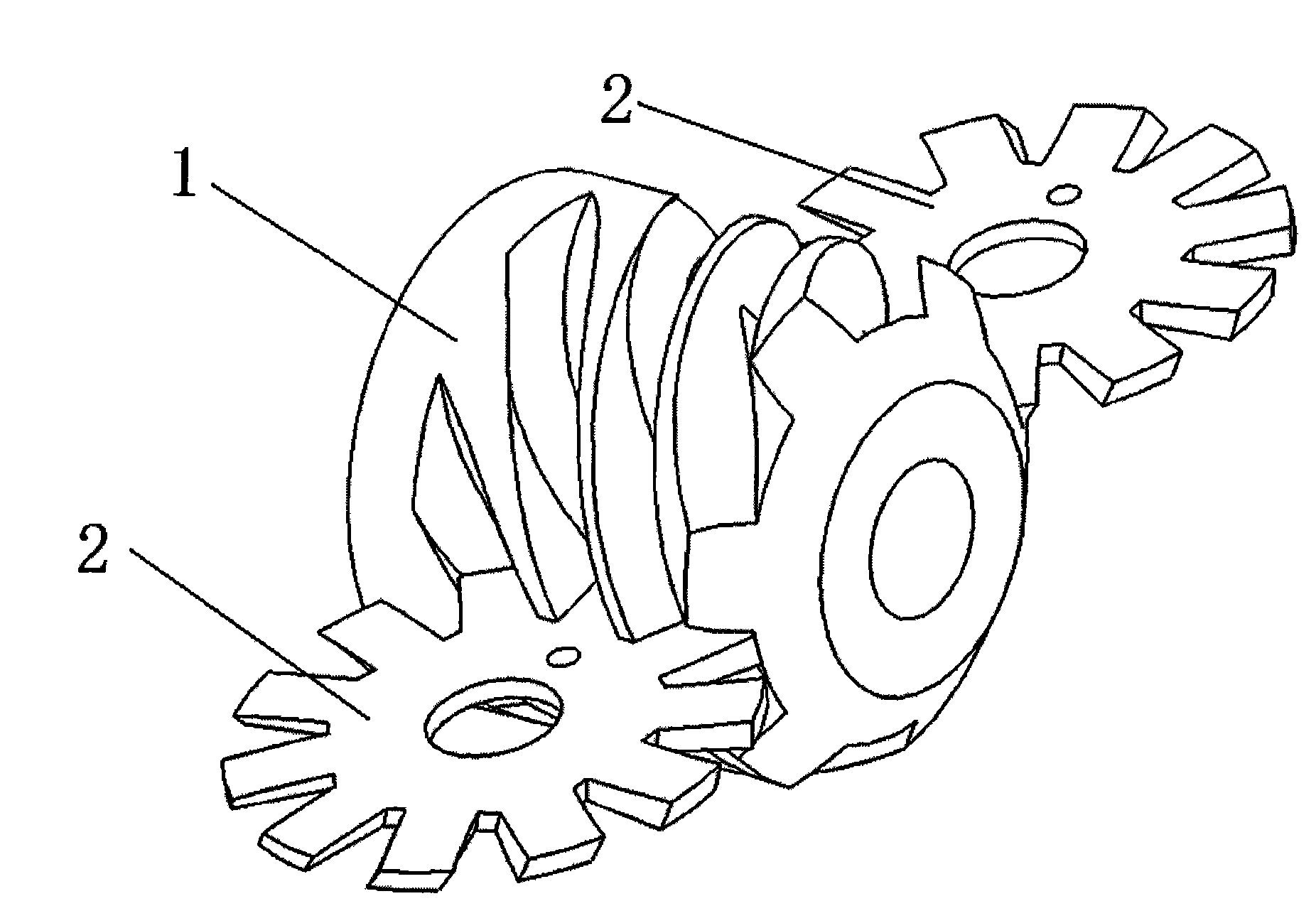

Point contact gear and meshing pair based on conjugate curves and machining tool thereof

ActiveCN103939575AReduce processing costsImprove transmission efficiencyPortable liftingGear teeth manufacturing toolsEngineeringGear tooth

The invention discloses a point contact gear and a meshing pair based on conjugate curves and a machining tool of the point contact gear and the meshing pair. The point contact gear comprises a convex gear and a concave gear which are in one-point or multi-point contact meshing, and a contact curve composed of meshing points on a tooth profile curved surface of the convex gear and a contact curve composed of meshing points on the concave gear are the conjugate curves. According to the point contact gear meshing pair based on the conjugate curves, a convex gear tooth surface and a concave gear tooth surface are in one-point or multi-point contact at the same time according to the meshing mode of the meshing pair, and the contact tracks of the contact points on the tooth surfaces are smooth space curves. The meshing characters of the conjugate curves are inherited by the transmission, point contact tooth profiles are high in contact strength, high in bearing capacity, high in transmission efficiency and low in lubricating oil temperature rise, the sliding ratio is greatly lowered, and abrasion is low. Meanwhile, gear meshing achieves one-point contact or double-point contact or multi-point contact at the same time through different contact curves according to different use needs, and the problem that an existing point contact gear with a ball race pipe type envelope surface with a sphere center moving along a circle center curve as a tooth profile curved surface only achieves one-point contact in the meshing process is solved.

Owner:CHONGQING UNIV

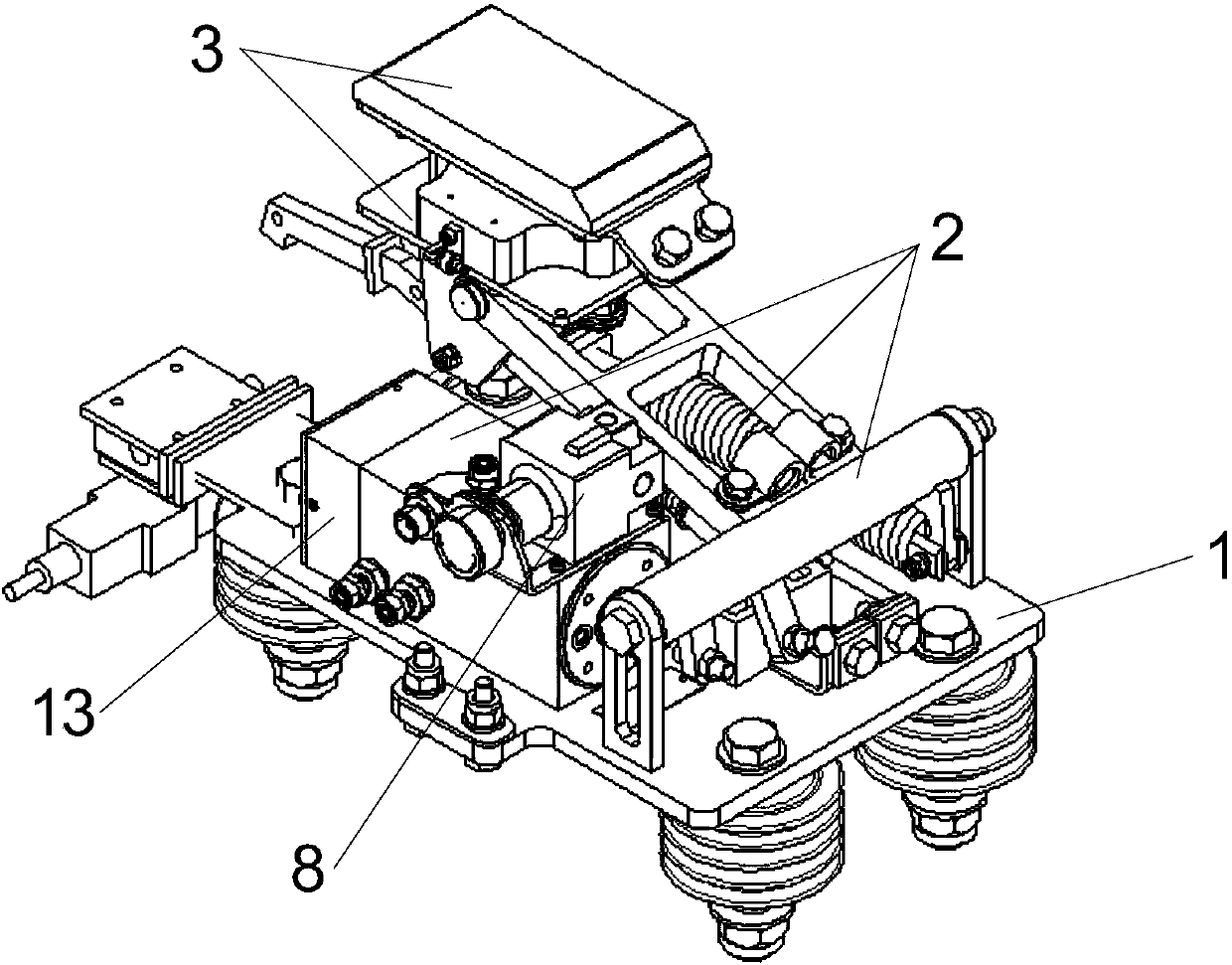

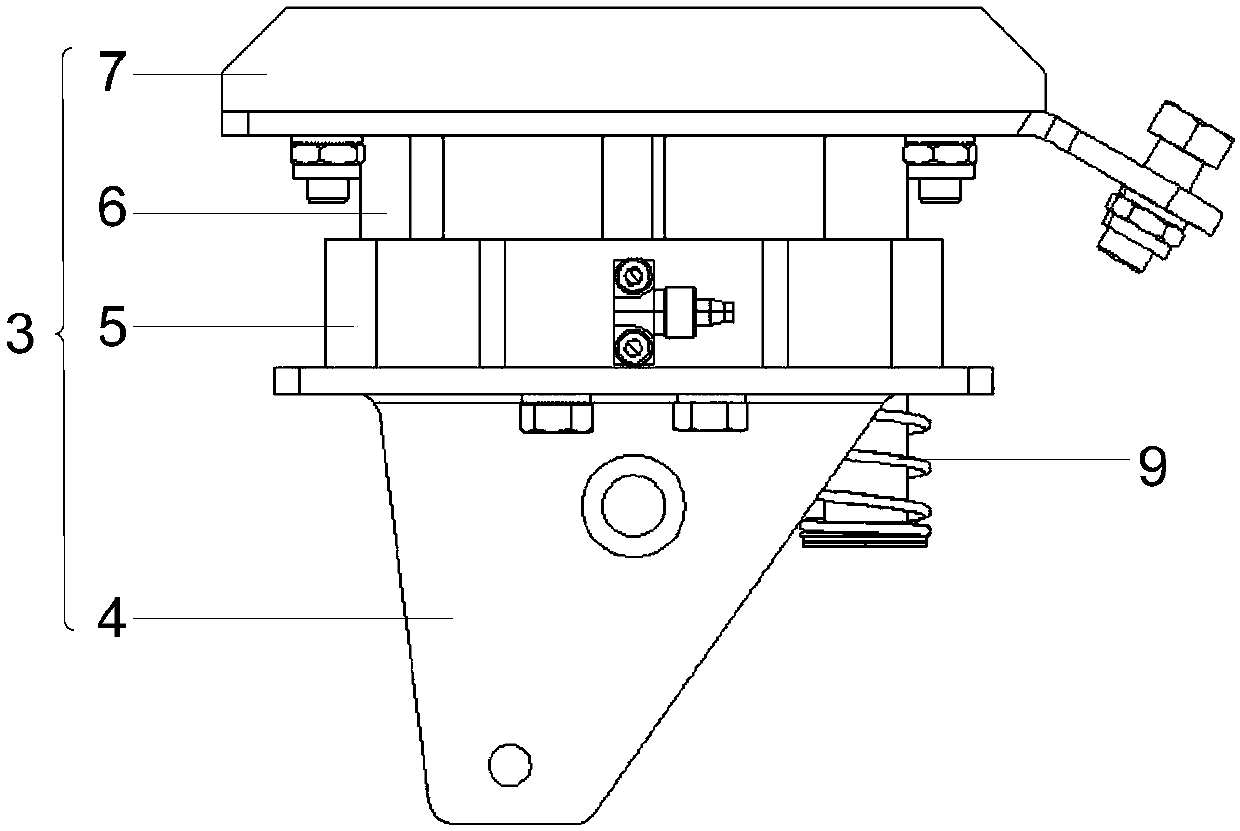

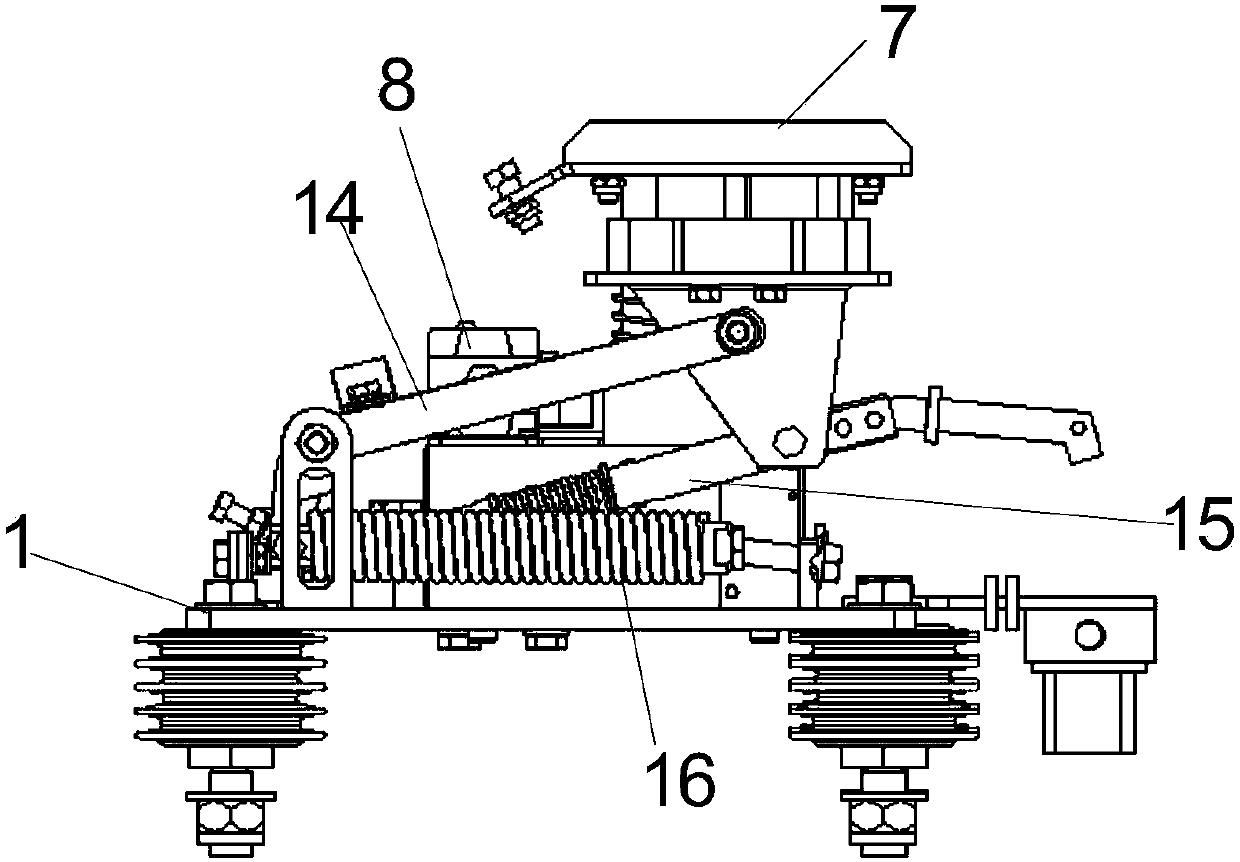

Magnetic levitation vehicle current collector

The invention discloses a magnetic levitation vehicle current collector. The current collector includes a base, a lifting bow assembly arranged on the base and a bow head assembly arranged on the lifting bow assembly; the bow head assembly includes a bow head support connected with the lifting bow assembly, a buffering cylinder body arranged on the bow head support, a guiding rod matched with thebuffering cylinder body in a sliding mode and a sliding board fixed to the guiding rod and used for being in electrical contact with a contact rail; additionally, a pressure adjusting valve used for controlling the pressure value of the buffering cylinder body to be maintained at a preset pressure value is arranged between the buffering cylinder body and a corresponding pressure source. Accordingto the structure of the current collector above, by arranging the pressure adjusting valve between the buffering cylinder body and the corresponding pressure source, when the sliding board is in contact with the contact rail, the contact strength can always remain at the preset pressure valve, and fast response to high-frequency vibration, resulted from unevenness of the contact rail, of the sliding board can be achieved, so that the current collection stability of the current collector is further improved.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

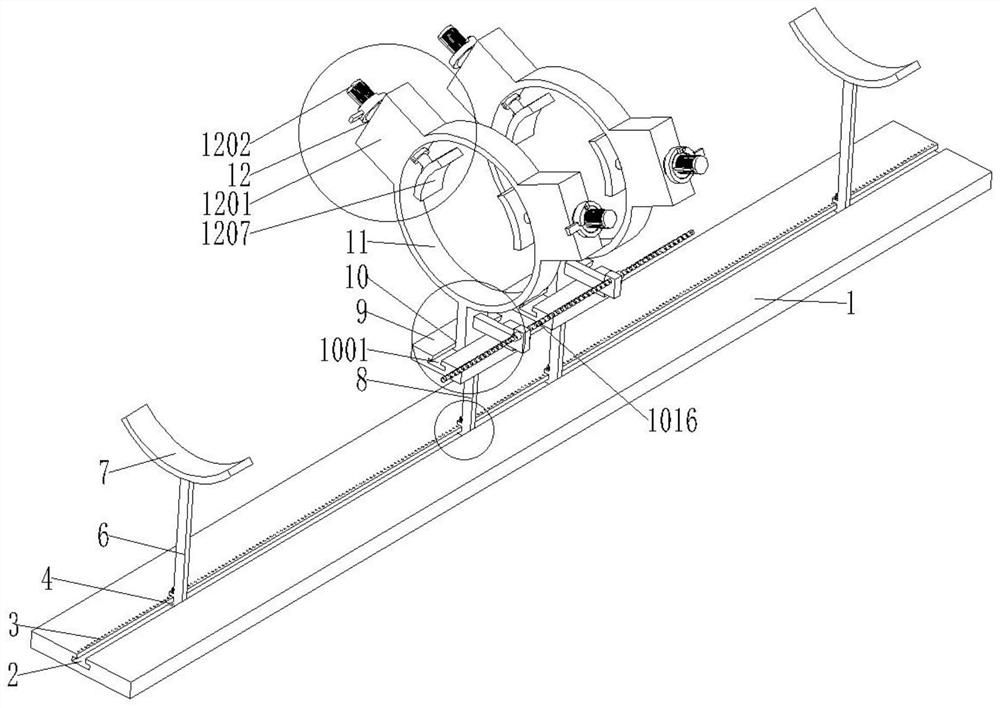

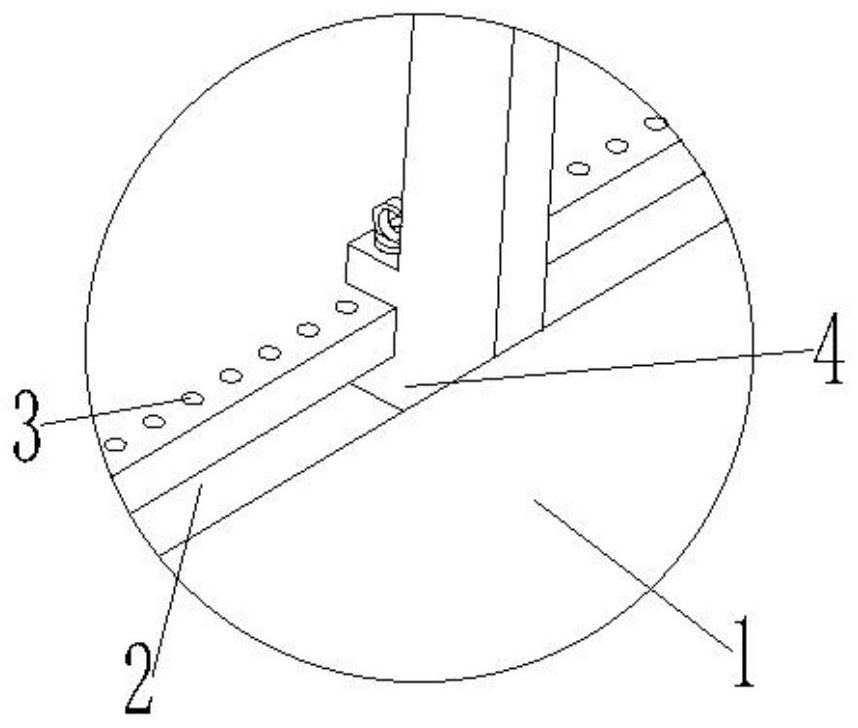

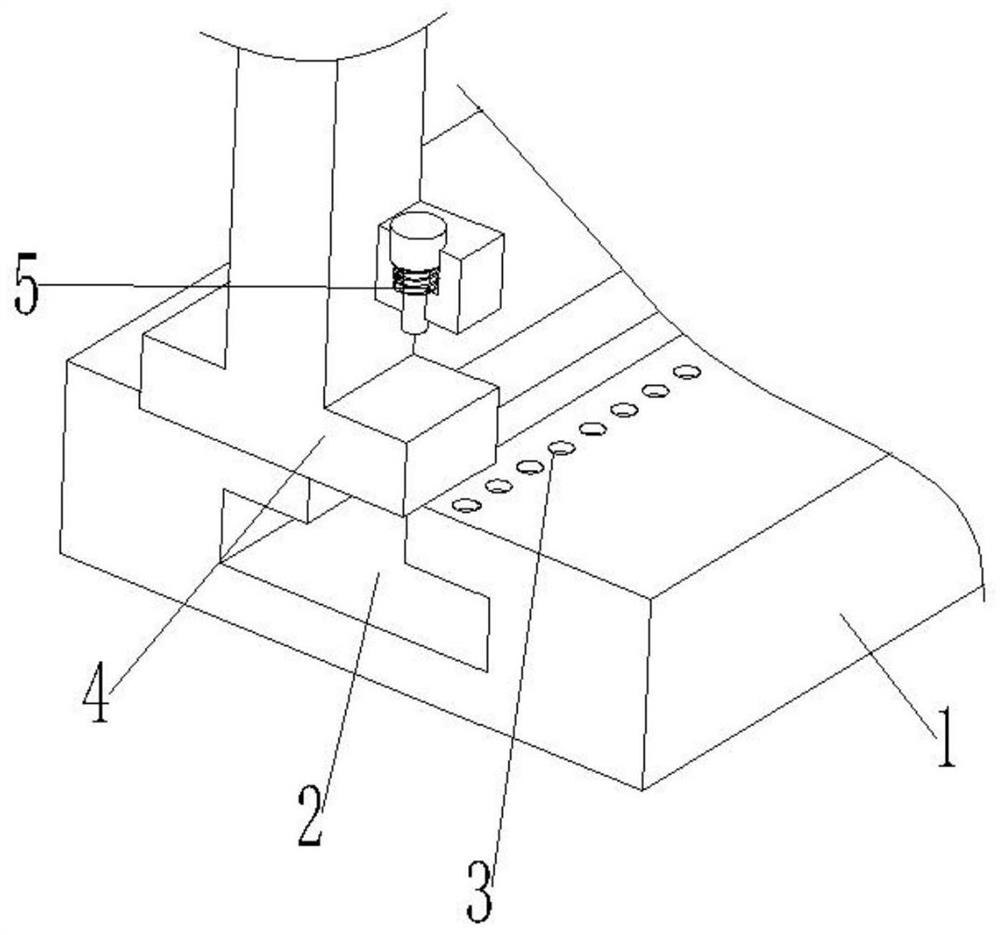

Pipeline butt joint device for building construction and using method thereof

InactiveCN111716070AEasy to placeConvenient docking workWelding/cutting auxillary devicesAuxillary welding devicesButt jointArchitectural engineering

The invention provides a pipeline butt joint device for building construction. A first supporting frame, an arc-shaped supporting plate on the first supporting frame and a second supporting frame anda fixing ring on the second supporting frame can be adjusted according to the length of a pipeline to be in butt joint; and the distance between the first supporting frame and the second supporting frame is changed, namely the distance between the arc-shaped supporting plate and the fixing ring is changed to adapt to the length of the pipeline, so that the pipeline to be in butt joint is convenient to place, the pipeline can be placed according to the actual situation of the pipeline butt joint work, the pipeline butt joint device has high applicability for pipeline placement, and convenienceis brought to the pipeline butt joint work. Through an operation method of the pipeline butt joint device for building construction, the contact strength of the butt joint position of a pipeline opening is improved, the welding work is facilitated, and the working quality is guaranteed.

Owner:京山俊平机电科技有限公司

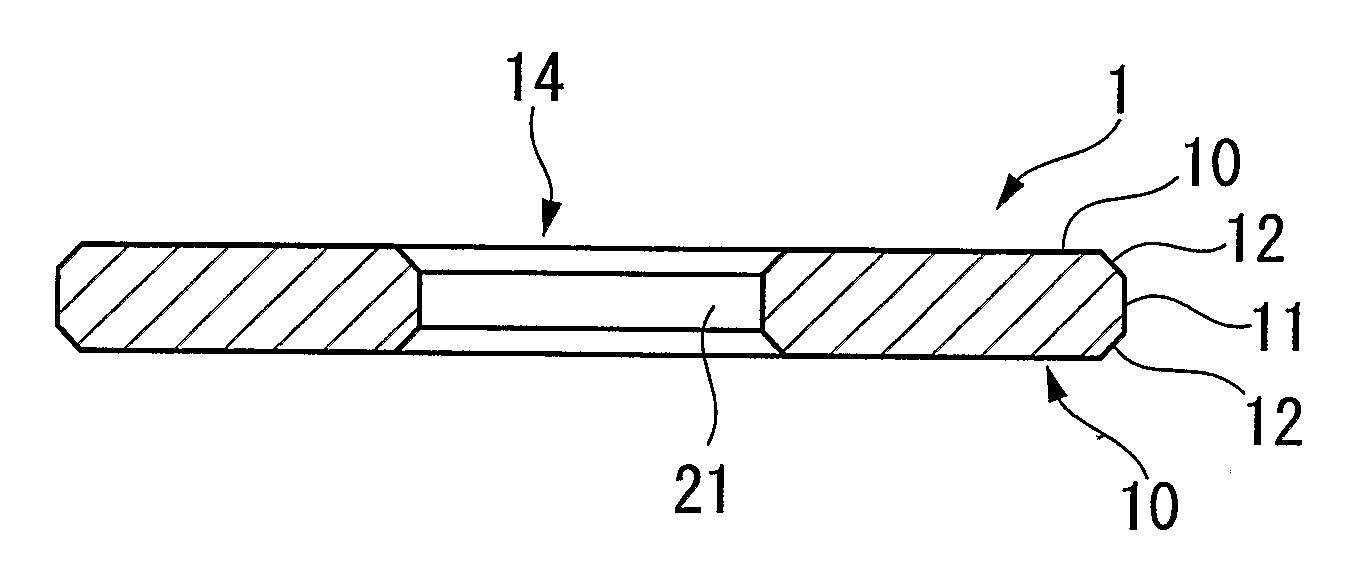

Substrate for magnetic recording medium, magnetic recording medium, and magnetic recording and reproducing apparatus

ActiveUS20090226767A1No deterioration of electromagnetic conversion characteristicSmall surface roughnessMagnetic materials for record carriersBase layers for recording layersSurface roughnessNon magnetic

The invention provides a magnetic recording medium substrate product which enables enhancement of contact strength between a substrate end surface and a soft magnetic layer, as well as suppression of occurrence of corrosion, a magnetic recording medium including the substrate product, which exhibits no deterioration of electromagnetic conversion characteristics and has excellent durability and a magnetic recording and reproducing apparatus including the magnetic recording medium. The magnetic recording medium substrate product includes a disk-shaped non-magnetic substrate having a circular hole in a center portion thereof, and having a chamfer formed at least one of a portion between a main surface on which a magnetic layer is to be formed and an outer end surface and a portion between the main surface and an inner end surface defining the circular hole, wherein the chamfer has a surface roughness (Ra) falling within a range of 4.0 Å≦Ra≦100 Å, preferably 4.0 Å≦Ra≦50 Å, as measured by means of an AFM.

Owner:SHOWA DENKO KK

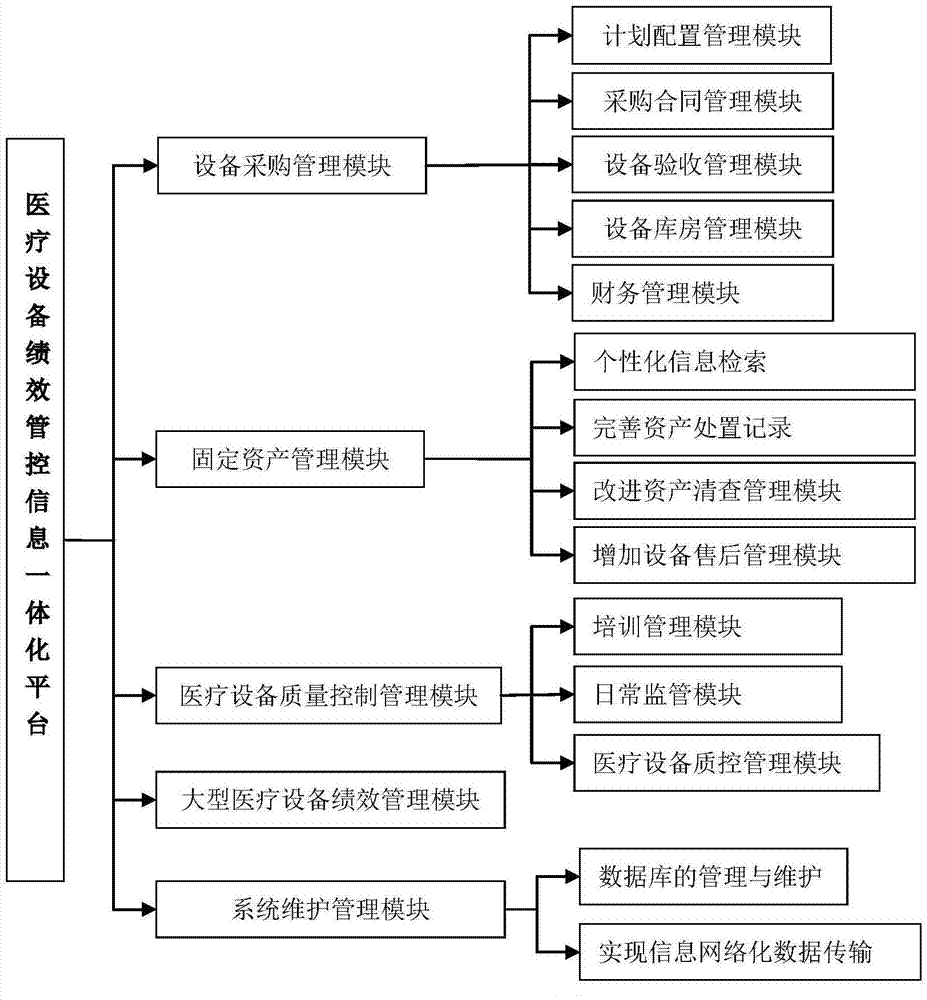

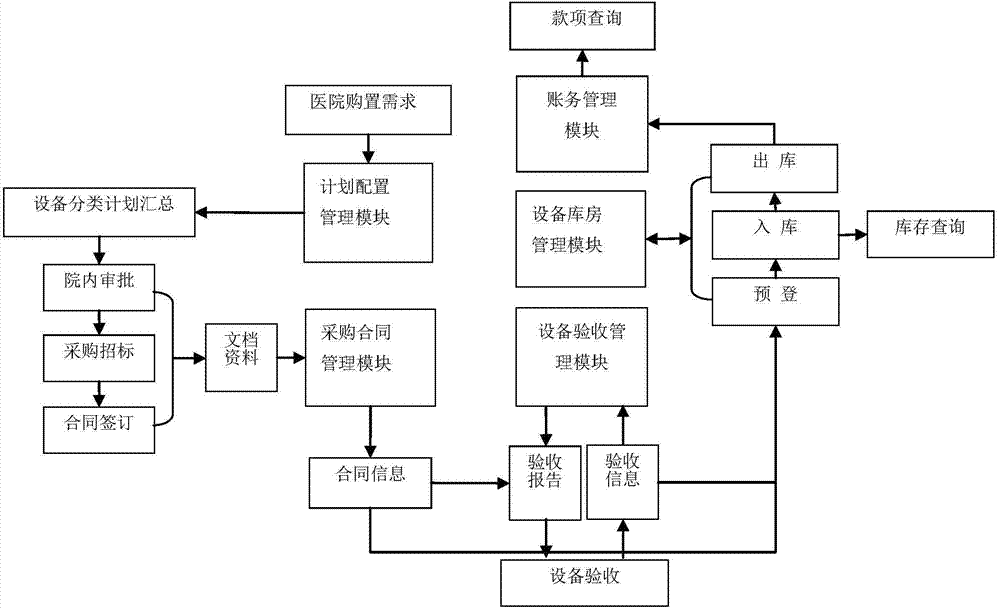

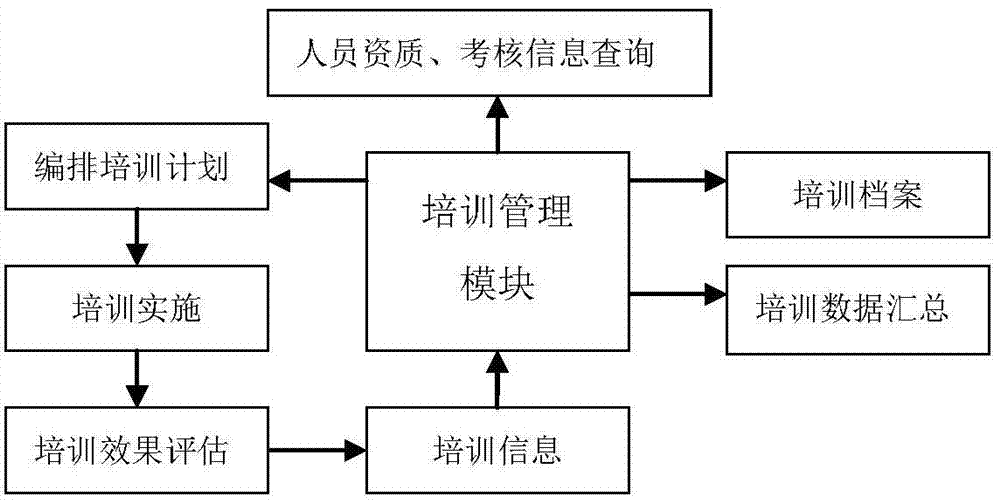

Medical facility performance management and control information integrated platform

InactiveCN104732336AQuality improvementGuaranteed uptimeResourcesMedical equipmentSystem maintenance

The invention discloses a medical facility performance management and control information integrated platform. The medical facility performance management and control information integrated platform comprises a facility purchasing management module, a fixed asset information management module, a medical facility quality control and management module, a large-medical-facility performance management module and a system maintenance management module. By means of the medical facility performance management and control information integrated platform, a digitized and informationized data exchange platform is provided for quality control over and quality management on medical facilities, the management functions of different departments are fused, the summarized information of the facilities in the whole service life is provided, and the information extracting and contact strength of managers is improved. The medical facility performance management and control information integrated platform has the advantages that related permission of management departments is set according to the management content and the management requirements of the facilities in different stages of the full service life and different aspects, the different management functions and the different analysis inquiry functions are achieved, the effect of information sharing is sufficiently developed, paths are unified, repeated working doing or information non-correspondence is avoided, the inquiring work efficiency is improved, and data foundations are provided for decision makers.

Owner:JILIN UNIV FIRST HOSPITAL

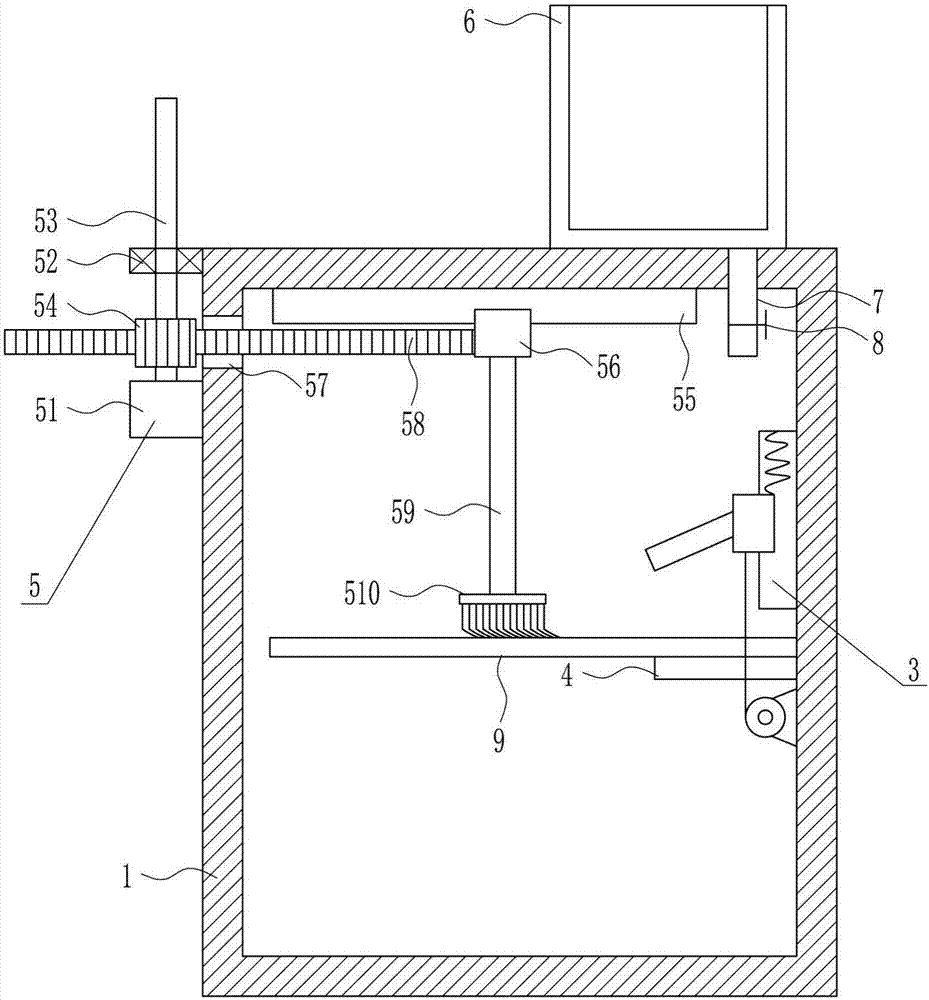

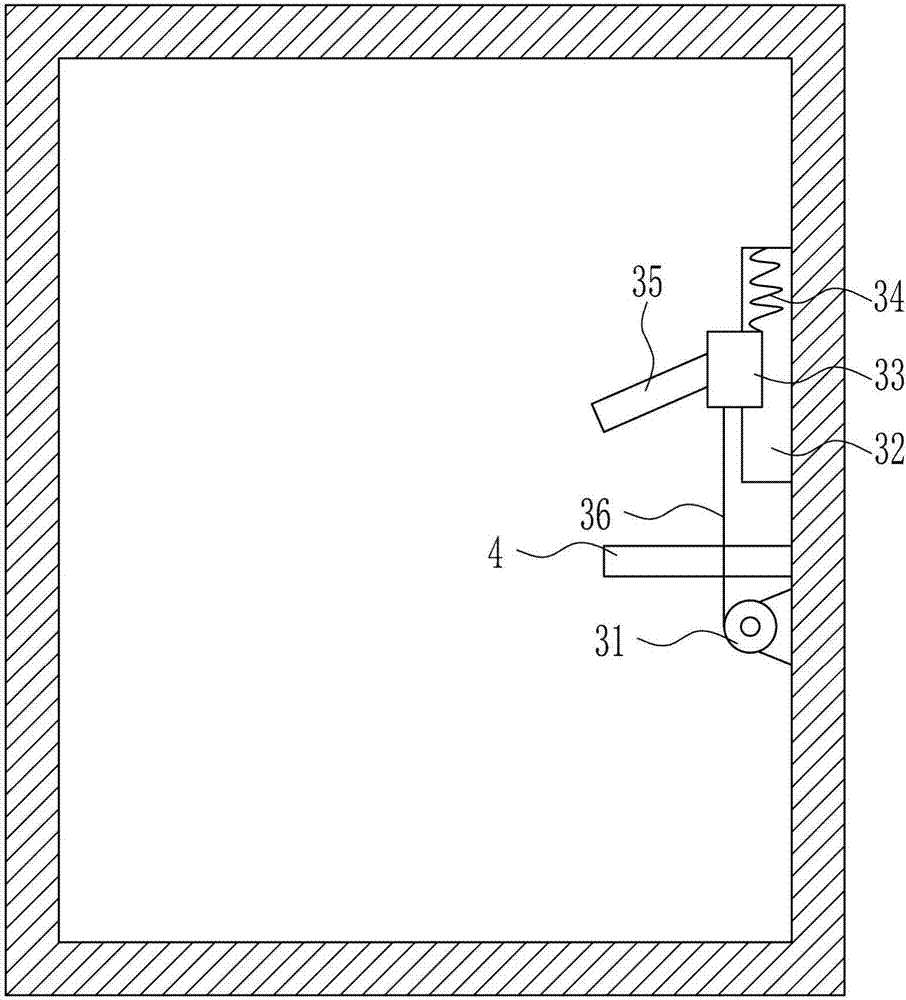

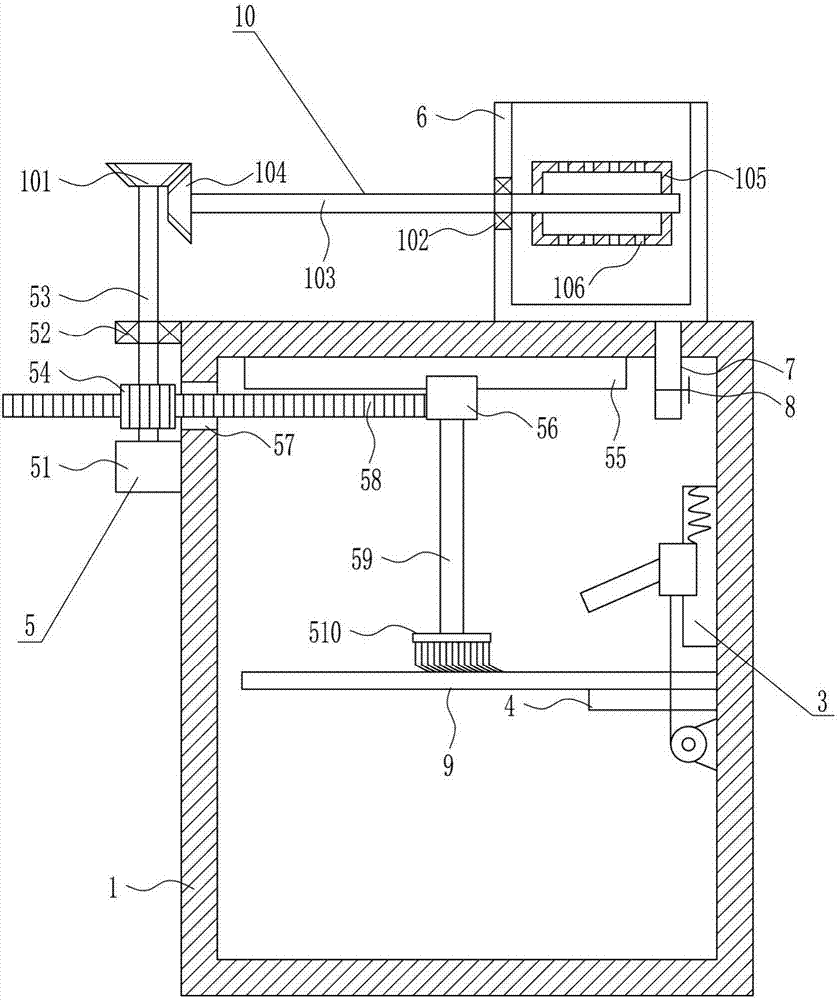

Quick cleaning device for testing equipment

InactiveCN107362992AReduce resistanceStir wellCleaning using toolsCleaning using liquidsEngineeringUltimate tensile strength

The invention relates to a cleaning device for testing equipment, in particular to a quick cleaning device for the testing equipment. The technical problem to be solved is to provide the quick cleaning device which is used for the testing equipment and is high in cleaning speed, clear to clean and small in labor intensity. To solve the technical problem, the quick cleaning device for the testing equipment is provided. The quick cleaning device comprises a cleaning box and the like. A fixing device is arranged on the right side face of the cleaning box. A containing plate is arranged on the lower portion of the right side face of the cleaning box and horizontally arranged. The right side face of the containing plate is connected with the right side face in the cleaning box in a bolt connecting manner. A cleaning device body is arranged on the top of the cleaning box. Cleaning components of the cleaning device body are located in the cleaning box. According to the quick cleaning device for the testing equipment, a caliper rule is cleaned after being fixed, and the cleaning effect is good; and through the contact of contact wheels and the caliper rule, the contact strength of the caliper rule and a hairbrush is increased, and the effects of the high cleaning speed, clear cleaning and small labor intensity are achieved.

Owner:CHINA JILIANG UNIV

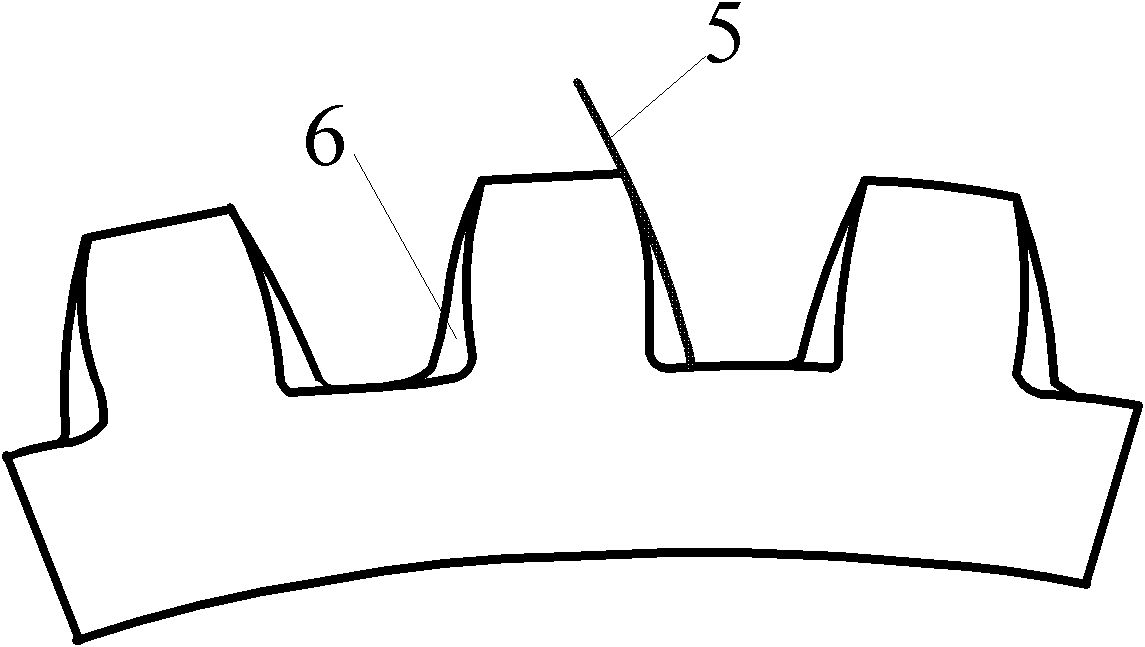

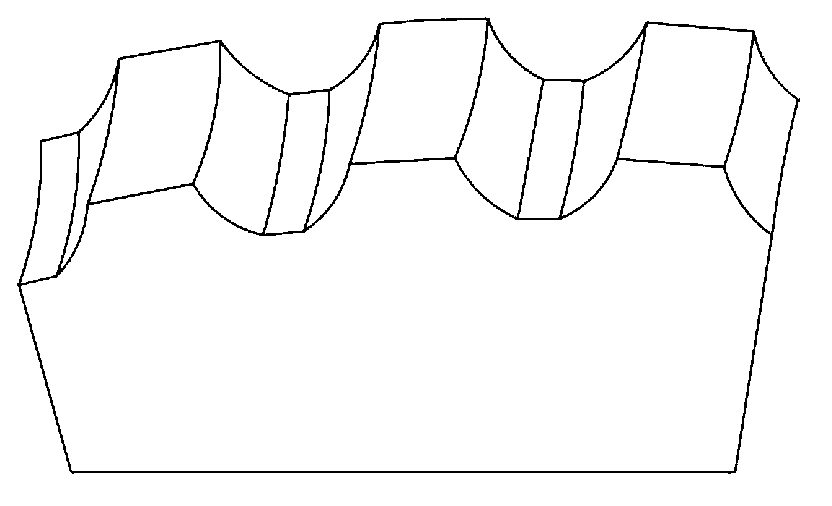

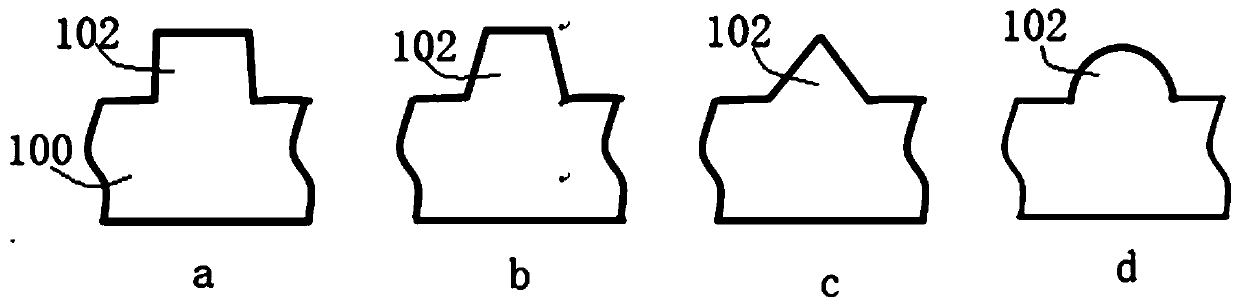

Bevel gear with combined arc tooth profile curves and involute tooth profile curves

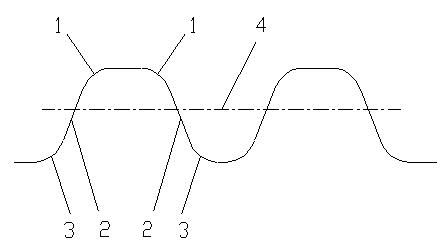

InactiveCN102072308AImprove contact strengthExcellent running-in performancePortable liftingGearing elementsInvolute gearEngineering

The invention discloses a bevel gear with combined arc tooth profile curves and involute tooth profile curves, wherein the tooth profile curves of the bevel gear comprise a top convex-arc segment, an involute segment and a root concave-arc segment, wherein the top convex-arc segment, the involute segment and the root concave-arc segment are sequentially connected from the top to the root; the top convex-arc segment and the root concave-arc segment are both tangential to the involute segment; and the radius of the root concave-arc segment is larger than that of the top convex-arc segment. The bevel gear of the invention has the advantages of separability of center distance of the involute gear; the bevel gear is simple in manufacturing, convenient in measuring, large in contact strength of the arc gear, excellent in running-in performance and the like; the contact stress of the gear surface can be largely reduced and the loading ability of the gear surface can be largely improved. In addition, the bevel gear does not have undercutting phenomenon, and the minimum number of teeth can be one, so that the bevel gear has remarkable meaning for realizing light weight of the gear and the transmission device thereof.

Owner:CHONGQING UNIV

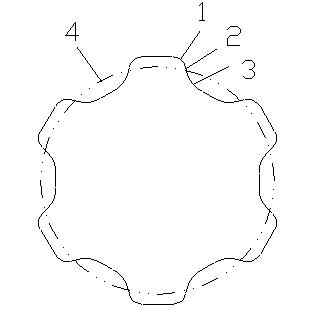

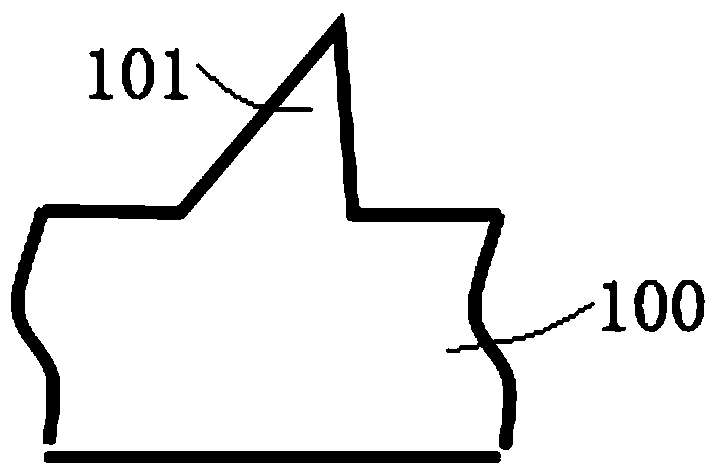

Involute arc tooth profile bevel gear and meshing pair thereof

ActiveCN101975264AImprove carrying capacityReduce contact stressToothed gearingsPortable liftingInvolute gearTooth number

The invention discloses an involute arc tooth profile bevel gear and a meshing pair thereof. The tooth profile curve of bevel gear is formed by the way that an arc does helical motion along the tooth surface contact line on involute helicoids, thus having the advantages that involute gear center distance has separability and is convenient to measure, involute gear is convenient to manufacture and an arc gear has high contact strength and good running-in property, tooth surface contact stress is reduced, tooth surface carrying capacity is greatly improved, and processing is convenient; and the tooth curve of the arc and the radial length of involute participating in meshing are short, thus avoiding undercutting phenomenon of standard gear, so that minimum tooth number of the gear can reach 1. Compared with the gear in the prior art, weight and size are greatly reduced; and the meshing pair adopts the way that a convex gear is meshed with a concave gear, and carrying capacity is high.

Owner:CHONGQING UNIV

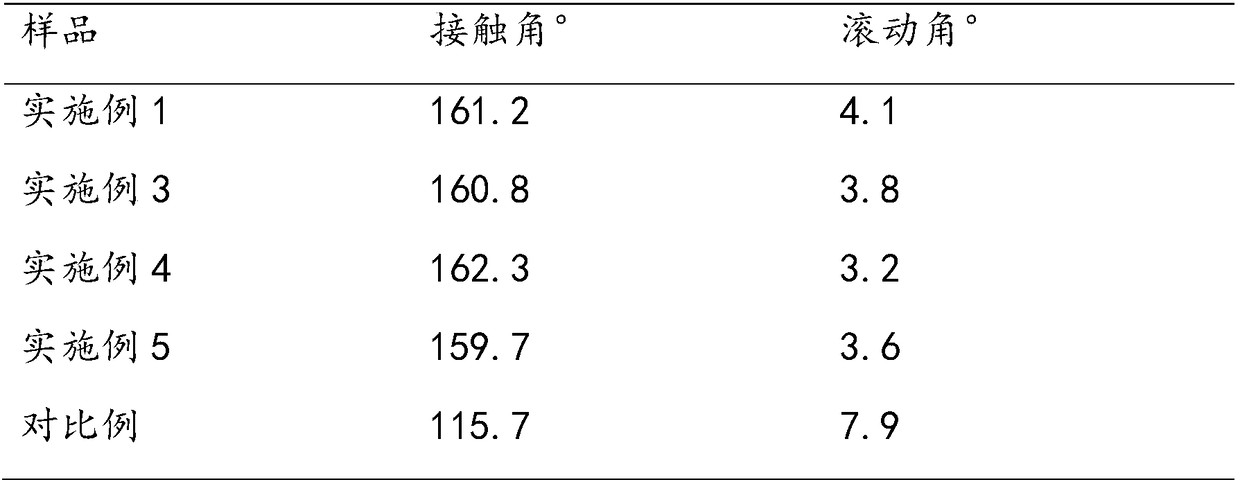

Processing technology of UV-curing fluorine-containing wear-resistant hydrophobic coating

ActiveCN108587381AHas hydrophobic and oleophobic propertiesImprove waterproof performanceCoatingsWear resistantLipophobicity

The invention discloses a processing technology of a UV-curing fluorine-containing wear-resistant hydrophobic coating. The processing technology comprises the following steps: a, preparing hydrophobicnano SiO2 / TiO2 particles; b, preparing an organic silicone fluorine-containing acrylate emulsion; c, preparing a bottom-layer hydrophobic coating emulsion; e, spraying the bottom-layer hydrophobic coating emulsion; and f, spraying a surface hydrophobic coating. The processing technology disclosed by the invention has the beneficial effects that a double-layer cooperation manner of the bottom-layer hydrophobic coating and the surface hydrophobic coating is adopted, so that the coating has the properties of hydrophobicity and lipophobicity while adhesion of the waterproof coating and a target material is ensured, and water resistance of the target material is improved; the bottom-layer hydrophobic coating is cured by acrylate, so that contact strength of the bottom-layer hydrophobic coatingand the surface of the target material can be provided, and the compactness of the waterproof coating can be improved; and a structure of a nano material is stabilized through the organic silicone modified fluorine-containing acrylate, fluorine-containing silane and fluorine-containing acrylate are also used, so that hydrophobicity of the surface-layer hydrophobic coating is improved.

Owner:GUANGZHOU SUN EMPEROR INTELLIGENT TECH +1

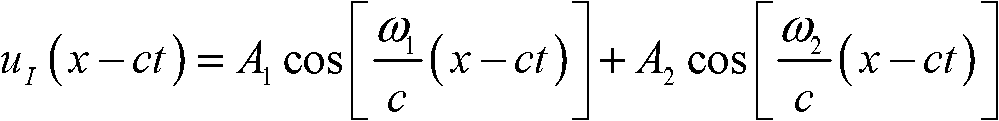

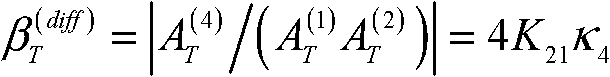

Method for detecting interface contact strength by double frequency ultrasound

InactiveCN101949894AAnalysing solids using sonic/ultrasonic/infrasonic wavesVibration amplitudeSonification

The invention provides a method for detecting interface contact strength by double frequency ultrasound, which mainly comprises the following steps of: generating double frequency ultrasound exciting signals by using a signal generator, and amplifying by using a power amplifier; transmitting the signals by utilizing a transmitting transducer, receiving the signals by utilizing a receiving transducer after the transducers are calibrated; exciting the double frequency ultrasonic signals in a sample to be detected, and processing the signals by utilizing fast Fourier transform; converting the obtained electric signal amplitude into the absolute displacement amplitude; and calculating a nonlinear parameter, a linear contact strength value and a second-order contact strength value. A calibration procedure for absolute vibration amplitude is introduced, and the concrete contact strength value can be calculated, so the quantitative detection on a solid interface can be realized. The double frequency ultrasound is adopted for detection; and compared with the conventional solid interface contact strength ultrasound detection method, the technology can effectively enhance the detection for the contact strength of the solid interface.

Owner:NANJING UNIV

Silicon carbide substrate for forming magnetic head

InactiveUS6437943B1Quality improvementHigh strengthManufacture head surfaceHeads using thin filmsThermal radiationUltimate tensile strength

To provide a magnetic-head substrate capable of improving the heat radiation characteristic while keeping a mechanical strength and a milling characteristic equal to those of a conventional Al2O3-TiC system and preventing an device from contacting a medium face and moreover superior in film contact strength, electrical withstand voltage, and face quality. The magnetic-head substrate is constituted of a sintered body containing 99 wt % or more of silicon carbide and 0.3 wt % or less of free carbon and having a relative density of 99% or more.

Owner:KYOCERA CORP

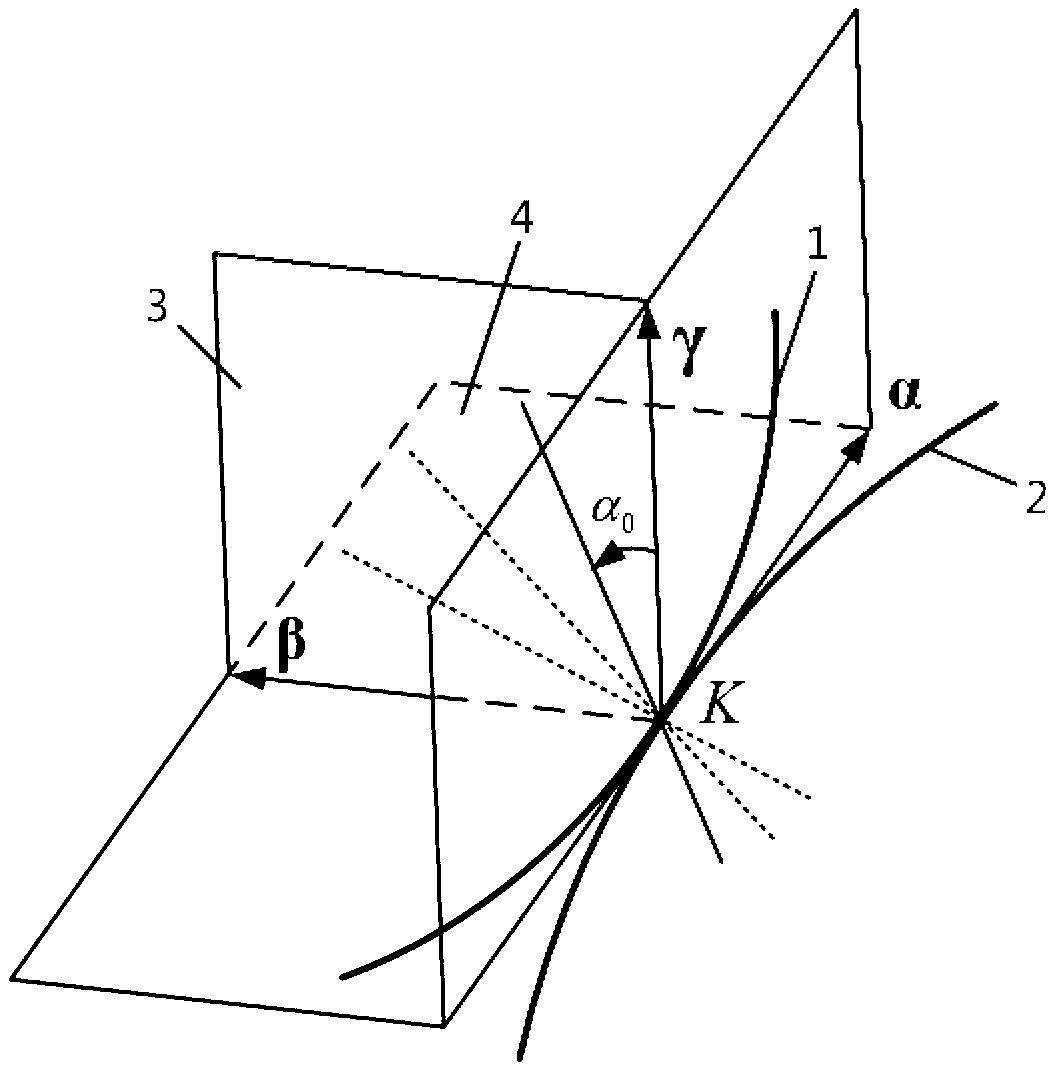

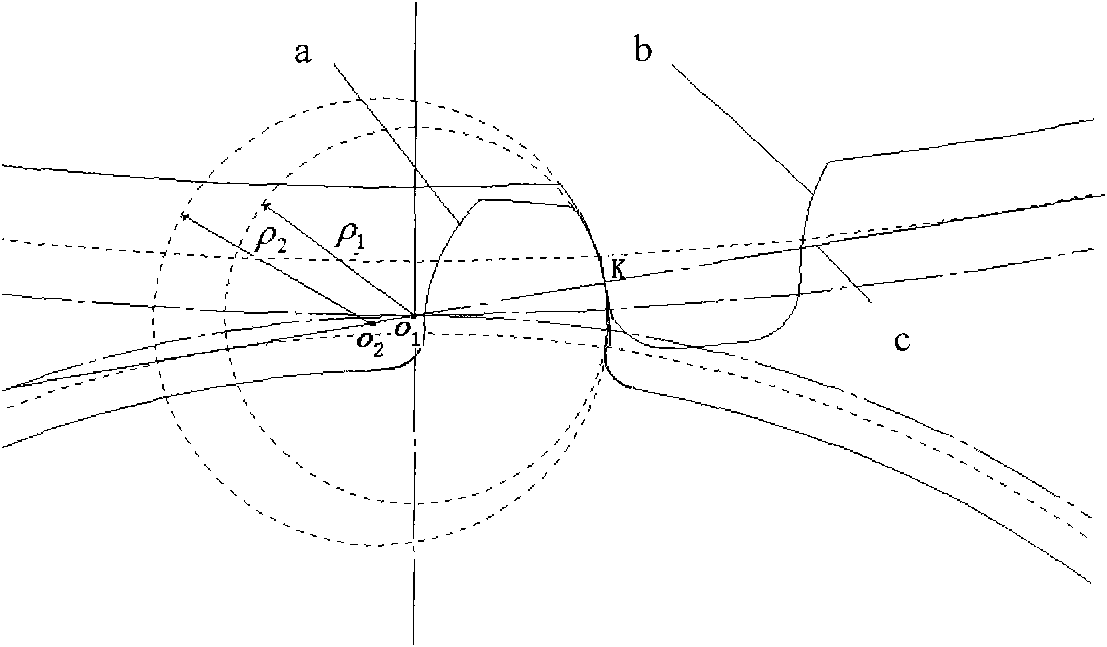

Involute gear transmission device based on line and plane conjugation

ActiveCN102162503AImprove contact strengthImprove carrying capacityPortable liftingToothed gearingsGear driveGear wheel

The invention discloses an involute gear transmission device based on line and plane conjugation and particularly relates to an involute gear. The involute gear transmission device disclosed by the invention comprises an involute conjugated meshing pair, wherein a smooth curve shown in the specification is selected from the gear surface of one gear in the meshing pair; the master normal vector direction of the smooth curve is consistent to the normal direction of the gear surface; the curve shown in the specification and the gear surface of the other gear in the meshing pair form line and plane conjugated meshing; the gear surface of the gear is a tubular meshing surface; the tubular meshing surface is a ball race enveloping surface of which the ball center moves along an equidistant line; the equidistant line is a smooth curve with the equidistance a along the master normal vector direction of the curve shown in the specification; the radius of a ball in a ball race is the distance a between an equidistance curve and the curve shown in the specification; and the distance a is less than the minimum curvature radius of the original involute profile meshing section. In the invention, by changing the involute gear transmission into the line and plane conjugated meshing pair, the meshing process adopts point contact and approximately pure rolling meshing, the contact strength is high, the bearing capacity is high, the sliding ratio is greatly reduced, the direction of the end surface is still the direction of the involute meshing pair, and the advantages that the center distance in the involute gear transmission can be divided and the like are succeeded.

Owner:CHONGQING UNIV

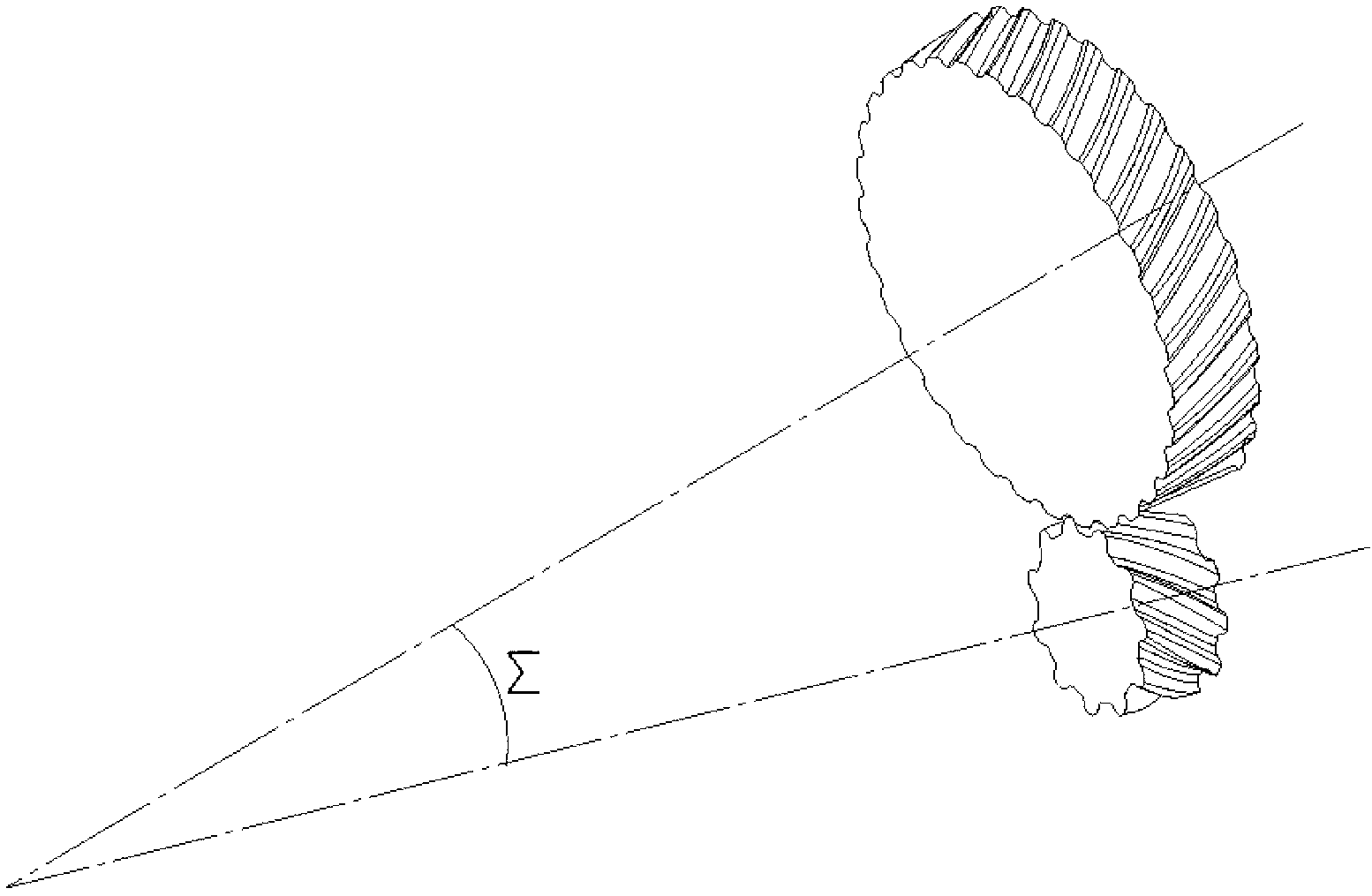

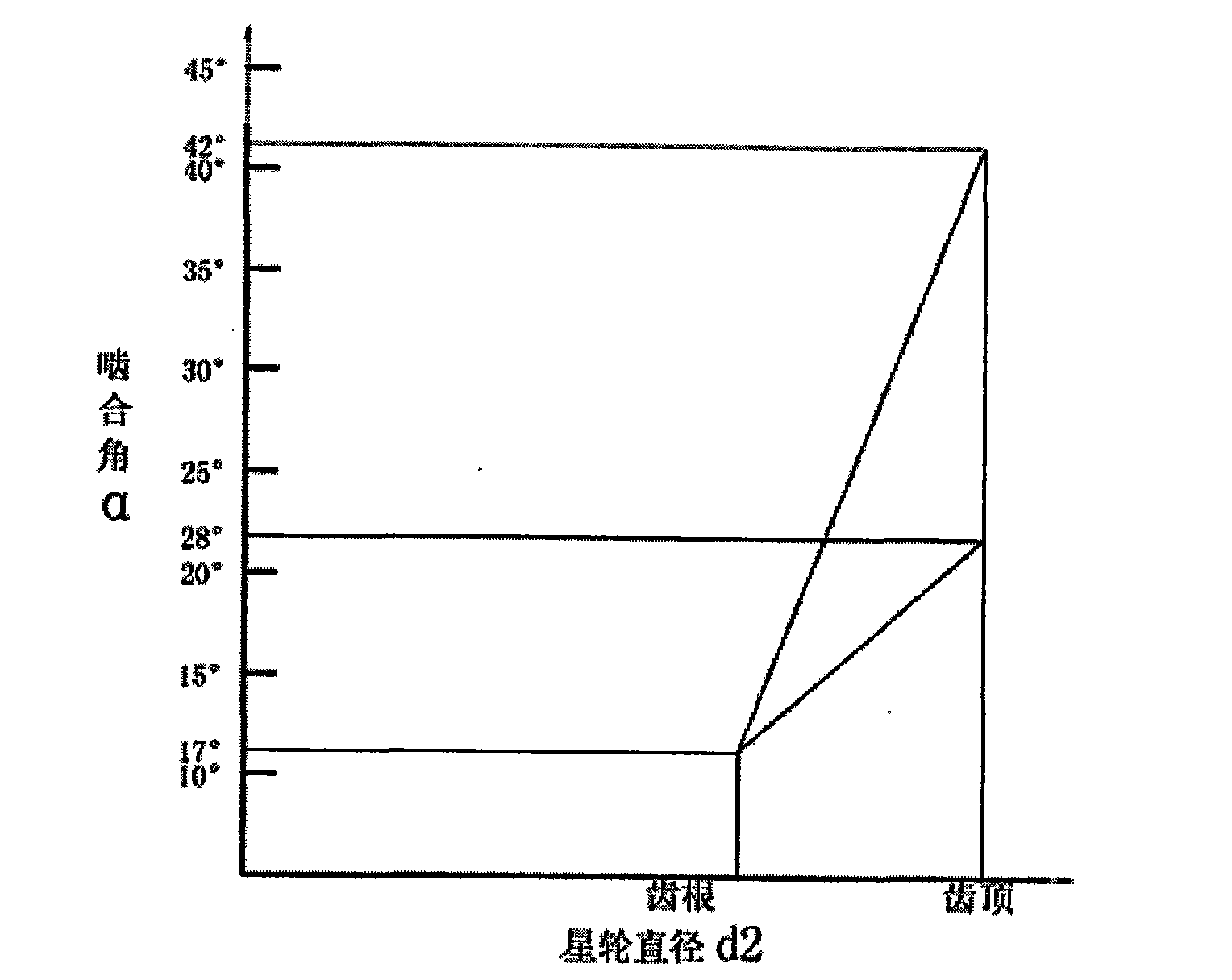

Single-screw meshing mechanism with reducing generatrix two-time enveloping single-screw meshing molded line

InactiveCN101649837ADecrease the inclinationRotary piston pumpsRotary piston liquid enginesWorking pressureEngineering

The invention discloses a single-screw meshing mechanism with a reducing generatrix enveloping single-screw meshing molded line. The reducing generatrix envelops the single-screw meshing molded line two times, the meshing line of the screw and a star wheel can form a meshing surface with width of about 2mm; simultaneously, an instant contact line vertical to the original meshing line also exists;both of the two places can form a dynamic pressure liquid film, which improves the contact strength of the meshing tooth surface and prolongs the service life of the star wheel. The dip angle of the meshing line can be reduced by half, and thus, the working pressure of the single-screw compressor and an expander can exceed 4MPa and can reach 4MPa-10MPa.The invention widens the application field of the single-screw compressor and the expander.

Owner:上海孚创螺杆技术有限公司

Input device, microcomputer and information processing method

An input device includes: a display unit indicating an image of an input position; a contact position detecting unit detecting a position of an object brought into contact with a contact detecting layer provided on a display layer of the display unit; a contact strength detecting unit detecting contact strength of the object brought into contact with the contact detecting layer; a feature quantity extracting unit extracting a feature quantity related to the detected contact strength; and a special process executing unit comparing the extracted feature quantity with a predetermined threshold, and executing special processes.

Owner:KK TOSHIBA

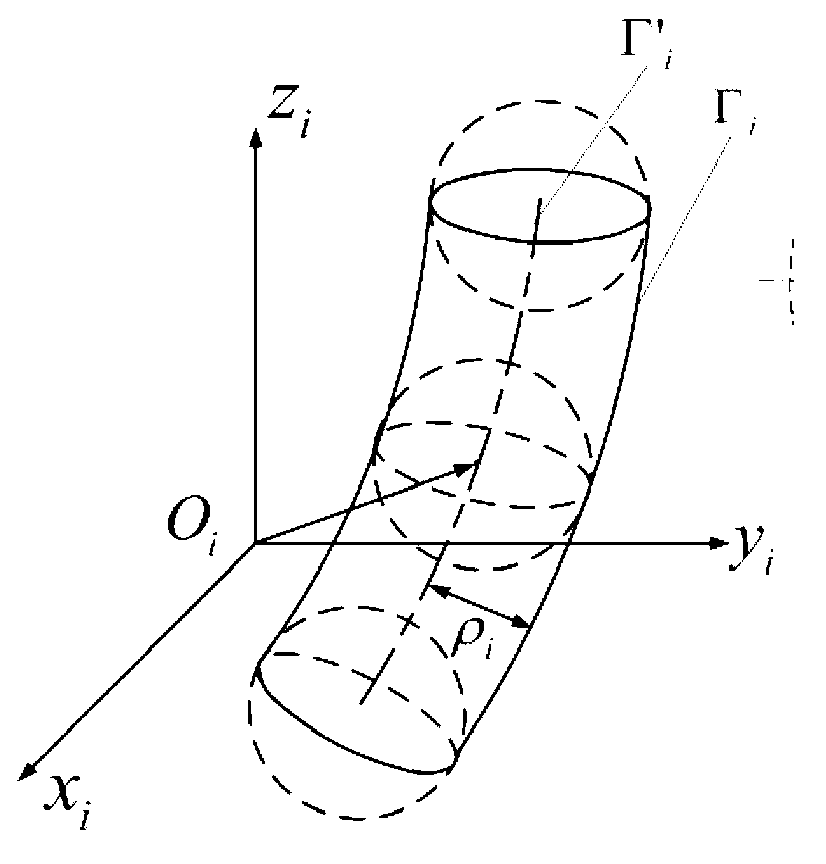

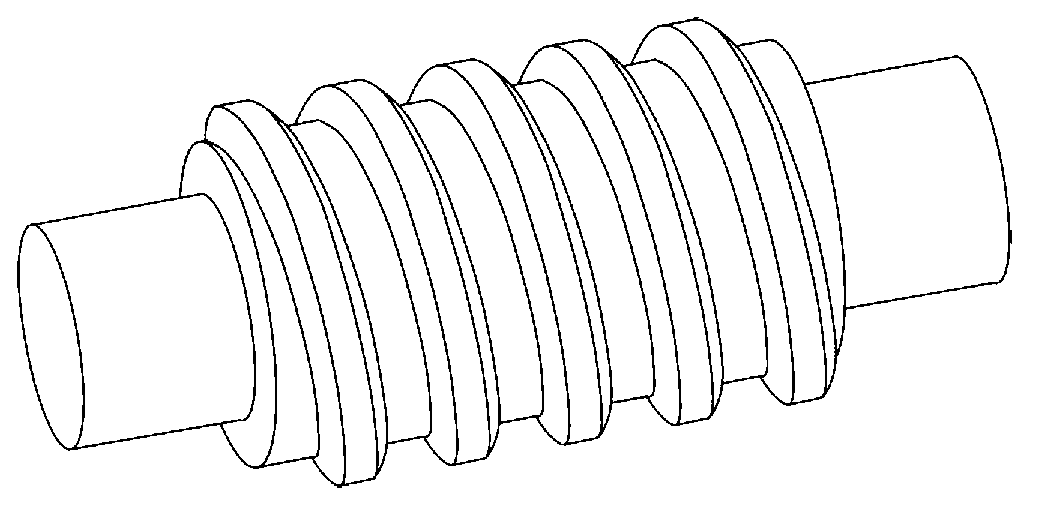

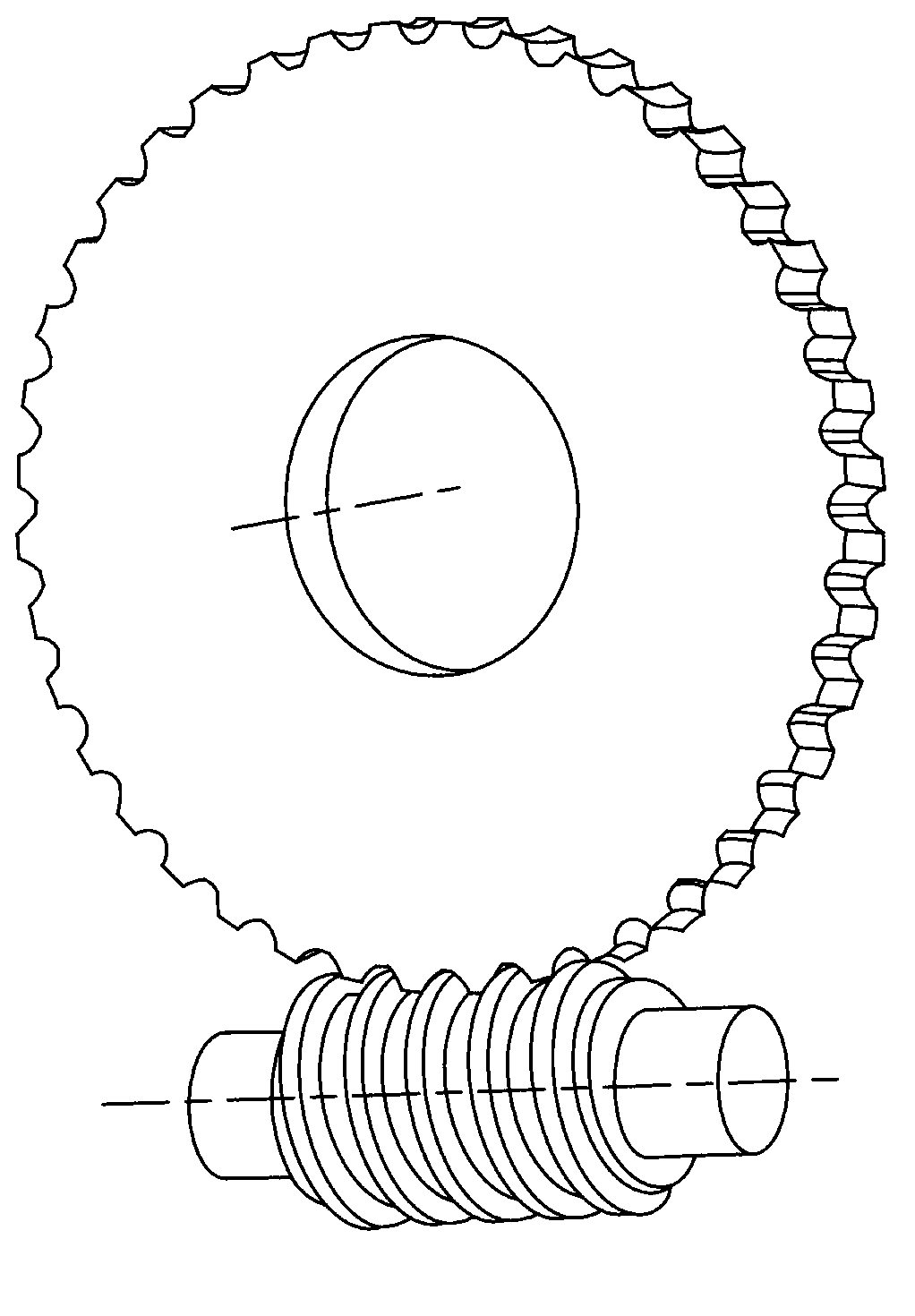

Worm and worm gear on basis of conjugate curves, and mesh pair with worm and worm gear

ActiveCN103047393AReduce temperature riseReduce wearPortable liftingToothed gearingsCarrying capacityEngineering

The invention discloses a worm and a worm gear on the basis of conjugate curves, and a mesh pair with the worm and the worm gear. The worm gear and worm mesh pair comprises the worm gear and the worm which are meshed with each other; a contact curve gamma 1 which consists of meshed points on a tooth profile curved surface of the worm and a contact curve gamma 2 which consists of meshed points on a tooth profile curved surface of the worm gear are the conjugated curves; the tooth profile curved surface of the worm is a spherical enveloping surface in the shape of a tube nest, and the spherical center of the spherical enveloping surface moves along circle center curves gamma 1' equally distanced from the contact curve gamma 1; and the tooth profile curved surface of the worm gear is a spherical enveloping surface in the shape of a tube nest, and the spherical center of the spherical enveloping surface moves along circle center curves gamma 2' equally distanced from the contact curve gamma 2. The worm gear, the worm and the worm gear and worm mesh pair on the basis of the conjugate curves have the advantages that the tooth profile curved surfaces of the worm gear and the worm which are meshed with each other are the spherical enveloping surfaces in the shapes of the tube nests, and the meshed points between the worm gear and the worm move along the conjugate curves; and the mesh characteristics of the conjugate curves are inherited for the worm gear and worm mesh pair, the contact strength of tooth profiles which are in concave-convex point contact with one another is high, the carrying capacity and the transmission efficiency are high, and temperature rise of lubricating oil and abrasion are low.

Owner:CHONGQING UNIV

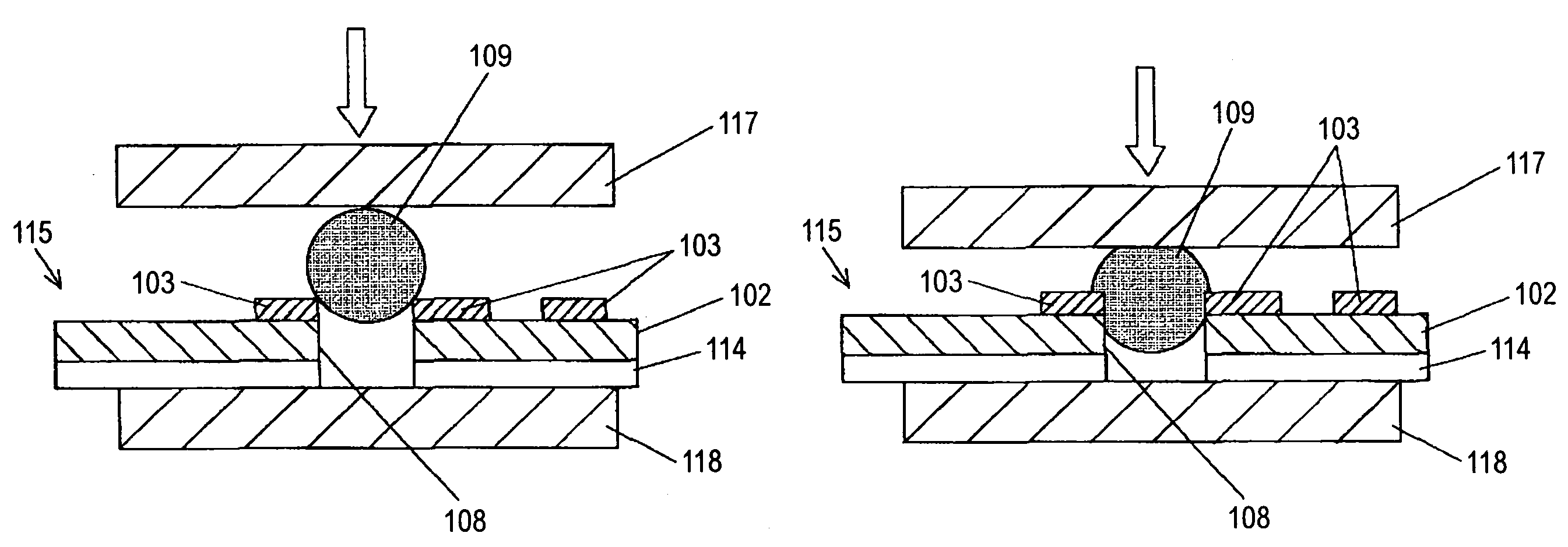

Interconnect structure of an integrated circuit and manufacturing method thereof

ActiveUS20070128845A1High densityImprove contact strengthSemiconductor/solid-state device detailsPrinted circuit aspectsFiberPliability

Owner:IND TECH RES INST

Manufacturing method of flexible printed wiring board

InactiveUS7543376B2Improve connection reliabilityIncrease production capacityPrinted circuit assemblingLine/current collector detailsElectrical conductorContact strength

Owner:PANASONIC CORP

Dissimilar metal rolling bonding method with embedded type rib and groove interlocking

ActiveCN111318565AHigh bonding strengthIncrease binding areaMetal rolling stand detailsRollsComposite plateUltimate tensile strength

The invention discloses a dissimilar metal rolling bonding method with embedded type rib groove interlocking, and belongs to the field of bi-metal composite plate preparing. The method comprises the following steps of S1, single-side convex rib rolling, wherein a flat roller and a figure roller with a groove are matched, a first plate blank is rolled, and a convex rib is formed on the single sidesurface of the first plate blank; S2, preassembling rolling, wherein a second plate blank and the first plate blank are embedded, the first plate blank is embedded into the second plate blank to formchain type connection, and an embedded composite workpiece is formed; and S3, asymmetrical rolling, wherein the embedded composite workpiece is subjected to asymmetrical forming rolling, and a dissimilar metal composite plate is formed. The problem that in the prior art, the bonding strength of a dual-metal composite plate is low totally can be solved, the rolling bonding method that embedded typeribs and grooves are manufactured in dissimilar metal contact, and through asymmetrical rolling, rib and groove interlocking is achieved is adopted, measures of combining mechanical type connection,generation of an interlocking structure and increasing the diffusion rate are used, and the interface contact strength can be sufficiently improved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

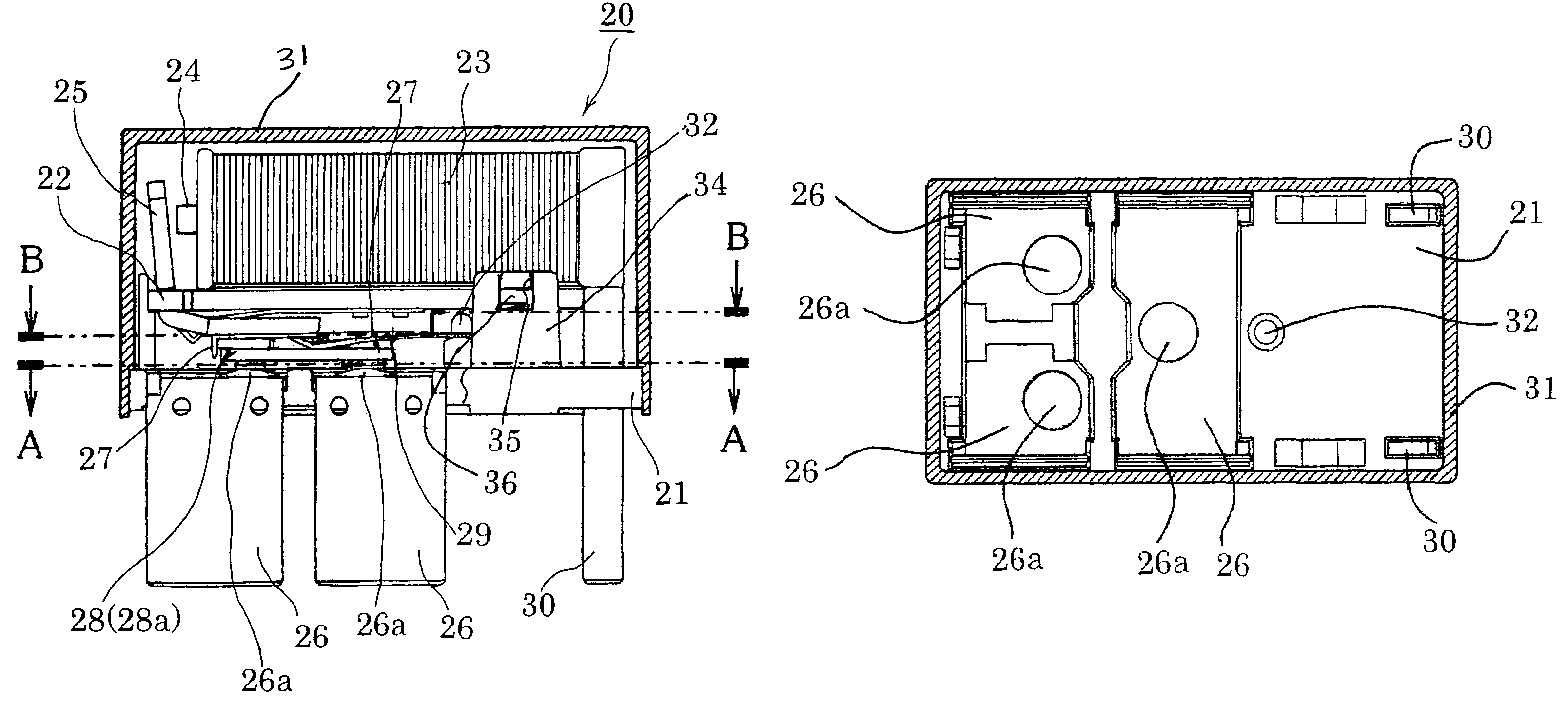

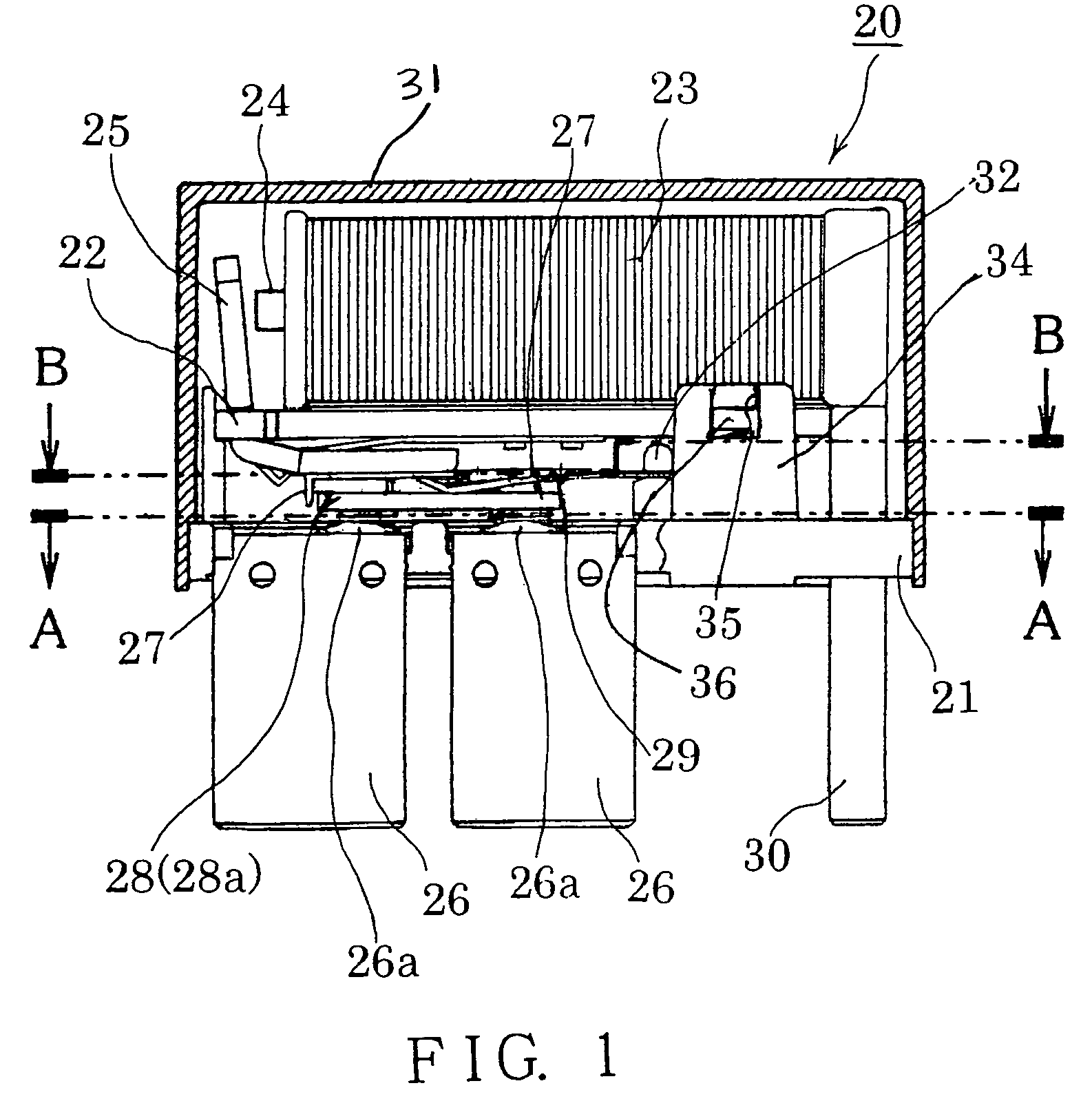

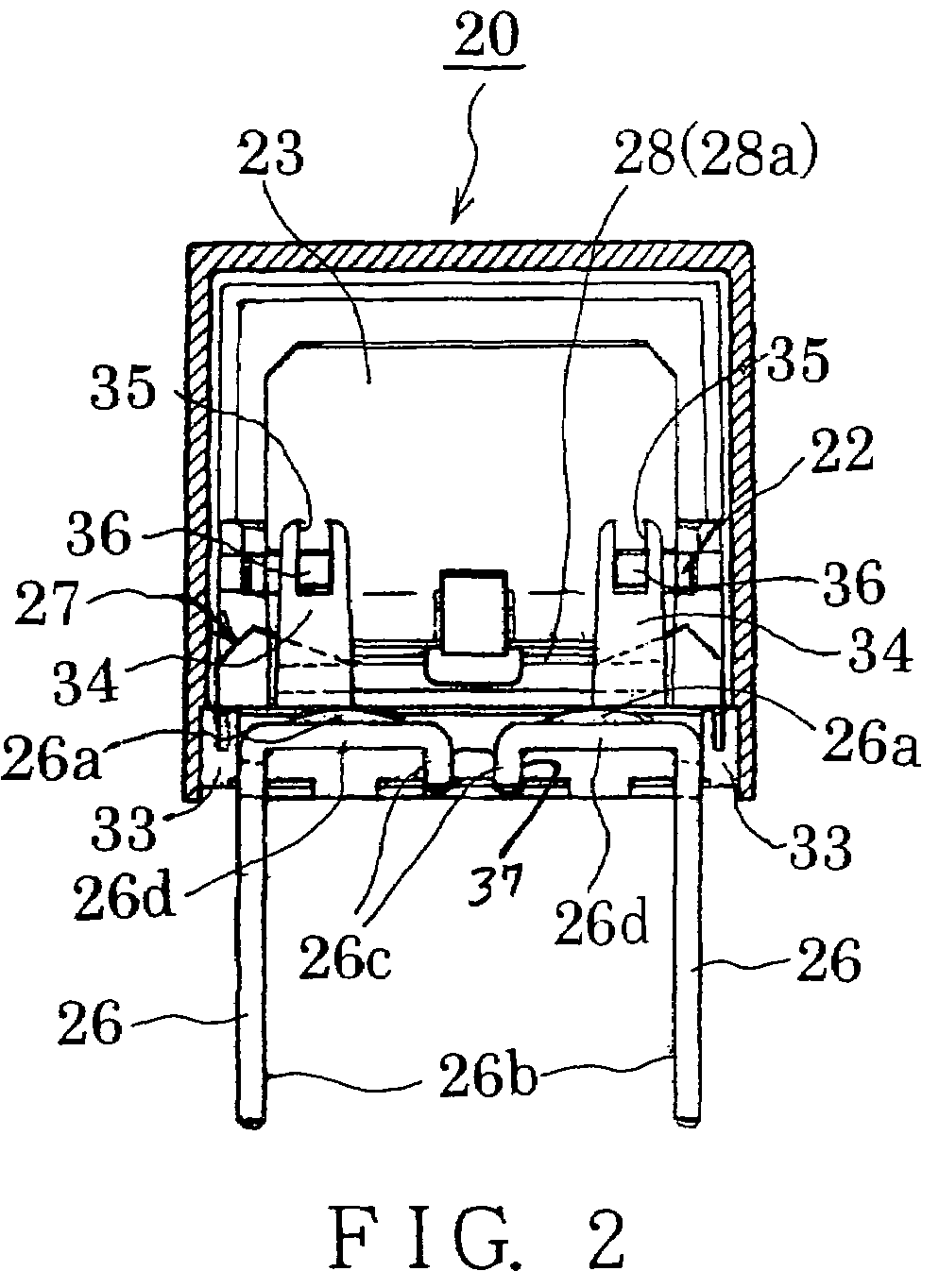

Electromagnetic relay

ActiveUS7439834B2Lower internal resistanceElectromagnetic relay detailsSelector switchesInternal resistanceContact strength

To reduce the internal resistance of small electromagnetic relays of a one-circuit three-contact gap type in order to make it possible to allow large electric currents and at the same time to improve the connection between the fixed contacts and the moveable contacts. Fixed contacts on the fixed terminals are positioned at each apex of an approximate triangle on the upper surface of the insulation base. Moveable contacts are installed on the lower surface of the moveable plate, and are respectively placed in a position which corresponds to each of the fixed contacts. The moveable plate is fastened to the moveable spring whose both ends are held onto the sides of the insulation base, and moves at a specified distance from the fixed contacts due to the pressure of the moveable spring. The construction results in the movable contacts contacting their corresponding fixed contacts at the three positions with uniform contact strength.

Owner:UCHIYA THERMOSTAT

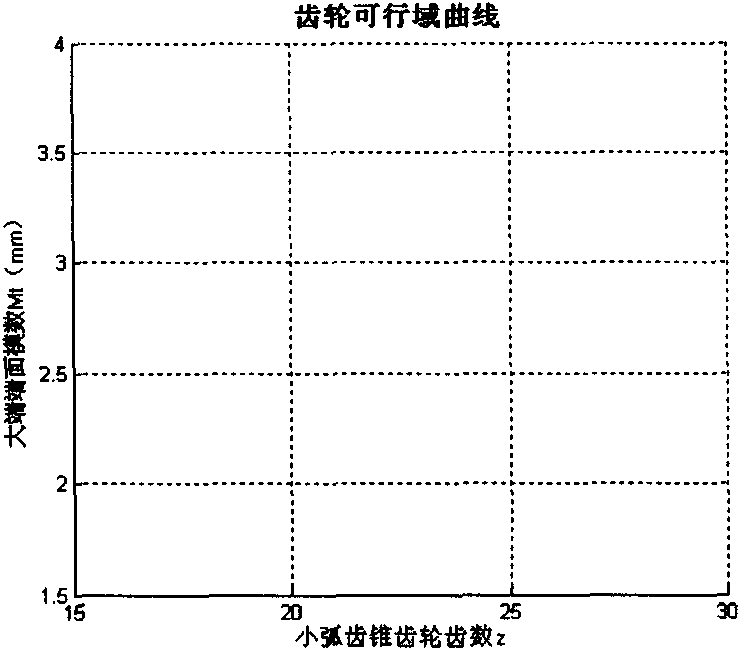

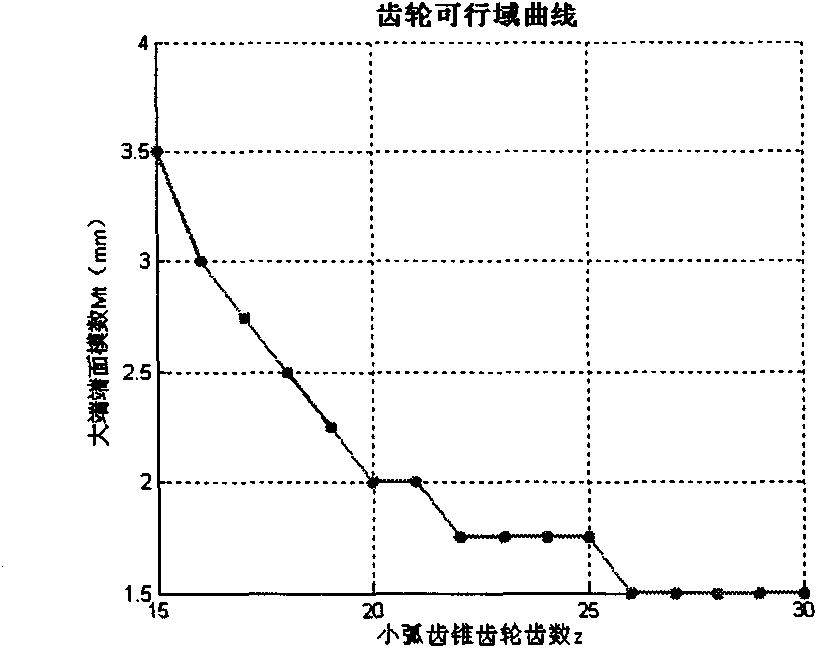

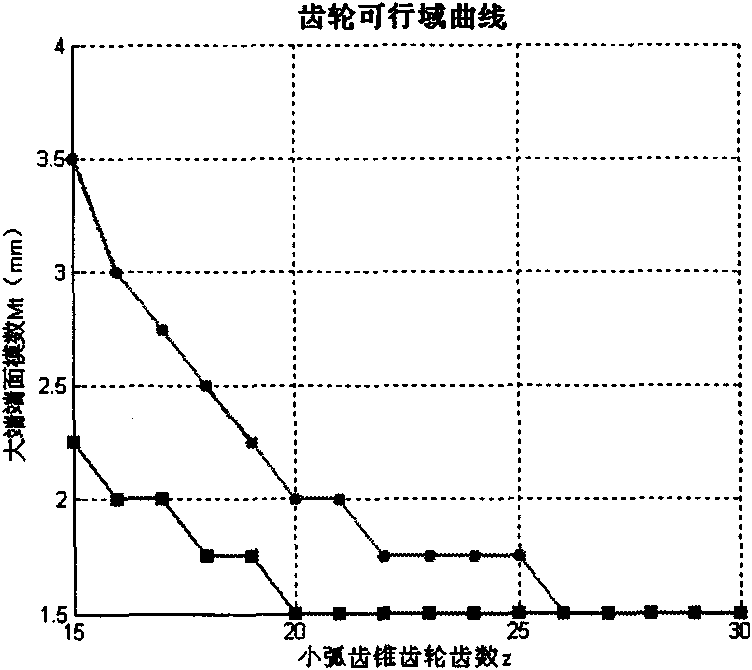

Design method of spiral bevel gear

The invention relates to a design method of a spiral bevel gear, which is technically characterized in that a coordinate system is established by using the tooth number z of small spiral bevel gears as an abscissa and using the end surface module mi of larger ends as an ordinate, a tooth number-module curve satisfying critical condition thereof is respectively drawn according to contact strength constraint conditions and bending strength constraint conditions, and a public area above the two curves is a feasible region satisfying strength reliability requirements. On the basis, the overlap ratio of the gear under the specific tooth number is marked, so that the optimal solution of gear driving is obtained in the feasible region simultaneously satisfying an overlap ratio constraint condition. Then a tooth number-module curve corresponding to a preset volume is drawn, and a discrete optimal solution with the smallest volume is found by continuously changing a preset volume value. A gearreliability optimization method disclosed by the invention breaks through a traditional reliability optimization method, overcomes the defects of an existing optimization method and is the design method which can be applied to the reliability optimization of all gears.

Owner:南通欧特建材设备有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com