Patents

Literature

200results about How to "Improve contact strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

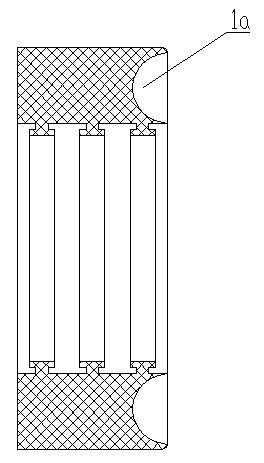

Integral honeycombed catalyst for SCR flue-gas denitration and preparation method therefor

ActiveCN101444727AImprove catalytic performanceIncrease contact areaDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsSodium BentoniteFlue gas

The invention relates to an integral honeycombed catalyst for SCR flue-gas denitration and a preparation method therefor. Titanium dioxide, bentonite and meerschaum are taken as carries, soaked for loading active components, formed, dried and baked to prepare the integral honeycombed catalyst. The carries comprise titanium dioxide 60-90%, bentonite 0-20% and meerschaum 0-10% by weight; the active components comprise WO3 5.0-10.0% OR MoO3 5.0-9.0%, V2O5 0.3-5.0%, and CeO2 0.0-2.0% or Nb2O5 0.0-1.0% by weight; and the total of the components is 100%. The catalytic activity is high, the denitration efficiency is high, and the service life is long; titanium dioxide, bentonite and meerschaum are taken as the carries, soaked for loading the active components, formed, dried and baked to prepare the integral honeycombed catalyst; and the preparation method is scientific, reasonable, simple and feasible.

Owner:ZHONGCAI HIGH NEW MATERIAL +1

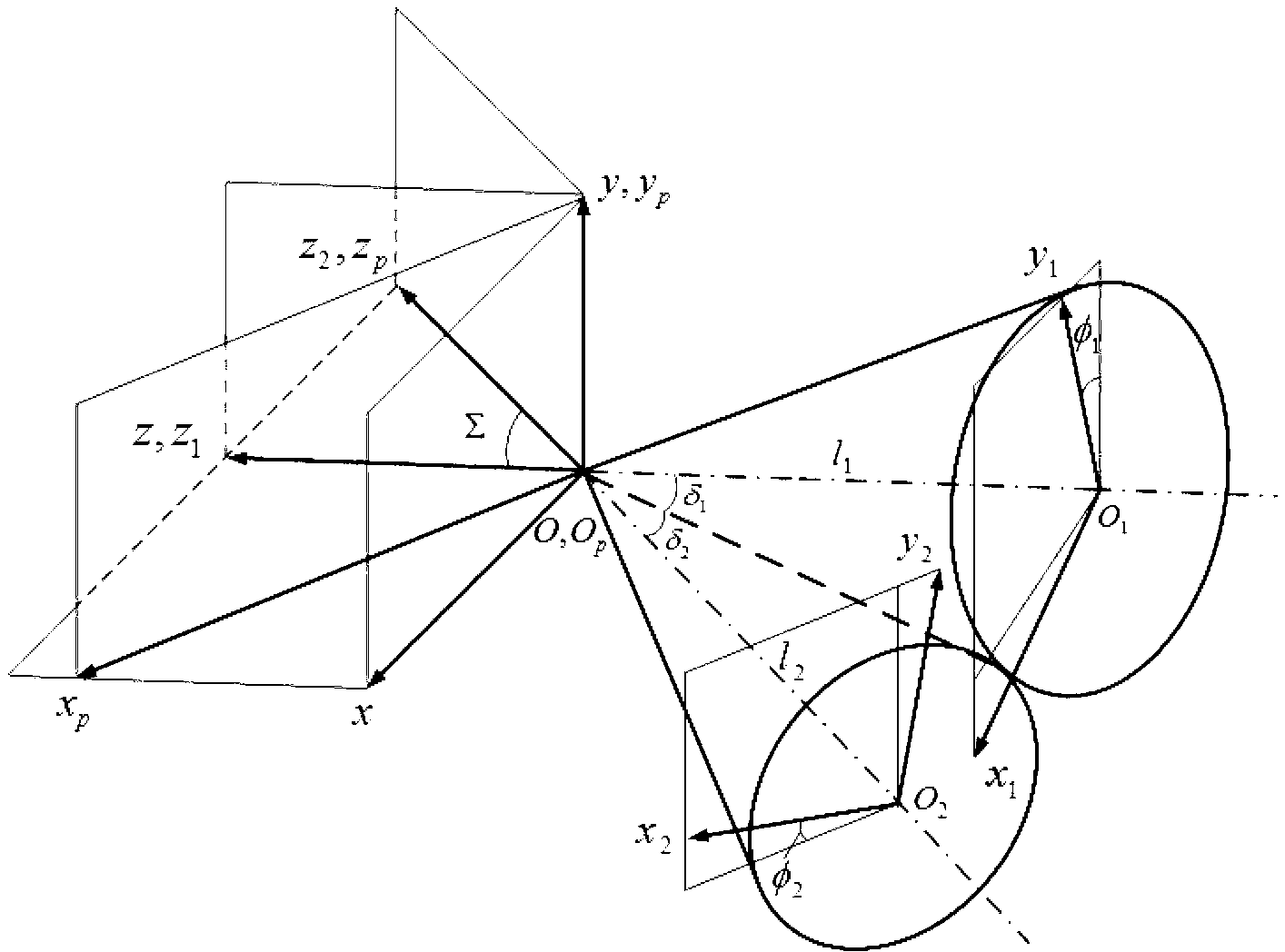

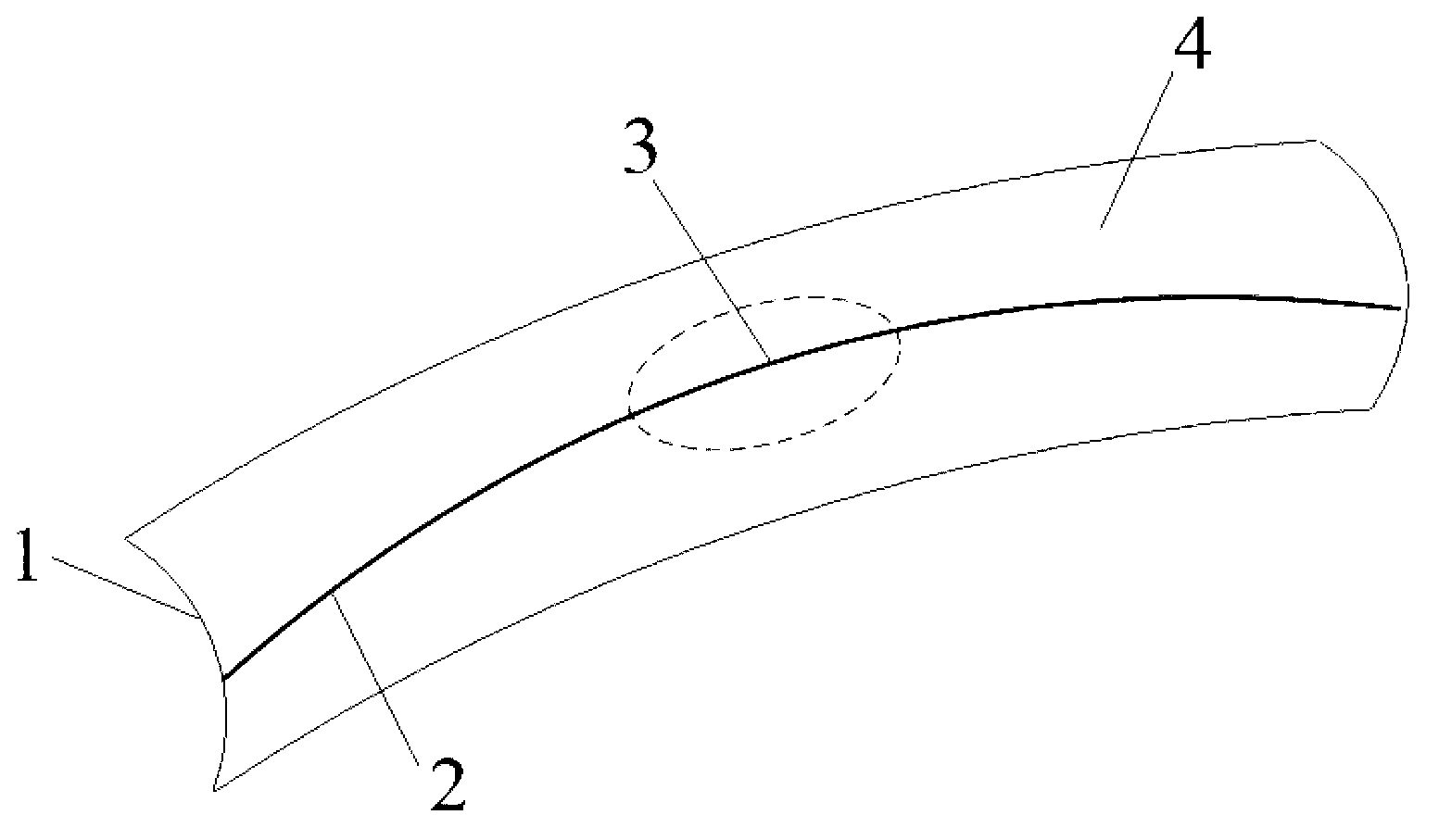

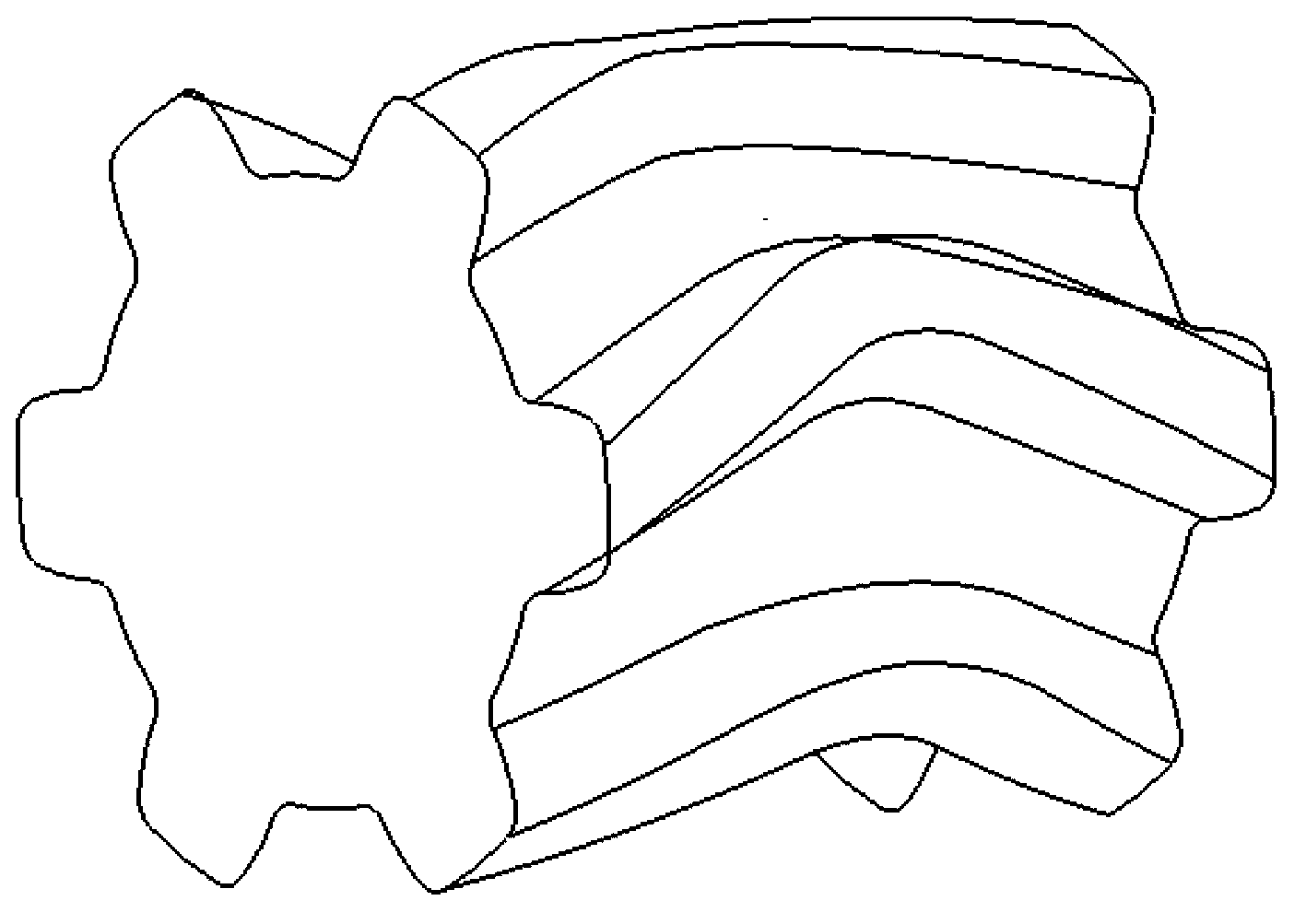

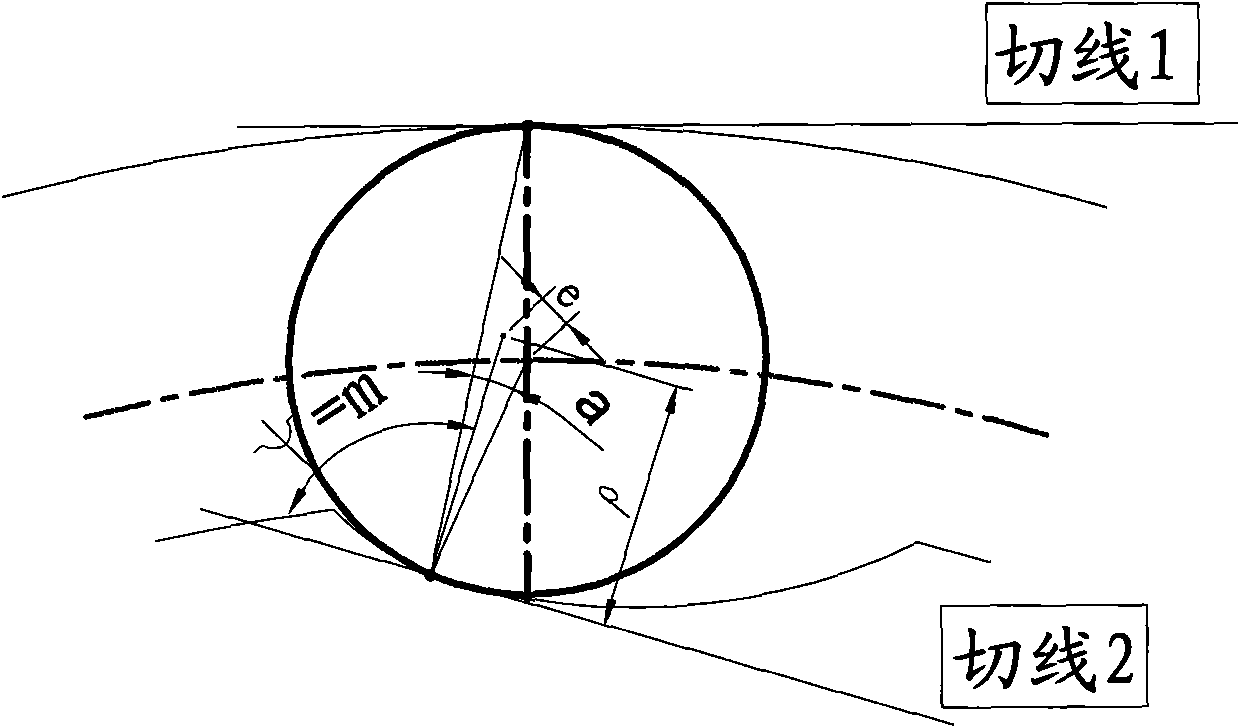

Bevel gear based on conjugate curves and meshing pair thereof

ActiveCN103075493AEasy to processImprove contact strengthToothed gearingsPortable liftingEngineeringContact Transmission

The invention discloses a bevel gear based on conjugate curves and a meshing pair thereof. The meshing pair comprises a bevel gear I and a bevel gear II which are mutually in point meshing and have arc tooth profile curves, and a contact curve gamma1 consisting of meshing points on the tooth profile curve of the bevel gear I and a contact curve gamma2 consisting of meshing points on the tooth profile curve of the bevel gear II are conjugate curves. According to the bevel gear transmission meshing pair based on the conjugate curves, the tooth profile curves of the mutually meshed bevel gear I and bevel gear II are respectively in an arc shape, the meshed tooth surfaces of the bevel gear I and the bevel gear II move along the conjugate curves, the meshing characteristics of the contact curves are succeeded, and the meshing of the contact curves between the tooth surfaces is high in contact strength; a contact transmission process is close to pure rolling along an axial direction, and the transmission efficiency is high; the tooth surfaces are easy to process and manufacture, transmission errors are small, and the service life is long; under the conditions of equivalent transmission ratio and center distance, the selection and determination of a small tooth number and a large modulus can be realized; and the transmission requirements of high speed, heavy load, large power and high efficiency can be met.

Owner:CHONGQING UNIV

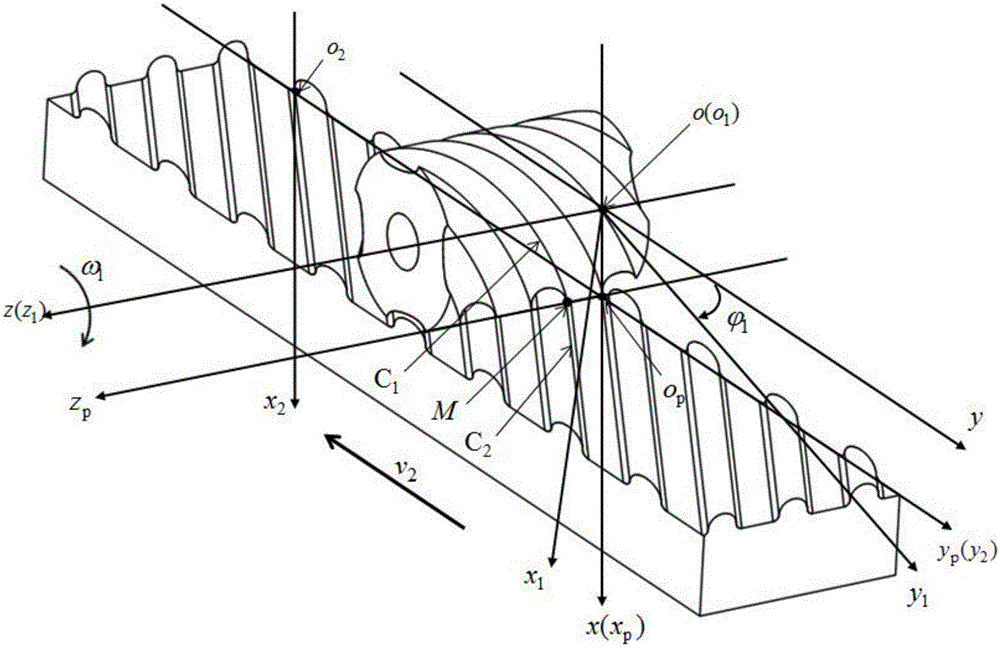

Curve conjugation based symmetrical cambered surface conjugate curve gears and engagement pair thereof

ActiveCN102853054AImprove contact strengthImprove transmission efficiencyPortable liftingGearing elementsSmall toothContact Transmission

The invention discloses curve conjugation based symmetrical cambered surface conjugate curve gears and an engagement pair thereof. The engagement pair comprises a gear I and a gear II, wherein the gear I and the gear II are engaged with each other in a point contact mode, and a contact curve gamma 1 which is composed of engagement points on a tooth profile cambered surface of the gear I and a contact curve gamma 2 which is composed of engagement points on a tooth profile cambered surface of the gear II are conjugate curves. According to the engagement pair of the curve conjugation based symmetrical cambered surface conjugate curve gears, the contact curve gamma 1 of the gear I and the contact curve gamma 2 of the gear II which form the engagement pair are conjugate curves, and engagement points between the gear I and the gear II move along contact curves; the engagement pair has the advantages of point contact engagement, tooth profiles of point contact have the high contact strength, the contact transmission process is close to pure rolling along the axial direction, and the transmission efficiency is high; and the selection and the determination of the small tooth number and the large modulus can be achieved on the conditions of the same transmission ratio and the same center-to-center distance, the transmission requirements of high speed, heavy load, high power and high efficiency can be met, and the engagement pair has broad application prospects.

Owner:CHONGQING UNIV

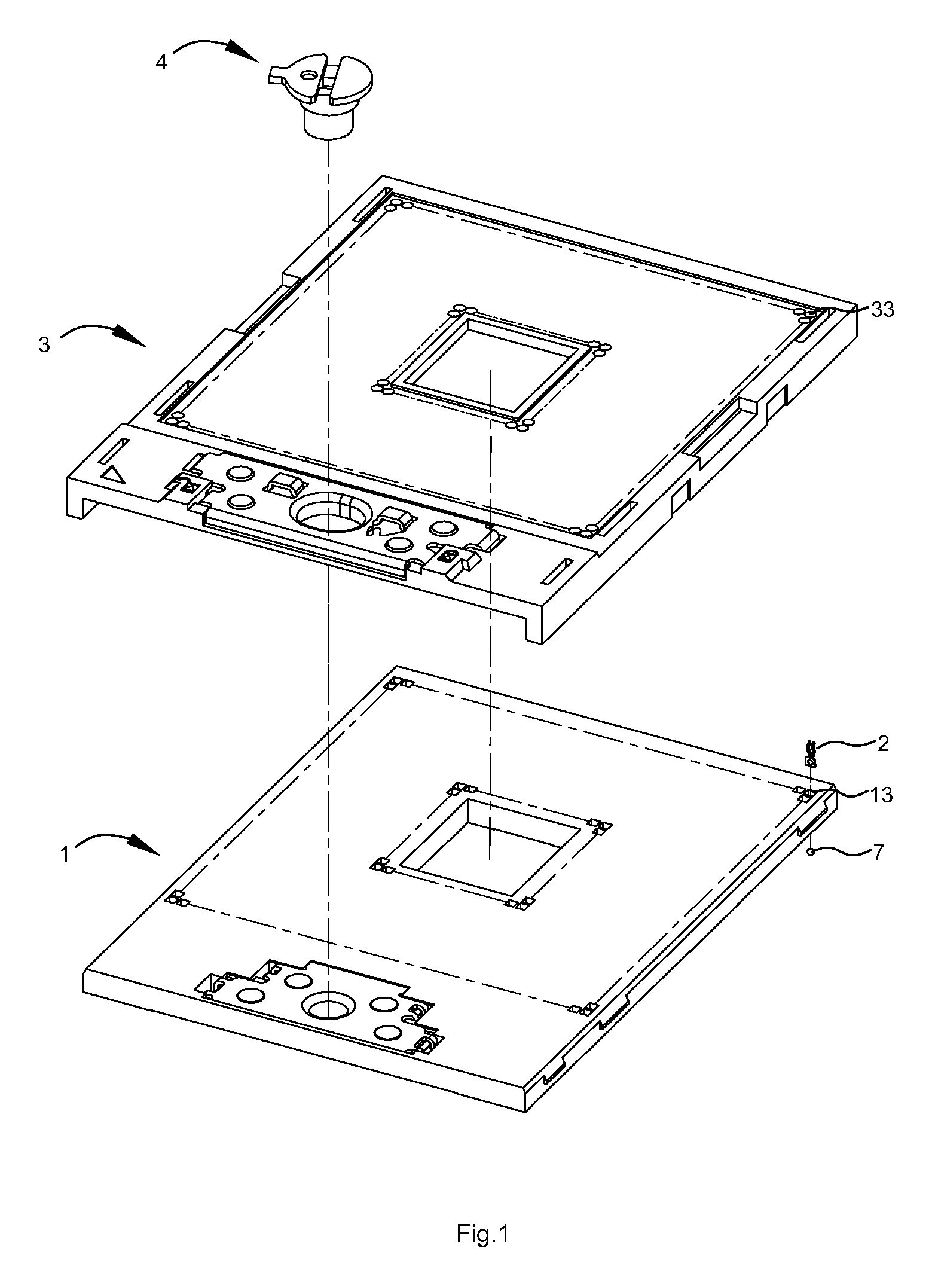

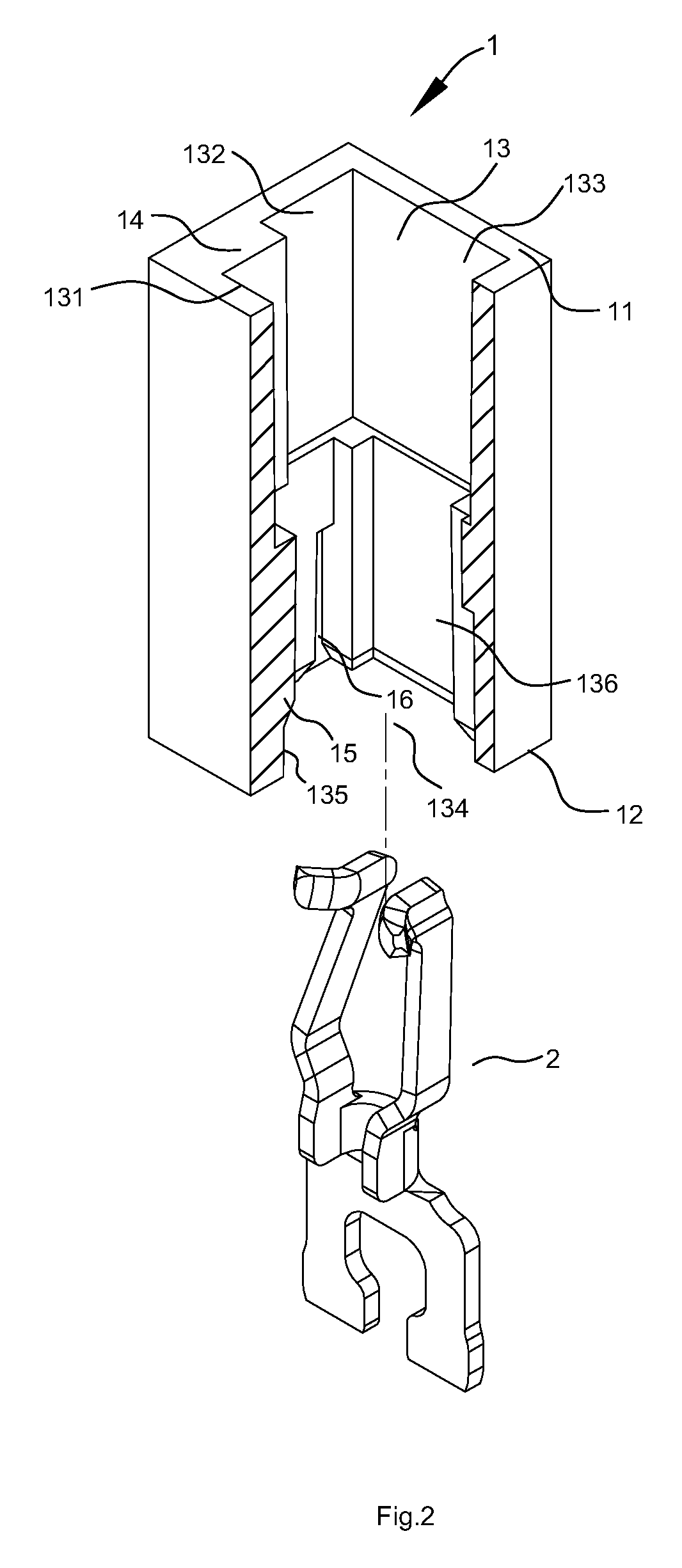

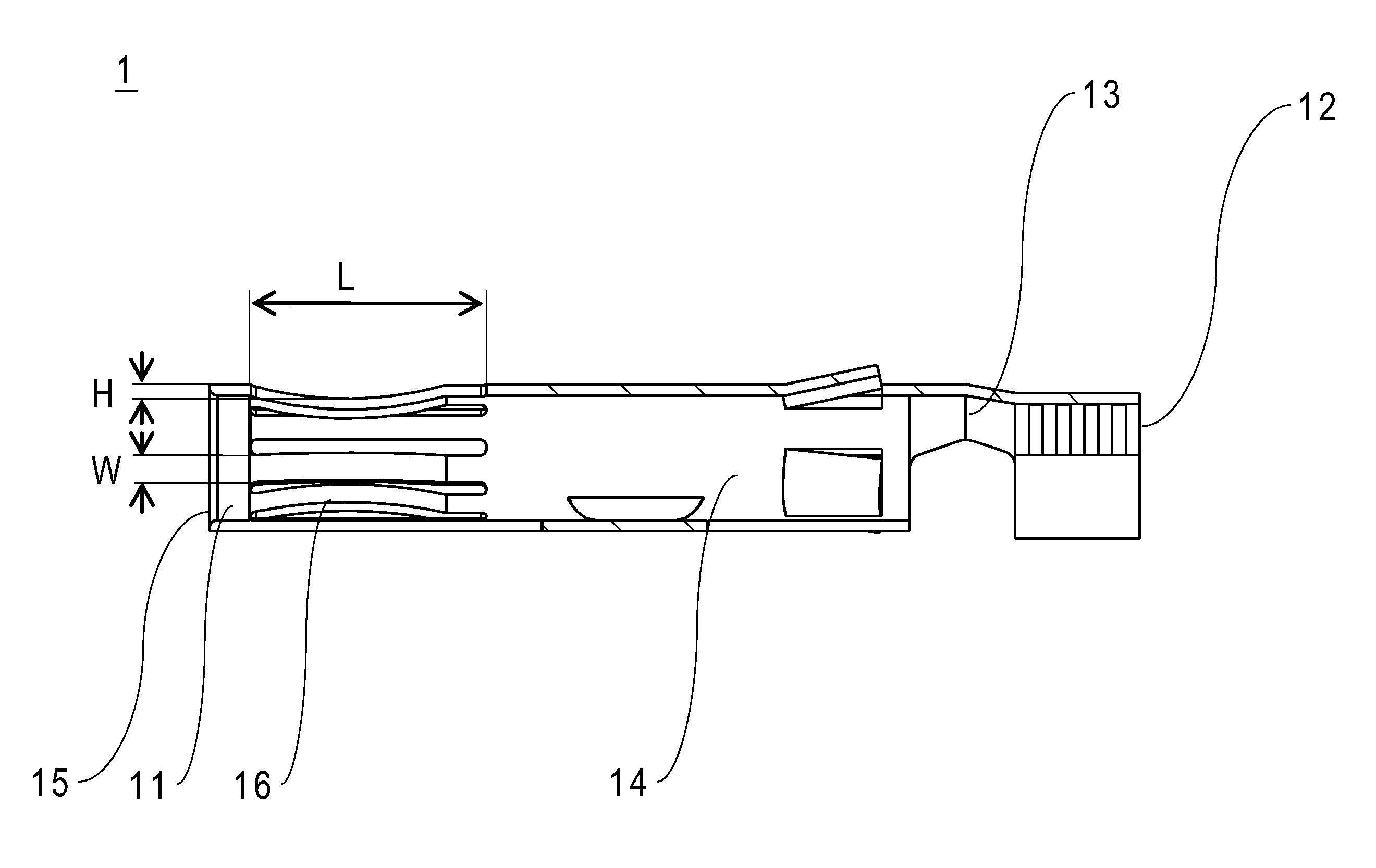

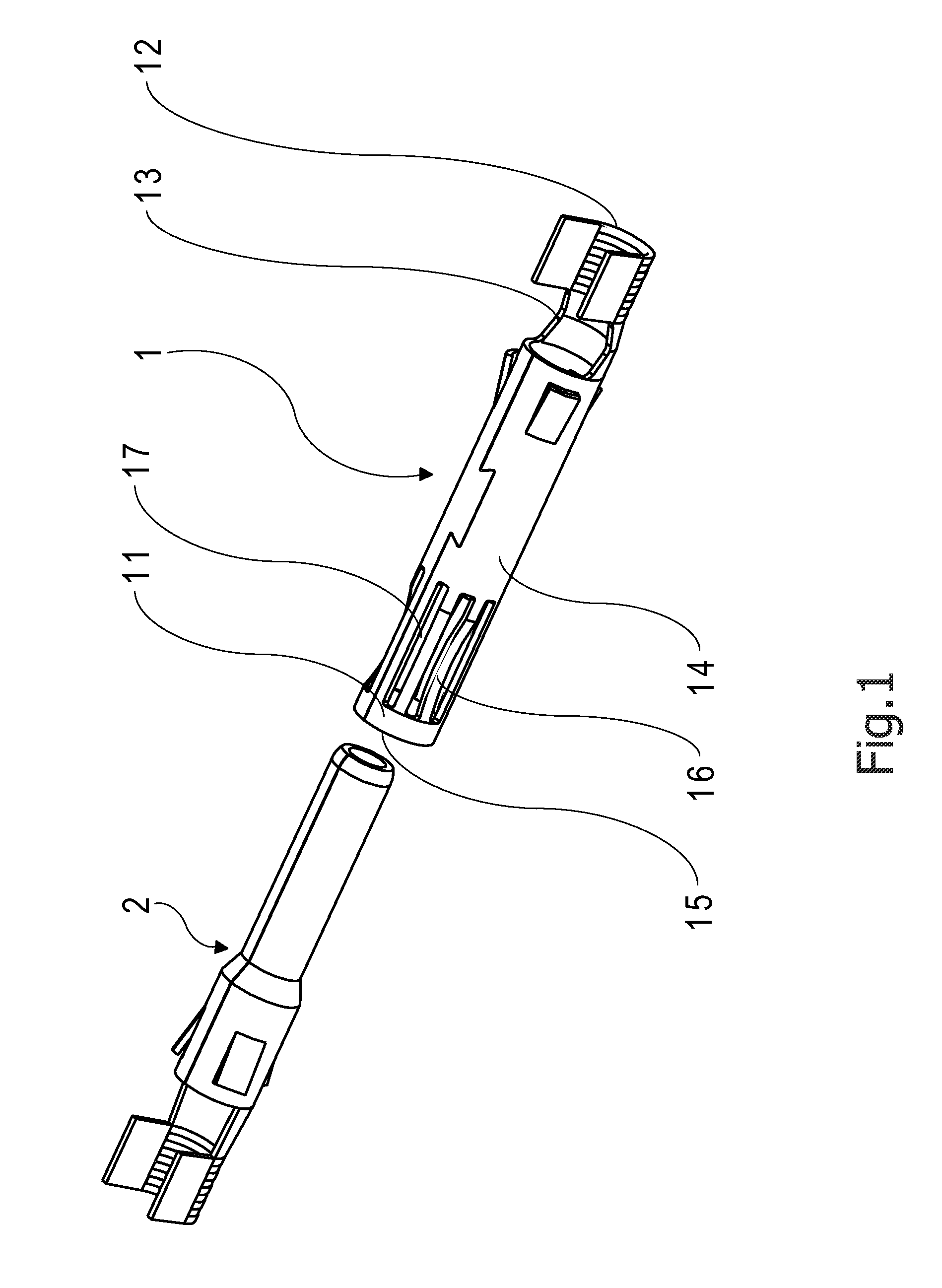

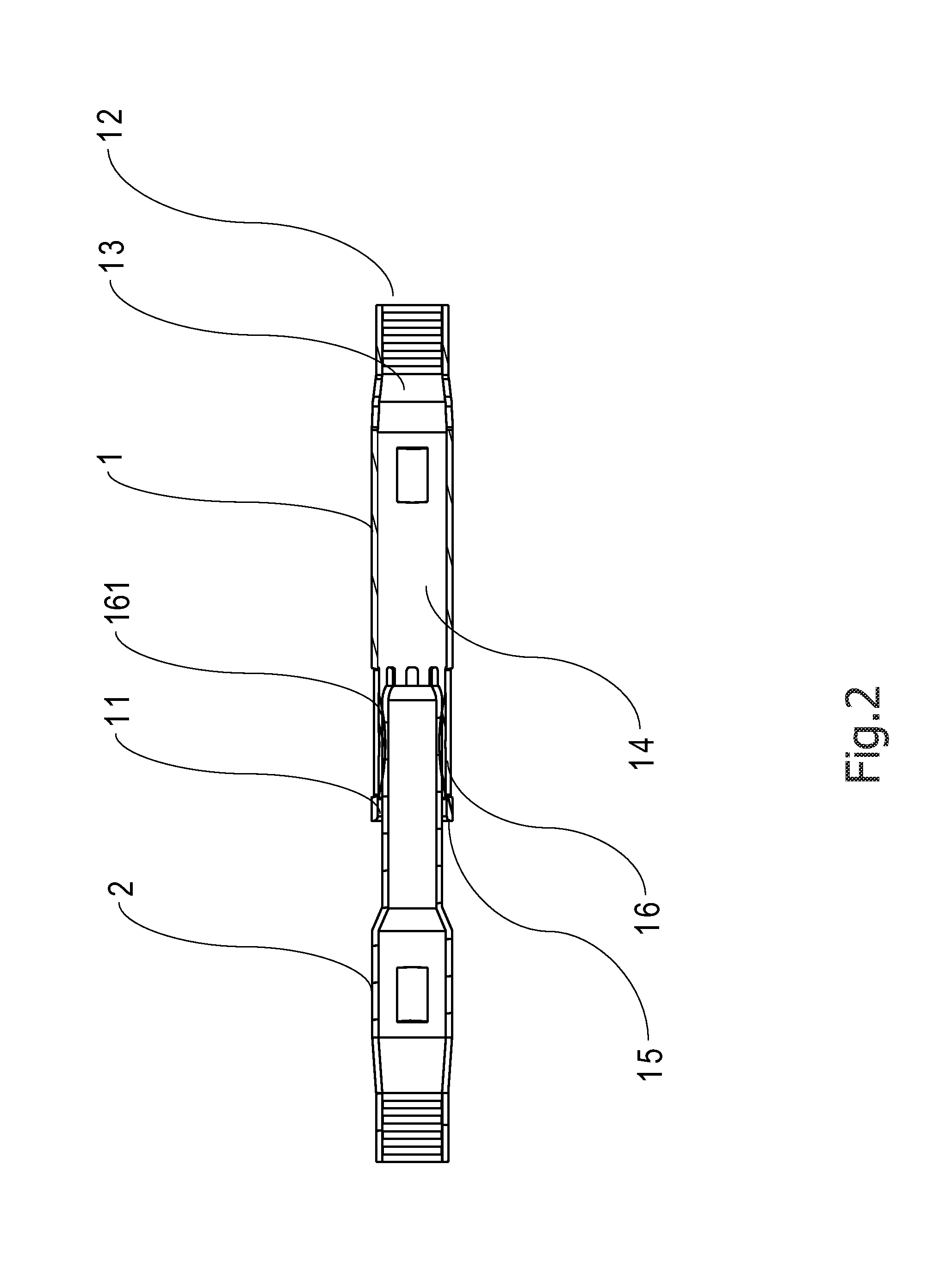

Electrical connector

ActiveUS20100297866A1Reliable electrical connectionAvoid damageCoupling contact membersElectric connection basesEngineeringElectrical connector

Disclosed is an electrical connector including a plurality of conductive terminals. The conductive terminal comprises a base and a pair of arms. Each arm includes a connection part extending forwardly from the base, a first bending part bent and extending upwardly from the connection part, a second bending part bent upwardly from the first bending part, a first elastic arm extending upwardly from the second bending part, and a contact section formed at a rear end of the first elastic arm. The first and second bending part are bent away from the other arm while the first elastic arm extends toward the other arm. The minimum distance between the two first elastic arms and that between the two second bending parts are larger than the minimum distance between the two connection parts and that between the two contact sections.

Owner:LOTES

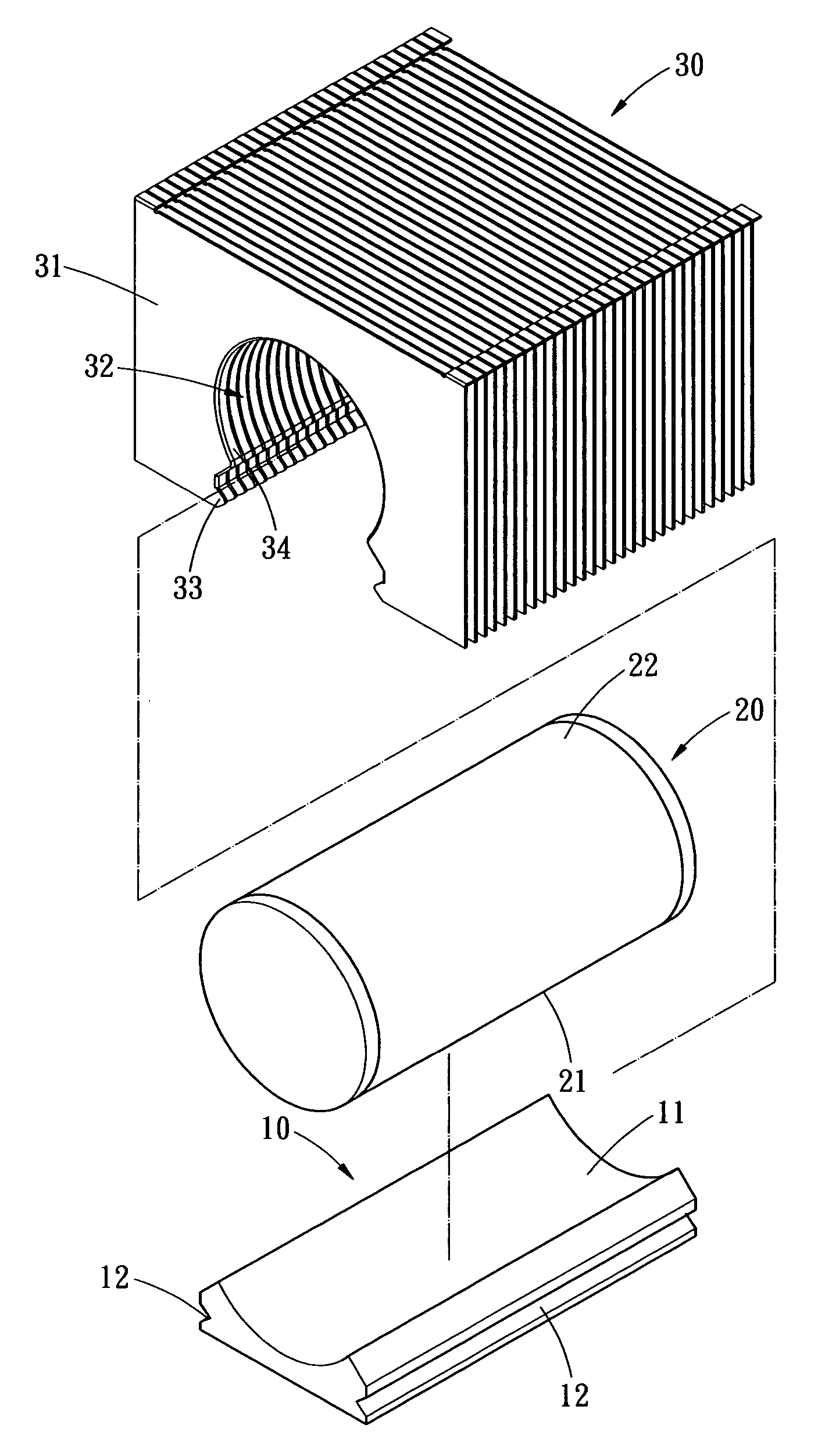

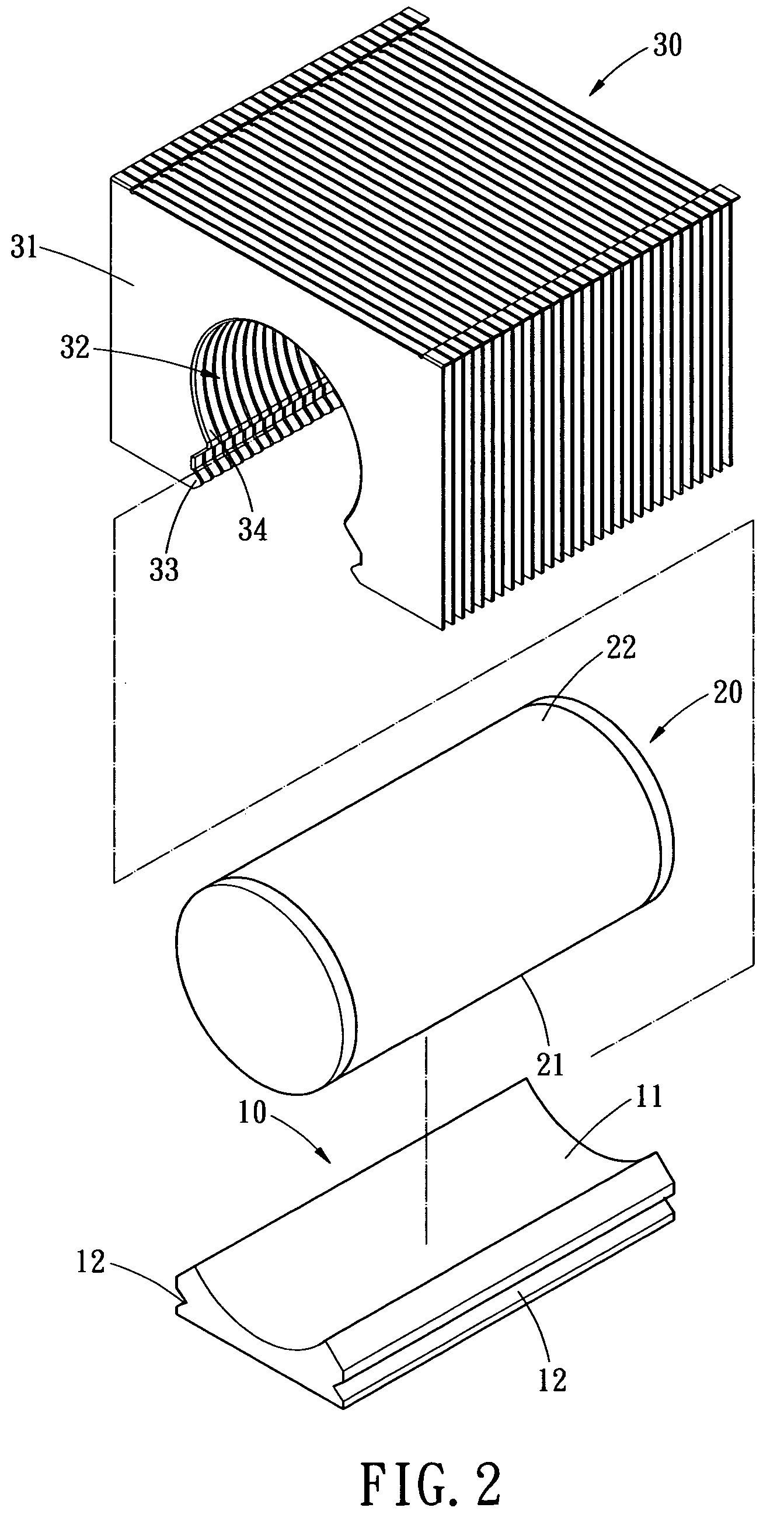

Heat dissipation structure

InactiveUS20050195569A1Improve contact strengthReduce thermal resistanceSemiconductor/solid-state device detailsSolid-state devicesEngineeringHeat spreader

A heat dissipation structure installed on a computer central processing unit or a heat generating device, has a thermal conductive base, at least one heat pipe and a heat sink. The thermal conductive base has a supporting part and a first interlocking part. The supporting part allows the heat pipe mounted thereon. The heat sink has a plurality of fins configured with a receiving slot and a second interlocking part. The second interlocking part is engaged with the first interlocking part, while the receiving slot and the supporting part of the thermal conductive base enclose the heat pipe therein to form the heat dissipation structure. By the connection between the thermal conductive pipe and the heat sink, the contact intensity between various devices is increased, such that the heat conduction performance is improved.

Owner:HSU HUL CHUN

Waterproof connector and female terminal therein

ActiveUS8079885B1Improve contact strengthReliable electrical connectionCoupling contact membersElectric connection basesStructural engineeringElectric cables

A female terminal of a connector has a connection end for connecting with the core of a cable and a contact end for being inserted by a slender male terminal and making electrical contact therewith. The contact end includes a hollow cylinder whose two ends are connected to a neck and formed with an opening, respectively, and whose inner diameter ranges from 3.0 mm to 6.0 mm. The middle section of the hollow cylinder is provided with a plurality of resilient strips extending along an axial direction of the hollow cylinder, such that a slot is formed between each two adjacent resilient strips. Each resilient strip has two ends connected to the hollow cylinder and is 4.5 mm to 12.5 mm in length and 0.5 mm to 1.1 mm in width. Each resilient strip has a central portion deflected toward the axis of the hollow cylinder by a displacement ranging from 0.2 mm to 0.8 mm.

Owner:KS TERMINALS INC

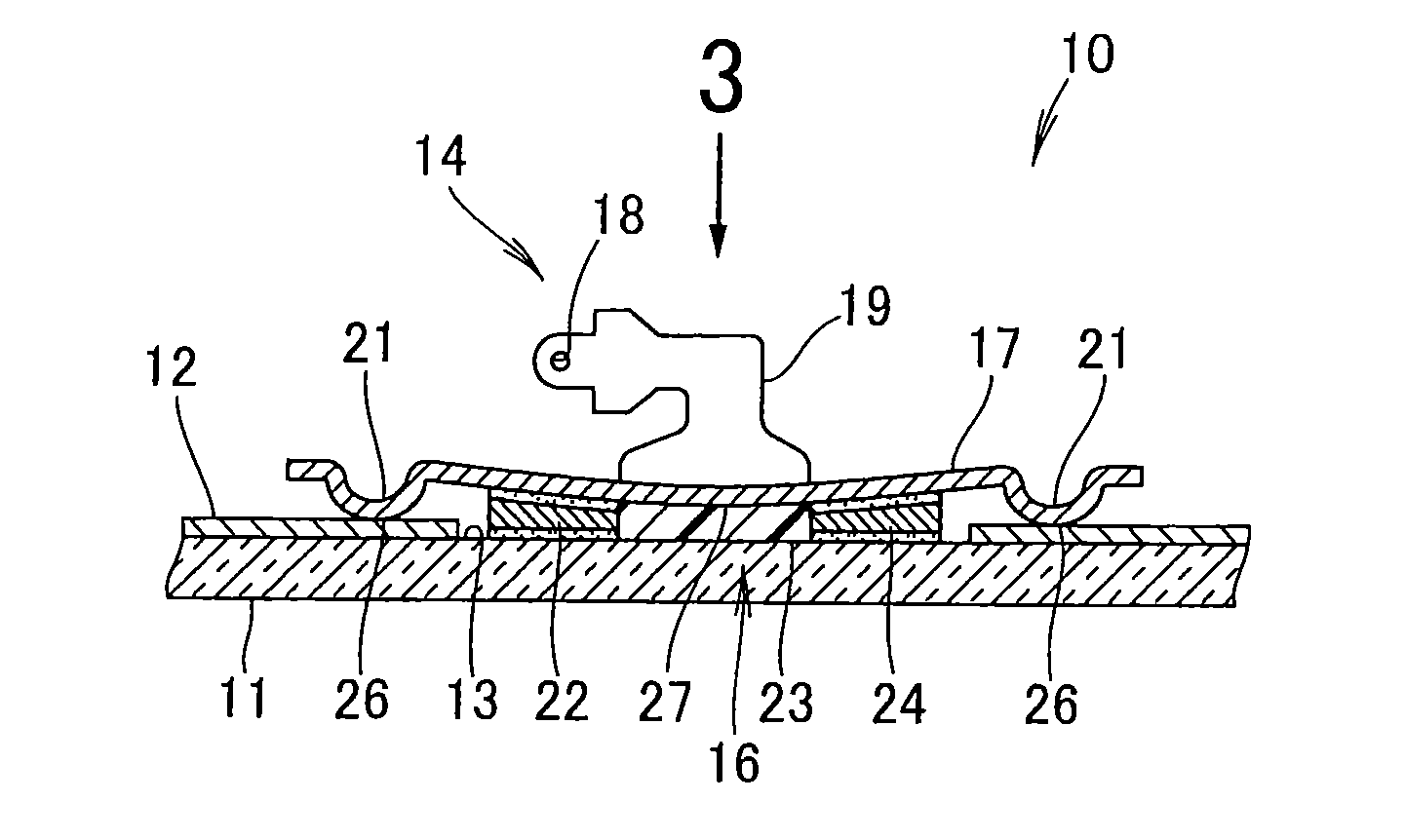

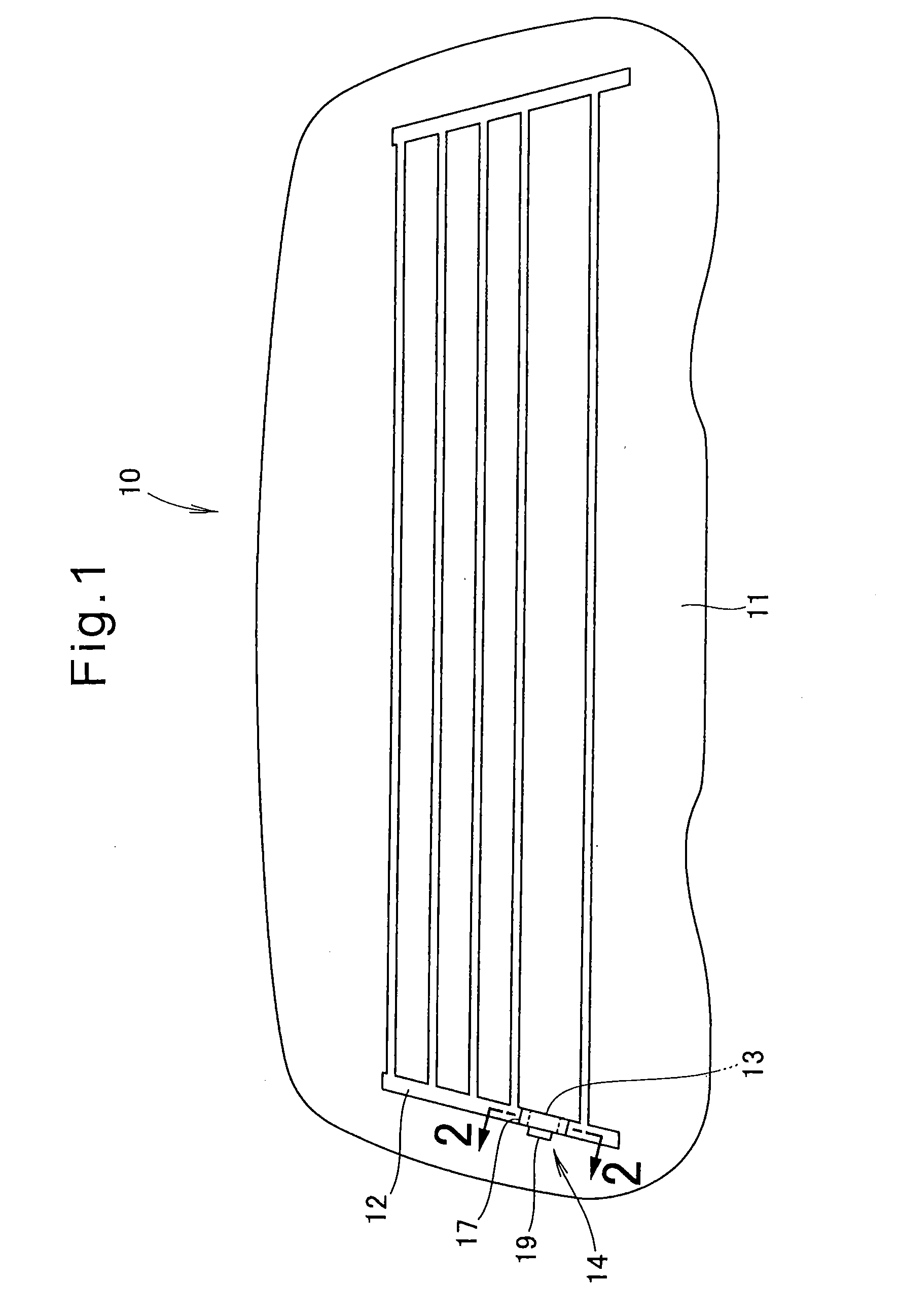

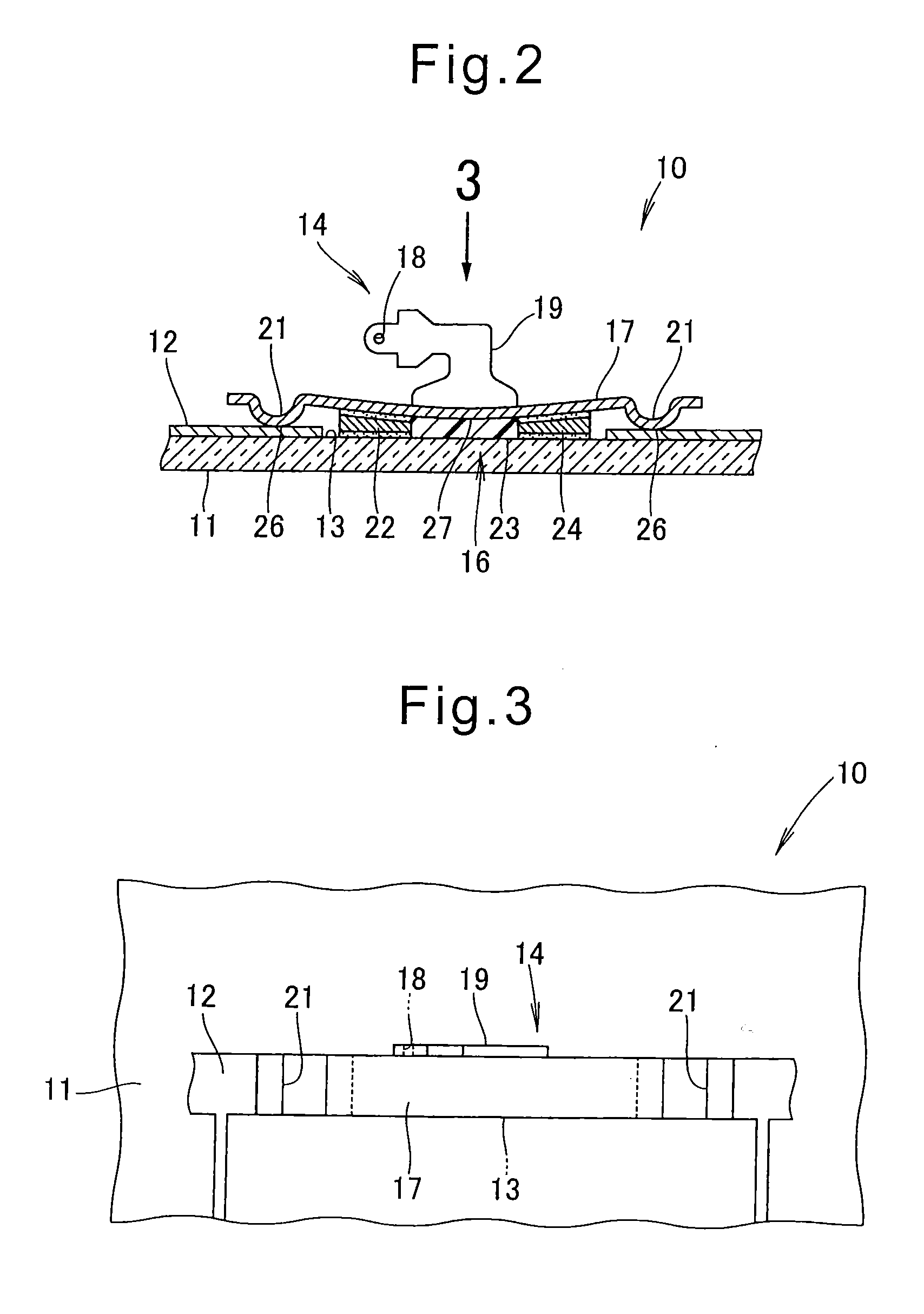

Glass with terminal

InactiveUS20120067641A1Good contact strengthImprove contact strengthElectrically conductive connectionsTransparent/reflecting heating arrangementsEngineeringAdhesive

A glass-with-terminal, in which a terminal is bonded to a glass without using solder, is disclosed. The glass-with-terminal has a configuration wherein a terminal (14) is bonded to a glass (11) provided on the surface thereof with a silver print (12). The terminal (14) includes a bent portion (21) formed, in at least one end of the terminal, to be bent toward the silver print (12). The terminal (14) is bonded to the glass (11) through an adhesive (23), so that the bent portion (21) makes contact with the upper surface of the silver print (12).

Owner:3M INNOVATIVE PROPERTIES CO +1

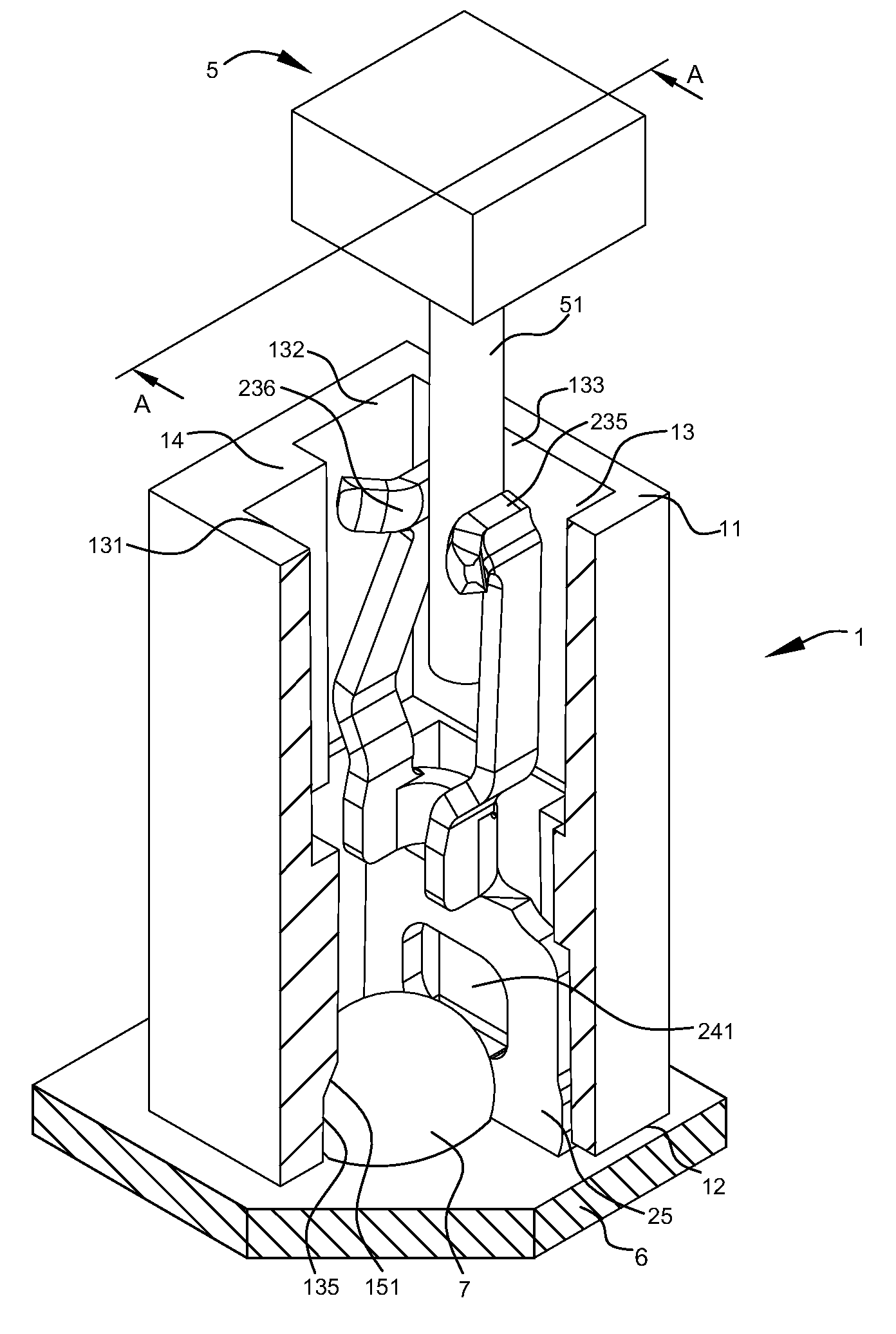

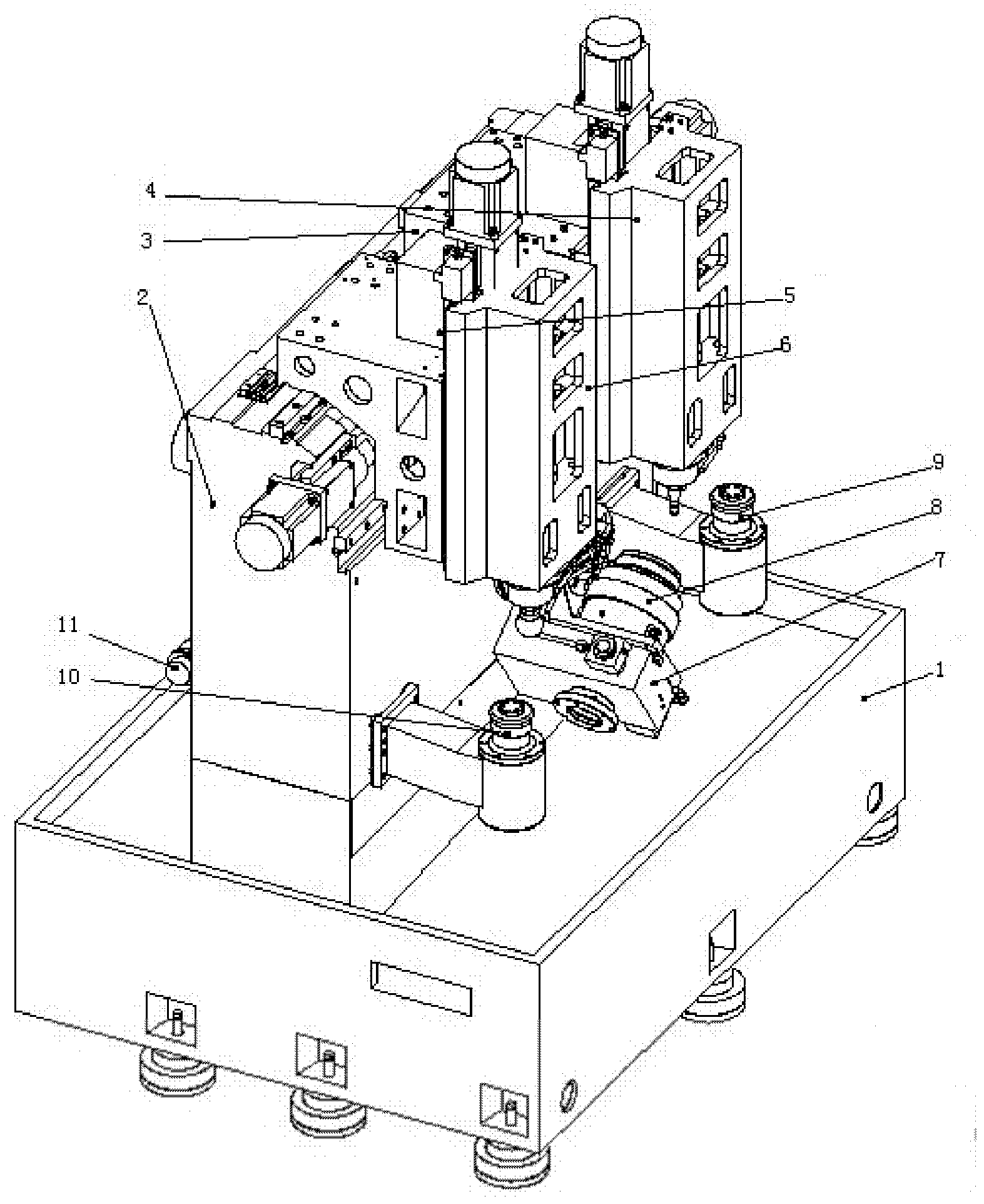

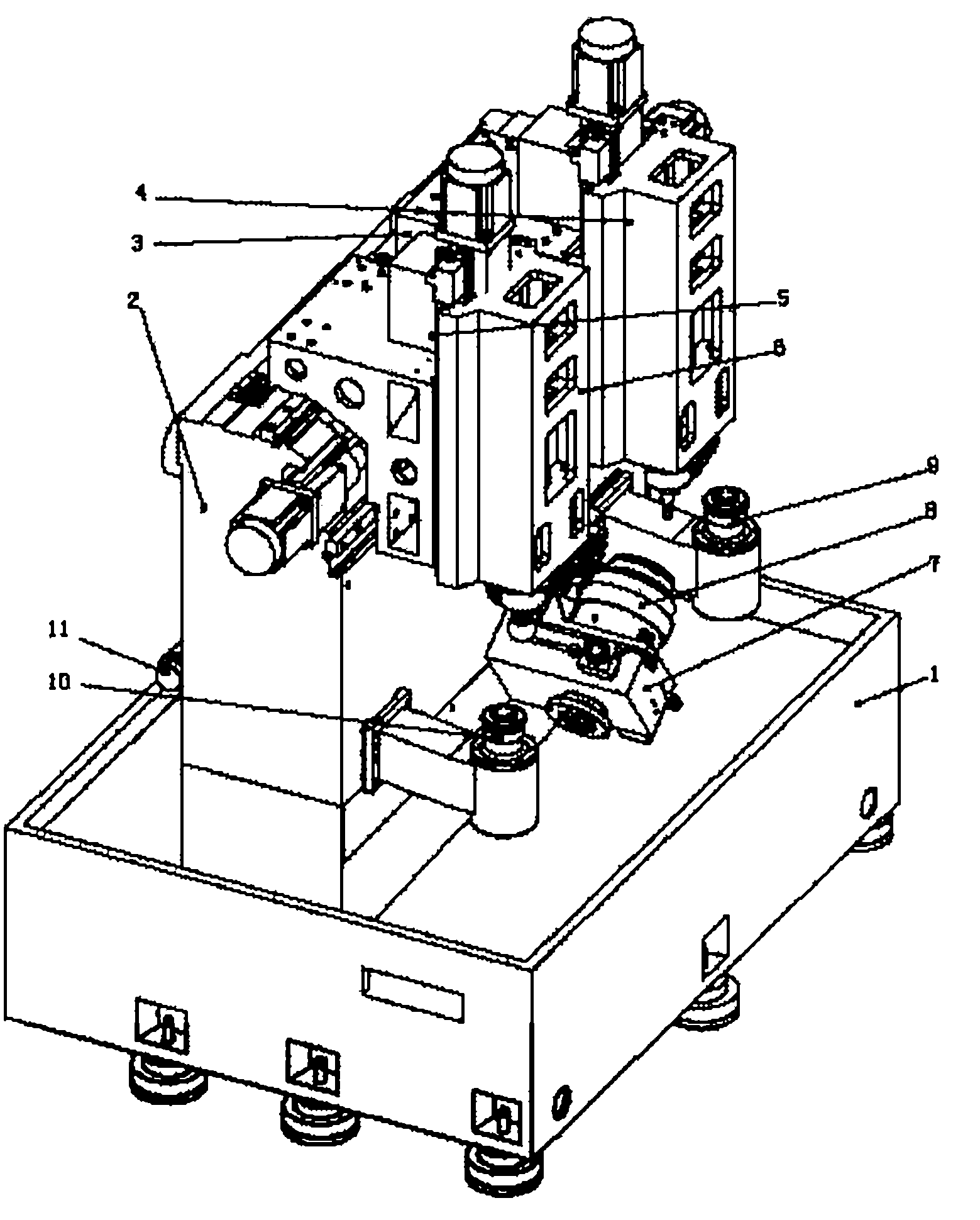

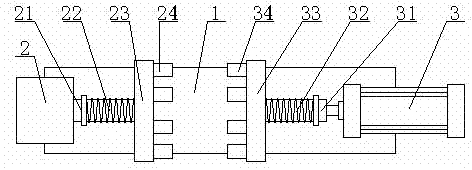

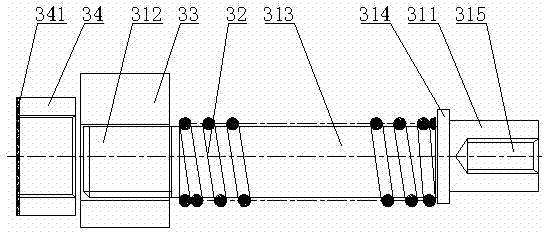

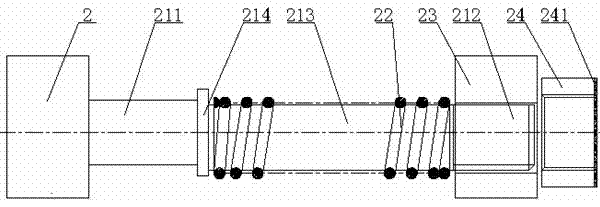

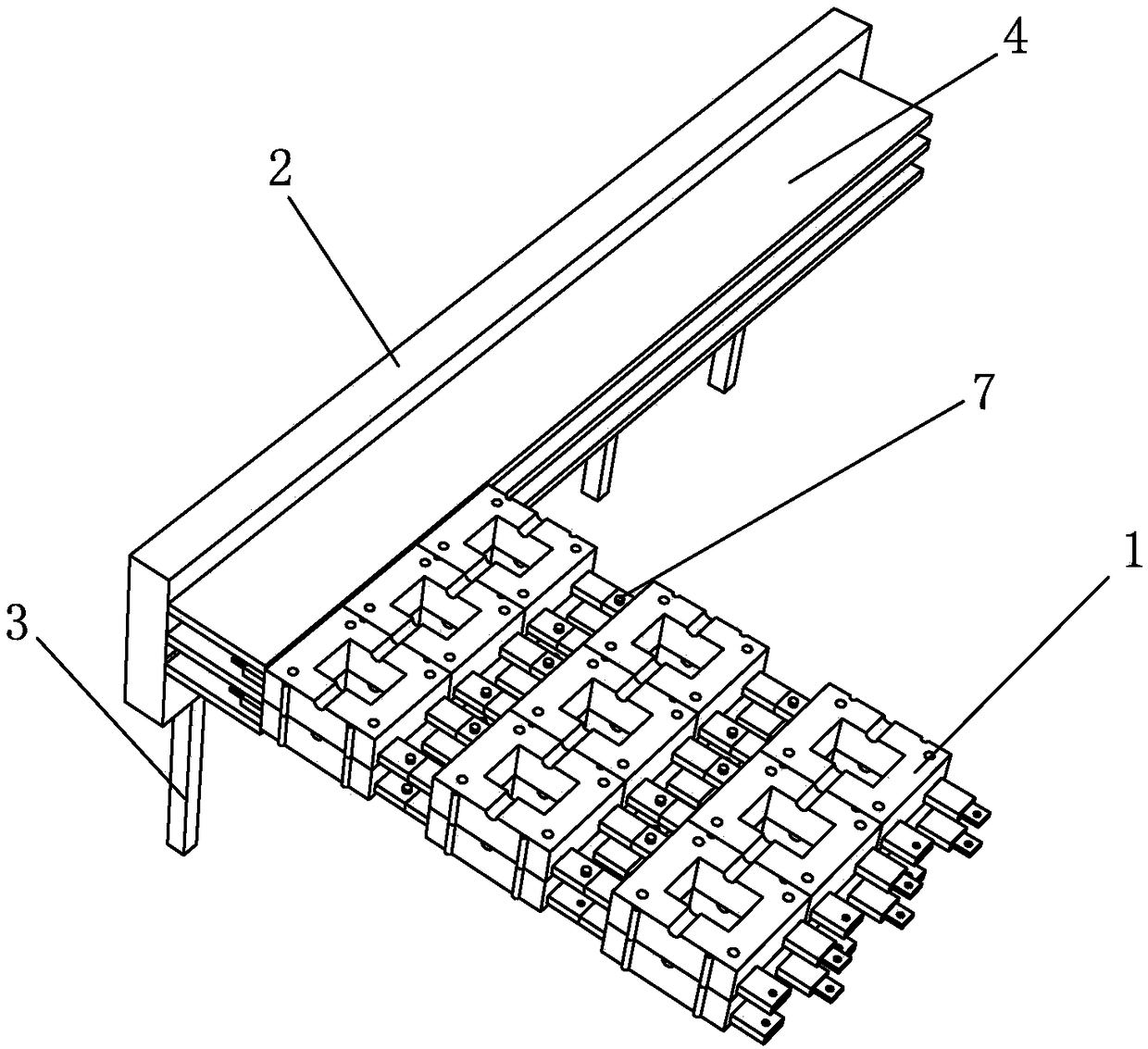

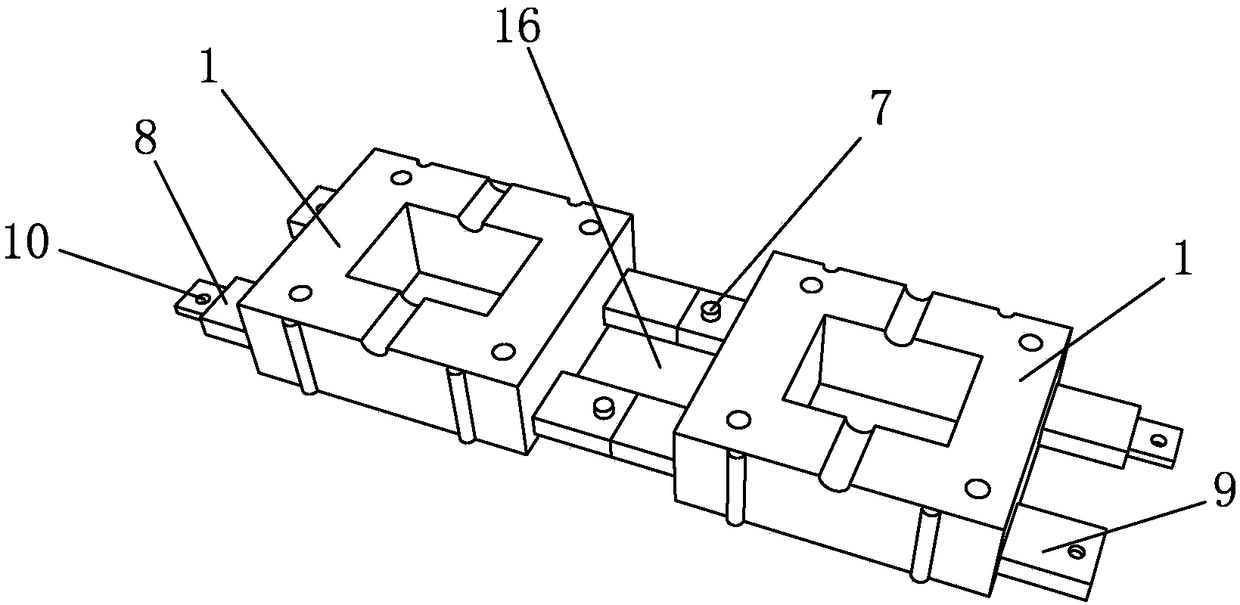

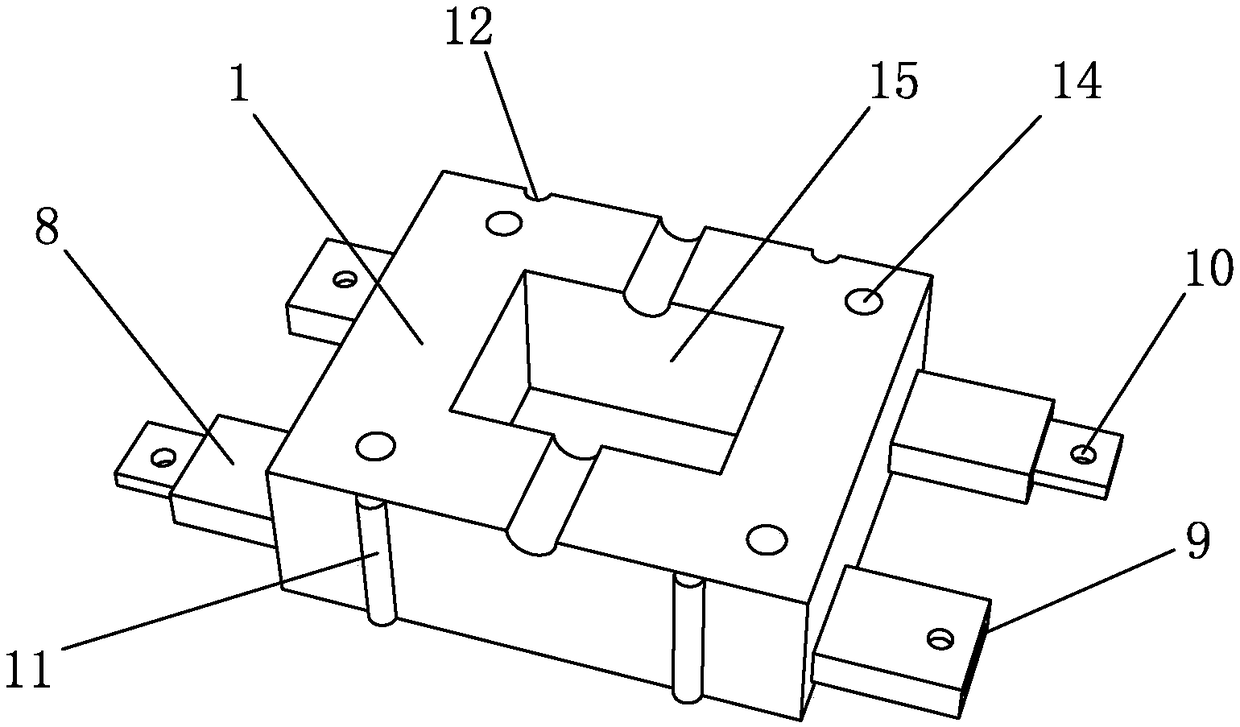

Double-station CNC (computer numerical control) vertical ball cage arc raceway groove and ball hole grinding machine

InactiveCN102601713AImprove contact strengthHigh strengthAbrasive surface conditioning devicesGrinding machinesEngineeringMechanical engineering

The invention discloses a double-station CNC (computer numerical control) vertical ball cage arc raceway groove and ball hole grinding machine. The grinding machine is characterized in that a cage-shaped column is installed on the rear part of the upper surface of a cage-shaped machine body; a first sliding saddle and a second sliding saddle are installed on the cage-shaped column in parallel and can slide left and right along the cage-shaped column; a first main shaft box is fixed on the first sliding saddle and can slide up and down along the sliding saddle; a raceway groove grinding wheel is fixed on the first main shaft box; a second main shaft box is fixed on the second sliding saddle and can slide up and down along the sliding saddle; a ball hole grinding wheel is fixed on the second main shaft box; a swing rotary table is installed on the upper surface of the cage-shaped machine body in the middle of the front side of the cage-shaped column; a positioning fixture is installed on the swing rotary table; and a swing transmission component of the swing rotary table is arranged at the rear of the cage-shaped column and drives the swing rotary table to rotate in an indexing manner. The double-station CNC vertical ball grinding machine is formed by integrating the CNC vertical ball cage arc raceway groove grinding machine, the ball cage ball hole grinding machine and the swing rotary table carrying out swing motion. The grinding machine has a reasonable structure and is convenient to operate.

Owner:ANHUI LICHENG MACHINERY EQUIP

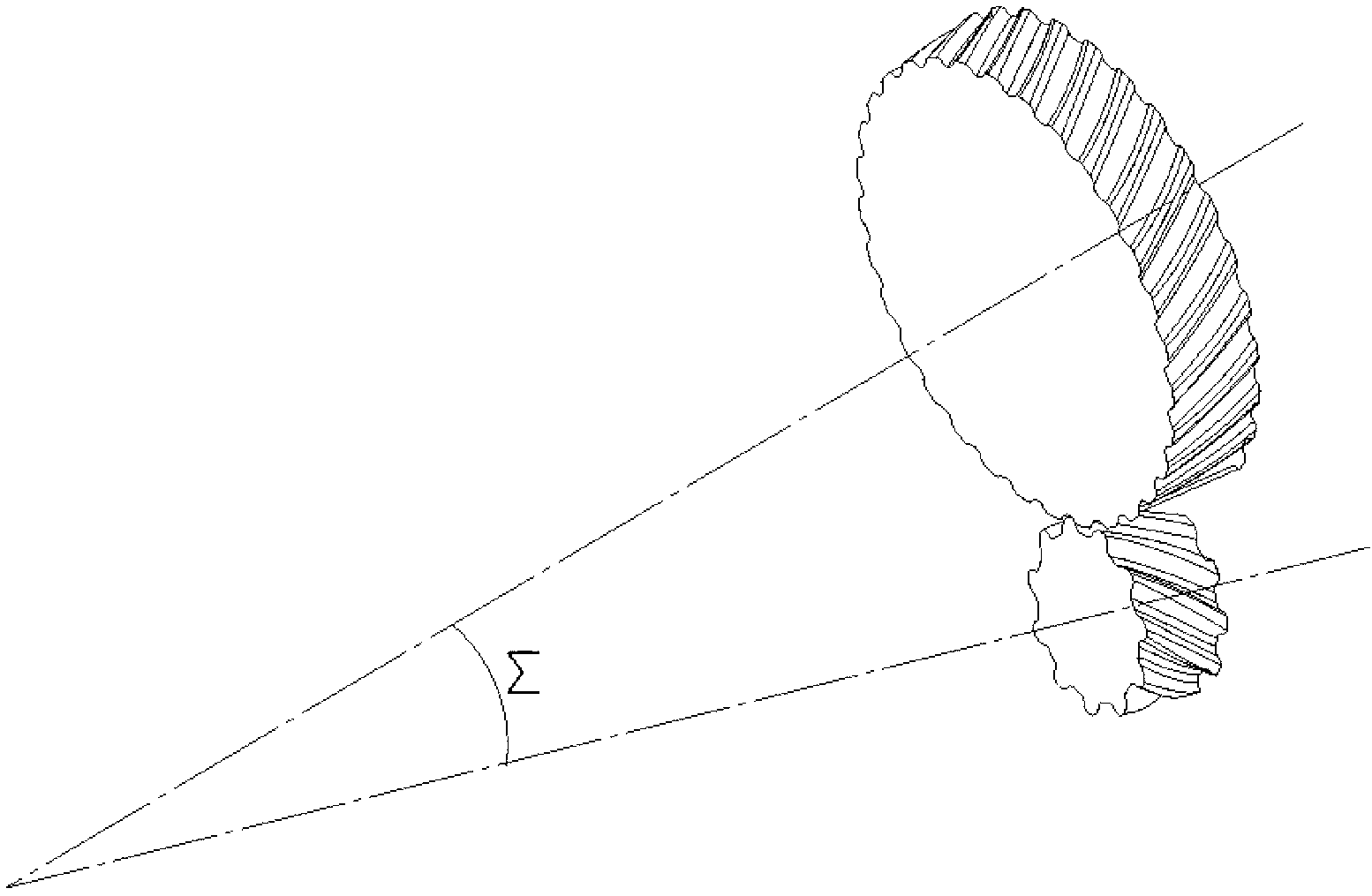

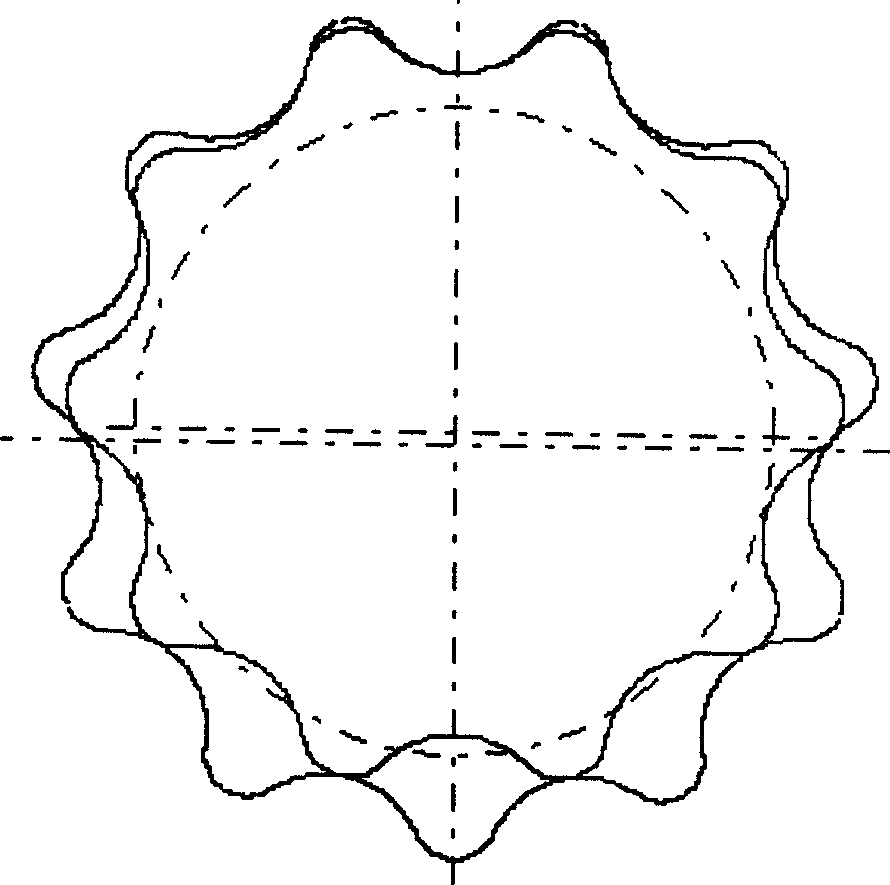

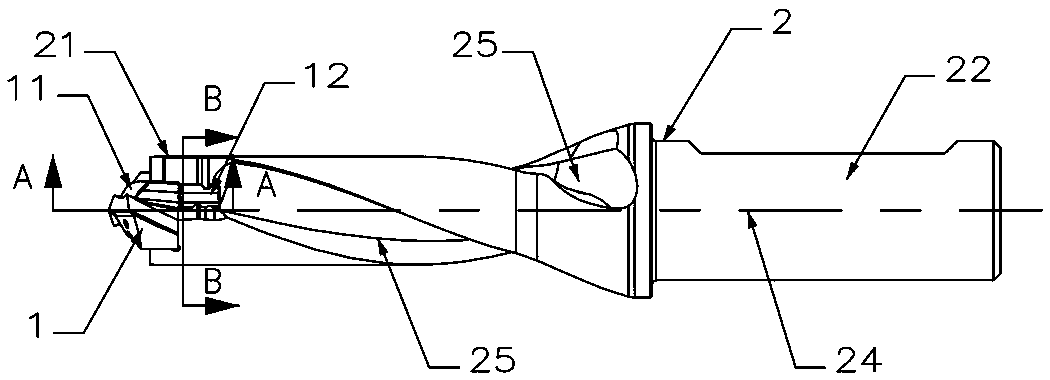

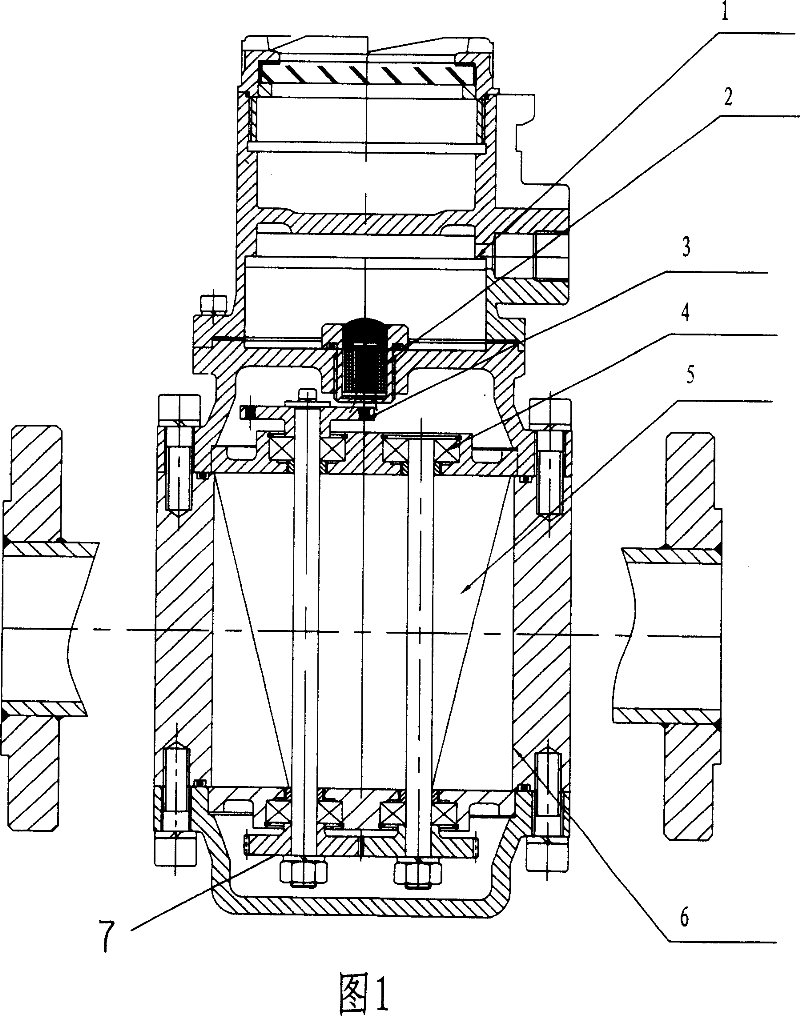

Conical cycloid wheel planet transmission means

InactiveCN1482380AImprove carrying capacityImprove machining accuracyToothed gearingsGear wheelOutput device

A conical cycloid wheel planet transmission means related to a differential teeth planetary reduction gear, the conical cycloid planet wheel is positioned in the main body and mounted in the bearing at the center of the eccentric shaft, forming a conical cycloid wheel planet engagement pair with the conical internal gears having the same cone angle, and forming a gap eliminating output device with the output components. The transmission gear according to the invention has zero transmission error and zero return difference feature, and greater load-bearing capacity.

Owner:CHONGQING UNIV

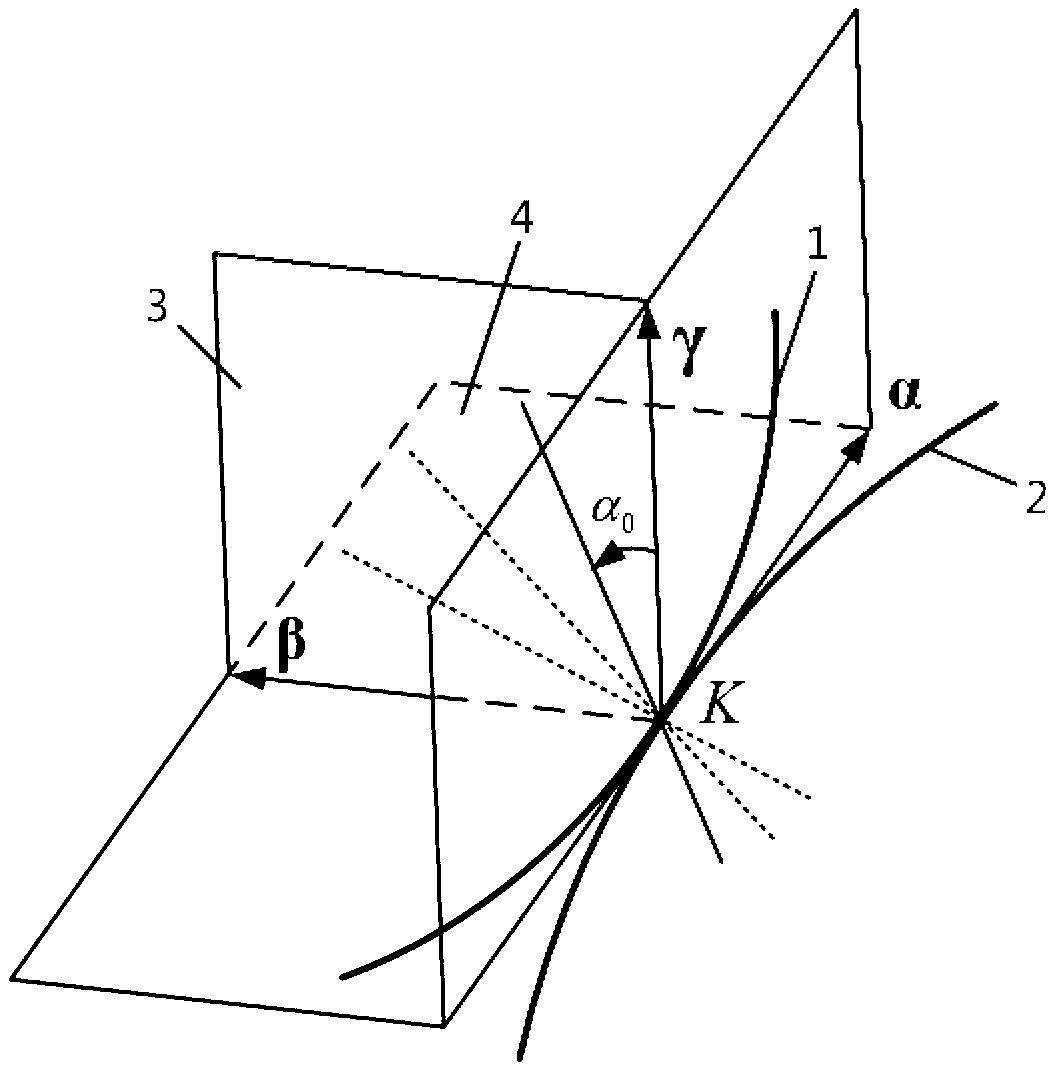

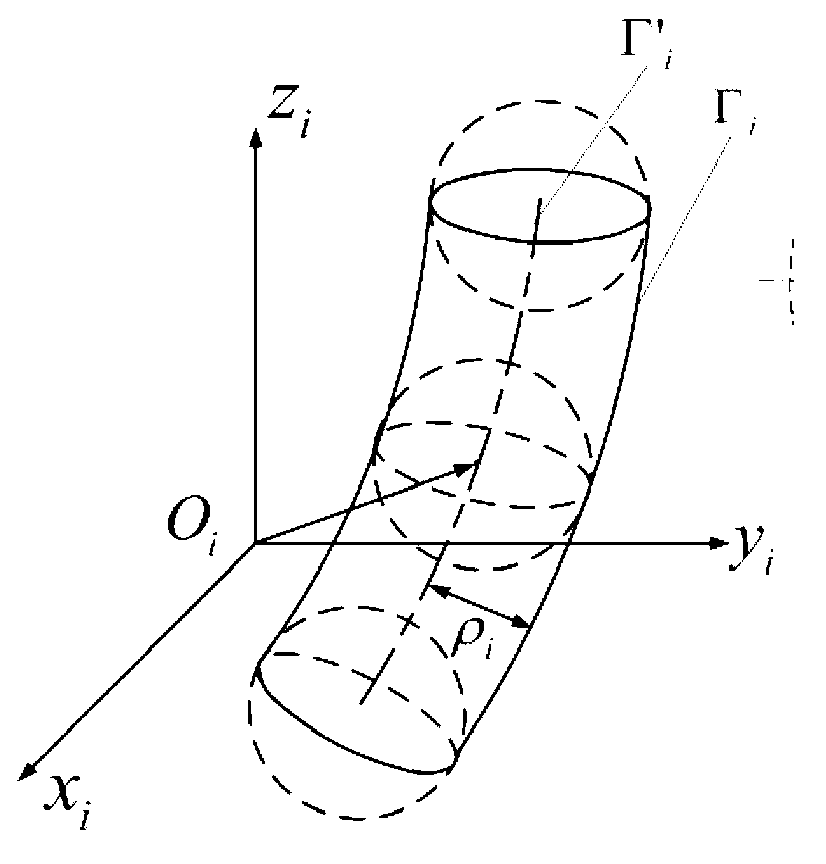

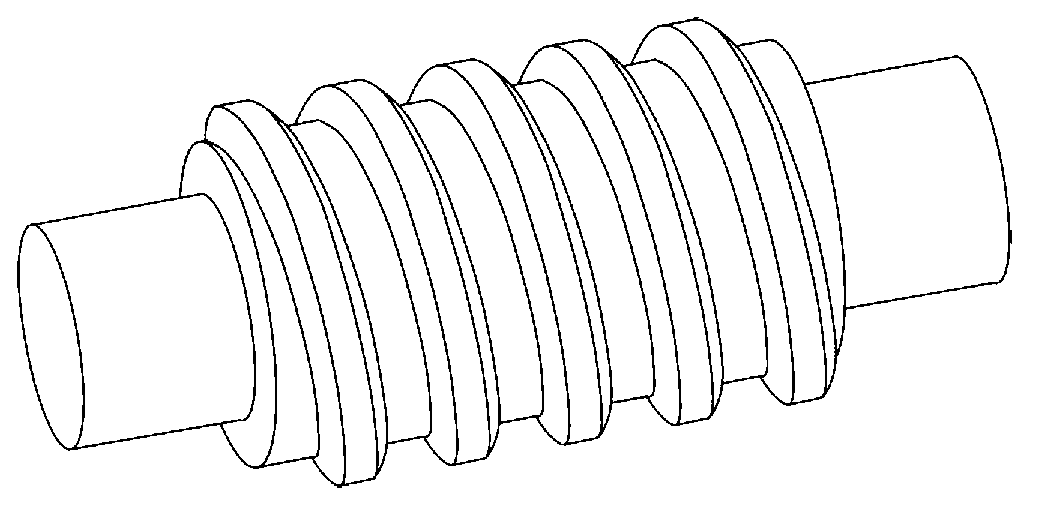

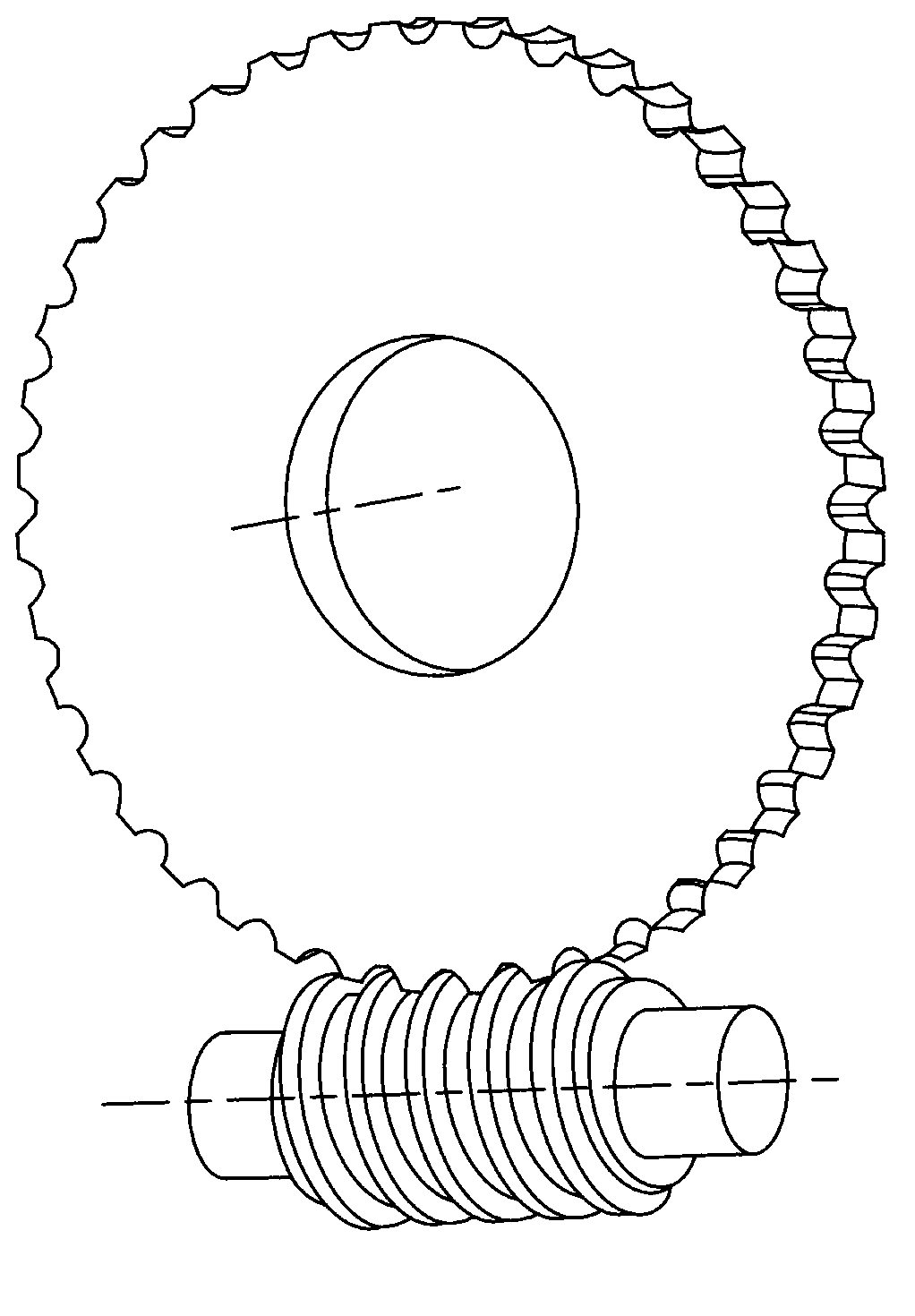

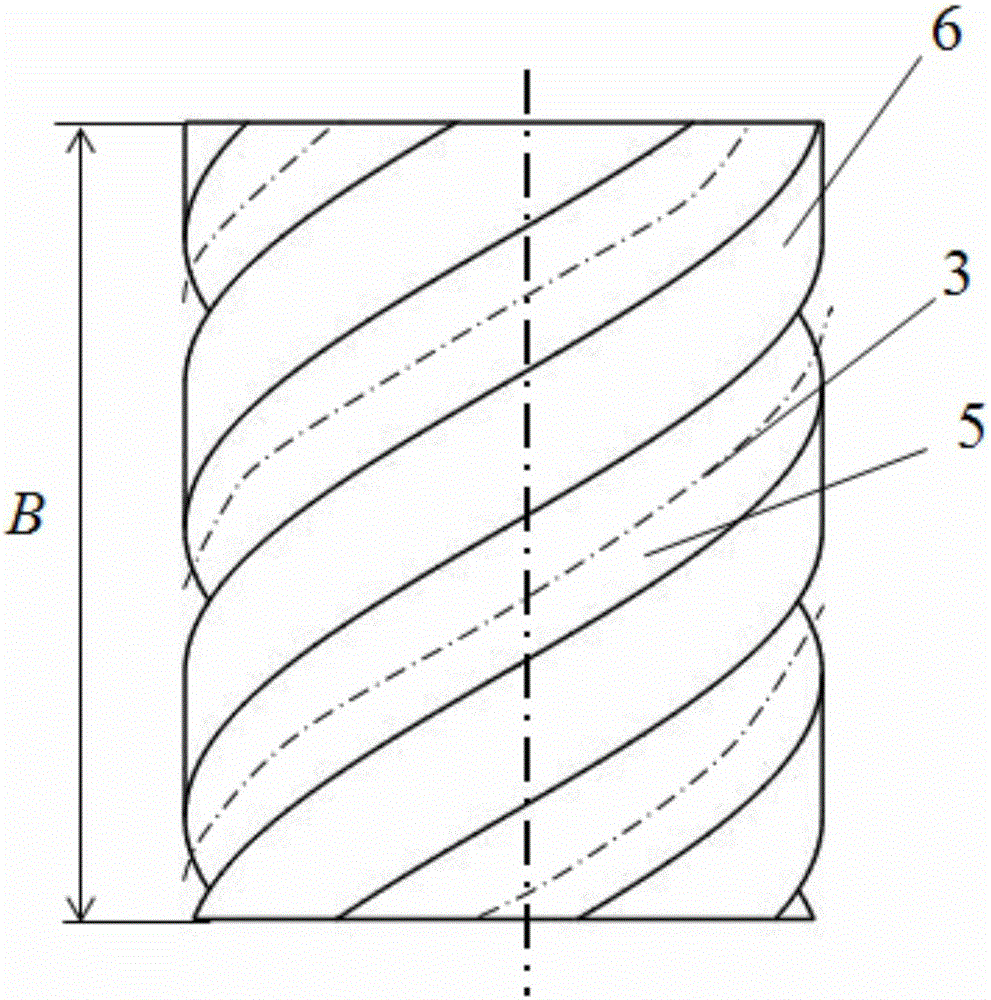

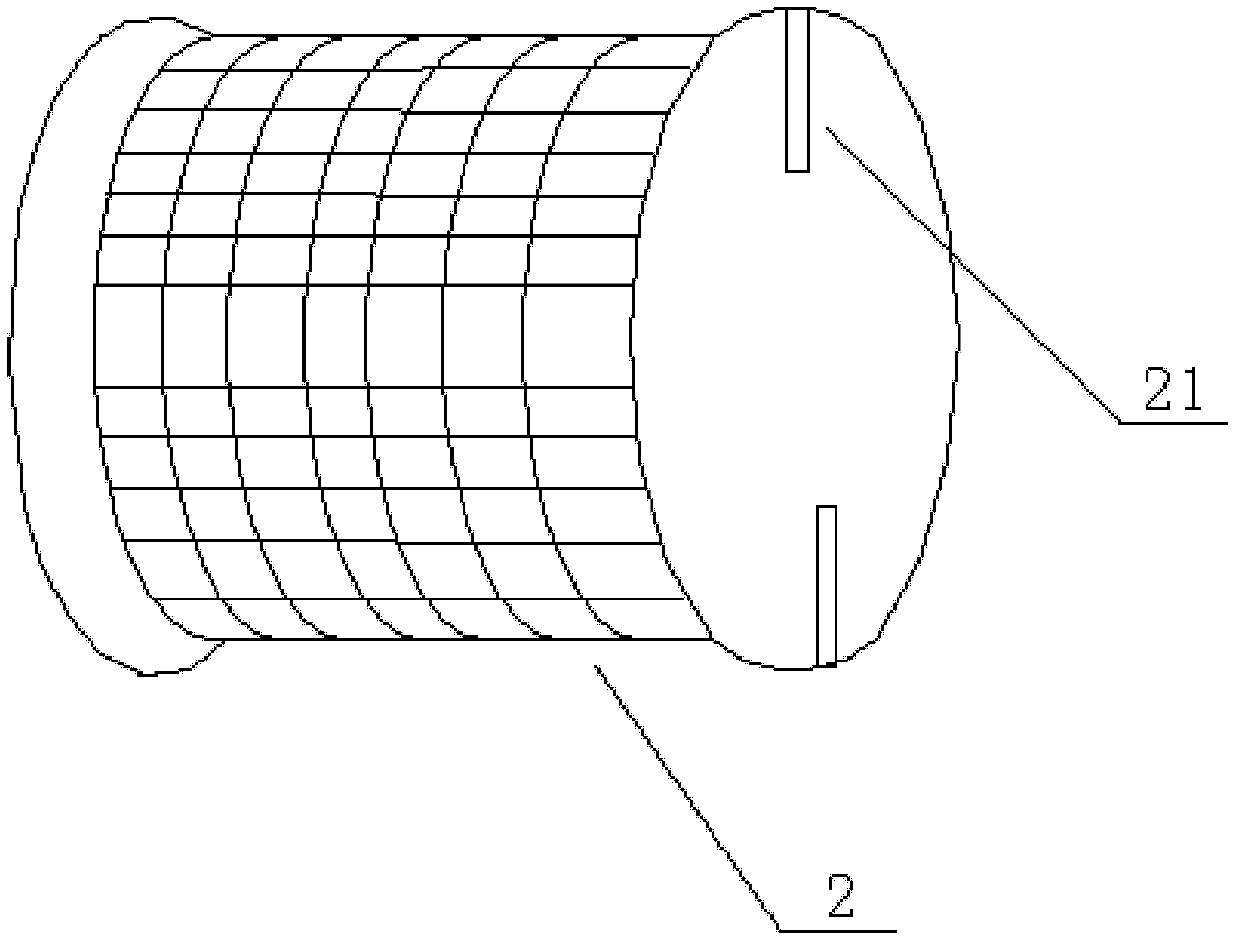

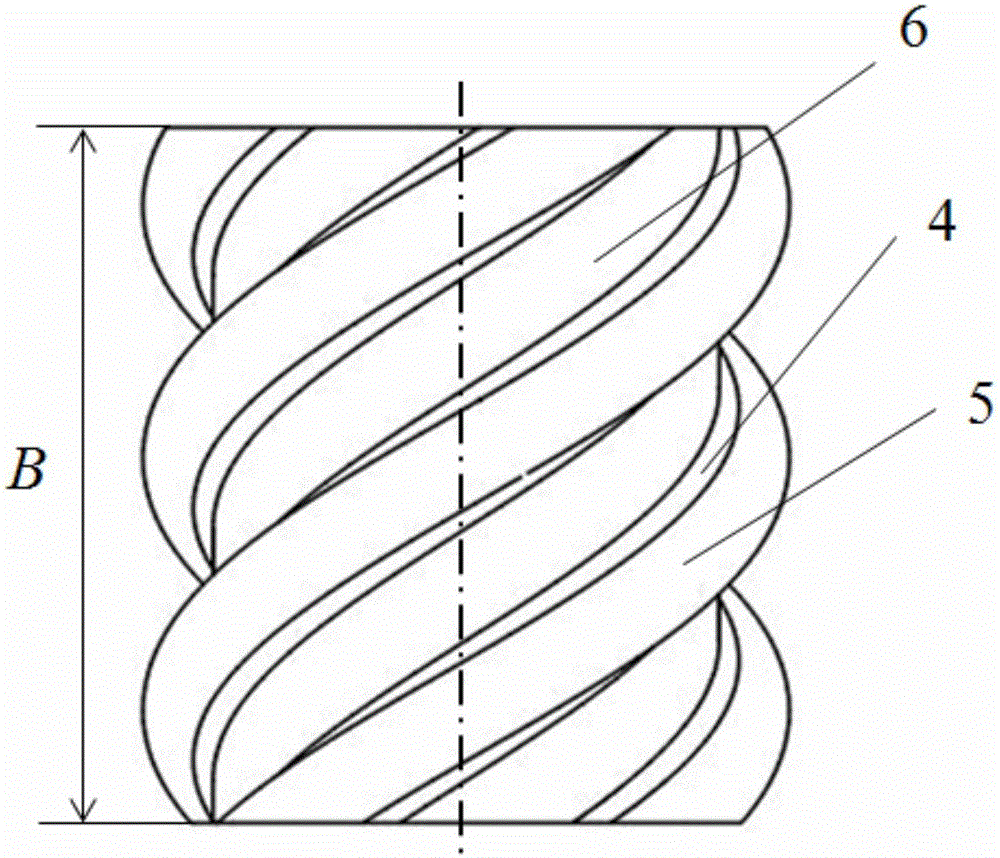

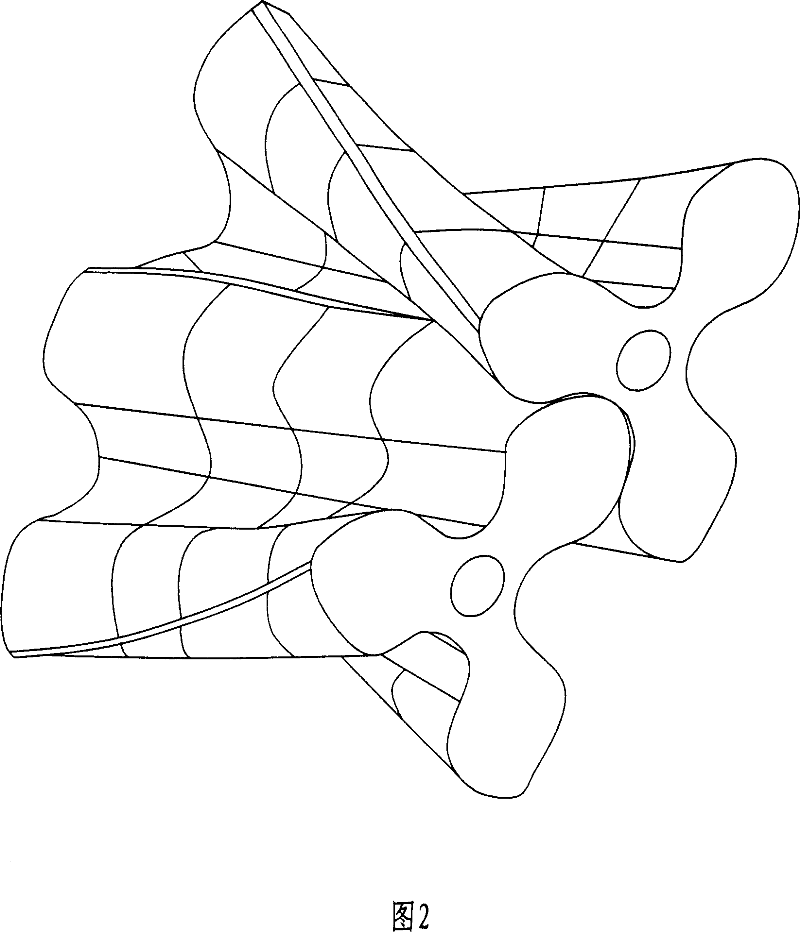

Worm and worm gear on basis of conjugate curves, and mesh pair with worm and worm gear

ActiveCN103047393AReduce temperature riseReduce wearPortable liftingToothed gearingsCarrying capacityEngineering

The invention discloses a worm and a worm gear on the basis of conjugate curves, and a mesh pair with the worm and the worm gear. The worm gear and worm mesh pair comprises the worm gear and the worm which are meshed with each other; a contact curve gamma 1 which consists of meshed points on a tooth profile curved surface of the worm and a contact curve gamma 2 which consists of meshed points on a tooth profile curved surface of the worm gear are the conjugated curves; the tooth profile curved surface of the worm is a spherical enveloping surface in the shape of a tube nest, and the spherical center of the spherical enveloping surface moves along circle center curves gamma 1' equally distanced from the contact curve gamma 1; and the tooth profile curved surface of the worm gear is a spherical enveloping surface in the shape of a tube nest, and the spherical center of the spherical enveloping surface moves along circle center curves gamma 2' equally distanced from the contact curve gamma 2. The worm gear, the worm and the worm gear and worm mesh pair on the basis of the conjugate curves have the advantages that the tooth profile curved surfaces of the worm gear and the worm which are meshed with each other are the spherical enveloping surfaces in the shapes of the tube nests, and the meshed points between the worm gear and the worm move along the conjugate curves; and the mesh characteristics of the conjugate curves are inherited for the worm gear and worm mesh pair, the contact strength of tooth profiles which are in concave-convex point contact with one another is high, the carrying capacity and the transmission efficiency are high, and temperature rise of lubricating oil and abrasion are low.

Owner:CHONGQING UNIV

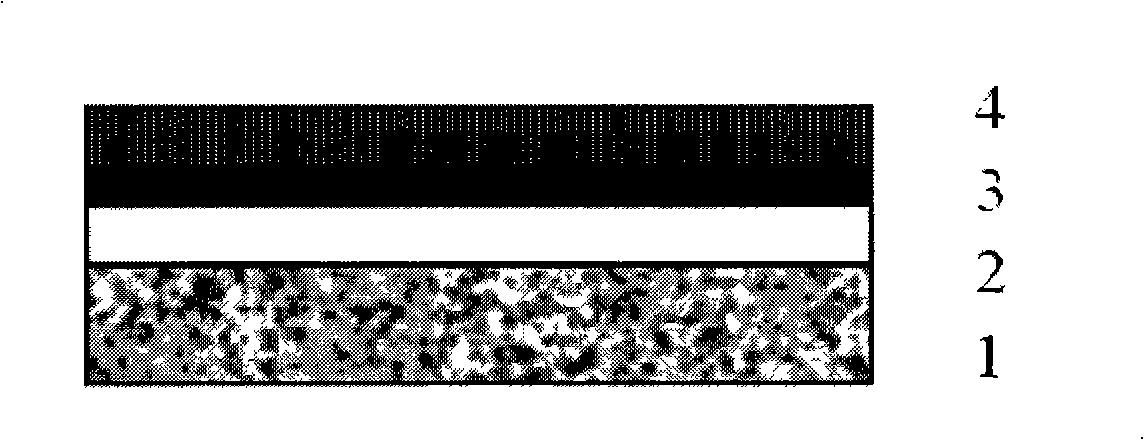

Low temperature solid-oxide fuel battery three-in-one component MEA and preparation thereof

InactiveCN101304093ASimple preparation processReduce interface resistanceFuel cells groupingFinal product manufactureFuel cellsTransition layer

The invention discloses a three-in-one component MEA of a low temperature solid oxide fuel cell and a preparation thereof, which comprises an anode substrate, an electrolyte diaphragm layer and a cathode, wherein, a perovskite-type oxide transition layer is arranged between the electrolyte diaphragm layer and the cathode. Under the same condition, the performance of the low temperature solid oxide fuel cell prepared by using the method can be increased by more than 30 percent compared with the cell that has no diaphragm layer added.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

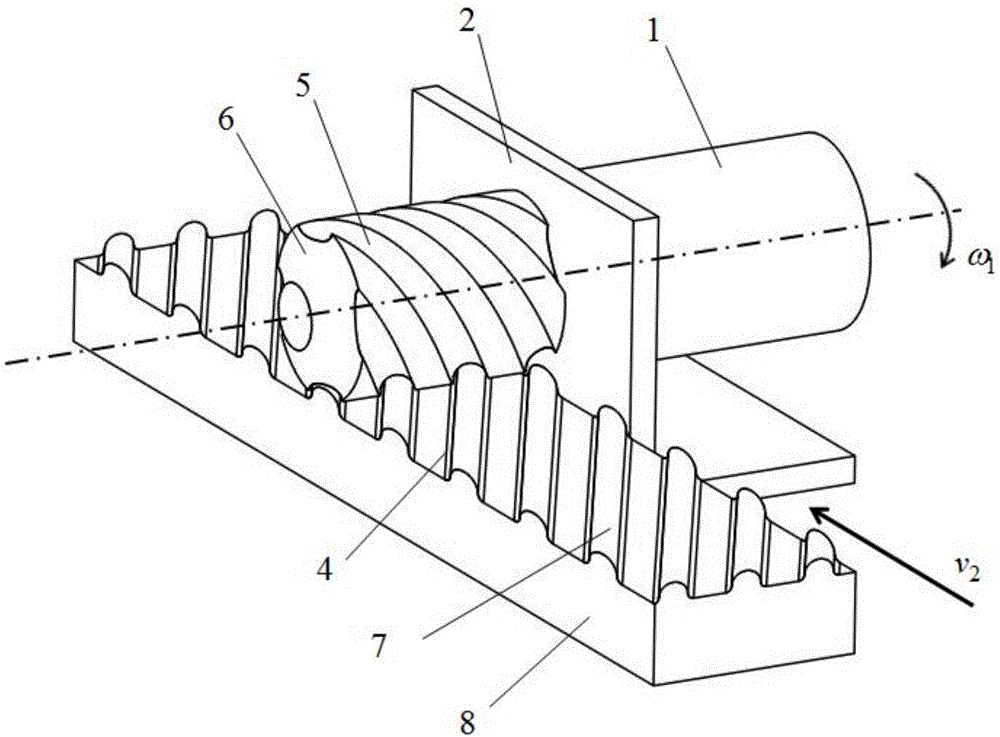

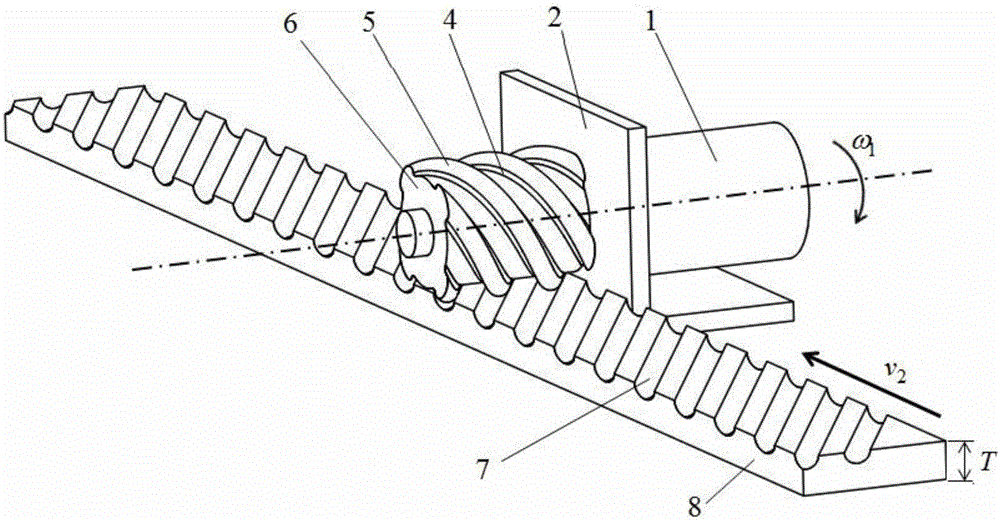

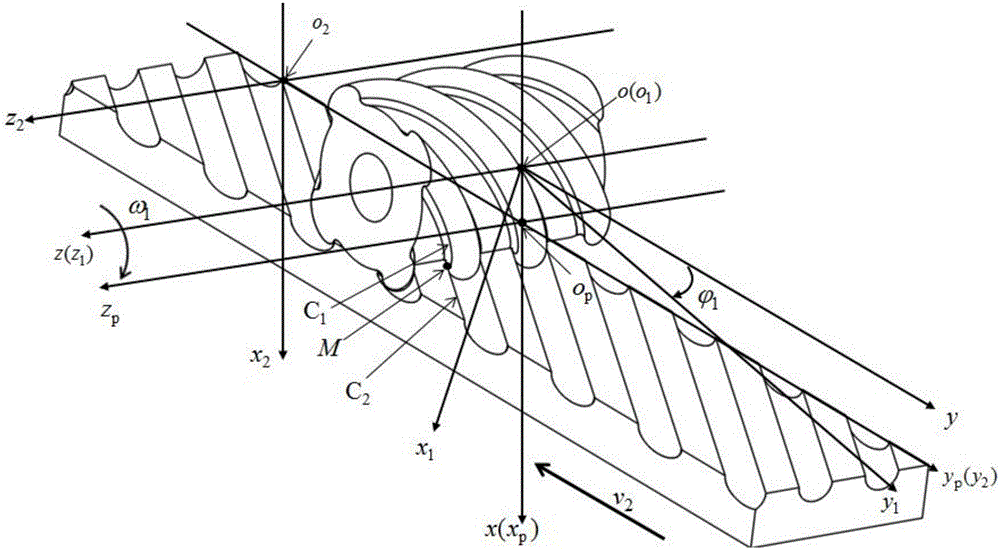

Circular-arc concave-convex engaged gear and rack mechanism without relative slide

ActiveCN106763592AImprove transmission efficiencyAvoid wear and tearGeometric CADPortable liftingGear wheelOverlap ratio

The invention relates to a circular-arc concave-convex engaged gear and rack mechanism without relative slide. The circular-arc concave-convex engaged gear and rack mechanism comprises a transmission pair consisting of a spiral circular-arc gear and a circular-arc rack, wherein spiral concave circular-arc tooth sockets are uniformly distributed in the outer surface of the spiral circular-arc gear; convex circular-arc teeth are uniformly distributed on the surface of the circular-arc rack; the spiral concave circular-arc tooth sockets are matched with the convex circular-arc teeth; the spiral circular-arc gear is connected with a rotating shaft of a driving device; the center line of each spiral concave circular-arc tooth socket is equal-lifting-distance cylindrical helix; and the structural shape of the spiral circular-arc gear and the structural shape of the circular-arc rack are determined by design parameters. When the mechanism is mounted, correct engagement of the spiral concave circular-arc tooth sockets and the convex circular-arc teeth needs to be guaranteed to realize the transmission of the circular-arc gear and the circular-arc rack. When the gear and rack mechanism disclosed by the invention is in transmission, failures modes, such as the slide of tooth surfaces, agglutination of the tooth surfaces, wear of the tooth surfaces, and plastic deformation of the tooth surfaces are avoided; the gear and rack mechanism has the advantages of being high in overlap ratio, simple in structure, easy to process, high in transmission efficiency, high in bearing capacity and the like; and the gear and rack mechanism is suitable for being popularized and applied in the field of mini machinery, micro-machinery and conventional machinery.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

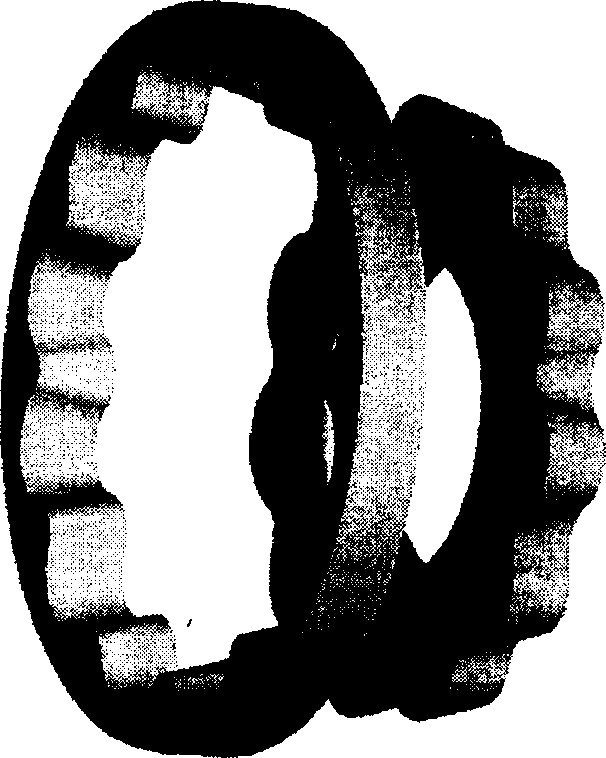

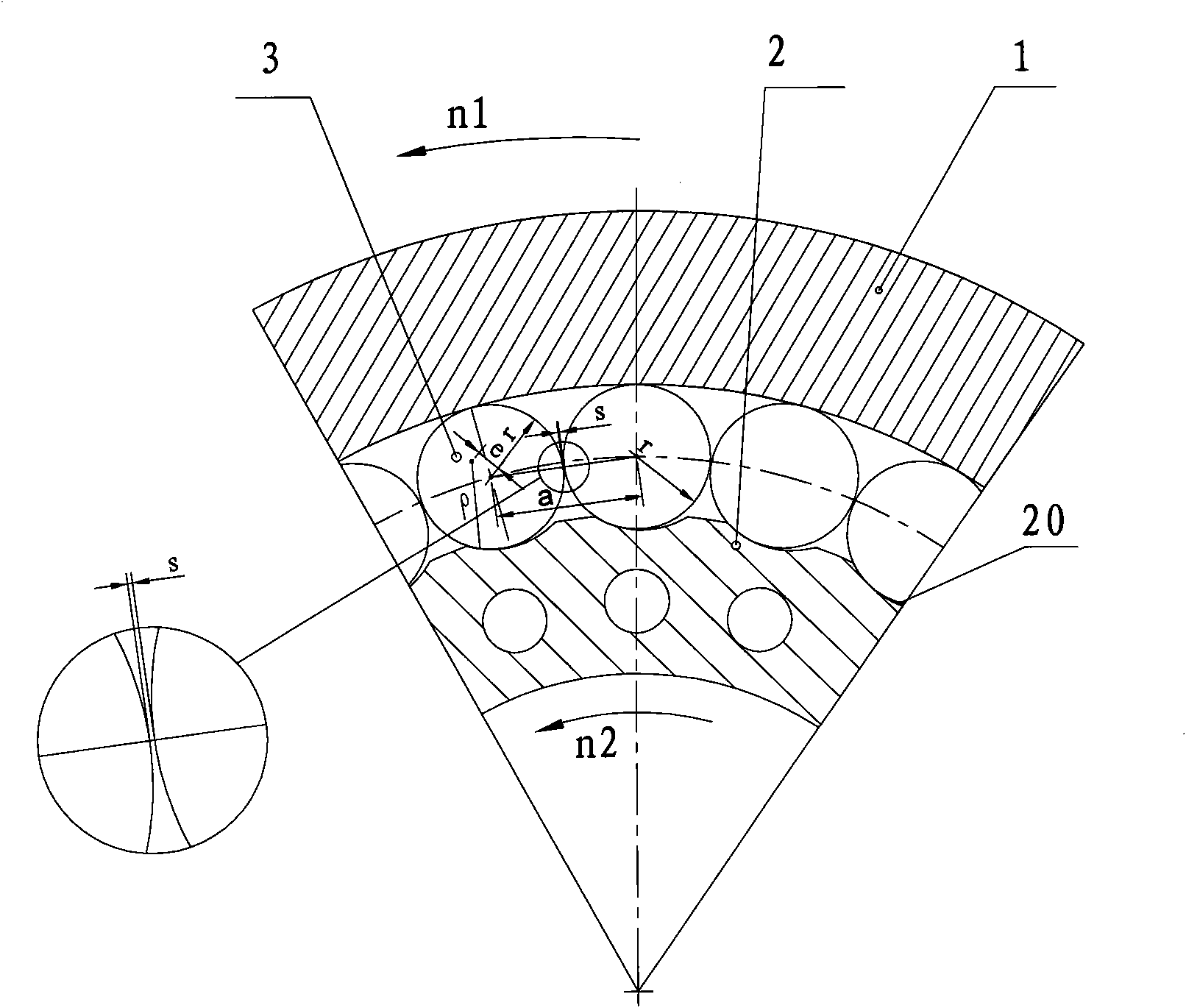

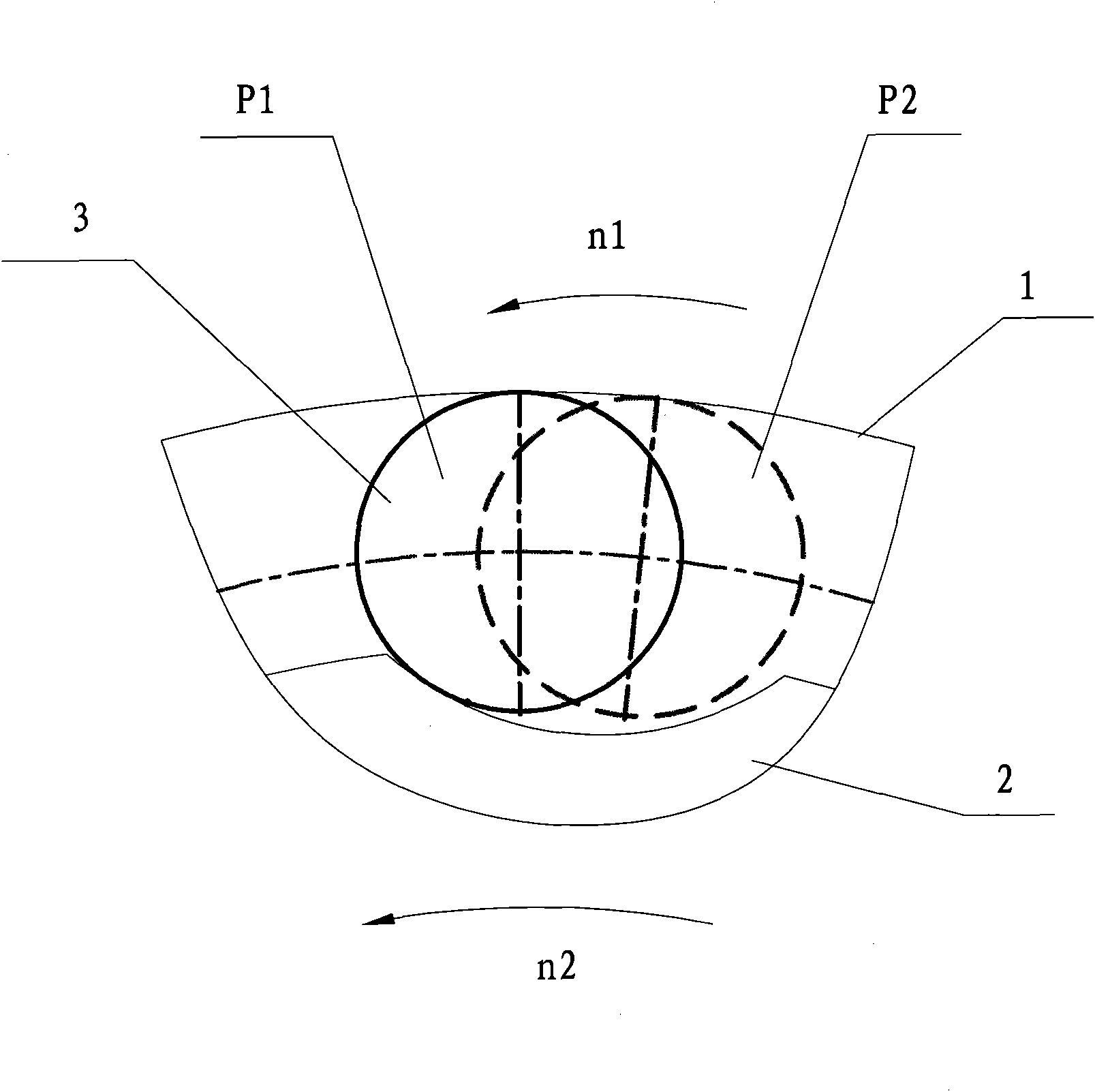

Bearing type overrunning clutch structure

ActiveCN101956772AImprove carrying capacityAvoid failureFreewheel clutchesEngineeringUltimate tensile strength

The invention discloses a bearing type overrunning clutch structure. The bearing type overrunning clutch structure comprises an outer ring and an inner star wheel; a plurality of rollers are arranged between the outer ring and the inner star wheel; an outer cylindrical surface of the inner star wheel is provided with a plurality of concave curve grooves; each concave curve groove respectively corresponds to a roller; and the gap s between adjacent rollers is between 0 and 0.2 mm. The bearing type overrunning clutch structure has the main characteristics that: the number of the rollers is increased in the same space to ensure that the gap between adjacent rollers is between 0 and 0.2 mm; meanwhile, the outer cylindrical surface of the inner star wheel is provided with a plurality of concave curve grooves, so that the contact strength is improved. Structurally, compared with a lifting pin roller type overrunning clutch, the bearing type overrunning clutch structure has the advantages that a spring lifting pin mechanism is removed, and compared with a three-feet spring-pushed spacer ring type overrunning clutch, the bearing type overrunning clutch structure has the advantage that: a three-feet spring and a spacer ring are removed. Experiments show that: the bearing type overrunning clutch structure has the advantages of rational structural design, simple manufacturing process, high manufacturing precision, high working reliability, and capability of bearing large torque and impact force, and working for a long time under high-speed heavy load.

Owner:TRANF TECH XIAMEN CO LTD

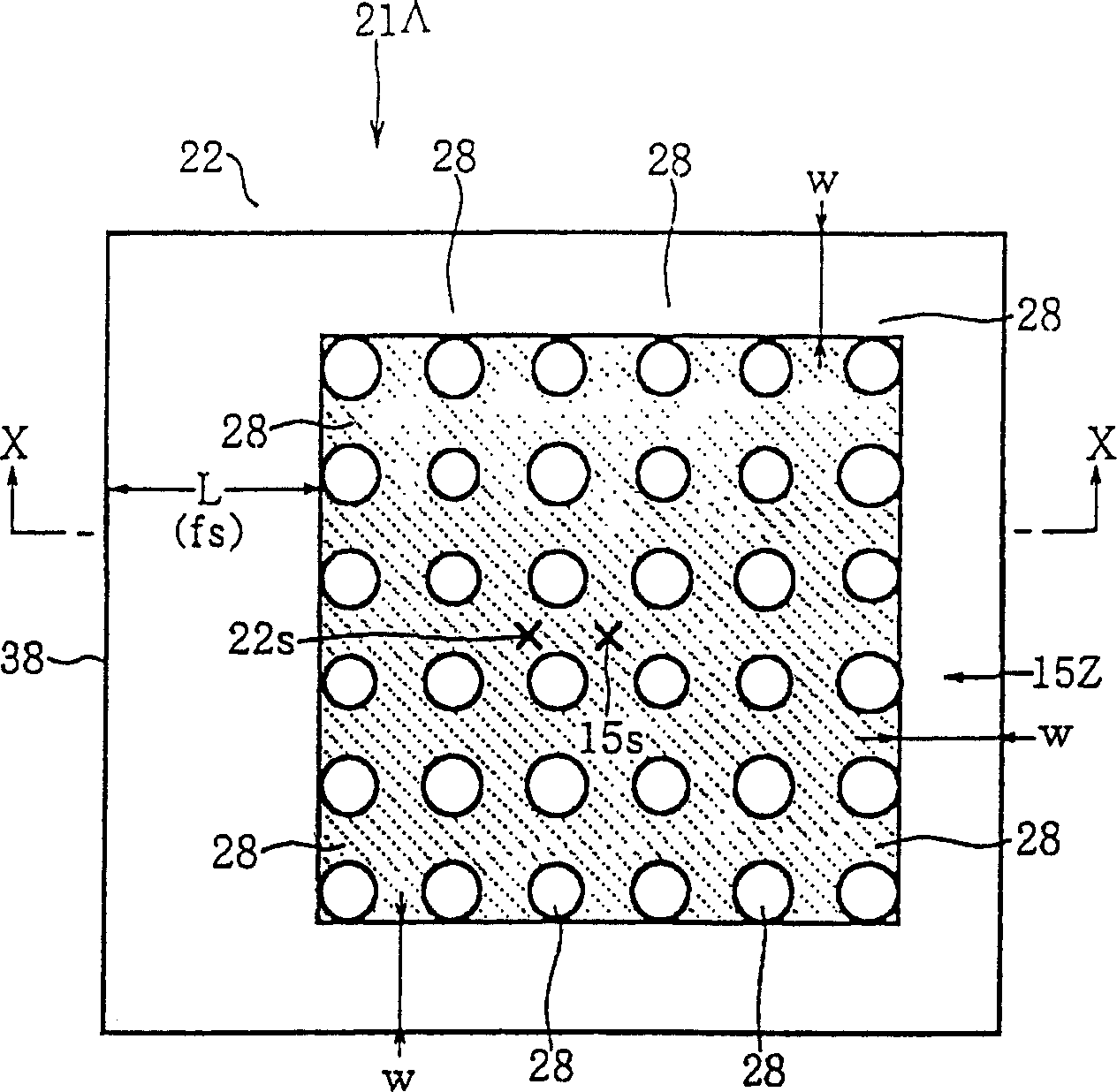

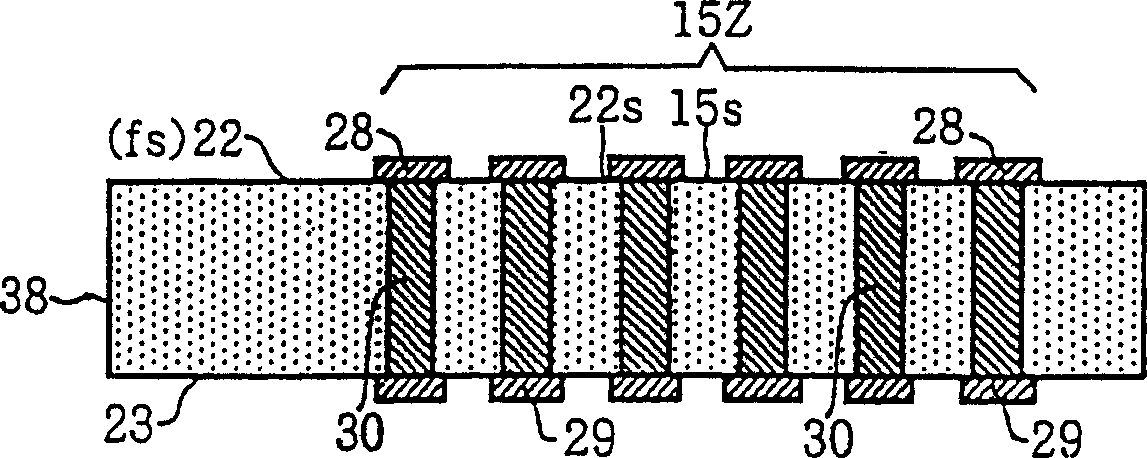

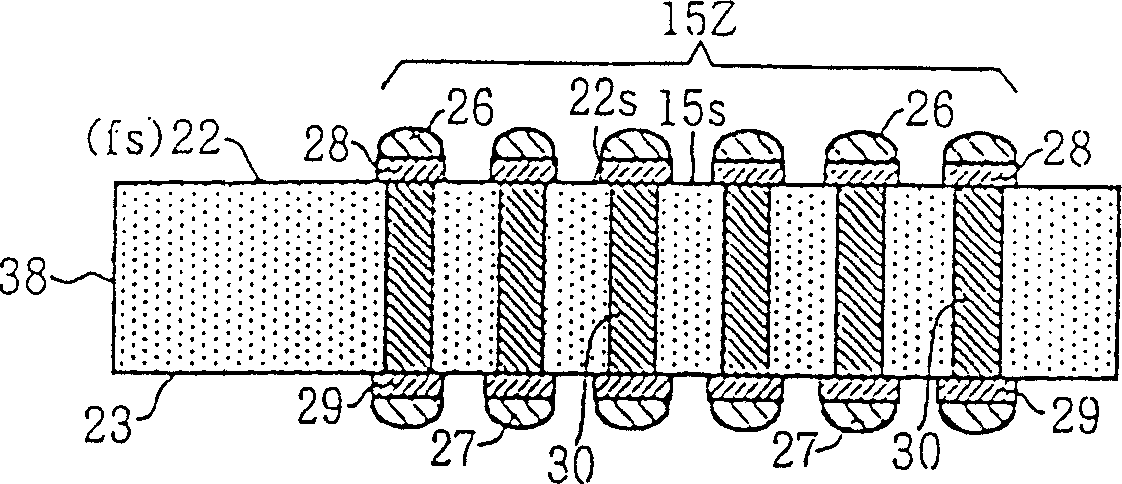

Intermediate substrate, and structure having semiconductor element, intermediate substrate and substrate

InactiveCN1574310AImprove contact strengthImprove reliabilityPrinted circuit assemblingFinal product manufactureEngineeringSemiconductor components

An intermediate substrate comprising: an intermediate substrate body containing an insulating material, and having a first face to be mounted with an semiconductor element and a second face opposing to said first face; and a semiconductor element mounting area including a plurality of first face terminals arranged on said first face, and being surrounded by an outermost periphery of said plurality of first face terminals, wherein a center of said semiconductor element mounting area is eccentric with respect to a center of said first face.

Owner:NGK SPARK PLUG CO LTD

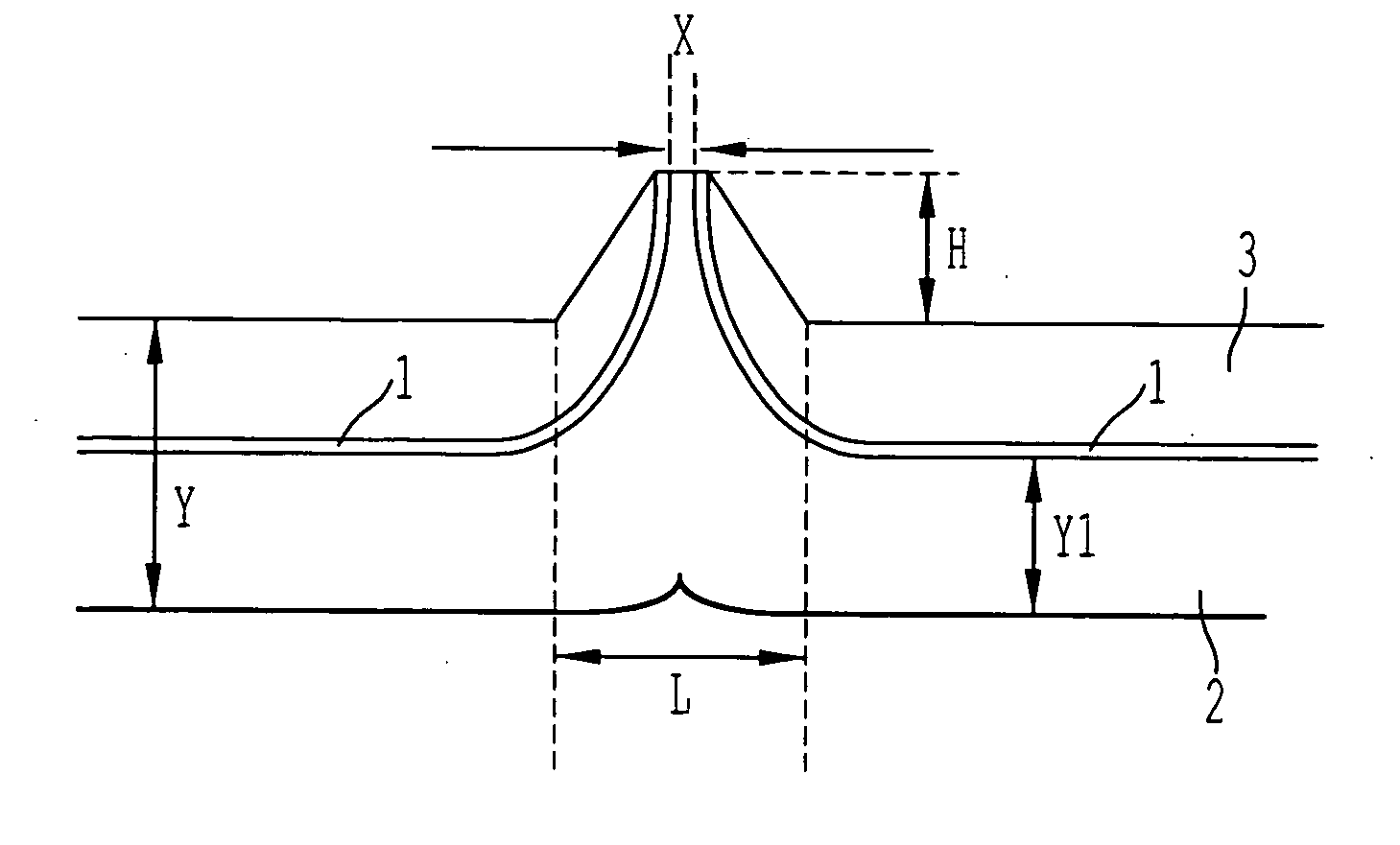

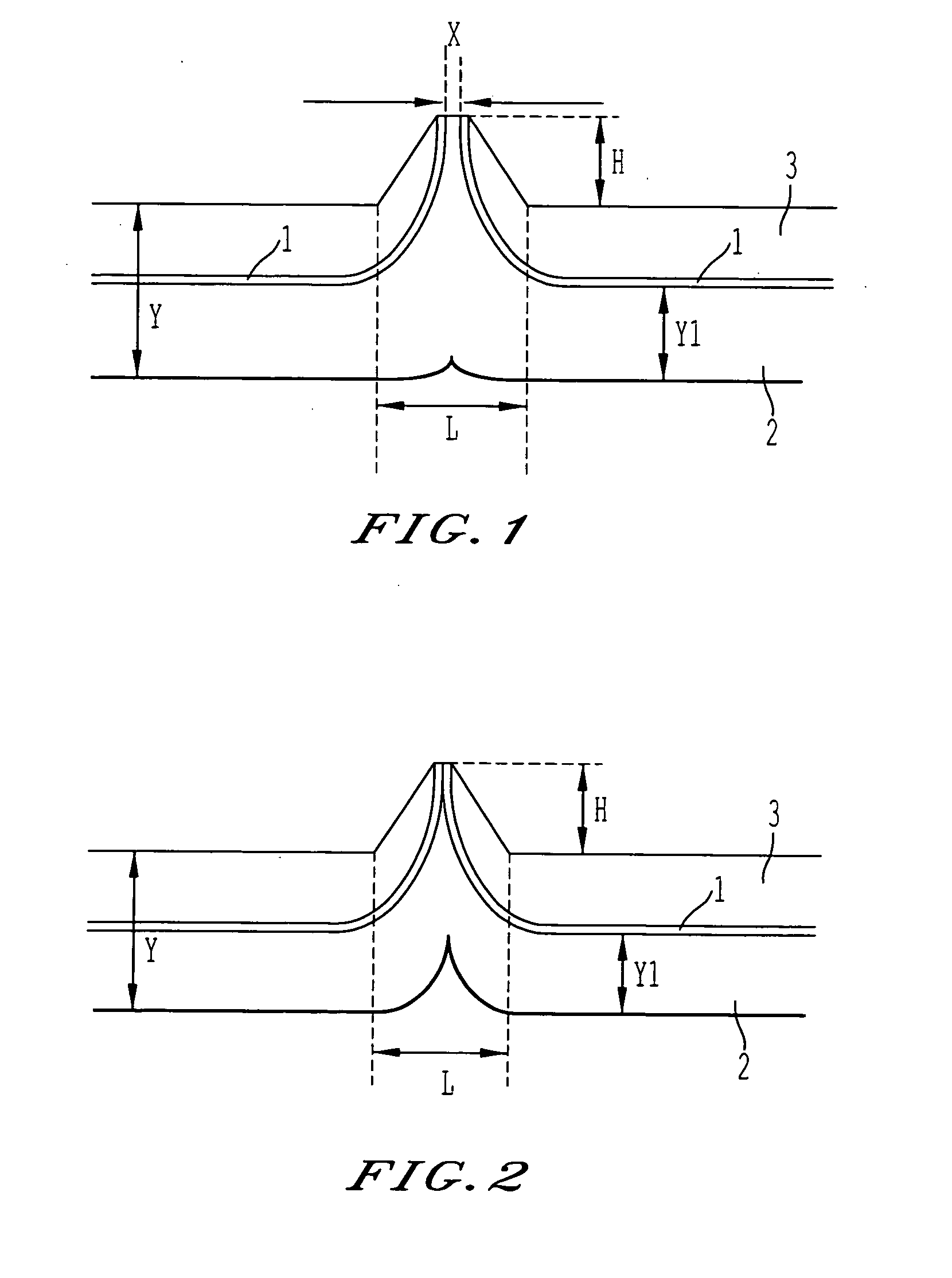

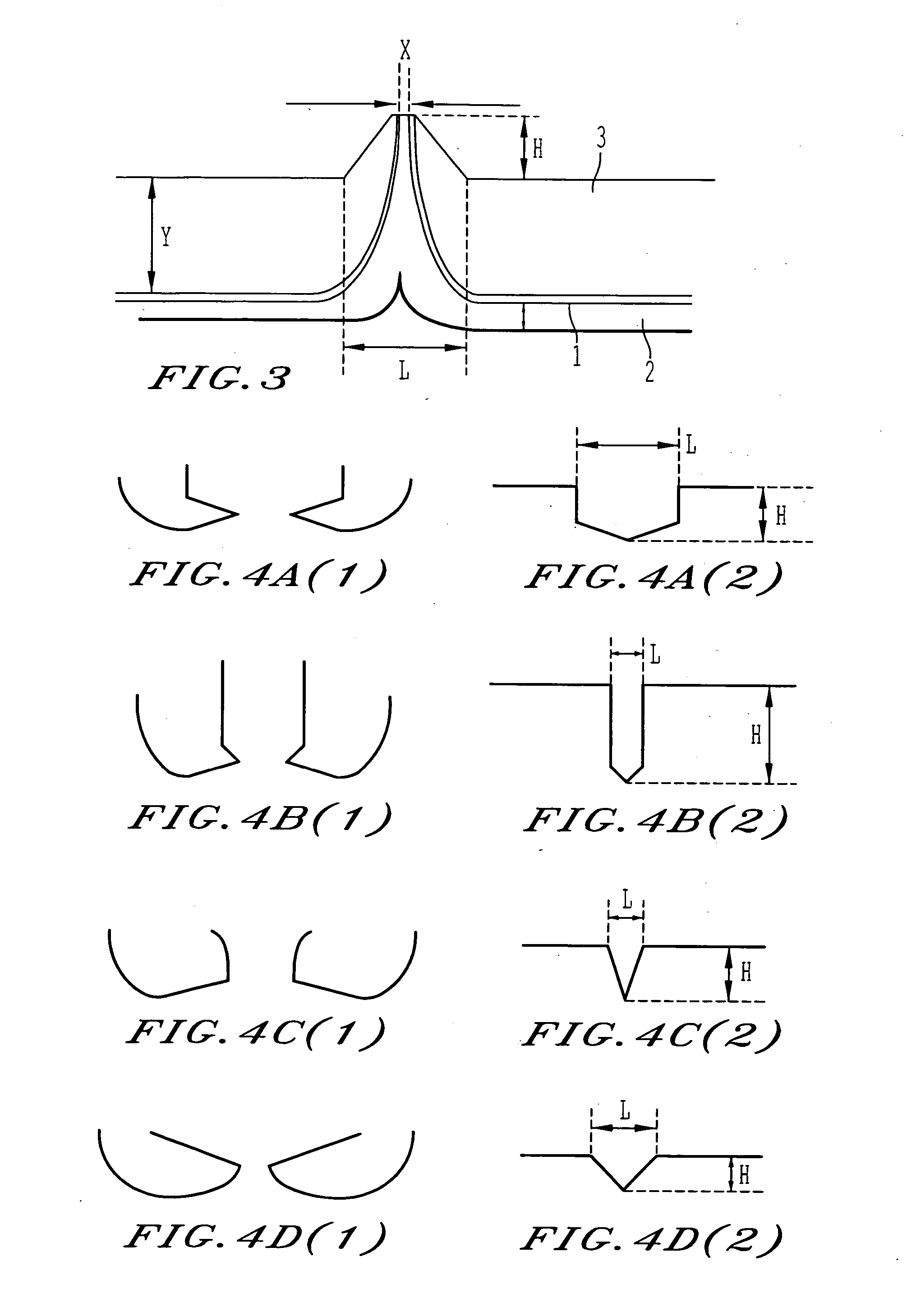

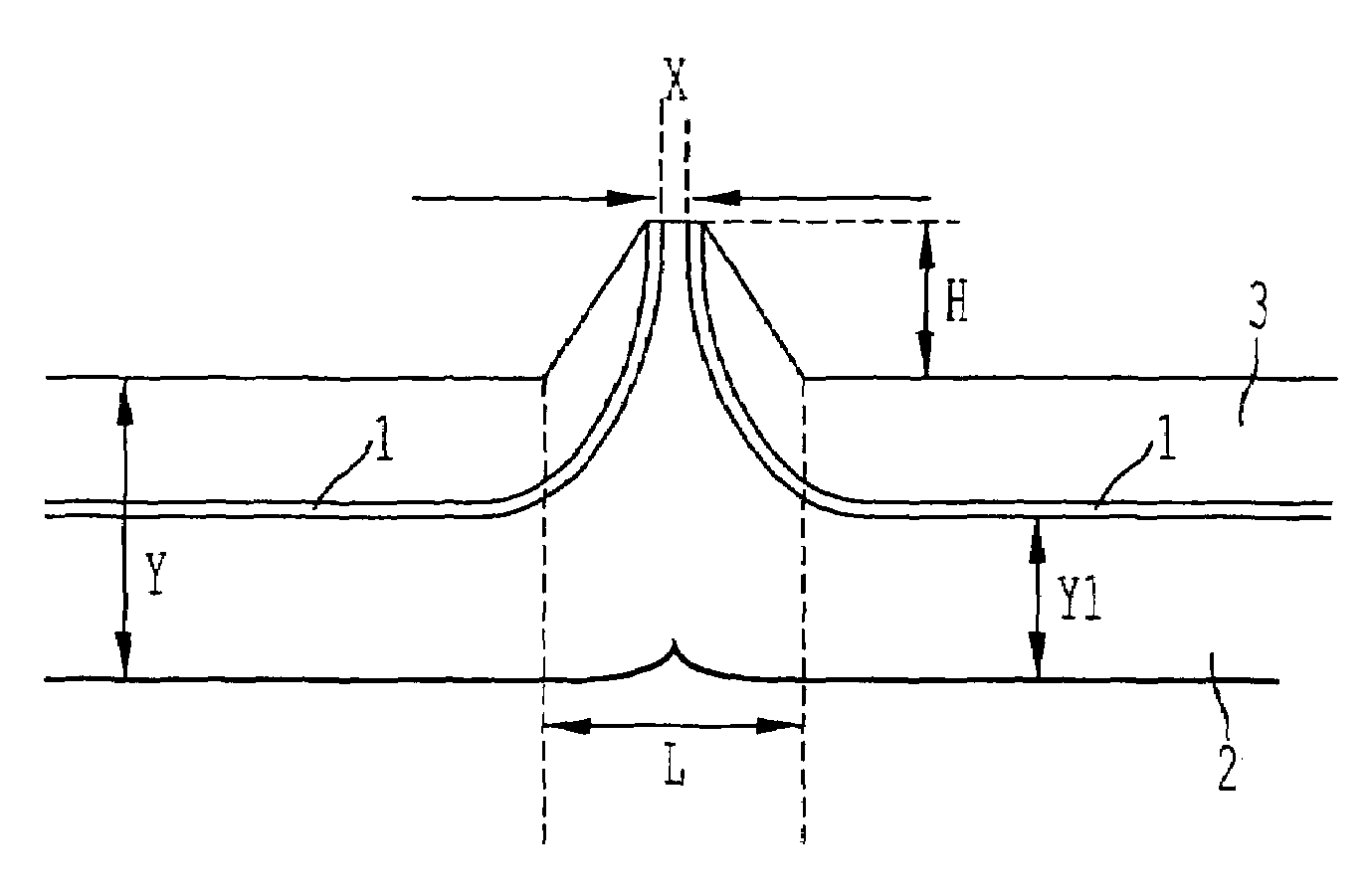

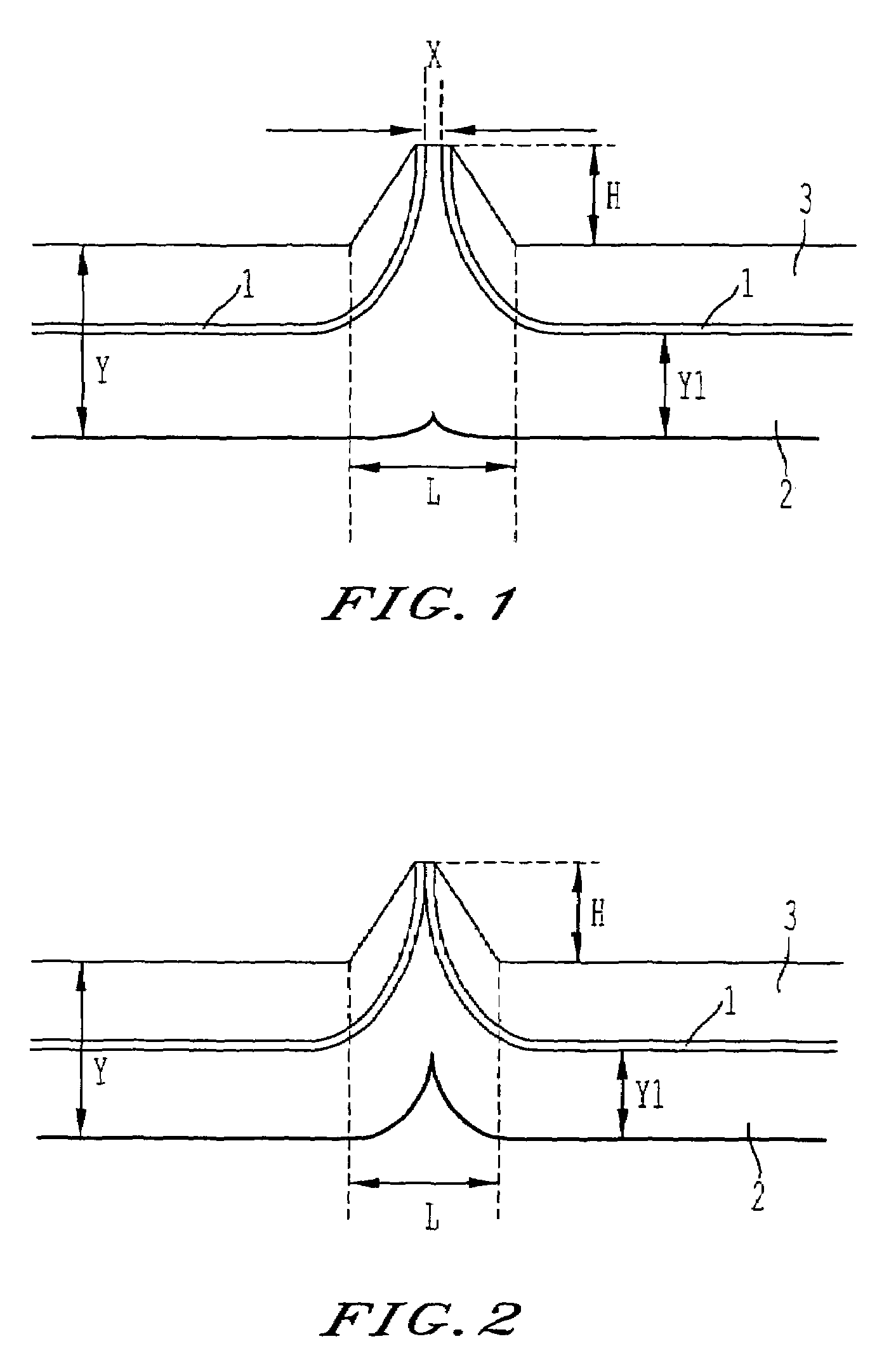

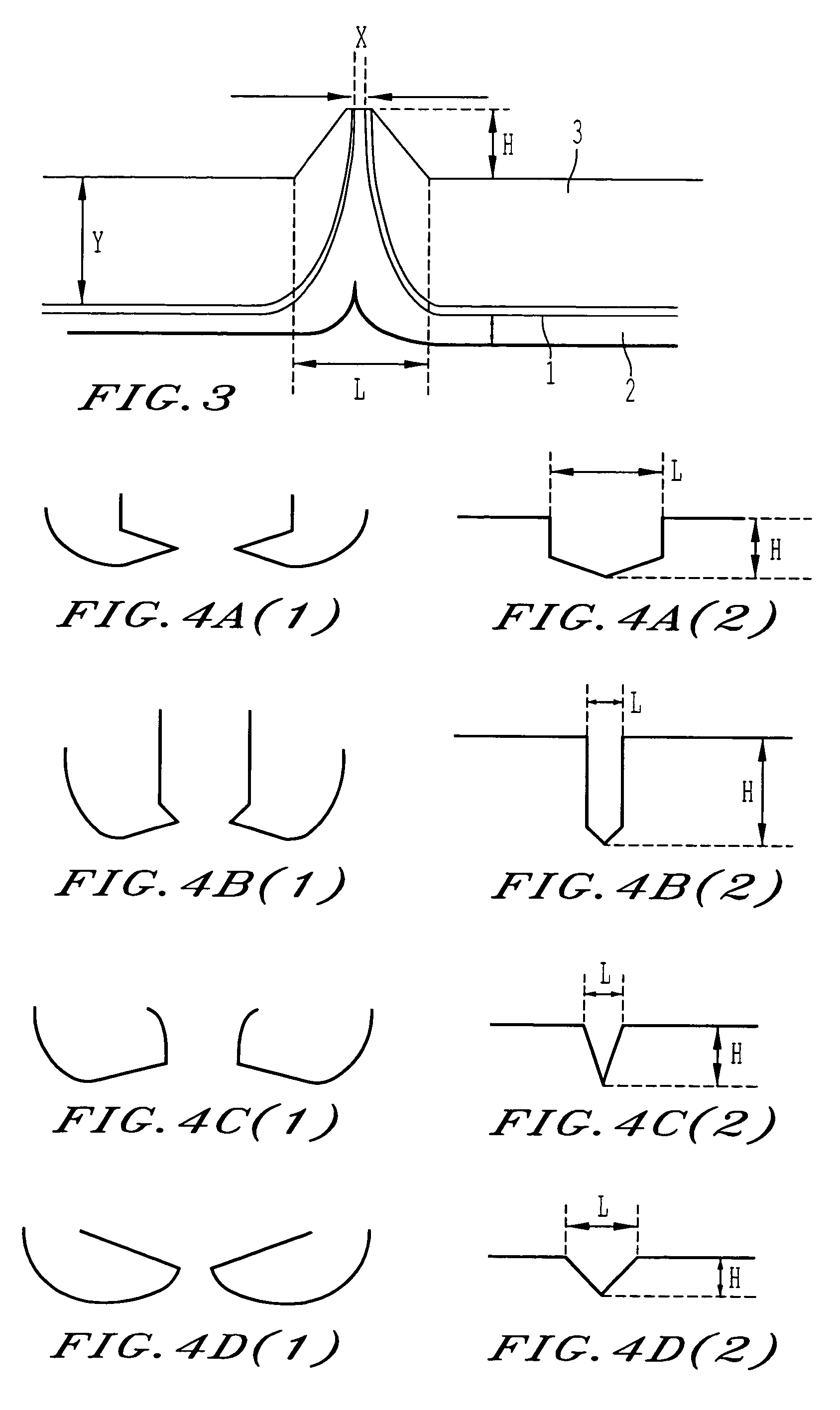

Fuel Container

InactiveUS20040170786A1Improve barrier propertiesHigh crystallinityLarge containersDomestic containersEngineeringTotal thickness

A fuel container with high fuel barrier properties is provided. The fuel container is a coextrusion blow-molded fuel container having a container body made of a layered structure. The layered structure comprises: a barrier layer made of a barrier resin (A); and an inner layer and an outer layer made of a thermoplastic resin (B) that is different from the barrier resin (A); wherein a ratio (X / Y) of a distance (X) between end portions of the barrier layer at a pinch-off part of the fuel container and an average thickness (Y) of the container body is at least 1 / 10000 and at most 1 / 10; and wherein a ratio (Y1 / Y) between a total thickness (Y1) of the layers of the container body that are located on the inside with respect to the barrier layer and an average thickness (Y) of the container body is at least 3 / 10 and at most 7 / 10.

Owner:KURARAY CO LTD

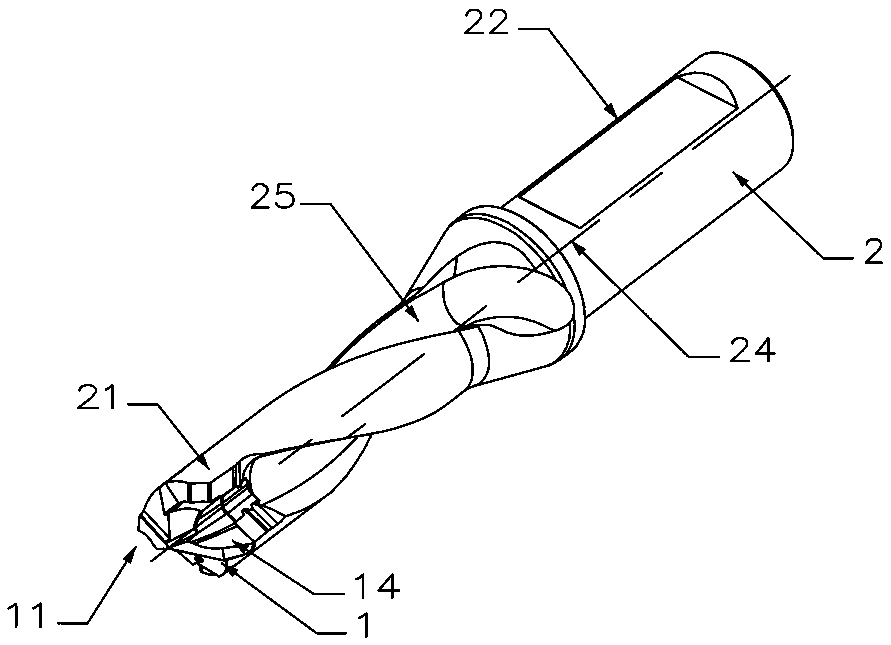

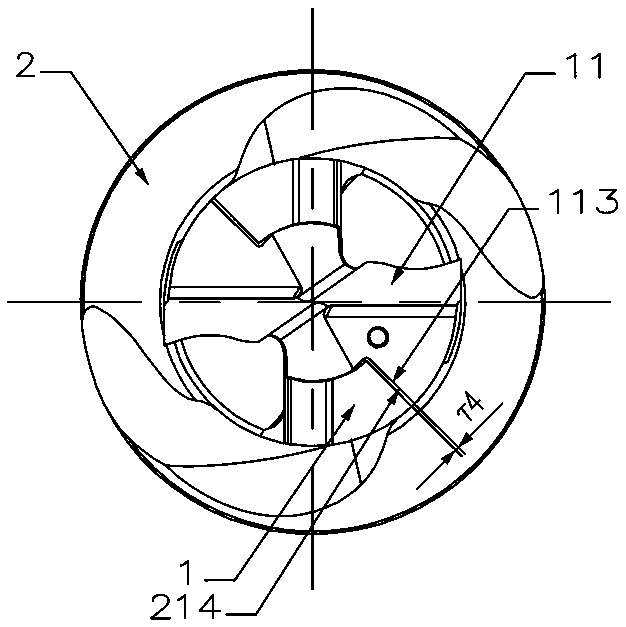

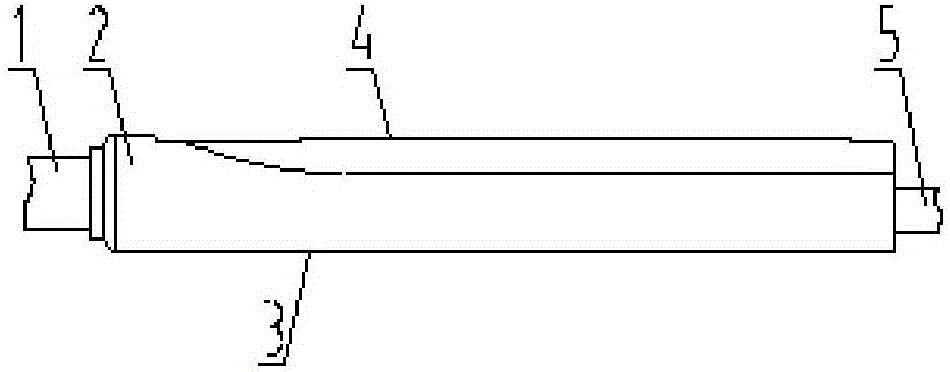

Stably clamping drilling tool

ActiveCN109262027AEasy clampingReduce manufacturing difficultyTransportation and packagingChucksBiomedical engineeringLambda

The invention discloses a stably clamping drilling tool. A projection is spirally twisted into a recess along the direction of a center shaft, an outer circumferential surface is matched with an innercircumferential surface to achieve changing interference magnitude lambda in the cutting part clamping process of a clamping component, and -0.1mm<=lambda<=0.05mm. The drilling tool has the advantages of rapidness in assembly and disassembly, no axial looseness, high positioning precision, simplicity in manufacture, good interchangeability and the like.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

Fuel container

InactiveUS7208210B2Improve barrier propertiesSuppresses fuel permeationLarge containersDomestic containersEngineeringTotal thickness

Owner:KURARAY CO LTD

Clamping device for voltage-withstanding testing of capacitor core group

InactiveCN103487613AGood jointImprove contact strengthMeasurement instrument housingEngineeringMechanical engineering

The invention discloses a clamping device for voltage-withstanding testing of a capacitor core group. The clamping device comprises a base, a fixing portion and a movable portion opposite to the fixing portion. The fixing portion comprises an end base, a first connecting rod, a first spring, a first installing base and multiple first fixing chutes, wherein the end base is fixedly arranged on the base, the first connecting rod is connected with the end base and the first installing base, and the multiple first fixing chutes are arranged on the first installing base. The movable portion comprises an air cylinder, a second connecting rod, a second spring, a second installing base and second fixing chutes, wherein the air cylinder is fixedly arranged on the base, the second connecting rod is connected with the air cylinder and the second installing base, and the second fixing chutes are arranged on the second installing base and are correspondingly opposite to the first fixing chutes. By adopting the mechanical combined design, the clamping device for the voltage-withstanding testing of the capacitor core group has the advantages of buffering pressure of the capacitor core group and being good in contact surface and can effectively avoid a phenomenon that a metal spraying layer of the end face of the metalized core group is damaged due to over-large impact force or the arc discharge damage is produced by poor contact surfaces caused by too low pressure.

Owner:ANHUI SAFE ELECTRONICS

Construction method of water purification type ecological protection bank

ActiveCN108411852AReasonable and ingenious structural designImprove structural strengthCoastlines protectionWater flowEngineering

The invention discloses a construction method of a water purification type ecological protection bank. The construction method of the water purification type ecological protection bank comprises the following steps of a, opening a foundation pit; b, dividing regions; and c, building the ecological protection bank. According to the construction method of the water purification type ecological protection bank provided by the invention, through designing a fixed support and an installation plate, the top part of the ecological protection bank can be further installed and fixed, so that the structural strength and the structural stability of the ecological protection bank are improved, and the ecological protection bank can resist the impact force of a water flow; meanwhile, when bottom-layerecological building blocks are paved, through designing reinforced gear blocks, not only can the structural strength of the bottom-layer ecological building blocks be ensured, but also the contact strength between the bottom-layer ecological building blocks and soil can be improved, so that the ecological protection bank is not easy to deform; meanwhile, each two adjacent ecological building blocks can be spliced and further connected and fixed through fixed screws, so that the connecting strength between the adjacent ecological building blocks is effectively ensured; and an auxiliary plantinghole is formed between each two adjacent ecological building blocks and is matched with ecological planting holes of the ecological building blocks, so that a greening area of the ecological protection bank is enlarged.

Owner:ZHEJIANG UNIV OF WATER RESOURCES & ELECTRIC POWER

Low temperature superconducting magnet joint lap joint soldering technology

InactiveCN106299949AImprove reliabilityReduce contact resistanceSoldered/welded connectionsSuperconducting magnets/coilsLap jointTin plating

The invention discloses a low temperature superconducting magnet joint lap joint soldering technology which comprises the steps of single joint copper surface tin-plating and double joint lap joint soldering. Compared with a traditional joint lap method, the technology provided by the invention has the advantages that through single joint copper surface tin-plating, a tin material can completely infiltrate and cover the copper surface of a joint, and oxide and impurities in the tin material can be easily removed; when double joint lap joint soldering is carried out, new solder and flux are not added, and flux and oxide residues on the joint contact surface are prevented; double joint lap joint uses automatic pressurization and heating equipment, which realizes precise control of heating and pressing rate of a lap joint process; and the technology has the advantages of high field operability, high joint reliability, low contact resistance and high contact strength.

Owner:合肥聚能电物理高技术开发有限公司

Compressed packer sealing cylinder for oil and gas fields

ActiveCN102041975AMeet job requirementsAvoid damageSealing/packingStatic friction coefficientTemperature resistance

The invention discloses a compressed packer sealing cylinder for oil and gas fields, comprising a rubber cylinder which is sheathed on an inner core of a packer when in use. An outer sleeve made of polytetrafluoroethylene is sleeved outside the rubber cylinder. When the compressed packer sealing cylinder is in use, the rubber cylinder is compressed to radially expand and deform to act on the outer sleeve so that the outer sleeve tightly clings to an outer sleeve of an oil and gas well to form axial sealing; by utilizing the characteristics of the polytetrafluoroethylene, such as high temperature resistance, higher strength in comparison with rubber, low static friction coefficient, corrosion resistance and the like, the contact strength of a sealing surface is improved and the sealing cylinder can satisfy the using requirements on the corrosive working condition that the pressure is 90-105Mpa and the temperature is 160-180DEG C; in addition, axial sealing of the inner core of the packer is formed by the inward expansion of the rubber cylinder so as to meet the operating requirement of the packer. Furthermore, the rubber cylinder is internally provided with a pressure bearing core bar; when the rubber cylinder is compressed for a certain distance, the pressure bearing core bar plays a supporting role to bear continuously increased pressure, thereby preventing the rubber cylinder from being damaged when the deformation of the rubber cylinder is increased continuously, greatly enhancing the pressure bearing capability of the sealing cylinder and prolonging the service life.

Owner:贵州国塑科技管业有限责任公司

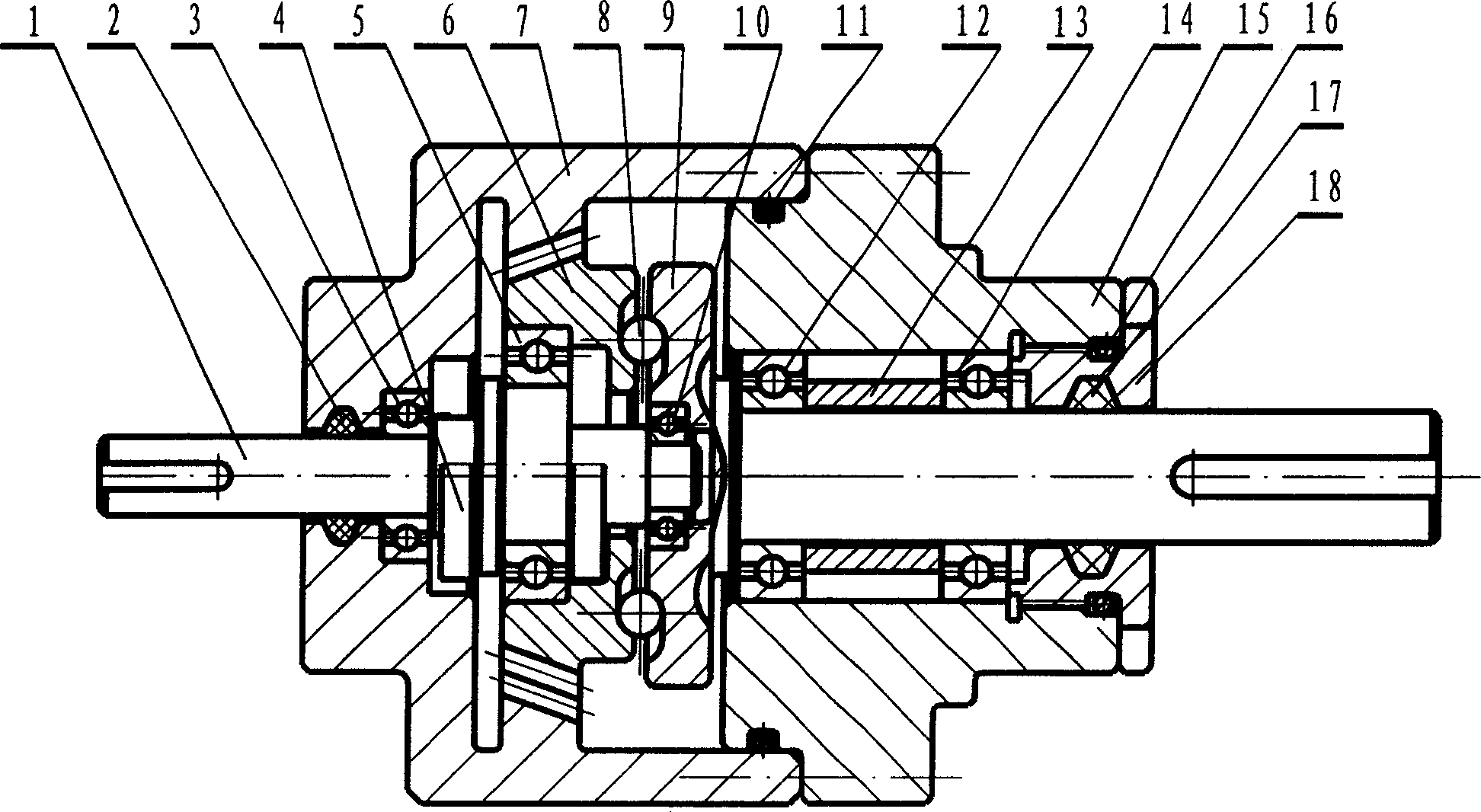

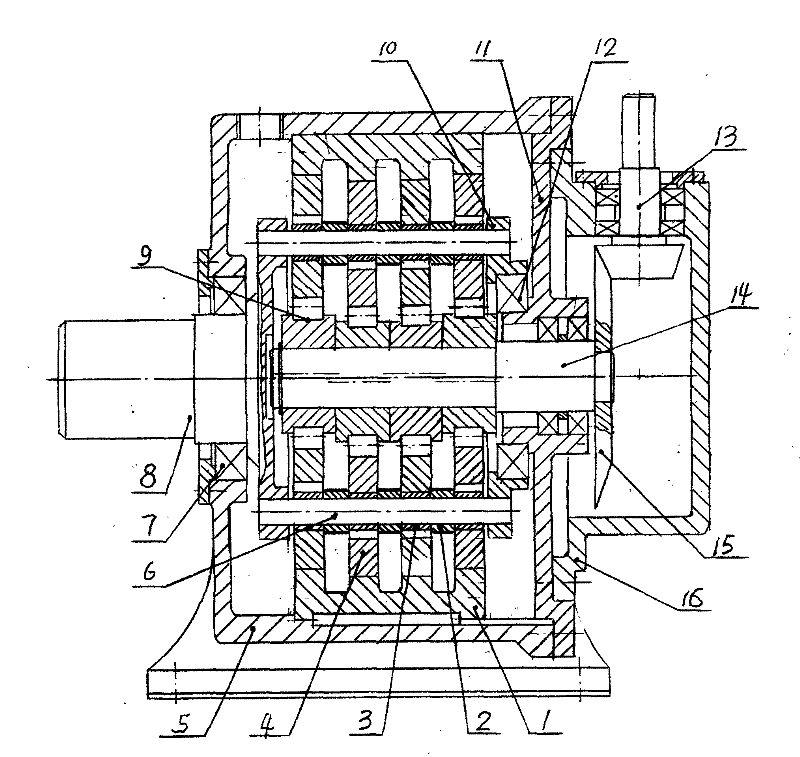

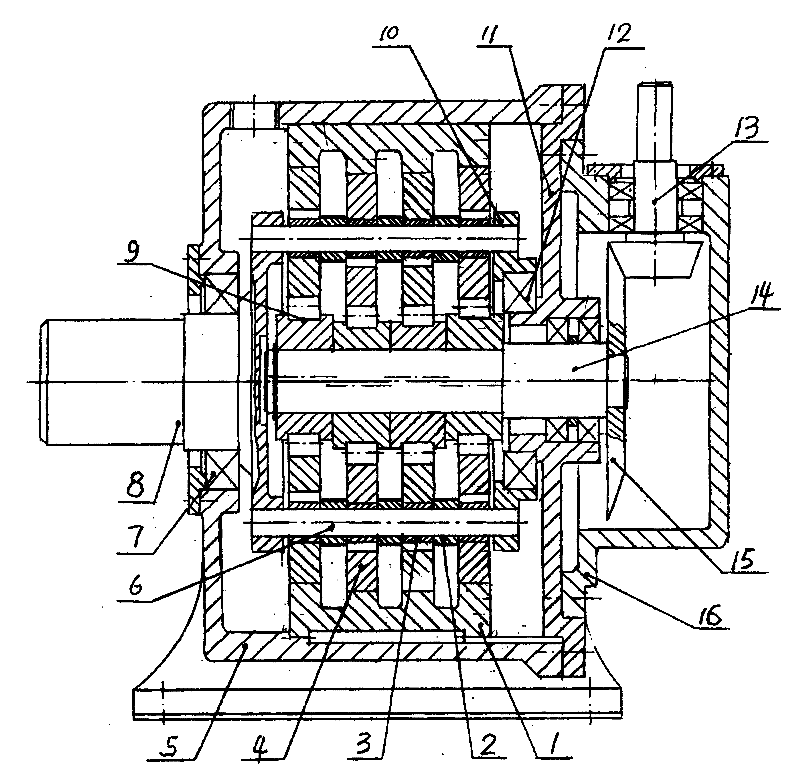

Reducer with bevel gear and hypocycloid in large transmission ratio for ore grinding machine

InactiveCN102192280ASmall radius of curvatureImprove contact strengthToothed gearingsReduction drivePhase difference

The invention relates to the technical field of reducing the speed of an ore grinding machine. A reducer with a bevel gear and a hypocycloid in large transmission ratio for an ore grinding machine is characterized by comprising a bevel gear pair and a cycloid transmission part; the bevel gear pair comprises driving and driven bevel gears and the cycloid transmission part is composed of a machine body, an input shaft, eccentric bearings, a cycloid gear, an inner cycloid gear ring, a W mechanism and bearings; the W mechanism comprises an output shaft, a column pin, a uniform loading disc and an annular plate; in the W mechanism, the output shaft is supported on an inner hole of the machine body through utilizing the bearing and an inner hole of the uniform loading disc is supported on the outer circle of a flange of an end cover through utilizing the bearing; in four single-eccentric bearings: the phase difference between the first bearing and the second bearing and the phase difference between the third bearing and the fourth bearing are 180 DEG and the phase of the second bearing is same as that of the third bearing. In the invention, the reducer has the beneficial effects as follows: (1) the hypocycloid gear is engaged by purely rolling, so that the bearing capability is improved by 2-3 times; (2) the length of the axial direction is reduced by 45-55% and the cost is reduced by 40-50%; (3) the reversed installation service life of the cycloid gear is doubled; and (4) the inertia force and the inertia moment are completely balanced in theory when the reducer is operated.

Owner:吴小杰

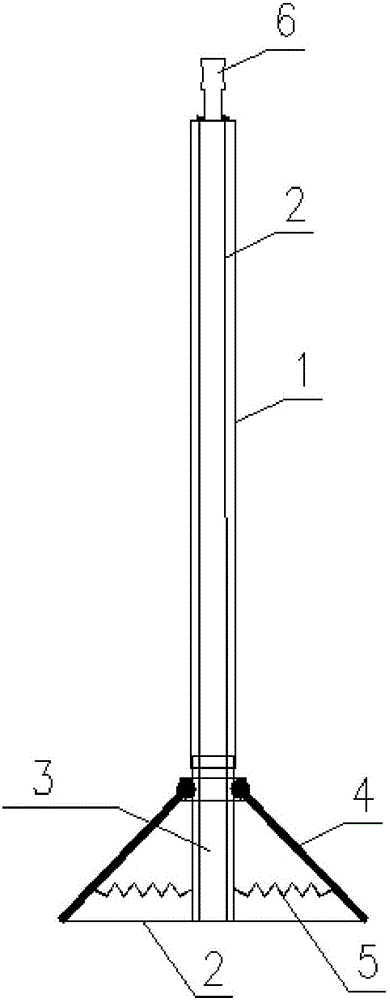

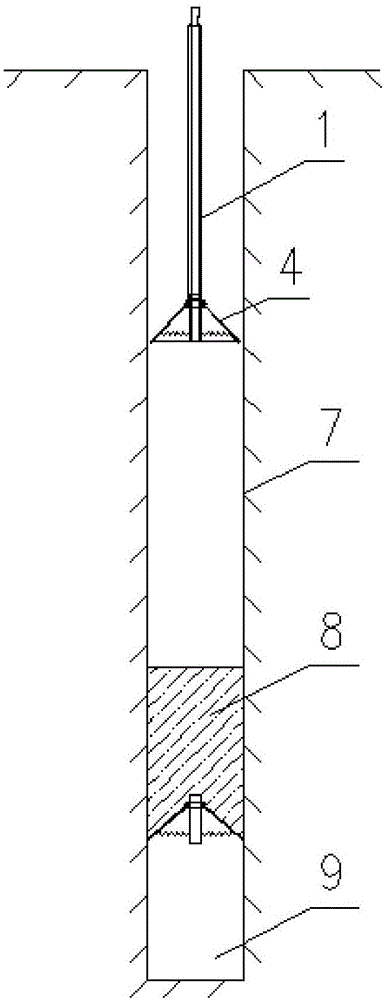

Blasting engineering air spacing device

The invention relates to a blasting engineering air spacing device. The blasting engineering air spacing device comprises an operating rod and a supporting frame. The operating rod is provided with an operating rod connecting rod formed in the axial direction of the operating rod. The supporting frame comprises a fixing rod. The fixing rod is provided with a fixing rod connecting hole formed in the axial direction of the fixing rod. The top of the outer wall of the fixing rod is provided with at least two hinged fulcrum rods. Every two adjacent fulcrum rods are connected through a flexible connector. The outer wall of each fulcrum rod is connected with the outer wall of the fixing rod through a spring. The lower end of each fulcrum rod is fixedly connected with a connecting rope. The top of the fixing rod is in threaded connection with the bottom of the operating rod. The connecting ropes sequentially penetrate through the fixing rod connecting hole and the operating rod connecting rod from the bottom of the fixing rod and then are fixedly arranged on the top of the operating rod, and therefore the springs are in a compressed state.

Owner:CHINA HYDROELECTRIC ENGINEERING CONSULTING GROUP CHENGDU RESEARCH HYDROELECTRIC INVESTIGATION DESIGN AND INSTITUTE

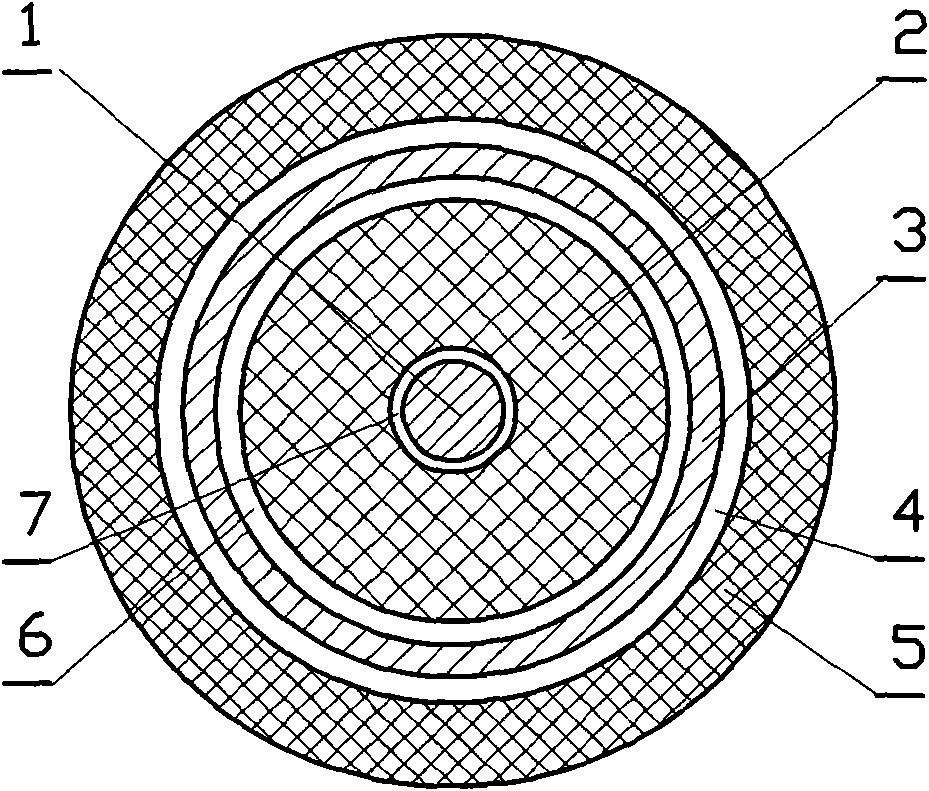

High-performance radiant leaky coaxial cable

InactiveCN101651245APrevent mutual slippageLow dielectric constantInsulated cablesWaveguidesSurface layerElectrical conductor

The invention discloses a high-performance radiant leaky coaxial cable which comprises an inner conductor, an insulating layer, an outer conductor and an outer jacket, wherein the inner conductor is embedded in the outer conductor through the insulating layer, and the inner conductor and the outer conductor are positioned at the position of a concentric circle; the outer conductor is provided witha plurality of rabbets along the longitudinal direction; the insulating layer sequentially comprises an inner insulating surface layer, an insulating foaming layer and an outer insulating surface layer from the inside out; and a bonding layer which is a natural adhesive coating or a synthetic adhesive coating is arranged between the outer conductor and the outer jacket. The coaxial cable not onlyhas excellent bending mechanical property and waterproof and anti-corrosion property, but also has excellent information transmission performance. Meanwhile, the coaxial cable also has the characteristics of simple structure and convenient mounting and construction.

Owner:JIANGSU DONGQIANG

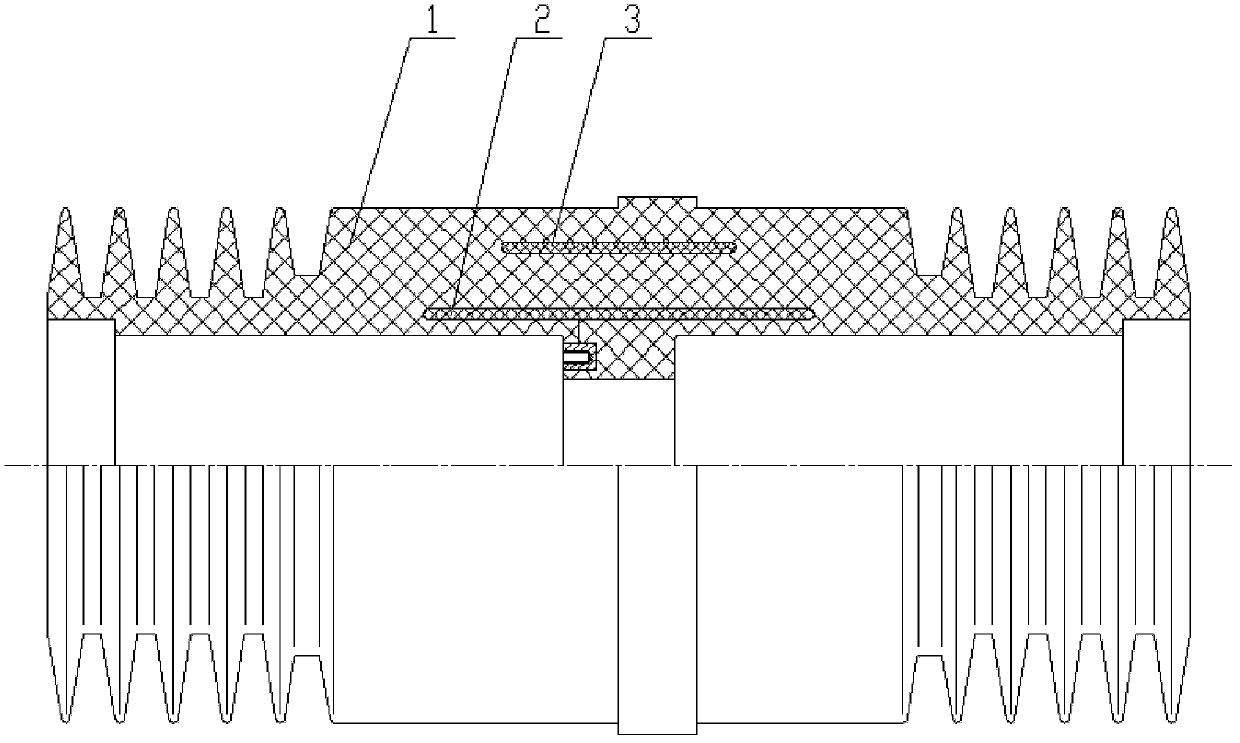

Wall feed-through sleeve with high-low voltage shielding

InactiveCN103296620AExtended service lifeReduce electrical stressElectrical apparatusLow voltageCorona discharge

The invention relates to the field of electrical equipment, in particular to a wall feed-through sleeve. The wall feed-through sleeve with high-low voltage shielding comprises a wall feed-through sleeve body made of insulating materials. A flange used for installing and fixing the wall feed-through sleeve body is arranged on the wall feed-through sleeve body. A shielding layer wraps the interior of the position of the flange on the wall feed-through sleeve body. The shielding layer comprises a high-voltage shielding cover and a grounded low-voltage shielding cover, wherein the high-voltage shielding cover is used for achieving high-voltage shielding. The high-voltage shielding cover is located on the inner wall of the wall feed-through sleeve body. Insulating materials are arranged between the high-voltage shielding cover and the low-voltage shielding cover. Due to the fact that the shielding layer wraps the interior of the position of the flange of the wall feed-through sleeve body, electric field distribution is improved, electric stress on the insulating materials by an electric field is reduced, corona discharge is reduced or eliminated, the service life of the wall feed-through sleeve is prolonged, and reliable operation of a network system is ensured.

Owner:上海旭然电器有限公司

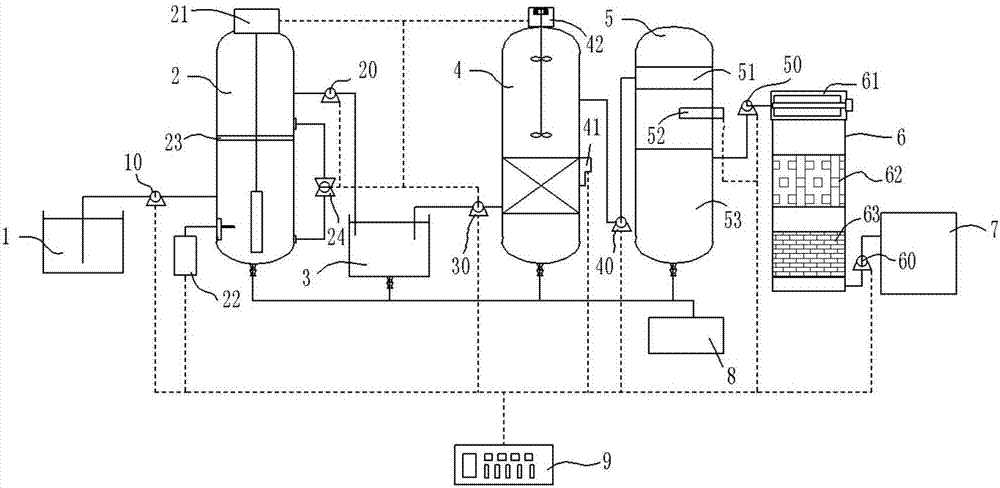

Equipment and method for degrading industrial organic wastewater by coupling ultrasonic ozone-microelectrolysis

InactiveCN108002650AReduce surface tensionImprove permeabilityWater treatment parameter controlSpecific water treatment objectivesEngineeringTower

The invention discloses equipment and a method for degrading industrial organic wastewater by coupling ultrasonic ozone-microelectrolysis. The equipment mainly comprises an ultrasonic ozone treatmenttank, a pH regulating tank, a microelectrolysis treatment tank, a biodegradation tank, an adsorption filtering tower, a wastewater treatment device and a PLC automatic controller, wherein the ultrasonic ozone treatment tank is connected with the pH regulating tank; the pH regulating tank is connected with the microelectrolysis treatment tank; the microelectrolysis treatment tank is connected withthe biodegradation tank; the biodegradation tank is connected with the adsorption filtering tower; the wastewater treatment device is connected with drainage valves of the ultrasonic ozone treatment tank, the pH regulating tank, the microelectrolysis treatment tank and the biodegradation tank; the PLC automatic controller is connected with the electrical installations of the equipment through wires. The method comprises the following steps: ultrasonic ozone treatment, iron-carbon microelectrolysis treatment, biodegradation treatment and wastewater purifying treatment; the treatment process provided by the invention has the characteristic of high efficiency.

Owner:SOUTH CHINA INST OF ENVIRONMENTAL SCI MEP

Convex-concave engaged arc gear and rack mechanism without relative sliding

ActiveCN106523632AAvoid wear and tearAvoid gluingPortable liftingGearing elementsEngineeringSpiral line

The invention relates to a convex-concave engaged arc gear and rack mechanism without relative sliding. The convex-concave engaged arc gear and rack mechanism without relative sliding comprises a transmission pair consisting of a spiral arc gear and an arc rack, wherein the spiral arc gear is connected with a rotating shaft of a driver; spiral convex arc teeth are uniformly distributed on the outer surface of the spiral arc gear; center lines of the spiral convex arc teeth of the spiral arc gear are equal-lift cylindrical spiral lines; concave arc tooth grooves are uniformly distributed in the upper surface of the arc rack; the spiral convex arc teeth are matched with the concave arc tooth grooves; and the structural shape of the spiral arc gear and the structural shape of the arc rack are determined by design parameters. When the mechanism is mounted, the spiral convex arc teeth are correctly engaged with the concave arc tooth grooves, and therefore, arc gear and rack transmission is realized. The arc gear and rack mechanism does not have failure modes such as tooth surface relative sliding, tooth surface gluing, tooth surface abrasion and tooth surface plastic deformation, has the advantages of high contact ratio, simple structure, high transmission efficiency, high bearing capacity and the like, and is suitable for being popularized and used in the fields of tiny machines, micro-machines and conventional machines.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

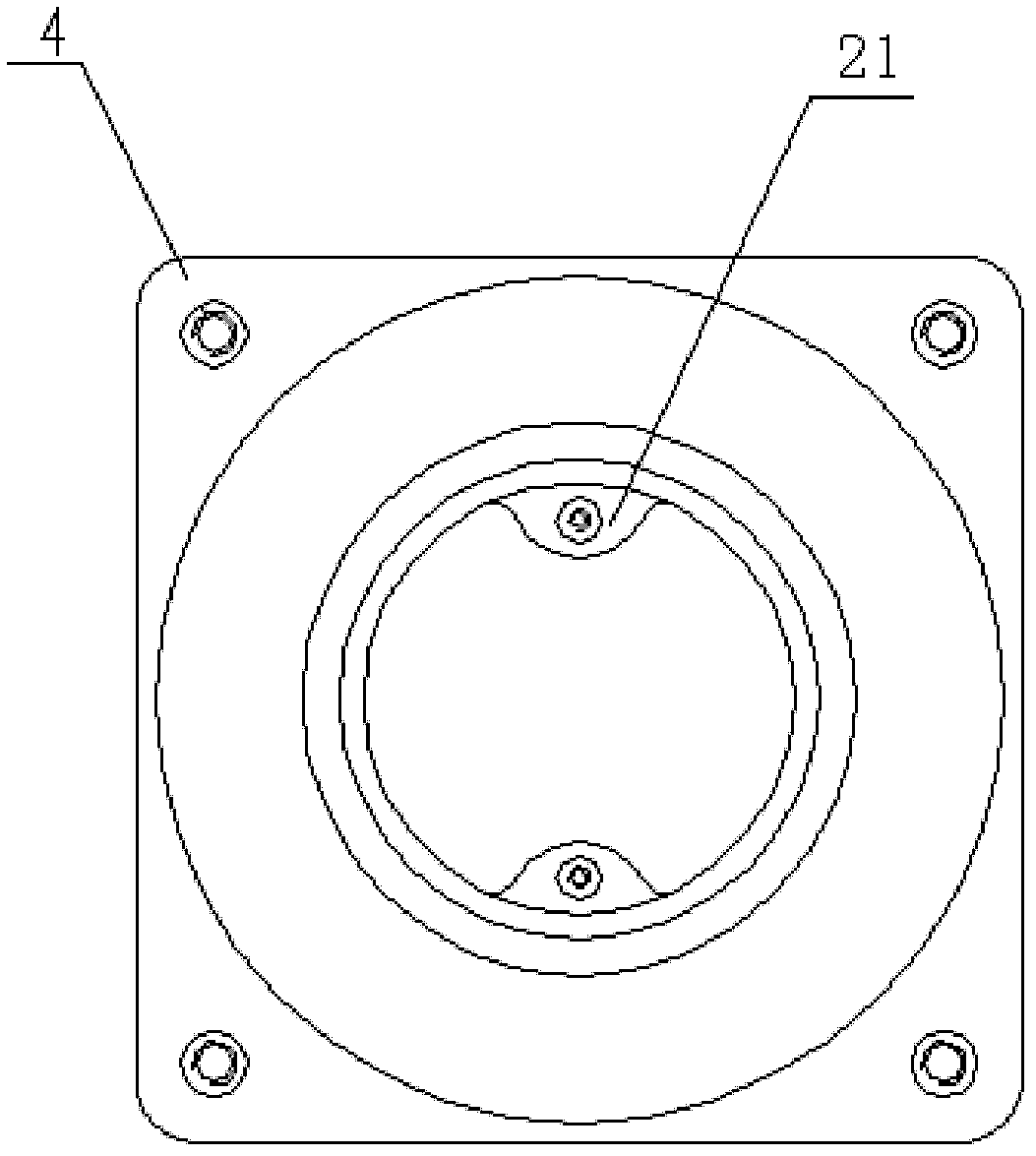

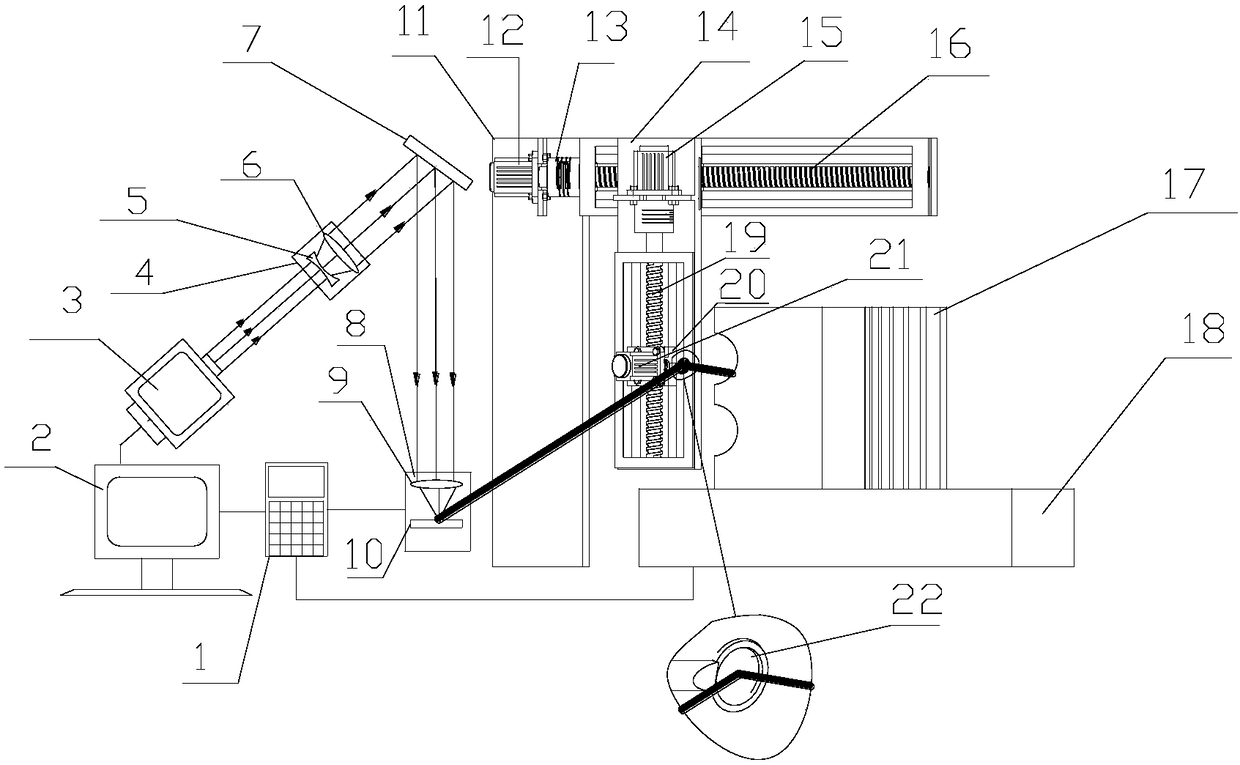

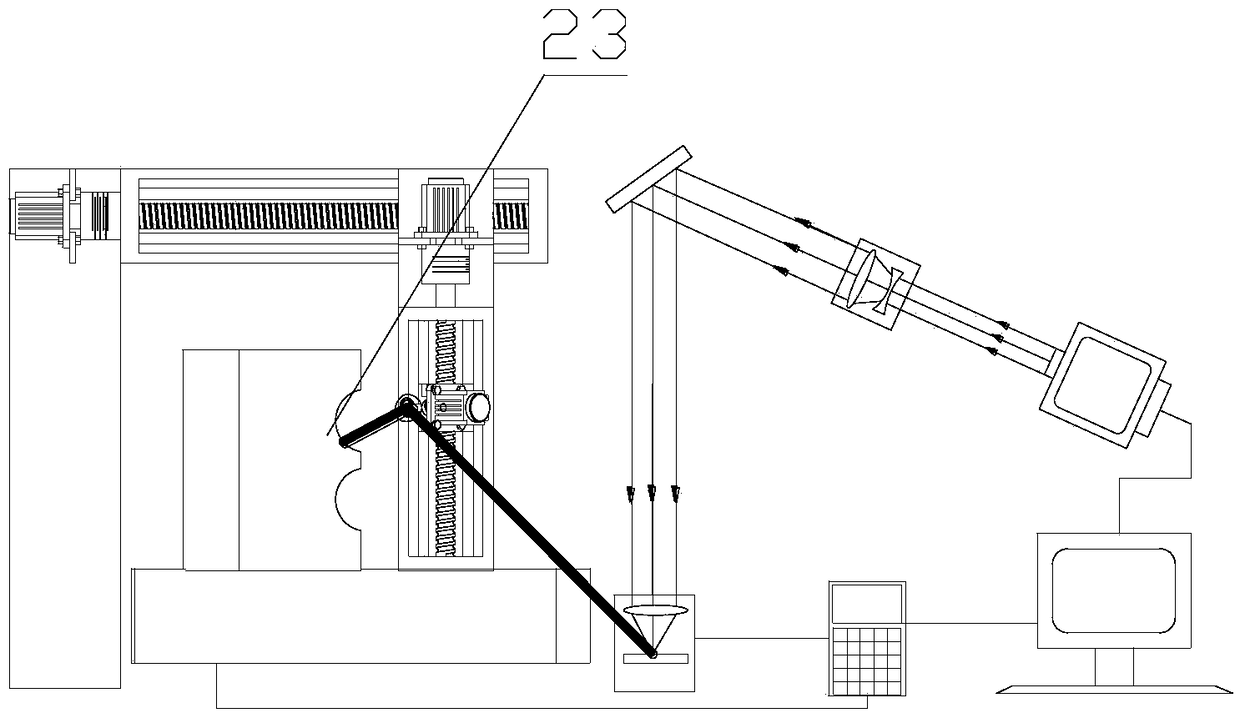

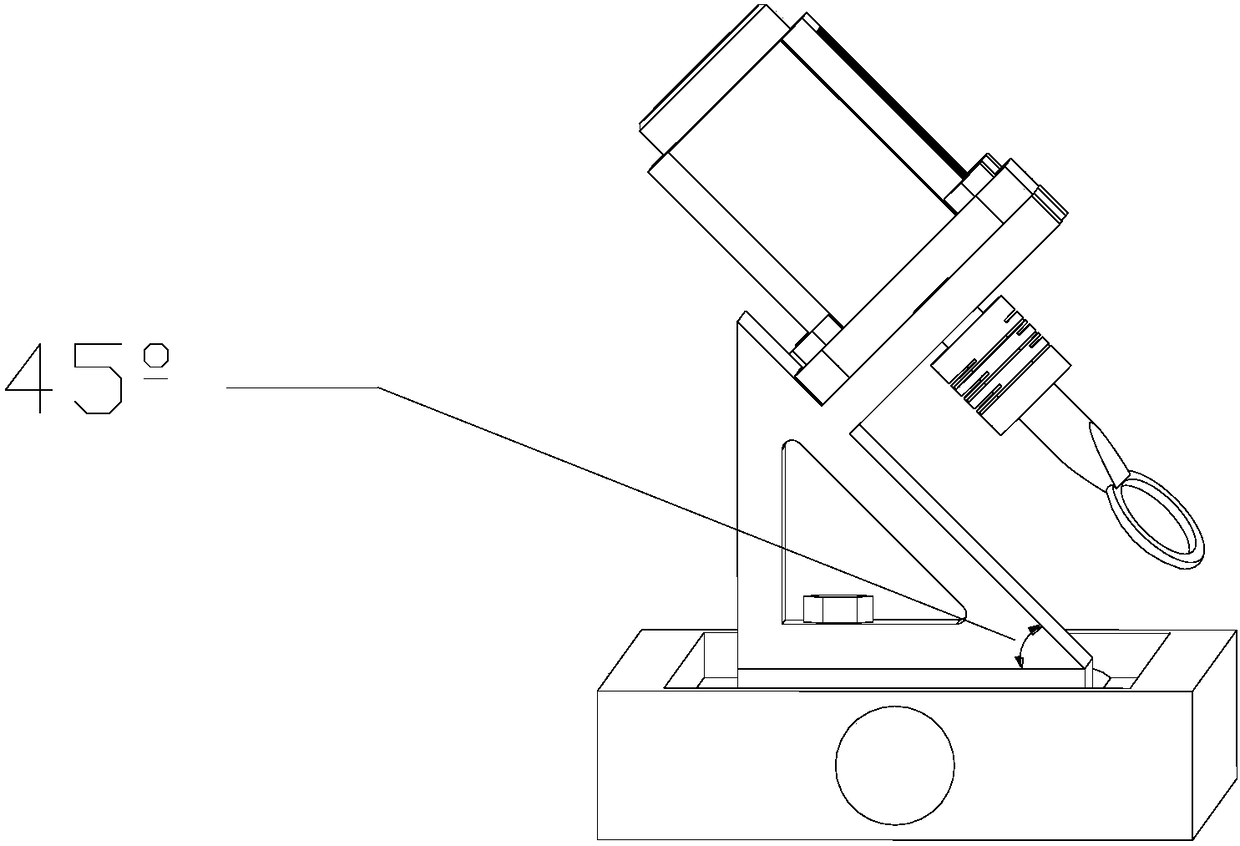

Variable pitch/yaw bearing ring raceway laser phase change hardening method and machining device

ActiveCN108559819AAdd depthImprove contact strengthFurnace typesHeat treatment furnacesCorrosionRefraction

The invention relates to the technical field of laser machining application, in particular to a variable pitch / yaw bearing ring raceway laser phase change hardening method and a machining device. A cantilever beam and a ball screw on a supporting frame are controlled to adjust the needed machining position, a focusing device is adjusted through a digital controller to shoot lasers to a third refractor, and a third servo motor is used for controlling the third refractor to rotate so that machining from the top of a raceway to the bottom can be achieved; the lasers are constantly perpendicular to the machining position under the refraction action of the refractor; the digital controller controls the horizontal rotation speed of a rotation platform, and machining of the surfaces of differentsizes and different types of bearing ring raceways with the diameter being 2 or more meters can be achieved; stable dislocated and refined grains can be formed on the surface layer and the sub-surfacelayer of the bearing ring raceway through self-cooling of a workpiece; and meanwhile, the maximum hardened layer depth of the bearing ring raceway is improved, the contact strength and anti-fatigue performance of the bearing ring raceway are effectively improved, and abrasion resistance and corrosion resistance of the bearing workpiece are improved.

Owner:JIANGSU UNIV

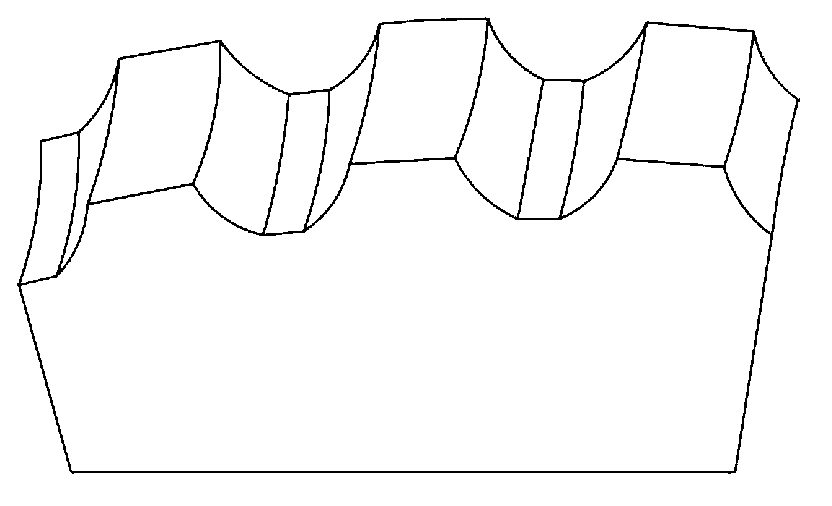

3-teeth double-rotor flowmeter

InactiveCN101042301AImprove contact strengthNot easy to pittingVolume indication and recording devicesVolume/mass flow by mechanical effectsEngineeringNatural gas

This invention relates to one three-gear gas and double rotor flow meter for natural gas and coal gas, which comprises the structure as: meter chamber is connected to transfer magnetic steel, sensor, electrical meter, wherein, meter chamber has rotors; the rotor is for three gear spiral rotor in arc swing shape; the gear is composed of four section curves from tip to long swing line, short line and opening line and arc line; meter chamber connects double rotor through bearing and drive gear; the double rotor axis front end is connected to drive gear geared with two drive gears; one rotor back end is fixed on emission magnetic steel.

Owner:SHANGHAI YINUO INSTR

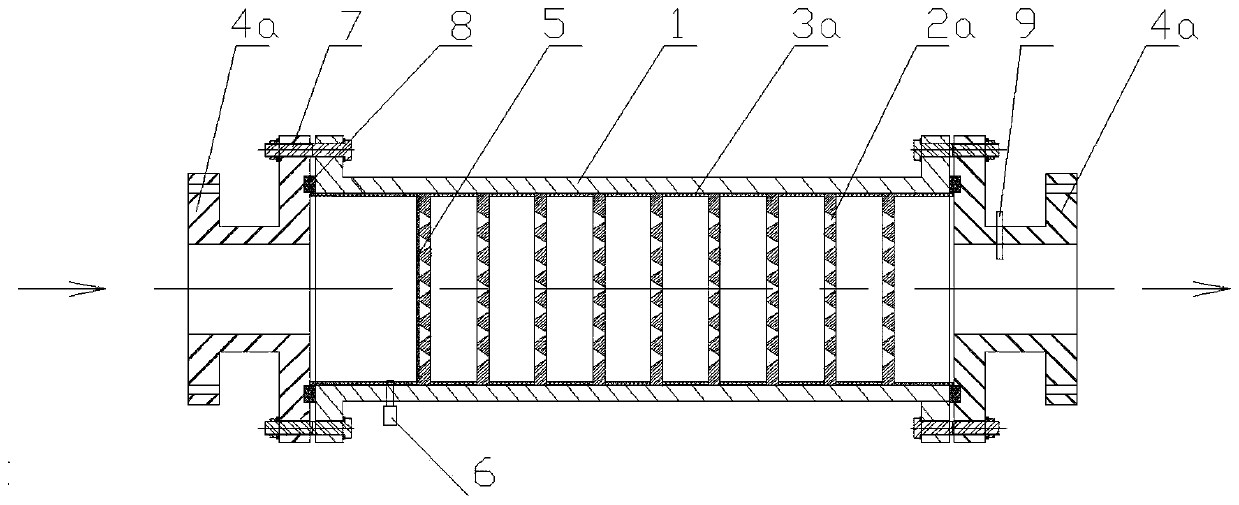

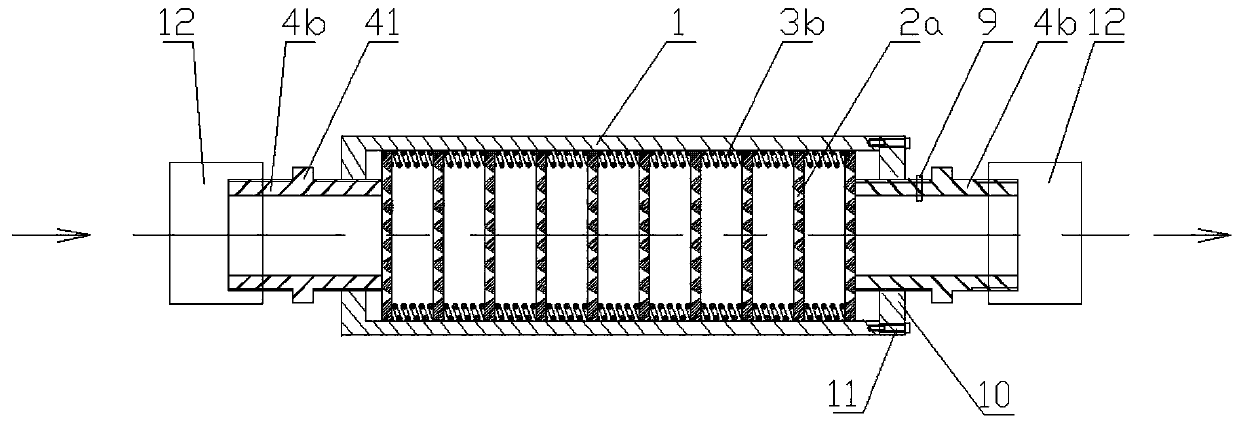

Adjustable turbulence scale inhibitor device and scale inhibition method

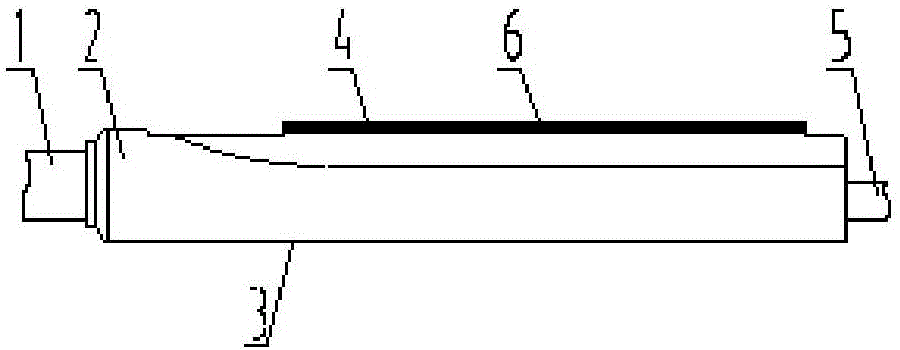

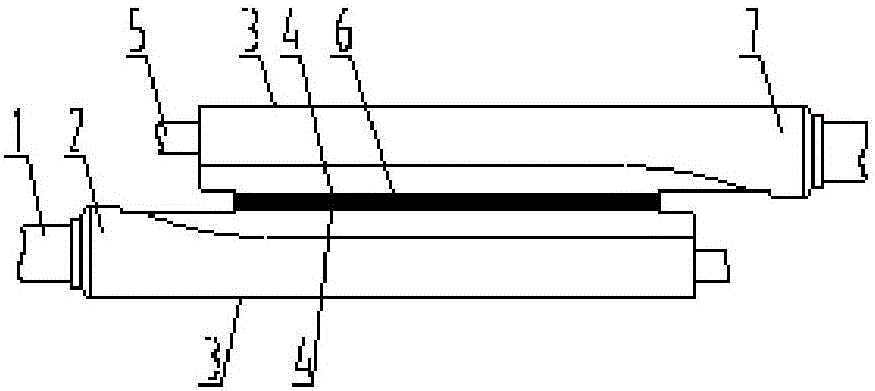

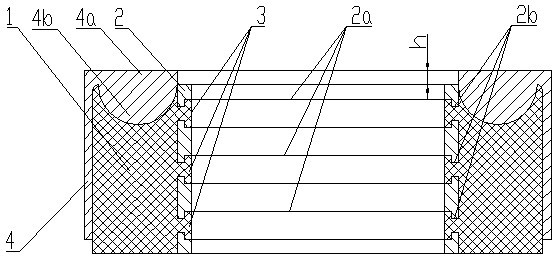

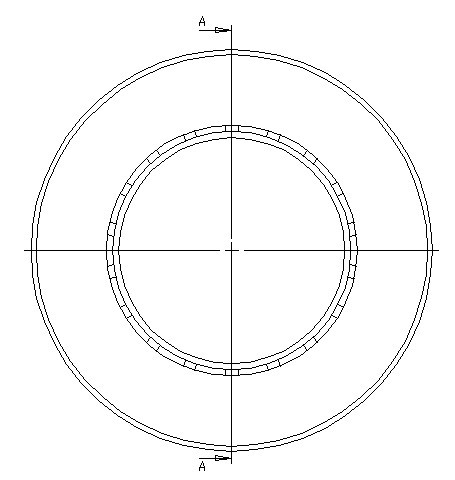

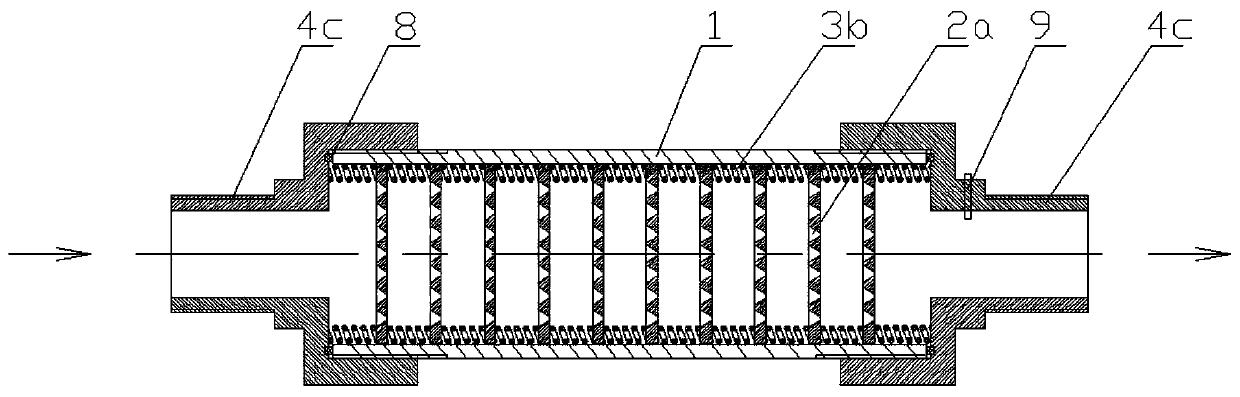

PendingCN111186918AImprove contact strengthIncrease water speedScale removal and water softeningWater flowEngineering

The invention relates to an adjustable turbulence scale inhibitor device and a scale inhibition method. The adjustable turbulence scale inhibitor device comprises a cylinder, an adjustable scale dissolving assembly, an inlet connecting piece and an outlet connecting piece, wherein the adjustable scale dissolving assembly is composed of a plurality of turbulence bodies, and the distance among the turbulence bodies can be adjusted; the turbulence bodies are made of a catalyst alloy; one end of the cylinder is a water inlet, and the other end of the cylinder is a water outlet; the inlet connecting piece is arranged at one end of the water inlet of the cylinder, and the outlet connecting piece is arranged at one end of the water outlet of the cylinder. According to the device and the method, the turbulent flow body interval or the system water pressure in the scale dissolving assembly can be adjusted according to the dynamically detected water flow speed value, so that the purpose of stable scale inhibition is achieved.

Owner:罗光政 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com