Equipment and method for degrading industrial organic wastewater by coupling ultrasonic ozone-microelectrolysis

A technology of organic wastewater and ultrasonic wave, applied in water/sewage treatment equipment, chemical instruments and methods, oxidized water/sewage treatment, etc., can solve the problems of low current efficiency, improve utilization rate, high raw material utilization rate, and strengthen penetration force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

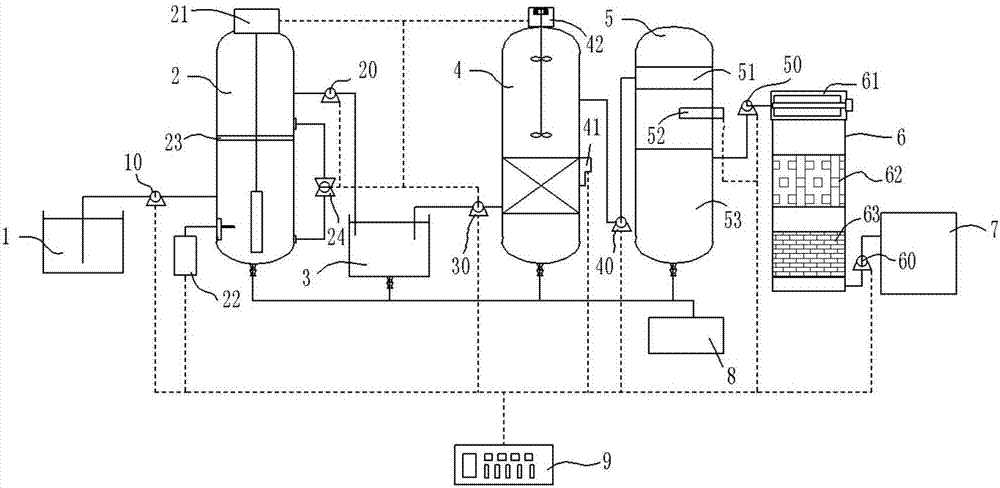

[0023] Embodiment 1: as figure 1 The equipment for degrading industrial organic wastewater by ultrasonic ozone-micro-electrolysis coupling mainly includes raw water collection pool 1, ultrasonic ozone treatment pool 2, pH adjustment pool 3, micro-electrolysis treatment pool 4, biodegradation pool 5, and adsorption filtration tower 6. Water purification pool 7, waste water treatment device 8 and PLC automatic controller 9; the ultrasonic ozone treatment pool 2 is provided with a membrane module 23, a water inlet 1, and a water outlet 1, and the membrane module 23 is arranged at the water inlet of the ultrasonic ozone treatment pool 2 Between one and water outlet one, an ultrasonic reactor 21 is arranged at the upper end of the ultrasonic ozone treatment pool 2, a plasma ozone generator 22 is arranged at the lower left side of the ultrasonic ozone treatment pool 2, and a reflux device is arranged on the right side of the ultrasonic ozone treatment pool 2 24. The raw water collec...

Embodiment 2

[0029] Embodiment 2: The difference from Example 1 is that the method for degrading industrial organic wastewater with ultrasonic ozone-micro-electrolysis coupling is:

[0030] (1) Ultrasonic ozone treatment: introduce high-concentration organic industrial wastewater into the ultrasonic ozone treatment pool 2, open the ultrasonic reactor 21 to degrade the wastewater by vibration, the ultrasonic vibration frequency is 30KHZ, and the intensity is 10W / cm 2 After 2min, the plasma ozone generator 22 is opened and the plasma ozone mixed gas is blown into the waste water for aeration, the gas-water volume ratio is 2.5:1, and the ultrasonic reactor 21 and the plasma ozone generator 22 are closed after 50 min to obtain the front-end treated waste water; Wherein, the step (1) plasma ozone mixed gas is formed by mixing plasma ozone and air, the plasma ozone comes from the oxygen bottle, and the volume percentage of the plasma ozone is 25%. Tiny bubbles can improve the utilization rate of...

Embodiment 3

[0034] Embodiment 3: The difference from Example 1 is that the method for degrading industrial organic wastewater with ultrasonic ozone-micro-electrolysis coupling is:

[0035] (1) Ultrasonic ozone treatment: introduce high-concentration organic industrial wastewater into the ultrasonic ozone treatment pool 2, open the ultrasonic reactor 21 to degrade the wastewater by vibration, the ultrasonic vibration frequency is 45KHZ, and the intensity is 15W / cm 2 After 3min, the plasma ozone generator 22 is opened and the plasma ozone mixed gas is blown into the wastewater for aeration, the gas-water volume ratio is 3:1, and the ultrasonic reactor 21 and the plasma ozone generator 22 are closed after 60min to obtain the front-end treated wastewater; Wherein, the step (1) plasma ozone mixed gas is formed by mixing plasma ozone and air, and the plasma ozone comes from an oxygen bottle, and the volume percentage of plasma ozone is 35%. Tiny bubbles can improve the utilization rate of ozone...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com