Patents

Literature

231results about How to "Sufficient reaction time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

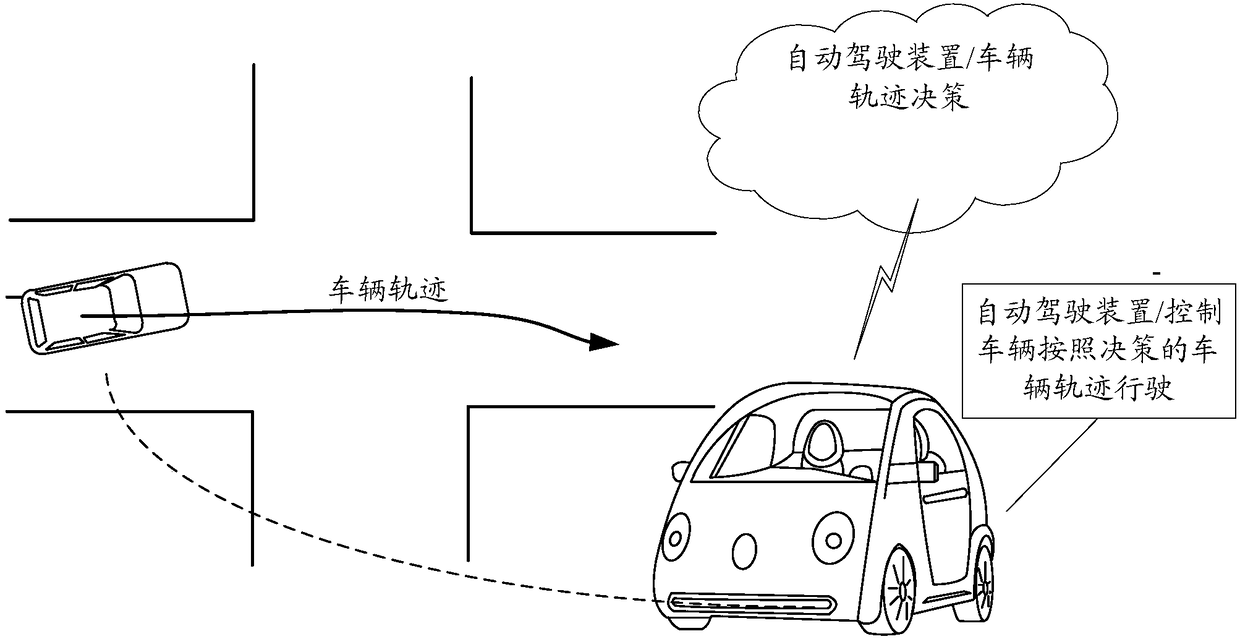

Automatic driving method and device and vehicle

ActiveCN108459588ASufficient reaction timeAccuracy controllablePosition/course control in two dimensionsVehiclesTraffic signalEngineering

The invention discloses an automatic driving method and device and a vehicle. The method comprises the following steps: detecting a traffic signal at an intersection in the driving direction of the vehicle; determining a path from the vehicle position to a target position of the intersection; applying different acceleration curves to the path to obtain different trajectories corresponding to the path, wherein the trajectories comprise speed and time of each position in the path; according to the state indicated by the traffic signal, selecting a driving model corresponding to the traffic stateof the intersection; selecting a trajectory matched with the vehicle speed from the different trajectories; and according to the selected trajectory, carrying out at least one slow-down driving process and at least one constant speed driving process on the path, and then, reaching the intersection. The method can control the vehicle to drive safely and stably under the environment comprising theintersection.

Owner:TENCENT TECH (SHENZHEN) CO LTD

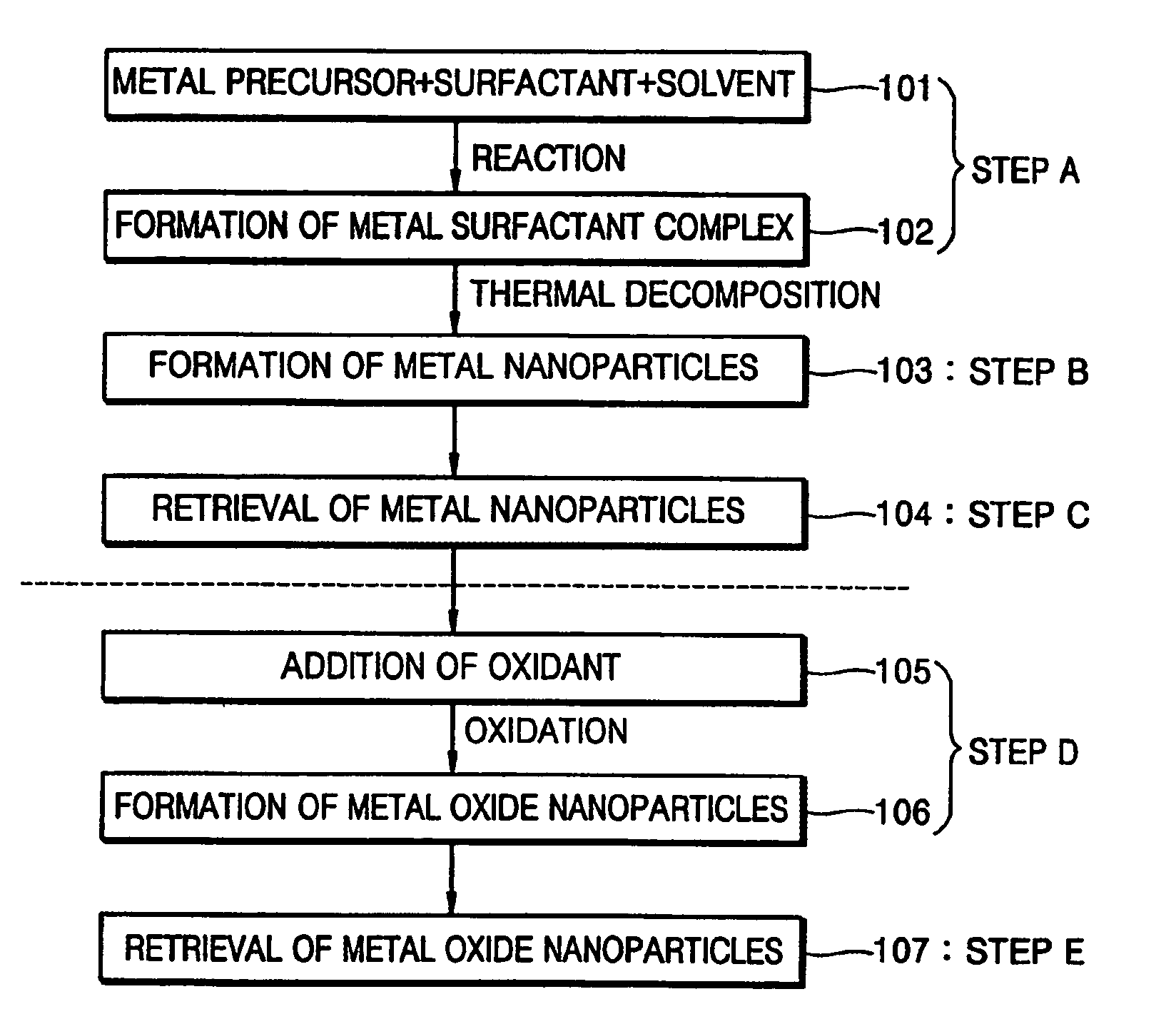

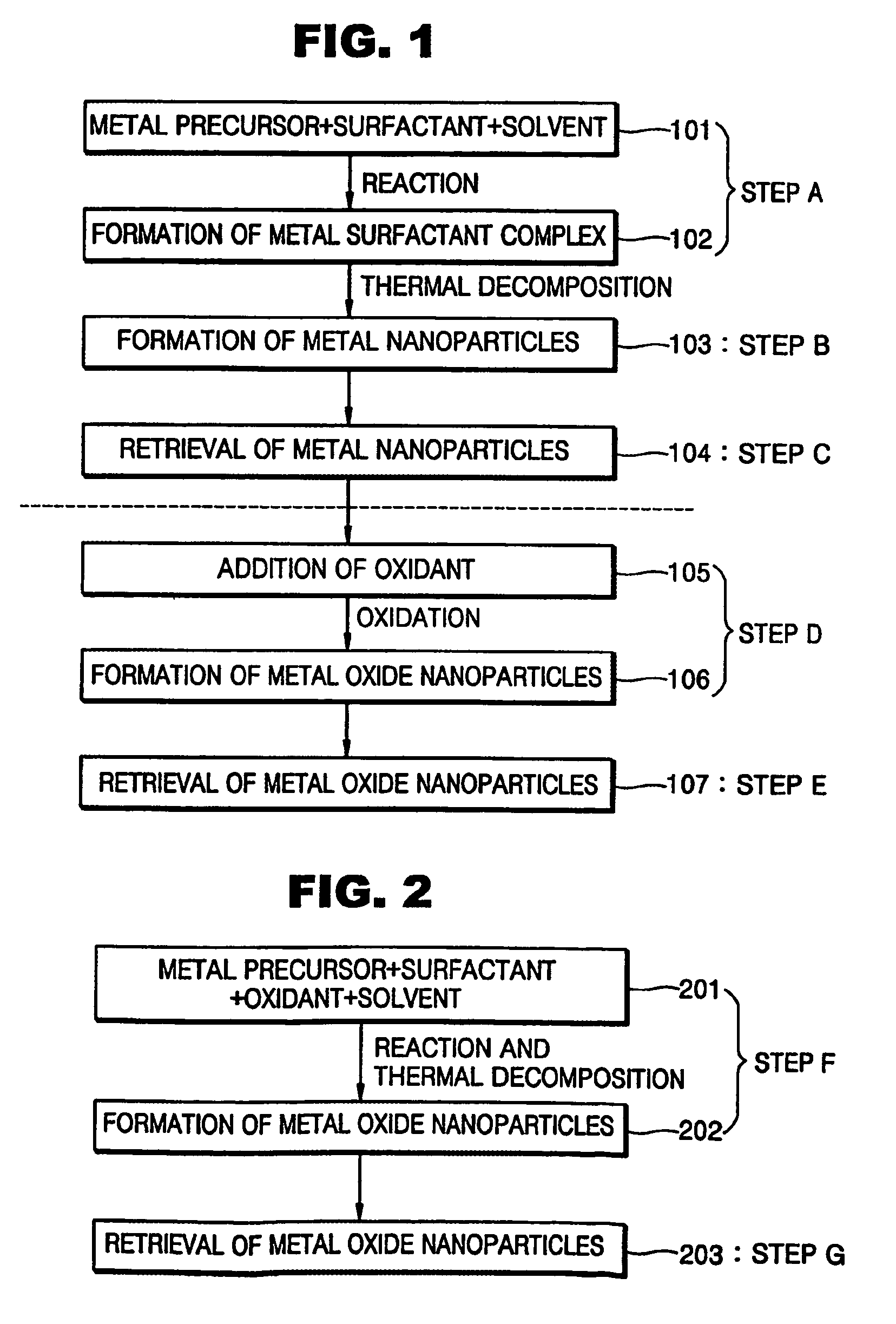

Synthesis of mono-disperse and highly crystalline nano-particles of metals, alloys, metal-oxides, and multi-metallic oxides without a size-selection process

InactiveUS7407527B2Sufficient reaction timeInduce precipitationMaterial nanotechnologyOxygen/ozone/oxide/hydroxideMetal oxide nanoparticlesSynthesis methods

A synthetic method of fabricating highly crystalline and monodisperse nanoparticles of metals, multi-metallic alloys, monometallic oxides and multi-metallic oxides without a size selection process are disclosed. A typical synthetic method comprises the steps of, synthesis of a metal surfactant complex from the reaction of a metal precursor and a surfactant, high temperature thermal decomposition of the metal surfactant complex to produce monodisperse metal nanoparticles, and completing the formation of synthesized metal, metal alloy or metal oxide nanoparticles by adding a poor solvent followed by centrifuging. For obtaining highly crystalline monodisperse nanoparticles, additional steps are necessary as described in the invention. The resulting nanoparticles have excellent magnetic property for many applications.

Owner:SEOUL NAT UNIV R&DB FOUND

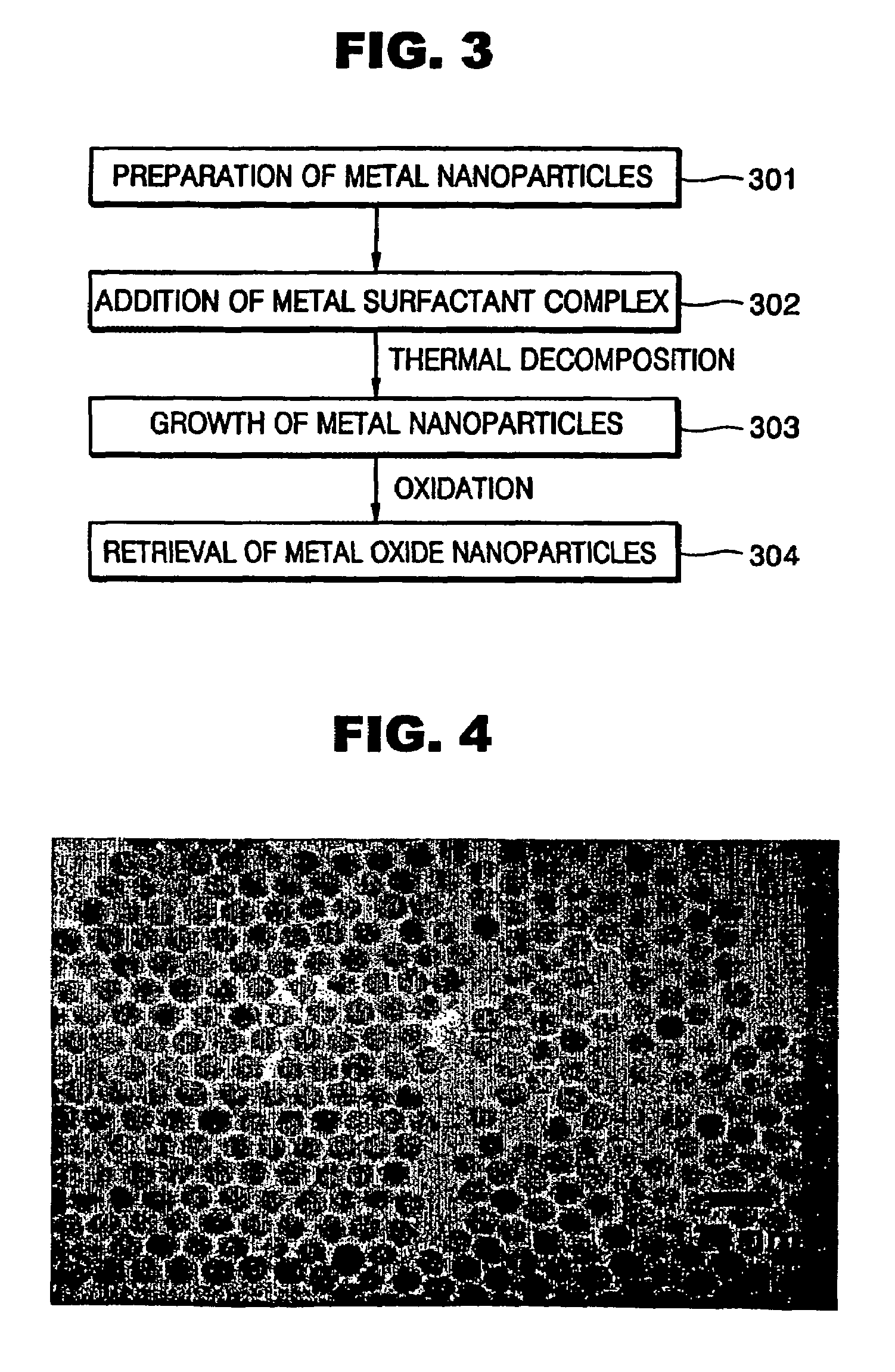

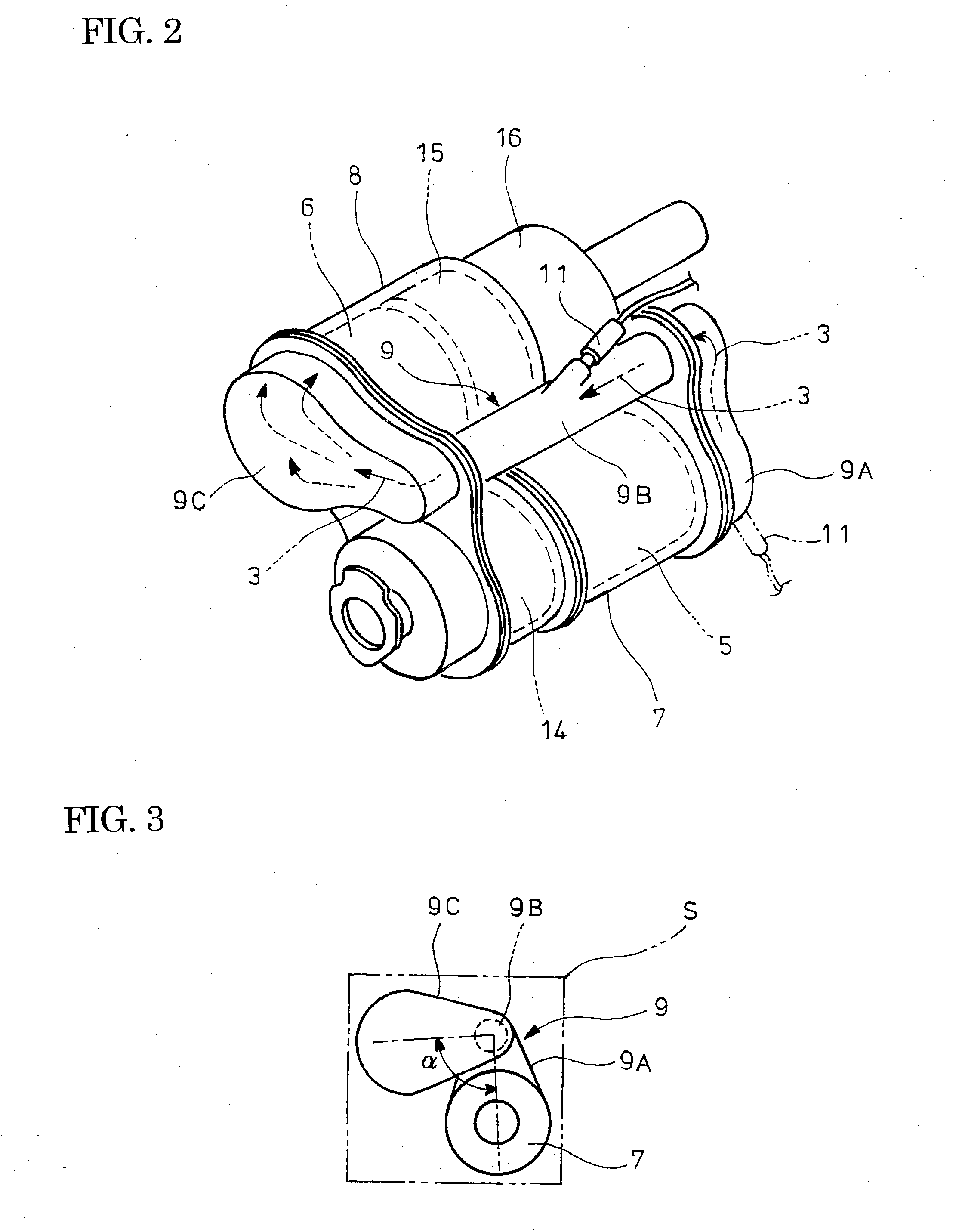

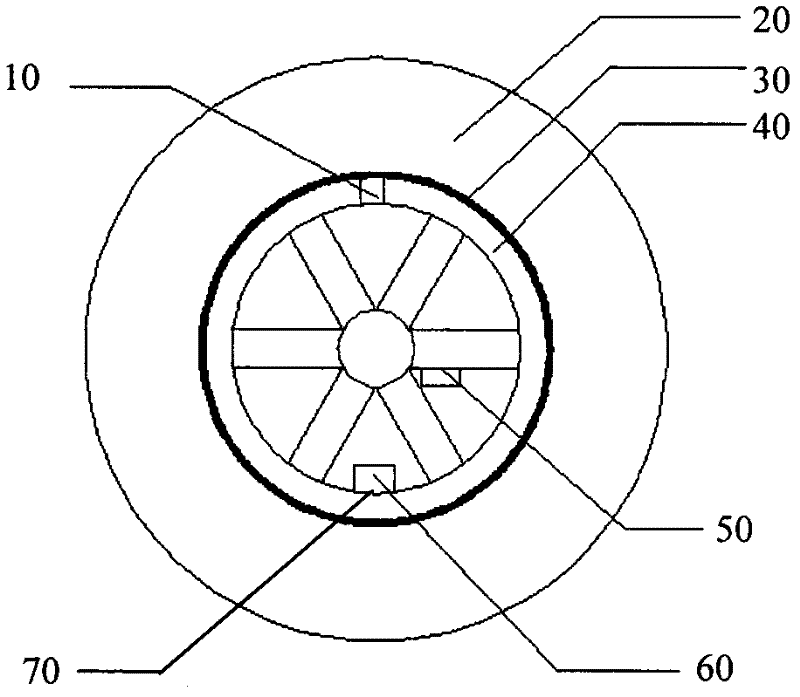

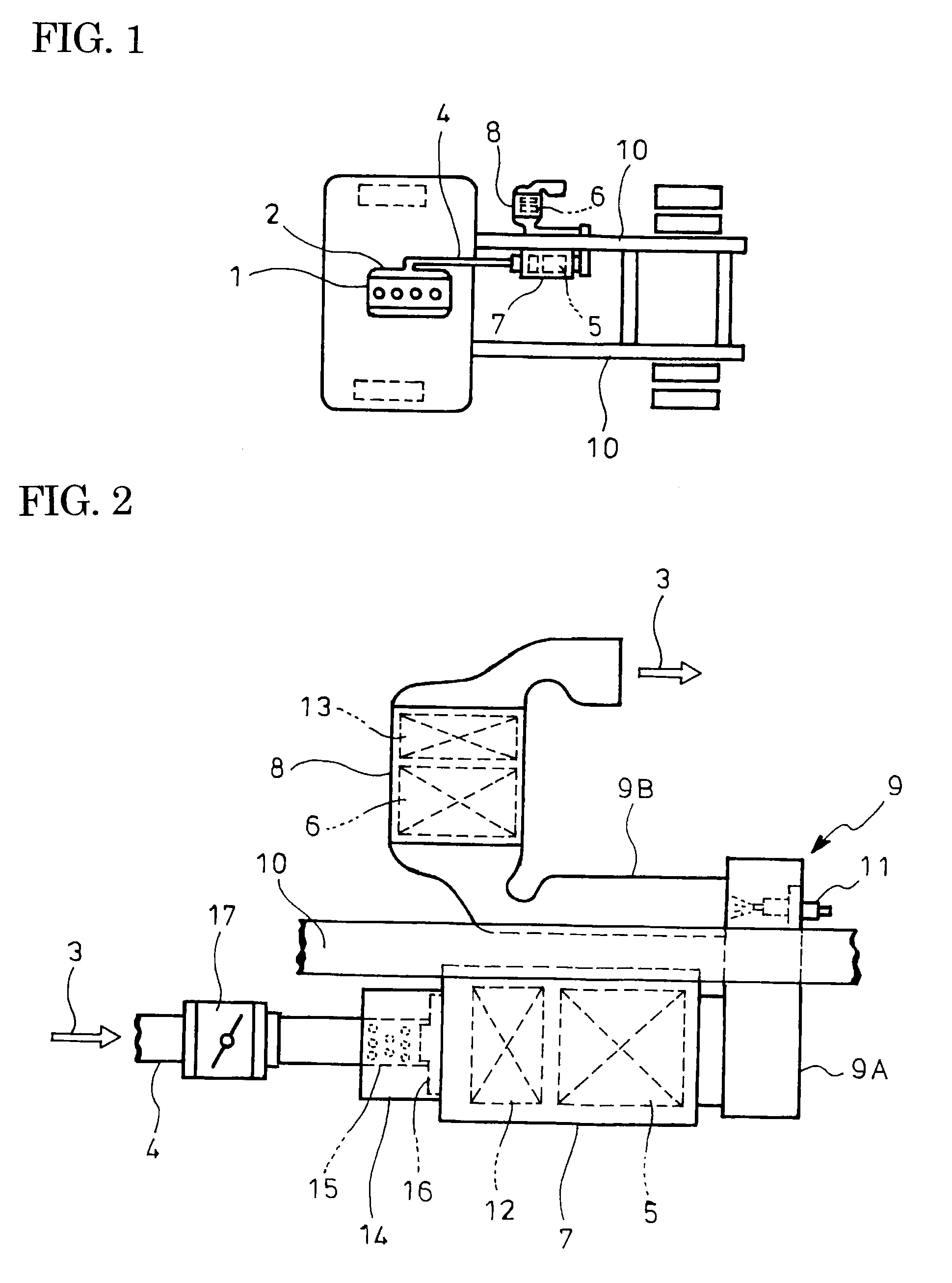

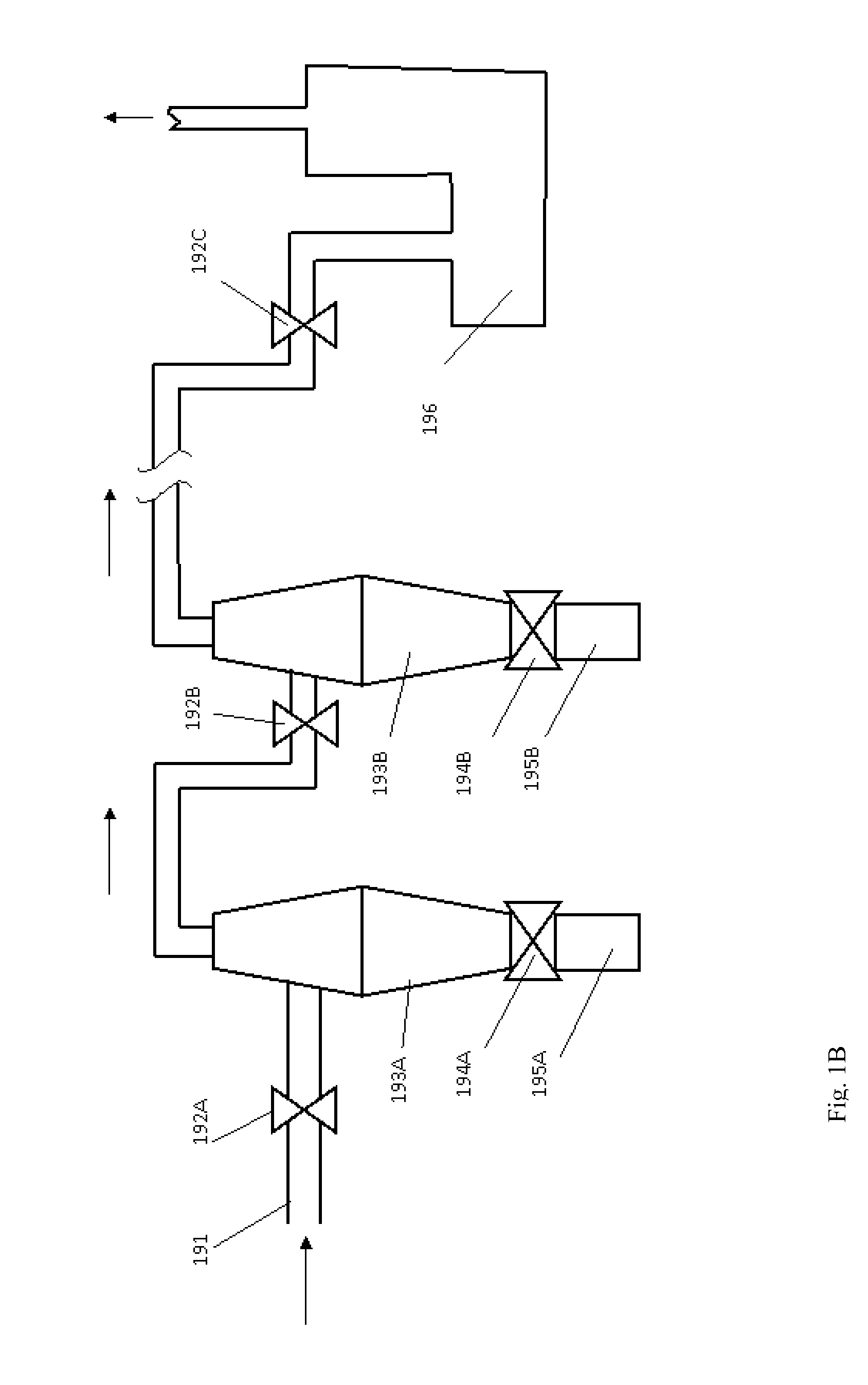

Exhaust emission control device

ActiveUS20100000203A1Sufficient reaction timeClosely arrangedGas treatmentElectrical controlParticulatesOxygen

The object of the invention is to improve mountability on a vehicle by realizing a compact arrangement of a particulate filter 5 and selective reduction catalyst 6 while ensuring satisfactory reaction time for generation of ammonia from urea water. In an exhaust emission control device having particulate filter 5 incorporated in an exhaust pipe 4, selective reduction catalyst 6 capable of selectively reacting NOx with ammonia under the presence of oxygen being arranged downstream of the particulate filter, urea water as reducing agent being adapted to be added between the selective reduction catalyst 6 and the particulate filter 5, the particulate filter 5 is arranged in parallel with the selective reduction catalyst 6. An S-shaped communication passage 9 is arranged for introduction of the exhaust gas 3 from a rear end of the particulate filter 5 to a front end of the adjacent selective reduction catalyst 6 in a forward folded manner. A urea water addition injector 11 is arranged midway of the communication passage 9.

Owner:HINO MOTORS LTD

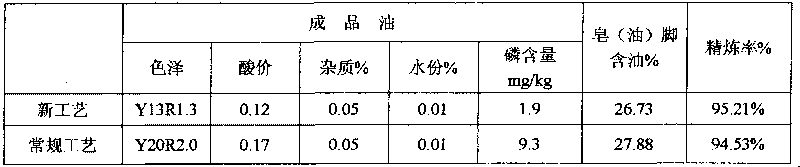

Novel process for refining oil-tea camellia seed crude oil

ActiveCN101735886AReduce side effectsLow reaction temperatureFatty-oils/fats refiningOil and greaseVegetable oil

The invention discloses a novel process for refining oil-tea camellia seed crude oil, which belongs to the technical field of grease refining in the fine and further processing of farm and sideline products. A process flow comprises the following steps: filtering the oil-tea camellia seed crude oil to eliminate impurities; performing a first low temperature acid reaction; performing low temperature alkali refining; removing soap; performing water washing after first acid adding; performing second water washing; and de-coloring and deodorizing the obtained product to obtain first-level oil-tea camellia seed oil. The novel process is characterized by improving the oil obtaining rate of refining, lowering production cost, improving product quality and stability and the like, and is used for refining the oil-tea camellia seed crude oil and refining rap oil, peanut oil and other vegetable oil.

Owner:HUNAN XINJINHAO TEA OIL

Preparation method and application of micro-nano sparkling water

InactiveCN105417674AImprove purification effectSufficient reaction timeClimate change adaptationAgricultural fishingMicro nanoSuction force

The invention discloses a preparation method of micro-nano sparkling water. The method sequentially includes the following steps of firstly, exerting pressure on gas-liquid mixed fluid to make the fluid rotate at a high speed, guiding the gas-liquid mixed fluid into an elliptic container, and forming a negative pressure axis in the middle of the elliptic container through the gas-liquid mixed fluid; secondly, concentrating mixed gas in the gas-liquid mixed fluid or external gas to the negative pressure axis under the suction force of the negative pressure axis in the elliptic container; thirdly, spraying the high-speed-rotating gas-liquid mixed fluid out of jet ports of the two ends of the elliptic container to product micro-nano bubbles. Compared with the prior art, the advantages of the micro-nano sparkling water are explored and applied to the field of scientific and technological agriculture such as soilless cultivation, fruit and vegetable cleaning, biological repairing, dirty water processing and the like, and a solution is provided for further utilizing the micro-nano sparkling water.

Owner:天津颐品农庄电子商务有限公司

Slurry for desulfuration and denitration of recirculating fluidized bed boiler

ActiveCN102179161AImprove desulfurization effectRealize comprehensive utilizationLighting and heating apparatusDispersed particle separationFluidized bedProcess engineering

The invention discloses slurry for desulfuration and denitration of a recirculating fluidized bed boiler, which comprises desulfurizing agent slurry and a denitrfying agent solution. Composite desulfurizing and denitrfying agent slurry is prepared by adopting a calcium based absorbing agent, an additive, a co-additive and an amino reducing agent according to a certain proportion and programs and used for being atomized and sprayed into a region at the top of the recirculating fluidized bed boiler through a nozzle to react with SO2 and NOx in smoke to generate sulfate and N2. By applying the slurry disclosed by the invention, the problems of low desulfuration efficiency of calcined limestone doped in the recirculating fluidized bed boiler and low utilization rate of the desulfurizing agent are solved, desulfuration and denitration are realized simultaneously, the desulfuration efficiency reaches 85-95 percent and the denitration efficiency reaches 50-70 percent. The slurry has the advantages of low investment and operation costs and convenience for implementation.

Owner:SHANDONG UNIV

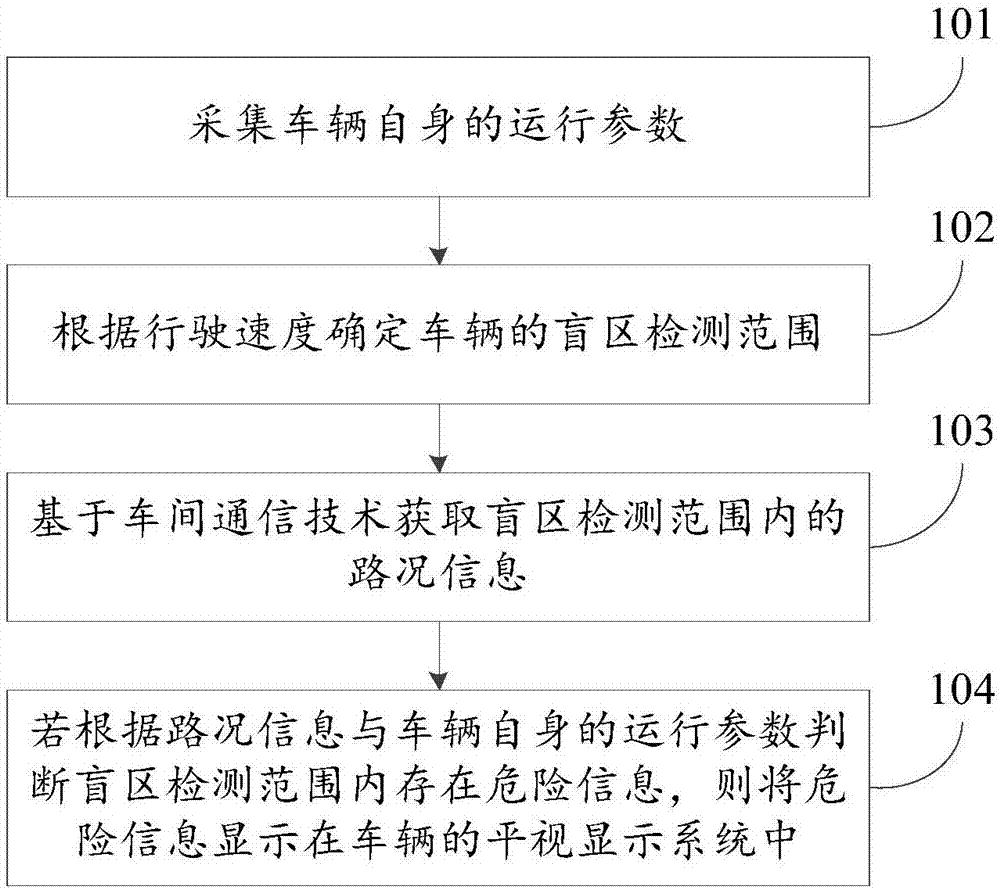

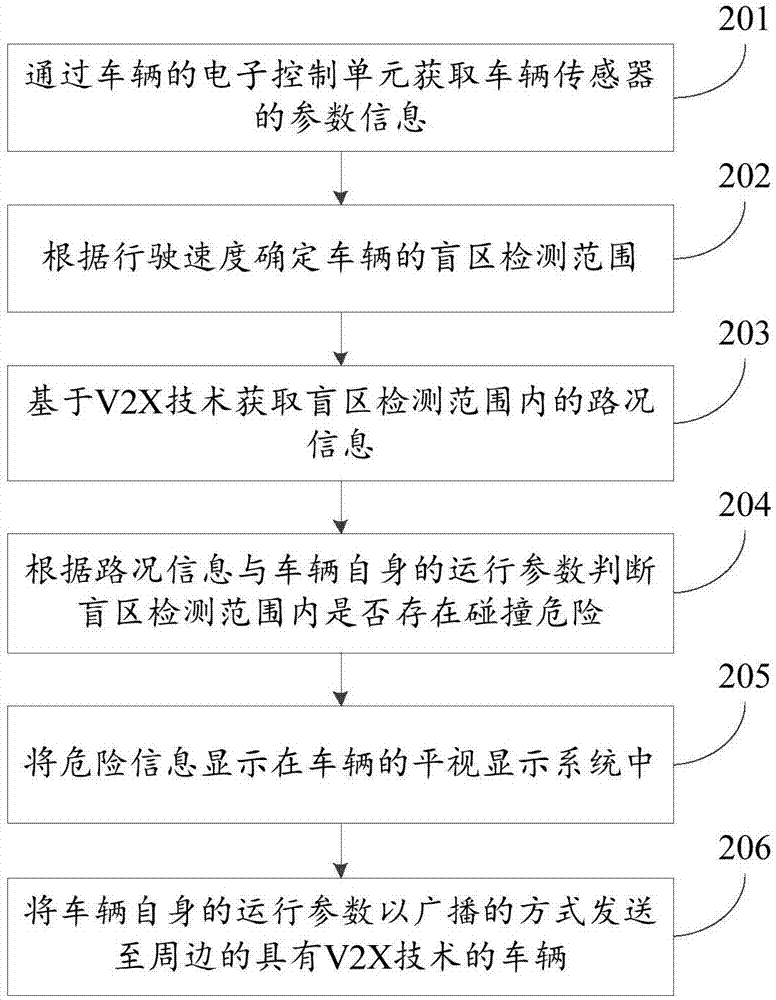

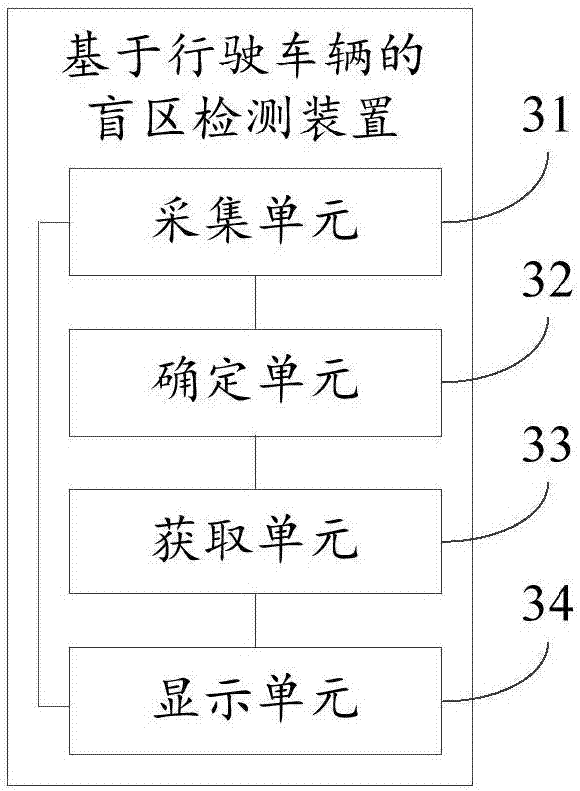

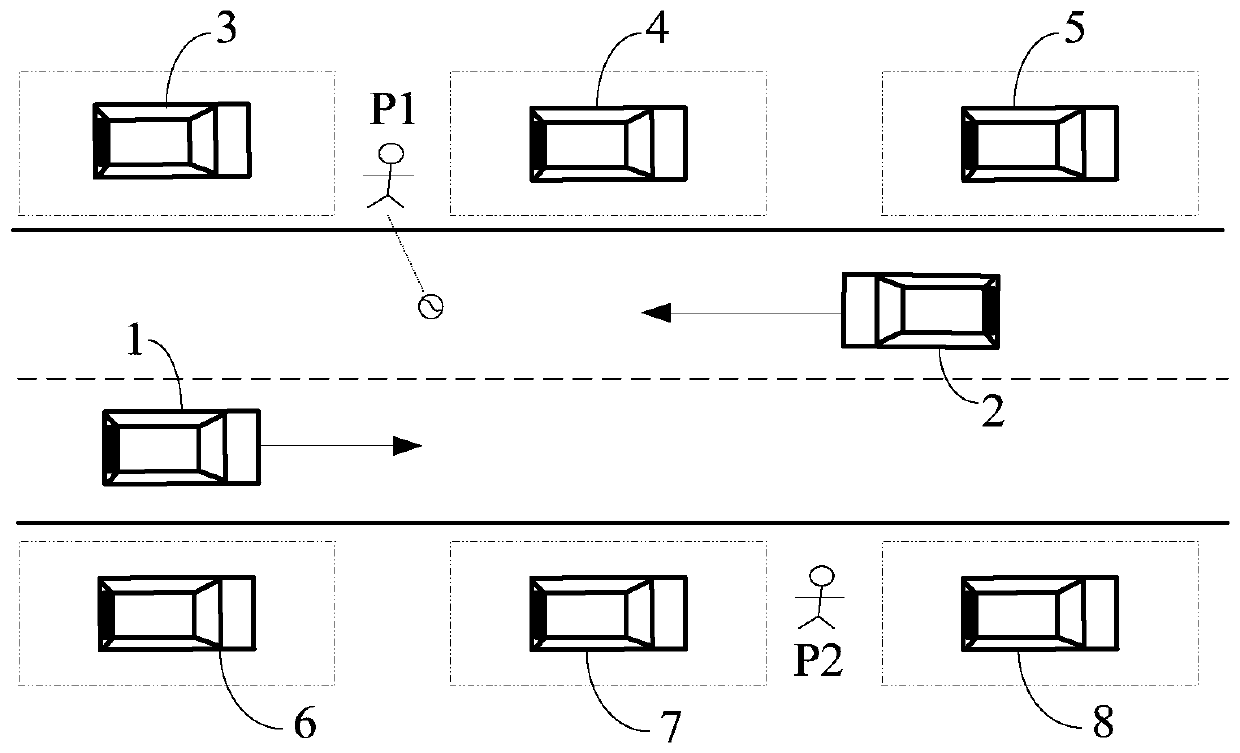

Driving-vehicle-based blind zone detection method and apparatus, terminal, and vehicle

InactiveCN108010383ASufficient reaction timeAvoid dangerAnti-collision systemsSignalling/lighting devicesHead-up displayOperating speed

The invention, which relates to the field of the smart car technology, discloses a driving-vehicle-based blind zone detection method and apparatus, a terminal, and a vehicle so that the potential riskaround the vehicle during a driving process can be displayed by using a head-up display system so as to warn the driver for safety driving. The method comprises: running parameters of a vehicle itself are collected, wherein the running parameters include a current running speed of the vehicle; according to the running speed, a blind zone detection range of the vehicle is determined; on the basisof a vehicle-to-vehicle communication technology, road condition information in the blind zone detection range is obtained; and if dangerous information exists in the blind zone detection region basedon the road condition information and the running parameters of the vehicle, the dangerous information is displayed in the head-up display system of the vehicle. The driving-vehicle-based blind zonedetection method and apparatus, the terminal, and the vehicle are mainly used for detection and early warning for the blind zone of the vehicle.

Owner:BEIJING CHJ AUTOMOTIVE TECH CO LTD

Traffic light identification system in driving process

InactiveCN105303860ASufficient reaction timeAvoid running red lightsRoad vehicles traffic controlEngineeringGreen-light

The invention discloses a traffic light identification system in the driving process. The system comprise the steps of image collection, image preprocessing, traffic light positioning, color discrimination, color space conversion, countdown display and voice prompt. The system can be used to automatically discriminate a traffic light in front, and thus, prompts a driver, and enables enough response time; and the driver can take measures timely and is prevented from running the red light or missing the green light, and accidents are avoided.

Owner:四川膨旭科技有限公司

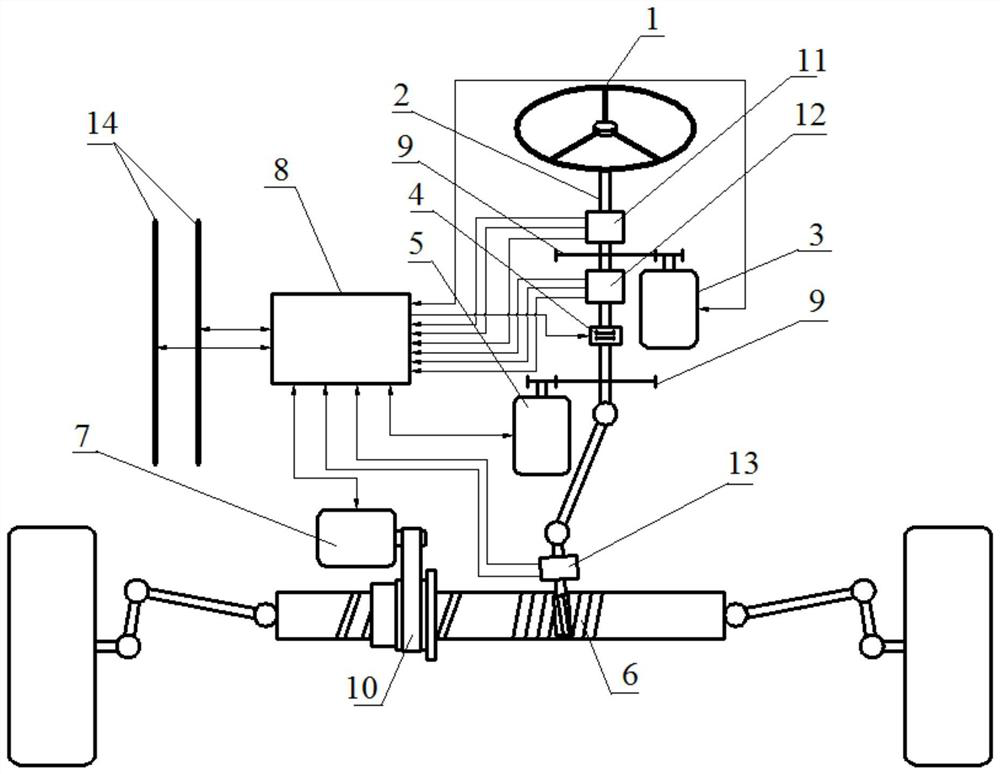

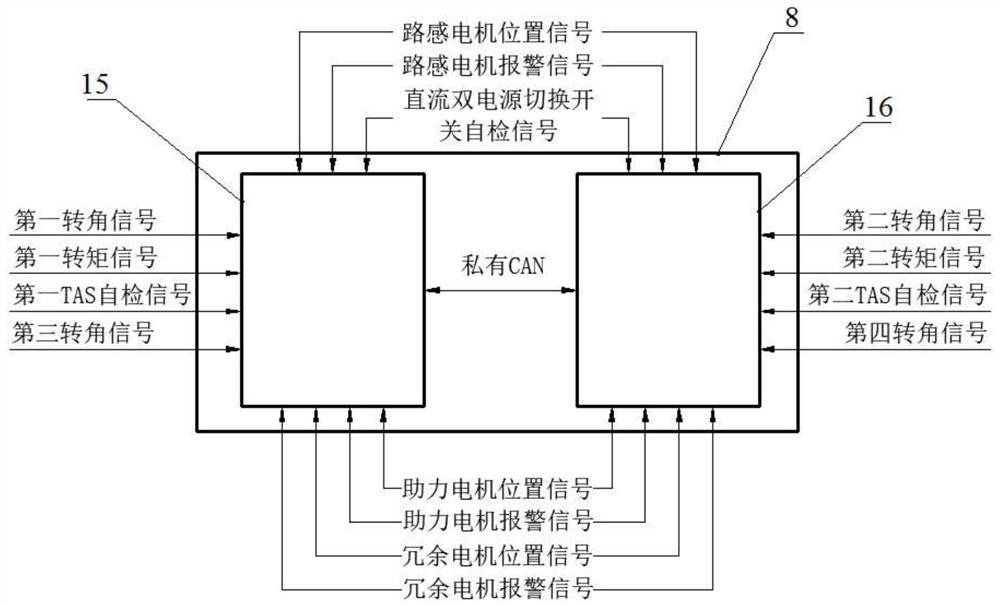

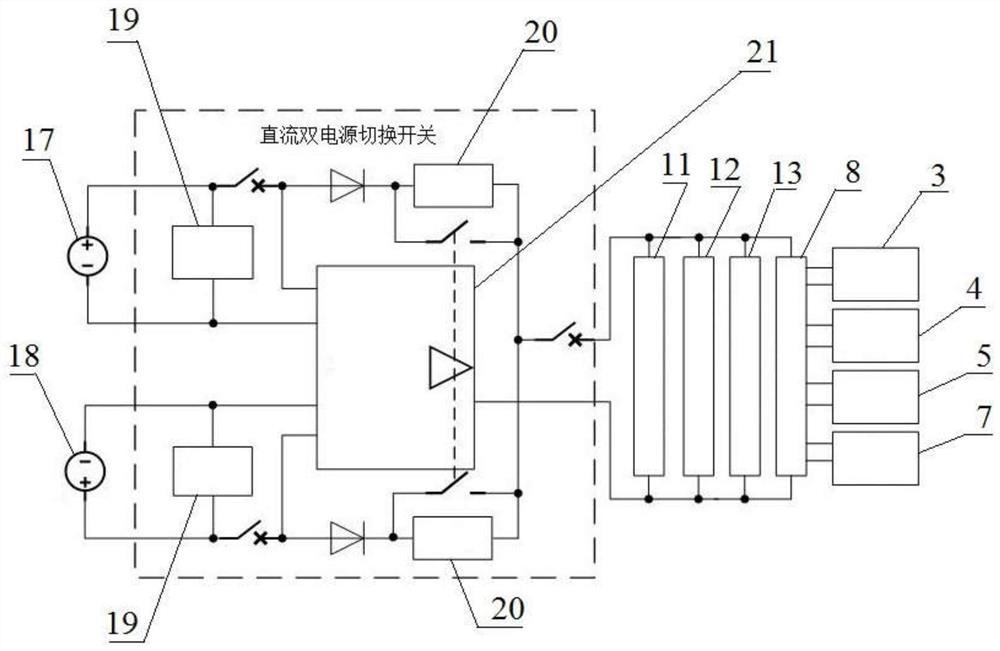

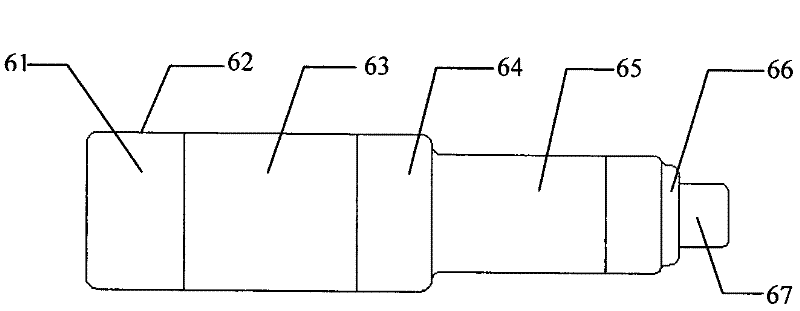

Intelligent automobile redundant steer-by-wire device and control method thereof

ActiveCN112590921AImplement redundant backupSufficient reaction timeSteering linkagesAutomatic steering controlSteering wheelSteering column

The invention discloses an intelligent automobile redundant steer-by-wire device and a control method thereof. The intelligent automobile redundant steer-by-wire device comprises a steering wheel, a steering column, a road sensing motor, an electromagnetic clutch, a redundant motor, a gear rack steering gear, a power-assisted motor and a control unit, and the steering wheel is assembled at the topend of the steering column; and the road sensing motor, the electromagnetic clutch, the redundant motor and the gear rack steering gear are sequentially assembled on the steering column. The controlmethod comprises the steps that the steering device starts to work only when it is detected that a vehicle is started, and the steering device comprises two working modes and corresponding control methods, namely the driving auxiliary mode control method and the the automatic driving mode control method. The intelligent automobile redundant steer-by-wire device and a control method thereof have the advantages that redundant backup of the sensor, the motor, the control unit and the power source is achieved, and the service life can be prolonged. When slave ECU monitors that master ECU fails, the control right is taken over immediately, other structures are not needed, and seamless switching of the control right is easy to realize.

Owner:JILIN UNIV

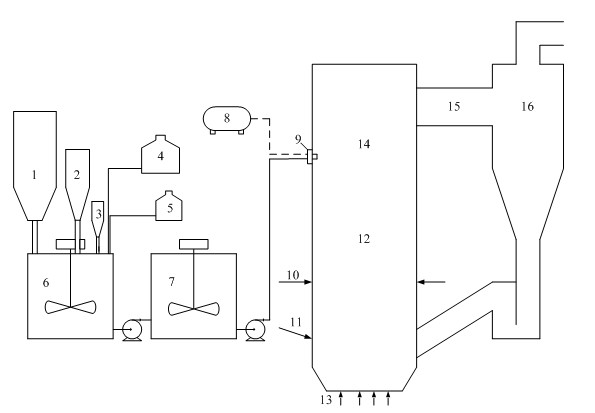

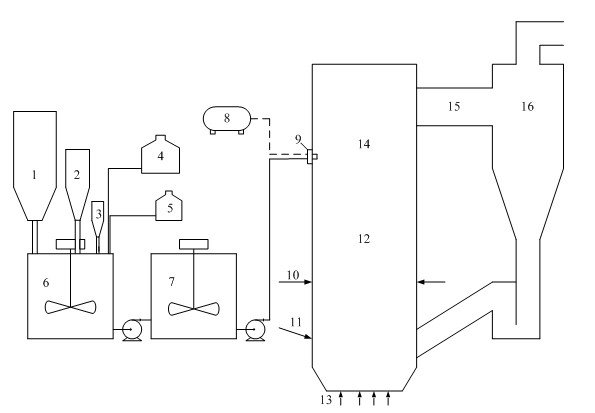

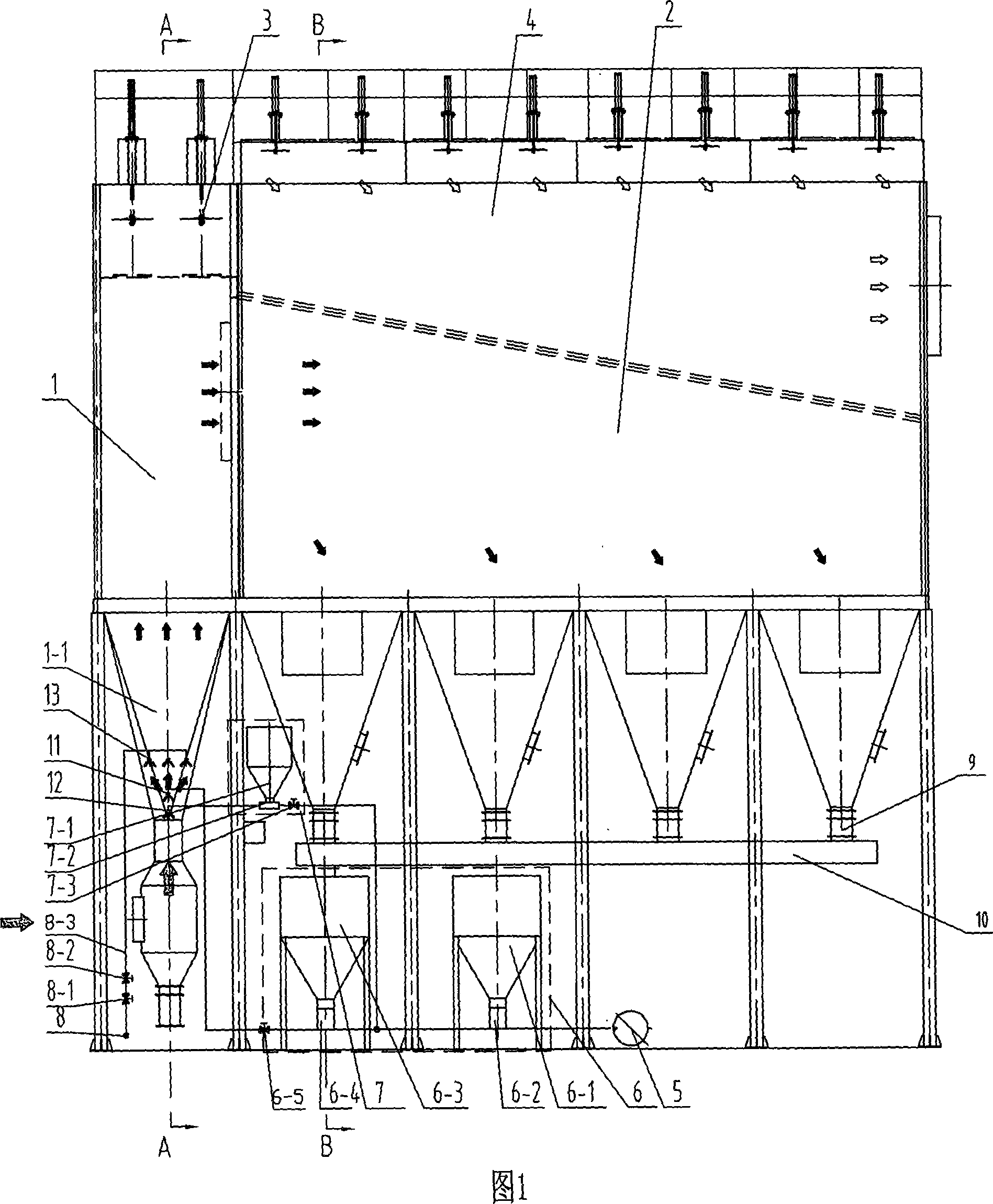

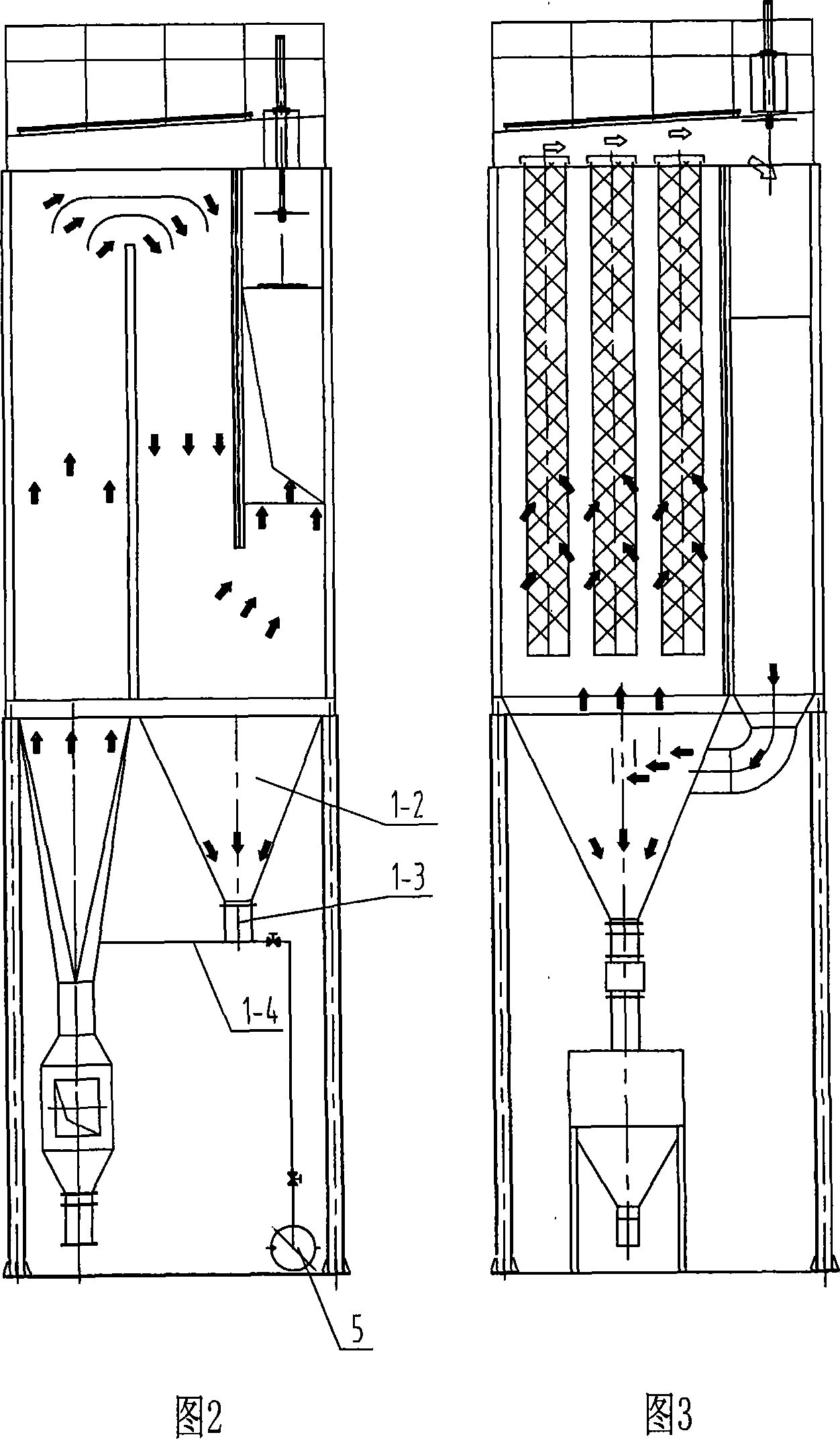

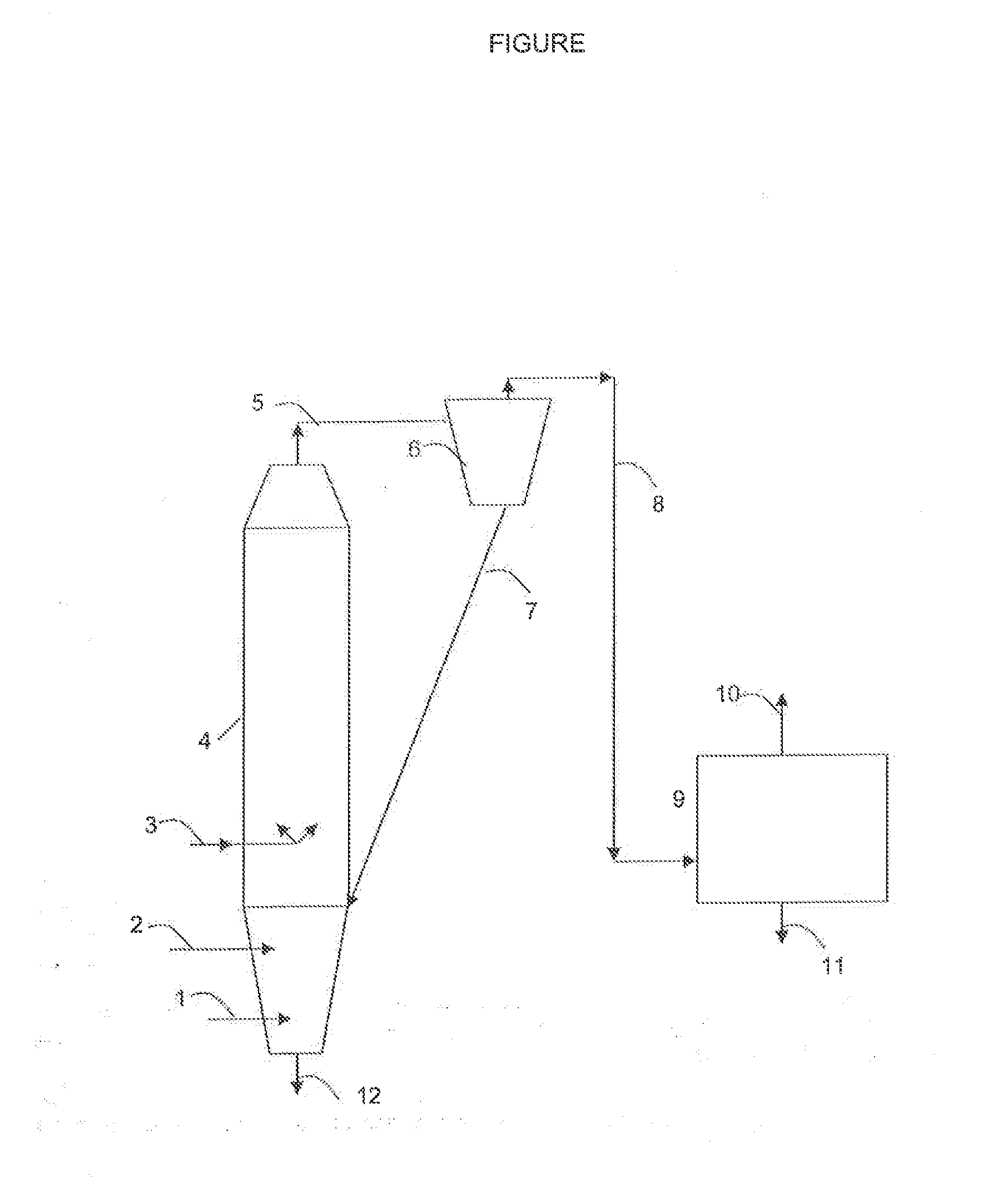

Method and device for treating solid waste burning tail gas

ActiveCN101099921ACompact structureSmall footprintCombination devicesLighting and heating apparatusToxic gasBaghouse

The present invention relates to tail gas treating process and apparatus, and is especially process and apparatus for treating high temperature fume containing acid gas, heavy metal, dioxin and other toxic gas from incinerating solid waste. The treating process includes the first reaction of the high temperature fume with deacidifying agent, active carbon and atomized water to eliminate toxic gases, and the subsequent reaction in a bag-type dust remover with one emergency passage for reaching high waste gas treating effect. The apparatus for treating high temperature fume has simple structure, low cost, low running expense, and long service life.

Owner:CHANGZHOU XINWU MACHINERY

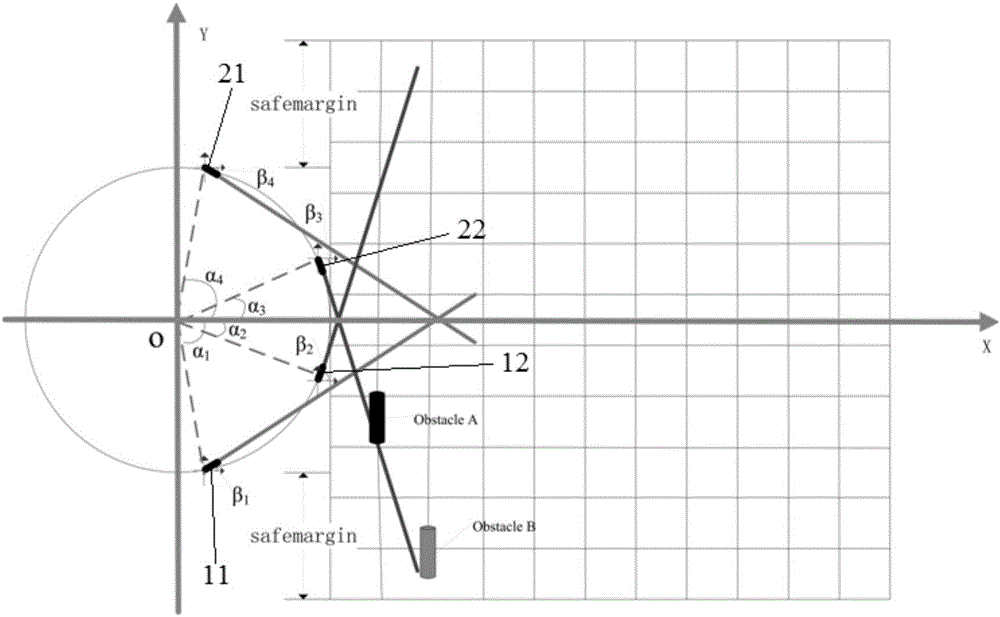

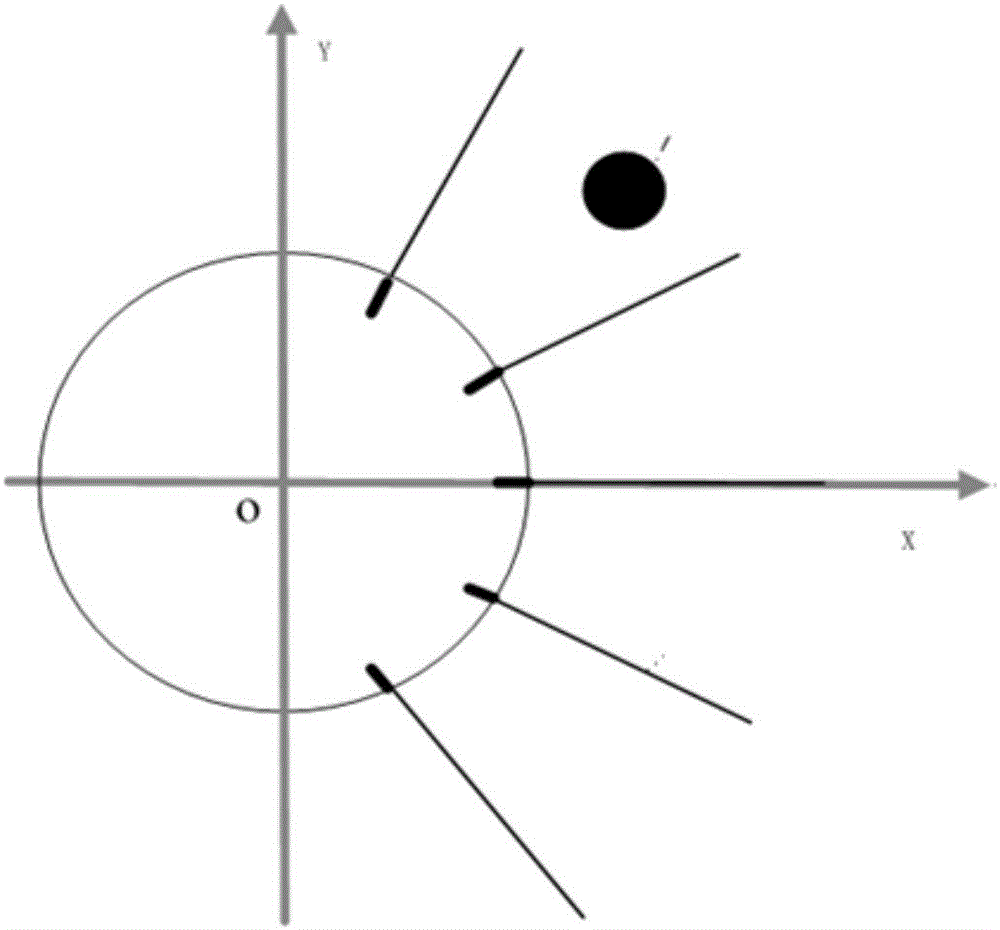

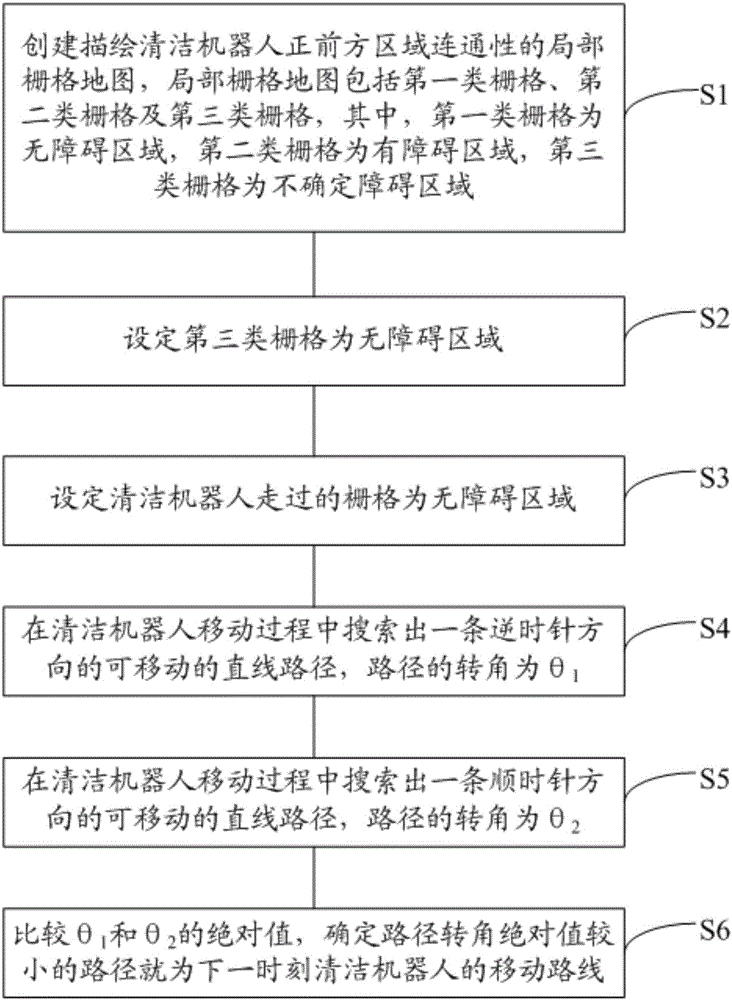

Cleaning robot and obstacle avoiding method thereof

ActiveCN106264359AAchieve collision-free navigationStable autonomous obstacle avoidance abilityAutomatic obstacle detectionTravelling automatic controlDistance sensorsEngineering

The invention discloses a cleaning robot and an obstacle avoiding method thereof. A plurality of distance sensors are mounted at the edge of the cleaning robot by means of non-radial arrangement to ensure that all areas right in front of the cleaning robot can be detected. The distance sensors are mounted on the cleaning robot by means of non-radial arrangement, so that the cleaning robot has stable autonomous obstacle avoiding ability.

Owner:海博(苏州)机器人科技有限公司

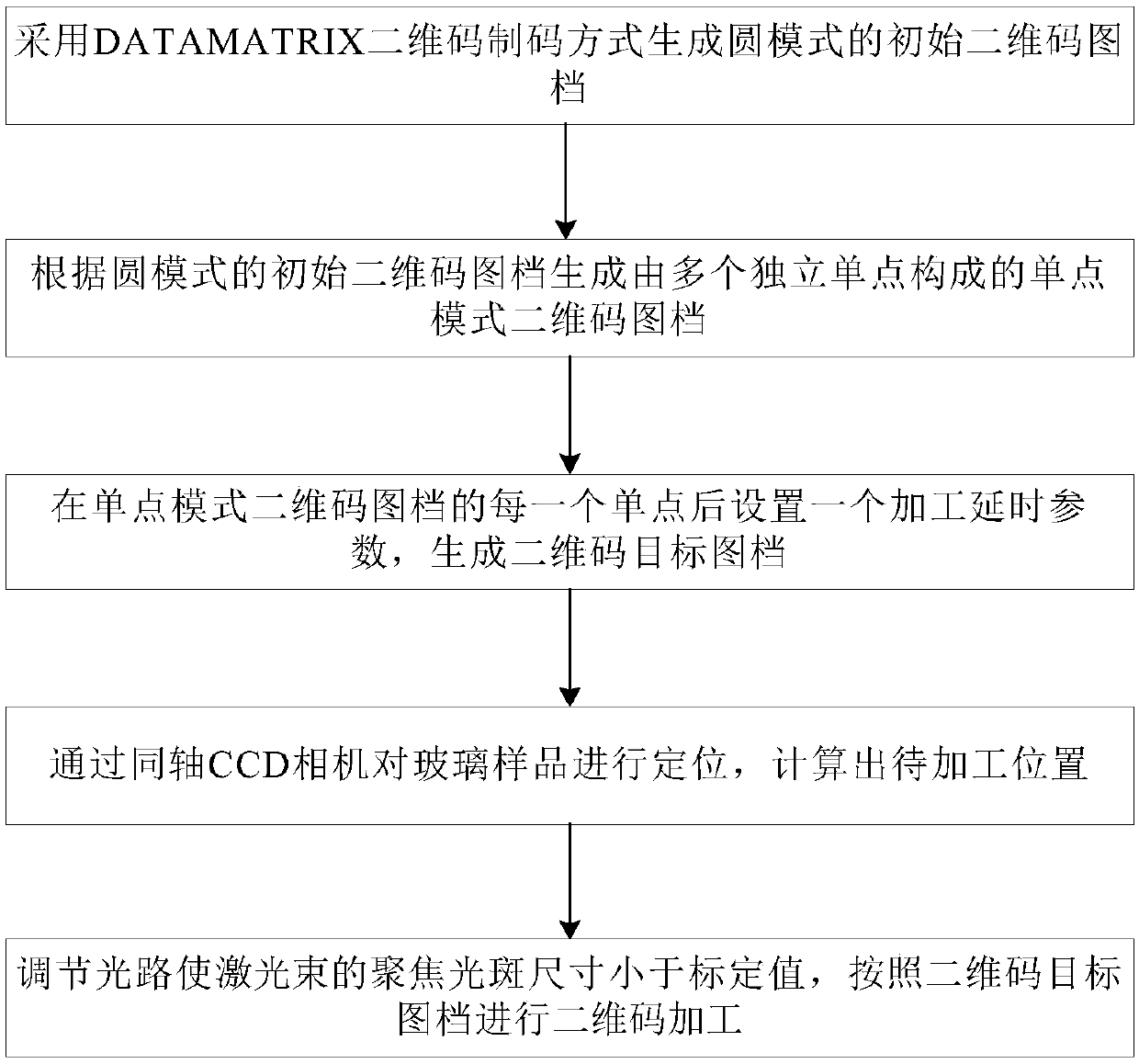

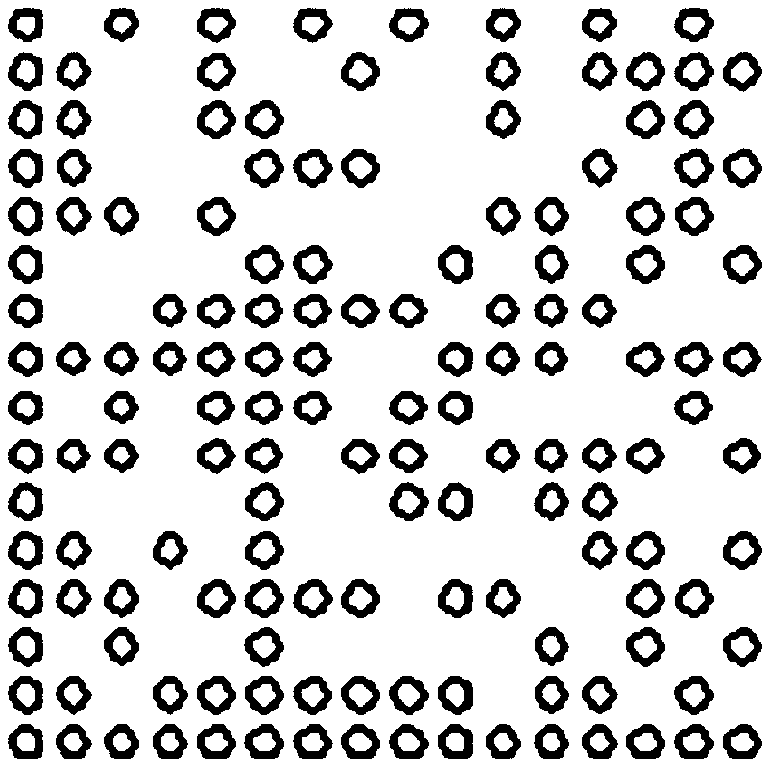

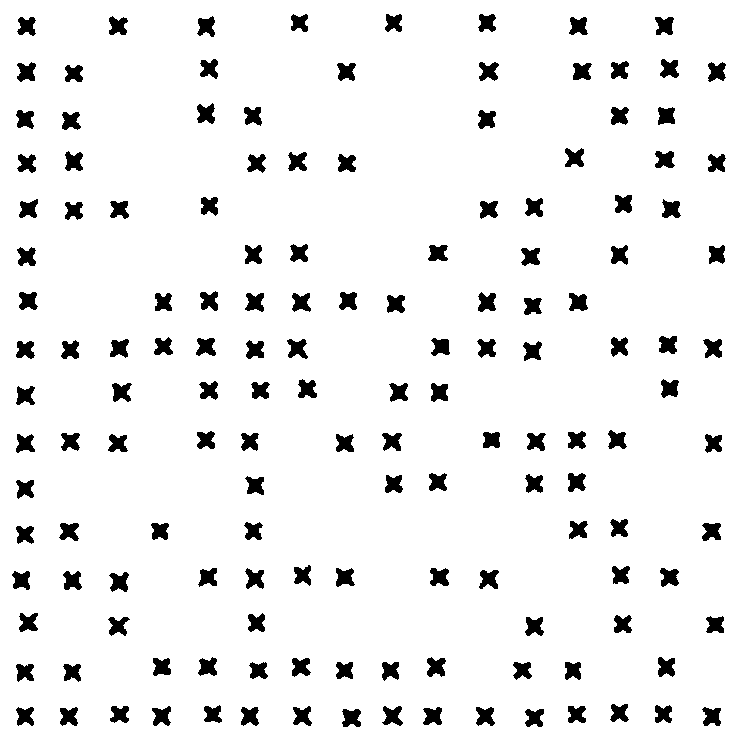

Method for engraving miniature two-dimensional code in glass laser

ActiveCN110626086ASufficient reaction timeAvoid smearingAblative recordingPicosecond laserLaser engraving

The invention relates to the technical field of laser engraving, in particular to a method for engraving a miniature two-dimensional code in glass laser. The method for engraving the miniature two-dimensional code in the glass laser comprises the following steps that a DATAMATRIX two-dimensional code encoding method is used for generating an initial two-dimensional code drawing file of a circle pattern; and a single-point mode two-dimensional code drawing file composed of a plurality of independent single points is generated according to the initial two-dimensional code drawing file of the circle pattern; processing delay parameters are arranged behind the each single point of the single-point mode two-dimensional code drawing file, and a target two-dimensional code drawing file is generated; a glass sample is located through a coaxial CCD camera, and the position to be processed is calculated; and an optical path is adjusted to enable the focused spot size of a laser beam to be smaller than a calibration value, a focus point of the laser beam is moved to the position to be processed inside the glass sample, and the two-dimensional code processing is carried out according to the target two-dimensional code drawing file. The tailing phenomenon caused by a galvanometer when the action time of a picosecond laser is extremely short is effectively prevented, and two-dimensional small-size engraving is enabled to be possible.

Owner:WUHAN HGLASER ENG CO LTD

Emergent inflation device for tyre burst prevention

The invention belongs to the technical field of vehicle passive safety, and concretely relates to an emergent vehicle tyre inflation device for processing a tyre burst situation. The device comprises a pressure sensor, a tyred air bag, a central controller, an explosive gas generator, a flexible glass fiber tube and a tyre burst alarm. When tyre burst occurs, the explosive gas generator receives an instruction of the central controller, and a pulse electronic igniter ignites electric primer and further ignites gunpowder; a large amount of gases which are generated when the gunpowder is combusted are filtered by a filter screen and enter the tyred air bag through going along the flexible glass fiber tube, the air bag is rapidly inflated to support the vehicle as a temporary tyre; and the tyred air bag which has two layers is characterized in that: the inner layer is an annular inner air bag, and the outer layer comprises four isolated independent air bag chambers. The device of the invention has the advantages of fast inflation speed, large gas amount, high safety and reliability, and the like.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

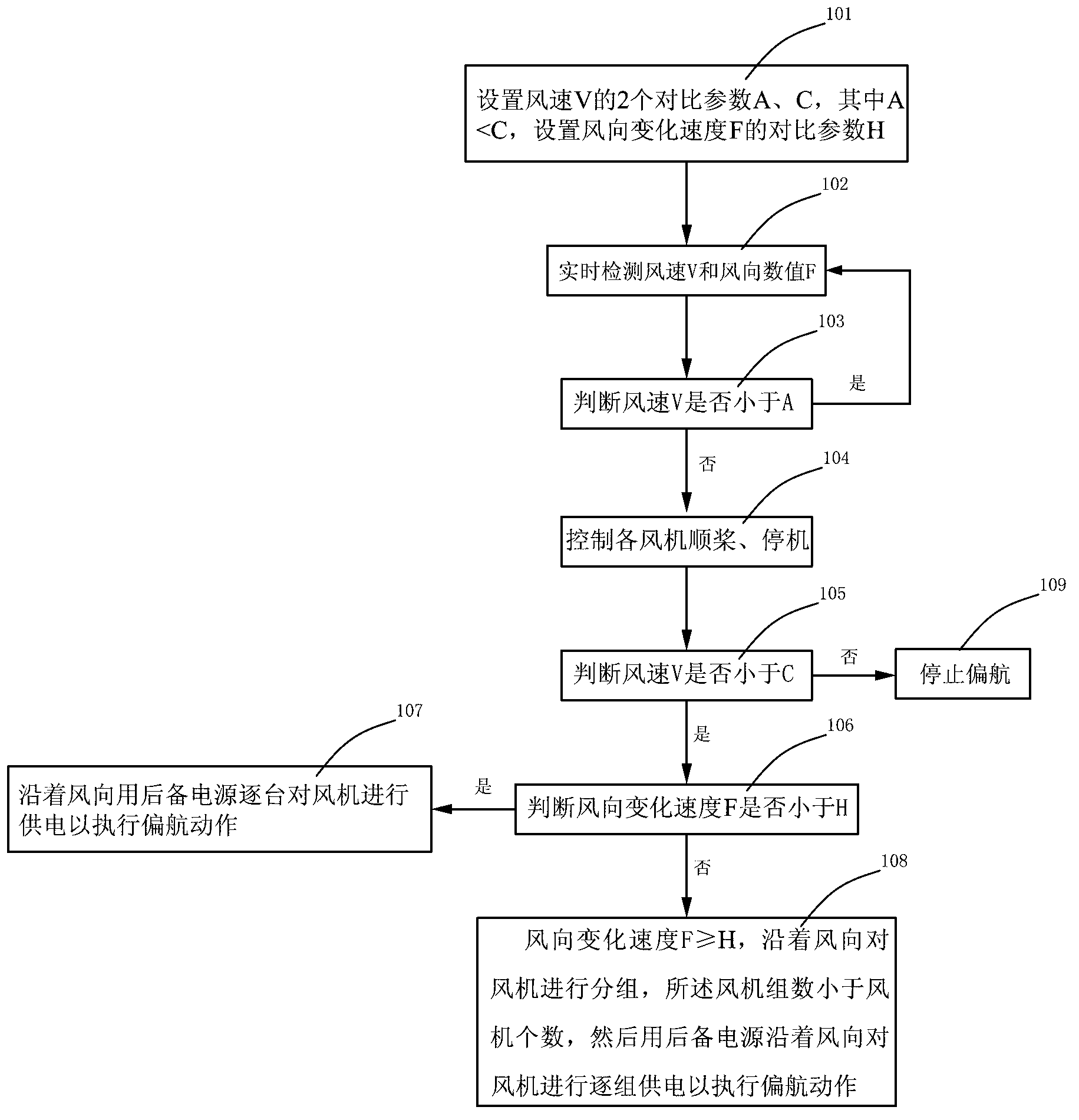

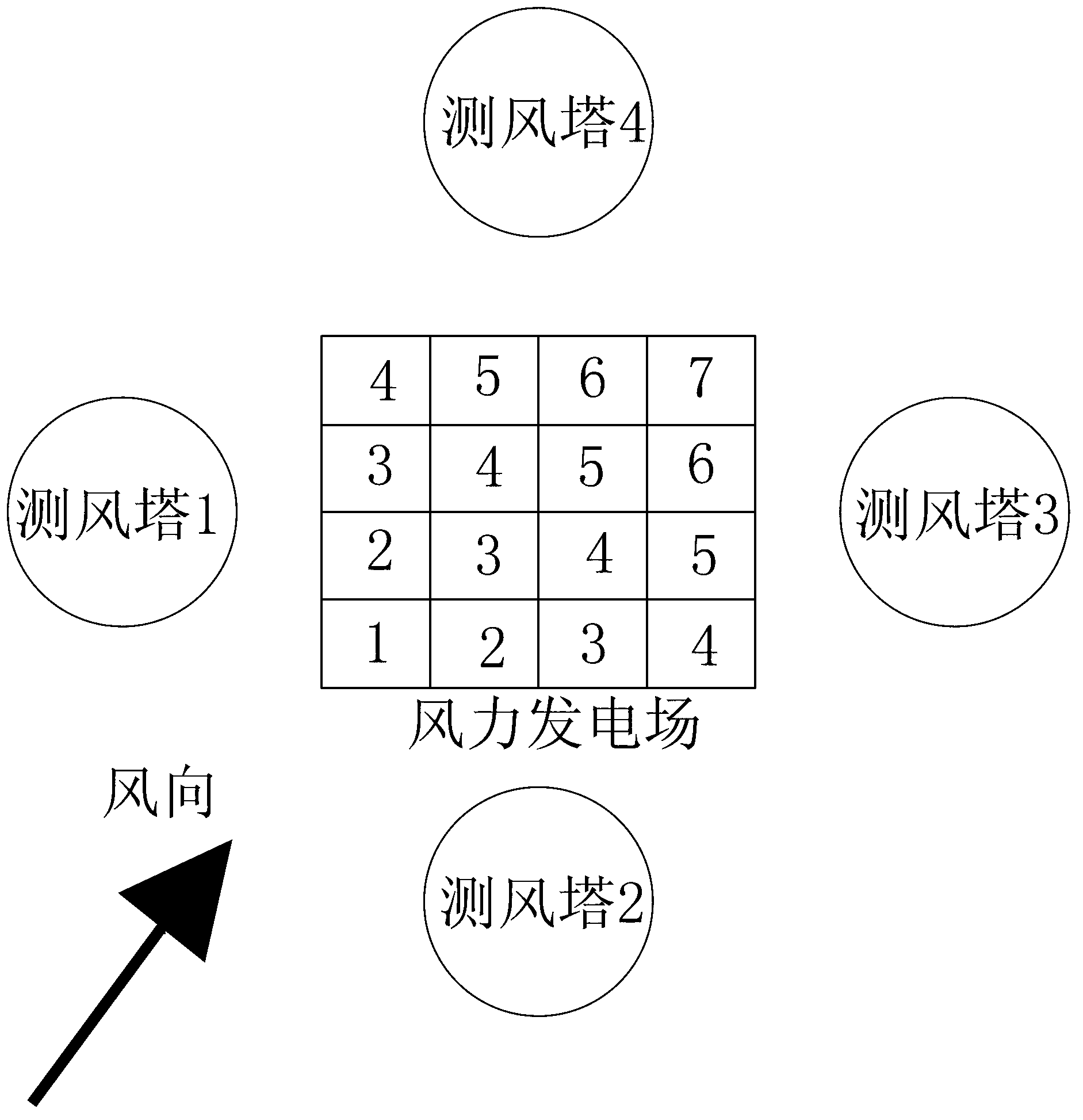

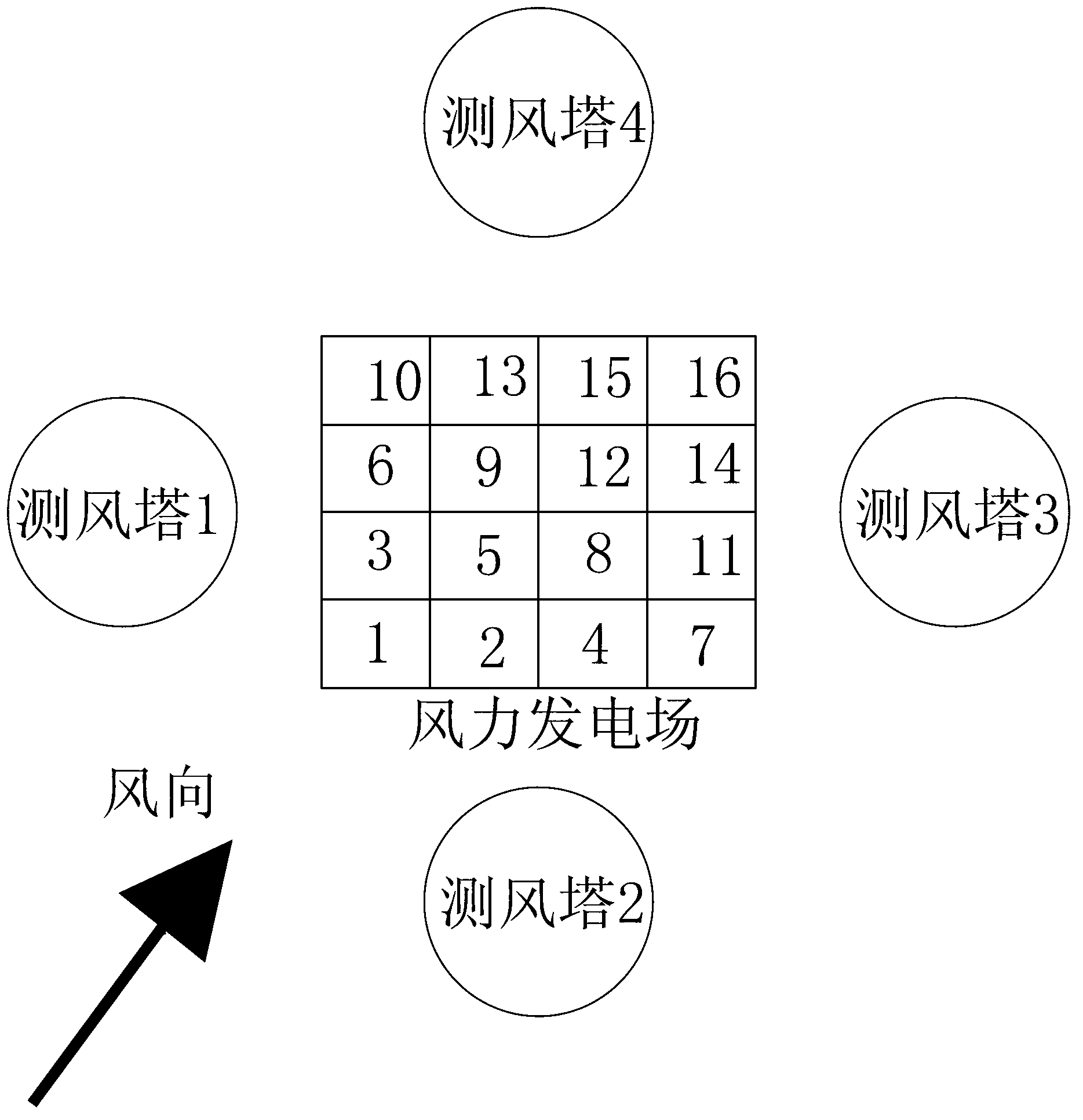

Anti-typhoon control method for wind power plant

ActiveCN103321840AReduce construction investment costsSufficient reaction timeWind motor controlMachines/enginesControl mannerTyphoon

The invention discloses an anti-typhoon control method for a wind power plant. Different yawing power supply is performed according to wind speed levels so as to perform yawing motions and effectively cope with typhoon. When A<=wind speed V<C and F<=H, a standby power supply is utilized to supply power to fans one by one along the wind direction so as to perform the yawing motions, the implementation process can be achieved by utilizing the standby power supply small in capacity, and construction investment cost in adopting a high-capacity standby power supply is reduced in the control mode. When A<=wind speed V<C and F>=H, the fans are divided into groups along the wind direction, output power of the adopted standby power supply in the yawing power supply mode does not need to be designed to provide power needed for simultaneous yawing of all the fans in the wind power plant in one time, the output power of the standby power supply only needs to meet the power needed for the group with the maximum fan number so that the control process can be achieved, the capacity of the standby power supply can be effectively reduced, and the construction investment cost is reduced.

Owner:GUANGDONG MINGYANG WIND POWER IND GRP CO LTD

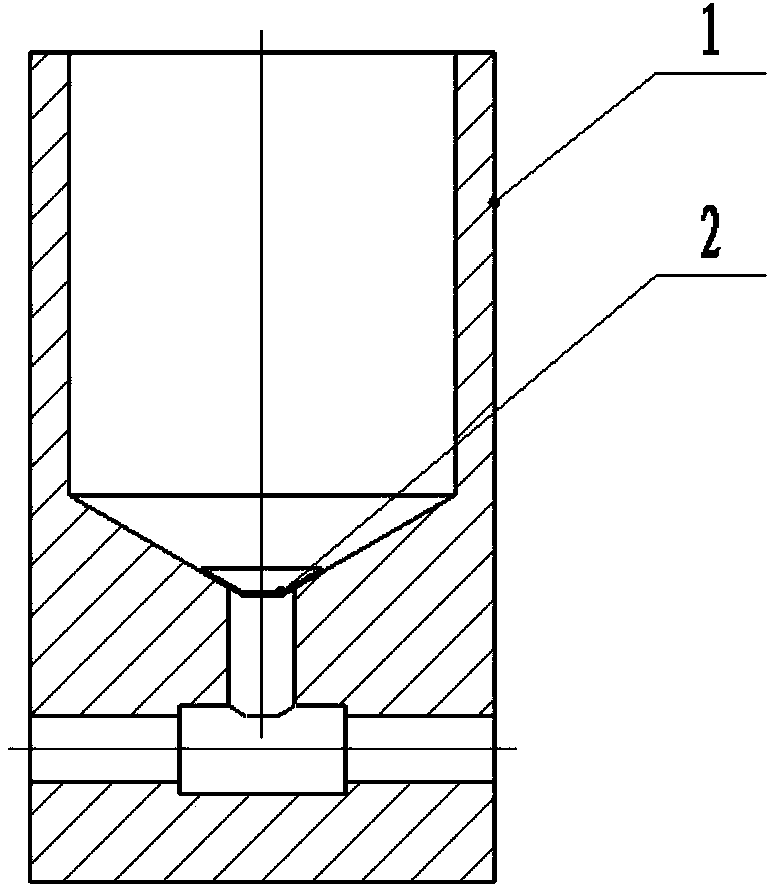

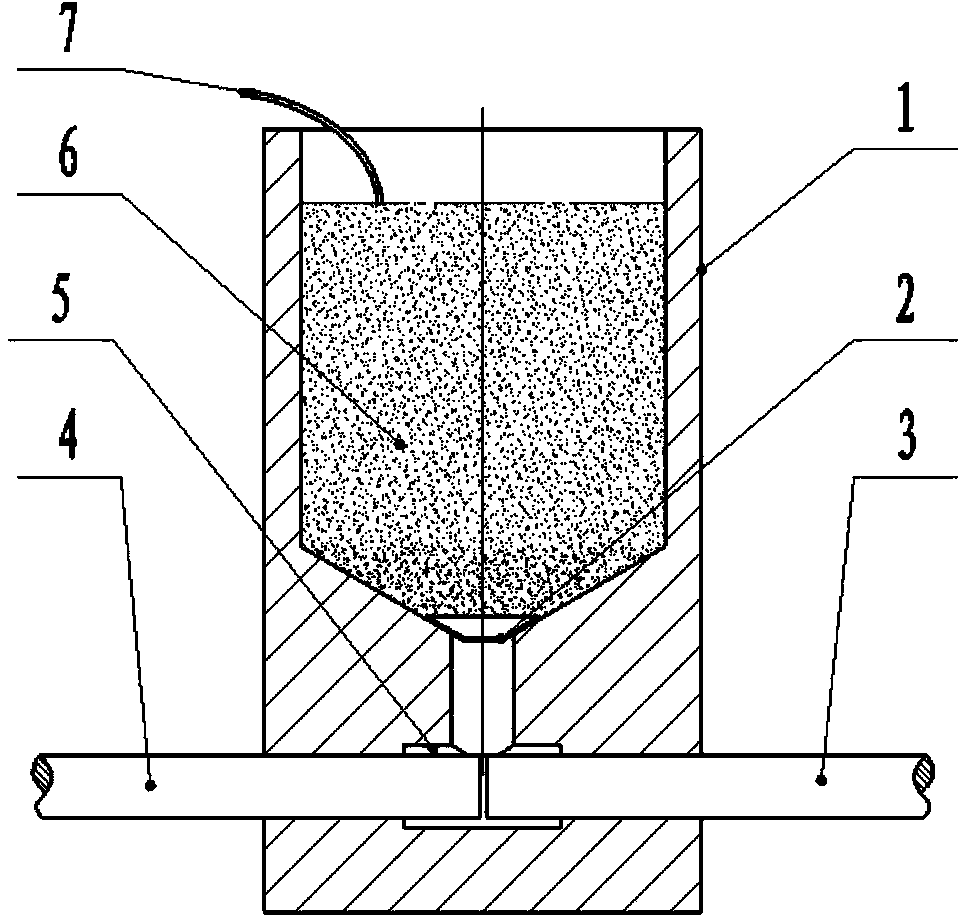

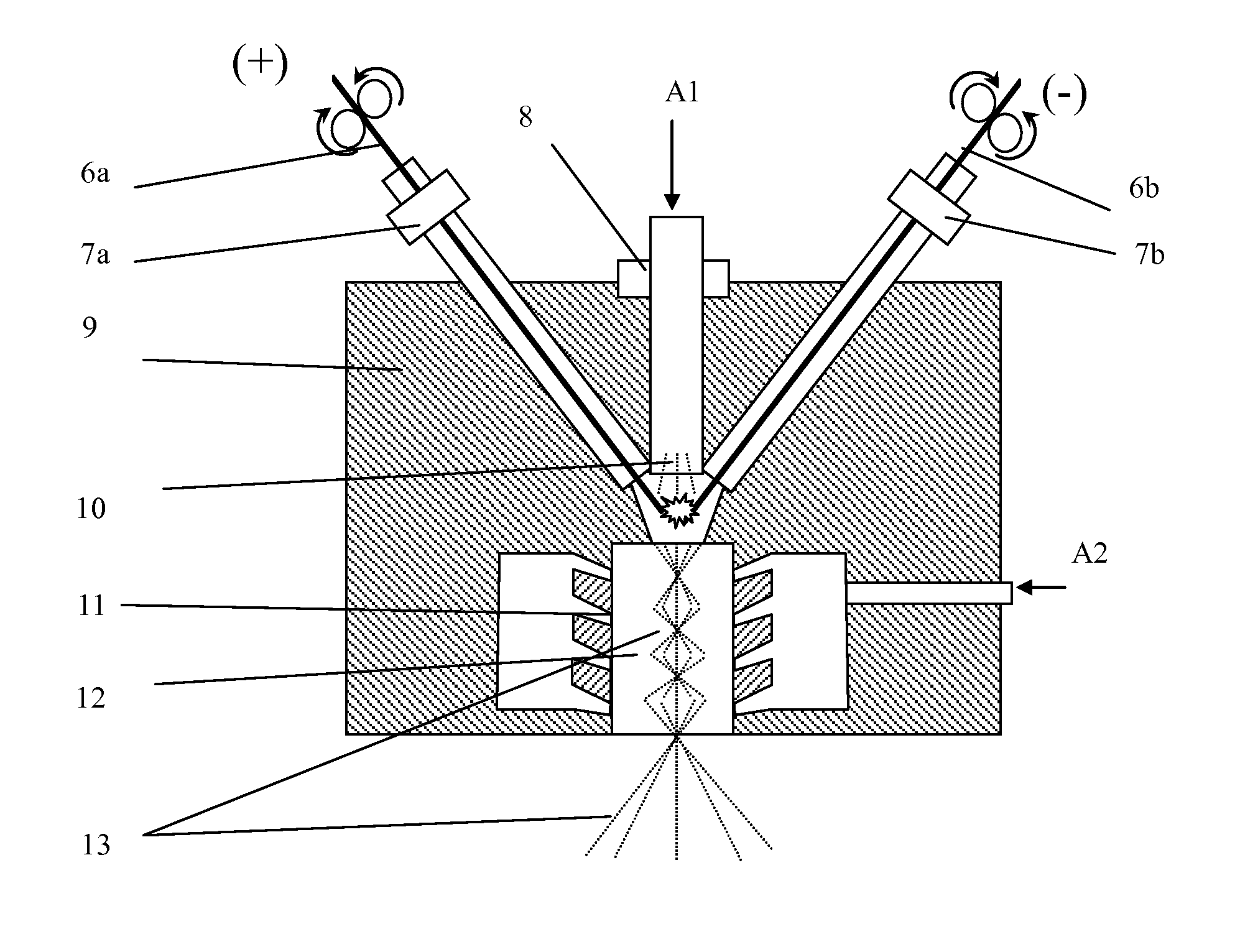

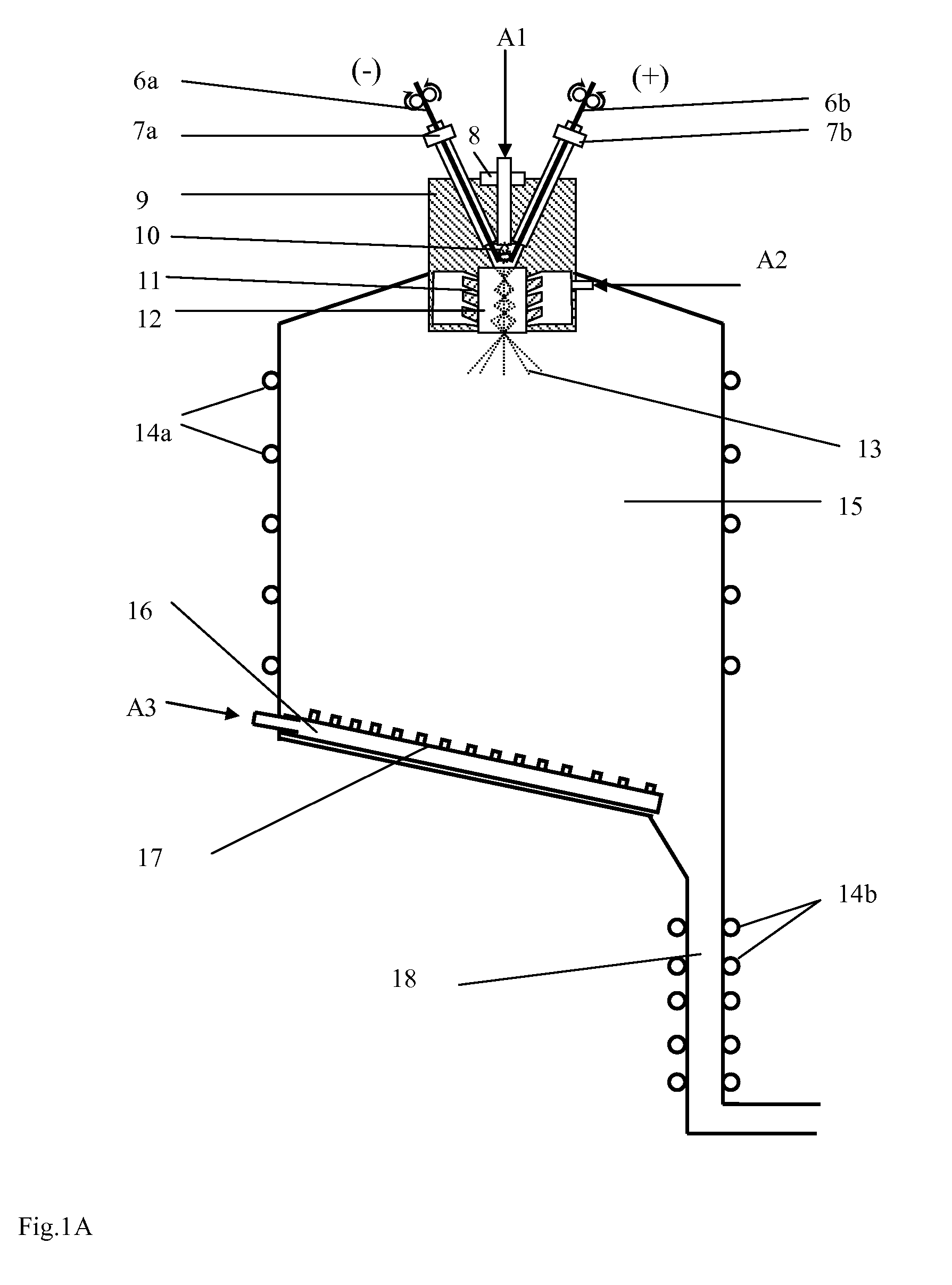

Iron-based nonelectric welding device

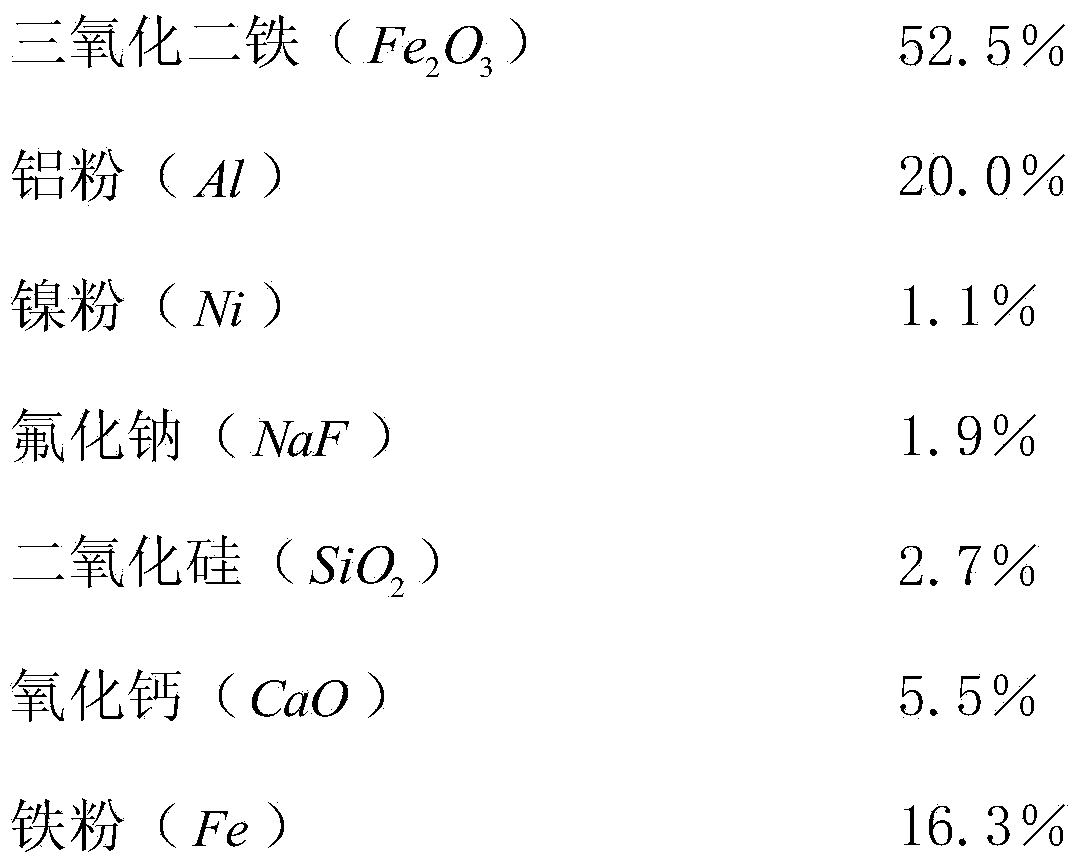

ActiveCN103506755ARealize the purpose of weldingReduce the extent of galvanic corrosionWelding/cutting media/materialsSoldering mediaElectrode potentialMetallic aluminum

Provided is an iron-based nonelectric welding device. The body of the iron-based nonelectric welding device is a disposable die filled with iron-based soldering flux, wherein the iron-based soldering flux contains 48%-57% of ferric oxide powder, 15%-25% of metallic aluminum powder, 0.2%-2.8% of metallic nickel powder, 0.5%-4% of fluorite powder, 1%-6% of silicon dioxide powder, 3.1%-8.2% of calcium oxide powder and 12%-21% of metallic iron powder. The disposable die is formed through single-pressing and stoving after rick fat oil is mixed with standard sand. The soldering flux mainly comprises ferric oxide, ferrous powder and a little of nickel powder, and iron-nickel alloy is produced on soldering points through self-propagating reaction after ignition; the iron-nickel alloy is approximately equal to parent metal steel of a grounding device in electrode potential, and galvanic corrosion of parent metal cannot caused. The die is good in thermal insulation effect and low in price, links of cleaning, die sinking, die filling and the like are reduced through one-time use, time is saved, and scalding risks of staff are reduced. The reaction speed of soldering flux ranges from 45 seconds to 60 seconds and longer than common self-propagation by 20 seconds, the possibility of splashing of reaction products is reduced, evacuation is facilitated, and safety is good.

Owner:武汉长威电气有限责任公司

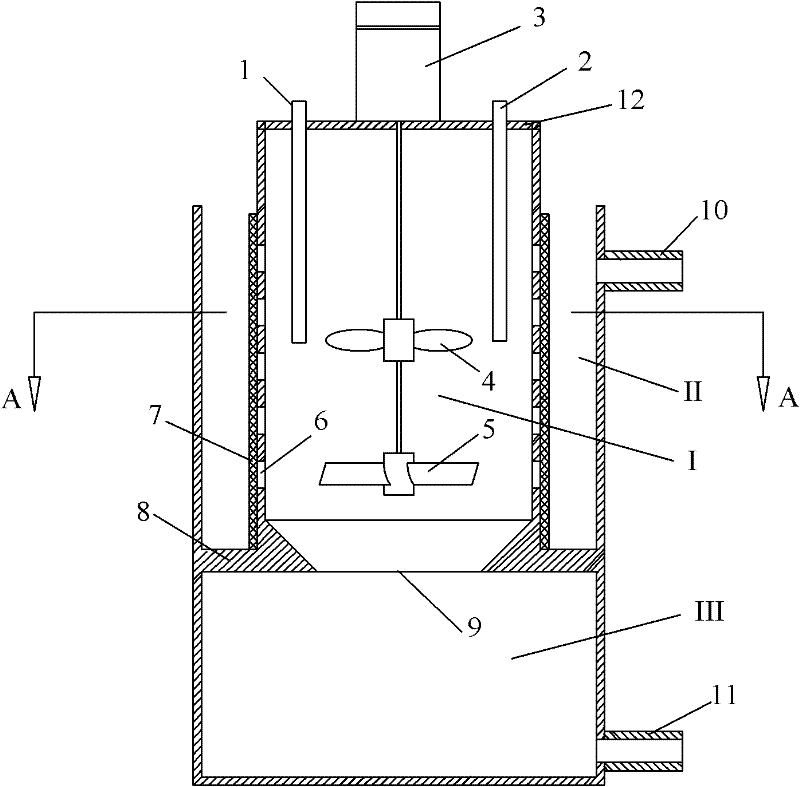

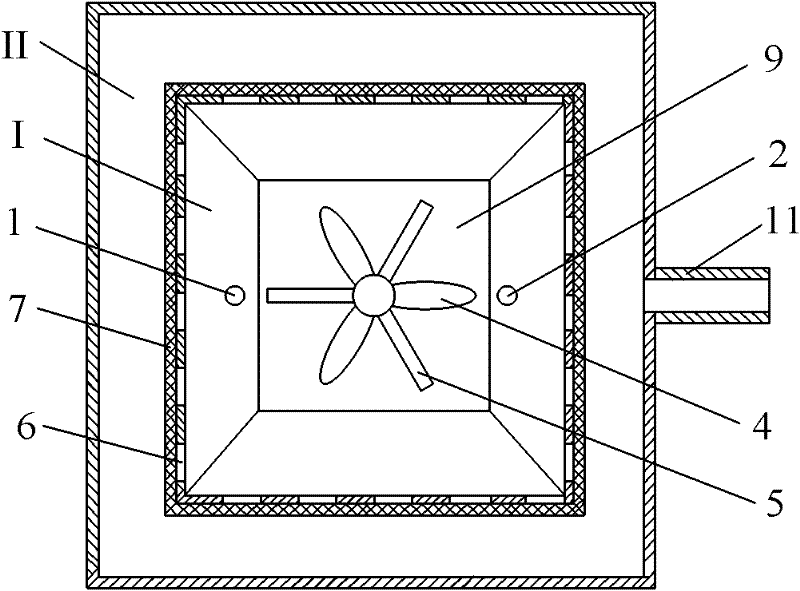

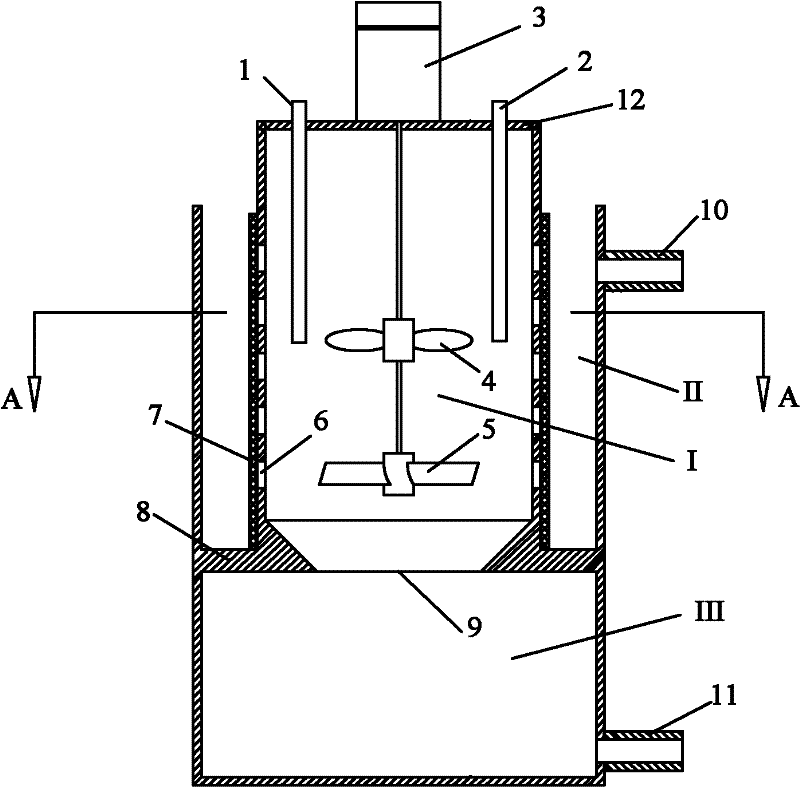

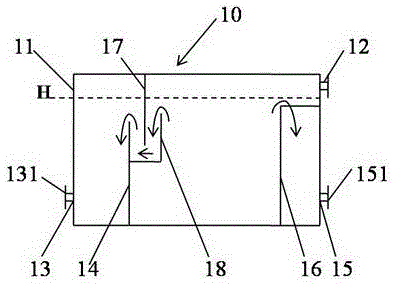

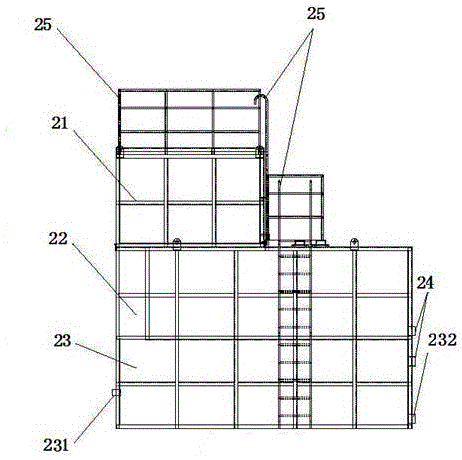

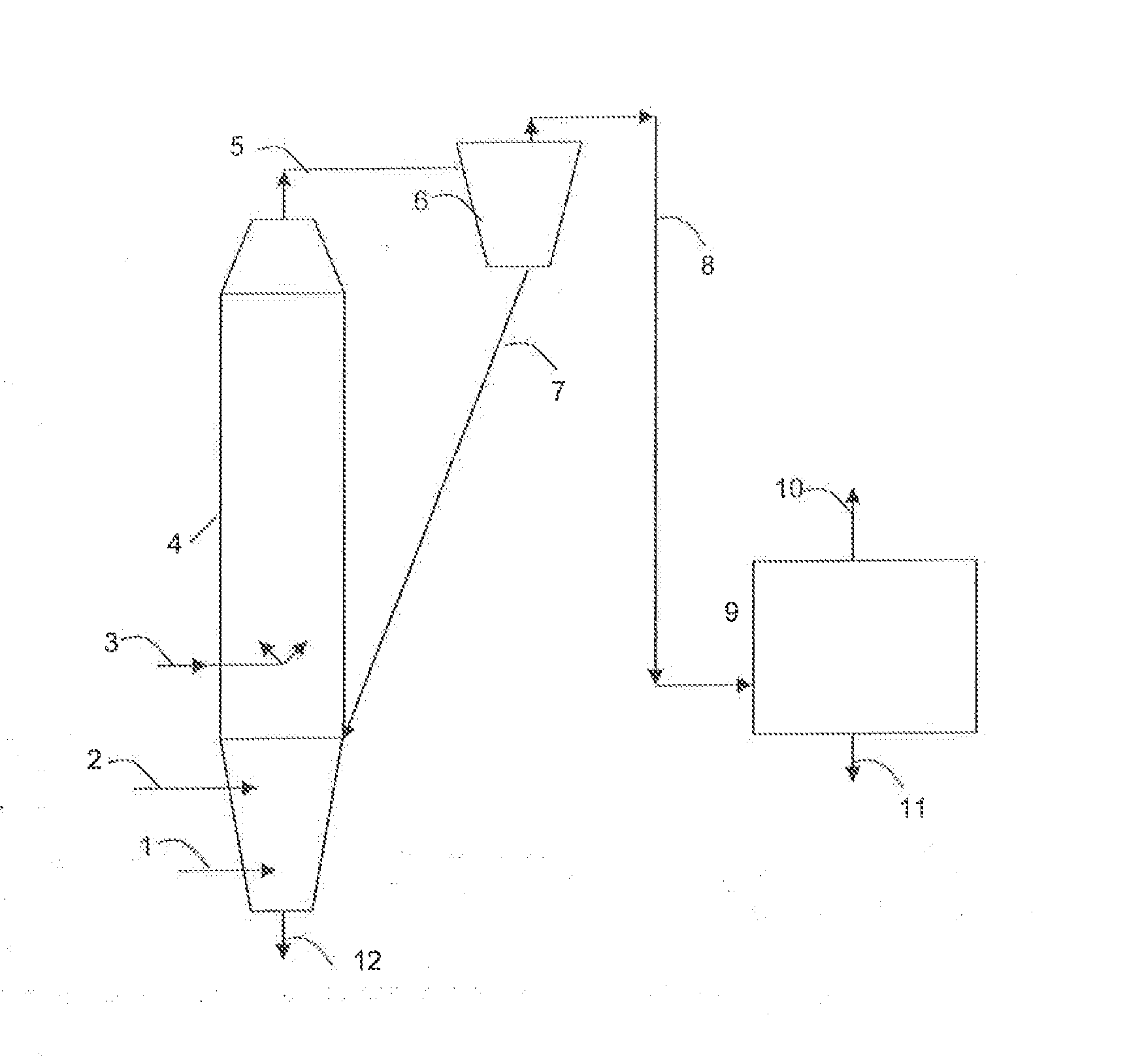

Integrated reactor suitable for purifying and impurity-removing of pyrolusite leachate

InactiveCN102226234ASmall footprintEnhanced reaction ability and solid-liquid separation abilityProcess efficiency improvementChemistryHeavy metals

The invention discloses an integrated reactor which is suitable for the purifying and impurity-removing of pyrolusite leachate. The main structure of the reactor is that, a reactor cylinder is divided into an upper portion and a lower portion by a partitioning layer arranged in the cylinder, wherein the upper portion serves as a removing reaction zone, and the lower portion serves as a precipitating and separating zone. The removing reaction zone is divided into a main reaction zone and a filtrate zone by a filtering layer arranged in the removing reaction zone. The partitioning layer is provided with a channel for the main reaction zone to communicate with the precipitating and separating zone. A stirrer is provided in the main reaction zone. An outlet of a feeding pipe is positioned in the main reaction zone. A filtrate discharging pipe is arranged on the upper part of the filtrate zone cylinder. A precipitate discharging port is arranged close to the bottom of the precipitating and separating zone cylinder. With the reactor provided by the present invention, processes of neutralizing, iron-removing precipitating (or heavy-metal-removing sulfurizing), filtrating and gravity settling are integrated, such that land occupation of equipment and construction investment can be substantially reduced. Separating capability of the reactor is good, water quality of the filtrate is good, workload of subsequent impurity removing can be reduced, a filtrating medium is not easy to be obstructed, and the service life of the reactor is long.

Owner:SICHUAN UNIV

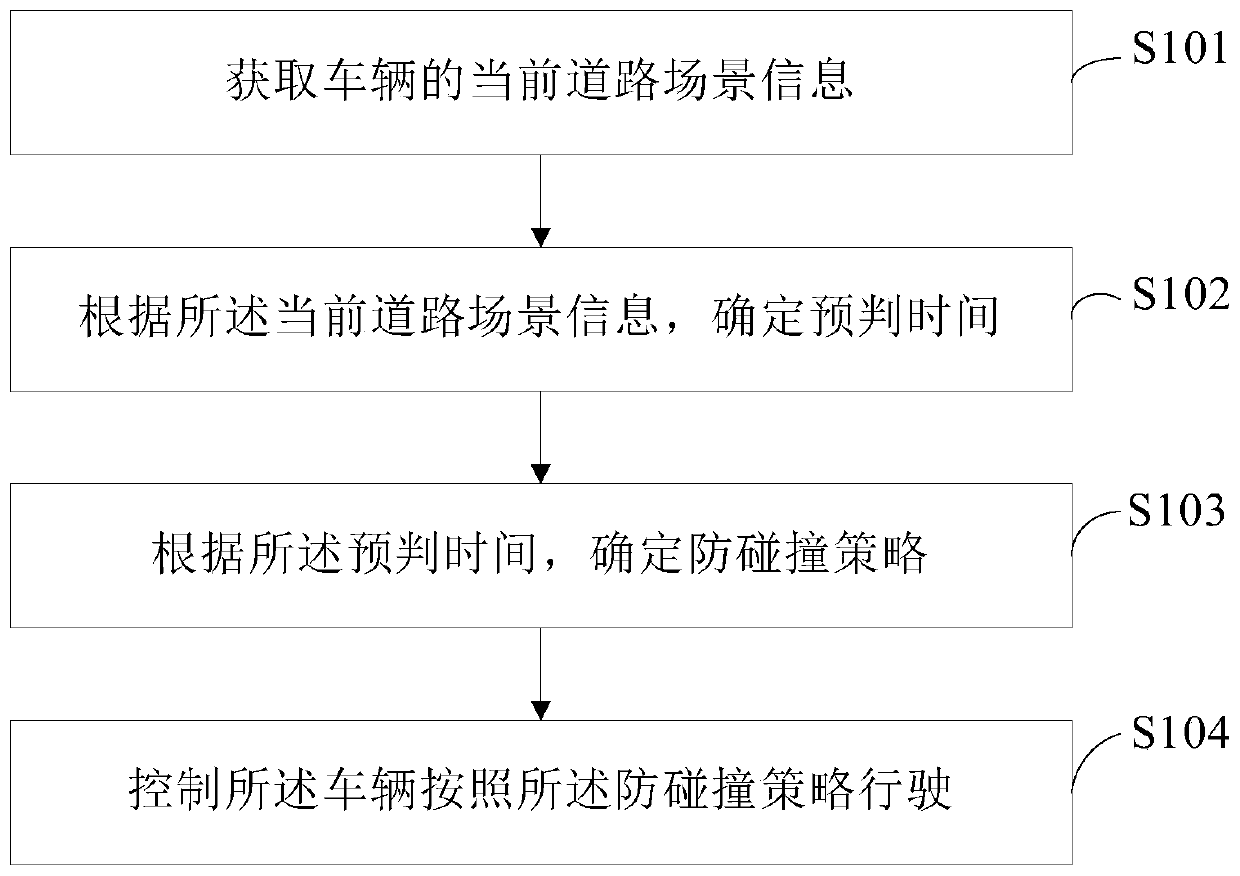

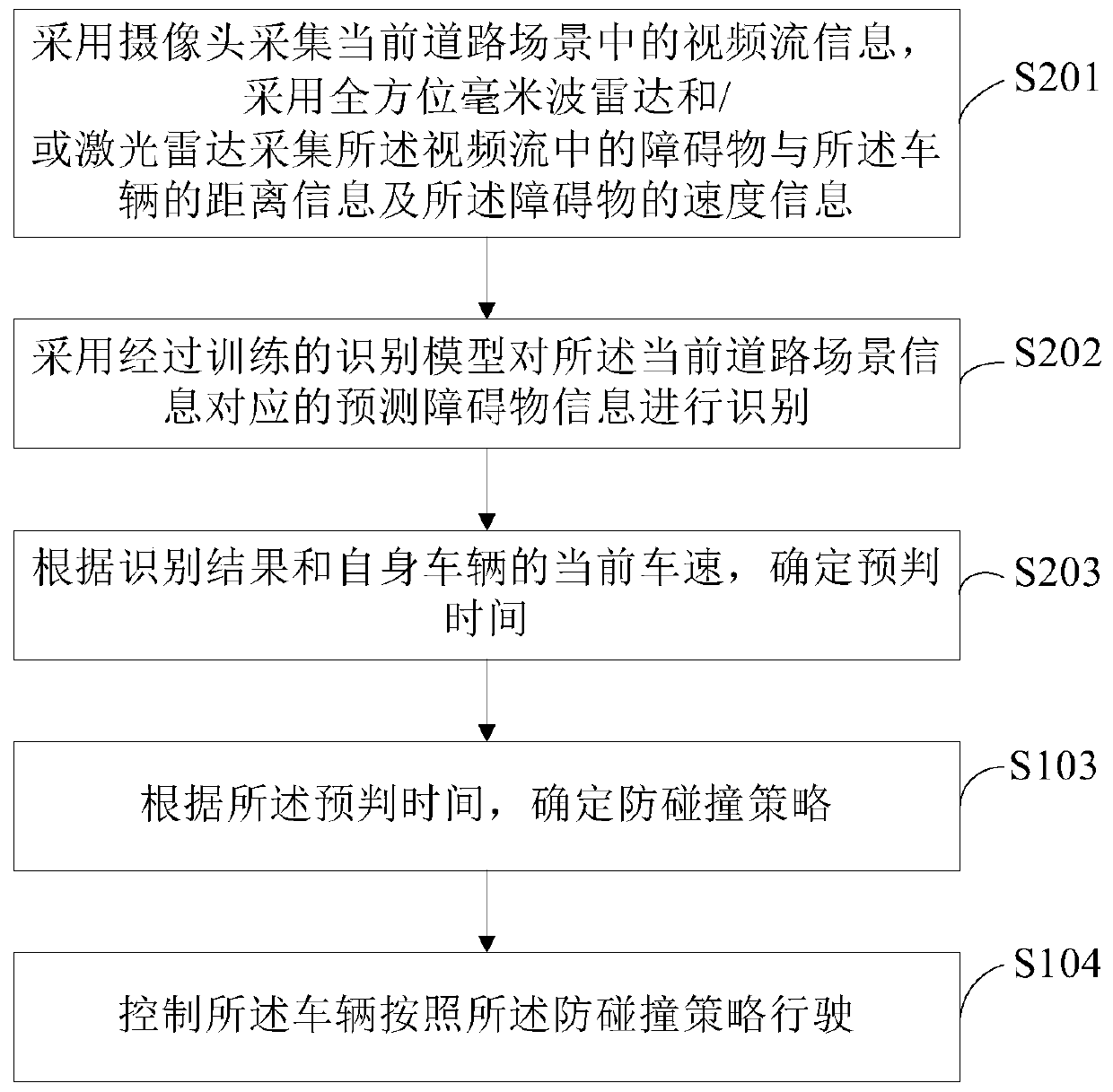

Vehicle anti-collision pre-judging method and device, equipment and readable storage medium

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

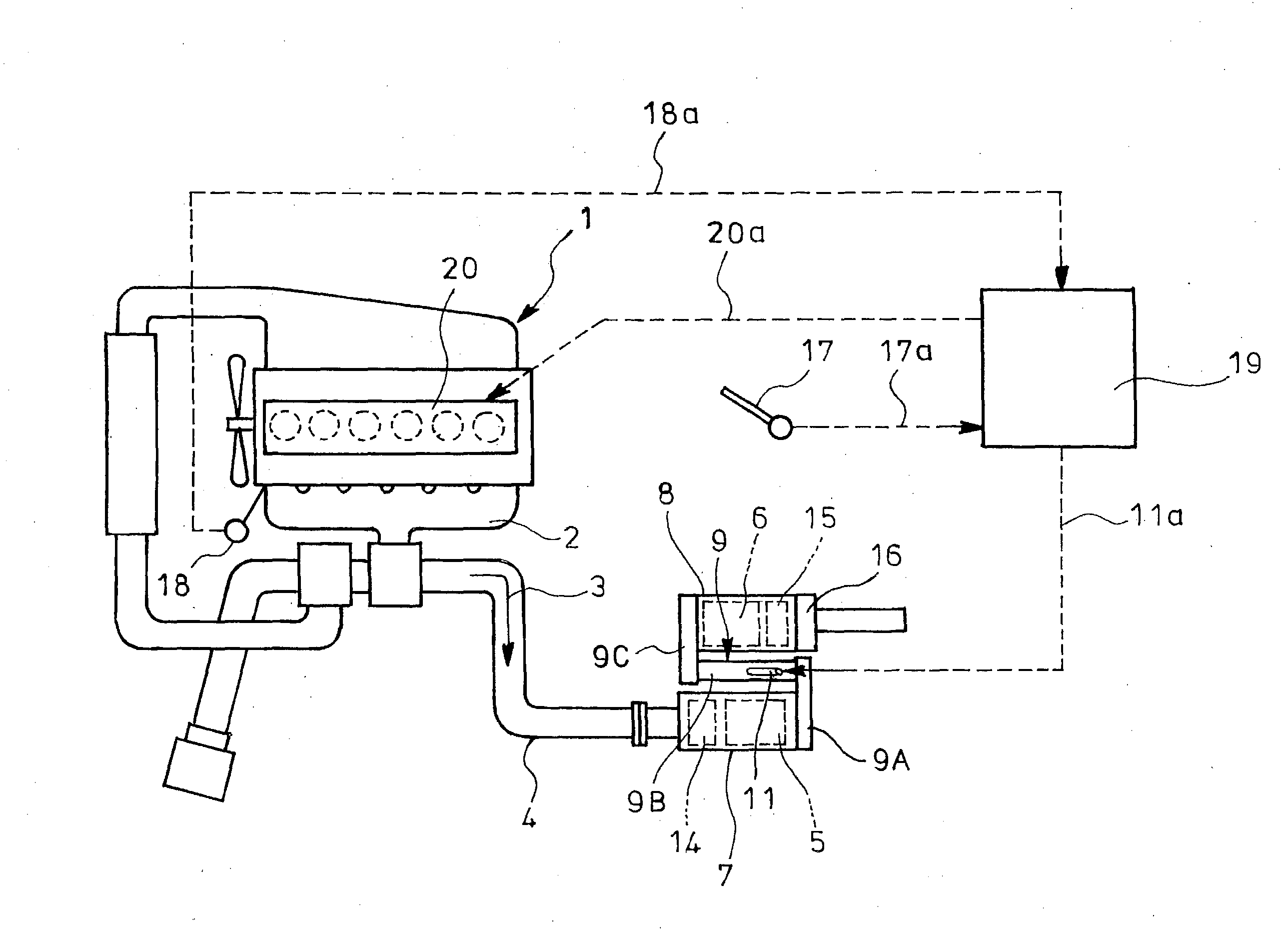

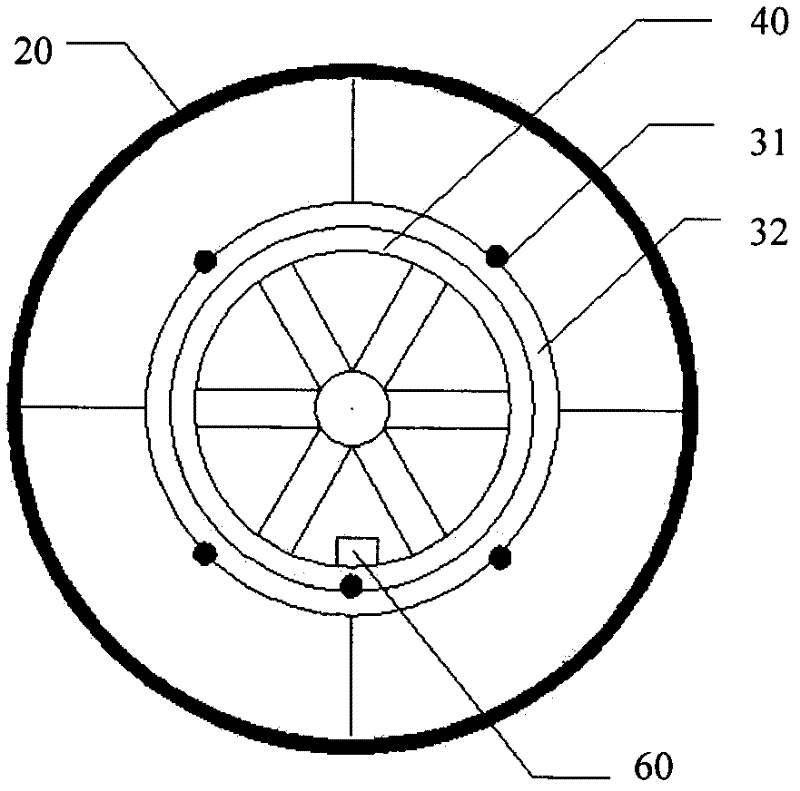

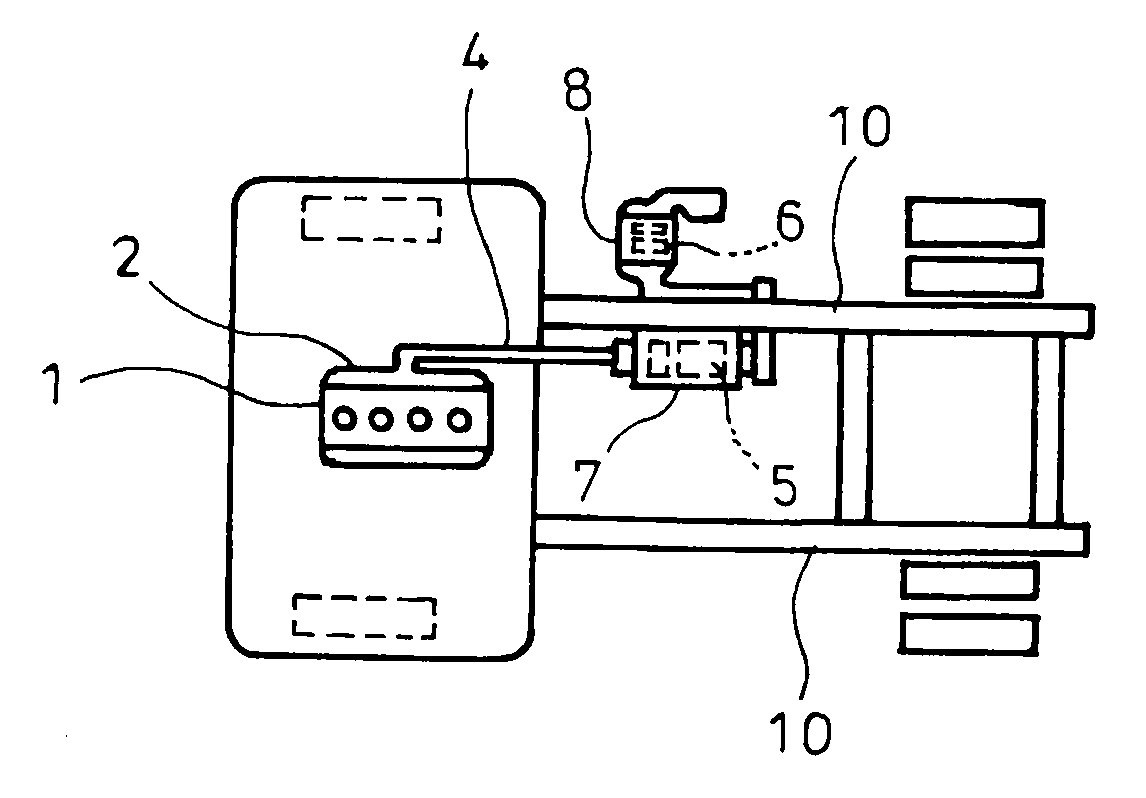

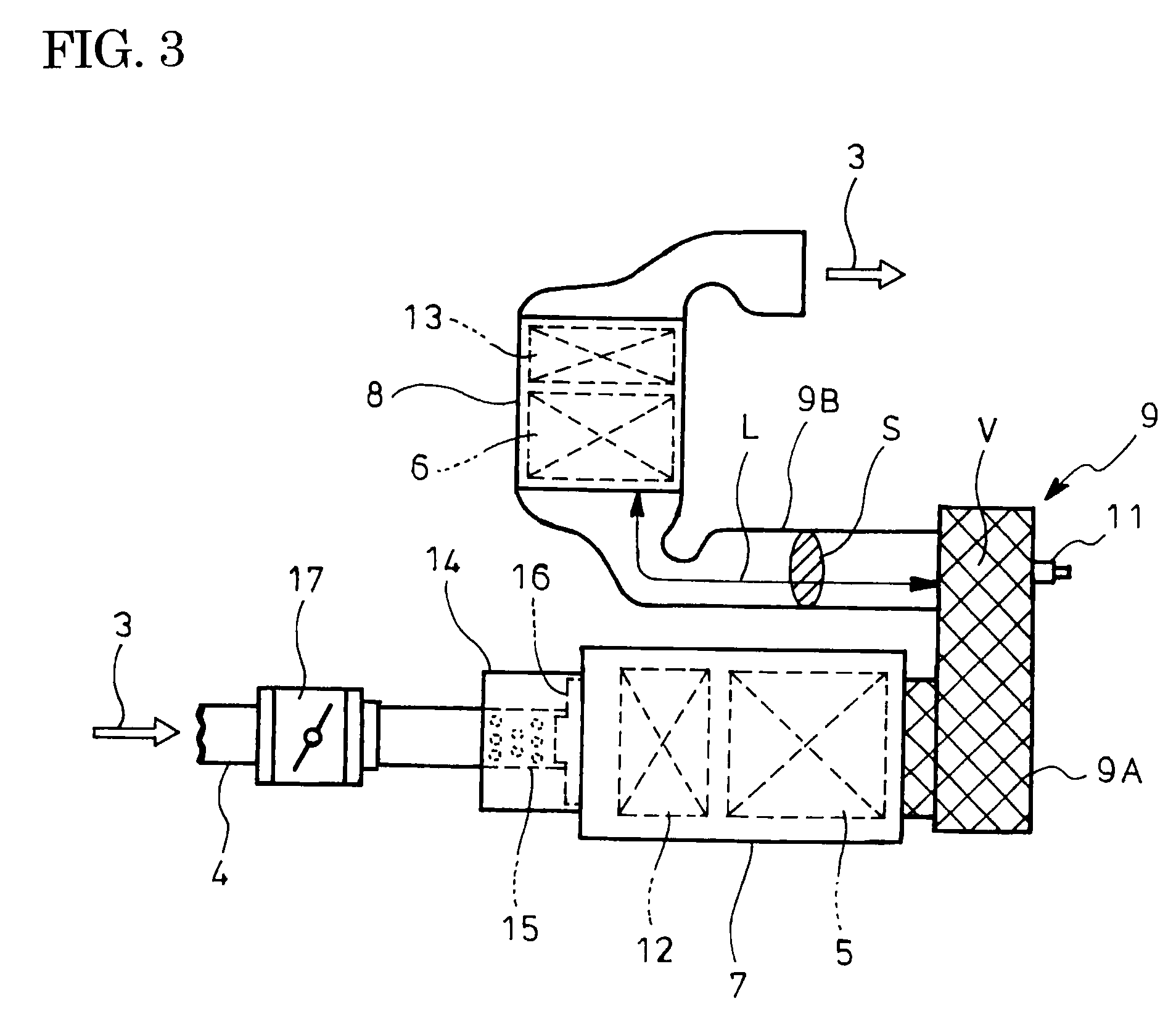

Exhaust emission control device

ActiveUS20100132333A1Sufficient reaction timeClosely arrangedElectrical controlInternal combustion piston enginesParticulatesOxygen

The invention has its object to realize compact arrangement of particulate filter 5 and selective reduction catalyst 6 for improved mountability on a vehicle while a sufficient reaction time is ensured for generation of ammonia from urea water. In an exhaust emission control device with the filter 5 and the catalyst 6 capable of selectively reacting NOx with ammonia even in the presence of oxygen being incorporated in an exhaust pipe 4, urea water as reducing agent being addible therebetween, the filter 5 is arranged in a fore-and-aft direction of a vehicle and along a frame 10 of the vehicle. The catalyst 6 is arranged in a vicinity of an inlet end of the filter 5 and directed laterally outward of the vehicle. A communication passage 9 is arranged to guide the exhaust gas 3 discharged from an outlet end of the filter 5 to an inlet end of the catalyst 6 in a forwardly fold-back manner. A urea water adding injector 11 (urea water adding means) for addition of urea water is arranged midway of the passage 9.

Owner:HINO MOTORS LTD

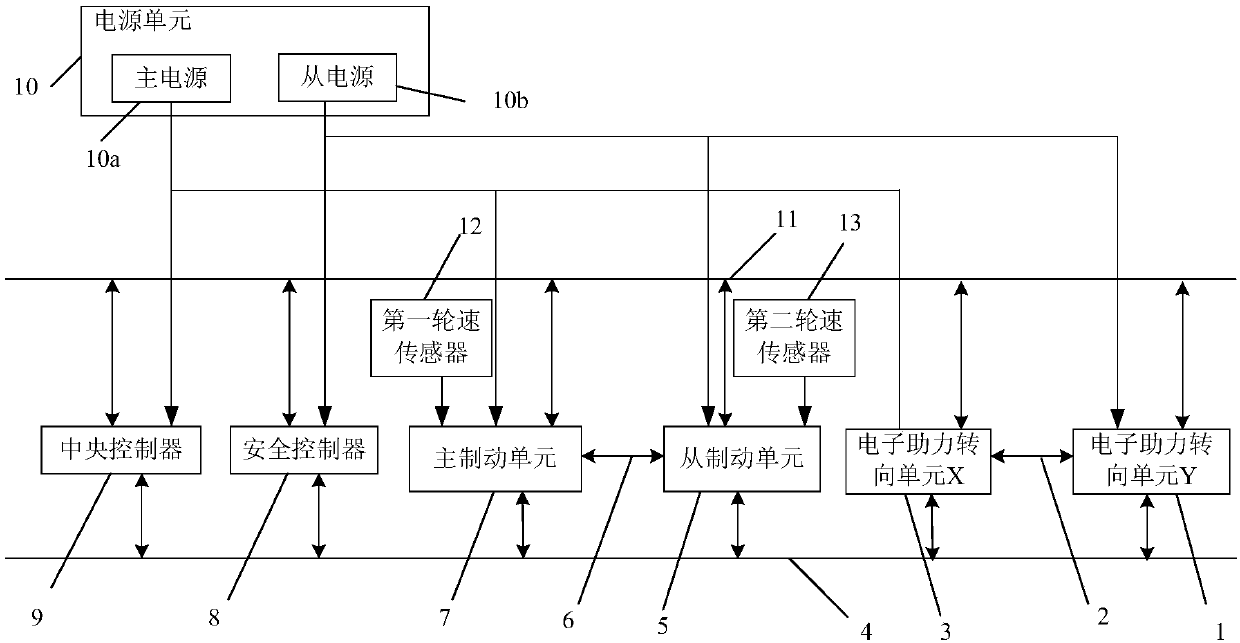

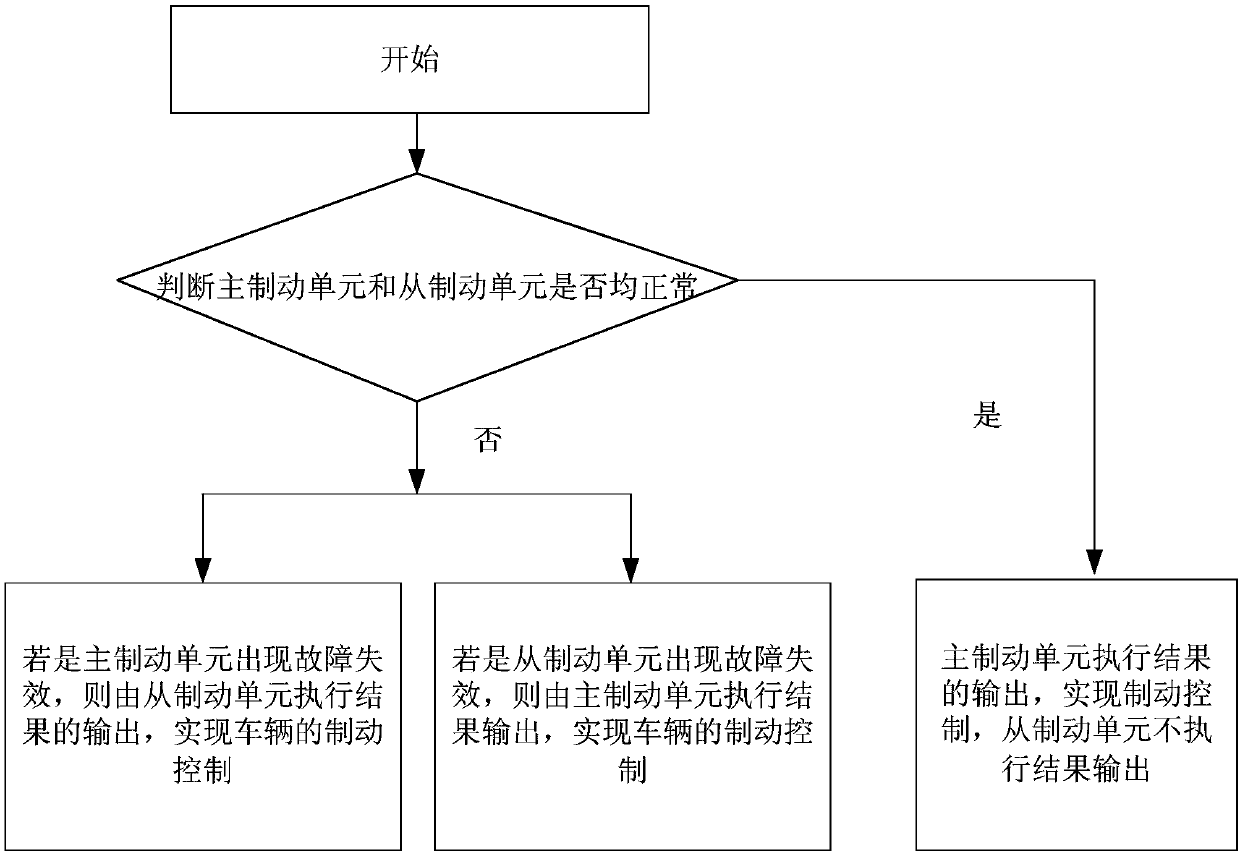

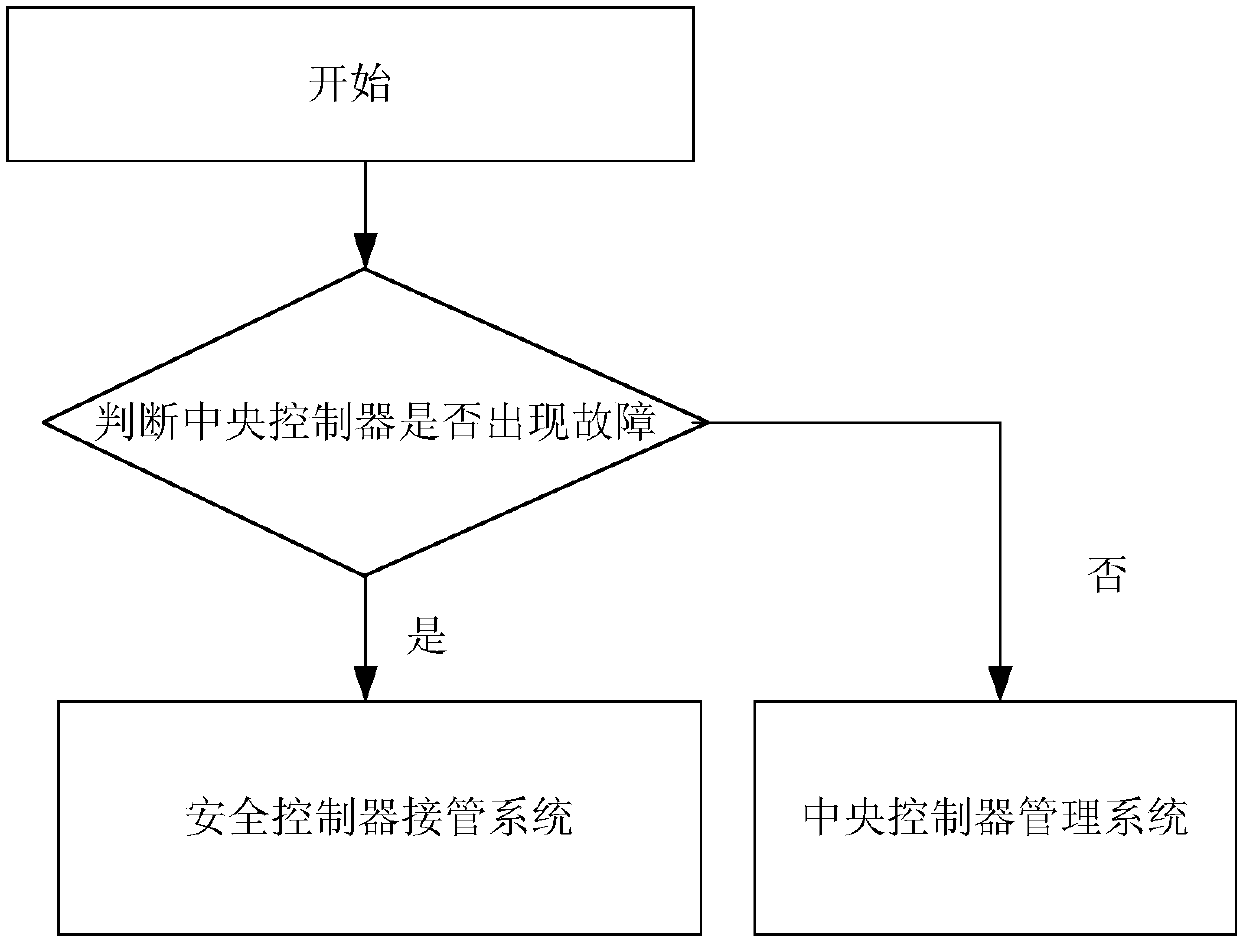

Redundant electronic steering braking system

ActiveCN109733460AMeeting safety requirements for autonomous drivingQuick responseElectrical steeringElectric energy managementAutopilotBraking system

The invention discloses a redundant electronic steering braking system which comprises two electronic power-assisted steering units, a main braking unit and a slave braking unit. The two electronic power-assisted steering units are used for jointly controlling an automobile to steer. The main braking unit is used for receiving a control command from an automobile bus, calculating the control command and executing result output. The slave braking unit is used for receiving the control command from the automobile bus, calculating the control command and deciding whether result output is executedor not on the basis of a state signal of the main braking unit. The redundant electronic steering braking system can meet the requirement for automatic driving safety.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

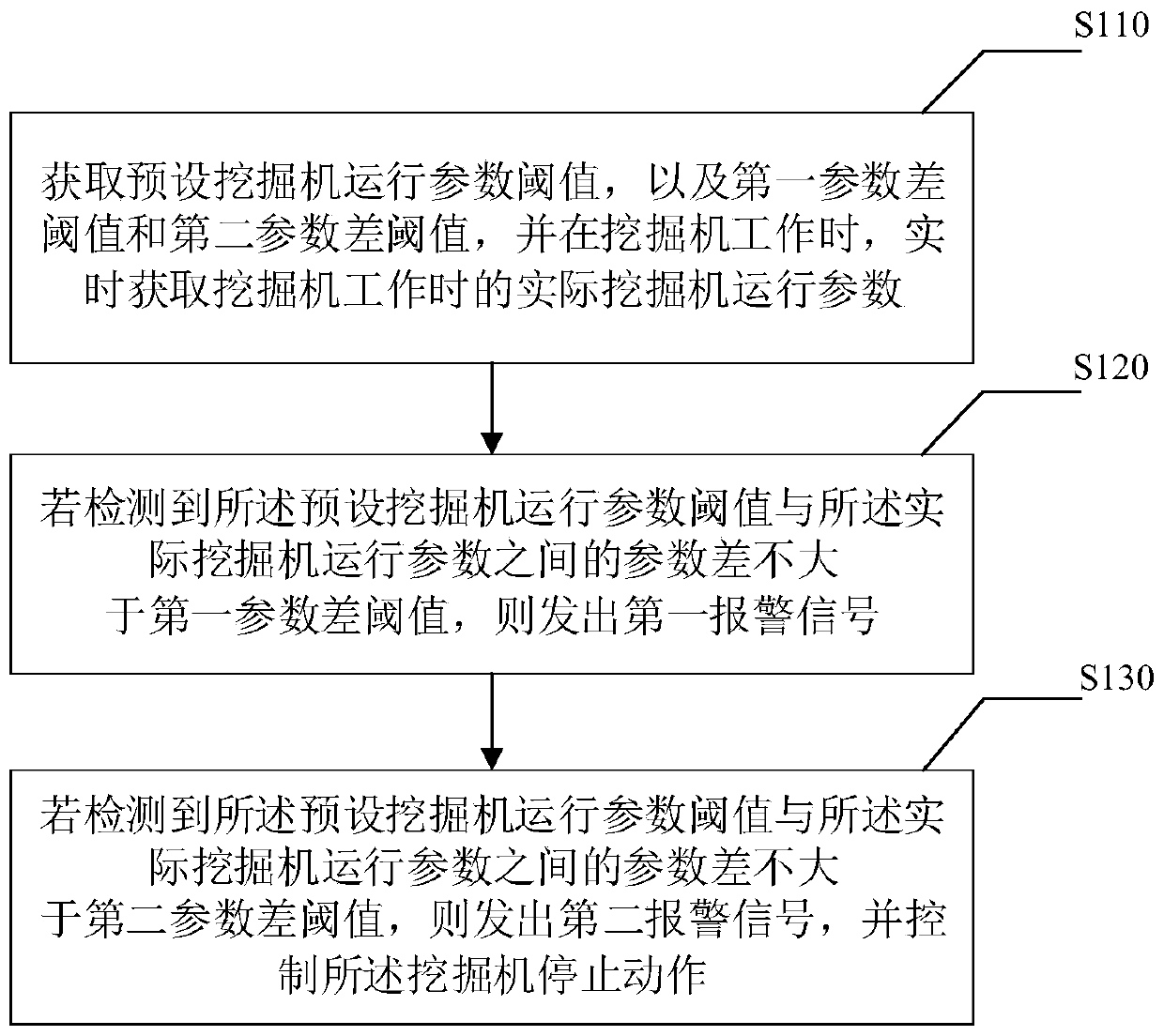

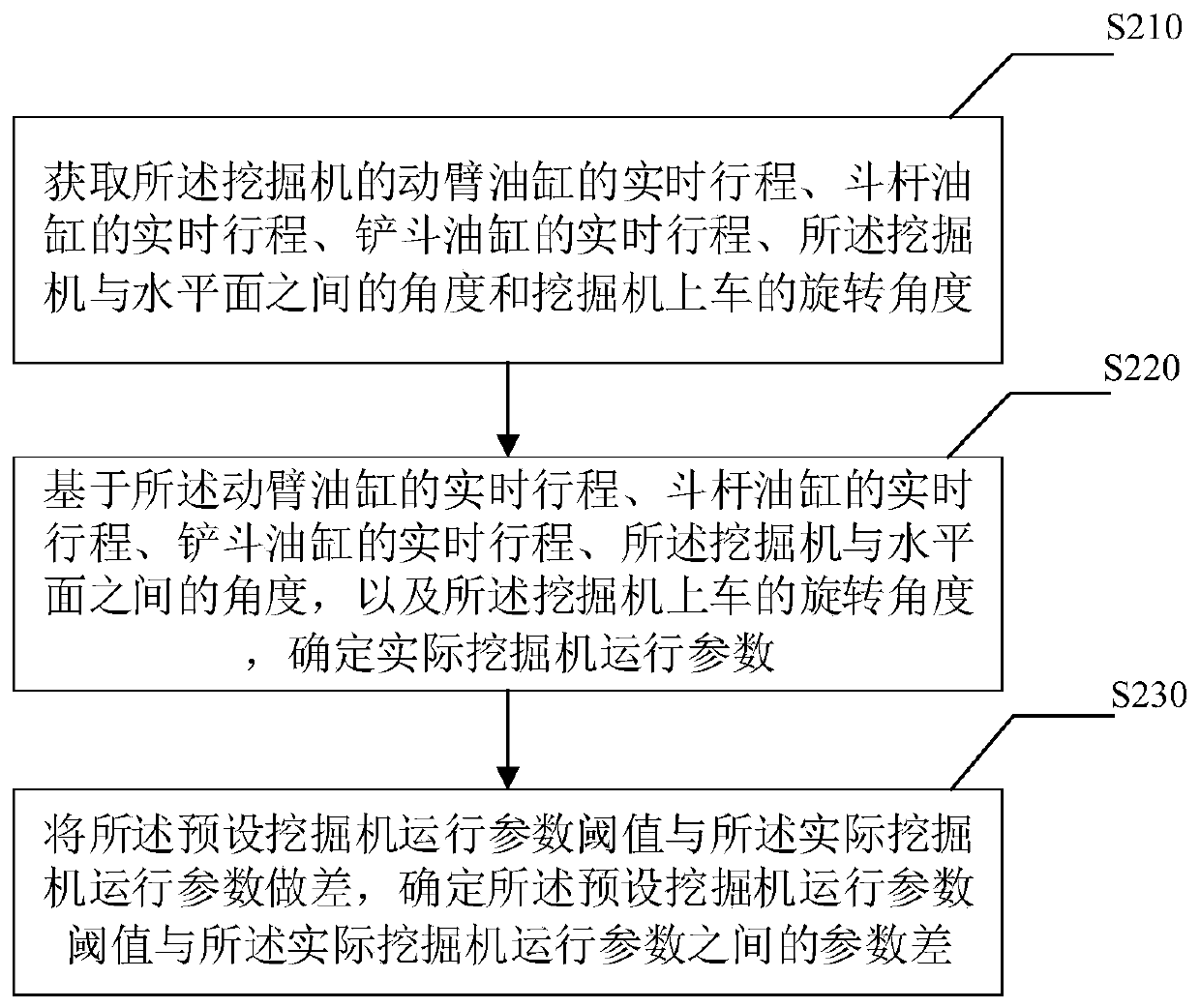

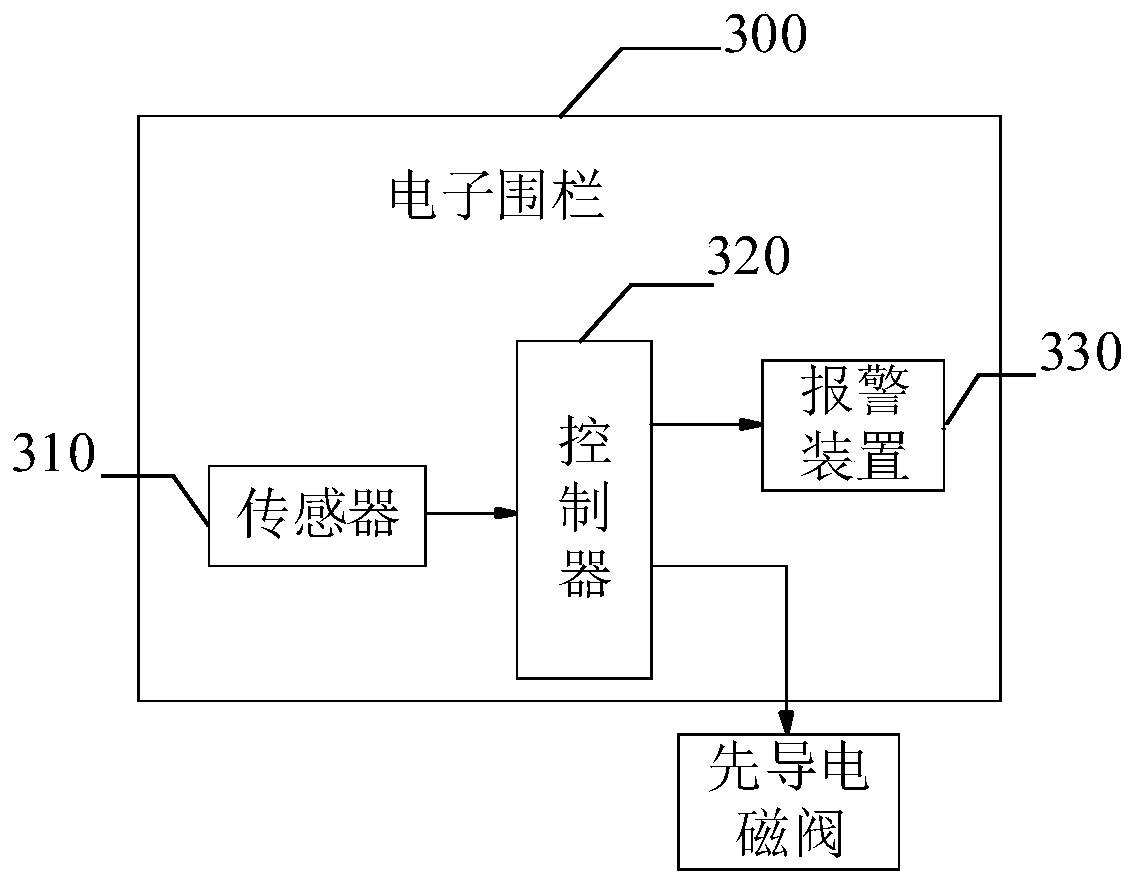

Work method of electronic fence for excavator, electronic fence and excavator

InactiveCN111501865AIncrease early warning processSufficient reaction timeProgramme controlComputer controlSystems engineeringExcavator

The invention provides a work method of an electronic fence for an excavator, the electronic fence and the excavator, and relates to the technical field of electronic fences. The work method comprisesthe steps of obtaining preset excavator running parameter threshold values, first parameter difference threshold values and second parameter difference threshold values, and when the excavator works,obtaining actual excavator running parameters in real time during work of the excavator; if it is detected that the parameter differences between the preset excavator running parameter threshold values and the actual excavator running parameters are not larger than the first parameter difference threshold values, sending out a first alarm signal; and if it is detected that the parameter differences between the preset excavator running parameter threshold values and the actual excavator running parameters are not larger than the second parameter difference threshold values, sending a second alarm signal, and controlling the excavator to stop action. Therefore, before the excavator stops action, a pre-warning process exists, and enough reaction time is left for drivers.

Owner:SANY HEAVY MACHINERY

Apparatus for producing refractory compound powders

InactiveUS20130236582A1Easy to adaptPrevent formation of high melting point compound crustOxygen/ozone/oxide/hydroxideMultiple metal hydridesReactive gasProduct gas

Owner:LIU BO +1

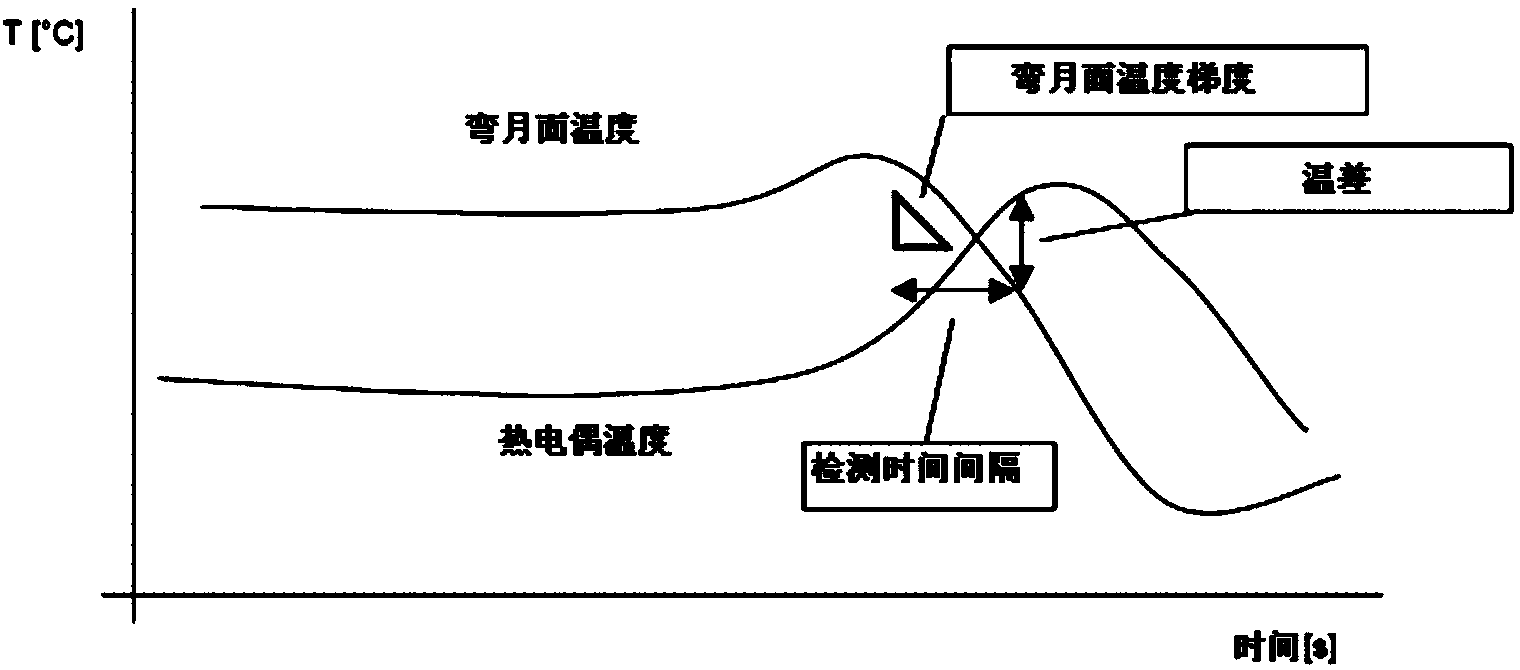

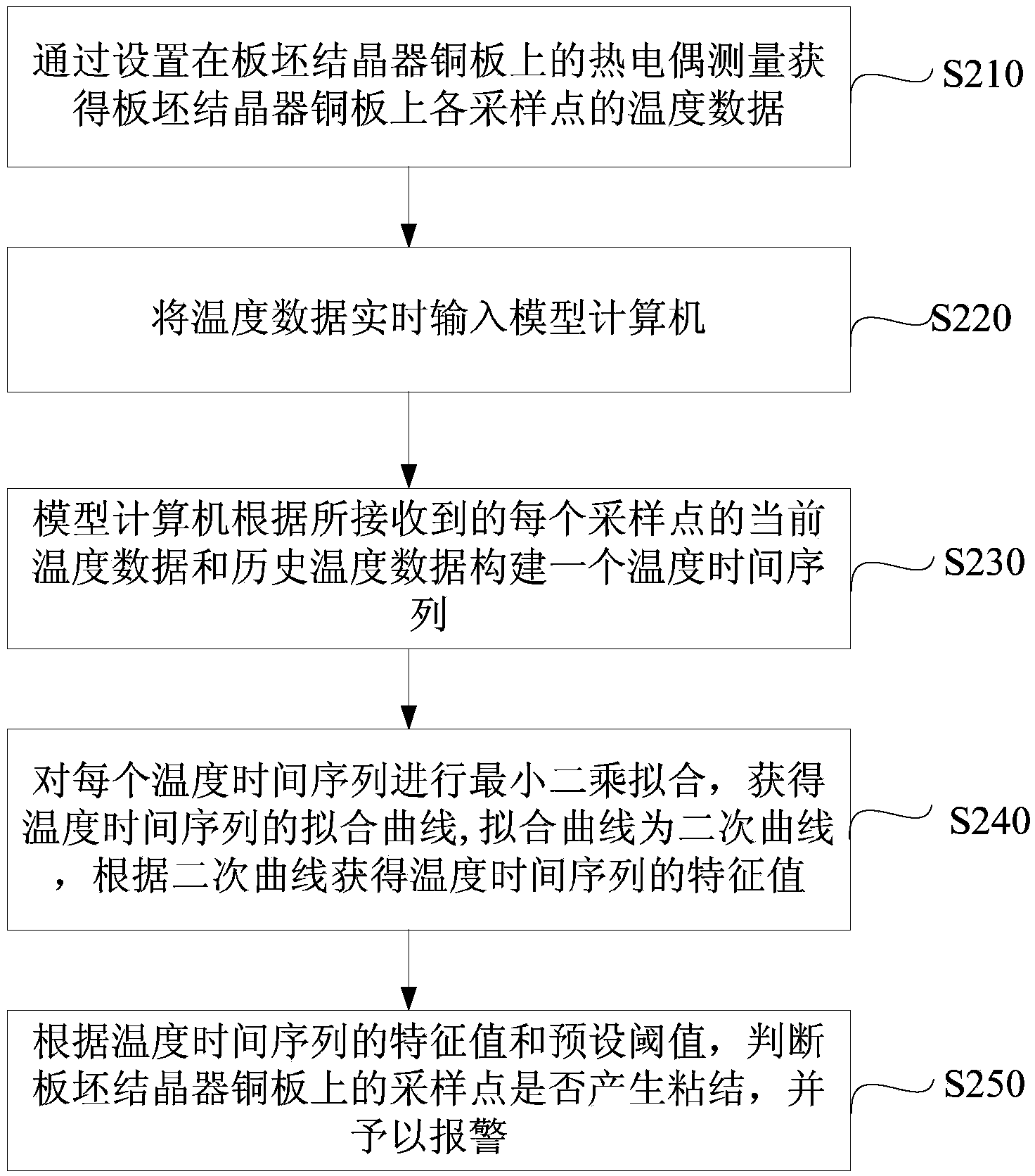

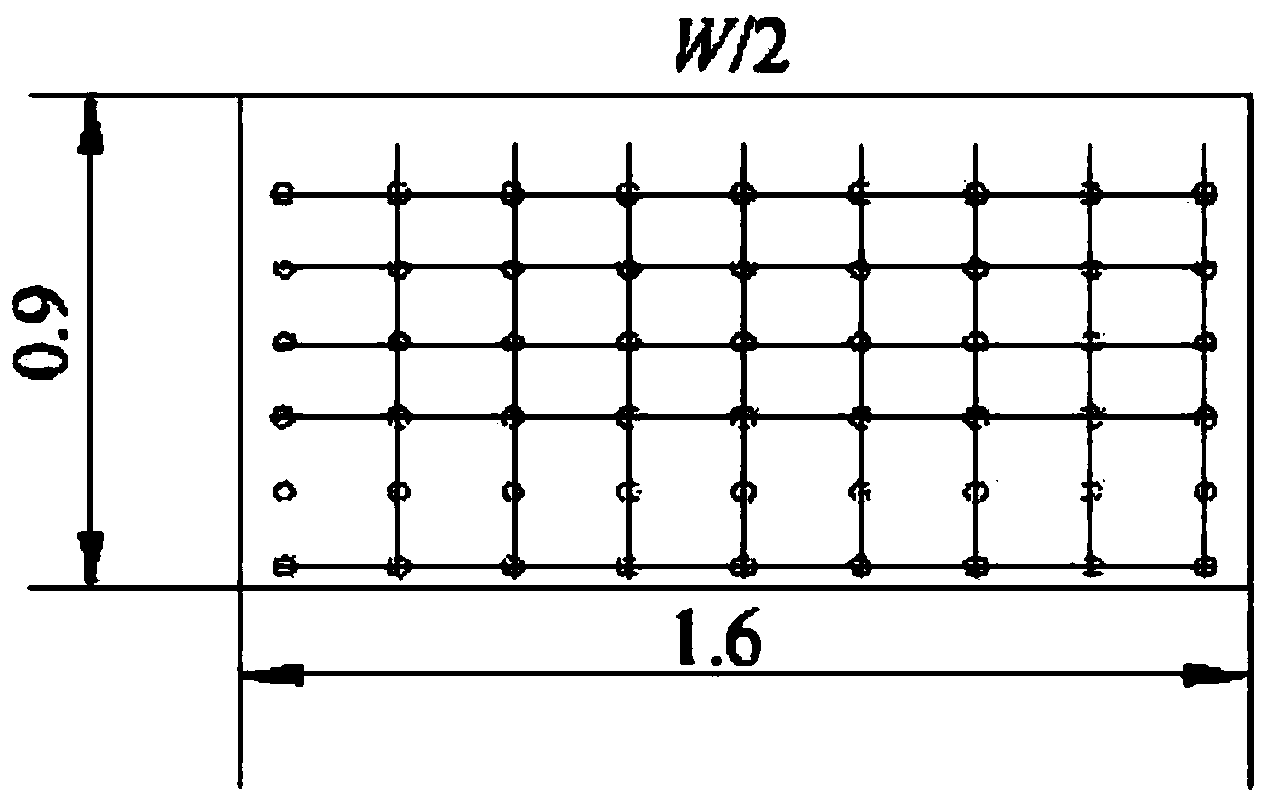

Bleed-out forecasting method and system based on least squares

The invention provides a bleed-out forecasting method and system based on least squares. The method includes the steps that temperature data of all sampling points on copper plates are obtained through thermocouples arranged on the slab crystallizer copper plates, and the temperature data are input to a normatron in real time; the normatron constructs a temperature time sequence according to the received current temperature data and the received historical temperature data of each sampling point; least square fit is performed on each temperature time sequence, a fitted curve of the temperature time sequence is obtained, the fitted curve is a quadratic curve, and a characteristic value of the temperature time sequence is obtained according to the quadratic curve; according to the characteristic value of the temperature time sequence and a preset threshold, whether the sampling points on the copper plates adhere to one another or not is judged, and an alarm is given. With the bleed-out forecasting method and system based on least squares, the characteristics of the temperature curve caught when adhering occurs in the early stage can be obtained, and therefore a bleed-out alarm can be given in advance.

Owner:CONTINUOUS CASTING TECH ENG OF CHINA

Mud-water separation apparatus and mud-water separation method

ActiveCN105837003AEasy to operateFlexible operationSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesEngineeringTextile

The invention discloses a mud-water separation apparatus, comprising a pressure-stabilizing and flow-stabilizing device, a dosing tank, a flocculating device, a homogenizing and leveling device, a concentration and dehydration device and a pressurized dehydration device which are all arranged on a frame. A mud outlet of the pressure-stabilizing and flow-stabilizing device is connected with the flocculating device; a mixed reagent from the dosing tank enters the flocculating device via a flocculating agent conveyer pipe; mud obtained after flocculation flows out from the flocculating device and enters the concentration and dehydration device for preliminary dehydration via the homogenizing and leveling device and then enters the pressurized dehydration device for extrusion and dehydration; and dehydrated dry mud is transported out. The mud-water separation method comprises the following steps: (1) subjecting mud and a flocculating agent to a mixed reaction; (2) placing mud on filter cloth and allowing the mud to undergo stationary dehydration relative to the filter cloth; and (3) placing mud between two layers of the filter cloth and carrying out peristaltic dehydration through extrusion by a pressure roller. Compared with the prior art, the mud-water separation apparatus and mud-water separation method provided by the invention have the advantages of great efficacy, low energy consumption, high stability, great treating capacity, capacity of realizing continuous treatment, etc.

Owner:上海尔速机械设备有限公司

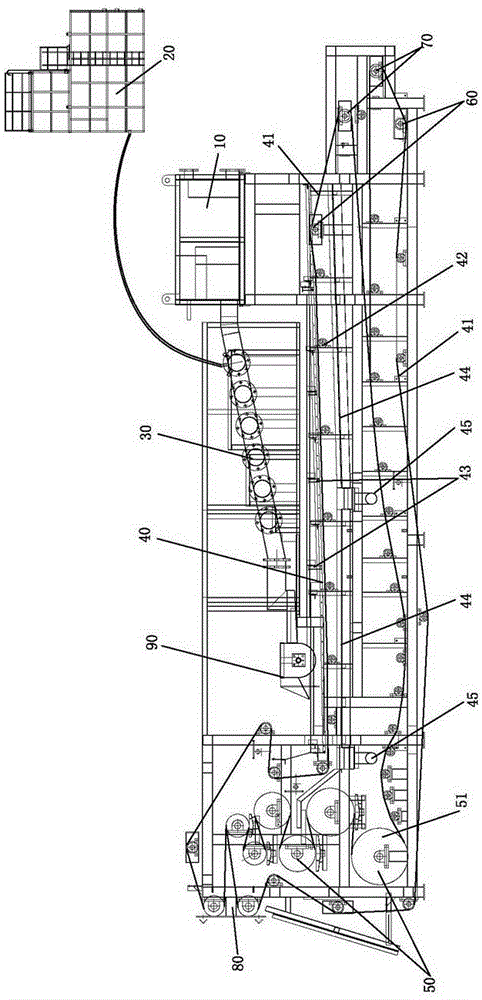

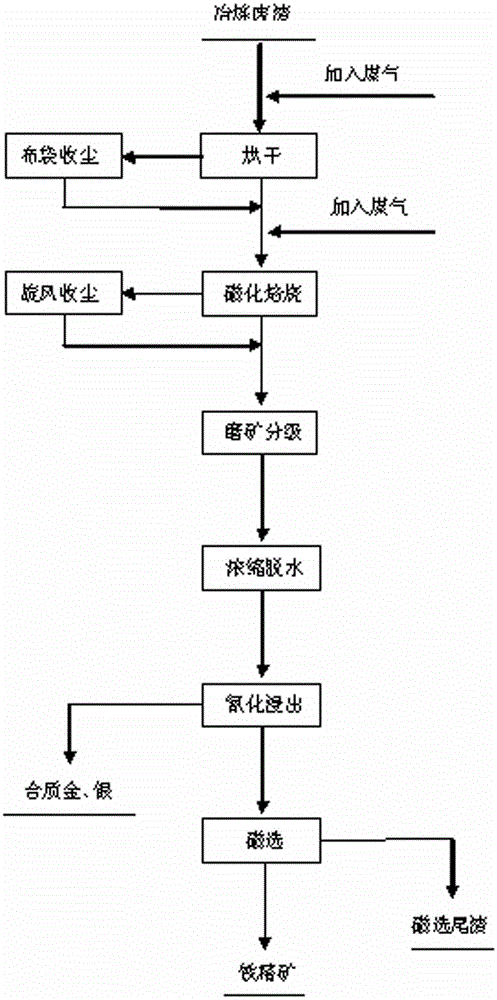

Smelting residue flash magnetizing roast comprehensive recycling technology

ActiveCN102912116ANo accumulationNo consequences of hot wind blowingProcess efficiency improvementEconomic benefitsMoisture

The invention belongs to the metallurgical industry, and particularly relates to a smelting residue flash magnetizing roast comprehensive recycling technology. The technology is realized as follows: drying and thrashing smelting residues to obtain a powdery material with the moisture content not more than 3% and the particle size of -0.074 not less than 80%; preheating the powdery material and then roasting in a magnetized roaster at the temperature of 750-780 degree C; separating gas from solid and cooling; grinding, grading and concentrating roasted ore; all-sliming cyanidation leaching gold and silver; recycling gold and silver through carbon absorption to obtain gold and silver active carbon; and cyaniding tailings and performing magnetic separation to obtain iron ore concentrate. The technology disclosed by the invention can solve problems about treatment of gold, silver and iron smelting residues, not only can comprehensively recycle gold, silver and iron, but also can reduce pollution of the smelting residues to the environment, as a result, the waste is turned into the wealth, the national policy of energy conservation and emission reduction is met, certain economic benefits are created for an enterprise, and the pollution to the environment is reduced.

Owner:河南黄金产业技术研究院有限公司

Steel pipeline anticorrosive material and preparation method of steel pipeline anticorrosive material

ActiveCN102850857AHigh temperature indentation hardnessGuaranteed productionAnti-corrosive paintsSteel qualityPolypropylene

The invention discloses a steel pipeline anticorrosive material and a preparation method of the steel pipeline anticorrosive material. The steel pipeline anticorrosive material comprises the following ingredients in proportion by weight: 44 to 54 parts of polypropylene, 3 to 12 parts of high-density polyethylene powder, 0.3 to 2.4 parts of anti-aging agents, 0.06 to 1.2 parts of antioxidant, 0.06 to 1.2 parts of lubricating agents, 0.06 to 0.6 parts of degradation inhibitors and 0.06 to 0.6 parts of initiators, wherein all ingredients are uniformly mixed in a highly mixed pot and are then extruded out through a reactive double-screw-rod extruding machine with the length-diameter ratio being 52:1, the extruded ingredients are subjected to strip pulling, air cooling and grain cutting, the temperature is set to be 180 DEG C to 220 DEG C, and the rotation speed of screw rods is set to be 180 to 400 turns per minute. Compared with the anticorrosive material in the market, the steel pipeline anticorrosive material has the advantages that the processing applicability is wide, high Vicat, high hardness and good low-temperature toughness are realized, and long service life at high temperature and requirements on the anticorrosive material when passing through specific districts such as water, sand and stone soil and oceans are met.

Owner:四川仁智新材料科技有限责任公司

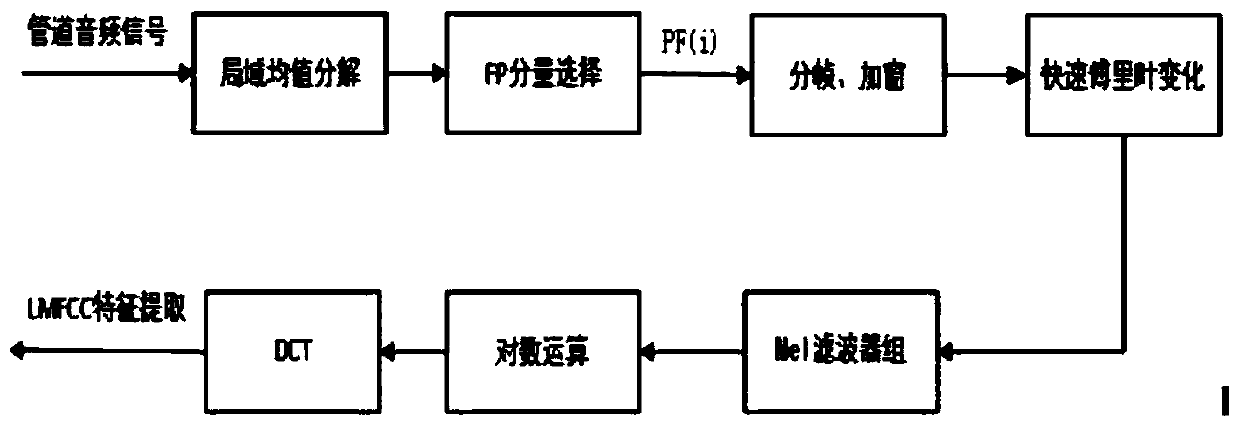

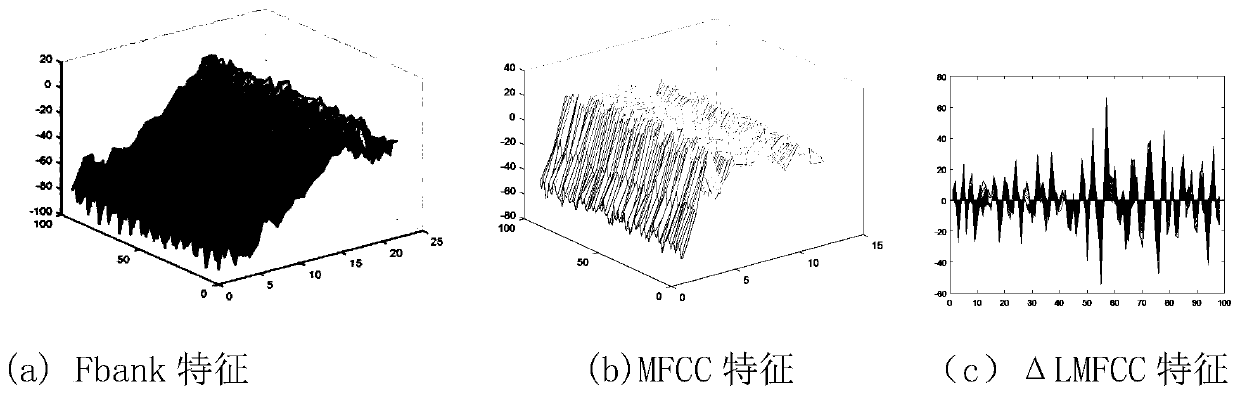

Natural gas pipeline leakage detection method based on LSTM recurrent neural network

ActiveCN111022941AImprove accuracySufficient reaction timePipeline systemsFeature extractionEngineering

The invention provides a natural gas pipeline leakage detection method based on an LSTM recurrent neural network. The natural gas pipeline leakage detection method comprises the following steps: step1, collecting pipeline leakage audio data; step 2, performing feature extraction on the audio data by adopting an improved Mel-frequency cepstral coefficient MFCC method; step 3, constructing a natural gas pipeline leakage detection model based on a long-term and short-term memory LSTM recurrent neural network; and step 4, carrying out training and parameter optimization on the pipeline micro-leakage detection model, and verifying the robustness of the model. Compared with the prior art, the natural gas pipeline leakage detection method provided by the invention has the technical effects or advantages: in a parameter optimization process of the pipeline leakage detection model, according to the natural gas pipeline leakage detection method based on the LSTM recurrent neural network, the pipeline state can be detected, the accuracy of pipeline leakage detection is improved, sufficient reaction time is provided, the possibility of safety accidents is reduced, and the natural gas pipelineleakage detection method has certain theoretical research value and wide application prospects.

Owner:山西天浩清洁能源有限公司

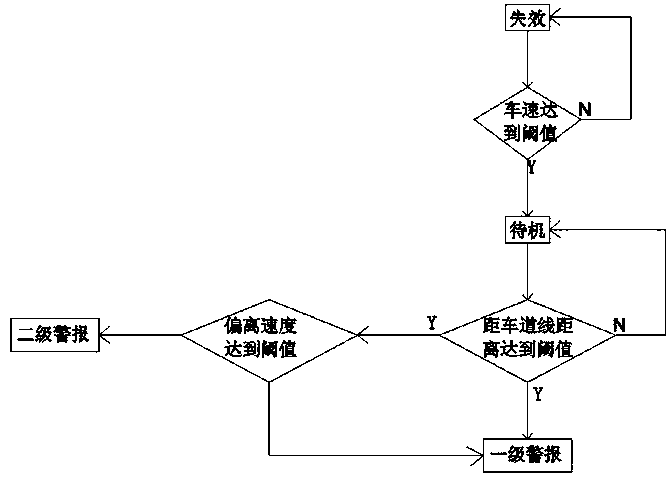

A lane departure warning system

ActiveCN109080536ASufficient reaction timeSignalling/lighting devicesElectric/fluid circuitReal time acquisitionDriver/operator

The invention relates to a lane departure warning system, which is characterized in that: the system comprises an environment sensing mechanism, a control mechanism and an execution mechanism; the lane departure warning system comprises an environment sensing mechanism, a control mechanism and an execution mechanism. The environment sensing mechanism collects the driving state of the automobile inreal time and processes the corresponding data through the control mechanism. The control mechanism discriminates the data processing result collected by the environment sensing mechanism through thecontrol policy mechanism, and the execution mechanism executes the operation according to the discrimination information of the control mechanism. The lane departure warning system of the present invention provides a lane departure warning system, As that distance from the lane line and the preview distance are use as the judging basis, whether the posture of the vehicle body deviates from the lane line is judged, the alarm distance is reminded, the driver is guaranteed to have sufficient reaction time, the correct habit operation can be carried out, and when the deviation occurs and the alarming grade is reached, the alarming signal is sent out; If the driver does not intervene in the operation, the vehicle will continue to be in an offset state and will continue to alarm; The system stops when the driver intervenes to turn on the steering light or to return the steering wheel.

Owner:GELUBO TECH CO LTD

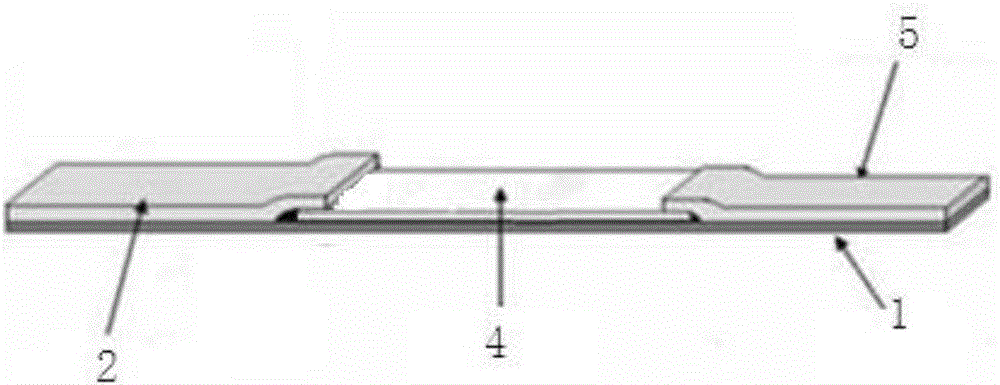

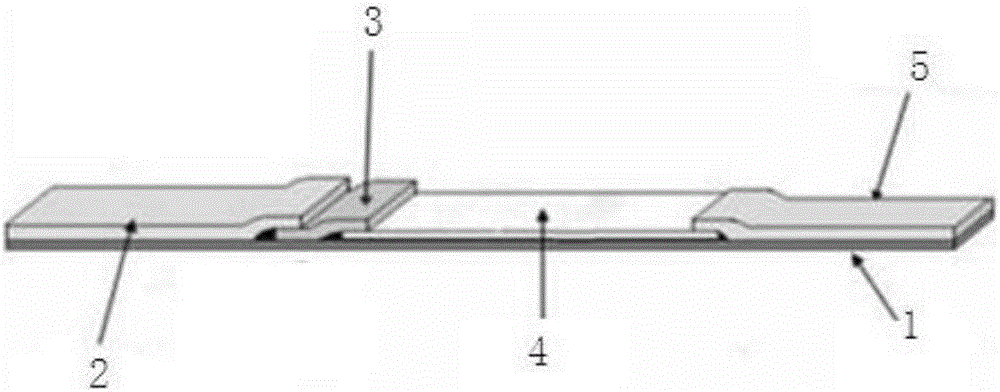

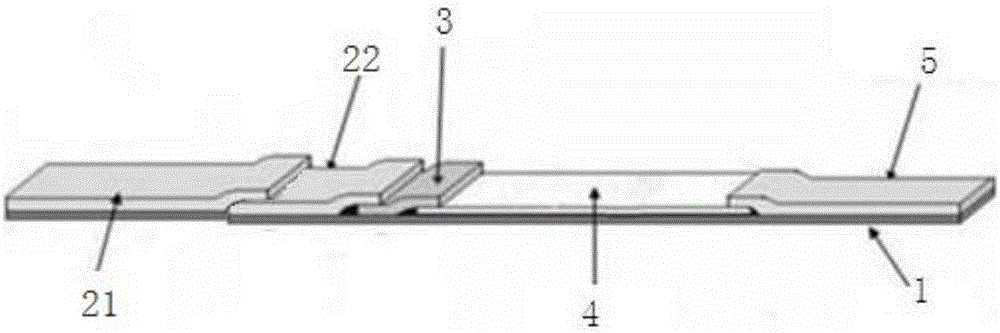

Lateral chromatographic test paper for chemical detection and detection method of lateral chromatographic test paper

PendingCN106645133ASolve problems that cannot coexistHigh sensitivityMaterial analysis by observing effect on chemical indicatorPolyesterGlass fiber

The invention provides lateral chromatographic test paper for chemical detection. The test paper is assembled according to a lateral chromatographic structure based on a reaction sequence of the chemical detection. The test paper comprises a detection reaction condition preparation area, a detection color development area and a water absorption area which are successively arranged on a bottom plate, wherein the detection reaction condition preparation area is qualitative filter paper, quantitative filter paper, glass cellulose membrane, water absorption paper or polyester cellulose membrane test paper loaded with a reaction reagent, and the detection color development area is qualitative filter paper, quantitative filter paper, glass cellulose membrane, water absorption paper or polyester cellulose membrane. The test paper is uniform in color development, capable of solving the problem in the existing detection method that various reaction reagents cannot coexist on a piece of paper and breaking the limitation of the chemical detection test paper, and is more reliable in detection result.

Owner:CHENGDU HEYU TECH CO LTD

Methods for removing contaminants from exhaust gases

ActiveUS20160082389A1Eliminates and reduces concernSufficient reaction timeGas treatmentNitrogen compoundsIndustrial gasSorbent

Industrial gas streams such as flue gas streams are treated for nitrogen oxides and other contaminants in dry or semi-dry scrubbers. After the flue gas stream has been contacted with a sorbent, ozone is mixed downstream into the flue gas stream thereby oxidizing the nitrogen oxides and other contaminants. The oxidized contaminants is contacted with sorbent present in the gas stream in the remaining height or volume of the scrubber downstream of ozone injection; and The sorbent is then separated from the flue gas stream leaving the dry or semi-dry scrubber.

Owner:MESSER IND USA INC

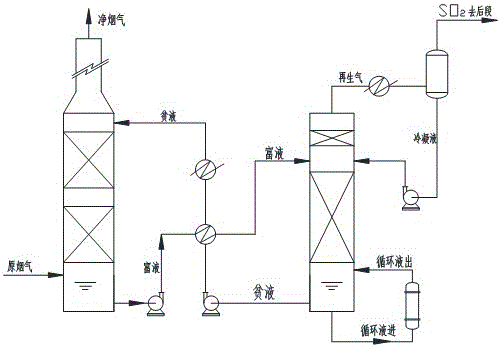

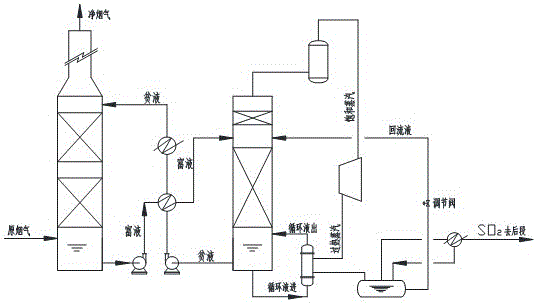

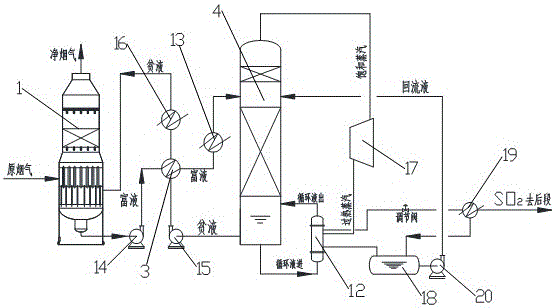

Regenerable cyclic absorption flue gas desulfurization technology

InactiveCN106310881AImprove desulfurization efficiencyReduce circulationDispersed particle separationLiquid layerFlue gas

The invention discloses a regenerable cyclic absorption flue gas desulfurization technology which comprises the following steps of: delivering flue gas into an absorbent liquid layer in a bubbling tower, to obtain a purified gas and rich liquor; delivering the rich liquor to a regeneration tower through a barren and rich liquor heat exchanger, performing heat exchange between barren liquor without SO2 and rich liquor, and then delivering to the bubbling tower as an absorbent for cyclic use. The bubbling tower is adopted to replace a filling tower and a spraying tower used at the existing desulfurization section, and under the matching of the regeneration section, the desulfurization effect of the flue gas can be obviously improved, the effective sulfur capacity of the absorbent can be increased, so that the cyclic quantity and loss of the absorbent in the regenerable cyclic absorption method can be reduced, the regenerable energy consumption of the absorbent can be reduced, the economic benefit of the regenerable cyclic desulfurization technology can be increased, and the application range can be expanded.

Owner:CHENGDU HUAXITANG ENVIRONMENTAL PROTECTION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com