Method and device for treating solid waste burning tail gas

A tail gas treatment and tail gas technology, which can be applied to combined devices, separation methods, chemical instruments and methods, etc., can solve the problems of high investment and operating costs, low pollutant removal rate, etc., and achieves a small footprint, ideal mass transfer, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

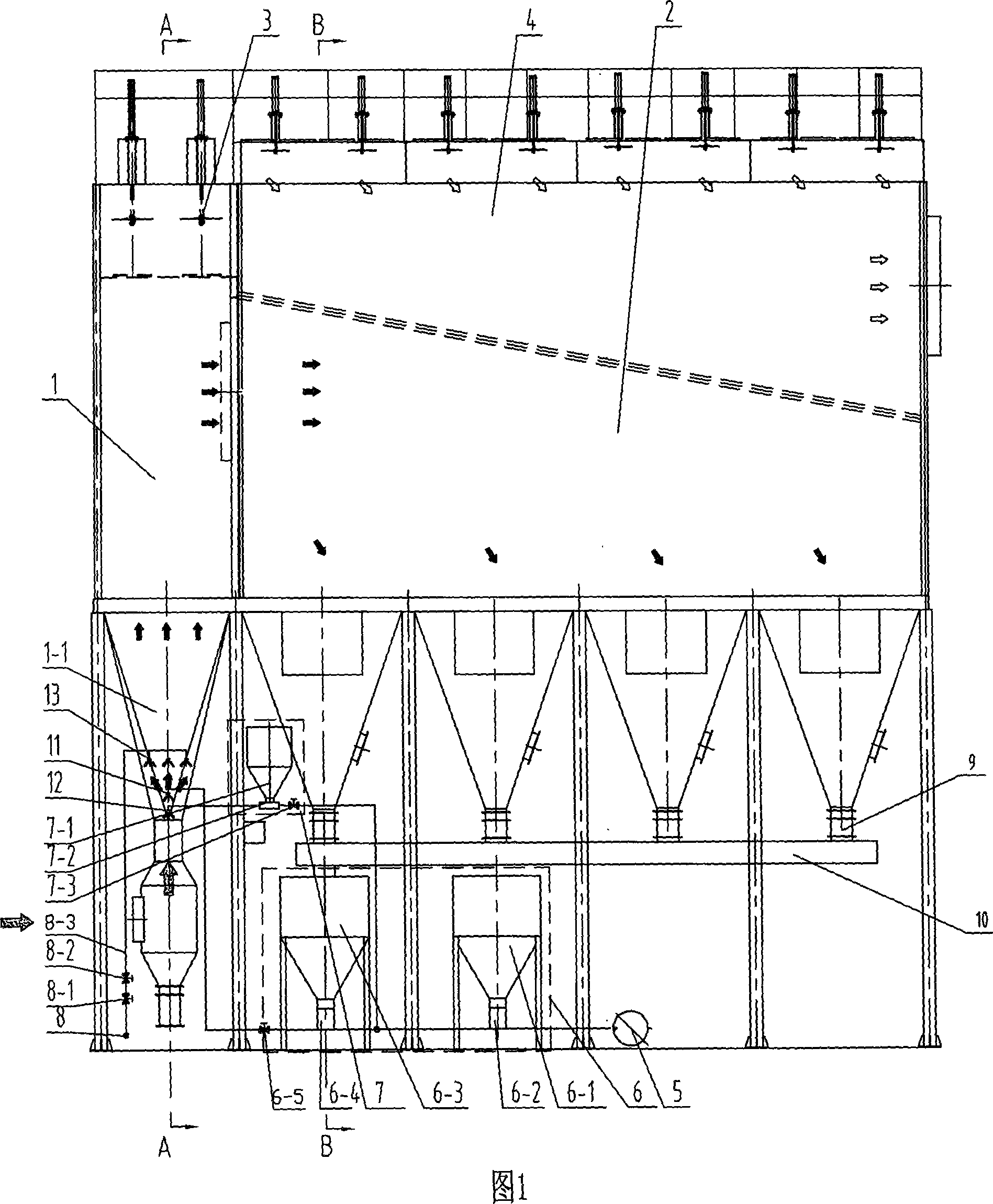

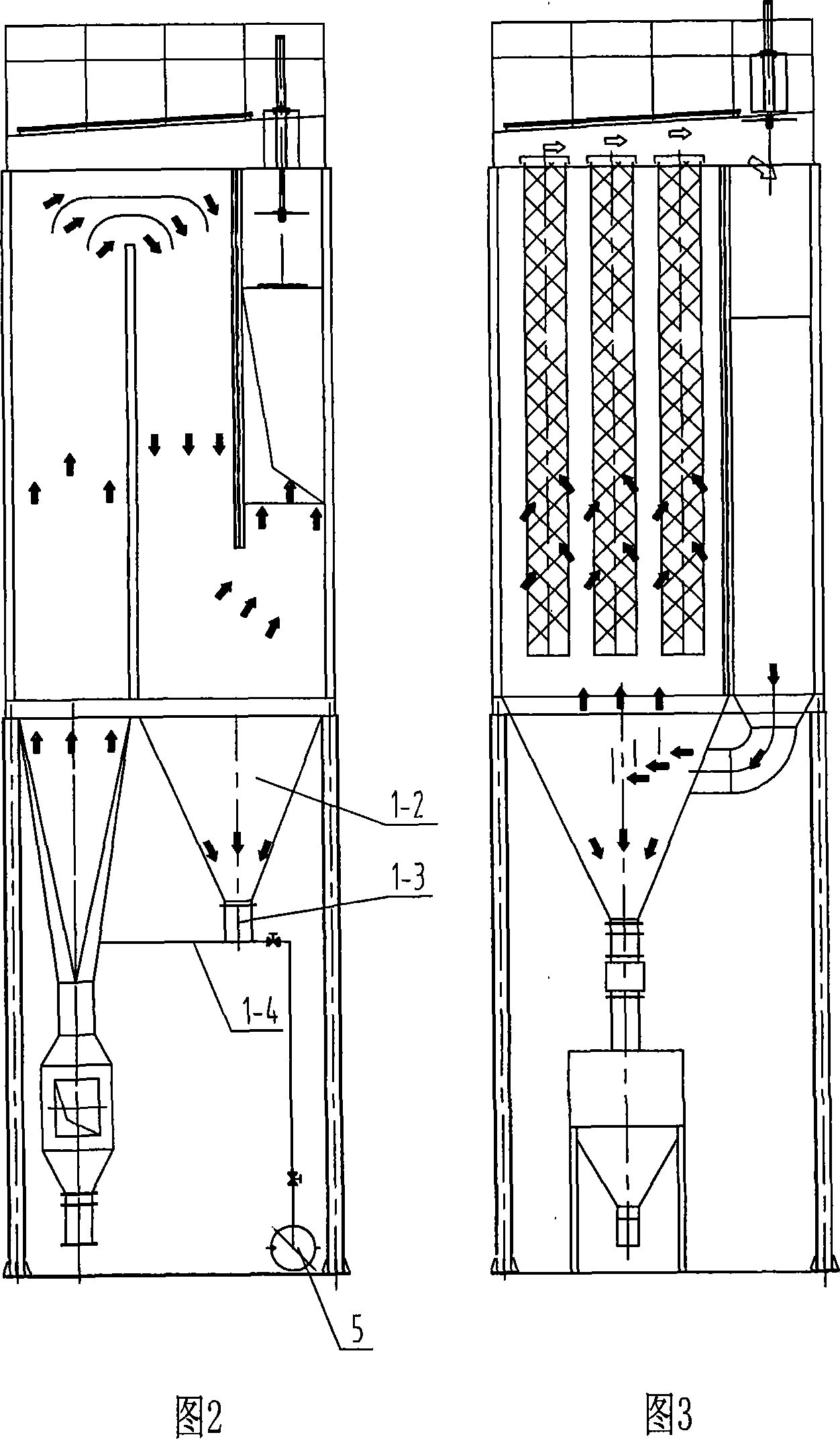

[0015] The best embodiment of the solid waste incineration tail gas treatment device of the present invention as shown in Figures 1 to 3 has a flue gas pretreatment chamber 1, a bag filter 2, a blower pump 5, a deacidification agent supply system 6, an active Carbon supply system 7, water supply system 8, emergency channel 4 and emergency channel valve 3; the entrance of emergency channel 4 is set in flue gas pretreatment chamber 1, emergency channel 4 is set in bag filter 2, and emergency channel valve 3 is installed in emergency channel 4, the entrance of the emergency channel 4 is connected to the atmosphere; the flue gas pretreatment chamber 1 is connected to the bag filter 2, and the inlet of the flue gas pretreatment chamber 1 is provided with a variable diameter port 1-1, and a variable diameter port 1- 1 is equipped with deacidification agent nozzle 11, activated carbon nozzle 12 and atomization nozzle 13, and the spraying direction of deacidification agent nozzle 11, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com