Patents

Literature

159results about How to "Efficient mass transfer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

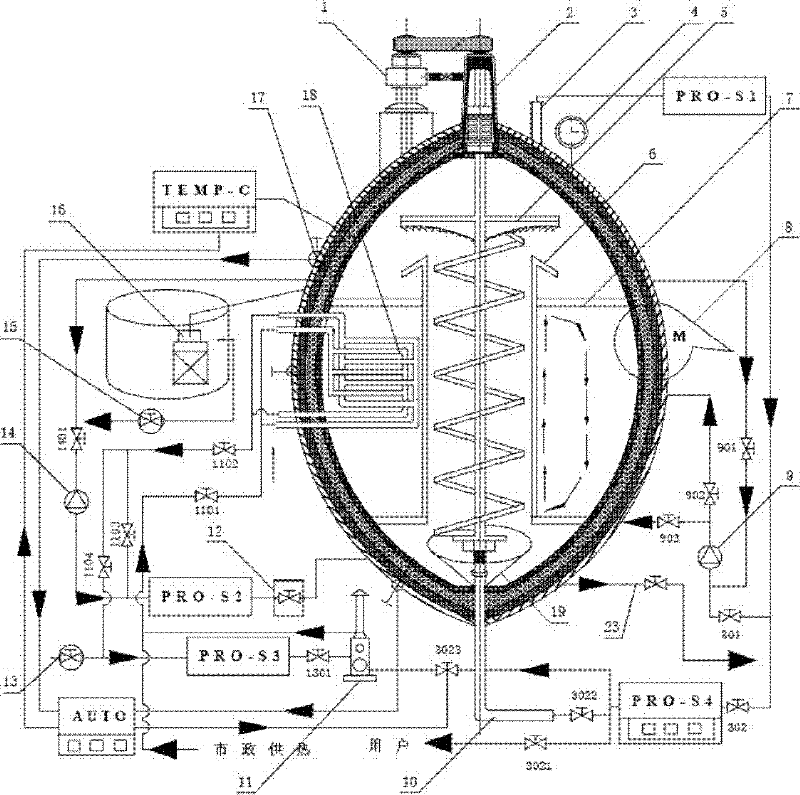

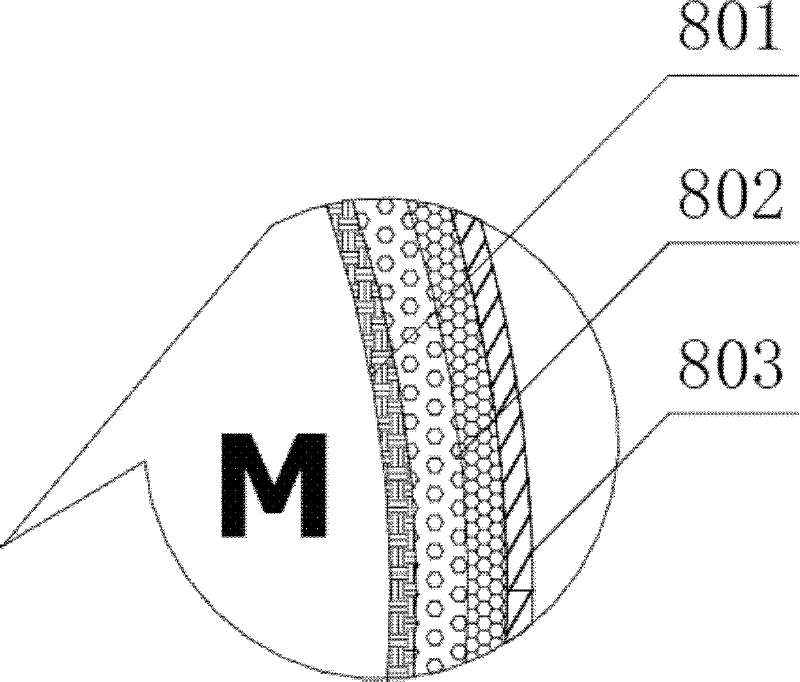

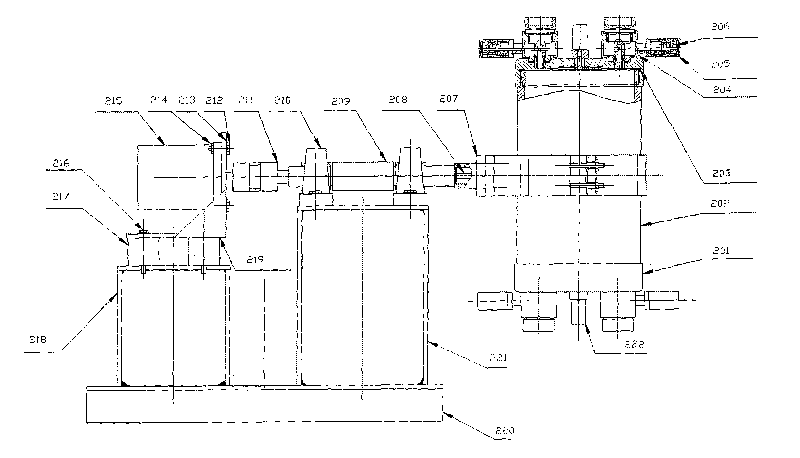

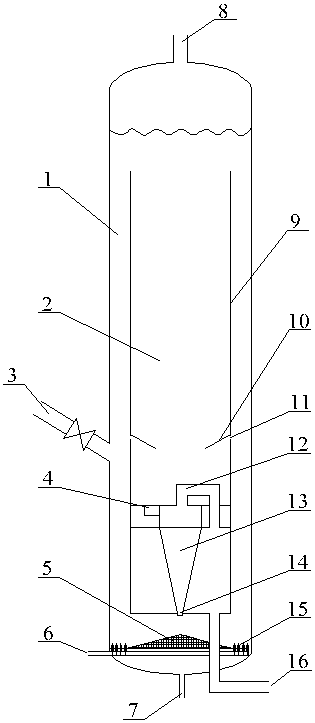

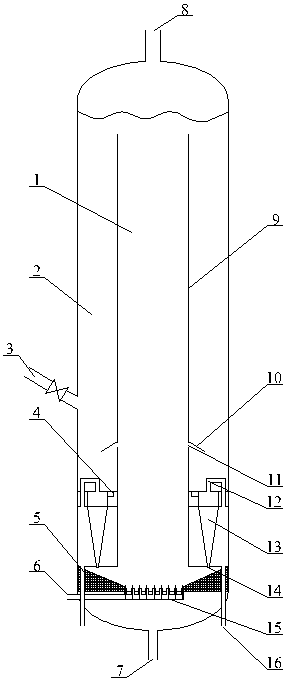

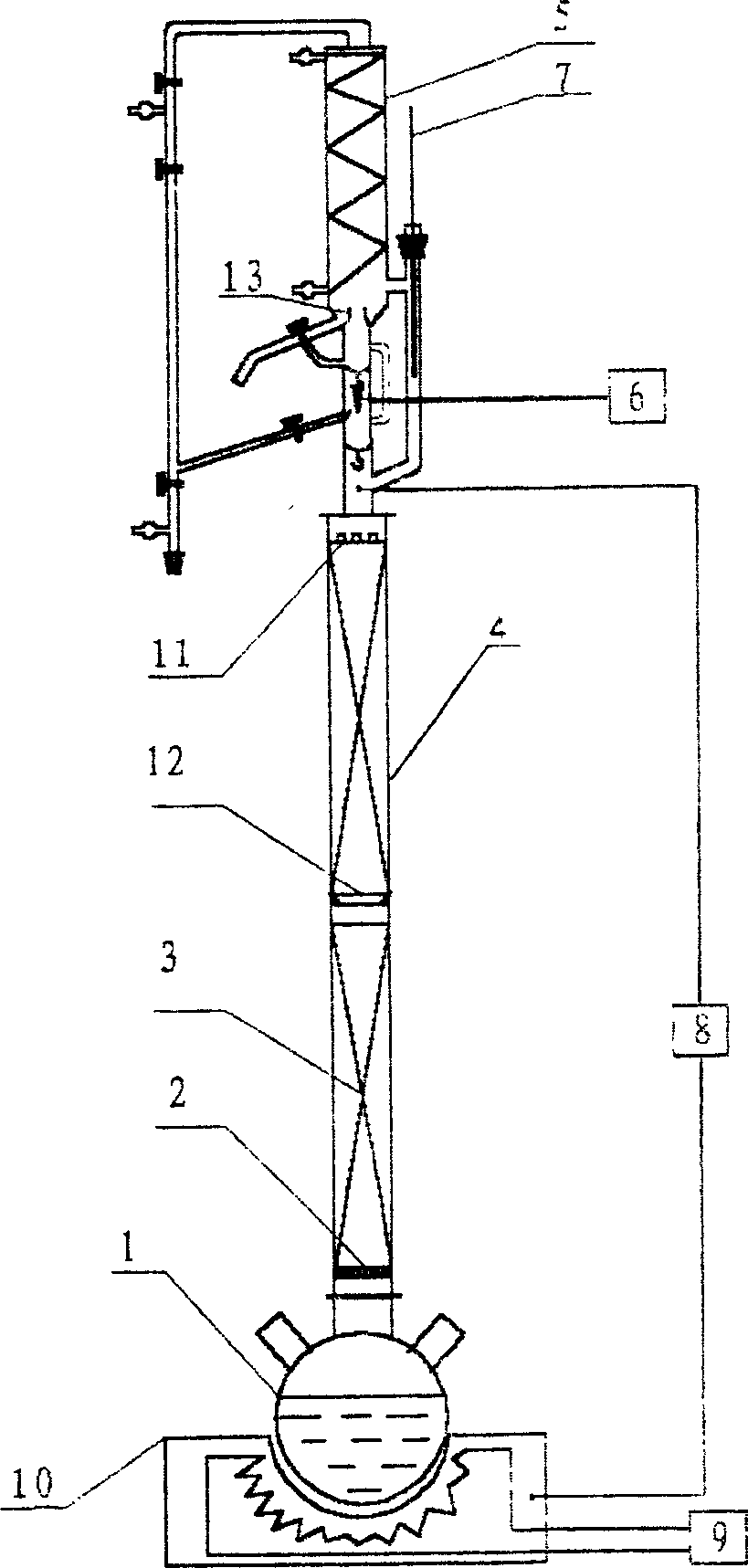

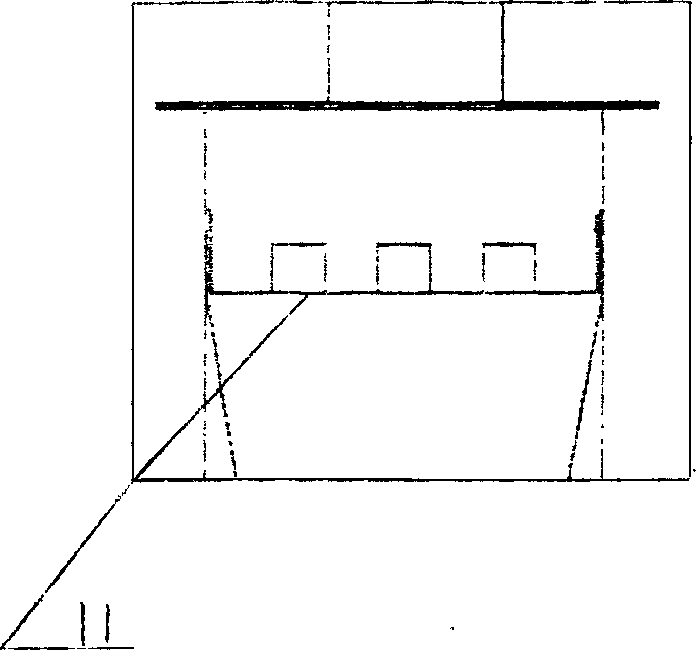

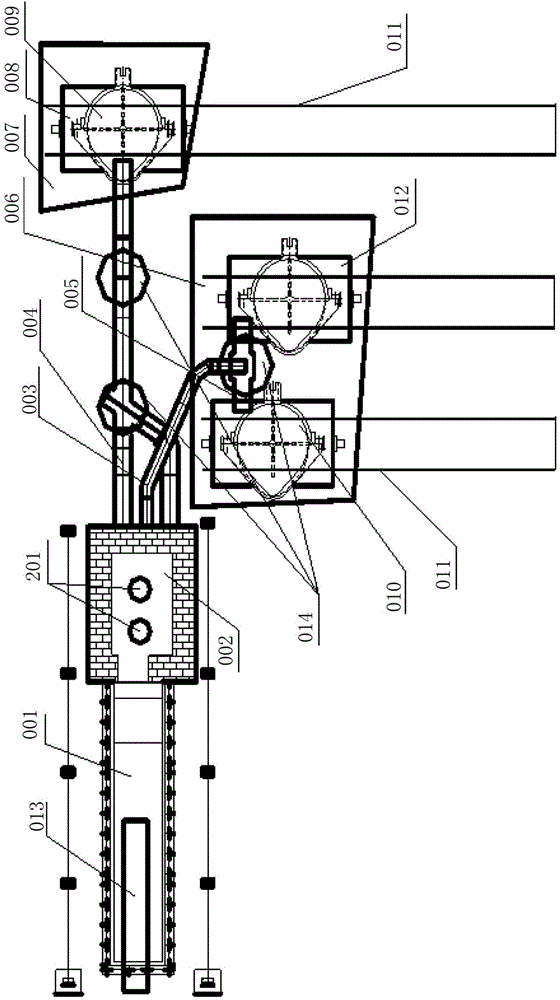

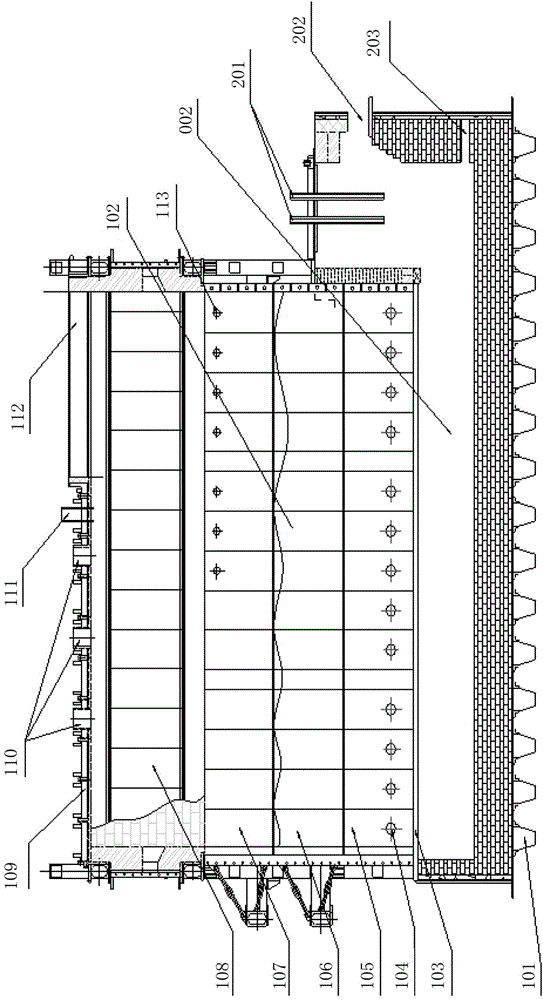

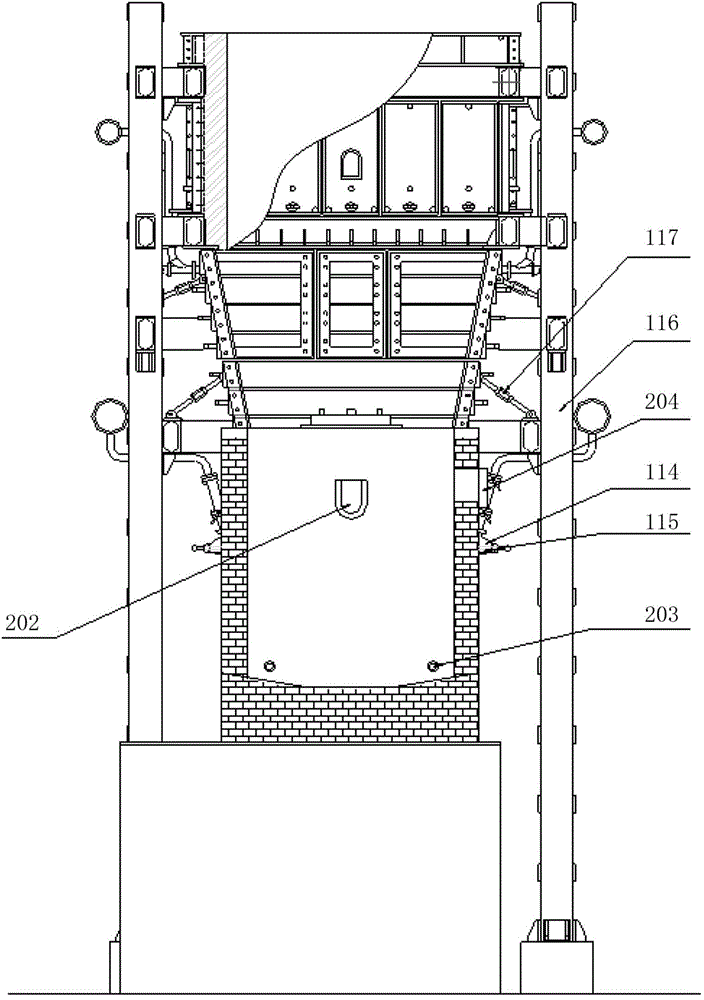

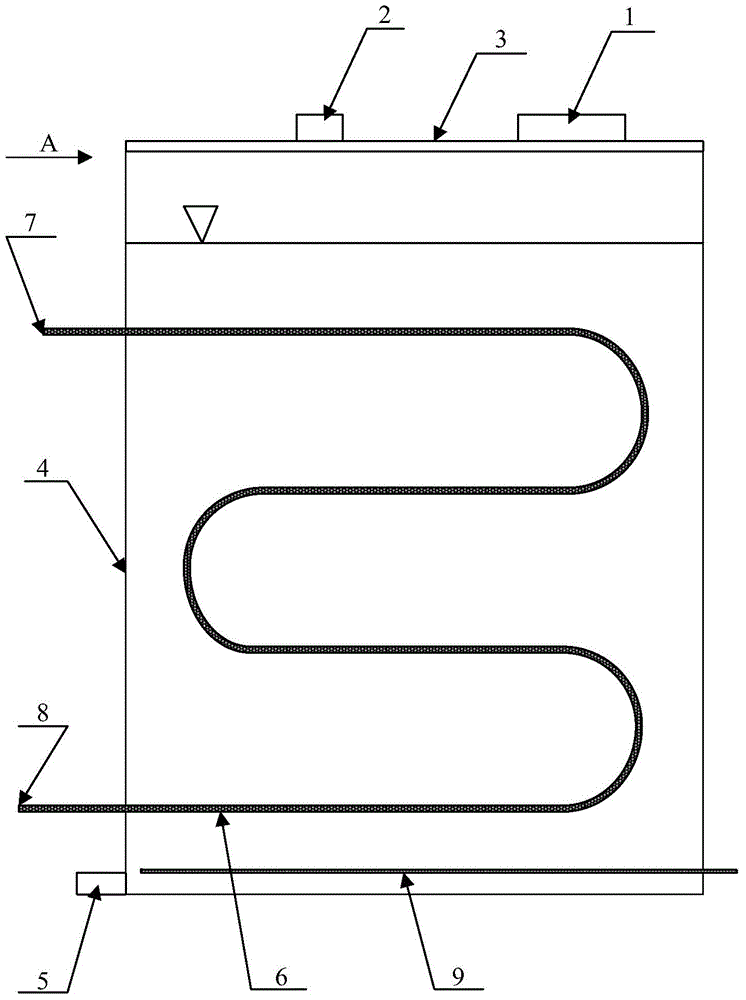

Multi-cycle stirring egg-shaped anaerobic fermentation system

ActiveCN102517199ASimple structureReasonable designBioreactor/fermenter combinationsBiological substance pretreatmentsAgricultural engineeringSlurry

The invention discloses a multi-cycle stirring egg-shaped anaerobic fermentation system. The system comprises a fermentation tank body and a driving device arranged on the fermentation tank body, wherein the fermentation tank body is egg-shaped, the center of the inner cavity of the fermentation tank body is provided with an inner barrel type spiral stirrer, the outside of the inner barrel type spiral stirrer is provided with a stirrer inner barrel, a temperature heating device is arranged between the wall of the fermentation tank body and the stirrer inner barrel, the bottom of the inside ofthe tank is provided with an umbrella-shaped gas flow distribution device; the upper part of the fermentation tank body is provided with a vent pipe and a pressure control device, the bottom of the fermentation tank body is provided with an umbrella-shaped gas flow distribution device gas inlet pipe and a mud-discharging and sand-discharging outlet; and the side wall of the fermentation tank bodyis communicated with a biogas circulation system, a biogas slurry circulation system, a gas-liquid circulation system, a heating system, a temperature control system and a biogas residue and biogas slurry storage pool respectively. The multi-cycle stirring egg-shaped anaerobic fermentation system adopts multi-cycle stirring to increase the stirring efficiency of the system; and the anaerobic fermentation environment is improved, the fluid is mixed evenly, the temperature difference slightly fluctuates, the energy consumption of the system is low, the fermentation rate is high and the system is suitable for popularization and application.

Owner:INNER MONGOLIA HUAMENG KECHUANG ENVIRONMENTAL PROTECTION TECH ENG CO LTD

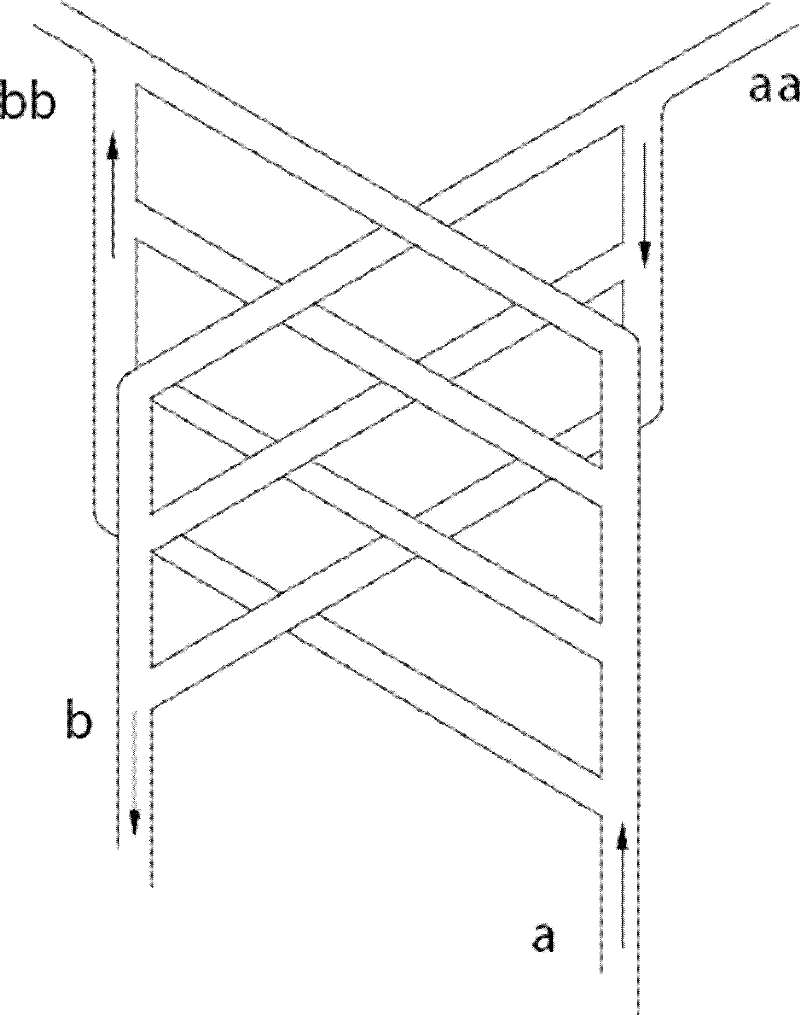

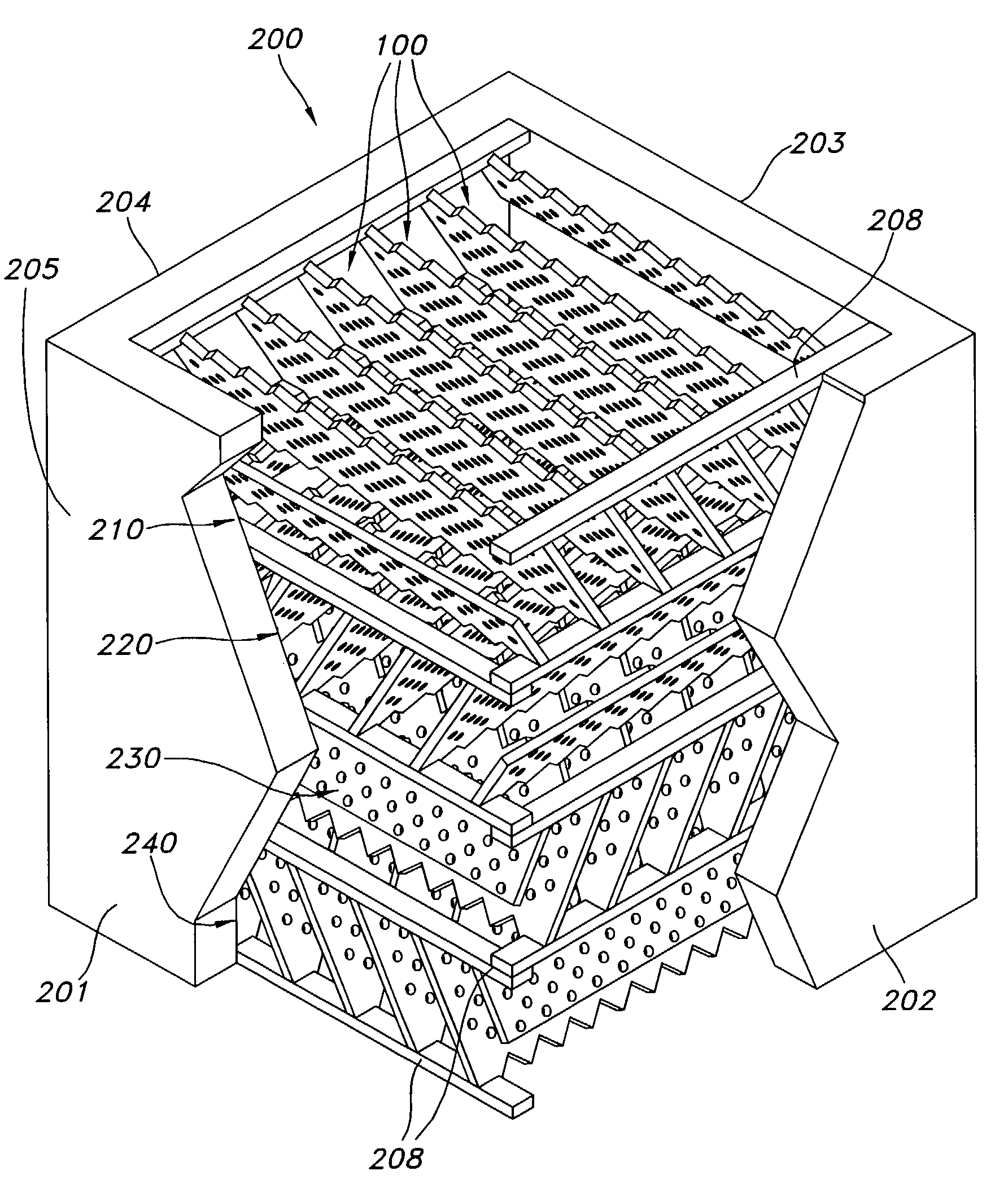

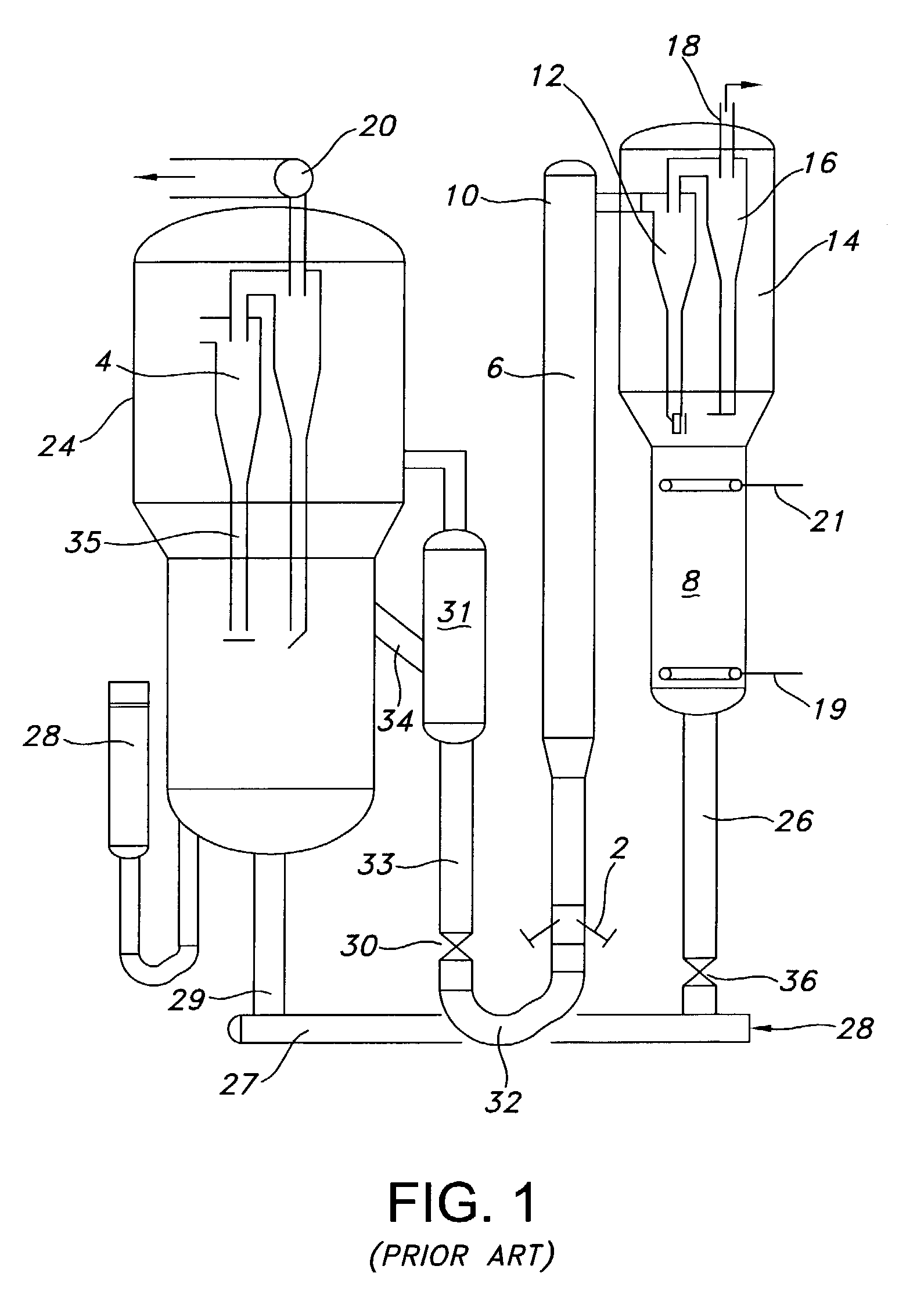

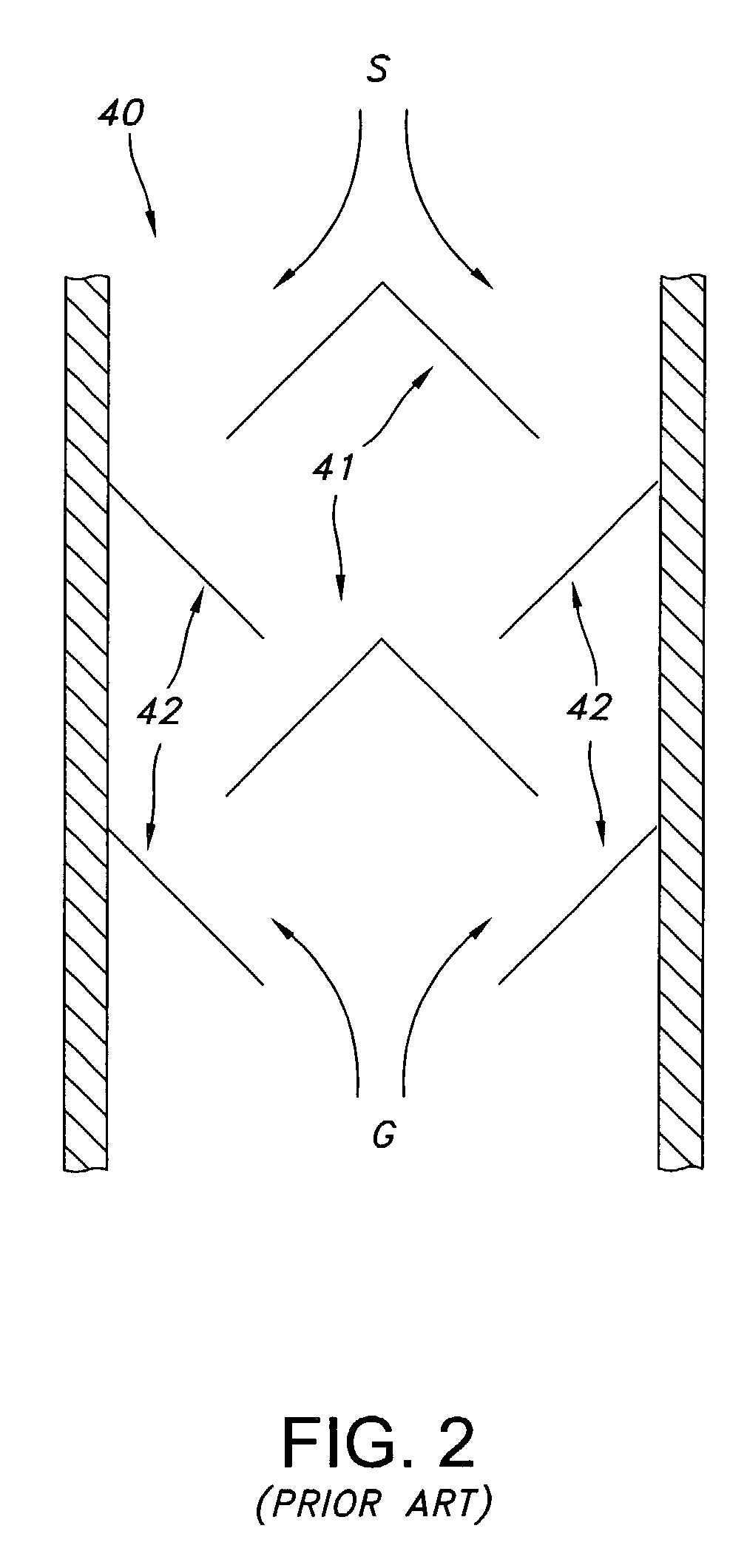

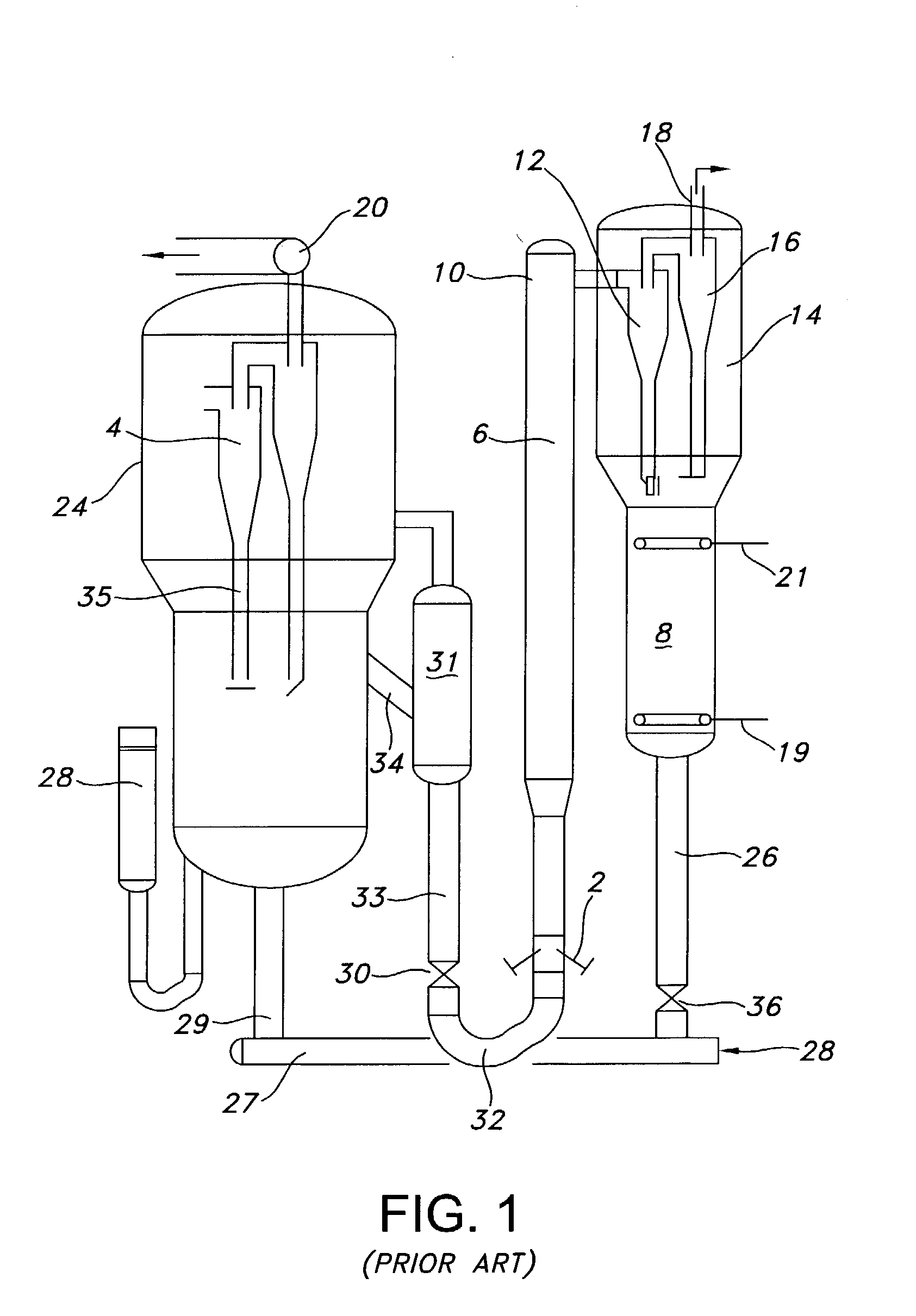

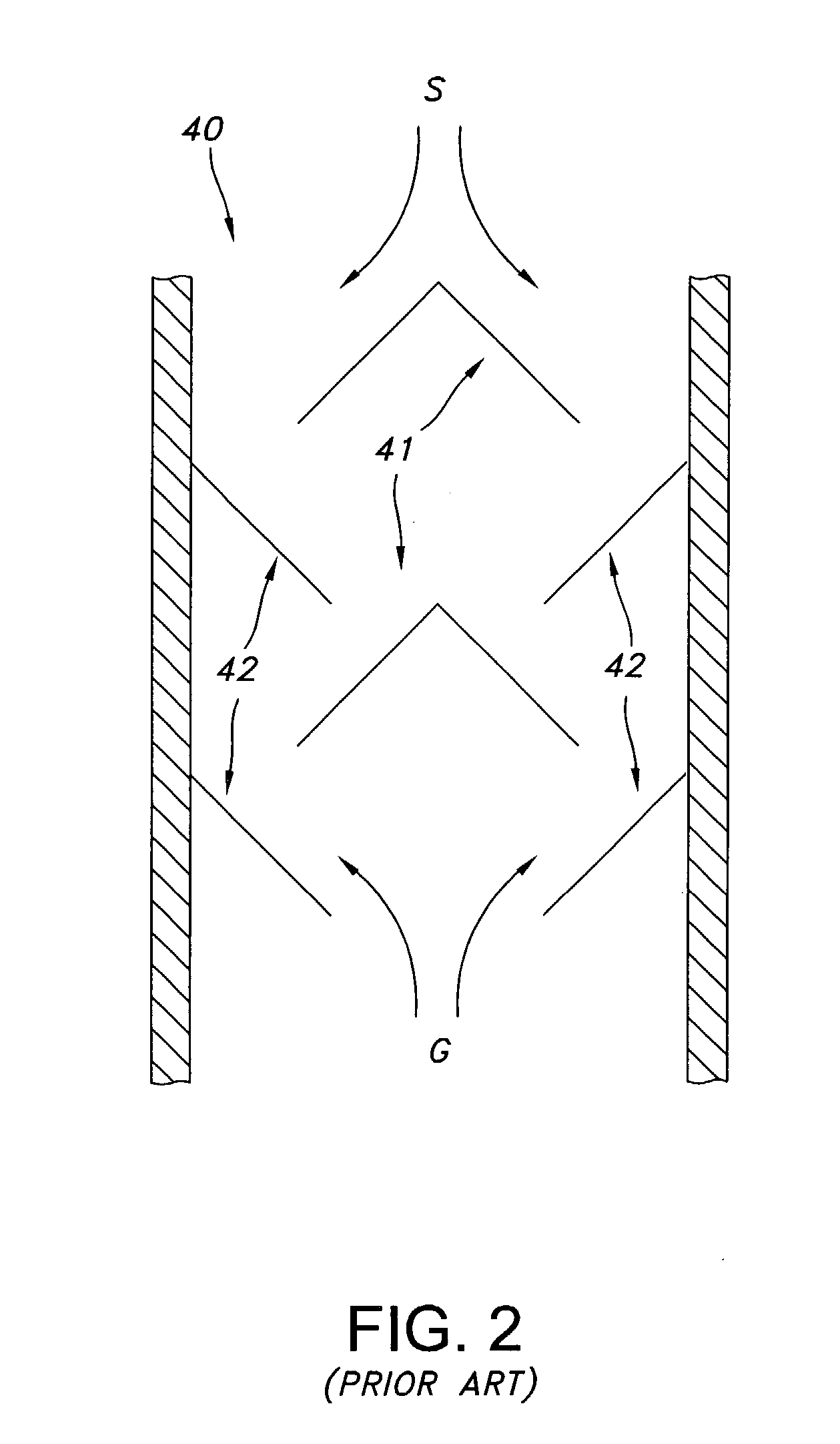

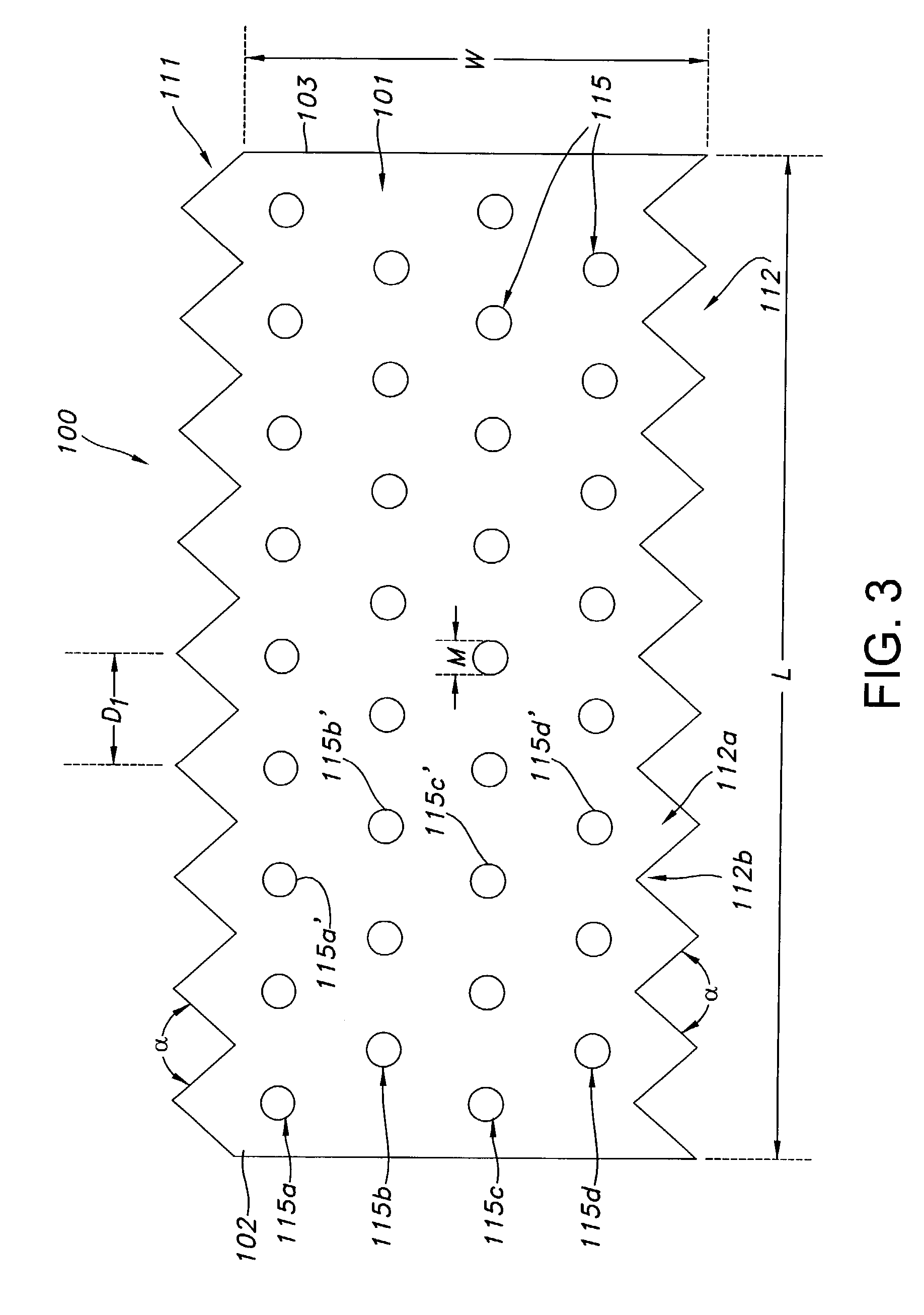

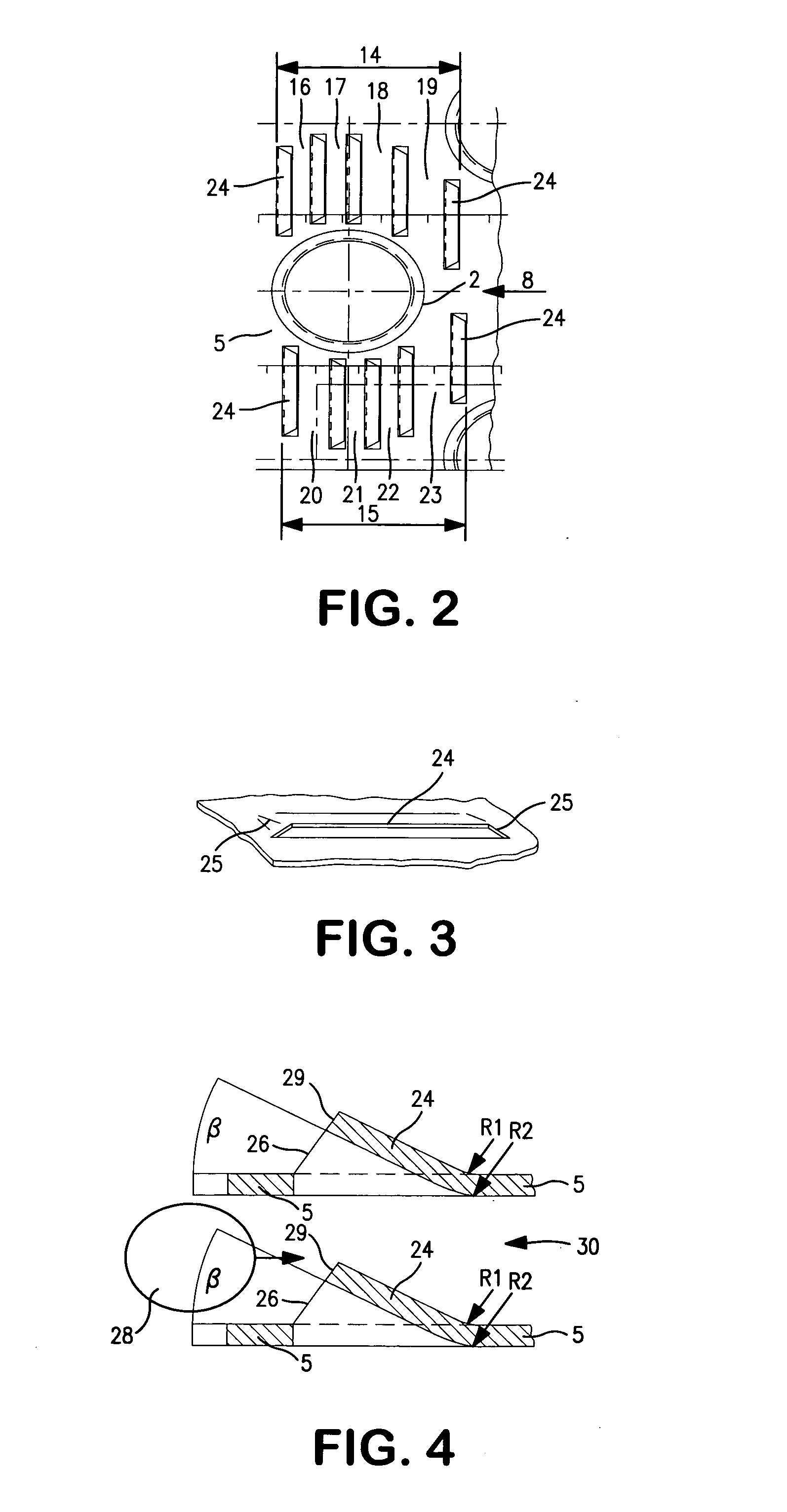

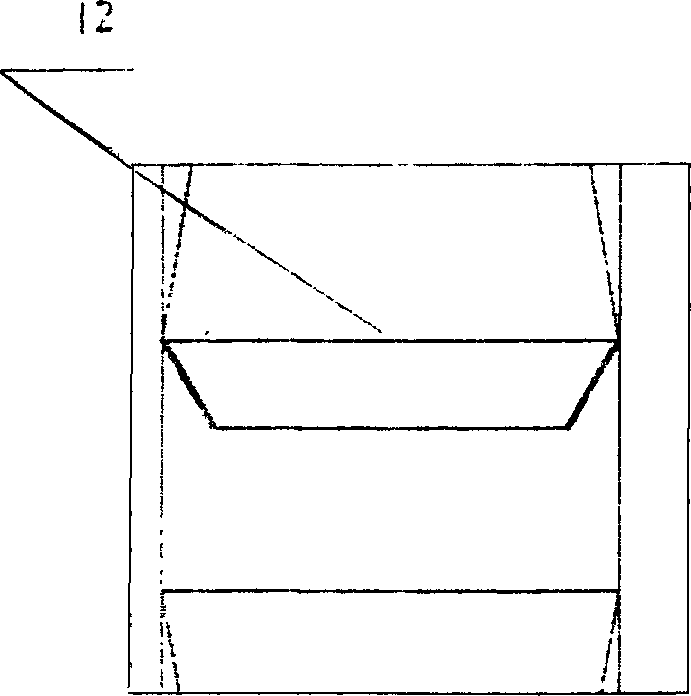

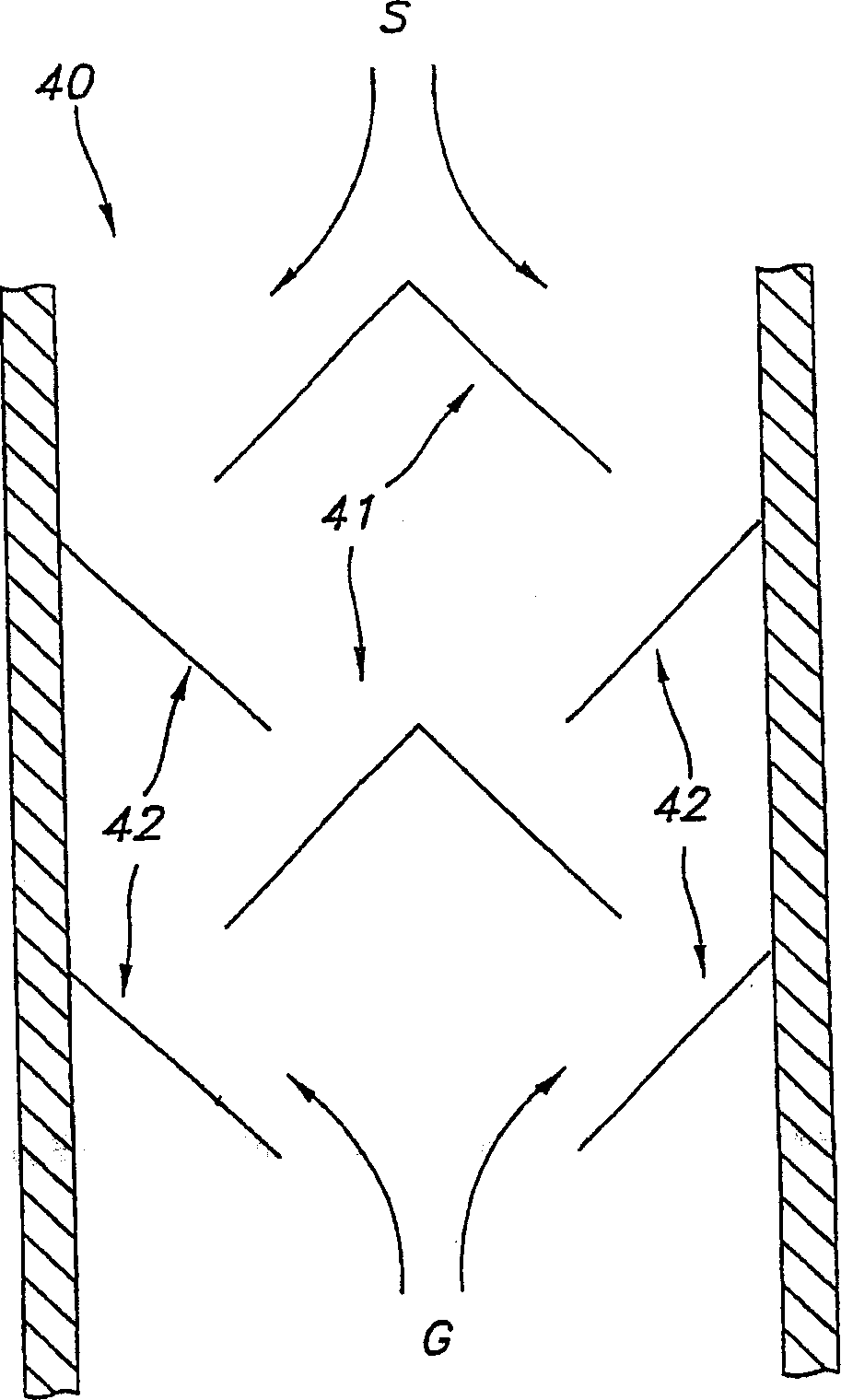

Apparatus for countercurrent contacting of gas and solids

ActiveUS7179427B2Efficient mass transferPrevent channelingCatalytic crackingSynthetic resin layered productsCounter flowSolid particle

An apparatus for the countercurrent contacting of a gas and downflowing solid particles includes a housing and a plurality of baffles positioned within the housing. The baffles are arranged in at least first and second vertically spaced levels in successively lower position, each of the first and second levels including a row of at least two baffles oriented parallel to one another and inclined from horizontal so as to facilitate movement of the solid particles and provide the maximum area for flow. Baffles are oriented so as to laterally shift the direction of downflowing particles transversely as the particles move from one level to the next lower level and avoid channeling of the phases. The number of baffles, length and spacing is optimized to provide maximum interfacial area for interaction between the phases.

Owner:LUMMUS TECH INC

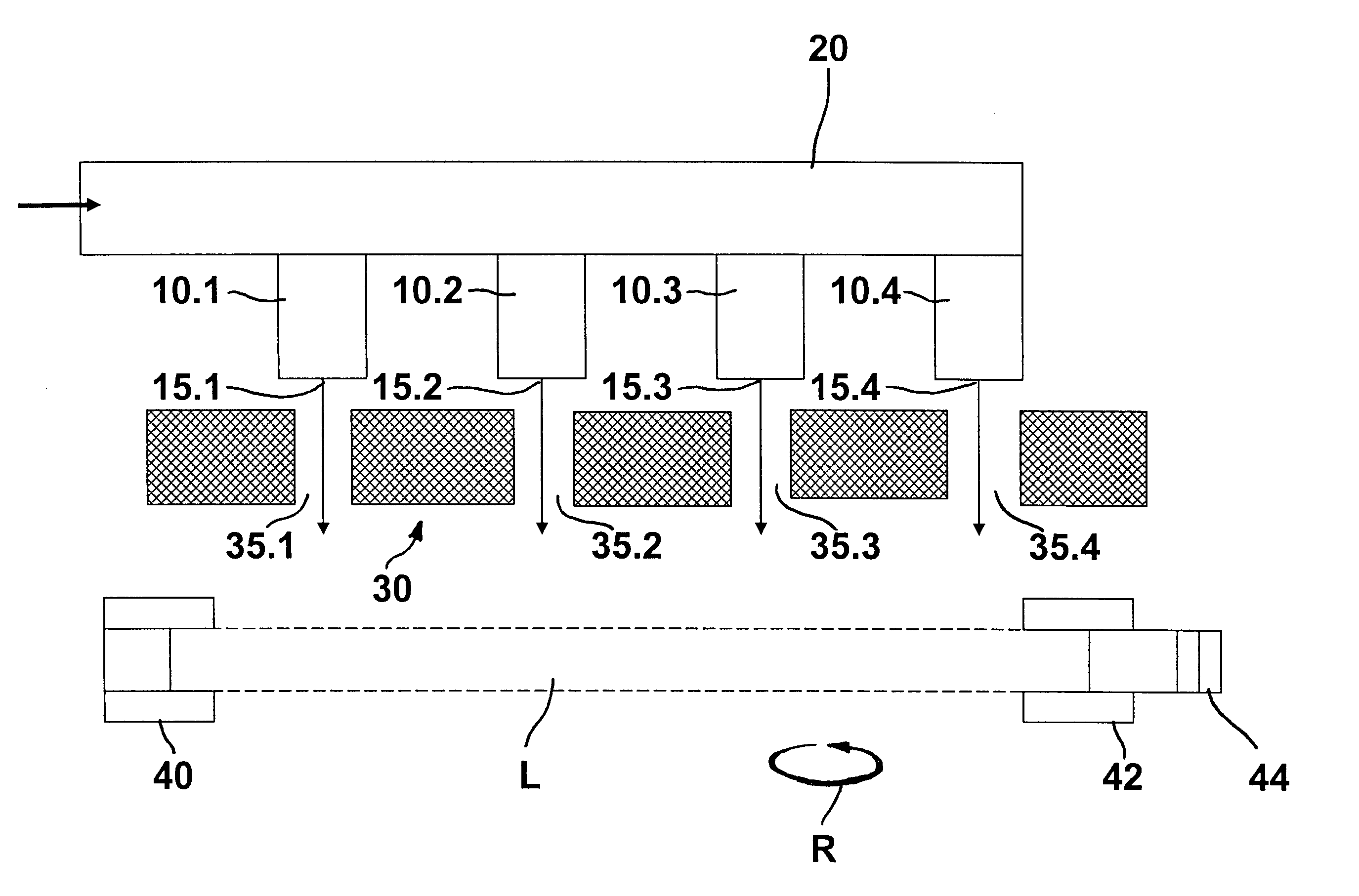

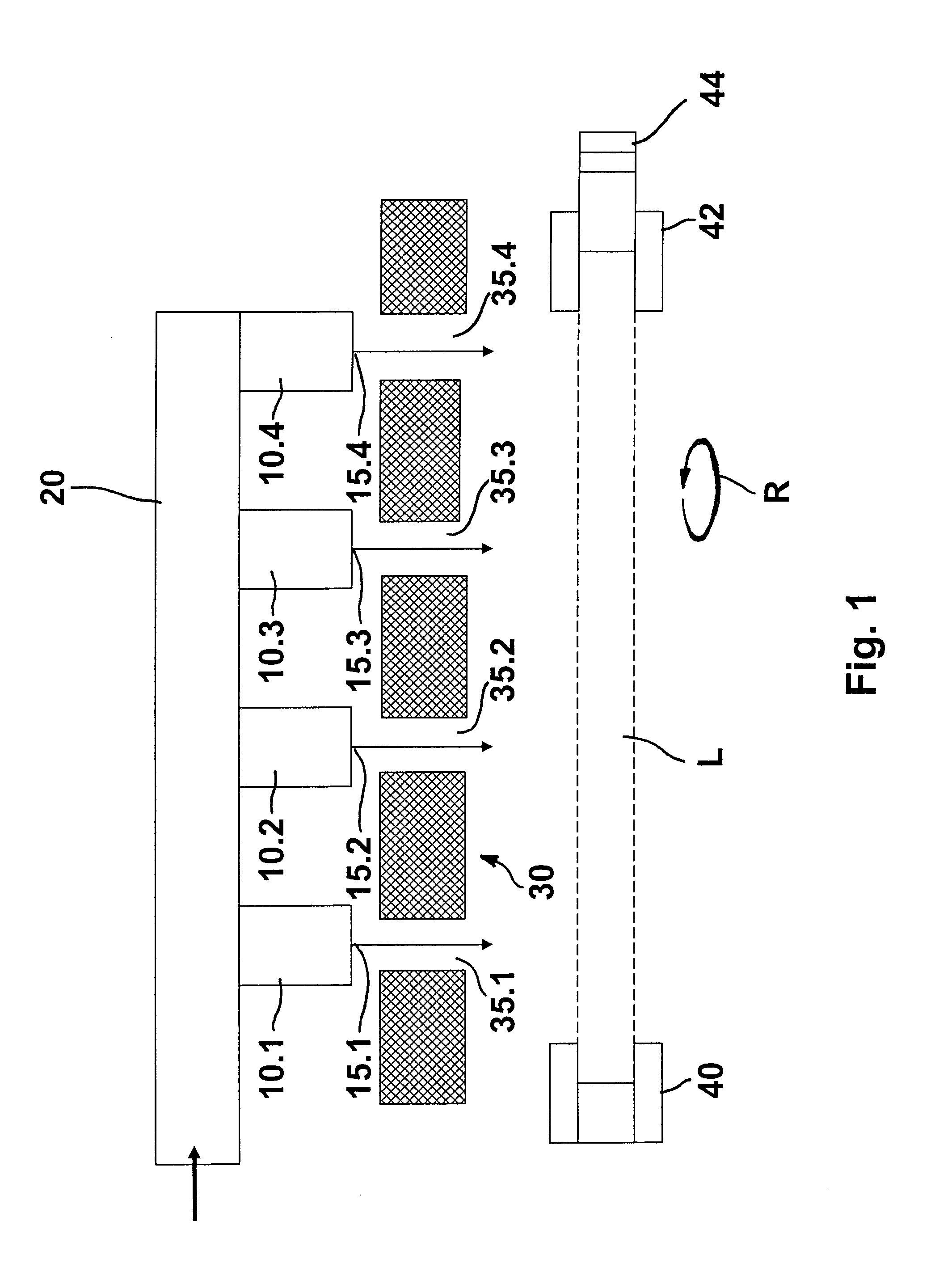

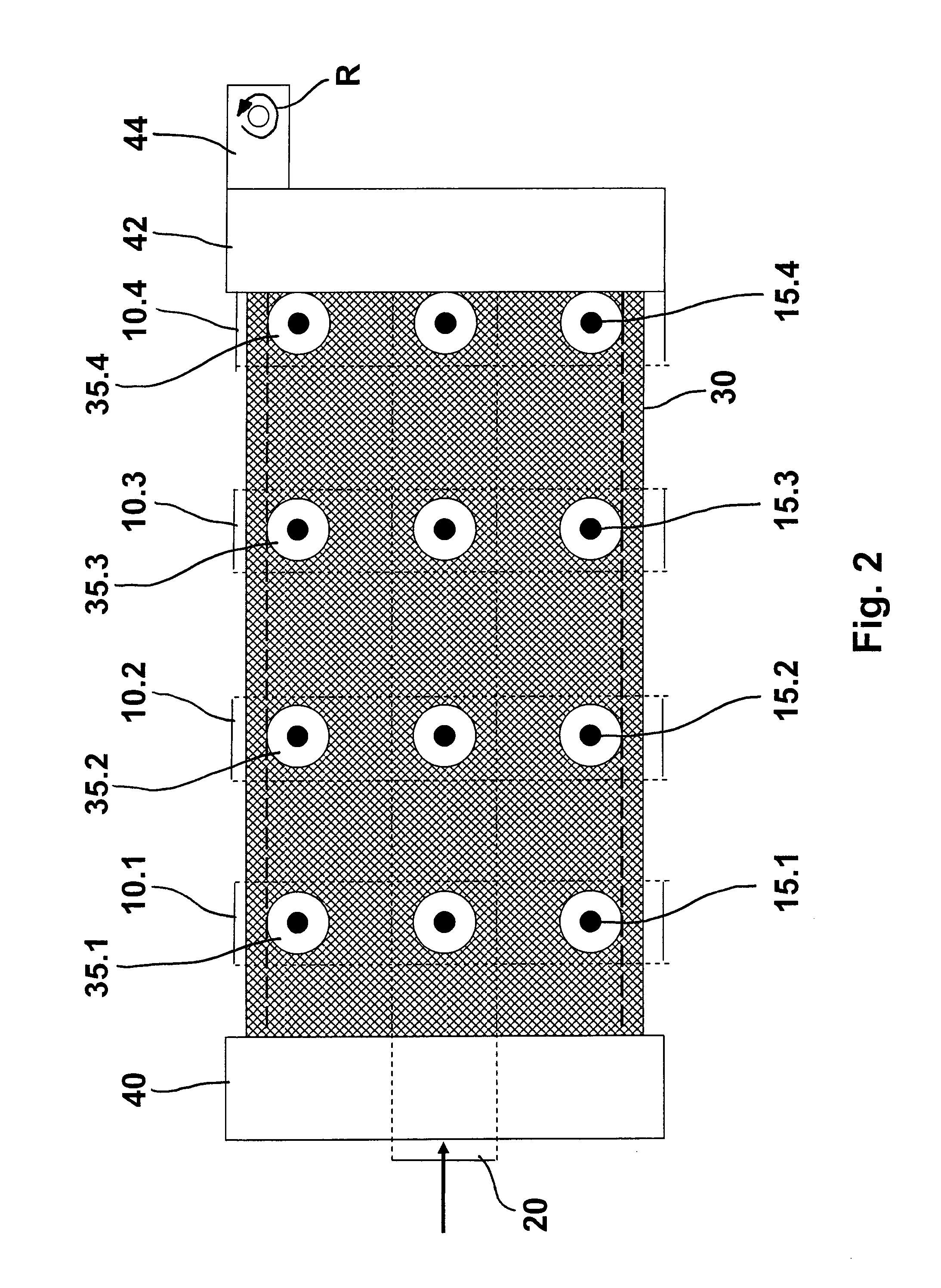

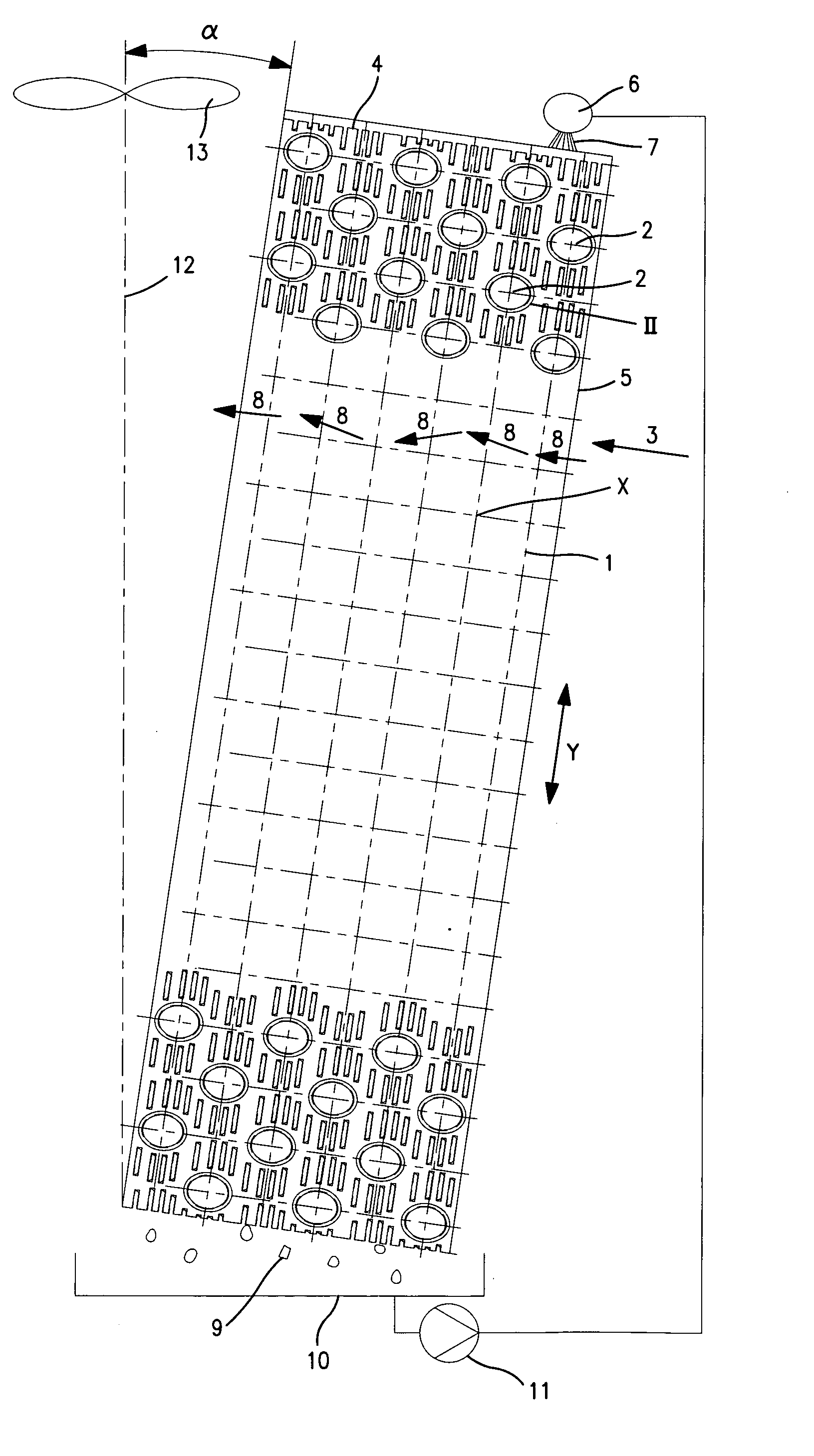

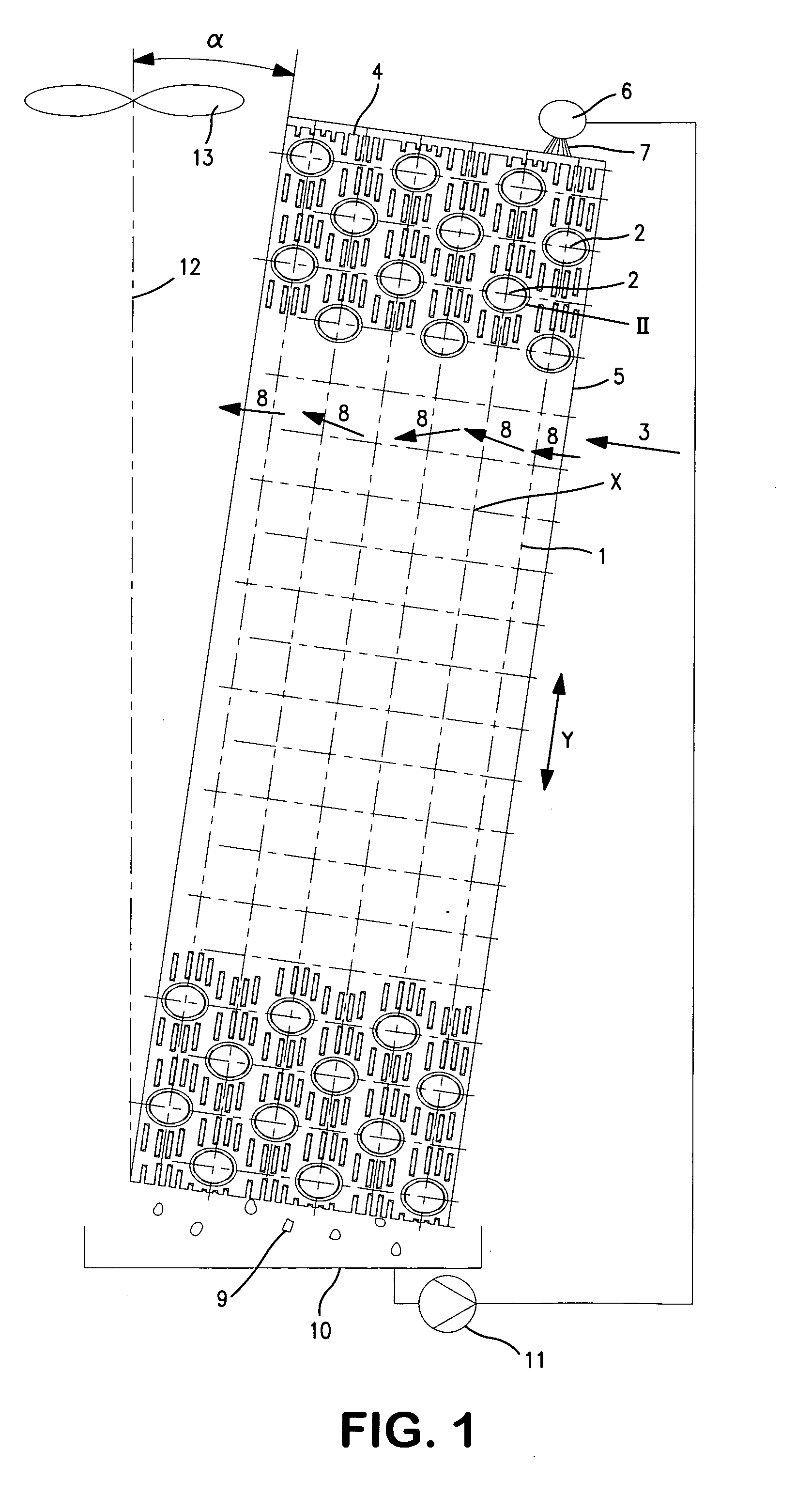

Apparatus and method for the electrolytic treatment of a plate-shaped product

ActiveUS20100176004A1Uniformity in effect of treatmentEvenly distributedAnodisationCellsBiomedical engineeringElectrode

An apparatus for the electrolytic treatment of the product L using a treatment agent is used to make the treatment of a plate-shaped product more uniform. This apparatus includes: devices for retaining 40, 42 the product L in the apparatus, one or a plurality of flow devices 10, which each include at least one nozzle 15 and are disposed situated opposite the product L, one or a plurality of counter electrodes 30, which are inert relative to the treatment agent and are disposed parallel to at least one treatment surface, means for generating a relative movement 44 between the product L, on the side, and the flow devices 10 and / or the counter electrodes 30, on the other side, in at least one direction parallel to a treatment surface. The product L can be immersed into the treatment agent during the treatment.

Owner:ATOTECH DEUT GMBH

Methods for reducing the formation of by-products in the production of recombinant polypepticles

ActiveUS20040101449A1Efficient mass transferPrevent channelingCatalytic crackingFluidised-bed furnacesSolid particleMechanical engineering

An apparatus for the countercurrent contacting of a gas and downflowing solid particles includes a housing and a plurality of baffles positioned within the housing. The baffles are arranged in at least first and second vertically spaced levels in successively lower position, each of the first and second levels including a row of at least two baffles oriented parallel to one another and inclined from horizontal so as to facilitate movement of the solid particles and provide the maximum area for flow. Baffles are oriented so as to laterally shift the direction of downflowing particles transversely as the particles move from one level to the next lower level and avoid channeling of the phases. The number of baffles, length and spacing is optimized to provide maximum interfacial area for interaction between the phases.

Owner:LUMMUS TECH INC

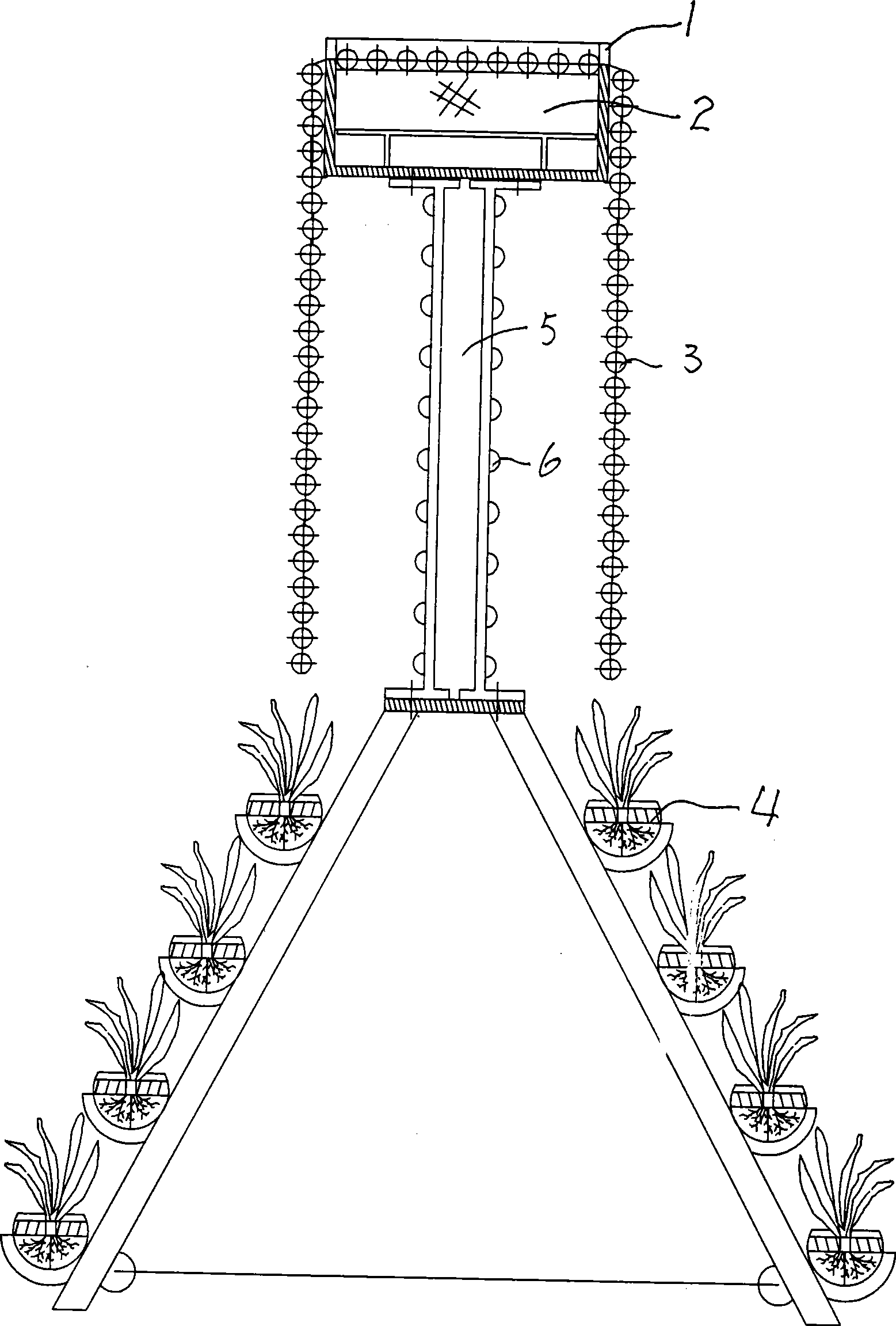

Photocatalysis-plant cooperated water purifying method for pisciculture water

InactiveCN101475282ASolve the accumulationRelease fullyWater/sewage treatment by irradiationEnergy based wastewater treatmentGlass ballPhotocatalytic reaction

The invention relates to a photocatalysis-plant synergy water purifying method for fish-farming water, which comprises the following steps that: 1) sewage in a fish pond is pumped into a filter tank by a diving pump, solid impurities are filtered by sponge foam, and the intercepted solid impurities are discharged by a blowdown valve; 2) clear water filtered by sponge foam falls into a nacreous glass catalytic reaction curtain which is vertically hung on the side wall of the filter tank to contact and react with a photocatalysis material, wherein the nacreous glass catalytic reaction curtain is formed by connecting glass balls in series and in parallel, and the surfaces of the glass balls are burnt and plated with a TiO2 series catalytic material; and 3) the catalyzed water falls into a plant culture tank; and the water flows into the fish pond after pollutants in the water are reduced. The method has the advantages of good natural light transmission, high mass transfer efficiency, no oxygen supplement and nitrogen release power consumption and no blockage, and the practical characteristics of low cost and continuous work. Except for the water pollution treatment for circulating water fish-farming, the method can also be applied to low concentration water treatment of the occasions of environmental protection, civicism, landscape greenbelts and the like.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI +1

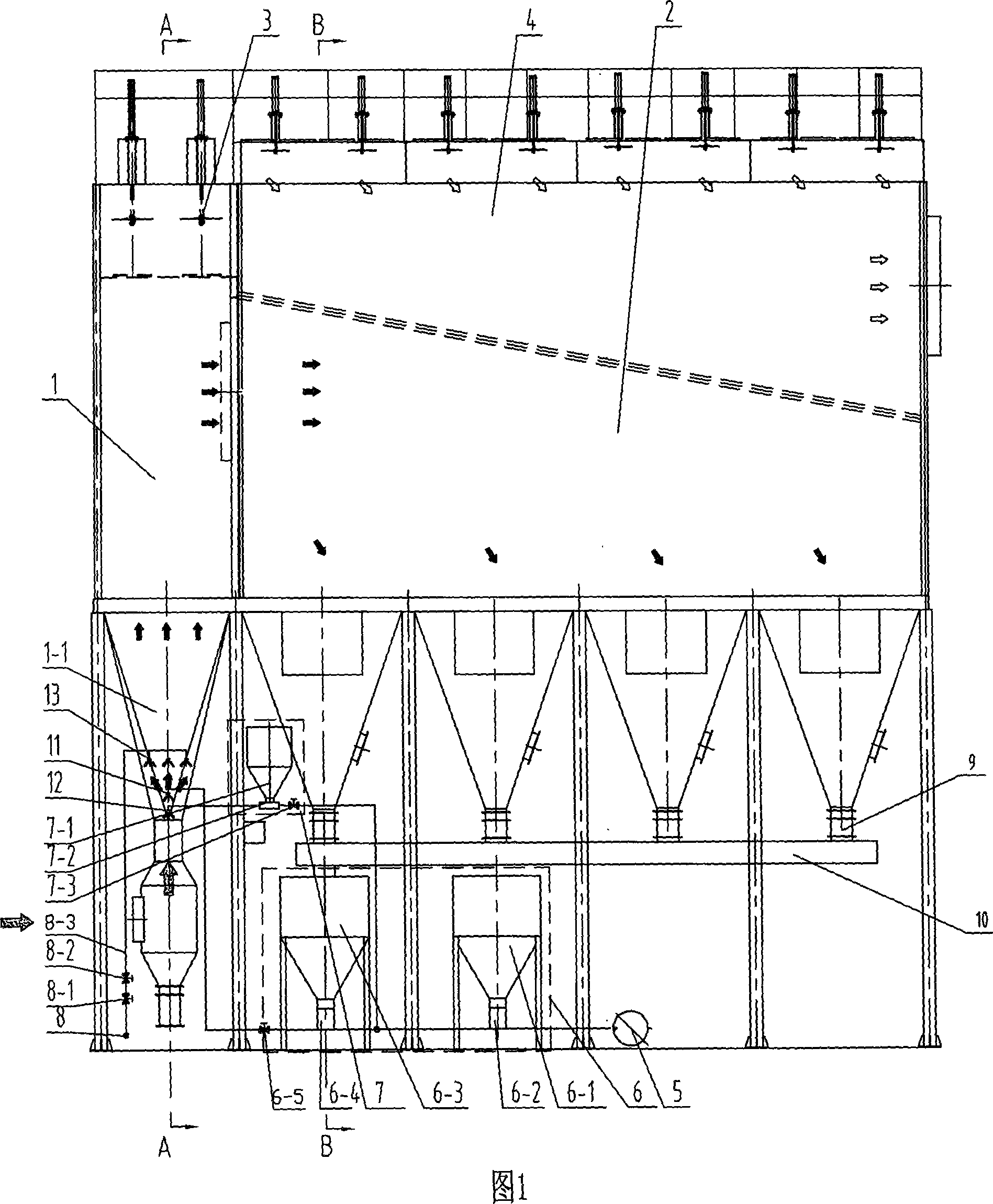

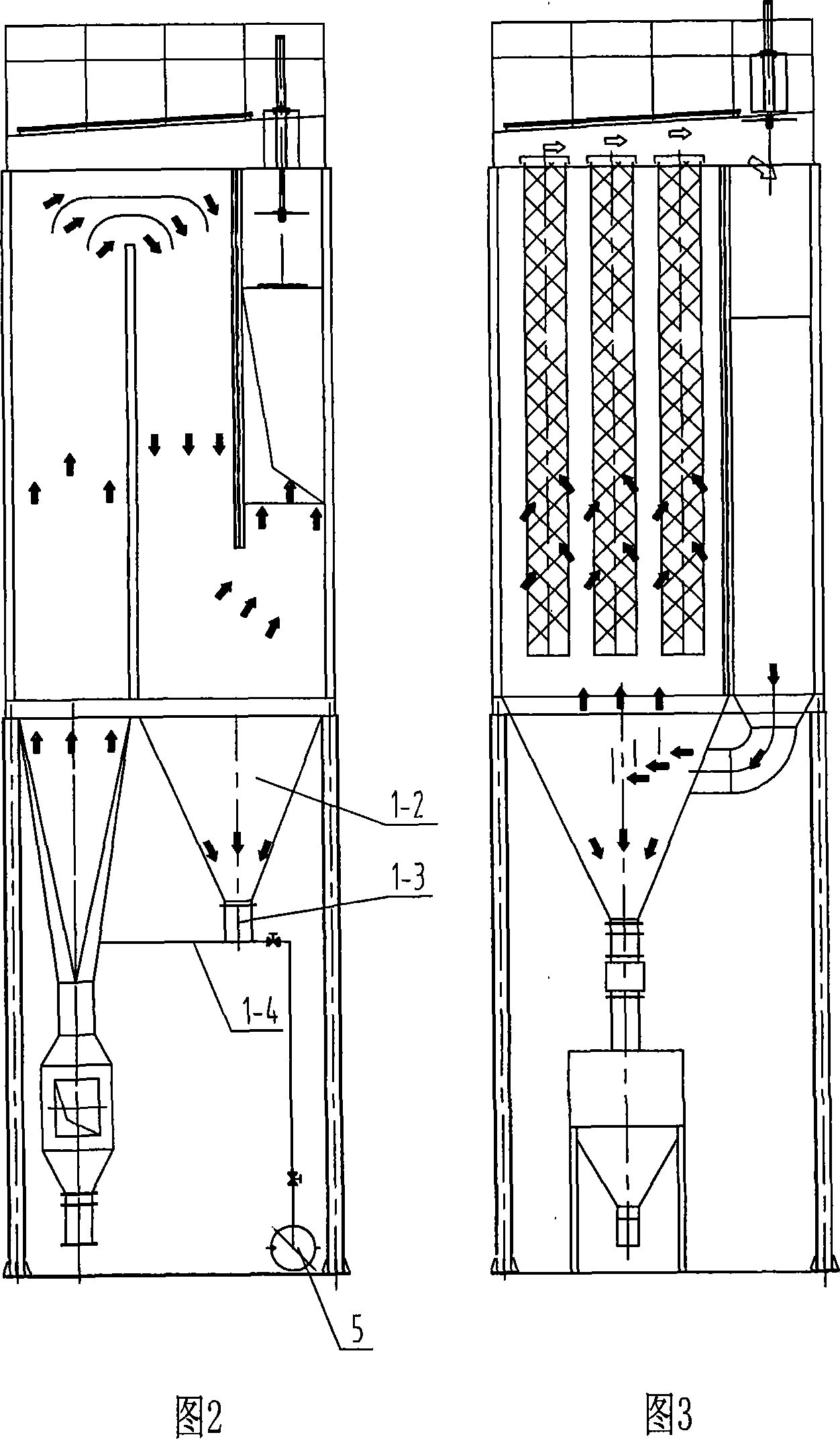

Method and device for treating solid waste burning tail gas

ActiveCN101099921ACompact structureSmall footprintCombination devicesLighting and heating apparatusToxic gasBaghouse

The present invention relates to tail gas treating process and apparatus, and is especially process and apparatus for treating high temperature fume containing acid gas, heavy metal, dioxin and other toxic gas from incinerating solid waste. The treating process includes the first reaction of the high temperature fume with deacidifying agent, active carbon and atomized water to eliminate toxic gases, and the subsequent reaction in a bag-type dust remover with one emergency passage for reaching high waste gas treating effect. The apparatus for treating high temperature fume has simple structure, low cost, low running expense, and long service life.

Owner:CHANGZHOU XINWU MACHINERY

Composite filler tower for extracting oil-water system

InactiveCN101073713AImprove mass transfer efficiencyEfficient mass transferLiquid solutions solvent extractionChemical industryOil water

The invention is concerned with a kind of extractive complex filling tower to oil-water system as the equipment for liquid-liquid mass transfer during the chemical industry production. The tower relates to fine part, heavy phase filling part, filling part, light phase filling part and settlement part from up to down. The filling part has at least two group complex filling units and each group complex filling unit has A, B and C filling layers from up to down. The A, B and C filling layer are all wave filling made up of more than two wave plates. The filling part of the tower uses filling with different structure to carry crash-assemble-speedup-crash again of the dispersed phase and it will enhance the mass transfer efficiency of extraction course.

Owner:TIANJIN UNIV

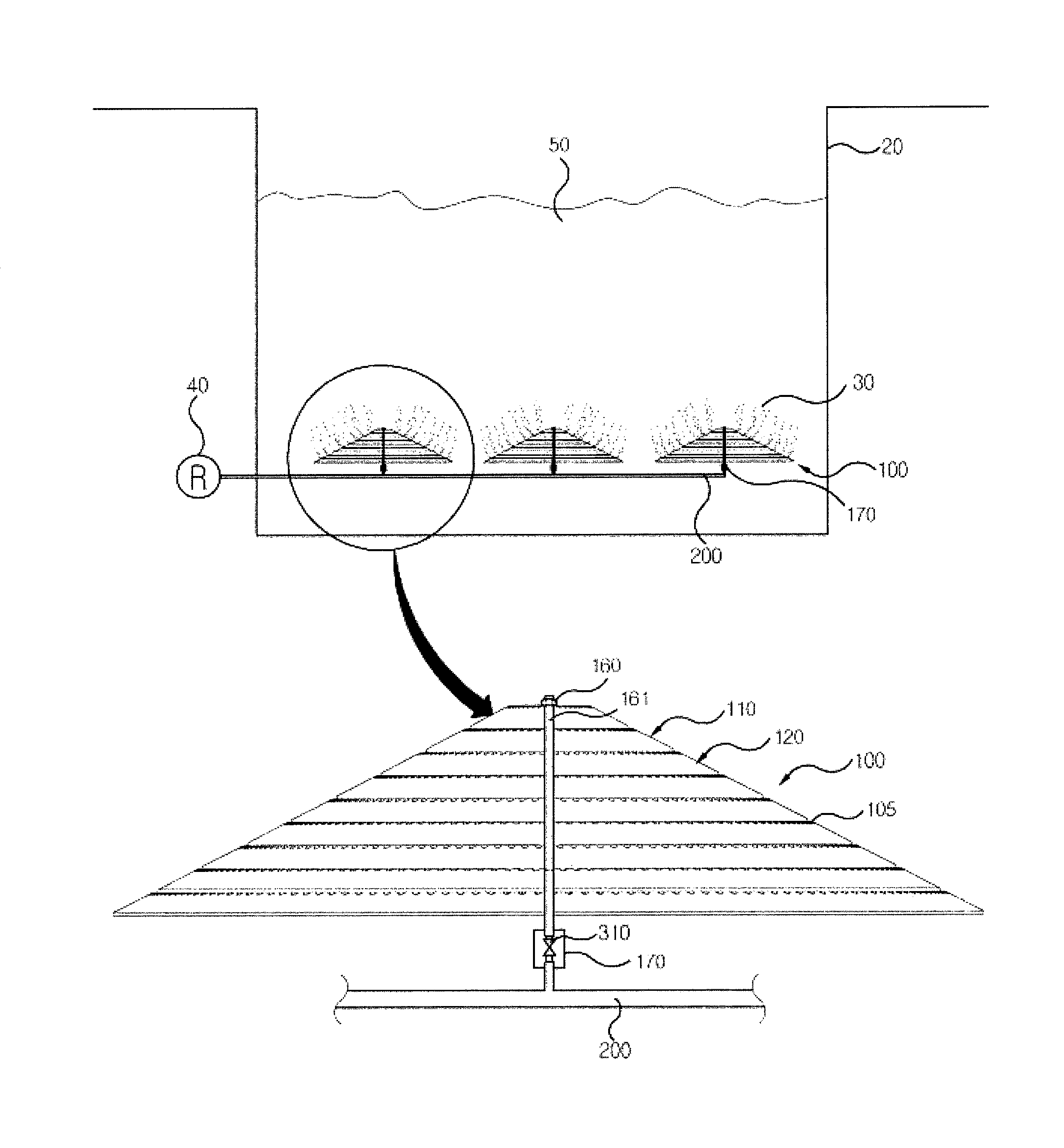

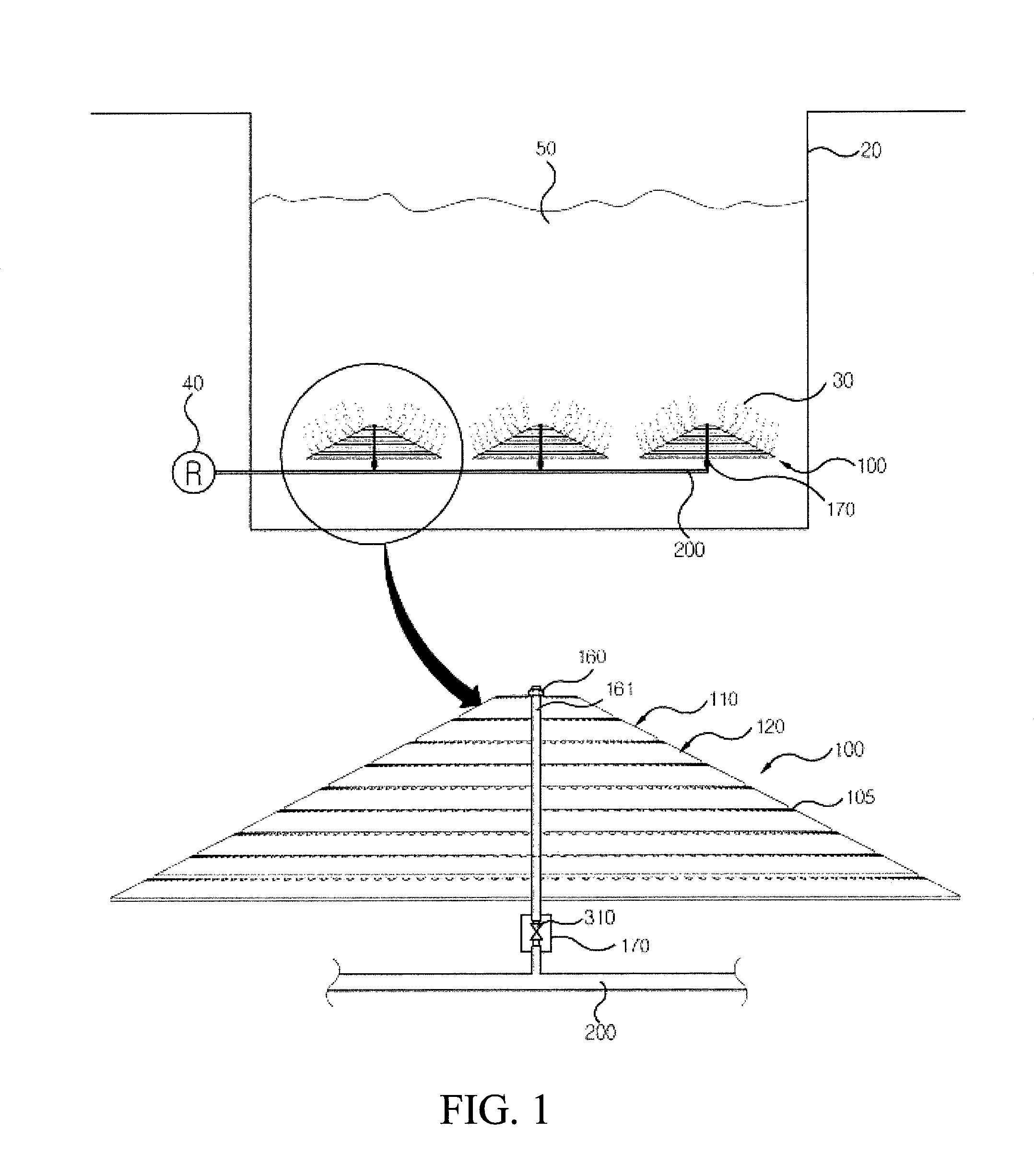

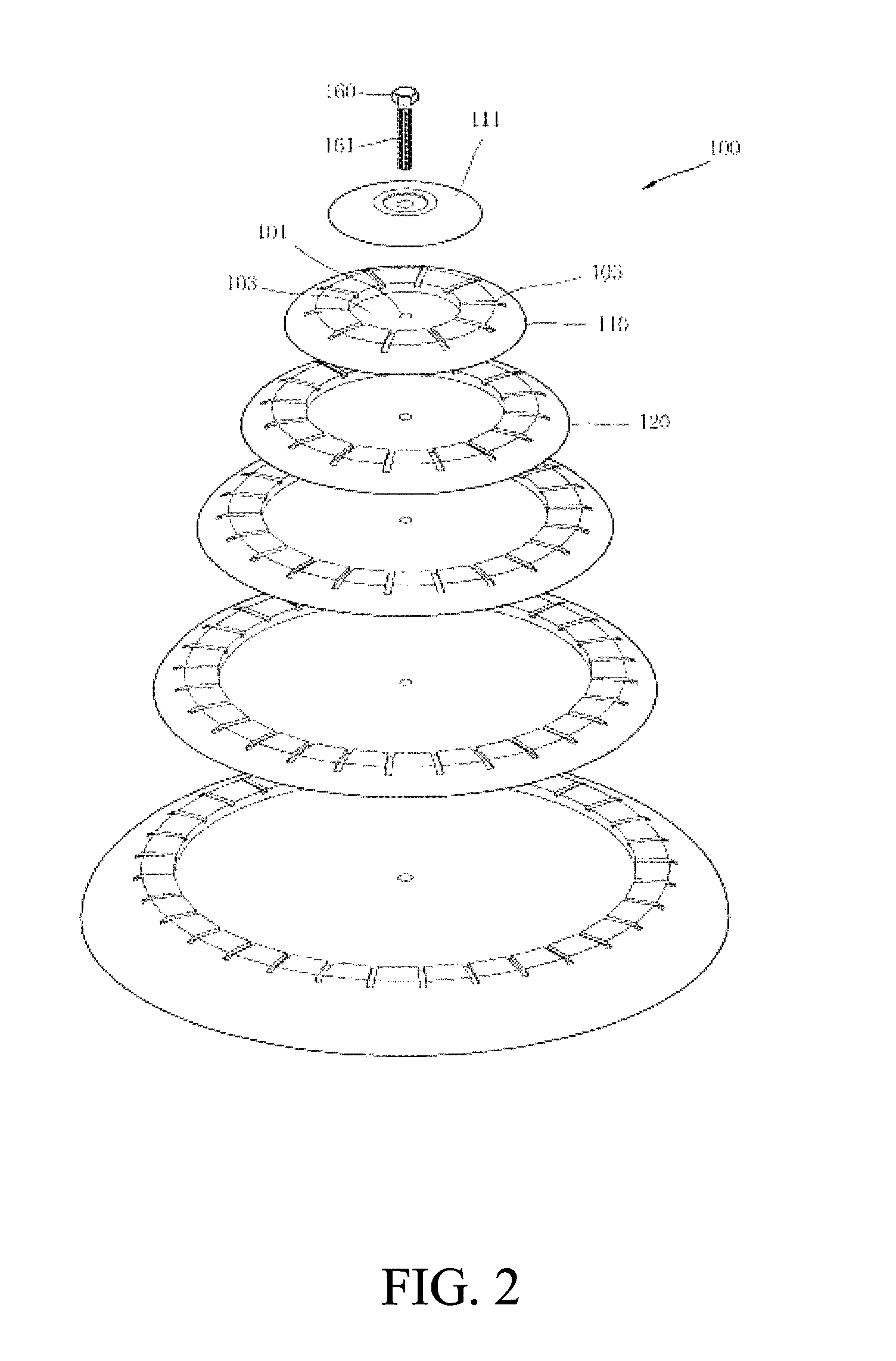

Multi-disc air diffuser

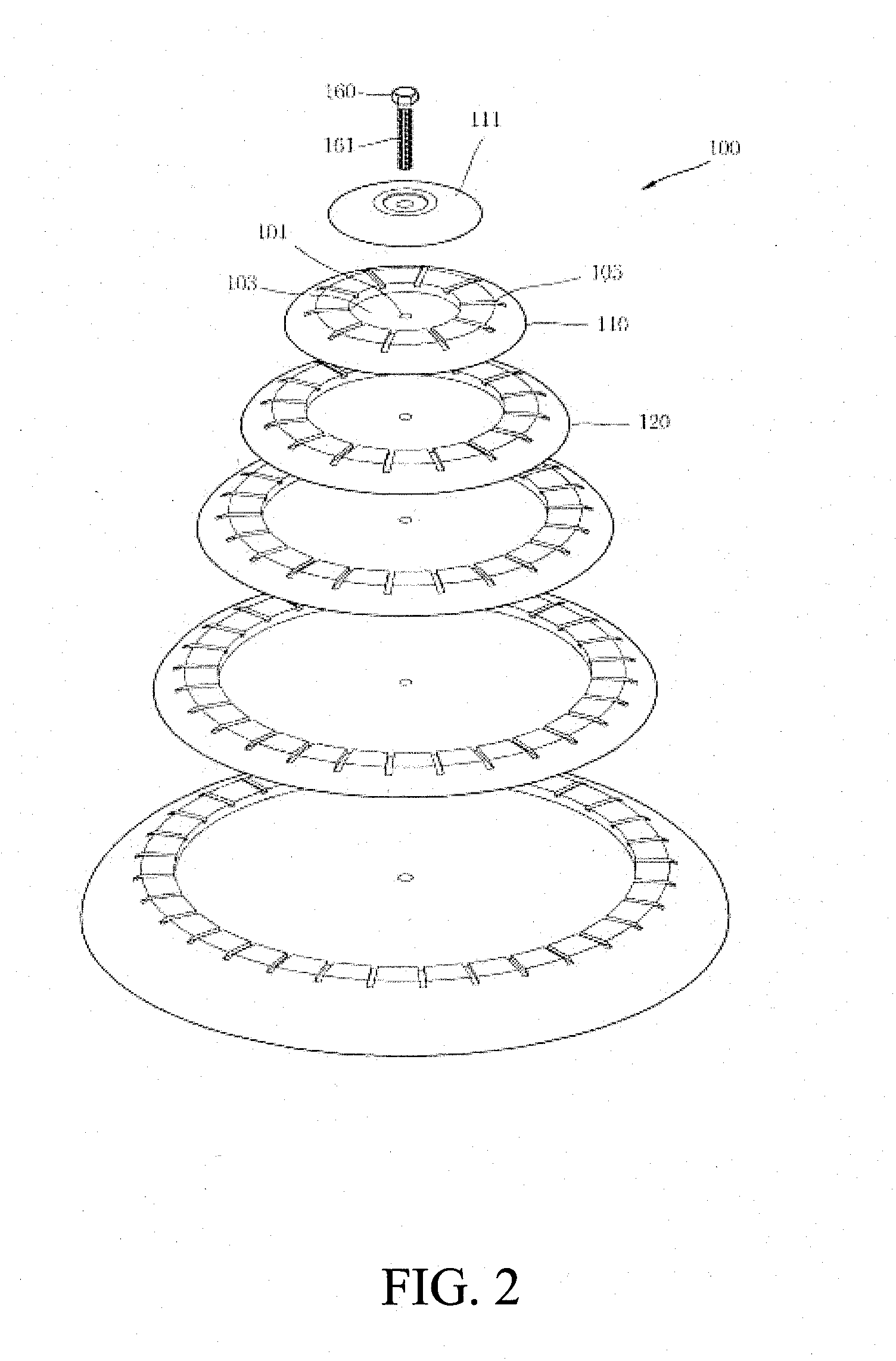

InactiveUS20110304063A1Increase contact areaPrevent nozzle cloggingUsing liquid separation agentMixing methodsCheck valveNozzle

A multi-disc air diffuser according to the present invention comprises a bolt having a vent groove formed in a longitudinal direction thereof; a plurality of discs, each of the discs having a bolt joint section to be passed through the bolt, an air room for holding the air supplied through the vent groove, and a nozzle section having a plurality of nozzles which are arranged in an end part of the air room at a regular size and intervals, wherein the lower surface of each of the discs is more than the upper surface thereof and the outer circumference surface of each of the discs is formed to be inclined; and a backflow prevention section for joining to an end part of the bolt to adhere closely the discs to one another, connecting the vent groove to an air supply pipe, and having a check valve to prevent the air flowing backward from the vent groove to the air supply pipe.

Owner:ANT21

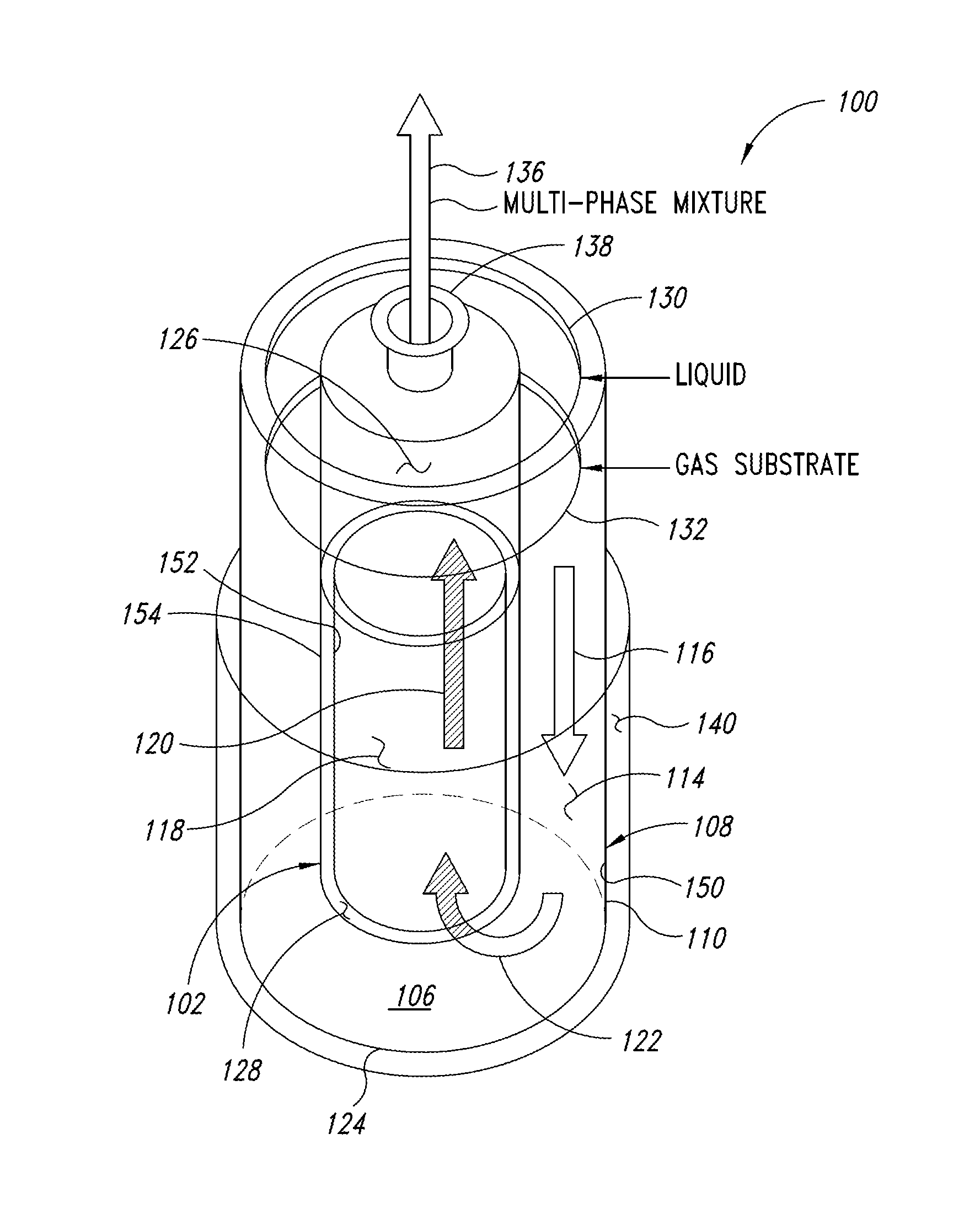

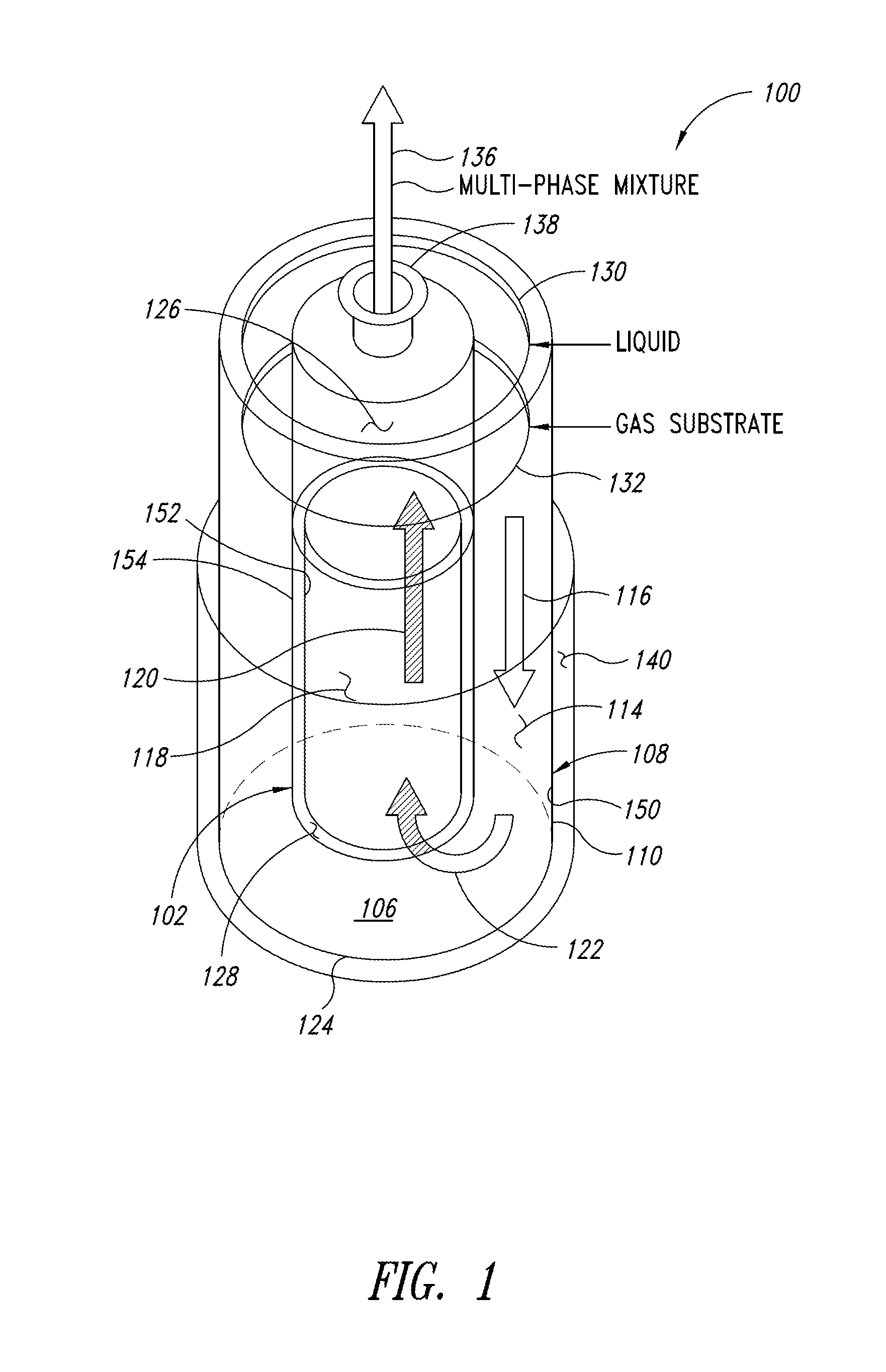

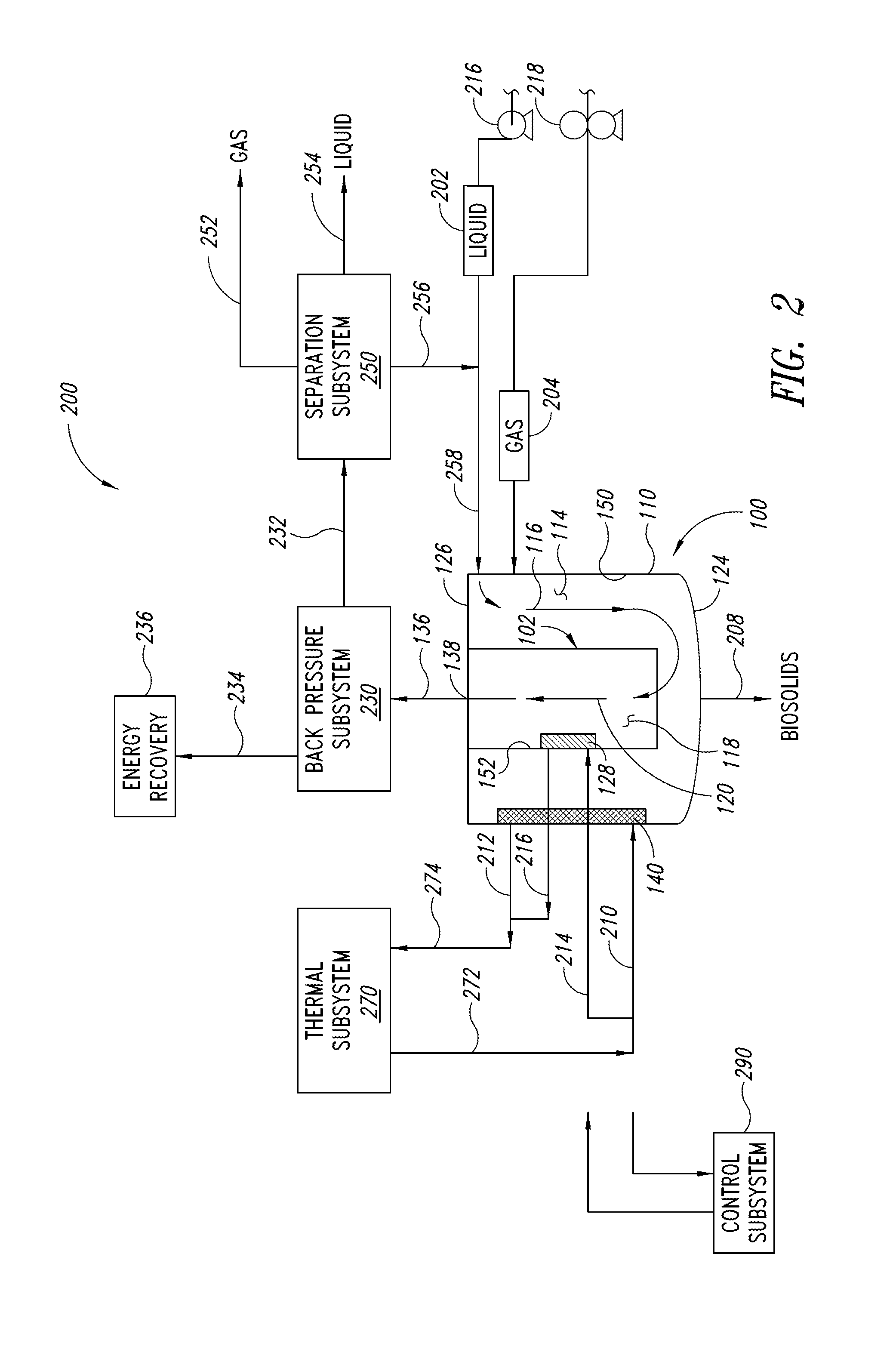

Gas-fed fermentation systems

ActiveUS20150259639A1Efficient mass transferDesigned can be scalableBioreactor/fermenter combinationsBiological substance pretreatmentsLiquid mediumProduct gas

Owner:CALYSTA

Bioreactor

ActiveCN101709266ACompatible with growing conditionsEligible for trainingTissue/virus culture apparatusPeristaltic pumpMetabolite

The invention relates to a bioreactor, which is formed by serially connecting a reciprocating-rotation cell culture tank assembly module (104), a gas-dispersion control assembly module (102) and a liquid flow direction control assembly module (103) through a cell culture solution circulation pipeline. A carrier suspension conglutinated with cells is injected into a cell culture tank of a reciprocating bioreactor, and along with the rotation of a step motor and a double-headed peristaltic pump in the liquid flow direction control assembly module, the output of a preceding state hemodialysis unit or a culture solution in a culture solution container enters the circulation pipeline. When the culture solution reaches a dialysis column (301), a corresponding gas is diffused into the culture solution. Then, the culture solution with the corresponding gas is sent into the cell culture tank. After the exchange of substance with cells in the culture tank, the culture solution containing metabolites of cultured cells is sent back into the preceding state hemodialysis unit or the culture solution container through an output port of the cell culture tank and the culture solution circulation pipeline.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

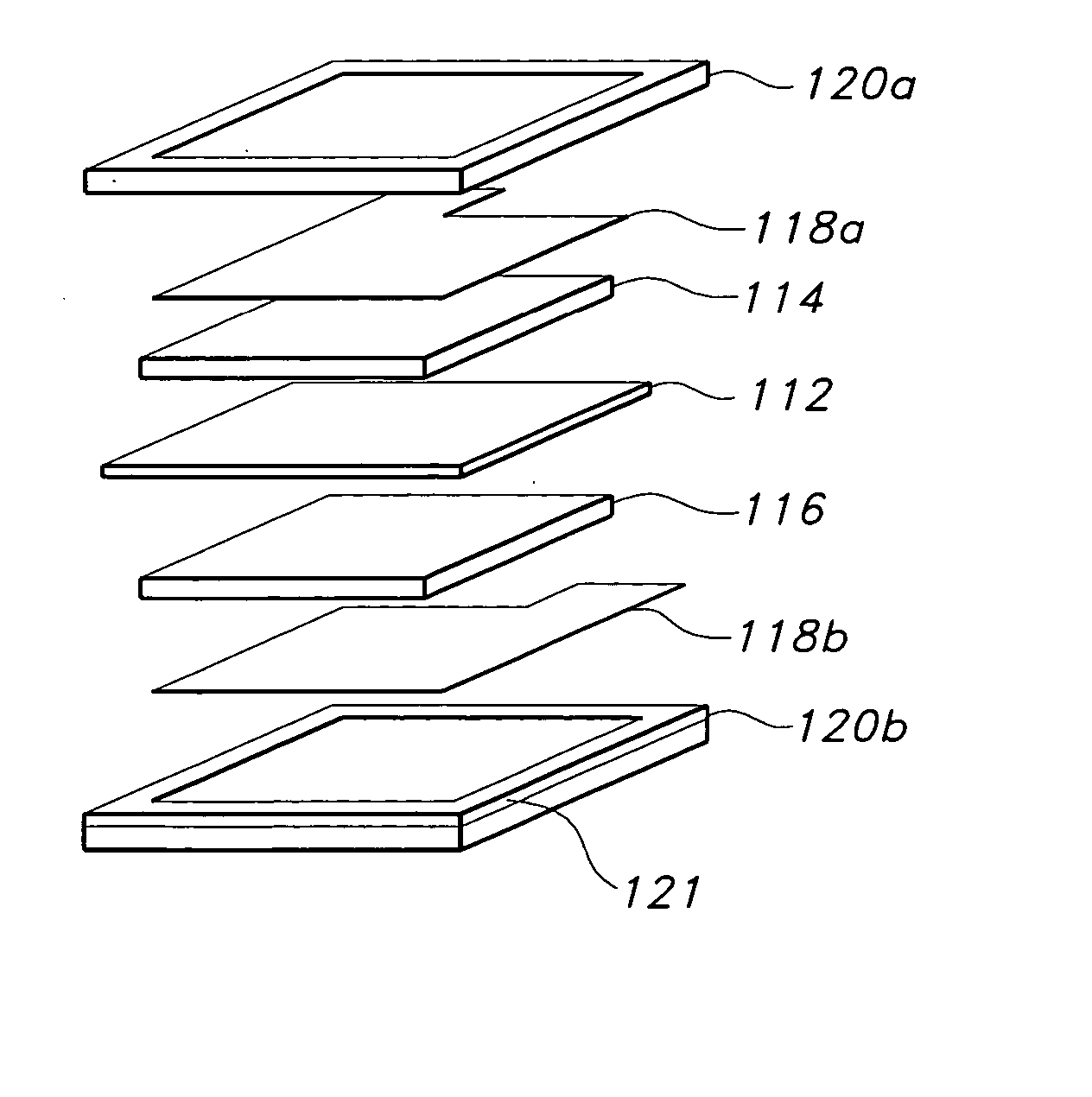

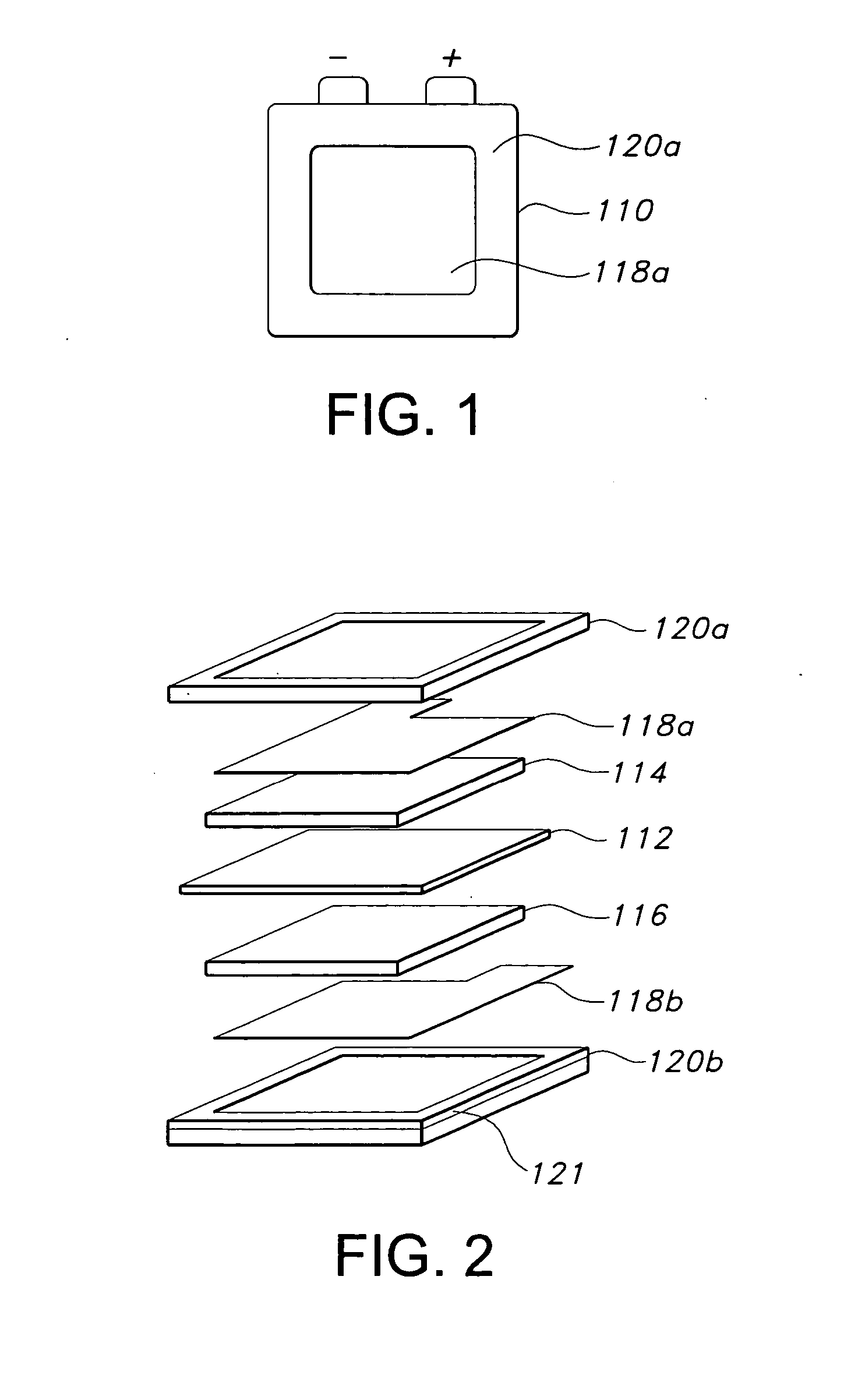

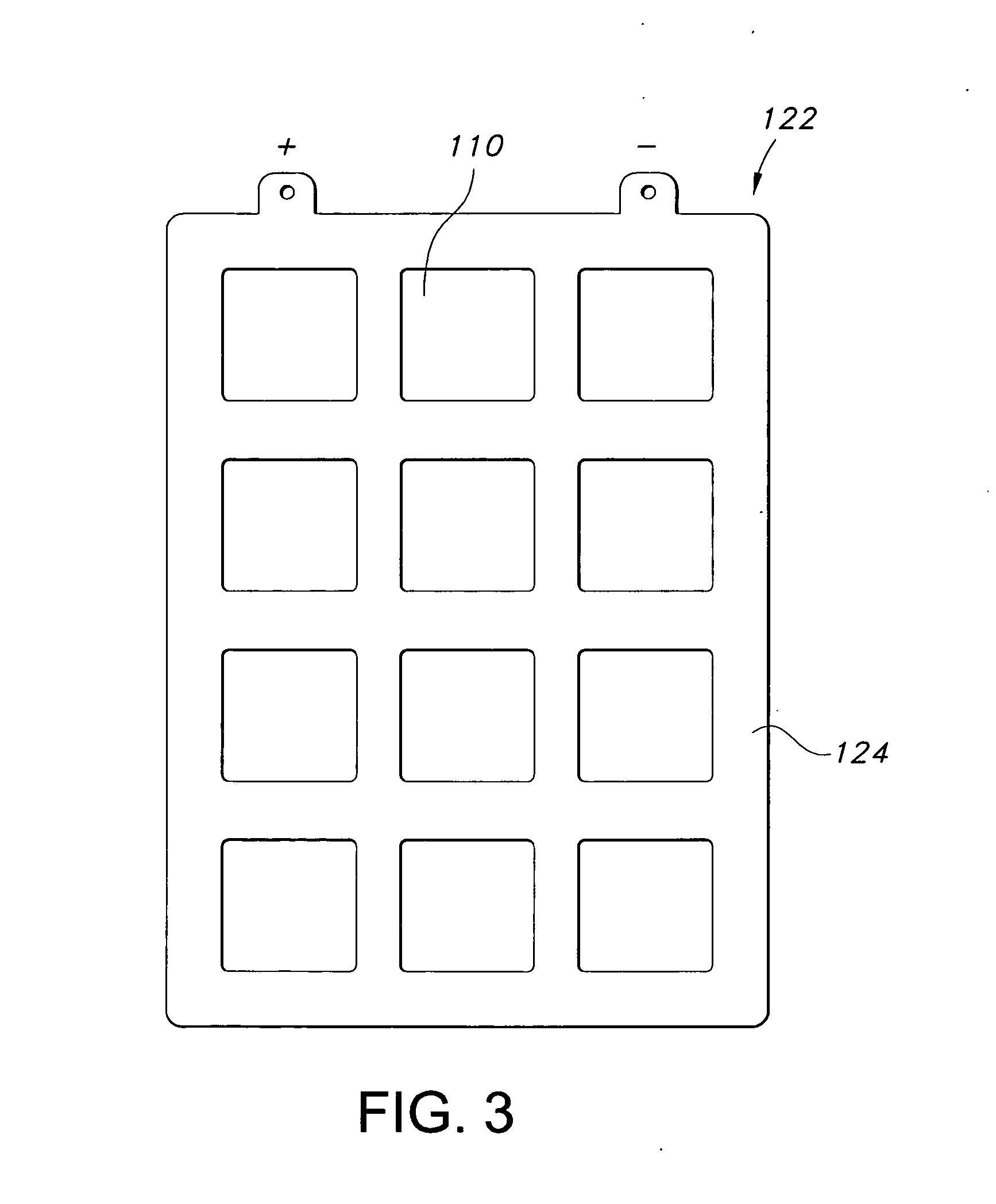

Planar fuel cell stack and method of fabrication of the same

InactiveUS20060286436A1Reduce internal contact resistanceReduce layeringFuel cells groupingPrimary cellsFuel cellsAtmospheric air

The present invention provides a system and method for forming an air breathing fuel cell that includes an air permeable cathode layer positioned to be in contact with atmospheric air and an electrically conductive, fuel permeable anode backing layer positioned to be in contact with a mixture of fuel and water, wherein the anode and cathode layers are divided by a pre-swollen electrolyte membrane, and the anode and cathode layers are in contact with electrical current collecting members. The present invention also provides a fuel cell stack consisting of fuel cells of the present invention arranged in a grid-like format within a support frame that is configured to provide electrical connections between the fuel cells.

Owner:UNIV OF CONNECTICUT

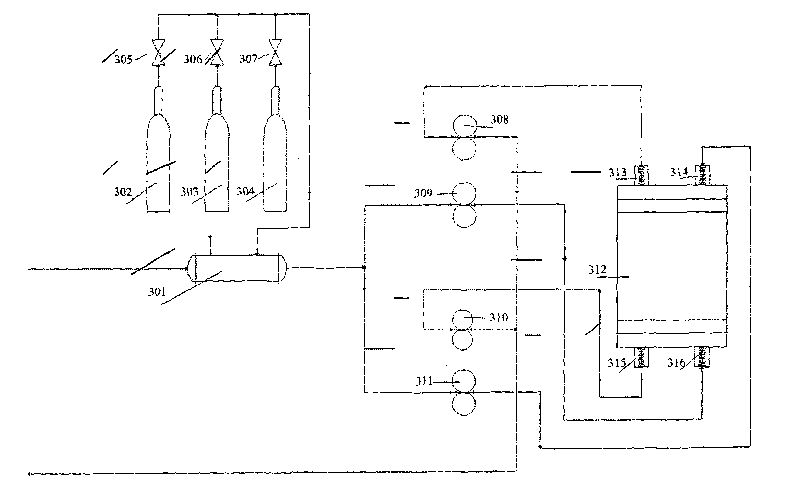

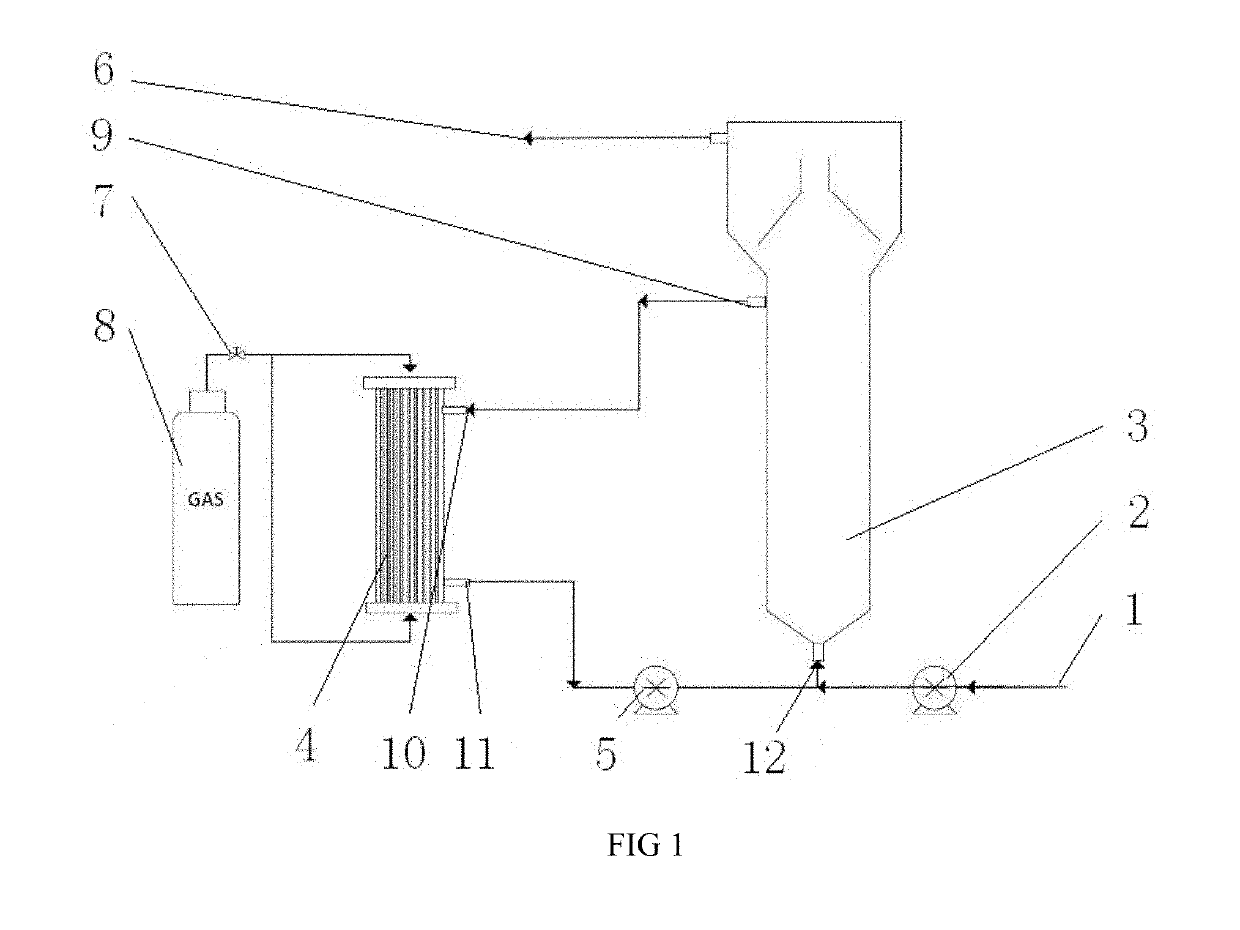

Novel Membrane Aeration Anaerobic Granular Sludge Reactor and Efficient Nitrogen Removal and Greenhouse Gas Emission Reduction Method Thereof

ActiveUS20190202722A1Reduce solubilityLarge gas-liquid mass transfer resistanceWater treatment parameter controlDispersed particle filtrationSolubilityGas cylinder

The present invention discloses a novel membrane aerated anaerobic granular sludge reactor, belonging to the technical field of wastewater treatment. The reactor solves the problems of low solubility of gas substances in an aqueous solution, large gas-liquid mass transfer resistance and low mass transfer rate. The top of a reactor body is provided with a water outlet, and the middle side wall of the reactor body is provided with a middle water outlet; the middle water outlet of the reactor body is connected with a water inlet of a membrane module; a water outlet of the membrane module is connected with a bottom water inlet of the reactor body through a circulating pump, a water inlet is connected with the bottom water inlet of the reactor body through a feed pump, a high pressure gas cylinder outputs high pressure gas to the membrane module, and a gas pressure regulating valve is arranged between the high pressure gas cylinder and the membrane module. The novel membrane aerated anaerobic granular sludge reactor improves the content of a gas substrate therein, and shortens the formation time of granular sludge. The method for efficient nitrogen removal and greenhouse gas mitigation has higher nitrate and ammonia removal rates and a higher dissolved methane removal rate within a shorter time.

Owner:HARBIN INST OF TECH

Hybrid dry cooler heat exchange with water-droplet slit and water-droplet splitting louver for heat exchangers with primarily latent heat transfer

InactiveUS20080041087A1Effective massImprove cooling effectEfficient regulation technologiesStationary conduit assembliesEngineeringLouver

Hybrid dry cooler heat exchangers with one or more tube-fin heat exchange assemblies including at lease one such assembly wetted by water dropped on it with the first of such assembly stamped to provide arrays of slit / louver combinations breaking up water droplets and averting flight of droplets into a gas flowing between adjacent fins.

Owner:JAEGGIGUNTNER SCHWEIZ

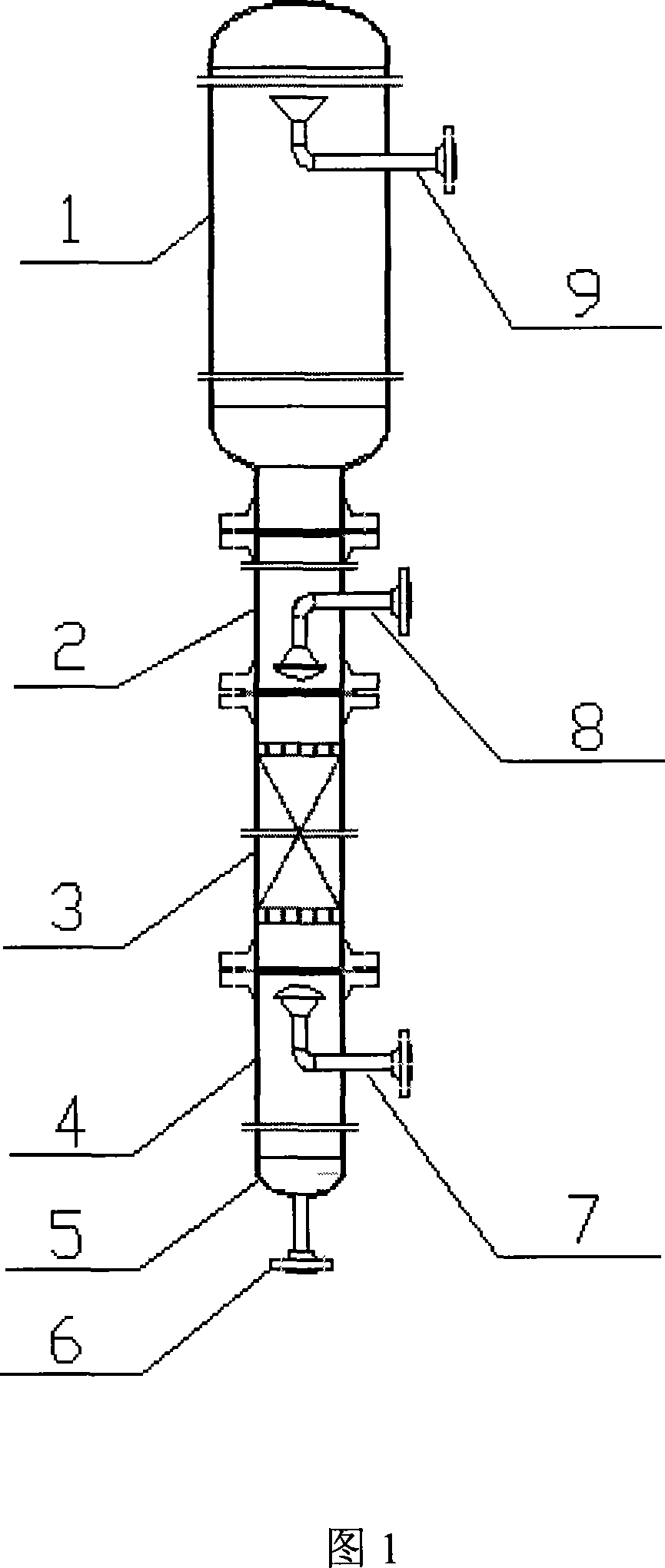

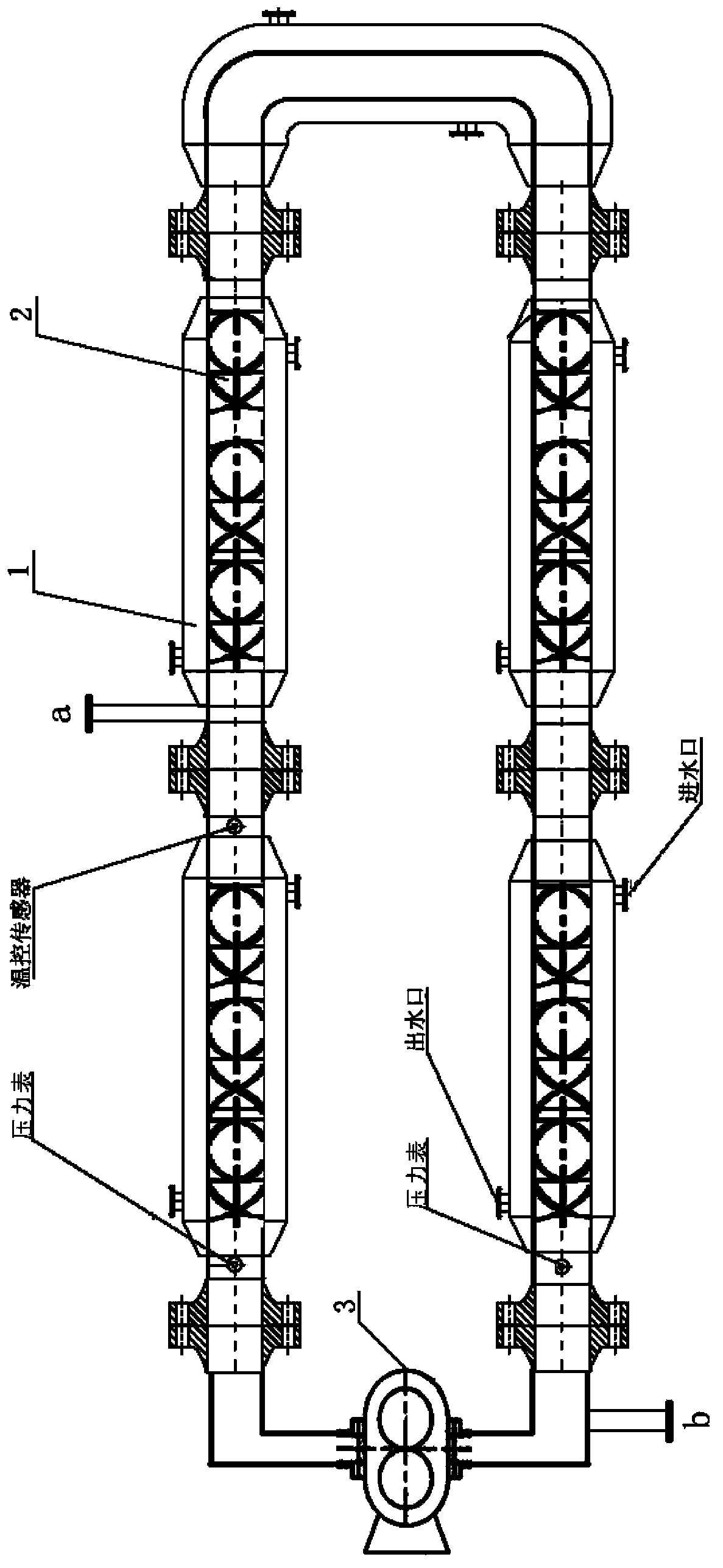

Inner loop reactor with reacting and separating functions

ActiveCN106345375AEnsure the efficiency of liquid-solid separationReduce energy consumptionChemical/physical/physico-chemical reactor detailsInner loopThree-phase

The invention relates to an inner loop reactor with reacting and separating functions. The reactor comprises a rising pipe, a downspout, a solid feeding port, a hydrocyclone inlet, an anti-flowing dead zone internal component, a liquid inlet, an air inlet, an air outlet, a flow guide drum, an air flow guide cone, an air vent, an overflow port, a hydrocyclone, a bottom flow port, an air-liquid integrated distributor and a liquid outlet, wherein the hydrocyclone is arranged at the lower part of the downspout of the loop reactor; the air flow guide cone and the air vent exist in the downspout, so that air can be prevented from entering the hydrocyclone; after the slurry enters the hydrocyclone, the solid-containing slurry enters the rising pipe through the bottom flow port, and clean products without solids flow out from a top flow port; and an external valve is used for controlling the flow of the clean products. The inner loop reactor has a simple structure, is low in cost, requires no special liquid-solid separating device, can simultaneously perform air-liquid-solid three-phase reaction, mass transfer and separation, and is suitable for the air-liquid-solid three-phase reaction taking solid grains as catalysts.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI +1

Polyacrylonitrile copolymer spinning solution and preparation method thereof

ActiveCN103421141AImprove the forceEnhanced mass transferFibre chemical featuresSpinning solutions preparationPolymer scienceAcrylonitrile

The invention relates to a polyacrylonitrile copolymer spinning solution and a preparation method thereof. In the invention, copolymerization reaction is performed on acrylonitrile in a tubular reactor containing a static mixer component; the tubular reactor, which contains the static mixer component and has the characteristics of mass transfer, efficient heat transfer, continuous and stable reaction and no mechanical stirring, is adopted to prepare the polyacrylonitrile copolymer spinning solution with high molecular weight and narrow molecular weight distribution. The polyacrylonitrile copolymer spinning solution is obtained after copolymerization reaction is performed on reaction liquid composed of monomers, a radical initiator and a solvent, wherein the percent concentration by weight of the monomers in the reaction liquid is 15% to 20%; the weight of the radical initiator is 0.4% to 1% of that of the monomers; the solvent is in balancing amount; the monomers are an acrylonitrile monomer and a comonomer. The dynamic viscosity of the polyacrylonitrile copolymer spinning solution provided by the invention is 200 to 800 Pa.S, and the molecular weight distribution is 1.5 to 2.6.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Multi-disc air diffuser

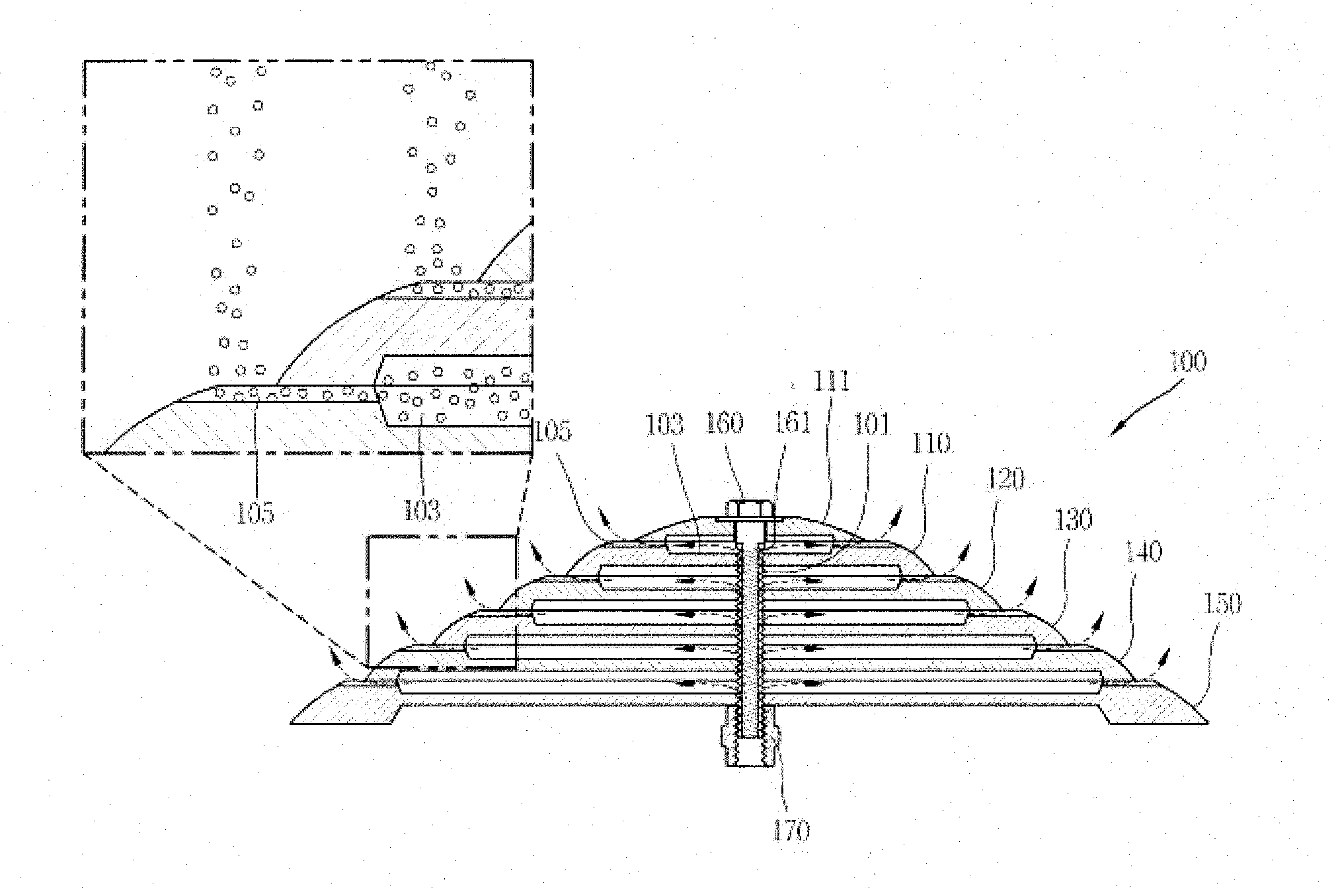

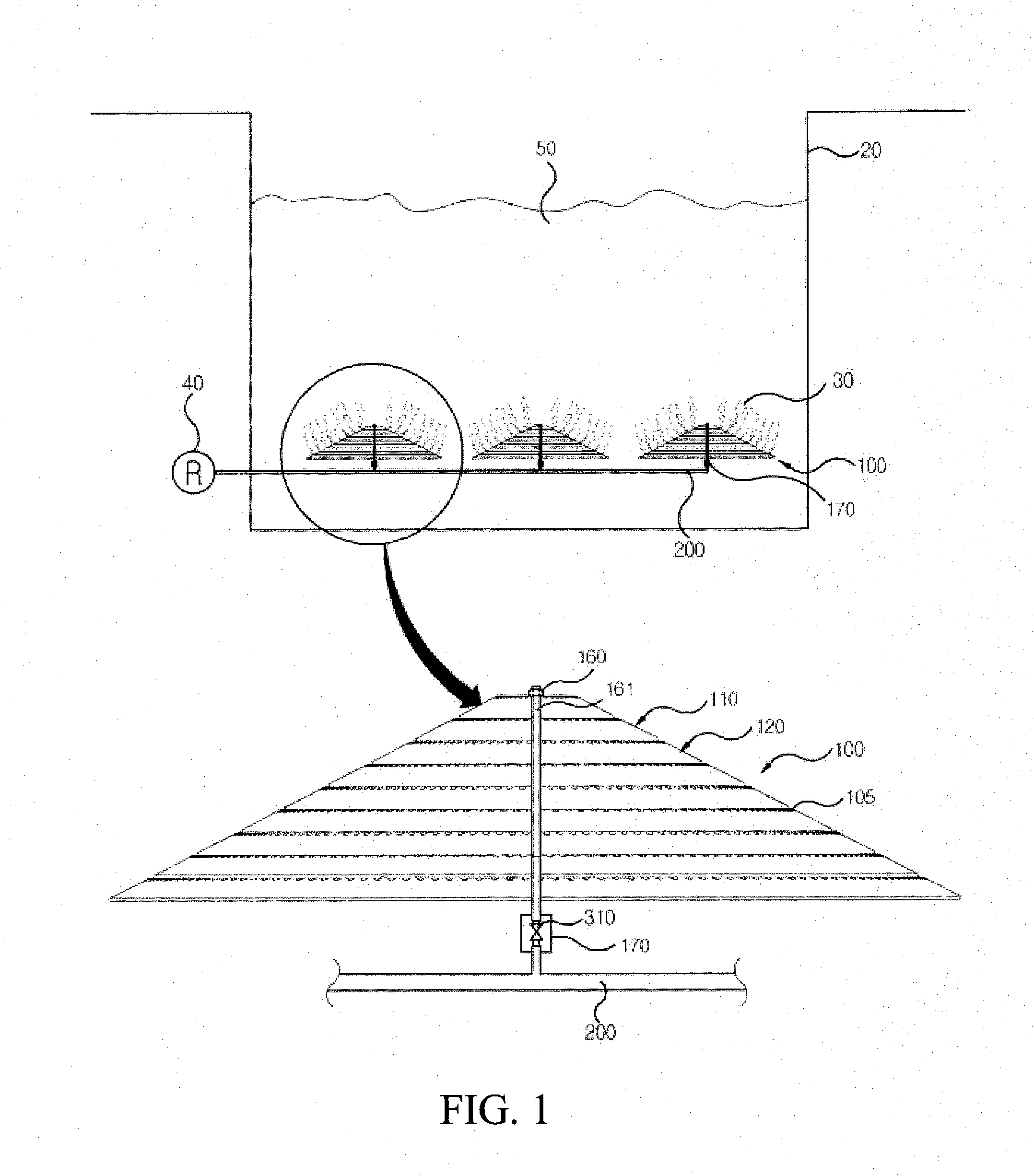

InactiveUS8833743B2Efficient mass transferIncrease contact surfaceCarburetting airTreatment using aerobic processesEngineeringCheck valve

A multi-disc air diffuser according to the present invention comprises a bolt having a vent groove formed in a longitudinal direction thereof; a plurality of discs, each of the discs having a bolt joint section to be passed through the bolt, an air room for holding the air supplied through the vent groove, and a nozzle section having a plurality of nozzles which are arranged in an end part of the air room at a regular size and intervals, wherein the lower surface of each of the discs is more than the upper surface thereof and the outer circumference surface of each of the discs is formed to be inclined; and a backflow prevention section for joining to an end part of the bolt to adhere closely the discs to one another, connecting the vent groove to an air supply pipe, and having a check valve to prevent the air flowing backward from the vent groove to the air supply pipe.

Owner:ANT21

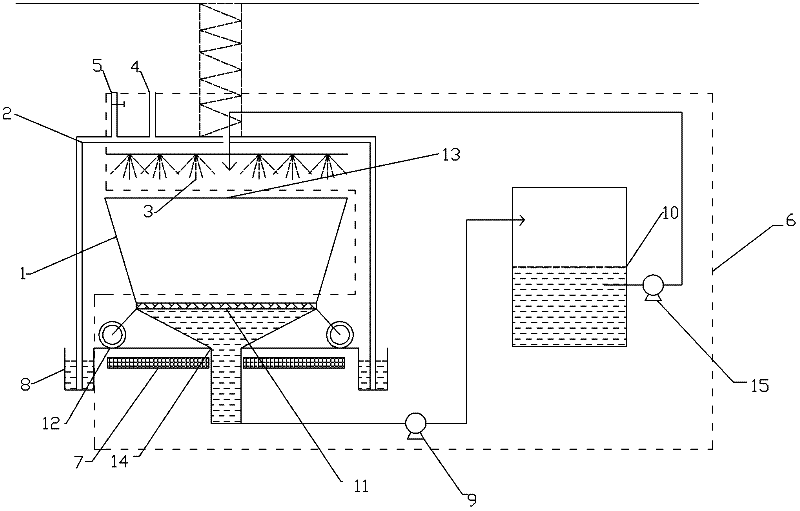

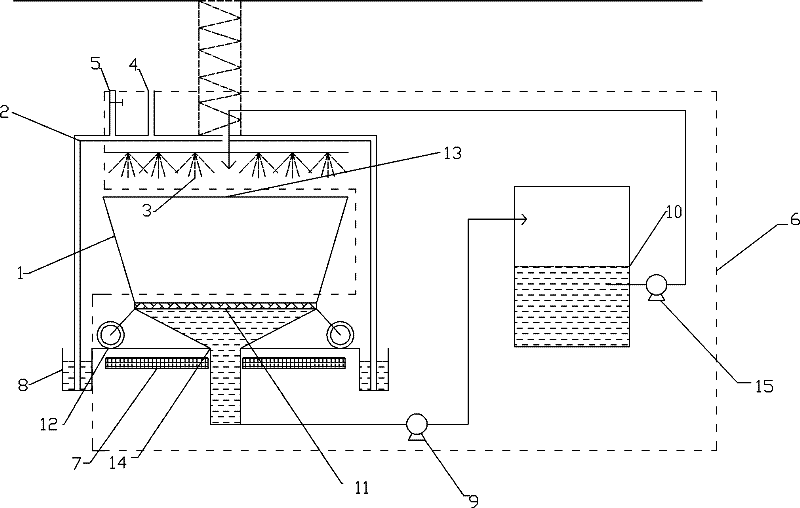

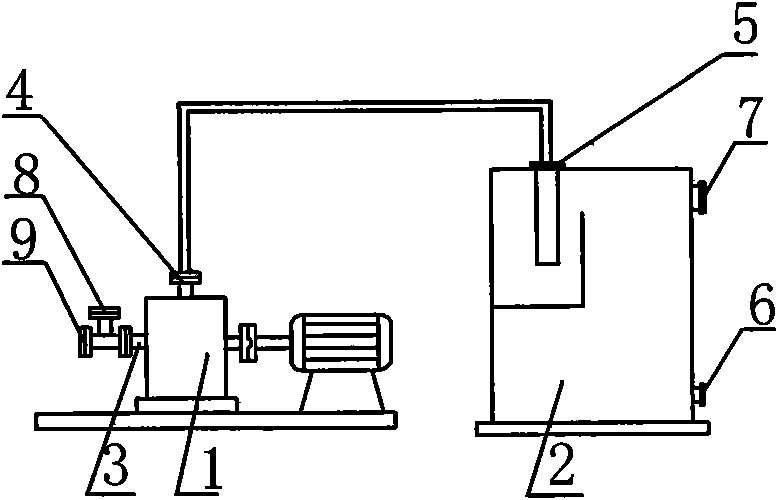

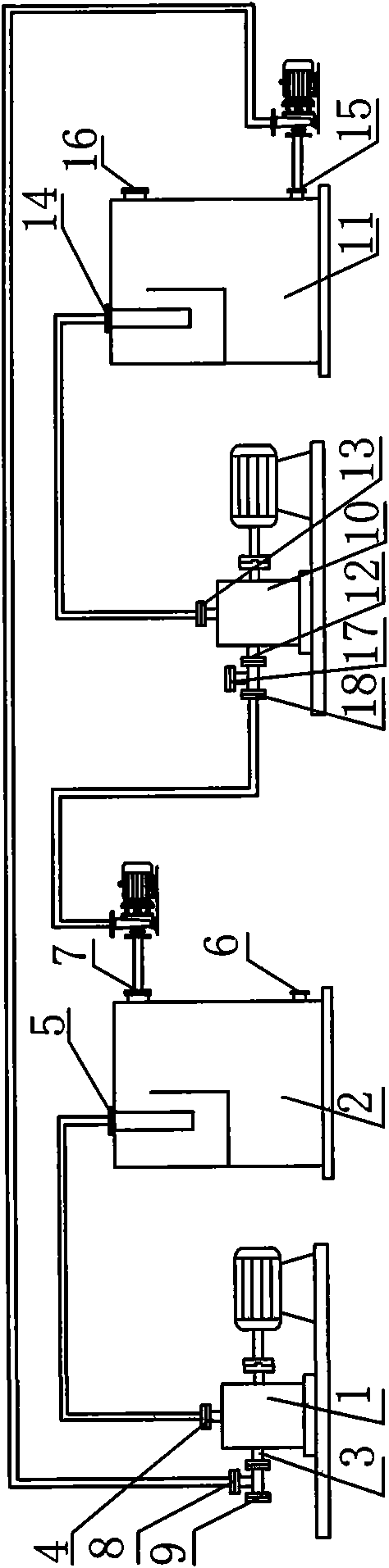

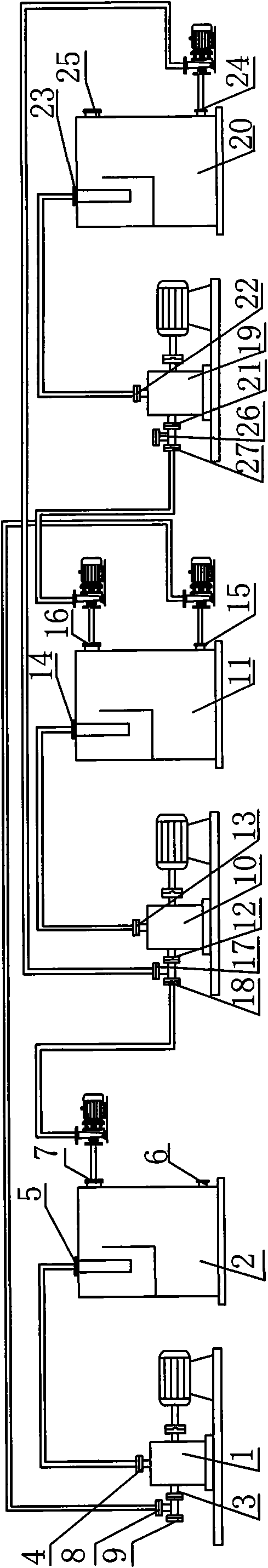

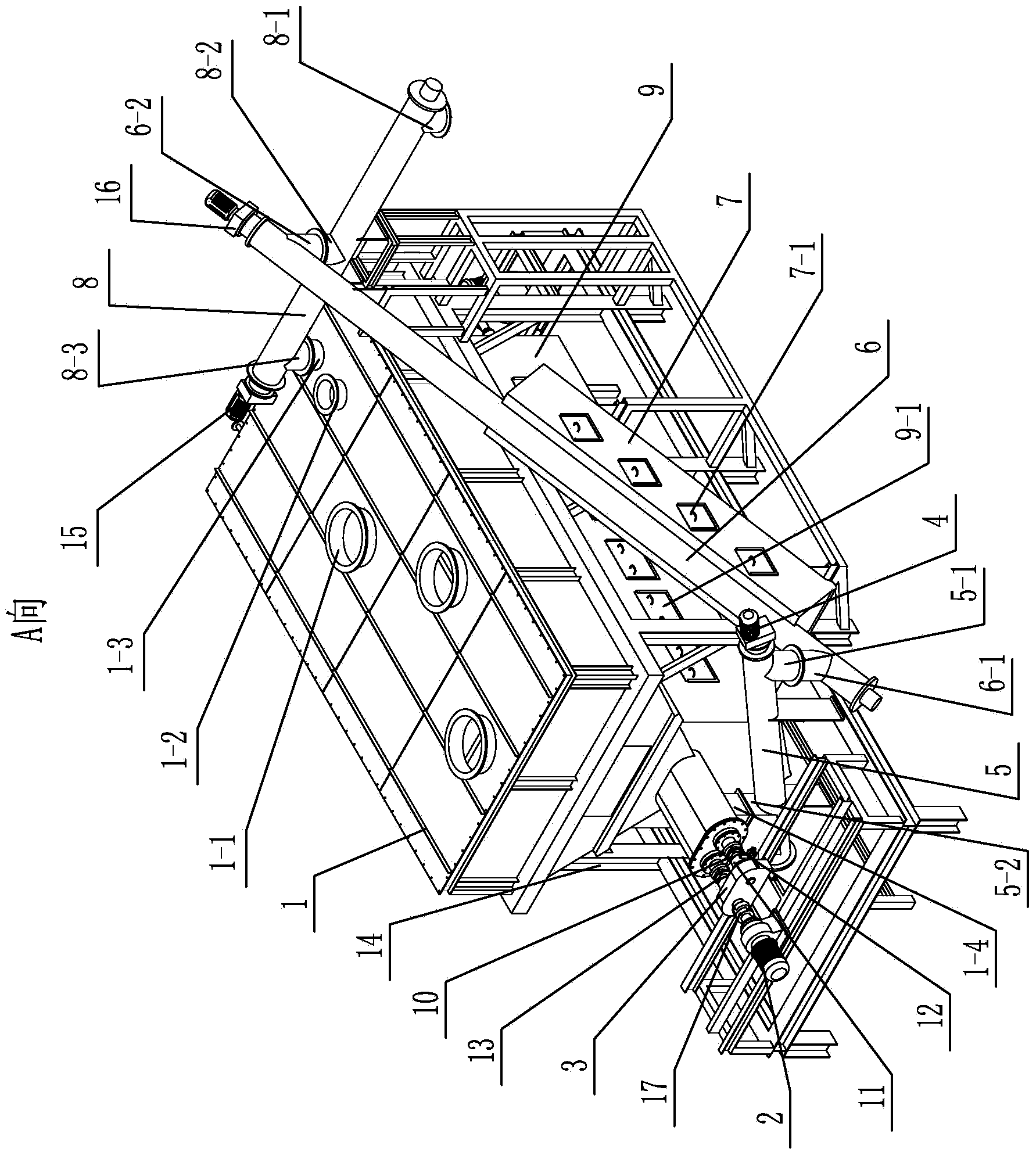

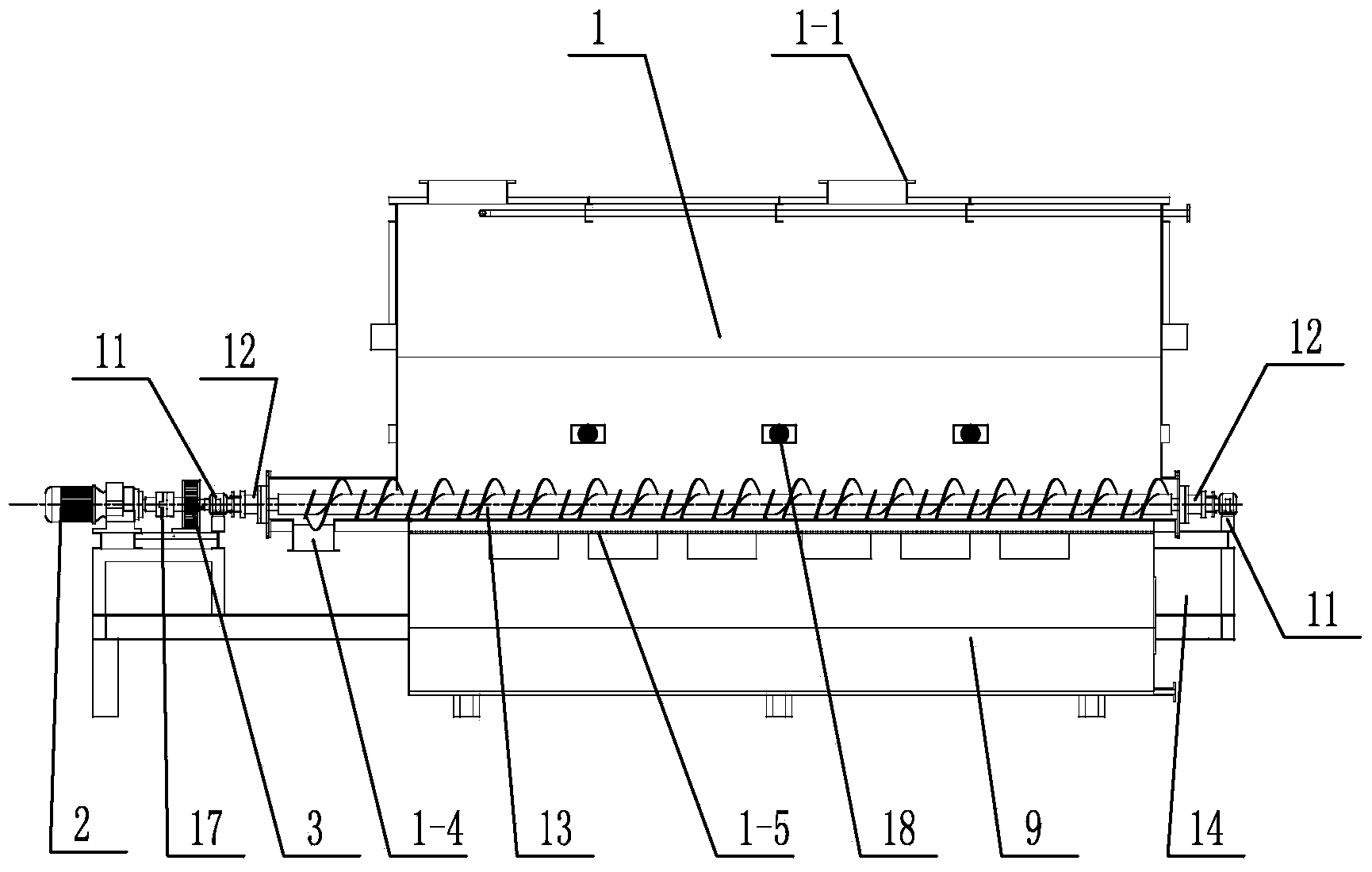

Container type dry fermentation system

InactiveCN102533523AReduce the difficulty of uninstallationReduce the difficulty of feedingBioreactor/fermenter combinationsBiological substance pretreatmentsTemperature controlSpray nozzle

The invention belongs to the technical field of garbage recycling and the development and the utilization of biological energy sources and especially relates to a container type dry fermentation system. The convenience in charging and discharging is achieved through a manner that a stainless steel cover is matched with a wheeled movable dry fermentation device, and an opening of the movable dry fermentation device is used for charging and the discharging is carried out by directly withdrawing a bottom perforated baffle, wherein the stainless steel cover can vertically stretch out and draw back and is fixedly arranged on the ceiling of a fermentation room; the temperature control in a dry fermentation process is achieved through a temperature-controlling device built in the ground surface,meanwhile, a foam plastic board heat-insulating material is applied to the cover body, therefore, the temperature of the dry fermentation process is maintained; water grooves are paved on the ground surface along the bottom contour of the stainless steel cover, so that an anaerobic environment is guaranteed by using a water seal manner; and the leachate circulation is achieved through a leachate circulation system, i.e. a leachate collecting tank, pumps and spraying nozzles. According to container type dry fermentation system, the difficulty in the charging / discharging of dry fermentation canbe solved, meanwhile, the environmental conditions required for the dry fermentation process can be controlled, so that the efficiency of the dry fermentation is increased, and meanwhile, the transportation cost and the energy consumption are reduced.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

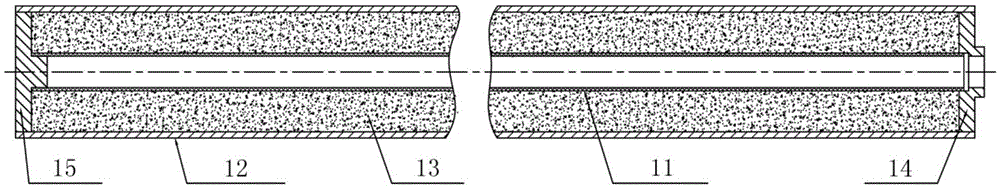

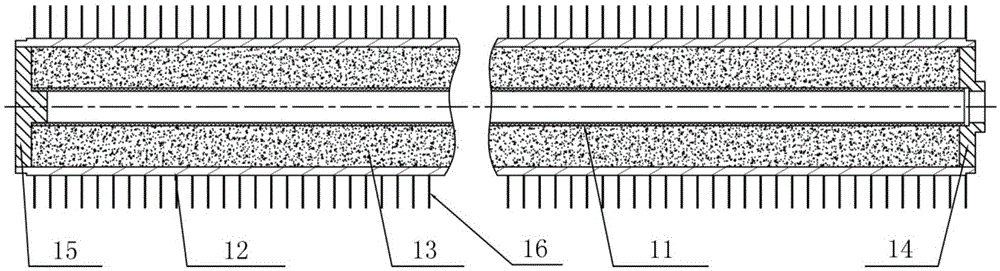

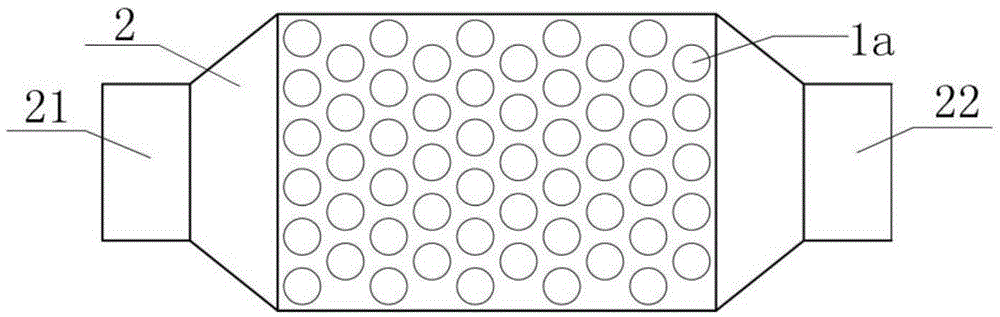

Adsorption bed structure

ActiveCN105571208AReduce size and weightReduce volumeEnergy efficient heating/coolingClimate change adaptationMetal meshEngineering

The invention provides an adsorption bed structure. The adsorption bed structure comprises an adsorption bed housing and at least one unit tube; an inlet and an outlet are formed in the adsorption bed housing to allow an external medium to go in and out; the unit tube is arranged within the adsorption bed housing; the unit tube comprises a metal tube and a metal mesh tube which sleeve each other, an adsorbent filled between the metal tube and the metal mesh tube, and a front end cover and a rear end cover which are arranged at two end portions of the unit tube to seal the adsorbent; and the external medium circulates on a surface, back on to the adsorbent, of the metal tube. The adsorption bed structure provided by the present invention may enable the adsorbent to have relatively high packing density, and the adsorption bed to have a small size and packing volume.

Owner:SHANGHAI JIAO TONG UNIV

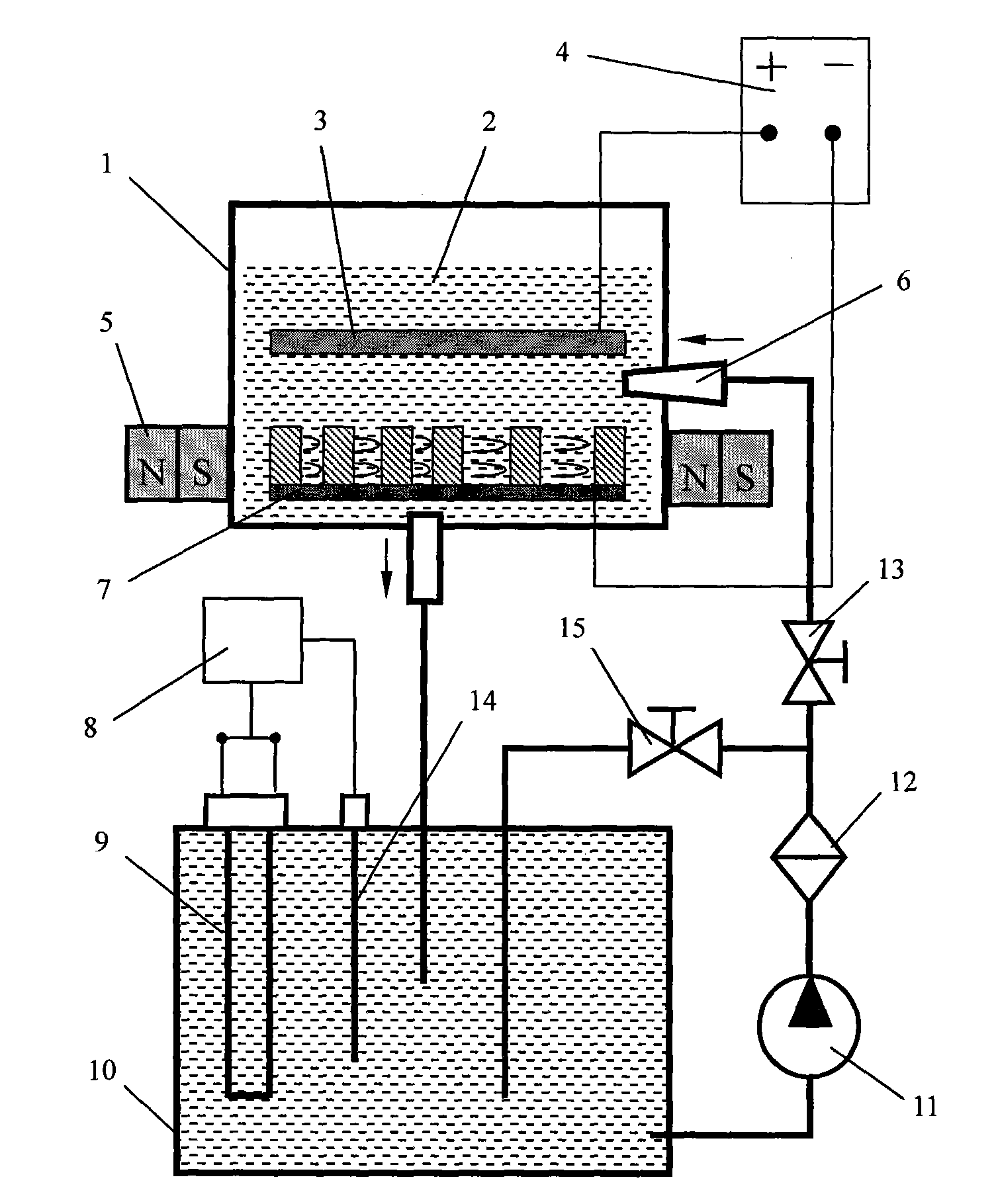

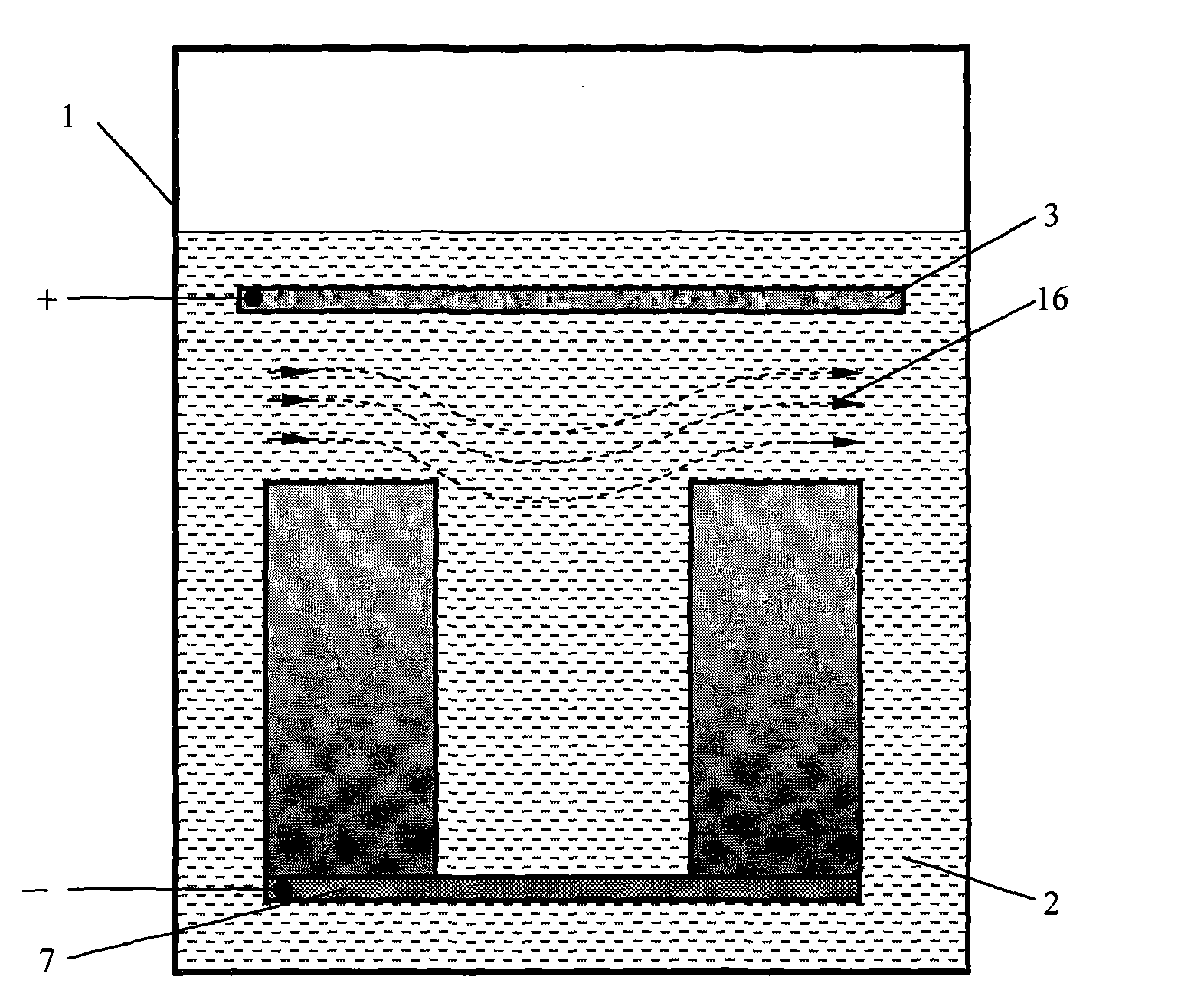

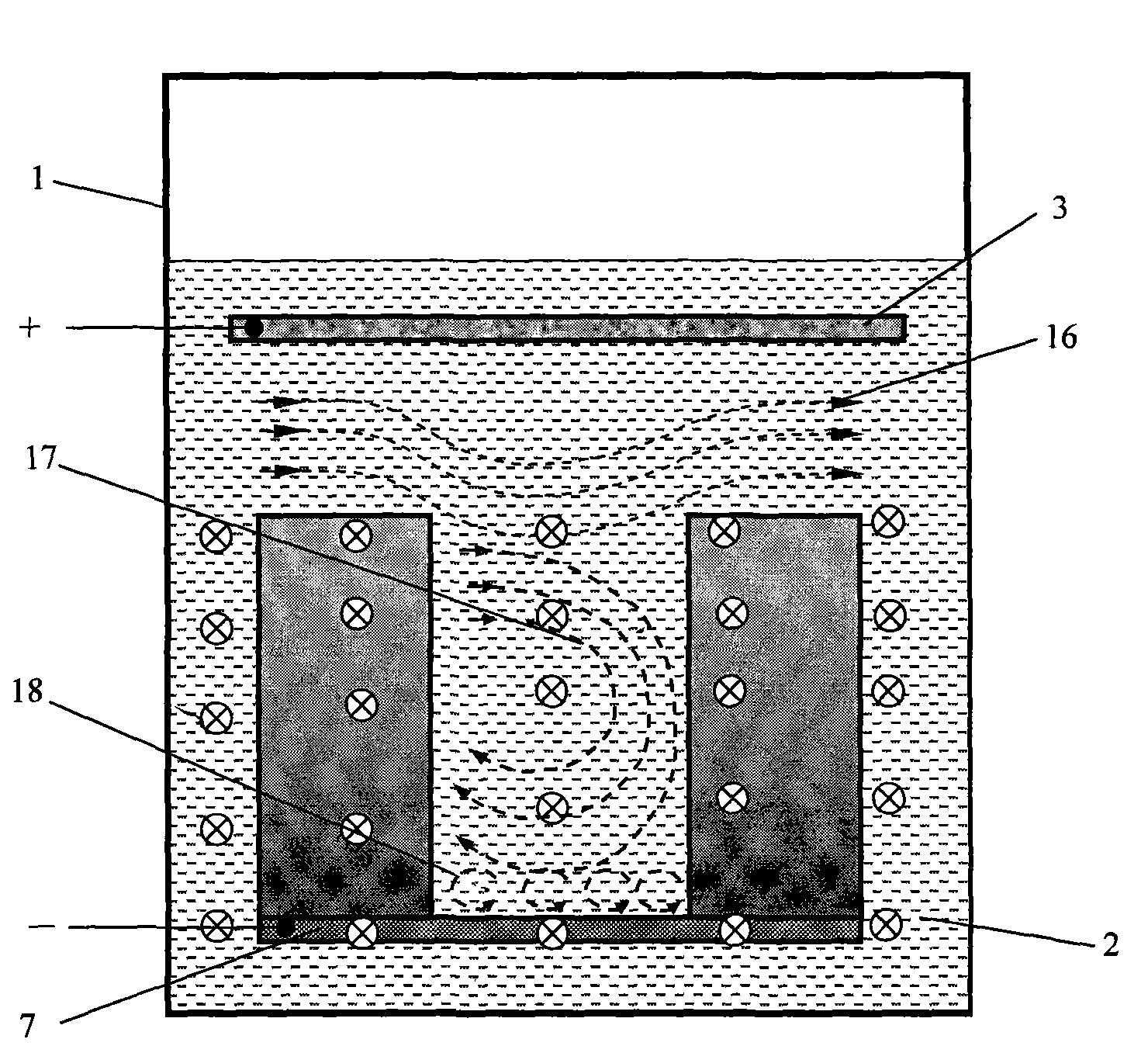

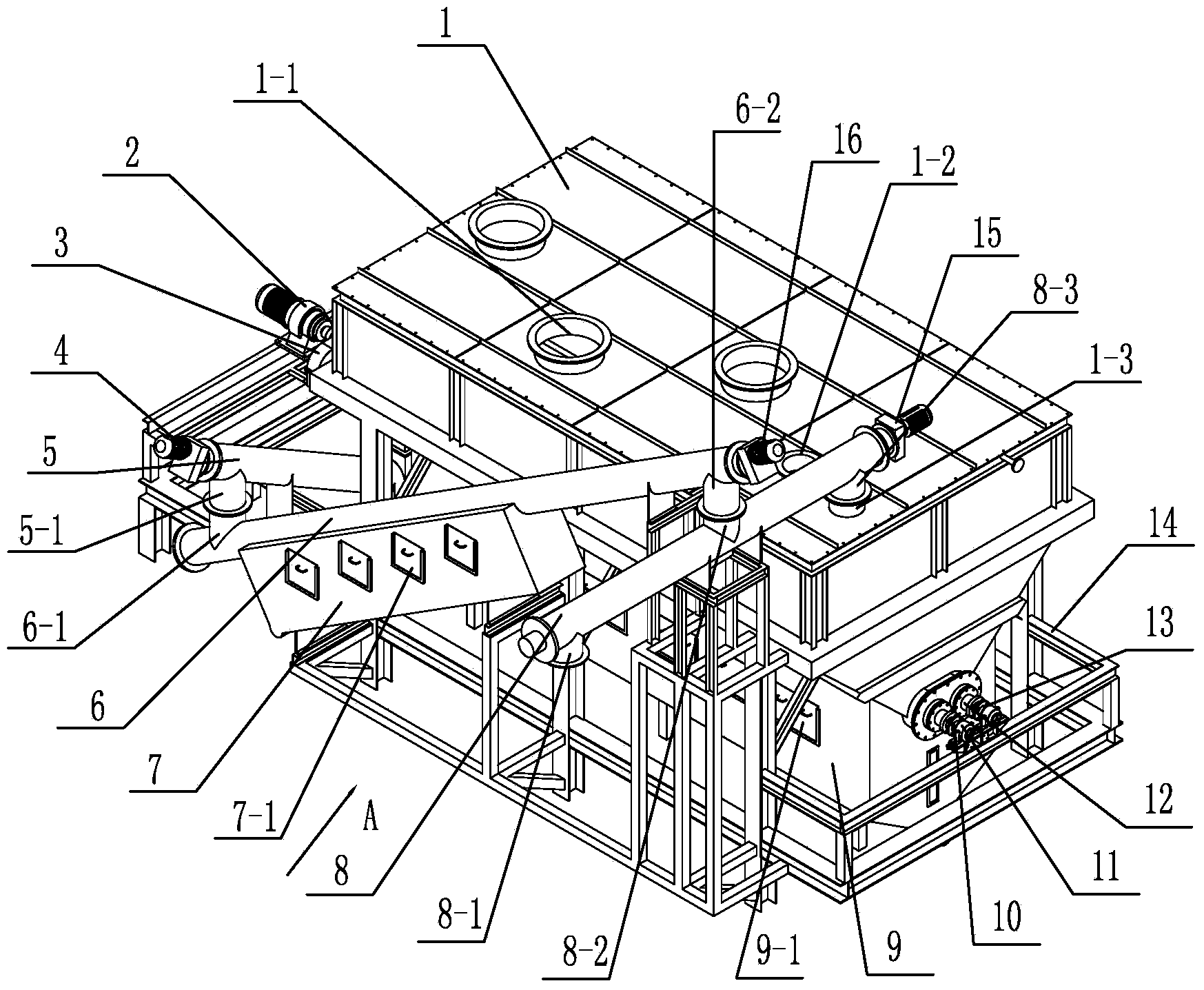

Micro-electroforming method based on magnetic force-driven convection effect and device thereof

InactiveCN102102213AEfficient mass transferSimple methodElectroforming processesPhotoresistWidth ratio

The invention discloses a micro-electroforming method based on the magnetic force-driven convection effect and a device thereof, belonging to the electrochemical micromachining field. The method comprises the following steps: an anode and cathode core mould is placed in an electroforming groove, electroforming solution is added in the electroforming groove, the cathode and anode are electrified, when the electroforming layer on the core mould reaches a defined thickness, the solution supply and electroforming are stopped, the core mould is taken out to demould and remove photoresist; and in the electroforming process, a magnetic field perpendicular to the current direction of the anode and cathode is superposed on the outside of the core mould. The device used for implementing the method contains a electroforming system, an electroforming solution temperature control system and an electroforming solution circulating system, wherein the outside of the core mould in the electroforming system is provided with a magnetic field generator. By adopting the method of the invention, the problem that the liquid phase mass transfer of high depth-to-width ratio (depth-to-diameter ratio) micro-electroforming is limited can be solved; and the prepared casting has uniform thickness, fewer sedimentation defects and compact structure.

Owner:HENAN POLYTECHNIC UNIV

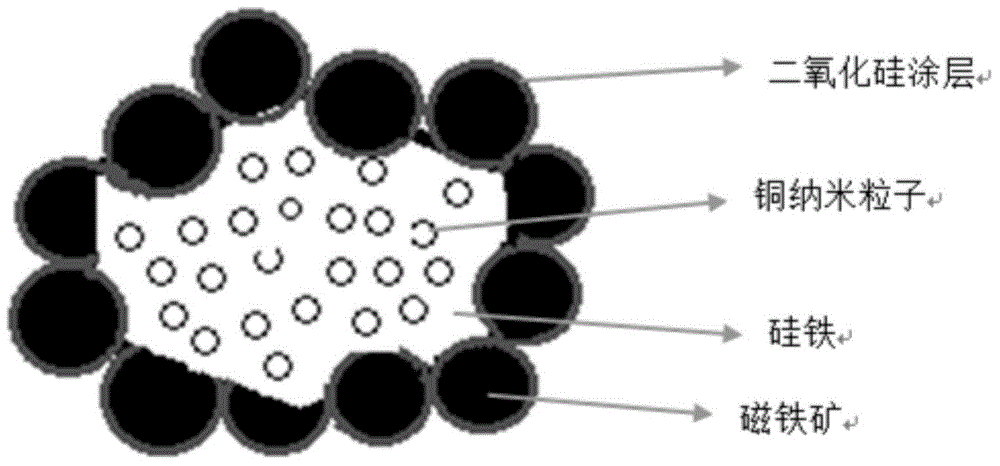

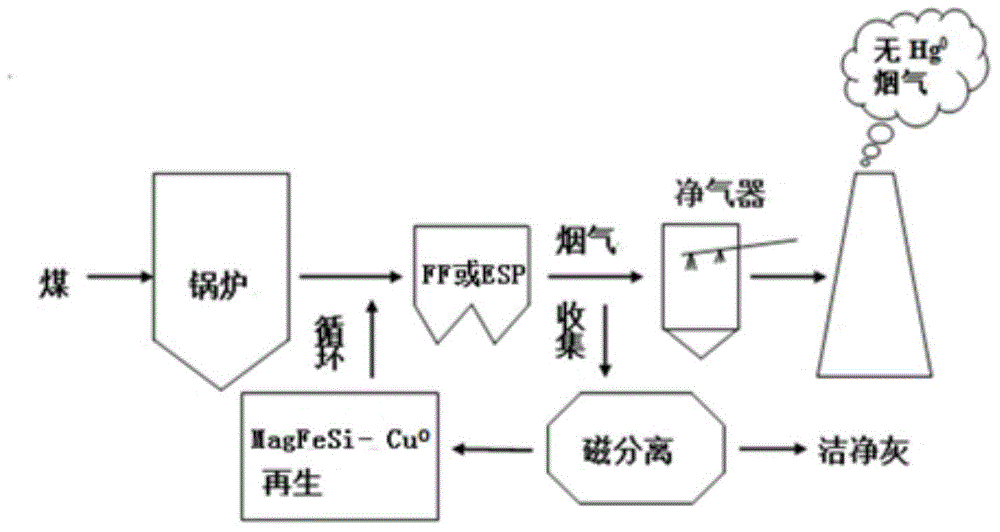

Magnetic adsorbent for removing Hg0 from flue gas and preparation and application of magnetic adsorbent

ActiveCN104525093AReduce manufacturing costImprove mercury removal efficiencyGas treatmentOther chemical processesSorbentSilica coating

The invention relates to a magnetic adsorbent for removing Hg0 from flue gas and preparation and application of the magnetic adsorbent. The magnetic adsorbent is MagFeSi-Cu0. The preparation method includes the first step of putting Fe3O4 nano particles in deionized water, adding Na2SiO3, adding a mixture into ethyl alcohol, adding NH3*H2O for a sol-gel reaction, conducting steam treatment and conducting drying to obtain magnetic particles of a silicon dioxide coating; the second step of introducing copper nano particles into the surface of silicon iron and sintering the magnetic particles of the silicon dioxide coating and the silicon iron to obtain the magnetic adsorbent. The magnetic adsorbent is applied to removing Hg0 from the flue gas. An adsorbent of mercury is the magnetic adsorbent, the coal-fired flue gas passes through a filter material, the mercury in the flue gas is caught by the magnetic adsorbent in the filter material, a dry drum magnetic separator is used for adsorbent spending and flying ash extraction, the used magnetic adsorbent MagFeSi-Cu0 will be regenerated and cycled, and therefore use cost of the adsorbent will be lowered.

Owner:DONGHUA UNIV +1

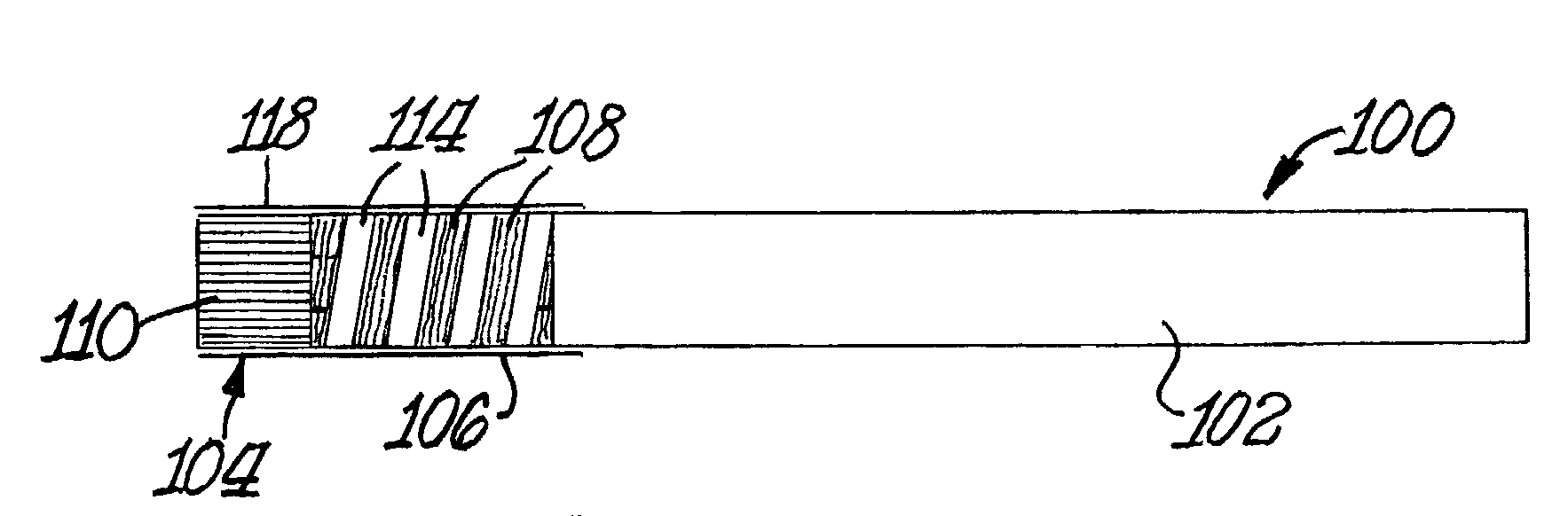

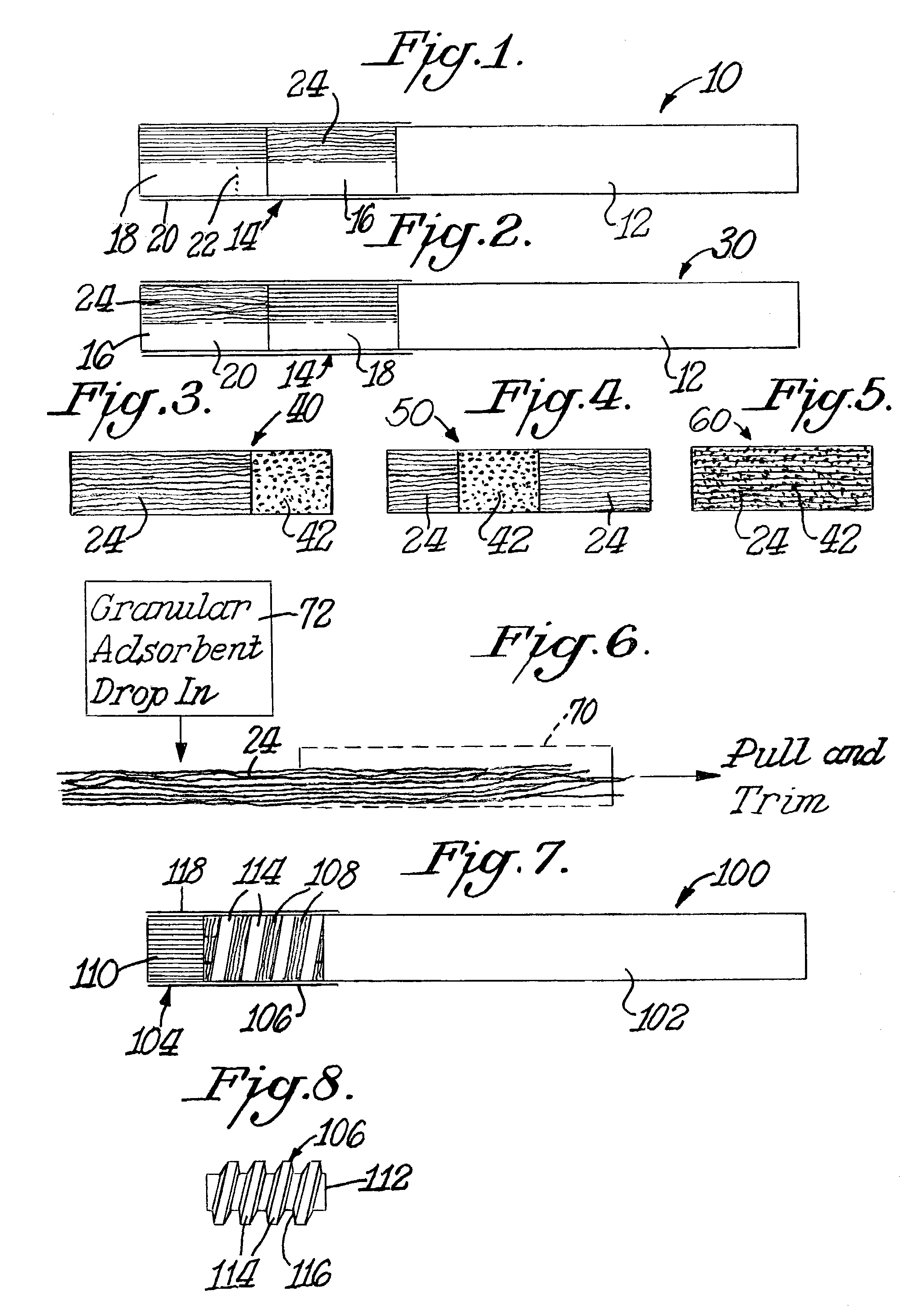

Activated carbon fiber cigarette filter

ActiveUS7552735B2Improve adsorption efficiencyLonger path lengthCigar manufactureTobacco smoke filtersActivated carbonCigarette filter

A cigarette filter for removing gas phase constituents from mainstream cigarette smoke as the smoke is drawn through the filter primarily comprises an activated carbon fiber filter section including a bundle of activated carbon fibers. Particulate adsorbent materials such as granules, beads or course powders may be dispersed amongst the activated carbon fibers to aid in removal of the gas phase constituents. Additionally, the activated carbon fiber filter section may be used in combination with a separate bed or beds of particulate adsorbent material. In one embodiment, the activated carbon fibers are positioned within a helical groove on the outside of a threaded rod within the activated carbon fiber filter section. Relatively smaller amounts of activated carbon fibers produce the same smoke constituent reduction as larger amounts of particulate adsorbent material.

Owner:PHILIP MORRIS USA INC

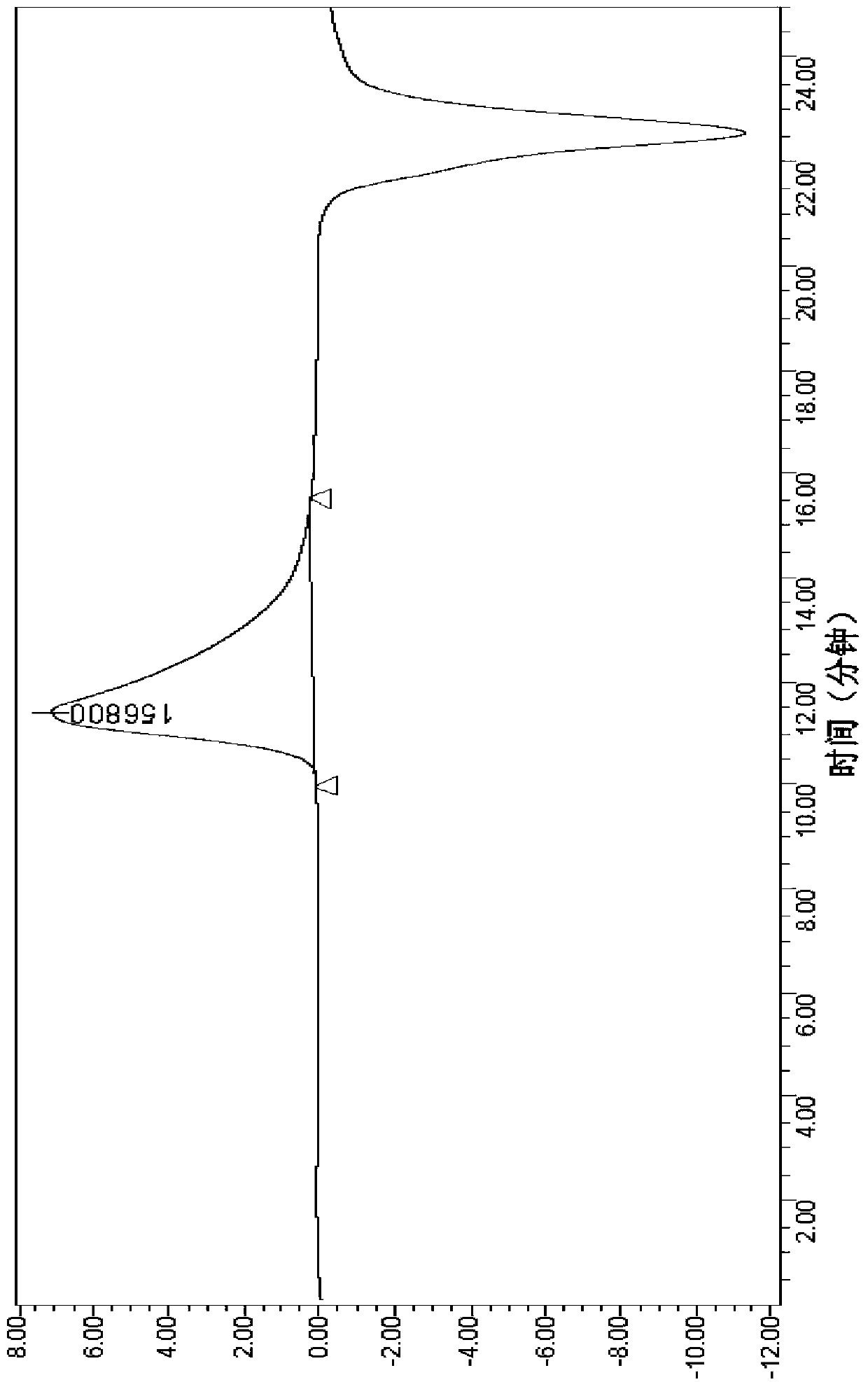

Method for simultaneously separating and purifying racemic optical amyl alcohol, optical active amyl alcohol and isoamyl alcohol from fusel oil or mixed amyl alcohol and its equipment

InactiveCN1443739ATake advantage ofReduce energy consumptionOrganic compound preparationHydroxy compound preparationIt equipmentIsoamyl alcohol

The present invention adopts single tower, on the basis of general precision rectification process adds flooding operation, its total reflux is implemented at twice, reflux ratio of 4-80, and betweentwo stages of total reflux the light component can be fractionized out from top of tower and the water content is removed. It provides the equipment for implementing the above-mentioned method. It istechnically characterized by adopting high-effective precision rectification filling material and electromagnetic needle pendulum reflux ratio control instrument, height of filling layer is 140-150 cm, its complete condenser is water-splitting complete condenser, and upper portion of filling layer and its middle portion are respectively equipped with returned liquor distributor and oblique cone ring baffle.

Owner:SICHUAN UNIV +1

Apparatus for countercurrent contacting of gas and solids

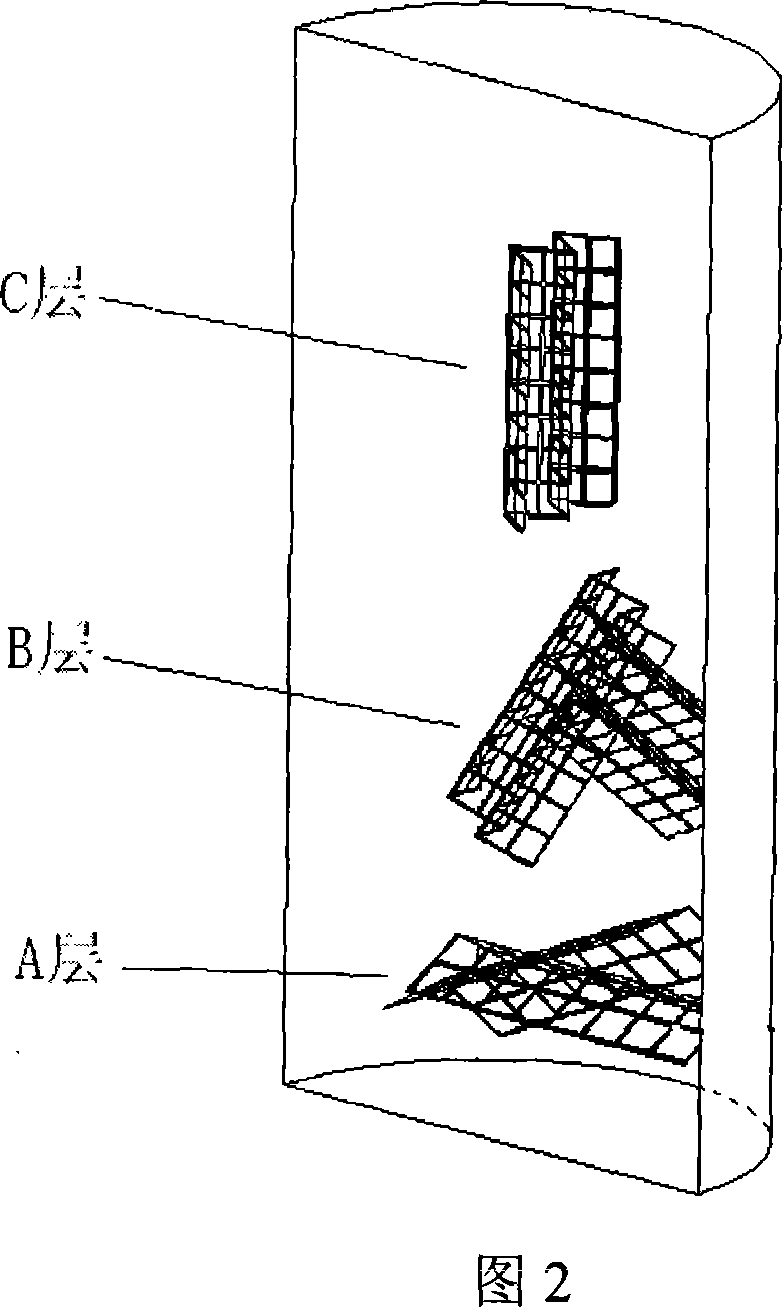

InactiveCN1735454AEfficient mass transferLarge "interface" areaCatalytic crackingChemical/physical processesCounter flowSolid particle

An apparatus (200) for the countercurrent contacting of a gas and downflowing solid particles includes a housing (205) and a plurality of baffles (100) positioned within the housing. The baffles are arranged in at least first and second vertically spaced levels in successively lower position, each of the first and second levels including a row of at least two baffles oriented parallel to one another and inclined from horizontal so as to facilitate movement of the solid particles and provide the maximum area for flow. Baffles are oriented so as to laterally shift the direction of downflowing particles transversely as the particles move from one level to the next lower level and avoid channeling of the phases. The number of baffles, length and spacing is optimized to provide maximum interfacial area for interaction between the phases.

Owner:ABB LUMMUS GLOBAL INC

Copper smelting device with high-oxygen-enrichment double-side-blowing melting bat and operation method of copper smelting device

ActiveCN104593617AIncrease useful gas contentReduce take awayRotary drum furnacesCrucible furnacesMelting tankSlag

The invention relates to a copper smelting device with a high-oxygen-enrichment double-side-blowing melting bat and an operation method of the copper smelting device and belongs to the technical field of copper smelting devices and processes. According to the method, a large-volume hearth is used, the continuous production is performed, a single furnace is adopted so as to meet the periodic production of a PS converter, smelting slag continuously overflows from a smelting slag outlet and matte is directly discharged from a matte outlet formed in the bottom end of the hearth. During the smelting slag is discharged, the flowing direction of the smelting slag is controlled by virtue of a switching chute so that the smelting slag can be continuously discharged; the ratio of Fe to SiO2 in the smelting slag is controlled at 1.6-1.8, the ratio of a fuel to input materials is controlled at 2-2.5% and the content of copper in the smelting slag is less than or equal to 0.65%. The method has the characteristics of small construction investment, low production cost, good working environment, high degree of automation, high utilization rate of plant building and the like.

Owner:CHIFENG FUBANG COPPER

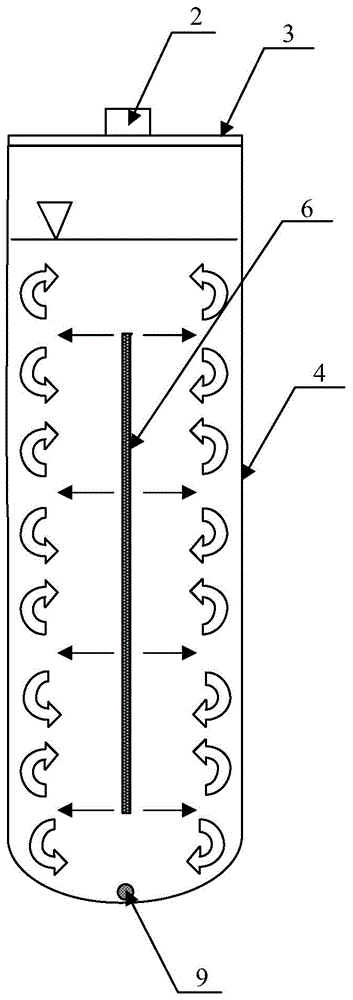

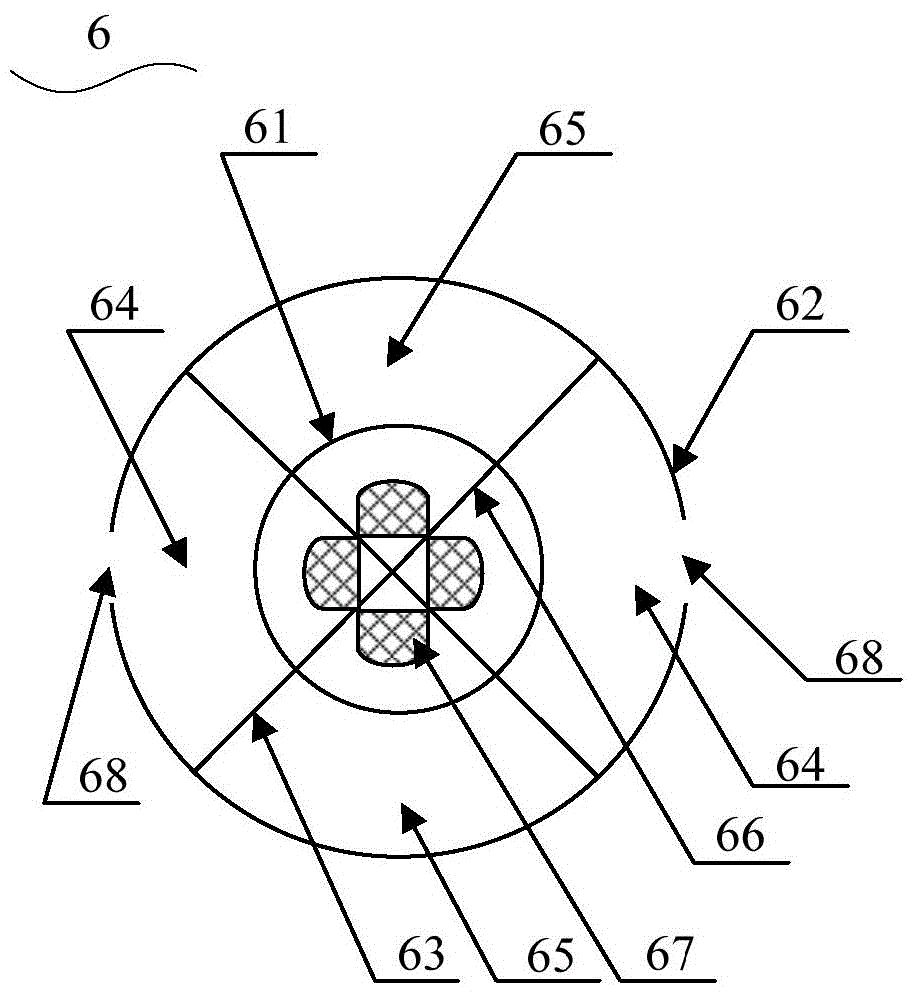

Flat plate photobioreactor

ActiveCN106318858AAchieve circular flowEfficient use ofBioreactor/fermenter combinationsBiological substance pretreatmentsTemperature controlPhotobioreactor

The invention provides a flat plate photobioreactor, which comprises a reactor main body and at least one multifunctional coiled pipe which is arranged in the reactor main body. By virtue of the multifunctional coiled pipe, the circulating flow of algae liquid in an optical direction is achieved, so that the effective utilization of a flash effect is achieved; gas can shoot into the algae liquid at different heights, so that gas-liquid mass transfer becomes more efficient and temperature control and dissolved oxygen repelling are conducted more efficiently; in addition, on the basis of a relatively strong scouring effect of a jet flow from the coiled pipe to a sidewall face on the wall face, the attachment of algae on the inner wall of the reactor and on the coiled pipe can be effectively relieved and cleaning times can be reduced; and by combining internal and external light sources, the purpose of enlarging an individual reactor body can be achieved by adding the multifunctional coiled pipes, so that the the limitation that the flat plate photobioreactor can be enlarged just by adding reactor units is overcome, which is conducive to the implementation of industrialization.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

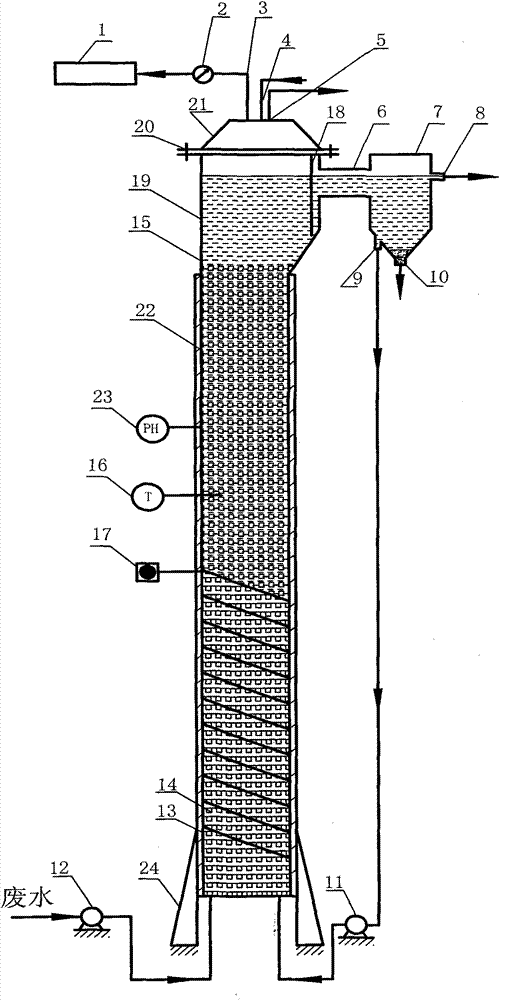

Anaerobic fluidized bed bioreactor and using method thereof

InactiveCN103663688AImprove mass transfer efficiencyPromote growthWaste based fuelTreatment with anaerobic digestion processesHigh concentrationIndustrial waste water

The invention relates to a method for anaerobic reaction by using an anaerobic fluidized bed bioreactor. The method includes: (A) inoculating an anaerobic sludge liquid; (B) adding waste water prepared by human, growing an anaerobic bacterium biological membrane on zeolite particles; and (C) adding high concentration industrial waste water or residual sludge mud from town sewage treatment factories for anaerobic digestion. In the inventive method, the zeolite particles with smaller volume are used as biological carriers, the bacterium biological membrane is adhered to the particles, a mass transfer efficiency between the industrial waste water and the residual sludge and the bacterium biological membrane is improved by using the huge specific surface of the small particles. The method for anaerobic reaction by using the anaerobic fluidized bed bioreactor has higher treatment capacity, after stable running, an average volume load can reach 30-35KgCOD / m<3>.d, the mass transfer efficiency between the industrial waste water and the residual sludge and the bacterium biological membrane is improved, the advantages of a fluidized bed technology are fully utilized, so that the treatment efficiency of the industrial waste water and the residual sludge of a sewage plant is greatly improved.

Owner:TIANJIN UNIV OF SCI & TECH

Extraction device

InactiveCN101898048ALarge mass transfer areaEasy to phaseLiquid solutions solvent extractionPhase splittingEngineering

The invention discloses an extraction device comprising an emulsifying machine (1) and a phase-splitting apparatus (2). The emulsifying machine (1) is provided with an emulsifying machine inlet (3) and an emulsifying machine outlet (4), the phase-splitting apparatus (2) is provided with a mixed phase inlet (5), a heavy phase outlet (6) and a light phase outlet (7), the emulsifying machine inlet (3) is connected with an extracted object inlet (8) and a solvent inlet (9), and the emulsifying machine outlet (4) is connected with the mixed phase inlet (5) of the phase-splitting apparatus. When multistage extraction devices are combined, the light phase outlet of the phase-splitting apparatus in the extraction device at the current level is connected with the solvent inlet of the extraction device at the next level through a pipeline provided with a pump, and the heavy phase outlet of the phase-splitting apparatus in the extraction device at the next level is connected with the extracted object inlet of the extraction device at the current level through the pipeline provided with the pump. The invention has high extraction efficiency, small size, less occupied area, simple operation and capability of saving apparatus investment and running cost.

Owner:WENGFU (GRP) CO LTD

Mechanical and biochemical reaction device applied to coarse pulp of kitchen waste

ActiveCN103521503AReasonable structureSimple and fast operationSolid waste disposalThree levelCoupling

Owner:WELLE ENVIRONMENTAL GRP CO LTD

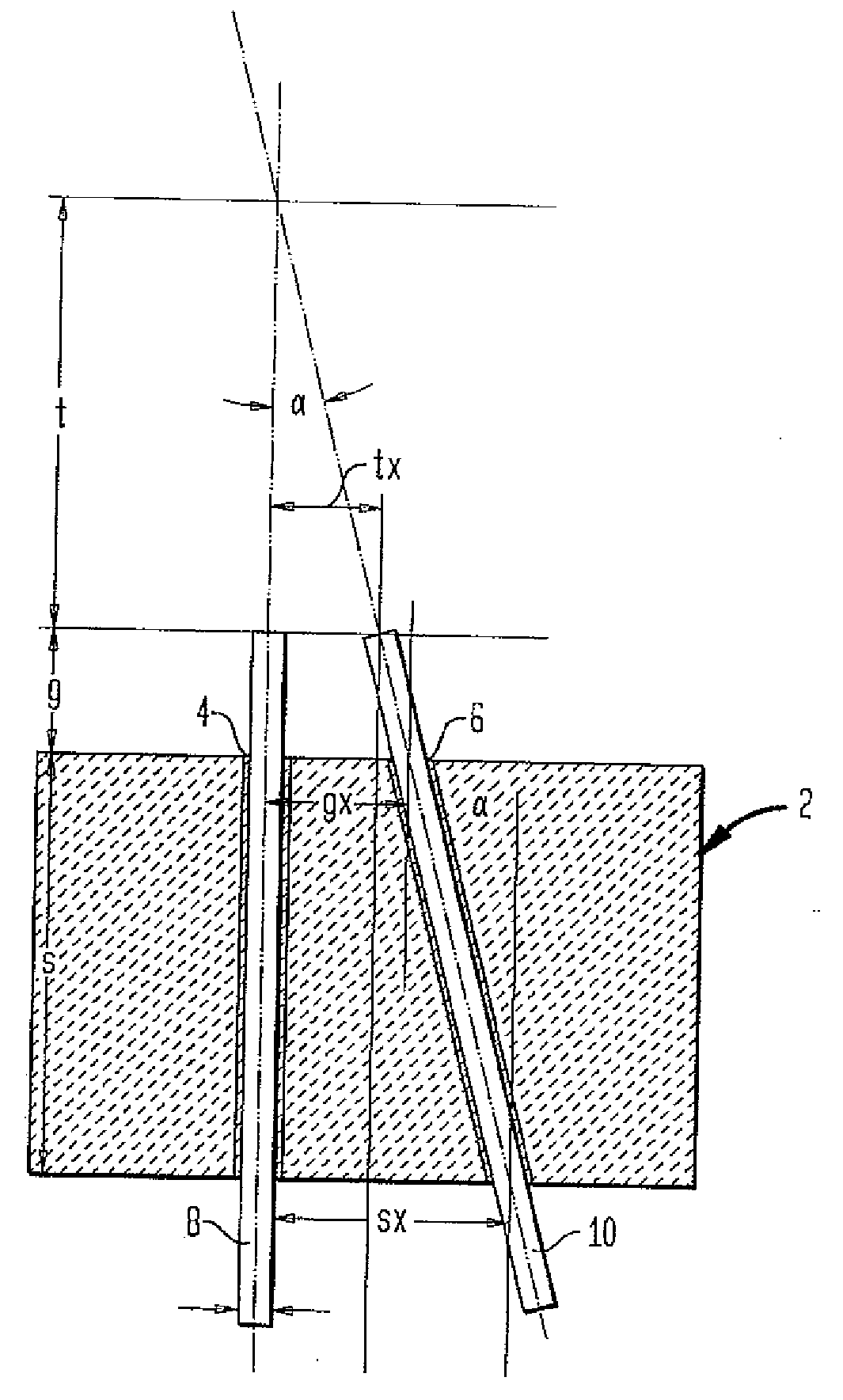

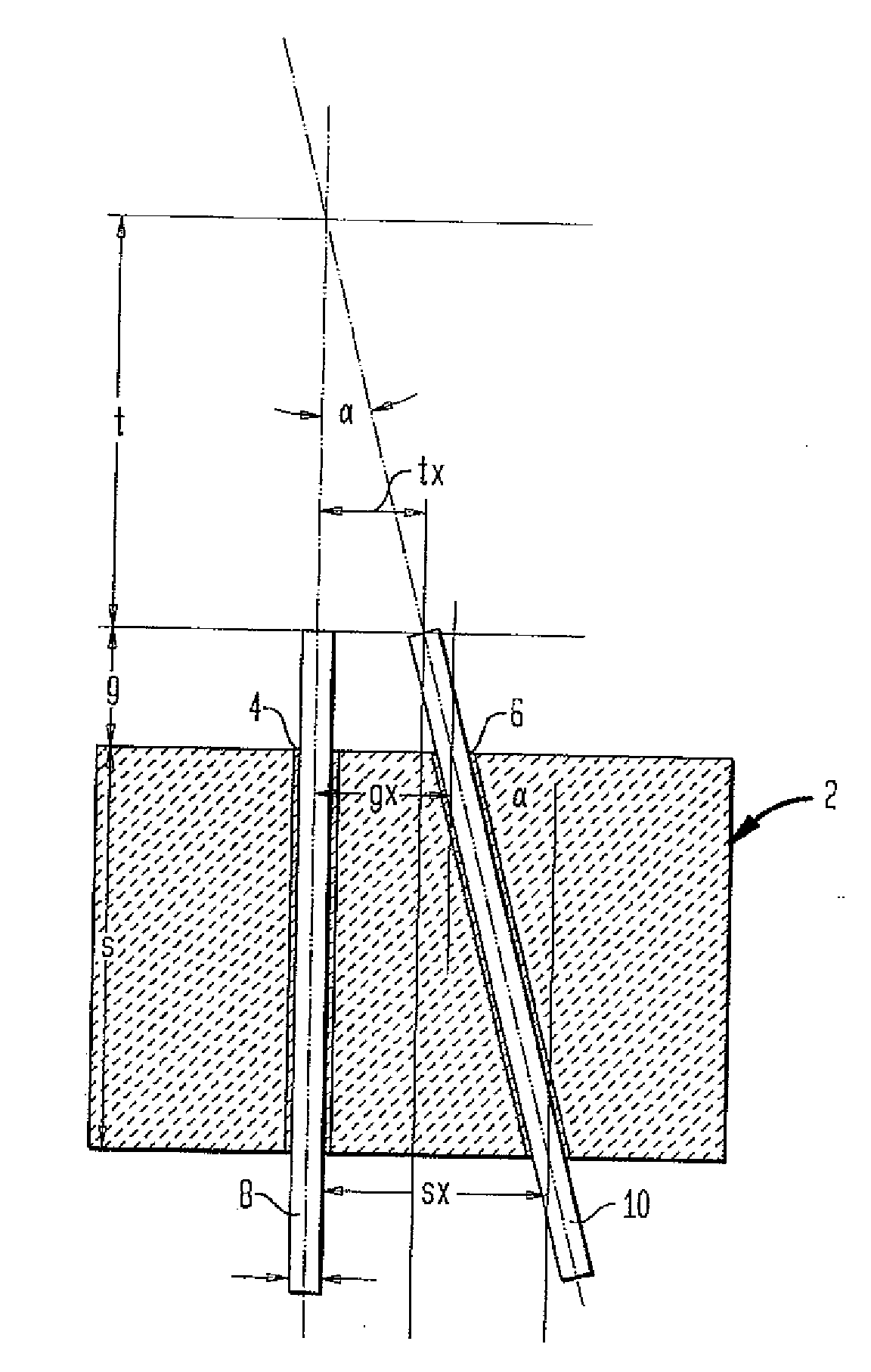

Bubbling brick

InactiveUS20090044569A1Efficient mass transferPurge the melt of gas componentsStirring devicesGlass furnace apparatusBrickMetallurgy

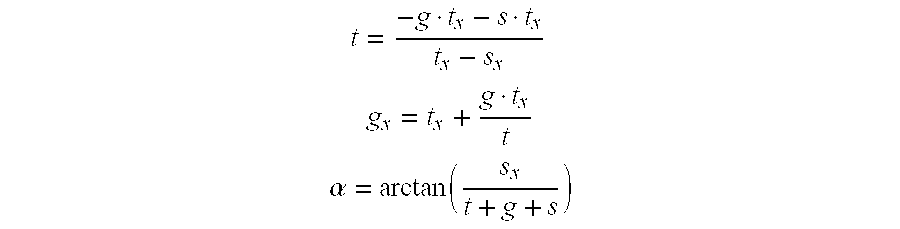

The invention pertains to a bubbling brick with at least two bores for introducing two different gases into a glass melt. In order to increase the variability of the glass melt process, these bores together form an included angle α>0.

Owner:LINDE AG

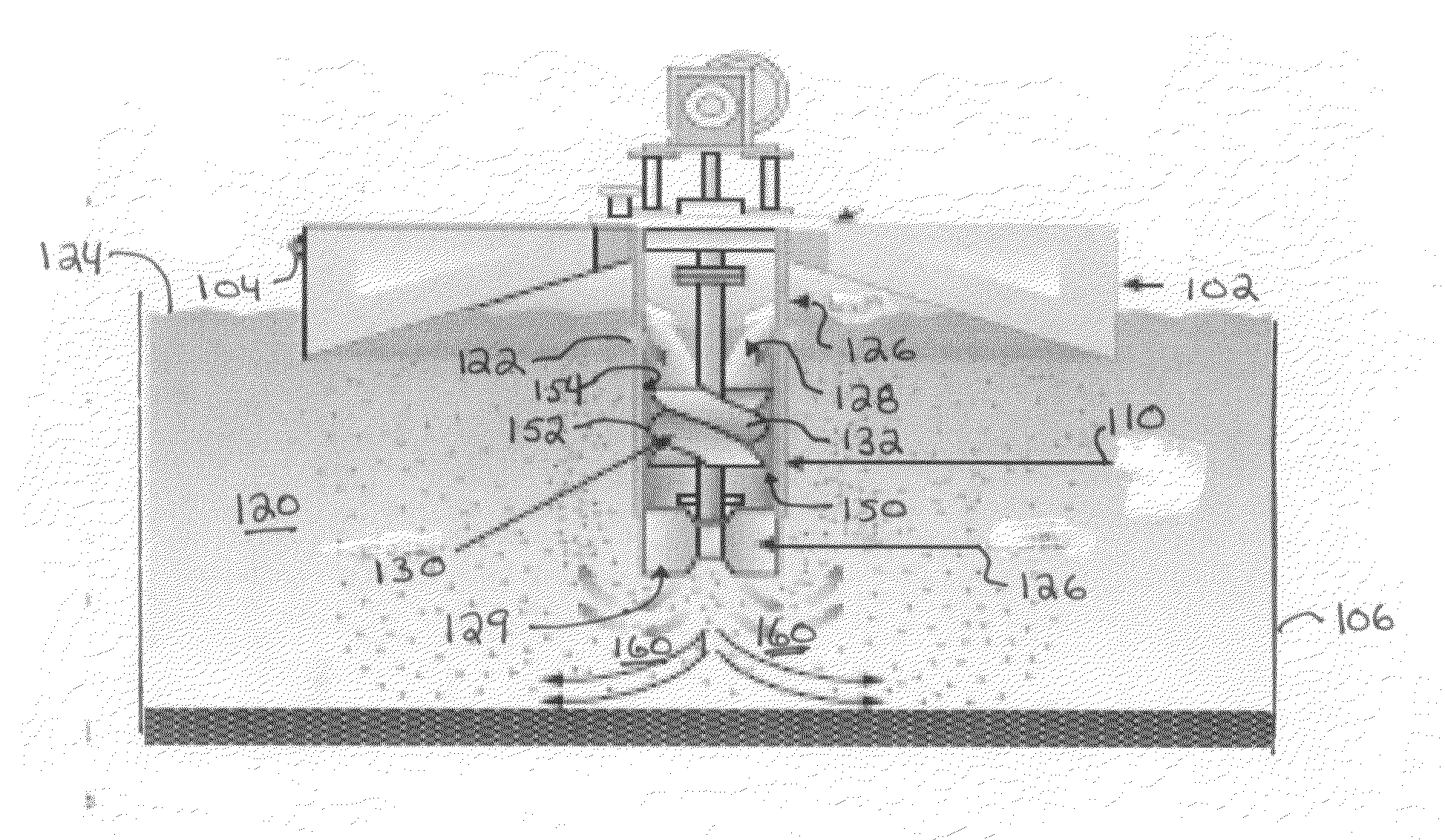

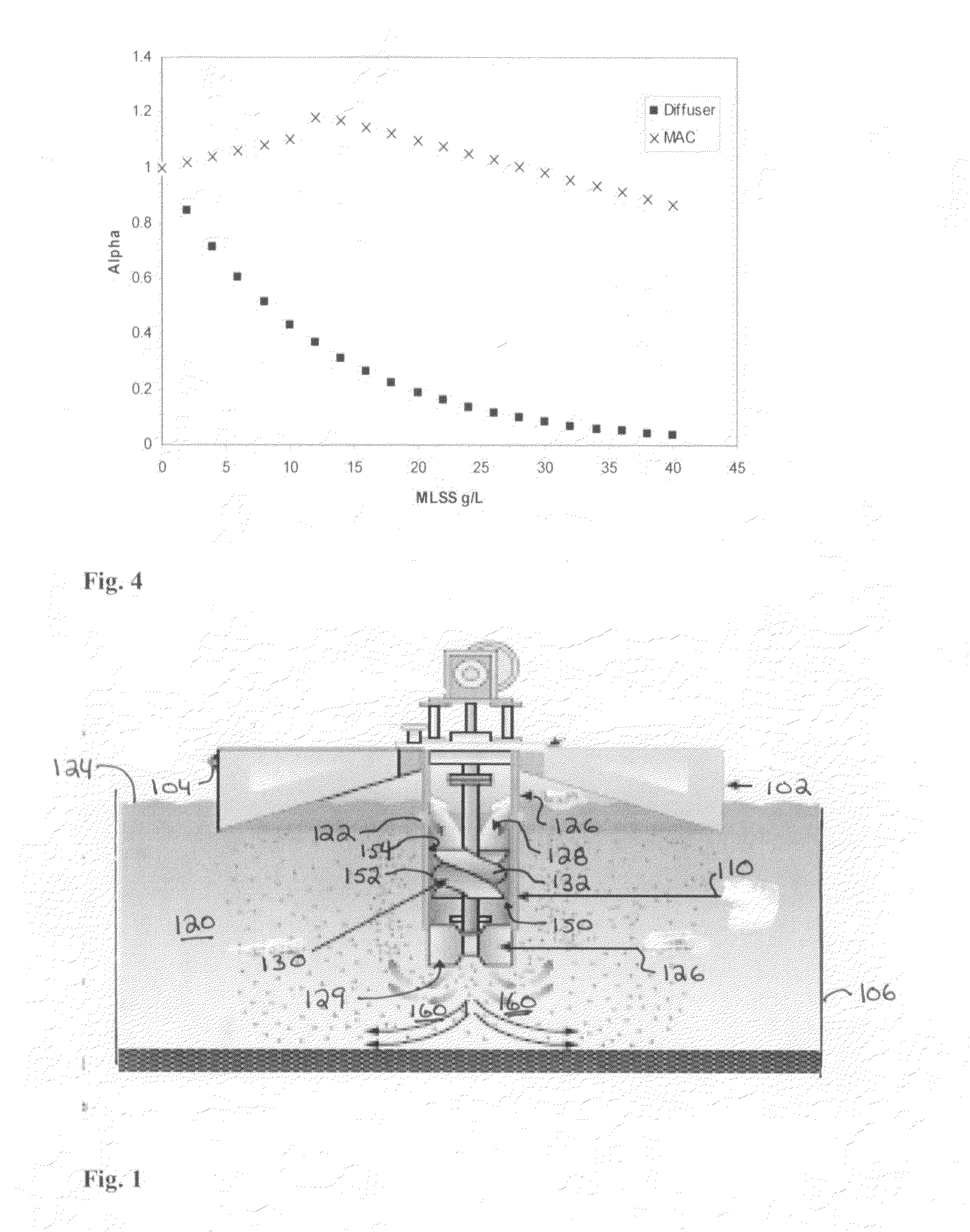

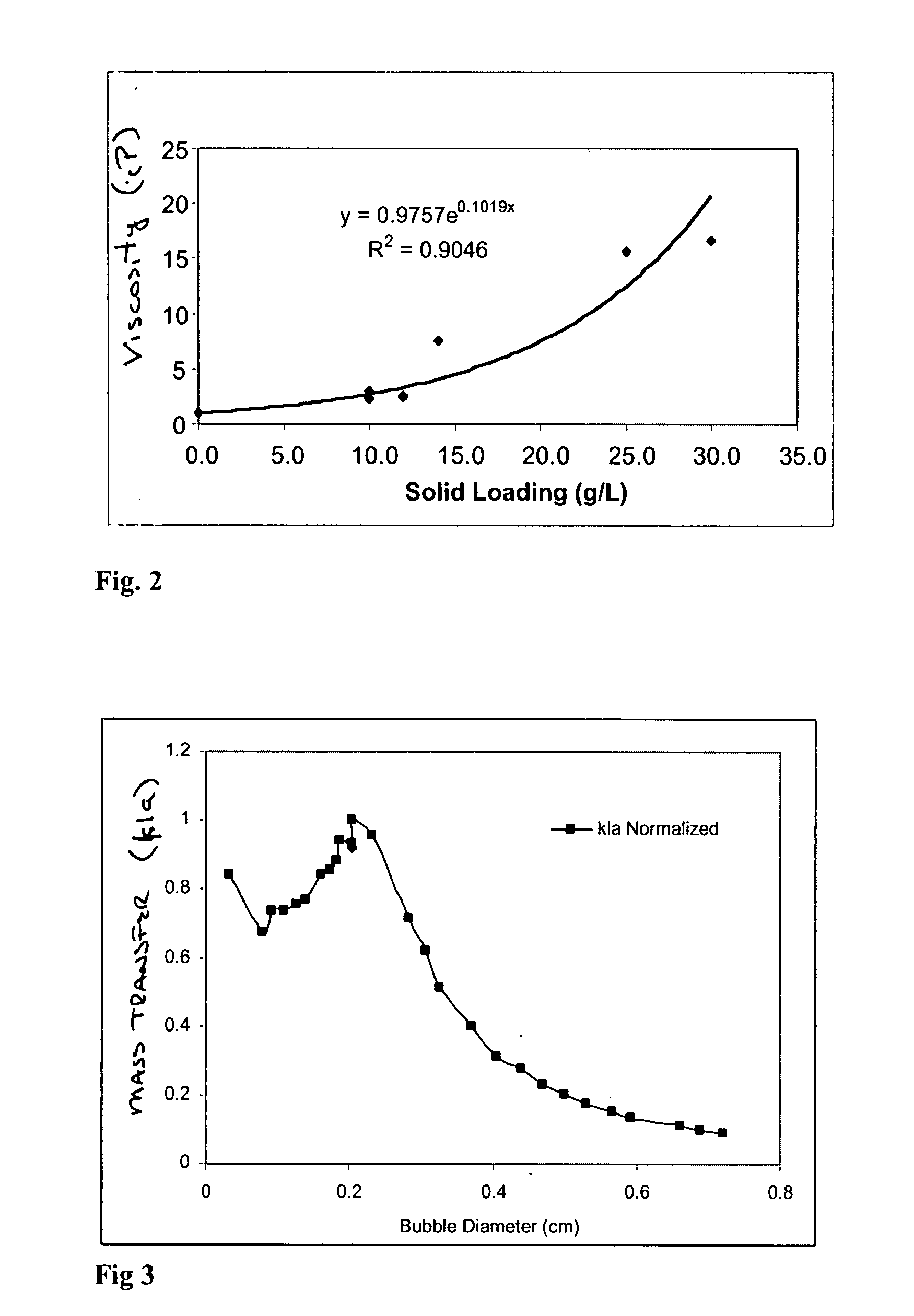

System and method for oxygenating an aerobic sludge digester

InactiveUS20080116132A1Efficient mass transferGreat bubble residence timeTreatment using aerobic processesRotary stirring mixersImpellerSludge

A system and method for oxygenating an aerobic sludge digester is provided. The disclosed embodiments include an aerobic sludge digester tank or vessel having a mechanically agitated contactor disposed therein, an oxygen injection subsystem adapted to inject oxygen into the digester tank proximate the mechanically agitated contactor. The embodiments of the mechanically agitated contactor include an agitator or impeller disposed within the draft tube which makes the draft tube the primary site for the gas-liquid mixing. In particular, the agitator or impeller is adapted to create gas bubbles having an average diameter between about 0.3 mm and 3.0 mm which are then dispersed into the aerobic digester. The mass transfer efficiency associated with the present system and method is enhanced from the combined effect of oxygen dissolution into the sludge and greater bubble residence time.

Owner:PRAXAIR TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com