Method for simultaneously separating and purifying racemic optical amyl alcohol, optical active amyl alcohol and isoamyl alcohol from fusel oil or mixed amyl alcohol and its equipment

An optically active and simultaneous separation technology, applied in the field of rectification, can solve the problems of increased investment in automatic control facilities, increased heat required for evaporation, and complicated extraction control process, achieving good separation and purification effects, reducing equipment investment, and improving The effect of separation and purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

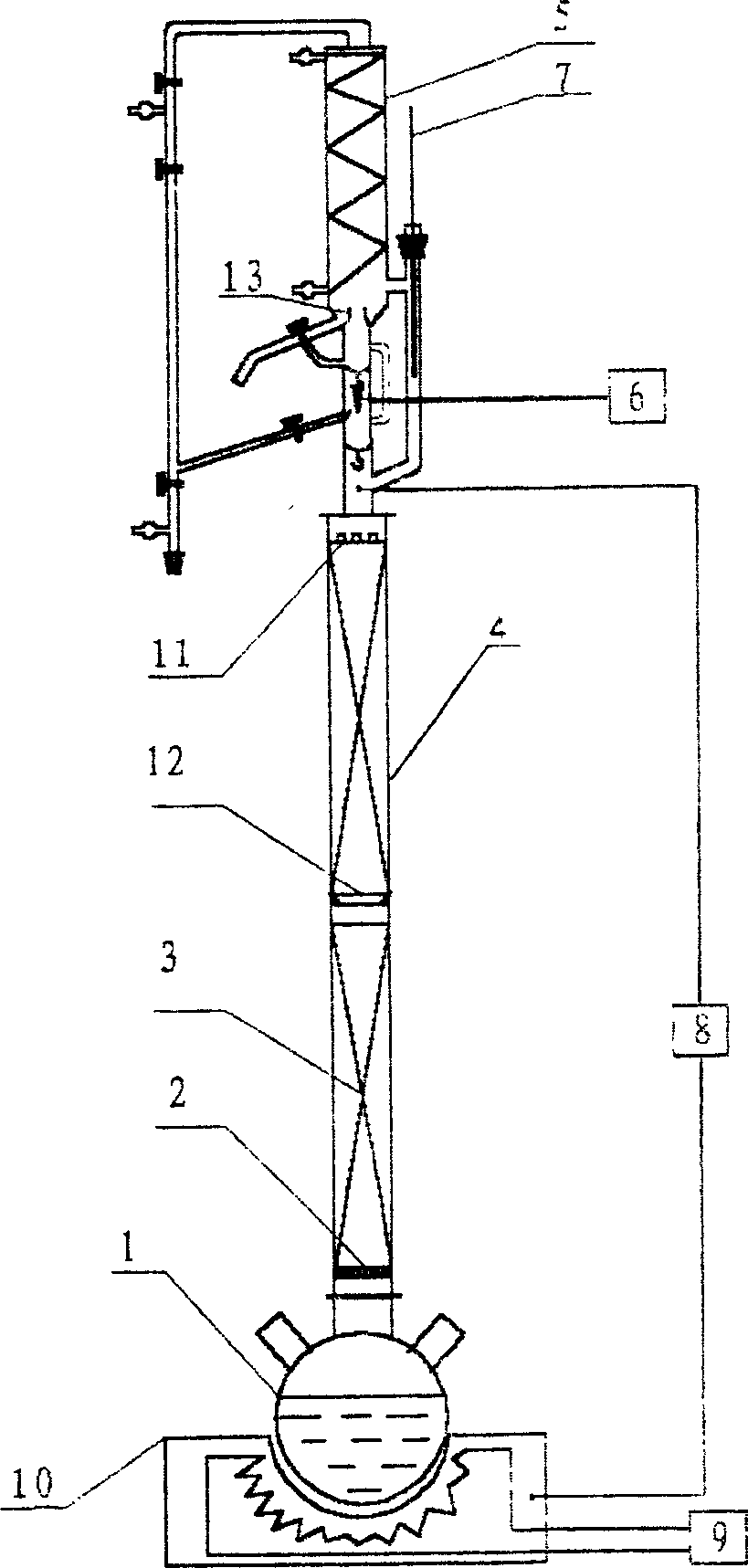

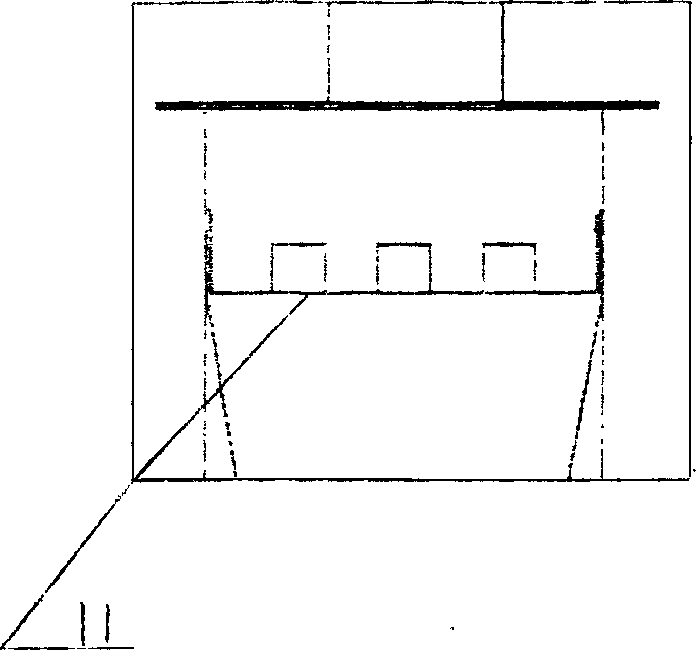

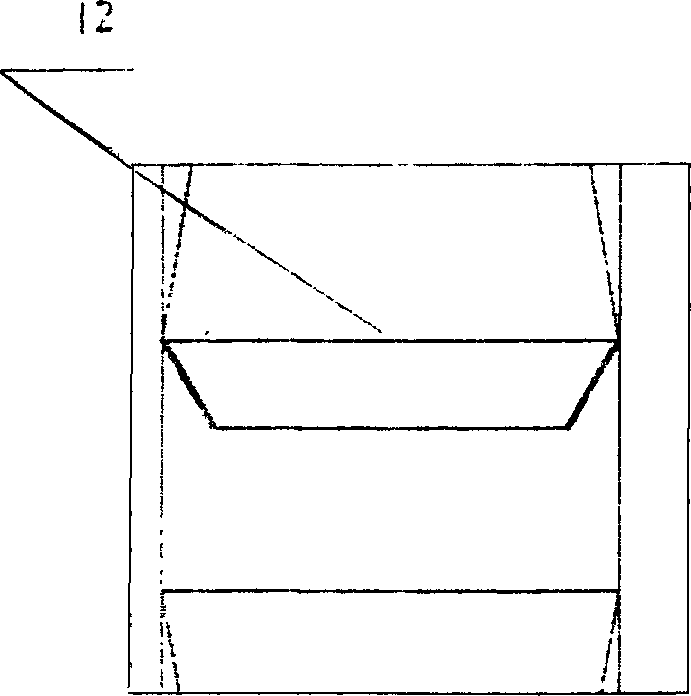

[0036]In this embodiment, the diameter of the rectifying tower is 30mm, and the filler is stainless steel triangular wire filler of φ3.5×3.5, and the height of the filler layer is 140cm.

[0037] 600 grams of pretreated fusel oil (2-methyl-1-butanol content 10%) is introduced into such as figure 1 In the shown rectification kettle 1 with a certain amount of zeolite, then adjust the stabilized power supply 9 to slowly heat the raw materials in the rectification kettle 1 through the electric heating furnace 10 until the liquid floods, and carry out the liquid flooding operation for 30 minutes, and the liquid flooding Three times, 3 minutes each time, so that the packing layer 3 located on the packing carrying grid 2 in the rectification column 4 is fully wetted. Then adjust the voltage-stabilized power supply 9 to control the heating capacity of the electric heating furnace 10 so as to control the vaporization rate, maintain a constant vaporization rate, and carry out total refl...

Embodiment 2

[0041] In this embodiment, the diameter of the rectifying tower is 20mm, the packing is stainless steel triangular wire packing of φ2.5×2.5, and the packing layer height is 150cm.

[0042] The 2-methyl-1-butanol content obtained in Example 1 is 460 grams of mixed pentanols of 55% introduced figure 1 , 2 . In the device shown in 3 (because embodiment 1 has carried out the description of technological process to the device, so the following embodiments, including this embodiment, are all omitted), the temperature rises to make the raw material boil until liquid flooding, and carry out liquid flooding Operate for 25 minutes, flood three times, each time for 2 minutes; then carry out the first stage of total reflux operation for 0.5 to 1.5 hours; then in the range of controlling the reflux ratio of 5 to 10, distill light components and water from the top of the tower, And remove the water; then carry out the second stage of total reflux operation for 2 hours; after the system is ...

Embodiment 3

[0045] This embodiment adopts the device of embodiment 2. It is worth noting that the main purpose of this example is to pre-concentrate the 2-methyl-1-butanol in the mixed pentanol, so as to be used as a raw material for further rectification, which is beneficial to improve the overall efficiency of the entire separation and purification.

[0046] 570 grams of pretreated fusel oil (2-methyl-1-butanol content is 10%) is introduced figure 1 , 2 , In the device shown in 3, the temperature is raised to make the raw materials boil until they are flooded, and the flooding operation is performed for 40 minutes, and the flooding operation is performed three times, each time for 5 minutes, and then the first full reflux operation is performed for 0.5 to 1 hour, and then the reflux is controlled. The rectification operation is carried out for ratios 4 to 6, and fractions of different temperature sections are collected from the top of the tower. When the 2-methyl-1-butanol in the frac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com