Patents

Literature

151results about How to "Good separation and purification effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for extracting high-purity mogroside V from siraitia grosvenorii

ActiveCN106008645AReduce water consumptionReduce extraction timeMembranesSemi-permeable membranesOrganic solventMicrowave

The invention discloses a method for extracting high-purity mogroside V from siraitia grosvenorii, and relates to the extraction method of the mogroside V. The method includes the specific steps: raw material pretreatment, extraction, centrifugation, enzymolysis, ultrafiltration, nanofiltration, decolorization, concentration, microwave drying, and crushing. The membrane technique is adopted for separation and purification, only pure water is used as a solvent, an organic solvent is discarded, and the method has the advantages of simple operation, safe and environmental-protection products, simple process, high quality and low price, and can realize the continuous large-scale industrial production.

Owner:JIANGXI HAIFU BIOENG

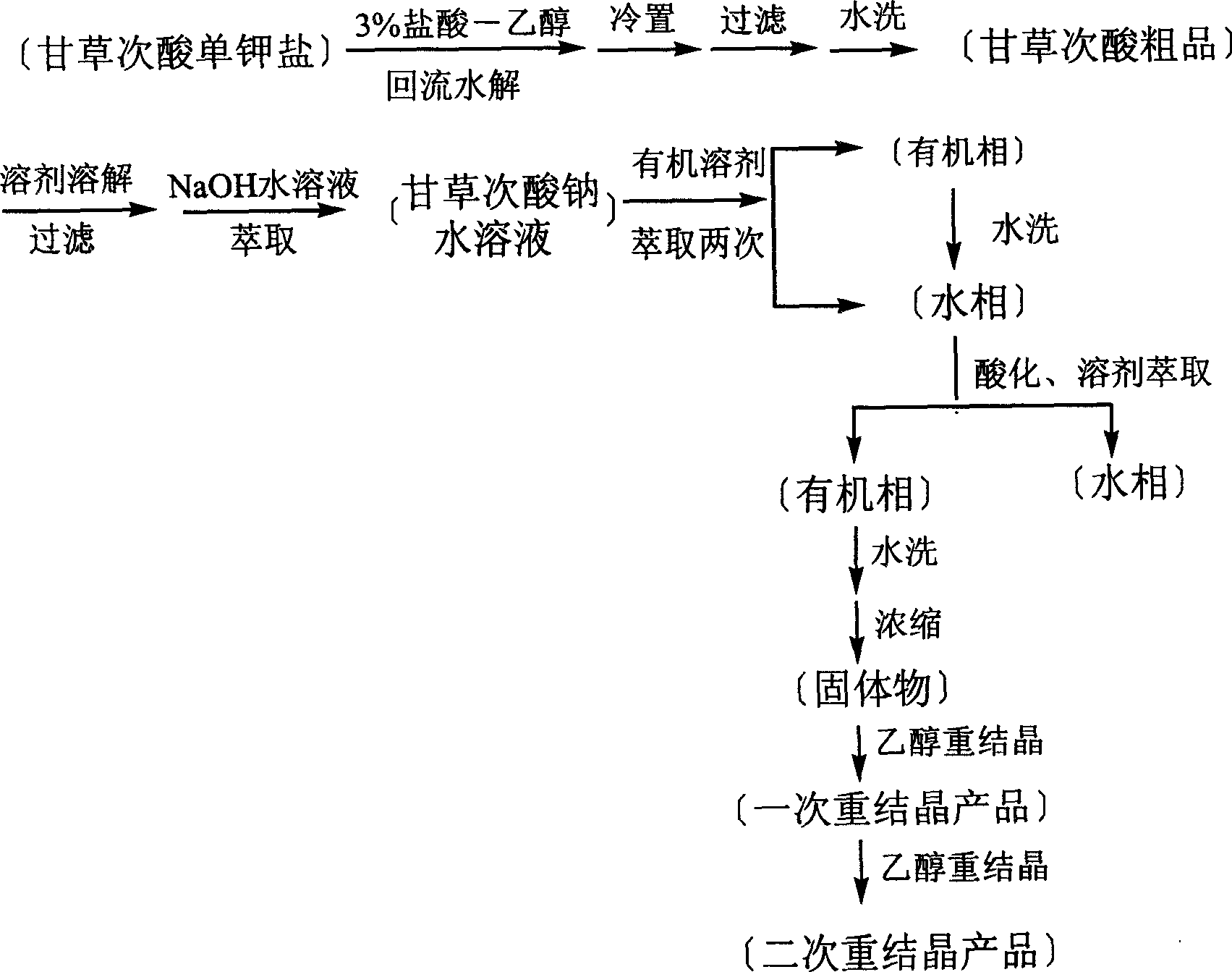

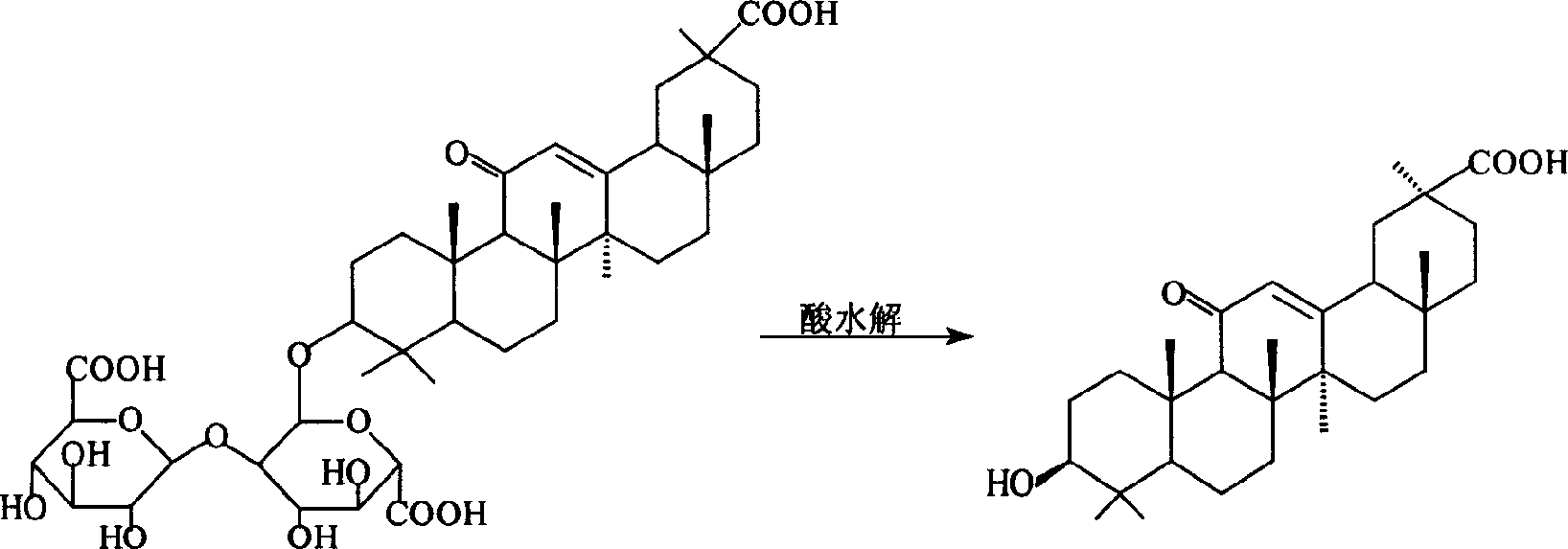

Method for preparing enoxolone

The invention discloses a method for preparing glycyrrhetinic acid. It adopts the glycyrrhizic acid crude product as raw material, and utiizes the processes of ethyl alcohol extraction, using ammonia water to regulate pH value, concentrating and recovering ethyl alcohol, adding water to make dissolution, using ADS-10 macroporous adsorption resin to remove impurity component so as to purity the glycyrrhizic acid being in effluent of resin column, the making acid hydrolysis to obtain the glycyrrhetinic acid crude product, making further purification so as to obtain high-purity glycyrrhetinic acid. The advantage of said invention lies in that the glycyrrhizic acid with different purities can be used to prepare glycyrrhetinic acid, the purification of glycyrrhetinic acid has no need of column chromatography, and adopts the method for making respective extraction at twice by using organic solvent.

Owner:NANKAI UNIV +1

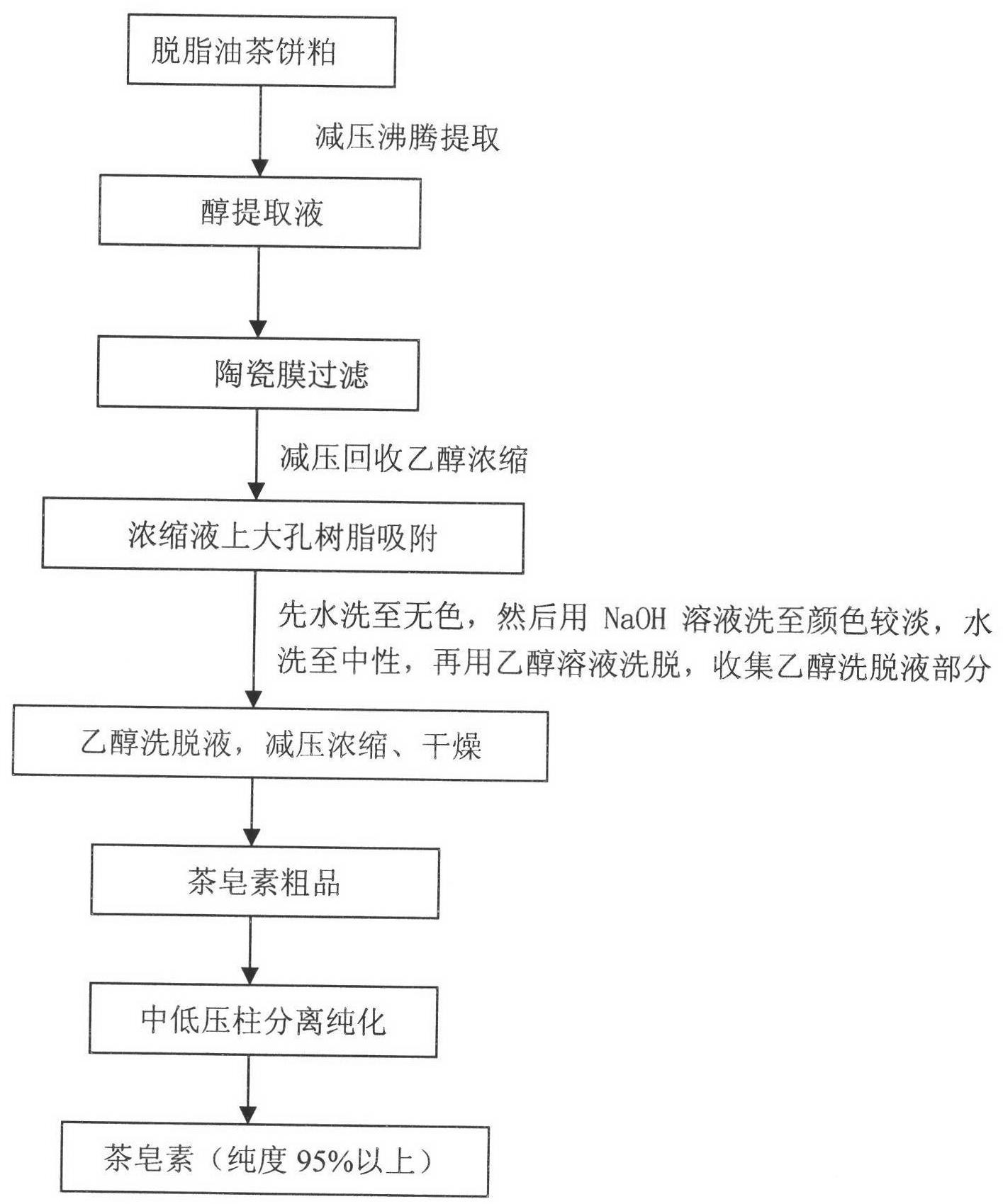

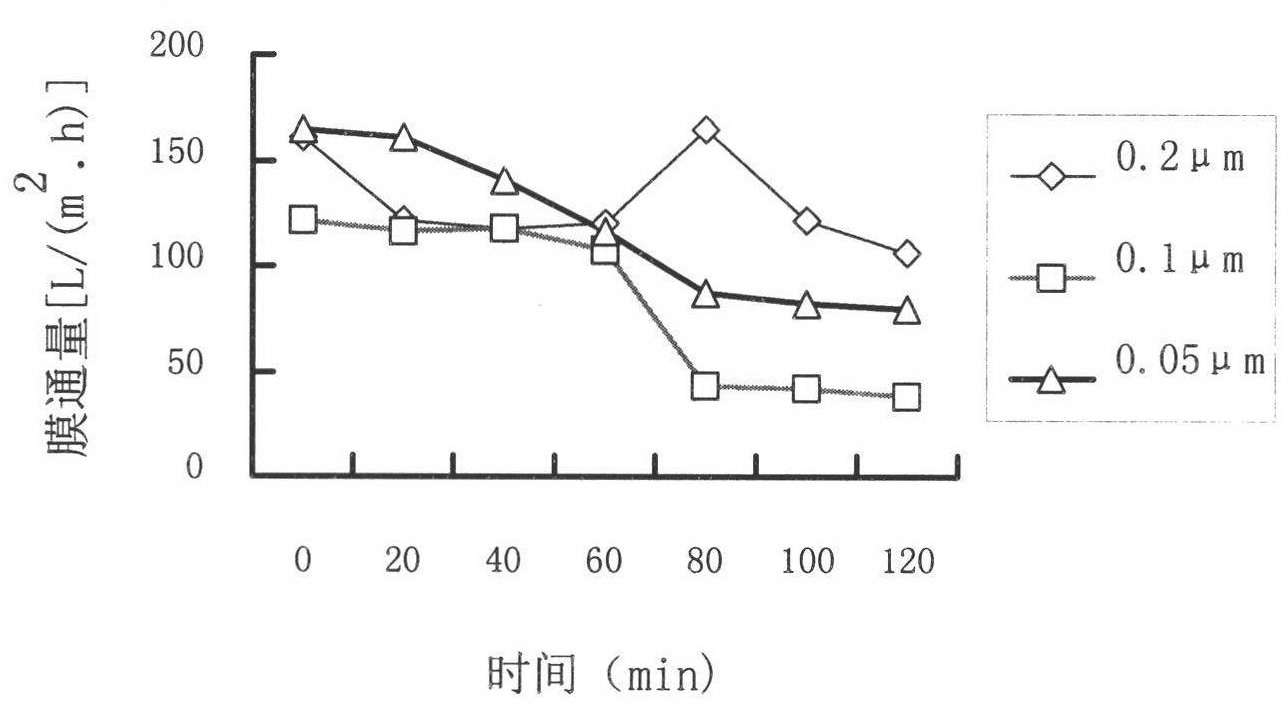

Method for extracting high-purity tea saponin from oil-tea-cake by decompression boiling

ActiveCN102276679AImprove extraction efficiencyLow extraction temperatureSugar derivativesSteroidsSolventChemistry

The invention relates to a method for extracting high-purity tea saponin from an oil-tea-cake by decompression boiling. In the method, a degreased oil-tea-cake is used as a raw material, hydrous ethanol is used as an extraction solvent, and decompression boiling is adopted for extraction; after being filtered, extract passes through a ceramic membrane; ethanol is recovered from the tea saponin solution passing through the ceramic membrane, and the tea saponin solution is concentrated; and the concentrated solution is adsorbed through macroporous resin and chromatographically separated by medium and low pressure columns to prepare the high-purity tea saponin. The tea saponin prepared by adopting the technology has light color and high purity of over 95 percent, and the method becomes a novel technology for producing tea saponin product in the industry.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Hepatic carcinoma targeted photo-thermal therapeutic agent as well as preparation method and application thereof

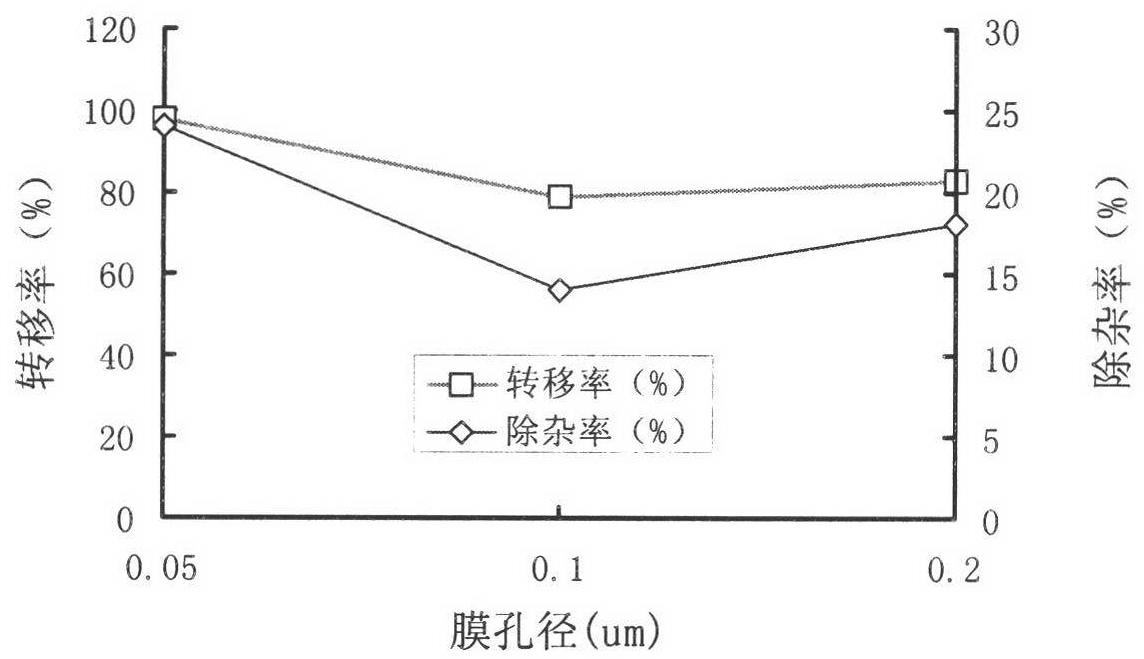

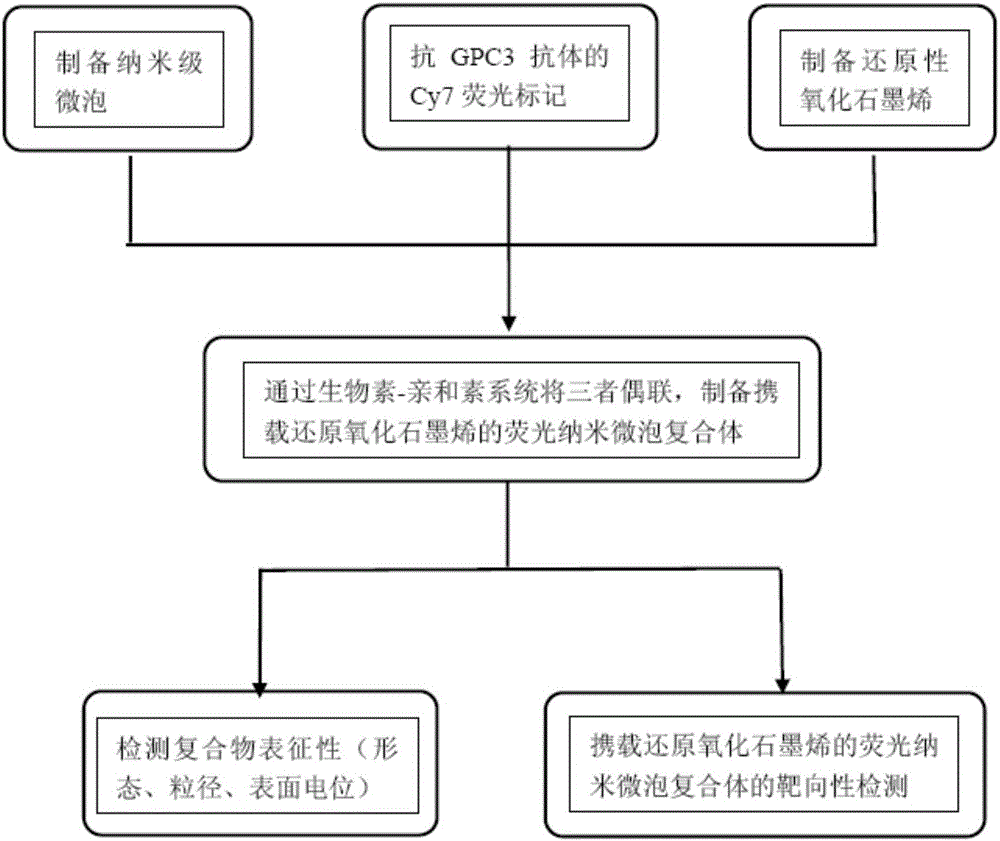

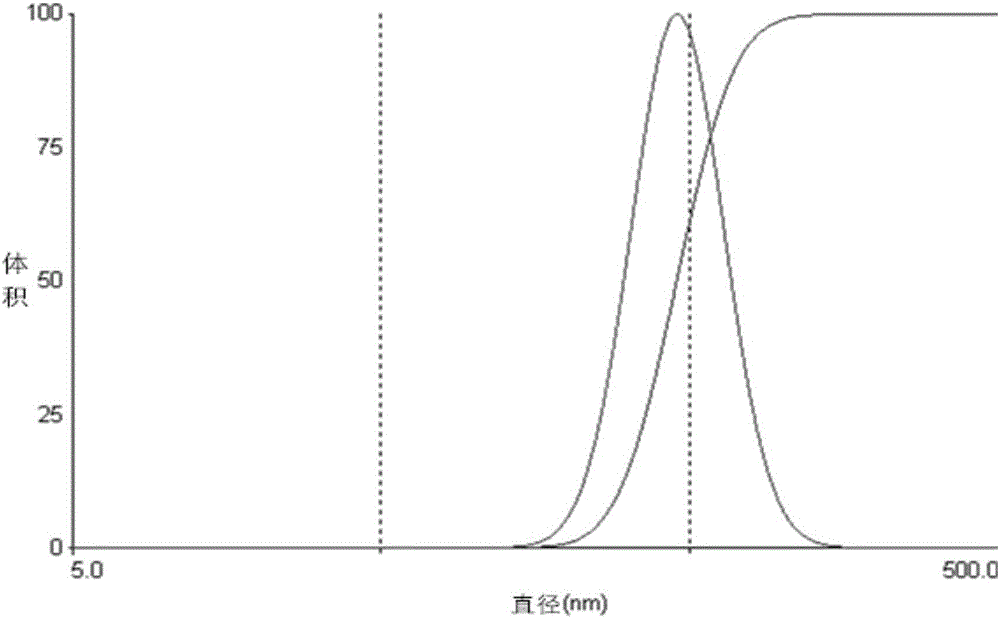

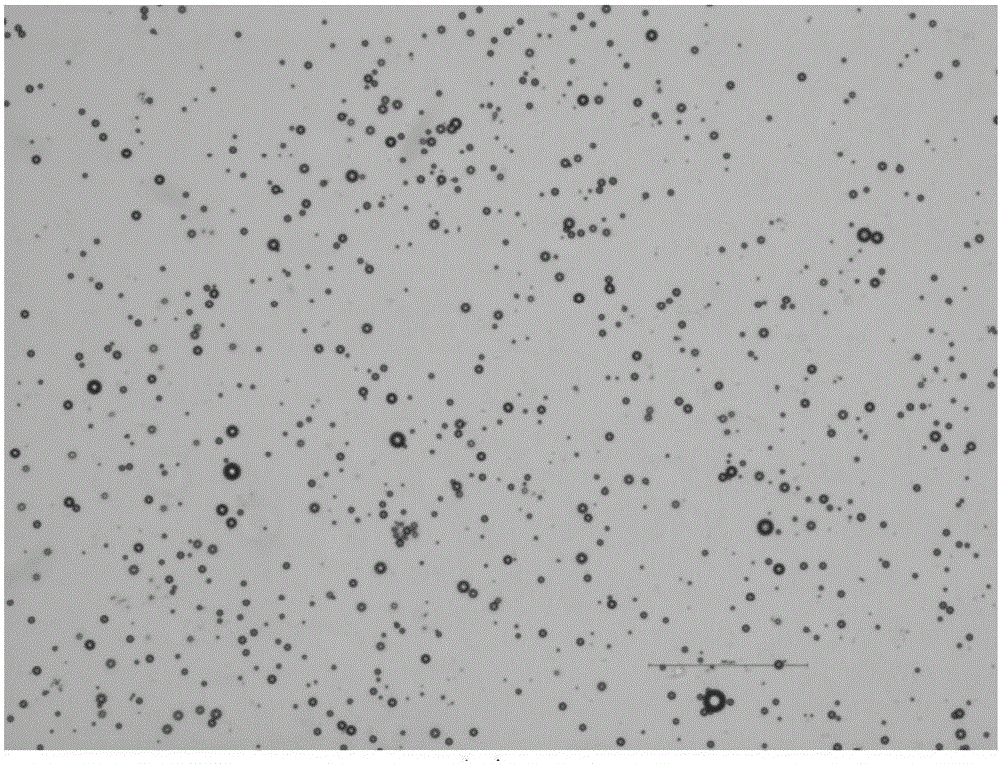

ActiveCN106075440AGood separation and purification effectWith ultrasoundEnergy modified materialsDigestive systemFluorescenceHepatic carcinoma

The invention provides a hepatic carcinoma targeted photo-thermal therapeutic agent as well as a preparation method and an application thereof and belongs to the field of biomedical engineering. The hepatic carcinoma targeted photo-thermal therapeutic agent is prepared with the method comprising the following steps: (1) preparing biotinylation nanometer microbubbles; (2) preparing a Cy7 fluorescently-labeled biotinylation anti-GPC3 (glypican3) antibody; (3) preparing biotinylation RGO (reduced graphene oxide); (4) coupling the products prepared in the step (1), step (2) and step (3) through a biotin-avidin system to obtain the hepatic carcinoma targeted photo-thermal therapeutic agent. The hepatic carcinoma targeted photo-thermal therapeutic agent has ultrasonic and fluorescence imaging functions, mediates RGO targeted delivery with an ultrasound-targeted microbubble destruction technology, monitors a photo-thermal therapeutic process in real time, can be used for preparing drugs for hepatic carcinoma therapy and has excellent clinical application value.

Owner:HARBIN MEDICAL UNIVERSITY

Brasenia schreberi polysaccharide preparation method

The invention relates to a Brasenia schreberi polysaccharide preparation method. The preparation method comprises the following steps: drying a raw material fresh Brasenia schreberi, and crushing to obtain Brasenia schreberi powder; adding water to the Brasenia schreberi powder for dilution, adjusting the pH value of the obtained solution, adding papain, carrying out enzymatic hydrolysis treatment under controlled conditions, filtering, concentrating, adding a mixture containing organic solvents comprising chloroform and n-butanol, and stirring for removing proteins; carrying out dialysis desalting through a dialysis membrane, carrying out alcohol precipitation, collecting the obtained precipitate, washing, and drying to obtain crude Brasenia schreberi polysaccharides. The preparation method has a high protein removal rate, a small polysaccharide loss and a good separation and purification effect, and determination results show that the protein removal rate reaches above 80%, and the purity of the obtained crude Brasenia schreberi polysaccharides reaches above 70%. The preparation method has the advantages of reasonable technology, advanced technique, feasible operation, and suitableness for the large-scale factory production.

Owner:山东好当家海森药业有限公司

Method for improving purity of eicosapentaenoic acid ethyl ester in fish oil

ActiveCN106117050AHigh purityReduce contentOrganic compound preparationCarboxylic acid esters preparationDocosahexaenoic acid ethyl esterDistillation

The invention discloses a method for improving purity of eicosapentaenoic acid ethyl ester in fish oil. The method comprises steps as follows: the fish oil is subjected to transesterification, and a fatty acid ethyl esterification product is obtained; the fatty acid ethyl esterification product is subjected to urea inclusion, and a urea inclusion mixture is obtained; the urea inclusion mixture is subjected to at least three stages of molecular distillation, and a molecular distillation product is obtained; the molecular distillation product is subjected to rectification. According to the method, the technology is simple, the content of eicosapentaenoic acid ethyl ester in the fish oil can be effectively increased, meanwhile, the content of docosahexaenoic acid ethyl ester is reduced, and the separation effect is good, so that eicosapentaenoic acid ethyl ester can be better applied to industrial production.

Owner:四川欣美加生物医药有限公司

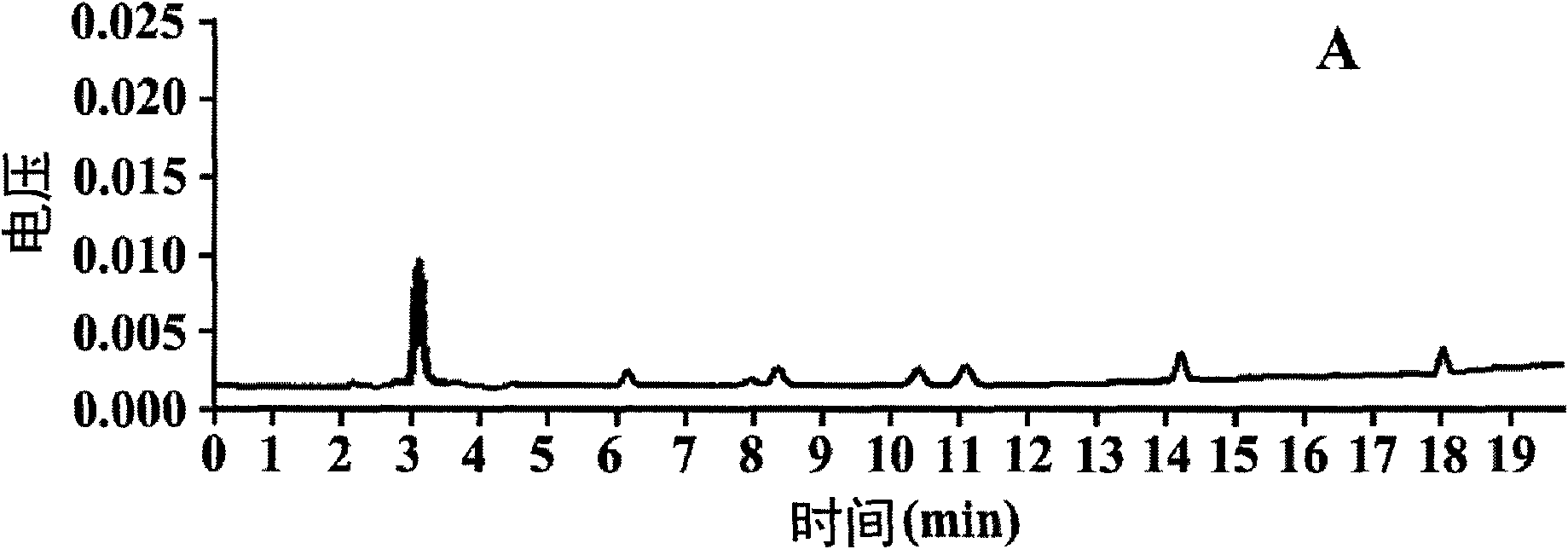

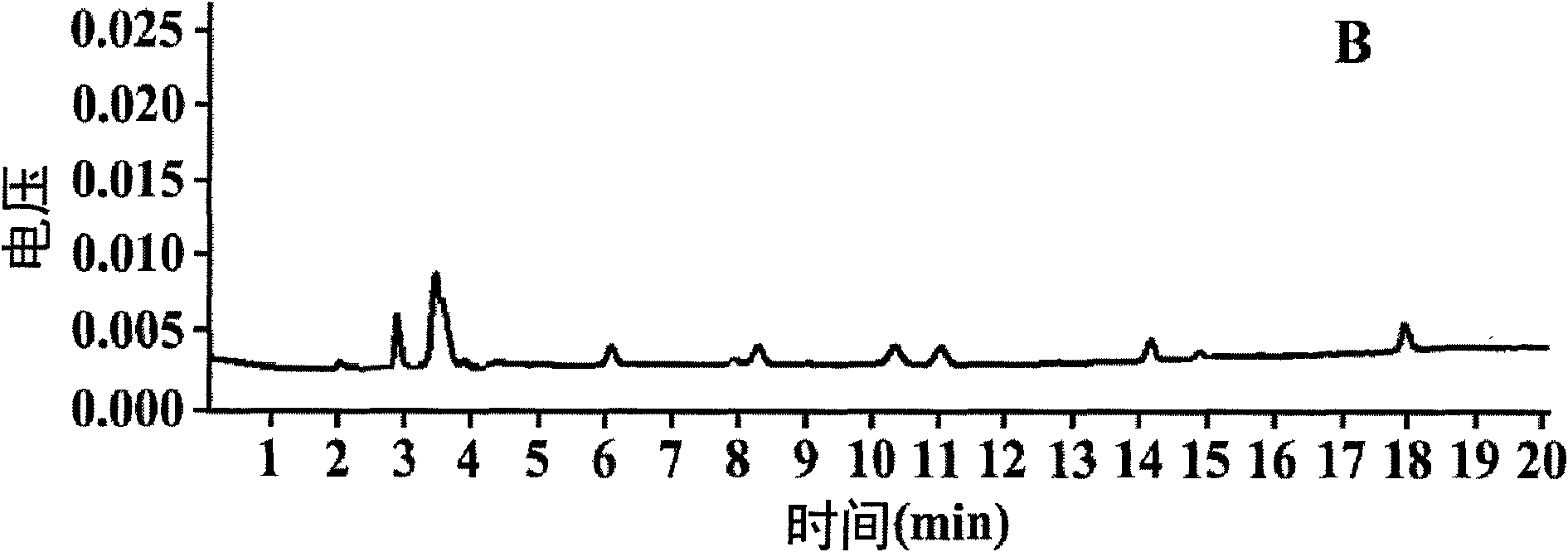

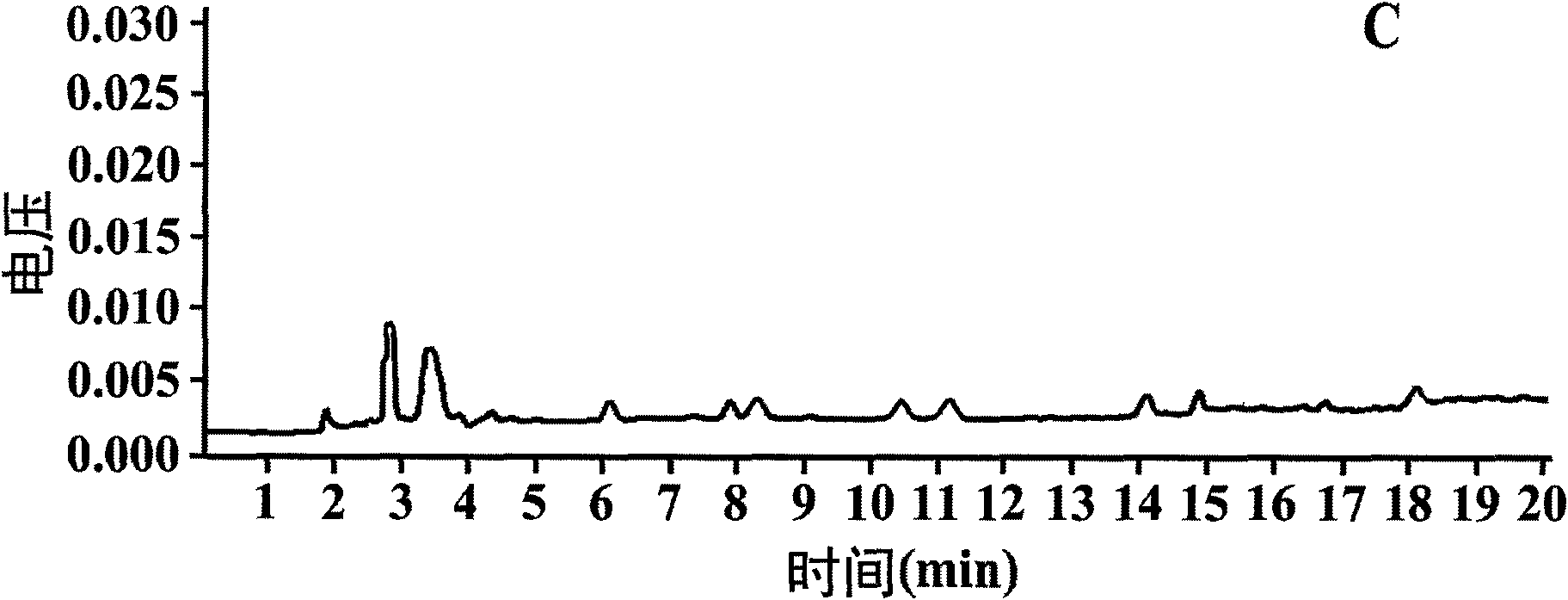

Efficient separation and purification method for multi-residue sulfonamide antibiotics in biological samples

InactiveCN102279232AAchieve interferenceReduce distractionsComponent separationOther chemical processesCross-linkBiological pump

The invention relates to a method for efficiently separating and purifying multiresidue sulfonamide antibiotics in a biological sample. The method is characterized by comprising the following steps of: (1) preparing a molecular imprinted polymer, comprising the steps of burdening according to the mol ratio of template molecule to functional monomer to cross linking agent of being 1: (2-8): 25 and obtaining the molecular imprinted polymer with special identification function to the sulfonamide antibiotics by adopting a body polymerization method; (2) weighing certain amount of biological sample to be separated into a mortar, grinding the biological sample by the mortar, adding right amount of the molecular imprinted polymer, and further homogenating to obtain a homogenated sample, wherein the weight ratio of the biological sample to be separated to the molecular imprinted polymer is 2: (1-5), and (3) placing the homogenated sample in a solid phase extraction column, sequentially rinsing with 2.0-4.0ml of water, 2.0-4.0ml of 10wt% acetonitrile aqueous solution, and then eluting with 3.0-5.0ml of methanol / methanoic acid mixed solution; and separating the sulfonamide antibiotics from the biological sample to be separated by being instantly dissolved in the methanol / methanoic acid mixed solution. The method provided by the invention has wide selectivity and good separation and purification effect.

Owner:NINGBO UNIV

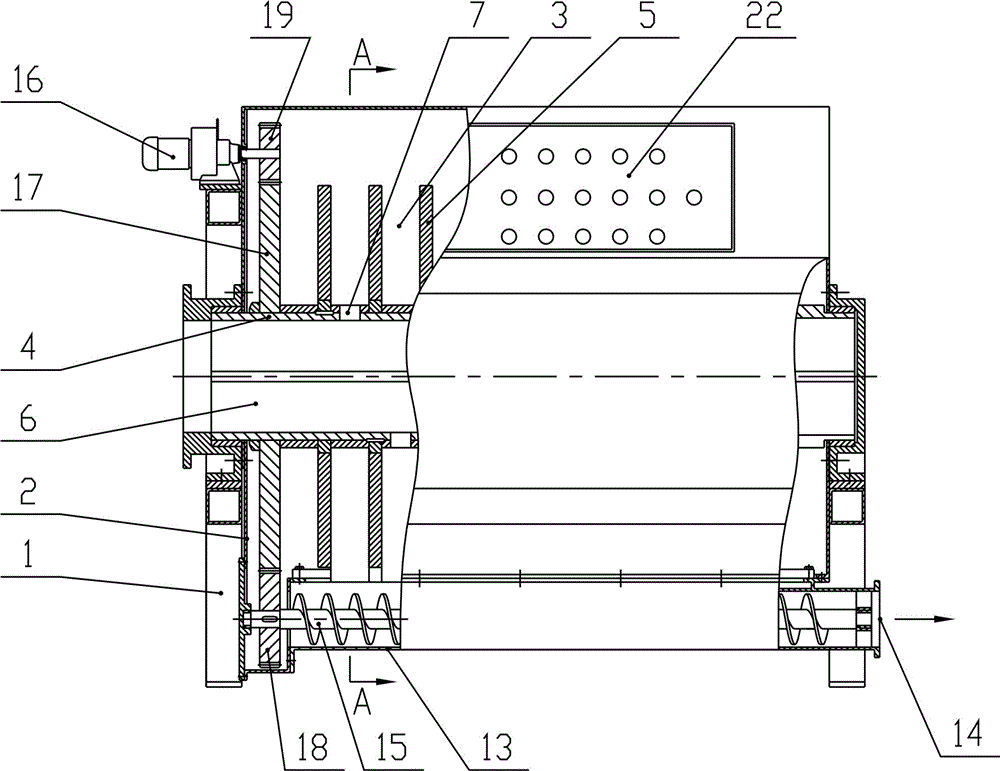

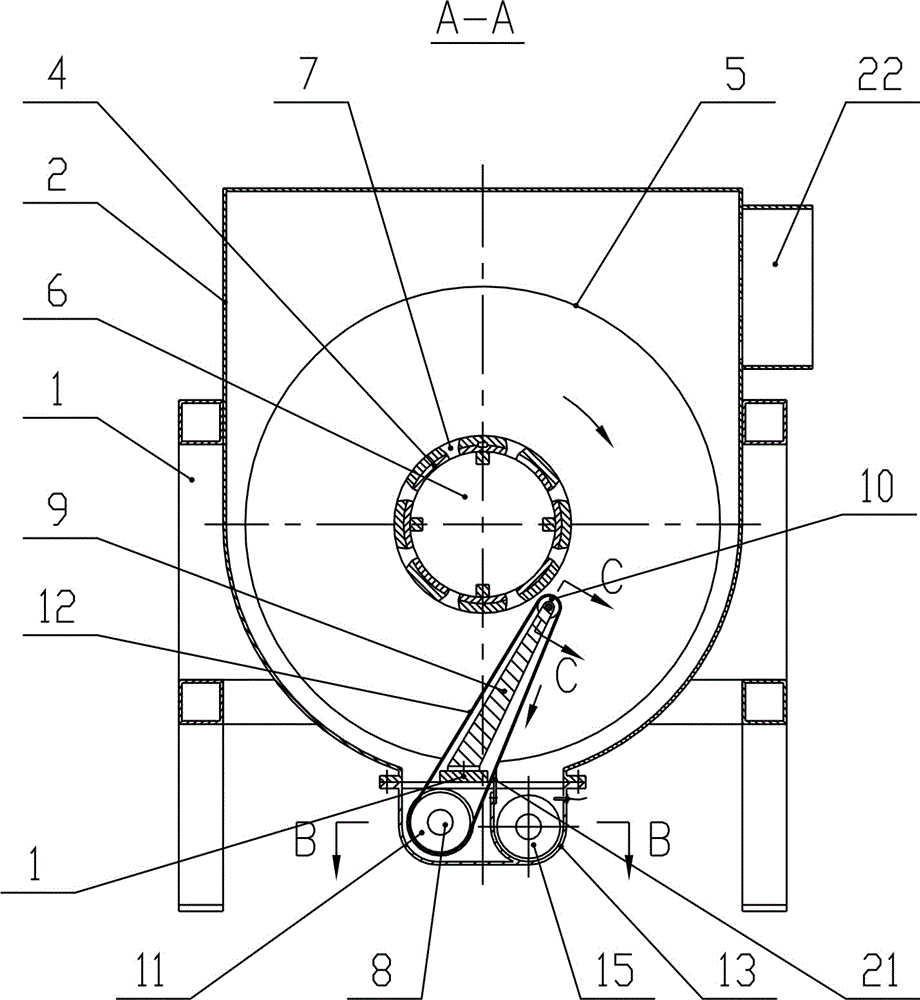

Radial-flow magnetic wastewater separative purification equipment

ActiveCN102745784AHigh magnet utilizationShort stayWater/sewage treatment by magnetic/electric fieldsMagnetic tension forceWastewater

The invention discloses radial-flow magnetic wastewater separative purification equipment which comprises a frame, a water tank, a fluid connector, a residue scraping mechanism and a transmission mechanism, wherein the fluid connector, the residue scraping mechanism and the transmission mechanism are arranged on the water tank which is disposed on the frame. The equipment is characterized in thata hollow shaft is arranged in the water tank through a bearing block and provided with a plurality of magnetic disks, at least one end of the hollow shaft is open, and the open end and an external pipeline are in a dynamic sealed structure. The hollow shaft is provided with a plurality of through holes communicated with a cavity channel of the hollow shaft, and the residue scraping mechanism comprises a residue scraping component and a residue conveying component. Compared with existing semi-immersed disk type magnetic separators in advection or streaming modes, the equipment has the advantages that fully-immersed operation of magnetic disks is realized by means of radial flows, is lower in investment cost, smaller in occupied area, high in impact load bearing capacity and lower in energyconsumption, and is new-generation disk type magnetic separative purification equipment.

Owner:CHENGDU YUANRONG ENVIRONMENTAL TECH +1

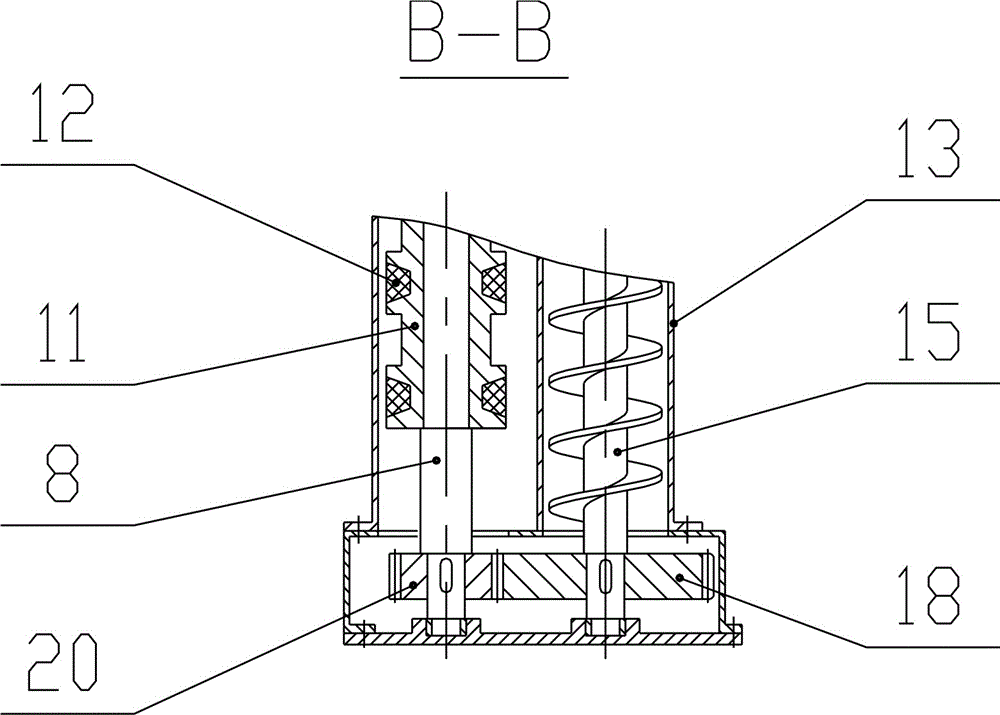

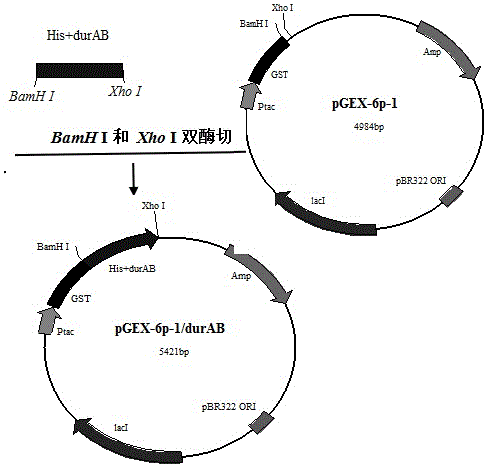

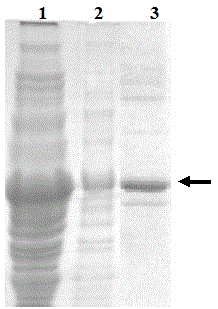

Recombinant bacterium for preparing bacteriocin durancin GL and preparation method and application of recombinant bacterium

ActiveCN104593313ASimple ingredientsEfficient separationBacteriaFermentationBiotechnologyMicroorganism

The invention provides a recombinant bacterium for preparing bacteriocin durancin GL, a preparation method and application of the recombinant bacterium and relates to the microbial biotechnical field. The recombinant bacterium carries a coding gene of a fusion protein formed by connecting the bacteriocin durancin GL, a purification tag and a restriction enzyme cutting site. The method for preparing the bacteriocin durancin GL comprises the following steps: inducing the recombinant bacterium to express the fusion protein; crushing to obtain lysate; centrifuging and taking a supernate; carrying out HisTrap HP column and GSTrap 4B column separation or GSTrap 4B column separation and collecting an eluting peak; and carrying out enzymolysis by enterokinase and removing the purification tag to obtain the bacteriocin durancin GL. The recombinant bacterium provided by the invention is convenient to construct and can efficiently express the recombinant bacteriocin durancin GL. The bacteriocin durancin GL is efficiently separated by virtue of affinity chromatography, and the restriction enzyme cutting site is hydrolyzed to obtain the bacteriocin durancin GL with activity.

Owner:NANJING UNIV OF FINANCE & ECONOMICS

Coarse taxol product separating and purifying process

InactiveCN1526708AGood separation and purification effectHigh yieldOrganic chemistryWater solubleSolvent

The present invention separates and purifies taxol by means of column chromatographic process with macroporous resin, such as AB-8, D101, D201 and AK-9 as fixed phase and polar solvent, such as water solution of ethanol or acetone, as flowing phase, with the effluent flow rate is 0.6-1.5 L / hr. The effluent with taxol content lower than cephalotmannine content is concentrated and dried to obtain intermediate taxol product A; and effluent with taxol content higher than cephalotmannine content is concentrated and dried to obtain intermediate taxol product B. The said process can separate and purify coarse taxol product with 9-20% content to obtain intermediate taxol product with 40-60% content in the yield as high as 80%. The process can eliminate water soluble impurity from the coarse product.

Owner:丁志坚

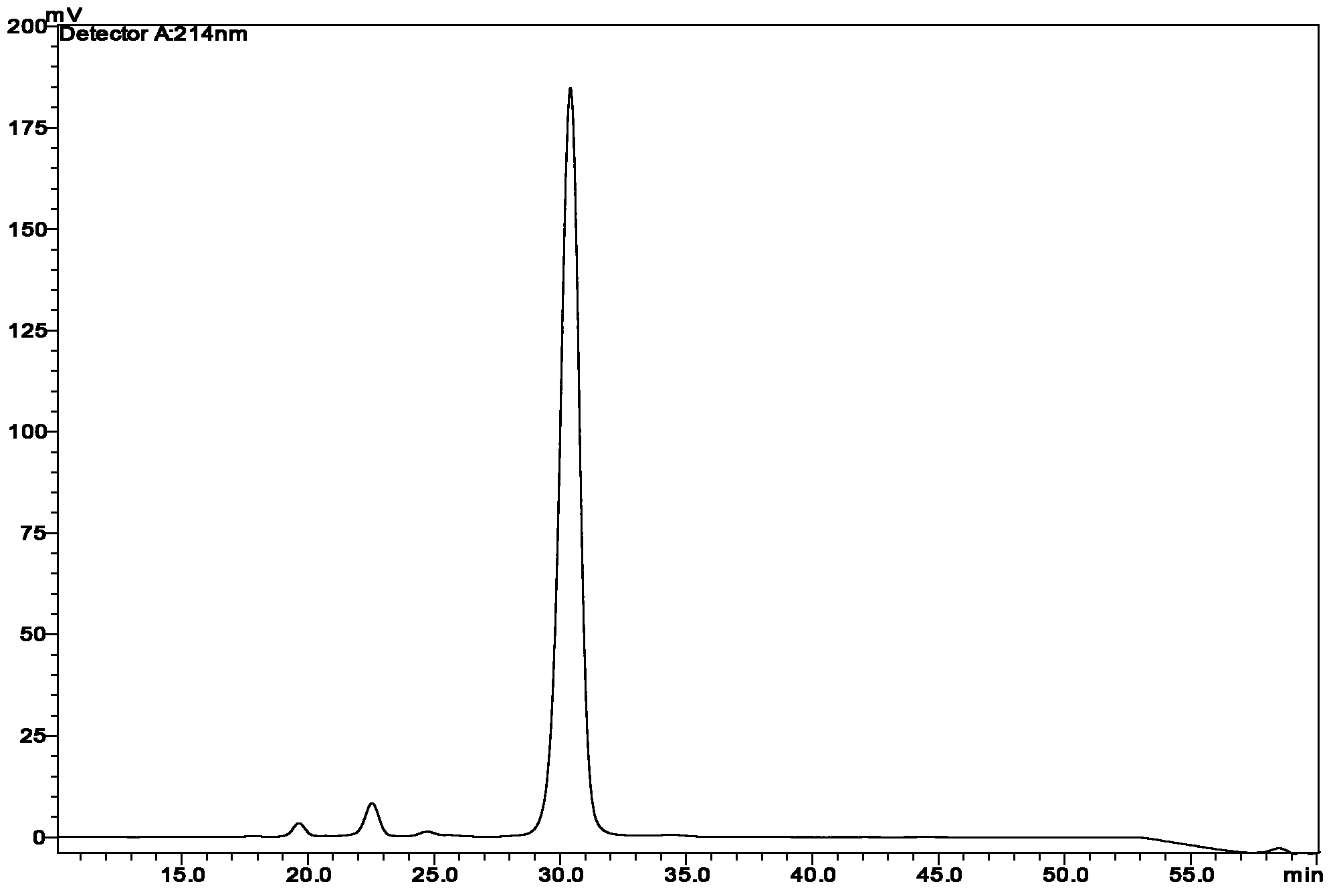

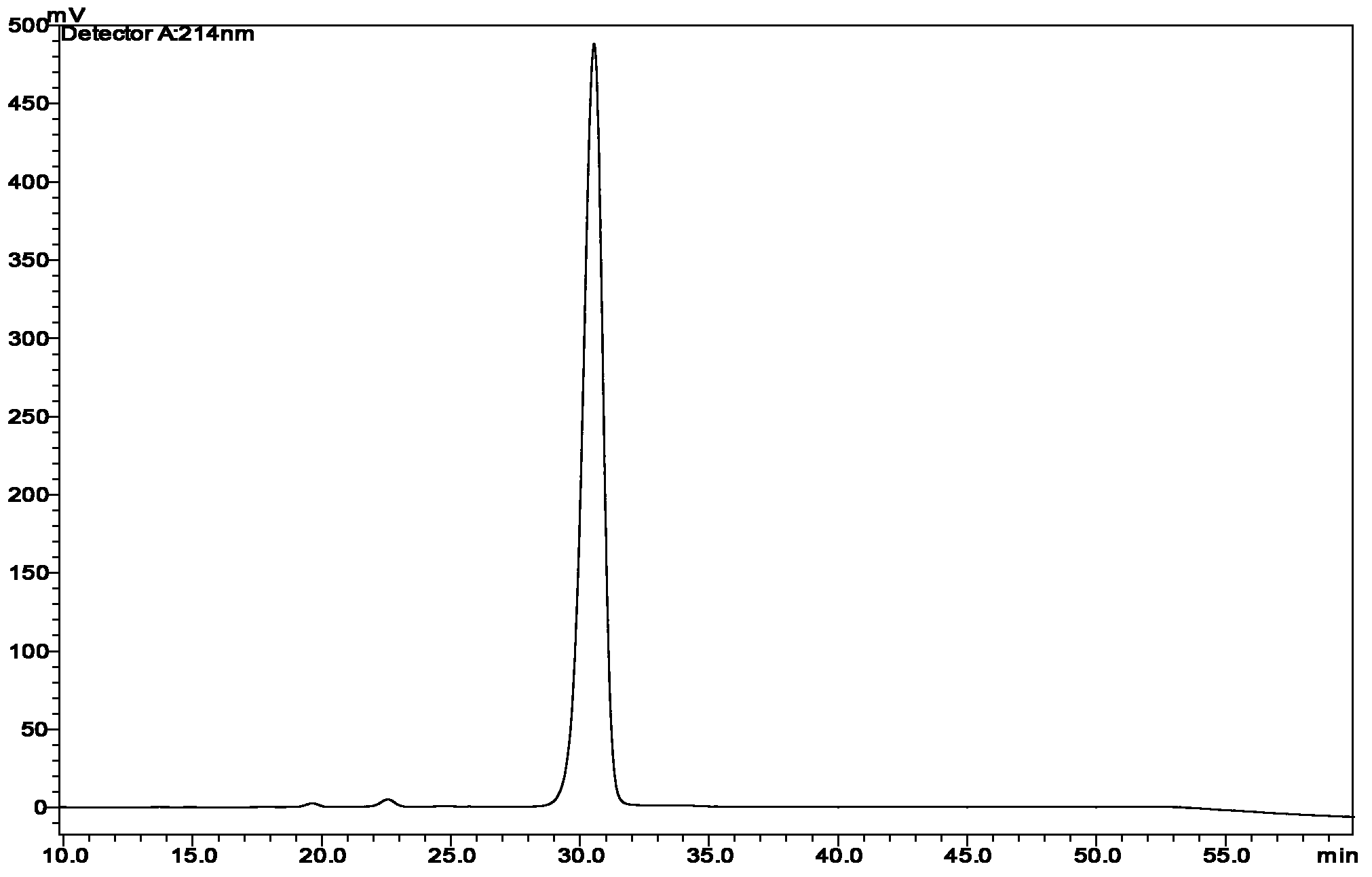

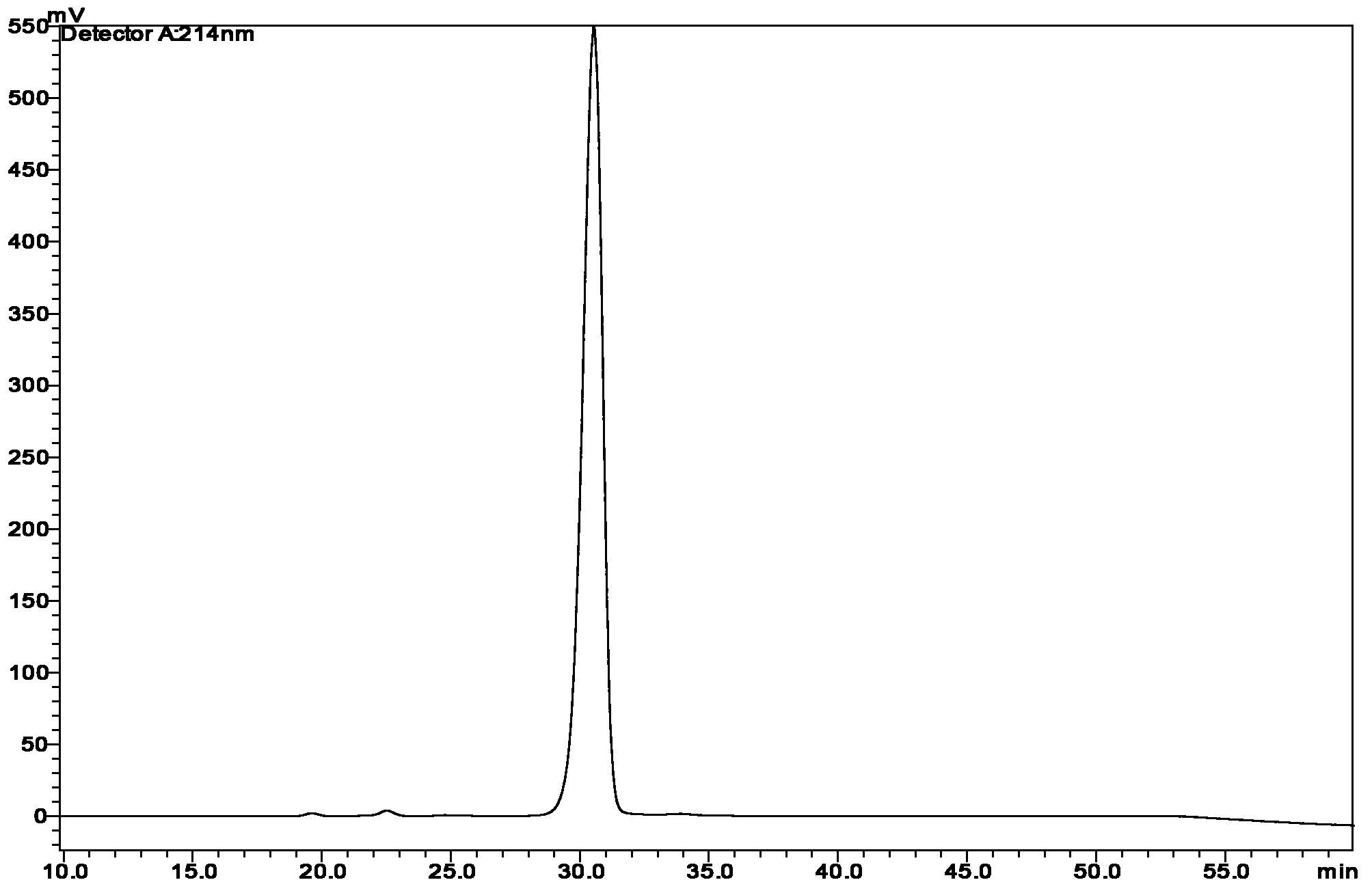

Chromatographic purification method of fatty acid mono-acylation insulin

ActiveCN103275210AHigh purityEasy to operatePeptide preparation methodsInsulinsStationary phaseOrganic solvent

The invention discloses a chromatographic purification method of fatty acid mono-acylation insulin. The chromatographic purification method comprises the steps of separating the fatty acid mono-acylation insulin by employing a medium- and low-pressure chromatographic system, and using an organic polymer reversion phase chromatographic material as a stationary phase, and taking at least one organic solvent mixable with water and at least one buffering agent substance as an elution moving phase with the pH (Potential of Hydrogen) value of 2-4. The chromatographic purification method has simple steps, is easy to amplify, and low in economic cost, and can increase the purity of a sample from original 50-60% to 98% by one step.

Owner:ZHUHAI UNITED LAB

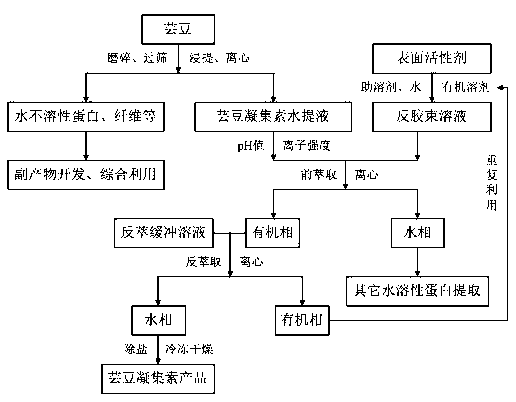

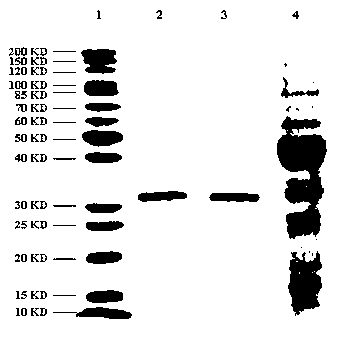

Method for microwave-assisted reverse micelle separation and purification of kidney bean agglutinin

InactiveCN103073627AImprove solubilityHigh selectivityPeptide preparation methodsPlant peptidesAgglutinin-BPurification methods

The invention discloses a method for microwave-assisted reverse micelle separation and purification of kidney bean agglutinin, and relates to a separation and purification method of the agglutinin, aiming at solving the problems of low ratio, high cost, more processes and long time for separation and purification of the kidney bean agglutinin. According to the method for the microwave-assisted reverse micelle separation and purification of the kidney bean agglutinin, the agglutinin is directly separated and purified from kidney bean agglutinin water extract; and the method comprises a pre-extraction process and a back extraction process. Under an auxiliary effect of microwave, water-soluble protein in kidney bean is quickly dissolved into the water extract, so that the dissolubility is greatly improved, and the leaching time is shortened. Based on a liquid-liquid extraction principle, the selectivity of extraction is improved, and high-efficiency pre-extraction and back extraction of the kidney bean agglutinin can be realized. By applying a reverse micelle extraction technology, a better separation and purification effect can be achieved with only the pre-extraction and back extraction steps; the method has simple steps and is convenient to operate; and the pre-treatment time can be greatly shortened in combination with microwave assistance so as to save the cost.

Owner:HARBIN INST OF TECH

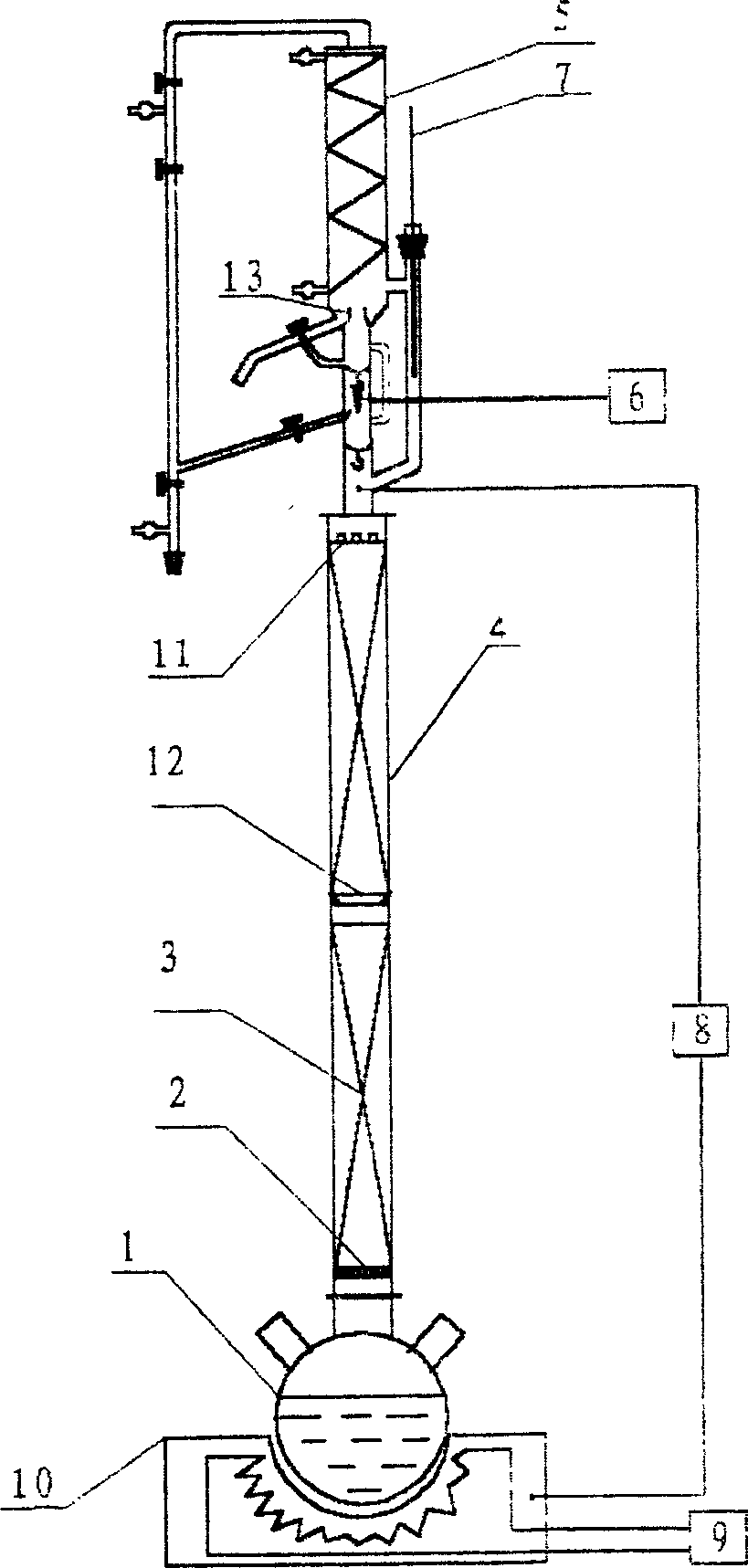

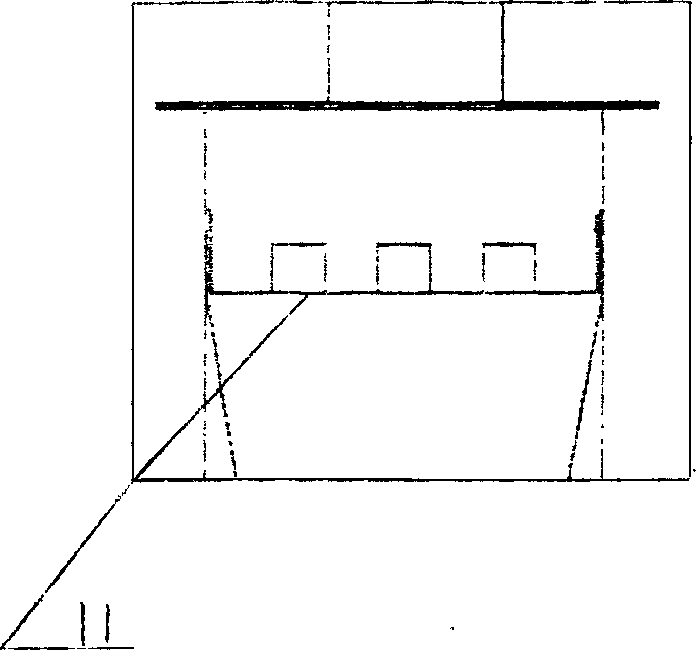

Method for simultaneously separating and purifying racemic optical amyl alcohol, optical active amyl alcohol and isoamyl alcohol from fusel oil or mixed amyl alcohol and its equipment

InactiveCN1443739ATake advantage ofReduce energy consumptionOrganic compound preparationHydroxy compound preparationIt equipmentIsoamyl alcohol

The present invention adopts single tower, on the basis of general precision rectification process adds flooding operation, its total reflux is implemented at twice, reflux ratio of 4-80, and betweentwo stages of total reflux the light component can be fractionized out from top of tower and the water content is removed. It provides the equipment for implementing the above-mentioned method. It istechnically characterized by adopting high-effective precision rectification filling material and electromagnetic needle pendulum reflux ratio control instrument, height of filling layer is 140-150 cm, its complete condenser is water-splitting complete condenser, and upper portion of filling layer and its middle portion are respectively equipped with returned liquor distributor and oblique cone ring baffle.

Owner:SICHUAN UNIV +1

Novel production process for total flavones of hippophae rhamnoides

InactiveCN103054915ARich sourcesImprove extraction efficiencyCardiovascular disorderPlant ingredientsSilica columnAdditive ingredient

The invention discloses a novel production process for total flavones of hippophae rhamnoides. The process comprises the steps as follows: washing raw materials; adding into a feeding hopper; rotating a mainframe of an extraction tank set; enabling materials to be fed into the front end of the extraction tank set backwardly and slowly; at the same time, enabling extracting solvents to enter into extraction tanks from a liquid inlet pipe at the tail end of the extraction tank set, penetrate through the moving materials from the rear ends of the tanks and flow to the front ends; and enabling the solid phase materials and the liquid phase materials to be fully contacted in the inverse motion so as to extract effective ingredients from the medicinal materials. Dregs are forcedly conveyed to a discharge hole for discharge through a discharge conveyer and squeezed by a special squeezer to squeeze out residual liquor in the dregs from the tissues of the medicinal materials so as to reduce the content of the residual liquor in the dregs. The extraction efficiency is higher and the extraction process is safer. The macroporous adsorption resin and the silica column chromatography for purification are selected and used at the same time, so that the separation effect is better. The finished total flavones of hippophae rhamnoides with the highest yield of 2% and the content of more than 70% can be obtained.

Owner:DAXINGANLING LINGOBERRY BOREAL BIOTECH CO LTD

Production technology for extracting usnic acid from usnea longissima

InactiveCN103044372AReduce contentImprove extraction efficiencyOrganic chemistryUsnea longissimaEngineering

The invention discloses a production technology for extracting usnic acid from usnea longissima. The technology comprises the steps that a raw material is subjected to coarse grinding, and fed in from a feeding hopper; an extraction tank unit host rotates to slowly push the material from the front end of a unit backwards; an extraction solvent enters an extraction tank from a liquid inlet tube at the tail end of the unit, passes through the moving material from the back end of the tank, and flows towards the front end; and solid and liquid substances are contacted fully in an inverse motion, so that effective components in the medicinal material are extracted. Dregs are forcibly pushed to a dreg discharge port by a discharge transport and then discharged; a special juice squeezer squeezes the dregs; residual medicine liquor in the dregs is squeezed out of a medicinal material tissue; and the content of the residual medicine liquor in the dregs is reduced. The extraction efficiency is higher, and the extraction is more complete. The method adopts a continuous extraction tank unit for extraction, and is combined with a silica gel column chromatography for purification, so that a separating effect is better. Finished usnic acid with a maximum yield of 1% and the content above 95% can be obtained.

Owner:DAXINGANLING LINGOBERRY BOREAL BIOTECH CO LTD

Preparation method of drug-resistant pseudomonas aeruginosa broad-host range phage

InactiveCN101962631AEasy to prepareGood separation and purification effectViruses/bacteriophagesAntibiotic YCulture mediums

The invention discloses a preparation method of drug-resistant pseudomonas aeruginosa broad-host range phage, which relates to a preparation method of phage and solves the problem of poor separation and purification effect in the traditional separation method of the pseudomonas aeruginosa phage. The method comprises the following steps: 1, selecting a sewage sample; 2, preparing a lysis solution; 3, carrying out mixed cultivation on the lysis solution and a pseudomonas aeruginosa host cell suspension to obtain a mixed solution; 4, preparing a single phage plaque; and 5, inoculating the phage into a pseudomonas aeruginosa-containing culture medium, culturing until the pseudomonas aeruginosa is completely dissolved, and finally filtering. The preparation method of pseudomonas aeruginosa phage has the advantages of simple operation, good separation and purification effect and no phage breakage. The prepared drug-resistant pseudomonas aeruginosa broad-host range phage can be used for manufacturing autoimmune (vaccines) biological agents for treating diseases caused by the infection of drug-resistant pseudomonas aeruginosa, can be especially used as a topical spray for treating epidermal infectious diseases, and can avoid the drug-resistant pseudomonas aeruginosa produced by the use of antibiotics.

Owner:INST OF MICROBIOLOGY HEILONGJIANG ACADEMY OF SCI

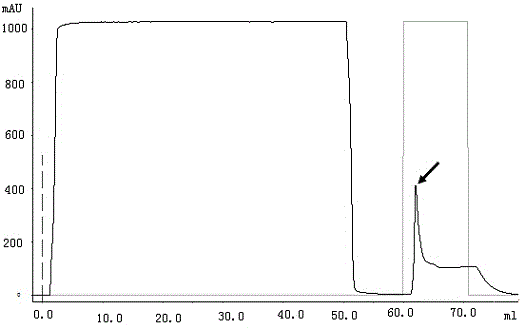

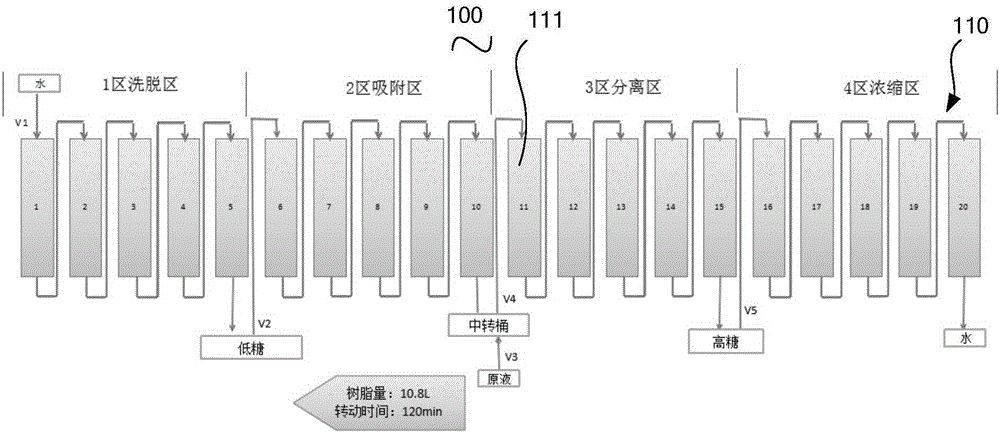

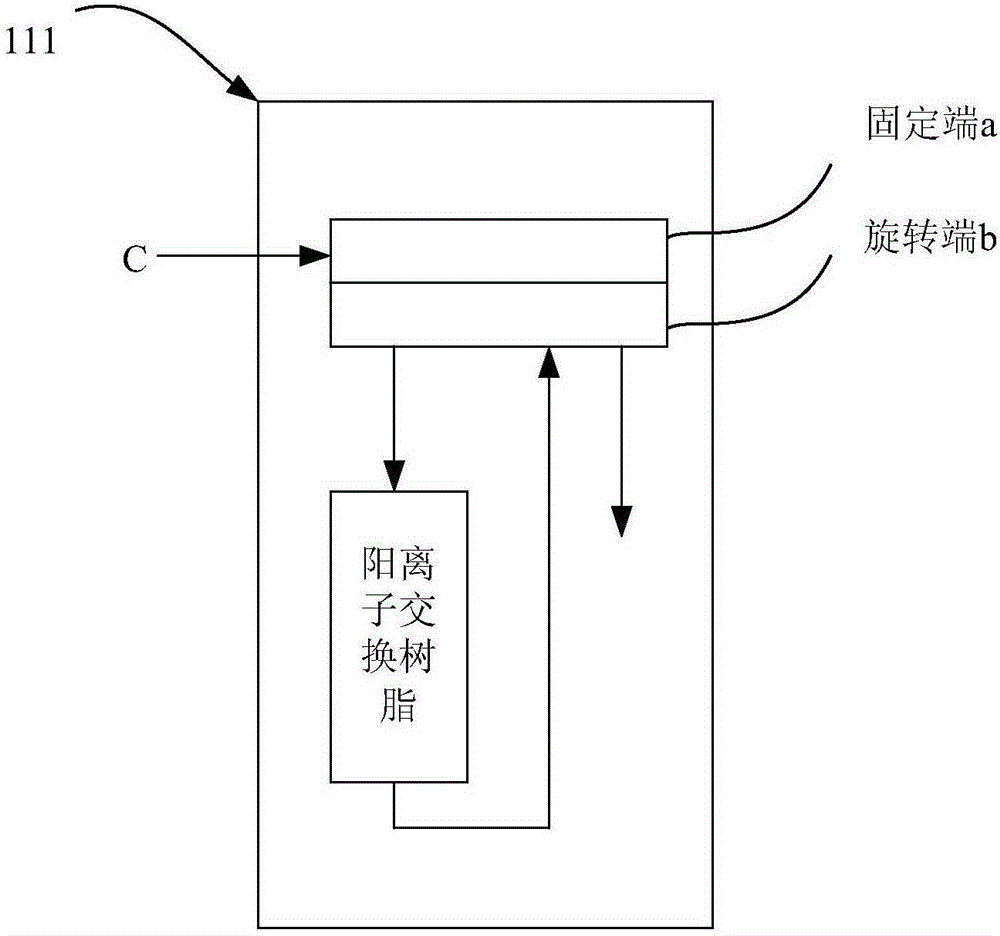

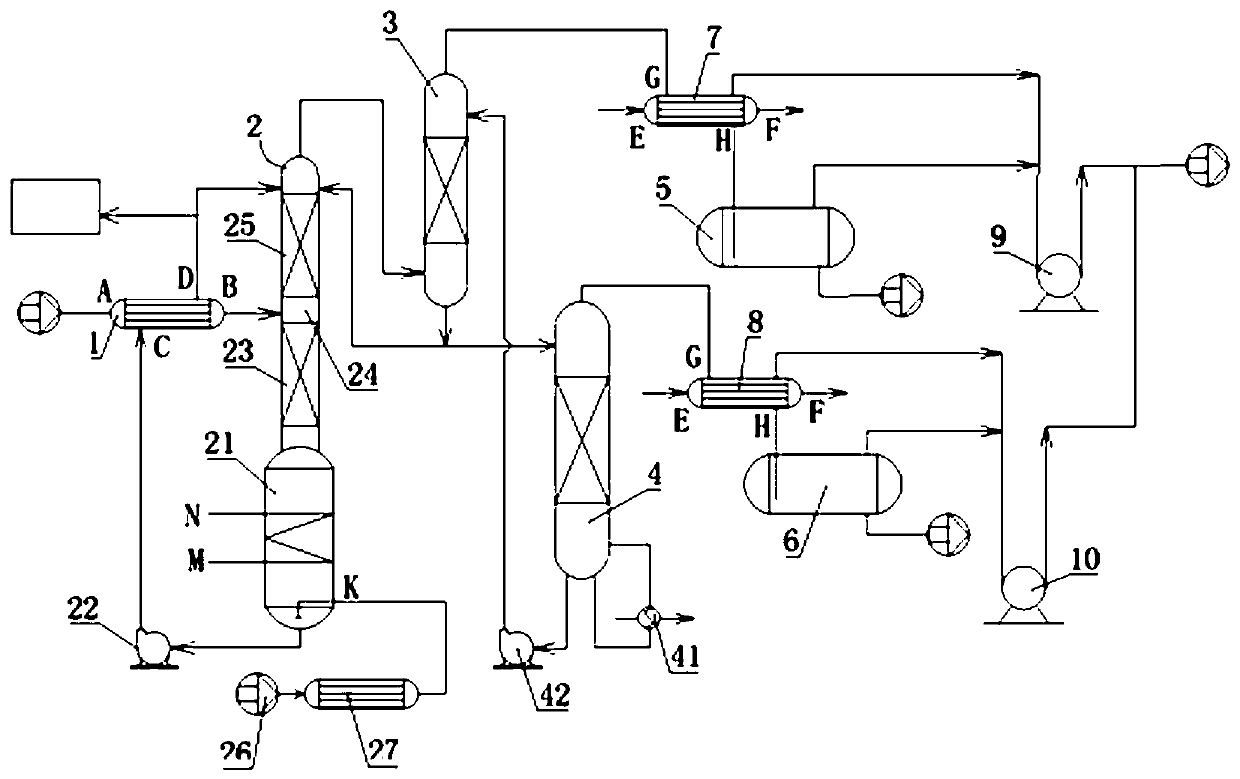

Continuous chromatographic separation and purification system for separating sugar in inulin

ActiveCN105194904AGood separation and purification effectImprove utilization and process yieldsSolid sorbent liquid separationPolyfructoseChemistry

The invention provides a continuous chromatographic separation and purification system for separating sugar in inulin. A plurality of separation units which are connected together in series are driven by a turntable to rotate, and when the turntable rotates a circle, under the action of cation exchange resin filled in the separation units, fructo-oligosaccharide flows out of an elution area, polyfructose flows out of a separation area, and recycled water flows out of a concentration area. In such a manner, an inulin solution is separated and purified, so that links of exchange, washing, recycling, leaching and the like in an original fixed bed are integrated in the same system to achieve a better separation and purification effect.

Owner:YANTAI INST OF COASTAL ZONE RES CHINESE ACAD OF SCI

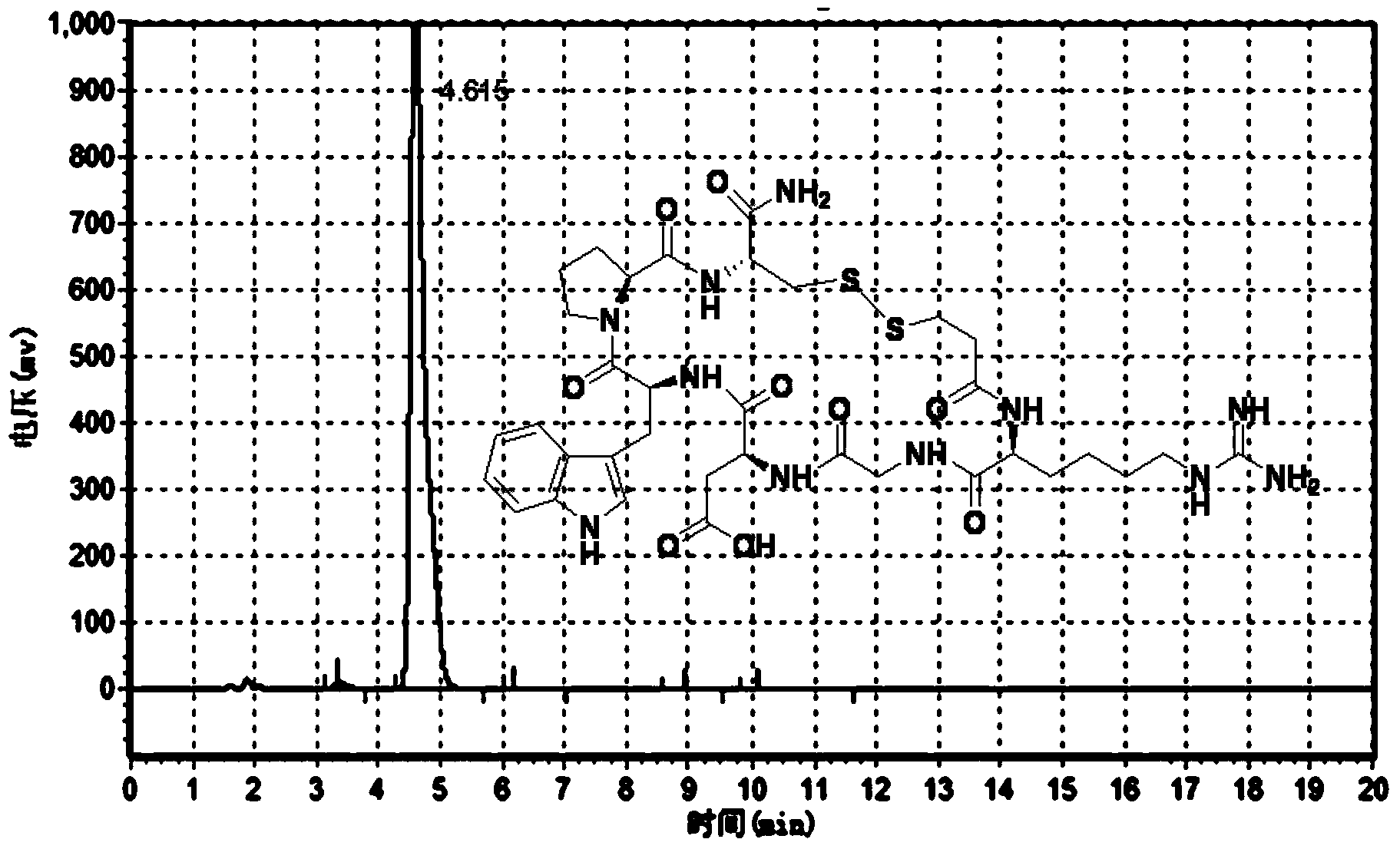

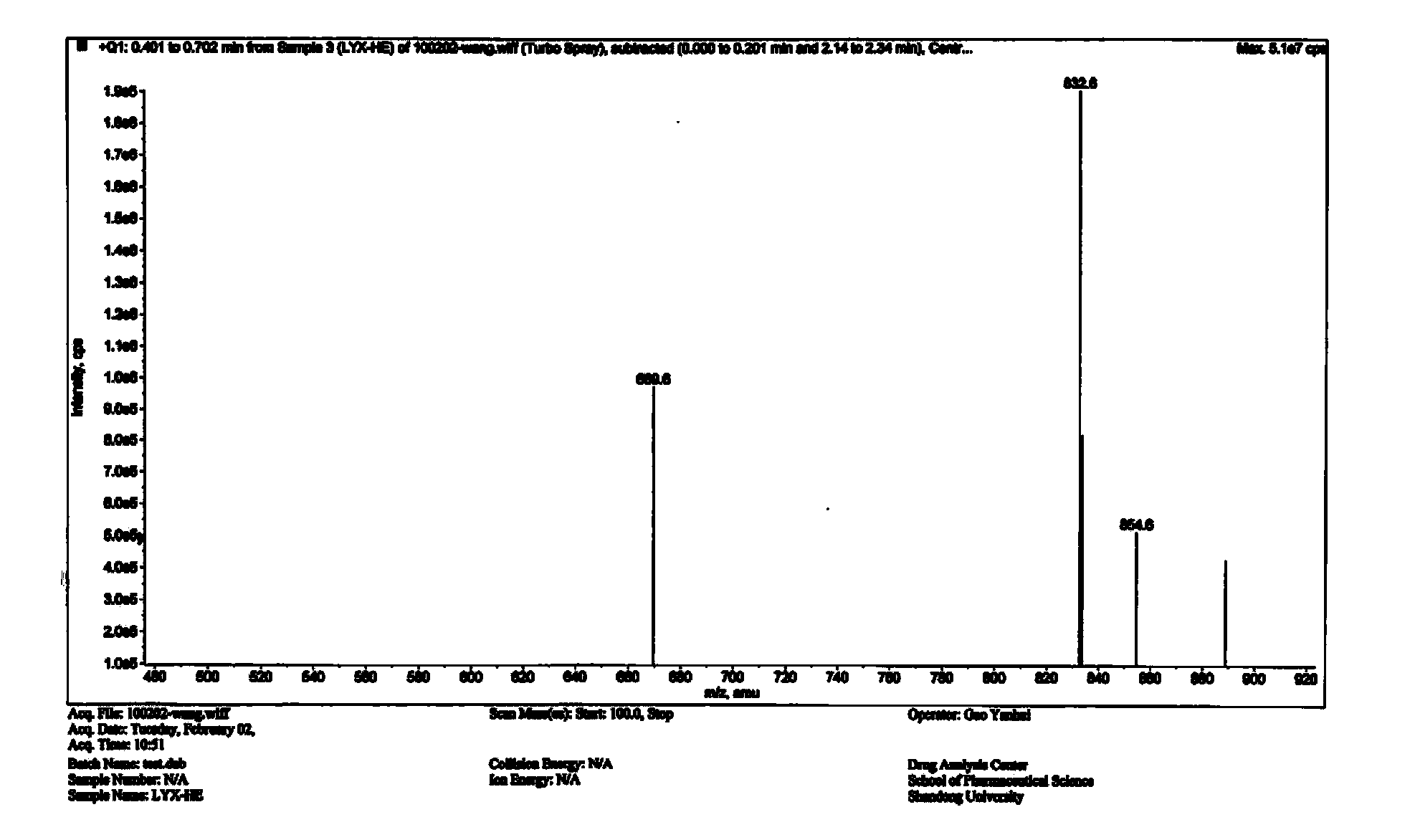

Liquid-phase synthesis method of eptifibatide

ActiveCN103450346AImprove cyclization efficiencyLess side effectsPeptide preparation methodsBulk chemical productionSide chainSynthesis methods

Owner:山东博创生物科技有限公司

Large-scale preparation method of BCG-CpG-DNA

The invention provides a method for preparing Bacilli Calmette-Gurin CpG-DNA (BCG-CpG-DNA) by utilizing Q Sepharose HP ion exchange. The method comprises the following steps: carrying out culture breeding of BCG, cracking to obtain a BCG lysate, centrifuging the lysate, directly removing impurities comprising polysaccharides, proteins, RNA and the like from the centrifuged BCG lysate to obtain purified BCG-CpG-DNA. There is no organic solvent residual in the BCG-CpG-DNA prepared through the method.

Owner:NAT INST FOR FOOD & DRUG CONTROL

Fritillariae cirrhosae bulbus polysaccharide extraction, separation and purification technology

ActiveCN106397622AOvercoming the low extraction rateOvercome purityBulk chemical productionDEAE SephadexPyridinium

The invention discloses a fritillariae cirrhosae bulbus polysaccharide extraction, separation and purification technology. As a novel supercritical CO2 extraction technology is utilized, the defects that a general method is low in extraction rate and not high in purity are overcome; quaternary ammonium salt cetyl pyridinium chloride monohydrate and fritillariae cirrhosae bulbus polysaccharide can precipitate in water solution with low ionic strength; when the ionic strength is high, precipitate can be dissolved, dissociated and released, and the purification effect is good; DEAE-Sephadex ionic exchange column chromatography is utilized to further remove neutral impurities and impurities with positive charges, and the separation and purification effect is better.

Owner:CHONGQING THREE GORGES MEDICAL COLLEGE

Preparation method of high-purity anthocyanins by extracting from roselle

InactiveCN105859675AReduce water consumptionReduce extraction timeOrganic chemistryChemical industryEnzymatic hydrolysisUltrafiltration

The invention discloses a preparation method of high-purity anthocyanins by extracting from roselle, and relates to the extraction method of anthocyanins. The preparation method successively comprises the following specific steps: raw material pretreatment, extraction, enzymatic hydrolysis, centrifugalization, ultrafiltration, nanofiltration, concentration, microwave drying and crushing. The preparation method has the beneficial effects that the purity of an anthocyanin extract of the roselle can be improved from 2 to 3% to 30% or above, the energy can be saved, the process is simple, the cost is low, and the mass production can be facilitated.

Owner:JIANGXI HAIFU BIOENG

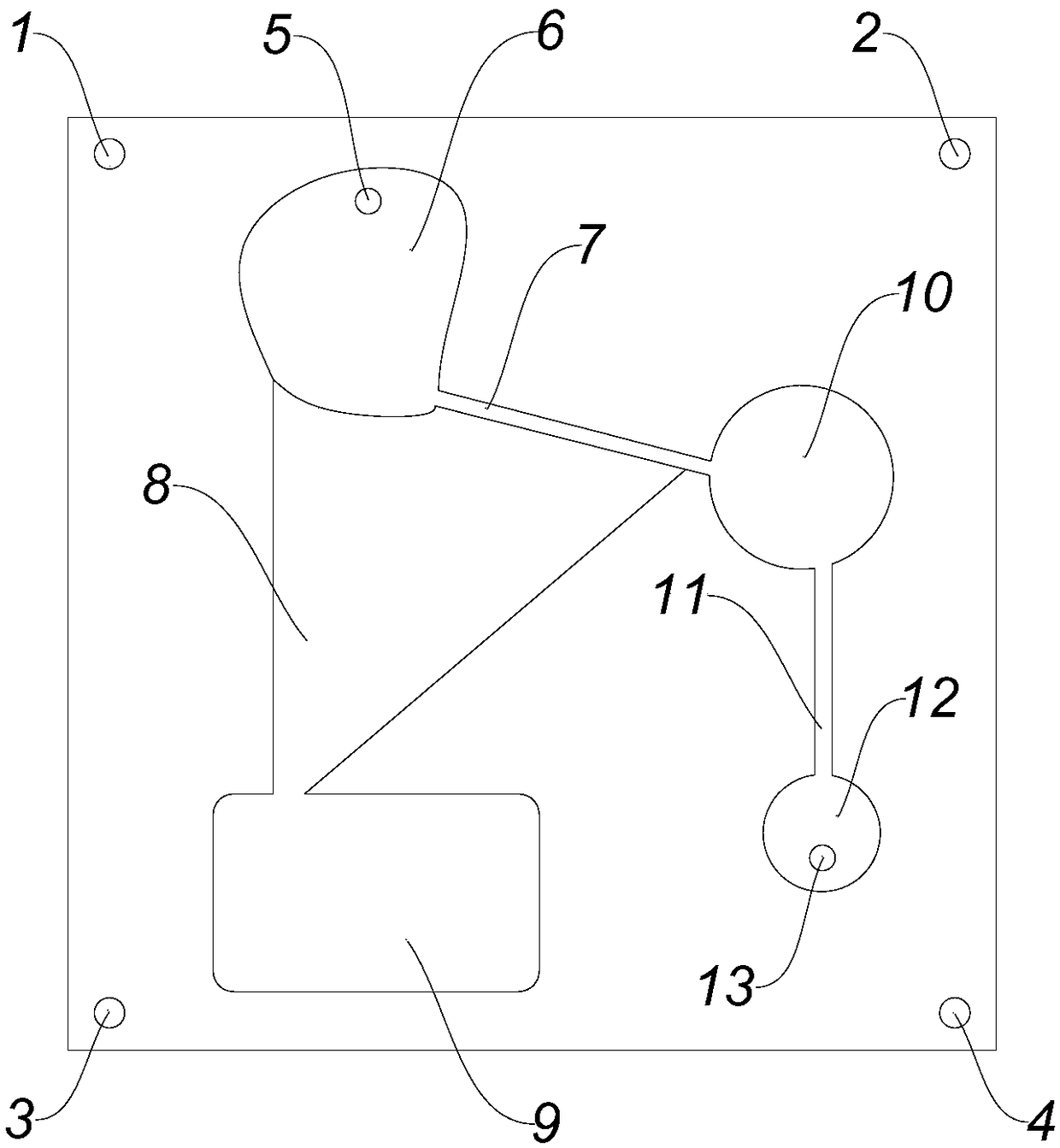

Micro-fluidic chip for enriching and purifying CTCs (circulating tumor cells)

PendingCN108660060AAvoid lossAvoid damageBioreactor/fermenter combinationsBiological substance pretreatmentsLiquid wasteDrug biological activity

The invention discloses a micro-fluidic chip. The micro-fluidic chip comprises positioning holes located in four corners of a chip body, a sample adding hole, a sample reaction cavity, a physical screening flow channel, a liquid waste flow channel, a liquid waste collecting cavity, a magnetic adsorption cavity plated with a magnet on the upper surface, a product flow channel, a product collectingcavity and a product absorption hole, wherein the sample reaction cavity and the magnetic adsorption cavity are communicated through the physical screening flow channel; the magnetic adsorption cavityand the product collecting cavity are communicated through the product flow channel; the lower side wall of the physical screening flow channel is communicated with the liquid waste flow channel through a notch formed in the lower side wall. The invention further discloses a method for enriching and purifying CTCs (circulating tumor cells) by adopting the micro-fluidic chip. An experiment can becompleted by only one centrifugal machine, the operation is fast and simple, an expensive EpCAM antibody is not needed, and the cost is relatively low; the obtained CTCs not only expresses the type ofthe EpCAM antibody, but also has better separation and purification effects, no immunomagnetic beads exist on the surface, and biological activity of the micro-fluidic chip is better.

Owner:苏州绘真医学检验有限公司 +2

Method for preparing saikoside from bupleurum longiradiatum

InactiveCN103040887ARich sourcesImprove extraction efficiencyAntipyreticAnalgesicsBupleurum longiradiatumEngineering

The invention discloses a method for preparing saikoside from bupleurum longiradiatum. The method comprises the steps that a raw material is subjected to coarse grinding, and fed in from a feeding hopper; an extraction tank unit host rotates to slowly push the material from the front end of a unit backwards; an extraction solvent enters an extraction tank from a liquid inlet tube at the tail end of the unit, passes through the moving material from the back end of the tank, and flows towards the front end; and solid and liquid substances are contacted fully in an inverse motion, so that effective components in the medicinal material are extracted. Dregs are forcibly pushed to a dreg discharge port by a discharge transport and then discharged; a special juice squeezer squeezes the dregs; residual liquor in the dregs is squeezed out of a medicinal material tissue; and the content of the residual liquor in the dregs is reduced. The extraction efficiency is higher, and the extraction is more complete. The method adopts a continuous extraction tank unit for extraction, and is combined with a silica gel column chromatography for purification, so that a separating effect is better. Finished saikoside with a maximum yield of 4% and the content above 95% can be obtained.

Owner:DAXINGANLING LINGOBERRY BOREAL BIOTECH CO LTD

A kind of separation method of chenodeoxycholic acid and ursodeoxycholic acid

ActiveCN102286051AGood separation and purification effectHigh yieldSteroidsChenodeoxycholic acidEquivalence ratio

The invention discloses a method for separating chenodeoxycholic acid from ursodesoxycholic acid, which belongs to the technical field of biochemical separation and is characterized by comprising the following steps in turn: (1) preparing column loading solution, namely dissolving mixture of ursodesoxycholic acid and chenodeoxycholic acid in alkaline aqueous solution according an equivalence ratio of 1:2.5, regulating the pH value of the solution to 7 to 8, and diluting deionized water till the solid content is 10 to 20 percent; (2) loading onto a column for absorption, namely pumping the column loading solution into a resin column filled with nonpolar porous synthetic absorbent; (3) desorbing, namely preparing eluting solution by using water soluble organic solvent, and pumping the eluting solution into the resin column for desorbing; and (4) performing post-treatment, namely concentrating under vacuum, recovering solvent, adding acid solution into the concentrated product to regulate the pH value to 2 to 3, precipitating, filtering, washing till the pH value is 7, drying, crystallizing and drying under vacuum to obtain a finished product. The method has the advantages that: the macroporous resin has high separation and purification performance and high accuracy; the ursodesoxycholic acid is separated from chenodeoxycholic acid with high yield; the process is simple; the production cost is low; and the industrial production efficiency is high.

Owner:上海华震科技有限公司

Production method for extracting hyperin from pyrola rotundifolia

InactiveCN103030674ARich sourcesImprove extraction efficiencySugar derivativesSugar derivatives preparationSlagEngineering

The invention discloses a production method for extracting hyperin from pyrola rotundifolia. The method comprises the steps that raw materials are subjected to coarse grinding and then put in from a feeding hopper; an extraction tank unit host rotates; the materials are slowly pushed from the front end of a unit backwards; an extracting solvent enters an extracting tank from a liquid inlet tube at the tail end of the unit, passes through the moving materials from the rear end of the tank, and flows to the front end; and solid and liquid substances are sufficiently contacted in a reverse motion, so that active ingredients in medicinal materials are extracted. Dregs are forcibly pushed to a slag hole by a discharge transport and then discharged, a special juice squeezer extrudes the dregs and extrudes residual liquor in the dregs out of a medicinal material tissue, the residual liquor content of the dregs is reduced, the extraction efficiency is higher, and the extraction is more complete. The production method adopts continuous extraction and multi-stage extraction, and is combined with silicagel column chromatography for purification, the separation effect is better, and the finished hyperin with a maximum yield of 0.6% and content of above 95% can be obtained.

Owner:DAXINGANLING LINGOBERRY BOREAL BIOTECH CO LTD

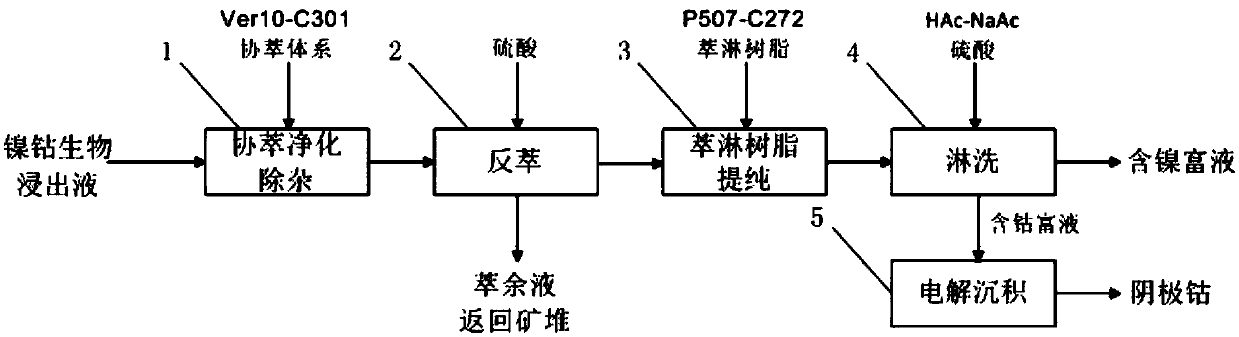

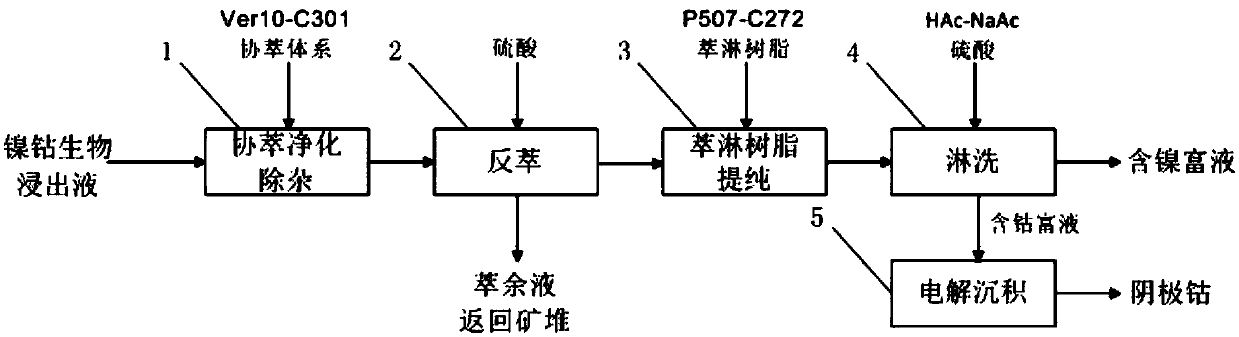

Short flow process for preparing high-purity cobalt from low-content nickel-cobalt bioleaching solution

InactiveCN109971954AReduce pollutionHigh selectivityProcess efficiency improvementPregnant leach solutionBuffer solution

The invention discloses a short flow process for preparing high-purity cobalt from a low-content nickel-cobalt bioleaching solution. The short flow process for preparing the high-purity cobalt from the low-content nickel-cobalt bioleaching solution comprises the following steps that (1) a combined extractant is added into a diluent Mextral DT100 to prepare an organic phase; (2) co-extraction is carried out on the nickel-cobalt bioleaching solution at an initial pH of 1.5 to 3.0 and an equilibrium pH of 3.0 to 4.0; (3) sulfuric acid is added in the organic phase for back extraction to realize nickel-cobalt preconcentration and deep purification; (4) double-extractant extraction resin is prepared; and (5) a HAc-NaAc buffer solution with pH of 3.0 to 5.5 and the sulfuric acid with pH of 1.0 to 3.5 are separately used for two-stage gradient leaching, and a cobalt-containing rich solution obtained by leaching is concentrated and then subjected to electrolytic deposition to obtain a cathodecobalt product. The short flow process for preparing the high-purity cobalt from the low-content nickel-cobalt bioleaching solution has the advantages of multilevel and high efficiency, high selectivity, good mass transfer effect and the like, the purification separation purification efficiency of the cobalt solution is improved, and simple process, easy operation and little environmental pollution are achieved.

Owner:GRIMAT ENG INST CO LTD

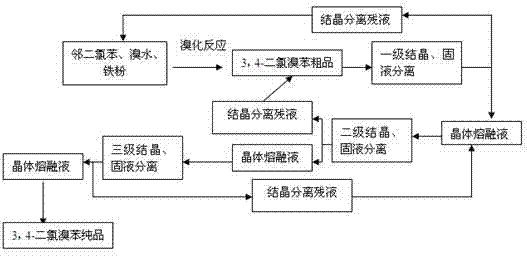

Method for preparing 3,4-dichloro bromobenzene

ActiveCN103922892AAvoid pollutionGood separation and purification effectHalogenated hydrocarbon preparationSide reactionBromine water

The invention belongs to the chemical engineering field, and particularly discloses a method for preparing 3,4-dichloro bromobenzene. The method comprises steps of adding reduced iron powder into the raw material o-dichlorobenzene, inletting bromine water under certain pressure and temperature, and carrying out bromination reaction in a bromination kettle; carrying out multistage crystallization on the crude bromized 3,4-dichloro bromobenzene through solution, so as to purify the 3,4-dichloro bromobenzene, wherein the crude bromized 3,4-dichloro bromobenzene is crystallized by at least one stage, generally by multiple stages, namely, from one stage to three stages, so that a complete cycle of crystallization and purification of the 3,4-dichloro bromobenzene product is formed. The method has the main beneficial effects that the product is not polluted by foreign solvents or other materials, for the byproduct 2,3- dichloro bromobenzene generated in preparation of 3,4-dichloro bromobenzene through o-dichlorobenzene is used as the solvent; particularly, reduction of the yield of 3,4-dichloro bromobenzene caused by intensified side reaction of the 2,3- dichloro bromobenzene due to rectification high temperature is avoided; the method has the characteristics of high yield of the product, high purity and high production efficiency.

Owner:福建桦智工程技术有限公司

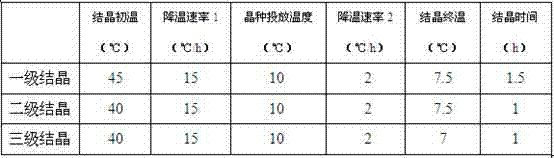

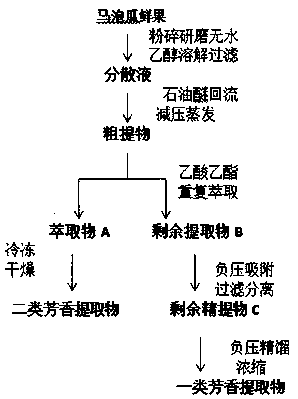

Preparation method of aromatic extracts from field muskmelon

InactiveCN108467793AImprove extraction efficiencyGood separation and purification effectEssential-oils/perfumesChemistryPetroleum ether

The invention relates to the technical field of biomaterials, in particular to a preparation method of aromatic extracts from field muskmelon. The method comprises the steps as follows: firstly, fruitfield muskmelons are crushed, ground and then dissolved with absolute ethyl alcohol, an ultrasonic dispersion device is used for accelerating dissolution of effective substances, then, a dispersion liquid is subjected to reflux and reduced pressure evaporation with petroleum ether, a crude extract is obtained and subjected to full extraction with ethyl acetate, and an extract A and a residual extract B are obtained; a class-2 aromatic extract rich in ester aromatic substances can be obtained from the extract A through freeze drying, and a class-1 aromatic extract containing furans, aldehydesand sulfur-containing compounds can be obtained from the residual extract B through negative-pressure adsorptive filtration and rectification treatment. By the aid of the method, classified extractionof various aromatic substances in the field muskmelons can be realized, the extraction rate of effective substances is high, and the product purity is high after classified purification.

Owner:HEFEI SHENWO HORTICULTURE CO LTD

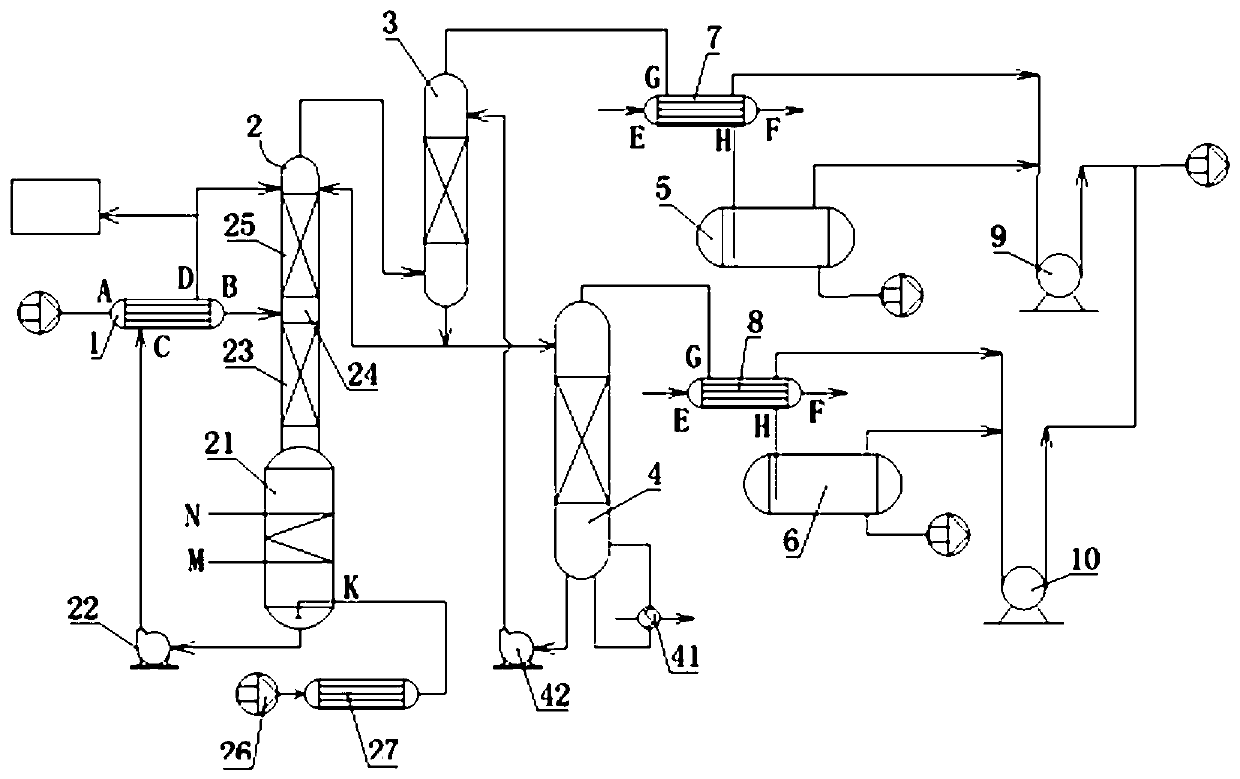

Process and system for producing cyclohexane plasticizer by liquid phase hydrogenation of o-benzene plasticizer

ActiveCN111170853AGood separation and purification effectImprove the heating effectOrganic compound preparationVacuum distillation separationBenzenePolymer science

The invention relates to a process and a system for producing a cyclohexane plasticizer by liquid phase hydrogenation of an o-benzene plasticizer. The process for preparing a cyclohexane plasticizer by liquid phase hydrogenation of an o-benzene plasticizer comprises the following steps: (1) heated inert gas is introduced into the bottom of a reduced pressure distillation tower in a pulse pneumaticconveying manner; and (2) a plasticizer product is preheated and then enters the bottom of the reduced pressure distillation tower, and the inlet of the plasticizer product on the reduced pressure distillation tower is higher than the inlet of the inert gas, so that the plasticizer product is mixed and heated with the rising inert gas flow in the downward flowing process, and the target product is separated from the by-product. According to the process and the system disclosed by the invention, heated inert gas is fed into the reduced pressure distillation tower in a pulse manner, and the characteristic that the flow of inert gas is changing is utilized to better simulate the characteristics of fluidization, mixing and heating at the bottom of the reduced pressure distillation tower, so that better mixing, heating, separation and purification effects on the plasticizer product are realized.

Owner:ZHENGZHOU RAILWAY VOCATIONAL & TECH COLLEGE

Method for extracting taurocholic acid in sheep bile through column chromatography isolation method

The invention discloses a method for extracting taurocholic acid in sheep bile through a column chromatography isolation method. The method comprises the following steps: filtering, performing protein precipitation treatment, performing depigmentation treatment, salting out, extracting, dewatering concentration and performing column chromatography isolation. According to the method, the sheep bile serves as an extracting raw material, the extraction cost of the taurocholic acid is reduced, the extraction process is simple, and the income is higher. The taurocholic acid is extracted through the column chromatography isolation, the column chromatography isolation is good in purification effect, the extracted taurocholic acid does not have a fishy smell and is high in purity, the product is high in yield, the extraction process is simple, and industrial production is promoted.

Owner:安徽九凤生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com