Continuous chromatographic separation and purification system for separating sugar in inulin

A continuous chromatography, separation and purification technology, applied in the field of liquid separation and purification, can solve the problems of low resin utilization efficiency, low resin utilization rate, large discharge of acid-base waste liquid, etc., achieve good separation and purification effect, improve production efficiency, improve Effect of Utilization and Process Yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

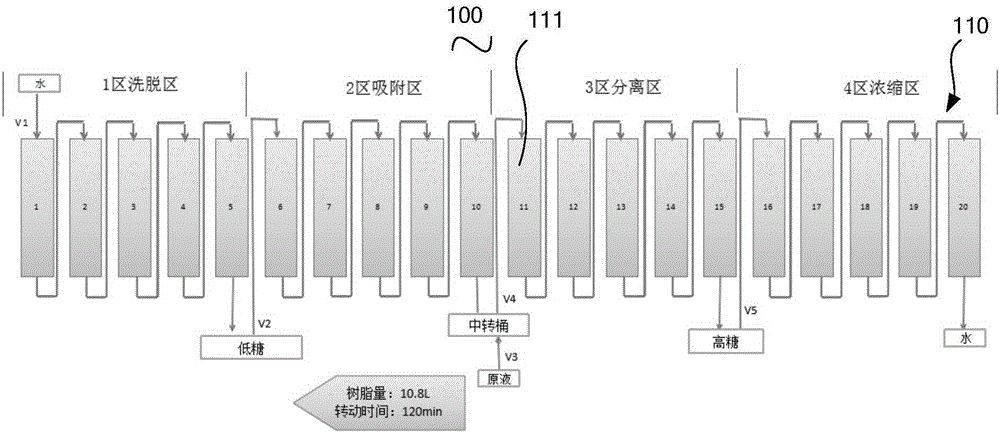

[0039] A. Prepare 10L of 100g / L inulin solution, connect the instrument according to the operating rules, connect 75L pure water to zone 1, and connect 5L pure water to zone 2 and zone 3;

[0040] B. Set the experimental parameters of the panel and pump flow, press the "turntable origin" button at the same time, clear the time, and set the feeding flow rate of the peristaltic pump to 5ml / min;

[0041] location

Set flow rate (ml / min)

Exit 1 (District 1)

60

Exit 6 (District 2)

44

Exit 11 (District 3)

49

Exit 16 (District 4)

40

[0042] C. Turn on the switch of the pump, press the "Turntable Start" button, and then ensure that the instrument runs normally without leakage;

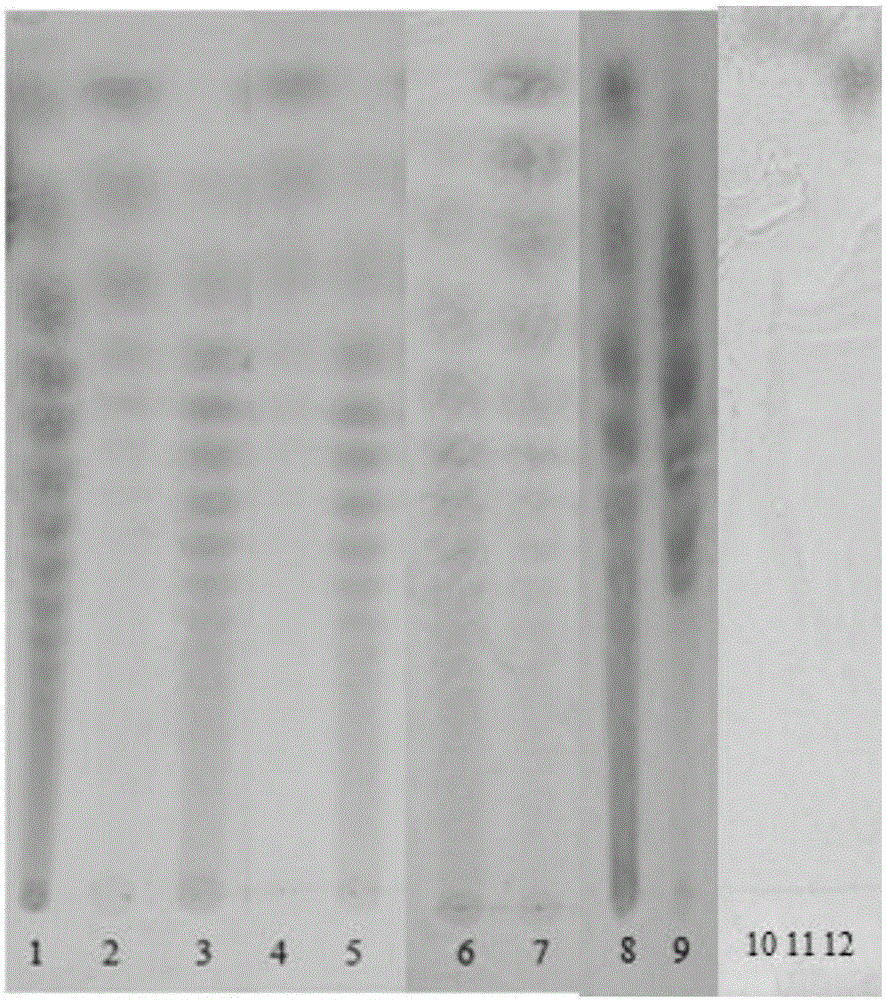

[0043] D. Samples were taken after 24 hours of experiment operation, and the samples taken were analyzed on the TLC plate. image 3 2nd and 3rd TLC results.

Embodiment 2

[0045] A. Prepare 10L of 200g / L inulin solution, connect the instrument according to the flow chart, connect 75L pure water to zone 1, and connect 5L pure water to zone 2 and zone 3;

[0046] B. Set the experimental parameters of the panel and pump flow, press the "turntable origin" button at the same time, clear the time, and set the feeding flow rate of the peristaltic pump to 4ml / min

[0047] location

Set flow rate (ml / min)

Exit 1 (District 1)

50

Exit 6 (District 2)

42

Exit 11 (District 3)

46

Exit 16 (District 4)

36

[0048] C. Turn on the switch of the pump, press the "Turntable Start" button, and then ensure that the instrument runs normally without leakage;

[0049] D. Samples were taken after 24 hours of experiment operation, and the samples taken were analyzed on the TLC plate. image 3 4th and 5th TLC results.

Embodiment 3

[0051] A. Prepare 10L of 200g / L inulin solution, connect the instrument according to the flow chart, connect 75L pure water to zone 1, and connect 5L pure water to zone 2 and zone 3;

[0052] B. Set the experimental parameters of the panel and pump flow, press the "turntable origin" button at the same time, clear the time, and set the feeding flow rate of the peristaltic pump to 5ml / min;

[0053] location

Set flow rate (ml / min)

Exit 1 (District 1)

50

Exit 6 (District 2)

39

Exit 11 (District 3)

44

Exit 16 (District 4)

40

[0054] C. Turn on the switch of the pump, press the "Turntable Start" button, and then ensure that the instrument runs normally without leakage;

[0055] D. Samples were taken after 24 hours of experiment operation, and the samples taken were analyzed on the TLC plate. image 3 The results of the 7th and 6th thin-layer chromatography.

[0056] see image 3 For each strip from left to right: 1s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com