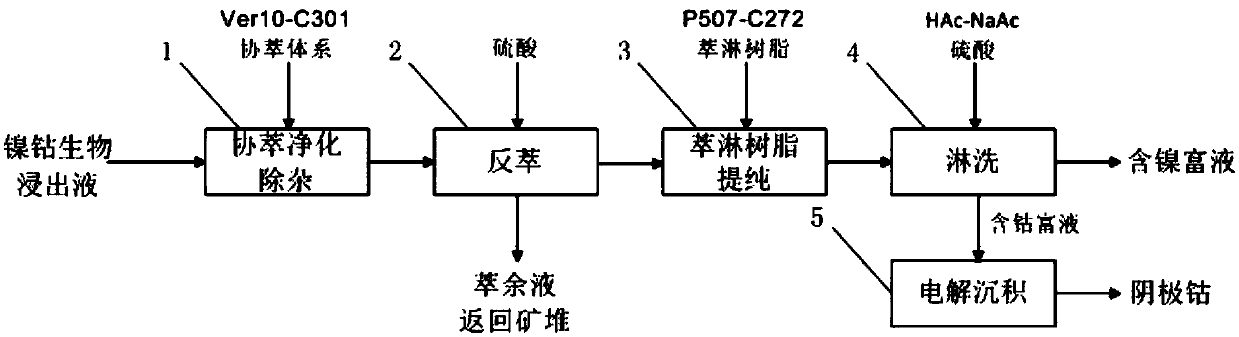

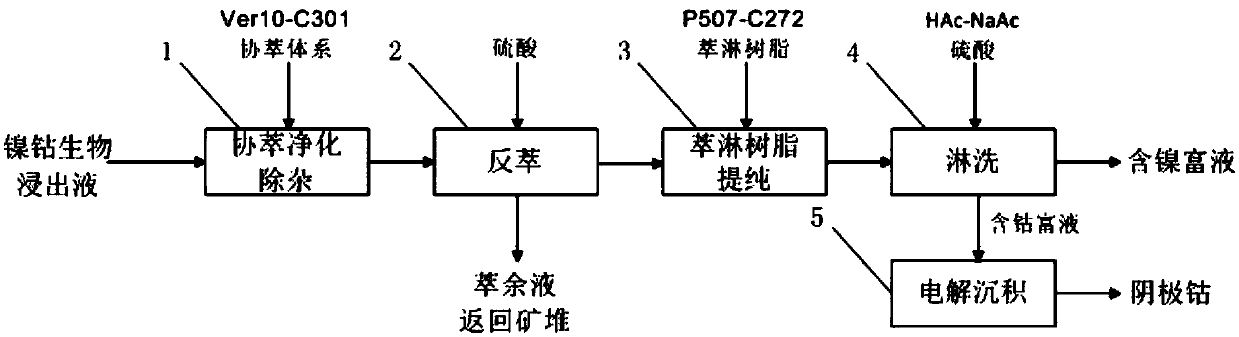

Short flow process for preparing high-purity cobalt from low-content nickel-cobalt bioleaching solution

A bioleaching, short process technology, applied in the direction of improving process efficiency, can solve the problems of complex purification, separation and purification process, long process flow and high processing cost, and achieve the effect of good mass transfer effect, simple process and high selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Since a nickel-cobalt ore is a low-grade complex and refractory sulfide ore, the content of valuable metal nickel-cobalt in the bioleach solution obtained by bioheap leaching is low, which makes purification and separation difficult. The traditional extraction and separation efficiency is low and the process is complicated, which seriously affects Comprehensive recovery of nickel and cobalt.

[0036] As shown in Table 1, it is the composition analysis of the nickel-cobalt bioleach solution after the nickel-cobalt ore is bioheap leached to remove iron.

[0037] Table 1

[0038] element co Ni Cu Fe Ca Mg Contentmg / L 198 1840 3.22 0.39 390 14760

[0039] The biological leachate is separated and purified by the process of the present invention, and the specific steps are divided into:

[0040] Step 1: Cooperative extraction is used to deeply purify the nickel-cobalt leaching solution. The specific process is as follows:

[0041] (1) T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com