Patents

Literature

91 results about "Co extraction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for extracting lithium salts in lithium-containing brine

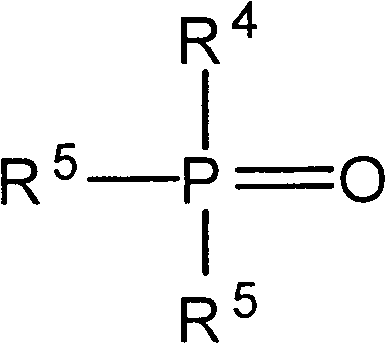

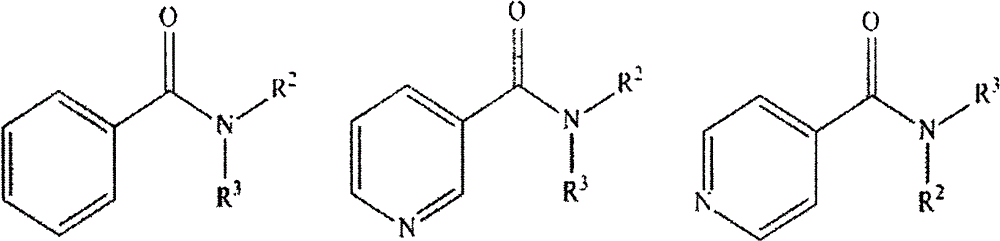

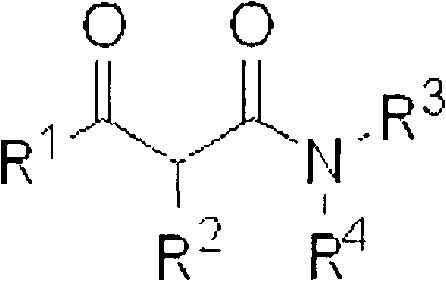

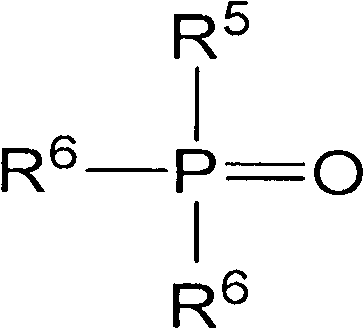

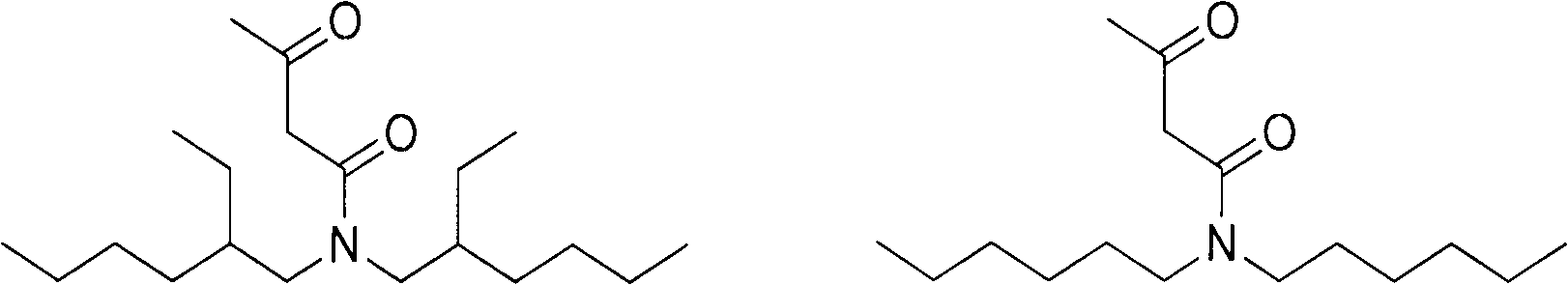

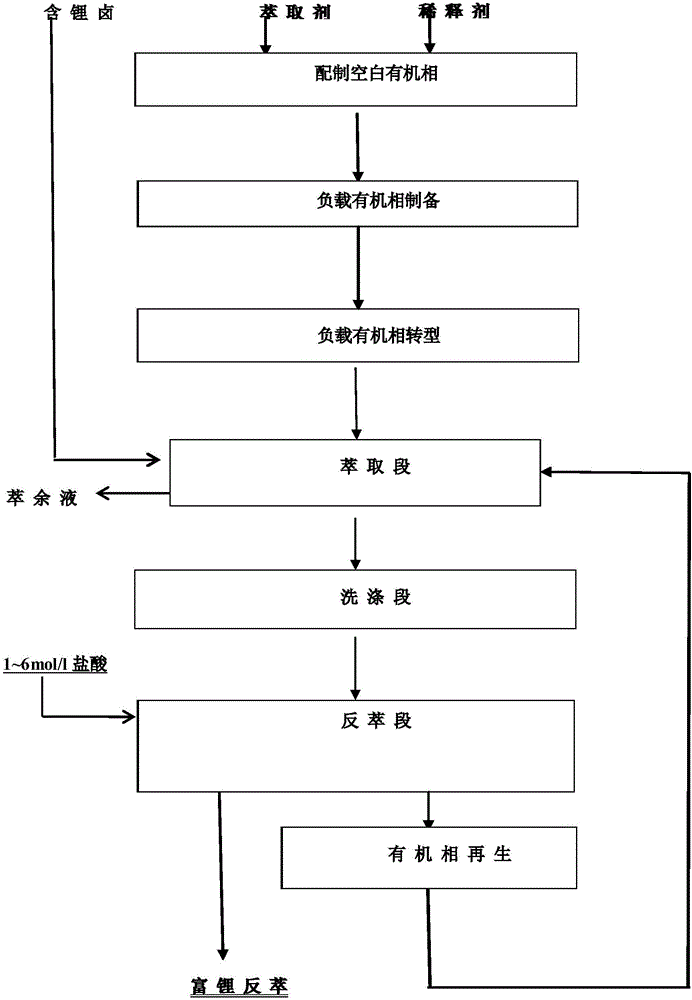

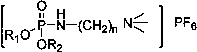

ActiveCN103055539AReduce dosageReduce corrosionLithium compoundsLiquid solutions solvent extractionLithiumStructural formula

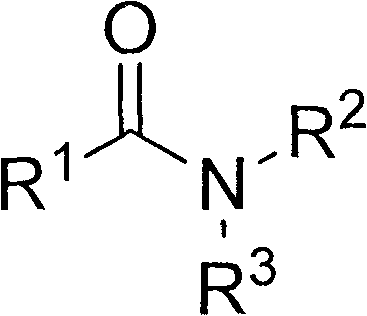

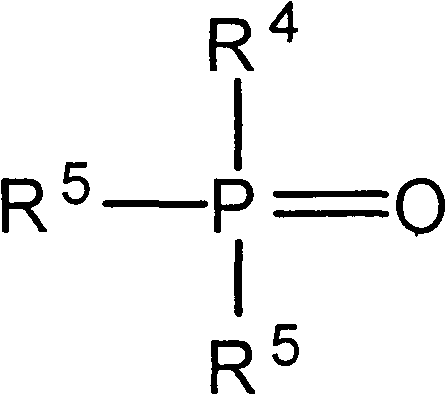

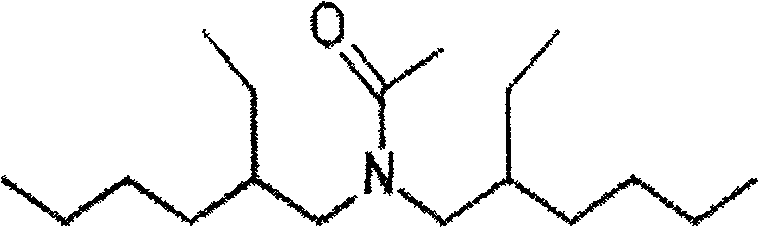

The invention provides a method for extracting lithium salts in lithium-containing brine. Lithium is extracted through a co-extraction agent, an extraction agent and a diluent, wherein the extract is a mixture of an amide compound and a neutral phosphorus oxide compound, the structural formula of the amide compound is shown in the specification, and the structural formula of the neutral phosphorus oxide compound is shown in the specification. The method provided by the invention further optimizes the properties of extracted lithium, so that the method is more applicable to the industrial application.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI +1

Method for extracting lithium salts in lithium-containing brine through extraction method

ActiveCN103055538AReduce dosageReduce corrosionLithium compoundsLiquid solutions solvent extractionLithiumDiluent

The invention provides a method for extracting lithium salts in lithium-containing brine through an extraction method. Lithium is extracted through a co-extraction agent, an extraction agent and a diluent, wherein the extract is a mixture of an amide compound and a neutral phosphorus oxide compound, the structural formula of the amide compound is shown in the specification, and the structural formula of the neutral phosphorus oxide compound is shown in the specification. The method provided by the invention further optimizes the properties of extracted lithium, so that the method is more applicable to industrial application.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI +1

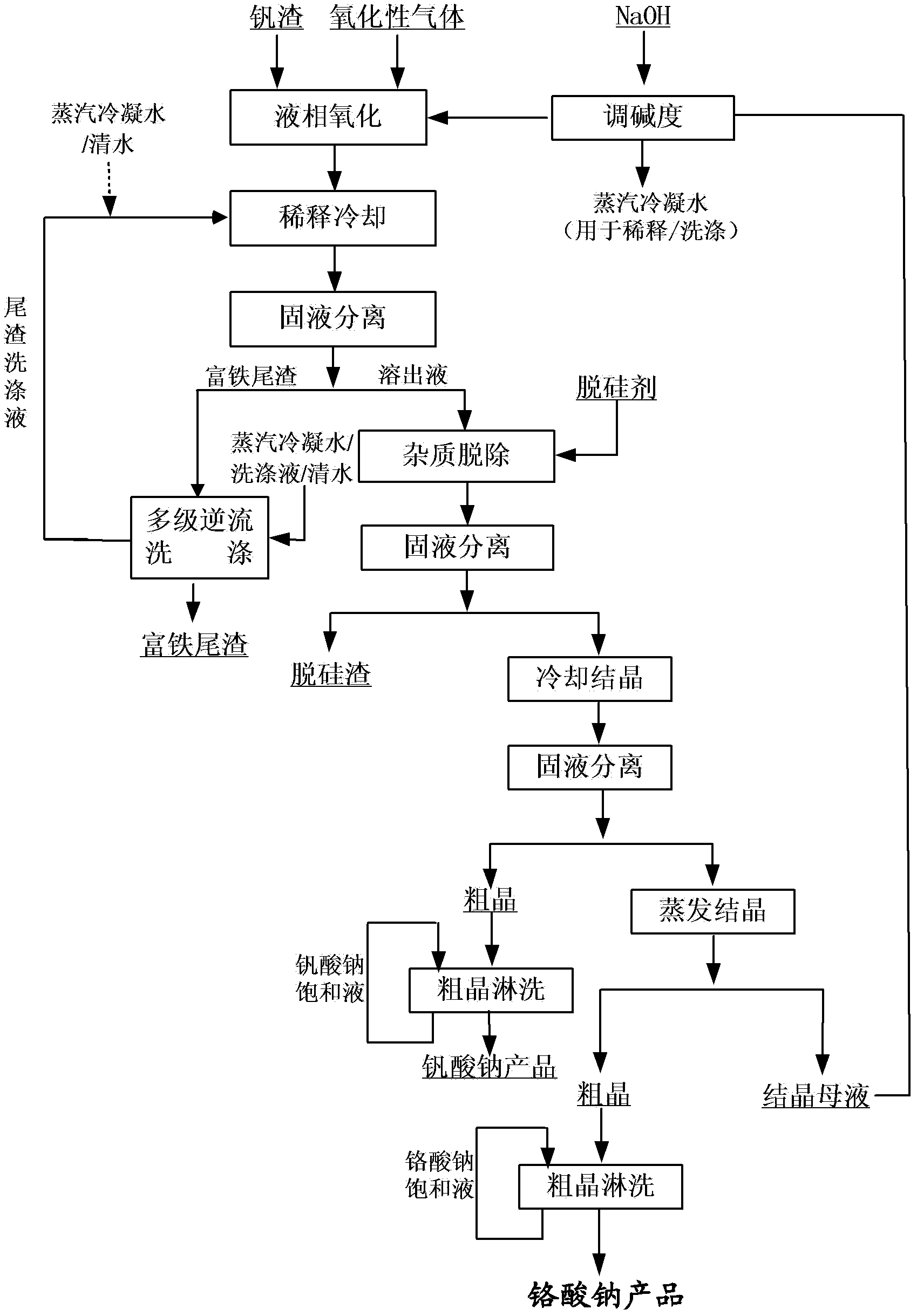

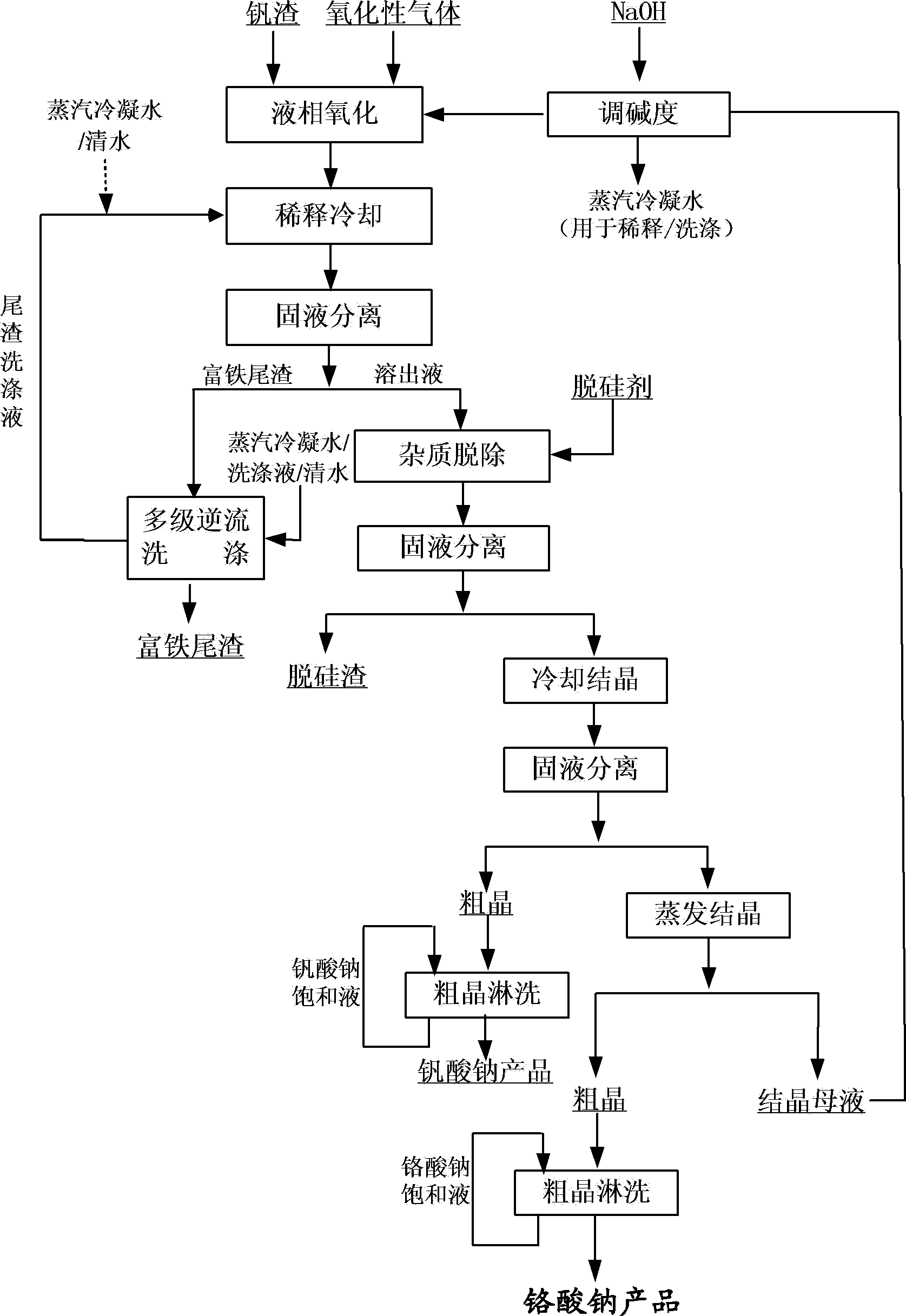

Method for cleaner production of sodium vanadate and sodium chromate by pressure leaching of vanadium slag

ActiveCN102531056ASimple ingredientsAchieve separationChromates/bichromatesVanadium compoundsSlagSlurry

The invention relates to a method for cleaner production of sodium vanadate and sodium chromate by pressure leaching of vanadium slag. The method comprises the following steps of: (1) mixing materials, namely mixing the vanadium slag and a solution of NaOH to obtain a reaction material; (2) reacting, namely performing oxidization reaction on the vanadium slag and oxidizing gas in the solution of NaOH under high pressure to obtain solid-liquid mixed slurry of a solution containing NaOH, Na3VO4, Na2CrO4 and water-soluble impurity components, and iron-rich tailings; (3) performing solid-liquid separation; (4) removing impurities; (5) crystallizing sodium vanadate; and (6) crystallizing sodium chromate. The method is easy to operate and is high in safety; and the operating temperature is greatly lower than the temperature of the traditional vanadium extraction process, energy consumption is low, the high-efficiency co-extraction of vanadium and chromium is realized, and the extraction rate of vanadium and chromium is over 95 percent.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

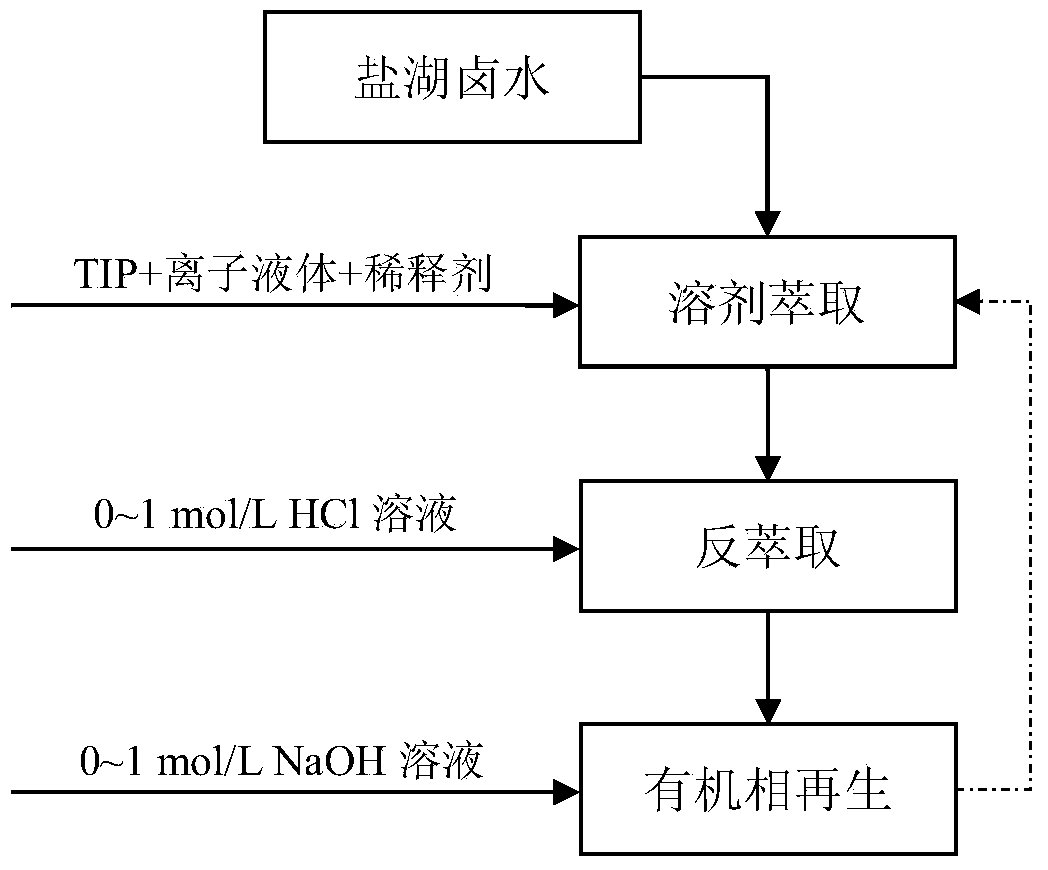

Method for efficiently extracting lithium from salt lake brine

ActiveCN103710549AAvoid interferenceHigh separation factorProcess efficiency improvementSeparation factorIonic liquid

The invention relates to a method for efficiently extracting lithium from salt lake brine. The method comprises the following steps: (1) forming an extraction organic phase by an extraction agent, a co-extraction agent and a diluent, and then mixing the extraction organic phase with salt lake brine according to the volume ratio of (3-4):2 for three-stage extraction with single extraction time being 2-10 minutes to obtain an organic phase; and (2) mixing the organic phase obtained in step (1) with a reverse extraction acid solution (0-1 mol / L) for three-stage reverse extraction with single reverse extraction time being 2-10 minutes, and collecting an aqueous phase which is an aqueous solution containing lithium ions. The co-extraction agent of an extraction system of the method is hydrophobic ionic liquid, compared with conventional synergist ferric trichloride, the interference caused by iron ions is avoided, the reverse extraction acidity is greatly reduced, more importantly the lithium-magnesium separation factor is significantly improved, and the elution step of magnesium ions is reduced; in addition, the method provided by the invention is easy in process, easy to control, high in operation reliability, and good in recyclability of the organic phase, and greatly reduces the production cost for extracting the lithium from the salt lake brine.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

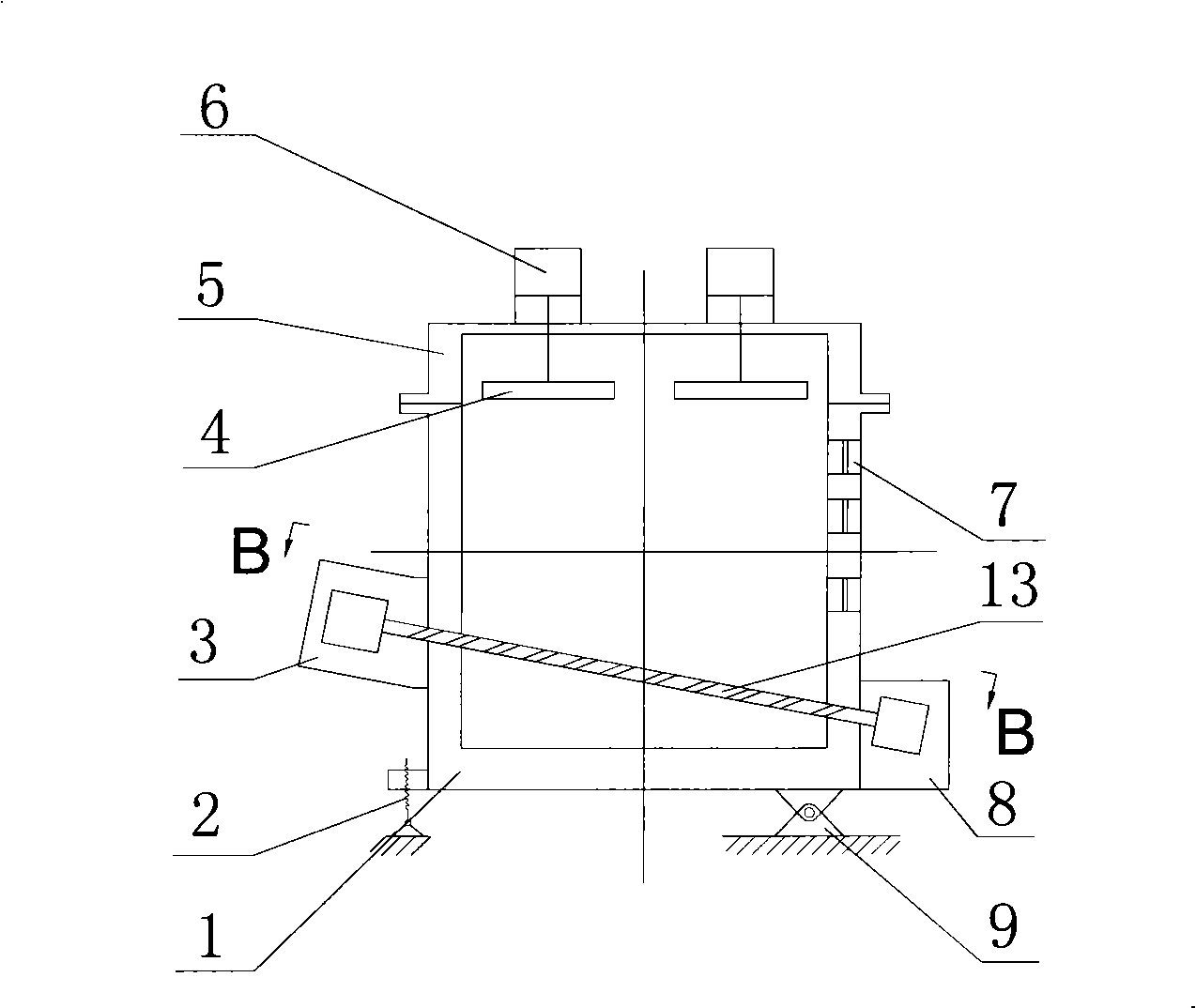

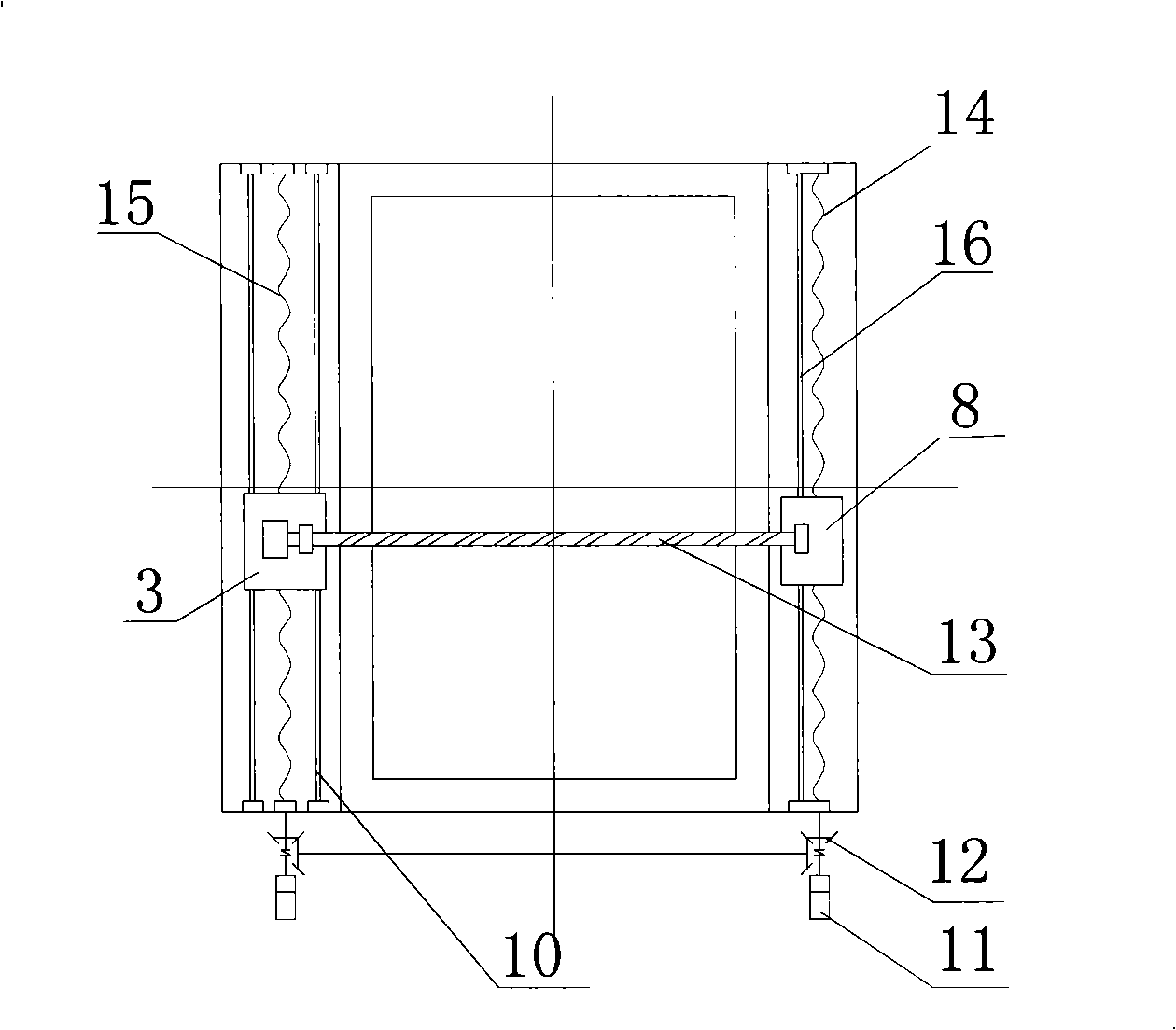

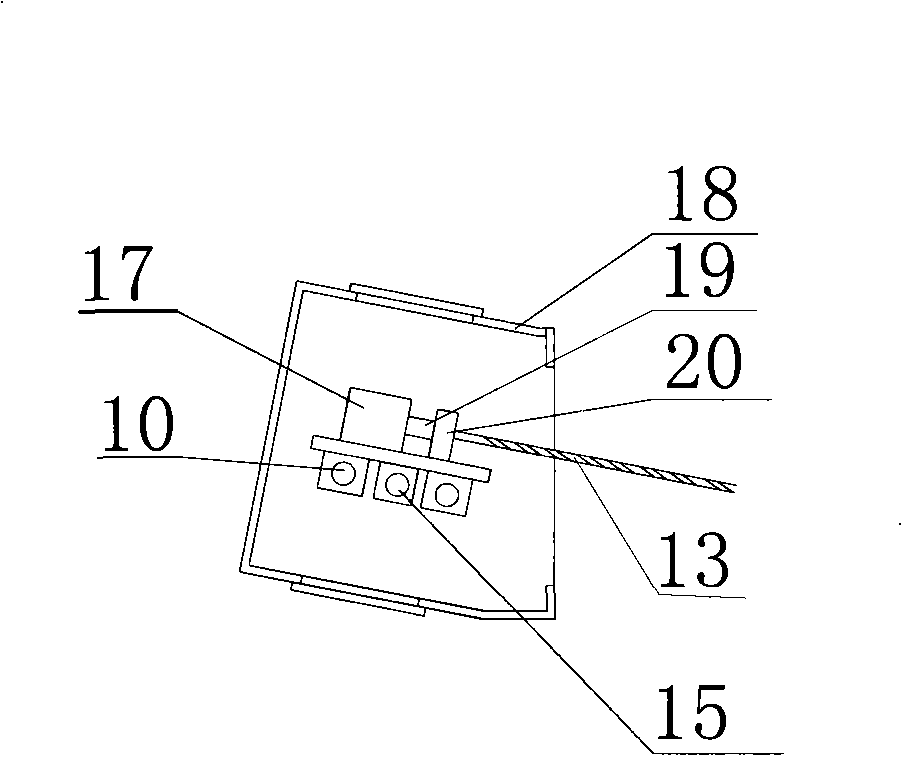

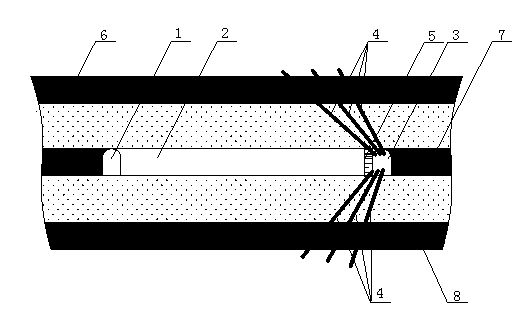

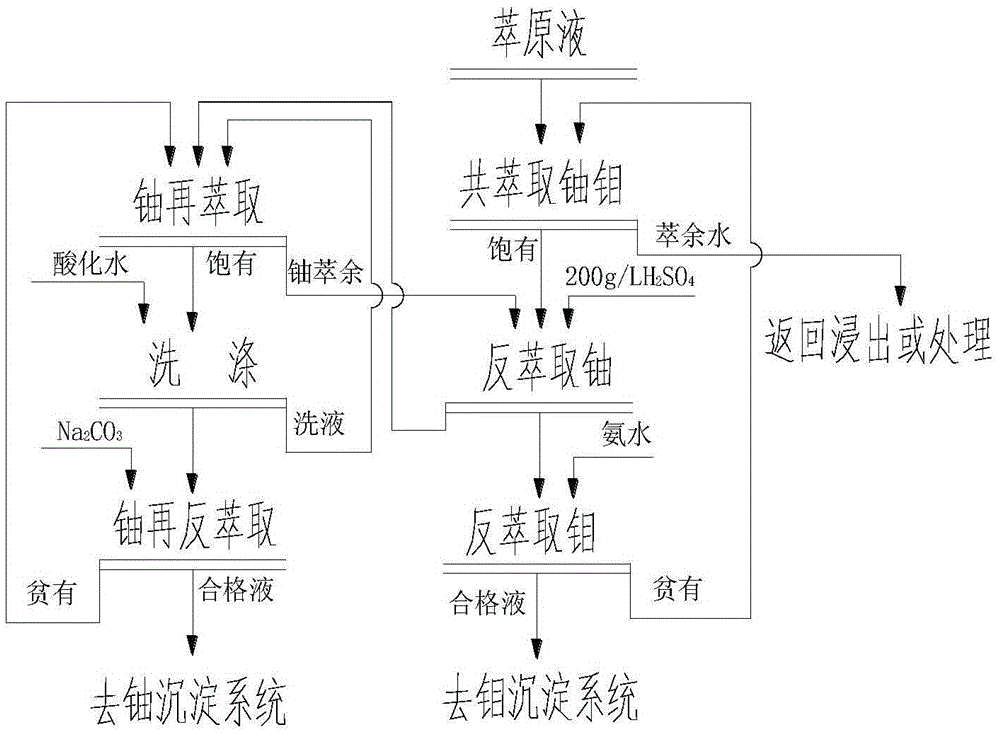

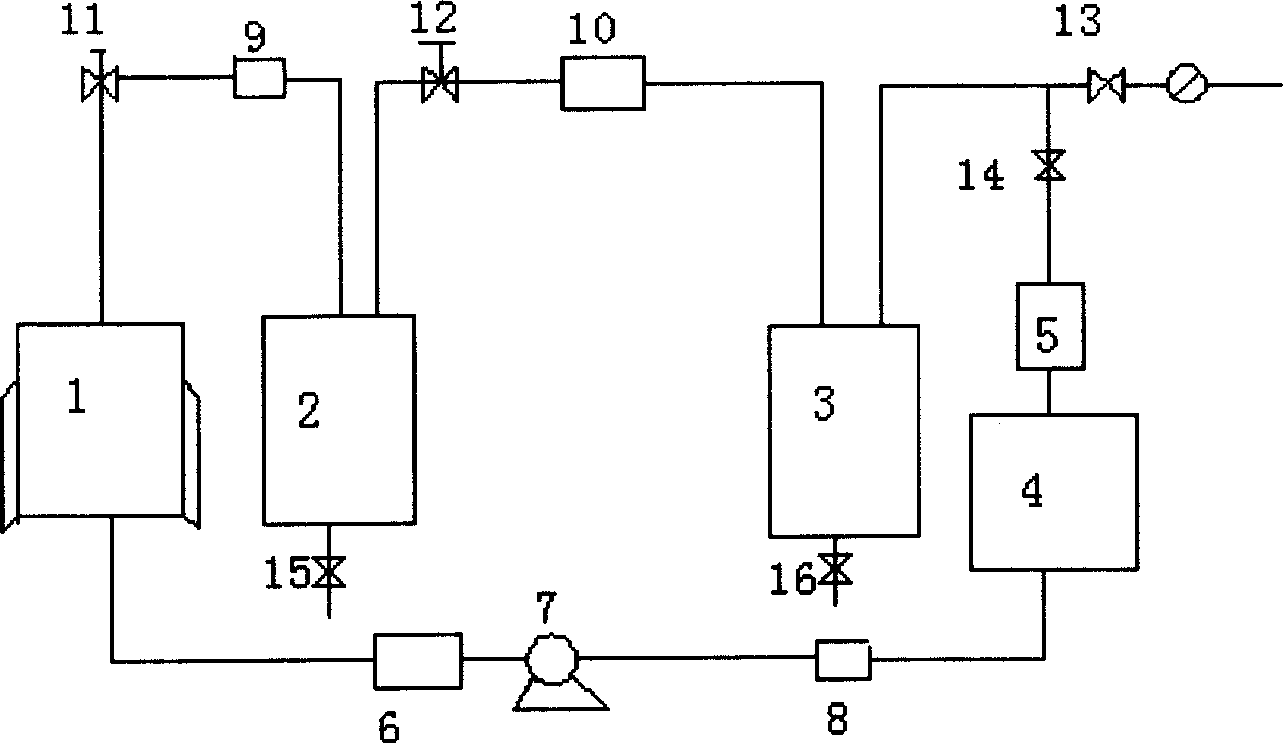

Three-dimensional simulated experiment bench for coal and mash gas co-extraction

The invention discloses a three-dimensional simulation experiment table which mines coal and gas together. The experiment table includes a box body. The box body is provided with a pressurizing device used for uniformly loading on the rocks in the box body to realize mine pressure simulation. The experiment table is also provided with a coal mining device which can move at the bottom part of the box body to simulate the process of cutting coals by a coal mining machine. The box body is also provided with an air inlet device and a plurality of gas detecting sensors used for the simulation experiment of the gas to move in a porous medium in a mining field during the process of simulating the coal bed mining and the desorption and moving rules of the gas in the coal rock bodies that are relieved from pressure, deformed and crashed during the process of comprehensively researching the coal bed mining to work out the space-time evolvement and distribution rules of the coupling between the gas moving and the coal rock body cranny. Then the simulation research and mining scheme design on mining coal and gas together are carried out according to the researching result.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Method for extracting lithium salt from lithium-contained brine by using extraction process

The invention provides a method for extracting lithium salt from lithium-contained brine by using an extraction process. The method comprises the step of extracting lithium by using a co-extraction agent, an extraction agent and a diluent, wherein the extraction agent is a mixture of an amide compound and a neutral phosphorus oxide compound, the amide compound has the structural formula shown in the specification, and the neutral phosphorus oxide compound has the structural formula shown in the specification. The method provided by the invention is used for further optimizing the performance of the extracted lithium and is more suitable for industrial application.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI +1

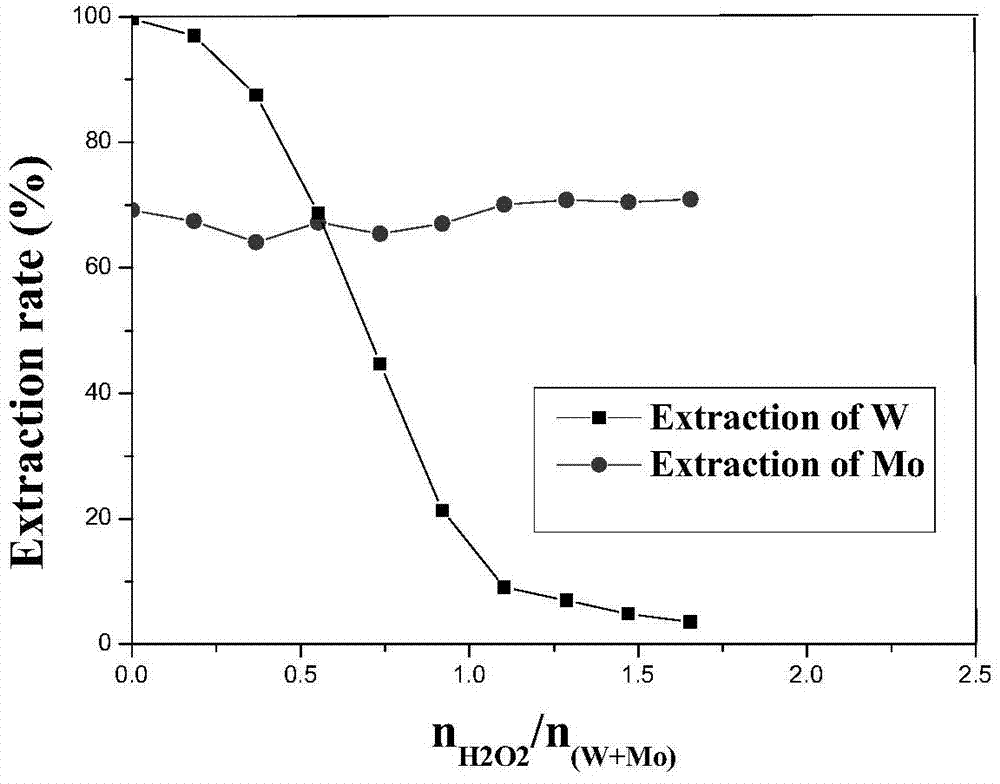

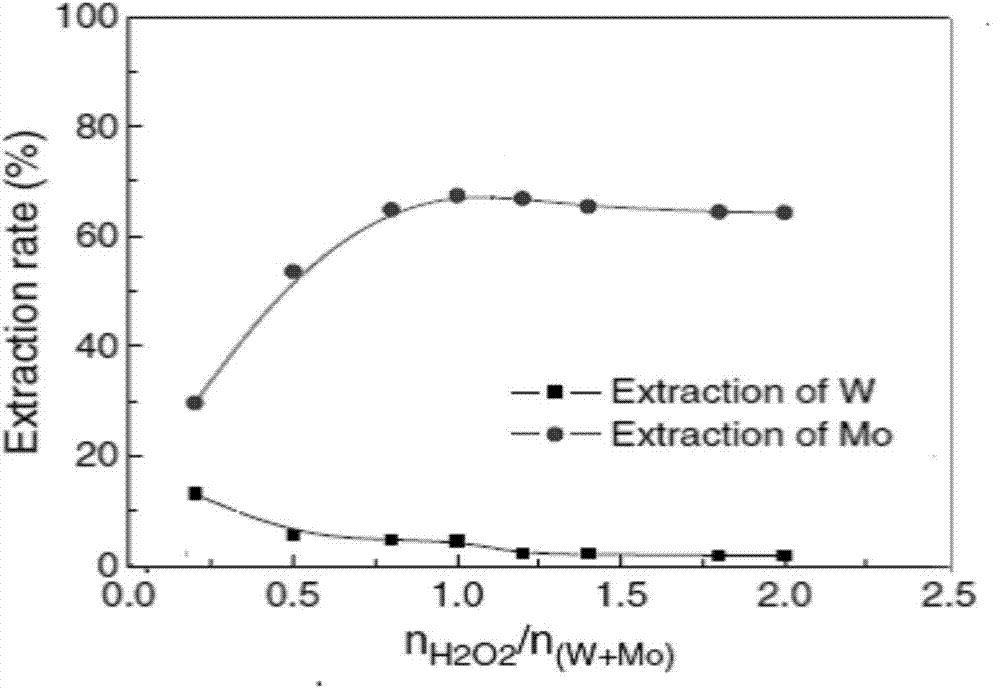

Method for extraction and separation of tungsten and molybdenum from tungsten and molybdenum mixed solution

ActiveCN102876906AOvercoming Difficult Phase Splitting ProblemsOvercoming the problem of large loss in tungsten co-extractionProcess efficiency improvementTungstateDiluent

The invention provides a method for extraction and separation of tungsten and molybdenum. Hydrogen peroxide is filled in the tungsten and molybdenum mixed solution, the pH value is regulated to be acidic, and the acid tungsten mixed solution is taken as a water phase feed liquid to carry out extraction and separation with an organic phase. The organic phase comprises trialkylphosphine oxide, tributyl phosphate and a diluting agent; the organic phase conducts the multi-stage extraction with the water phase feed liquid, molybdenum is extracted into the organic phase, and tungsten is left in a raffinate, so that the separation of tungsten and molybdenum is achieved. The load-bearing organic phase adopts an alkaline back-extraction agent to carry out back-extraction to obtain a molybdenum-contained solution, and the organic phase subjected to the back-extraction returns to the extraction process. Tungsten and molybdenum are extracted and separated in the tungsten and molybdenum mixed solution containing H2O2 by adopting a novel binary mixture extracting agent, the method has the advantages that extraction and the back-extraction are high in split-phase speed, the separation effect of tungsten and molybdenum is good, the tungsten co-extraction loss is low, the loss of the organic phase as well as the environmental pollution is low, the industrialization is easy to realize, and the method is especially suitable for separating tungsten and molybdenum in the tungstate solution with high molybdenum content.

Owner:CENT SOUTH UNIV +1

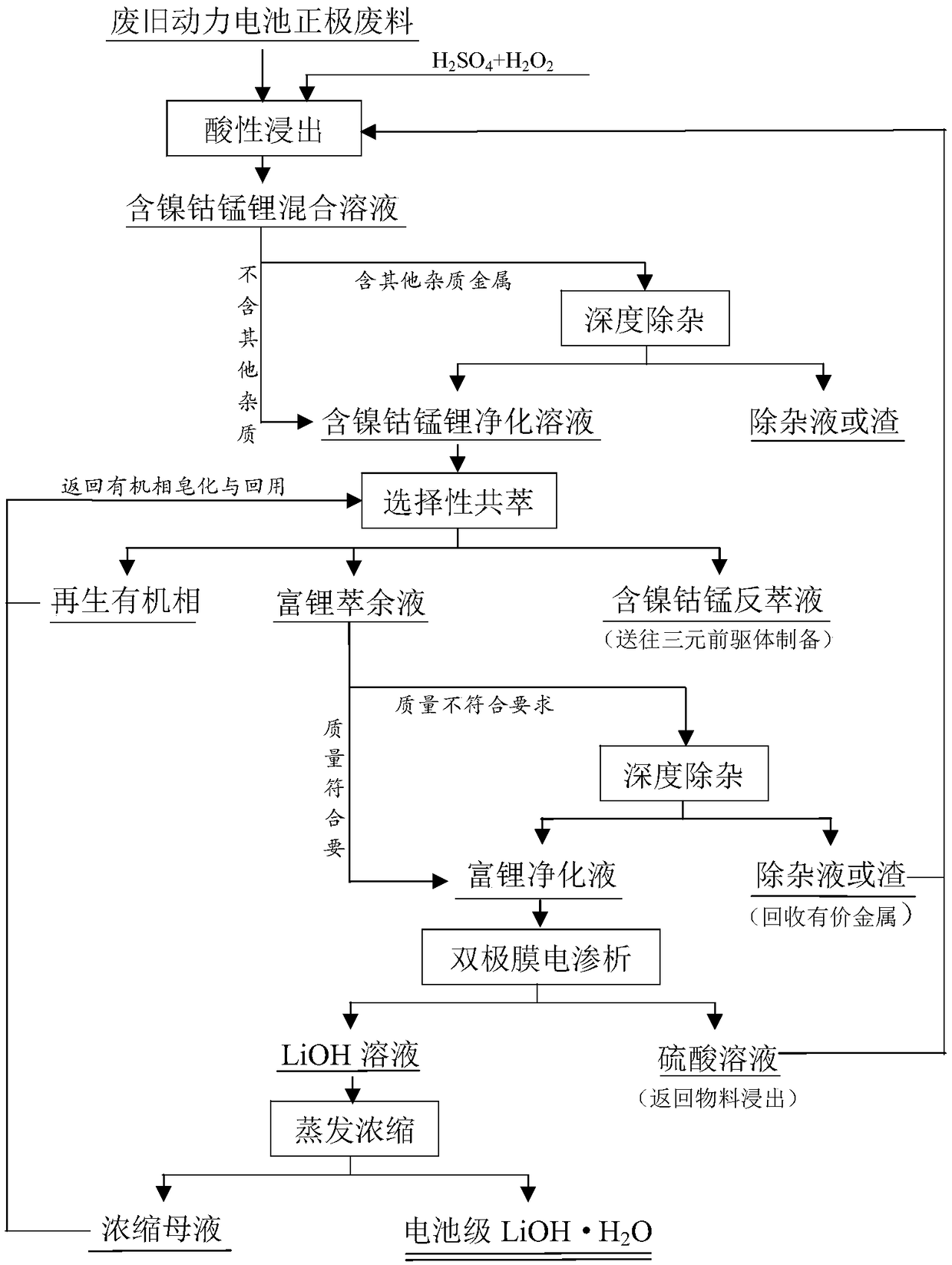

Method for recovering valuable metal from waste power battery cathode waste material

ActiveCN108517409AAvoid high alkali consumptionAvoid conversionWaste accumulators reclaimingProcess efficiency improvementManganeseRaffinate

The invention discloses a method for recovering valuable metal from a waste power battery cathode waste material. The method comprises the following steps that (1) the waste power battery cathode waste material is subjected to acid dipping treatment, and a nickel cobalt manganese and lithium containing mixed solution is obtained; (2) the nickel cobalt manganese and lithium containing mixed solution is subjected to impurity removal, nickel cobalt manganese and lithium containing purified liquid and impurity removed liquid or impurity removed residue are obtained; (3) nickel cobalt and manganeseare separated from the nickel cobalt manganese and lithium containing purified liquid through a selective co-extraction method, and nickel cobalt and manganese containing strip liquid and lithium-rich extraction raffinate are obtained; (4) lithium-rich extraction raffinate is subjected to deep impurity removal treatment, and lithium-rich purified liquid and impurity removal liquid or impurity removal residue are obtained; (5) the lithium-rich purified liquid is treated by adopting a bipolar membrane electrodialysis method after being subjected to deep degreasing treatment, and a lithium hydroxide solution and a sulfuric acid solution are generated; and (6) the lithium hydroxide solution is evaporated and concentrated, and a battery-level lithium hydroxide monohydrate and concentrated mother liquid are obtained. The recovery rate of nickel cobalt manganese and lithium is higher than 98%, and appreciation of metal products is achieved while the valuable metal is efficiently recovered.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

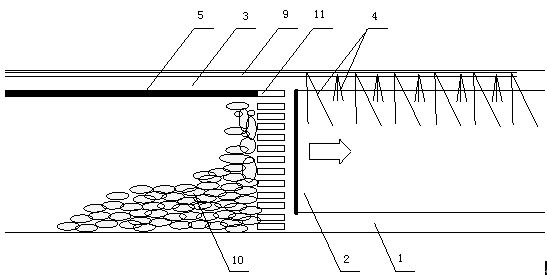

Co-extraction method for pillar-less coal and gas of advanced entry-retaining construction extraction engineering

InactiveCN102635392AImprove reliabilityExtended extraction timeUnderground miningSurface miningEngineeringMechanical engineering

The invention relates to a co-extraction method for pillar-less coal and gas of advanced entry-retaining construction extraction engineering. The co-extraction method comprises the following steps: firstly, pre-constructing a drill hole on a front directional coal layer of a coal extraction working surface; confirming positions of top and bottom plate of the coal layer in a wedge-shape vertical crack area; before starting a gob-side entry retaining process, drilling gas extraction drill holes on the top plate, bottom plate and two sides of gob-side in front of the coal extraction working surface, and then forward pushing the coal extraction working surface to cross the gas extraction drill holes; while forward pushing, finishing the gob-side entry retaining behind the coal extraction working surface; and sealing the gas extraction drill holes on the top plate, bottom plate and two sides of gob-side when a flow value of to-be-extracted gas pressure is greatly reduced. The drilling construction in the retaining entry is unnecessary, the demand on the size of the cross section of the retaining entry is reduced, the demand on restraining volume of the cross section is reduced and the time for efficiently extracting gas is prolonged.

Owner:CHINA UNIV OF MINING & TECH

Method for extracting and separating tungsten and molybdenum in high-phosphorus mixed solution containing tungsten and molybdenum

ActiveCN104711422ARealize extraction and separationSimple methodProcess efficiency improvementPhosphomolybdic acidPhosphate

The invention relates to a method for extracting and separating tungsten and molybdenum in a high-phosphorus mixed solution containing tungsten and molybdenum. The method comprises the following steps: adding hydrogen peroxide in the high-phosphorus mixed solution containing tungsten and molybdenum for acidity adjustment and control, and converting phosphotungstic acid and phosphomolybdic acid into peroxy-phosphotungstic acid and peroxy-phosphomolybdic acid; then, taking a mixture of tributyl phosphate (TBP) and methyl phosphate dimethyl heptyl ester (P350) as an extracting agent, extracting the peroxy-phosphomolybdic acid into an organic phase, and leaving the peroxy-phosphotungstic acid in an aqueous phase; from now on, after decomposing the peroxy-phosphotungstic acid in extraction raffinate in the way of heating or ultraviolet irradiation or introduction of sulfur dioxide, extracting tungsten in the solution again with a fresh mixed extracting agent, and finally realizing extraction and separation of tungsten and molybdenum from complex material liquid. The method is small in tungsten co-extraction loss, can effectively solve the extraction and separation problem of tungsten and molybdenum in the high-phosphorus mixed solution containing tungsten and molybdenum, and is easy to realize industrialization.

Owner:CENT SOUTH UNIV

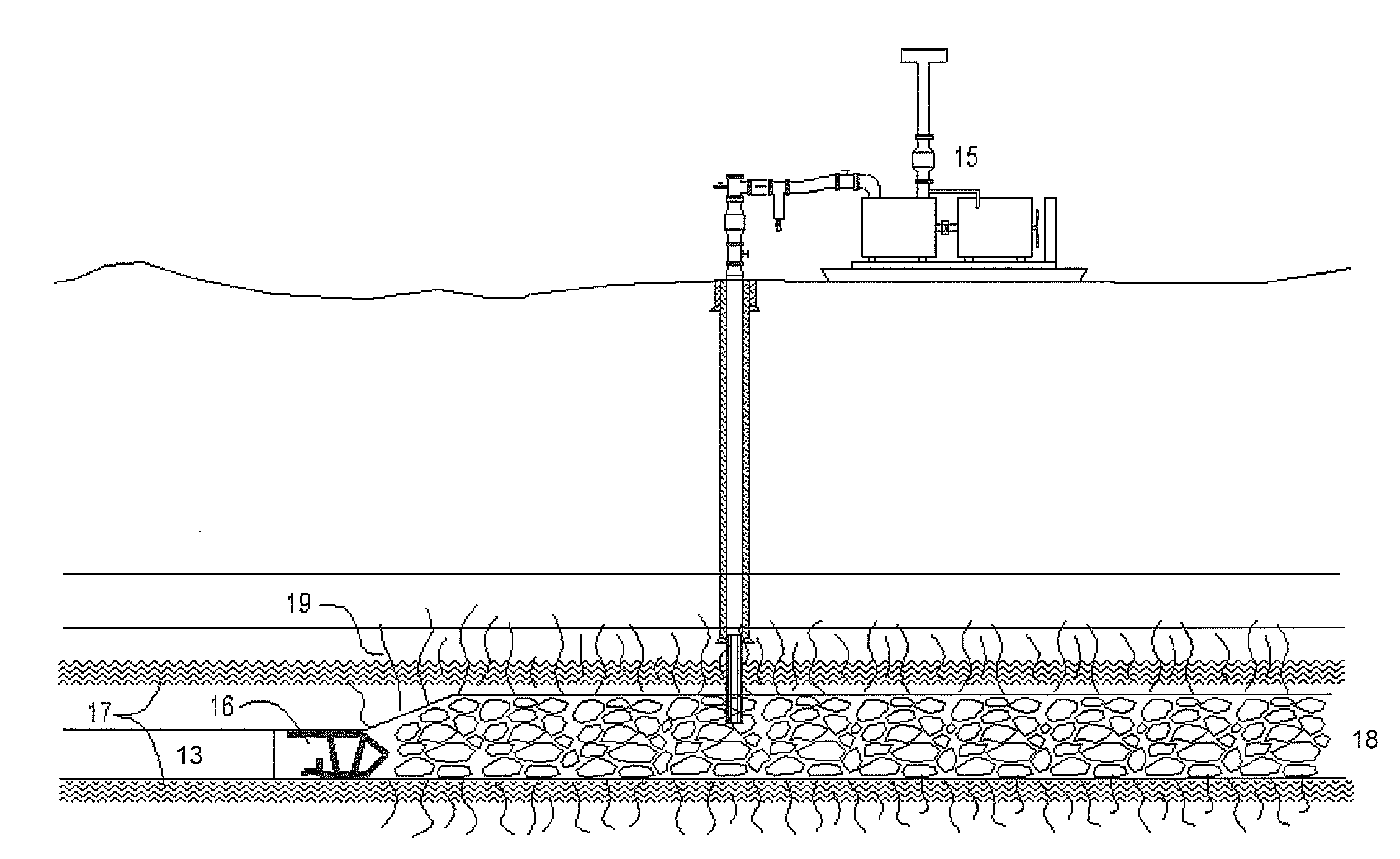

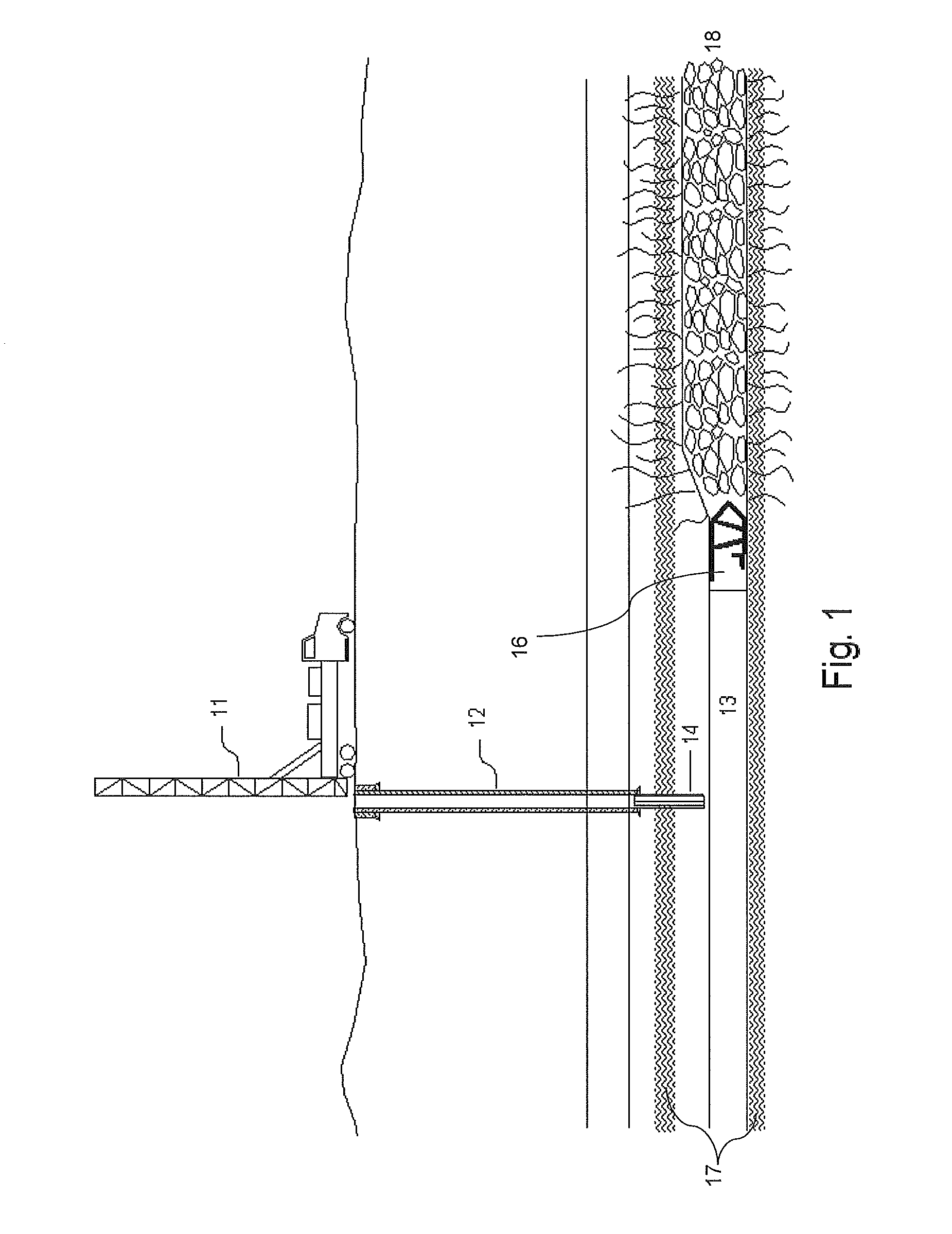

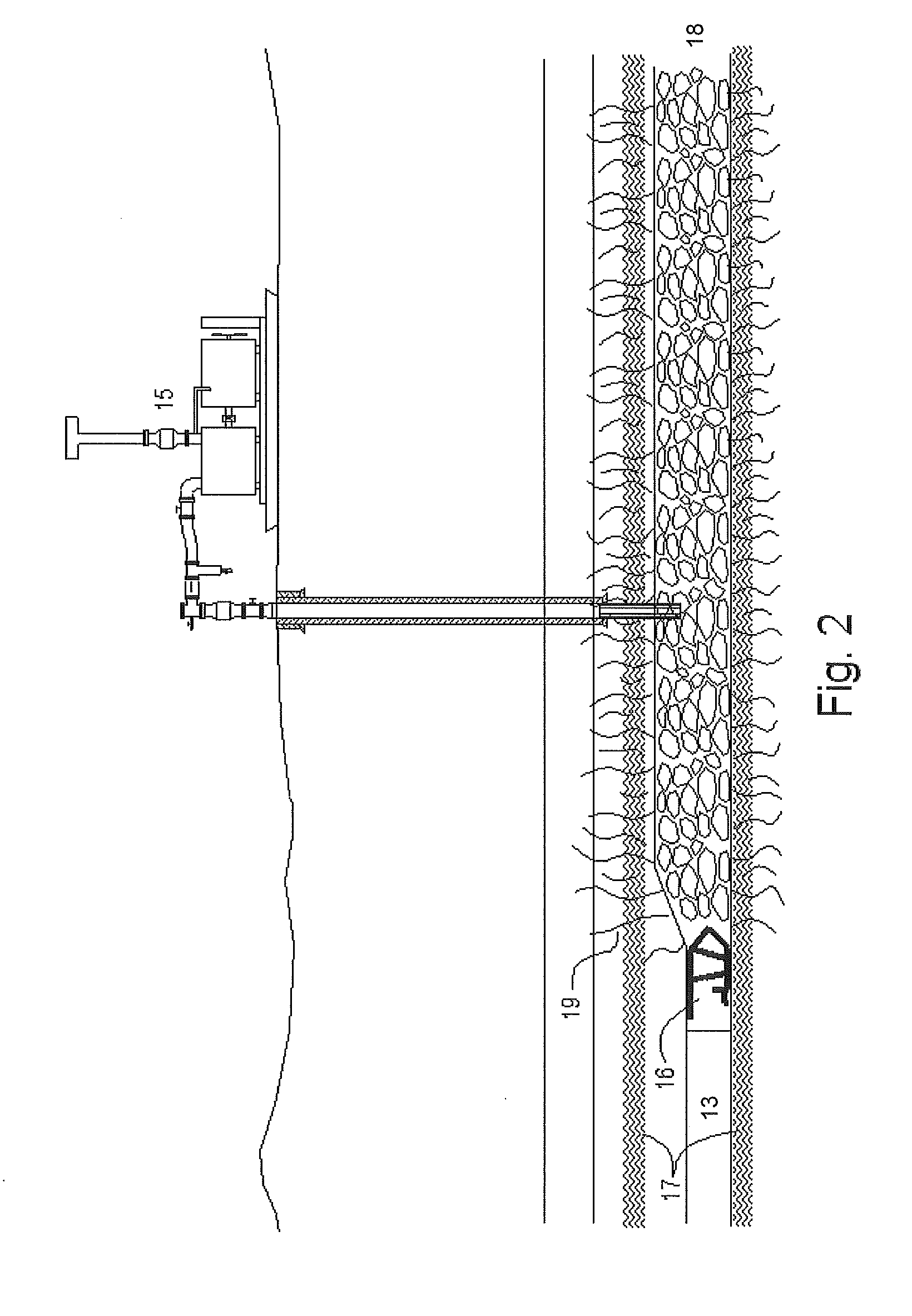

Mining method for co-extraction of non-combustible ore and mine methane

ActiveUS20090315388A1Safer working environment undergroundAvoid excessive dilutionDisloding machinesUnderground miningMineralogyMethane

Mining method for co-extraction of non-combustible ore and mine methane A method for co-extracting non-combustible ore (e.g., trona) and methane from an underground formation comprising at least one methane-bearing layer and a non-combustible ore bed having a rock roof, comprising:providing a well having a downhole end positioned above the ore bed roof;mining an ore region from an initial cavity and removing the mined ore, thereby creating a subsequent cavity;advancing the mining step to another ore region from the subsequent cavity;allowing the roof of the initial cavity to cave so as to create a gob;repeating the mining, advancing and caving steps, the caving being effective in generating fluid communication between the gob and the well downhole end and in fracturing the methane-bearing layer so as to release methane into the gob; andrecovering a gob gas comprising released methane through the well to the surface.

Owner:SOLVAY CHEM INC

Method for extracting lithium from salt lake brine by extraction method

ActiveCN106636673APhase separation effect is goodFacilitate the control of hydrolysisProcess efficiency improvementContaminated waterways/lakes/ponds/rivers treatmentProtonationSimple Organic Compounds

The invention relates to a method for extracting lithium from salt lake brine by an extraction method. The method is suitable for a production process that lithium carbonate and lithium chloride are prepared from high magnesium-lithium ratio salt lake brine and concentrated old brine which contains lithium of salt pan. Co-extraction agent FeCl3, extraction agent and diluent are adopted to carry out lithium extraction, wherein the extraction agent is mixture of neutral phosphorus oxide compound A and phase modifier B, the phase modifier B is organic compound which can generate protonation reaction with the neutral phosphorus oxide compound A in an extraction reaction process, an extraction complex composition obtained after the extraction agent is used for lithium extraction is xLiFeCl4.yHCl.aA.bB, and the extraction complex can be easily dissolved in diluent; an extraction system has good phase splitting performance and reverse extraction and regeneration performance, and the lithium extraction technology of the extraction method is further optimized. The method has a low requirement on equipment, the adopted organic compound is cheap and can be easily obtained, and therefore, the method is suitable for industrial application.

Owner:JIANGXI HZONE LITHIUM TECH

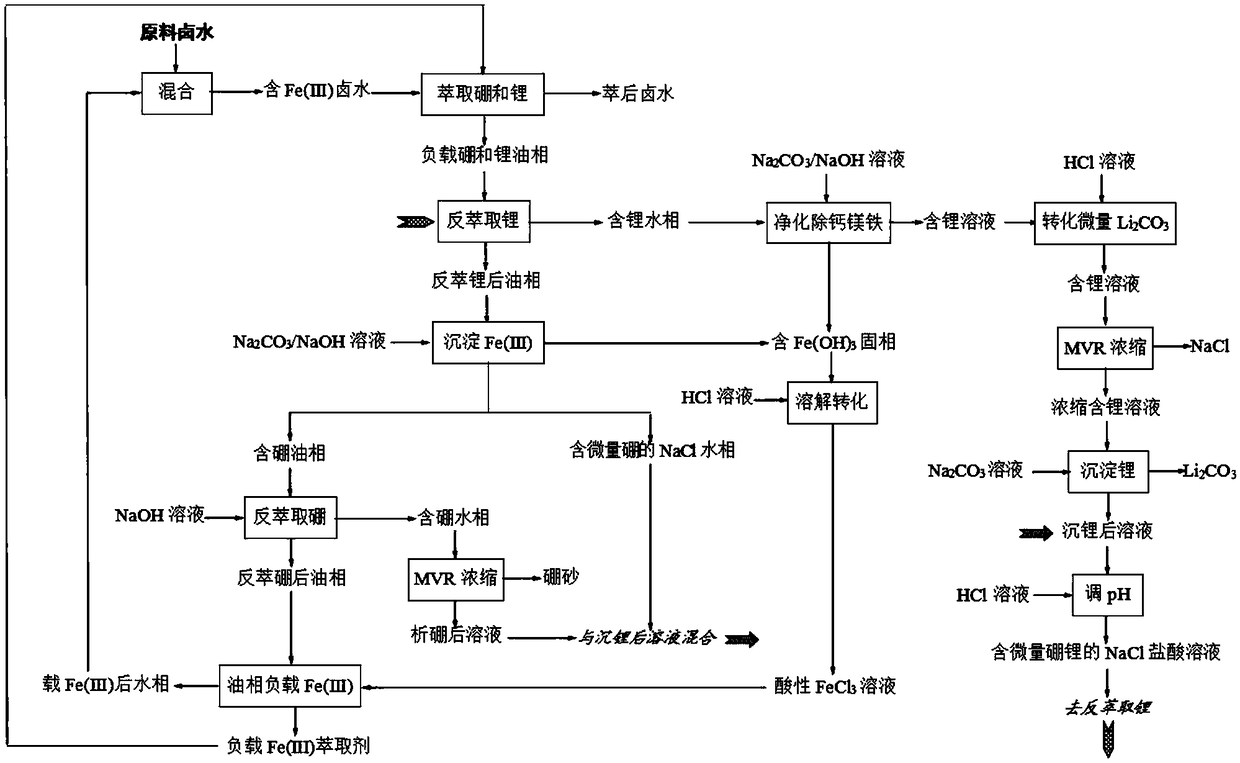

Co-extraction method of boron and lithium in brine

ActiveCN108342595ATo overcome the problem of low stabilityOvercome stabilityProcess efficiency improvementBoratesLithium chlorideLithium carbonate

The invention discloses a co-extraction method of boron and lithium in brine; and a mixing extraction system is adopted to synchronously extract boron and lithium in the brine to realize separation ofboron and lithium from a brine basal body. Lithium and boron in an organic phase are reversely extracted by adopting acid solution and alkali solution to realize separation of boron and lithium. Lithium-contained reverse extracting liquid is condensed for cooling crystallization to prepare lithium chloride or precipitation to prepare lithium carbonate, and is directly condensed for crystallization to prepare boron sand or is acidified for concentration crystallization to prepare boric acid. The method only relates to conventional separation and enrichment operations, is simple in process andclosed in circulation, and realizes efficient recovery of boron and lithium. In addition, as boron and lithium are synchronously extracted, on the basis of simplifying operations and process steps, the problems of low extraction rate, weak organic phase stability and the like caused by mutual interference between boron extraction and lithium extraction organic phases in step-by-step boron and lithium extraction are solved.

Owner:TIANJIN UNIV OF SCI & TECH

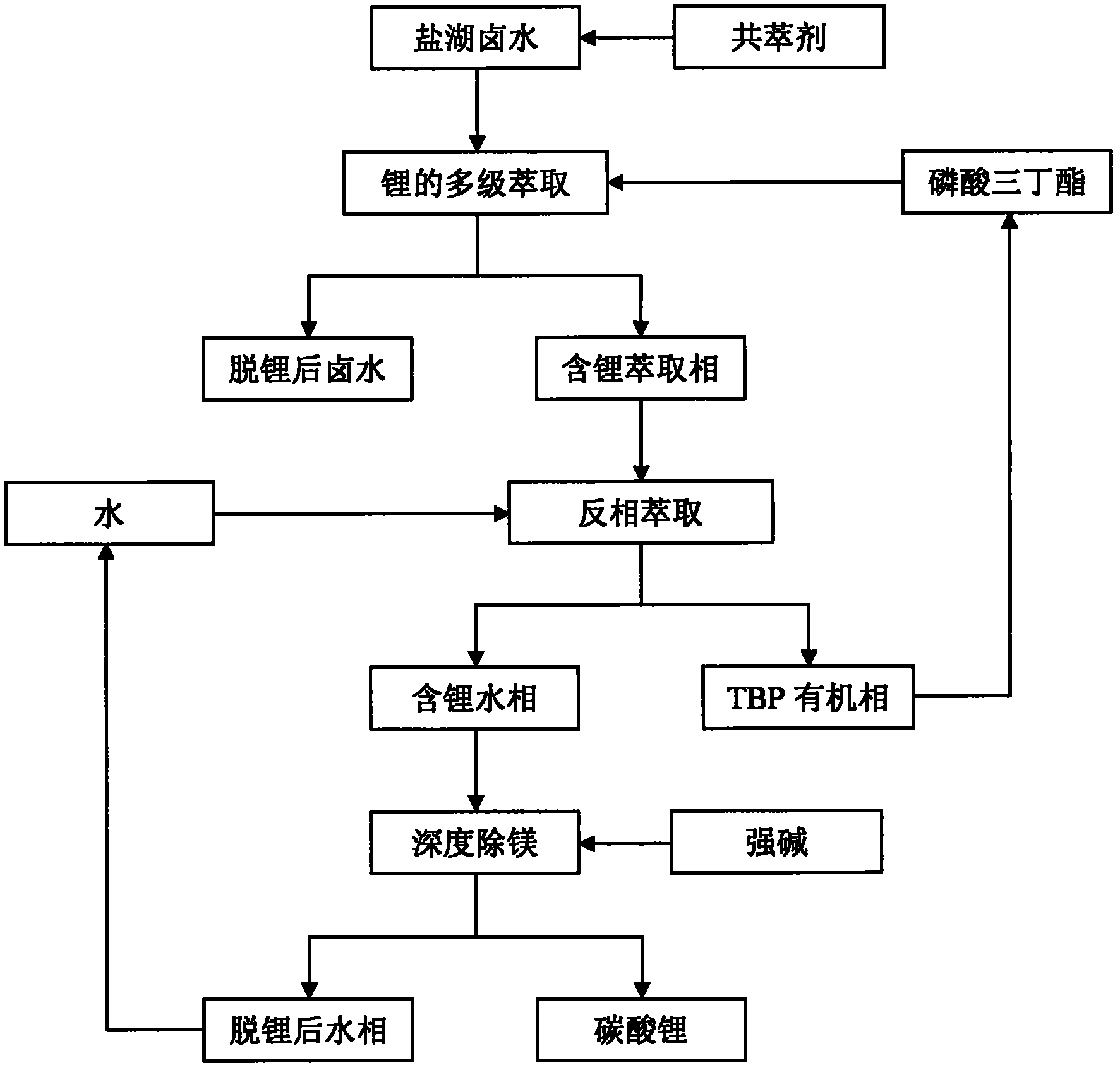

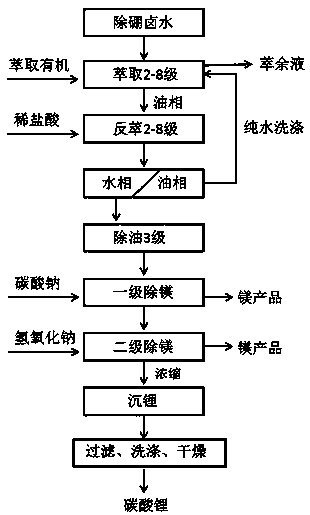

Method for separating magnesium and extracting lithium from salt lake brine with high magnesium-lithium ratio

InactiveCN102633284AStable in natureEasy to separateMagnesium carbonatesLithium carbonates/bicarbonatesHigh magnesiumKerosene

The invention discloses a method for separating magnesium and extracting lithium from salt lake brine with a high magnesium-lithium ratio. With adoption of the method, tributyl phosphate is taken as an extractant, number 200 solvent oil or kerosene is taken as a diluent, perchlorate is taken as a co-extraction agent, and water is taken as a stripping agent to form an extraction system; and lithium carbonate is prepared through extraction, reversed-phase extraction and deep magnesium removal by the salt lake brine. The method has the following beneficial effects: 1. the property of the co-extraction agent is stable, lithium magnesium separation can be carried out in neutral brine and the pH value of an aqueous phase needs not to be controlled; 2. the emulsification phenomenon doesn't exist and a third phase doesn't appear in the extraction process, two phases are easy to separate, the reversed-phase extraction is carried out by water and the device has little corrosion; and 3. the whole technique is simple in process, high in lithium extraction rate, good in separation effect and low in economic cost, is suitable for industrial production of the salt lake brine and is low in environmental damage degree because the co-extraction agent in water can be recycled.

Owner:XIANGTAN UNIV

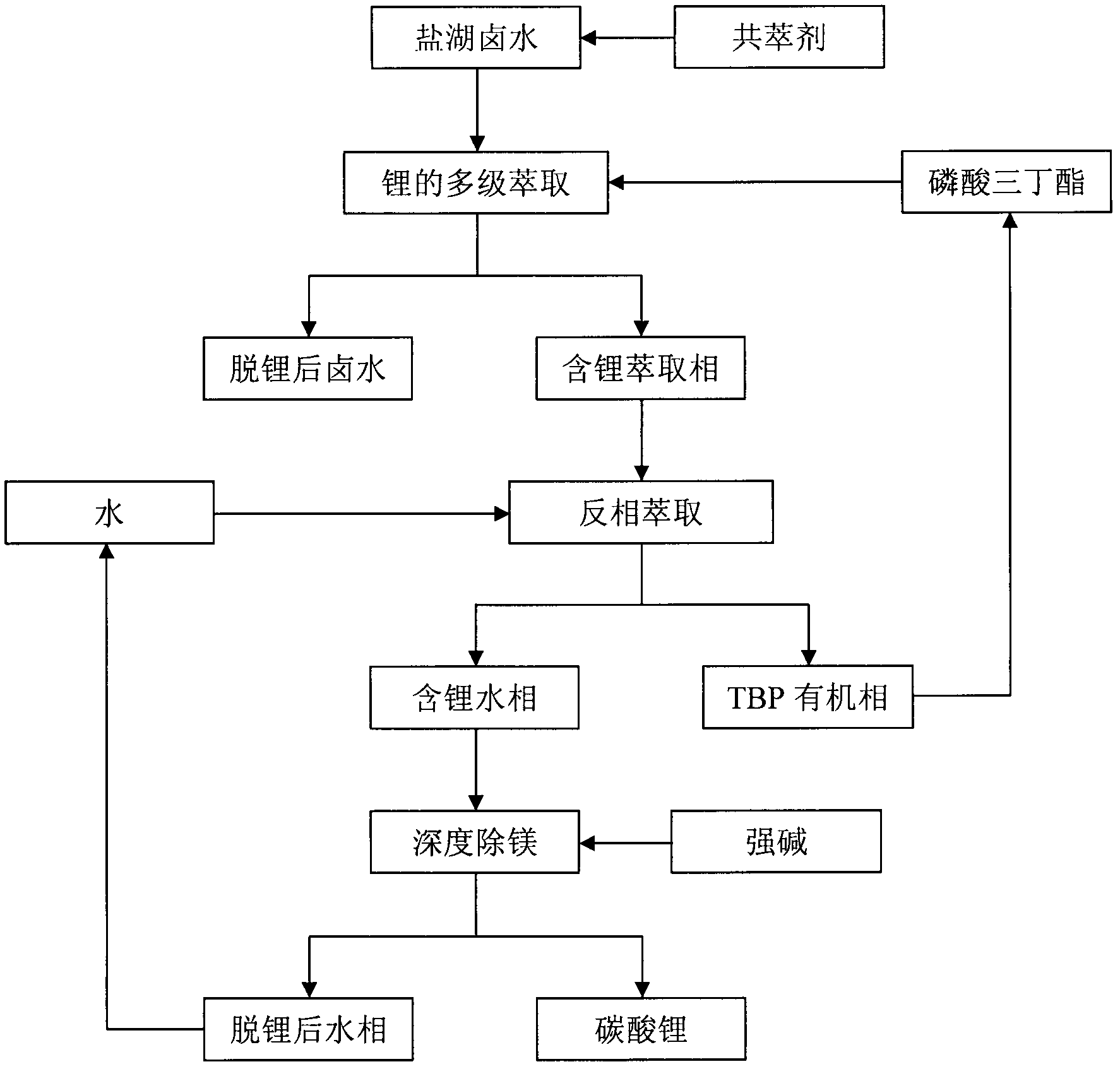

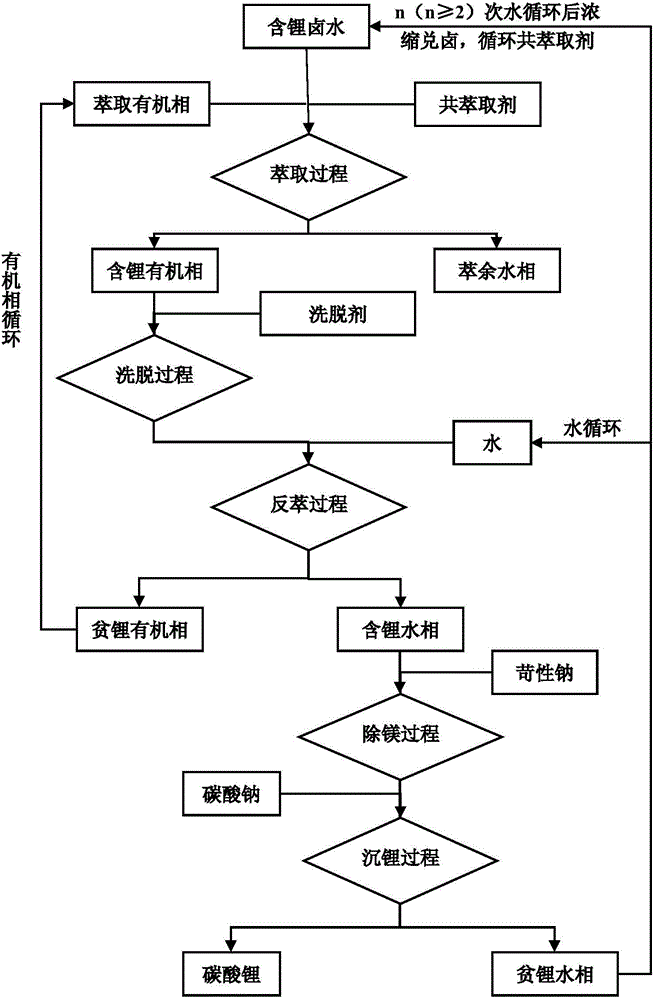

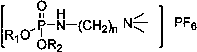

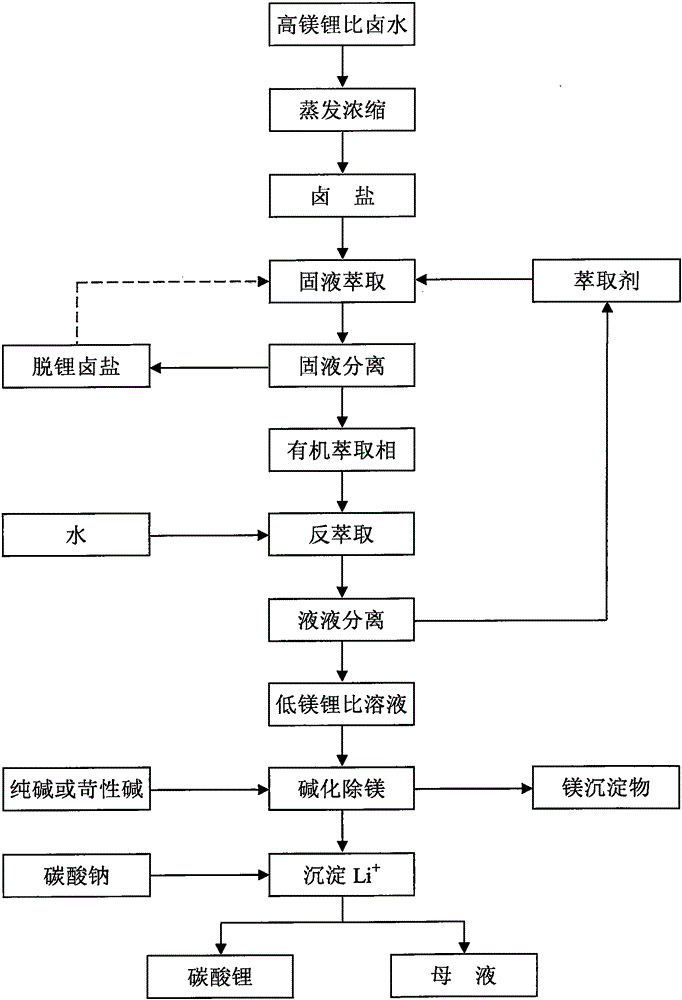

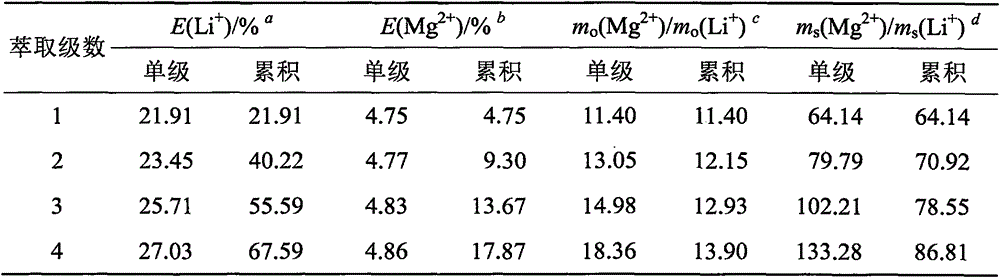

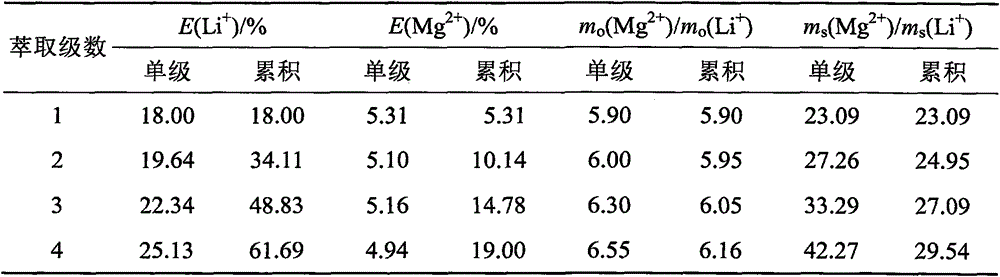

Novel co-extraction system for extraction of lithium from high magnesium-lithium ratio bittern and co-extraction method using the same

ActiveCN104404268AHigh extraction rateHigh stripping rateProcess efficiency improvementHigh magnesiumPotassium hexafluorophosphate

The invention discloses a novel co-extraction system for extraction of lithium from high magnesium-lithium ratio bittern. The novel co-extraction system comprises an extraction agent and a co-extraction agent. The co-extraction agent is a mixture of one or more of potassium hexafluorophosphate, sodium hexafluorophosphate, magnesium hexafluorophosphate, calcium hexafluorophosphate, potassium fluoborate, sodium fluoborate, magnesium fluoborate and calcium fluoborate. The novel co-extraction method for extraction of lithium from high magnesium-lithium ratio bittern comprises extraction, back extraction, deposition for magnesium removal and deposition for lithium acquisition, wherein aiming at bittern with a magnesium-lithium ratio greater than 100, an elution process is used between extraction and back extraction. The novel co-extraction system has simple processes and a high lithium extraction rate, effectively reduces a magnesium-lithium ratio of bittern, has obvious advantages than the traditional ferric trichloride extraction system, can be used for extraction of lithium from salt lake bittern and is especially suitable for solving the problem of high difficulty of extraction of lithium from salt lake bittern with a high magnesium-lithium ratio.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for recovering valuable metal from high nickel lithium ion battery cathode scrap

InactiveCN109055746AImprove efficiencyEasy to operateWaste accumulators reclaimingProcess efficiency improvementManganeseCobalt

The invention discloses a method for recovering valuable metal from high nickel lithium ion battery cathode scrap. Firstly, manganese and cobalt are selectively extracted from high nickel leaching solution by the solvent extraction method; then, nickel and lithium in the raffinate are further separated by the solvent extraction method; finally, the selective oxidation precipitation method is applied to the manganese and cobalt separated by extraction to precipitate manganese ions to achieve the separation of cobalt and manganese. Compared with the traditional method of sequentially separatingelements from the leaching solution, by virtue of the co-extraction characteristics and the redox property difference of the cobalt and the manganese, the method not only separates the cobalt and themanganese from nickel and lithium in one step, but also separates the cobalt and the manganese with high efficiency, and only the two elements of nickel and lithium are left in the raffinate, so thatthe system is simple and the separation effect is greatly improved. The medicament used in the method is cheap, the operation process is simple, the adverse effect of the excessive nickel component onseparation and extraction can be overcome, and the whole component recovery of nickel, cobalt, manganese and lithium resources in the high nickel lithium ion battery scrap is realized.

Owner:CENT SOUTH UNIV

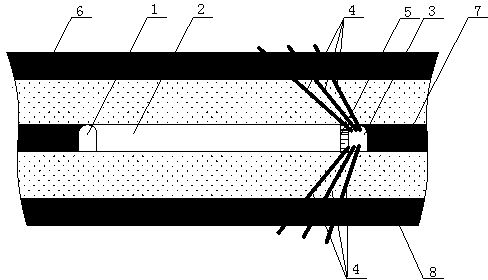

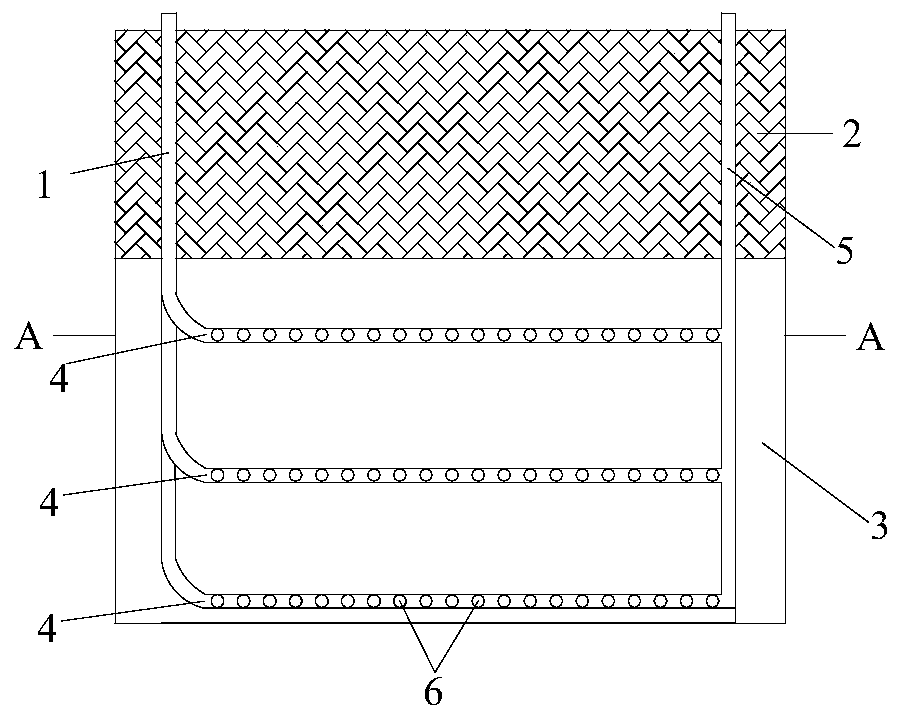

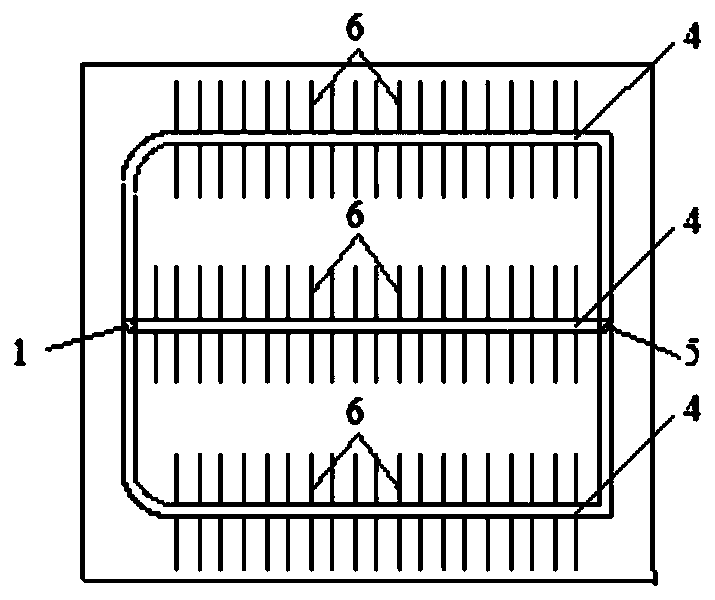

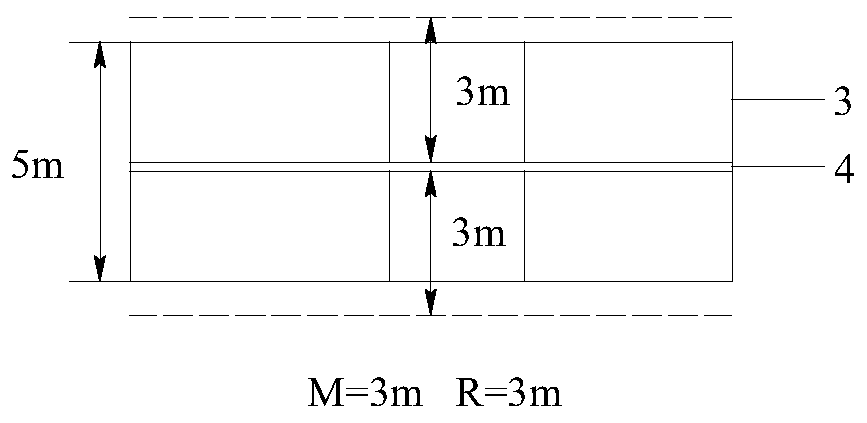

Deep coal bed gas and heat co-extraction method

ActiveCN110318675AImprove breathabilityImprove permeabilityFluid removalDirectional drillingWater vaporHydraulic fracturing

The invention discloses a deep coal bed gas and heat co-extraction method. The method comprises the steps that 1, a first vertical drilling well is constructed, a heat-preserving casing pipe is adopted for carrying out gas sealing and heat isolating protection for a well hole; 2, construction of a layering horizontal well is carried out according to the thickness of a coal bed, the layering numberK is determined according to the coal bed real thickness M and the gas drainage radius R, and K is equal to M / 2R; 3, a second vertical drilling well is constructed; 4, circumferential dispersing holes of the horizontal well are constructed, and then first extraction of gas is carried out; 5, hydraulic fracturing is carried out on all the drilled holes, a three-dimensional fracture mesh is formed,and then second extraction of the gas is carried out; 6, the first vertical drilling well serves as a water injecting well, the second vertical drilling well serves as a steam output well, the wateris injected into the deep coal bed, the principle of heat transfer is utilized for transferring geothermal energy into the water steam, and the water steam is extracted and utilized. According to themethod, gas extraction and geothermal energy exploitation can be carried out for the deep coal bed which is 1500-3000 meters, the geothermal extraction efficiency is improved, energy is saved, emission is reduced, and the geological environment problems of water and soil pollution, thermal pollution and the like are prevented.

Owner:SHANDONG UNIV OF SCI & TECH

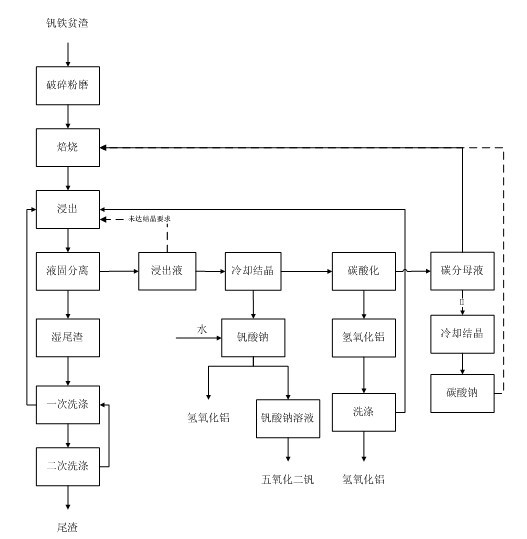

Cleaner production process for synchronously extracting vanadium and aluminum from aluminothermic vanadium iron slag

ActiveCN102586610ARealize co-existenceAchieve separationProcess efficiency improvementSlagAluminium hydroxide

The invention relates to a cleaner production process for synchronously extracting vanadium and aluminum from aluminothermic vanadium iron slag, and belongs to the technical field of metallurgy. The technical scheme is that: the vanadium iron slag is subjected to sodium oxide roasting by using high-proportion Na2CO3 as a roasting transforming agent, vanadium and aluminum of a clinker obtained after sodium oxide roasting are synchronously dissolved out by using an aqueous solution, sodium vanadate crystals containing aluminum hydroxide are crystallized, the purity of the obtained Al(OH)3 is over 95 percent, the purity of vanadium pentoxide is over 98 percent, the co-extraction of the vanadium and the aluminum, the separation of the vanadium and the aluminum and the cyclic utilization of sodium salt are realized, the recovery rate of the vanadium is over 85 percent, the recovery rate of the aluminum is over 60 percent, the weight of tailings is reduced by 40 to 50 percent after leaching, and the tailings can be used for preparing an aluminum-magnesium flocculant by an acid method. The high-efficiency extraction of the vanadium is realized, the resource reutilization of an aluminum element in the slag is also realized, wastewater discharge is avoided in the whole production process, CO2 gas for carbonation can be replaced by roasting flue gas, the proportion of carbon emission isreduced, and the process has remarkable economic and environmental benefits, and can be effectively applied to the treatment of the aluminothermic vanadium iron slag and related materials.

Owner:HEBEI IRON AND STEEL

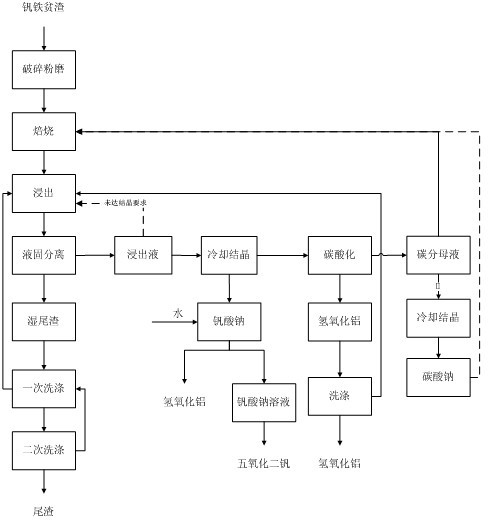

Process for extracting lithium in salt lake brine through phosphate ion liquid to produce lithium carbonate

InactiveCN108866352AHigh extraction rateShorten layering timeProcess efficiency improvementLithium carbonates/bicarbonatesPhosphate ionIonic liquid

The invention provides a process for extracting lithium in salt lake brine to produce lithium carbonate. An extraction system comprises an extraction agent, a co-extraction agent and a diluent, wherein the extraction agent is phosphate ionic liquid containing lithium extraction functional groups, and sodium carbonate is added into solution subjected to extraction and oil removal for primary magnesium removal, after filtering, sodium hydroxide is added into the filtrate for secondary deep magnesium removal, the filtrate is concentrated, sodium carbonate is added for lithium precipitation, filtering is carried out to obtain a filter cake, washing with hot water is carried out, then drying is carried out, and the lithium carbonate is obtained. According to the extraction system, the saturation capacity of the extraction agent is increased by 1 time compared with that of an existing extraction agent and reaches 4 g / L, dilute hydrochloric acid can be used for back extraction, an organic phase is only washed with pure water so that the extraction agent can be regenerated, the process route is simplified, and the production cost is greatly reduced; and according to the process, a soap chemical sequence and an iron removal process are eliminated, so that industrial large-scale production is better facilitated.

Owner:青海柴达木兴华锂盐有限公司

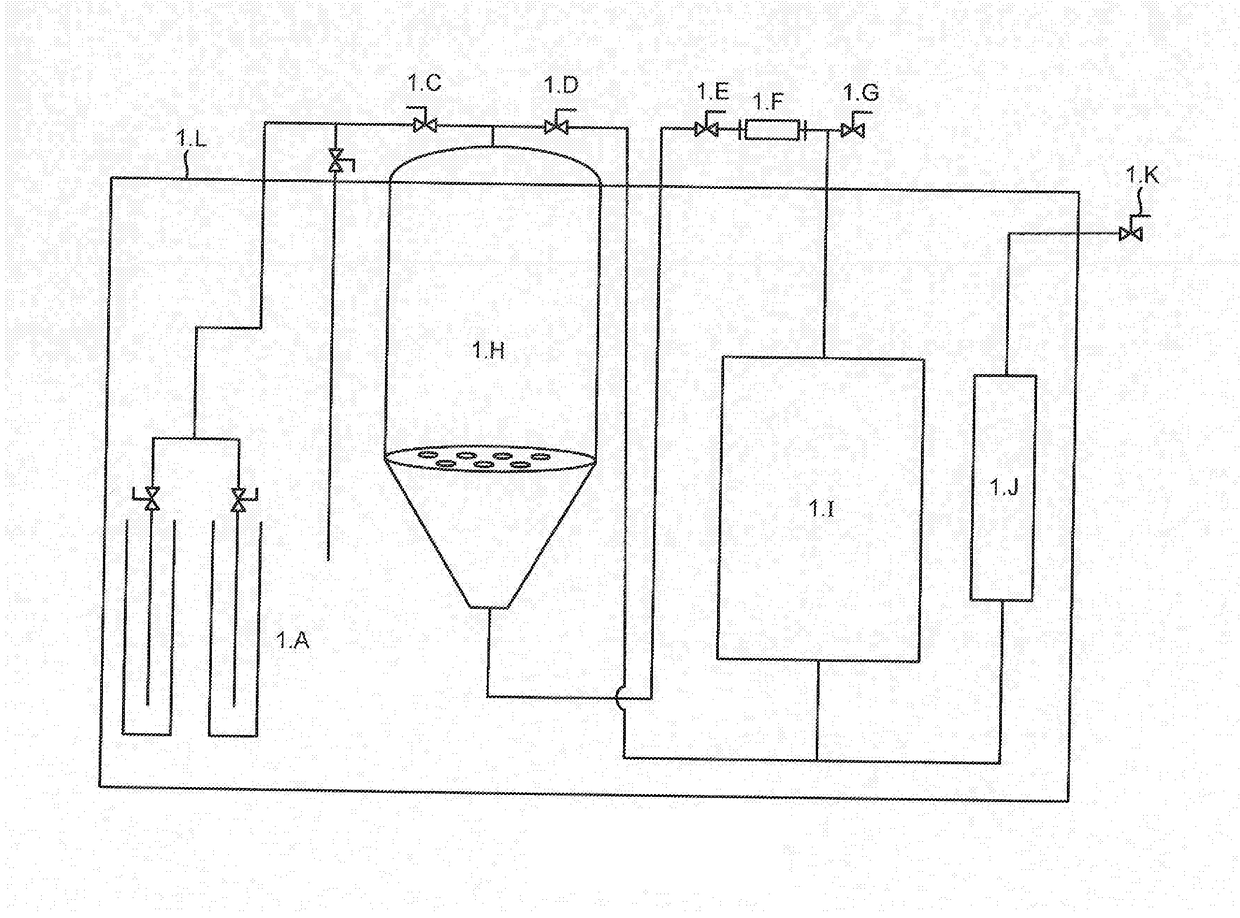

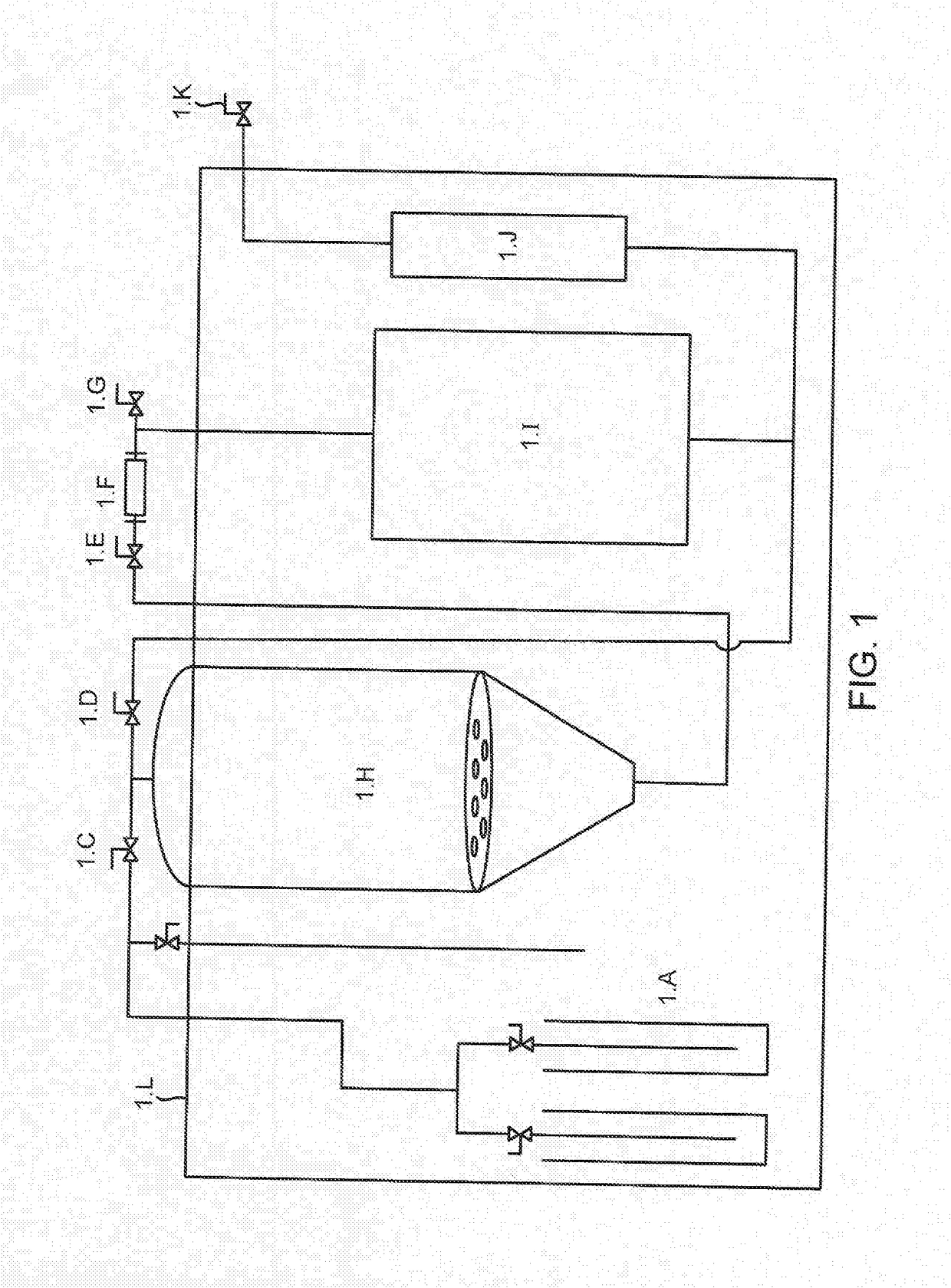

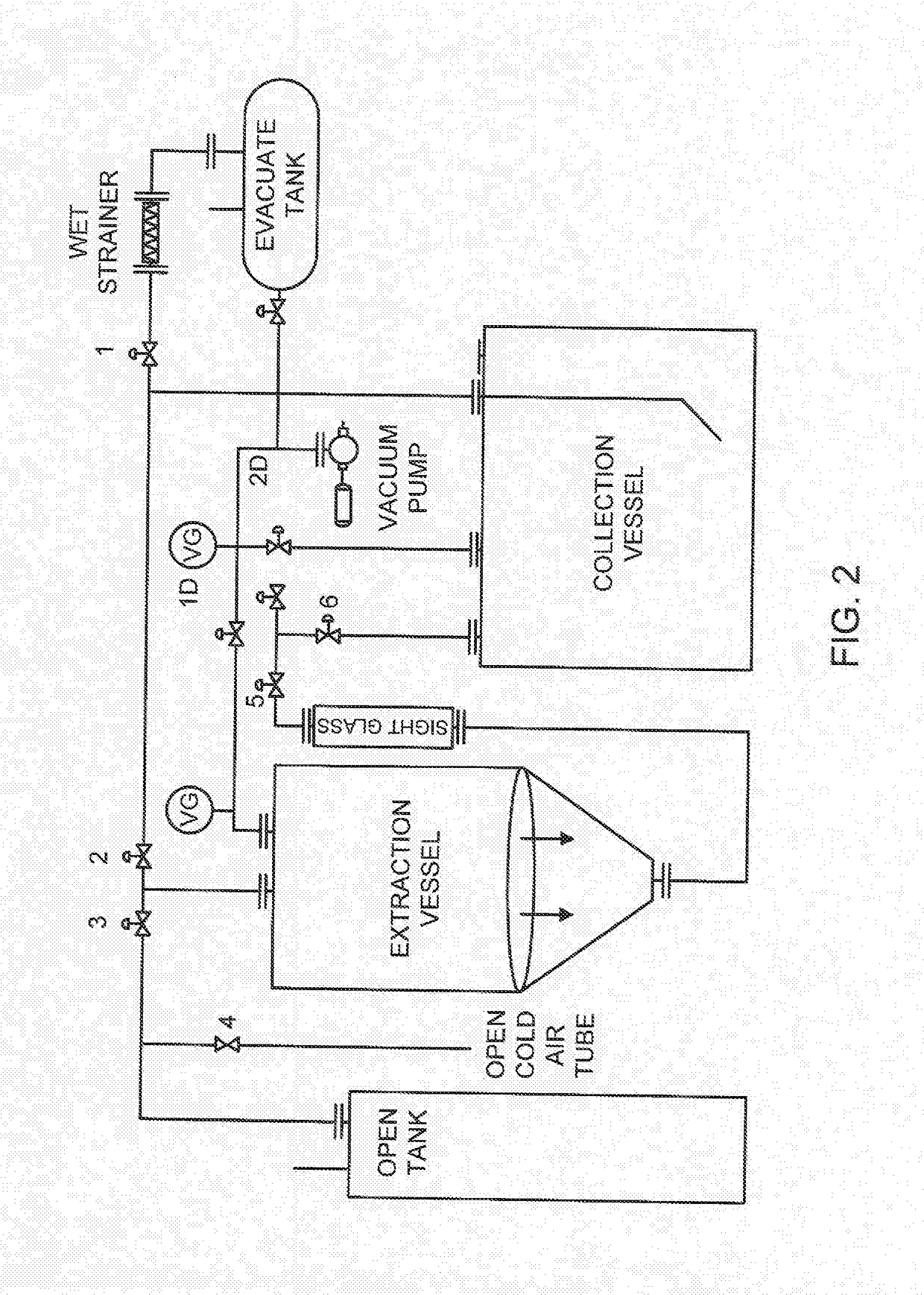

Methods to Reduce Chlorophyll Co-Extraction Through Extraction of Select Moieties Essential Oils and Aromatic Isolates

ActiveUS20170312651A1Essential-oils/perfumesCompression machines with cascade operationAlcoholChlorophyll c

A system, machines and methods for extracting select moieties, flavonoids, and essential oils from plant material without co-extracting chlorophyll, lipids and other undesirable constituents from plants. Super-cooled extraction techniques are taught. Likewise, according to embodiments methods provides 100% grain ethyl alcohol extract with a concentration of chlorophyll that is below 1%.

Owner:CAPNA IP CAPITAL LLC

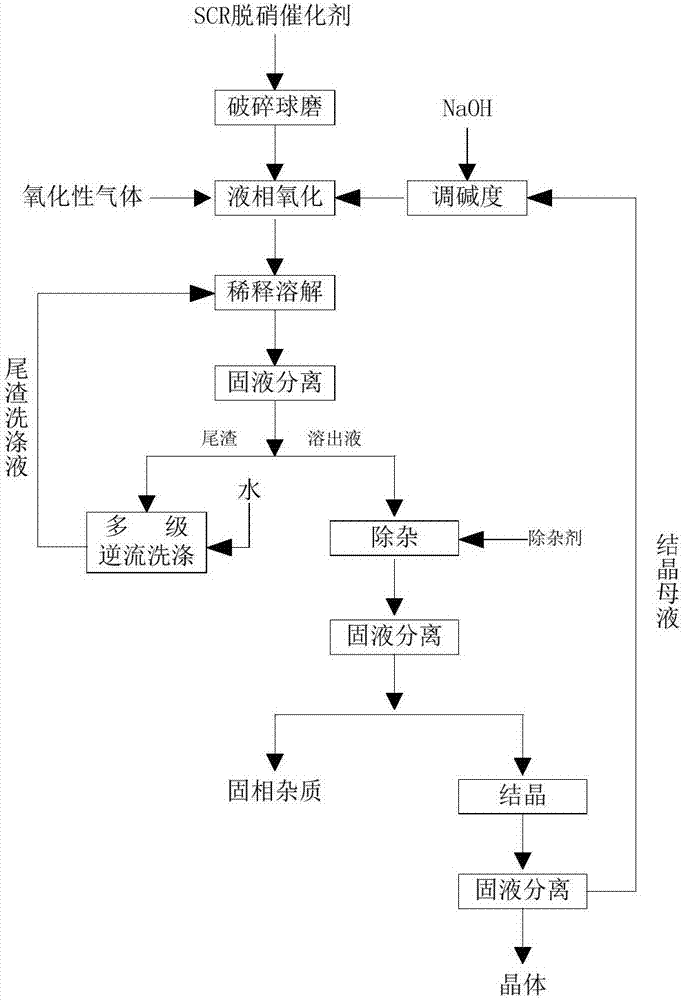

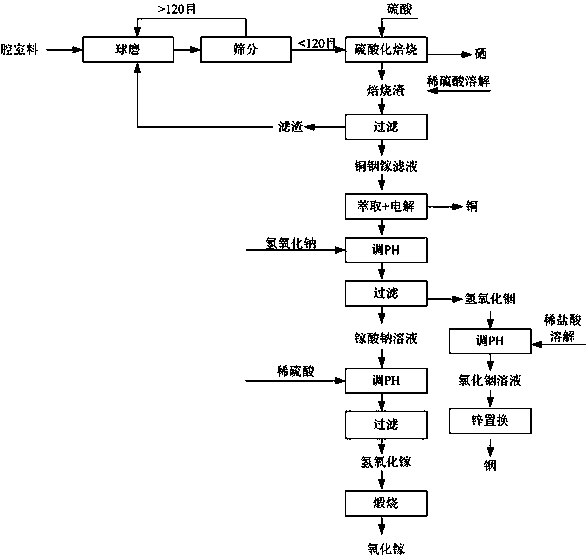

Method for realizing efficient co-extraction of tungsten and vanadium from waste SCR (Selective Catalytic Reduction) denitrification catalyst

InactiveCN107459059AHigh extraction rateLow reaction temperatureVanadium compoundsTungsten compoundsTungstenSodium hydroxide

A method for realizing high-efficiency co-extraction of vanadium and tungsten from waste SCR denitration catalysts. The waste SCR denitration catalysts are reacted with sodium hydroxide solution under an oxidizing gas of 0.2-5Mpa and then separated from solids and liquids. The content of vanadium and tungsten in the tailing slag obtained by the method of the invention is low, and the one-time extraction rate of vanadium and tungsten is higher than 95%, which realizes efficient co-extraction of vanadium and tungsten in the denitrification catalyst.

Owner:HEBEI IRON AND STEEL

Method for producing lithium carbonate by separating magnesium out of low-lithium bittern and enriching lithium

ActiveCN105152190AEasy to operateThe process is easy to realizeOrganic compounds purification/separation/stabilisationMagnesium carbonatesAlkaneEvaporation

The invention discloses a method for producing lithium carbonate by separating magnesium out of low-lithium bittern and enriching lithium. The method includes the steps of converting salt lake bittern serving as raw materials into halide salt through evaporation dehydration and crystallization separation, directly extracting halide salt through trixylyl phosphate alkane ester or a mixture of trixylyl phosphate alkane ester and monohydric alcohol, obtaining an organic extraction phase and the rest of halide salt after solid-liquid separation, conducting back extraction on the organic extraction phase through water to obtain a low-magnesium-lithium-ratio lithium-rich solution, and obtaining lithium carbonate through condensation and alkalization magnesium removal. The method has the advantages that processes related to the solid-liquid extraction method are simple, co-extraction agents are not needed, the solute distribution drive force is large, and the method is not influenced by bittern extractant two-phase balance; multiple stages of extraction processes are conducted on halide salt, the extraction rate of Li+ is larger than 90%, and the mass ratio of magnesium to lithium in the extraction phase is remarkably decreased; phase splitting is easy due to liquid-liquid back extraction, and the back extraction rates of Li+ and Mg2+ are both larger than 90%; the extraction process is operated under the neutral or weak-acid condition, the production cost is low, and the method is particularly suitable for producing lithium carbonate after separating magnesium out of bittern with the magnesium-lithium mass ratio of 120 or lower.

Owner:GUANGZHOU TINCI MATERIALS TECH

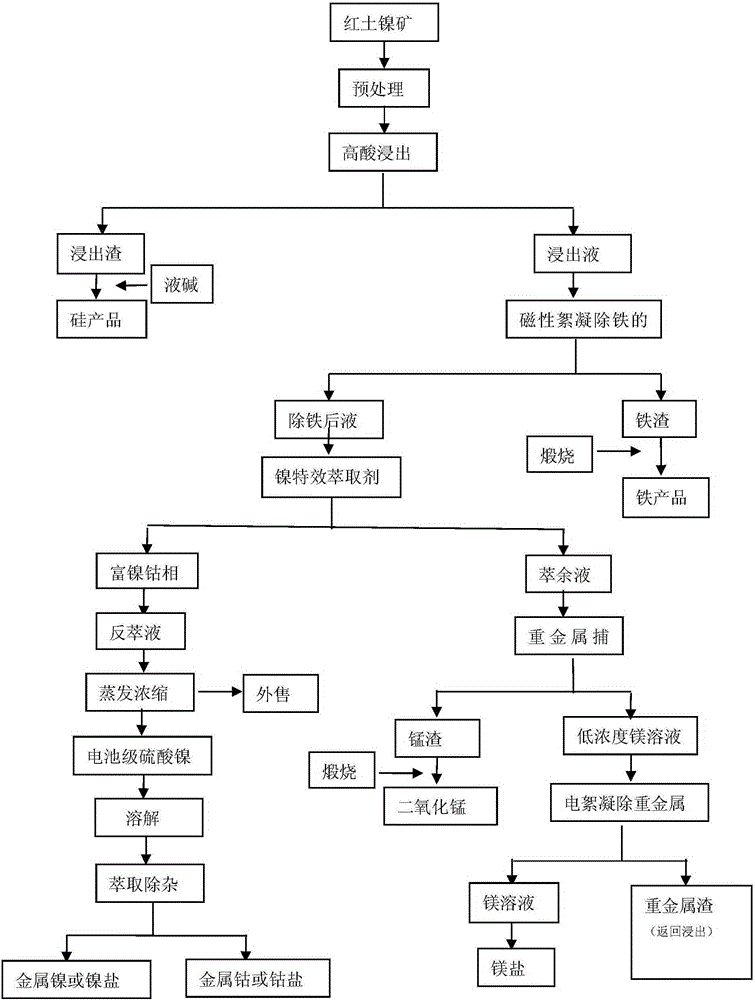

Method for laterite-nickel ore resourceful treatment and comprehensive recycling

ActiveCN105296744ALittle changeHigh recovery rateProcess efficiency improvementMagnesium saltManganese

The invention discloses a method for laterite-nickel ore resourceful treatment and comprehensive recycling. The method includes the main steps of pretreatment, high acid leaching to obtain silicon, precursor iron extracting through magnetic flocculation iron removal, Ni-Co extraction separation, adsorption to obtain manganese, electric flocculation treatment of waste water and magnesium salt work section. The method for laterite-nickel ore resourceful treatment and comprehensive recycling has the following advantages that (1) the process is short; (2) few types of intermediate materials and washing water are used; (3) the change range of potential of hydrogen (pH) value of a solution is small; (4) the heavy metal treatment cost is low; (5) waste water and waste residues can be comprehensively utilized; (6) the nickel recovery rate is high. By means of the novel process route, resources in laterite-nickel ores can be comprehensively utilized, extraction of nickel, cobalt, manganese, iron, magnesium, silicon and the like is included, intermediate residues are not generated, material reverting is also avoided, the comprehensive processing cost is remarkably reduced, and economic benefits and social benefits are remarkable.

Owner:广西银亿再生资源有限公司 +1

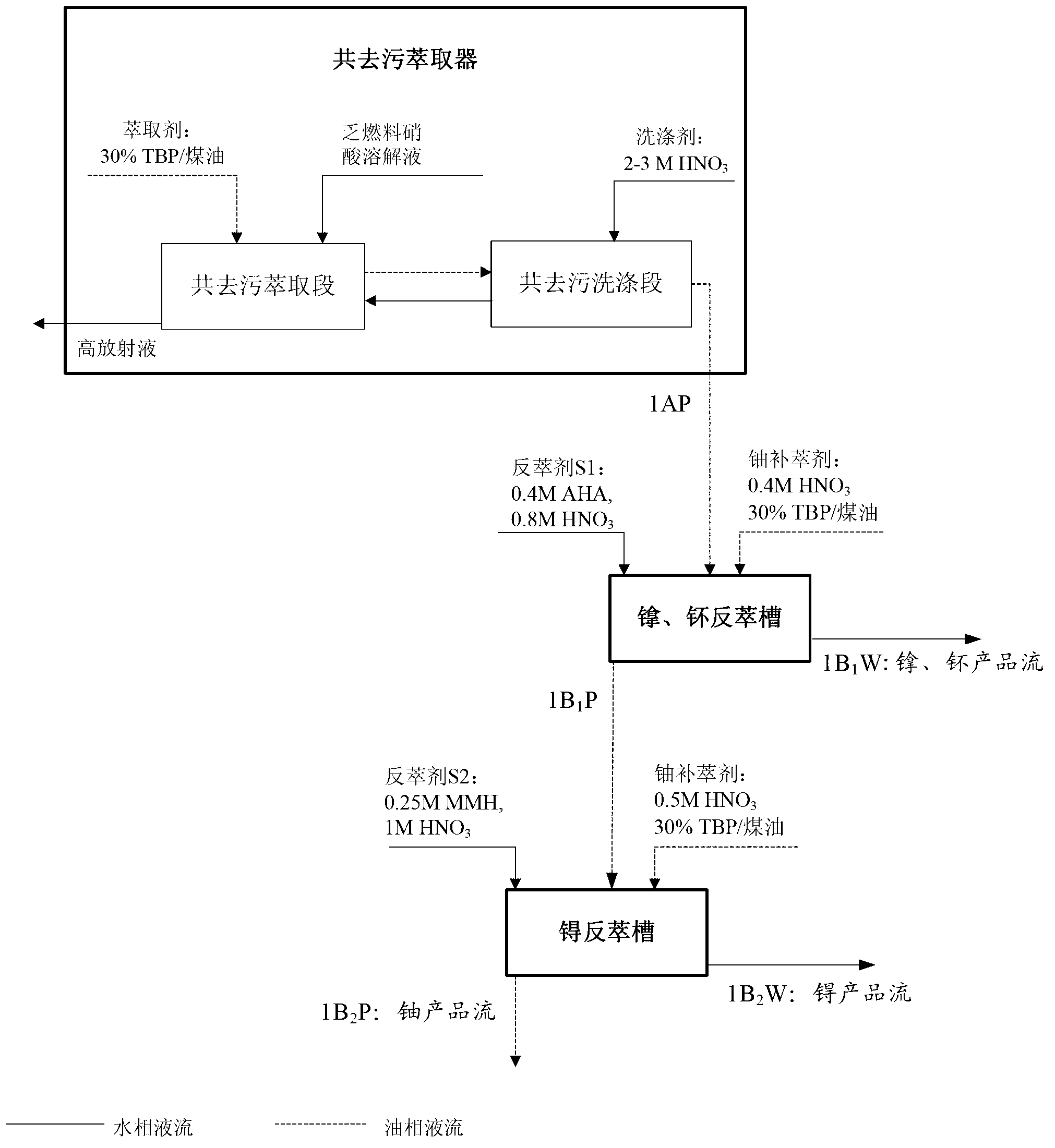

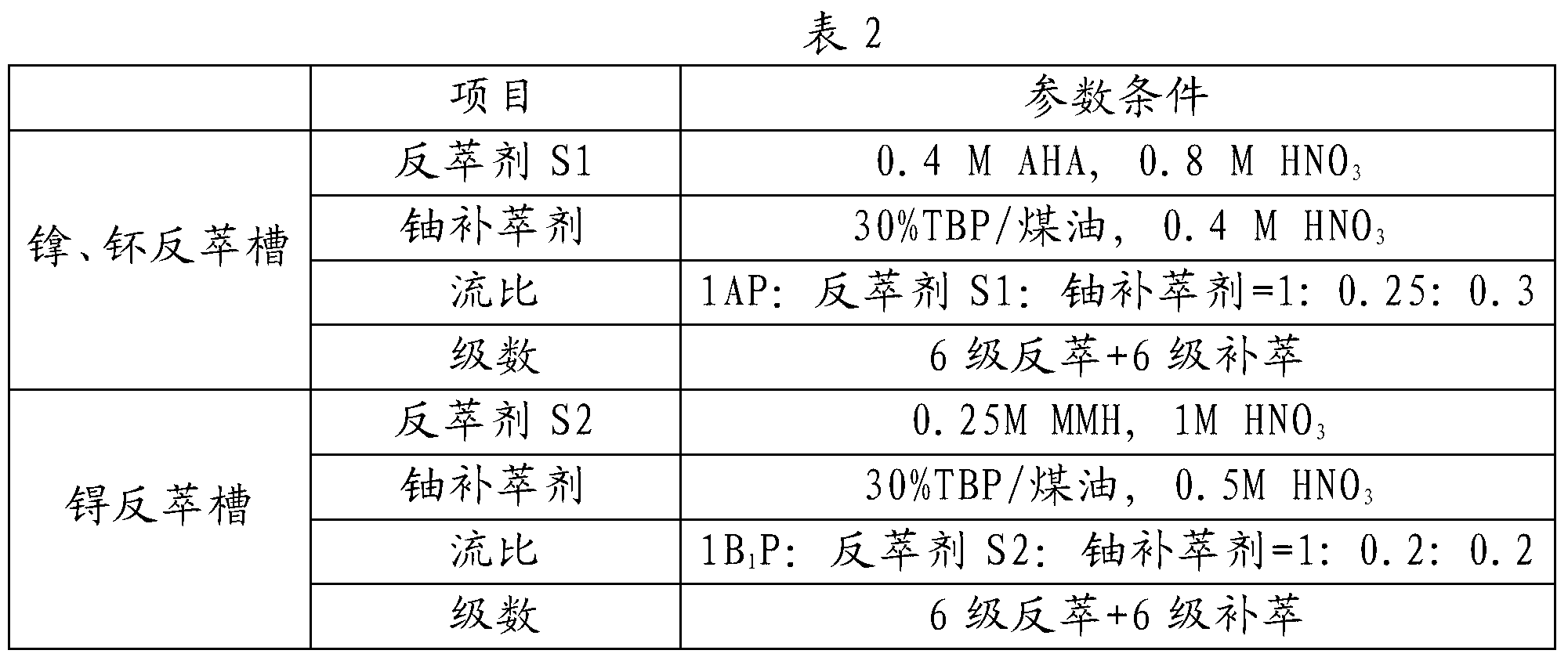

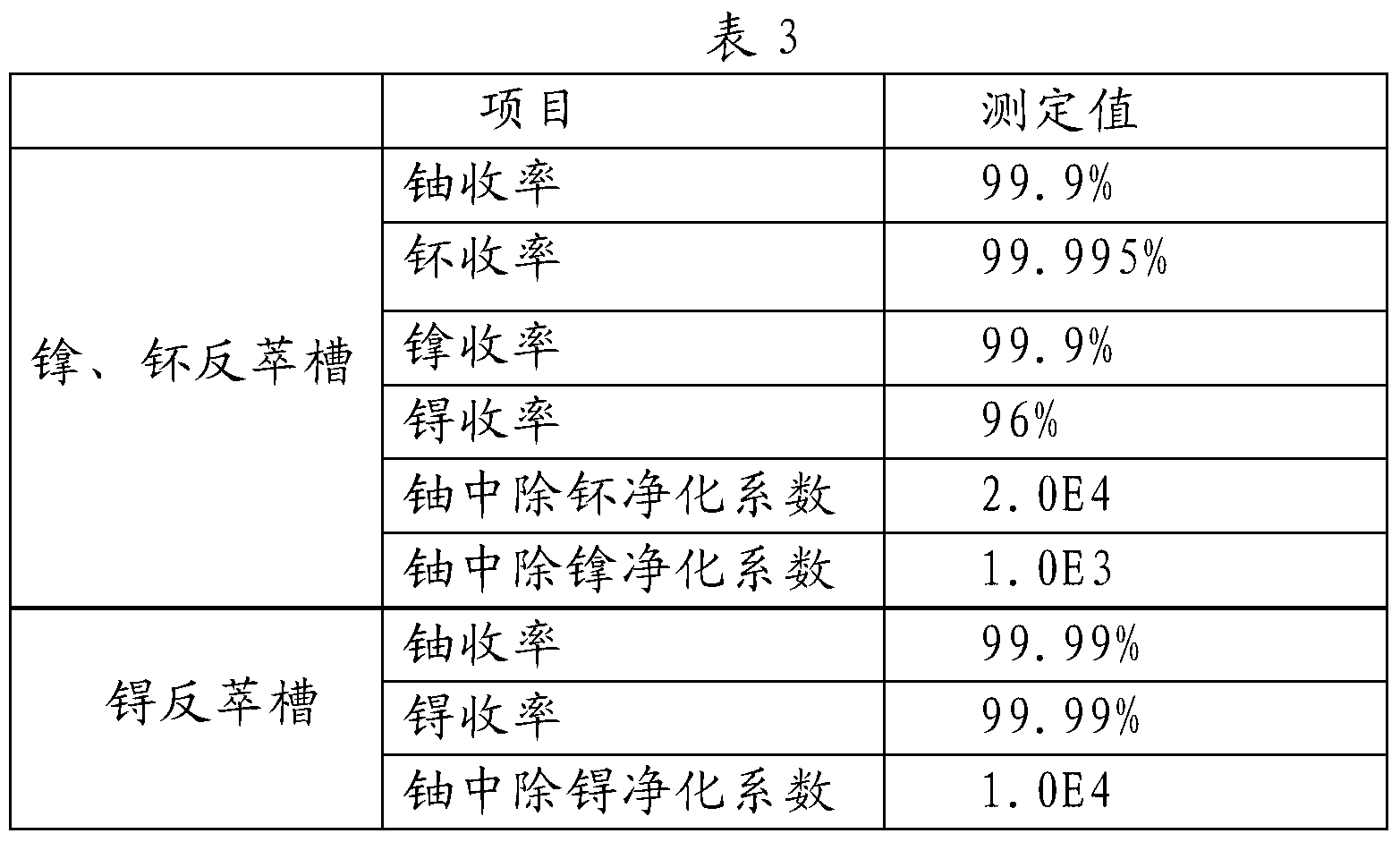

PUREX process for separating technetium

ActiveCN103325431AStep-by-step restore implementationGo simpleRadioactive decontaminationTechnetiumSalt free

The invention relates to a PUREX process for separating technetium. The PUREX process includes the steps: (1) co-decontamination and co-extraction: co-extracting uranium, plutonium, neptunium and the technetium in spent fuel nitric acid solution into an organic phase and washing co-extraction liquid; (2) plutonium and neptunium reverse extraction: reversely extracting the plutonium and the neptunium in the co-extraction liquid into a water phase by reverse extraction agents S1 containing AHA and then adding uranium supplement extraction agents for supplement extraction to obtain the water phase containing the plutonium and the neptunium and an oil phase containing the uranium and the technetium; (3) technetium reduction and reverse extraction: reducing and reversely extracting the technetium in the oil phase containing the uranium and the technetium into the water phase by reverse extraction agents S2 containing reducing agents and then adding uranium supplement extraction agents for supplement extraction to obtain a water phase containing the technetium and an oil phase containing the uranium, wherein the oil phase containing the uranium enters a subsequent uranium purification process. The neptunium, the plutonium and the technetium are reduced step by step through a step-by-step reduction method, the technetium can be separated out, the trend of elements is simpler and more uniform, all the reducing agents are salt-free reagents, remaining reagents are easily damaged, and the subsequent process is less affected.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Recycling method for copper-indium-gallium-selenium materials

Owner:HANERGY MOBILE ENERGY HLDG GRP CO LTD

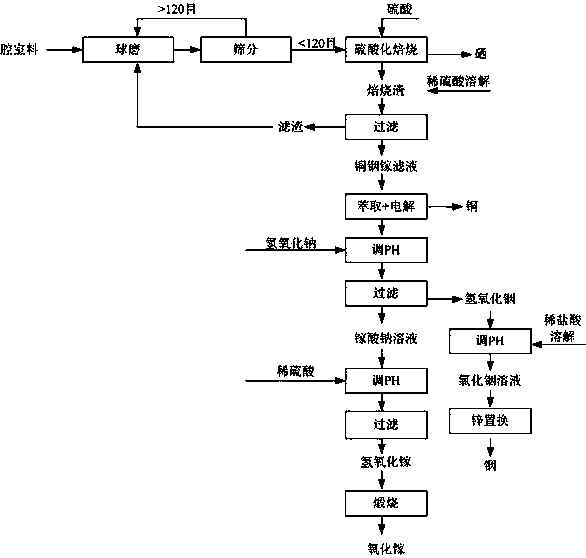

Method for synchronously extracting and separating uranium and molybdenum

The invention belongs to the technical field of hydrometallurgy, and particularly relates to a method for synchronously extracting and separating uranium and molybdenum. Overcoming the defects in the prior art is the purpose, a method for acid leaching of uranium and molybdenum in a solution is provided, wherein the method is simple in technology, high in uranium and molybdenum recycling rate, capable of not introducing complex ions and environmental-friendly, and the method is suitable for industrial application. Efficient uranium and molybdenum separation can be achieved through N235 uranium and molybdenum co-extraction-200 g / L sulfuric acid solution uranium back extraction-ammonium hydroxide molybdenum back extraction-P204 uranium re-extraction-Na2CO3 uranium repeated back extraction, and the uranium and molybdenum extraction rate is high and can reach more than 99.5%. The contact frequency between an extraction stock solution and an organic phase can be reduced through co-extraction of uranium and molybdenum, the generating amount of suspended matter in the extraction residual water phase is reduced, and the entrainment loss of the organic phase is reduced. Circular utilization of a P204 extraction residual solution (200 g / L sulfuric acid solution) is achieved, and the consumption amount of reagent sulfuric acid is reduced. The accumulation of sodium sulfate in the uranium sediment motor liquor can be reduced. The complex ions hard to treat are not introduced in the whole technology process, and later waste water treatment is facilitated.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

Method for recovering scandium from intermediate products formed in the hydrometallurgical processing of laterite ores

InactiveUS20140314639A1Rare earth metal compoundsProcess efficiency improvementHydrometallurgyLaterite

The invention provides a method for recovering scandium from scandium-containing intermediate products, formed during hydrometallurgical processing of scandium-containing feed materials, including: (a) leaching of the scandium-containing intermediate products with a suitable acid at a controlled pH selected to maximize scandium extraction and minimize the co-extraction of impurities, (b) solid / liquid separation, to obtain a scandium-containing leach solution; (c) selective precipitation of the scandium at a controlled pH from the scandium-containing leach solution using a suitable base, (d) solid / liquid separation, to obtain an upgraded scandium concentrate and a barren solution for return to the hydrometallurgical process. A further upgraded scandium concentrate can be obtained by (e) alkaline leaching of the upgraded scandium concentrate for additional removal of impurities, and (f) solid / liquid separation to obtain a further upgraded scandium concentrate and impurities-containing base solution.

Owner:VALE LIMITED

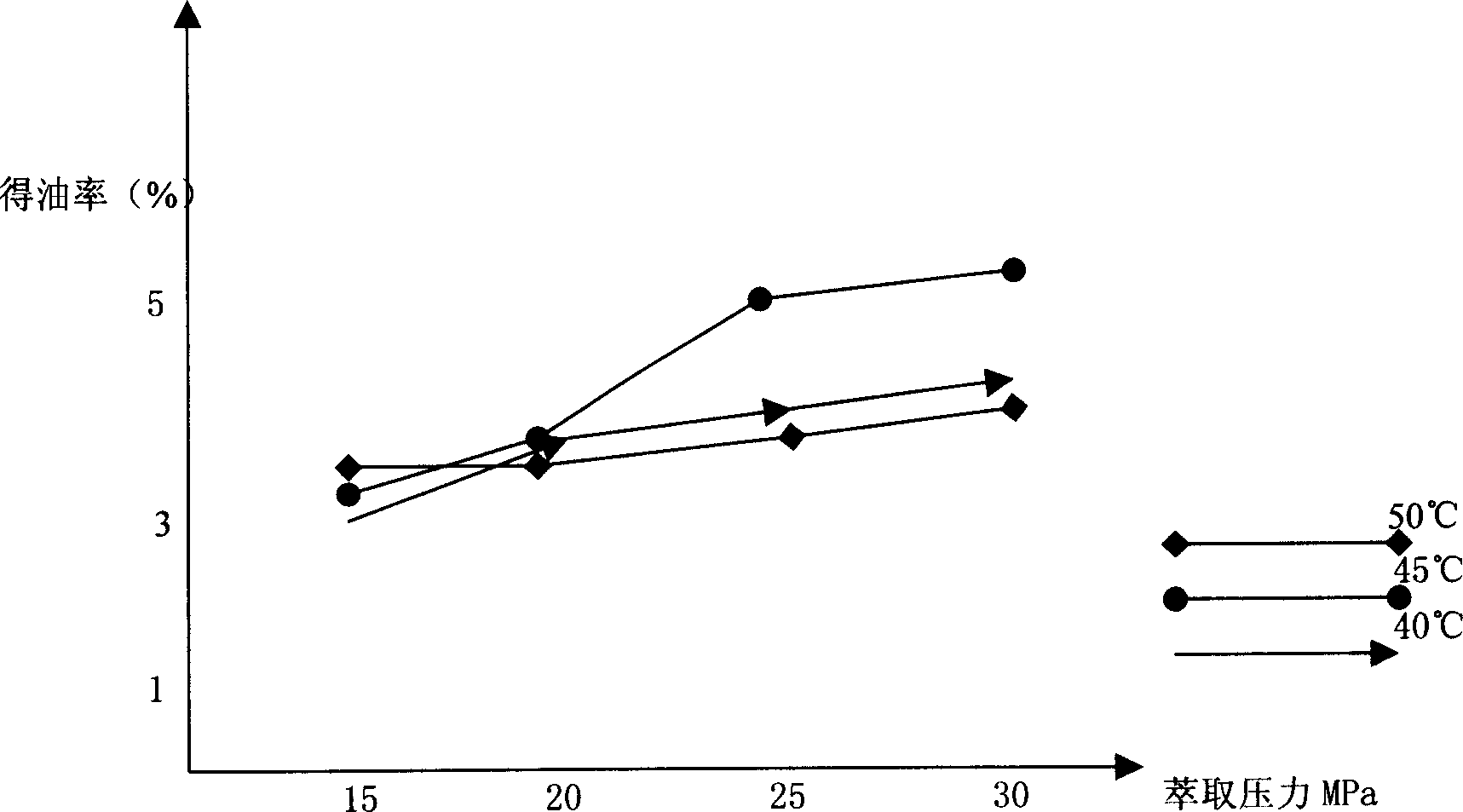

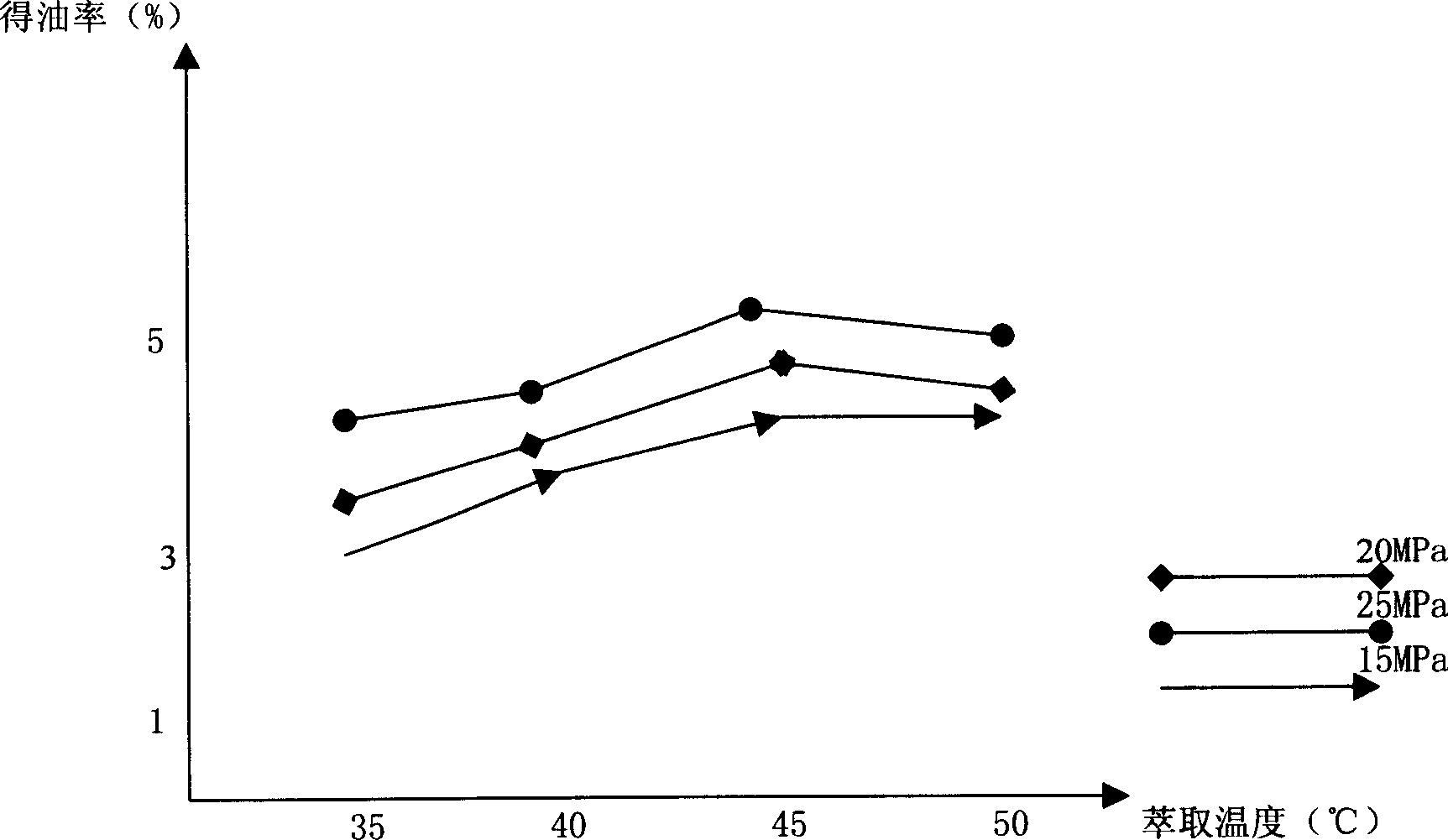

Supercritical CO extraction of Angelica dehurical oil resin

The invention belongs to the field of extraction technology; he radix angelicae dahuricae oil resin extracted out belongs to food conditioner. The purpose of the patent is to ameliorate the deficiency of the current technology, to decrease the remainder of the organic solvent, and to improve the flavor of the extractant. The supercritical fluid CO2 extraction method of the radix angelicae dahuricae oil resin is as following, the radix angelicae dahuricae power of a certain quantity is put into the extraction kettle, then the temperature is set, when the temperature reach the setting value by heating or refrigeration, the system will be compressed by CO2 with the high pressure pump, when the pressure of the extraction kettle and the isolation kettle reach the setting value, the flux of CO2 is adjusted to a certain value at the same time, keep the extraction for a while at a unvarying temperature, pressure and flux, and then put the radix angelicae dahuricae oil resin out. The technology of this patent is simple, the time of it is just as much as one sixth of that of the solvent method, the extraction ratio is 5.04%, is 1.78% higher than the extraction ratio of solvent method which is 3.26%. The radix angelicae dahuricae oil resin extracted with the method has not solvent remainder, the color and the aroma of it is pure.

Owner:TIANJIN TANGCHAO FOOD IND CO LTD

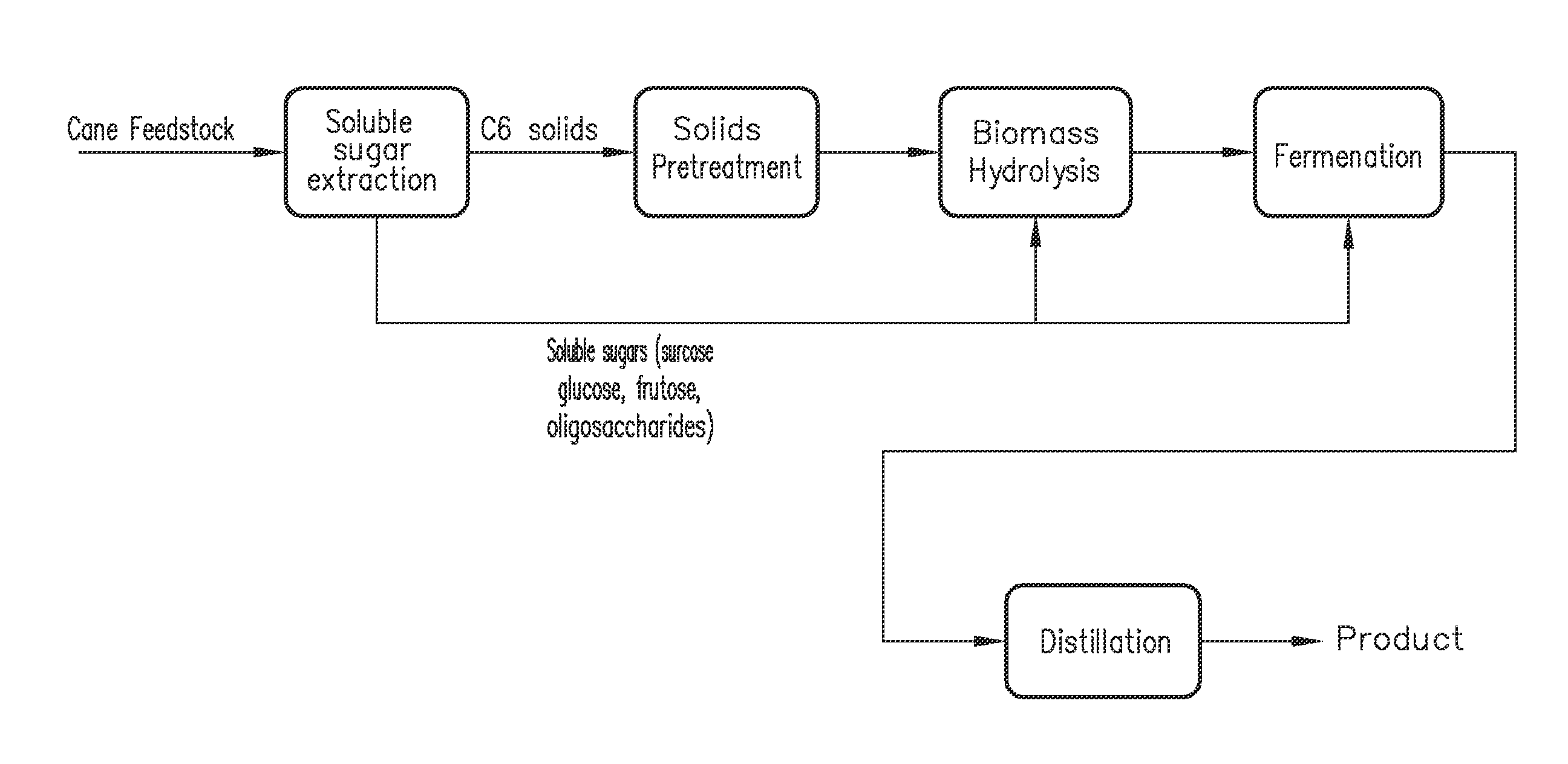

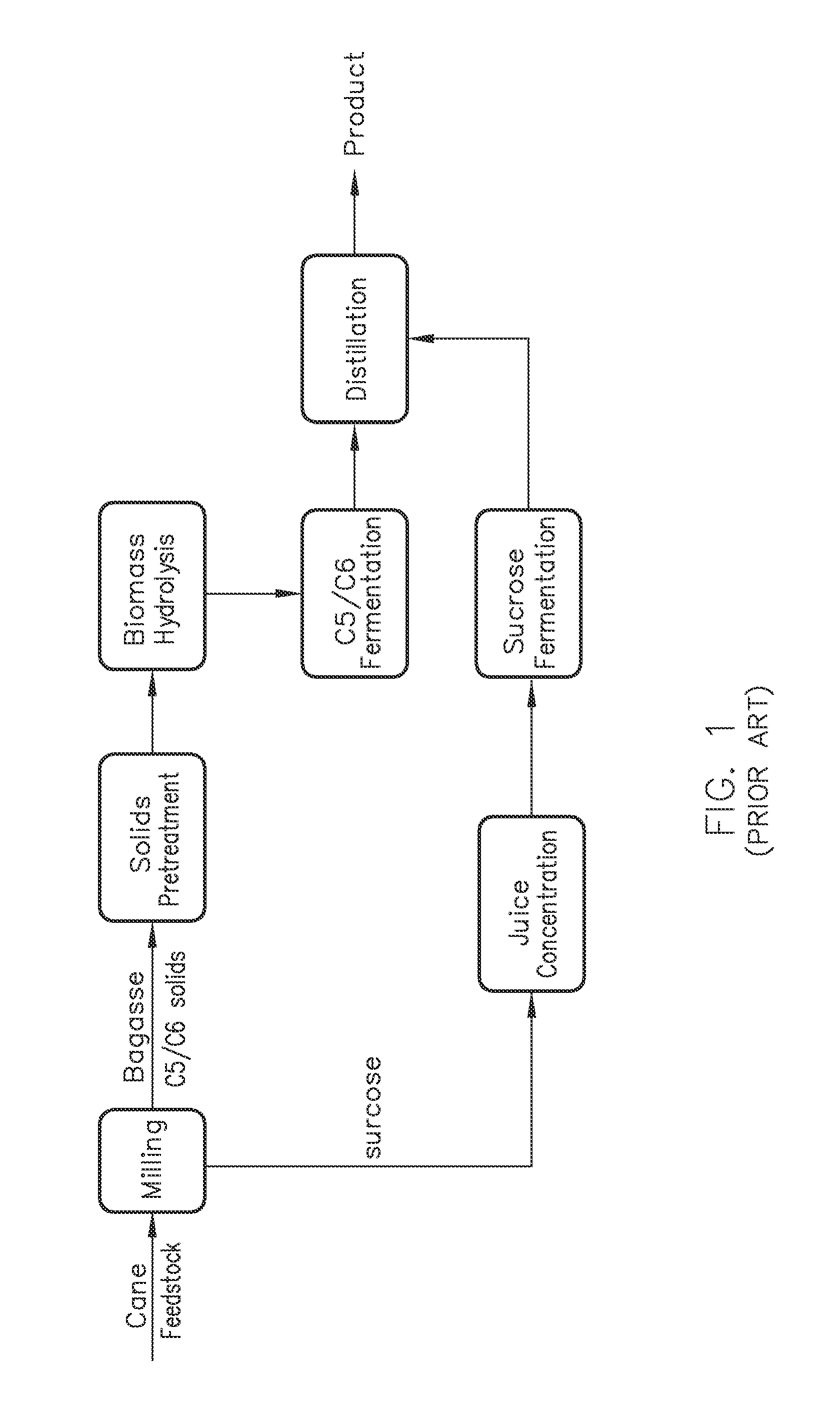

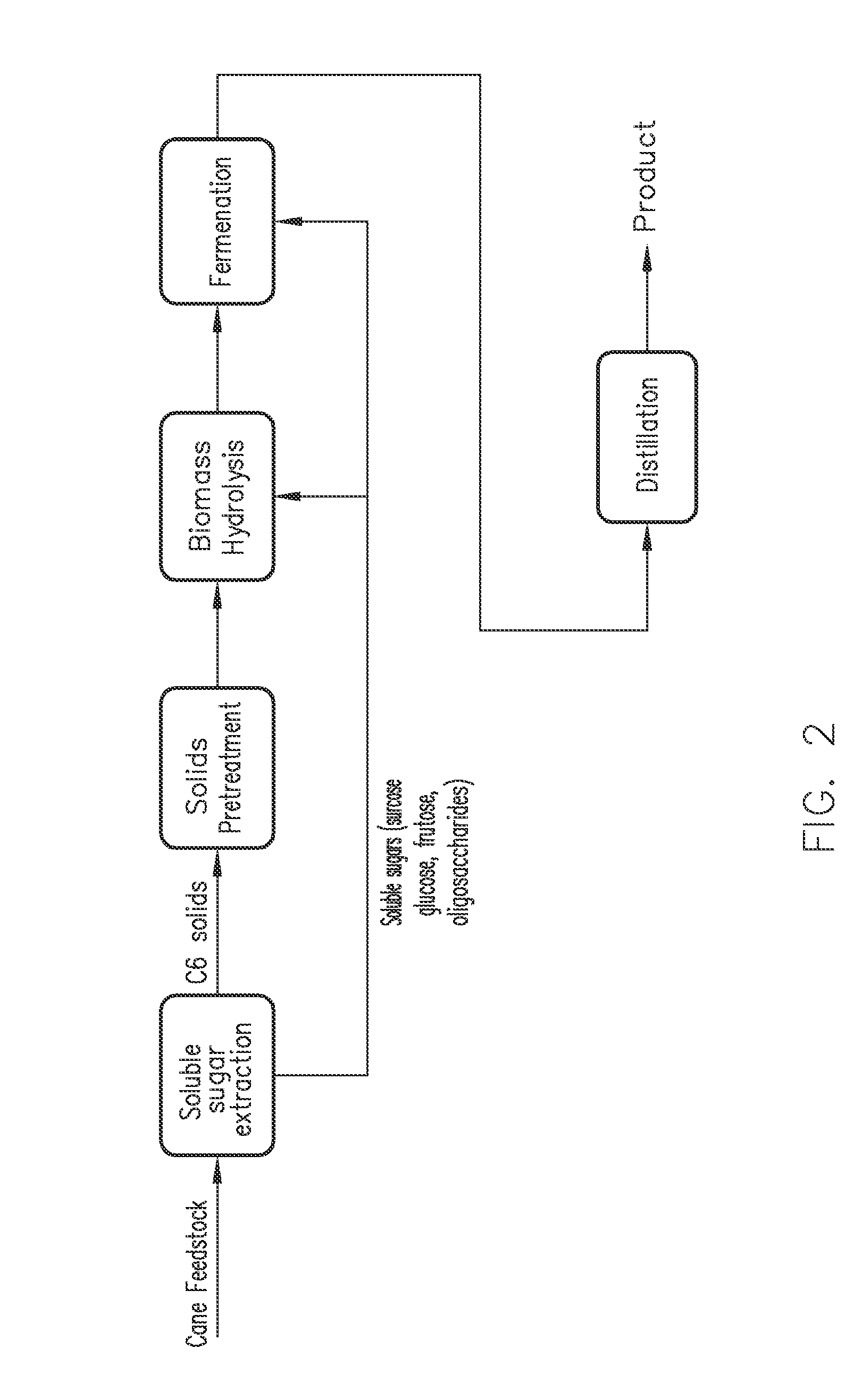

Liquid co-extraction process for production of sucrose, xylo-oligosaccharides and xylose from feedstock

InactiveUS20150307952A1Improved technicallyImproved economically viable conversion processSugar productsOrganic compound preparationSucroseSaccharophagus degradans

Owner:PRENEXUS HEALTH INC

Method for naturally culturing Ganoderma lucidum liquid fermentation and fully utilizing fermentation product

InactiveCN109234331ALow costImprove securityMicroorganismsMicroorganism based processesSaccharumSucrose

The invention provides a method for naturally culturing Ganoderma lucidum liquid fermentation and fully utilizing a fermentation product. According to the method, a liquid culture medium of Ganodermalucidum was prepared with tomato (or carrot) and bran water extract as growth factor, trace element, organic nitrogen source and sucrose as carbon source. That fermentation conditions were 150 rpm rotation speed, 28 DEG C temperature and 5 d fermentation time. At that end of fermentation, mycelium and fermentation broth are collect, and the mycelium is used for co-extraction of ganoderma lucidum polysaccharide and triterpene to prepare extract containing high-content polysaccharide and triterpene, and the fermentation broth with mycelium removed is used for processing ganoderma lucidum fermented health beverage. The invention can effectively improve the fermentation benefit of Ganoderma lucidum, has no waste generation, does not cause environmental pollution, and has great popularization and application prospect.

Owner:NINGDE NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com