Three-dimensional simulated experiment bench for coal and mash gas co-extraction

A simulation experiment, gas technology, applied in the direction of gas discharge, ground mining, mining equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

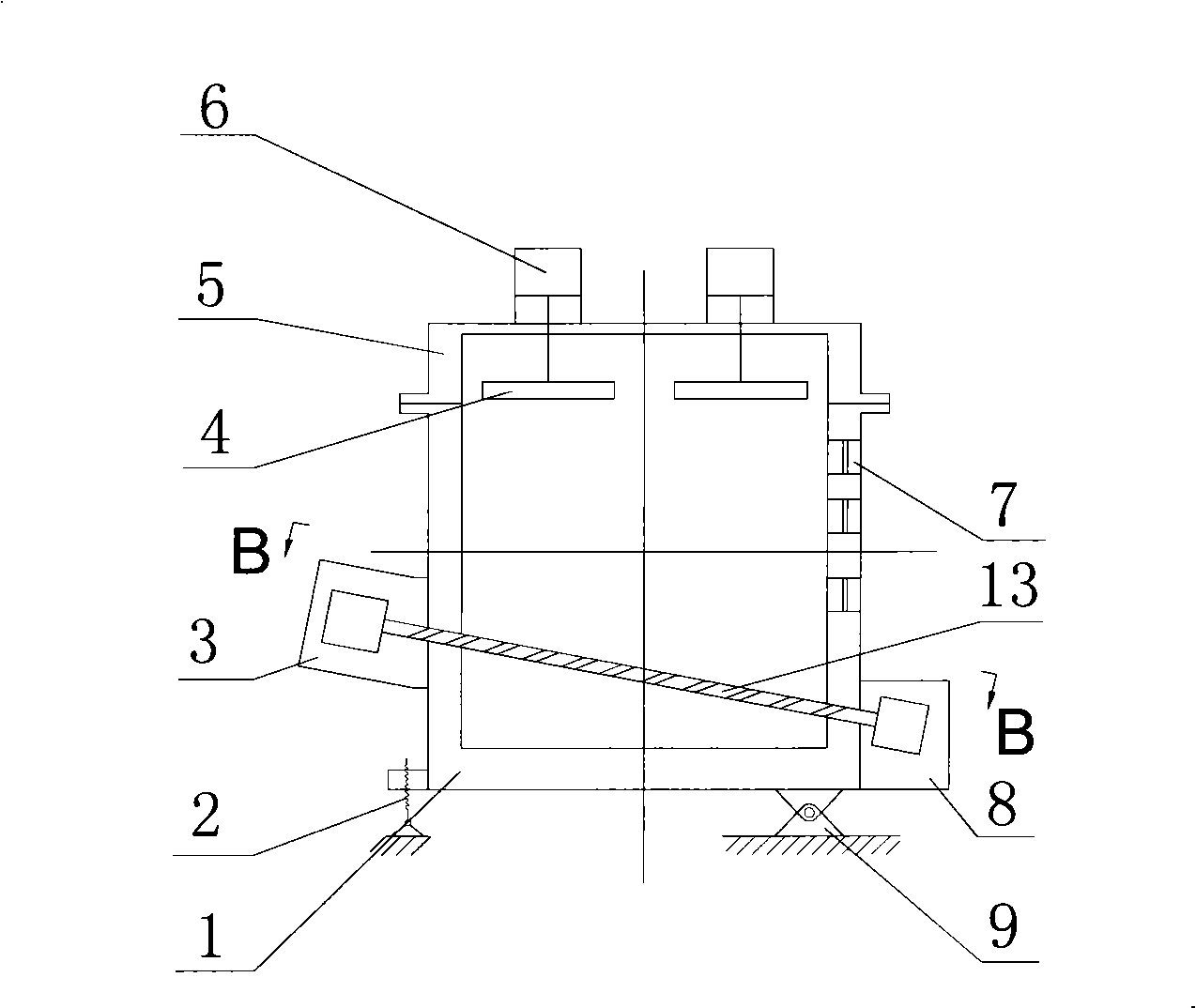

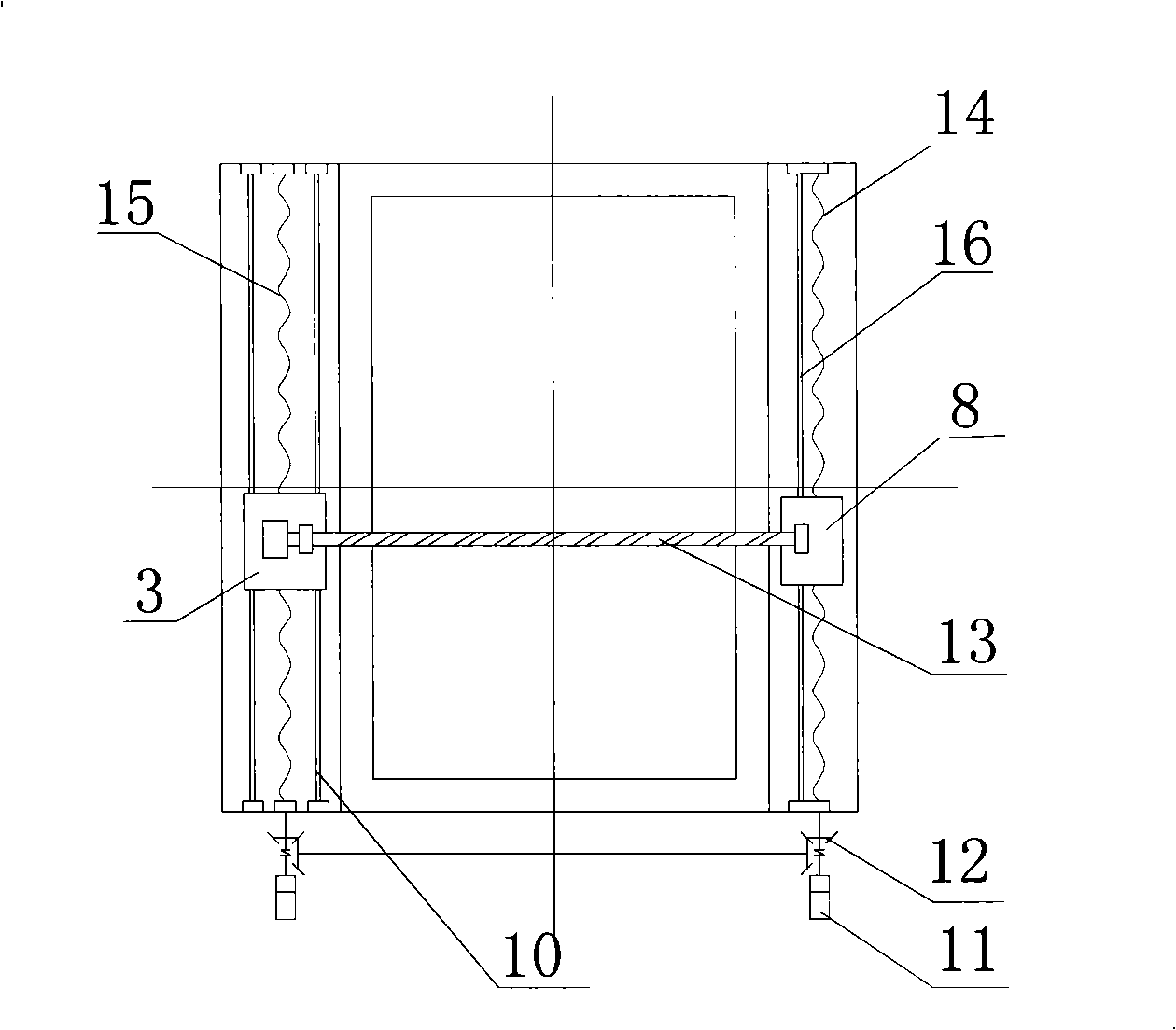

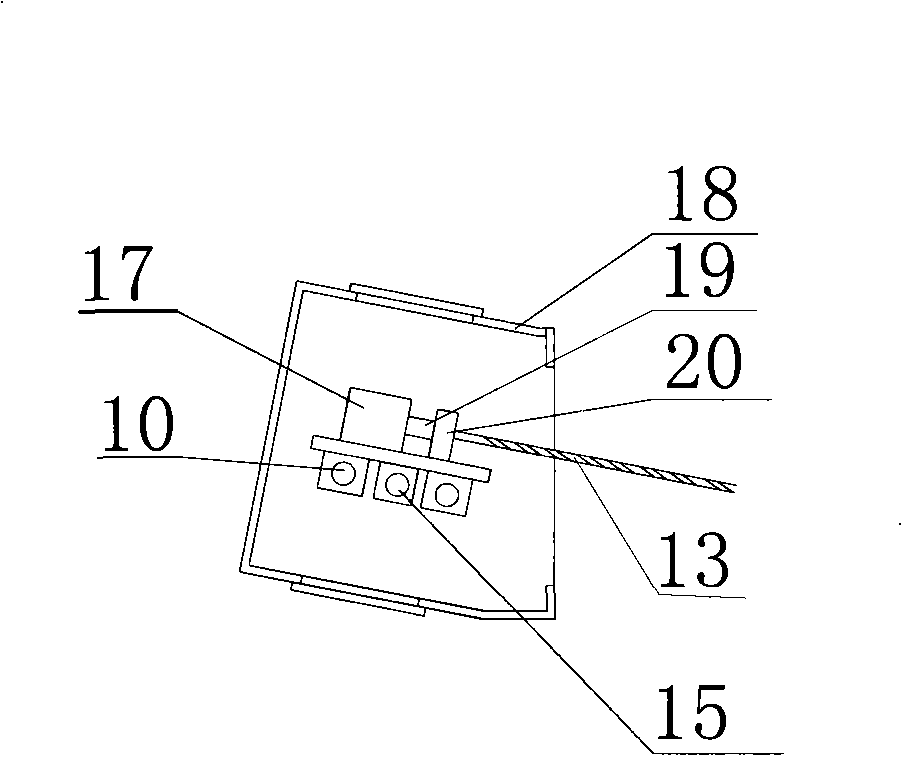

[0014] The three-dimensional simulation test bench for co-mining of coal and gas of the present invention is preferably implemented as follows: figure 1 , figure 2 As shown, it includes a box body 1, and the box body 1 is provided with a pressurizing device for loading the ore in the box body 1, and the ore can be coal and gangue. A coal mining device is also provided, and the coal mining device can move on the box body 1 to simulate mining of the coal in the box body 1 . The box body is also provided with an air intake device and a plurality of gas detection sensors for detecting gas movement in the box body 1 .

[0015] The upper part of the box body 1 is provided with an upper cover 5 to facilitate loading and unloading of ore into the box body 1 . A plurality of oil cylinders 6 can be arranged on the upper cover 5, the cylinder body of the oil cylinder 6 is fixed on the box body 1, and the piston rod of the oil cylinder 6 extends into the inside of the box body 1, and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com