Patents

Literature

123 results about "Barium chromate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Barium chromate, named barium tetraoxochromate(VI) by the IUPAC, is a yellow sand like powder with the formula BaCrO₄. It is a known oxidizing agent and produces a green flame when heated, a result of the barium ions.

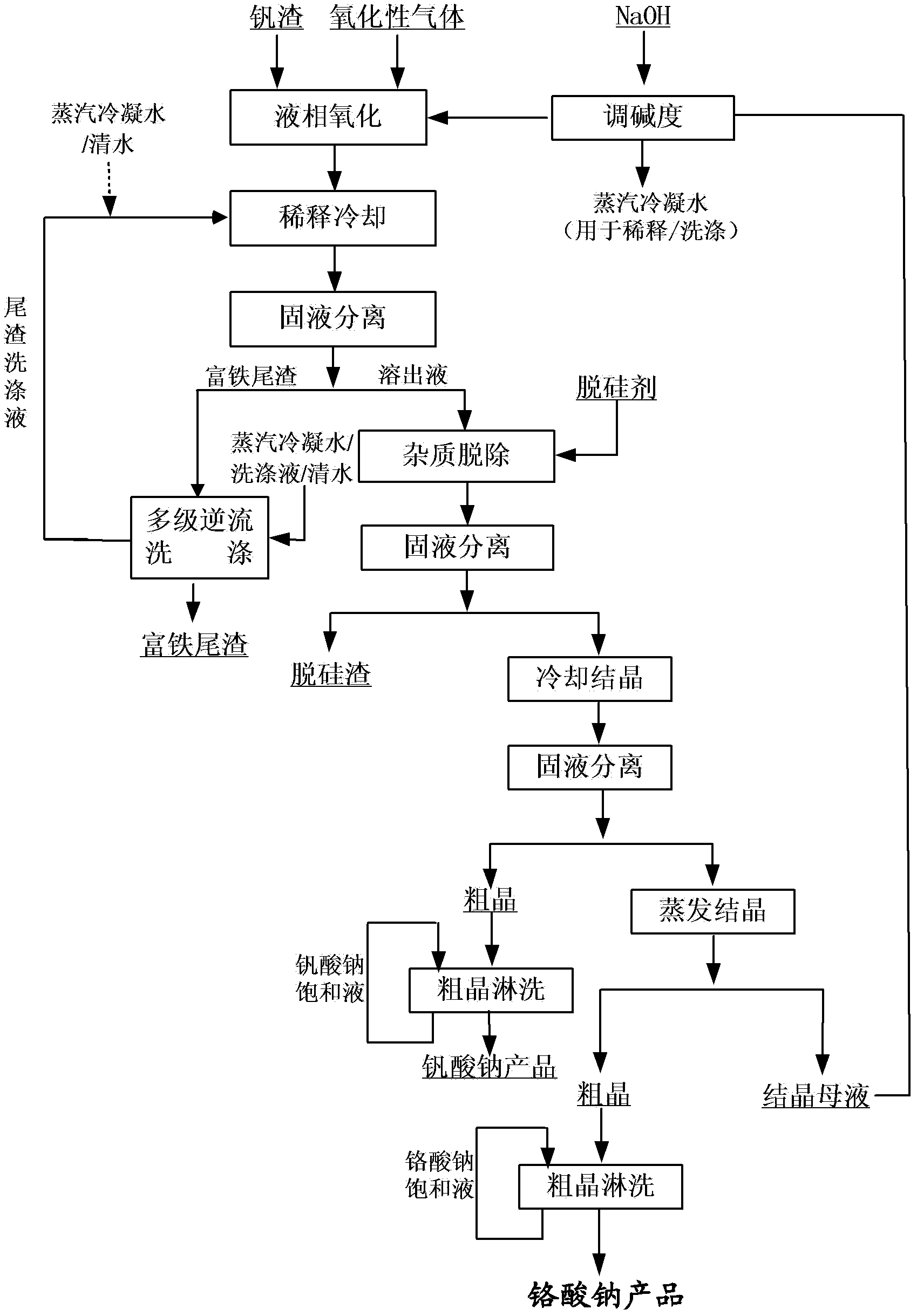

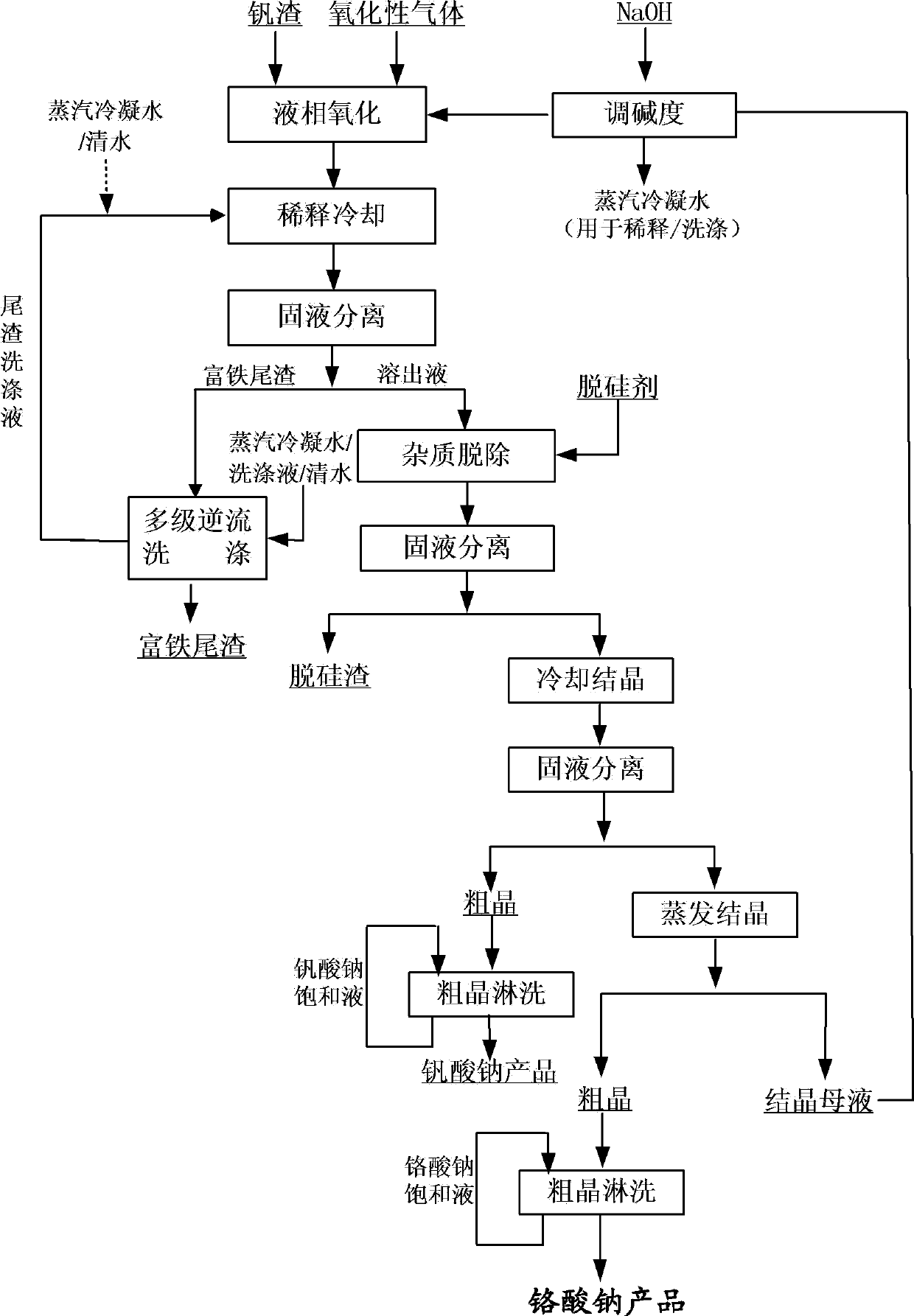

Method for cleaner production of sodium vanadate and sodium chromate by pressure leaching of vanadium slag

ActiveCN102531056ASimple ingredientsAchieve separationChromates/bichromatesVanadium compoundsSlagSlurry

The invention relates to a method for cleaner production of sodium vanadate and sodium chromate by pressure leaching of vanadium slag. The method comprises the following steps of: (1) mixing materials, namely mixing the vanadium slag and a solution of NaOH to obtain a reaction material; (2) reacting, namely performing oxidization reaction on the vanadium slag and oxidizing gas in the solution of NaOH under high pressure to obtain solid-liquid mixed slurry of a solution containing NaOH, Na3VO4, Na2CrO4 and water-soluble impurity components, and iron-rich tailings; (3) performing solid-liquid separation; (4) removing impurities; (5) crystallizing sodium vanadate; and (6) crystallizing sodium chromate. The method is easy to operate and is high in safety; and the operating temperature is greatly lower than the temperature of the traditional vanadium extraction process, energy consumption is low, the high-efficiency co-extraction of vanadium and chromium is realized, and the extraction rate of vanadium and chromium is over 95 percent.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Treating agent for stabilizing rust layer on surface of weathering-resistant steel and method for preparing same

InactiveCN103173754AShorten the stabilization timeStable transformationMetallic material coating processesPyrophosphateSolvent

The invention discloses a method for preparing a treating agent for stabilizing the rust layer on the surface of weathering-resistant steel. The treating agent comprises 25-45% by weight of alkyd varnish, 4-12% by weight of copper pyrophosphate, 2-10% by weight of barium chromate, 1-14% by weight of Fe3O4, 20-50% by weight of Fe2O3, 1-10% by weight of solvent oil and 0.5-5% by weight of dispersing agent. The treating agent is simple in construction process, and the test of soaking the treating agent in 3% sodium chloride shows that the rust-layer stabilization time can be shortened by more that 50%. The whole method is safe to operate, is simple in process and low in cost and is easy to realize large-scale industrial production, and a sample has good performance.

Owner:武汉钢铁有限公司

Method of preparing chromium oxide using precarbonation wet reducing potassium chromate or sodium chromate

InactiveCN1410356AIncrease acidityImprove the reduction conversion rateChromium trioxideSucrosePotassium

A process for preparing chromium oxide from potassium (or sodium) chromate by the pre-carbonating and wet reduction method includes such steps as preparing the aqueous solution of potassium (or sodium) chromate, pre-carbonating by CO2 gas, reducing by a reducer to obtain the hydrate of chromium oxide, filtering, drying, high-temp. calcining under protection of inertial gas, washing and drying to obtain the alpha-Cr2O3.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

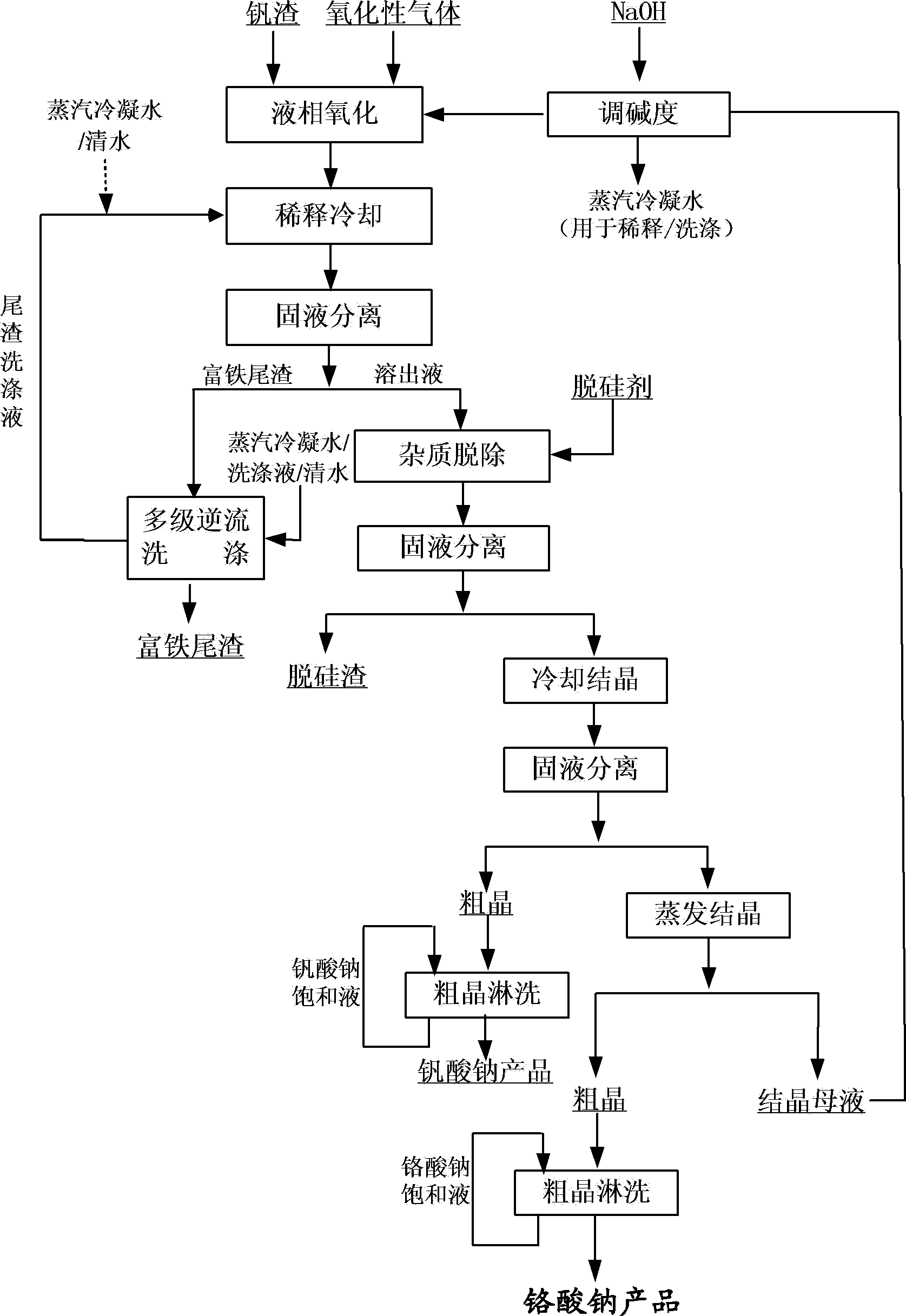

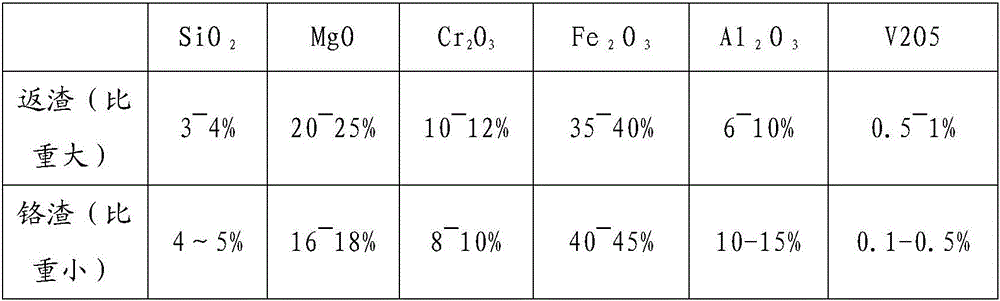

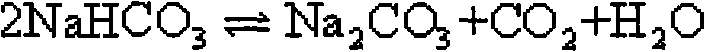

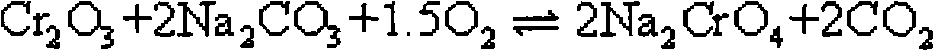

Process for producing sodium chromate by calcium-free calcination

The invention relates to a method to manufacture sodium chromate. It adopts non- calcium roasting technics to realize industrialized production. With chromite, soda and chrome dregs without calcium as charging after mixing evenly, coal dust as fuel, the steps are as follows: coal injection baking in burner, leaching clinker, gravity sorting chrome dregs without calcium and recycling useful dregs as filling. It is the first time that fillings are composed with iron ore, chromite and soda after baking. With shortening technics route and reducing equipment investment, the invention can reduce production cost. Without segregation and adhibiting wall, roasting heat is easy to control.

Owner:TIANJIN CHEM RES & DESIGN INST +1

Anticorrosive environment-friendly spray paint formula

InactiveCN105199580ABright colorGood light fastnessAnti-corrosive paintsPolyurea/polyurethane coatingsDiacetone alcoholChemical industry

The invention discloses an anticorrosive environment-friendly spray paint formula, and relates to the field of chemical industries. The anticorrosive environment-friendly spray paint formula comprises the following components in parts by weight: 28 to 35 parts of glacial acetic acid, 3 to 7 parts of organic fluorine epoxy resin, 7 to 12 parts of epoxy modified organic silicon resin, 2 to 6 parts of glycol monomethyl ether, 6 to 9 parts of dimethyl sulfoxide, 8 to 13 parts of zinc phosphate, 8 to 13 parts of barium chromate, 1 to 4 parts of ethanol, 2 to 7 parts of polyacrylate, 1 to 4 parts of alcohol soluble resin, 7 to 13 parts of diacetone alcohol, 6 to 9 parts of zinc oxide, 8 to 13 parts of toluene diisocynate, 3 to 7 parts of n-butyl acetate, 12 to 16 parts of benzophenone, 9 to 13 parts of triethanolamine and 3 to 7 parts of diphenyl polysiloxane. The paint is bright in color and good in air-curing resisting effect, can substitute medium chrome yellow in inorganic pigment, is applicable to the outer wall paint, and has no harm of heavy metals, no harmful substances, good environment protection effect, little odor, no peculiar smell after being smeared on the wall, good mechanical performance, excellent electric insulation performance, dampness and water resistance, rust and cold resistance and ozone aging resistance.

Owner:王海平

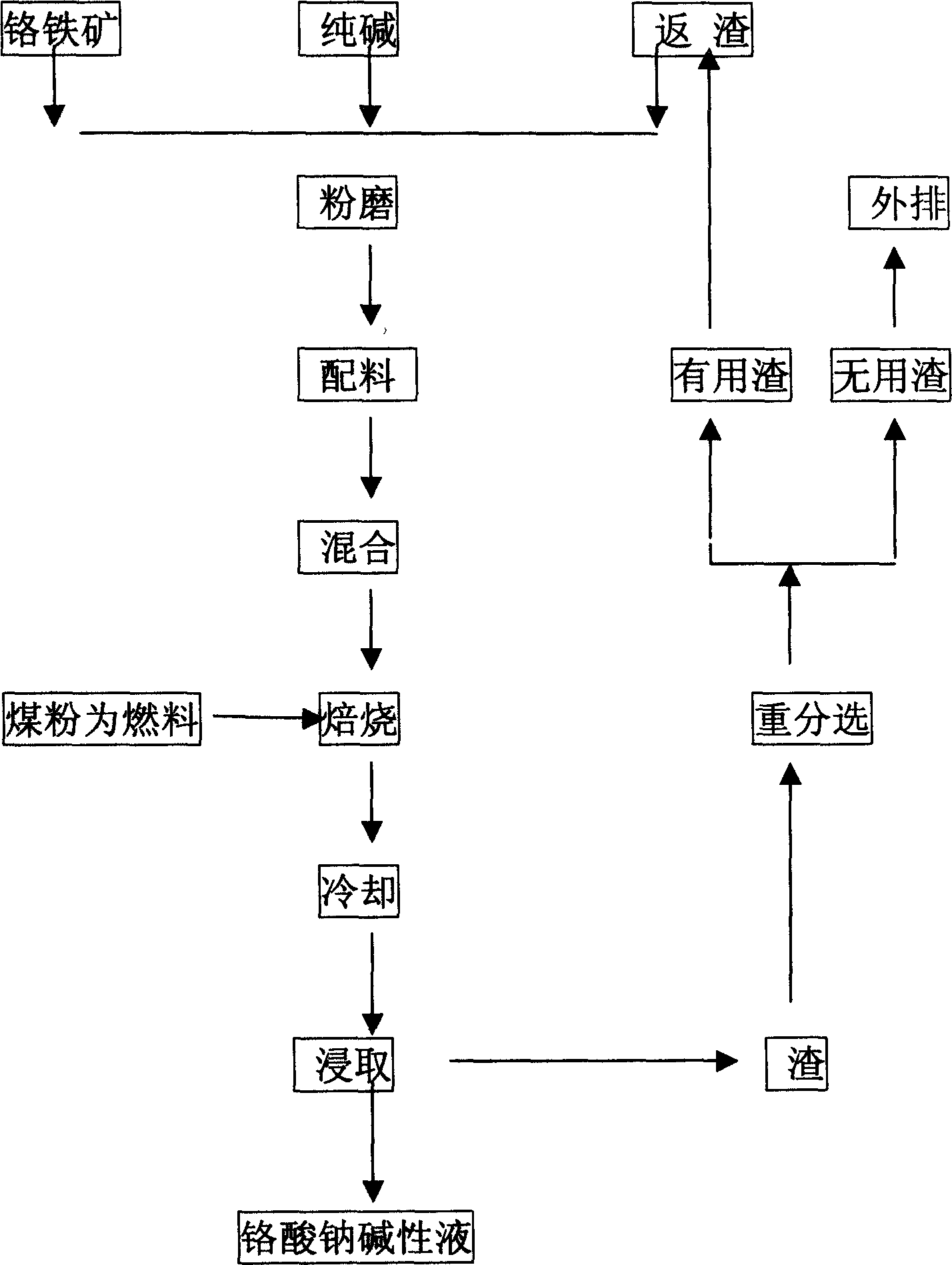

Method for preparing sodium chromate by mixing chromite and ferrochrome and device for method

The invention discloses a method for preparing sodium chromate by mixing chromite and ferrochrome and a device for the method. The method comprises the following steps: measuring and mixing chromite and ferrochrome with sodium carbonate, sodium nitrate and sodium peroxide; pelleting the mixture with extracted liquid sodium chromate in a pelletizer; drying in a drier; returning part of the clinker to a flame kiln after the material is dried and cooled, so that chromite and ferrochrome are decomposed and oxidized in the form of fused liquid phase in molten salts so as to obtain the clinker of sodium chromate; and continuously soaking, filtering and cleaning after the clinker is cooled so that a chromium chemical primary product of liquid sodium chromate is obtained, wherein the flame kiln comprises a U-shaped kiln body, a partition wall and a low-position molten salt suction port, wherein the partition wall and the low-position molten salt suction port are arranged in the U-shaped kiln body; one or more blowing oxygen lances and one or more charging holes are arranged at the top of the kiln body, and a smoke outlet is arranged on the upper side of the kiln; and one or more oxygen lances are arranged at the bottom of the kiln. According to the method disclosed by the invention, the oxidation rate is as high as 98%, the clinker extraction rate is as high as 99.97%, and the chromium yield is 97.96%.

Owner:HUBEI POLYTECHNIC UNIV

Method for producing sodium chromate by roasting chromium ore and small amount of soda

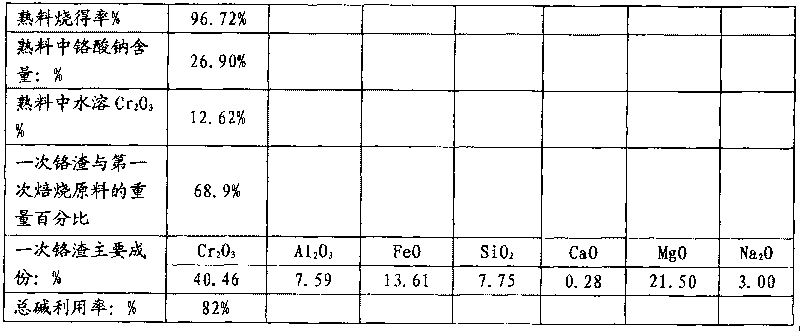

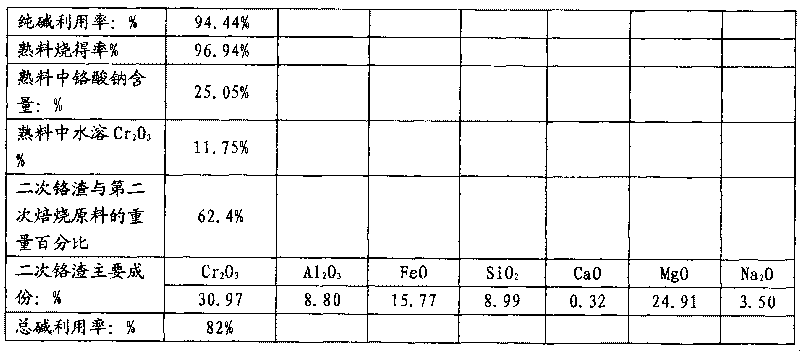

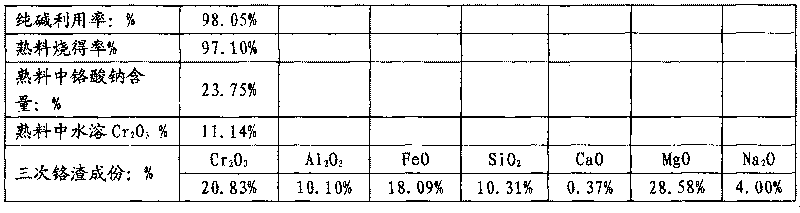

The invention discloses a method for producing sodium chromate by roasting chromium ore and a small amount of soda. The method is characterized in that chromium ore and calcined soda are mixed, wherein the added quantity of the calcined soda is 35% to 45% of theoretical required amount for complete reaction with dichromium trioxide in the chromium ore; then the mixture is added to a rotary kiln for first roasting, the temperature of materials at a hot space in the kiln is 1000 DEG C to 1050 DEG C, wrought materials are cooled and leached to obtain a sodium chromate leaching solution and first chromium dregs; the first chromium dregs are dried and crashed for second roasting with newly added calcined soda, the use amount of the calcined soda is 30% to 50% of theoretical required amount for complete reaction with the dichromium trioxide in the first chromium dregs; the sodium chromate leaching solution and second chromium dregs can be obtained through roasting and leaching processes, the second chromium dregs, limestone and newly added calcined soda are roasted for the third time, the use amount of the calcined soda in the third roasting is 35% to 75% of theoretical required amount for complete reaction with the dichromium trioxide in the second chromium dregs, and the use amount of the limestone is 2% to 5% of the sum of weight of three raw materials of the second chromium dregs, the calcined soda and the limestone; and the sodium chromate leaching solution and third chromium dregs are obtained after leaching. By adopting method of the invention, the utility ratio of the calcined soda is also enhanced greatly.

Owner:XINJIANG SING HORN GRP CO LTD

Highly dispersible fine powder of alkaline earth metal carbonate

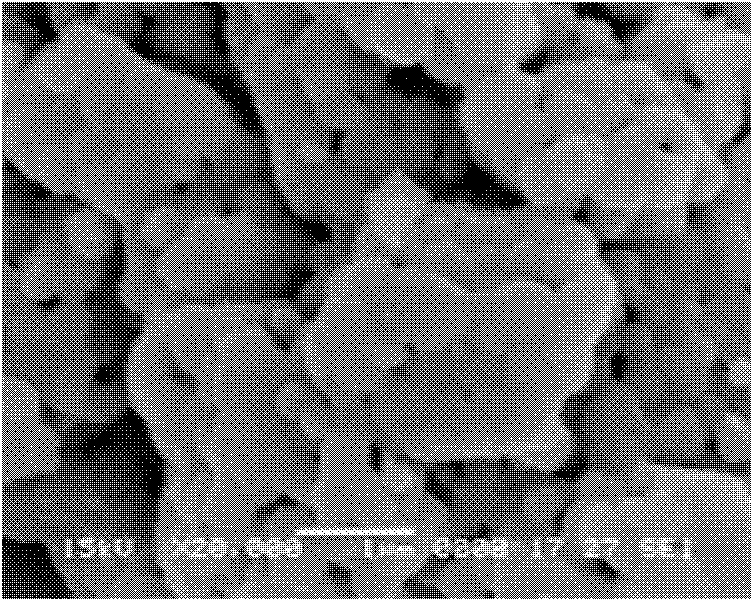

InactiveUS20100040885A1Well mixedGood dispersionCalcium/strontium/barium carbonatesMaterial nanotechnologyMean diameterAlkaline earth metal

A fine powder of an alkaline earth metal carbonate selected from the group consisting of barium carbonate, strontium carbonate and calcium carbonate, in which a primary particle of the powder has a mean diameter of 30 to 90 nm, in which the mean diameter is measured on a circle obtained from a projected area of the primary particle, and in which an accumulated volume of micropores having a pore size in the range of 10 to 20 nm is not less than 5×10−2 cm3 / g can be easily dispersed in an aqueous medium in the form of essentially primary particles by an industrially employable dispersing method.

Owner:UBE IND LTD

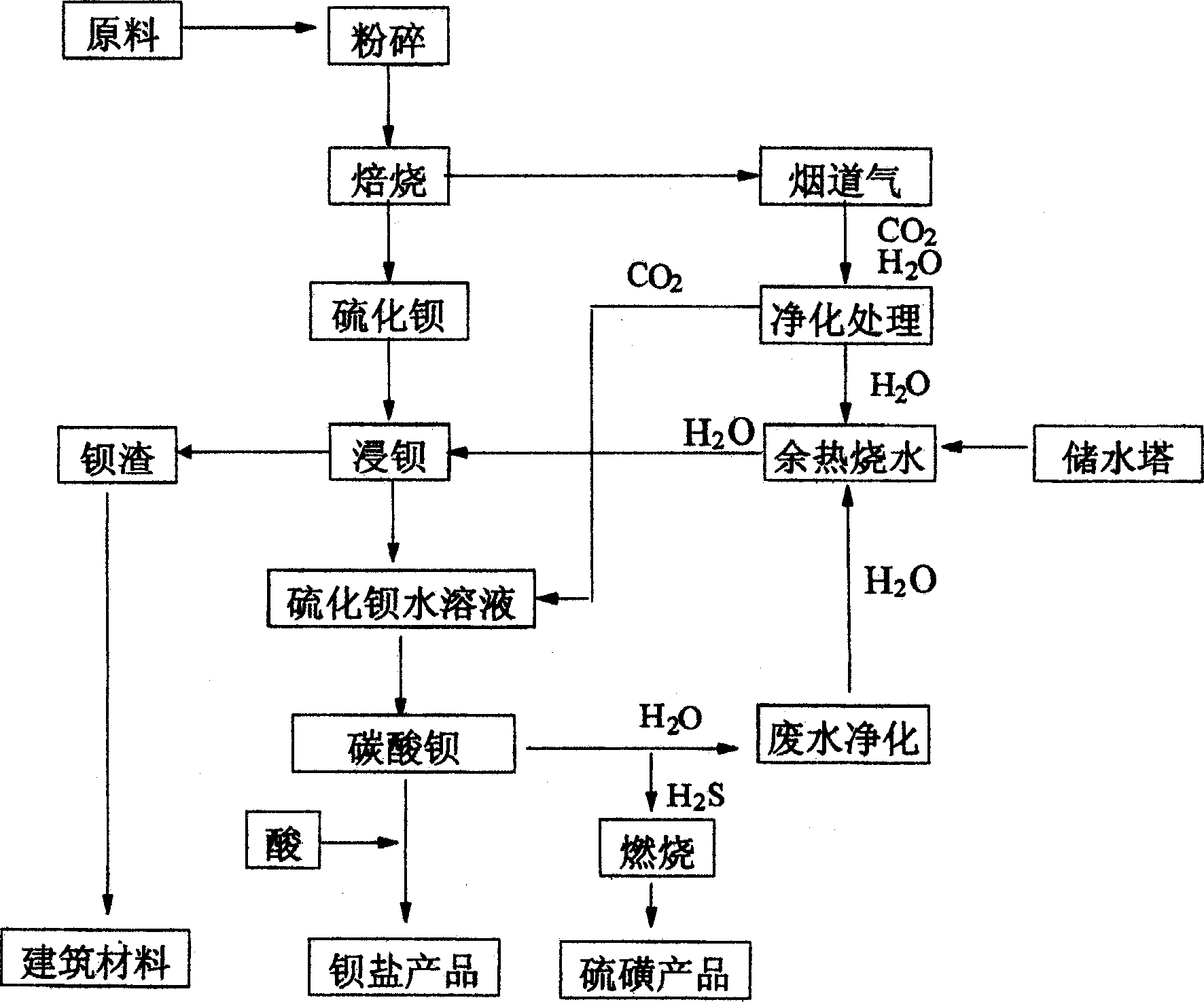

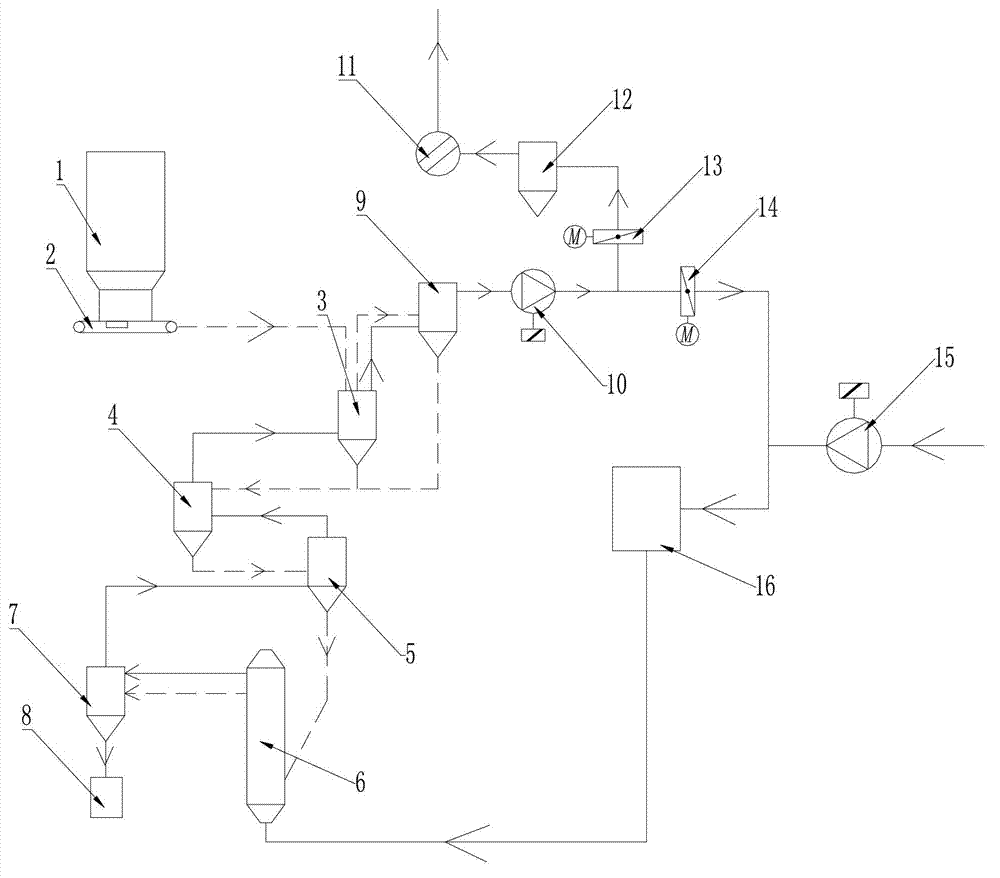

Method of producing barium sulfide and flue gas by calcining coal and barite to synthesize barium carbonate

A process for preparing barium carbonate from coal and barite includes such steps as pulverizing coal and barite, mixing in ratio of 1: 3, calcining in rotary furnace to generate barium sulfide and fume containing CO2 and ash, immersing barium sulfide in water to become aqueous solution, cleaning the fume to obtain CO2 gas, filling it in said aqueous solution of barium sulfide, and reaction to obtain barium carbonate.

Owner:陆巧芳

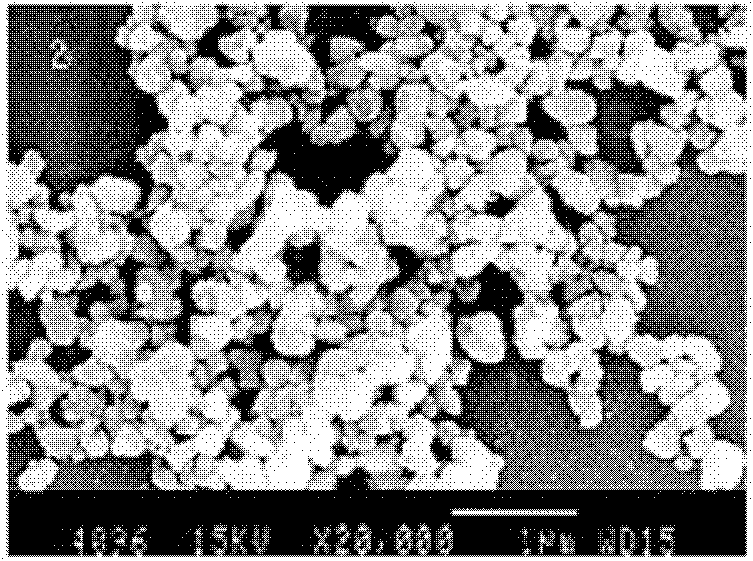

Rare earth doped barium titanate particles and preparation method thereof

The invention discloses rare earth doped barium titanate particles and a preparation method thereof. The preparation method comprises the following steps of: adding barium carbouate powder, amide reagent solution for decomposing a rare earth oxide, titanium oxide powder and absolute ethanol into a ball mill sequentially; performing ball milling on the mixture for 90+ / -30min, wherein the mol ratioof the barium carbonate to the titanium dioxide is 1.000+ / -0.020 and the mol ratio of rare-earth ions to barium ions is between 0.001 and 0.005; performing vacuum drying on materials which are subjected to the ball milling and then initially sintering the dried materials; crushing the sintered materials, washing the crushed materials by using deionized water and sintering the washed materials forthe second time; decentralizing the obtained product to obtain liquid-phase doped rare earth-barium titanate power; and then placing the rare earth-barium titanate power into an osmosis furnace to perform osmosis in nitrogen (N2) at the temperature of between 800 and 1,000 DEG C for 4h to obtain the target particles. The resistivity of the prepared doped barium titanate particles is obviously changed.

Owner:HUNAN SEEDER ELECTRONICS CERAMIC TECH IND PARK DEV CO LTD

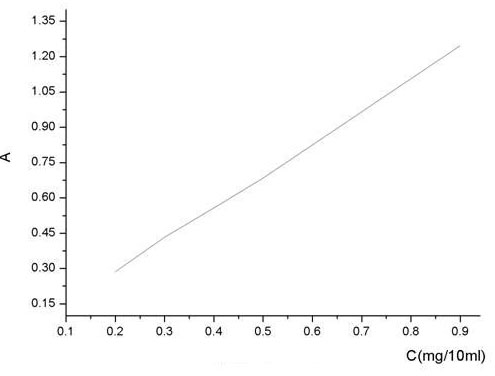

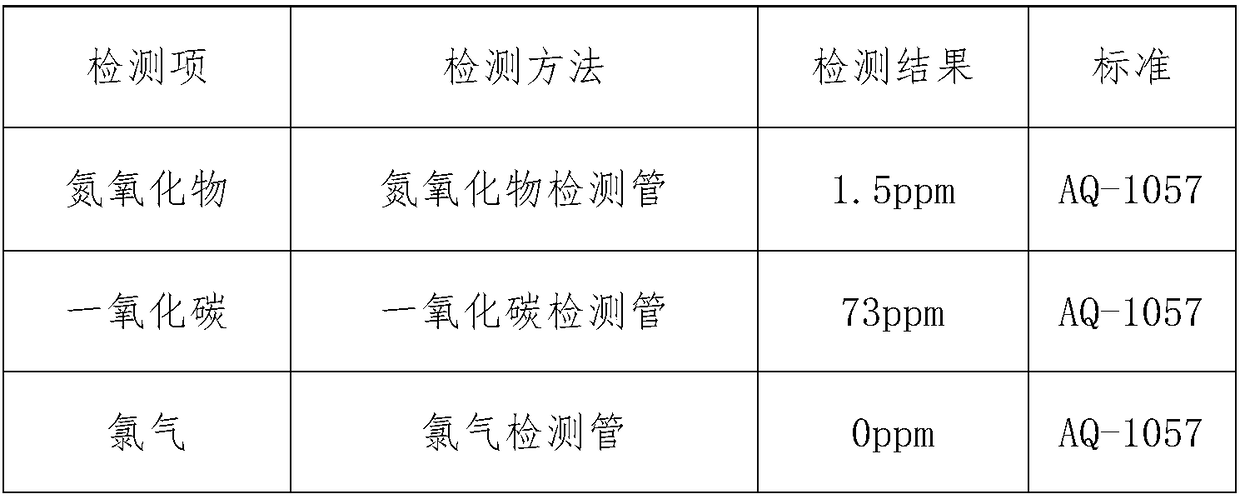

Determination method for total sulfur in water quality

ActiveCN104807949AColor/spectral properties measurementsChemical analysis using precipitationSulfate radicalsDecomposition

The invention discloses a determination method for total sulfur in water quality. The method includes the following four steps: while sulfurous gas which can leak out is fixed by calcium oxide, potassium permanganate oxidation, nitric acid oxidation, hydrochloric acid regulation and barium chromate spectrophotometry are used for determining sulfate radical, which is converted into sulfur content. During total sulfur determination in water sample, calcium oxide and potassium permanganate are first added to oxidate sulfide ions under alkaline condition, sulfur in other valence states is then oxidated or decomposed into the sulfate radical under the joint oxidation of potassium permanganate and nitric acid, hydrochloric acid solution is then added to regulate the water sample and remove the color of the potassium permanganate, finally, the sulfate radical content in water quality is determined by barium chromate spectrophotometry, and total sulfur content is worked out. According to the characteristics of the sulfur in different valence states in water quality, by fixation, oxidation and decomposition, the method finally converts the sulfur in all valence states into the sulfate radical, and utilizes barium chromate spectrophotometry to determine the sulfate radical, and thereby the total sulfur in water quality is determined. Determination is simple, the result is accurate, and the method can be applied in fields such as environment protection and monitoring, food monitoring and sulfur balance analysis.

Owner:CHANGCHUN GOLD RES INST

Anti-corrosive paint formula

InactiveCN104559760ABright colorGood light fastnessAnti-corrosive paintsEpoxy resin coatingsDiacetone alcoholEpoxy

The invention relates to an anti-corrosive paint formula which comprises components in parts as follows: 40 parts of titanium dioxide, 50 parts of glacial acetic acid, 5 parts of organic fluorine epoxy resin, 10 parts of epoxy modified organic silicon liquid resin, 4 parts of ethylene glycol monomethyl ether, 8 parts of dimethyl sulfoxide, 10 parts of zinc phosphate, 10 parts of barium chromate, 6 parts of aluminium triphosphate, 3 parts of diethyl phosphinic acid aluminum, 4 parts of N-methyl-2-pyrrolidone, 1 part of ethanol, 4 parts of polyacrylate, 1 part of alcohol-soluble resin, 10 parts of diacetone alcohol, 8 parts of zinc oxide and 9 parts of toluene diisocyanate. Paint prepared with the formula has bright color and good sun-proof effect, medium chrome yellow in inorganic pigment can be replaced, and the paint is applicable to an exterior wall coating material and is free of heavy metal harm.

Owner:QINGDAO JIASHANG CREATIVE CULTURE

Tungsten-based delay powder for detonator and use of tungsten-based delay powder

InactiveCN104045496AImprove assembly efficiencyTroubleshoot delay interval issuesExplosivesDetonatorsDetonatorEconomic benefits

The invention relates to a tungsten-based delay powder for a detonator and a use of the tungsten-based delay powder. The formula of the tungsten-based delay powder mainly comprises barium chromate, tungsten powder and potassium perchlorate, and as the circumstances may require, extra calcium fluoride and diatomite can be added; the components of the formula are manually mixed together in a certain ratio, the mixture is further mixed for 4 hours in a ball mill, and then the mixed delay powder is put in a lead tube having the diameter of phi10 to phi16, next, the steps of sleeving, rolling, drawing and lead cutting are carried out, and finally, the tungsten-based delay powder for the detonator can be obtained; the tungsten-based delay powder is further prepared into a cylinder core having the diameter of 2mm, a middle layer made of pure lead is arranged to sleeve the cylinder core, an outer layer made of a lead-antimony alloy is arranged to cover the middle layer, and then a one-section lead delay element for the detonator is formed. The properties of the tungsten-based delay powder are capable of meeting the national standard requirements, the assembly efficiency of the delay powder is high, and after being launched, the delay powder is capable of creates the economic benefit of billions of Yuan for an enterprise; besides, the delay time interval problem of the delay powder is solved, and the safety is improved.

Owner:GUANGDONG MINGHUA MACHINERY

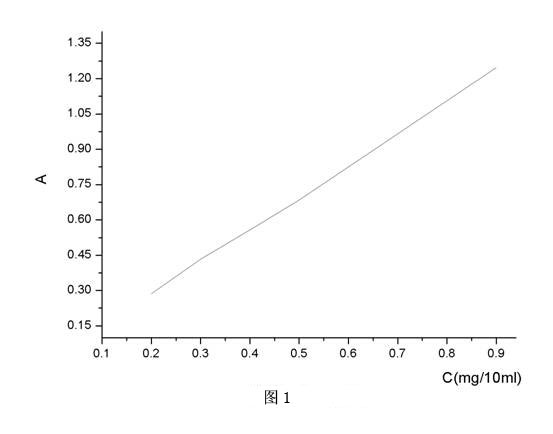

Method for measuring sulfur in graphite

ActiveCN101893556AAccurate measurementSimple and fast operationColor/spectral properties measurementsAbsorbanceBarium chromate

The invention discloses a method for measuring sulfur in graphite, which comprises the following steps of: (1) putting the graphite into a porcelain crucible filled with aldrin, fully stirring the graphite and the aldrin uniformly to obtain a mixture, and then adding the aldrin to uniformly cover the mixture so as to finally obtain a sample; (2) putting the sample in the step (1) into a high temperature furnace; (3) taking out the sample from the high temperature furnace, filtering the taken-out sample and fixing the volume; (4) putting the sample solution in the step (3) into a color comparison tube, adding acid suspension of barium chromate into the color comparison tube, mixing the solution uniformly, and then standing the solution to obtain mixed solution; (5) adding calcium-containing aqueous ammonia clarified liquid into the mixed solution in the step (4), mixing the solution uniformly and then standing the solution; (6) filtering the solution in the step (5) to a cuvette by using dried intermediate-speed quantitative filter paper; and (7) measuring the corresponding absorbance of the solution at 370 nanometers of wavelength by using a 1cm cuvette and using reagent blank as contrast, and searching the quantity of the corresponding sulfate ions from a standard curve. The method has the advantages of low equipment investment, simple and convenient operation and accurate detection result by adopting a spectroscopic luminosity measuring method.

Owner:山东聊城莱鑫超硬材料有限公司

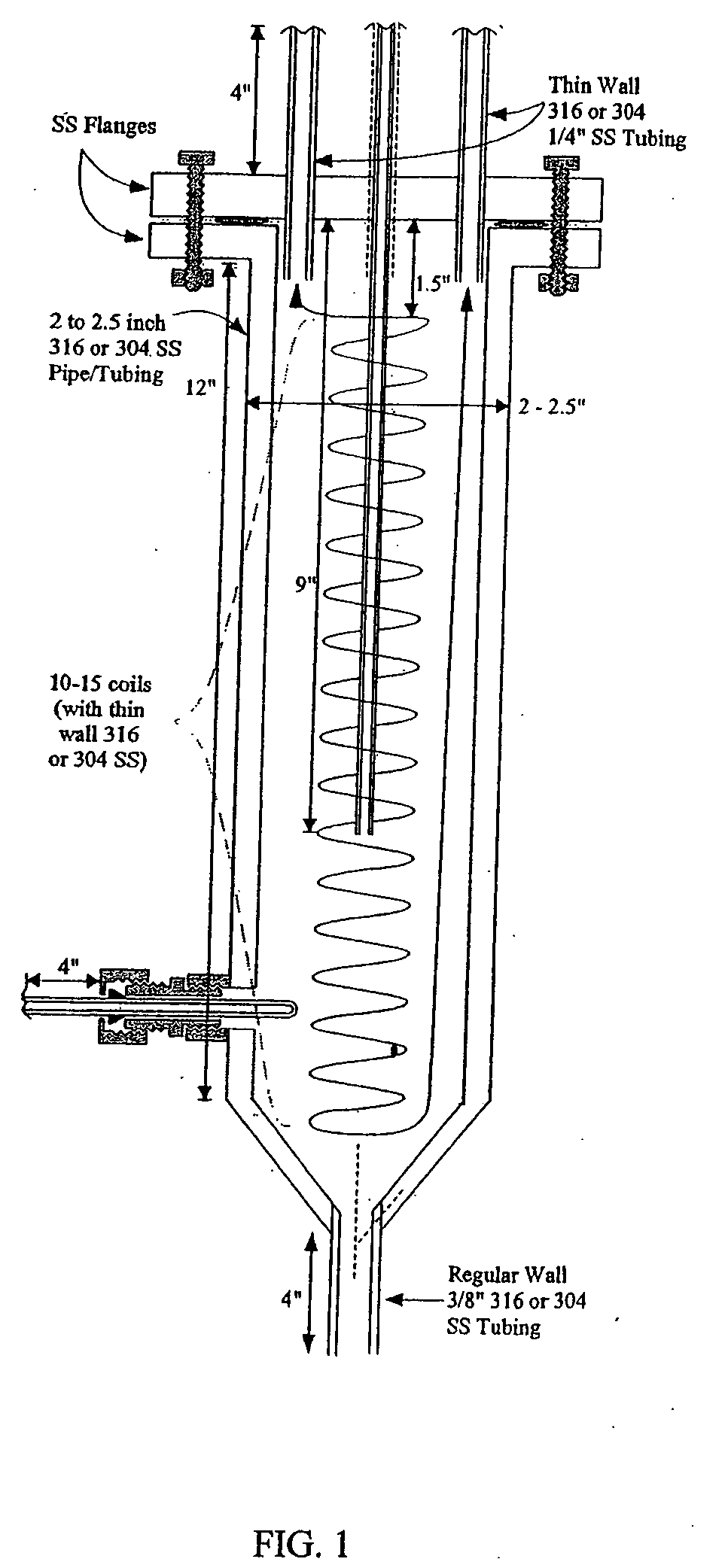

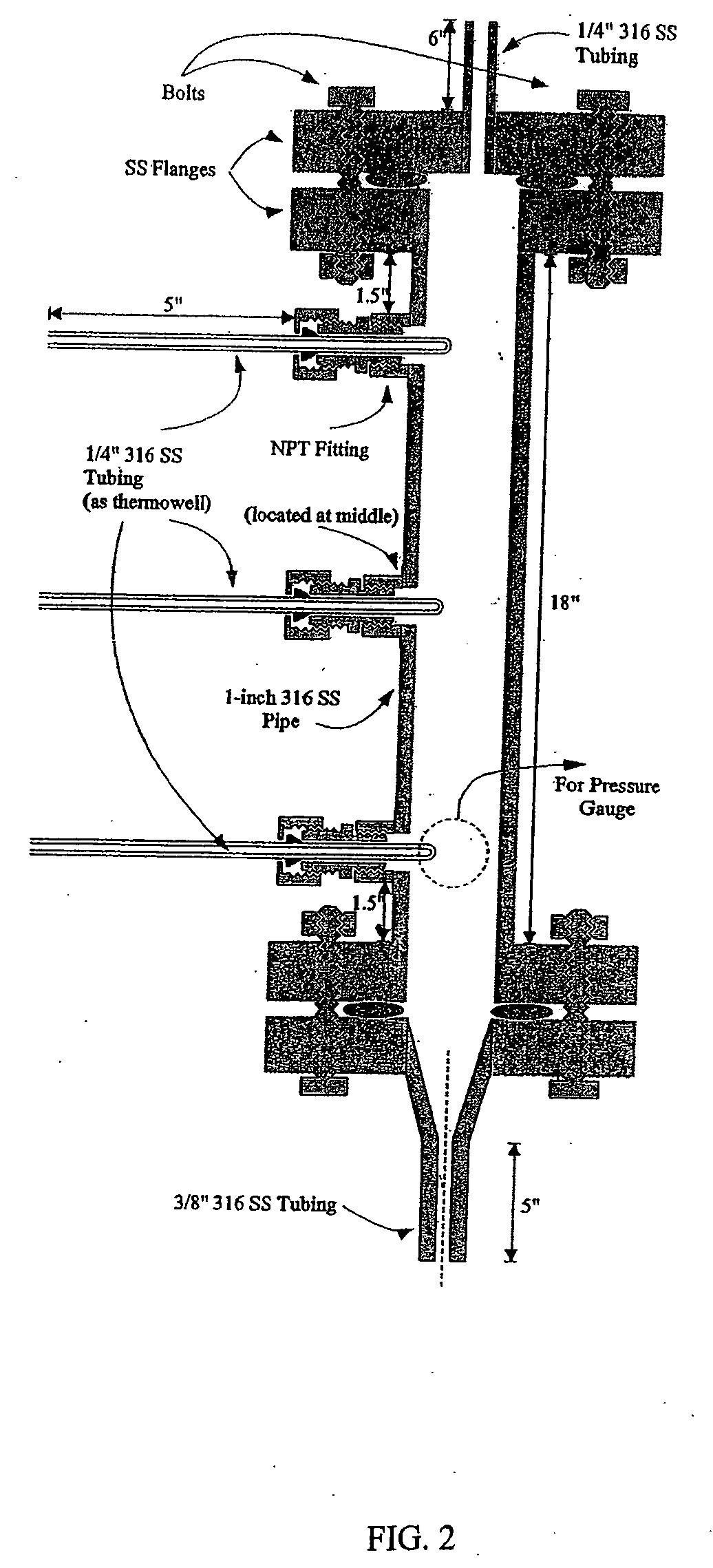

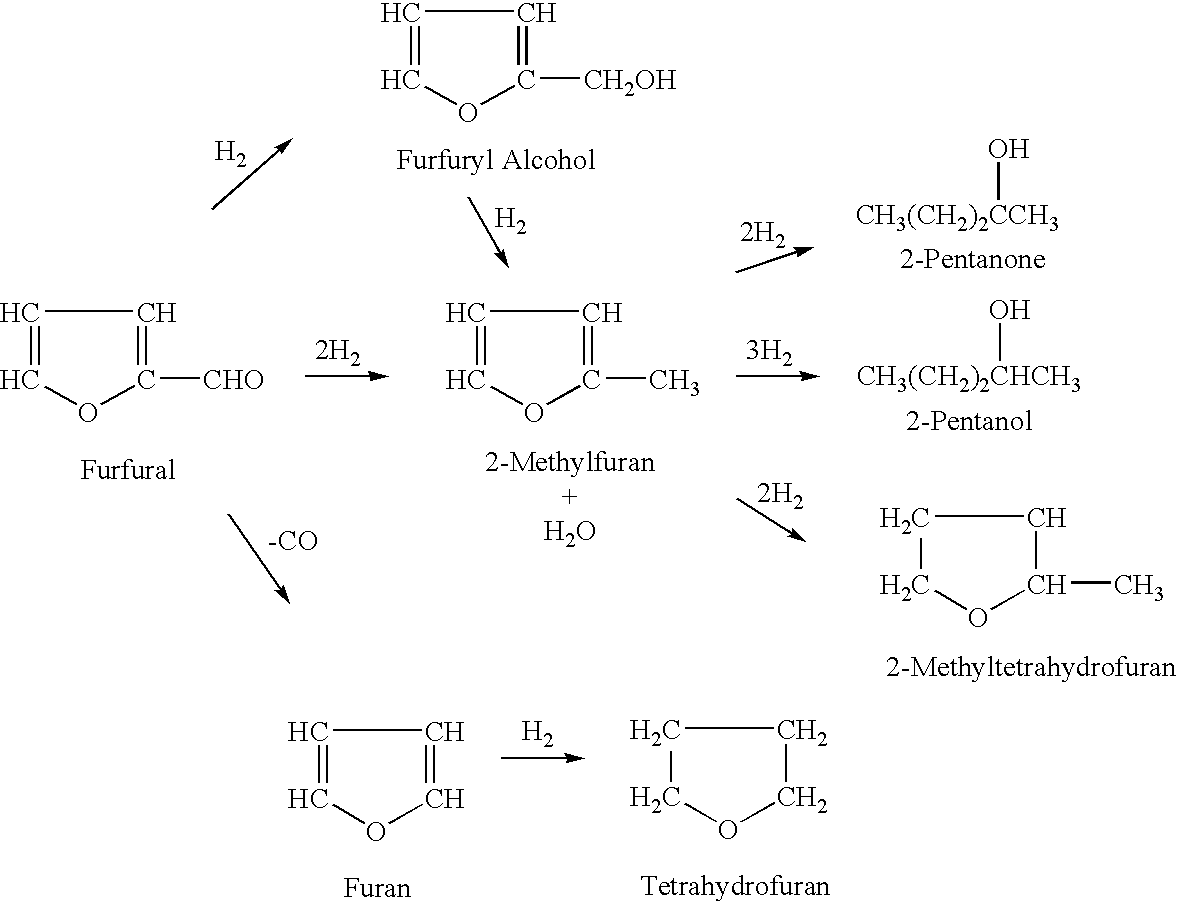

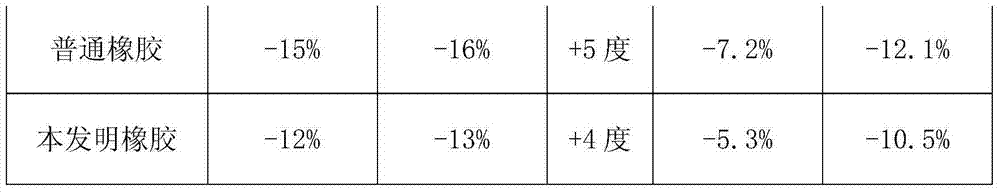

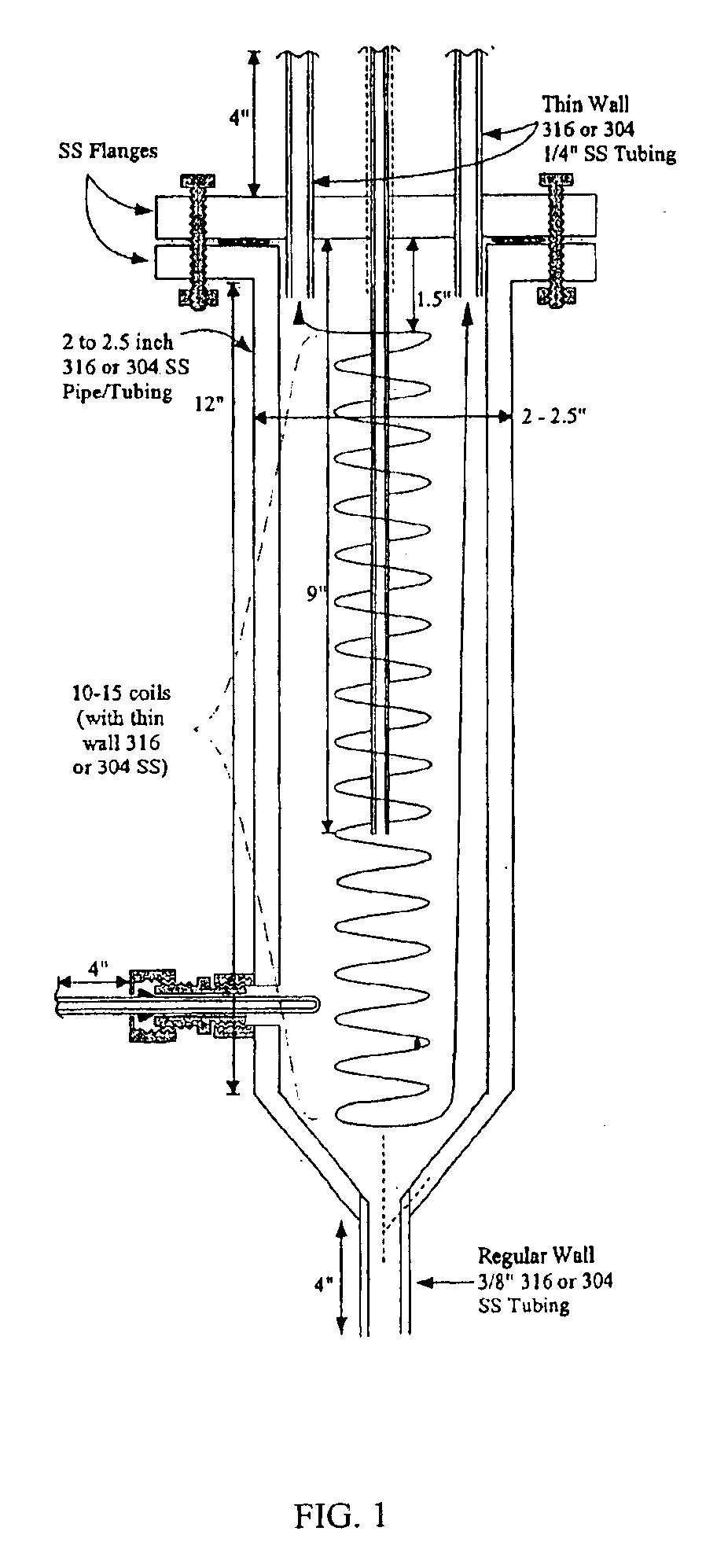

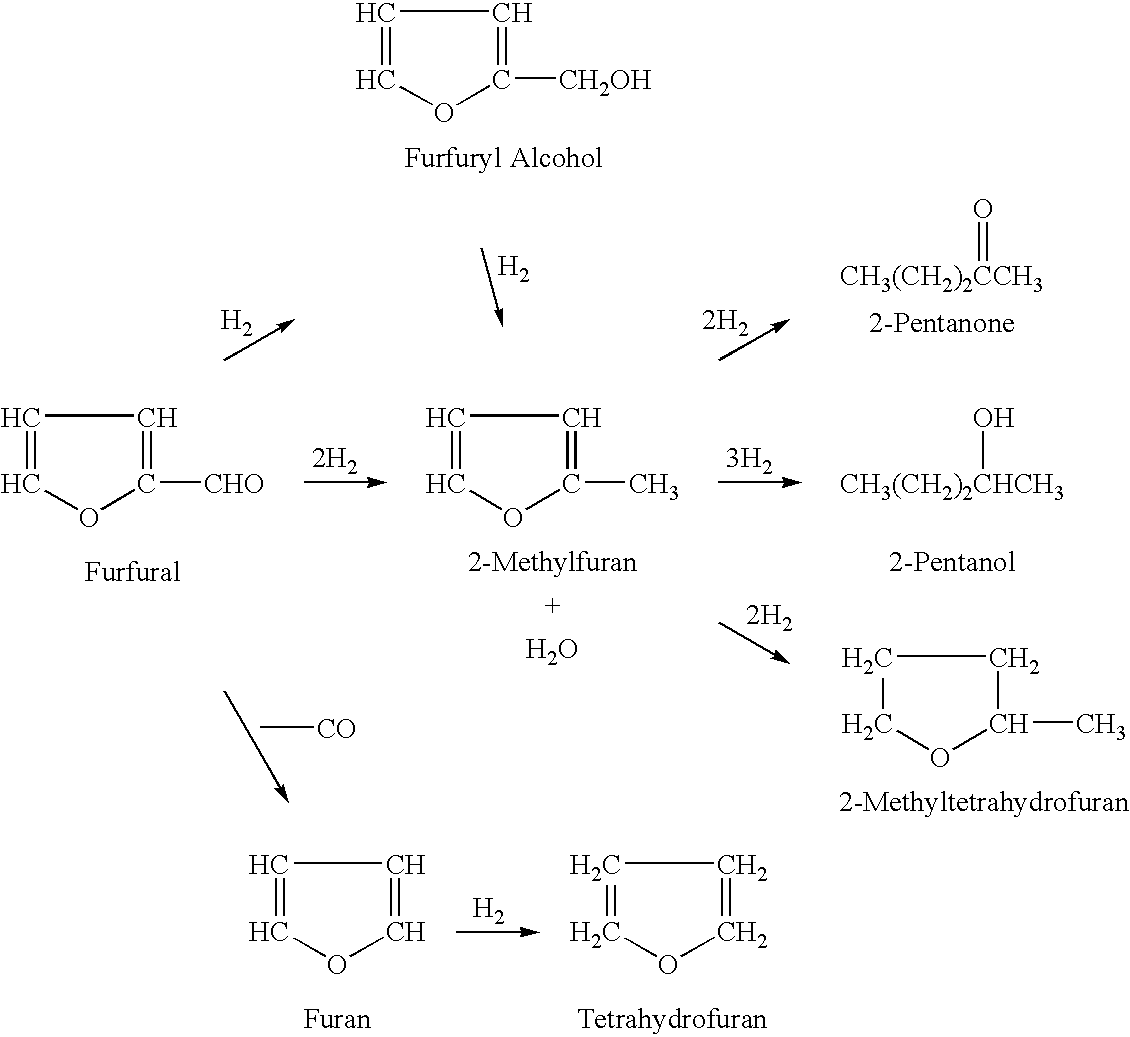

Processes for the preparation of 2-methylfuran and 2-methyltetrahydrofuran

Processes are disclosed for the preparation of 2-methylfuran and 2-methyltetrahydrofuran. The continuous vapor-phase processes are commercially viable and efficient because they permit the preparation of 2-methylfuran and 2-methyltetrahydrofuran using commercially-available catalysts, namely, a reduced copper-based catalyst consisting essentially of cupric oxide, chromium (III) oxide, manganese oxide and barium chromate and a reduced nickel-based catalyst consisting essentially of nickel, nickel (II) oxide, aluminum oxide and silica. An apparatus comprising two inline hydrogenators is used for preparing the 2-methylfuran or 2-methyltetrahydrofuran.

Owner:PURE ENERGY

Method for preparing barium hydroxide by using barium carbonate

ActiveCN102923748AFast heat and mass transferShorten the timeCalcium/strontium/barium oxides/hydroxidesChemical reactionBarium peroxide

The invention discloses a method for preparing barium hydroxide by using barium carbonate. The method comprises the following steps of firstly grinding ores containing barium carbonate into ore powder, carrying out high-temperature roasting on the ore powder in a suspension fluidized state to obtain roasted ore containing barium hydroxide, soaking the roasted ore in water to react and generate a barium hydroxide solution, carrying out solid-liquid separation on the barium hydroxide solution, cooling and crystallizing to obtain barium hydroxide products. The method for preparing the barium hydroxide by using the barium carbonate, disclosed by the invention, has the advantages that the heat transfer area of the ore powder is large, each ore particle can uniformly and totally finish a chemical reaction, the reaction time is short, and the utilization rate of barium carbonate is high.

Owner:HUNAN SHIZHUYUAN NON FERROUS METAL

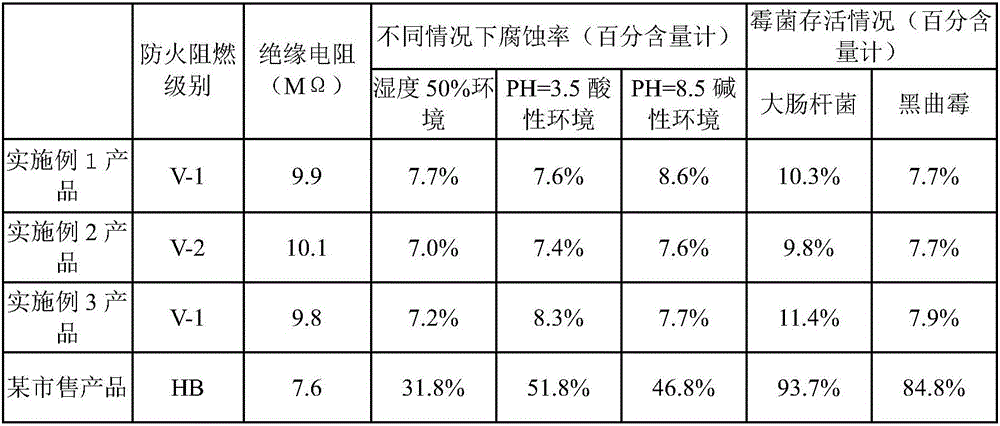

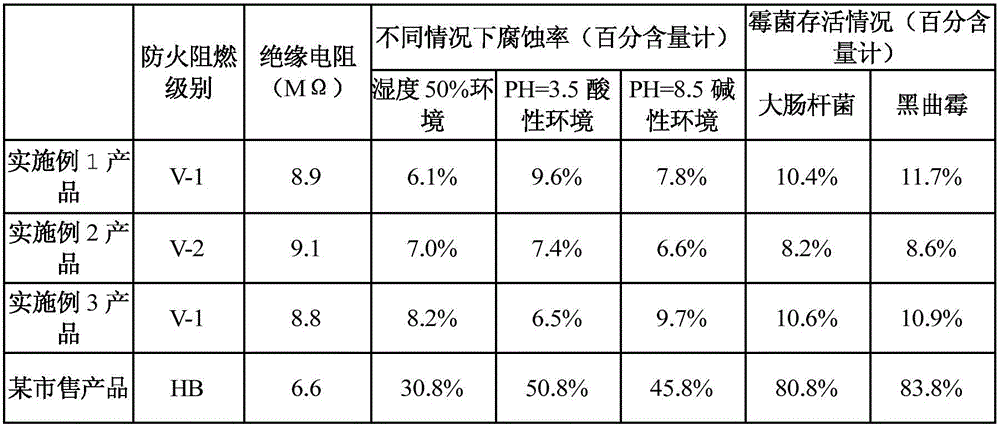

Flame-retarding, acid-alkali-resisting wear-resisting fire hose material

InactiveCN106349721AExcellent flame retardantExcellent flame retardant acid and alkali resistanceDecabromobiphenyl etherDecabromodiphenyl ether

The invention relates to a flame-retarding, acid-alkali-resisting wear-resisting fire hose material. The flame-retarding, acid-alkali-resisting wear-resisting fire hose material is prepared from rosin resin, p-tert-octyl phenolformaldehyde resin, amino resin, polyethylene wax emulsion, tall oil fatty acid, butyl acetate, isoamyl propionate, diethylene glycol dimethyl ether, dimethyl fumarate, sodium perborate, imidazoline, ammonium fluosilicate, guanidine phosphate powder, phenyl triethoxy silane, sodium pyrophosphate, chromium oxide, chromium chloride, menthol, barium chromate powder, ferrous orthophosphate, ethylenedioxydiethyl bis, tricresol phosphate ester, decabromodiphenyl ether, nanometer magnesium hydroxide, lignin, morpholine, polyoxyethylene polyoxy propyl alcohol amine ether, alkyl polyglucoside, propylamine, sodium ricinoleic acid. The product has excellent flame retardance, acid-base resistance, anti-mildew and anti-microbial performances, and the product performance is improved.

Owner:袁华

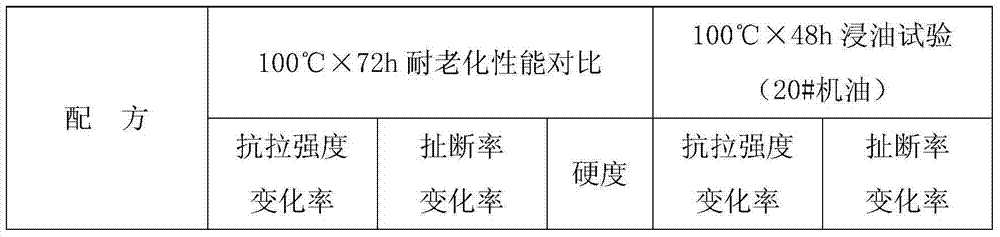

Butadiene-acrylonitrile rubber and fluororubber composite sealing gasket material and preparation method thereof

The invention discloses a butadiene-acrylonitrile rubber and fluororubber composite sealing gasket material. The butadiene-acrylonitrile rubber and fluororubber composite sealing gasket material is characterized in that the butadiene-acrylonitrile rubber and fluororubber composite sealing gasket material is prepared from the following raw materials in parts by weight: 80-90 parts of butadiene-acrylonitrile rubber, 20-24 parts of fluororubber, 1-2 parts of tetrabenzylthiuramdisulfide, 12-14 parts of silicon dioxide, 2-3 parts of zinc oxide, 3-4 parts of calcium ferrite, 1-2 parts of zinc phosphate, 10-12 parts of barium chromate, 1-2 parts of 2-mercaptobenzimidazole, 1-2 parts of accelerator CZ, 1-2 parts of accelerator M, 30-34 parts of N330 carbon black, 24-28 pars of N550 carbon black, 8-10 parts of epoxy linseed oil and 10-12 parts of modified attapulgite. The processing property of the rubber material is improved due to adding of the modified attapulgite; the environment-friendly accessory ingredients are used to reduce toxic and side effects and environmental pollution; the butadiene-acrylonitrile rubber and fluororubber composite sealing gasket material has reasonable formula, simple process, low cost, and good oil resistance, corrosion resistance and ageing resistance.

Owner:马鞍山市中澜橡塑制品有限公司

Processes for the preparation of 2-methylfuran and 2-methyltetrahydrofuran

Processes are disclosed for the preparation of 2-methylfuran and 2-methyltetrahydrofuran. The continuous vapor-phase processes are commercially viable and efficient because they permit the preparation of 2-methylfuran and 2-methyltetrahydrofuran using commercially-available catalysts, namely, a reduced copper-based catalyst consisting essentially of cupric oxide, chromium (III) oxide, manganese oxide and barium chromate and a reduced nickel-based catalyst consisting essentially of nickel, nickel (II) oxide, aluminum oxide and silica. An apparatus comprising two inline hydrogenators is used for preparing the 2-methylfuran or 2-methyltetrahydrofuran.

Owner:PURE ENERGY

Method for producing sodium chromate through calcium-free enriched oxygen or pure oxygen roasting

InactiveCN106495220AHigh Chromium ConversionRapid roasting reactionChromates/bichromatesEnergy consumptionBarium chromate

The invention discloses a method for producing sodium chromate through calcium-free enriched oxygen or pure oxygen roasting, mainly aims to solve problems that conventional calcium-free roasting rotary kiln production in China and outer countries is relatively low in chromium conversion rate, long in kiln material reaction time, relatively high in roasting temperature and the like, and aims to achieve the purposes that through enriched oxygen roasting (or pure oxygen roasting), the reaction velocity is increased, the chromium conversion rate is increased, the energy consumption is reduced, the waste residue discharge is reduced, the production efficiency is improved and the cost is lowered.

Owner:GANSU JINSHI CHEM

A detection reagent for detecting sulfate contents in a water body

InactiveCN103323409ALow priceEasy to carryColor/spectral properties measurementsPotassium hydroxideSurface water

The invention relates to a detection reagent for detecting sulfate contents in a water body. The detection reagent is prepared by steps of weighing barium chromate, calcium chloride, trichloroacetic acid, absolute ethyl alcohol, and polyvinylpyrrolidone according to a weight ratio of 2:1:4:10:20; dissolving the trichloroacetic acid into the absolute ethyl alcohol, adding the polyvinylpyrrolidone and mixing uniformly; allowing the mixture to stand and be exposed to air for 24h; grinding into powder after the ethyl alcohol is volatilized; and mixing with the barium chromate and the calcium chloride. When the detection reagent is used, after steps of adding 0.1-0.3 g of the detection reagent into 5-10 mL of a water sample, shaking and mixing for 3 min, adding 0.1g of potassium hydroxide and mixing uniformly, and filtrating, then the filtrate can be detected by the detection reagent by using a spectrophotometer or a colorimeter. The detection reagent provided by the invention has advantages of carry convenience, low price, and accurate and reliable results, and can be applied for on-site quantitative determination of sulfate concentrations for surface water, underground water, production water, domestic water, and the like.

Owner:TONGJI UNIV

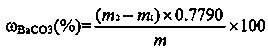

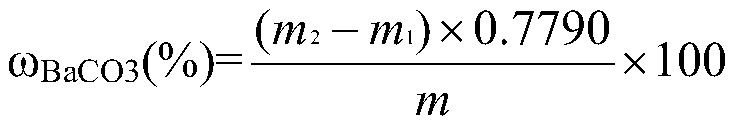

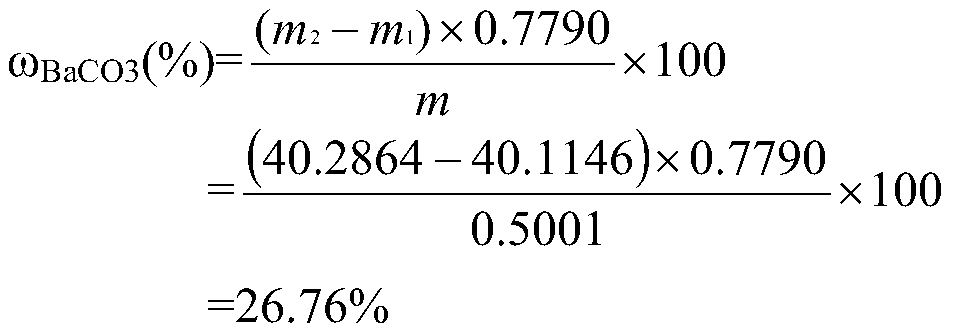

Method for detecting content of barium carbonate in witherite

InactiveCN110095373AEliminate the effects ofImprove stabilityMaterial analysis by observing effect on chemical indicatorMaterial weighingSediment FilterBarium sulfate

The invention discloses a method for detecting the content of barium carbonate in witherite. The method comprises steps of sample preparation, reagent and solution preparation, barium sulfate sedimentremoving, barium chromate sediment generation, barium chromate sediment filtering and drying, and analysis result calculation and the like. The detecting method has a large detection range; influences on the detection result by impurities like barium sulfate, silicate and calcium carbonate can be eliminated effectively; the detection result has high stability, reproducibility and accuracy; and the detecting method is simple and is easy to learn and no high requirement on the analysis staff is needed. The method has the broad application prospects and has the important significance in evaluating the witherite quality grade and omprehensive application.

Owner:玉溪新兴钢铁有限公司

Flame retardation and antibiosis fabric

InactiveCN106009857AExcellent flame retardantGood acid and alkali resistanceFireproof paintsAntifouling/underwater paintsDiethylene glycol diethyl etherPolymer science

The invention relates to a flame retardation and antibiosis fabric. A gunny cloth fabric is bonded with a protection coating layer, and the coating layer comprises a-olefin elastomer, polymethyl methacrylate, isoprene rubber, tall oil fatty acid, butyl acetate, allyl sulfide, diethylene glycol diethyl ether, diethylene glycol butyl ether, propiconazole, sodium monofluorophosphate, dodecyl ethoxy sulfobetaine, dimethyl fumarate, cuprous chloride, metatitanic acid, silicon carbide fibers, phenyltriethoxysilane, chromium oxide green, chromium chloride, barium chromate powder, sodium cellulosate, trimethyl phosphate, polyacrylonitrile fibers, dibasic lead stearate, tris(butoxyethyl)phosphate, starch ether, vinyltris(beta-methoxyethoxy)silane, ethylamine, diethylenetriamine, alkylphenol polyoxyethylene and divinyl benzene. The flame retardation and antibiosis fabric has superior flame, acid-alkali, mildew and bacterium resistance, and improved performances.

Owner:李红玉

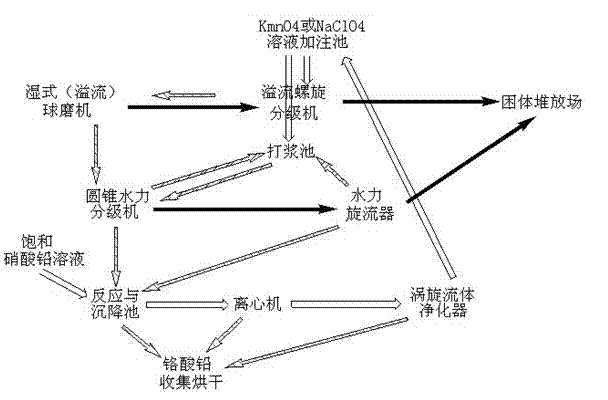

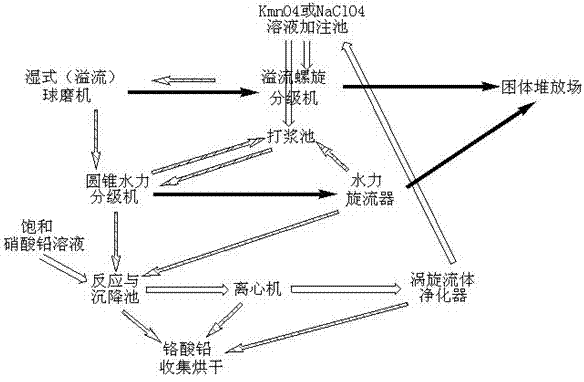

Method for industrially eliminating toxic ingredients in chromium slag

InactiveCN102249330ASignificant progressElimination of Cr(Ⅵ)Chromates/bichromatesSlagIndustrial water

The invention relates to a method for industrially eliminating toxic ingredients in chromium slag. The method sequentially comprises the following steps: (1) carrying out refluxing for the chromium slag through 1-5% of a KMnO4 solution or a NaClO2 solution, wherein the volume of the KMnO4 solution or the NaClO2 solution is 1-2 times the volume of the chromium slag, then carrying out grinding until the chromium slag has a particle size less than 1 mm; (2) carrying out refluxing and washing for the grinded chromium slag through industrial water in a screw ore washer, wherein the volume of the industrial water is 2-5 times the volume of the chromium slag; (3) collecting the chromium slag, and separating the solid from the washing solution through a cone hydraulic classifier and a hydroclone;(4) collecting the washing solution, and adjusting a pH value of the washing solution to 6-8, followed by adding a saturated CaCl2 solution or a saturated BaCl2 solution until precipitation is not generated; (5) collecting the precipitation, wherein the precipitation is calcium chromate or barium chromate, and carrying out cycling utilization of the supernatant. With the chromium slag detoxication process provided by the present invention, the chromium (Cr) (VI) is eliminated, the total Cr is thoroughly reduced so as to completely meet environmental protection requirements.

Owner:WUHAN TEXTILE UNIV

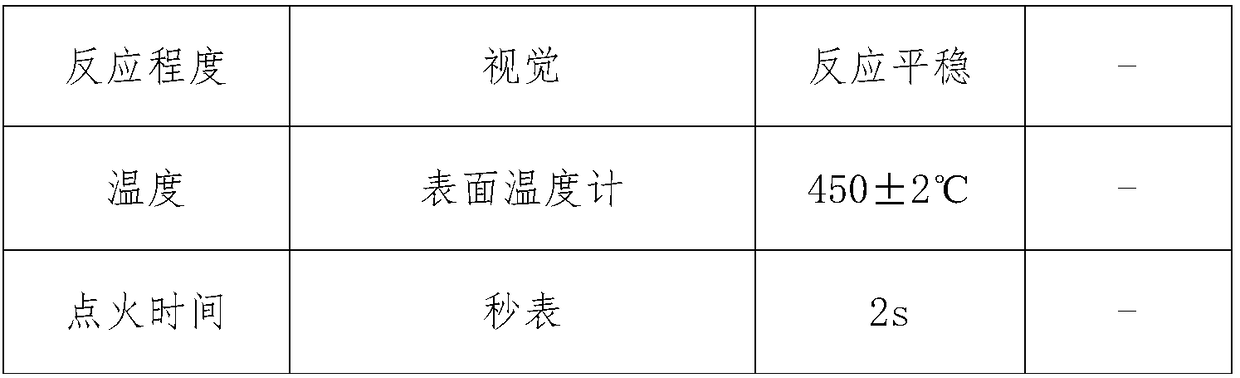

Oxygen candle starting mix and preparation method thereof

ActiveCN108083235AFast burning absorptionRapid Burn Absorption Initiator Fire Hitter SpawnsOxygen preparationAdhesiveDecomposition

The invention discloses oxygen candle starting mix and a preparation method thereof. The oxygen candle starting mix is prepared from the following components in parts by mass: 70-90 parts of barium chromate, 5-15 parts of a metal monomer, 3-10 parts of an adhesive and 0-5 parts of chlorate. The preparation method disclosed by the invention comprises the following step: pressing the barium chromate, the metal monomer, the adhesive and the chlorate according to the formula proportions, thereby obtaining the oxygen candle starting mix. As zirconium powder is replaced by magnesium powder or aluminum powder, magnesium oxide on the surface of the magnesium powder is a catalyst for decomposing chlorate, the decomposition temperature of the chlorate is reduced, harmful gas nitrogen oxides generated from detonating caps of actuators can be rapidly combusted and absorbed, and meanwhile combustion residues are loosened without swelling, thus being safe and reliable.

Owner:SHAANXI STAR EXPLOSION SAFETY POLYTRON TECH INC

Method for cleaner production of sodium vanadate and sodium chromate by pressure leaching of vanadium slag

ActiveCN102531056BSimple ingredientsAchieve separationChromates/bichromatesVanadium compoundsSlagSlurry

The invention relates to a method for cleaner production of sodium vanadate and sodium chromate by pressure leaching of vanadium slag. The method comprises the following steps of: (1) mixing materials, namely mixing the vanadium slag and a solution of NaOH to obtain a reaction material; (2) reacting, namely performing oxidization reaction on the vanadium slag and oxidizing gas in the solution of NaOH under high pressure to obtain solid-liquid mixed slurry of a solution containing NaOH, Na3VO4, Na2CrO4 and water-soluble impurity components, and iron-rich tailings; (3) performing solid-liquid separation; (4) removing impurities; (5) crystallizing sodium vanadate; and (6) crystallizing sodium chromate. The method is easy to operate and is high in safety; and the operating temperature is greatly lower than the temperature of the traditional vanadium extraction process, energy consumption is low, the high-efficiency co-extraction of vanadium and chromium is realized, and the extraction rate of vanadium and chromium is over 95 percent.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for preparing sodium chromate by adopting sulfate byproduct iron cake as calcium-free roasting filler

ActiveCN104098139APlay a role in catalytic oxidationImprove contact effectChromates/bichromatesFiltrationCatalytic oxidation

The invention discloses a method for preparing sodium chromate by adopting sulfate byproduct iron cake as a calcium-free roasting filler. The method mainly comprises the following steps: batching of sulfate byproduct iron cake, chromite and caustic soda, preheating of the ball material, high-temperature oxygen-enriched calcination, wet milling and pressure filtration. According to the invention, the sulfate byproduct iron cake is adopted as a filler, so that the gas contact property is good during roasting, meanwhile, a catalytic oxidation role is played and the sulfate byproduct iron cake is efficiently utilized. The chromium yield in the filtrate is relatively high and can be more than 90%; the filter residue contains more than 50% of Fe2O3 which can be all used for preparing stainless steel, so that the problem of underlying environmental pollution of Cr<6+> is solved from the pollution source.

Owner:SICHUAN YINHE CHEM

Oxygen candle

ActiveCN108083234ACryogenic decomposition continuousPurify oxygen purityOxygen preparationDecompositionAdhesive

The invention discloses an oxygen candle which comprises an absorption inflammable layer, a heating layer and a main candle layer, wherein the heating layer is arranged between the absorption inflammable layer and the main candle layer; the main candle layer consists of the following components in percentage by mass: 90-96% of chlorate, 1.5-5% of a catalyst, 0-3% of fuel, 1.5-2.5% of an adhesive and 0.5-1.5% of a stabilizing agent; the heating layer consists of the following components in percentage by mass: 70-80% of chlorate, 5-15% of a catalyst, 5-12% of fuel and 3.0-6.0% of an adhesive; the absorption inflammable layer consists of the following components in percentage by mass: 5-15% of fuel, 80-90% of barium chromate, 3-5% of an adhesive and 0-1% of chlorate. By adjusting the types and ratios of the catalysts, the decomposition temperature of an oxygen generation agent, namely the chlorate, is reduced, oxygen can be relatively easily released under a low temperature condition, then the amount of elegant metals in the absorption inflammable layer is reduced, and meanwhile due to addition of a flame retardant, the release velocity of energy of the elegant metals is controlled.

Owner:SHAANXI STAR EXPLOSION SAFETY POLYTRON TECH INC

Preparation method of sodium bichromate

ActiveCN102649584AHigh carbonation rateHigh purityChromates/bichromatesChromium CompoundsSodium bicarbonate

The invention provides a preparation method of sodium bichromate. The preparation method comprises the following steps of: (1) adding 700-1,350 g.L<-1> sodium chromate neutral solution of a chromium compound in terms of Na2Cr2O7.2H2O into a carbonization reactor; (2) continuously supplying carbon dioxide into the carbonization reactor, and controlling partial pressure of carbon dioxide to be 0.01-1.5 MPa, reaction temperature to be 15-105 DEG C and reaction time to be 0.5-8.0 h; (3) separating carbonized feed liquid obtained by the step (2) to obtain carbonized liquid and sodium bicarbonate crystals, wherein the concentration of the chromium compound in the carbonized liquid is 700-1,350 g.L<-1> in terms of Na2Cr2O7.2H2O; and (4) crystallizing and dehydrating the carbonized liquid to obtain the sodium bichromate. By preparing the sodium bichromate through the preparation method, the conversation rate from the sodium chromate to the sodium dichromate can reach 95-100 percent, the quality of the sodium bichromate is high, and the sulfate content is less than 0.1 percent by weight.

Owner:SICHUAN YINHE CHEM

Rust-bearing anti-rust paint

InactiveCN102408831AEfficient conversionSolve the adsorption problemAnti-corrosive paintsZinc phosphateEmulsion

The invention relates to a rust-bearing anti-rust paint which is mainly prepared from rust-bearing anti-rust paint emulsion, calcium ferrite, zinc phosphate, zinc oxide, barium chromate, aluminum tripolyphosphate, mica ferric oxide, talcum powder, kaolin, wollastonite powder, water, curing agent and the like. The rust-bearing anti-rust paint has uvioresistant capacity, and can postpone aging of the paint film. The paint film has the characteristics of favorable corrosion resistance, high durability, acid / alkali / salt / water corrosion resistance, high adhesive force, high impact resistance, excellent bending resistance, long corrosion resistance time and the like.

Owner:ZHANGJIAGANG YONGFA PAINT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com