Tungsten-based delay powder for detonator and use of tungsten-based delay powder

A technology for delaying charge and detonator, applied in the direction of detonator, explosive, weapon accessories, etc., can solve the problems of complex production, low assembly efficiency, many quality problems, etc., to solve the problem of delay time interval, high assembly efficiency, and improved safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

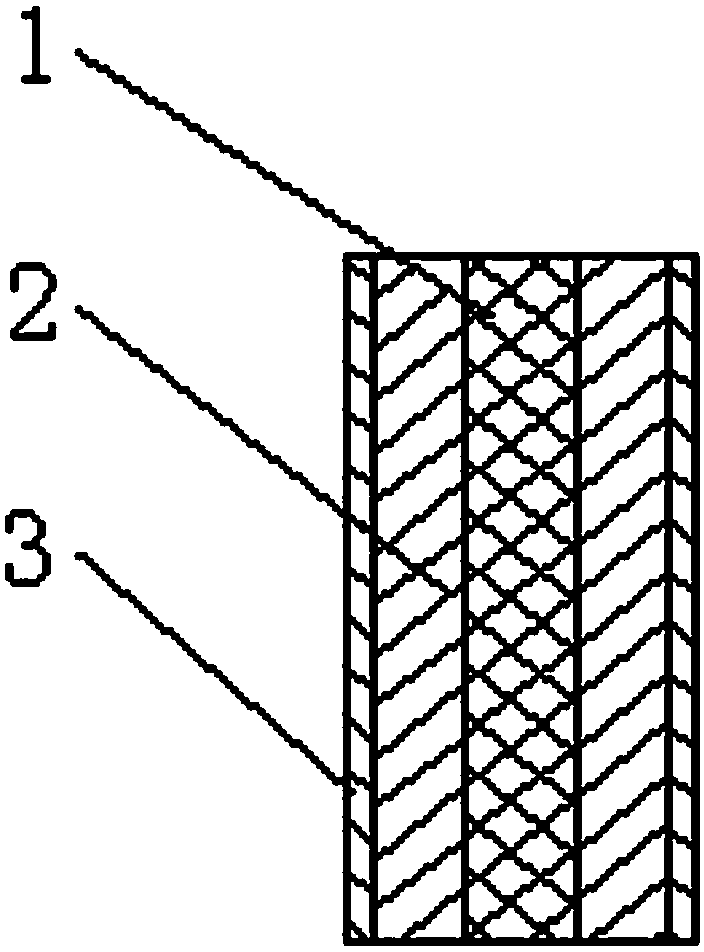

[0016] When preparing a one-stage lead delay body with a delay time of 500ms to 1500ms, first select barium chromate 848, tungsten powder 960 and potassium perchlorate 230 according to the weight ratio, then manually mix the above formula, put it into a ball mill and mix for 4 hours. Then fill the mixed delay medicine into a lead pipe with a diameter of φ10~φ16mm, and then operate according to the procedures of casing, rolling, drawing, and lead cutting to obtain a tungsten-based delay medicine for detonators, and then put the tungsten Delay medicine is prepared into a cylindrical core with a diameter of 2mm, and an intermediate layer made of pure lead is arranged outside the cylindrical core, and an outer layer made of lead-antimony alloy is arranged outside the intermediate layer, thereby making a delayed A one-stage lead delay body with a time of 500ms ~ 1500ms.

Embodiment 2

[0018] When preparing a one-stage lead delay body with a delay time of 1500ms ~ 3500ms, first select barium chromate 950, tungsten powder 880, potassium perchlorate 210 and calcium fluoride 60 according to the weight ratio, then manually mix the above formula and put it into a ball mill After further mixing for 4 hours, fill the mixed delay drug into a lead pipe with a diameter of φ10~φ16mm, and then operate according to the procedures of casing, rolling, drawing, and cutting lead to obtain a tungsten-based delay for detonators. medicine, and then prepare a tungsten-based delayed medicine into a cylindrical core with a diameter of 2 mm, and an intermediate layer made of pure lead is arranged outside the cylindrical core, and an outer layer made of lead-antimony alloy is arranged outside the middle layer. Thus a one-stage lead delay body with a delay time of 1500ms to 3500ms is prepared.

Embodiment 3

[0020] When preparing a one-stage lead delay body with a delay time of 3500ms to 5500ms, first select barium chromate 1000, tungsten powder 800, potassium perchlorate 210 and calcium fluoride 120 according to the weight ratio, then manually mix the above formula and put it into a ball mill After further mixing for 4 hours, fill the mixed delay drug into a lead pipe with a diameter of φ10~φ16mm, and then operate according to the procedures of casing, rolling, drawing, and cutting lead to obtain a tungsten-based delay for detonators. medicine, and then prepare a tungsten-based delayed medicine into a cylindrical core with a diameter of 2 mm, and an intermediate layer made of pure lead is arranged outside the cylindrical core, and an outer layer made of lead-antimony alloy is arranged outside the middle layer. Thus, a one-stage lead delay body with a delay time of 3500ms to 5500ms is prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com