Method of producing barium sulfide and flue gas by calcining coal and barite to synthesize barium carbonate

A barium sulfide and flue gas technology, applied in the direction of calcium carbonate/strontium/barium, etc., can solve the problems of waste water pollution, waste of resources, air pollution, etc., and achieve the effects of reducing costs, improving comprehensive economic benefits, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

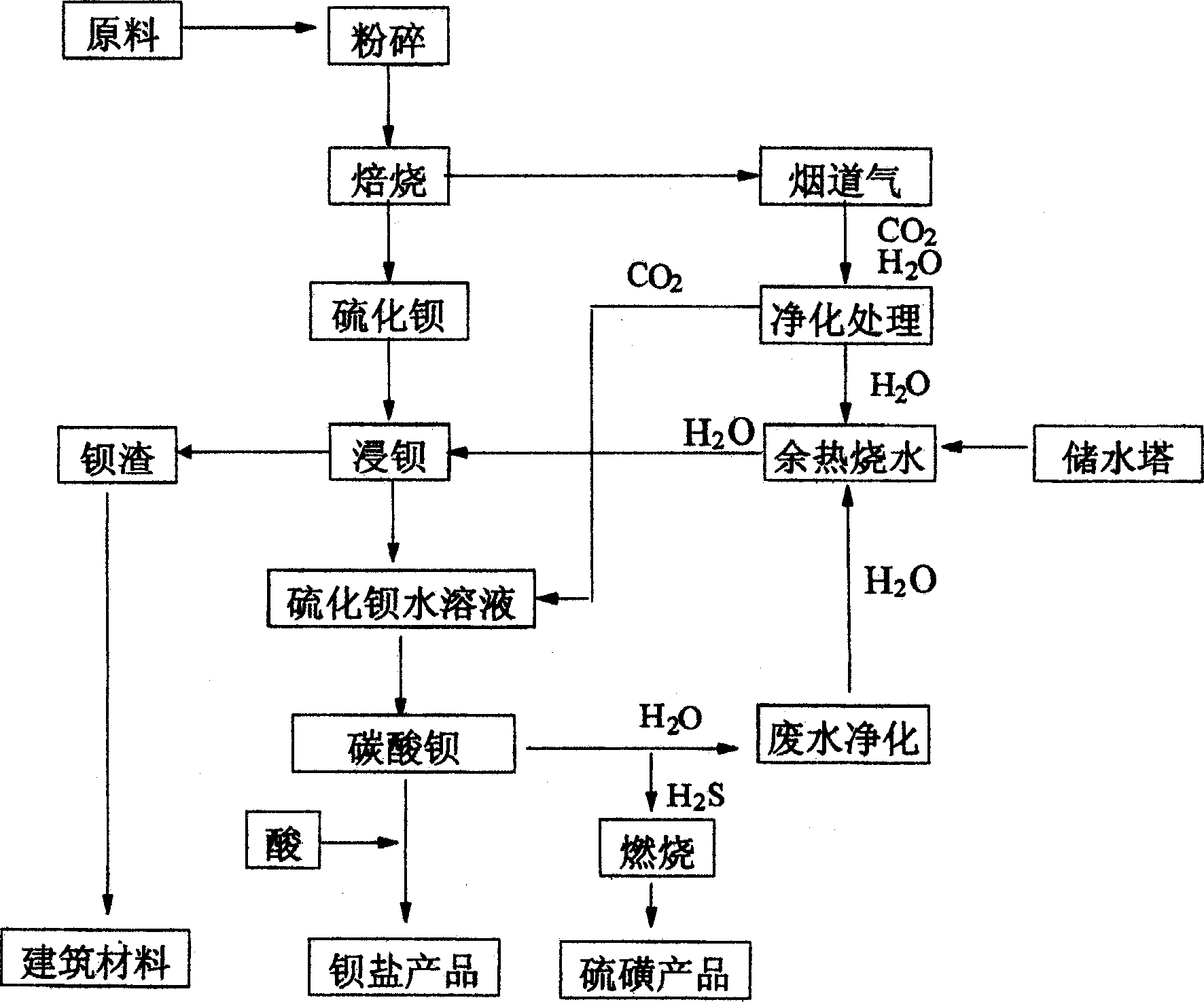

[0028] The process has achieved ideal results through small test, pilot test and industrial test. The coal and barite are crushed into particles below 1.5 cm in a ratio of 3:1, and 0.5 tons of coal and 1.5 tons of barite are sent to the converter for roasting. At a high temperature of 1100 ° C, after 1.5 hours, Barite is reduced to barium sulfide, and flue gas is generated at the same time; one ton of barium sulfide is soaked with three tons of water to make barium sulfide aqueous solution; the flue gas is purified to obtain pure carbon dioxide gas, and the carbon dioxide gas is passed into the barium sulfide aqueous solution The main products are barium carbonate and hydrogen sulfide waste gas; the hydrogen sulfide gas produced in the synthesis is oxidized and reduced to produce sulfur, which further controls the pollution of the waste gas to the atmosphere. The barium slag contains a small amount of barium sulfide, which is reduced to barium sulfate and ferrous sulfide with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com