Process for producing sodium chromate by calcium-free calcination

A technology of calcium-free roasting and sodium chromate, applied in the direction of chromate/dichromate, etc., which can solve problems such as research, long process route, and problem of wall formation that cannot be fundamentally solved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

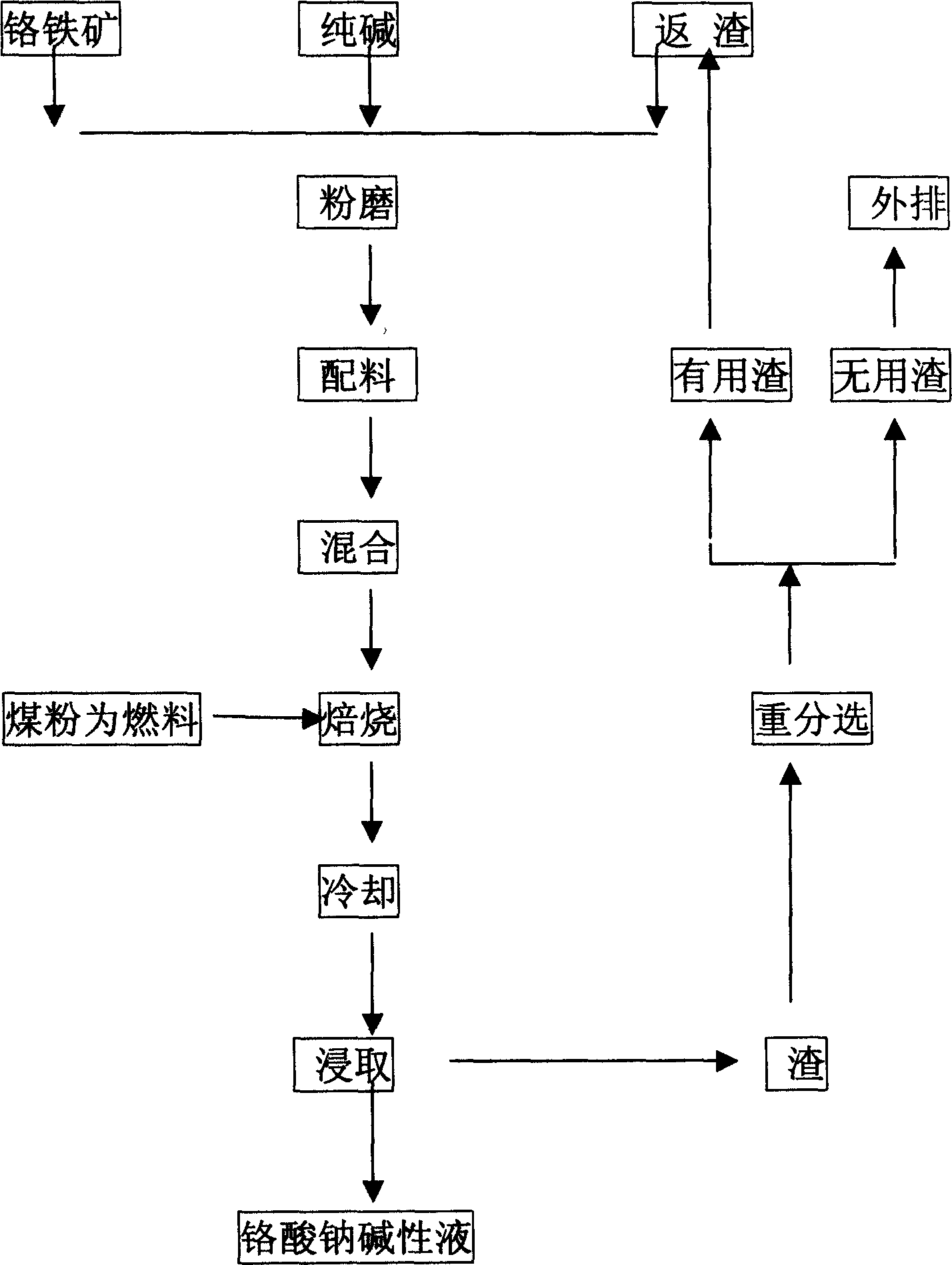

Method used

Image

Examples

example 1

[0011] Example 1: Chromite (Cr 2 o 3 = 45 ± 1%) grinding to 200 mesh and passing 98%, soda ash crushing to 80 mesh passing 90%, calcium-free slag sorting and grinding to 100 mesh passing 98%. The three materials are mixed evenly, and the material ratio is chromite: soda ash: chromium slag=26:21:53 (weight ratio). The powder is roasted in the rotary kiln, the reaction temperature is 1130 degrees, and the temperature of the flue gas at the kiln tail is 610 degrees. The material stays in the rotary kiln for 4 hours and 10 minutes, and the high temperature zone stays for 60 minutes. The material does not segregate and does not form a wall. The clinker chromium oxidation rate is 93%. After leaching and filtering, the chromium slag does not contain calcium chromate, and the leaching rate of hexavalent chromium is greater than 99.1%. After the chromium slag is sorted, 74% of the coarse slag is returned as filler, and the remaining chromium slag is detoxified and discharged for sto...

example 2

[0012] Example two: raw material is the same as example 1, chromite: soda ash: chromium slag=25: 20: 55, the powder is roasted in the rotary kiln, the reaction temperature is 1080 degrees, the flue gas temperature at the kiln tail is 590 degrees, and the residence time of the material is in the rotary kiln 4 hours, in which the residence time in the high temperature zone is 65 minutes, the material does not form a wall, the clinker chromium oxidation rate is 94%, and the hexavalent chromium leaching rate is greater than 99.4%.

example 3

[0013] Example three: the raw material is the same as example 1, the batching is the same as example 2, the reaction temperature is 1070 degrees, the kiln tail flue gas temperature is 630 degrees, the material residence time is 4 hours, and the high temperature zone residence time is 60 minutes. The material does not segregate, does not form a wall, the clinker chromium oxidation rate is 93%, and the hexavalent chromium leaching rate is greater than 99.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com