Patents

Literature

359 results about "Sodium chromate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sodium chromate is the inorganic compound with the formula Na₂CrO₄. It exists as a yellow hygroscopic solid, which can form tetra-, hexa-, and decahydrates. It is an intermediate in the extraction of chromium from its ores. Sodium chromate, like other hexavalent chromium compounds, is toxic and carcinogenic.

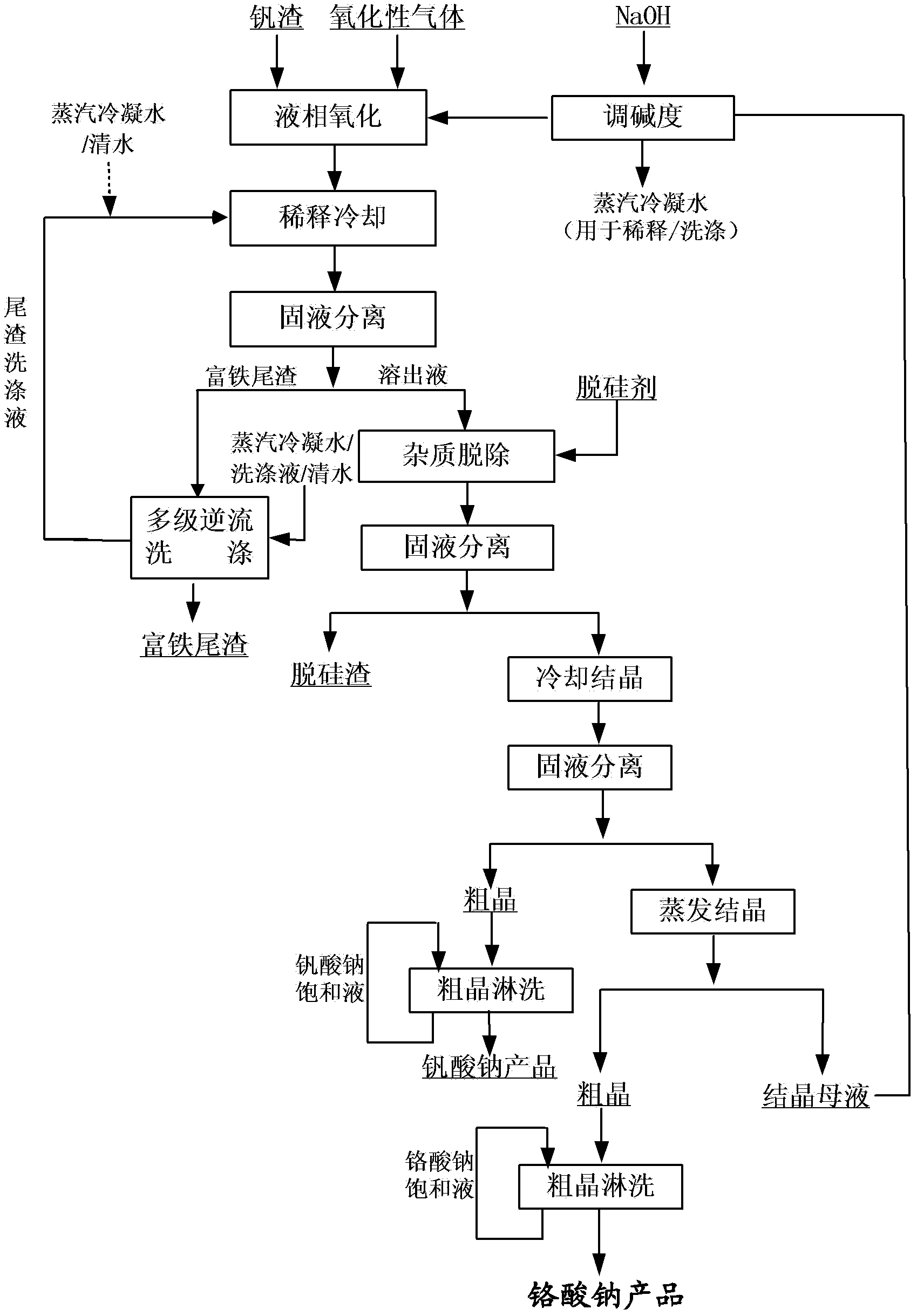

Method for cleaner production of sodium vanadate and sodium chromate by pressure leaching of vanadium slag

ActiveCN102531056ASimple ingredientsAchieve separationChromates/bichromatesVanadium compoundsSlagSlurry

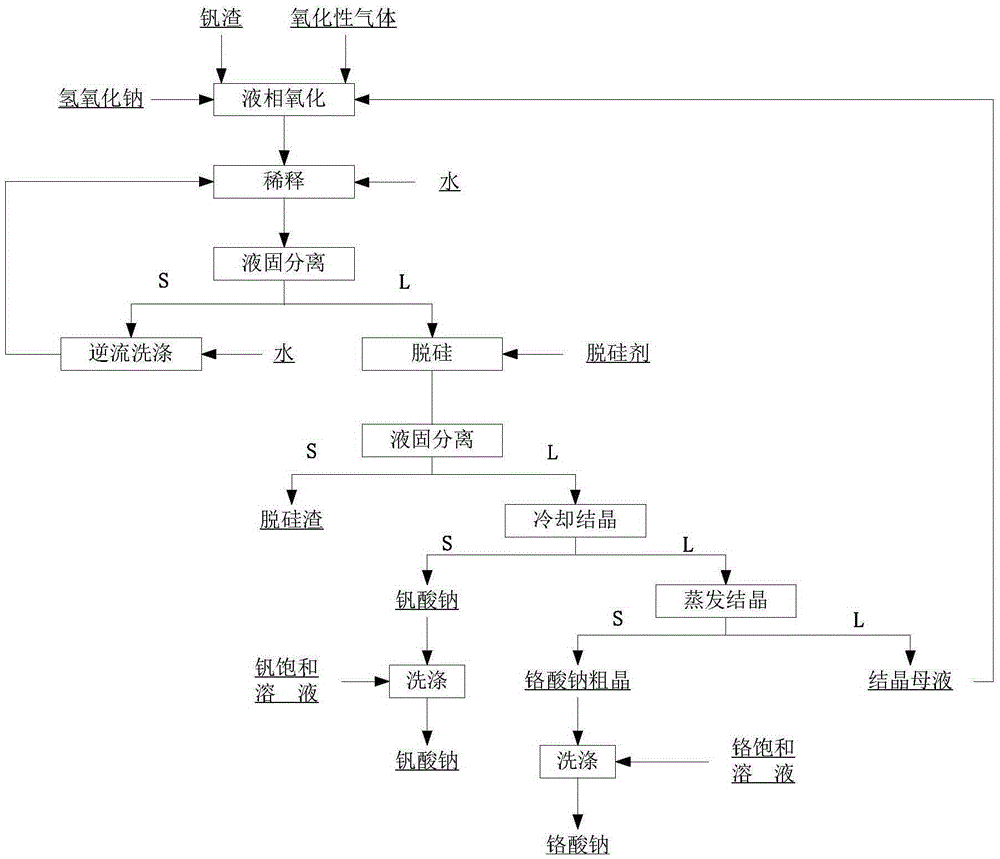

The invention relates to a method for cleaner production of sodium vanadate and sodium chromate by pressure leaching of vanadium slag. The method comprises the following steps of: (1) mixing materials, namely mixing the vanadium slag and a solution of NaOH to obtain a reaction material; (2) reacting, namely performing oxidization reaction on the vanadium slag and oxidizing gas in the solution of NaOH under high pressure to obtain solid-liquid mixed slurry of a solution containing NaOH, Na3VO4, Na2CrO4 and water-soluble impurity components, and iron-rich tailings; (3) performing solid-liquid separation; (4) removing impurities; (5) crystallizing sodium vanadate; and (6) crystallizing sodium chromate. The method is easy to operate and is high in safety; and the operating temperature is greatly lower than the temperature of the traditional vanadium extraction process, energy consumption is low, the high-efficiency co-extraction of vanadium and chromium is realized, and the extraction rate of vanadium and chromium is over 95 percent.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

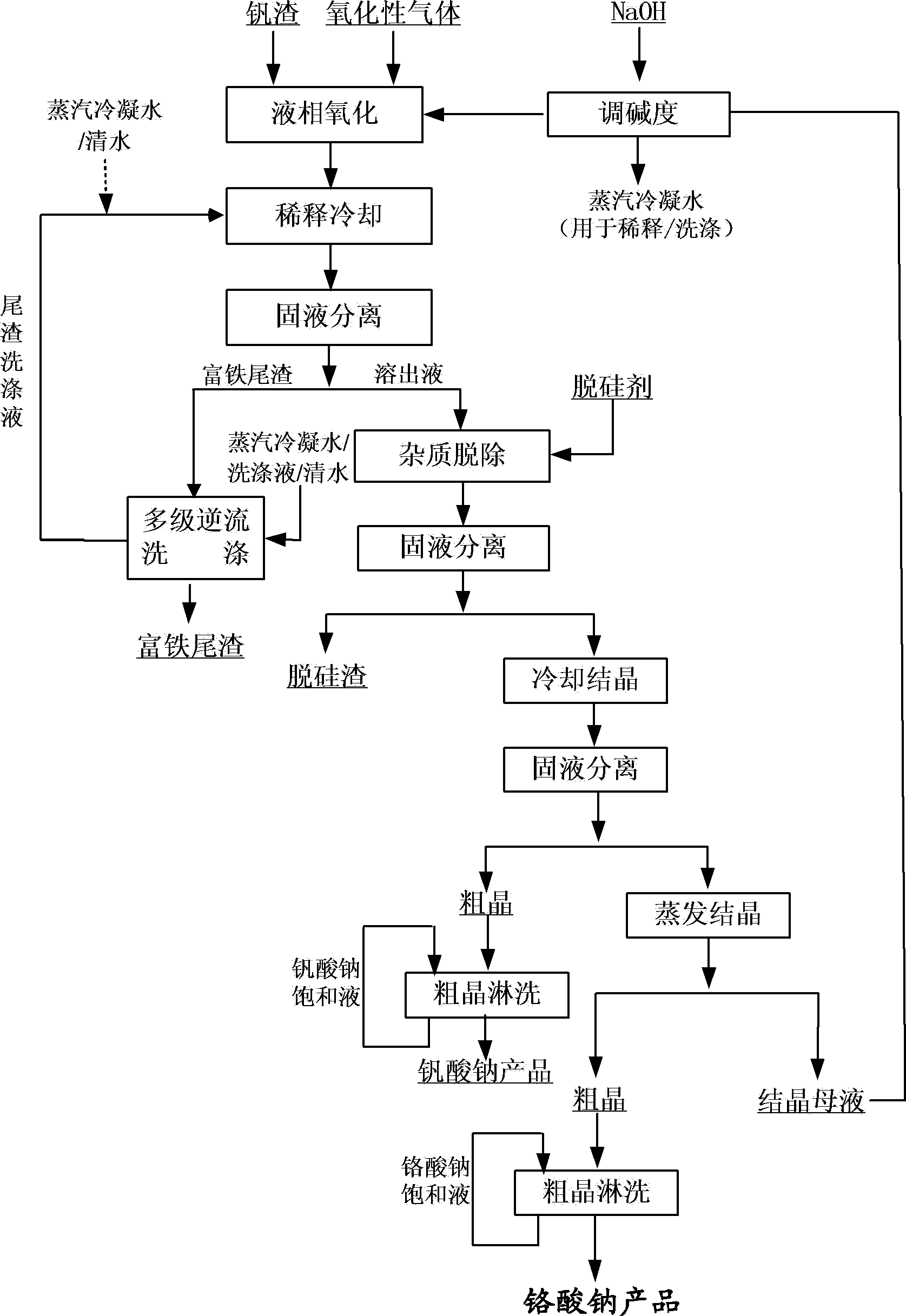

Clean production method for preparing sodium chromate from chromite

InactiveCN101659444AObvious superiorityLow reaction temperatureChromates/bichromatesSlagSodium nitrate

The invention relates to a clean production method for preparing sodium chromate from chromite, which comprises the following steps of: reacting the chromite with an oxidizing gas in a medium of NaOH-NaNO3-H2O, wherein sodium nitrate serves as a catalytic medium and is not consumed in the reaction; obtaining a mixed reaction product of an alkali liquor, the sodium chromate and iron slag after thereaction; leaching the mixed reaction product, performing liquid-solid separation of the alkali liquor and a crystal slag mixture (a mixture of a sodium chromate crystal and the iron slag), dissolvingthe mixture of the iron slag and the sodium chromate crystal, performing liquid-solid separation of the solution of the iron slag and the sodium chromate crystal, performing evaporative crystallization of the sodium chromate solution, rinsing and drying the obtained sodium chromate solution, obtaining qualified sodium chromate products; and circulating the crystallized mother liquor and the alkali liquor together to decompose the chromite. In the method, the chromium conversion ratio is above 99 percent and the chromium content ratio in the slag is less than 0.5 percent.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

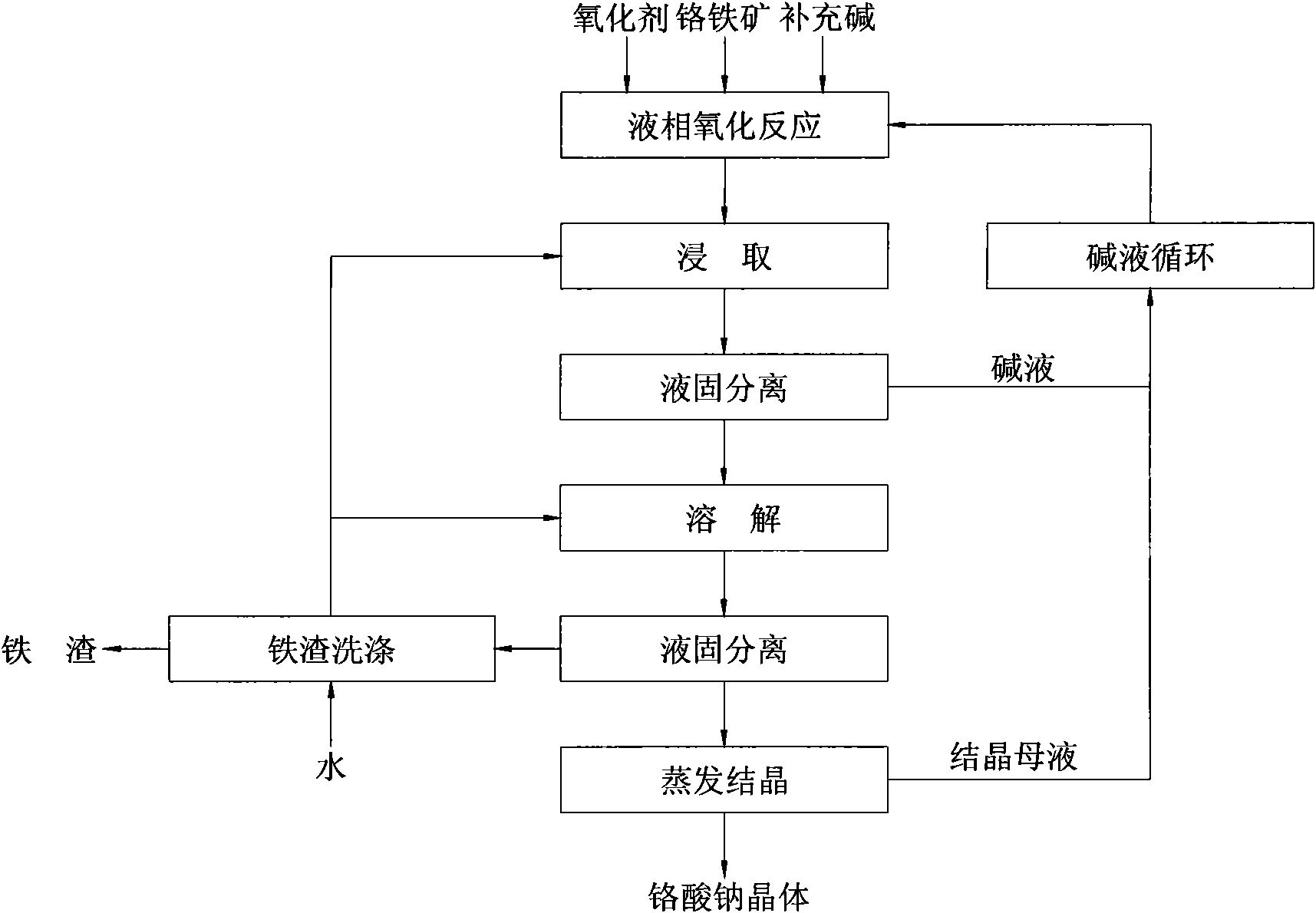

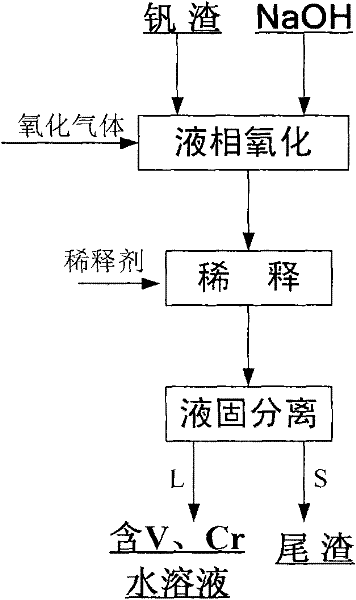

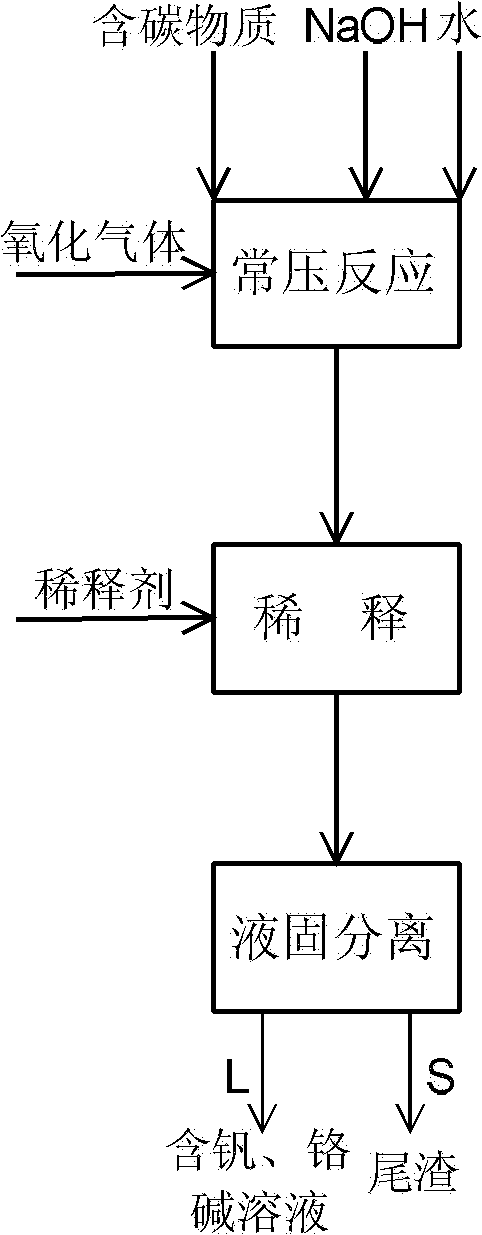

Method for decomposing chromium-containing vanadium slag by using sodium hydroxide molten salt

InactiveCN102127654ALower decomposition temperatureReduce the temperatureProcess efficiency improvementDecompositionSlag

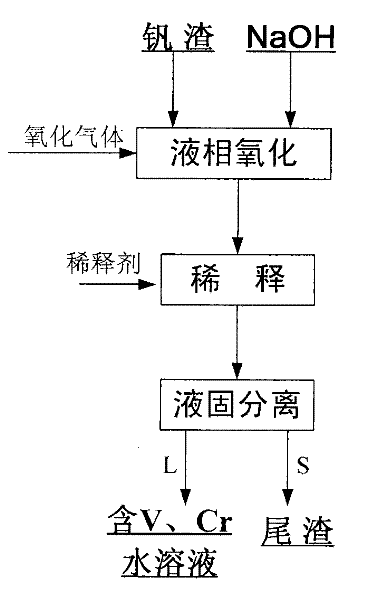

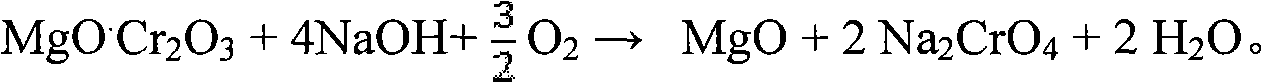

The invention relates to a method for decomposing chromium-containing vanadium slag by using sodium hydroxide molten salt, which comprises the following steps of: weighing NaOH and the vanadium slag in a mass ratio of 2.5:1-6:1; putting the weighed NaOH into a normal pressure reaction kettle, heating to the temperature of between 500 and 600 DEG C, adding the weighed vanadium slag into the NaOH molten salt, introducing oxidizing gas and performing liquid-phase oxidation reaction at the temperature of between 500 and 600 DEG C for 0.5 to 6 hours to obtain reaction slurry after the reaction is finished; diluting by using a diluent until the concentration of the sodium hydroxide in the slurry is 100 to 500g / L to obtain mixed slurry containing the sodium hydroxide, sodium vanadate, sodium chromate and tailings; and performing filtering separation on the mixed slurry at the temperature of between 80 and 130 DEG C to obtain the tailings and aqueous solution containing vanadium and chromium.The decomposition temperature is lower than the conventional sodium treatment roasting temperature, vanadium and chromium resources can be co-extracted, the extraction ratio is high, and the method is easy to operate.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for recycling vanadium, chromium, titanium and iron from vanadium-titanium magnetite ore

ActiveCN102061397AHigh recovery rateSimple processProcess efficiency improvementSteelmakingMagnetite

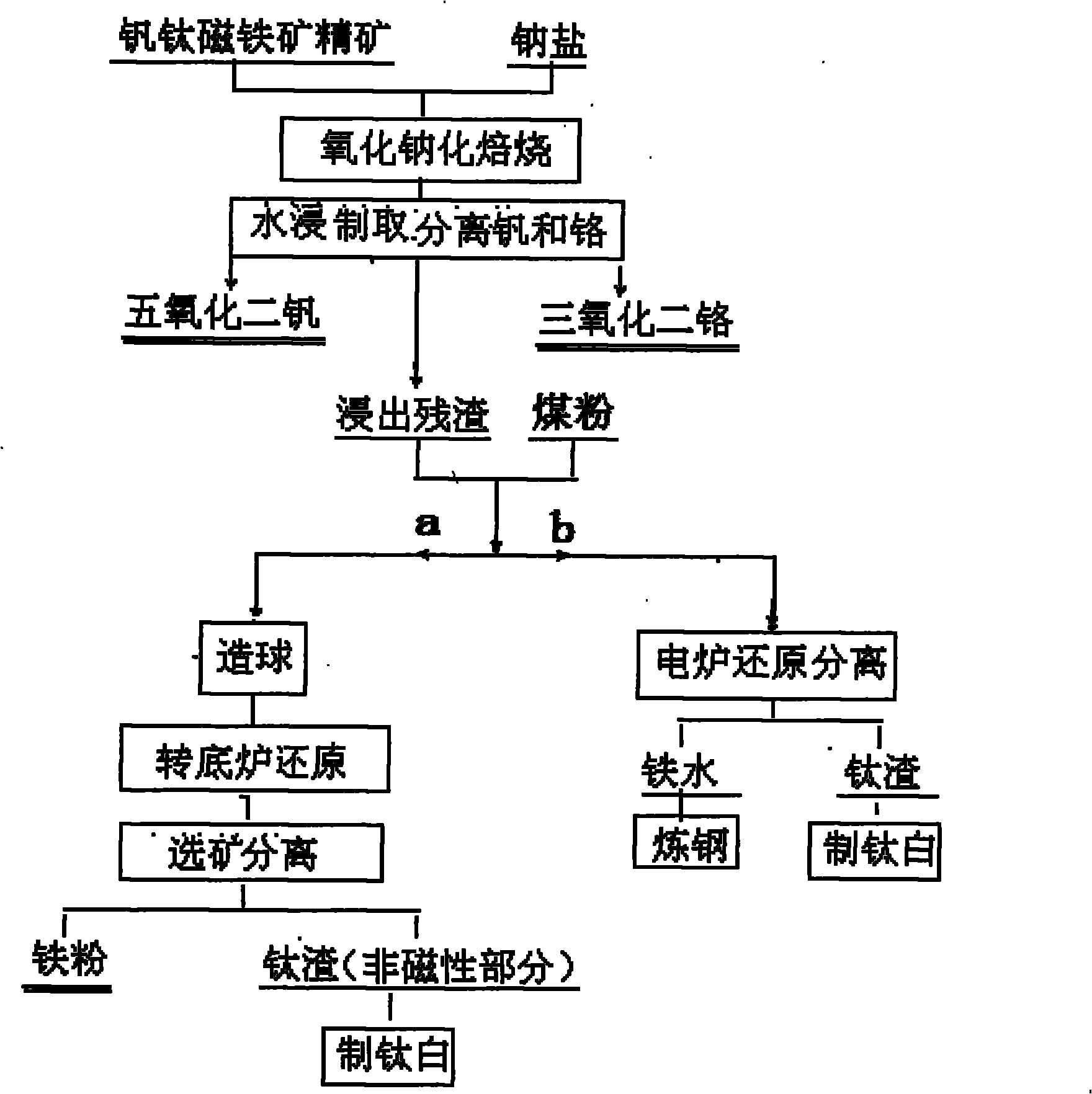

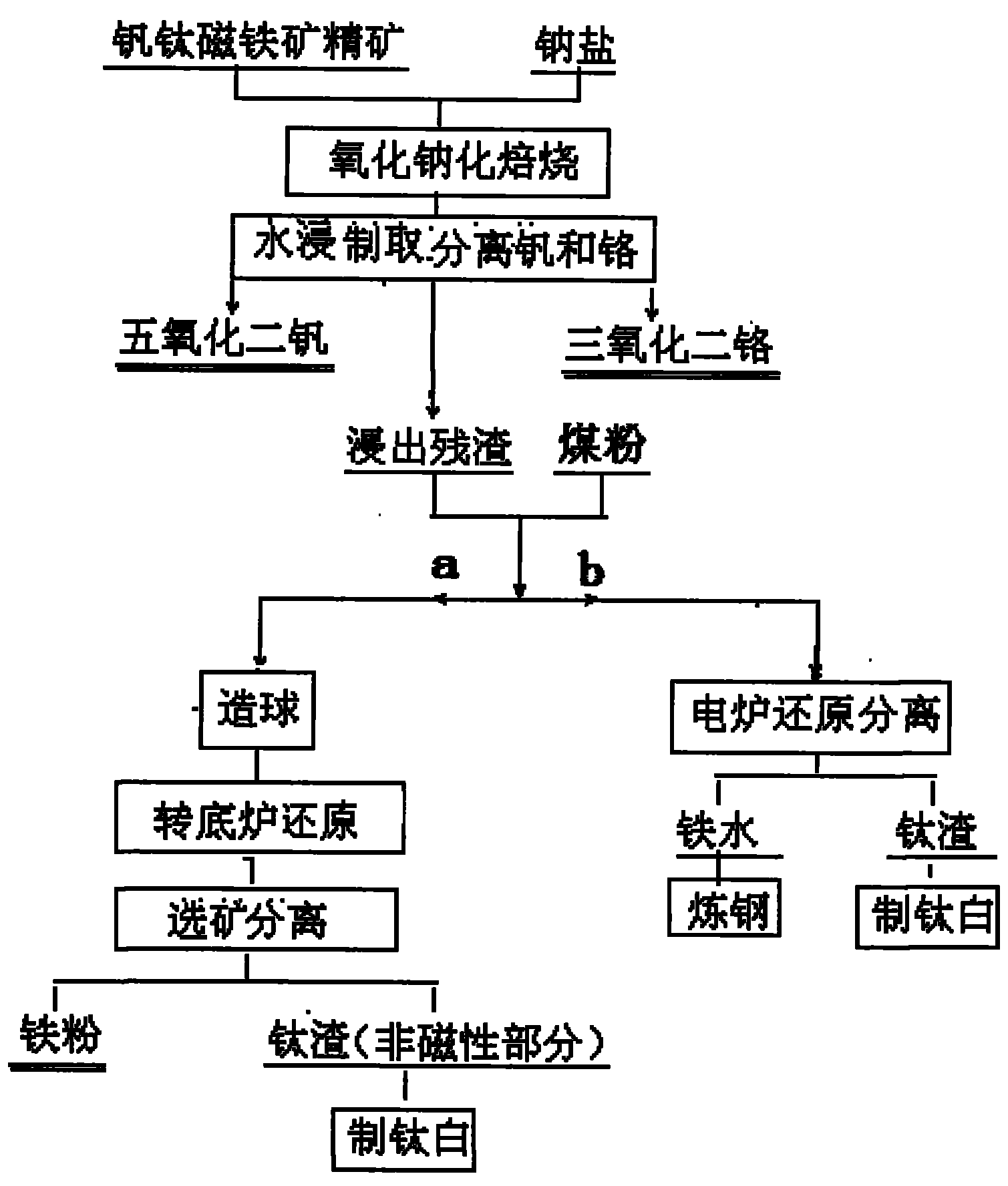

The invention discloses a method for recycling valuable elements from vanadium-titanium magnetite ore, which comprises the following steps of: crushing the ore or concentrate, adding sodium salt, performing oxidizing roasting, converting vanadium and chromium into water-soluble sodium vanadate and sodium chromate, performing water leaching in solution, and separating the vanadium and chromium from the solution to obtain vanadium pentoxide and chromium sesquioxide products; and adding coal dust into the leached residue for pelletizing, reducing in a rotary hearth furnace, magnetically separating iron and titanium, using the obtained magnetic iron powder as a raw material for powder metallurgy or steelmaking, and using a nonmagnetic product containing more than 50 percent of TiO2 as a raw material for extracting the titanium; or reducing iron from the leached residue in an electric furnace, using the obtained molten iron as a raw material for steelmaking and using electric furnace slag containing more than 50 percent of TiO2 as a raw material for extracting the titanium. The method is short in process flow and economical; and the recovery rate of the vanadium, chromium, titanium and iron is high.

Owner:SICHUAN LOMON MINING & METALLURGY +1

Method for extracting chromium and vanadium from vanadium slag at low temperature and normal pressure

ActiveCN105400967ALow reaction temperatureReduce reaction energy consumptionSlagReaction temperature

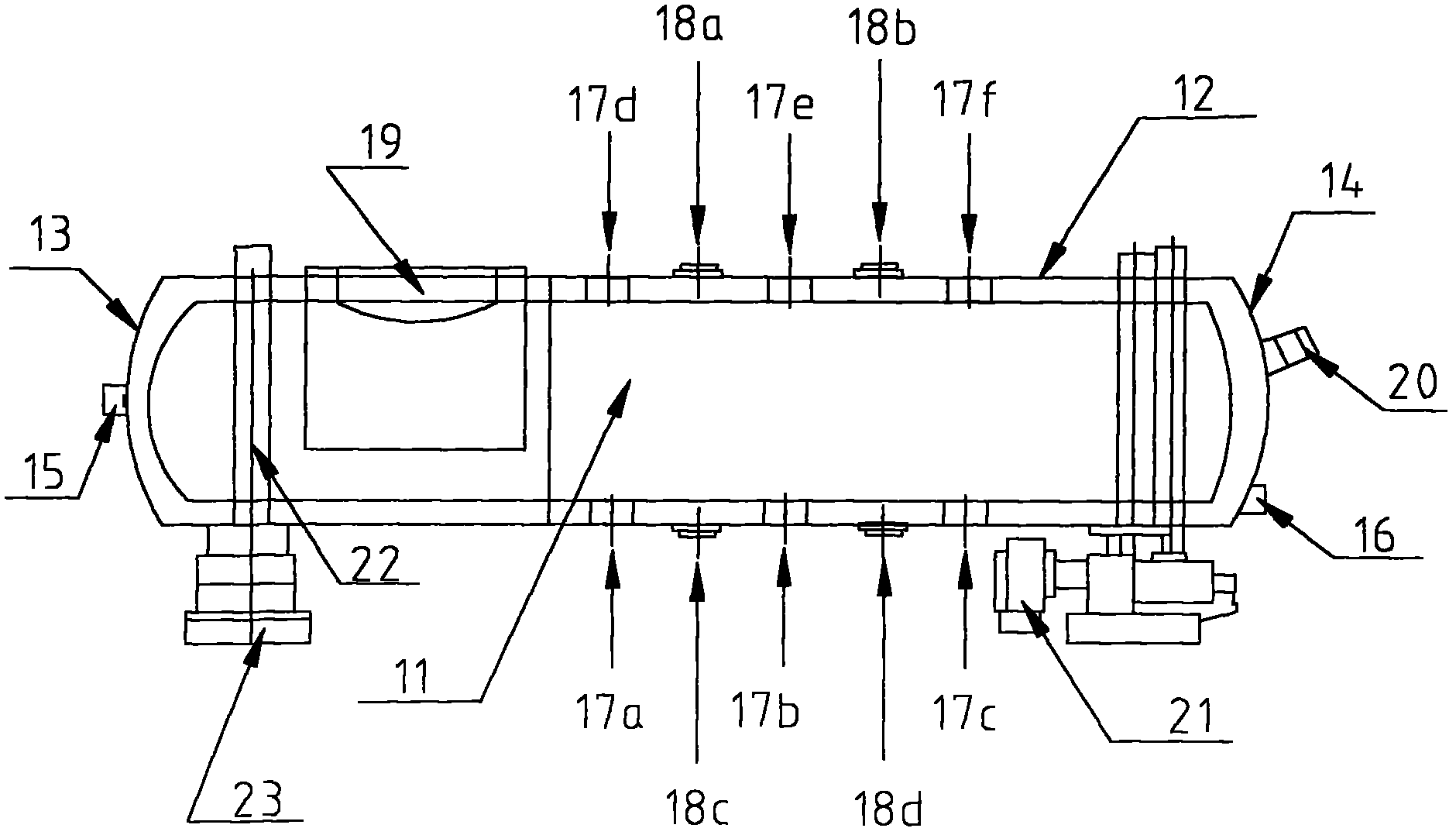

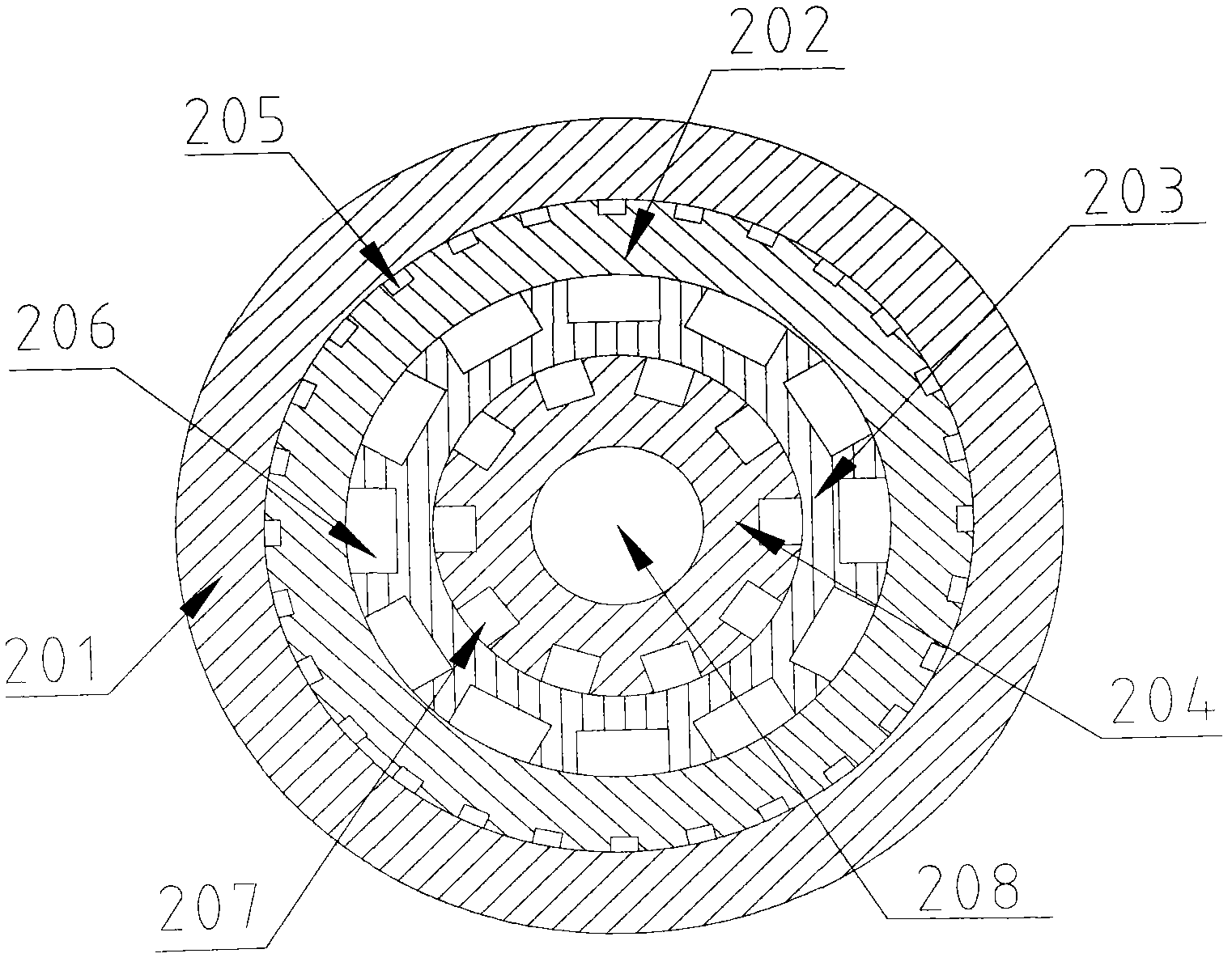

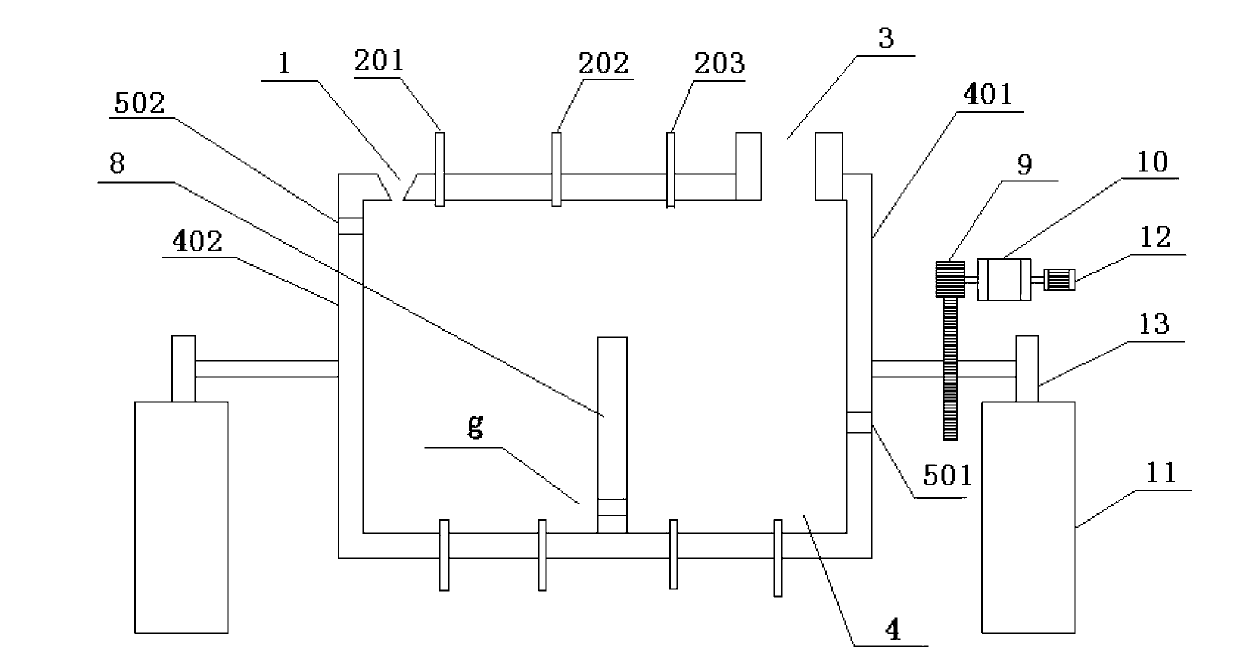

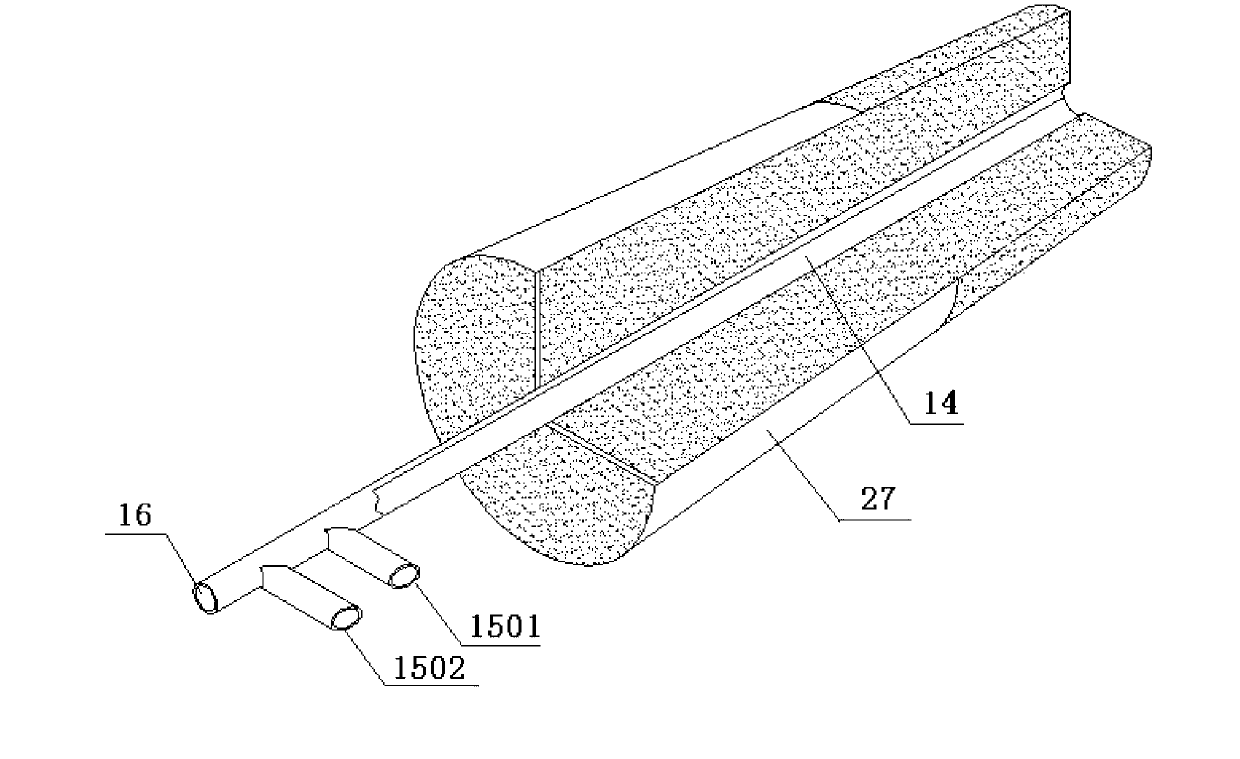

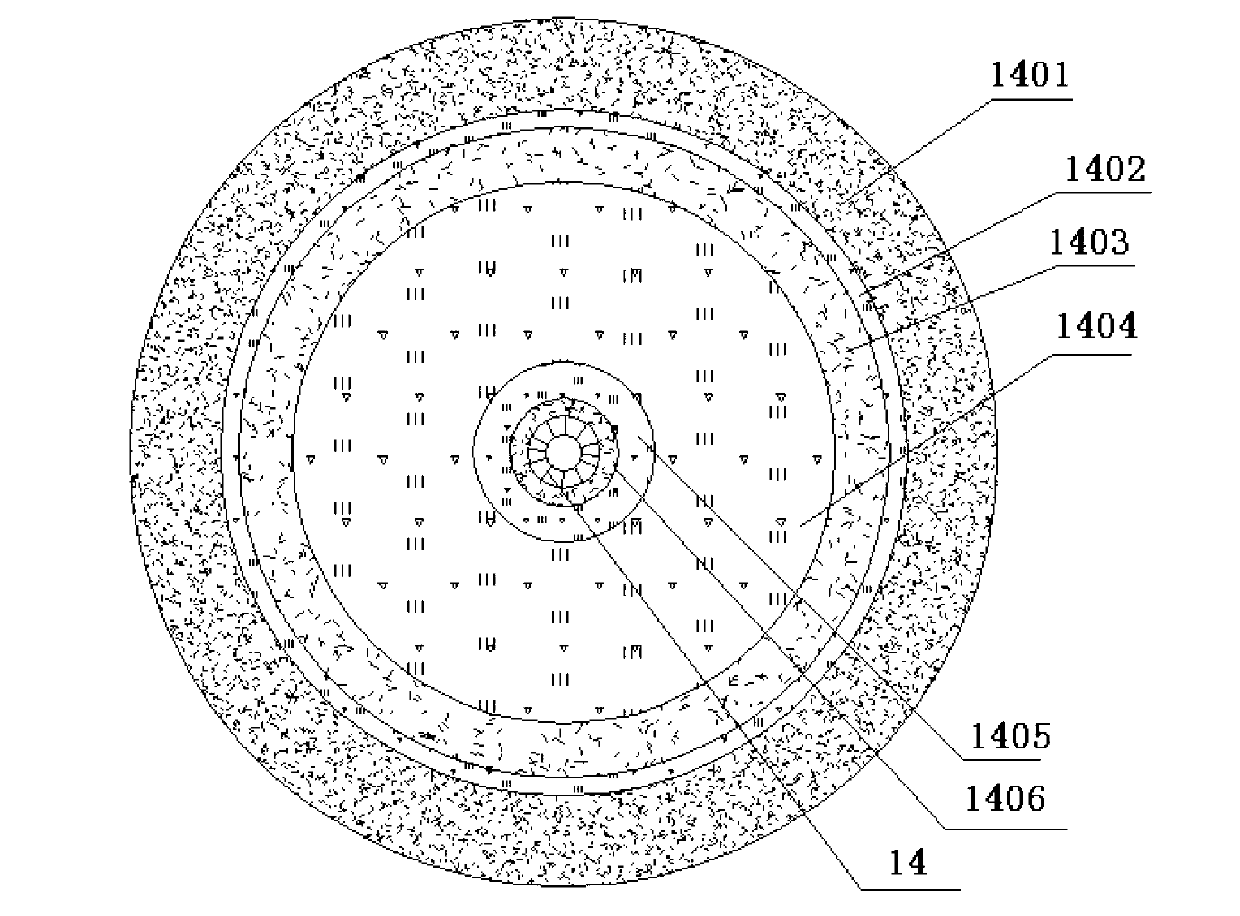

The invention relates to the field of vanadium slag hydrometallurgy and vanadium chemical engineering, in particular to a method for extracting chromium and vanadium from vanadium slag at a low temperature and the normal pressure. The method comprises the following steps that firstly, burdening, wherein the vanadium slag and a NaOH solution are mixed to form reaction slurry; secondly, reaction, oxide gas is led into the reaction slurry through a micro-hole arrangement device to carry out normal-pressure oxidative leaching, and after the reaction, solid-liquid mixed slurry of a solution containing NaOH, Na3VO4, Na2CrO4, water soluble impurity components and iron-rich tailings is obtained; thirdly, solid-liquid separation; fourthly, impurity removing; fifthly, sodium vanadate crystallization; and sixthly, sodium chromate crystallization. According to the method, chromium and vanadium efficient common extraction can be achieved, the extraction efficiency of both chromium and vanadium can be higher than 85%, more importantly, after the micro-hole gas distribution manner is adopted, the oxygen solubility can be obviously improved, the reaction temperature and alkali concentration are obviously reduced compared with those of an existing vanadium extraction method, the operation safety is greatly improved, and reaction energy consumption is reduced.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

Method for pollution-free production of sodium chromate by pressure leaching of chromite

ActiveCN101817561AObvious superioritySimple ingredientsChromates/bichromatesReaction temperatureHydrometallurgy

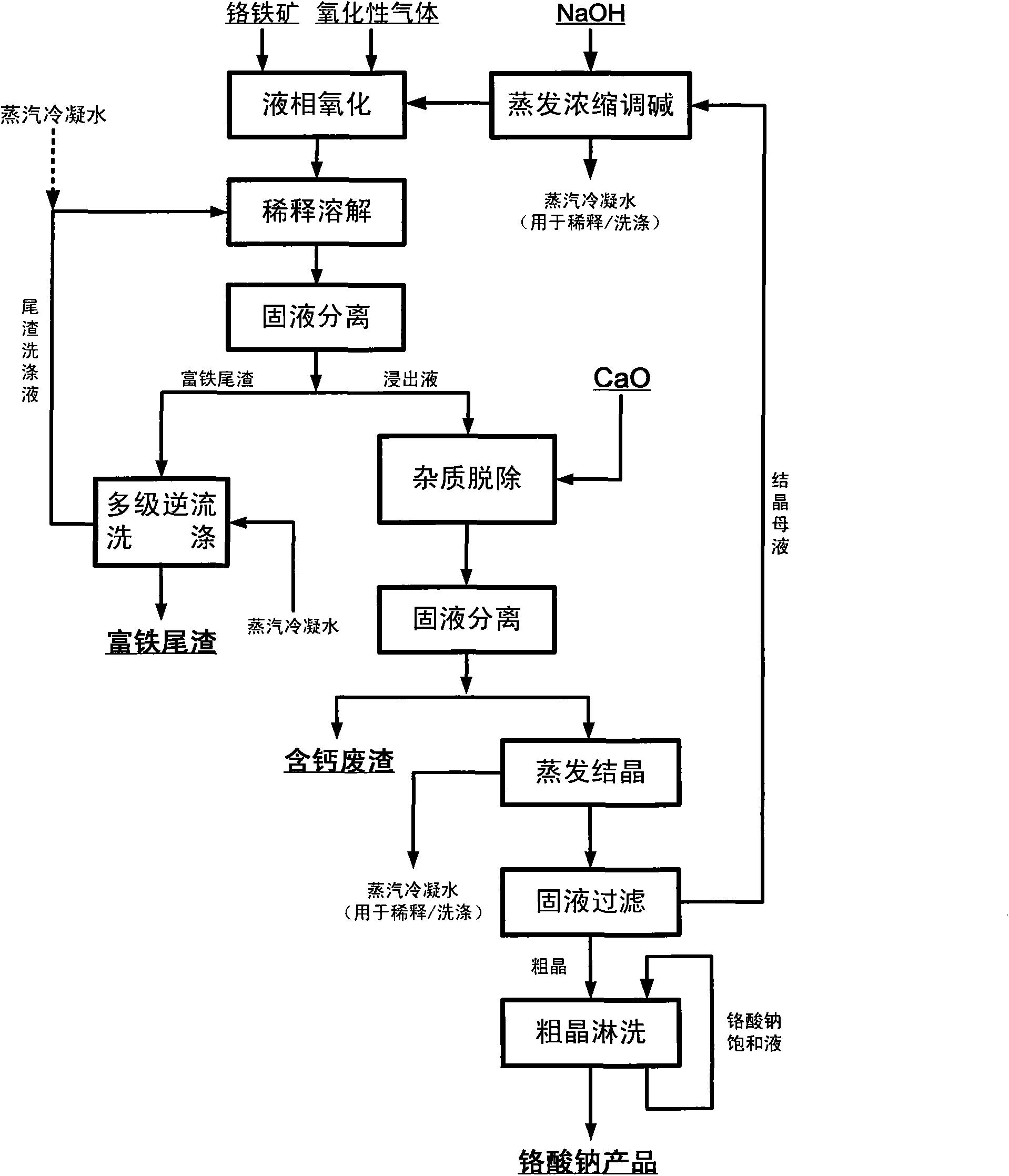

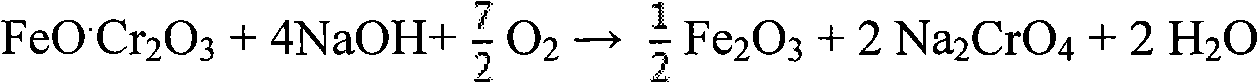

The invention belongs to the field of chromite hydrometallurgy and chromium chemical industry, and in particular relates to a method for the pollution-free production of sodium chromate by pressure leaching of chromite. The method comprises the following steps of: 1) reacting the chromite with oxidizing gas in solution of NaOH; 2) diluting the product obtained by the step 1) and making subcrystalline sodium chromate to fully enter a liquid phase; 3) performing solid-liquid separation on the solid-liquid mixed slurry obtained by the step 2); 4) adding calcium oxide into the obtained diluent for removing impurities; and 5) evaporating and crystallizing the obtained solution without the impurities to obtain a sodium chromate crystal and crystallization mother solution; after the solid-liquid separation, rinsing the sodium chromate crystal by using saturated solution of sodium chromate; and drying to obtain a qualified sodium chromate product. The method has the advantages of simple reaction system component, no difficultly separated phase introduced in the system, contribution to high-efficiency separation of the sodium chromate, great reduction in reaction temperature, low energy consumption, effective reduction in production cost of the sodium chromate, and high chromium leaching yield.

Owner:HUBEI ZHENHUA CHEMICAL CO LTD

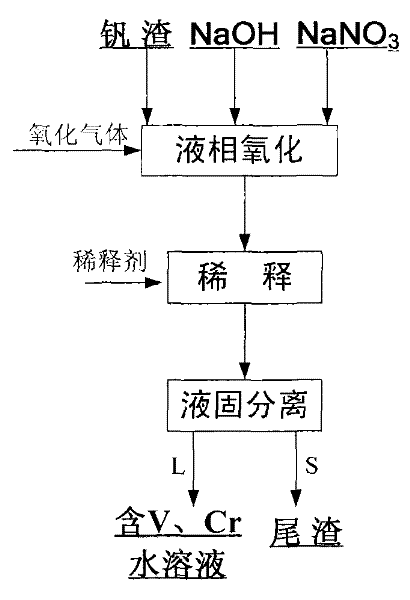

Method for decomposing vanadium slag by liquid phase oxidation

ActiveCN102127656ALow reaction temperatureReduce energy consumptionProcess efficiency improvementSlagResource utilization

The invention relates to a method for decomposing vanadium slag by liquid phase oxidation. The method comprises the following steps of: weighing materials according to a mass ratio of NaOH to NaNO3 of 0.2:1-4:1 and the mass ratio of the total amount of the NaOH and the NaNO3 to the vanadium slag of 2.5:1-6:1; placing the weighed NaOH and NaNO3 into a normal-pressure reaction kettle; heating to the temperature of between 330 and 480 DEG C; adding the weighed vanadium slag into NaOH-NaNO3 molten salt; introducing oxidizing gas; performing liquid phase oxidation reaction at the temperature of between 330 and 480 DEG C for 0.5 to 6 hours to obtain reaction slurry; diluting the reaction slurry with a diluting agent until the sodium hydroxide concentration of feed liquid is between 100 and 500g / L to obtain mixed slurry of sodium hydroxide, sodium nitrate, sodium vanadate, sodium chromate and tailings; and performing filtering separation to obtain the tailings and aqueous solution containingvanadium and chromium. The method has a low reaction temperature, high safety and high utilization rate of vanadium and chromium resources, is operated under normal pressure and is easy to industrially implement, and the vanadium and the chromium in the vanadium slag are extracted together; and the decomposed tailings comprise 0.5 to 1 weight percent of vanadium (based on V2O5) and 0.5 to 1 weight percent of chromium (based on Cr2O3).

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

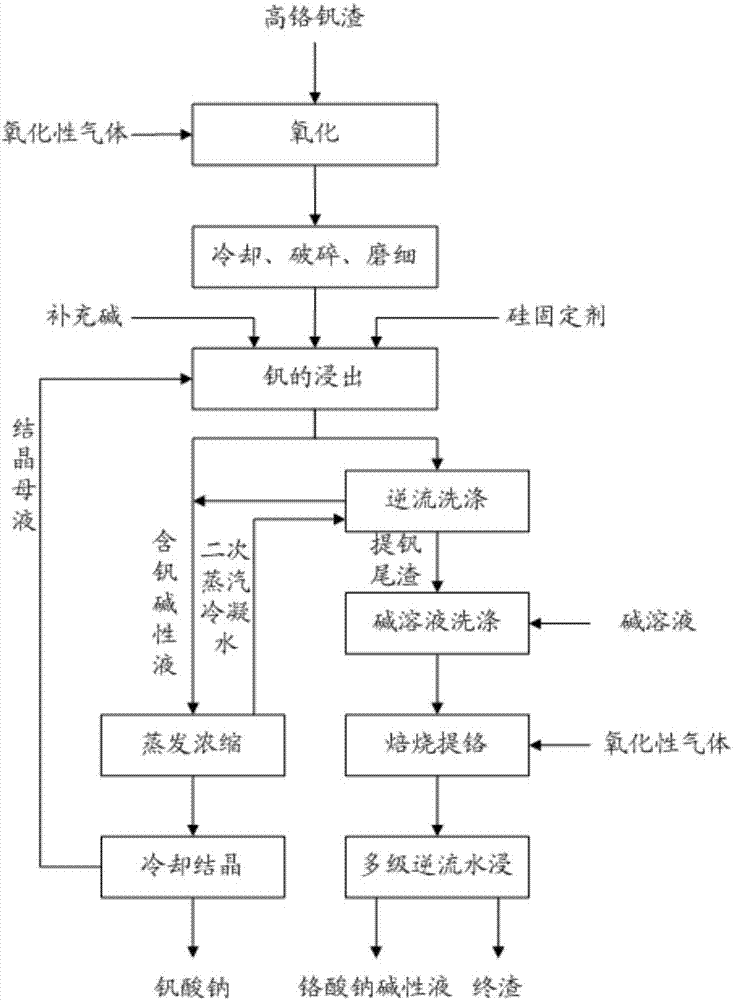

Cleaning process for producing sodium vanadate and sodium chromate alkali solution by high chromium vanadium slag

ActiveCN103757425AImprove resource utilizationImprove separation rateChromates/bichromatesVanadium compoundsSlagSilicon

The invention relates to a cleaning process for producing sodium vanadate and sodium chromate alkali solution by high chromium vanadium slag. The method provided by the invention comprises the main steps of: introducing oxidizing gas into the high-temperature high chromium vanadium slag separated from molten iron to oxidize vanadium into pentavalent vanadium; leaching vanadium out of the high chromium vanadium slag with an alkali solution, adding a silicon fixing agent for synchronized fixing of silicon, evaporating and concentrating the alkali leaching solution, cooling and crystallizing to prepare sodium vanadate, and reusing the cooling crystallization mother liquor; and conducting immersion cleaning and mixing on the vanadium-extracted tailings subjected to multistage countercurrent washing with alkali solution with a certain concentration, carrying out a roasting reaction in roasting equipment, and immersing reaction clinker with water and filtering to obtain an alkali solution of sodium chromate and the final slag. The method has the advantages of simple process, strong operability, recovery rate of vanadium greater than 98%, recovery rate of chromium more than 95% and separation rate of vanadium and chromium greater than 99%, thereby achieving efficient extraction and separation of vanadium and chromium.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

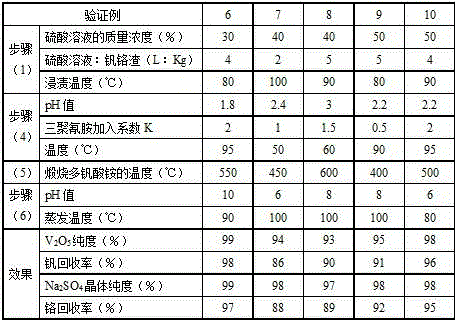

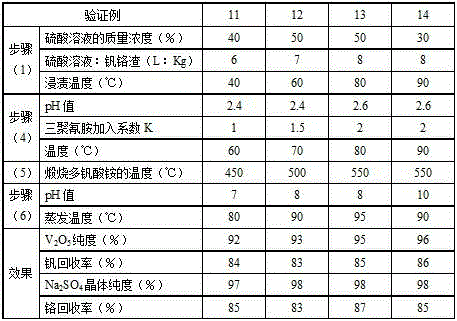

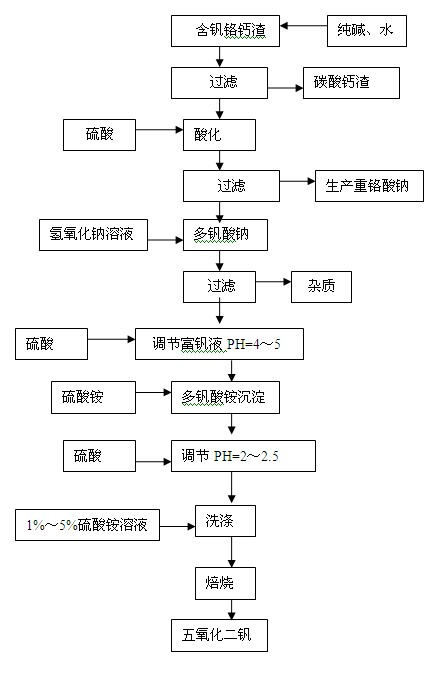

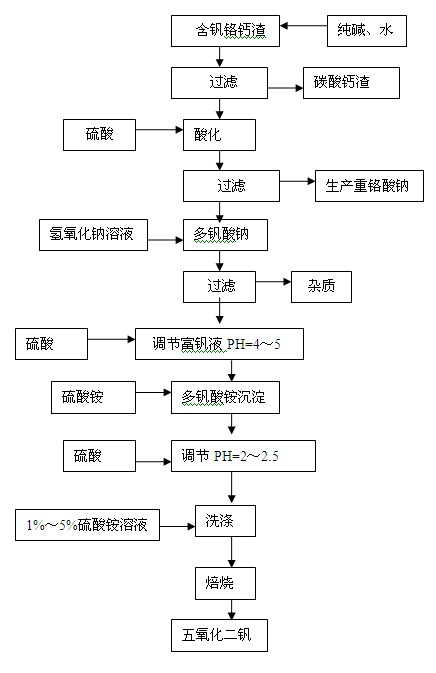

Method for separating and recovering vanadium and chromium from vanadium-chromium slag

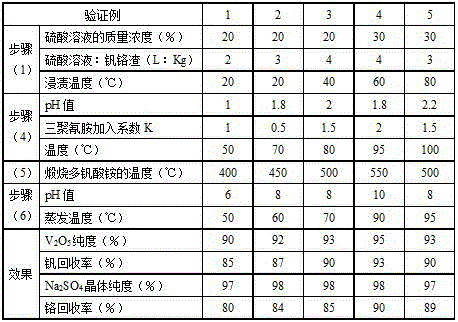

The invention discloses a method for separating and recovering vanadium and chromium from vanadium-chromium slag. The method comprises the following steps: (1) adding the vanadium-chromium slag to a sulfuric acid solution for soaking, and filtering to obtain filter liquor in which vanadium ions and chromium ions are dissolved; (2) precipitating the filter liquor under an alkaline condition to obtain paste in which liquor and solids are mixed; (3) adding an excessive oxidizing agent to the paste in which liquor and solids are mixed to obtain a mixed solution containing high-valence vanadium ions and high-valence chromium ions; (4) adding a vanadium precipitant under an acidic and heating condition to obtain vanadium-containing precipitate and filter liquor; (5) roasting the vanadium-containing precipitate to obtain vanadium pentoxide, cooling and standing the filter liquor to separate out sodium sulfate crystals and separate out filter liquor containing chromium ions; and (6) precipitating the filter liquor containing chromium ions under the alkaline condition, then evaporating the obtained clear liquor to obtain sodium chromate crystals. The method for separating and recovering vanadium and chromium from the vanadium-chromium slag has the advantages of simple technical process, easiness in operation and relatively low equipment investment, the extraction rates of vanadium and chromium are relatively high, and the purity of vanadium pentoxide and the purity of sodium chromate crystals are also relatively high.

Owner:CHONGQING UNIV

Process for preparing chromic oxide by hydrothermal reducing sodium chromate or sodium acid chromate

InactiveCN101456588AHigh reduction conversion rateAchieve recyclingChromium oxides/hydratesSlurryHigh pressure

The invention relates to technology for preparing chromium oxide through hydrothermal reduction of sodium chromate or sodium dichromate, which comprises: preparing the sodium chromate or the sodium dichromate into an aqueous solution, placing the aqueous solution and starch or starch derivatives into a high-pressure reaction kettle for hydrothermal reduction, and obtaining chromic hydroxide slurry; filtering and separating the chromic hydroxide slurry to obtain chromic hydroxide filter cakes and a chromic hydroxide mother solution; and performing high-temperature roasting on the filter cakes to obtain chromium oxide products. The technology has short technological flow, simple operation, low cost and mild reaction conditions, and does not have overhigh requirements on equipment; not only the product quality is better than that of the prior method but also the reduction and conversion rate of sexavalent chromium reaches more than 98 percent; and the whole technology forms a closed cycle, realizes recycling of mixed alkali, the mother solution and a washing liquid, does not discharge pollutant in any form during the whole process, and fundamentally avoids pollution.

Owner:CENT SOUTH UNIV

Molten liquid phase roasting method of chromite

The invention relates to a molten liquid phase roasting method of chromite. The molten liquid phase roasting method comprises the following step of: performing molten liquid phase roasting on a mixture comprising chromite and optional sodium chromate in a horizontal rotary kiln in the presence of oxygen at 350-1,500 DEG C to obtain sodium chromate, wherein the mixture also comprises one or more of soda, sodium bicarbonate, sodium sulfate and sodium hydroxide; the horizontal rotary kiln comprises a kiln body and two end parts at the two ends of the kiln body; the two end parts are provided with a high-position liquid phase outlet and a low-position liquid phase outlet respectively; the kiln body is provided with an oxygen lance and a feed port; the oxygen lance and the feed port are arranged in a stagger way so as not to be on the same cross section of the kiln body; and a smoke outlet which is positioned on the kiln body is arranged between the high-position liquid phase outlet and one of the feed port and the oxygen lance closer to the high-position liquid phase outlet. According to the method, the chromite is in molten liquid phase in a molten salt system, so that the chromium conversion rate is greatly increased, the yield is increased, and the problem of high probability of wall attachment of a calcium-free roasting process is substantially solved.

Owner:SICHUAN YINHE CHEM

Method of preparing chromium oxide using precarbonation wet reducing potassium chromate or sodium chromate

InactiveCN1410356AIncrease acidityImprove the reduction conversion rateChromium trioxideSucrosePotassium

A process for preparing chromium oxide from potassium (or sodium) chromate by the pre-carbonating and wet reduction method includes such steps as preparing the aqueous solution of potassium (or sodium) chromate, pre-carbonating by CO2 gas, reducing by a reducer to obtain the hydrate of chromium oxide, filtering, drying, high-temp. calcining under protection of inertial gas, washing and drying to obtain the alpha-Cr2O3.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Process for roasting chromite resources in ring kiln through pure oxygen by using low-temperature method and harmlessly and deeply utilizing chromium residue

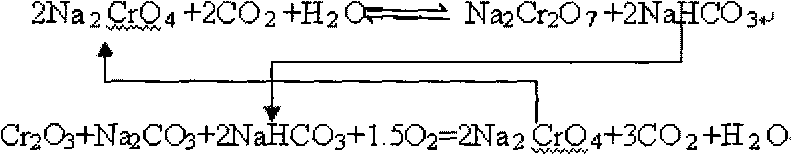

InactiveCN101824530AImprove resource conversion rateMagnesium carbonatesChromium trioxideSodium bicarbonateSlag

The invention belongs to the field of metallurgy and chemical engineering. The process comprises the following steps of: firstly, crushing chromite, adding sodium hydroxide and a catalyst to be oxidized and roasted by using a low-temperature pure oxygen method; diluting, cooling, extracting and filtering to obtain a sodium chromate crystal and ferrum-magnesium slag; adding an alkali washing solution into a sodium hydroxide solution to back extract to obtain the sodium hydroxide solution for recycling; adding water into the sodium chromate crystal and ferrum-magnesium slag to be dissolved and feeding filtrate into a carbonizer to decompose to extract aluminum; carbonizing, evaporating, condensing and crystallizing the extracted solution to obtain sodium chromate; and carbonizing ferrum-magnesium filter slag to generate sodium bicarbonate, reacting to generate a magnesium hydrogen carbonate solution, heating and cracking to generate a magnesium carbonate product and drying a filter cake to obtain ore refined powder; and secondly, crushing chromium residue, adding sodium bicarbonate in the ration of 1:8, adding a catalyst for calcination, cooling and adding water to soak; adding an aluminum hydroxide crystal into supernatant liquid, carbonizing and decomposing to remove aluminum in a reaction tank; filtering and washing an aluminum hydroxide product; adding a reducing agent into the filtrate to reduce hexavalent chromium to generate anhydrous chromium hydroxide and drying and roasting to obtain chromium sesquioxide; and returning the filtrate to a system for mixing after pyrolyzing and extracting to remove magnesium.

Owner:白向南 +2

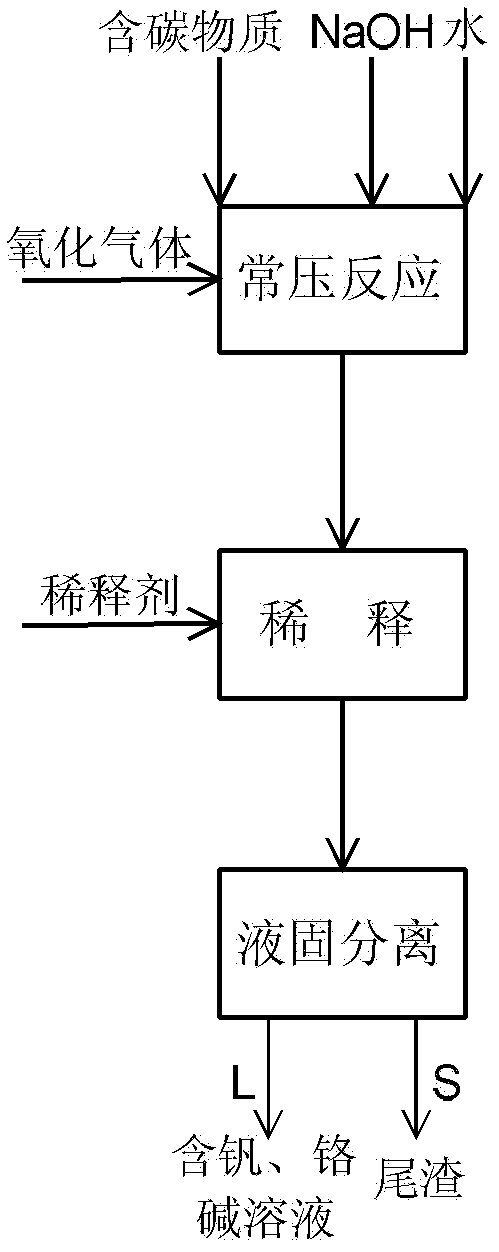

Method for decomposing vanadium slag under normal pressure by adding carbon-containing substance into sodium hydroxide solution

The invention relates to a method for decomposing vanadium slag under normal pressure and extracting vanadium and chromium by adding a carbon-containing substance into a sodium hydroxide solution. The method comprises the following steps of: uniformly mixing the vanadium slag and the carbon-containing substance, and adding the mixture, water and NaOH into a normal pressure reactor; introducing oxidizing gas for oxidization reaction, and diluting reaction slurry obtained by the reaction by using a diluent to obtain mixed slurry containing NaOH, sodium vanadate, sodium chromate, sodium silicate and tailings; and filtering and separating the mixed slurry to obtain the tailings, and an alkaline solution containing the vanadium and the chromium. The operating temperature of the method is below the boiling point of the solution, and the method can be implemented under normal pressure, and is easy to implement and high in safety; and the operating temperature is far lower than the temperature of the traditional vanadium extracting process, the extraction ratio of the vanadium is high, the chromium can be partially extracted synchronously, the total vanadium contained in the tailings is 0.2 to 0.6 weight percent (based on V2O5), and the leaching rate of the chromium is 8-20 percent.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Roasting method for producing sodium chromate using chrome iron ore as raw material

InactiveCN1418823AAvoid scaringSolve the pollution of the environmentChromates/bichromatesBrucitePericlase

The method for preparing sodium chromate by calcining chromite includes the following steps: pulverizing chromite and sieving with 200 mesh sieve, adding sodium carbonate whose added amount is 80-150% of chromite amount, and adding magnesite, baudisserite, periclase, brucite or synthetic magnesium oxide, magnesium hydroxide and magnesium carbonate and calcining them at 1000-1200 deg.c for 10-60 min. under the condition of oxidation atmosphere, then extracting clinker and dissolving sodium chromate so as to obtain the goal of preparing sodium chromate. The conversion rate of chromite can be upto 97-99.5%.

Owner:TIANJIN CHEM RES & DESIGN INST

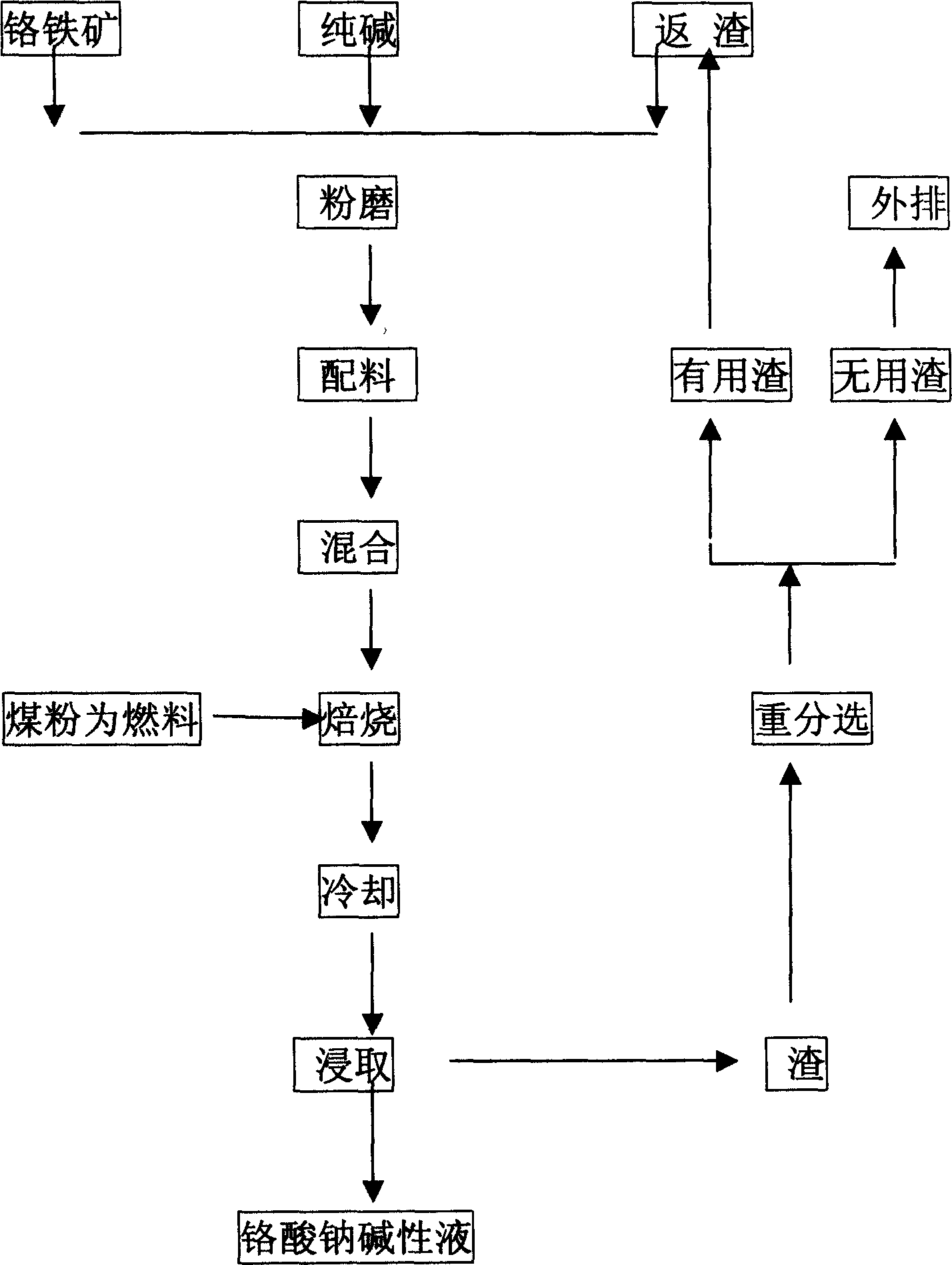

Process for producing sodium chromate by calcium-free calcination

The invention relates to a method to manufacture sodium chromate. It adopts non- calcium roasting technics to realize industrialized production. With chromite, soda and chrome dregs without calcium as charging after mixing evenly, coal dust as fuel, the steps are as follows: coal injection baking in burner, leaching clinker, gravity sorting chrome dregs without calcium and recycling useful dregs as filling. It is the first time that fillings are composed with iron ore, chromite and soda after baking. With shortening technics route and reducing equipment investment, the invention can reduce production cost. Without segregation and adhibiting wall, roasting heat is easy to control.

Owner:TIANJIN CHEM RES & DESIGN INST +1

Method for recycling vanadium pentoxide and sodium dichromate

ActiveCN102021345AEfficient separationRealize comprehensive utilizationSolid waste disposalProcess efficiency improvementProcess engineeringSodium dichromate

Owner:GANSU JINSHI CHEM

Process for preparing sodium dichromate

InactiveCN101693556AReduce Chloride ContentReduce Sulfate LevelsChromates/bichromatesCarbonizationSodium dichromate

The invention provides a process for preparing sodium dichromate, namely producing the sodium dichromate through a carbonization method comprising: converting sodium chromate into the sodium dichromate via carbon dioxide under pressurizing condition; delivering sodium chromate neutral liquor with impurities removed to a carbonization tower after a cascade reaction of more than three continuous towers; obtaining carbonizing liquor by controlling different gradient parameters (concentration and temperature of the carbonizing liquor, partial pressure of the carbon dioxide, carbonizing time and the like), continuously carbonizing and separating under pressure; obtaining sodium dichromate finished products through concentrating, filtering, evaporating, crystallizing and centrifugal dehydrating.

Owner:SICHUAN YINHE CHEM

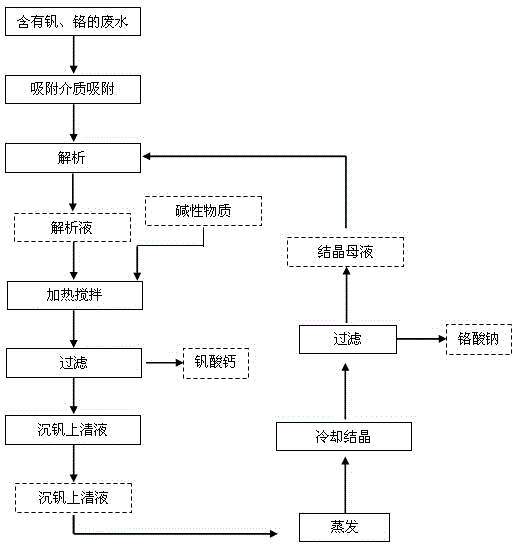

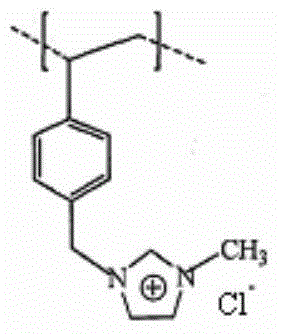

Method for treating waste water containing vanadium and chromium

ActiveCN104556522AHigh adsorption rateEfficient separationMultistage water/sewage treatmentChromates/bichromatesDesorptionWastewater

The invention relates to a method for treating waste water containing vanadium and chromium. The method comprises the following steps of: (1) adsorption: adopting an adsorbing medium to adsorb vanadium and chromium ions in the waste water containing vanadium and chromium; (2) desorption: adding a desorption agent into the adsorbing medium containing vanadium and chromium ions obtained in the step (1) to carry out desorption; (3) vanadium precipitation: adding alkaline substances into desorption solution, stirring to be uniform, and then filtering to obtain a calcium-vanadate product and vanadium-precipitated supernant; (4) chromium crystallization: carrying out evaporating concentration and cooling crystallization on the vanadium-precipitated supernant to obtain a sodium-chromate crude product and crystallizing mother liquor; (5) recrystallization: heating and dissolving the sodium-chromate crude product, and carrying out cooling crystallization to obtain a sodium-chromate product and cooling-crystallizing mother liquor; and (6) returning of the crystallizing mother liquor: returning the crystallizing mother liquor to the step (2) as the ingredient of the analysis solution to be repeatedly utilized. The method has the advantages that the recovery rate for the vanadium and chromium elements in the waste water reaches 99.9% or higher, simultaneously high-purity calcium vanadate and sodium chromate are obtained, and no waste water and waste residue are generated in the whole process.

Owner:HEBEI IRON AND STEEL

Method of separating and recovering sodium vanadate, sodium chromate and sodium carbonate from vanadium slag vanadium extraction liquor

ActiveCN107760868AHigh efficiency of separation and recoveryEasy to separateCarbonate purificationChromates/bichromatesSlagWastewater

The invention relates to a method of separating and recovering sodium vanadate, sodium chromate and sodium carbonate from vanadium slag vanadium extraction liquor. The method is characterized by comprising the following steps: firstly, separating and recovering vanadium in the vanadium slag vanadium extraction liquor by means of a calcium salt precipitation method; then concentrating and enrichingsodium vanadate and sodium carbonate in molybdenum precipitation post liquor by means of an electrodialysis process; returning fresh water obtained by electrodialysis to vanadium slag for a sodium modification and cinder roasting leaching step for recycled use; and separating and recovering sodium vanadate and sodium carbonate in strong water by means of a circular concentration-crystallization method. The method provided by the invention has the advantages of being good in separating effect of sodium vanadate, sodium chromate and sodium carbonate, simple in process, simple to operate, free of waste water and residual slag, environment-friendly and the like, and is suitable for industrialized application of vanadium slag vanadium extraction.

Owner:CENT SOUTH UNIV

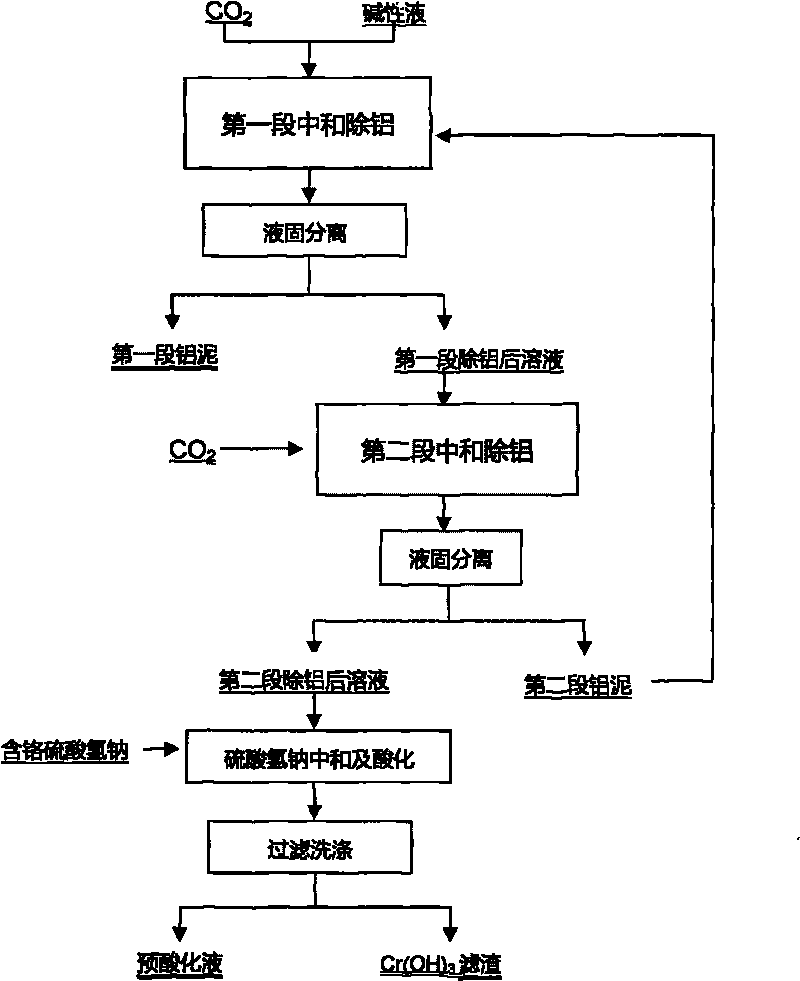

Neutralization aluminum removing method for sodium chromate alkali solution

InactiveCN101723461ACoarse particlesReduce moisture contentChromates/bichromatesHydrogen SulfateAluminium hydroxide

The invention relates to a neutralization aluminum removing method for a sodium chromate alkali solution. The carbon dioxide is used as a neutralizer for the neutralization aluminum removal of the sodium chromate alkali solution, and a two-section neutralization method is adopted; in the first section, a neutralization pH value is controlled so that most of aluminum in the alkali solution forms and separate aluminium hydroxide sediment with thick and big particles; in the second section, the residual aluminum in the solution is completely neutralized and precipitated by continuously using the carbon dioxide, and the aluminum sediment precipitated in the second section is returned to the first section; the solution after the neutralization aluminum removal by the carbon dioxide is neutralized and acidized by a by-product chromium-contained sodium hydrogen sulfate in the production process of chromium salt, the chromium-contained sodium hydrogen sulfate is comprehensively utilized, and the trivalent chromium is recycled. The invention has the advantages of easy separation and washing of aluminum mud, low water content, low chromium band loss, easy comprehensive utilization, and the like.

Owner:CENT SOUTH UNIV

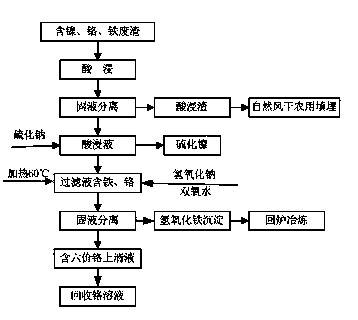

Processing method for recovering nickel, chromium and iron from stainless steel factory waste residue

ActiveCN104098148AHigh recovery rateEasy to separateIron oxides/hydroxidesChromates/bichromatesFerric hydroxideNickel sulfide

The invention discloses a processing method for recovering nickel, chromium and iron from stainless steel factory waste residue. The method is as below: adding mixed acid into the stainless steel factory waste residue, leaching out nickel, chromium and iron in the waste residue, and filtering to separate a pickle liquor and leaching residue; adding sodium sulfide to the pickle liquor under normal temperature, and after reaction conducting solid-liquid separation to obtain nickel sulfide and a filtrate; heating the filtrate, and adding a sodium hydroxide solution and a hydrogen peroxide solution; converting trivalent chromium into hexavalent chromium to stay in the supernatant by an alkali leaching oxidation method, and converting trivalent iron into a ferric hydroxide precipitate, conducting solid-liquid separation to obtain a sodium chromate solution; and recovering the chromium, smelting down the ferric hydroxide precipitate for smelting utilization, and subjecting the acid leaching residue to natural air drying for agricultural landfill. The whole process of the invention does not produce contaminants, and realizes complete recovery and utilization of resources; and the process is simple, easy to operate and low in cost, can effectively solve the problem of waste residue pollution in the production of stainless steel, and has high economic benefit and environmental benefit.

Owner:江苏森力威冶金设备有限公司

Method for preparing sodium chromate by mixing chromite and ferrochrome and device for method

The invention discloses a method for preparing sodium chromate by mixing chromite and ferrochrome and a device for the method. The method comprises the following steps: measuring and mixing chromite and ferrochrome with sodium carbonate, sodium nitrate and sodium peroxide; pelleting the mixture with extracted liquid sodium chromate in a pelletizer; drying in a drier; returning part of the clinker to a flame kiln after the material is dried and cooled, so that chromite and ferrochrome are decomposed and oxidized in the form of fused liquid phase in molten salts so as to obtain the clinker of sodium chromate; and continuously soaking, filtering and cleaning after the clinker is cooled so that a chromium chemical primary product of liquid sodium chromate is obtained, wherein the flame kiln comprises a U-shaped kiln body, a partition wall and a low-position molten salt suction port, wherein the partition wall and the low-position molten salt suction port are arranged in the U-shaped kiln body; one or more blowing oxygen lances and one or more charging holes are arranged at the top of the kiln body, and a smoke outlet is arranged on the upper side of the kiln; and one or more oxygen lances are arranged at the bottom of the kiln. According to the method disclosed by the invention, the oxidation rate is as high as 98%, the clinker extraction rate is as high as 99.97%, and the chromium yield is 97.96%.

Owner:HUBEI POLYTECHNIC UNIV

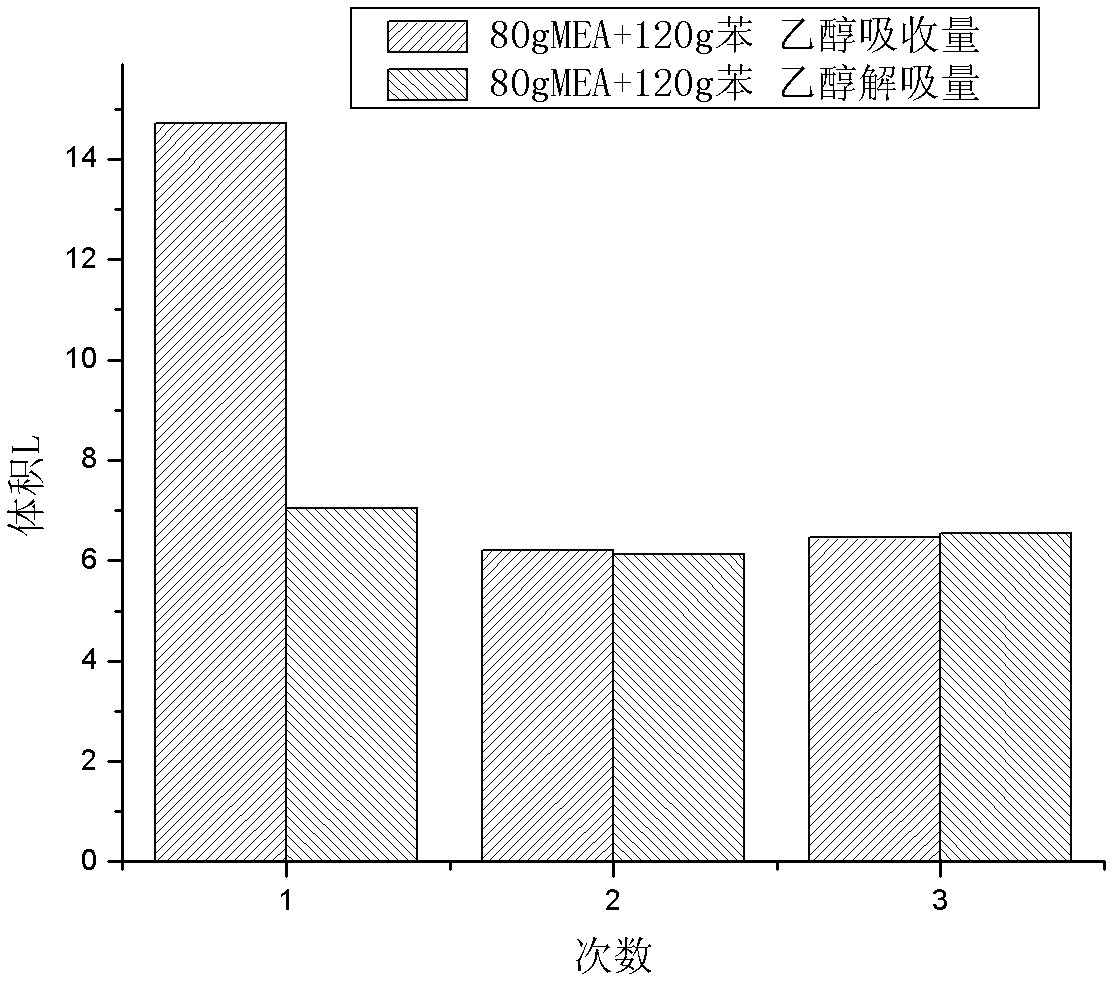

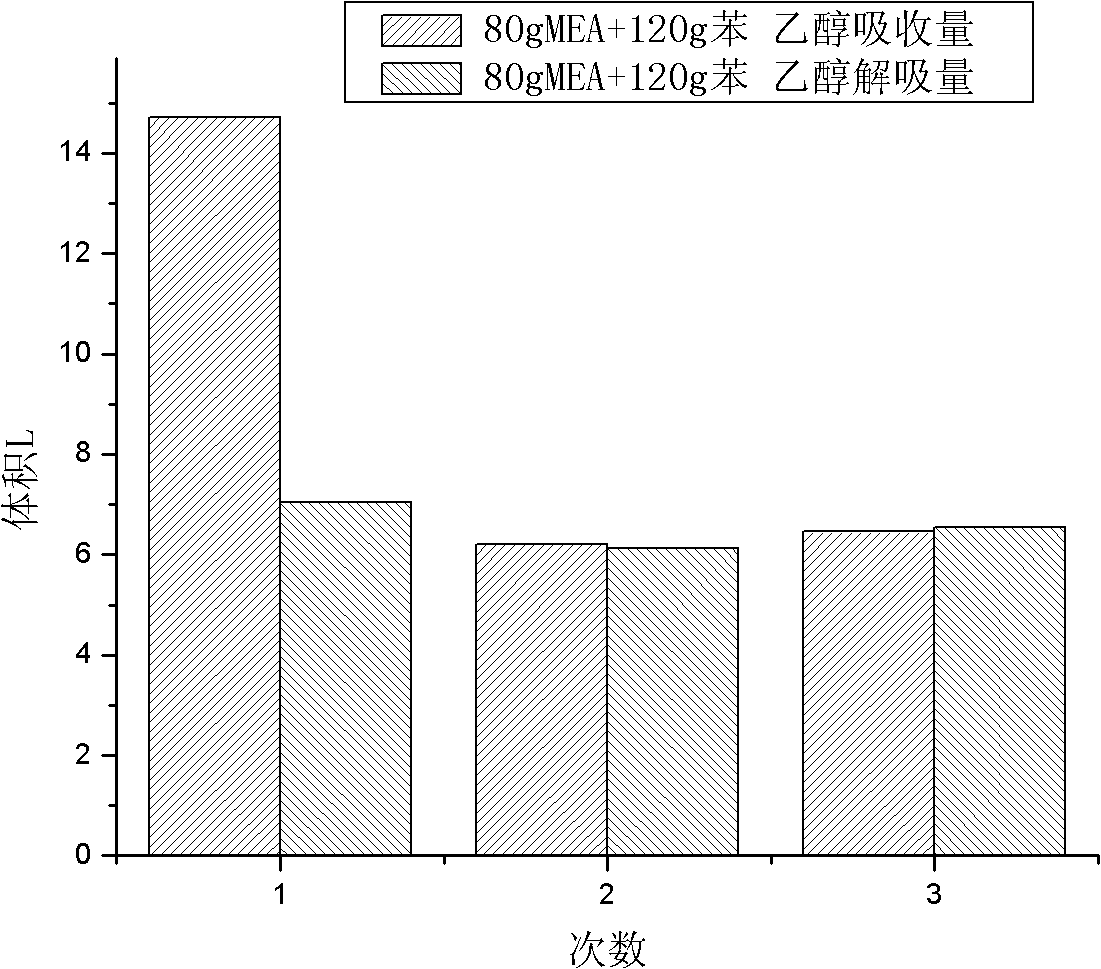

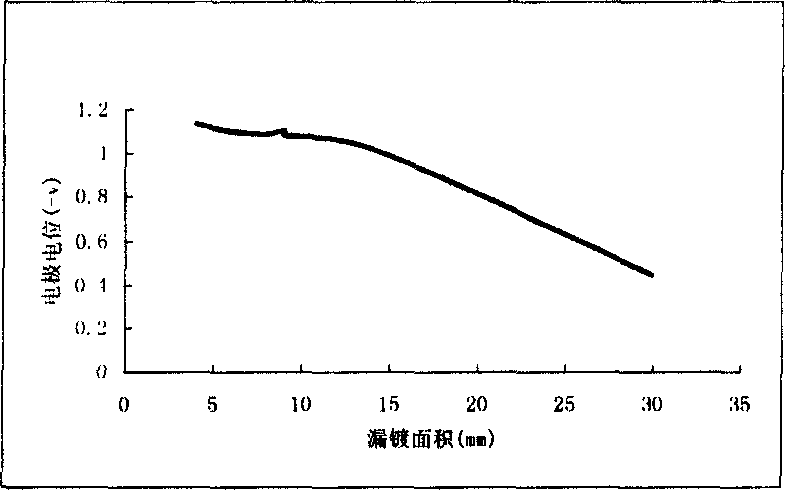

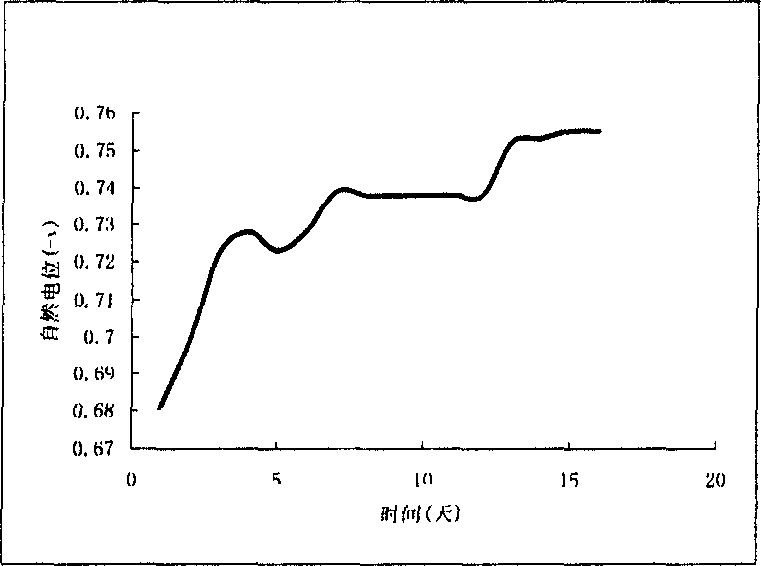

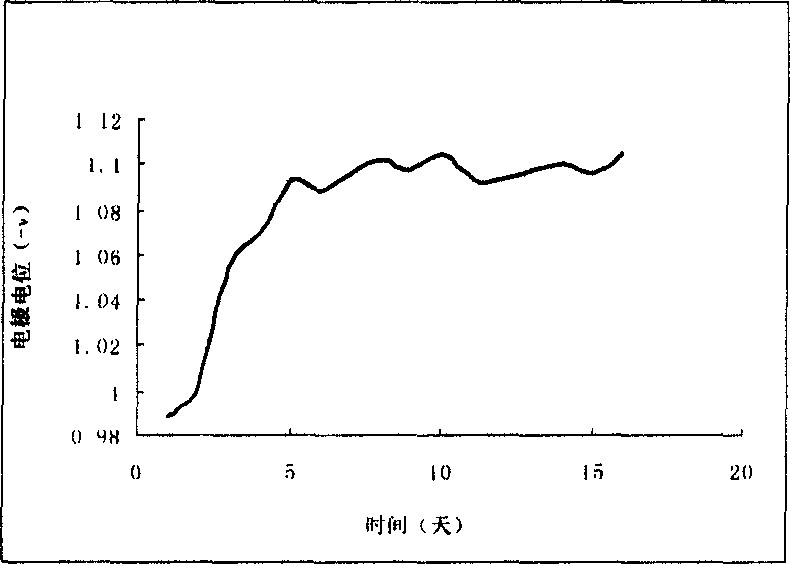

A method for capturing carbon dioxide in mixed gas with composite decarburization solution

InactiveCN102284227APromote absorptionIncrease desorptionCarbon compoundsDispersed particle separationAbsorption capacityChemical reaction

The invention relates to a composite decarburization solution for capturing carbon dioxide in mixed gas, belonging to the technical field of carbon dioxide gas capture. It relates to a composite decarburization solution, which is composed of solvent benzyl alcohol, phenyl alcohol, N-methylpyrrolidone or a mixture thereof, main absorption component MEA, auxiliary absorption components EDA, DETA and TETA, active components PZ and 2, 3-butanedione, the corrosion inhibitor is sodium chromate, and the antioxidant is sodium metavanadate and copper carbonate. Since the composite decarburization liquid uses a mixed solvent, it not only improves the absorption capacity, purification degree and desorption rate of carbon dioxide, expands the reaction temperature range, but also reduces the volume of the desorption tower, greatly reduces regeneration energy consumption, and reduces equipment investment and operating costs. The invention is mainly used for capturing carbon dioxide in various chemical reaction tail gas, ore decomposition gas, combustion flue gas, natural gas, city gas and biogas, and has broad application prospects.

Owner:DALIAN UNIV OF TECH

Corrosion prevention technique of aluminum zinc rare earth alloying for oil pipe

InactiveCN1563471AHigh hardnessImprove corrosion resistanceHot-dipping/immersion processesCorrosion preventionRare earthZinc

This invention relates to ZnAl rare earth alloy antiseptic technology mainly solving the problem of poor antiseptic results of current or / tubs characterizing including the following steps: the inside and outside wall surfaces of the oil tube are de-fat, washed, washed with acid and processed with coating aid to be put into a Zn solution tank containing liquid ZnAl rare earth alloy under 430deg.C-440deg.C to be coated and taken out to be passivated with heavy sodium chromate and HNo3 and washed, said liquid alloy applies alloying method in smelting.

Owner:DAQING OILFIELD CO LTD

Method for producing sodium chromate by roasting chromium ore and small amount of soda

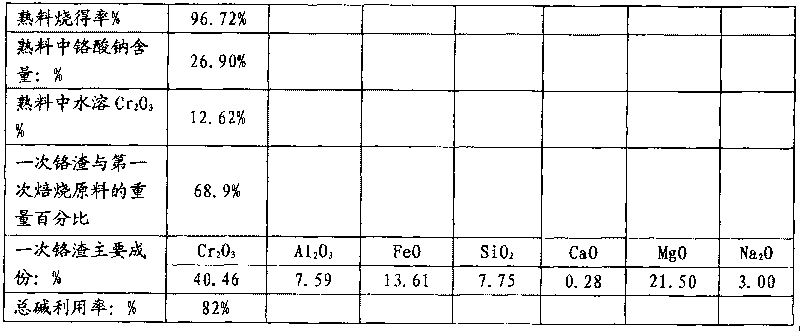

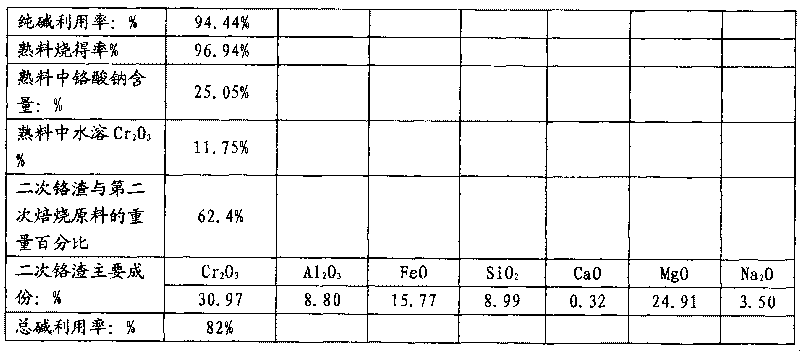

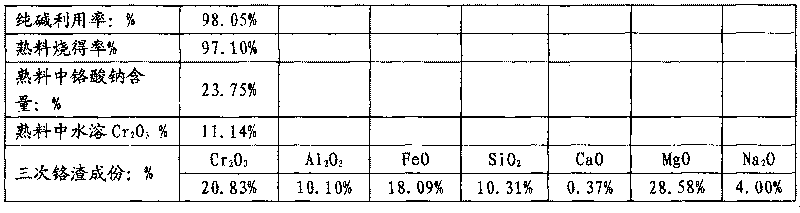

The invention discloses a method for producing sodium chromate by roasting chromium ore and a small amount of soda. The method is characterized in that chromium ore and calcined soda are mixed, wherein the added quantity of the calcined soda is 35% to 45% of theoretical required amount for complete reaction with dichromium trioxide in the chromium ore; then the mixture is added to a rotary kiln for first roasting, the temperature of materials at a hot space in the kiln is 1000 DEG C to 1050 DEG C, wrought materials are cooled and leached to obtain a sodium chromate leaching solution and first chromium dregs; the first chromium dregs are dried and crashed for second roasting with newly added calcined soda, the use amount of the calcined soda is 30% to 50% of theoretical required amount for complete reaction with the dichromium trioxide in the first chromium dregs; the sodium chromate leaching solution and second chromium dregs can be obtained through roasting and leaching processes, the second chromium dregs, limestone and newly added calcined soda are roasted for the third time, the use amount of the calcined soda in the third roasting is 35% to 75% of theoretical required amount for complete reaction with the dichromium trioxide in the second chromium dregs, and the use amount of the limestone is 2% to 5% of the sum of weight of three raw materials of the second chromium dregs, the calcined soda and the limestone; and the sodium chromate leaching solution and third chromium dregs are obtained after leaching. By adopting method of the invention, the utility ratio of the calcined soda is also enhanced greatly.

Owner:XINJIANG SING HORN GRP CO LTD

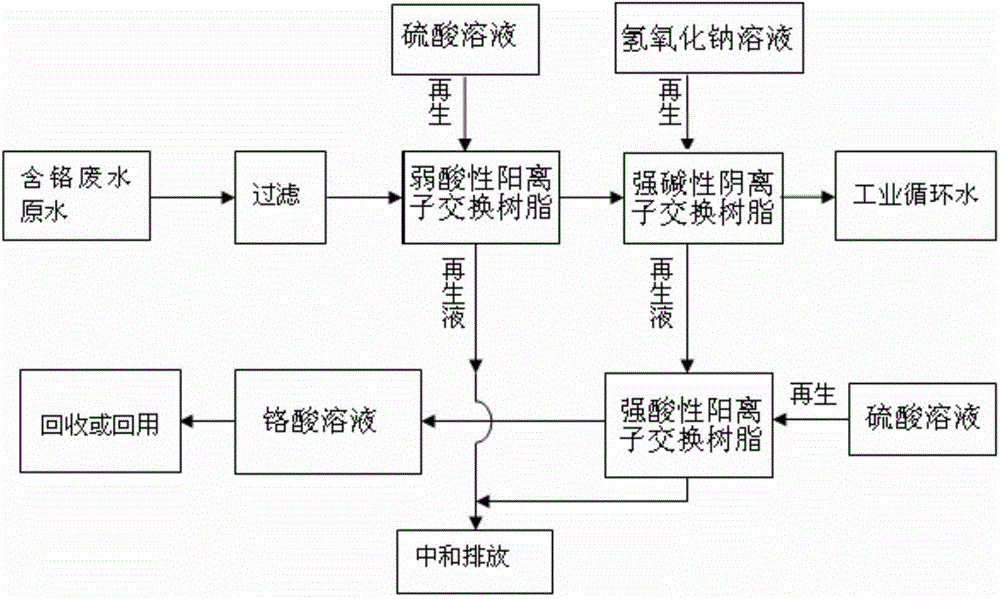

Chromium-containing wastewater treatment method capable of realizing zero emission of pollutants

ActiveCN104355365AResolve Total ChromiumSolve Cr <sup>6+<</sup> Water contaminantsTreatment involving filtrationIon exchangeIon-exchange resin

The invention discloses a chromium-containing wastewater treatment method capable of realizing zero emission of pollutants. The method comprises the following steps: adjusting the pH value of filtered chromium-containing wastewater to 8-11, adsorbing substances except chromium in the chromium-containing wastewater through weak-acidity cation exchange resin, enabling chromium ions in the wastewater to be converted to hexavalent chromium, eluting resin for regenerating, and neutralizing and then discharging regenerated liquid; adjusting the pH value to 8-11, performing ion exchange through strong-alkalinity anion exchange resin, adsorbing chromium ions in the wastewater, and eluting the resin through a sodium hydroxide solution so as to obtain a sodium chromate solution; performing sodium removal through strong-acidity cation exchange resin so as to obtain a chromic acid solution; neutralizing and discharging regenerated liquid after the resin is eluted for regenerating. The treatment method is simple and easy to control, no secondary pollution in the treatment process is generated, and meanwhile, cleaning production is realized; the discharged water is the chromic acid solution and can be recycled, so that recycling application is realized, and zero emission of wastewater and pollutants is realized; the recycle treatment and running cost and the investment cost are reduced greatly.

Owner:武汉武钢绿色城市技术发展有限公司

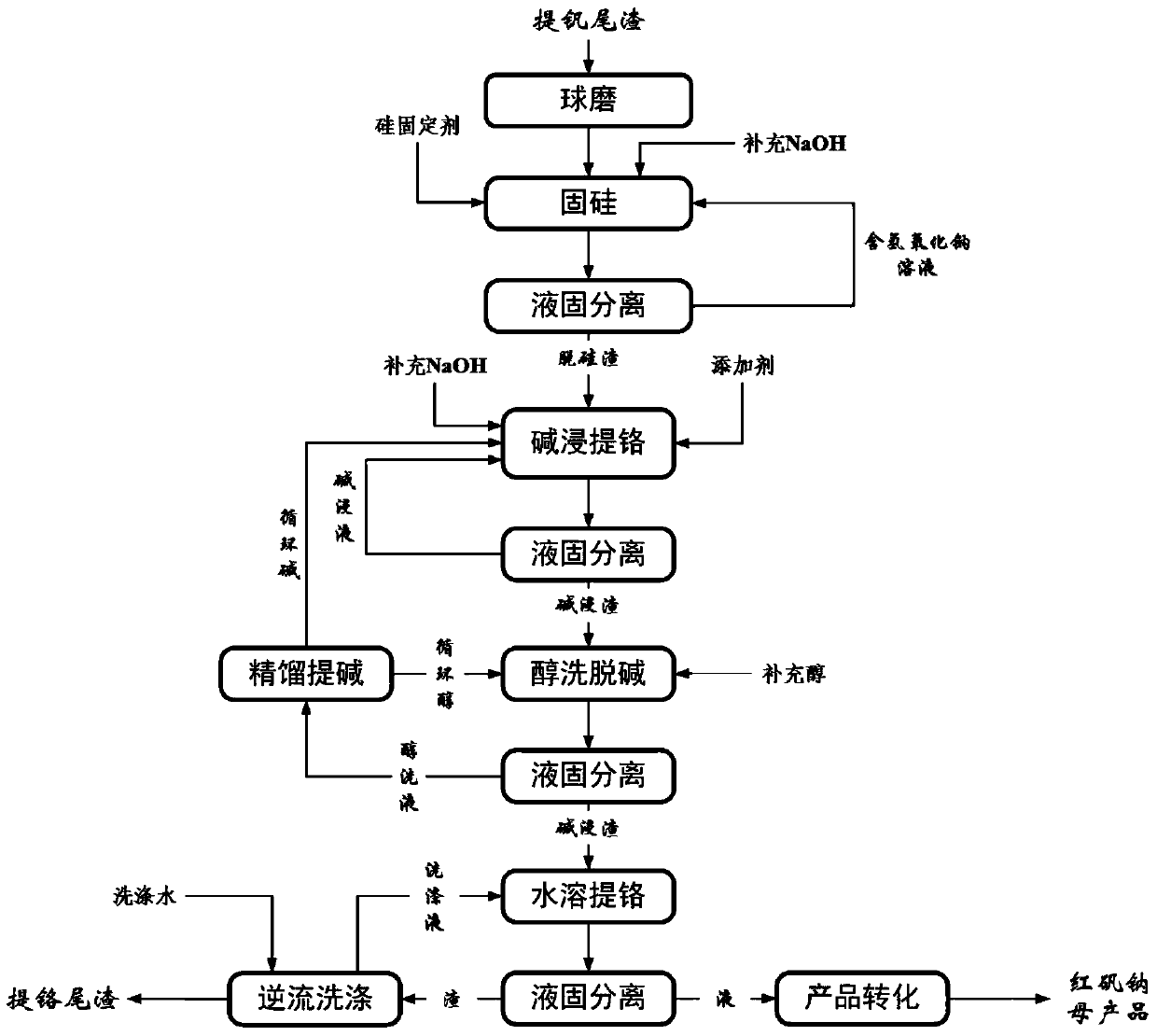

Clean process method for efficiently extracting chromium in extracted vanadium tailings

ActiveCN104195346AFor subsequent useImprove resource utilizationProcess efficiency improvementSiliconMaterials science

The invention discloses a clean process method for efficiently extracting chromium in extracted vanadium tailings. For the extracted vanadium tailings, a silicon fixing agent is added while silicon is leached with low-concentration sodium hydroxide; the silicon is converted into an inert compound in the alkaline leaching and chromium extracting process; the inert compound is subjected to alkaline leaching and chromium extracting to obtain sodium chromate alkali solution with lower silicon content and iron-enriched tailings, so that high-efficiency extraction of the chromium in the extracted vanadium tailings and comprehensive utilization of valuable components are realized. According to the clean process method disclosed by the invention, the high-efficiency extraction of the chromium in the extracted vanadium tailings can be realized, the extraction rate of the chromium is larger than 85 percent, and the content of the silicon in the obtained sodium chromate alkali solution is lower.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

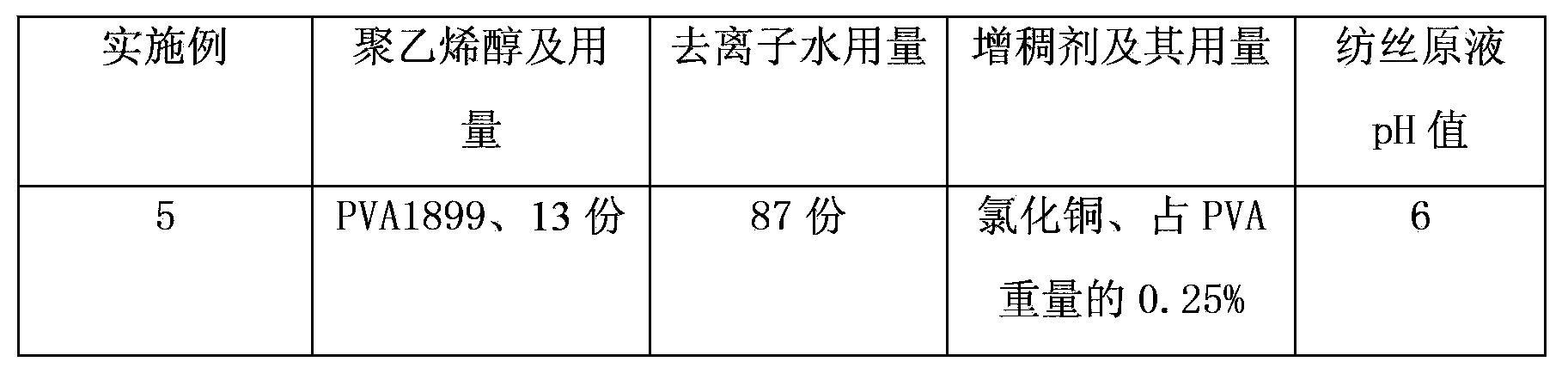

Fine-denier or superfine-denier polyvinyl alcohol fiber and preparation method thereof

ActiveCN103388189AImprove spinnabilityReduce the amount addedArtificial filament heat treatmentMonocomponent synthetic polymer artificial filamentFiberCopper nitrate

A preparation method of a fine-denier or superfine-denier polyvinyl alcohol fiber comprises the following steps: dissolving 10-15 parts of polyvinyl alcohol in 85-90 parts of deionized water at 95-98DEG C for 2-5h to form a homogeneous solution, adding a thickening agent having a weight being 0.1-2% of the weight of polyvinyl alcohol, adjusting the pH value of the homogeneous solution to 3-6.5 through using acetic acid, and allowing the viscosity of the homogeneous solution to 5000-30000cp in order to prepare a polyvinyl alcohol spinning stock solution, wherein the thickening agent comprises anyone of boric acid, borax, copper sulfate, copper chloride, copper nitrate, sodium chromate, potassium chromate and titanium sulfate; moulding the spinning stock solution to obtain a nascent fiber; and post-processing the nascent fiber to prepare the polyvinyl alcohol fiber. The low-concentration polyvinyl alcohol spinning stock solution has the advantages of good spinnability, good storage stability, stable and continuous spinning process, and relatively few phenomena of broken filaments; and the yield is above 95%. The obtained fiber has a low linear density in a range of 0.16-1.00dtex, a tensile strength of 5-8cN / dtex and an elongation at break of 5-15%, and the Rp value of the obtained formalized fiber is 110-125DEG C.

Owner:CHINA PETROCHEMICAL CORP +2

Process for producing sodium chromate from chromite through dissolution in acid and oxidization

The invention discloses a process for producing sodium chromate from chromite through dissolution in an acid and oxidization. The chromite is dissolved in an acid and thus oxidized into hexavalent chromium; and then the hexavalent chromium is extracted from the mixed solution to obtain the sodium chromate product, and meanwhile other chemical material components in the chromite can be extracted and prepared into a series of chemical products. The whole process flow has no slag discharged and causes no secondary pollution; and the whole process is clean, energy-saving and environment-friendly, so that the economic benefit and social benefit of an enterprise can be greatly improved.

Owner:唐翔

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com