Molten liquid phase roasting method of chromite

A technology of chromite and molten liquid, which is applied in the field of molten liquid phase roasting of chromite, which can solve the problems of high impurity content, high free alkali and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] ① According to the molar ratio of chromite (calculated as dichromium oxide): soda ash: sodium bicarbonate = 1: 0.8: 4, prepare powdered raw meal, mix evenly, extrude and granulate to obtain granular raw meal;

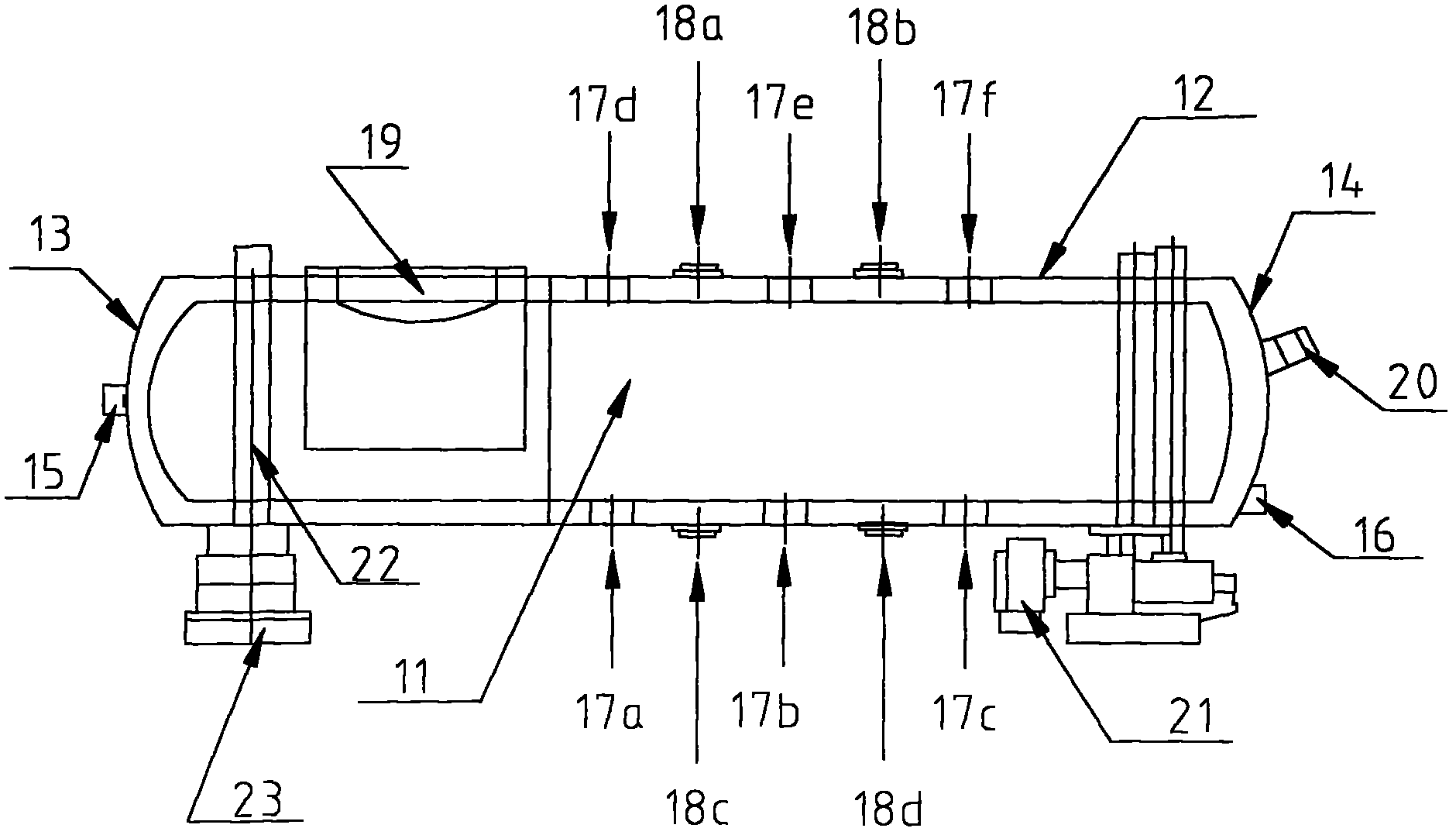

[0071] ②Put the granular raw meal into the cylindrical horizontal rotary kiln through the feeding port 18a-18b, start the burner, control the reaction temperature to 1150°C, and keep it at this temperature for 30 minutes;

[0072] ③ Then, continuously inject air into the horizontal rotary kiln through oxygen lances 17a-17c, and react at 1150°C for 2 hours, during which the reaction mixture is in a molten liquid phase; and

[0073] ④The gas generated in the horizontal rotary kiln is removed from the flue gas outlet, and the liquid phase clinker is removed through the high-level liquid phase outlet, leached with water, and filtered to obtain sodium chromate alkaline liquid and iron slag. The measured chrome ore conversion rate (that is, the percentage of chromium i...

Embodiment 2

[0075] ① According to the molar ratio of chromite (calculated as dichromium trioxide): soda ash: sodium chromate=1: 2: 1.2, prepare powdered raw meal, mix evenly, extrude and granulate to obtain granular raw meal;

[0076] ②Put the granular raw meal into the cylindrical horizontal rotary kiln through the feeding port 18a-18b, start the burner, control the reaction temperature to 950°C, and keep it at this temperature for 30 minutes;

[0077] ③ Then, continuously spray oxygen-enriched air with an oxygen volume concentration of 65% into the horizontal rotary kiln through oxygen lances 17a-17c, and react at 950°C for 4.5h, during which the reaction mixture is in a molten liquid phase; and

[0078] ④The gas generated in the horizontal rotary kiln is removed from the flue gas outlet, and the liquid phase clinker is removed through the high-level liquid phase outlet, leached with water, and filtered to obtain sodium chromate alkaline liquid and iron slag. It is determined that the c...

Embodiment 3

[0080] ① According to the molar ratio of chromite (in terms of chromium trioxide): soda ash: sodium hydroxide = 1: 8: 0.5, prepare powdered raw meal, mix evenly, extrude and granulate to obtain granular raw meal;

[0081] ②Put the granular raw meal into the cylindrical horizontal rotary kiln through the feeding port 18a-18b, start the burner, control the reaction temperature to 520°C, and keep it at this temperature for 40 minutes;

[0082] ③ Then, continuously spray oxygen-enriched air with an oxygen volume concentration of 65% into the horizontal rotary kiln through oxygen lances 17a-17c, and react at 520°C for 0.8h, during which the reaction mixture is in a molten liquid phase; and

[0083] ④ The gas generated in the horizontal rotary kiln is removed from the flue gas outlet, and the molten liquid phase clinker is removed through the high-level liquid phase outlet, leached with water, and filtered to obtain sodium chromate alkaline liquid and iron slag. It is determined tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com