Patents

Literature

34 results about "Calcium chromate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Calcium chromate (CaCrO₄) is a bright yellow solid. It normally occurs as the dihydrate, although the very rarely natural (mineral) form, known as chromatite, is anhydrous. Very toxic.

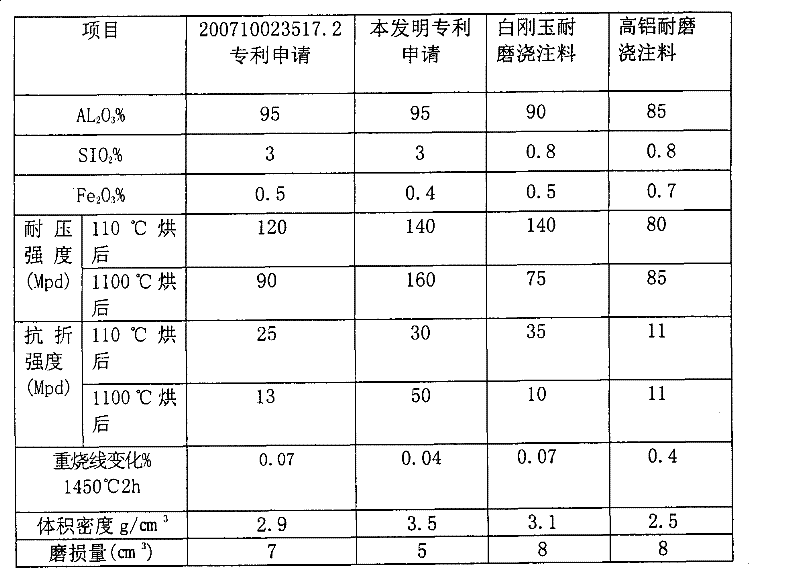

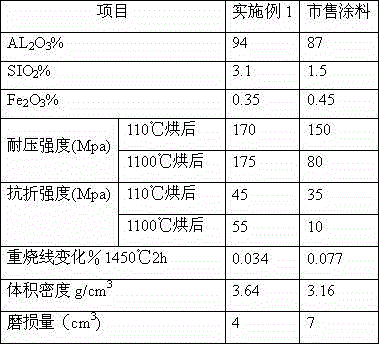

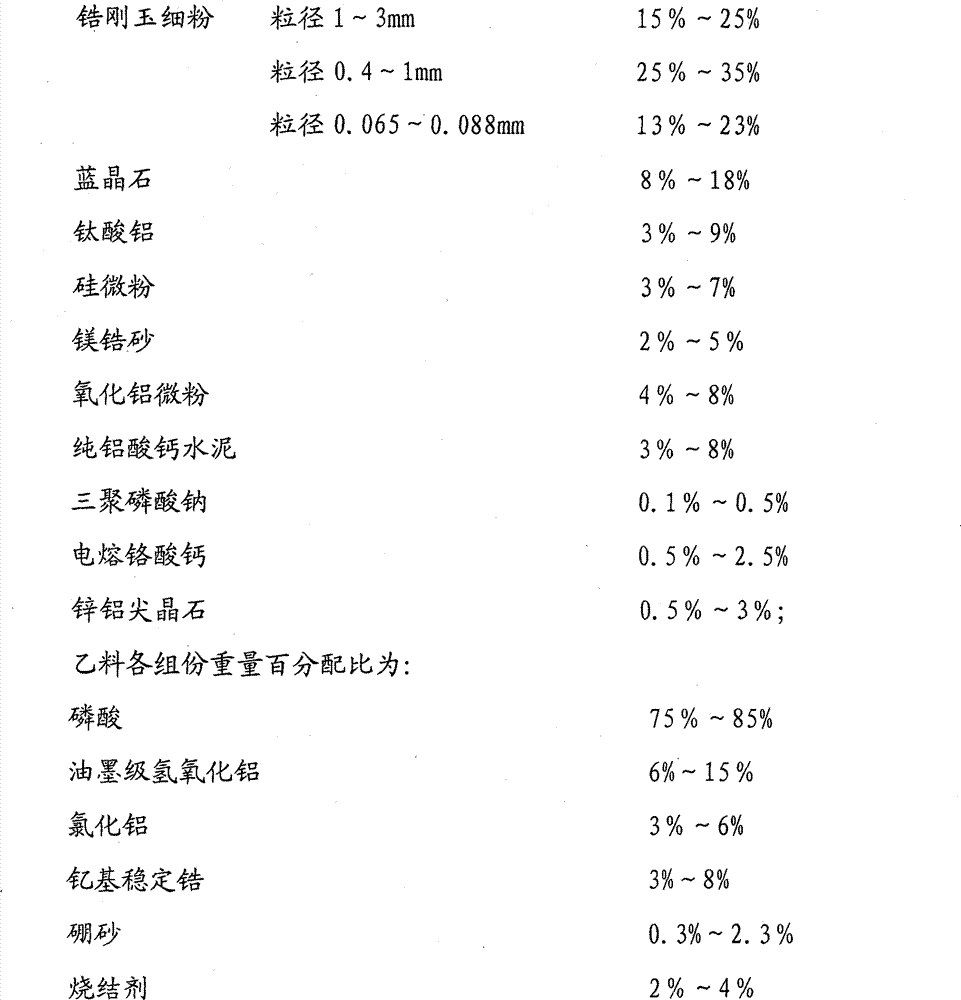

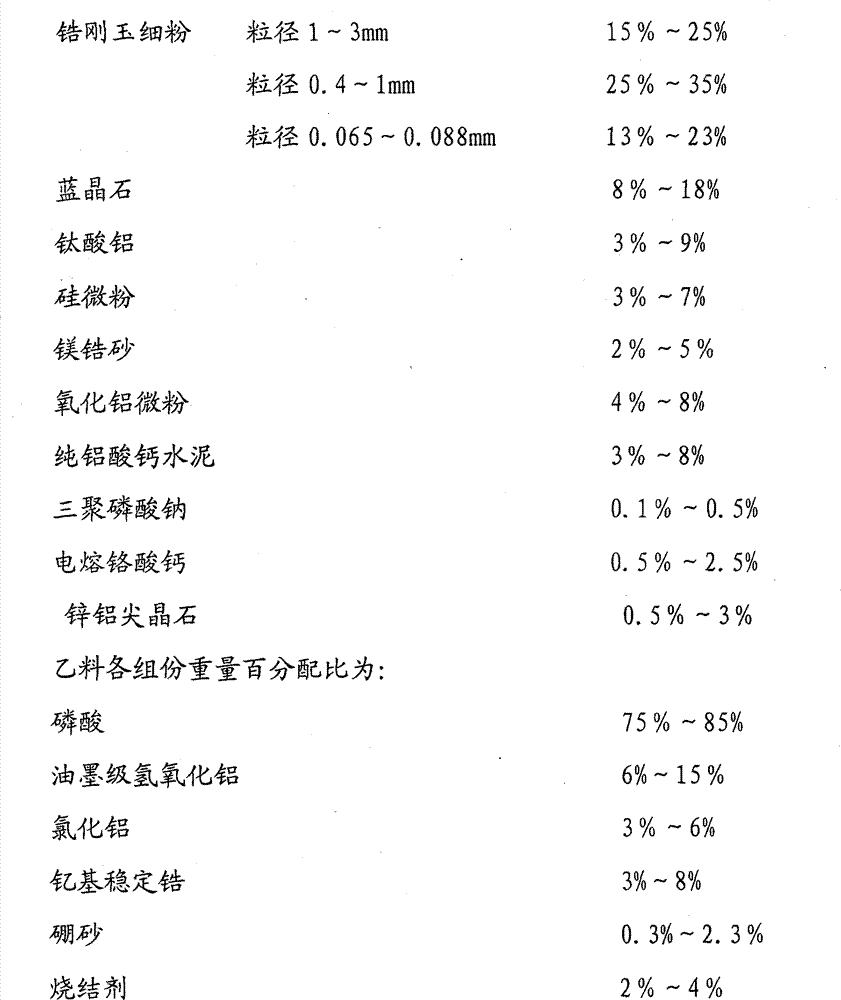

High-temperature wear-resistant repairing coating and preparation method thereof

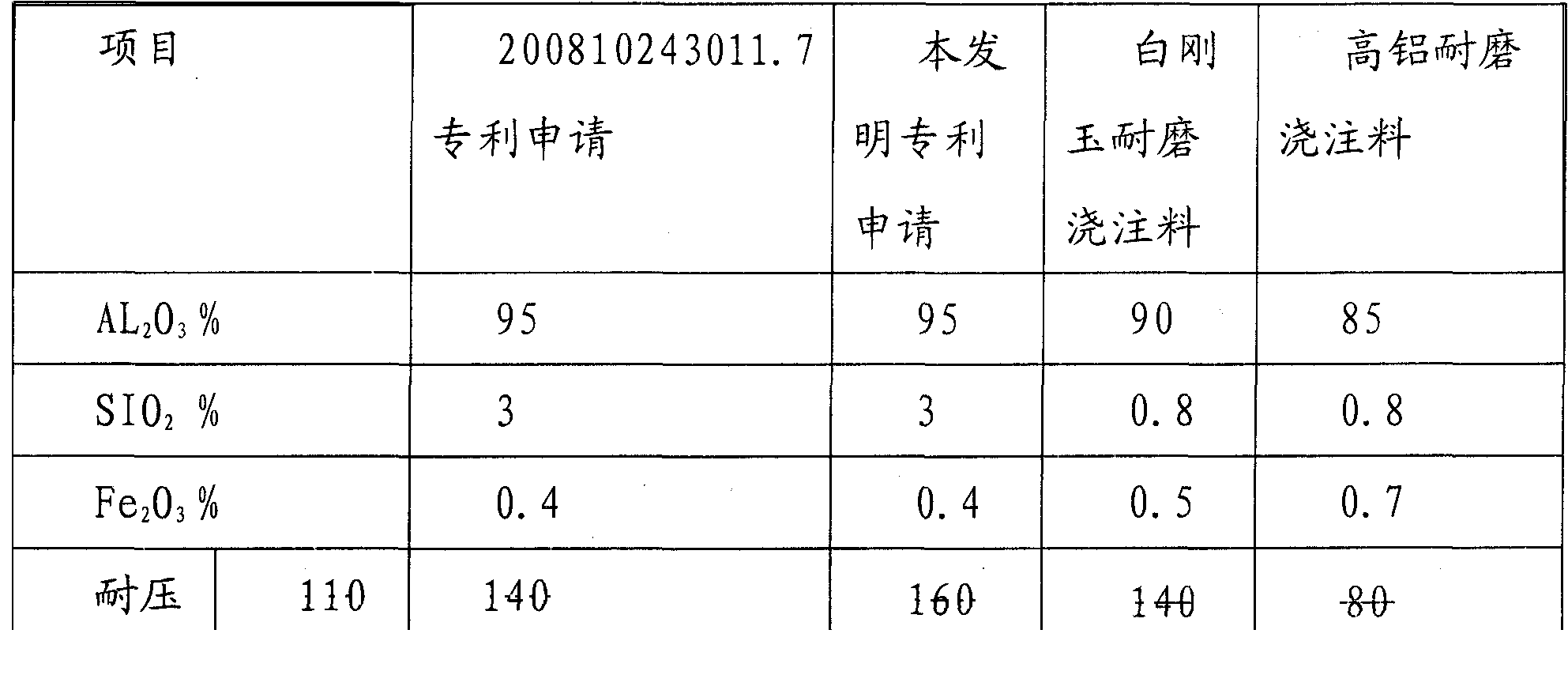

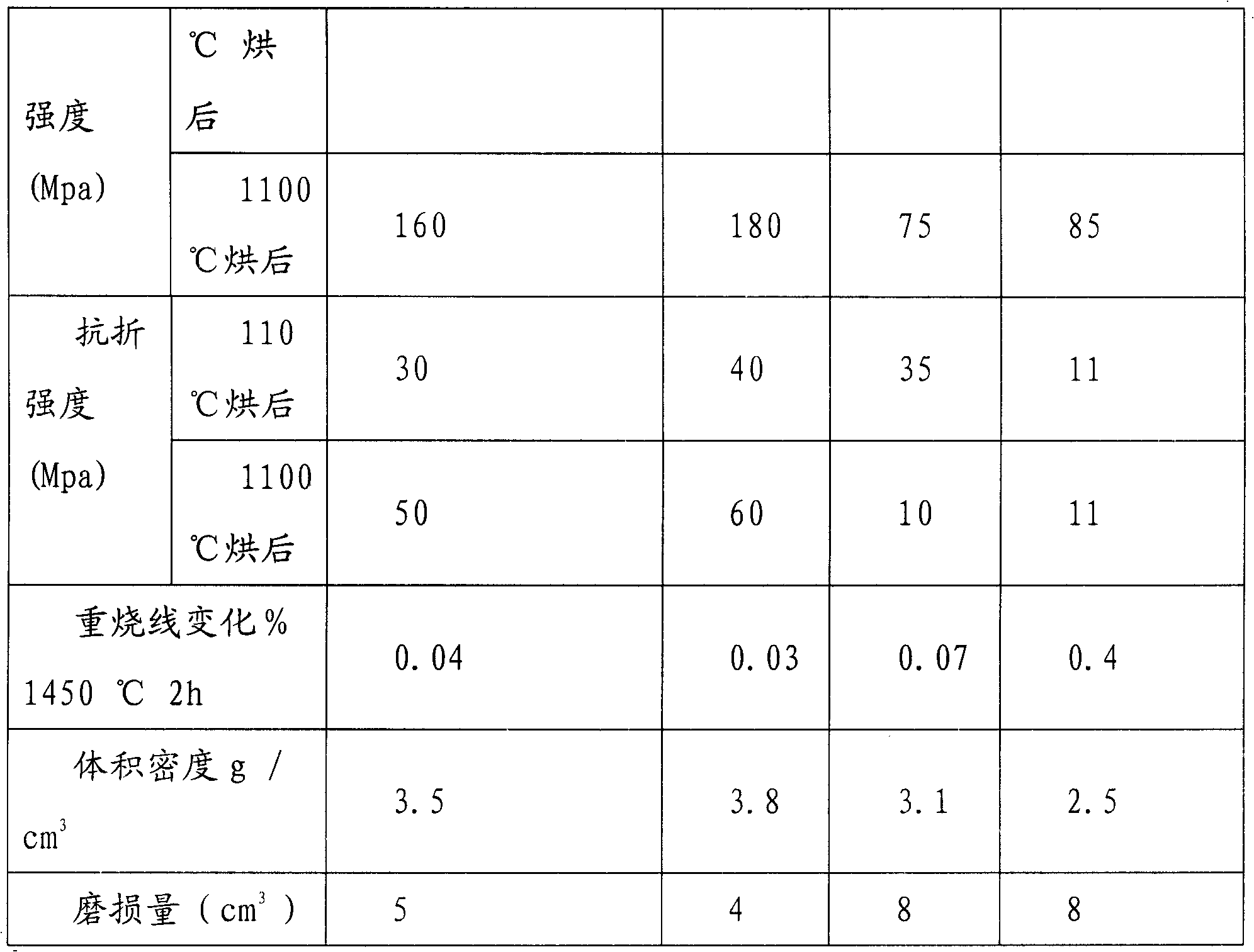

ActiveCN102134164AHigh compressive strengthHigh densityFireproof paintsSpecial surfacesWear resistantZircon

The invention relates to a high-temperature wear-resistant repairing coating and a preparation method thereof, and the coating comprises a material A and a material B with a weight ratio of 70-85:30-15, wherein the material A is prepared by zirconia corundum fine powder, kyanite, aluminium titanates, silicon micropowder, magnesium zircon sand, alumina micropowder, pure calcium aluminate cement, sodium tripolyphosphate, fused calcium chromate, and zinc aluminate gahnite; and the B material is prepared by phosphoric acid, ink-grade aluminium hydroxide, aluminium chloride, yttrium-stabilized zirconium, borax, and a medium-temperature agglutinant. The product has excellent wear resistance, corrosion resistance, erosion resistance, thermal shock stability, and a high caking property; using the product, the running period of a circulating fluidized bed boiler is increased from about 3500 hours to over 18000 hours for accumulating running time; the problem that the boiler liner needs to be repaired and replaced frequently is overcome; human and material resources are saved; and the production efficiency is greatly improved.

Owner:YIXING GUOQIANG FURNACE IND

High temperature abrasion-proof paint and method for producing the same

The invention relates to a 318 high-temperature wear-resistant coating and a preparation method thereof, in particular to a rapid repair material for repairing various abrasive bricks and wear-resistant casting damage positions in circulating fluidized bed boilers of fuel electric plants. At the same time, the invention provides a method for producing the high-temperature wear-resistant coating, and belongs to the technical field of refractory material. The rapid repair material consists of a material A and a material B according to the weight portion proportion of 70-85 to 30-15, wherein the material A is prepared by zircon corundum, fine corundum powder, cyanite, yttrium-stabilized zirconium, silicon micropowder, alumina micropowder, pure calcium aluminate cement, trimeric sodium phosphate, and fused calcium chromate; and the material B is prepared by phosphorous acid, ink grade aluminum hydroxide, zirconia ultrafine powder, yttrium-stabilized zirconium, and fused calcium chromate.

Owner:YIXING GUOQIANG FURNACE IND

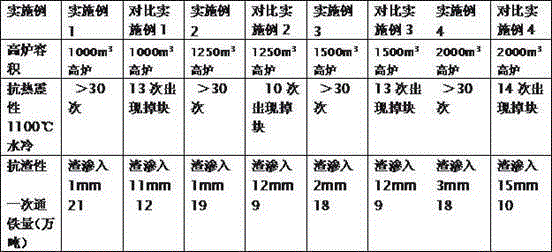

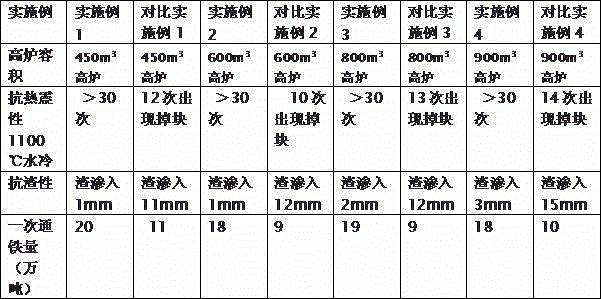

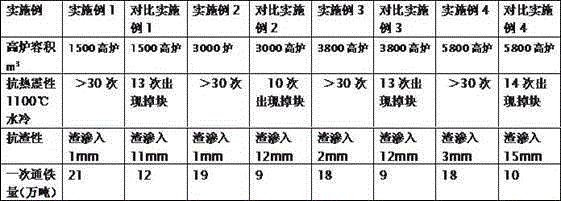

Large blast furnace main iron runner castable

InactiveCN105152669AImprove corrosion resistanceImprove thermal shock resistanceChromium nitrideThermal shock

The invention relates to a large blast furnace main iron runner castable, and belongs to the field of refractory castables. The large blast furnace main iron runner castable is prepared from, by weight, 5-8 parts of 8-5 mm chromium nitride, 15-20 parts of 5-3 mm chromium nitride, 10-15 parts of 3-1 mm sillimanite, 8-15 parts of 1-0 mm calcium chromate, 2-5 parts of partial clay powder, 3-7 parts of cobaltous oxide aluminum powder, 5-10 parts of cutting powder, 3-8 parts of amorphous graphite powder, 1-2 parts of composite charcoal powder, 0-3 parts of molybdenum trioxide powder, 3-5 parts of alumina micro powder, 1-5 parts of magnesium oxide iron powder, 1-3 parts of rho-aluminum oxide, 0-5 parts of electric smelting pure calcium aluminate cement and an addition agent, wherein the addition agent is prepared from, by weight, 0.1-0.2 part of calcium lignosulphonate, 0.01-0.05 part of nanometer potato powder, 0.01 part of malic acid and 0.1 part of C12H14N4O5S2. A blast furnace iron runner made of the castable has the advantages of being good in thermal shock resistance, high in corrosion resistance, large in iron exchanging amount and long in life.

Owner:张婷

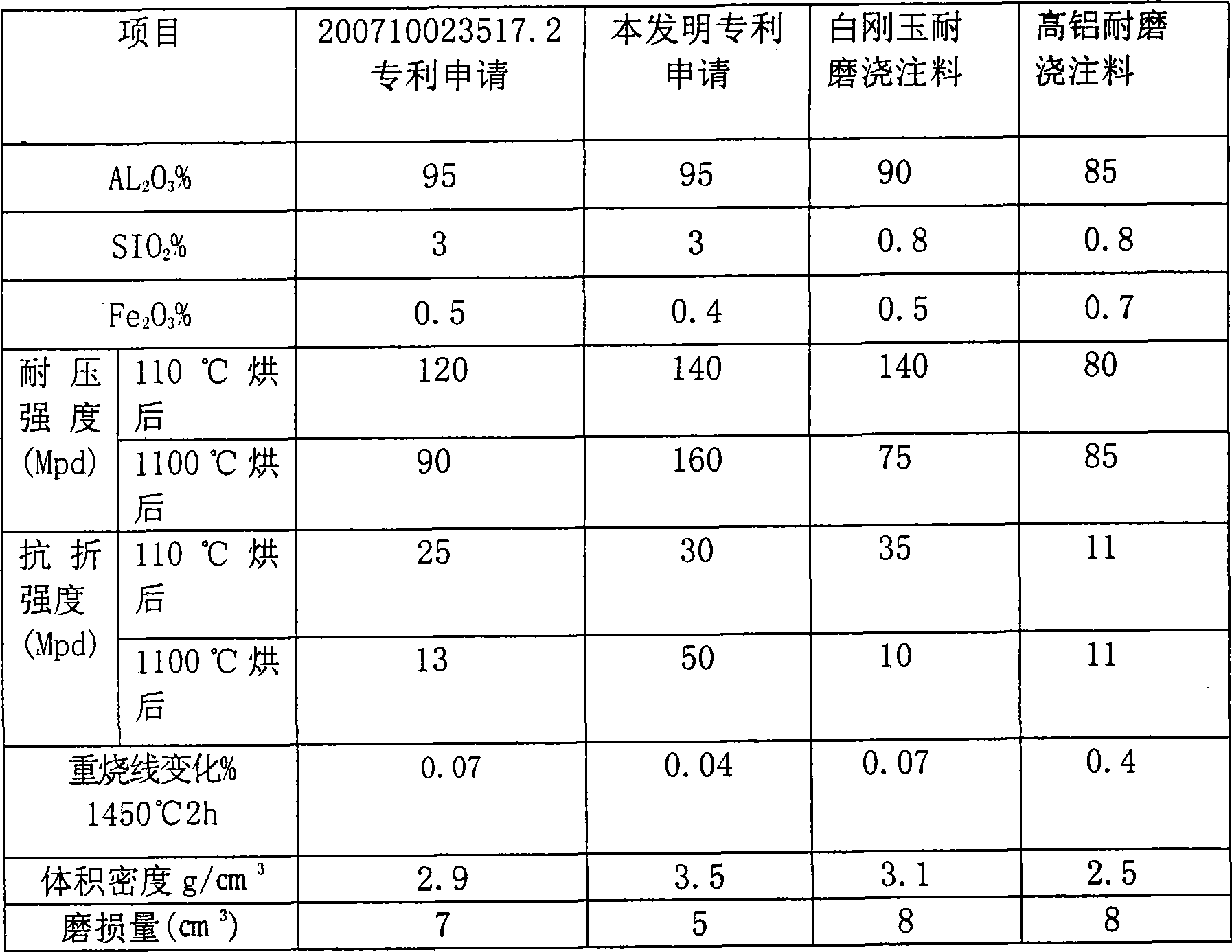

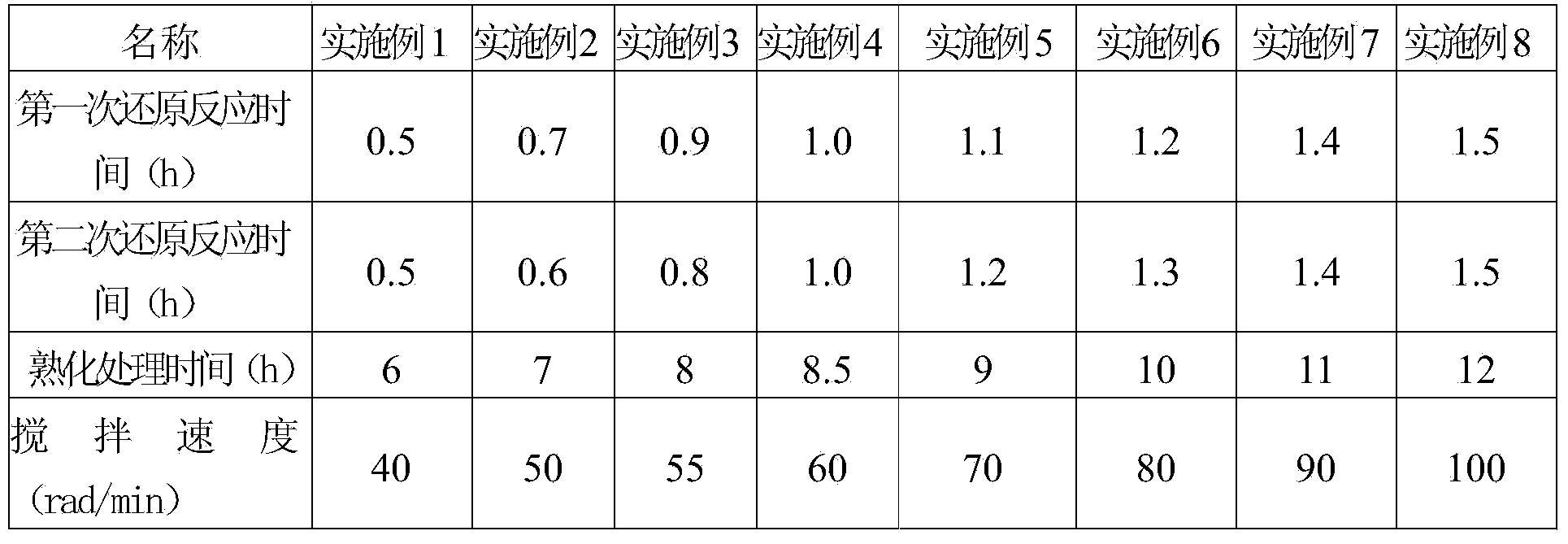

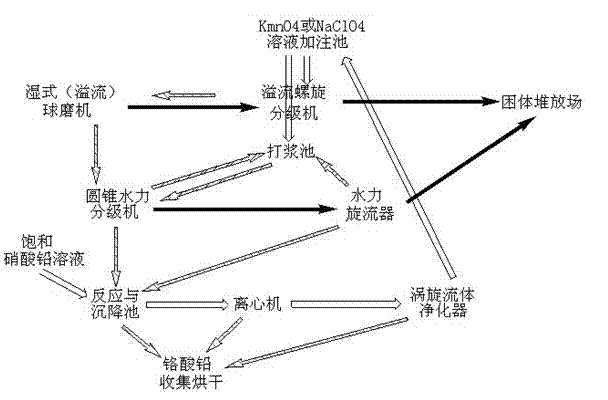

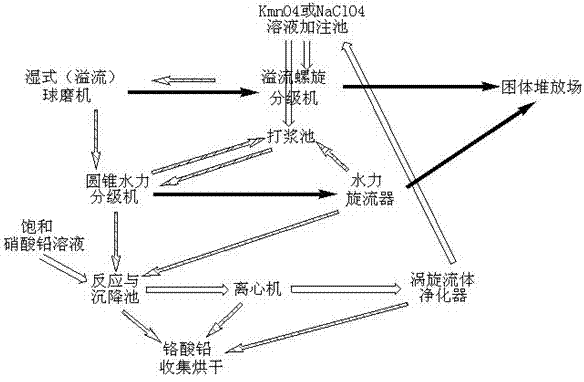

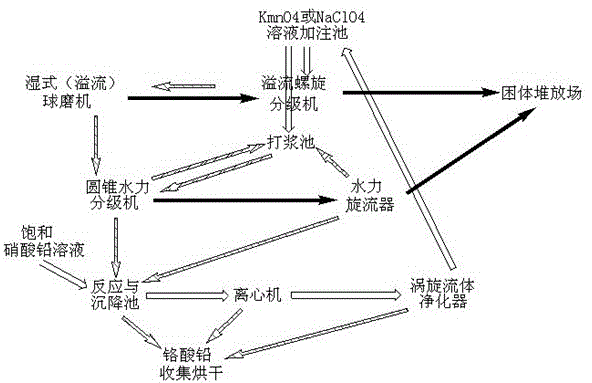

Wet detoxification method for chromium slag and chromium-containing pollutants

ActiveCN103934256AShorten the timeImprove ball milling efficiencySolid waste disposalSulfate radicalsChromium(III) hydroxide

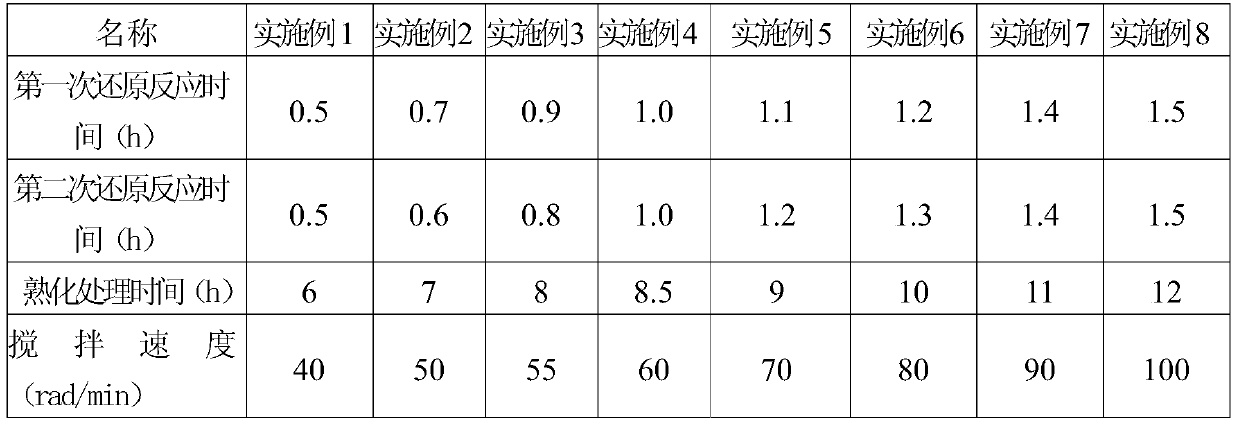

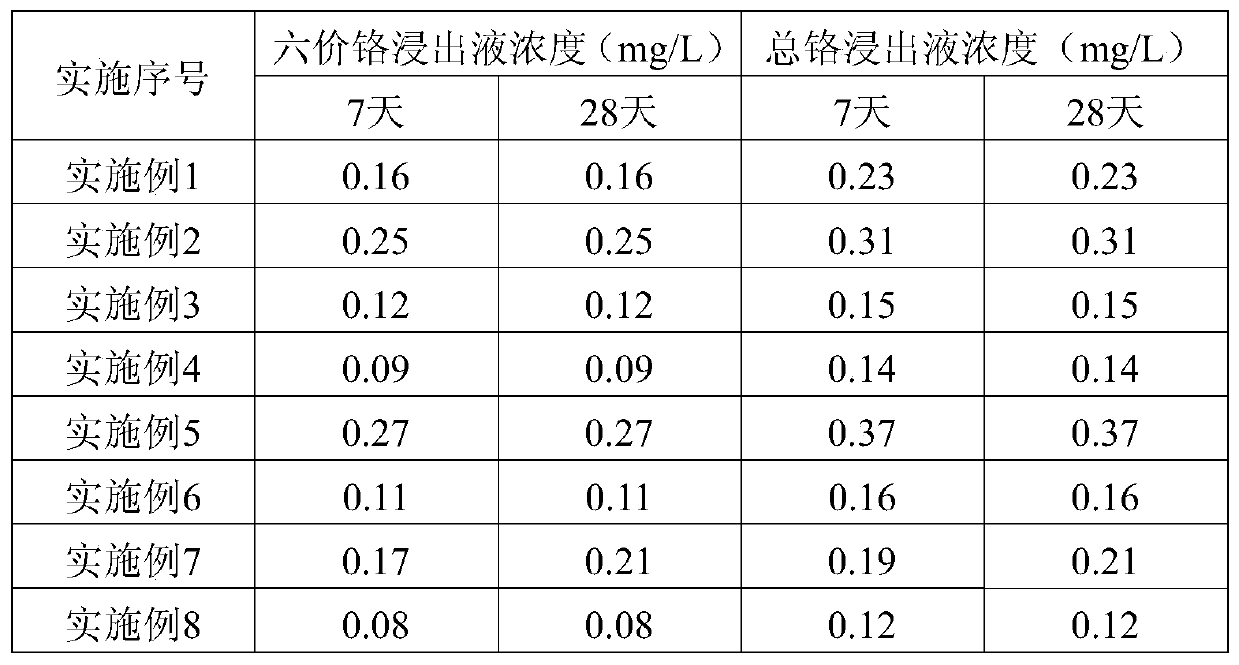

The invention relates to a wet detoxification method for chromium slag and chromium-containing pollutants. The wet detoxification method comprises the following steps: screening and crushing the chromium slag and the chromium-containing pollutants, performing wet milling on the chromium slag and the chromium-containing pollutants in a ball mill, adding a filtrate containing sulfate ions, leaching out acid-soluble calcium chromate in chromium slag slurry, adding the chromium slag slurry and a first reducing agent sequentially into a reaction tank, stirring and mixing the chromium slag slurry with the first reducing agent to perform reduction reaction, reducing the acid-soluble calcium chromate in chromium slag slurry to trivalent chromium, adding concentrated sulfuric acid and to stirring and mixing for regulating, adjusting pH value of the chromium slag slurry to be 7+ / -0.5, then adding a second reducing agent into the reaction tank and stirring and mixing for reducing, stirring the reduced slag slurry to cure the reduced slag slurry, and converting hexavalent chromium in the chromium slag slurry to chromic hydroxide sediment; and separating solid and liquid of the cured chromium slag slurry. The wet detoxification method has the characteristics of low cost, no waste liquid, no slag returning phenomenon, good detoxification effect and capability of being applicable to the large-scale industrial production.

Owner:WELLE ENVIRONMENTAL GRP CO LTD

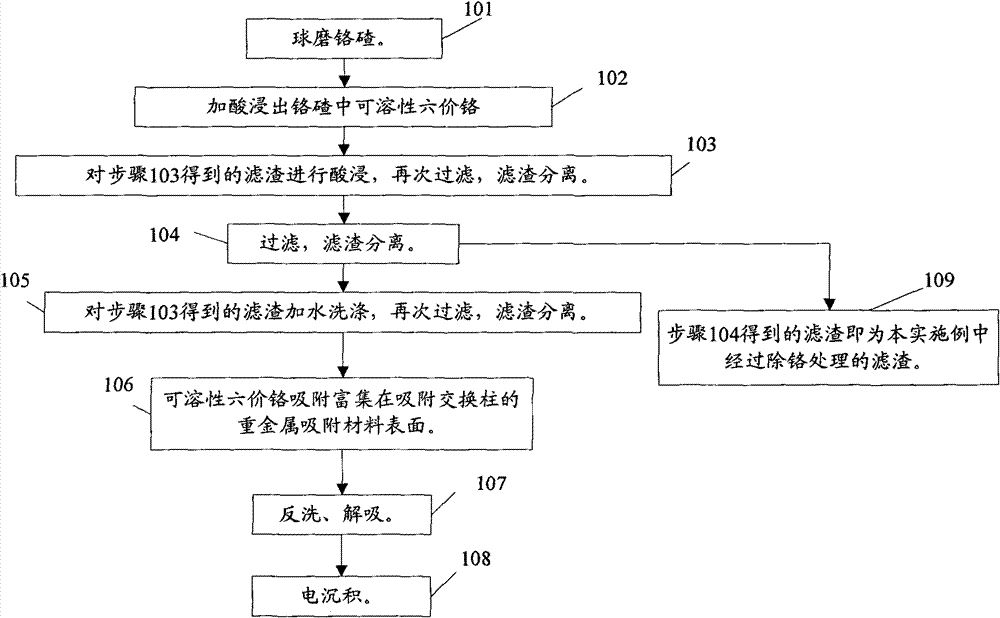

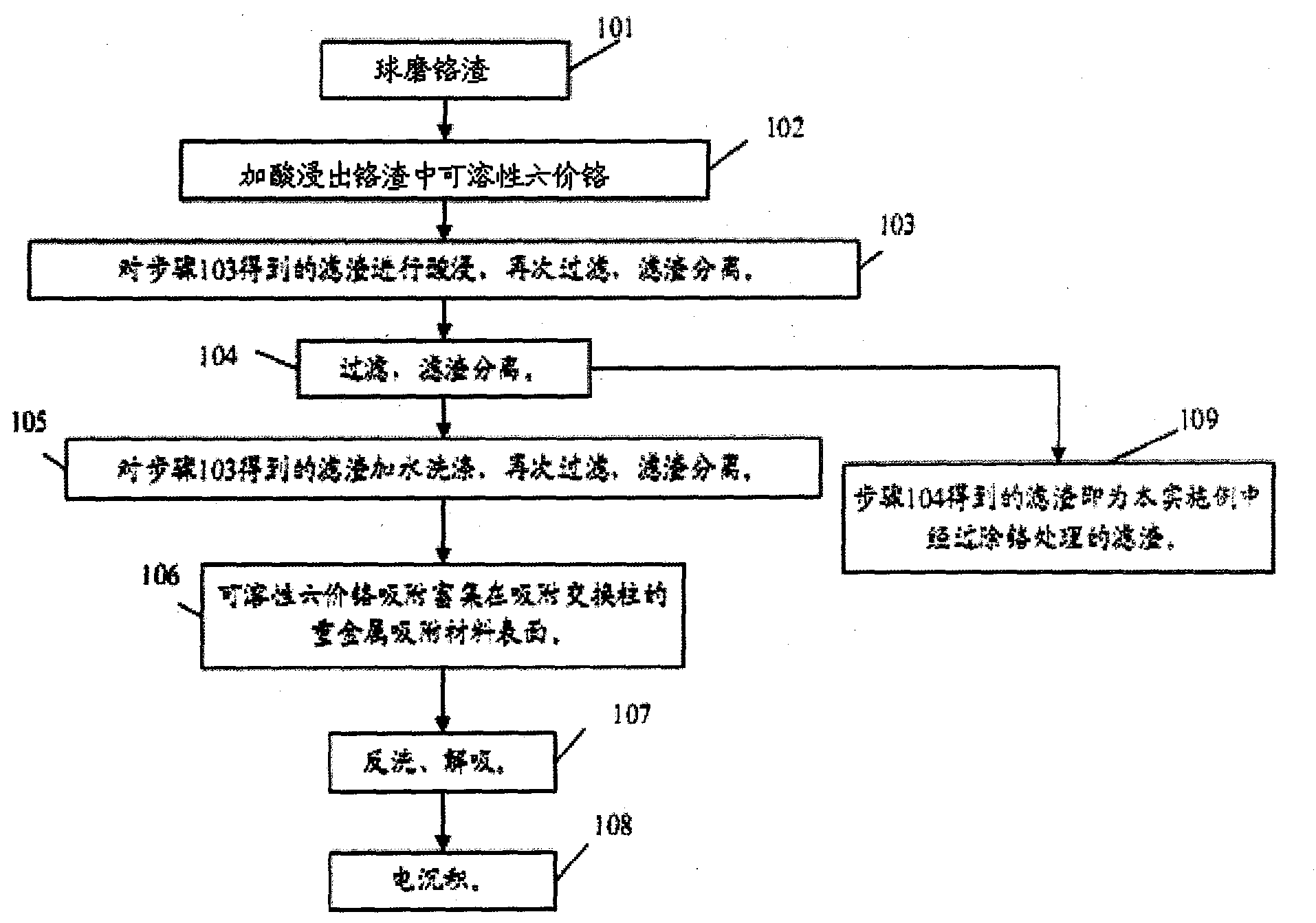

Treatment process method of chrome slag

InactiveCN102816933AHigh recovery rateAvoid pollutionPhotography auxillary processesProcess efficiency improvementDesorptionSlag

The invention relates to the field of heavy metal recovery and treatment, and discloses a treatment process method of chrome slag. The method comprises the steps that: chrome slag is subjected to ball milling; the milled chrome slag is leached by using sulfuric acid, such that water-soluble sodium chromate tetrahydrate, calcium chromate, chrome calcium aluminate, basic iron chromate, chemically adsorbed hexavalent chromium, and dicalcium silicate-calcium chromate and iron calcium aluminate-calcium chromate which are hard to dissolve in water and can be dissolved in acid can be obtained by leaching. The reaction can be shown as: Ca2SiO4-CaCrO4+H2SO4+(x-1)H2O; CaSiO3.xH2O+CaCrO4+CaSO4, 4CaO.Al2O3Fe2O3-CaCrO4+H2SO4+(y-1)H2O; and CaO.Al2O3.yH2O+2CaO.Fe2O3+CaCrO4+CaSO4. A mixed material obtained by leaching is subjected to solid-liquid separation; a filter residue is washed by using water; solid-liquid separation is carried out again; a filtrate is delivered through an absorption exchange column loaded with a heavy metal absorption material; soluble chrome is absorbed and enriched in the surface of the heavy metal absorption material; backwashing and desorption are carried out, such that a concentrated chrome solution is obtained; and the solution is treated in a electrodeposition process, and chrome is recovered. With the technical scheme provided by the embodiment of the invention, highly toxic chromium element in the chrome slag can be removed, and heavy metal can be recovered and utilized. The method is beneficial for environment protection.

Owner:工信华鑫科技有限公司

Method for industrially eliminating toxic ingredients in chromium slag

InactiveCN102249330ASignificant progressElimination of Cr(Ⅵ)Chromates/bichromatesSlagIndustrial water

The invention relates to a method for industrially eliminating toxic ingredients in chromium slag. The method sequentially comprises the following steps: (1) carrying out refluxing for the chromium slag through 1-5% of a KMnO4 solution or a NaClO2 solution, wherein the volume of the KMnO4 solution or the NaClO2 solution is 1-2 times the volume of the chromium slag, then carrying out grinding until the chromium slag has a particle size less than 1 mm; (2) carrying out refluxing and washing for the grinded chromium slag through industrial water in a screw ore washer, wherein the volume of the industrial water is 2-5 times the volume of the chromium slag; (3) collecting the chromium slag, and separating the solid from the washing solution through a cone hydraulic classifier and a hydroclone;(4) collecting the washing solution, and adjusting a pH value of the washing solution to 6-8, followed by adding a saturated CaCl2 solution or a saturated BaCl2 solution until precipitation is not generated; (5) collecting the precipitation, wherein the precipitation is calcium chromate or barium chromate, and carrying out cycling utilization of the supernatant. With the chromium slag detoxication process provided by the present invention, the chromium (Cr) (VI) is eliminated, the total Cr is thoroughly reduced so as to completely meet environmental protection requirements.

Owner:WUHAN TEXTILE UNIV

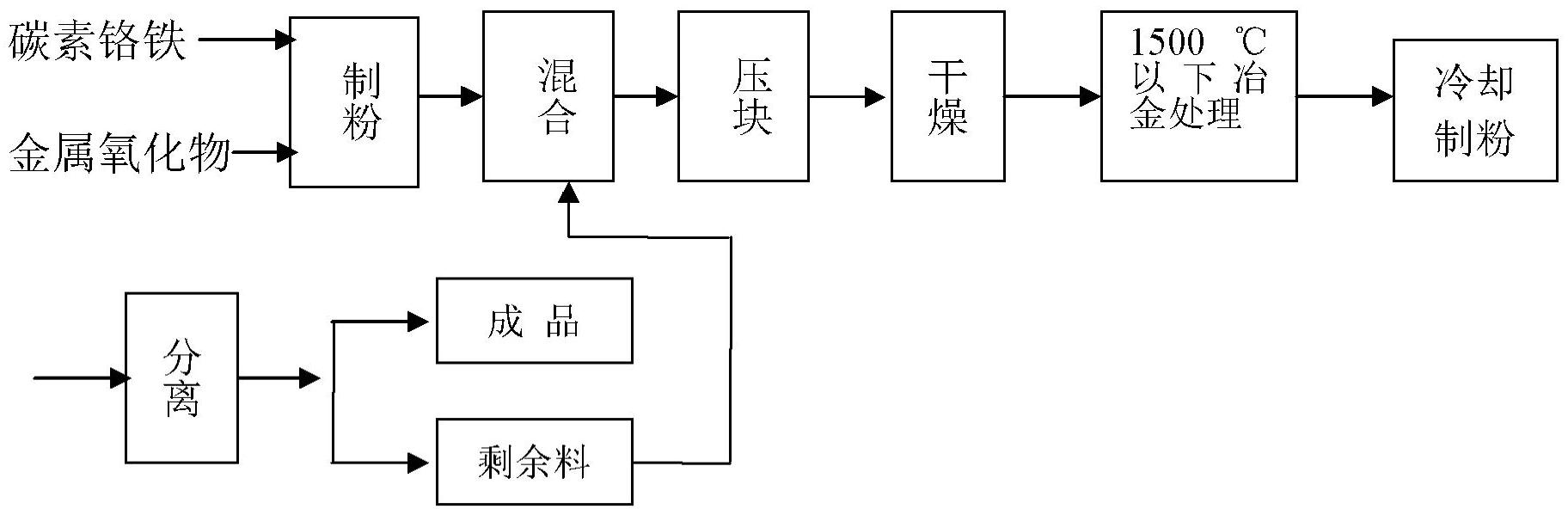

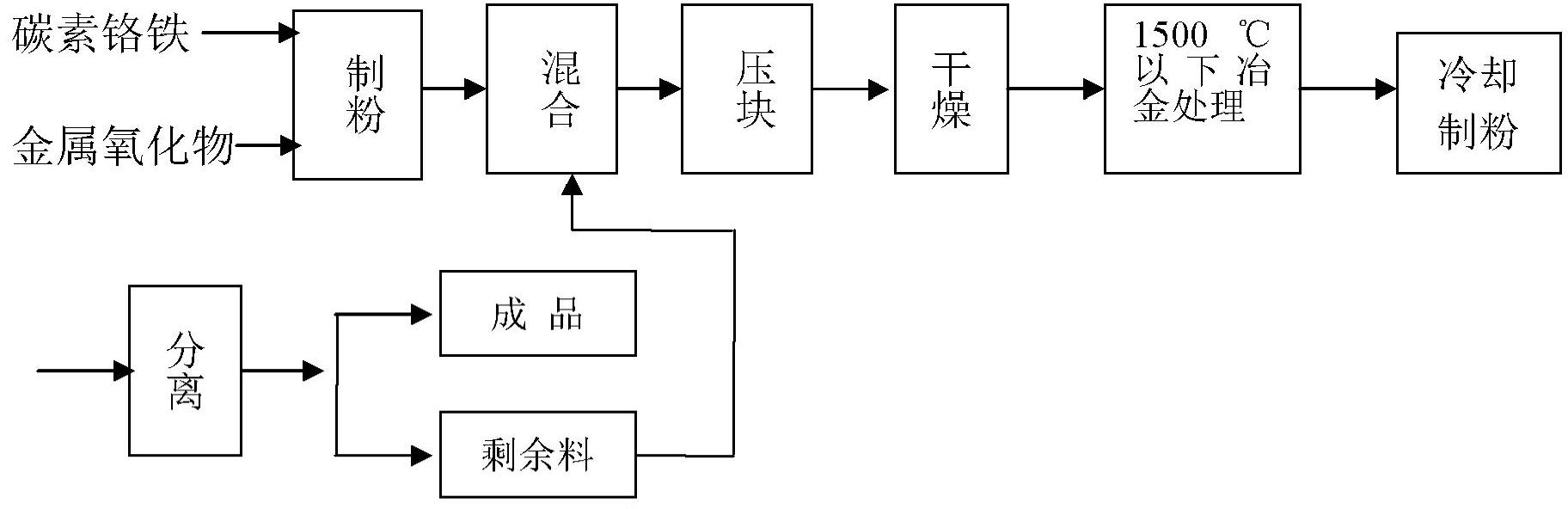

Clean environment-friendly production technique of chromic oxide

InactiveCN102642869ASolve the problem of relying on the use of chemical agents such as acidsSolve the pollution of the environmentChromium trioxideSocial benefitsEnvironmental effect

The invention relates to a clean environment-friendly production technique of chromic oxide. The invention mainly solves the technical problem that the existing production technique has a great impact on the environment, can not implement industrial production due to the immature production technique, or the like. The technical scheme is as follows: the technique comprises the following steps: mixing the main raw material carbon ferrochrome powder and the auxiliary material metal oxide powder, compacting, drying, carrying out a solid-solid metallurgical process at 500-1500 DEG C to convert chrome in the carbon ferrochrome into chromic oxide, cooling to obtain powder, and separating to obtain the chromic oxide. The invention solves the problem of environment pollution due to sexavalent chrome and calcium chromate in the prior art; and the production technique is simple, has obvious social benefit, can easily implement industrial large-scale production, greatly enhances the production efficiency, and obviously enhances the economic benefit.

Owner:HUNAN LIANZHI METALLURGY NEW MATERIAL

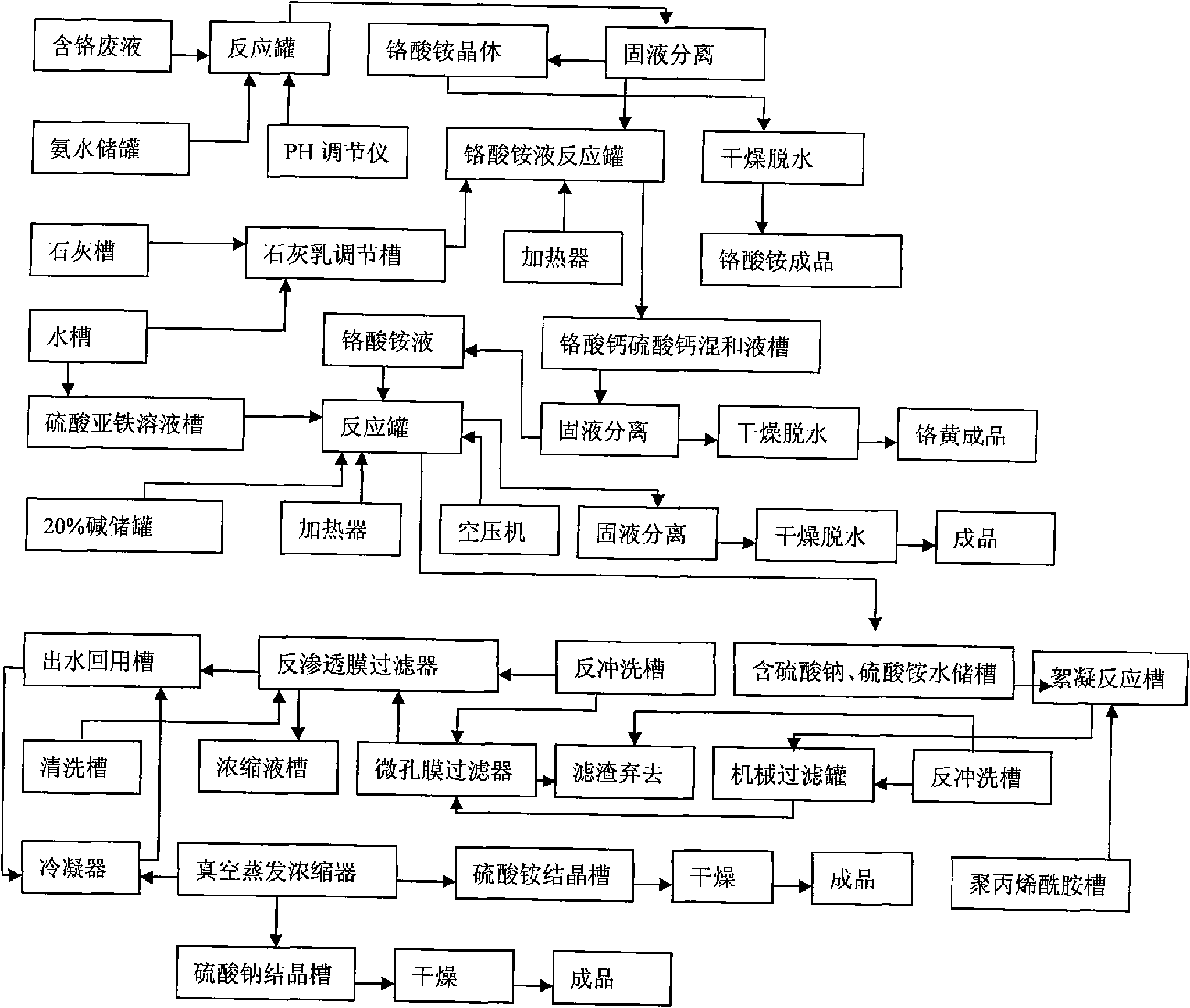

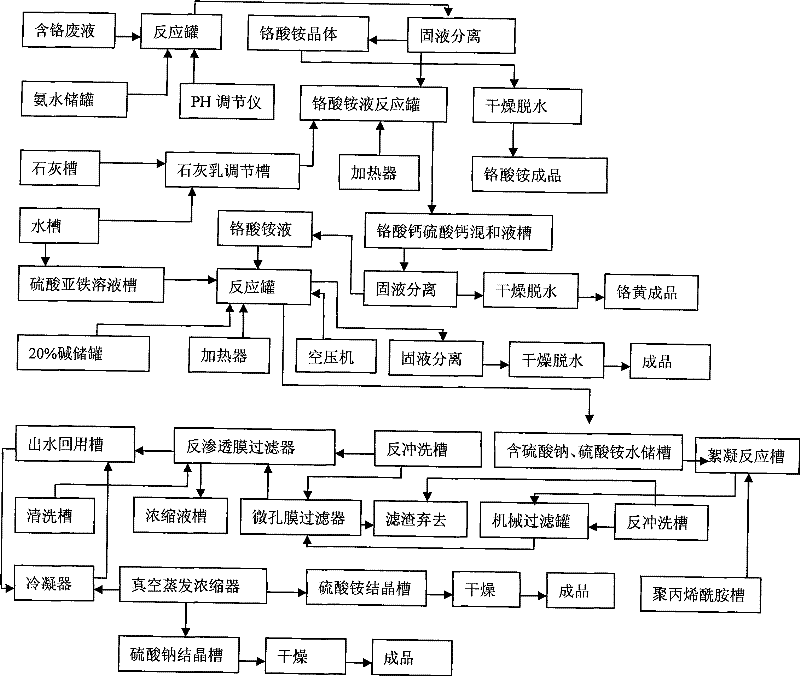

Zero emission treatment method of completely turning chromium-containing waste liquor into useable resources.

InactiveCN101618902AStrong process versatilityEasy to controlWater contaminantsWater/sewage treatment bu osmosis/dialysisLiquid wasteFiltration

The invention relates to a zero emission treatment method of completely turning chromium-containing waste liquor into useable resources. In the method, first enabling chromium-containing waste liquor to react with ammonia water to form ammonium chromate crystallized sediment; using sulphuric acid liquid to adjust pH value of mother liquor, then adding lime cream alkaline liquor to carry out neutralization reaction to generate cocrystallized sediment of calcium chromate and calcium sulphate; solid-liquid separating the liquid part and the sediment part; drying and dewatering the sediment part to obtain chrome yellow; adding ferrous sulphate to the liquid part to react and then carrying out atmospheric oxidation and solid-liquid separation to obtain the sediment part which is ferrite; carrying out filtration, concentration and cooling crystallization to respectively generate sodium sulphate crystallization and ammonium sulphate crystallization and then carrying out solid-liquid separation; drying and dewatering the sediment part and recovering the sodium sulphate and ammonium sulphate; mixing the liquid part and the liquid part before reverse osmosis membrance is filtered and then treating the mixture in recycling manner. The method of the invention not only features good commonality but also treats various conventional chromium-containing waste liquor; in addition, the method features easily controlled process conditions, simple equipment, easy realization of large-scale production, reduction of treatment cost, thus being a technology featuring reduction and decontamination for treating chromium-containing waste liquor as a usable resource.

Owner:刘文治 +2

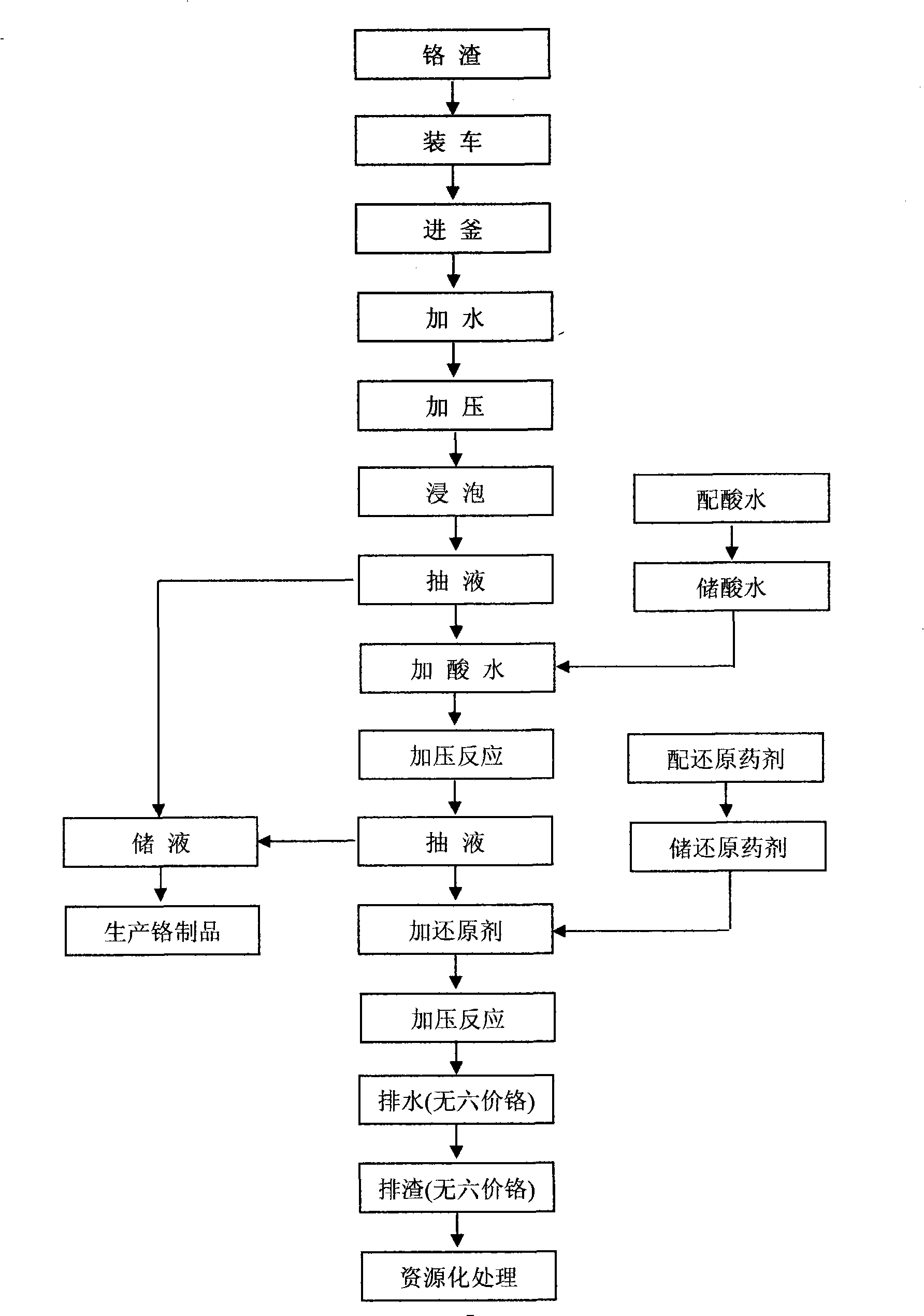

Chromic salt production and extracting and reducing method of hexavalent chromium from chromic slag left behind society

InactiveCN101288795AReduce the content of hexavalent chromiumReduce processing costsSolid waste managementCement productionBrickSlag

The invention discloses a method for extracting and reducing sexivalent chrome in chromium residue which is produced in chromate production and remained in the society. The method of the invention adopts a porous slot to load chromium residue (needing no grinding disposal); the sexivalent chrome liquor in the chrome residue is extracted under the conditions of pressurizing high-temperature saturation, high-pressure and vacuum by adding water in an autoclave; acid water is then added in the autoclave to dip and dissolve calcium chromate in the chrome residue, which is then converted into sexivalent chrome solution; the sexivalent chrome liquor is then extracted under the conditions of high pressure and vacuum; reduction reagent (ferrous sulfate) is added in the autoclave to reduce the sexivalent chrome residual in the chrome residue and converts the sexivalent chrome residue into trivalent chromium which is then fixed in the chrome residue; the gained sexivalent chrome can be used for preparing chrome products; the disposed non-toxic chrome residue can be used for auxiliary materials of cement and concrete, brick aggregate used for building and natural filling and disposal.

Owner:李兴

High temperature abrasion-proof paint and method for producing the same

The invention relates to a 318 high-temperature wear-resistant coating and a preparation method thereof, in particular to a rapid repair material for repairing various abrasive bricks and wear-resistant casting damage positions in circulating fluidized bed boilers of fuel electric plants. At the same time, the invention provides a method for producing the high-temperature wear-resistant coating, and belongs to the technical field of refractory material. The rapid repair material consists of a material A and a material B according to the weight portion proportion of 70-85 to 30-15, wherein thematerial A is prepared by zircon corundum, fine corundum powder, cyanite, yttrium-stabilized zirconium, silicon micropowder, alumina micropowder, pure calcium aluminate cement, trimeric sodium phosphate, and fused calcium chromate; and the material B is prepared by phosphorous acid, ink grade aluminum hydroxide, zirconia ultrafine powder, yttrium-stabilized zirconium, and fused calcium chromate.

Owner:YIXING GUOQIANG FURNACE IND

Method for recycling chromium in electroplating sludge through sub-molten salt method

ActiveCN109280776AWell mixedLow melting pointProcess efficiency improvementAir atmosphereEcological environment

The invention belongs to the technical field of solid waste treatment, and discloses a method for recycling chromium in electroplating sludge through a sub-molten salt method. The method comprises thesteps of sufficiently stirring and mixing the electroplating sludge and an alkaline liquor so as to form a sludge slurry, then drying until the moisture content is lower than 20 percent, and obtaining dried sludge; roasting the dried sludge under the air atmosphere at 280 to 580 DEG C, then using water or a weak-acid water solution for leaching, filtering and separating to obtain a chromium-containing solution and a detoxified sludge slag. According to the method for recycling the chromium in the electroplating sludge through the sub-molten salt method provided by the invention, low melting points of alkali metal hydroxides such as NaOH and KOH are utilized, so that a sub-molten salt state is formed, and reactants are promoted to be mixed sufficiently and contact with air; and aiming at the situations of a calcium-containing element, sodium carbonate or potassium carbonate is added for promoting the formation of sodium chromate, potassium chromate and calcium carbonate, so that the formation of calcium chromate is avoided, and chromate is favorably dissolved sufficiently. By adopting the method, the recovery rate of the chromium is larger than 90 percent, the resource utilizationof the electroplating sludge is realized, and the method has favorable socioeconomic benefit and ecological environment benefit.

Owner:SOUTH CHINA UNIV OF TECH

Castable for main trough of middle-sized blast furnace

InactiveCN105254316AImprove corrosion resistanceImprove thermal shock resistanceAl powderChromium nitride

The invention relates to a castable for a main trough of a middle-sized blast furnace and belongs to the field of refractory castables. The castable is prepared from the following components in parts by weight: 5 to 8 parts of 8-5mm tabular corundum, 15 to 20 parts of 5-3mm chromium nitride, 10 to 15 parts of 3-1mm sillimanite, 8 to 15 parts of 1-0mm calcium chromate, 2 to 5 parts of slightly viscous clay powder, 3 to 7 parts of cobaltous oxide aluminum powder, 5 to 10 parts of cutting powder, 3 to 8 parts of amorphous graphite powder, 1 to 2 parts of composite carbon powder, 0 to 3 parts of molybdenum trioxide powder, 3 to 5 parts of alumina micro powder, 1 to 5 parts of magnesium oxide iron powder, 1 to 3 parts of rho aluminium oxide and 0 to 5 parts of electric smelting pure calcium aluminate cement; it is assumed that the sum of the total weight parts of main ingredients is 100%, then additives comprise the following components in part by weight: 0.1 to 0.2 part of calcium lignosulphonate, 0.01 to 0.05 part of nanometer potato powder, 0.01 part of malic acid and 0.1 part of C12H14N4O5S2. The main trough of the blast furnace prepared with the castable has the advantages of good thermal shock resistance, strong erosion resistance, a big iron influx and a long service life.

Owner:张婷

Multielement high-strength wear-resistant composite paint and preparation method thereof

InactiveCN104628403AImprove high temperature resistanceImprove stabilityWear resistantBound property

The invention relates to a refractory material and a preparation method thereof, particularly a multielement high-strength wear-resistant composite paint and a preparation method thereof. The multielement high-strength wear-resistant composite paint is composed of a main material and an auxiliary material, wherein the main material is composed of fused alumina zirconia fine powder, kyanite, pure calcium aluminate cement, aluminium titanate, magnesium zircon sand, silicon micropowder, aluminum oxide micropowder, sodium tripolyphosphate, calcium chromate and gahnite; and the auxiliary material is composed of phosphoric acid, aluminum hydroxide for inks, aluminum chloride, boron-iron-molybdenum alloy, borax and agglutinant. The multielement high-strength wear-resistant composite paint provided by the invention has the advantages of high compressive strength, higher hardness, high Mohs hardness, high density, favorable wear resistance, favorable erosion resistance, favorable scour resistance, high thermal shock stability and high binding property. When being used for a circulating fluid bed boiler, the multielement high-strength wear-resistant composite paint prolongs the service life of the paint coat, reduces the repair frequency and lowers the maintenance cost.

Owner:YIXING GUOQIANG FURNACE IND

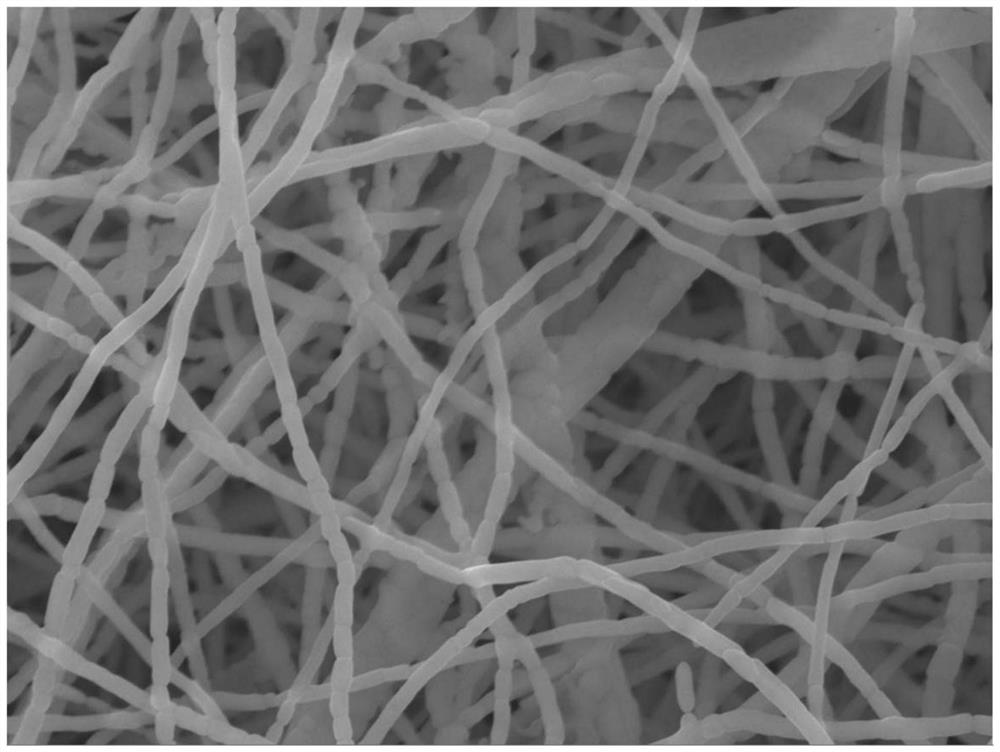

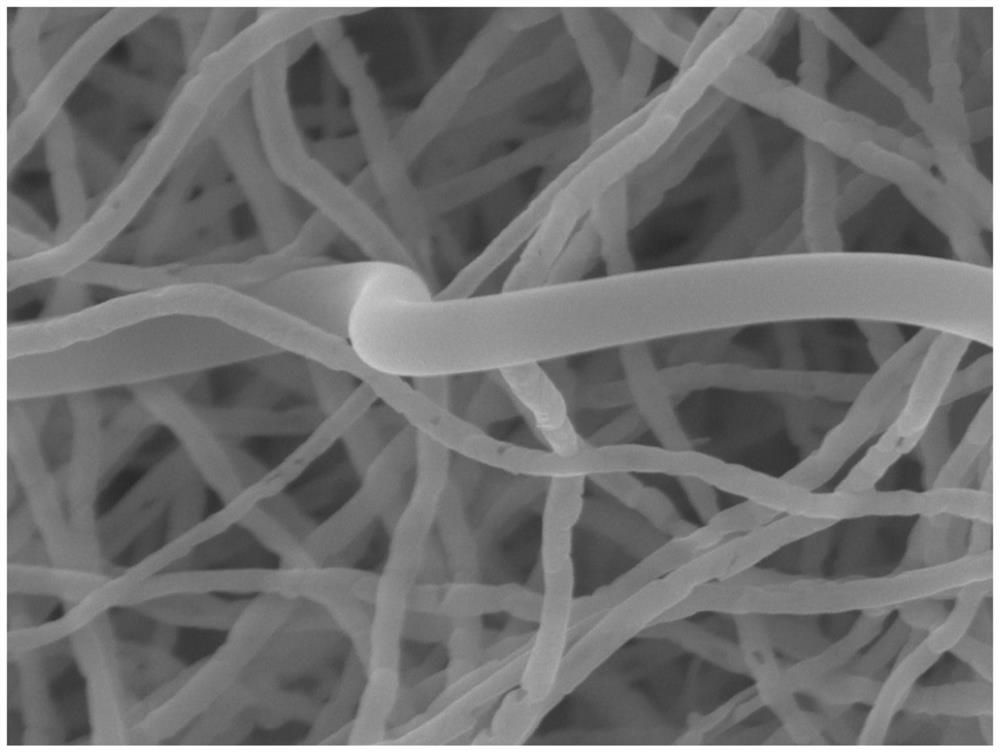

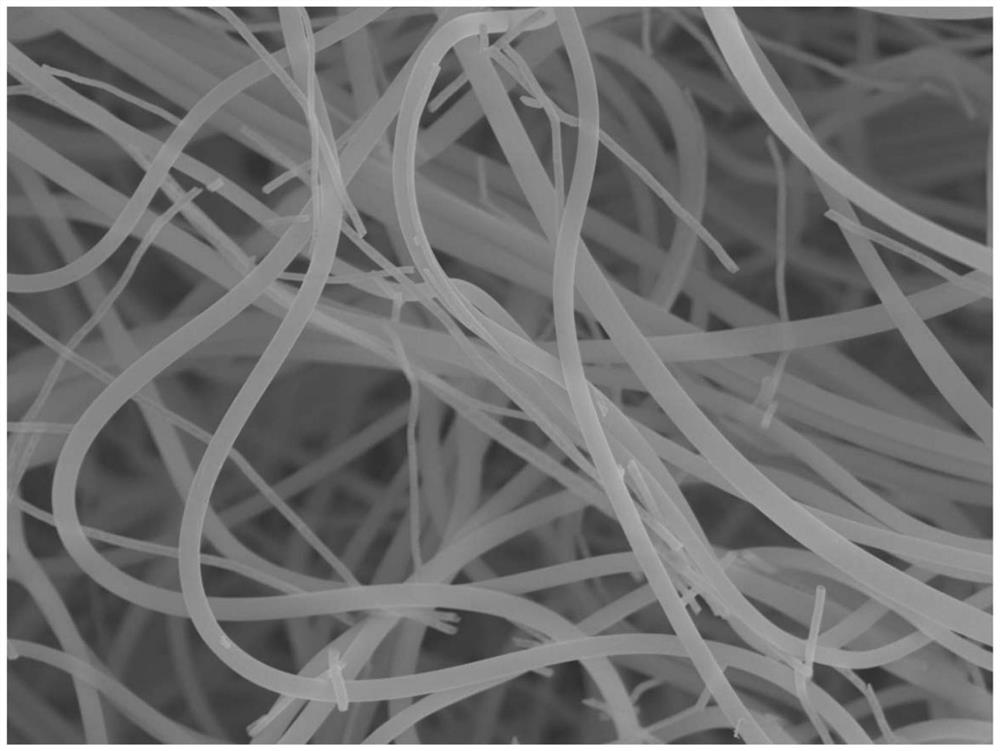

Flexible calcium lanthanum chromate/silicon oxide composite fiber material with high infrared emissivity as well as preparation method and application of flexible calcium lanthanum chromate/silicon oxide composite fiber material

PendingCN114561720ALarge specific surface areaImprove flexibilityChemical industryFibre chemical featuresFiberSpinning

The invention relates to a high-infrared-emissivity flexible calcium lanthanum chromate / silicon oxide composite fiber material and a preparation method and application thereof.The high-infrared-emissivity flexible calcium lanthanum chromate / silicon oxide composite fiber material is prepared through the following preparation method: (1) dissolving a silicon source and a chelating agent in a solvent A to obtain an inorganic precursor solution A, and then adding a spinning aid polymer to obtain a silicon oxide spinning solution; (2) dissolving a chromium source, a lanthanum source and a calcium source in a solvent B to obtain an inorganic precursor solution B, and then adding a spinning aid polymer to obtain a calcium lanthanum chromate spinning solution; (3) respectively putting the silicon oxide spinning solution and the calcium lanthanum chromate spinning solution into mutually independent spinning propulsion devices, and spinning on the same receiving roller to obtain composite gel nanofibers; and (4) drying and calcining the obtained composite gel nanofiber to obtain a target product. Compared with the prior art, the infrared emissivity of the composite fiber material is larger than 80%, and the composite fiber material can be independently used, and is good in flexibility, excellent in strength, easy to recycle and simple in preparation method.

Owner:DONGHUA UNIV +2

Wet detoxification method of chromium slag and chromium-containing pollutants

Owner:WELLE ENVIRONMENTAL GRP CO LTD

Main iron trough castable for small blast furnace

InactiveCN105218126AImprove corrosion resistanceImprove thermal shock resistanceChromium nitrideThermal shock

The invention relates to a main iron trough castable for a small blast furnace, belonging to the field of refractory castables. The main iron trough castable comprises the following components in parts by weight: 5-8 parts of 8-5mm tabular corundum, 15-20 parts of 5-3mm chromium nitride, 10-15 parts of 3-1mm sillimanite, 8-15 parts of 1-0mm calcium chromate, 2-5 parts of slightly-viscous clay powder, 3-7 parts of aluminum cobalt oxide powder, 5-10 parts of cutting powder, 3-8 parts of amorphous graphite, 1-2 parts of composite carbon powder, 0-3 parts of molybdenum trioxide powder, 3-5 parts of alumina micropowder, 1-5 parts of iron magnesium oxide, 1-3 parts of rho aluminum oxide and 0-5 parts of electrically-melted calcium aluminate cement; based on 100% of total weight parts of main materials, an additive comprises the following components in parts by weight: 0.1-0.2 part of calcium lignosulphonate, 0.01-0.05 part of nanometer potato flour, 0.01 part of malic acid and 0.1 part of C12H14N4O5S2. The blast furnace produced by using the castable has the characteristics of good thermal shock resistance, high erosion resistance, high iron throughput and long service life.

Owner:张婷

A kind of epoxy resin antirust paint and preparation method thereof

InactiveCN104059470BStrong adhesionImprove rust resistanceAnti-corrosive paintsEpoxy resin coatingsCyclohexanoneEpoxy

The invention relates to an epoxy resin antirust paint and a preparation method thereof, belonging to the technical field of polymer materials. The epoxy resin antirust paint of the present invention comprises the following raw materials in parts by weight: 40-60 parts of E-51 epoxy resin, 10-20 parts of polybutadiene, 100-200 parts of cyclohexanone, silane coupling 3-5 parts of aluminum stearate, 5-12 parts of aluminum stearate, 2-9 parts of calcium chromate, 5-19 parts of diatomaceous earth, 12-21 parts of zinc phosphochromate, 3-10 parts of potassium polymethacrylate , 30-50 parts of titanium dioxide, 10-20 parts of pigment, 30-50 parts of curing agent. The epoxy resin antirust paint of the present invention adopts E-51 epoxy resin, cooperates with other components, can solidify well at room temperature, and curing speed is faster, and according to the characteristic of functional coating, climate characteristic, anticorrosion coating construction The characteristics of the performance requirements meet the requirements of the validity period of the anti-corrosion protection.

Owner:BLUESTAR CHENGDU NEW MATERIALS

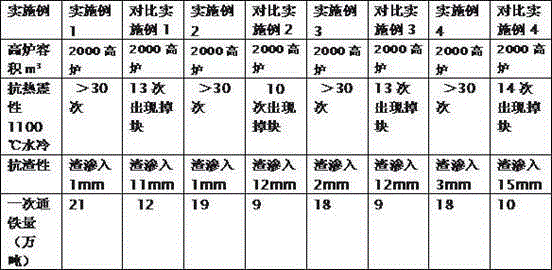

Castable for 2000m<3> blast furnace supporting iron runner

InactiveCN105218124AImprove corrosion resistanceImprove thermal shock resistanceMulliteChromium nitride

The invention relates to a castable for a 2000m<3> blast furnace supporting iron runner. The castable comprises a main material and an additive, wherein the main material comprises the following components in parts by weight: 5-8 parts of 5mm-8mm zirconium mullite, 15-20 parts of 3mm-5mm chromium nitride, 10-15 parts of 1mm-3mm sillimanite, 8-15 parts of 0-1mm calcium chromate, 2-5 parts of clay powder, 3-7 parts of cobalt aluminum oxide powder, 5-10 parts of cutting powder, 3-8 parts of amorphous graphite powder, 1-2 parts of composite carbon powder, 0-3 parts of molybdenum trioxide powder, 3-5 parts of alumina micro powder, 1-5 parts of magnesium iron oxide powder, 1-3 parts of rho alumina and 0-5 parts of electric-fused pure calcium aluminate cement; the additive comprises the following components in parts by weight of 100% of the main material: 0.1-0.2 part of calcium lignosulphonate, 0.01-0.05 part of nano potato powder, 0.01 part of malic acid and 0.1 part of C12H14N4O5S2. The blast furnace supporting iron runner prepared from the castable has the characteristics of good thermal shock resistance, strong erosion resistance, high iron influx and long service life.

Owner:万燕杰

Casting material for calcining kiln

The invention provides a casting material with high temperature resistance, high abrasion resistance and high alkali corrosion resistance for a calcining kiln with respective to shortcomings in the prior art, and further aims to provide a preparation method for the casting material. The technical scheme is that the casting material is characterized by consisting of the following components in percentage by weight: 1 percent of Taiyuan purple flower waste rock, 17 to 22 percent of calcium chromate, 17 to 19 percent of silicon carbide, 28 to 30 percent of ferrochrome slag, 5 to 10 percent of zinc ferrite, 5 to 8 percent of magnesia-zirconia olivine, 1 to 3 percent of magnesium potassium titanate, 1 to 2 percent of zirconium aluminium nitride, 3 to 5 percent of merwinite, 5 to 10 percent of alumina micro powder, 2 to 3 percent of calcium aluminium zirconate, 3 to 5 percent of high-alumina cement, and 0.5 percent of Ti3SiC2, 0.1 percent of methyl allyl alcohol polyoxyethylene ether, 0.05 percent of prenyl alcohol polyoxyethylene ether, 0.1 percent of aluminium potassium sulfate dodecahydrate, and 0.05 percent of potassium chromium alum dodecahydrate.

Owner:张婷

Treatment process method of chrome slag

InactiveCN102816933BHigh recovery rateAvoid pollutionPhotography auxillary processesProcess efficiency improvementDesorptionSlag

The invention relates to the field of heavy metal recovery and treatment, and discloses a treatment process method of chrome slag. The method comprises the steps that: chrome slag is subjected to ball milling; the milled chrome slag is leached by using sulfuric acid, such that water-soluble sodium chromate tetrahydrate, calcium chromate, chrome calcium aluminate, basic iron chromate, chemically adsorbed hexavalent chromium, and dicalcium silicate-calcium chromate and iron calcium aluminate-calcium chromate which are hard to dissolve in water and can be dissolved in acid can be obtained by leaching. The reaction can be shown as: Ca2SiO4-CaCrO4+H2SO4+(x-1)H2O; CaSiO3.xH2O+CaCrO4+CaSO4, 4CaO.Al2O3Fe2O3-CaCrO4+H2SO4+(y-1)H2O; and CaO.Al2O3.yH2O+2CaO.Fe2O3+CaCrO4+CaSO4. A mixed material obtained by leaching is subjected to solid-liquid separation; a filter residue is washed by using water; solid-liquid separation is carried out again; a filtrate is delivered through an absorption exchange column loaded with a heavy metal absorption material; soluble chrome is absorbed and enriched in the surface of the heavy metal absorption material; backwashing and desorption are carried out, such that a concentrated chrome solution is obtained; and the solution is treated in a electrodeposition process, and chrome is recovered. With the technical scheme provided by the embodiment of the invention, highly toxic chromium element in the chrome slag can be removed, and heavy metal can be recovered and utilized. The method is beneficial for environment protection.

Owner:工信华鑫科技有限公司

High-temperature wear-resistant repairing coating and preparation method thereof

ActiveCN102134164BHigh compressive strengthHigh densityFireproof paintsSpecial surfacesWear resistantSodium phosphates

A high temperature abrasion resistant repairing paint and the preparing method thereof are provided. The high temperature abrasion resistant repairing paint consists of material (A) and material (B) at weight part ratio of 70-85:30-15. The material (A) consists of zirconium corundum fine powder, cyanite, aluminum titanate, silicon micropowder, magnesia zirconia, alumina micropowder, pure calcium aluminate cement, trimeric sodium phosphate, electrofused calcium chromate and gahnite. The material (B) consists of phosphoric acid, ink grade aluminum hydroxide, aluminum chloride, yttrium-stabilized zirconia, borax and middle-temperature sintering agent. The repairing paint has excellent abrasion resistance, corrosion resistance, crushing resistance, thermal shock resistance and good cohesive property. The operating cycle of circulating fluidized bed boiler can be increased from 3500 hours to more than 18000 hours accumulatively by using the repairing paint.

Owner:YIXING GUOQIANG FURNACE IND

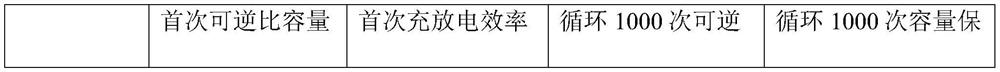

Silicon-carbon negative electrode material and preparation method thereof

PendingCN114373918AImprove electrochemical performanceEnough passivation spaceCell electrodesSecondary cellsLithium-ion batteryMaterials science

The invention relates to the technical field of lithium ion batteries, in particular to a silicon-carbon negative electrode material and a preparation method thereof.The preparation method of the silicon-carbon negative electrode material comprises the following steps that nanometer silicon and a dispersing agent are evenly mixed in a calcium chromate aqueous solution, and heating, filtering and drying are conducted to obtain a first intermediate product; uniformly mixing the first intermediate product with dopamine, and calcining in an inert atmosphere to obtain a second intermediate product; and putting the second intermediate product into a dilute sulfuric acid solution for reaction, filtering, cleaning and drying to obtain the silicon-carbon negative electrode material. The preparation method of the silicon-carbon negative electrode material is simple in operation process and convenient to operate, hydrofluoric acid does not need to be used, the manufacturing process is very environment-friendly, almost no potential safety hazard exists, and the silicon-carbon negative electrode material prepared by the preparation method has an egg yolk shell structure and is suitable for large-scale production. Enough passivation space can be provided for volume expansion of silicon, the conductivity is good, and the electrochemical performance of the lithium ion battery can be effectively improved.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

Major iron runner casting material for blast furnace

The present invention relates to a major iron runner casting material for a blast furnace, belongs to the field of refractory casting materials, and comprises the following components in parts by weight: 5-8 parts of 8-5mm chromium nitride, 15-20 parts of 5-3mm zirconium corundum, 10-15 parts of 3-1mm sillimanite, 8-15 parts of 1-0mm calcium chromate, 2-5 parts clay powder, 3-7 parts of cobalt aluminum oxide powder, 5-10 parts of cutting powder, 3-8 parts of amorphous graphite powder, 1-2 parts of composite carbon powder, 0-3 parts of molybdenum trioxide powder, 3-5 parts of aluminium oxide micro powder, 1-5 parts of magnesium iron oxide powder, 1-3 parts of rho-aluminium oxide and 0-5 parts of electric smelting pure calcium aluminate cement. Based on the total weight by parts of the main materials: 100%, the additives comprise the following components in parts by weight: 0.1-0.2 part of lignin calcium sulfonate, 0.01-0.05 part of nano potato powder, 0.01 part of malic acid and 20:1 parts of C12H14N4O5S. The iron runner for the blast furnace made of the casting material has the characteristics of good thermal shock resistance, high corrosion resistance, large iron influx and long service life.

Owner:张婷

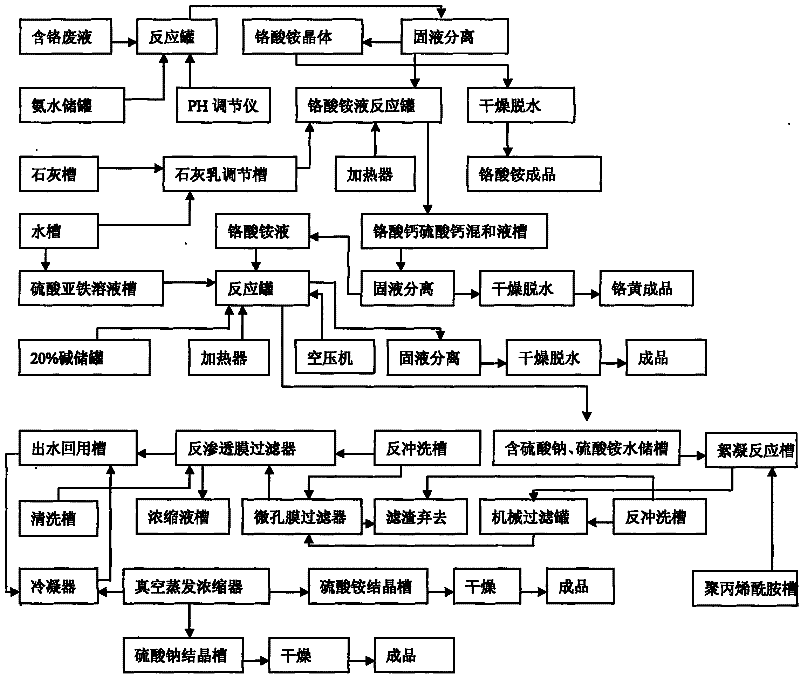

Zero emission treatment method of completely turning chromium-containing waste liquor into useable resources.

InactiveCN101618902BStrong process versatilityEasy to controlWater contaminantsWater/sewage treatment bu osmosis/dialysisLiquid wasteFiltration

Owner:刘文治 +2

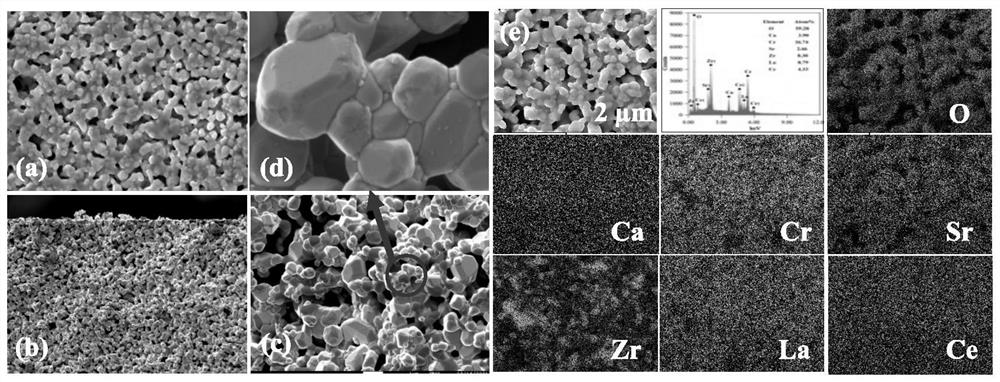

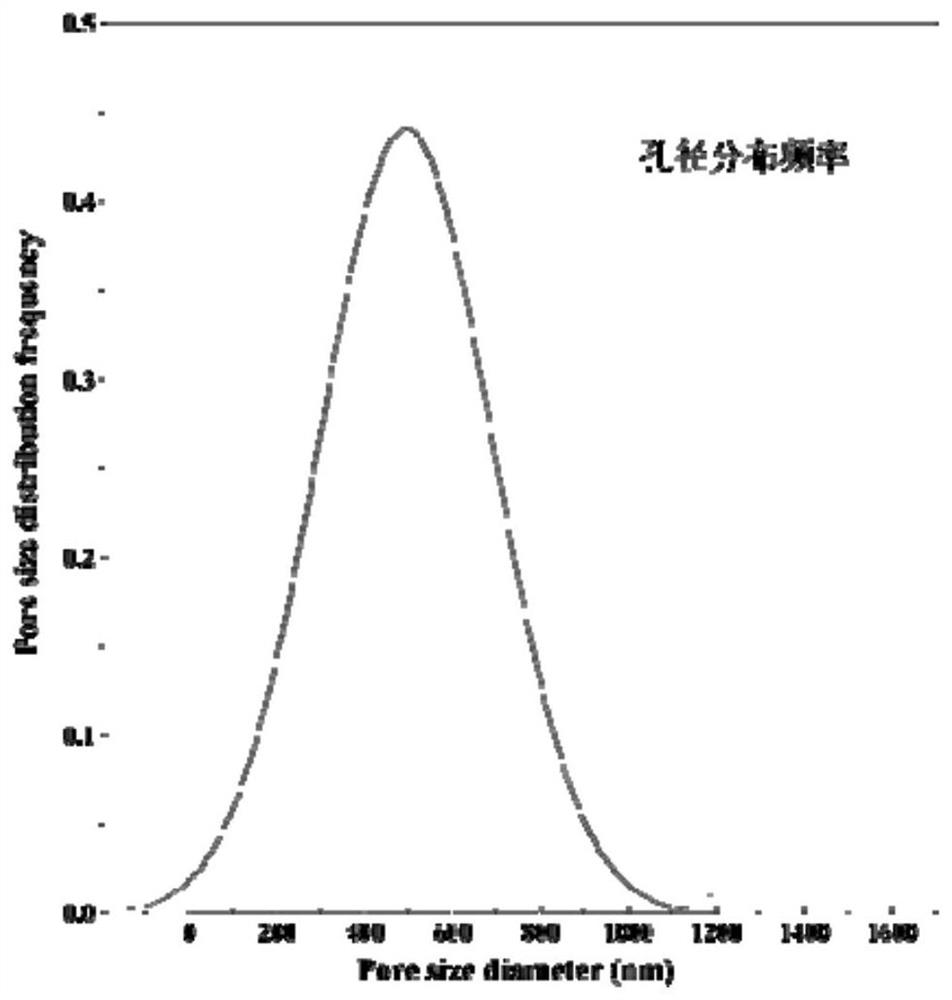

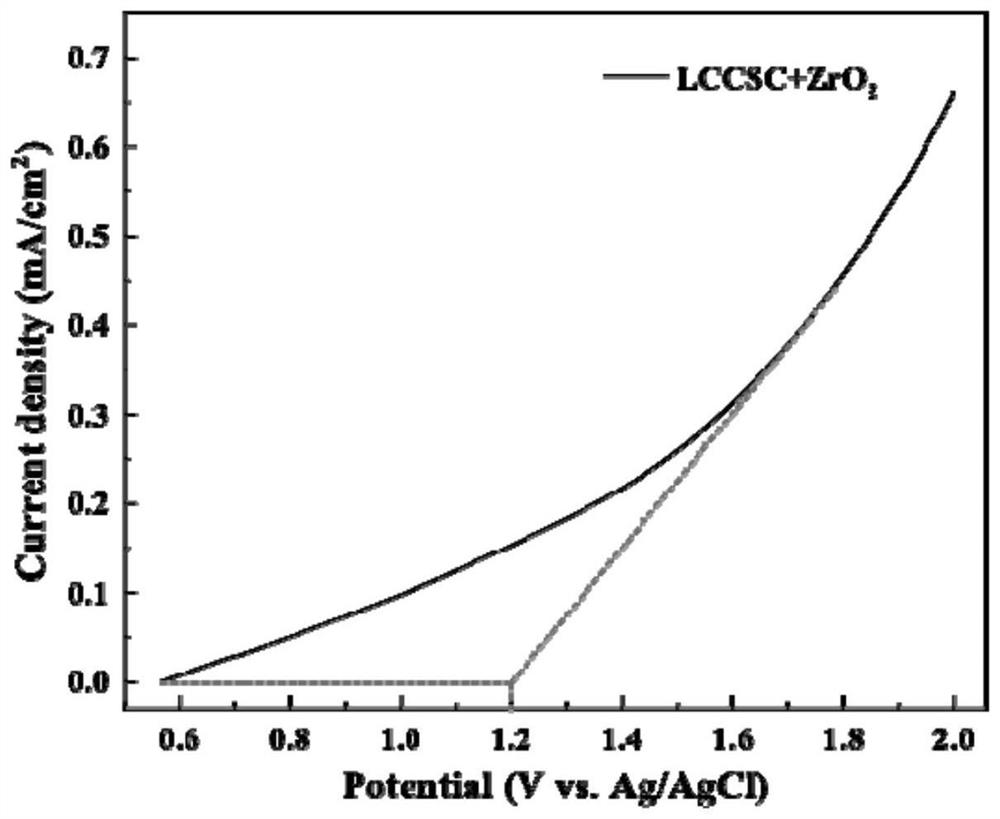

Perovskite type conductive ceramic membrane and preparation method and application thereof

PendingCN114682104ABoth interceptConductiveMembranesSemi-permeable membranesCompression moldingCross linker

The invention provides a perovskite type conductive ceramic membrane and a preparation method and application thereof, and the preparation method comprises the following steps: mixing nitrate solutions of chromium, lanthanum, cerium, strontium and calcium, sequentially adding a cross-linking agent and a chelating agent, adjusting the pH value to 7-8, heating and dehydrating the mixed solution to form xerogel, crushing the xerogel, and combusting to remove carbon, thereby obtaining the perovskite type conductive ceramic membrane. Then continuously grinding and annealing to prepare a lanthanum cerium strontium calcium chromate conductive ceramic precursor; then uniformly mixing the conductive ceramic powder with ceramic powder, a binder and a pore-forming agent, and carrying out ball milling treatment to prepare conductive ceramic fine powder; the conductive ceramic fine powder is placed in a mold, and a conductive ceramic blank is obtained through pressing in a vacuum compression molding and cold pressing mode; and calcining the prepared conductive ceramic blank in a high-temperature environment to prepare the perovskite conductive ceramic membrane. The conductive ceramic membrane can effectively solve the problems that an existing conductive ceramic membrane is unstable in electrochemical performance, low in mechanical strength of a conductive layer and short in service life.

Owner:BEIJING SINORICHEN ENVIRONMENTAL PROTECTION

Method for preparing chromate from oyster shells and tanning sludge

PendingCN113816424ALow costPrevent benefitSludge treatment by de-watering/drying/thickeningWater contaminantsChromate saltSludge

The invention discloses a method for preparing chromate by utilizing oyster shells and tanning sludge, which is a recycling method for recycling chromium by utilizing precipitate obtained by adding alkali to precipitate tanning wastewater, belongs to a solid waste recycling technology in the field of environment, and relates to a recycling technology for treating solid polluted wastes and treating wastes with wastes; therefore, the chromium sludge hazardous waste is treated, and the oyster shells are high-valued and recycled. The method comprises the following steps: firstly, drying and grinding a chromium precipitate; secondly, waste oyster shells collected from the seafood market and the seaside are naturally air-dried and deodorized, and then modifying the oyster shells to destroy the structures of the oyster shells; thirdly, roasting the ground chromium precipitate and the oyster shells or the modified oyster shells in a muffle furnace to obtain a calcium chromate salt product, thereby realizing the recycling and reutilization of the chromium element in the tannery sludge and the waste oyster shells in the environment.

Owner:FUZHOU UNIV

Method for industrially eliminating toxic ingredients in chromium slag

InactiveCN102249330BSignificant progressElimination of Cr(Ⅵ)Chromates/bichromatesSlagEnvironmental engineering

Owner:WUHAN TEXTILE UNIV

Refractory castable

InactiveCN105330307AImprove corrosion resistanceImprove thermal shock resistanceAl powderChromium nitride

The invention relates to refractory castable. The castable comprises a main material and additives. The main material is prepared from, by weight, 5-8 parts of barium aluminate with granularity of 5-8 mm, 15-20 parts of chromium nitride with granularity of 3-5 mm, 10-15 parts of andalusite with granularity of 1-3 mm, 8-15 parts of calcium chromate with granularity of 0-1 mm, 2-5 parts of partial clay powder, 3-7 parts of cobaltous oxide aluminum powder, 5-10 parts of cutting powder, 3-8 parts of earthy graphite powder, 1-2 parts of composite carbon powder, 0-3 parts of molybdenum trioxide powder, 3-5 parts of alumina micro powder, 1-5 parts of magnesium oxide iron powder, 1-3 parts of rho-alumina and 0-5 parts of electric smelting pure calcium aluminate cement. With the total weight parts of the main material being 100 parts, the additives are prepared from, by weight, 0.1-0.2 part of calcium lignosulphonate, 0.01-0.05 part of nanometer potato powder, 0.01 part of malic acid and 0.1 part of C12H14N4O5S2. A blast furnace iron groove prepared from the castable has the advantages of being high in thermal seismic resistance, high in corrosion resistance, large in iron exchange amount and long in service life.

Owner:山国强

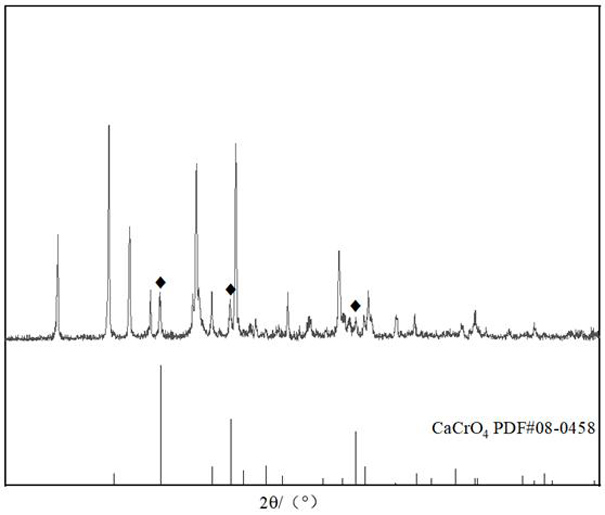

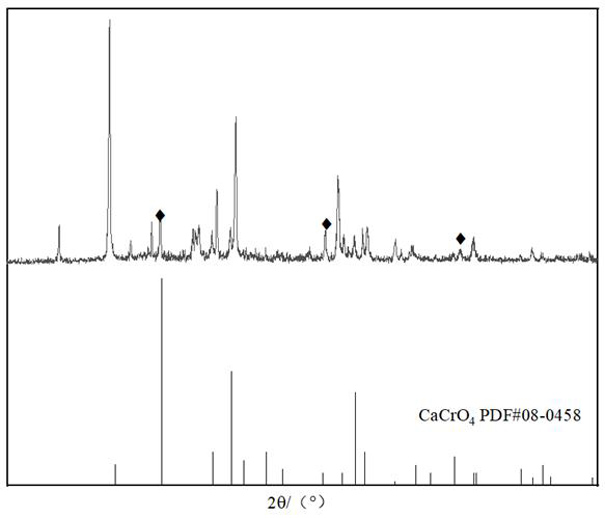

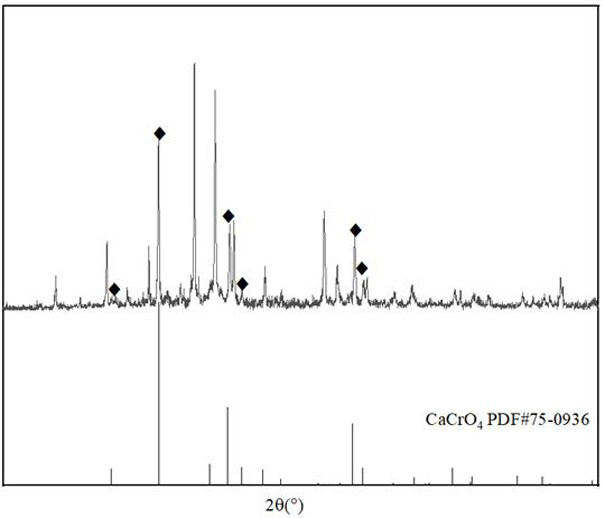

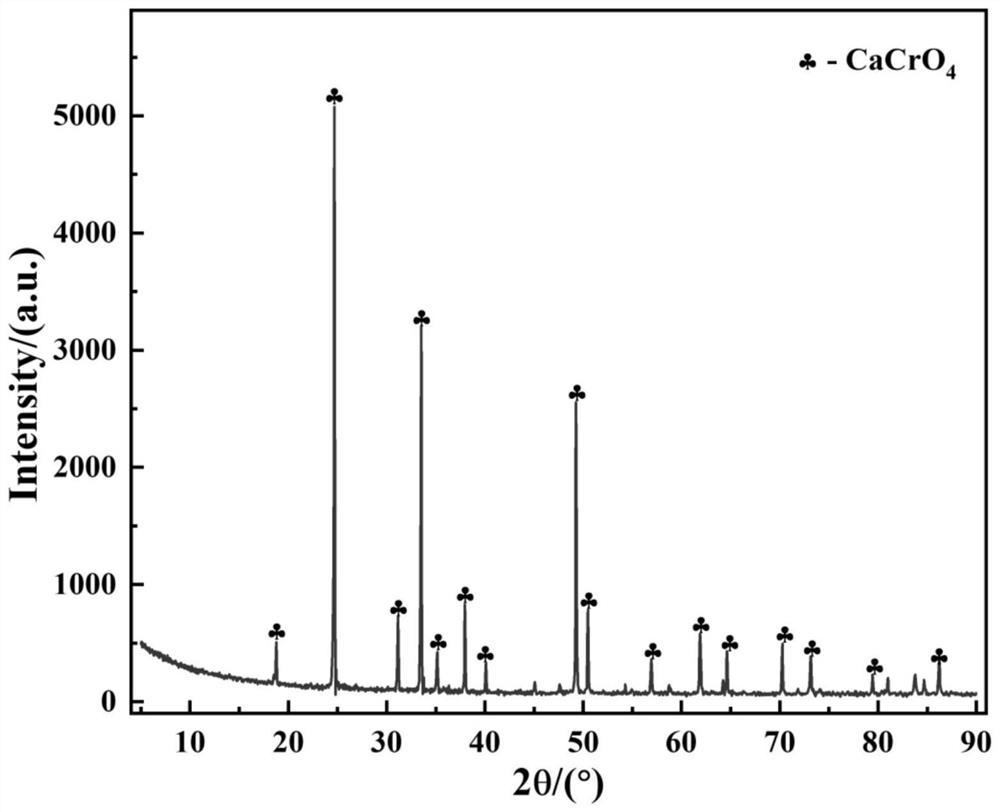

Method for quantitatively detecting calcium chromate in vanadium slag calcium roasting clinker

ActiveCN114018903ASolve problems that are difficult to quantifyMaterial analysis using wave/particle radiationAnalysis by thermal excitationPregnant leach solutionSlag

The invention relates to a method for quantitatively detecting calcium chromate in vanadium slag calcification roasting clinker. The method comprises the following steps: preparing a calcium chromate standard substance, selecting a standard medium, dissolving and leaching the obtained calcium chromate standard substance, marking the total chromium concentration in the obtained leachate as C1, leaching and dissolving the calcium chromate standard substance in an actual vanadium slag calcification vanadium extraction acid leaching medium, detecting and recording the chromium concentration in the leachate as C2, and calculating the acid leaching coefficient psi = C2 / C1; enabling the vanadium slag calcium roasting clinker to be subjected to a leaching experiment, and obtaining the chromium concentration in a leaching solution; and dividing the total chromium concentration in the obtained leachate by the acid leaching coefficient psi to obtain the total chromium concentration under the condition that the calcium chromate is completely dissolved, and further calculating the generation amount of the calcium chromate in the roasted clinker. According to the method, the generation condition of calcium chromate in the vanadium slag calcification roasting process is quantified on the basis of the acid leaching coefficient, the problem that calcium chromate is difficult to quantitatively characterize at present is solved, and a basis is provided for large-scale utilization of a vanadium slag calcification vanadium extraction process.

Owner:NORTHEASTERN UNIV

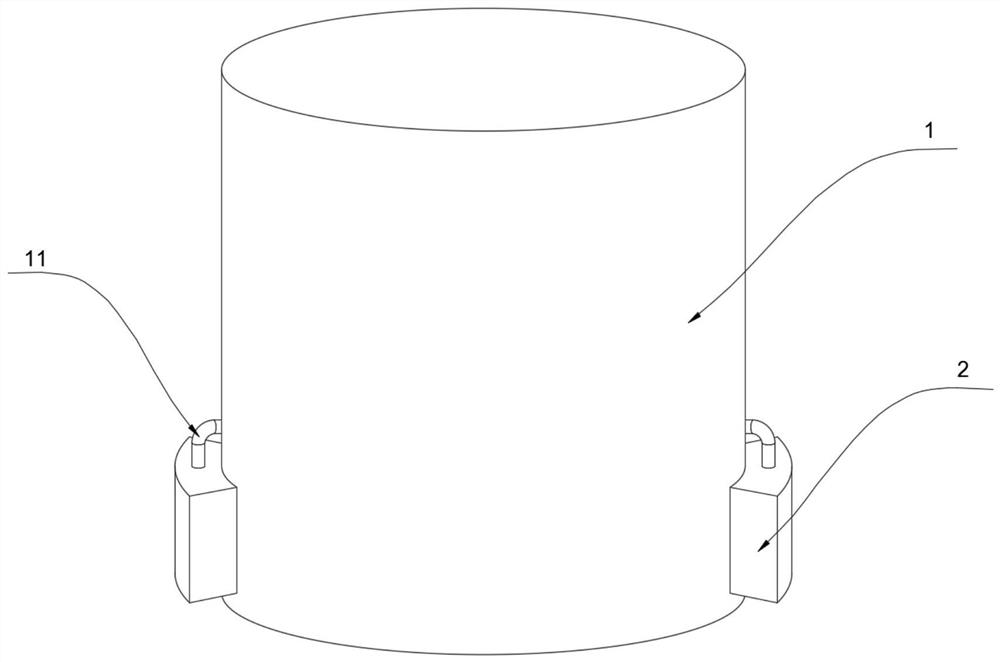

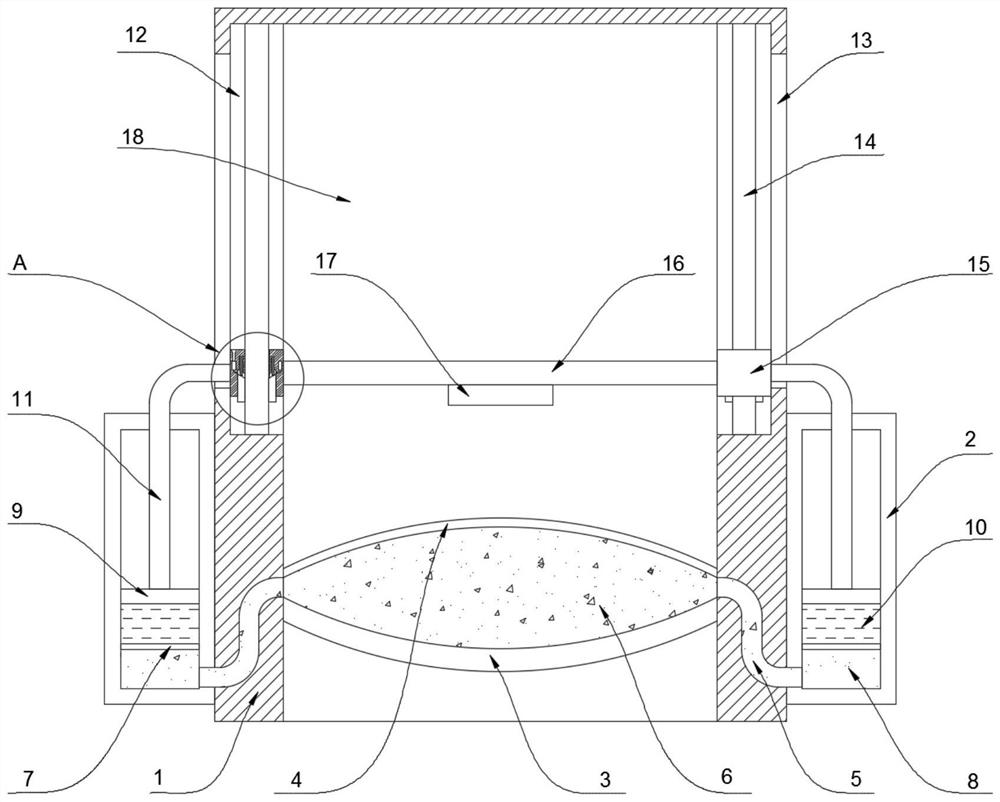

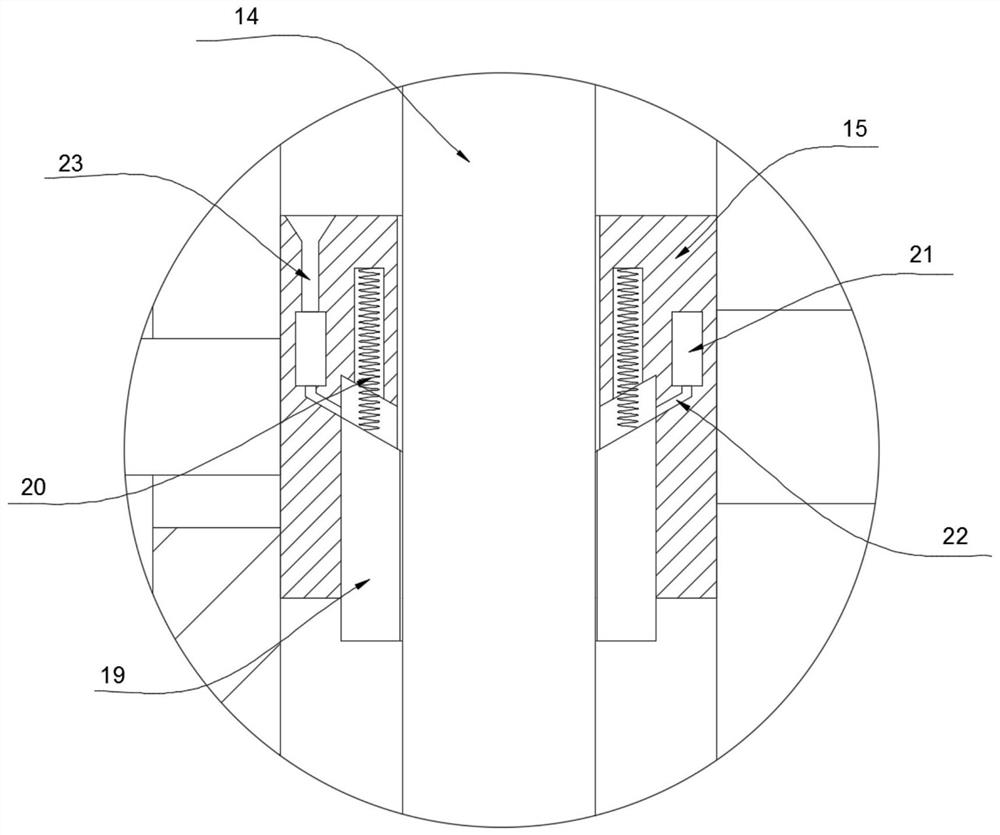

Self-adjusting and high-heat-dissipation LED lamp

InactiveCN112082095AReduce concentrationReduce frictionLighting heating/cooling arrangementsConduits/junctionsLiquid storage tankEngineering

The invention discloses a self-adjusting and high-heat-dissipation LED lamp. The lamp comprises a lamp body; the lamp body is of a cylindrical barrel structure; liquid storage tanks are symmetricallywelded and fixed to the two sides of the lamp body; a lens is fixed in the lamp body in a glued mode; a transparent film is fixed in the lamp body in a glued mode; the transparent film and the lens jointly form a cavity; grooves are symmetrically formed in the inner wall of the lamp body; sliding grooves are formed in the inner walls of the two grooves; sliding rods are fixedly welded to the interiors of the two grooves; sliding blocks are slidably connected to the sliding rods; a supporting plate is fixedly welded to the two sliding blocks jointly; and the LED lamp body is arranged on the supporting plate. The LED lamp has the advantages that when the LED lamp works for a relatively long time, a large amount of heat can be emitted, so that a calcium chromate saturated solution is separated out and the concentration of the calcium chromate saturated solution is reduced; and water in the calcium chromate solution flows into a sodium chloride solution through a semipermeable membrane, and a baffle is pushed, so that the LED lamp rises to leave a heat accumulation area on the surface of the lamp body and makes contact with a cold area on the surface of the lamp body for heat exchange.

Owner:德清县丰润电光源有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com