Method for industrially eliminating toxic ingredients in chromium slag

A technology for chromium slag and industrial water is applied in the field of eliminating toxic hexavalent chromium components in chromium slag and preparing calcium chromate or barium chromate, and can solve the problems of unsuitable treatment of bulk chromium slag, high treatment cost, and small amount of slag eaten. , to achieve the effect of being suitable for industrial utilization, eliminating environmental pollution and reasonable process structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

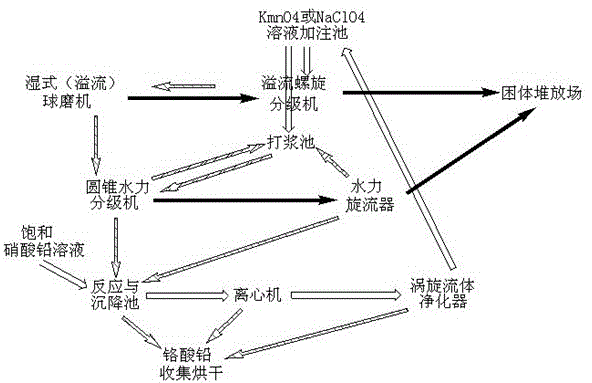

[0026] 1. Use a φ900×3000mm wet ball mill to grind 5 tons of 2‰KMnO 4 The solution and 5 tons of chromium slag were crushed to a particle size of <1 mm chromium slag.

[0027] 2. Transfer the above-mentioned chromium slag into the overflow spiral classifier, and wash it countercurrently with 15 tons of industrial water.

[0028] 3. All the above-mentioned water enters the cone hydraulic classifier and the hydrocyclone respectively to separate the chromium slag and mud in the water.

[0029] 4. Transfer the cleaning solution for separating chromium slag and mud into a 25-ton volume reaction tank.

[0030] 4. Use 5% hydrochloric acid solution to adjust the pH range of the leaching solution in the storage tank between 6 and 8, and add saturated CaCl 2 solution until no more precipitation occurs. Let it settle for 12 hours.

[0031] 5. Extract the supernatant and recycle it. The calcium chromate precipitate is dehydrated with a centrifuge and dried.

[0032] 6. Analysis ...

Embodiment 2

[0037] 1. Use a φ900×3000mm wet ball mill to grind 5 tons of 1‰NaClO 2 The solution and 5 tons of chromium slag were crushed to a particle size of <1 mm chromium slag.

[0038] 2. Transfer the above-mentioned chromium slag into the overflow spiral classifier, and wash it countercurrently with 15 tons of industrial water.

[0039] 3. All the above-mentioned water enters the cone hydraulic classifier and the hydrocyclone respectively to separate the chromium slag and mud in the water.

[0040] 4. Transfer the cleaning solution for separating chromium slag and mud into a 25-ton volume reaction tank.

[0041] 4. Use 5% hydrochloric acid solution to adjust the pH range of the leaching solution in the storage tank between 6 and 8, and add saturated BaCl 2 solution until no more precipitation occurs. Let it settle for 12 hours.

[0042] 5. Extract the supernatant and recycle it. The calcium chromate precipitate is dehydrated with a centrifuge and dried.

[0043] 6. Analysis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com