Patents

Literature

104results about How to "Reasonable process structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

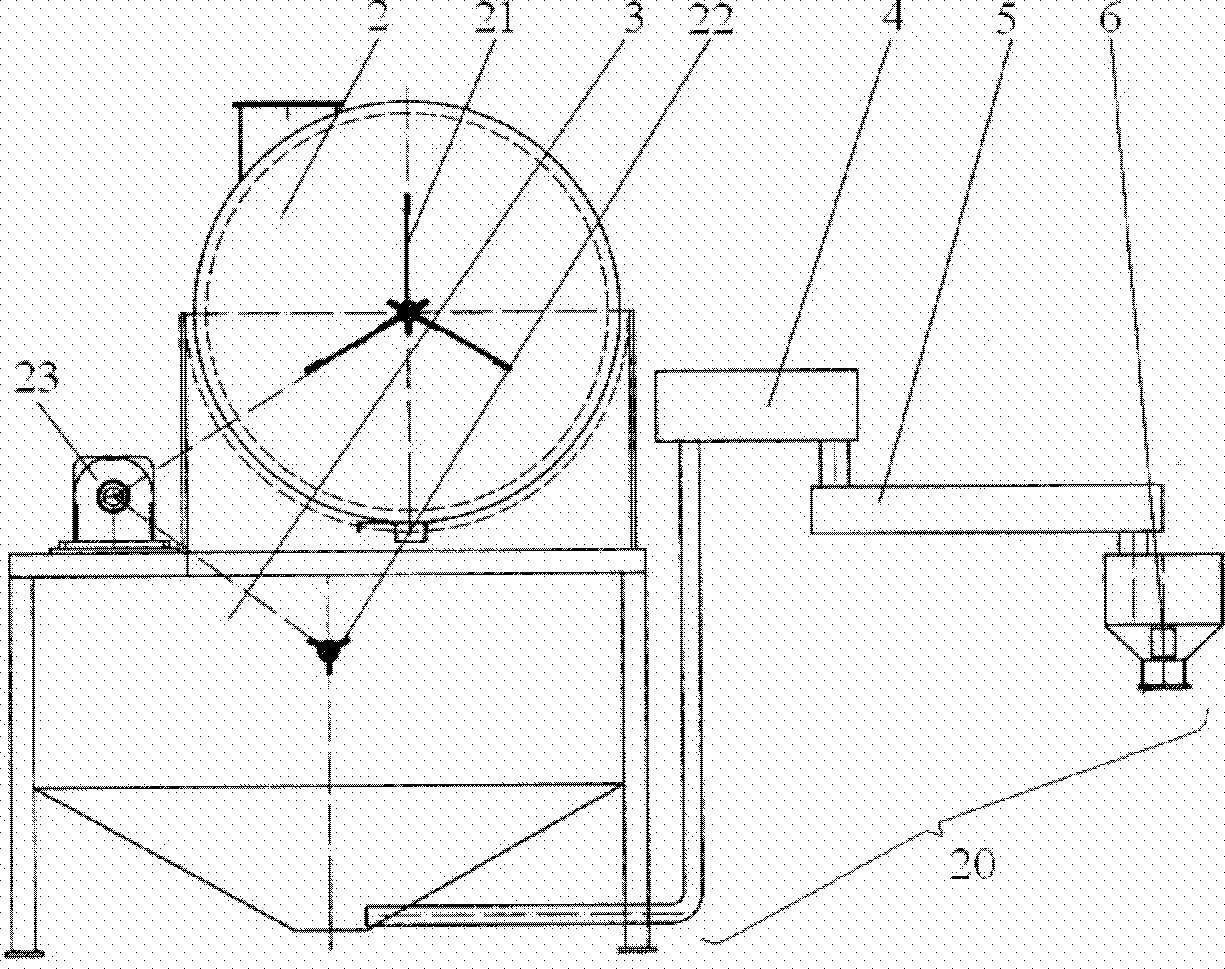

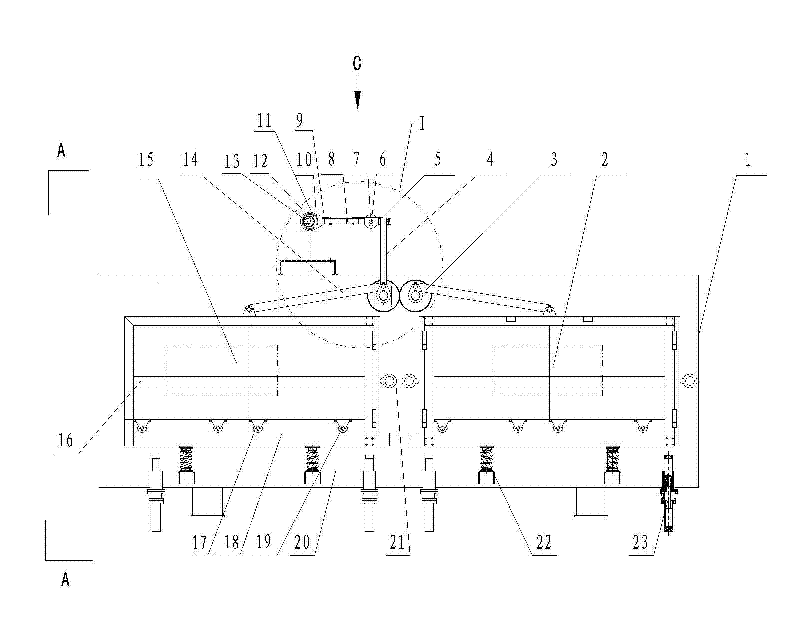

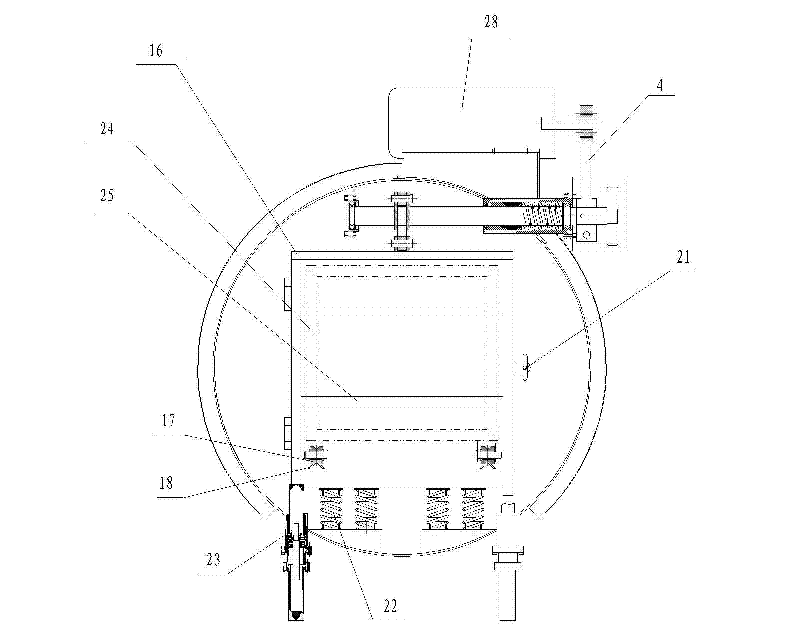

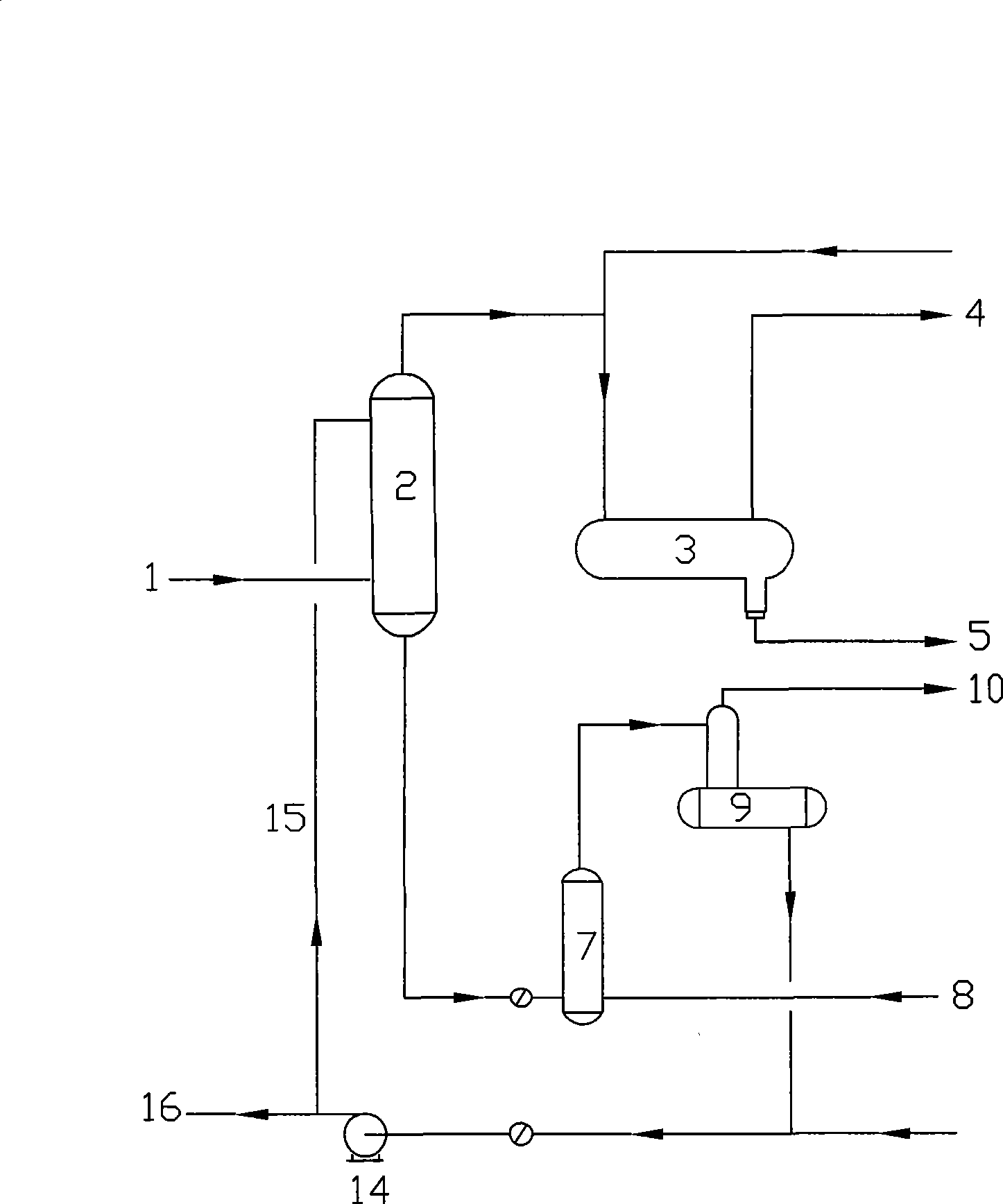

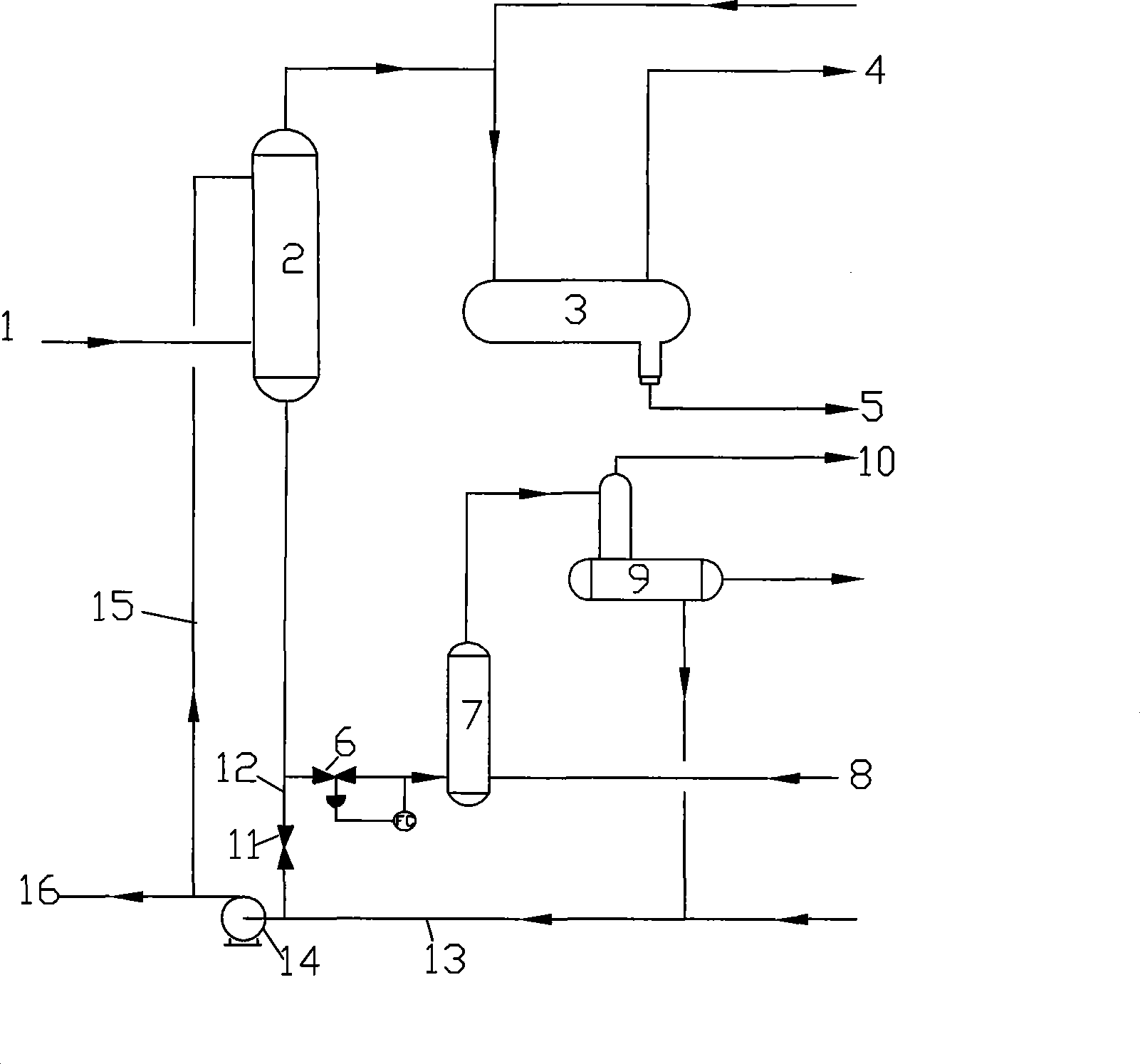

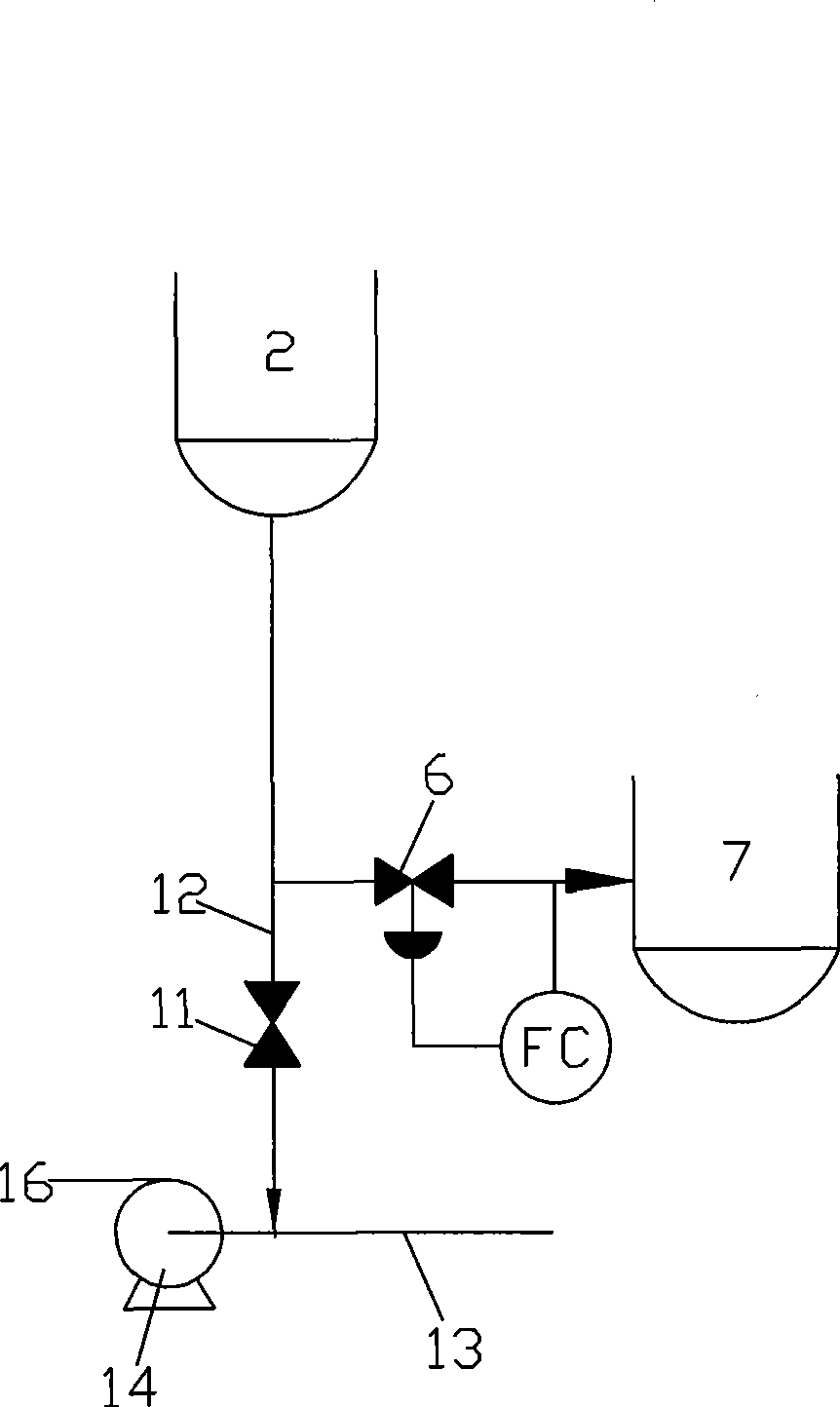

Liquid gas sweetening alkali liquor oxidized regeneration method and apparatus

ActiveCN101371967AGood dispersionImprove conversion rateDispersed particle separationEconomic benefitsOxygen

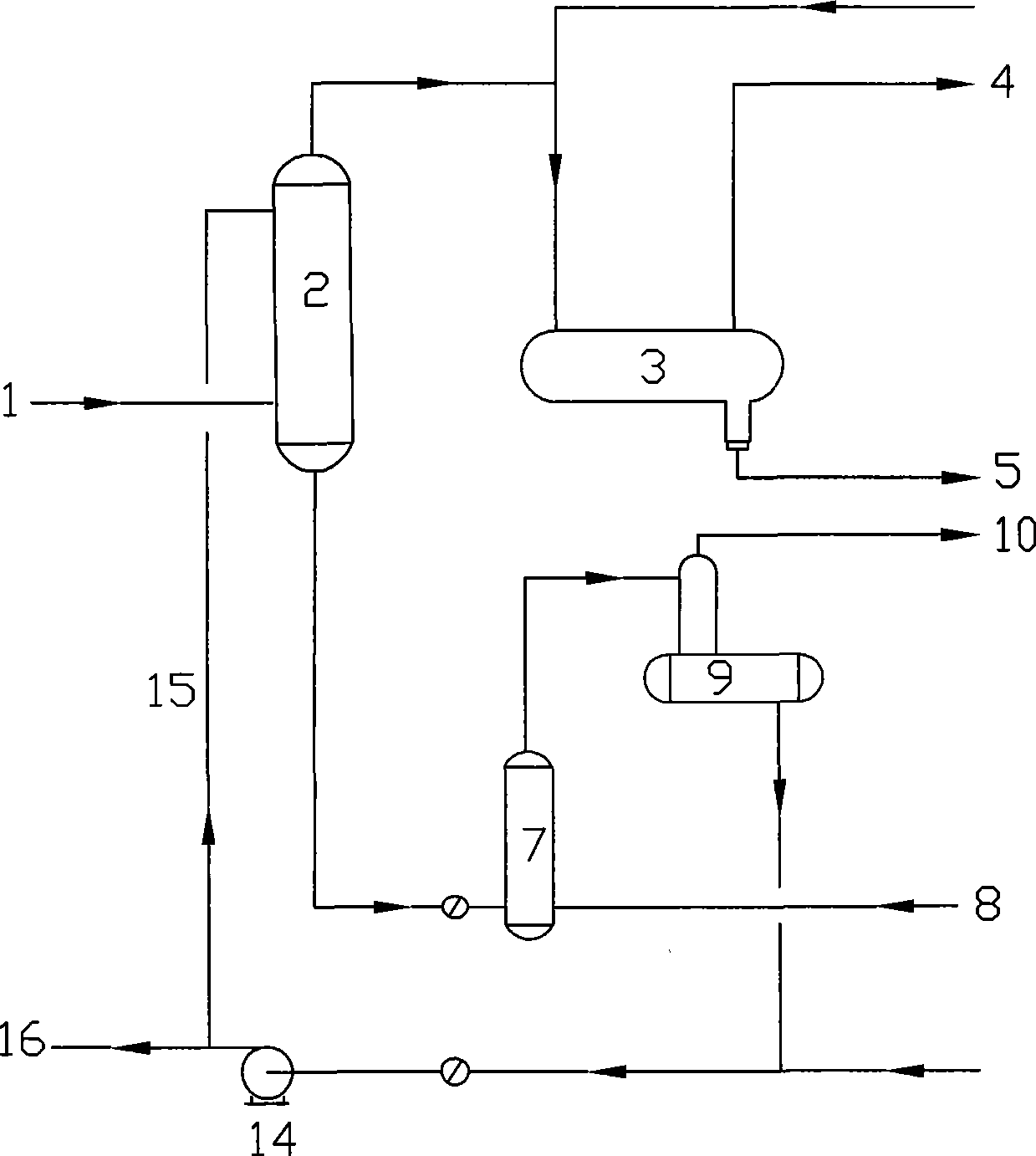

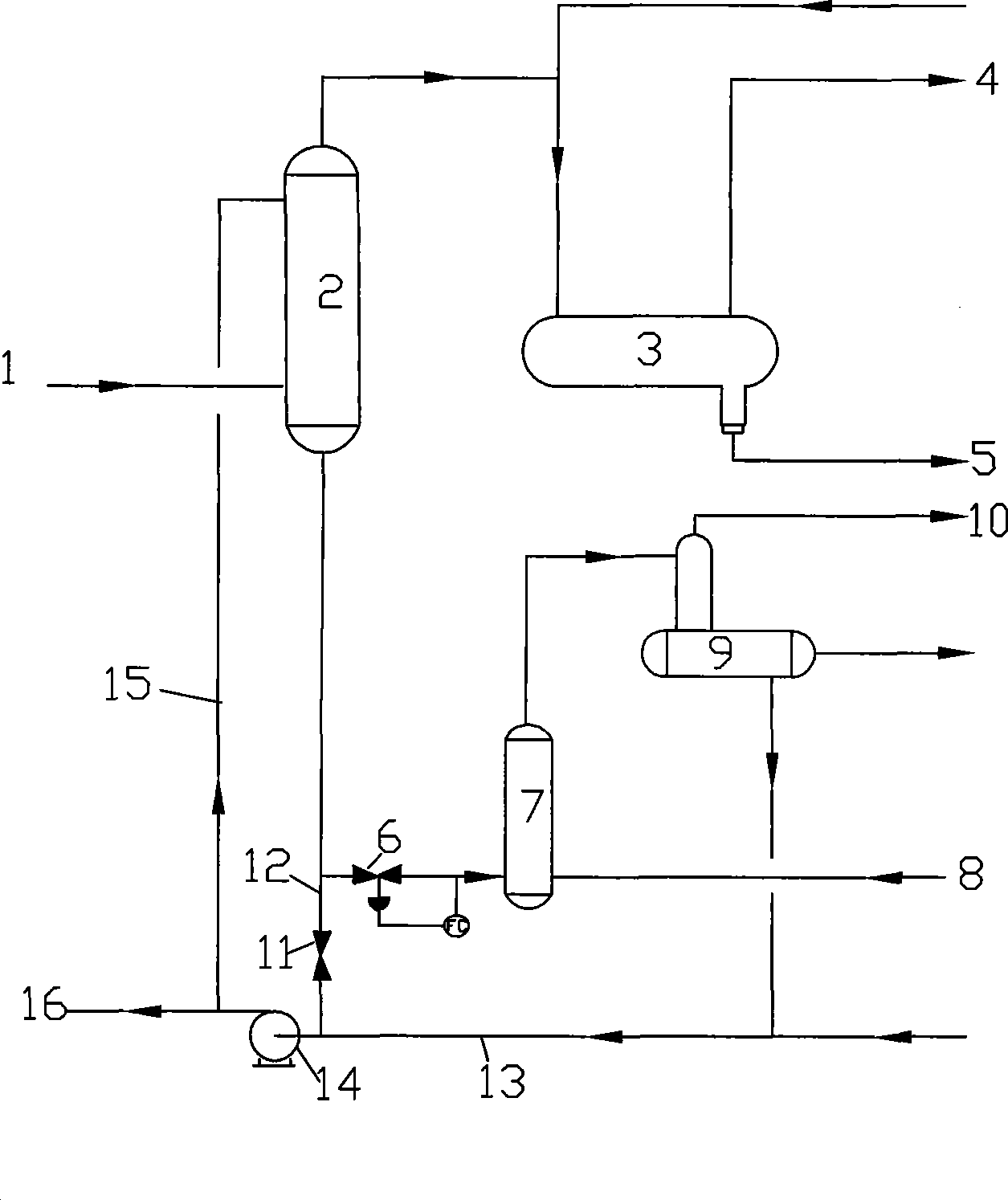

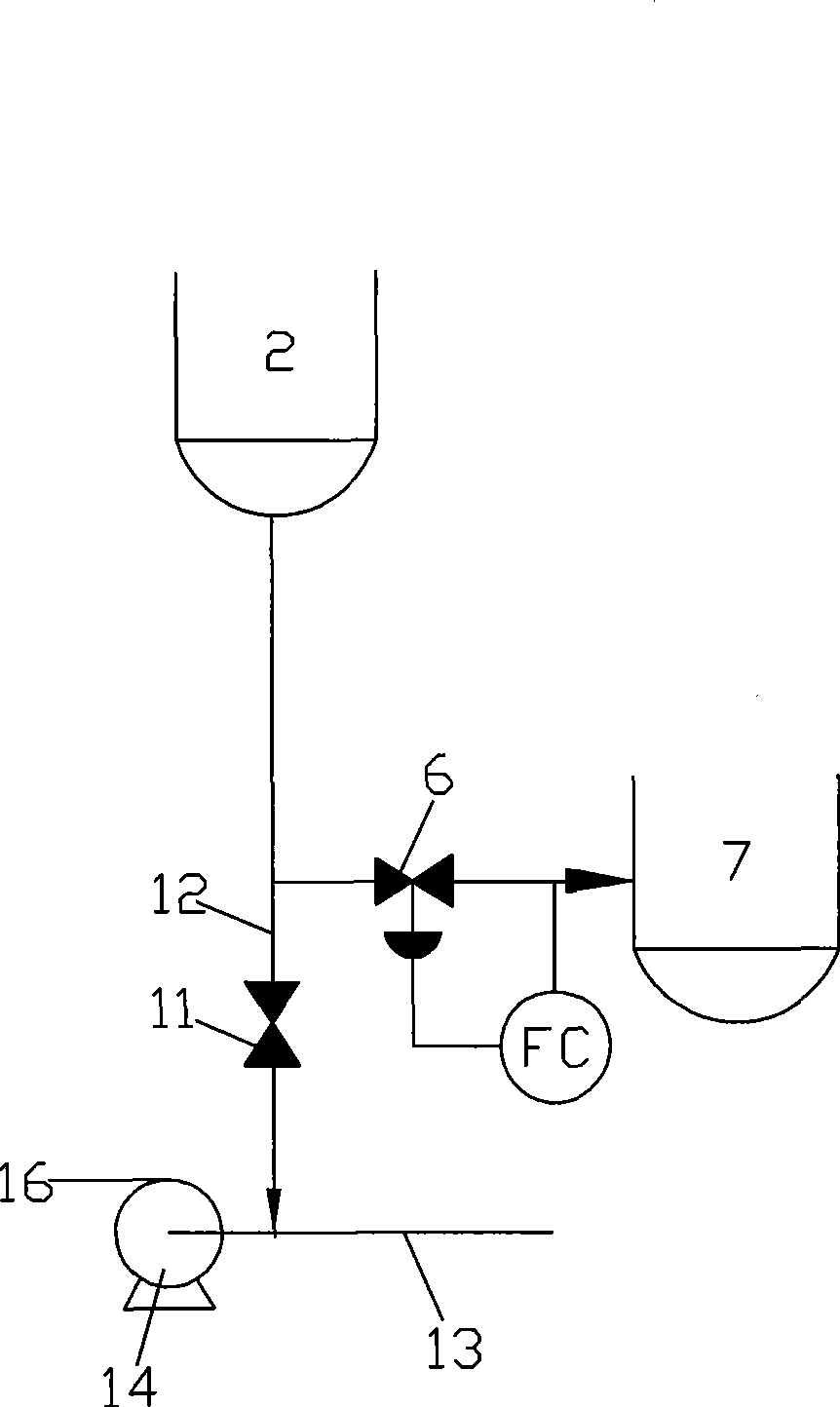

The present invention relates to a liquid gas sweetened alkali liquid oxygenating regeneration method. Sodium mercaptide in sweetened alkali liquid is transformed into sodium hydroxide and disulfide in air or oxygen-enriched air by catalyst to obtain regenerated alkali liquid after separation for recycling. The present invention is characterized in that a fraction of the sweetened alkali liquid is oxygenated and regenerated to obtain the regenerated alkali liquid which is mixed with the rest sweetened alkali liquid to be recycled into a sweetening reactor. The present invention also discloses a related device. The present invention has more reasonable technical method and structure, is very simple and easy for improving the traditional line and also has easy operation, easy implementation, low cost, good effect and outstanding economic benefit.

Owner:NINGBO ZHONGYI PETROCHEM TECH

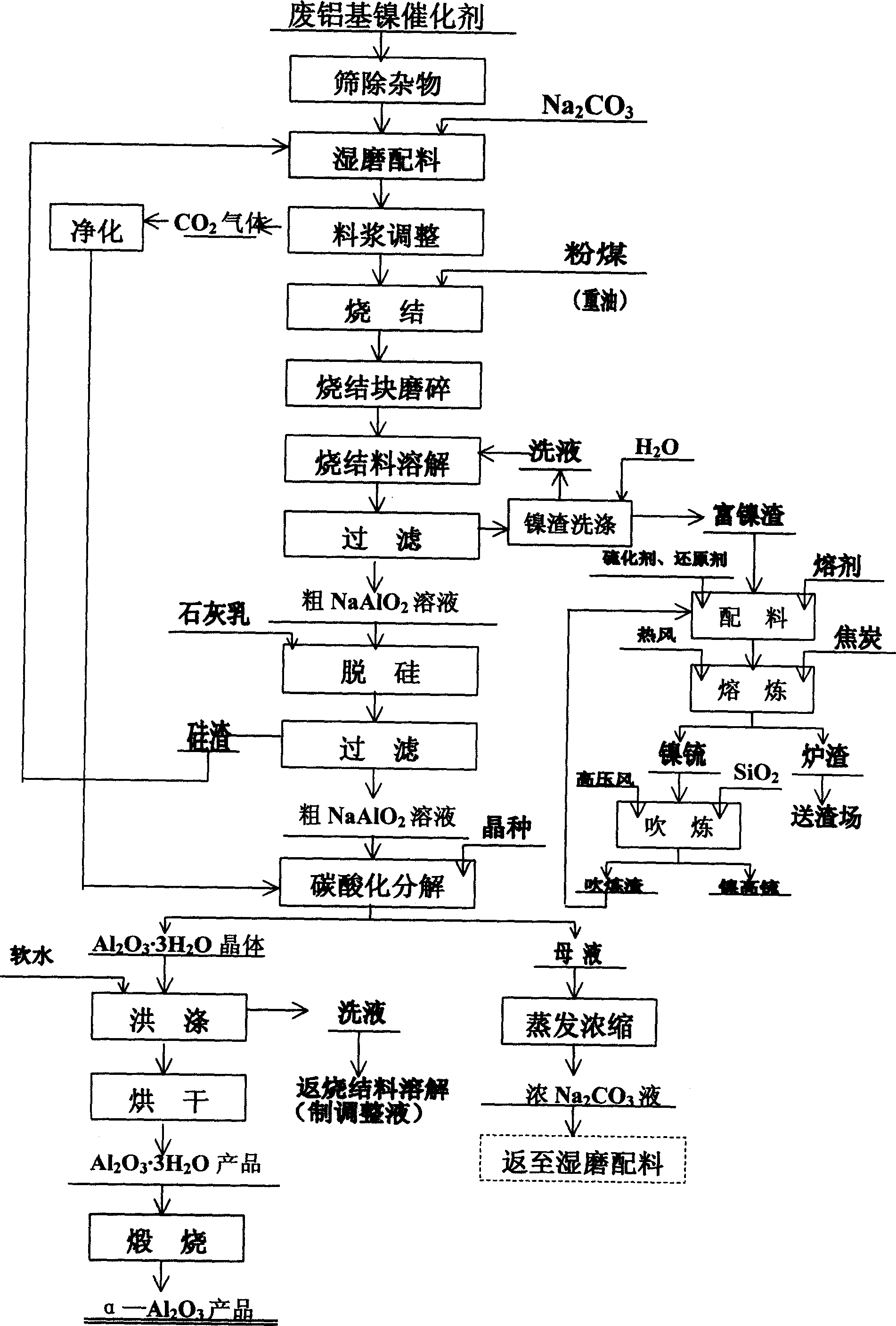

Method for recovering nickel and aluminum from waste aluminum based nickel-containing catalyst

InactiveCN1544666AEfficient separationEfficient recyclingProcess efficiency improvementDecompositionSodium aluminate

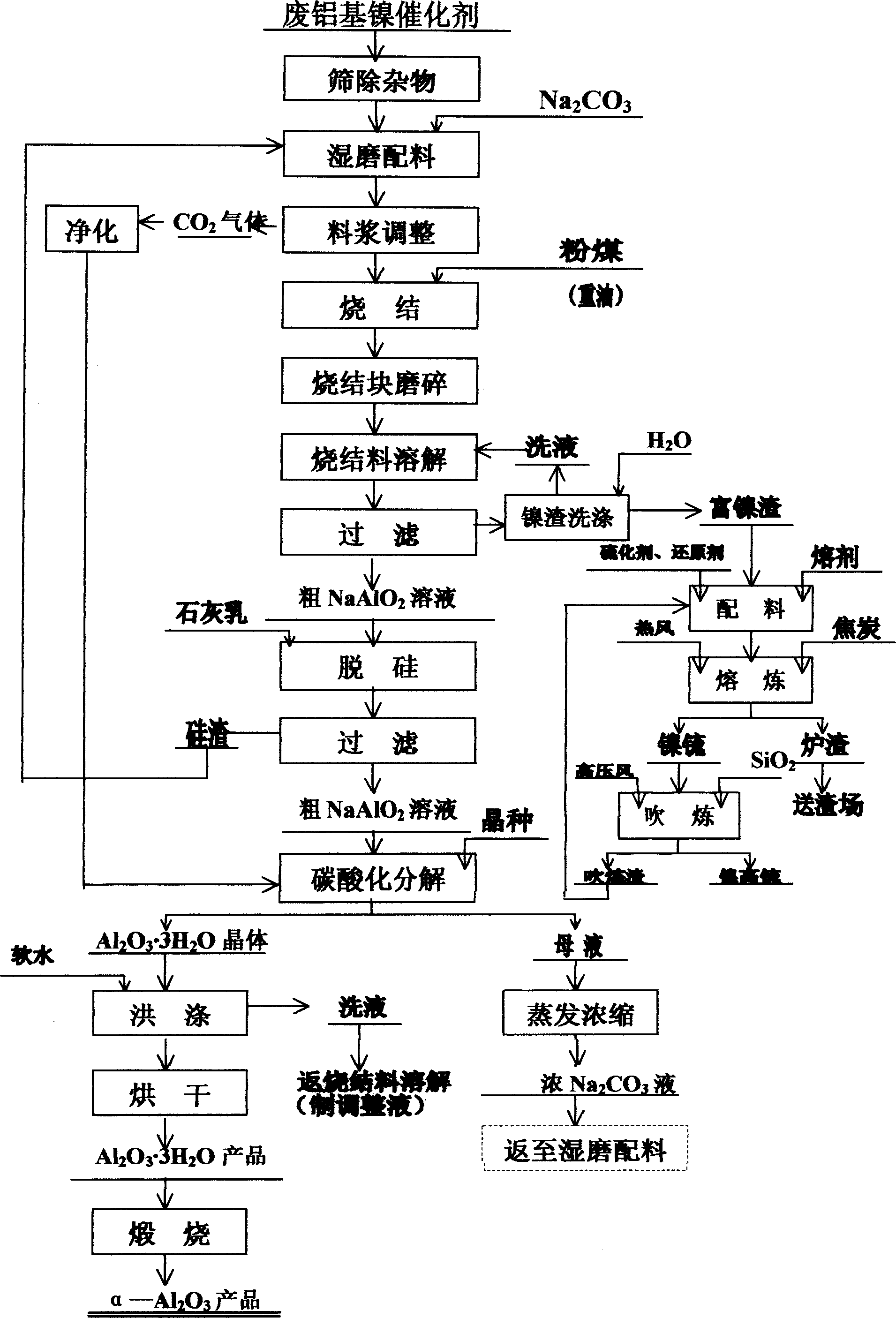

The invention is a method of recovering nickelic and aluminum from waste aluminum-based nickel catalyst, it has the characters of novel technique, reasonable flow, simple and convenient method and easy operation, and convenient scaled production, and benefits environmental protection. It includes the steps: sodium carbonate sintering and state-changing--boiling water dissolving sodium aluminate and separating aluminum--- making reducing-matte-making melting on nickel residues to obtain nickel matte Ni3S2-FeS-Ni-Fe alloy or copper-nickel matte Cu2S-Ni3S2-FeS alloy---blowing to obtain high-grade nickel matte Ni3S2 or high-grade copper-nickel matte Cu2S-Ni3S2-Cu-Ni alloy---desiliconizing crude NaAlO2 solution---making carbonated decomposition to obtain aluminum hydrate Al2O3íñ3H2O---calcining to obtain anhydrous aluminum oxide alpha-Al2O3. It is suitable to recover nickel and aluminum from the waste residue generated by extracting molybdenum and vanadium from waste aluminum-based nickelic catalysts and disabled catalysts containing nickel, aluminum, molybdenum and vanadium.

Owner:SHENYANG JIAHE METALLURGICAL FURNACE CHARGE

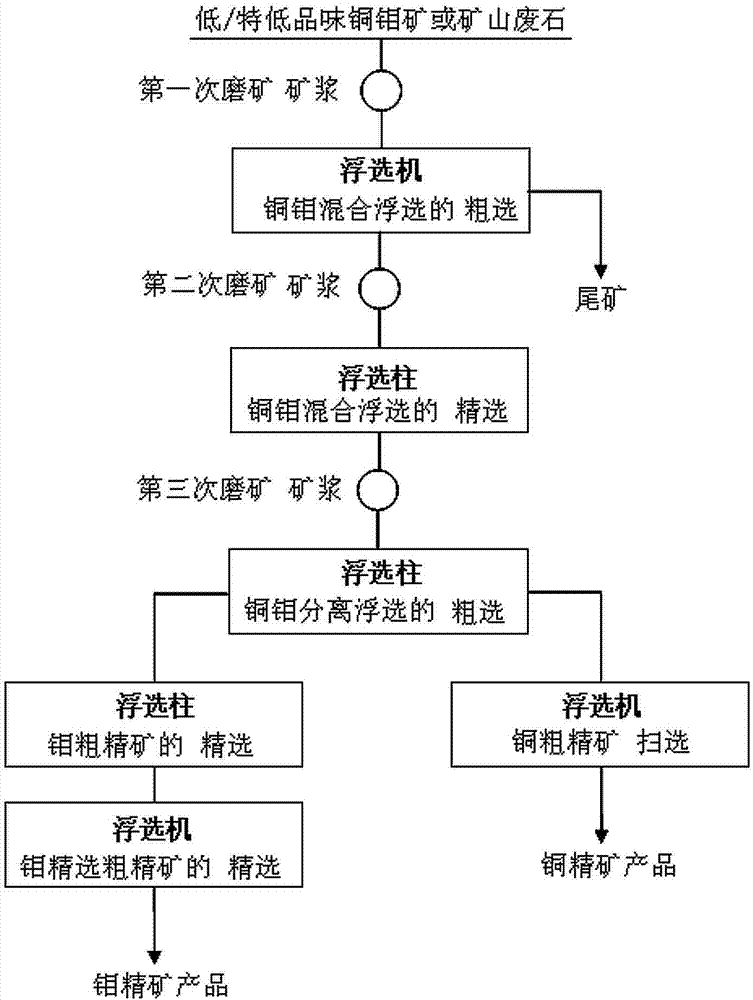

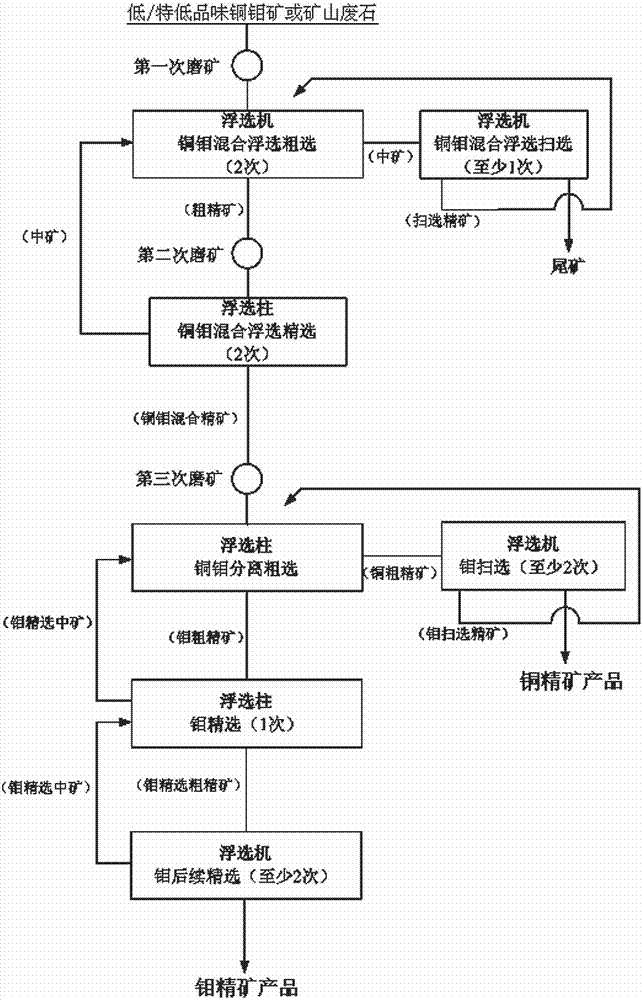

Flotation separation method of low / extra-low grade copper-molybdenum ore or chat

InactiveCN104722409AReduce production energy consumptionEasy to operate and controlFlotationCopperMaterials science

The invention discloses a flotation separation method of low / extra-low grade copper-molybdenum ores or chats. The raw material is smashed until the fineness of the raw material is 0.074 mm, the occupying rate ranges from 50% to 80%, the raw material is prepared into ore pulp with the weight ranging from 25% to 40%, the PH value of lime is adjusted and ranges from 7 to 9, and then copper-molybdenum bulk flotation and rougher flotation are conducted by a flotation machine, so that copper-molybdenum bulk flotation rough concentrate is acquired; the copper-molybdenum bulk flotation rough concentrate is smashed until the fineness of the copper-molybdenum bulk flotation rough concentrate is 0.043 mm, the occupying rate ranges from 50% to 80%, and the copper-molybdenum bulk flotation rough concentrate is prepared into ore pulp with the weight ranging from 20% to 35%; a flotation column is adopted to conduct the detailed flotation of the copper-molybdenum bulk flotation, and copper-molybdenum bulk concentrate is acquired, the copper-molybdenum bulk concentrate is re-smashed until the until the fineness of the copper-molybdenum bulk concentrate is 0.038 mm, the occupying rate ranges from 70% to 90%, and the copper-molybdenum bulk concentrate is prepared into ore pulp with the weight ranging from 15% to 30%; the flotation column is used for conducting the rougher flotation of copper-molybdenum, one or more times of flotation on the occupied copper rough concentrate and molybdenum rough concentrate are conducted by the flotation machine / flotation column, and the final copper concentrate and molybdenum concentrate are acquired. The flotation separation method can deal with extra-low hard-flotation copper-molybdenum ores or chats with the copper grade lower than 0.2% and the molybdenum grade lower than 0.01%, and the copper concentrate with the copper grade higher than 23% and the molybdenum concentrate with the molybdenum grade higher than 43% are acquired.

Owner:四川省冶金地质勘查院 +1

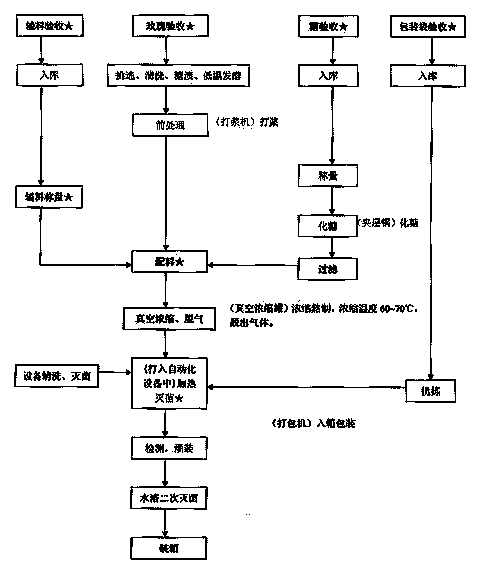

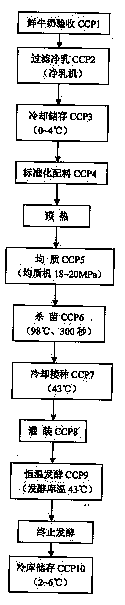

Fresh flower yoghourt and production method

InactiveCN103783158AReasonable process structureConsistent appearance and colorMilk preparationSugarFermentation

The invention relates to fresh flower yoghourt and a production method. The fresh flower yoghourt mainly comprises an isotrope acidification fermented product of edible fresh flower sugaring flower mud and fresh milk and has the unadulterated special flower nourishing smell, and the fresh flower is one or more of rose, arabian jasmine flowers, osmanthus fragrans, lily and lotus. The production method comprises the following steps of cleaning fresh petals, carrying out pickling on the fresh petals by using granulated sugar, carrying out low-temperature fermentation on the fresh petals, pulping, grinding the fresh pedals into mud, carrying out high-temperature sterilization on the fresh petals for later use, filtering and cleaning fresh milk passing acceptance inspection, and storing the fresh milk for later use at 0-4 DEG C; and mixing the flower mud and the fresh milk according to a proportion, simultaneously adding an emulsifying agent to carry out homogenization treatment, introducing fermentation bacteria after sterilization, and carrying out constant-temperature fermentation on the fermentation bacteria to obtain a finished fresh flower yoghourt. The fresh flower yoghourt has the characteristics that the texture is delicate and uniform, uniform fluid is formed after stirring, and can be pulled to be filiform, an appearance does not have fine particles, the luster is bright, the surface is flat, smooth and bright, the fresh flower yoghourt has mellow smell with the combination of fragrance and fermented milk, and the fresh flower yoghourt is tender, sour and sweet.

Owner:HONGHE YUNNIU DAIRY IND

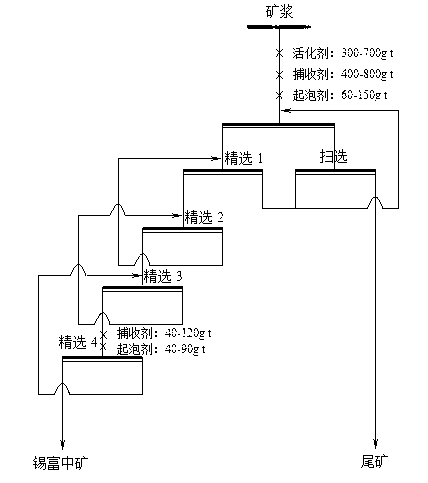

Method for recycling fine and superfine cassiterites from oxidized lode tin mud tailings

The invention relates to a method for recycling fine and superfine cassiterites from oxidized lode tin mud tailings and belongs to the technical field of mineral process engineering. The method comprises the following steps: adding water to the oxidized lode tin mud tailings and mixing slurry; during a roughing process, respectively adding activating agents, collecting agents and foaming agents in turn; roughing, thereby obtaining a foam product as a roughing concentrate and obtaining an in-slot product as a roughing middling; without adding any drug, scavenging the roughing middling, thereby obtaining the foam product as the scavenging middling and the in-slot product as the final tailing; returning the scavenging middling to the roughing operation for roughing again; and during a finely separating process, finely separating the roughing concentrate for four times, respectively returning the fine separating middling obtained from the finely separating operation at each time to the last operation for separating again, only adding the collecting agents and the foaming agents after finishing the fine separating for the third time, and separating and finally obtaining the tin-rich middling. According to the method, the process is simple, the flow structure is reasonable, the adaptability to raw materials is wider and the industrial implementation is easily performed.

Owner:KUNMING UNIV OF SCI & TECH

Method for utilizing waste hydro-treatment catalyst

ActiveCN103769173APhysical properties (lower than surfaceLow pore volumeOrganic compound preparationCarbonyl compound preparationPartial oxidationAcrolein

The invention discloses a method for utilizing waste hydro-treatment catalyst. The method utilizes waste hydro-treatment catalysts which have been used in partial oxidation of propane to prepare acrolein and hydro-treatment, recycles the Mo, Co, Ni, and alumina carriers in waste hydro-treatment catalysts, also fully recycles Ni and V which are deposited on the waste hydro-treatment catalysts, thus solves the pollution problem caused by waste catalysts, saves the resources, increases the economic profit, and is easy to carry out in technology.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing ferro-nickel alloy from nickel oxide material

The invention discloses a method for producing a ferro-nickel alloy from a nickel oxide material, and belongs to the field of ferrous metallurgy. The ferro-nickel alloy prepared from the nickel oxide material consists of irony laterite-nickel ore, magnesian laterite-nickel ore, iron simatic laterite-nickel ore and nickel-rich slag obtained after aluminum oxide, molybdenum oxide and vanadium oxide are separated by using a waste nickel-base catalyst, wherein the nickel accounts for 0.6-2.0% of the laterite-nickel ore, the nickel accounts for 4-10% of the nickel-rich slag, the mass ratio of the laterite-nickel ore to the nickel-rich slag is (98-60):(2-40). Additives are added into tthe nickel oxide of the ratio according to the method for producing the ferro-nickel alloy from the nickel oxide material, and are uniformly mixed and pressed into blocks so as to prepare a ferro-nickel alloy product which meets the requirements on ferronickel raw materials in stainless steel production, the energy is saved, the consumption is reduced, environment pollution is reduced, the novel process is reasonable in structure, preconcentration treatment on the laterite-nickel ore is not needed, high energy consumption equipment such as a blasting furnace and an electric furnace is not needed, the raw materials are high in adaptability, and great significance in improving the comprehensive utilization rate of nickel-poor oxidized ore and secondary nickel resource is achieved.

Owner:温德昌 +1

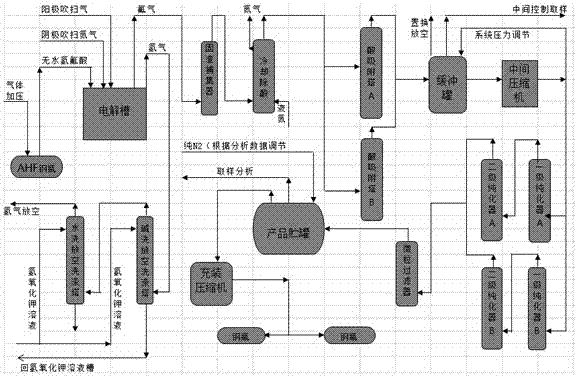

Production method and production device of high-purity fluorine gas and fluorine containing mixed gas

InactiveCN107459020AReasonable structureReliable handlingElectrolysis componentsFluorine/hydrogen-fluorideSorbentNitrogen gas

The invention discloses a production method and a production device of high-purity fluorine gas and fluorine containing mixed gas. The production device mainly consists of an anhydrous hydrogen fluoride steel cylinder, an electrolytic cell, a solid residue catcher, a cooling acid remover, an acid adsorption tower, a buffer tank, a middle compressor, a purifier, a particulate filter, a product storage tank, a filling compressor, a finished product container, and a hydrogen gas washing tower. The production method comprises the following steps that dry nitrogen gas fills the anhydrous hydrogen fluoride steel cylinder; liquid anhydrous hydrogen fluoride is added into the electrolytic cell; an electrolytic reaction is performed to produce fluorine gas; and orderly the fluorine gas enters the solid residue catcher for removing particulate materials, enters the cooling acid remover for removing HF, enters the acid adsorption tower for removing hydrogen fluoride gas, enters the buffer tank, is compressed by the middle compressor and sent into the purifier, enters the particulate filter for removing adsorption agent particles, enters the product storage tank and fills the product steel cylinder. The production method and production device provided by the invention have the beneficial effects that the fluorine gas purity is high, the production process is simple, the operation performance is safe and reliable, the system runs stably, and continuous production and linkage self-control can be realized.

Owner:SHANGHAI HELI IND GAS CO LTD

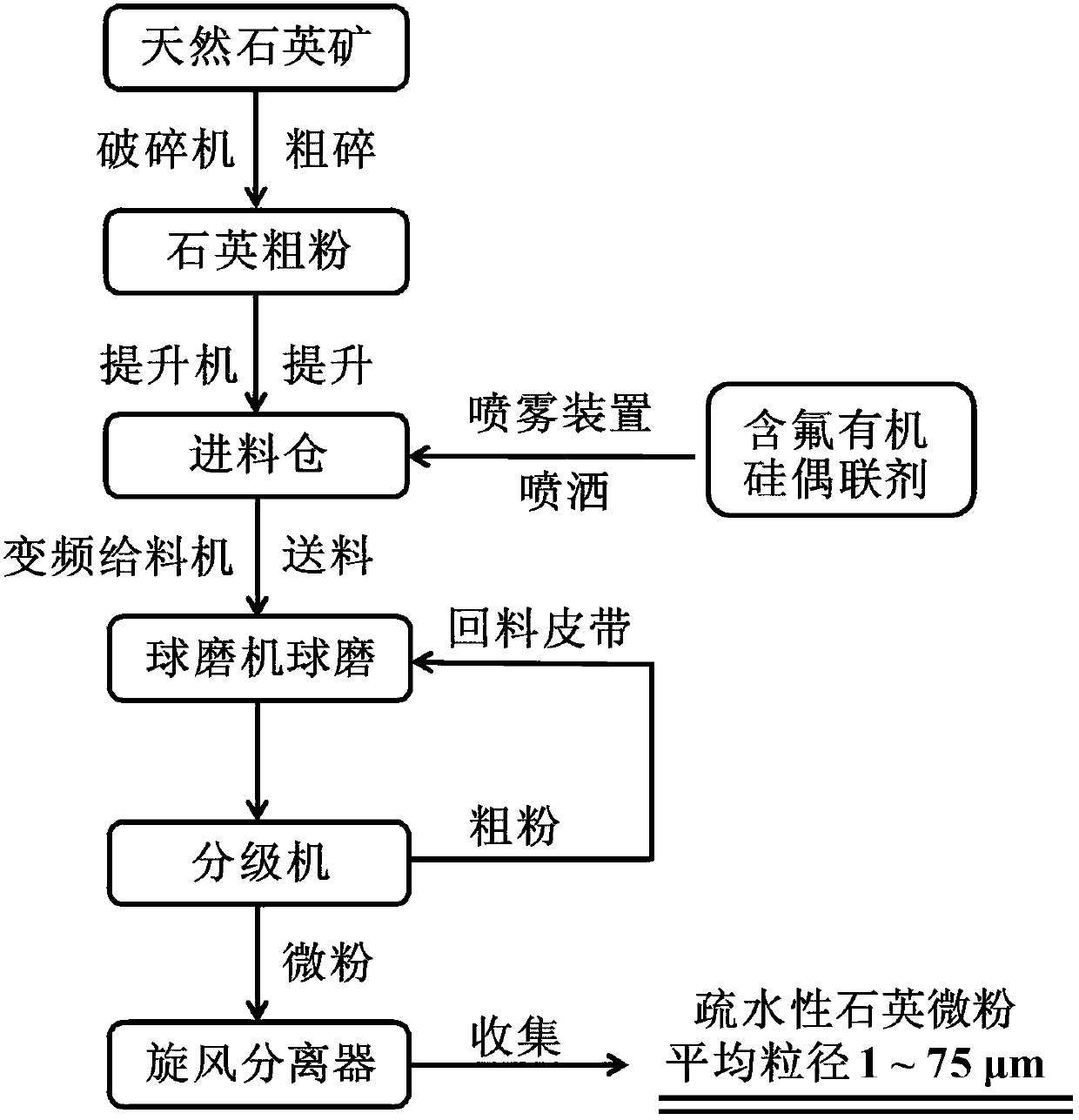

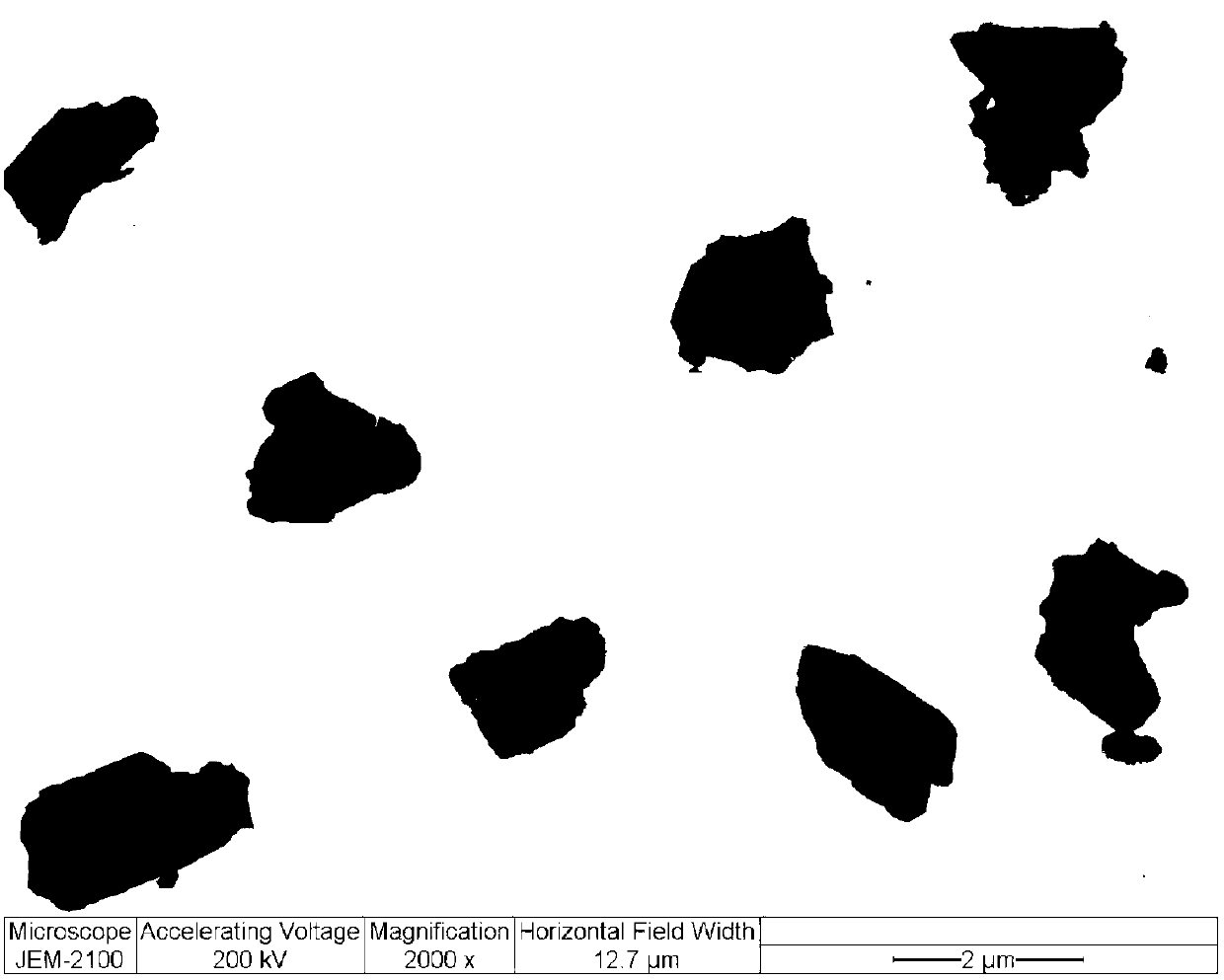

Hydrophobic quartz micro powder as well as integrated production process and application thereof

ActiveCN103342902AGood effectAdvanced production process control methodsPigment treatment with organosilicon compoundsPigment physical treatmentEpoxyPhysical chemistry

The invention discloses a hydrophobic quartz micro powder as well as an integrated production process and application thereof. The average particle size of the hydrophobic quartz micro powder is 1-75 microns, and the hydrophobic quartz micro powder contains 0.2-3% of a fluoric organic silicon coupling agent in percentage by mass; a fluoric silane coupling agent is used for performing surface graft modification on the quartz micro powder, so that the hydrophobicity and dispersity of the quartz micro powder can be effectively improved, and the added value of the conventional quartz micro powder is greatly improved; and the hydrophobic quartz micro powder can be used as a filler for epoxy resin to prepare outdoor epoxy resin products with strong hydrophobicity. Besides, integration is realized through multi-step processes including mineral separation, coarse crushing, fine grinding, hydrophobic modification, classification, collection and the like, so that the operation is simple, and the labor cost is reduced; and moreover, the spraying speed of the silane coupling agent is controlled, so that the grafting degree of the silane coupling agent on the surface of the quartz micro powder can be simply, conveniently and effectively adjusted, and then the hydrophobicity and dispersity of the quartz micro powder can be conveniently adjusted and controlled.

Owner:ZIYUAN COUNTY TIANSHENG NEW MATERIAL DEV

Waste hydrogenation catalyst utilization method

ActiveCN106944137AIncrease profitImprove pore structureOrganic-compounds/hydrides/coordination-complexes catalystsCatalystsHeteropoly acidFurfural

The present invention discloses a waste hydrogenation catalyst utilization method, which comprises: grinding a waste hydrogenation catalyst, soaking with ammonia water, adding alumina, a binder and an acid solution to the remaining solid, and carrying out mixing kneading molding; carrying out reducing treatment with hydrogen gas in a high pressure reaction kettle; adding a polyol and / or furfural solution to the high pressure reaction kettle, and carrying out a hydrogenation reaction; and drying the material obtained after the reaction until the surface is liquid-free, sequentially contacting an organic acid, ammonium or ammonia, and loading a heteropoly acid to produce the catalyst for ethylene preparation through ethanol dehydration. According to the present invention, with the method, the hydrogenation activity metal component and the carrier component in the waste hydrogenation catalyst are utilized, and the hydrogenation activity of the waste hydrogenation catalyst is completely utilized, such that the utilization rate of the waste catalyst is improved, the pollution problem of the waste catalyst is solved, and the obtained catalyst for ethylene preparation through ethanol dehydration has the excellent performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Punching technique for cambered surface punch forming

The invention discloses a punching technique for cambered surface punch forming. The punching technique comprises the following steps: a) punching and trimming: performing punching blanking processing on a to-be-processed workpiece, and then blanking an edge of the workpiece, thereby acquiring the shape and size required by the workpiece; b) raising and pressing a rough edge: raising the workpiece, and then performing rough edge pressing treatment on a mould after raising; c) forming radian: utilizing the upper and lower mould characteristics of a mould to finish the forming of the workpiece from a plane to a cambered surface; d) step forming and bending: performing step treatment on the formed cambered surface and bending the opposite angles on the two sides of the cambered surface, wherein the bending angle is at 30 degrees; f) laterally pushing and flattening: utilizing lateral pushing flattening devices on the two sides of the mould to laterally push and flatten the local surface of the workpiece. According to the technique, the structure is reasonable, the quality problem during a forming process of the cambered surface is effectively relieved, the precision of the formed cambered surface is ensured, the damage to the mould during the forming process is effectively reduced, and the production cost is lowered.

Owner:KUNSHAN HUANGJIA PRECISION MOLD

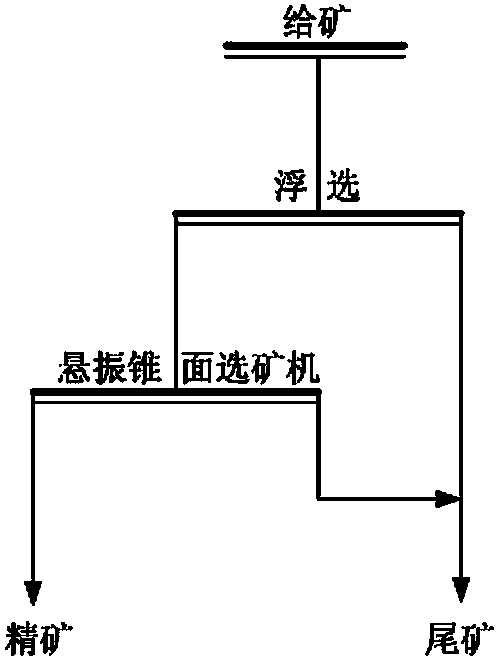

Fine fraction ilmenite flotation-gravity separation combined technology

InactiveCN103721843AGood enrichment efficiencySolve the technical problems of efficient recyclingWet separationRecovery methodIlmenite

The invention relates to a recovery method for ilmenite, in particular to a method for improving the recovery rate of fine fraction ilmenite of 5-100 microns. According to the method, flotation preconcentration is carried out first, and then gravity separation is carried out. The method comprises the steps of (1) flotation, wherein ilmenite with TiO2 concentration of 7-15wt% is subjected to flotation preconcentration, and TiO2 rough concentrate with the concentration of 18-25wt% is obtained; and (2) gravity separation, wherein preconcentration ore is subjected to gravity separation through a suspension vibration conical surface concentrating machine, separation surface taper is 5-10 degrees, vibration frequency is 300-400 per minute, and disc surface edge rotating speed is 0.8-2.5 meters per minute. The method has the advantages that the treating amount is large, the grading index is stable, the recovery rate is high, energy loss is low, sorting efficiency is high, the method is simple, and separation cost is lowered.

Owner:KUNMING UNIV OF SCI & TECH

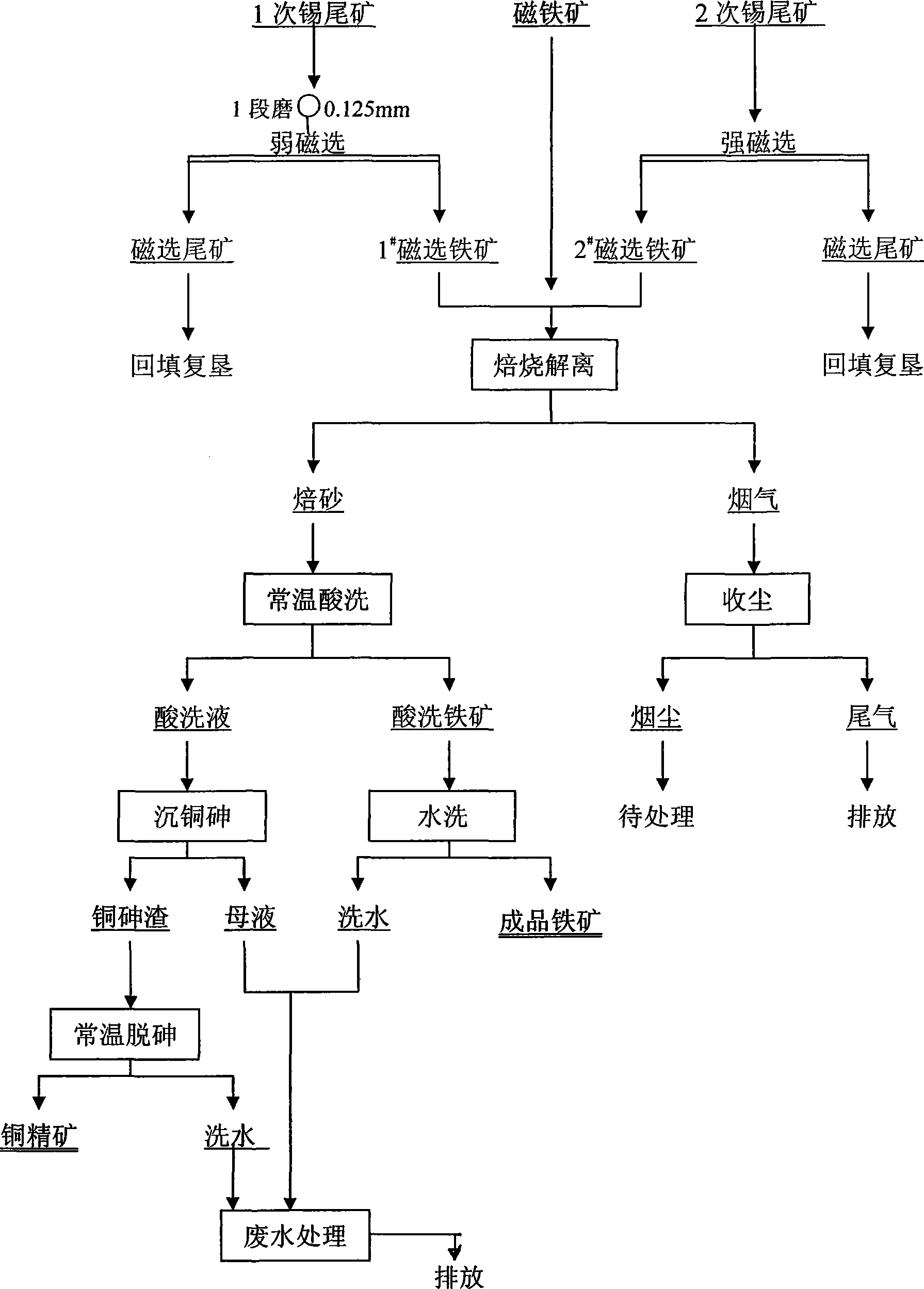

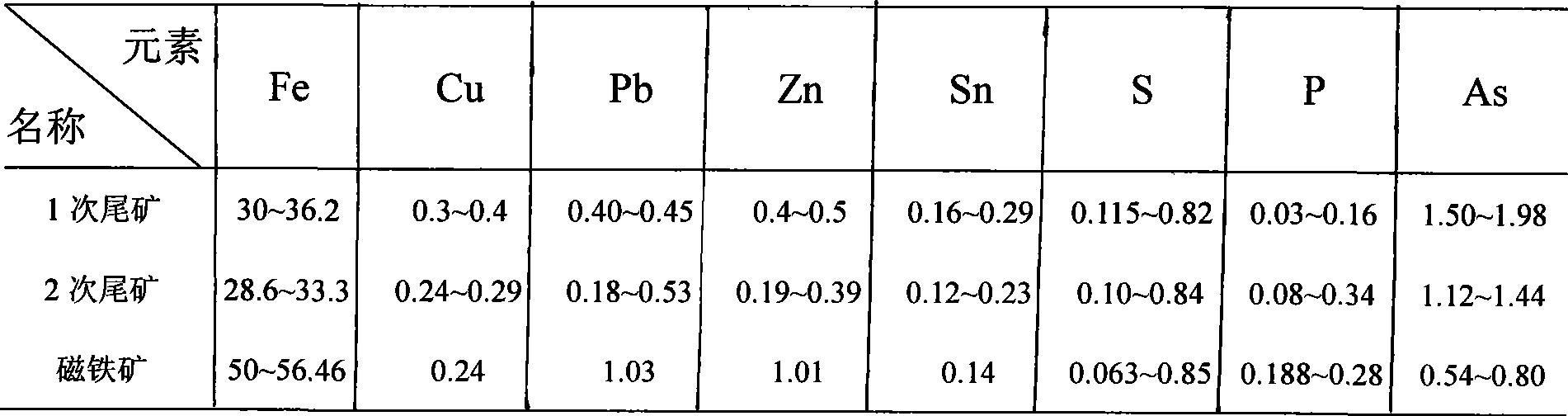

Method for producing iron ore concentrate by using poor-tin oxidized ore tailings

InactiveCN101545037ARestoring the ecological environmentWide adaptabilityMagnetic separationProcess efficiency improvementPhosphoniumImpurity

The invention relates to a method for producing iron ore concentrate by using poor-tin oxidized ore tailings, which comprises the following steps: by adopting a selection-smelting combined processing technique, producing magnetic separation iron ores by performing the first section of magnetic separation on the raw material poor-tin oxidized ore tailings; and performing roasting dissociation, acid cleaning and water cleaning treatment to remove impurities in the magnetic separation iron ores so as to obtain the iron ore concentrate. The iron ore concentrate containing 50 to 56.46 percent of iron also can be used as the raw material for producing the iron ore concentrate, which is also treated by the roasting dissociation, the acid cleaning and the water cleaning to obtain the iron ore concentrate. The iron grade of the iron ore concentrate reaches between 58 and 62 percent, and the content of harmful elements of sulfur, phosphonium, lead and arsenium also accords with the index requirement of the finished product of the iron ore concentrate. The method achieves the aims of effectively using ferrous metals in poor-tin tin oxide ore tailings, saving resources and energy sources, protecting the environment and comprehensively recycling associated metals.

Owner:GEJIU YULONG RENEWABLE RESOURCES MANAGEMENT

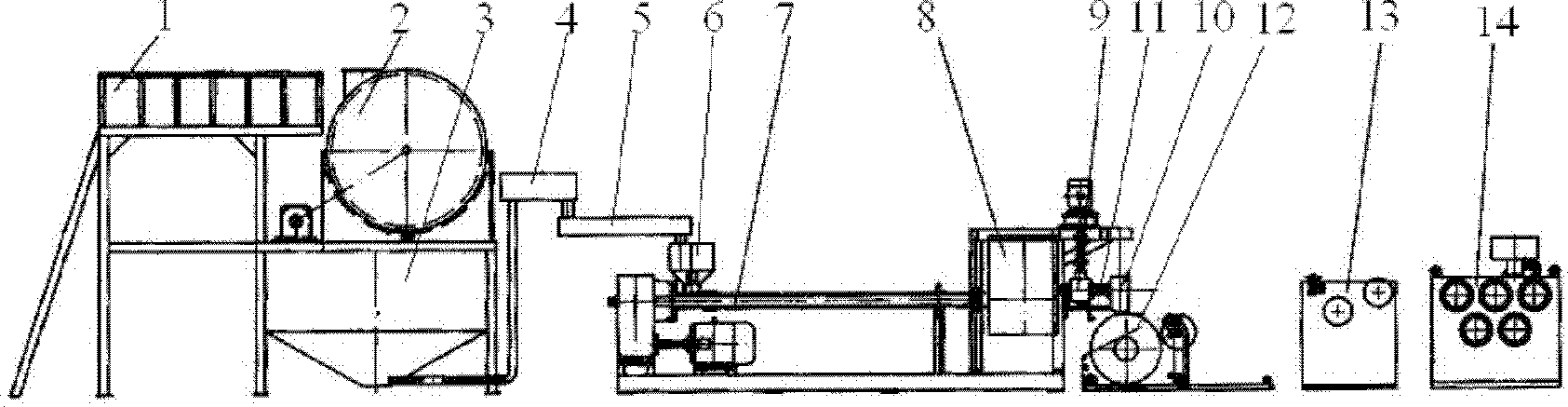

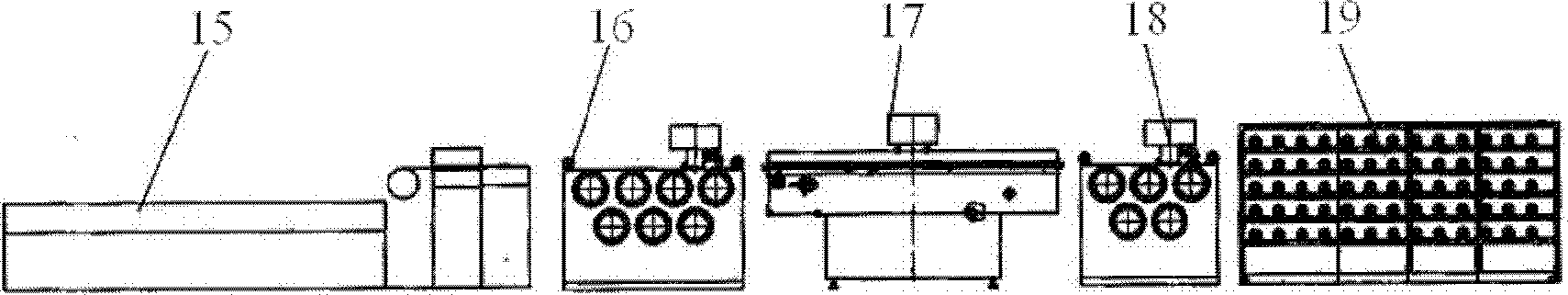

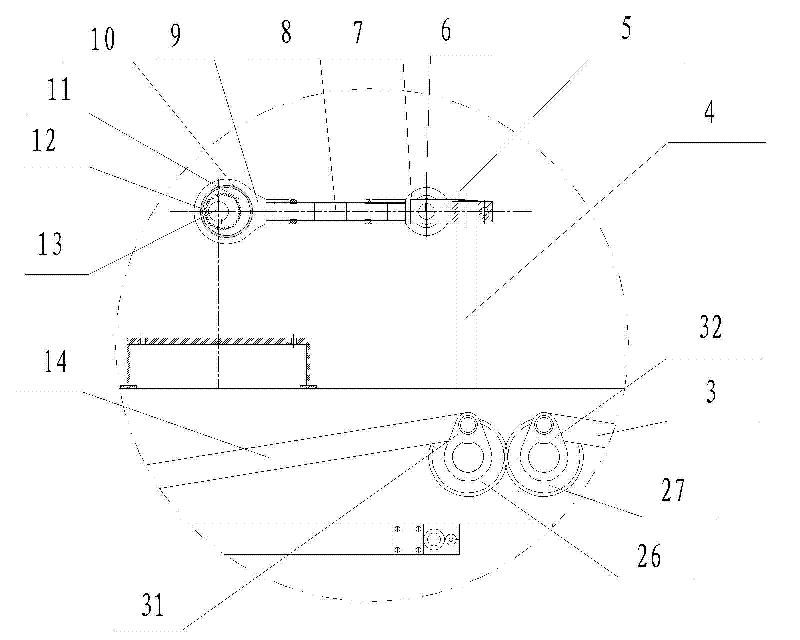

A plastic flat wire drawing unit

ActiveCN102534834BHigh strengthReduce pollutionArtificial thread manufacturing machinesStretch-spinning methodsFiberPolyethylene glycol

The invention discloses a plastic flat fiber extruding machine set. A storage mechanism and a vibratory screening conveyance mechanism are arranged in a drying conveyance device. An electrostatic casting device is arranged in the plastic flat fiber extruding machine set and between a die head and a fiber separation device. The structure of a draft gear is that: a front five-roller draft gear is arranged between the fiber separation device and an extrusion device; a seven-roller draft gear, a fiber shaping device and a rear five-roller draft gear are sequentially arranged between the extrusion device and a fiber collecting device; and the extrusion device adopts a water-heated extrusion mechanism. By the technical scheme, plastic flat fibers of a woven bag can be made of a raw material polyethylene glycol terephthalate (PET), so that the strength of the woven bag is strengthened, the raw material is saved, and waste mineral water bottle plastics can be recycled to realize the recycling of waste and reduce environmental pollution. The plastic flat fiber extruding machine set is rational in process and structure design, and the quality of the product is reliably ensured.

Owner:HENGYI PLASTIC EQUIP MFG

Preparation method of catalyst for oxidative hydrogenation of propane

ActiveCN103769136APhysical properties (lower than surfaceLow pore volumeHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsOrganic acidResource utilization

The invention discloses a preparation method of a catalyst for oxidative hydrogenation of propane. The method comprises the following steps: grinding waste residual oil desulfurization catalysts into powder, adding a strong inorganic acid into the powder, filtering, adding an organic acid into the filtrate, then adding pseudo-boehmite, stirring the solution and heating at the same time until the solution is totally evaporated so as to obtain a solid substance, and then subjecting the solid substance to processes of drying, burning, and forming so as to obtain the catalyst for oxidative hydrogenation of propane. The preparation method fully utilizes the waste residual oil hydro-desulfurization catalysts, improves the resource utilization rate, and greatly reduces the cost; furthermore, the obtained catalyst has a large specific surface area, the active metal is highly dispersed on the catalyst surface, thus the utilization rate of active metal is improved, so the catalytic activity and selectivity of the catalyst are both improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

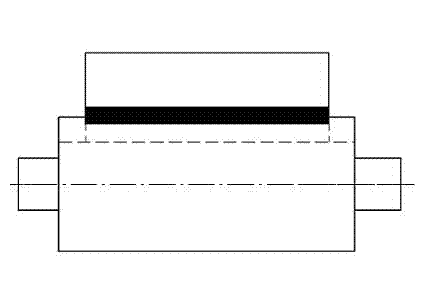

Cooling and sterilizing process for protein preparation and special horizontal type shaking table thereof

ActiveCN102247609AProcess parameters are easy to controlGood antibacterial effectLavatory sanitoryHeatGear wheelReducer

The invention relates to a cooling and sterilizing process for a protein preparation and a special horizontal type shaking table thereof. In the prior art, a sterilizing device for the protein preparation has the defects of poor stability and difficult control of parameters. The special shaking table comprises a cycloidal pin wheel speed reducer, a driving motor and a shaking table, wherein an eccentric outer gear, an eccentric inner gear, a gear shaft sleeve and a left gear base are fixedly arranged on the cycloidal pin wheel speed reducer and an output shaft of the driving motor; the left gear base is connected with one end of a regulating lead screw; the other end of the regulating lead screw is connected with a right bearing base; a shaking amplitude adjustment device is connected with the bearing base and one end of a shaking oscillating bar; the other end of the shaking oscillating bar is connected with one end of a rotating shaft of the shaking oscillating bar; and the other end of the rotating shaft of the shaking oscillating bar is connected with the shaking table by a transmission device in a shaking table cylinder body. The special horizontal type shaking table has a reasonable and compact structure, is reliable in strength, rigidity and toughness of key positions, small in assembly stress of parts and high process performance, process parameters are easy to control, and the optimal bacteriostatic effect can be achieved.

Owner:华原谷道生物科技西安有限公司

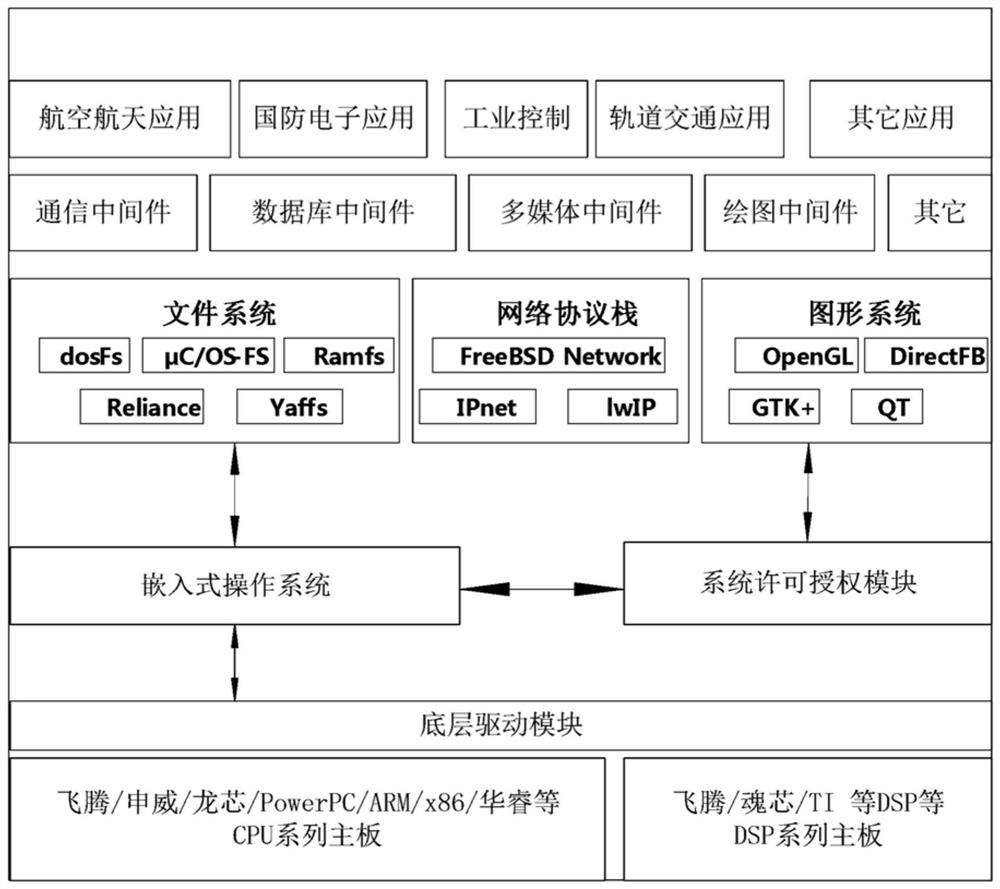

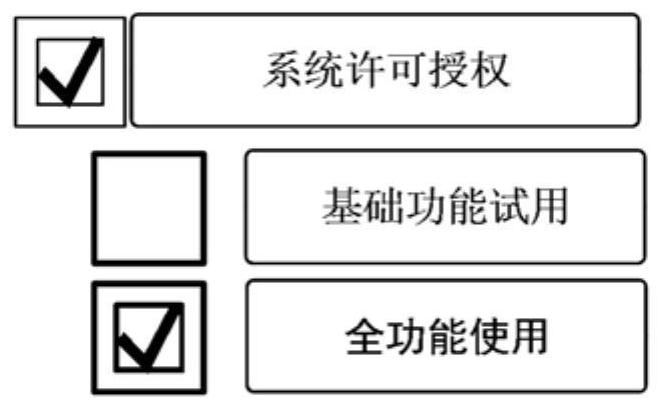

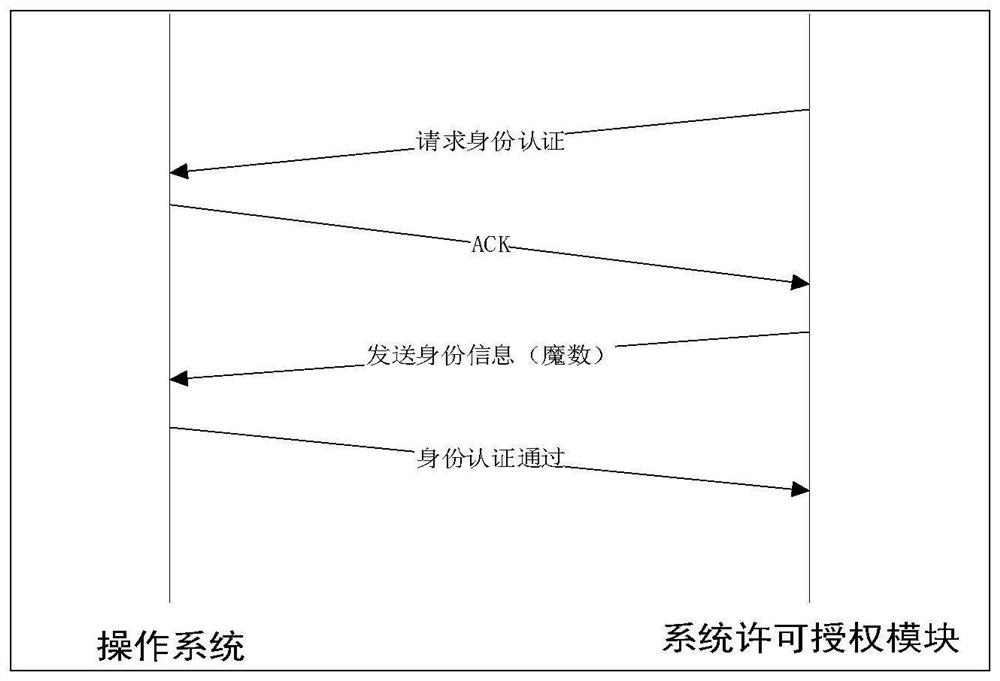

Permission authorization method and system for embedded operating system software

ActiveCN112364306ATroubleshoot Licensing IssuesPrevent illegal misappropriationProgram/content distribution protectionOperational systemEmbedded operating system

The invention provides a permission authorization method and a system for the embedded operating system softwaren. The method comprises the steps: S1, carrying out the IDE environment integration according to the IDE environment integration control information, and obtaining the IDE environment integration result information; s2, carrying out identity authentication according to the IDE environment integration result information and the identity authentication control information, and authority control information is obtained; s3, performing system activation according to the authority controlinformation to obtain system activation result information; s4, acquiring activation code protection information according to the system activation result information; and according to the activationcode protection information, completing activation, and obtaining embedded operating system software use permission authorization result information. The authorization permission problem of the embedded operating system on the equipment is solved, and illegal stealing and infringement of a user to the embedded operating system are avoided.

Owner:EAST CHINA INST OF COMPUTING TECH

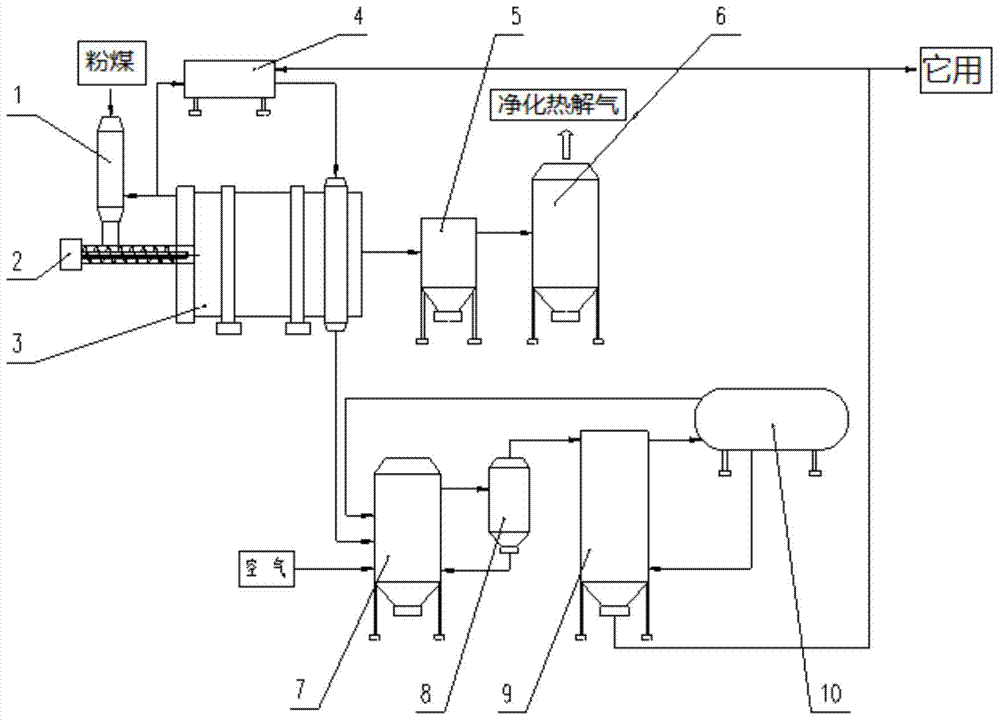

Low-rank pulverized coal pyrolysis and semicoke gasification composite process system

InactiveCN104726118AHigh content of active ingredientsHigh economic valueEnergy inputGasification processes detailsThermal stateProcess engineering

The invention provides a low-rank pulverized coal pyrolysis and semicoke gasification composite process system. A vertical preheater is connected with a feeding screw; the feeding screw is connected with a pyrolysis kiln; one branch of the pyrolysis kiln is connected with the preheater, while the other branch of the pyrolysis kiln is connected with a hot-blast heating furnace; the hot-blast heating furnace is connected with the pyrolysis kiln; the pyrolysis kiln is connected with a settling box; the settling box is connected with a high-temperature filter device; the pyrolysis kiln is connected with a semicoke gasifier; the semicoke gasifier is connected with a cyclone separator; the cyclone separator is connected with a waste heat boiler; the cyclone separator is connected with the semicoke gasifier; the waste heat boiler is connected with a steam pocket by use of a pipe; the low-rank pulverized coal is preheated to the range of 200-300 DEG C by use of a preheater, and then heated in a multi-tube heating rotary pyrolysis kiln to be pyrolyzed; and the pyrolysis gas goes into a subsequent filtering and cooling treatment device. The low-rank pulverized coal pyrolysis and semicoke gasification composite process system is capable of realizing integrated treatment of pulverized coal pyrolysis and direct semicoke gasification, and meanwhile, effectively and directly preparing a fuel gas or raw gas by use of thermal-state semicoke; the waste heat of the semicoke is utilized efficiently and a complex and low-efficiency semicoke waste heat recovery process is omitted.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

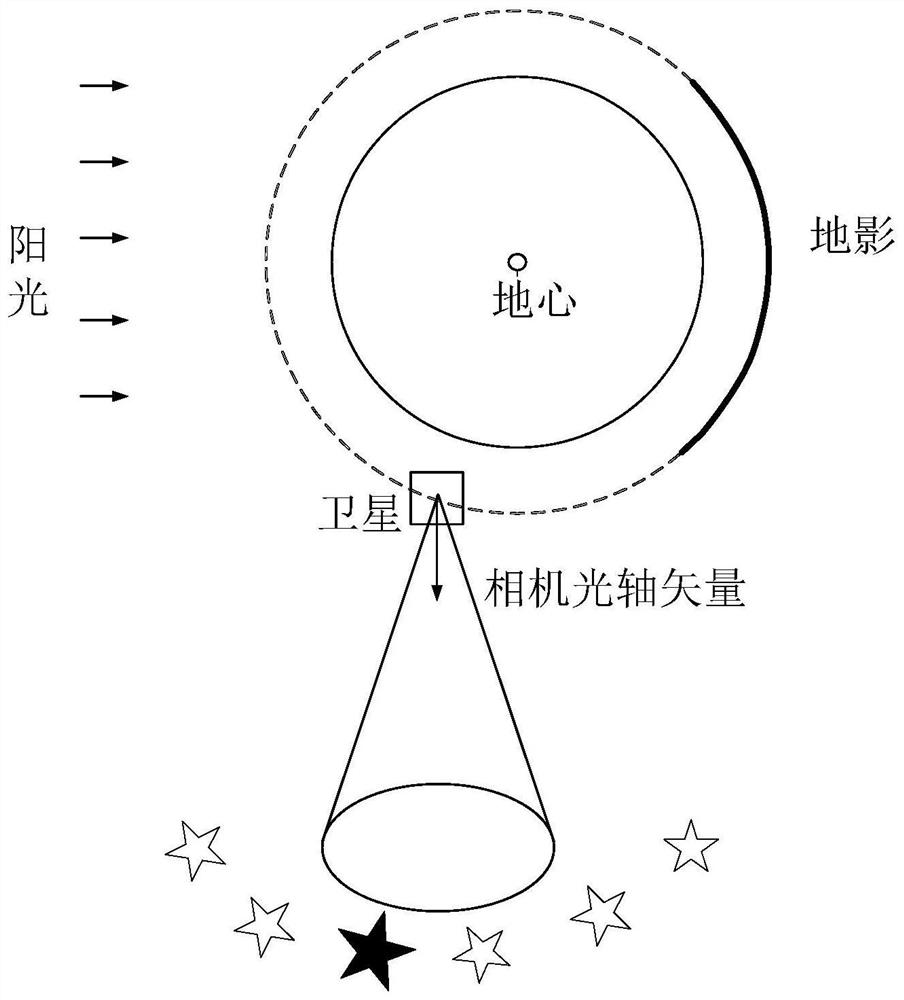

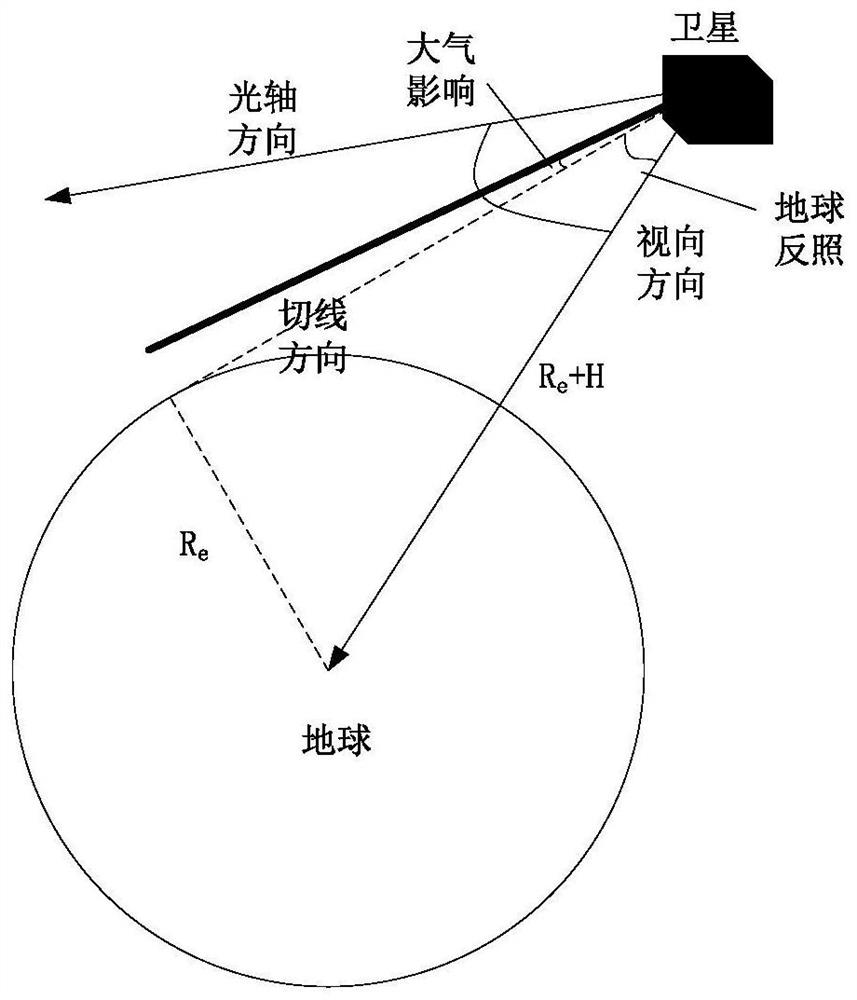

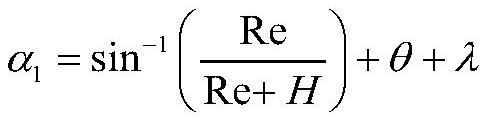

Forecasting method and system for evaluating satellite stability and pointing precision in-orbit performance

ActiveCN113063436AAccurate locationAccurate magnitude informationMeasurement devicesFixed starsSatellite observation

The invention provides a forecasting method and system for evaluating satellite stability and pointing precision in-orbit performance. The forecasting method comprises the following steps of S1, calculating a highlight protection angle of a star sensor, S2, calculating a strong light protection angle of the optical camera, S3, calculating an effective arc section of fixed star observation, and obtaining fixed star observation opportunity information, S4, calculating the projection of the optical axis vector of the optical camera in the inertial space, and S5, selecting a fixed star of which the maneuvering angle and the brightness both meet the requirements near the optical axis direction of the camera, obtaining the position and magnitude information of the target fixed star, and obtaining forecasting result information for evaluating the satellite stability and the pointing precision in-orbit performance. The method searches the fixed star suitable for satellite observation, predicts the fixed star observation opportunity, provides accurate fixed star position and star magnitude information, and provides support for evaluation of high-precision satellite stability and pointing precision.

Owner:SHANGHAI SATELLITE ENG INST

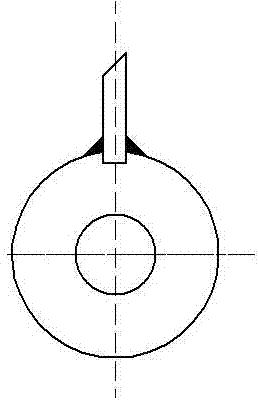

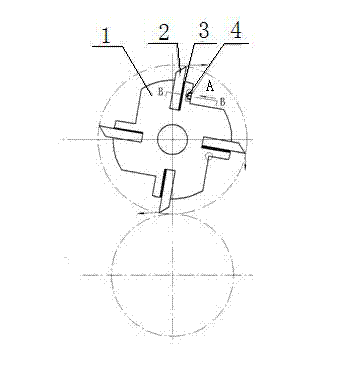

Scraper device

InactiveCN102806612ASolve the deformationSolve the phenomenon of deformation while processingStructural engineeringMachining process

The invention discloses a scraper device which comprises a drum (1) and scraper blades (2), wherein at least two knife slits are uniformly and symmetrically arranged on the circumference of the drum (1), the scraper blades (2) are arranged in the knife slits, and distance adjustors (3) are arranged in the knife slits and used for adjusting the distance from the tip of each scraper blade to the drum surface. The scraper device solves the problems in the prior art that the scraper is deformed during welding, the scraper which is welded with only one blade is biased, the welded scraper is deformed during the machining process and the knife is polished after being worn and a new knife is welded; and enables the blades to be changed only by dismounting the screws. The process and the structure are more reasonable, the operation is more convenient, and the manufacturing cost is reduced.

Owner:恒力石化股份有限公司

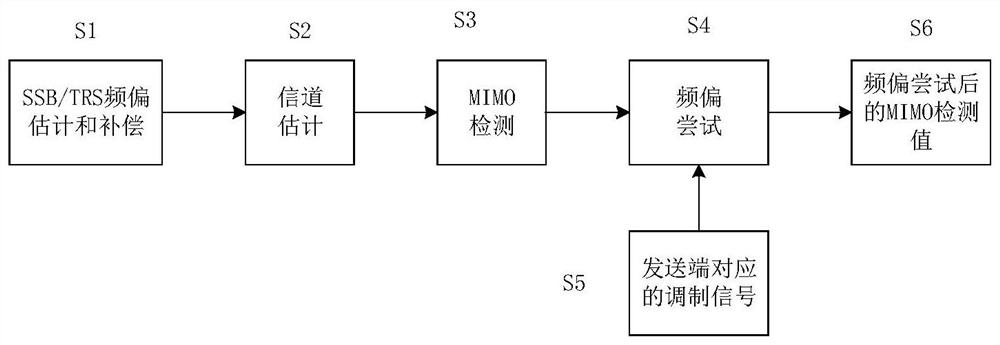

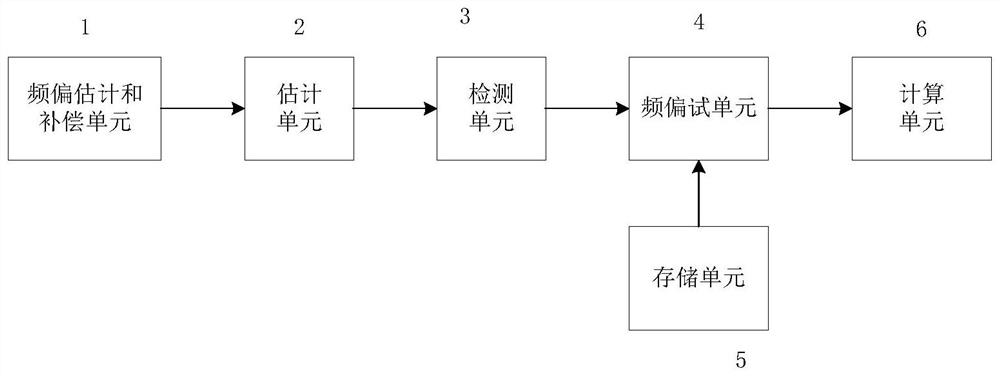

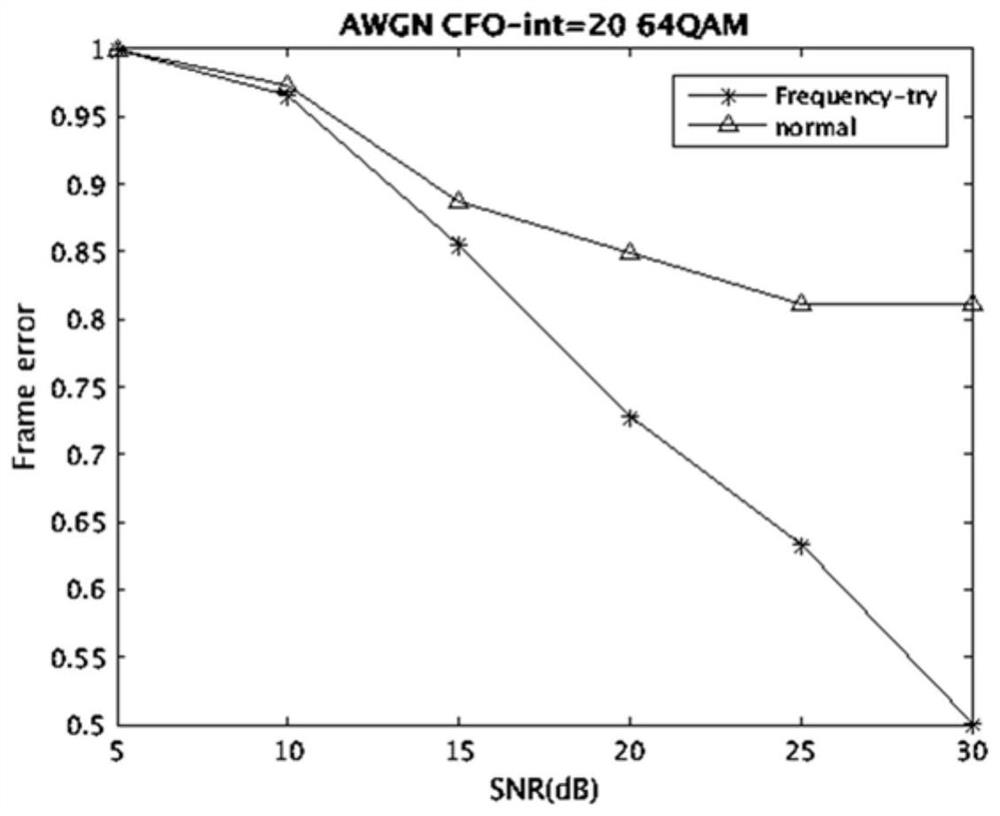

Joint frequency offset estimation method and system

ActiveCN112422472AHigh precisionImprove performanceSpatial transmit diversityMulti-frequency code systemsControl theoryFrequency offset

The invention provides a joint frequency offset estimation method and a joint frequency offset estimation system. The joint frequency offset estimation method comprises the following steps: S1, compensating a frequency offset estimation value using SSB or TRS; S2, after the compensated signal is subjected to intermediate processing, a channel estimation module being executed; S3, executing an MIMOdetection module on a result after channel estimation; S4, performing frequency offset attempt on a result after MIMO detection; S5, storing the signals modulated by the sending end, and taking the stored signals modulated by the sending end as entry data of a frequency offset attempt module; and S6, acquiring the MIMO detection signal after frequency offset adjustment. The SSB and TRS referencesignals are periodic reference signals, a certain error exists in frequency offset estimation, frequency offset attempt is introduced into the detection module to perform joint frequency offset estimation, and the precision of frequency offset estimation is further improved.

Owner:上海微波技术研究所(中国电子科技集团公司第五十研究所)

Waste hydrotreating catalyst utilization method

ActiveCN106944114APhysical properties (lower than surfaceLow pore volumePhysical/chemical process catalystsCatalystsHeteropoly acidFurfural

The present invention discloses a waste hydrotreating catalyst utilization method, wherein the waste hydrotreating catalyst is prepared into a catalyst for ethylene preparation through ethanol dehydration. The waste hydrotreating catalyst utilization method comprises: preparing a catalyst precursor A from a waste hydrotreating catalyst, and reducing the catalyst precursor A by using hydrogen gas in a high pressure reaction kettle; adding a polyol and / or a furfural solution to the high pressure reaction kettle, and carrying out a hydrogenation reaction; and drying the material obtained after the reaction until the surface is liquid-free, sequentially contacting an organic acid, ammonium or ammonia, and loading a heteropoly acid to produce the catalyst for ethylene preparation through ethanol dehydration. According to the present invention, with the method, the active metal and the alumina carrier in the waste hydrotreating catalyst are utilized, the metal impurities such as Ni, Fe and the like deposited on the waste hydrotreating catalyst are completely utilized, the pollution problem of the waste catalyst is solved, and the obtained catalyst for ethylene preparation through ethanol dehydration has the excellent performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

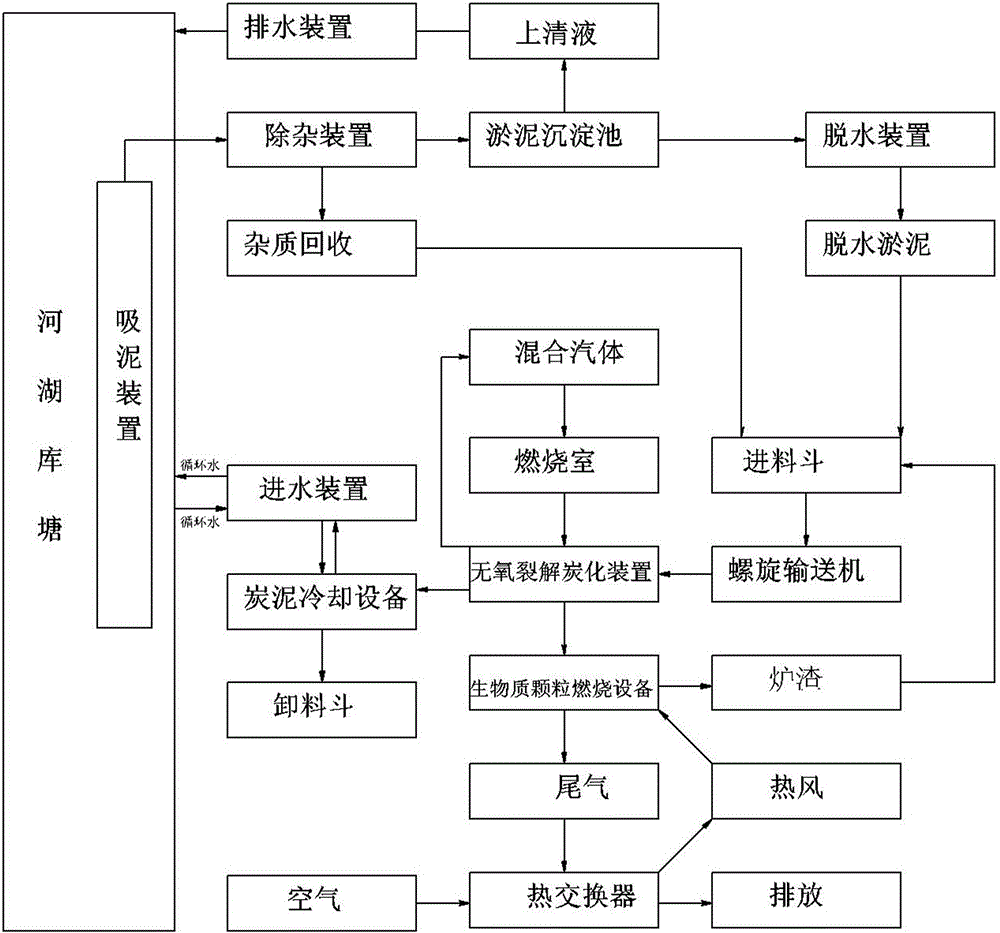

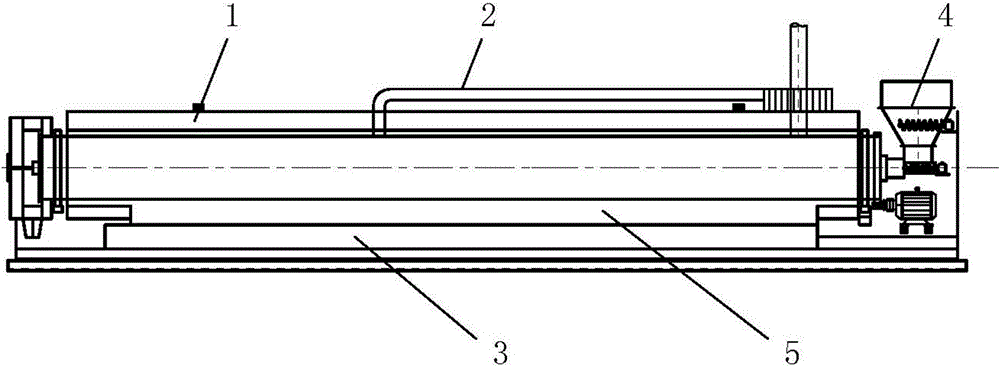

System and process for producing carbon mud by anaerobic cracking of sludge

PendingCN106007295AAchieving zero emissionsKeep it clean and stableSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisSludgeFilter press

The invention discloses a system and a process for producing carbon mud by anaerobic cracking of sludge. The system comprises a sludge sucking device, an impurity removing device, a dehydration device, a material conveying device, an anaerobic cracking carbonizing device, a water feeding device and a water discharging device. The anaerobic cracking carbonizing device comprises a converter body, a sludge feeder, a mixed gas processing device, a tail gas treatment device, a biomass particle combustion device and a carbon mud cooling device; the sludge feeder comprises a feed hopper and a screw conveyor mechanism. The impurity removing device comprises a vibrating grid; impurity is recovered and conveyed to the sludge feeder, and sludge is conveyed to the dehydration device through a pipeline. The dehydration device comprises a sludge pelletizer or filter press. The system and the process have the advantage of reasonable design, realize harmless treatment, reduction and recycling of sludge, and further realize technical effects that stacking sludge on floor is avoided, garbage moving is omitted, large space occupation for sludge conveying is avoided, and product recycling is achieved in sludge disposal.

Owner:浙江宜欣水利科技有限公司

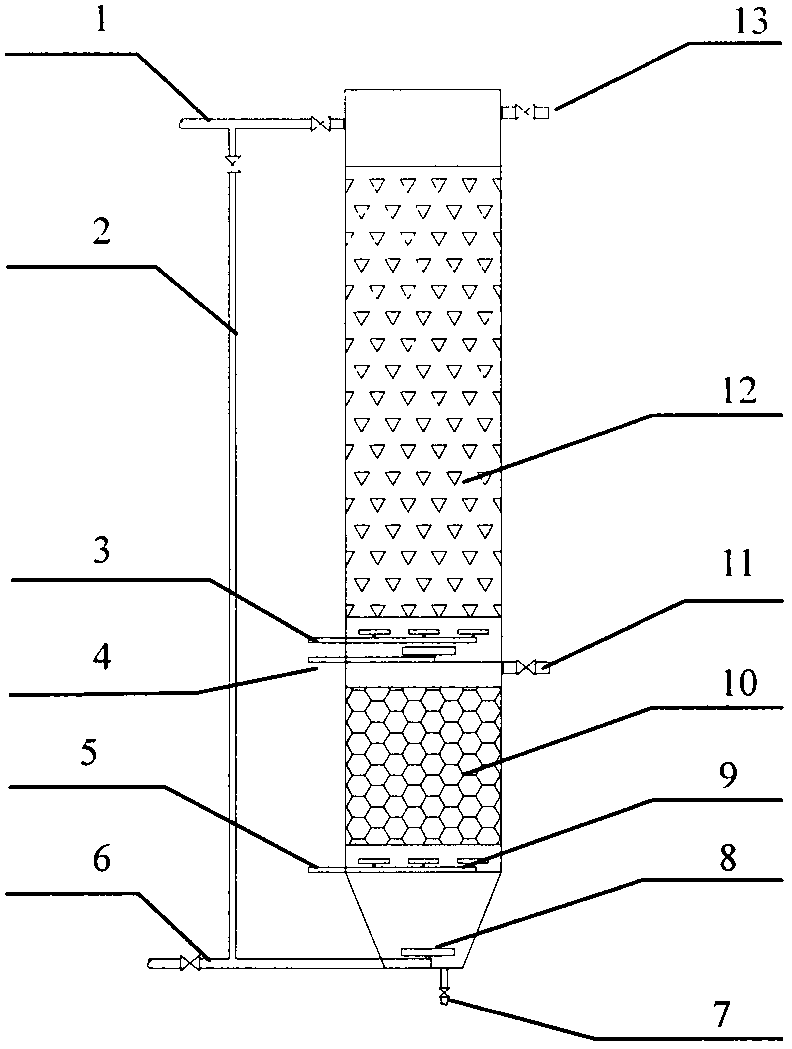

New technology for treating eutrophic brackish water

InactiveCN103864210ASmall footprintReasonable process structureTreatment with aerobic and anaerobic processesEutrophic waterFilter material

The invention relates to a eutrophic brackish water treating technology employing an A / O two-segment type multi-medium biological aerated filter. In order to enhance the nitrogen-phosphorus removing effect on the high-salt eutrophic water and solve the problem of bad biological adaptability of the high-salt environment, the apparatus disclosed by the invention is subjected to technological modification on the basis of a routine biological aerated filter. By arranging the two-segment pool structure, the lower segment is not subjected to aeration and the upper segment is subjected aeration, so that denitrified microbe survival environment with the anoxic lower segment and the aerobic upper segment is formed. The material filtering lower segment of the filter is filled with an anthracite filter material and is inoculated with efficient halophilic denitrifying bacteria. The filter upper segment is filled with a NaCl modified zeolite filter material and is inoculated with efficient halophilic denitrifying bacteria. The new technology has the advantages of being novel, high in nitrogen and phosphorus removing efficiency, and low in energy consumption.

Owner:天津市庆烁市政工程有限公司

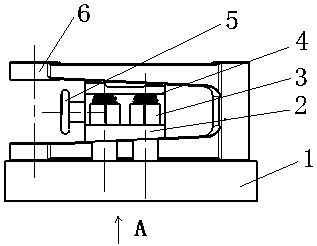

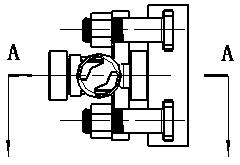

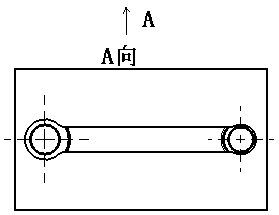

Novel clip clamping device

InactiveCN106392698AReasonable process structureEasy to usePositioning apparatusMetal-working holdersBiomedical engineering

The invention discloses a novel clip clamping device which comprises a base (1), a wedge (2), a handle (5) and a clip (6). The wedge (2) is fixedly connected to a T-shaped groove formed in the base (1) through bolts (4) and nuts (3). The bolts (4) enable the clip (6) and the wedge (2) to be clamped on the base (1) through the T-shaped groove formed in the base (1) via the nuts (3). The handle (5) is connected with the wedge (2), and clip (6) is positioned to the long groove of the base (1). According to the novel clip clamping device, the problem that according to an original clamping structure, the position precision of a machined hole is poor is solved, and the quality of a produced product is low after clip assembling, the process structure is more reasonable, use is more convenient, and a dual-station and multi-station structure improves the machining efficiency.

Owner:大连橡胶塑料机械有限公司

Liquid gas sweetening alkali liquor oxidized regeneration method and apparatus

ActiveCN101371967BGood dispersionImprove conversion rateDispersed particle separationEconomic benefitsOxygen

The present invention relates to a liquid gas sweetened alkali liquid oxygenating regeneration method. Sodium mercaptide in sweetened alkali liquid is transformed into sodium hydroxide and disulfide in air or oxygen-enriched air by catalyst to obtain regenerated alkali liquid after separation for recycling. The present invention is characterized in that a fraction of the sweetened alkali liquid is oxygenated and regenerated to obtain the regenerated alkali liquid which is mixed with the rest sweetened alkali liquid to be recycled into a sweetening reactor. The present invention also disclosesa related device. The present invention has more reasonable technical method and structure, is very simple and easy for improving the traditional line and also has easy operation, easy implementation, low cost, good effect and outstanding economic benefit.

Owner:NINGBO ZHONGYI PETROCHEM TECH

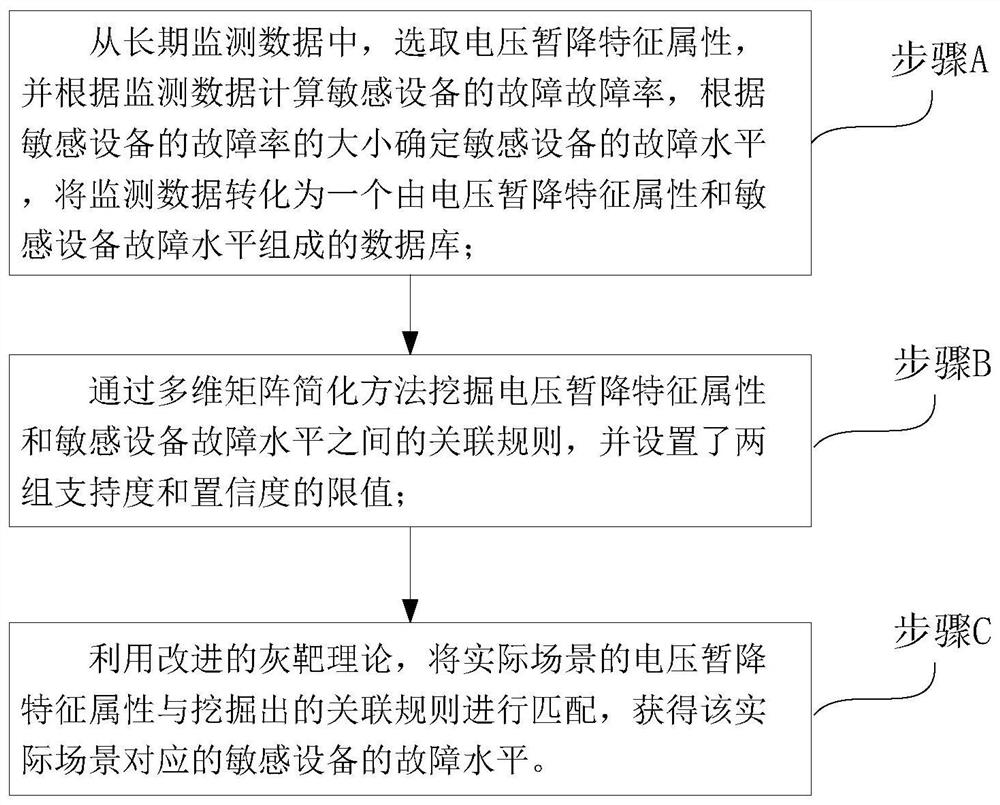

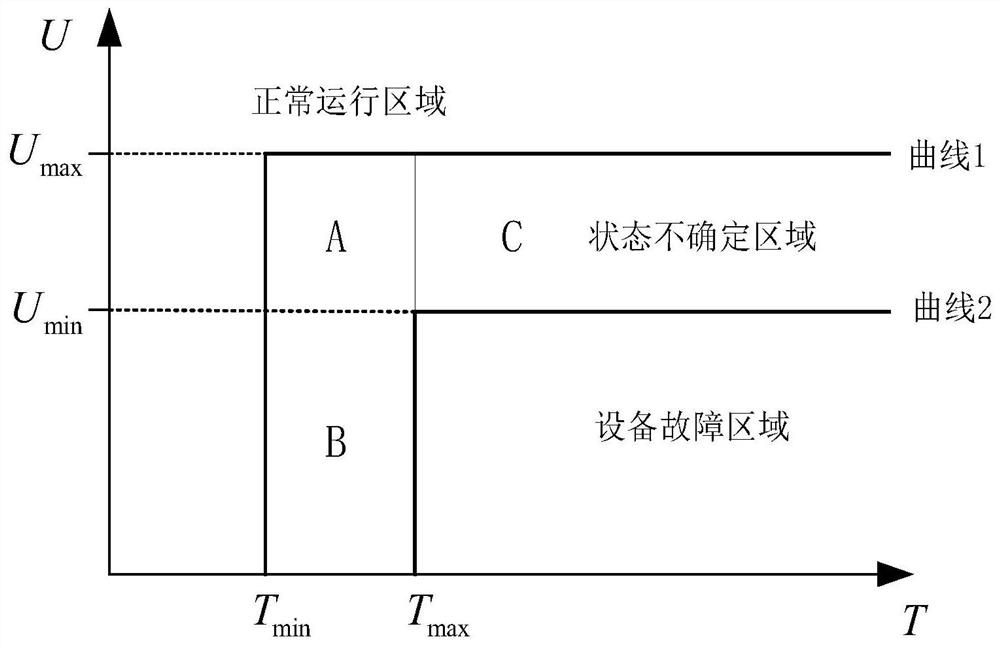

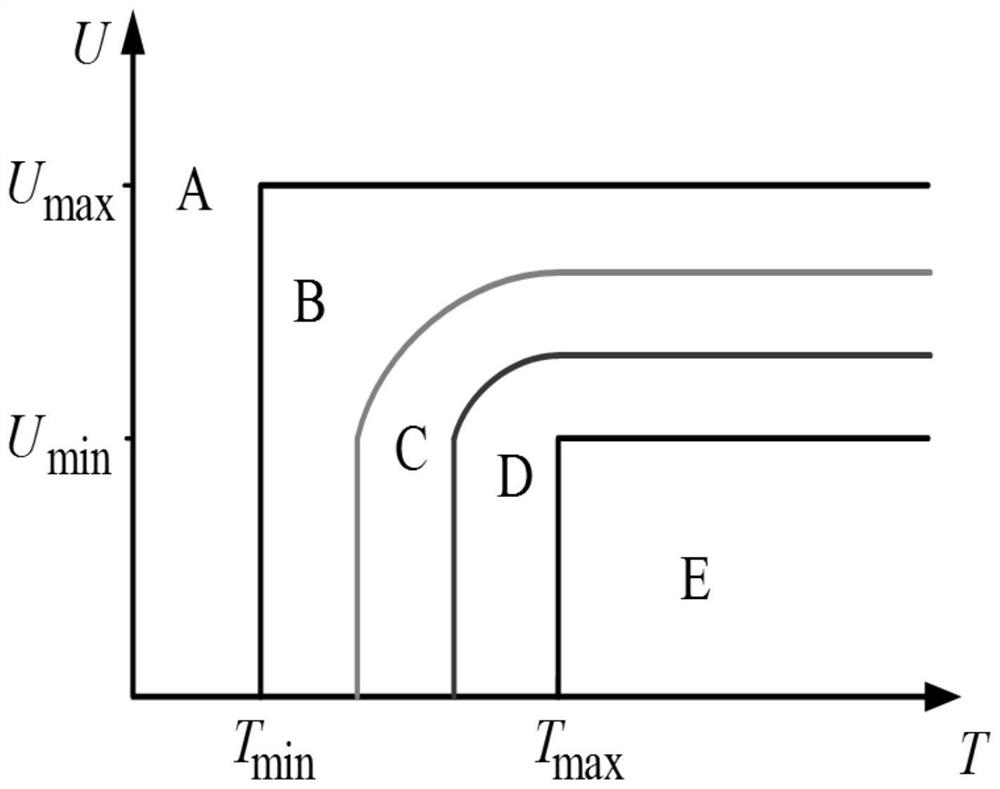

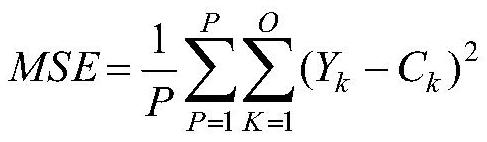

Voltage sag sensitive equipment fault level evaluation method based on data mining

ActiveCN112035527AReasonable process structureHigh precisionDigital data information retrievalCurrent/voltage measurementVoltage sagComputer science

The invention discloses a voltage sag sensitive equipment fault level evaluation method based on data mining, and the method comprises the steps: selecting a voltage sag characteristic attribute, calculating the fault rate of sensitive equipment according to monitoring data, and determining the fault level of the sensitive equipment according to the fault rate; converting the monitoring data intoa database consisting of a voltage sag characteristic attribute and a sensitive equipment fault level; mining an association rule between the voltage sag characteristic attribute and the fault level of the sensitive equipment, and setting two groups of support degree and confidence degree limit values; and matching the voltage sag characteristic attribute of the actual scene with the mined association rule by using an improved gray target theory to obtain the fault level of the sensitive equipment corresponding to the actual scene. According to a large number of voltage sag events, as long asa set of voltage sag characteristic attributes corresponding to the fault scene is constructed, the voltage sag characteristic attributes of the scene can be matched with the mined association rules,and the fault level of the sensitive equipment of the scene is obtained.

Owner:SICHUAN UNIV

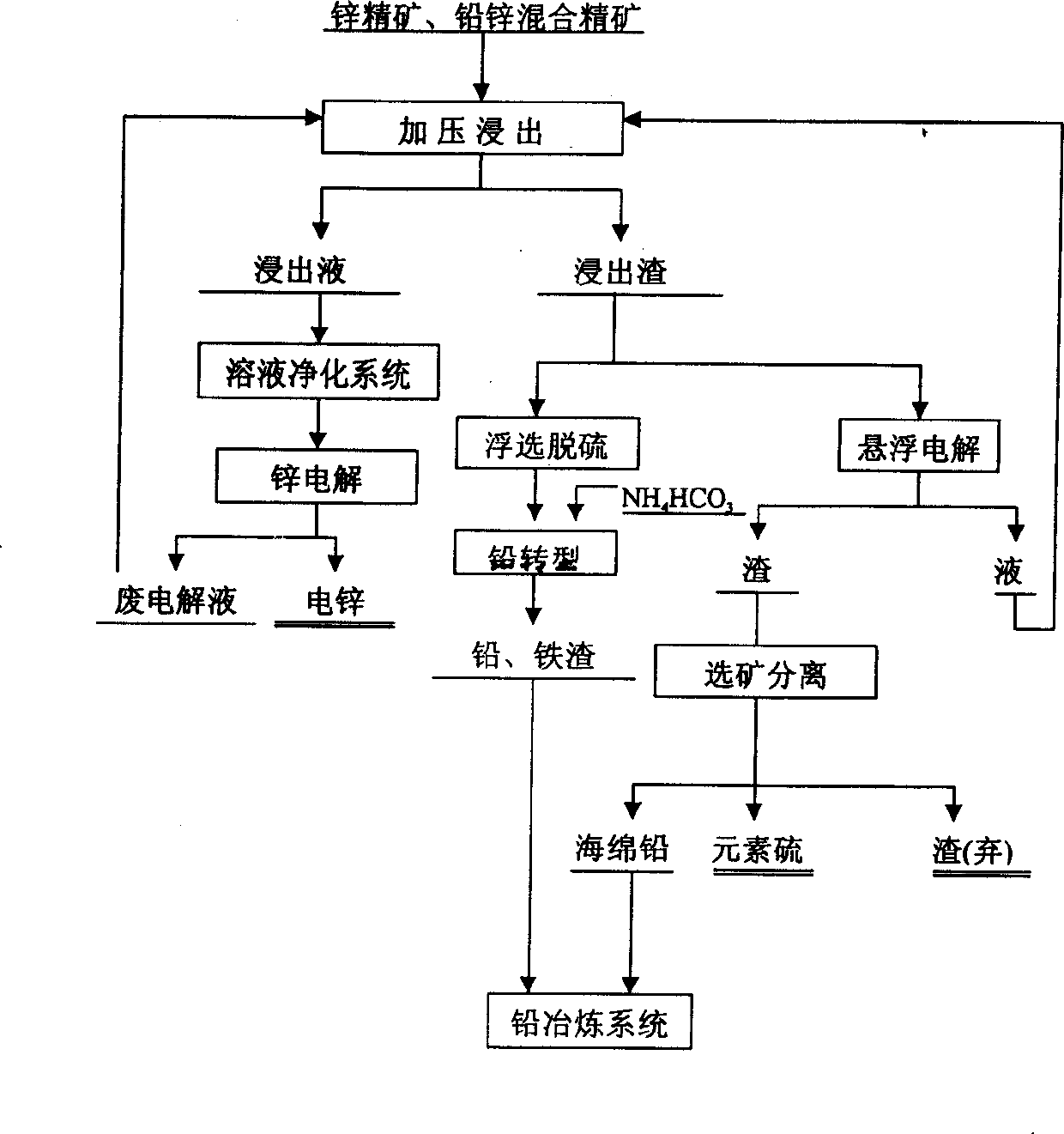

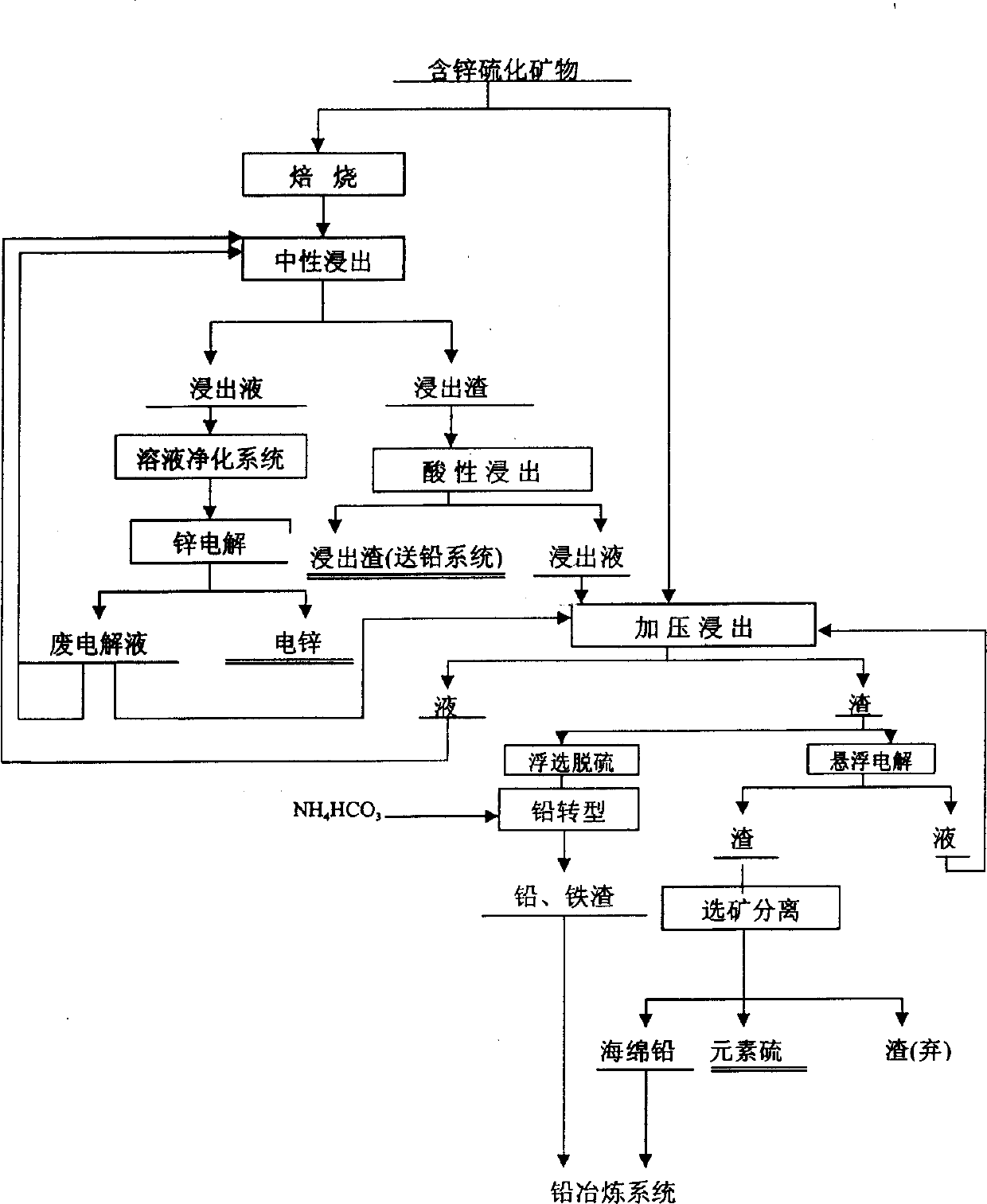

Process for extracting Zn from Zn-containing sulfide ore

InactiveCN1360064AEfficient leachingLower oxygen partial pressureProcess efficiency improvementHydrometallurgySulfide

A process for extracting zinc from the zinc-containing sulfide ore, mixed Pb / Zn ore, and zinc ore concentrate is characterized by that in the presence of oxygen gas and sulfuric acid, the granular ore with the granularity less than 50 microns in general (90%) is extracted in sulfuric acid at 100-130 deg.C and 200-1000 KPa. Its advantages are low extracting temp and high selectivity of zinc.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

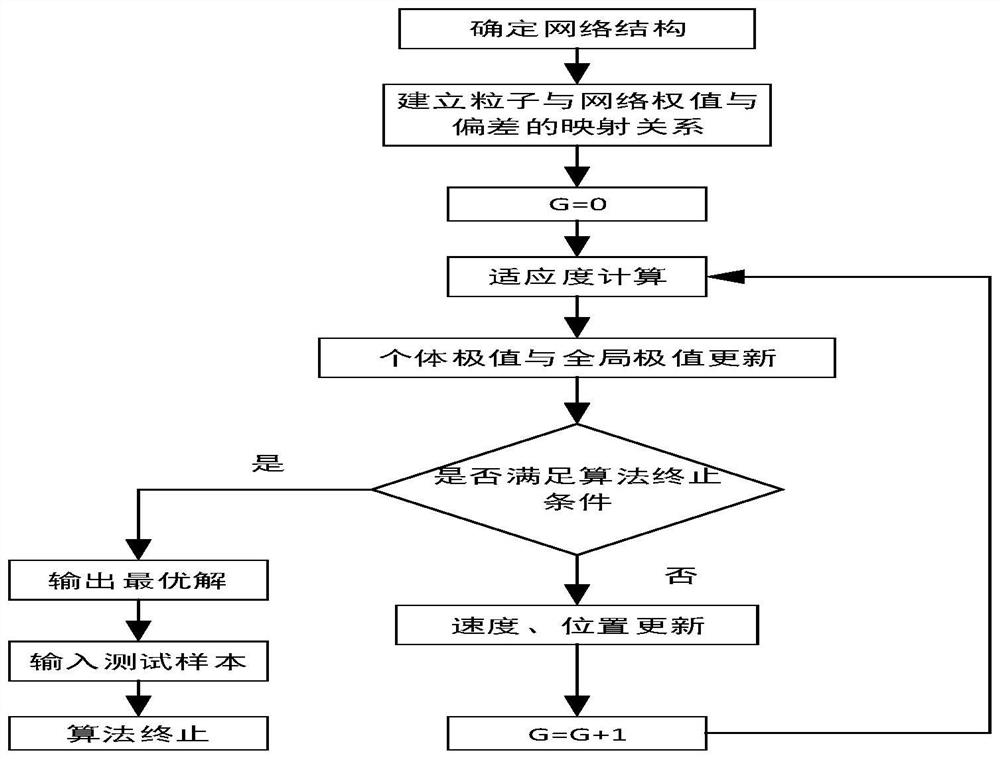

Warm ventilator fault detection method and system based on artificial intelligence algorithm

PendingCN113139606ADiagnose the cause of the failureReasonable process structureCharacter and pattern recognitionArtificial lifeAlgorithmResearch data

The invention provides a warm ventilator fault detection method and system based on artificial intelligence algorithm. The method comprises the steps: s1, initializing a BP model structure, and setting the number of neuron nodes of each layer of a network; s2, initializing a particle swarm; s3, calculating a particle fitness value; s4, comparing the fitness value and the global extreme value of the particle; s5, updating particle positions and velocity vector values; s6, outputting an optimal network according to the particle position updating result information and the velocity vector value updating result information, and obtaining the fault detection result information of the heating fan based on the artificial intelligence algorithm. Fault diagnosis is carried out on the heating ventilation air conditioner based on an artificial intelligence algorithm, and feedback data is provided by sensors with sampling points located at key parts of the heating ventilation system, the research data being provided by an owner intelligent control center.

Owner:上海联创设计集团股份有限公司

Method for recovering nickel and aluminum from waste aluminum based nickel-containing catalyst

InactiveCN1257292CEfficient separationEfficient recyclingProcess efficiency improvementDecompositionSodium aluminate

The invention is a method of recovering nickelic and aluminum from waste aluminum-based nickel catalyst, it has the characters of novel technique, reasonable flow, simple and convenient method and easy operation, and convenient scaled production, and benefits environmental protection. It includes the steps: sodium carbonate sintering and state-changing--boiling water dissolving sodium aluminate and separating aluminum--- making reducing-matte-making melting on nickel residues to obtain nickel matte Ni3S2-FeS-Ni-Fe alloy or copper-nickel matte Cu2S-Ni3S2-FeS alloy---blowing to obtain high-grade nickel matte Ni3S2 or high-grade copper-nickel matte Cu2S-Ni3S2-Cu-Ni alloy---desiliconizing crude NaAlO2 solution---making carbonated decomposition to obtain aluminum hydrate Al2O3íñ3H2O---calcining to obtain anhydrous aluminum oxide alpha-Al2O3. It is suitable to recover nickel and aluminum from the waste residue generated by extracting molybdenum and vanadium from waste aluminum-based nickelic catalysts and disabled catalysts containing nickel, aluminum, molybdenum and vanadium.

Owner:SHENYANG JIAHE METALLURGICAL FURNACE CHARGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com