Novel clip clamping device

The invention relates to a clamping device and a clip technology, which is applied in the field of new clip clamping devices, and can solve the problems of low processing efficiency, affecting product quality and low position accuracy, and achieve the effects of improving processing efficiency, convenient use and reasonable process structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

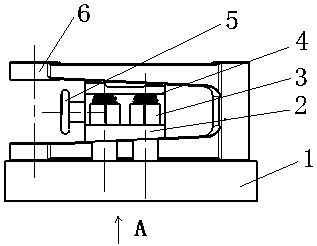

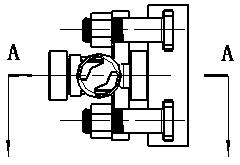

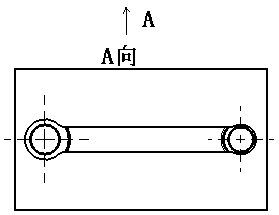

[0016] Such as Figure 1 to Figure 6 As shown, the new clip clamping device includes a base 1, a wedge iron 2, a handle 5 and a clip 6. The wedge iron 2 is fixedly connected to the T-shaped slot of the base 1 through a bolt 4 and a nut 3, and the bolt 4 passes through the base 1. The T-shaped slot on the top, the clip 6 and the wedge iron 2 are clamped on the base 1 through the nut 3, the handle 5 is connected with the wedge iron 2, the clip 6 is positioned on the long groove of the base 1, and the clip 6 is connected to the base 1 along the length direction. The T-slots are in the form of a single-station structure placed in parallel. The clips 6 can adopt a symmetrical or parallel-distributed double-station structure. The clips 6 can adopt a symmetrical and parallel-distributed multi-station structure. When used, the clips 6 are positioned On the long groove of the base 1, there is an arc line that can be aligned on the long groove. Use the handle 5 to connect the wedge iron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com