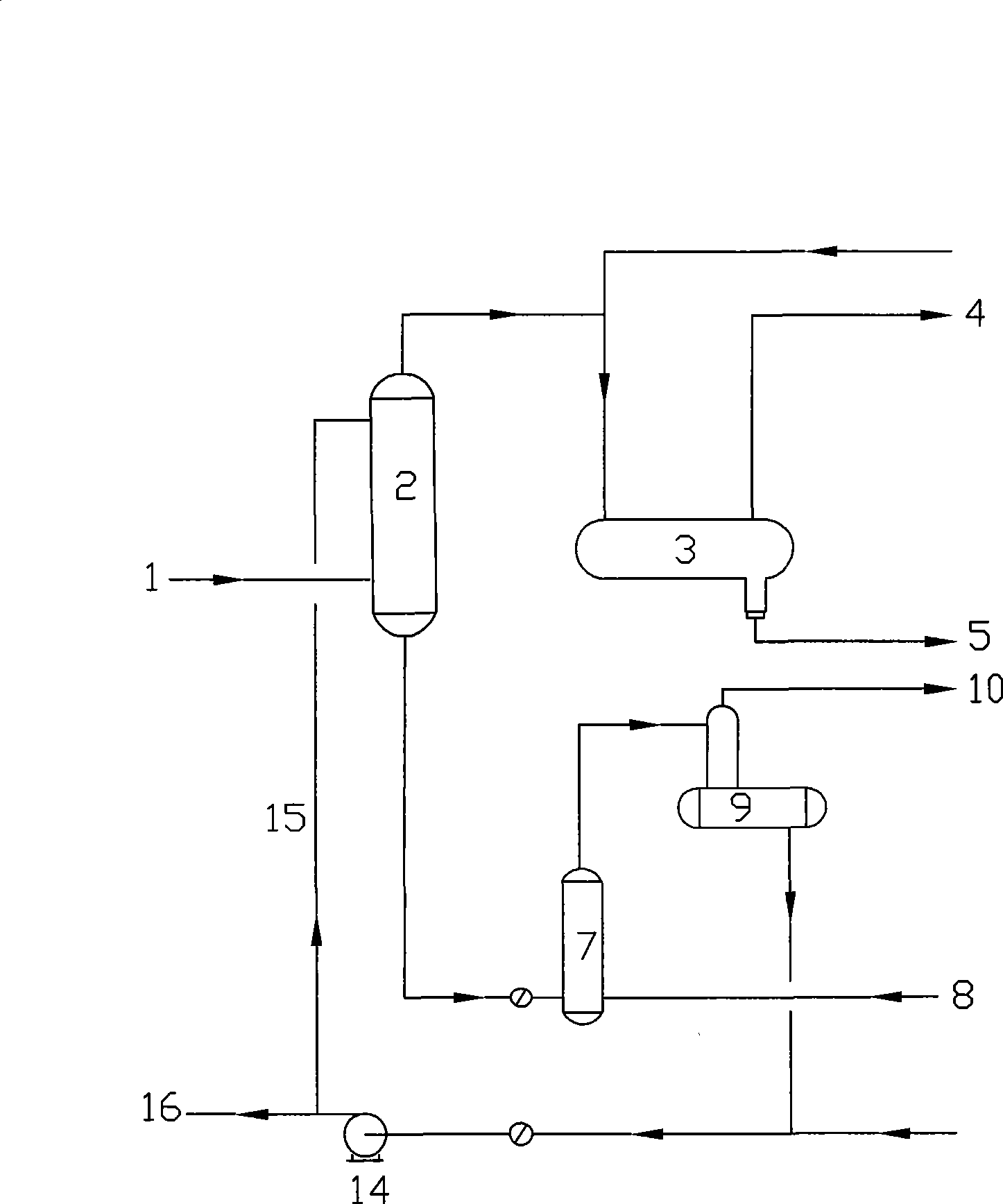

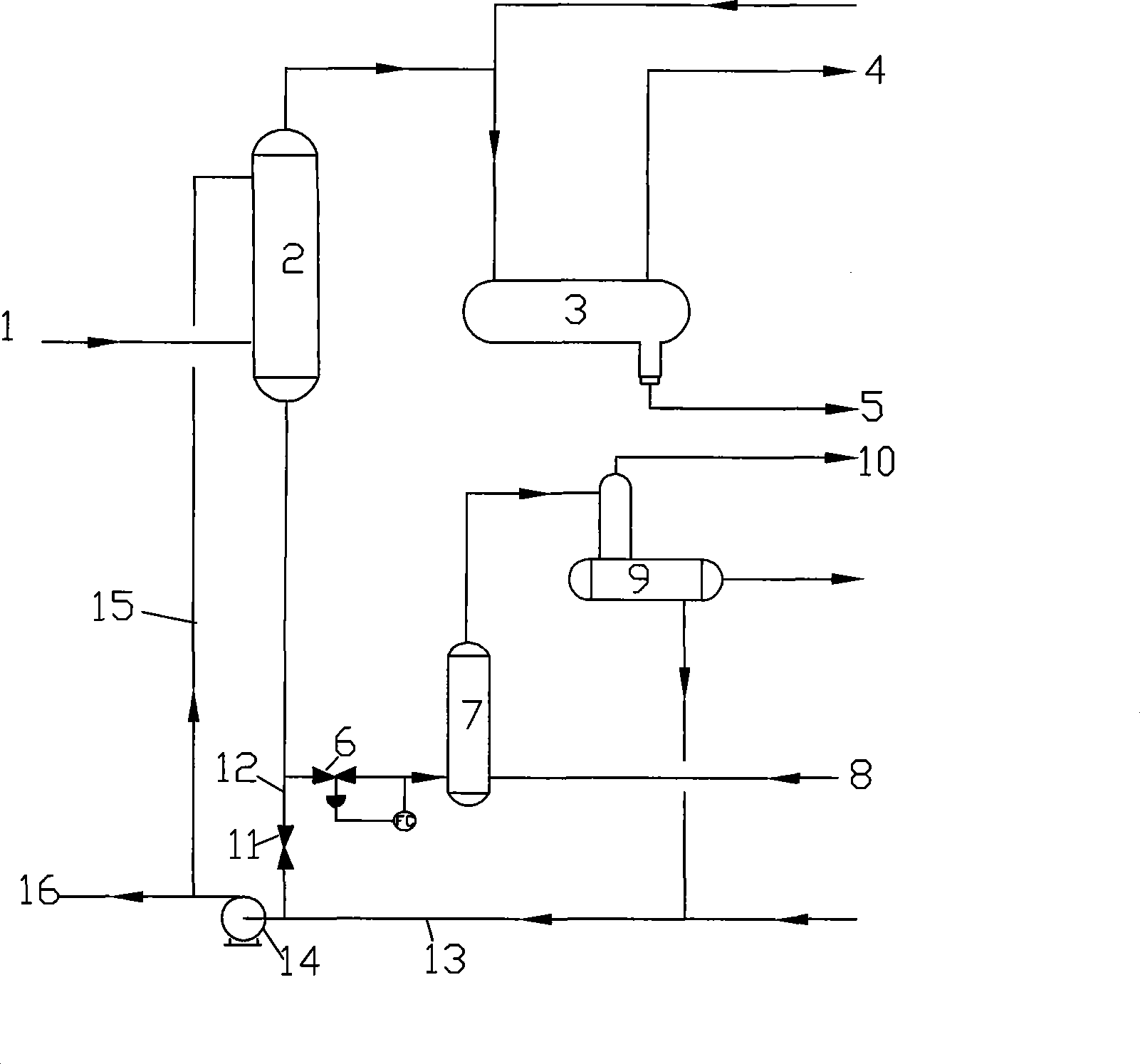

Liquid gas sweetening alkali liquor oxidized regeneration method and apparatus

A regenerative device and liquefied gas technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve problems that cannot be solved fundamentally, achieve reasonable and scientific process methods and structures, improve conversion rates, and reduce The effect of flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The liquefied gas with a feed rate of 35t / h is fed from the lower part of the extraction tower; the total sulfur content in the liquefied gas is 730mg / m 3 , of which mercaptan sulfur is 700mg / m 3 .

[0041] The lye with a feed rate of 8t / h is fed from the upper part of the extraction tower. The concentration of sodium hydroxide in the lye is 13%wt, the concentration of sodium mercaptide is 1.8% (calculated as sulfur), the concentration of disulfide is 820ppm (calculated as sulfur), and the concentration of sulfonated cobalt phthalocyanine as catalyst is 160ppm.

[0042] After most of the mercaptans are removed in the extraction tower, the liquefied gas passes through the water washing device. The total sulfur in liquefied gas is 87mg / m 3 , in which mercaptan sulfur is 9mg / m 3 .

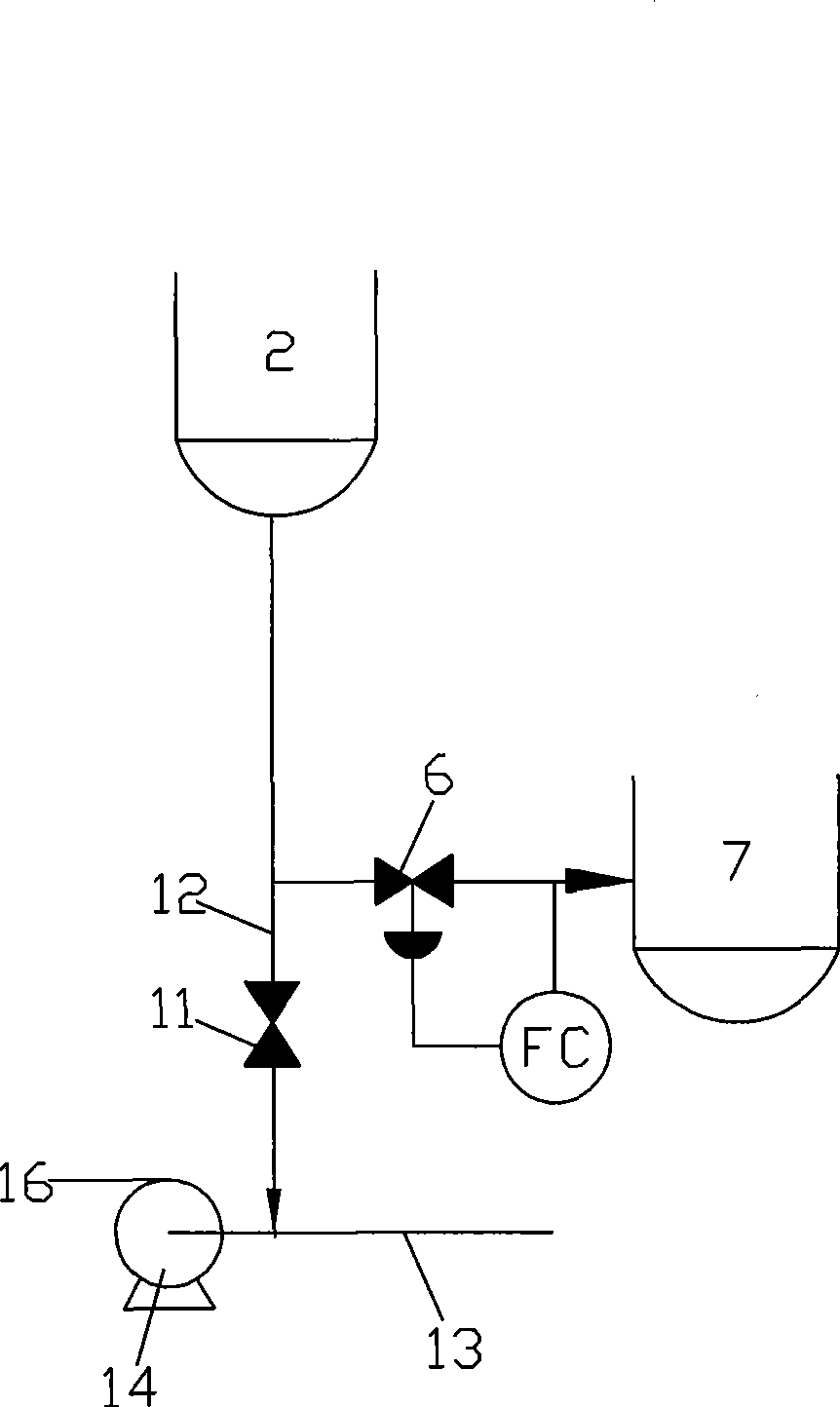

[0043] The lye comes out from the bottom of the extraction tower, passes through the circulation cross-line and the pressure control regulating valve, 6t / h of which is pressurized by the l...

Embodiment 2

[0049] The liquefied gas with a feed rate of 35t / h is fed from the lower part of the extraction tower; the total sulfur content in the liquefied gas is 750mg / m 3 , of which mercaptan sulfur is 720mg / m 3 .

[0050] The lye with a feed rate of 8t / h is fed from the upper part of the extraction tower. The concentration of sodium hydroxide in the lye is 13%wt, the concentration of sodium mercaptide is 1.8% (calculated as sulfur), the concentration of disulfide is 800ppm (calculated as sulfur), and the concentration of sulfonated cobalt phthalocyanine as catalyst is 160ppm.

[0051] After most of the mercaptans are removed in the extraction tower, the liquefied gas passes through the water washing device. The total sulfur in liquefied gas is 83mg / m 3 , in which mercaptan sulfur is 12mg / m 3 .

[0052] The lye comes out from the bottom of the extraction tower, passes through the circulation cross-over line and the pressure control regulating valve, 6t / h of which is pressurized by...

Embodiment 3

[0059] The liquefied gas with a feed rate of 35t / h is fed from the lower part of the extraction tower; the total sulfur content in the liquefied gas is 710mg / m 3 , of which mercaptan sulfur is 685mg / m 3 .

[0060] The lye with a feed rate of 8t / h is fed from the upper part of the extraction tower. The concentration of sodium hydroxide in the lye is 13.1%wt, the concentration of sodium mercaptide is 1.8% (calculated as sulfur), the concentration of disulfide is 780ppm (calculated as sulfur), and the concentration of sulfonated cobalt phthalocyanine as catalyst is 160ppm.

[0061] After most of the mercaptans are removed in the extraction tower, the liquefied gas passes through the water washing device. The total sulfur in liquefied gas is 71mg / m 3 , of which mercaptan sulfur is 11mg / m 3 .

[0062] The lye comes out from the bottom of the extraction tower, passes through the circulation cross-over line and the pressure control regulating valve, 6t / h of which is pressurized ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com